-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

YC6A、YC6B、YC6J 工程用系列发动机

使用说明书

YC6A、YC6B、YC6J

Series Construction Engine

Operation & Maintenance Manual

使用前请仔细阅读使用说明书

Please read the Manual carefully before using.

Summary of Contents for Yuchai YC6A Series

-

Page 1

YC6A、YC6B、YC6J 工程用系列发动机 使用说明书 YC6A、YC6B、YC6J Series Construction Engine Operation & Maintenance Manual 使用前请仔细阅读使用说明书 Please read the Manual carefully before using. -

Page 2

广西玉柴机器股份有限公司 Guangxi YuChai Machinery Co., Ltd. 二 00 八年六月 June.2008 言 Foreword 前 本说明书介绍了 YCA、YC6B、YC6J 工程用系列发动机的主要结构、技术参数、主要附 件的技术规格与数据以及使用和维护方面的基本知识,并对一些常见故障及其排除方法作了初步 的介绍。 This Instruction Manual introduces the YCA、 YC6B、 YC6J series construction engine about its structure and technical parameters, the technical specifications and data of its main accessories as well as the basics information on use and service. -

Page 3

The manual gives a detailed description for the basic model engine only, and any modifications of it are not laid out to which we ask our customers to pay due attention and understand it well. 本说明书的解释权归玉柴。 YuChai reserves the explanation right of this manual. 安全行车注意事项! Precautions for Safe Operation! 1.润滑油压力感应塞、水温感应塞、润滑油压力过低报警器这些零件非常重要,凡有失灵者, 须立即更换,以确保这些零件能正常工作。否则会造成因缺油烧坏曲轴或因缺水致使气缸盖过热… -

Page 4

9.凡新机运行 50~60 小时时,须及时通过玉柴的委托技术服务站进行走合保养,否则不予 实行发动机的保修。 Send the engine to a consignment technical service station of YuChai for run-in service… -

Page 5

when it runs 50-60hour, or you will waive the warranty for this engine. 10.冷却系统必须使用防冻液,否则由此引起的故障,不予实行免费保修。 Anti-freeze coolant shall be used in the cooling system; otherwise the consequent failure will not be included in the free warranty 11.严禁用户擅自拔插各接插件。 Customer is prohibited to insert or pull out the connectors. 12.严禁以水或任何清洗液冲洗发动机。… -

Page 6: Table Of Contents

19. 包装箱内随带下列随机文件(使用说明书、随机备件清单、随机工具清单、合格证、 装箱清单) ,用户开箱后应及时清点。 Random documents are included in the package: user’s manual, parts list, tool list, certification and packing list. Please check after opening. 录 Content 目 1 概述 General introduction ………………..18 1.1 产品特点 Product Feature ………………. 18 1.2 型号的组成及其代表意义…

-

Page 7

4.2 发动机的维护保养 Engine Maintenance …………..79 5 发动机常见故障及排除方法 ………………..82 Frequently-possible Troubles and Their Solution…………..82 5.1 发动机不能起动 Engine Fails to Start …………….82 5.2 发动机功率不足 Insufficient power of Engine ………….. 84 5.3 发动机运转时有不正常的杂声 ………………86 Abnormal Noise during Running of Engine …………… 86 5.4 排气冒黑烟… -

Page 8

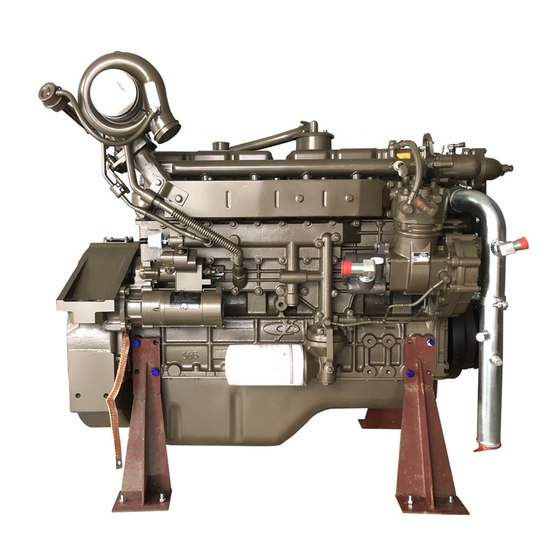

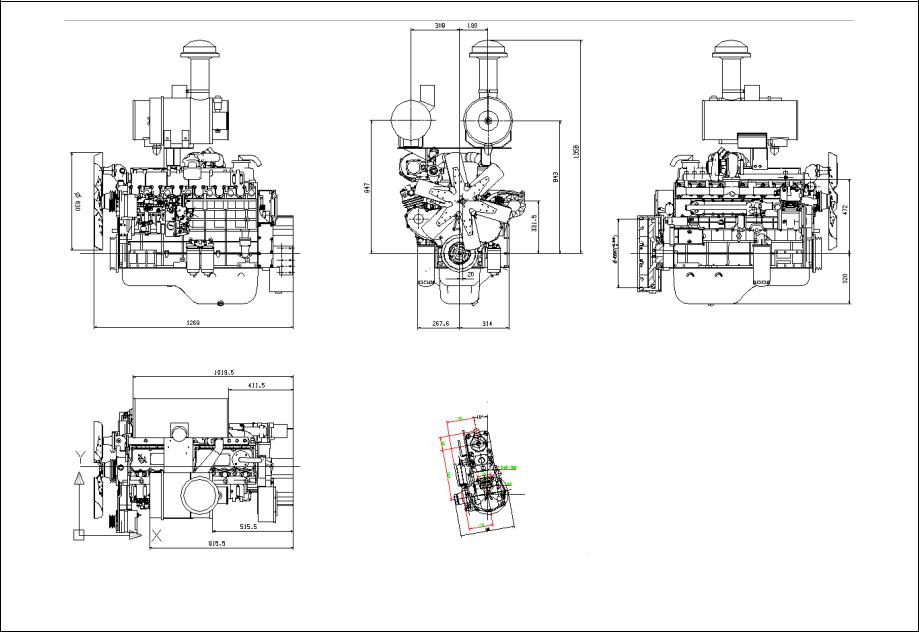

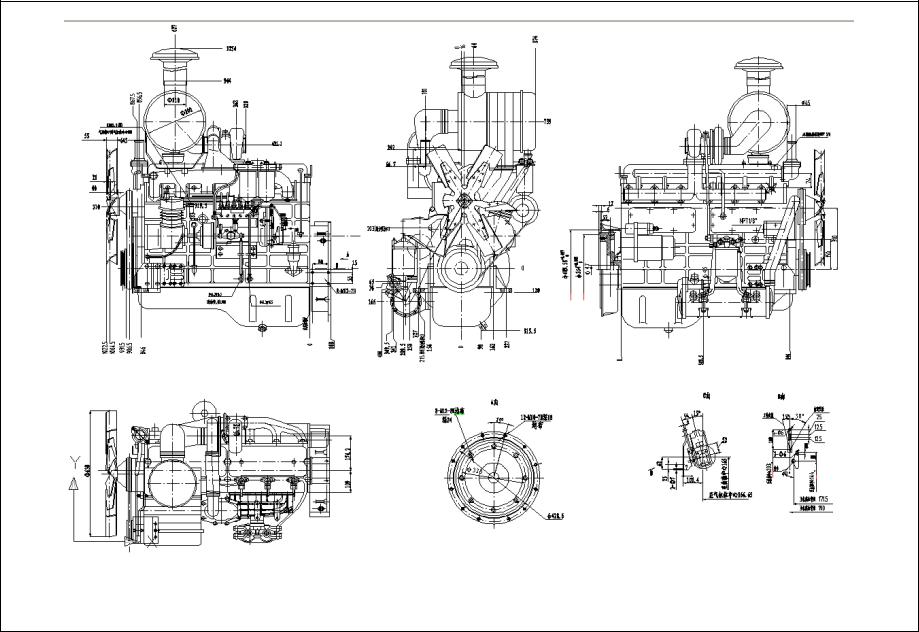

图 1 YC6A 系列柴油机外形安装图(实际跟配套布置会有小差距) Fig 1 Assembly Layout for YC6A Diesel Engine (may differ from the practical configuration) -

Page 9

图 2 YC6B 系列柴油机(非增压)外形安装图(实际跟配套布置会有小差距) Fig 2 Assembly Layout for YC6B Diesel Engine (non-Turbocharged) (may differ from the practical configuration) -

Page 10

图 3 YC6B 系列柴油机(增压)外形安装图(实际跟配套布置会有小差距) Fig 3 Assembly Layout for YC6B Diesel Engine (Turbocharged) (may differ from the practical configuration) -

Page 11

图 4 YC6J 系列柴油机外形安装图(实际跟配套布置会有小差距)… -

Page 12

Fig 4 Assembly Layout for YC6J Diesel Engine (may differ from the practical configuration) -

Page 13

YC6A 工程用系列发动机(A8700)外特性曲线图 YC6A series construction engine (A8700) external characteristic curve… -

Page 14

YC6B 工程用系列非增压发动机(B8C00、B9C00)外特性曲线图 YC6B series construction non-Turbocharged engine (B8C00、B9C00) external characteristic curve… -

Page 15

YC6B 工程用系列增压发动机(B7700)外特性曲线图 YC6B series construction Turbocharged engine (B7700) external characteristic curve… -

Page 16

YC6J 工程用系列发动机(J8000)外特性曲线图 YC6J series construction engine (J8000) external characteristic curve… -

Page 17: 概述 General Introduction

1.1 产品特点 Product Feature YC6A、YC6B、YC6J 系列是由玉柴自主开发而成的发动机,发动机有可靠、省油, 动力性好等优点,是一种理想的配套动力。 YC6A、 YC6B、 YC6J series engines are developed by Yuchai with advantages of reliability, fuel consumption saving and strong power. It is ideal power for construction. 1.2 型号的组成及其代表意义 Model number composition and its specific meaning 产品型号由阿拉伯数字和大写英文字母表示,其组成结构如下:…

-

Page 18: 主要用途及适用范围 Main Application Scope

When the engine needs to work at temperature lower than -15℃ or higher than 40℃, at the at the height above sea-level of higher than 2500 m, the user should consults YuChai Technical Dept. and Service Dept. to adopt effective measure or replace special engine to ensure the normal working.

