- Главная

- Сервис

- Руководства по ремонту

Руководства по ремонту ЯМЗ

Обращаем Ваше внимание, что руководства по ремонту постоянно дорабатываются и

обновляются. Имеющиеся на данной странице руководства имеют последнюю редакцию, а

значит могут отличаться от документов выпущенных ранее и поставленных в комплекте с

двигателем. Поэтому при пользовании документами обращайте внимание на год его

издания.

Руководство по ремонту двигателей ЯМЗ-536, ЯМЗ-5361, ЯМЗ-5363, ЯМЗ-53602, ЯМЗ-53622, ЯМЗ-53642

pdf, 94.67 МБ

Руководство по ремонту двигателей ЯМЗ-5344-10, ЯМЗ-53442

pdf, 85.64 МБ

Руководство по ремонту двигателей ЯМЗ-6565, 6585

pdf, 22.17 МБ

Руководство по ремонту двигателей ЯМЗ-5341-10, ЯМЗ-5341-11

pdf, 112.61 МБ

Руководство по ремонту двигателей ЯМЗ-236М2, 238М2

pdf, 23.42 МБ

Руководство по ремонту двигателей ЯМЗ-5342, ЯМЗ-5344

pdf, 89.11 МБ

Руководство по ремонту газовых двигателей ЯМЗ-53414,-53424,-53444

pdf, 74.16 МБ

Руководство по ремонту двигателей ЯМЗ-650

pdf, 17.07 МБ

Руководство по ремонту двигателей ЯМЗ-651

pdf, 30.27 МБ

6,76 Мб

Двигатели ЯМЗ-238Б, ЯМЗ-238БЕ, ЯМЗ-238БЕ2, ЯМЗ-238Д,

Формат: pdf

-

Год:

2010

-

Страниц:

354

-

Язык:

русский

-

Размер:

6,76 Мб

-

Категории:

Двигатели ЯМЗ

3,52 Мб

Руководство по эксплуатации двигателей ЯМЗ-650, ЯМЗ-6501,

Формат: pdf

-

Год:

2008

-

Страниц:

113

-

Язык:

русский

-

Размер:

3,52 Мб

-

Категории:

Двигатели ЯМЗ

10,6 Мб

Руководство по эксплуатации двигателей ЯМЗ-7511.10,

Формат: pdf

-

Год:

2017

-

Страниц:

337

-

Язык:

русский

-

Размер:

10,6 Мб

-

Категории:

Двигатели ЯМЗ

3,05 Мб

Каталог запчастей дизельных двигателей ЯМЗ-7511.10,

Формат: pdf

-

Год:

2005

-

Страниц:

154

-

Язык:

русский, английский

-

Размер:

3,05 Мб

-

Категории:

Двигатели ЯМЗ

28,4 Мб

Руководство по ремонту двигателя ЯМЗ-651 Евро 4

Формат: pdf

-

Год:

2012

-

Страниц:

154

-

Язык:

русский

-

Размер:

28,4 Мб

-

Категории:

Двигатели ЯМЗ

6,4 Мб

Двигатели ЯМЗ-536, ЯМЗ-5361, ЯМЗ-5362, ЯМЗ-5363, ЯМЗ-5364:

Формат: pdf

-

Год:

2016

-

Страниц:

285

-

Язык:

русский

-

Размер:

6,4 Мб

-

Категории:

Двигатели ЯМЗ

3,85 Мб

Руководство по эксплуатации двигателей ЯМЗ-850.10,

Формат: pdf

-

Год:

2008

-

Страниц:

150

-

Язык:

русский

-

Размер:

3,85 Мб

-

Категории:

Двигатели ЯМЗ

6,8 Мб

Двигатели ЯМЗ-5340, ЯМЗ-5341, ЯМЗ-5342, ЯМЗ-5344:

Формат: pdf

-

Год:

2016

-

Страниц:

161

-

Язык:

русский

-

Размер:

6,8 Мб

-

Категории:

Двигатели ЯМЗ

9,47 Мб

Руководство по эксплуатации БелАЗ-7547 и его модификаций

Формат: pdf

-

Год:

2007

-

Страниц:

276

-

Язык:

русский

-

Размер:

9,47 Мб

-

Категории:

Двигатели ЯМЗ

13,5 Мб

Руководство по эксплуатации автогрейдеров ЧСДМ ДЗ-98В

Формат: pdf

-

Год:

2018

-

Страниц:

119

-

Язык:

русский

-

Размер:

13,5 Мб

-

Категории:

Двигатели ЯМЗ

2,93 Мб

Техническое обслуживание и ремонт однодисковых сцеплений с

Формат: pdf

-

Год:

2005

-

Страниц:

63

-

Язык:

русский

-

Размер:

2,93 Мб

-

Категории:

Двигатели ЯМЗ

1,66 Мб

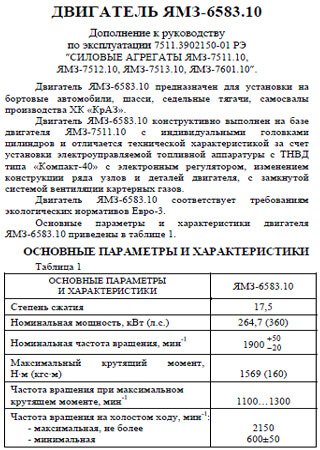

Руководство по эксплуатации двигателей ЯМЗ-6583.10

Формат: pdf

-

Год:

2012

-

Страниц:

57

-

Язык:

русский

-

Размер:

1,66 Мб

-

Категории:

Двигатели ЯМЗ

1,83 Мб

Руководство по эксплуатации двигателей ЯМЗ-6562.10 и

Формат: pdf

-

Год:

2012

-

Страниц:

68

-

Язык:

русский

-

Размер:

1,83 Мб

-

Категории:

Двигатели ЯМЗ

1,4 Мб

Руководство по эксплуатации двигателя ЯМЗ-6561.10

Формат: pdf

-

Год:

2012

-

Страниц:

46

-

Язык:

русский

-

Размер:

1,4 Мб

-

Категории:

Двигатели ЯМЗ

3,1 Мб

Ремонт двигателей ЯМЗ-236 и ЯМЗ-238

Формат: djvu

-

Год:

1974

-

Страниц:

216

-

Язык:

русский

-

Размер:

3,1 Мб

-

Категории:

Двигатели ЯМЗ

5,32 Мб

Руководство по эксплуатации двигателей ЯМЗ-236М2 и ЯМЗ-238М2

Формат: pdf

-

Год:

2010

-

Страниц:

172

-

Язык:

русский

-

Размер:

5,32 Мб

-

Категории:

Двигатели ЯМЗ

34,3 Мб

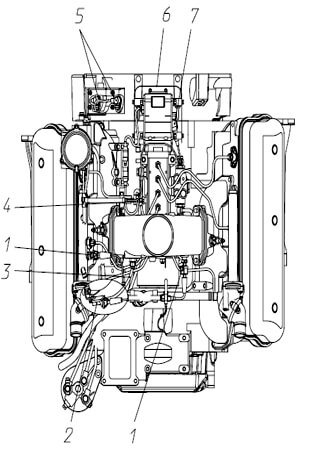

Устройство и ремонт двигателей ЯМЗ-7511.10, ЯМЗ-7512.10,

Формат: pdf

-

Год:

2007

-

Страниц:

329

-

Язык:

русский

-

Размер:

34,3 Мб

-

Категории:

Двигатели ЯМЗ

17 Мб

Руководство по ремонту двигателя ЯМЗ-650

Формат: pdf

-

Год:

2009

-

Страниц:

134

-

Язык:

русский

-

Размер:

17 Мб

-

Категории:

Двигатели ЯМЗ

5,1 Мб

Ремонт двигателей ЯМЗ-240, ЯМЗ-240Н и ЯМЗ-240Б

Формат: djvu

-

Год:

1978

-

Страниц:

311

-

Язык:

русский

-

Размер:

5,1 Мб

-

Категории:

Двигатели ЯМЗ

73 Мб

Каталог запчастей двигателей ЯМЗ-236, ЯМЗ-238, ЯМЗ-240 и их

Формат: exe

-

Год:

2009

-

Язык:

русский

-

Размер:

73 Мб

-

Категории:

Двигатели ЯМЗ

Каталог запчастей двигателей ЯМЗ-236, ЯМЗ-238, ЯМЗ-240, ЯМЗ-7511, ЯМЗ-7601, ЯМЗ-8401, ЯМЗ-8421, ЯМЗ-8424, ЯМЗ-850 и их модификаций дает представление о 32 различных модификациях дизелей, производимых ярославским предприятием.

1 2

- Главная

- Техническая информация

- Каталоги, руководства по эксплуатации и инструкции на двигатели ЯМЗ ОАО «Ярославский моторный завод» Автодизель

Каталоги, руководства по эксплуатации и инструкции на двигатели ЯМЗ ОАО «Ярославский моторный завод» Автодизель

- Manuals

- Brands

- Yaroslavl Engine Plant Manuals

- Engine

- YMZ-536

- Operation manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

«AVTODIZEL» JSC

(Yaroslavl Engine Plant)

E N G I N E S

YMZ-536,

YMZ-5361, YMZ-5362,

YMZ-5363, YMZ-5364

Operation Manual

536.3902150-В РЭ

Yaroslavl • 25.01.2012

Summary of Contents for Yaroslavl Engine Plant YMZ-536

-

Page 1

«AVTODIZEL» JSC (Yaroslavl Engine Plant) E N G I N E S YMZ-536, YMZ-5361, YMZ-5362, YMZ-5363, YMZ-5364 Operation Manual 536.3902150-В РЭ Yaroslavl • 25.01.2012… -