-

Page 19

Name A8900 A8700 YC6A180Z-T11 YC6A190Z-T10 型 号Model 型 式 立式、直列、水冷、四冲程 Type Vertical in-line, water-cooling, 4-stroke 进气方式 增压 Turbocharged Air intake way 直喷式缩口ω燃烧室 Direct injection tube sinking ω combustion 燃烧室形式 Combustion type chamber 气缸数Cylinder number 气缸直径 Cylinder diameter 活塞行程 Piston stroke (mm) 活塞总排量… -

Page 20

标定工况燃油消耗率 g/kW·h Fuel consumption rate at ≤240 rated working condition 最大扭矩工况燃油消 耗率 Fuel ≤225 consumption rate at max torque g/kW·h 格Technical specification 技 术 规 序号 名称 Name A8900 A8700 夏季:GB 252-2000优级品或一级品0号、10号轻柴油机, Summer: GB 252-2000 top grade or first rater 0 #, 10 # light diesel oil 柴油牌号… -

Page 21

夏季:CD40、CD15W—40,冬季: CD10W—30或与环境相适 应的不低于GB 11122-2006中CD级的其他柴油机油 Summer: CD40、CD15W—40, Winter: CD10W—30 or other 机油牌号 Oil brand diesel oil with grade not below CD grade of GB 11122-2006 corresponding with the environment 曲轴旋转方向(面向功 率输出端) Crankshaft rotation 逆时针 Anticlockwise direction (face to power output end) 供油提前角(上止点前… -

Page 22

润滑方式 压力润滑与飞溅润滑复合式 Lubricating method Pressure lubricating and splattering lubricating combined 起动方式 电起动 Electrical starting Starting method 机油容量 Capacity of engine 17~20 oil (L) 柴油机净质量 Diesel engine net weight 外形尺寸 长×宽× 高 Overall dimension 1234×800×1100 (length × width× height) (mm) 表1-2 YC6B(非增压)系列发动机主要技术参数 Table 1-2 YC6B (non-Turbocharged) series engine main technical parameter 格… -

Page 23

气缸数 Cylinder NO. 气缸直径 Cylinder diameter (mm) 活塞行程 Piston stroke (mm) 活塞总排量 L Total piston 6.871 displacement 压缩比 17.5:1 Compression ratio 气缸套型式 湿 式 Wet Cylinder sleeve type 标定功率 Rated power (kW) r/min 标定转速 Rated rotation 2000 2200 2300 1700 2200 speed(r/min) N·m… -

Page 24

最大扭矩工况燃油 消耗率 Fuel consumption rate ≤235 at max torque g/kW·h 夏季:GB 252-2000优级品或一级品0号、10号轻柴油机, Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel 柴油牌号 冬季:GB 252-2000优级品或一级品0号、-10号、-20号、-35号轻 Diesel oil brand 柴油。 Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # light diesel oil 最高空载转速… -

Page 25

夏季:CD40、CD15W—40,冬季: CD10W—30或与环境相适应 的不低于GB 11122-2006中CD级的其他柴油机油 Summer: CD40、CD15W—40, Winter: CD10W—30 or other 机油牌号 Oil brand diesel oil with grade not below CD grade of GB 11122-2006 corresponding with the environment 曲轴旋转方向(面向 功率输出端) Crankshaft rotation 逆时针 Anticlockwise direction (face to power output end) 供油提前角(上止点… -

Page 26

噪声限值 LwdB(A) Limit of noise ≤115 LwdB(A) 压缩压力 Compressing pressure ≥2.5 (n≥200r/min) 润滑方式 压力润滑与飞溅润滑复合式 Lubricating method Pressure lubricating and splattering lubricating combined 起动方式 电起动 Electrical starting Starting method 机油容量 15~18 Capacity of engine oil (L) 柴油机净质量 Diesel engine net weight 外形尺寸… -

Page 27

ype of 燃烧室形式 直喷式缩口ω燃烧室Direct injection type tube sinking ω combustion combustion chamber chamber 气缸数 Cylinder NO. 气缸直径 Cylinder diameter (mm) 活塞行程 Piston stroke (mm) 活塞总排量 L Total piston 6.871 displacement 压缩比 17.5:1 Compression ratio 气缸套型式 湿 式 Wet Cylinder sleeve 标定功率… -

Page 28

标定工况燃油消耗 g/kW·h 率 Fuel consumption ≤230 rate at rated working condition 最大扭矩工况燃油 消耗率 g/kW·h Fuel consumption ≤225 rate at max torque g/kW·h 夏季:GB 252-2000优级品或一级品0号、10号轻柴油机, Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel 柴油牌号Diesel oil 冬季:GB 252-2000优级品或一级品0号、-10号、-20号、-35号轻 brand 柴油。… -

Page 29

夏季:CD40、CD15W—40,冬季: CD10W—30或与环境相适应 的不低于GB 11122-2006中CD级的其他柴油机油Summer: CD40、 机油牌号 Oil brand CD15W—40, Winter: CD10W—30 or other diesel oil with grade not below CD grade of GB 11122-2006 corresponding with the 曲轴旋转方向(面向 功率输出端) Crankshaft rotation 逆时针Anticlockwise direction (face to power output end) 供油提前角(上止点 前曲轴转角) °CA Fuel supply advance angle 13±2… -

Page 30

压力润滑与飞溅润滑复合式Pressure lubricating and splattering 润滑方式 Lubricating method lubricating combined 起动方式 电起动 Electrical starting Starting method 机油容量 Capacity of engine 17~19 oil (L) 柴油机净质量 Diesel engine net weight kg 外形尺寸 长× 宽×高 Overall dimension 1133×725×889 (length × width× height) (mm) 表1-4 YC6J系列发动机主要技术参数 Table 1-4 YC6J series engine main technical parameter 格Technical specification 技… -

Page 31

气缸直径 Cylinder diameter (mm) 活塞行程 Piston stroke (mm) 活塞总排量 L Total piston 6.494 displacement 压缩比 16.5:1 Compression ratio 气缸套型式 湿 式 Wet Cylinder sleeve 标定功率 Rated power (kW) 标定转速 r/min Rated rotation 2200 2400 2200 2200 speed(r/min) 最大扭矩 N·m ≥405 Max. -

Page 32

夏季:GB 252-2000优级品或一级品0号、10号轻柴油机, Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel 柴油牌号Diesel oil 冬季:GB 252-2000优级品或一级品0号、-10号、-20号、-35号轻 brand 柴油。 Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # light diesel oil 最高空载转速 Max. rotation ≤2420 ≤2620 ≤2420… -

Page 33

供油提前角(上止点 前曲轴转角) Fuel supply advance angle (Top dead 16±2 point front crankshaft corner )°CA 喷油器型号 Fuel CKBL68S001/PF68S35 injector type 油嘴型号Fuel CDLLA147S071/DSLA147S071 nozzle type 喷油器开启压力 Fuel injector 23~24 opening pressure 排气烟度 FSN Exhaust smoke ≤3.5 level (FSN) 噪声限值 LwdB(A) Limit of noise ≤115 LwdB(A) 压缩压力… -

Page 34: 主要技术参数 Main Technical Parameter

外形尺寸 长× 宽×高 1137×800×1473 Overall dimension (length × width× height) (mm) 2.2 主要技术参数 Main technical parameter 表 1-5 YC6A、YC6B、YC6J 系列发动机主要零件配合间隙及磨损极限 Table 1-5 YC6A、YC6B、YC6J series engine main parts fitting clearance and wearing limit 配合公差 (mm) 序号 配合部位 图纸尺寸(mm) 配合性质 Fitting Name & Fitting Position Drawing dimension Fitting type clearance…

-

Page 35

clearance Camshaft bushing hole diameter / Camshaft journal 惰齿轮衬套孔径/惰齿轮轴 Idler 径向间隙 gear bushing hole diameter / idler 0.020~0.066 Radical gear shaft clearance 正时惰齿轮厚/惰轮轴高、 轴向间隙 0.07~0.025 Timing idler gear thick/ idler gear shaft … -

Page 36

活塞环压入 内径 第一道气环 First gas ring 量规内检查 0.45~0.60 Piston ring opening 闭口间隙 Close 0.30~0.45 第二道气环 Second gas clearance Ф108.00 clearance 0.25~0.40 after pressed into ring measure gauge check 油环 Oil ring 气缸孔径/活塞裙部最大直 径 径向间隙 Cylinder hole 0.130~0.195 Radical … -

Page 37

Piston seat hole Interference diameter/piston pin Clearance 径向间隙 主轴承孔径/主轴颈 0.05~0.15 Radical Main bearing bore diameter /main bearing diameter clearance 轴向间隙 曲轴止推面间隙 Axial 0.10~0.30 Crankshaft thrust plane clearance clearance 隔圈/凸轮轴止推片 间 隙 collar/Camshaft thrust … -

Page 38: 发动机主要结构及工作原理

表 1-7 其它螺栓拧紧力矩推荐值 Table 1-7 Recommended tightening moment of the plug screw of other bolts 螺纹直径(mm) 公制 Thread diameter Metric (mm) system 扭紧力矩(N·m) 8~12 16~20 27~34 61~68 115~129 Tightening moment of(N·m) 3 发动机主要结构及工作原理 Primary Structures and Working Principle of Engine 3.1 气缸体…

-

Page 39

气缸体后端面与正时齿轮室盖形成正时齿轮室,室内装有正时传动齿轮,机油泵由下部 中间齿轮传动。正时齿轮室盖与减振皮带轮上打有相应的刻度标志,用来检查供油正时和配 气正时。 The rear end of the cylinder block and timing gear chamber cover forms the timing gear chamber with timing transmission gear in it and the oil pump is driven by the lower middle gear. Corresponding scale marks are printed on the timing gear chamber cover and vibration absorbing belt pulley to check the fuel supply timing and air distribution timing. -

Page 40

Second time, 140~180N·m 第二次:140~180N·m Third time, 210~250N·m 第三次:210~250N·m 3.2.2 气缸垫 Cylinder gasket 气缸垫片置于气缸盖底部与气缸体顶部之间,在气缸盖螺母(螺栓)拧紧后, 对循环冷却水、机油、燃烧室的高压气体起密封作用,为钢架石棉板制成,表面涂有防粘层 涂料,拆气缸盖后重装,应更换气缸垫片。凡新机运行完磨合期后,应复紧缸盖螺栓到规 定的力矩,以防漏水、漏油、冲缸垫。特别注意:全钢质缸垫一经拆卸,不能重复使用! Cylinder gasket is installed between the bottom of cylinder head and the top of cylinder body. After tightening cylinder head cover nut (bolt), it could seal circulating cooling water, oil and high pressure gas in combustion chamber. -

Page 41

heat-resisting steel is installed on the intake valve of cylinder head and can be replaced (standard size or extra large size) after wearing. The seat angle and cone angle of intake valve and exhaust valve is 90°. The sinkage of valve shall be controlled strictly and technical requirement is 1±0.2 mm (Fig 2-2). -

Page 42

3.2.4 配气机构 Air distribution structure 配气机构采用顶置式配气机构,由气门组和气门传动组构成。气门组包括气门、气门弹簧、 气门锁夹、气门导管、气门座。气门传动组包括凸轮轴、气门挺杆、推杆、摇臂、凸轮轴正时 齿轮等。 Air distribution structure adopts overhead air distribution structure and it consists of valve group and valve transmission group. The valve group includes valve, valve spring, valve lock, valve duct and valve seat. Valve transmission group includes camshaft, valve lifter, push rod, rocker arm and camshaft timing gear. -

Page 43

crankshaft to the position were the first piston is on the compression TDC, then adjust the No. 1, 2, 3, 6, 7 and 10 valve. Rotate again the crankshaft for 360° to adjust the No. 4, 5, 8, 9, 11 and 12 valves. -

Page 44

and seized between camshaft timing gear and thrust plate. Fig 2-5 and Fig 2-4 过大则会引起凸轮轴窜动和气门正时不准,也容易造成供缸盖机油油孔的错位堵塞而上 不了油。进排气门摇臂各有 6 个,与气门杆端接触的头部有镶块,经氮碳共渗后,有很高的硬 度,耐磨性好。 If the clearance is too large, it will cause camshaft run out and incorrect valve timing and also will lead the misplacement of oil supply valve head oil hole and can not supply the oil. There are 6 rockers on each intake valve and exhaust valve, there is glut with valve lever on the connected end. -

Page 45: 曲柄连杆机构 Crank-Connecting Rod Mechanism

3.3 曲柄连杆机构 Crank-connecting Rod Mechanism 曲柄连杆机构是发动机的主要工作机构。其作用是把活塞的往复直线运动变为曲轴的旋 转运动,把燃气作用在活塞上的力转变成曲轴的扭矩并对外输出作功。曲柄连杆机构包括活 塞连杆组和曲轴飞轮组。活塞连杆组的零件见图 2-9。 Crank-connecting rod mechanism is one of main working mechanisms of the engine. It is used to turn reciprocating linear motion of the piston into rotating motion of the crankshaft, i.e. turn the force applied by the fuel gas in piston into the torque of the crankshaft which can be output to do work.

-

Page 46

assembly. 图 2-9 连杆活塞组件 图 2-10 活塞的安装及闭口间隙的测量 Fig2- 9 Link piston components Fig.2-10 installation of piston 活塞环在安装时应注意其倒角的方向。活塞环开口安装方向亦应按规定,见图 2-10, 。活 塞通过活塞冷却喷钩喷润滑油冷却, 它可保证活塞有效的冷却而不致于过热, 见图 2-11 注意不 可拆掉活塞冷却喷钩不用。 The chamfer direction should be noticed during the installation of the piston ring, refer to The installation direction of the piston ring should meet with the provision. -

Page 47

装配时,连杆杆身上的记号要朝前。将 连杆小头置于活塞销座中间, 活塞销装入销孔 内,用软金属轻轻敲打,装入后的活塞和连杆应摇动自如无阻滞现象。在更换活塞环时要注意 检查其轴向和开口间隙。 (图 2—12) 。 Install piston into cylinder liner according to the forward mark on the connecting rod body. Put the small head of connecting rob into the middle of piston pin, put the piston pin into the… -

Page 48

pin hole, then knock it lightly with soft metal see if the piston and connecting rob move freely and not to be clogged. Pay attention to check up the shaft orientation and opening clearances. (fig.2-12) 连杆螺栓的拧紧力矩为 200±20N·m,需分三次均匀拧紧, The tightening torque of the connecting rod bolt shall be 200±20 N·m, and it shall be tightened in three steps 第一次拧紧力矩:60~80N·m,… -

Page 49: 燃油系统 Fuel System

three times according to symmetrical position with the torque specified in Table 1-6. Since the flywheel is the connecting part for power output, the outer connecting dimensions are different depending on various manufacturers. Refer to the supply technical agreement for specified connecting dimensions.

-

Page 50

Please pay attention to the following when using: (1)检查油泵润滑油量是否充足,不足时应加足。 Check whether the lubricating oil in the pump is adequate. Fill full if inadequate. (2)放完输油管道及油泵内腔空气。 Exhaust the air in the fuel transfer pipe and fuel pump. (3)检查供油提前角是否正确,若不正确需调整。 Check whether the fuel supply advance angle is correct. Adjust it if incorrect. (4)检查断油装置是否起作用,若不起作用需妥善修复。… -

Page 51

advance angle; then tighten the 4 tightening bolts of the pump gear according to the torque requirement. 方法三:转动曲轴至第一缸供油,然后将曲轴转至所需要的供油提前角,再按方法一二拔 动喷油泵体或转动喷油泵凸轮轴至第一缸开始供油位置,扭紧紧固螺栓,检查供油提前角,若 符合要求,再按扭紧力矩要求扭紧紧固螺栓。 Method 3: rotate the crankshaft to first cylinder supplying fuel; rotate the crankshaft to the fuel supply advance angle as required; then move the fuel injection pump body or camshaft to first cylinder starting supply position as per Method 1 and Method 2;… -

Page 52

The user shall check the lubricating oil quantity in the advance device, and fill full when inadequate. (Fig-2-17). Fuel supply advance angle is important quality control item, and the adjustment shall be carried out by the special staff of Yuchai service station. 高压油泵的输油泵的结构如图 2—18,输油泵上设有手动驱动装置,用来排除燃油管路内… -

Page 53

Yuchai service station or to professional staff for adjustment to avoid accidents. Yuchai filter is of rotary paper filter element structure (Fig. 2-19), it is mainly used to separate water and oil and filter the bulky grain in diesel oil. The filter element of diesel engine filter shall be replaced for using accumulated 400 hours. -

Page 54

柴油滤清器为二级纸质滤芯旋装式(图 2—20) 。柴油机每累计工作时间 400 小时应更换 柴滤器整体滤心,以免因芯滤阻力过大而引起供油不足。 Yuchai filter is secondary rotary paper filter element structure (Fig. 2-20). The filter element of diesel engine filter shall be replaced for using accumulated 400 hours to avoid too large filter element resistance to lead the lacking of fuel supply. -

Page 55

nozzle model and opening pressure. The fuel injector matching parts are of high precision and the needle valve and body can’t be interchanged. The pressure of the fuel injector can be adjusted. The adjusting method is that: remove the pressure adjusting screw and tighten it clockwise to enlarge the fuel injection pressure, and tighten it anticlockwise to reduce the fuel injection pressure. -

Page 56

The fuel injector is installed on the cylinder cover to ensure the project height from the cylinder bottom (i. e. the project height of the fuel injector); the height of YC6A series engine shall be controlled at 4.2±0.1mm, and 2.4±0.1mm for YC6B and YC6J series. The height is not allowed to change when disassembling the fuel injector;… -

Page 57: 润滑系统 Lubrication System

3.5 润滑系统 Lubrication System 润滑系统的任务就是把清洁的、压力和温度适宜的润滑油送至柴油机的各摩擦表面进行 润滑,使柴油机各零件能正常工作。柴油机的润滑系统如图 2—24 所示。 Purpose of the lubrication system is to deliver clean lubricant with appropriate pressure and temperature to all friction surfaces of diesel engine to lubricate them so as to ensure normal operation of all parts and components of the engine. Engine lubricating system is shown in Fig 2-24.

-

Page 58

机油泵将油底壳的润滑油经集油器滤网过滤后泵入主油道,主油道沿气缸体纵向布置,润 滑油经机油滤清器座用油管引至水冷式机油冷却器,利用水与油的热交换对机油进行冷却后再 用油管引回机油滤清器座,并进入机油滤清器过滤后进入分油道向主轴承供油,并通过曲轴上 的油道润滑连杆轴承和凸轮轴轴承,从凸轮轴第二、第五道及相应的两条连接油管间歇地引向 摇臂轴总成,以便润滑摇臂轴衬套和气门间隙调整螺钉,然后机油沿推杆向下流至挺柱,多余 的机油经气缸盖上的推杆孔、气缸体上的空腔流回油底壳。齿轮等其余运动件的润滑靠曲轴转 动时曲拐搅动机油引起机油的飞溅进行润滑。 The lubricating oil in the oil pan flows over the filter net and the oil pump delivers the oil to main oil path; the main oil path is arranged vertically along the cylinder block; the oil pipe leads the lubricating oil through oil filter seat to water cooled oil cooler, the oil is cooled down utilizing the heat exchange of water and oil;… -

Page 59

机型,分为板式和铜管式两种。机油冷却器使用一段时间后,会结有水垢或其它杂物,影响冷 却效果和机油压力,尤其是使用的冷却水水质较差时更应注意。清洗机油冷却器的方法是:先把 进出水管及进出油管拆除,将冷却器从机体上卸下,板式的则拆开冷却器的盖板,将芯板子取 下,用柴油对芯板内腔进行冲洗,将内腔的油垢冲洗掉,然后清除芯板表面及水腔内的水垢, 以提高冷却效果。清除圬垢后,用干净的柴油冲洗,并擦拭干净。铜管式的则拆开两端端盖, 用钢丝扎紧干净的棉纱或布条,沾干净的柴油逐条铜管进行通洗,将管内的水垢清除干净,通 洗完后再用干净的柴油冲洗一次,端盖及壳体也要清洗干净。清洗后的机油冷却器组装时应注 意密封垫片应予以更换,组装时螺栓应按对角顺序均匀拧紧,以保证不出现渗漏现象。 Check the oil level in the oil pan regularly and the oil level shall be between the upper and lower scale of the oil dipstick (Fig 2-25). There is oil drain plug at the bottom of the oil pan to drain oil. -

Page 60

满新的或经清洗干净的滤清器,然后用少量清洁的机油润滑橡胶密封圈再安装滤清器。 The engine oil filter is of paper filter element, there are two types according to different users, one is rotary paper filter element structure and model number is JS0818. The filter of this type should be changed with shell. Another type filter is J1012 whose filter element is clean and can be reused. -

Page 61: 冷却系统 Cooling System

3.6 冷却系统 Cooling System 冷却系统采用强制闭式循环水冷却系统,主要由散热器(水箱) 、水泵、风扇、调温器、 机油冷却器、进出水管等零件组成(图 2—27) 。 Cooling system uses a forced closed cycle cooling system. It includes radiator (water tank), water pump, ventilating fan,thermostator, oil cooler and intake and exhaust water pipe. (Fig 2-27) 散热器下部出水口通过水管接机油冷却器的进水口,机油冷却器出水口通过水管接水泵, 水泵将冷却液泵入气缸体水道,冷却液先经过气缸体内部的水套冷却气缸,然后向上流动冷却 气缸盖,再经出水总管汇集到达调温器处。当冷却液温度低于 70℃时,调温器关闭,全部冷却 液旁通至水泵进口处,这时冷却液只在气缸体和气缸盖之间循环,可迅速暖车。当冷却液温度…

-

Page 62

冷却液应采用清洁干净的软水,采用防冻防锈液更佳。柴油机出水温度控制在 80℃~95 ℃,机油温度控制在 85℃~120℃较适宜。 (注意正常工作时机油温度是无法控制的,机油温 度一般比出水温度高 15℃~20℃) Clean soft water shall be used as coolant, and it is better to use anti-freeze anti-rust fluid. The water outlet temperature of the diesel engine shall be controlled at 80℃~95℃ and the oil temperature shall be controlled at 85℃~120℃. -

Page 63

50N force is applied between two belt pulleys. (Fig 2-29). The belt is C belt or ribbed belt. There are different specifications according to various models. Bring the old specification when replacing. The belt tightness could be adjusted through the adjustment of the positions of charging generator and adjusting plate. -

Page 64

调温器为腊式,安装于出水总管出水口内,柴油机在使用过程中,不要轻易把调温器拆掉, 以免影响柴油机的正常工作状态。 (图 2—31) Thethermostator is of wax type and installed in the water outlet of the pipe. It is not… -

Page 65: 启动装置、电气系统与仪表 Start Device, Electrical System And Instrument

allowed to remove thethermostator when using to avoid affecting the normal working condition of the diesel engine. 3.7 启动装置、电气系统与仪表 Start device, electrical system and instrument 电气系统原理图如图 2—32 所示。 The electric system principle is shown in Fig2-32 柴油机所用启动电机为四极四刷直流串激电动机,上述起动电机工作电压均为直流 24V, 最大输出功率 6.6KW,单线制负极接地(搭铁) 。电机小齿轮与飞轮齿圈的啮合用电磁铁控制 机械驱动并带有滚柱式单向离合器,以防止电机转子超速,当按下启动开关一次不能起动时,…

-

Page 66

at least 1 minute; the start time shall not exceed 10 sec to avoid the damage due to overheat. It is forbidden to press the start button again when the diesel engine and motor operate, otherwise, the gear and gear ring will hit each other to cause damage. When the engine starts to operate, release the button to reset the small gear. -

Page 67

voltage and adjust the contact. The clearance between armature iron and iron element of the adjustor shall be 1.4~1.5mm. 进气加热器安装于进气管与进气弯管接合处,是当环境温度较低时,使柴油机更易于起 动而设置的辅助启动装置。其工作原理是当空气从空气滤清器进入进气管流经加热器时,已 通电发热的电热板将流过的空气进行加热,温度升高后的空气被吸入气缸使柴油机易于起动 。与配置有进气加热器的柴油机配套的工程机械应设有带预热启动的启动开关,接线时注意 与加热器两个接线柱相联接的接线端子不要与柴油机外壳相碰,以免造成短路故障。在启动 时如需进行预热启动,则应先把启动开关板至预热位置,每次预热时间应控制在 40 秒内,然 后再将开关板至启动位置,对发动机进行启动. Air intake heater is installed at the joint of air intake pipe and elbow pipe. When the environmental temperature is low, the auxiliary start device could make the diesel engine easy to start. -

Page 68: 增压器 Turbocharger

3.8 增压器 Turbocharger YC6A、YC6B、YC6J 系列增压的柴油机均采用废气涡轮增压系统。其工作原理如下图所 示。柴油机排气管 1 接到增压器的涡轮壳 4 上,柴油机排出的高温和有一定压力的废气经涡轮 壳 4 进入喷嘴环 2,由于喷嘴环的通道面积由大到小,因而废气的压力和温度下降,而速度却 迅速提高。这个高速的废气气流,按着一定的方向冲击涡轮 3,使涡轮高速旋转。废气的压力、 温度和速度越高,涡轮转动越快。通过涡轮的废气最后排入大气。因为涡轮 3 与压气机叶轮 8 固装在同一根转轴上,所以叶轮与涡轮以相同的速度旋转,将经过空气滤清器滤清过的空气吸 入压气机壳。旋转的压气机叶轮将空气压力提高后进入气缸,由于空气密度增加,进入气缸的 空气量也增加,因而可以增加喷入气缸的油量,从而提高发动机功率,降低燃油消耗率。 YC6A、 YC6B、 YC6J series diesel engine adopts exhaust gas turbo Turbocharged system. The working principle is shown as following. The diesel engine exhaust pipe 1 is connected to the turbo housing 4 of the Turbocharger;…

-

Page 69

pressure to enter the cylinder. Since the air intensity increases, more air enters into the cylinder, so the fuel quantity injected into the cylinder increases, thus the engine power can be improved and the fuel consumption can be reduced. 涡轮增压器和增压柴油机在性能上有着密切的关系,如果增压器的性能改变,将直接影 响到柴油机的性能。为了使增压柴油机保持良好的综合性能,同柴油机一样,增压器在使用… -

Page 70

增压器系统常见故障及排除方法 Malfunction and Solution of Turbocharger 故障原因 Cause 排除方法 Solution ①进气系统堵塞 Air 检查空气滤清器与压气机之间的管路、压气机出口与进气管管路及进气 intake system 管、清理通畅。Check and clean the pipe between air filter and blocked compressor, compressor outlet and air intake pipe ②进气泄漏 检查空气滤清器与压气机之间的管路、 压气机出口与进气管之间的管路, Air intake leaking 进气管与发动机连接处等是否有泄漏、可拧紧紧固螺栓、更换垫片等零 件。Check whether there is leak between air filter and compressor, air intake pipe and connecting part.;… -

Page 71: 转向泵 Steering Pump

Turbocharger, if there is malfunction of the Turbocharger, contact the technical service station of Yuchai to solve the problem. The user is forbidden to disassemble the Turbocharger, otherwise, the quality warranty shall be not provided. If…

-

Page 72

形较大,需及时更换,否则油路会漏油。 Ensure the cleanness and notice the smoothness of pipeline and seal gaskets on oil inlet and outlet during the assembly, disassembly and replacement of pipeline. If the pipeline is distorted greatly, be sure to replace it in time; otherwise, the oil pipeline will leak oil. 特别注意:因转向泵属汽车安全件,其零件制造及装配有严格的要求,禁止非专业人员… -

Page 73

使用中应经常检查油罐中油量是否缺少,油液有无变质,杂质是否过多,如发现不良 状况,应及时添加或更换。 Frequently check the oil tank for its quantity and the hydraulic oil quality for its deterioration & impurities. Replenish or change oil in time in case of any unsatisfactory situations 进回油接头出现漏油现象时不允许采用涂密封胶排除,否则会造成转向泵失效。 Any leakage on the oil inlet & return joints can not be remedied by means of coating the sealant;… -

Page 74: 发动机的使用和维护保养

检查密封铜垫变形情况,去除脏物、毛剌或更 吸 油 口 密 封 不 良 Poor 换 Check the deformation of the copper sealing of the oil suction. sealing gasket, remove dirt and burr, or replace the gasket. 骨架密封圈损坏 Framed 更换骨架密封圈 Replace the framed sealing sealing ring is damaged. ring.

-

Page 75

Check the cooling fluid in radiator to make sure cooling smoothly. 检查排除燃油管路的空气和柴油滤清器的水; Check and drain the air in fuel pipeline and water in diesel filter. 检查油箱,若不够,添加燃油; Check fuel tank and add fuel if it is not enough. … -

Page 76

各汽车仪表的工作情况。发现有不正常现象,必须立即停车检查排除,必要时送修。 Working situation of all vehicle instruments: If there is fault, driver must stop the vehicle and check and solve the problem, driver can also call somebody to repair the vehicle if necessary. Running 4.1.3 运行 发动机起动之后, 依次使发动机在低速和中速下空车暖机, 当发动机冷却液温度高于 60℃, 润滑油温度高于… -

Page 77

把冷却液放完,以免冻坏机件。 In addition, you should pay due attention to the following: drain off the coolant to protect the engine & its components from freezing when the ambient temperature is lower than 5 ℃ and the engine is not ensured to be prevented from frrezing. 当气温低于-30℃时,应将蓄电池拆下,搬入暖室内保温,否则难以起动。… -

Page 78: 发动机的维护保养 Engine Maintenance

In order to ensure the diesel fuel can satisfy the requirements above and avoid the influence from impurity and water in diesel fuel to parts of engine diesel fuel system, Yuchai advices customers to buy diesel fuel at standard gas station. If necessary, customers had better have a fuel tank with fuel filter.

-

Page 79

护 Routine maintenance 检查油底壳及喷油泵内的机油量 Check the oil quantity in the oil pan and fuel injection pump. 检查“三漏”情况 Check leakage of fuel, coolant and oil 所有日常维护项目 All items of daily maintenance 清洗输油泵进油滤网 Clean the fuel inlet filtering net of 一 the fuel transfer pump 检查风扇皮带的松紧度… -

Page 80

检查电器线路各连接点的接触情况 Check the contact of the circuit connection 检 查 所 有 重 要 螺 栓 螺 母 的 拧 紧 情 况 Check the tightening of all key bolts and nuts. 若冷却系统结垢严重,水温高的应及时除垢 The furring shall be removed if there is much furring in the cooling system. -

Page 81

注意:三级保养完成的柴油机应有 50 小时的磨合期,不能马上高速高负荷运转,以免损伤机件,影响使 用寿命。 Note: run-in period of 50 hours is required for the diesel engine after 3-level maintenance, and it can’ work at high speed with heavy load to avoid damaging the parts and shortening the lifetime. 4.2.1 柴油机的使用: Operation of the diesel engine (1)检查准备:Check preparation … -

Page 82

机预热后才能起动) Start the diesel engine after the start preparation and confirmation of the requirement. (The diesel engine can be started after preheating in winter.) 起动柴油机时, 持续起动时间不能超过 10 秒钟; 二次起动的时间间隔不应少于 1 分钟; 若连续三次均无法起动,则应检查原因,排除故障,再行起动。 The continuous start time of the diesel engine shall not exceed 10 sec, and the interval between 2 starts shall be at least 1 min;… -

Page 83

Send it to repair if necessary. (4)停机:Engine shutoff 停车前怠速运行 3~5 分钟后才熄火,避免急速停车,特别是高转速高负荷运转时更应 如此。 The engine is shut off after 3~5 min operation at idle speed when the vehicle stops. Sudden stop shall be avoided, especially when the engine operates at high speed with heavy load. -

Page 84

n 严禁使用劣质机油, 否则将会对柴油机造成严重损害, 由此产生的故障玉柴不予保修。 It is forbidden to use poor quality oil, or it will lead serious damage to diesel engine. The malfunction for this reason shall not be guaranteed and repaired by Yuchai. n 当机油变稀、变稠、变黑、失去粘性时,必须及时更换机油,建议更换周期 150-250 小时。… -

Page 85

柴油滤清器建议使用 200-300 小时进行更换,请使用品质信誉好的柴油滤清器,建议 使用玉柴专用配件。 It is recommended to replace the diesel oil filter after using for 200-300 hours. Please select diesel oil filter with high reputation and excellent quality. Yuchai special part is recommended. (4)冷却液的使用: Application of cooling fluid 如使用水做为冷却液,应采用清洁干净的软水,不能使用井水、河水、泉水等硬水。… -

Page 86

station. The external appearance is clean and transparent, with no impurity, no thickness and no irritating smell. On the package there shall be detailed name of production unit, products specification and clear instruction and explain. 使用劣质的防冻液不但不能防冻防沸,反而会加速冷却系统的腐蚀。 Use poor quality antifreeze can not to prevent frostbite and boil, on the contrary, poor quality antifreeze will increase the corrosion of cooling system. -

Page 87: 发动机常见故障及排除方法

5 发动机常见故障及排除方法 Frequently-possible Troubles and Their Solution 5.1 发动机不能起动 Engine Fails to Start 故 障 原 因 Cause 排 除 方 法 Solution ① 起动机转速过低 检查起动系统,起动转速不得低于 110r/min。 Too low starter rotating Check starting system, and the starting rotating speed can speed.

-

Page 88

弹簧是否折断; fuel or low injected fuel Check whether the fuel injections pump plunger and fuel pressure. outlet valve is worn or clogged or not, plunger spring and fuel outlet valve spring is broken or not. ⑤ 起动系统故障: Starting system troubles 电路接线错误或接触不良:… -

Page 89: 发动机功率不足 Insufficient Power Of Engine

5.2 发动机功率不足 Insufficient power of Engine 故 障 原 因 Cause 排 除 方 法 Solution ① 进气堵塞 检查空气滤清器、进气管,清理或更换空气滤清器滤 芯。 Air intake is clogged. Check air cleaner and intake pipe. Clean or replace air cleaner element ② 排气背压过高 检查气门定时,必要时调整;清理排气管。 Too high exhaust back pressure. Check valve timing and adjust it as necessary;…

-

Page 90

fuel filter for clogging; replace the rotary element. ⑦ 喷油泵柱塞磨损过大 检查、更换。 Excessive wear of EUP plunger Check and replace ⑧ 传感器坏 检查、更换 Sensor fault Check and replace ⑨ 增压补偿管损坏漏气 更换。 Turbocharged supplement pipe Replace broken and qir leak ⑩ 喷油器雾化不良 检查喷油压力、清理积碳、调整及修理。… -

Page 91: 发动机运转时有不正常的杂声

5.3 发动机运转时有不正常的杂声 Abnormal Noise during Running of Engine 故 障 原 因 排 除 方 法 Cause Solution 检查装配正时是否正确 ①气缸内有异响 Check whether the timing is correct or not. There is abnormal sound in the 检查并调整配气定时。 cylinder Check and adjust the air distribution timing. ②连杆轴瓦、…

-

Page 92: 排气冒黑烟 Black Smoke From Exhaust Manifold

damaged, so the rotating part bumps with the housing. ⑦气门间隙过大, 在气缸盖处有较 调整气门间隙。 大响声 Adjust the valve clearance. The valve clearance is too big; there is bigger sound at the cylinder head. ⑧ 增 压 器 喘 振 清除压气机通道、废气通道的积碳及污物,运行海拔过 Turbocharger 高 。 Remove the carbon deposit and dirt in the surging passage air compressor and exhaust gas path;…

-

Page 93: 润滑油压力异常 Abnormal Lubricant Pressure

更换燃油。 ① 燃 油 质 量 差 、 含 水 份 过 多 Poor Replace the fuel. quality of fuel and too much content 检查调温器工作温度,必要时更换。 ②冷却水温度过低 Too low temperature of coolant Check the working temperature of thermostat, and replace it when necessary. 按专门人员检查和调整。…

-

Page 94

② 润滑油泵转子磨损或装配间隙过 更换润滑油泵。Replace lubricating oil pump 大 Worn inside/outside rotors of the lubricating oil pump, or too big assembly clearance 更换旋装式滤芯 ③润滑油滤清器堵塞 Clogged lubricating oil filter Replace the rotary element ④ 润滑油滤清器调压阀失灵 修复。 Failure of pressure adjustment of Repair. lubricating oil filter ⑤… -

Page 95: 润滑油消耗高、消耗量大

again when the oil temperature is normal. ② 溢流阀堵塞 检查、清洗。 Clogged overflow valve Check and clean. 5.7 润滑油消耗高、消耗量大 High Lubricating Oil Temperature and Bigger Consumption Quantity of Oil 故 障 原 因 Cause 排 除 方 法 Solution ①外部润滑油管路有泄漏 Lubricating oil 检查并修复。…

-

Page 96: 增压器常见故障及排除方法 Malfunction And Solution Of Turbocharger

water temperature sensor plug temperature is the same as the indicating temperature; if not, replace he sensor plug or water gauge ⑹冲缸垫 Rushing cylinder gasket 检查更换 Check and replace 重新按要求匹配 Match again as required ⑺改装情况下水箱、风扇匹配问题 Radiator and fan matching problem under refit 5.9 增压器常见故障及排除方法…

-

Page 97: 离合器常见故障及排除方法 Malfunction And Solution Of Clutch

5.10 离合器常见故障及排除方法 Malfunction and Solution of Clutch 故障原因 Cause 排除方法 Solution 1.离合器抖动 Clutch trembled 校正离合器压盘和从动盘的变形,消除不规则接触 Calibrate the distortion of clutch pressing plate and driven plate; eliminate abnormal touch 2. 油 路 堵 塞 或 有 大 量 空 气 进 入 Fuel 清理油污,调整分离轴承位置,更换从动盘总成,…

-

Page 98

the engine to check, repair and replace damaged parts. -

Page 99

(封底)Back cover 玉柴机器 绿色动力 Yuchai Machinery Green Power 执行标准 Implementation standard:Q/YC 456-2006 广西玉柴机器股份有限公司 Guangxi Yuchai Machinery Co,. Ltd. 地址 Add:88 Tianqiao West Road , Yulin,Guangxi,China 邮编 Post Code:537005 销售电话 Sales Tel:00886-775-3226931 传真 Fax:0086-775-3289856 网址 Website:www.yuchai.com…

Yuchai Yc 8 Models 2010 — Hydraulic Excavator Product Series

Yuchai Yc 8 Models 2010 — Hydraulic Exca

Adobe Acrobat Document

1.4 MB

Yuchai — Bosch ECU System for Diesel Engine

Yuchai — Bosch ECU System for Diesel Eng

Microsoft Power Point Presentation

8.7 MB

Yuchai YC4F E-II — PDF Manual

Yuchai YC4F E-II — PDF Manual.pdf

Adobe Acrobat Document

3.3 MB

Yuchai YC15-8 Hydraulic Excavator — Operation And Maintenance Manual

Yuchai YC15-8 Hydraulic Excavator — Oper

Adobe Acrobat Document

19.4 MB

Yuchai DL165H Skid Steer loader Owners Manual

Yuchai DL165H Skid Steer loader Owners M

Adobe Acrobat Document

10.8 MB

YUCHAI YC6J125Z-T20 PDF Service Manual

YUCHAI YC6J125Z-T20 PDF Service Manual.p

Adobe Acrobat Document

1.5 MB

|

Title |

File Size |

Download Link |

|

Excavadora Yuchai Yc135-7.pdf |

369.3kb |

Download |

|

Tuchai YC4F90-30(F51J 1) — Parts Catalogue of Diesel Engine.pdf |

3.4Mb |

Download |

|

Yuchai — Bosch ECU System for Diesel Engine.ppt |

8.7Mb |

Download |

|

Yuchai — Engine knowledge and related auto and fault analysis.pdf |

6.6Mb |

Download |

|

Yuchai DL165H Skid Steer loader Owners Manual.pdf |

10.8Mb |

Download |

|

YUCHAI Engine Trouble Feedback Sheet.doc |

64kb |

Download |

|

Yuchai SL730 Engine (YC6A, YC6B, YC6J) — Service Manual.pdf |

1.5Mb |

Download |

|

Yuchai YC 4F Series — Operation and Maintenance Manual for Diesel Engine.pdf |

3.6Mb |

Download |

|

Yuchai Yc 8 Models 2010 — Hydraulic Excavator Product Series.pdf |

1.4Mb |

Download |

|

Yuchai YC08-8(805) Hydraulic Excavator — Spare Parts Book.pdf |

6Mb |

Download |

|

Yuchai YC135-7 Hydraulic Excavator — Owners Manual.pdf |

4.6Mb |

Download |

|

Yuchai YC15-8 Hydraulic Excavator — Operation And Maintenance Manual.pdf |

19.4Mb |

Download |

|

Yuchai YC18-8 Hydraulic Excavator — Operation And Maintenance Manual.pdf |

19.4Mb |

Download |

|

Yuchai YC25-8 hydraulic digger Owners Manual.pdf |

4Mb |

Download |

|

Yuchai YC4D Diesel Engine Parts Catalog.pdf |

3Mb |

Download |

|

Yuchai YC4E Manual Euro II.pdf |

2.5Mb |

Download |

|

Yuchai YC4F E-II — PDF Manual.pdf |

3.3Mb |

Download |

|

Yuchai YC55SR Spare Parts Book.pdf |

7.1Mb |

Download |

|

YUCHAI YC6J125Z-T20 PDF Service Manual.pdf |

1.5Mb |

Download |

Yuchai Engineering Machinery is a Chinese manufacturer of small-sized construction machinery, founded in 1951. The company is headquartered in Guangxi Zhuang Autonomous Region,

China.

The company employs 16,000 employees. Total assets are estimated at $ 13.4 billion.

Today Yuchai is a manufacturer of diesel engines and small-sized construction equipment.

The main business of Yuchai consists of six sectors, namely diesel engines, construction machinery, auto parts, auto chemical products, handling materials, electromechanical products and special

vehicles, and also makes efforts in the development of tourism, real estate and hotel business.

The annual capacity and sales volume of about 600,000 diesel engines and 10,000 units of medium- and small-sized construction equipment, with such volumes, Yuchai occupies half of the diesel

engine market in China.

YUCHAI mini excavators:

- YUCHAI YC25-2

- YUCHAI YC15-6

- YUCHAI YC15-7

- YUCHAI YC15-8

- YUCHAI YC18-2

- YUCHAI YC18-8

- YUCHAI YC25-2

- YUCHAI YC35

- YUCHAI YC30-2

- YUCHAI YC35SR

- YUCHAI YC35-8

- YUCHAI YC35SR

- YUCHAI YC45

- YUCHAI YC45-6

- YUCHAI YC45-7

- YUCHAI YC45-8

Crawler excavators YUCHAI:

- YUCHAI YC55

- YUCHAI YC55-8

- YUCHAI YC75SR

- YUCHAI YC55SR

- YUCHAI YC75SR

- YUCHAI YC85

- YUCHAI YC85-6

- YUCHAI YC85-7

- YUCHAI YC85-8

- YUCHAI YC135

- YUCHAI YC135-6

- YUCHAI YC135-7

- YUCHAI YC135-8

- YUCHAI YC230LC-8

Backhoe loaders YUCHAI:

- YUCHAI CW-7

- YUCHAI LW-6

- YUCHAI LW-7

- YUCHAI LW-8

- YUCHAI SW-6

- YUCHAI SW-7

- YUCHAI CW-6

- YUCHAI CW-7

- YUCHAI YW-6

YUCHAI Loaders:

- YUCHAI YCZ07

- YUCHAI YCZ07

- YUCHAI YCZ10

- YUCHAI Bulldozers:

- YUCHAI YCT306-6

- YUCHAI YCT306-2

- YUCHAI YCT282S

- YUCHAI YCT282S-2

- YUCHAI YCT206

- YUCHAI YCT256

- YUCHAI YCT306-2

- YUCHAI YCT280P

YUCHAI Forklifts:

- YUCHAI YCC10E

- YUCHAI YCC15E

- YUCHAI YCC20E

- YUCHAI YCC25E

- YUCHAI YCC30E

- YUCHAI YCC35E

- YUCHAI YCC20C

- YUCHAI YCC20CD

- YUCHAI YCC50CD

- YUCHAI YCC25C

- YUCHAI YCC25CD

- YUCHAI YCC30C

- YUCHAI YCC30CD

- YUCHAI YCC35C

- YUCHAI YCC35CD

- YUCHAI YCC40

- YUCHAI YCC45

- YUCHAI YCC50CD

Yuchai Motor & Engines: owner’s, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

| Title | File Size | Download Links |

| Yuchai YC4D Diesel Engine Parts Catalog [PDF] | 2.7Mb | Download |

| Yuchai YC4E Manual Euro II [PDF] | 2.5Mb | Download |

| Yuchai YC4F E-II – PDF Manual [PDF] | 3.2Mb | Download |

| Yuchai – Bosch ECU System for Diesel Engine [PDF] | 2Mb | Download |

| Yuchai – Engine knowledge and related auto and fault analysis [PDF] | 6.4Mb | Download |

| Tuchai YC4F90-30(F51J 1) – Parts Catalogue of Diesel Engine [PDF] | 3.3Mb | Download |

| Yuchai YC 4F Series – Operation and Maintenance Manual for Diesel Engine [PDF] | 3.6Mb | Download |

For many years, Yuchai has been a pioneer in the production of engines for all significant forms of transportation. In China and most Asian nations, Yuchai engines are found in more than automobiles.

The Yuchai YC6108G engine powers all contemporary three-ton wheel loaders (YC6B125 is the same engine but with a different marking). The narrative is the same for forklifts. However, there are several engine options: The most popular engines for this kind of specialized equipment are the YC4108 and YCD4J22G.

The Yulin Quantang Industrial Cooperative was founded by the Chinese government in Yulin City, Guangxi Province, in July 1951. This company, Guangxi Yuchai Machinery Group Co., Ltd., was the precursor of the contemporary diesel engine factory.

The business was first set up as an agricultural firm, with the manufacturing of agricultural tools and units, auto repair, the processing of mechanical components, and the creation of low-power machinery among its primary duties.

The Yuchai factory didn’t take the first step toward becoming one of the biggest producers of diesel engines until 1959, eight years after the start of construction. The first Yuchai 2105 diesel engine was created and put into mass production, and for the ensuing 22 years, it dominated the market.

The YC6105Q and YC6105QA engines were introduced in the 1980s; the latter was a significant breakthrough and launched a new line of Chinese engines with direct injection technology.

Later, in 1991, the YC6105QA diesel engine was replaced with the YC6105QC, which was newer and more technologically sophisticated. And during the following ten years, he ended himself with a sizable portion of the Chinese engine market.

Since then, Yuchai has created a vast array of engines and put them into mass production, including the YC6108G diesel engine, which is the most well-known and frequently used in Chinese special equipment. There are dozens, if not hundreds, of state honors and medals for achievement in the engine and special equipment industries. Additionally, the engine construction industry’s top engineering research facility opened its doors in July 2007.

The Yulin Quantang Industrial Cooperative was founded by the Chinese government in Yulin City, Guangxi Province, in July 1951.

The first Yuchai 2105 ICE was created and put into industrial production in 1959.

A technical research facility that leads the engine manufacturing sector opened its doors in July 2007.

The most comprehensive selection of engine components and accessories in China, as well as internal combustion engines for Chinese wheel loaders, forklifts, excavators, and mini-equipment that meet European specifications, is all about Yuchai.

Marine engines

- YC4D Series (45-90 kW)

- YC4F Series (63-85 kW)

- YC6B Series (74-120KW)

- YC6A Series (112-162kw)

- YC6MK Series (176-257 kW)

- YC6T Series (220-396 kW)

- YC6CD Series (0-0kW)

- YC6C Series (478-706 kW)

- YC6TD Series (441-478 kW)

- YC6M Series (176-234 kW)

- YC6J Series (53-66KW)

- YC6MJ Series (0-0kw)

- YC6CL Series (550-550 kW)

- YC6CNL Series (147-680kw)

- YC8CL Series (1029-1200 kW)

Bus engines

- YC4F Series (66-85 kW)

- YC4FA Series (75-95 kW)

- YC4S Series (88-110 kW)

- YC4D Series (90-103 kW)

- YC4E Series (103-132 kW)

- YC4EG Series (103-132 kW)

- YC4G Series (132-162 kW)

- YC6J Series (132-180KW)

- YC6A Series (177-199 kW)

- YC6G Series (170-199 kW)

- YC6L Series (177-243 kW)

- YC6MK Series (250-294 kW)

- YC4DN Series (88-103 kW)

- YC6JN Series (110-166 kW)

- YC6GN Series (132-191 kW)

- YC6LN Series (177-206 kW)

- YC6MKN Series (206-276 kW)

- YC6KN Series (280-324KW)

Truck engines

- YC6K Series (389-389 kW)

- YC6L Series (257-257 kW)

- YC4EG Series (105-147 kW)

- YC4D Series (90-103 kW)

- YC4S Series (88-125 kW)

- YC4FA Series (66-95 kW)

- YC6KN Series (300-300KW)

Engines for construction equipment

- YC6A Series (115-148KW)

- YC6B Series (85-110 kW)

- YC6J Series (92-105 kW)

- YC4D Series (58-58 kW)

- YC6018G Series (92-92KW)

- YC4F Series (33-48KW)

Engines for agricultural machinery

- YC4D Series (50-77 kW)

- YC4F Series (45-48 kW)

- YC6J Series (110-121KW)

- YC6B Series (81-125KW)

- YC6A Series (128-191 kW)

- YC4A Series (62-120 kW)

- YC4B Series (66-74 kW)

Yuchai YC6M350L-D20

- Manuals

- Brands

- Yuchai Manuals

- Engine

- YC6B Series

Manuals and User Guides for Yuchai YC6B Series. We have 1 Yuchai YC6B Series manual available for free PDF download: Operation & Maintenance Manual

Yuchai YC6B Series Operation & Maintenance Manual (99 pages)

Construction Engine

Brand: Yuchai

|

Category: Engine

|

Size: 1.53 MB

Table of Contents

-

Table of Contents

6

-

概述 General Introduction

17

-

产品特点 Product Feature

17

-

型号的组成及其代表意义 Style Number Composition and Its Specific Meaning

17

-

主要用途及适用范围 Main Application Scope

18

-

技术特性 Technical Specification

18

-

主要性能(基本型)Main Specification (Basic)

18

-

主要技术参数 Main Technical Parameter

34

-

发动机主要结构及工作原理

38

-

Primary Structures of Engine and Working Principle

38

-

气缸体 Cylinder Block

38

-

曲柄连杆机构 Crank-Connecting Rod Mechanism

45

-

燃油系统 Fuel System

49

-

润滑系统 Lubrication System

57

-

冷却系统 Cooling System

61

-

启动装置、电气系统与仪表 Start Device, Electrical System and Instrument

65

-

增压器 Turbocharger

68

-

转向泵 Steering Pump

71

-

发动机的使用和维护保养

74

-

Operation and Maintenance of Engine

74

-

发动机的使用 Operation of Engine

74

-

发动机的维护保养 Engine Maintenance

78

-

发动机常见故障及排除方法

87

-

Frequently-Possible Troubles and Their Solution

87

-

发动机不能起动 Engine Fails to Start

87

-

发动机功率不足 Insufficient Power of Engine

89

-

发动机运转时有不正常的杂声

91

-

Abnormal Noise During Running of Engine

91

-

排气冒黑烟 Black Smoke from Exhaust Manifold

92

-

排气冒白烟、蓝烟

92

-

White Smoke and Blue Smoke from Exhaust Manifold

92

-

润滑油压力异常 Abnormal Lubricant Pressure

93

-

润滑油消耗高、消耗量大

95

-

增压器常见故障及排除方法 Malfunction and Solution of Turbocharger

96

-

离合器常见故障及排除方法 Malfunction and Solution of Clutch

97

-

发动机自行熄火

97

-

Shut-Off Automatically

97

Advertisement

Advertisement

Related Products

-

Yuchai YC6A Series

-

Yuchai YC6J Series

-

Yuchai YC60-9

-

Yuchai YC15-8

-

Yuchai YC18-8

-

Yuchai YC360LC-8

-

Yuchai YC08-8

-

Yuchai YC18SR

-

Yuchai YC135-8

-

Yuchai YC20SR

Yuchai Categories

Excavators

Portable Generator

Engine

More Yuchai Manuals

YC6A YC6B YC6J

YC6A YC6B YC6J Series Construction Engine

Operation & Maintenance Manual

Please read the Manual carefully before using.

Guangxi YuChai Machinery Co., Ltd.

00

June.2008

Foreword

YCA YC6B YC6J

This Instruction Manual introduces the YCA YC6B YC6J series construction engine about its structure and technical parameters, the technical specifications and data of its main accessories as well as the basics information on use and service. It also describes some common malfunctions and solutions.

YCA YC6B YC6J“ ”

Please read this manual carefully to understand and master the operation and maintenance requirements about YCA YC6B YC6J series construction engine prior to

putting the machine into operation and pay your particular attention to the Precautions for Safe Operation described below in order to enable the machine to bring its superior performance into full play and ensure its safe operation.

With continuous development and demand of the society, the engine will be uninterruptedly optimized and improved and its modified products will also be continuously increased. Except for especially great modifications in the design this manual will not be altered again. Therefore, after a certain period, there will be some discrepancies between the description in the manual and the actual engine, to which kindly ask our customers to pay due attention.

The manual gives a detailed description for the basic model engine only, and any modifications of it are not laid out to which we ask our customers to pay due attention and understand it well.

YuChai reserves the explanation right of this manual.

! Precautions for Safe Operation!

1.

Such parts as lubricating oil pressure sensing plug, water temperature sensing plug and alarm for too low lubricating oil pressure are very important. In case any failure, immediately replace it to ensure normal working of these parts, otherwise the crankshaft may be burned due to lack of the oil or the cylinder head may crack due to overheating resulted from lack of the water.

2.

After cleaning the oil filter or during the process of replacing filter gauze, reinstall the filter

only after refilling oil fully, and start the engine on idle running immediately after reinstallation; meantime, check if there is any sign of leakage to any filter. Correct the leaking filters or it may easily lead to crankshaft burn caused by oil shortage.

3. 3 5

Each time you start the vehicle, first start the engine on idle running for 3 to 5 minutes till the engine warms up and all gauges working in normal function, then start to move. Never put the vehicle to sudden acceleration from cold-start. For any dramatic speed-up on cold status will damage the instruments and their corresponding parts and components and accelerate the wear and tear of engine’s kinetic parts, consequently it will shorten the engine’s life cycle.

4. 3 5

Avoid any sudden stall and stop at high speed & high load status, the appropriate way is to gear down gradually and stop the vehicle after 3 5 minutes of engine idle running. Otherwise it will damage turbocharger and other moving parts and shorten engine service life consequently.

5.

Check often for the leakage and blockage of the intake piping and air cleaner to make them work normally. Do make adjustment or maintenance when there is leakage in the intake system and blockage in air cleaner, for they will damage the turbo-charger and cause the cylinder scoring, and will decrease the engine’s power at the same time , therefore maintain timely as the vehicle can be driven at pretty low speed .

6.

Start the engine on first gear, otherwise it may stop. 7.

Whenever the engine works abnormally, it shall be dealt with care. 8.

Don’t approach rotating components and directly touch the high temperature parts (such as exhaust pipe and turbocharger etc.) of the engine when you check it, don’t open the water tank cover immediately just after stop, for this may cause physical burn.

9. 50 60

Send the engine to a consignment technical service station of YuChai for run-in service

when it runs 50-60hour, or you will waive the warranty for this engine. 10.

Anti-freeze coolant shall be used in the cooling system; otherwise the consequent failure will not be included in the free warranty

11.

Customer is prohibited to insert or pull out the connectors. 12.

Water and any other cleaning agent are prohibited to use for washing and cleaning the engine.

13

Follow the instruction to drain water of fuel pre-filter, replace filter element assy. of pre-filter and filter element assy. of precision fuel filter.

14.

Make sure the ignition switch is turned off before dismounting and cutting off the battery.

15

Hoist and transport the engine in accordance with the precautions described on the outside the packaging case. The place for storage of the engine shall be well-ventilated, dry, clean and free of corrosive substances. See the mark on the package for preservation of the engine.

16.:

The basic information of the engine is on the nameplate, including: rated power, rated speed, series number, production date and implement standard. The nameplate of the engine is located at the top of the cylinder cover housing.

The engine type and ex-work number are printed on the platform in the middle of the cylinder lower margin.

18.

The safety warnings include user’s precaution, crankshaft steering/rotating danger and high temperature danger sticking on engine cover, clutch housing and cover on exhaust pipe respectively

19

Random documents are included in the package: user’s manual, parts list, tool list, certification and packing list. Please check after opening.

|

Content |

||||

|

1 |

General introduction ……………………………………………………………………………………… |

18 |

||

|

1.1 |

Product Feature ………………………………………………………………………………. |

18 |

||

|

1.2 Style number composition and its specific meaning |

||||

|

………………………………………………………………………………………………………………………… |

18 |

|||

|

1.3 |

Main application scope……………………………………………………… |

19 |

||

|

2 Technical specification……………………………………………………………………………….. |

20 |

|||

|

2.1 |

Main specification (basic) …………………………………………………… |

20 |

||

|

2.2 |

Main technical parameter …………………………………………………………… |

35 |

||

|

3 |

……………………………………………………………………………………. |

39 |

||

|

Primary Structures of Engine and working principle ……………………………………………………….. |

39 |

|||

|

3.1 |

Cylinder Block…………………………………………………………………………………….. |

39 |

||

|

3.2 |

Cylinder Head and Valve Train………………………………………………. |

40 |

||

|

3.3 |

Crank-connecting Rod Mechanism…………………………………………….. |

46 |

||

|

3.4 |

fuel system …………………………………………………………………………………… |

50 |

||

|

3.5 |

Lubrication System ………………………………………………………………………… |

58 |

||

|

3.6 |

Cooling System ……………………………………………………………………………….. |

62 |

||

|

3.7 |

Start device, electrical system and instrument……………. |

66 |

||

|

3.8 |

Turbocharger ……………………………………………………………………………………… |

69 |

||

|

3.9 |

Steering pump……………………………………………………………………………………. |

72 |

||

|

4 |

………………………………………………………………………………………. |

75 |

||

|

Operation and maintenance of engine………………………………………………………………………….. |

75 |

|||

|

4.1 |

Operation of engine……………………………………………………………………. |

75 |

|

4.2 |

Engine Maintenance ……………………………………………………………. |

79 |

|

|

5 |

………………………………………………………………………………………. |

82 |

|

|

Frequently-possible Troubles …………………………………………………………….and Their Solution |

82 |

||

|

5.1 |

Engine ………………………………………………………………..Fails to Start |

82 |

|

|

5.2 |

Insufficient ……………………………………………………..power of Engine |

84 |

|

|

5.3 |

………………………………………………………………………….. |

86 |

|

|

Abnormal Noise during Running ……………………………………………………………..of Engine |

86 |

||

|

5.4 |

Black Smoke ………………………………………………..from Exhaust Manifold |

87 |

|

|

5.5 |

………………………………………………………………………………………….. |

88 |

|

|

White smoke and Blue Smoke ………………………………………………from Exhaust Manifold |

88 |

||

|

5.6 |

…………………………………………… |

Abnormal lubricant pressure |

88 |

|

5.7 |

………………………………………………………………………………… |

90 |

|

|

Large Consumption of Lubricating …………………………………………………………………….Oil |

90 |

||

|

5.8 |

Too high …………………………………………………water outlet temperature |

90 |

|

|

5.9 |

…………………..Malfunction and Solution of Turbocharger |

91 |

|

|

5.10 …………………………..Malfunction and Solution of Clutch |

92 |

||

|

5.11 ……………………………………………………. |

Shut — off automatically |

92 |

1 YC6A

Fig 1 Assembly Layout for YC6A Diesel Engine (may differ from the practical configuration)

2 YC6B

Fig 2 Assembly Layout for YC6B Diesel Engine (non-Turbocharged) (may differ from the practical configuration)

3 YC6B

Fig 3 Assembly Layout for YC6B Diesel Engine (Turbocharged) (may differ from the practical configuration)

4 YC6J

Fig 4 Assembly Layout for YC6J Diesel Engine (may differ from the practical configuration)

YC6A A8700

YC6A series construction engine (A8700) external characteristic

curve

13

YC6B B8C00 B9C00

YC6B series construction non-Turbocharged engine B8C00 B9C00 external characteristic curve

14

YC6B B7700

YC6B series construction Turbocharged engine B7700 external characteristic curve

15

YC6J J8000

YC6J series construction engine (J8000) external characteristic

curve

16

1General introduction

1.1 Product Feature

YC6A YC6B YC6J ,,

YC6A YC6B YC6J series engines are developed by Yuchai with advantages of reliability, fuel consumption saving and strong power. It is ideal power for construction.

1.2

Model number composition and its specific meaning

The product style number is consisted of Arabic numbers and capital English letters, and the specific meaning is as follows:

17

Turbocharged

1.3 Main application scope

-15 40 2000-15 40 2500

The engine could work normally under temperature of -15 40 and at the height above sea-level of lower than 2000 m. it is forbidden to work in the water or in the fire. When the engine needs to work at temperature lower than -15 or higher than 40 , at the at the height above sea-level of higher than 2500 m, the user should consults YuChai Technical Dept. and Service Dept. to adopt effective measure or replace special engine to ensure the normal working.

2 Technical specification

2.1 Main specification (basic)

1 1 YC6A

Table 1-1 Main technical parameters of YC6A engine

|

Technical specification |

|||||

18

|

No. |

Name |

A8900 |

A8700 |

||

|

1 |

Model |

YC6A180Z-T11 |

YC6A190Z-T10 |

||

|

2 |

|||||

|

Type |

Vertical in-line, water-cooling, 4-stroke |

||||

|

3 |

Turbocharged |

||||

|

Air intake way |

|||||

|

4 |

ω Direct injection tube sinking ω combustion |

||||

|

Combustion type |

chamber |

||||

|

5 |

Cylinder |

6 |

|||

|

number |

|||||

|

6 |

mm |

108 |

|||

|

Cylinder diameter |

|||||

|

7 |

mm |

132 |

|||

|

Piston stroke (mm) |

|||||

|

L |

|||||

|

8 |

Total piston |

7.252 |

|||

|

displacement |

|||||

|

9 |

Compression |

17:1 |

|||

|

ratio |

|||||

|

10 |

Cylinder |

Wet |

|||

|

sleeve type |

|||||

|

11 |

kW |

130 |

140 |

||

|

Rated power (kW) |

|||||

|

r/min |

|||||

|

12 |

Rated rotation |

2300 |

2300 |

||

|

speed(r/min) |

|||||

|

13 |

N·m |

670 |

690 |

||

|

Max. torque(N·m) |

|||||

|

r/min |

|||||

|

14 |

Speed at max torque |

1500 1700 |

1500 1800 |

||

|

(r/min) |

|||||

19

|

g/kW·h Fuel |

||||||||

|

15 |

consumption rate at |

≤240 |

||||||

|

rated working |

||||||||

|

condition |

||||||||

|

16 |

Fuel |

≤225 |

||||||

|

consumption rate at |

||||||||

|

max torque g/kW·h |

||||||||

|

Name |

Technical specification |

|||||||

|

No. |

A8900 |

A8700 |

||||||

|

GB 252-2000 0 10 , |

||||||||

|

Summer: GB 252-2000 top grade or first rater 0 #, 10 # light |

||||||||

|

Diesel oil |

diesel oil |

|||||||

|

17 |

GB 252-2000 0 -10 -20 -35 |

|||||||

|

brand |

||||||||

|

Winter: GB 252-2000 top grade or first rater 0 #,-10 #, -20 #, -35 |

||||||||

|

# light diesel oil |

||||||||

|

Max. |

||||||||

|

18 |

rotation speed with |

≤2530 |

≤2540 |

|||||

|

no load r/min |

||||||||

|

Min. |

||||||||

|

19 |

rotation speed with |

700 750 |

||||||

|

no load r/min |

||||||||

|

20 |

Working |

1—5—3—6—2—4 |

||||||

|

order |

||||||||

|

Oil |

||||||||

|

21 |

fuel consumption |

≤0.5 |

||||||

|

ratio |

20

|

CD40 CD15W—40 CD10W—30 |

|||

|

GB 11122-2006 CD |

|||

|

22 |

Oil brand |

Summer: CD40 CD15W—40, Winter: CD10W—30 or other |

|

|

diesel oil with grade not below CD grade of GB 11122-2006 |

|||

|

corresponding with the environment |

|||

|

( |

|||

|

) |

|||

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|||

|

power output end) |

|||

|

( |

|||

|

) °CA Fuel |

|||

|

24 |

supply advance |

12±1 |

|

|

angle (Top dead |

|||

|

point front crankshaft |

|||

|

corner ) °CA |

|||

|

25 |

Fuel |

KBEL-P023A |

|

|

injector type |

|||

|

26 |

Fuel |

DSLA147P008 |

|

|

nozzle type |

|||

|

27 |

Fuel injector opening |

25 26 |

|

|

pressure MPa |

|||

|

FSN |

|||

|

28 |

Exhaust smoke level |

≤3.0 |

|

|

(FSN) |

|||

|

LwdB(A) |

|||

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|||

|

30 |

Compressing |

≥2.5 |

|

|

pressure |

|||

|

(n≥200r/min) MPa |

|||

21

|

31 |

|||||||||||

|

Lubricating method |

Pressure lubricating and splattering lubricating combined |

||||||||||

|

32 |

Electrical starting |

||||||||||

|

Starting method |

|||||||||||

|

L |

|||||||||||

|

33 |

Capacity of engine |

17~20 |

|||||||||

|

oil (L) |

|||||||||||

|

Diesel |

|||||||||||

|

34 |

engine net weight |

700 |

|||||||||

|

kg |

|||||||||||

|

× × |

|||||||||||

|

mm |

|||||||||||

|

35 |

Overall dimension |

1234×800×1100 |

|||||||||

|

(length × width× |

|||||||||||

|

height) (mm) |

|||||||||||

|

1 2 |

YC6B |

||||||||||

|

Table 1-2 YC6B (non-Turbocharged) series engine main technical parameter |

|||||||||||

|

Technical specification |

|||||||||||

|

No. |

Name |

||||||||||

|

B8W00 |

B9C00 |

B9D00 |

B8Q00 |

B8C00 |

|||||||

|

1 |

Model |

YC6B120-T1 |

YC6B125-T1 |

YC6B125-T1 |

YC6B105-K |

YC6B125-K |

|||||

|

2 |

Type |

||||||||||

|

Vertical in-line, water-cooling, 4-stroke |

|||||||||||

|

Natural air intake |

|||||||||||

|

3 |

|||||||||||

|

Air intake way |

Turbocharged |

||||||||||

|

4 |

Type of |

ω |

|||||||||

|

combustion |

Direct injection type tube sinking ω combustion chamber |

||||||||||

|

chamber |

|||||||||||

22

|

5 |

6 |

|||||||

|

Cylinder NO. |

||||||||

|

mm |

||||||||

|

6 |

Cylinder diameter |

108 |

||||||

|

(mm) |

||||||||

|

7 |

mm |

125 |

||||||

|

Piston stroke (mm) |

||||||||

|

L |

||||||||

|

8 |

Total piston |

6.871 |

||||||

|

displacement |

||||||||

|

9 |

17.5:1 |

|||||||

|

Compression ratio |

||||||||

|

10 |

Cylinder sleeve |

Wet |

||||||

|

type |

||||||||

|

11 |

kW |

85 |

92 |

92 |

75 |

92 |

||

|

Rated power (kW) |

||||||||

|

r/min |

||||||||

|

12 |

Rated rotation |

2000 |

2200 |

2300 |

1700 |

2200 |

||

|

speed(r/min) |

||||||||

|

13 |

N·m |

463 |

450 |

460 |

463 |

|||

|

Max. torque(N·m) |

||||||||

|

1300 |

1400 |

|||||||

|

14 |

r/min Speed at |

1400 1600 |

||||||

|

1400 |

1600 |

|||||||

|

max torque (r/min) |

||||||||

|

g/kW·h Fuel |

||||||||

|

15 |

consumption rate |

≤240 |

||||||

|

at rated working |

||||||||

|

condition |

||||||||

23

|

Fuel |

|||||||||||

|

16 |

consumption rate |

≤235 |

|||||||||

|

at max torque |

|||||||||||

|

g/kW·h |

|||||||||||

|

GB 252-2000 0 10 , |

|||||||||||

|

Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel |

|||||||||||

|

oil |

|||||||||||

|

17 |

GB 252-2000 0 -10 -20 -35 |

||||||||||

|

Diesel oil brand |

|||||||||||

|

Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # |

|||||||||||

|

light diesel oil |

|||||||||||

|

18 |

Max. rotation |

≤2200 |

2420 |

≤2530 |

1870±20 |

2420 |

|||||

|

speed |

with no |

2464 |

2464 |

||||||||

|

load r/min |

|||||||||||

|

Min. |

|||||||||||

|

19 |

rotation speed |

700 750 |

|||||||||

|

with no load r/min |

|||||||||||

|

20 |

Working |

1—5—3—6—2—4 |

|||||||||

|

order |

|||||||||||

|

1-2 Table 1-2 (continued) |

|||||||||||

|

Name |

Technical specification |

||||||||||

|

No. |

|||||||||||

|

B8W00 |

B9C00 |

B9D00 |

B8Q00 |

B8C00 |

|||||||

|

21 |

Oil fuel |

≤0.5 |

|||||||||

|

consumption |

|||||||||||

|

ratio |

24

|

CD40 CD15W—40 CD10W—30 |

|||

|

GB 11122-2006 CD |

|||

|

22 |

Summer: CD40 CD15W—40, Winter: CD10W—30 or other |

||

|

Oil brand |

diesel oil with grade not below CD grade of GB 11122-2006 |

||

|

corresponding with the environment |

|||

|

( |

|||

|

) |

|||

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|||

|

power output end) |

|||

|

( |

|||

|

) °CA |

|||

|

Fuel supply |

|||

|

24 |

advance angle |

13±2 |

|

|

(Top dead point |

|||

|

front crankshaft |

|||

|

corner ) °CA |

|||

|

25 |

Fuel |

CKBL68S001/PF68S35 |

|

|

injector type |

|||

|

26 |

Fuel |

CDLLA147S071/DSLA147S071 |

|

|

nozzle type |

|||

|

27 |

Fuel injector |

23 24 |

|

|

opening pressure |

|||

|

MPa |

|||

|

FSN |

|||

|

28 |

Exhaust smoke |

≤3.5 |

|

|

level (FSN) |

|||

25

|

LwdB(A) |

|||

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|||

|

Compressing |

|||

|

30 |

pressure |

≥2.5 |

|

|

(n≥200r/min) |

|||

|

MPa |

|||

|

31 |

|||

|

Lubricating method |

Pressure lubricating and splattering lubricating combined |

||

|

32 |

Electrical starting |

||

|

Starting method |

|||

|

L |

|||

|

33 |

Capacity of engine |

15~18 |

|

|

oil (L) |

|||

|

34 |

Diesel engine net |

650 |

|

|

weight |

kg |

||

|

× |

|||

|

× |

mm |

||

|

35 |

Overall dimension |

1133×725×889 |

|

|

(length × width× |

|||

|

height) (mm) |

|||

1 3 YC6B

Table 1-3 YC6B (Turbocharged) series engine main technical parameters

|

Technical specification |

|||||||||

|

No. |

Name |

B7700 |

B9A00 |

B9F00 |

B9K00 |

||||

|

1 |

Model |

YC6B160Z- |

YC6B140Z-T1 |

YC6B150Z-T1 |

YC6B150Z-T1 |

||||

|

2 |

Type |

||||||||

|

Vertical in-line, water-cooling, 4-stroke |

|||||||||

|

3 |

|||||||||

|

Air intake way |

Turbocharged |

||||||||

26

|

Type of |

ω Direct injection type tube sinking ω |

||||||||||||||

|

4 |

combustion |

||||||||||||||

|

combustion chamber |

|||||||||||||||

|

chamber |

|||||||||||||||

|

5 |

6 |

||||||||||||||

|

Cylinder NO. |

|||||||||||||||

|

mm |

|||||||||||||||

|

6 |

Cylinder diameter |

108 |

|||||||||||||

|

(mm) |

|||||||||||||||

|

7 |

mm |

125 |

|||||||||||||

|

Piston stroke (mm) |

|||||||||||||||

|

L |

|||||||||||||||

|

8 |

Total piston |

6.871 |

|||||||||||||

|

displacement |

|||||||||||||||

|

9 |

17.5:1 |

||||||||||||||

|

Compression ratio |

|||||||||||||||

|

10 |

Wet |

||||||||||||||

|

Cylinder sleeve |

|||||||||||||||

|

11 |

kW |

115 |

102 |

110 |

110 |

||||||||||

|

Rated power (kW) |

|||||||||||||||

|

r/min |

|||||||||||||||

|

12 |

Rated rotation |

2200 |

2000 |

2000 |

2100 |

||||||||||

|

speed(r/min) |

|||||||||||||||

|

13 |

N·m |

560 |

550 |

550 |

550 |

||||||||||

|

Max. torque(N·m) |

|||||||||||||||

|

14 |

r/min |

1400 |

1600 |

1400 |

1600 |

1400 |

1600 |

1400 |

1600 |

||||||

|

Speed at max |

|||||||||||||||

|

torque (r/min) |

27

|

g/kW·h |

||||||||

|

15 |

Fuel consumption |

≤230 |

||||||

|

rate at rated |

||||||||

|

working condition |

||||||||

|

g/kW·h |

||||||||

|

16 |

Fuel consumption |

≤225 |

||||||

|

rate at max torque |

||||||||

|

g/kW·h |

||||||||

|

GB 252-2000 0 10 , |

||||||||

|

Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel |

||||||||

|

Diesel oil |

oil |

|||||||

|

17 |

GB 252-2000 0 -10 -20 -35 |

|||||||

|

brand |

||||||||

|

Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # |

||||||||

|

light diesel oil |

||||||||

|

18 |

Max. rotation |

≤2420 |

≤2160 |

≤2200 |

≤2310 |

|||

|

speed |

with no |

|||||||

|

load r/min r/min |

||||||||

|

Min. |

||||||||

|

19 |

rotation speed |

700 750 |

||||||

|

with no load r/min |

||||||||

|

20 |

Working |

1—5—3—6—2—4 |

||||||

|

order |

||||||||

|

1-3 Table 1-3(continued) |

||||||||

|

Name |

Technical specification |

|||||||

|

No. |

||||||||

|

B7700 |

B9A00 |

B9F00 |

B9K00 |

|||||

|

21 |

Oil fuel |

≤0.5 |

||||||

|

consumption |

||||||||

|

ratio |

28

|

CD40 CD15W—40 CD10W—30 |

|||

|

22 |

Oil |

GB 11122-2006 CD Summer: CD40 |

|

|

CD15W—40, Winter: CD10W—30 or other diesel oil with grade |

|||

|

brand |

|||

|

not below CD grade of GB 11122-2006 corresponding with the |

|||

|

( |

|||

|

) |

|||

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|||

|

power output end) |

|||

|

( |

|||

|

) °CA |

|||

|

Fuel supply |

|||

|

24 |

advance angle |

13±2 |

|

|

(Top dead point |

|||

|

front crankshaft |

|||

|

corner ) °CA |

|||

|

25` |

Fuel |

CKBL68S001/PF68S35 |

|

|

injector type |

|||

|

26 |

Fuel |

CDLLA147S071/DSLA147S071 |

|

|

nozzle type |

|||

|

27 |

Fuel injector |

23 24 |

|

|

opening pressure |

|||

|

MPa |

|||

|

FSN |

|||

|

28 |

Exhaust smoke |

≤3.5 |

|

|

level (FSN) |

|||

|

LwdB(A) |

|||

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|||

|

Compressing |

|||

|

30 |

pressure |

≥2.5 |

|

|

(n≥200r/min) |

|||

|

MPa |

29

|

31 |

Pressure lubricating and splattering |

||||||||||

|

Lubricating method |

lubricating combined |

||||||||||

|

32 |

Electrical starting |

||||||||||

|

Starting method |

|||||||||||

|

L |

|||||||||||

|

33 |

Capacity of engine |

17~19 |

|||||||||

|

oil (L) |

|||||||||||

|

34 |

Diesel engine net |

650 |

|||||||||

|

weight kg |

|||||||||||

|

× |

|||||||||||

|

× |

mm |

||||||||||

|

35 |

Overall dimension |

1133×725×889 |

|||||||||

|

(length × width× |

|||||||||||

|

height) (mm) |

|||||||||||

|

1 4 |

YC6J |

||||||||||

|

Table 1-4 YC6J series engine main technical |

parameter |

||||||||||

|

Technical specification |

|||||||||||

|

No. |

Name |

||||||||||

|

J8400 |

J8500 |

J8000 |

J7M00 |

||||||||

|

1 |

Model |

YC6J120-T1 |

YC6J120-T10 |

YC6J125Z-T2 |

YC6J145Z-T2 |

||||||

|

2 |

Type |

||||||||||

|

Vertical in-line, water-cooling, 4-stroke |

|||||||||||

|

3 |

Air intake way |

Natural air intake |

Turbocharged |

||||||||

|

Type |

ω |

||||||||||

|

4 |

of combustion |

||||||||||

|

Direct injection type tube sinking ω combustion chamber |

|||||||||||

|

chamber |

|||||||||||

|

5 |

Cylinder |

6 |

|||||||||

|

NO. |

|||||||||||

30