Page 2

536.3902150-B РЭ This Manual contains design description and basic operating and maintenance rules for YMZ-536, YMZ-5361; YMZ-5362, YMZ-5363, YMZ-5364 Engines, assembly variants modifications. The Manual covers the engines assembled at AVTODIZEL JSC. It is aimed at people operating the above engines. -

Page 3

Dear Customer, The powerful and cost-effective powertrains and engines which you are beginning to use are reliable and easy to operate. However, it should be remembered that their lifetime largely depends on their regular and careful maintenance. Therefore, before starting operation, please CAREFULLY read this manual and strictly follow the rules… -

Page 4: Warning

WARNING 1. Failure-free functioning of the engine and its long operating life depend directly on their correct handling. Therefore carefully read this manual before starting the operation. 2. During the engine break-in period its mating parts become aligned, therefore further working efficiency largely depends on how strictly the rules specified in the NEW ENGINE BREAK-IN section have been followed.

-

Page 5: Application Range & Particularities Of Engine Assembly Sets

Basic Model and assembly sets of YMZ-530 Trucks, dumpers, rigids and tractors 4×2, 4×4, 6×2, 6×4, 6×6, 8×4 with GVM up to 36t, as well as MAZ YMZ-536 tractor and trailer rigs with gross train mass (GTM) up to 44 t…

-

Page 6

& variant Trucks 6×4 with GVM up to 26t and tractor and trailer rigs with gross train mass (GTM) up to 38 t, as YMZ-536-10 well as trucks with GVM not exceeding 33,5 t (AZ URAL), flat nose vehicle Delivery kit with AC compressor, for flat nose trucks… -

Page 7

Engine Model Final mounts & variant Delivery kit with AC compressor, for flat nose trucks YMZ-536-110* (AZ URAL) Delivery kit with AC compressor, for flat nose trucks YMZ-536-111* (AZ URAL) All-terrain trucks 6×4 and 6×6 with GVM up to 38t… -

Page 8

Engine Model Final mounts & variant All-terrain trucks 6×4 and 6×6 with GVM up to 38t YMZ-53642-10 and tractor and trailer rigs with (GTM) up to 44 t (AZ URAL), conventional cab vehicle YMZ-53642-11 Delivery kit for flat nose trucks (AZ URAL) Delivery kit with AC compressor, for conventional YMZ-53642-12 cab trucks (AZ URAL) -

Page 9

Engine Model Final mounts & variant and trailer rigs with GTM up to 36 t (MAZ) Delivery set with connectability to AC compressor YMZ-5361-01 (for MAZ) Delivery set with connectability to retarder (for YMZ-5361-02 MAZ) Delivery set with connectability to AC compressor YMZ-5361-03 and to retarder (for MAZ) Modifications and assembly sets of YMZ-5362… -

Page 10

Engine Model Final mounts & variant YMZ-53622-110 Delivery kit for flat nose trucks (AZ URAL) YMZ-53622-111 Delivery kit for flat nose trucks (AZ URAL) Delivery kit with AC compressor, for conventional YMZ-53622-120 cab trucks (AZ URAL) Delivery kit with AC compressor, for conventional YMZ-53622-121 cab trucks (AZ URAL) Delivery kit with AC compressor, for flat nose trucks… -

Page 11

Engine Model Final mounts & variant Modifications and assembly sets of YMZ-5364 Delivery set for articulated municipal buses LiAZ- YMZ-5364 6212 and LiAZ-6213 type, GVM no more than 28 t All terrain trucks 6×6, with GVM up to 30t, as well YMZ-53642-10 as AZ URAL tractor and trailer rigs with GTM up to 36t;… -

Page 12

— powertrain with MZF 430 Clutch and YMZ-0905-10 Gear Box with remote gear control, 250 mm roller overhang to the right, without speedometer. Engines YMZ-536, YMZ-5361, YMZ-5362, YMZ-5363, YMZ-5364 and their delivery kits are in accordance with UN EEC Regulations № 49-04-B1 Engines YMZ-53602-10, YMZ-53622-10, YMZ-53642-10 and their delivery… -

Page 13: Technical Specifications

TECHNICAL SPECIFICATIONS YMZ-536 (Fig. 1 and 1a) is the basic model of six-cylinders- in-line engines manufactured by JSC AVTODIZEL (YMZ). YMZ-536-10 (Fig. 1b and 1c), YMZ-536-30 (Fig. 1d and 1e), YMZ-5361, YMZ-5362 (Fig. 1f and 1g), YMZ-5363 and YMZ-5364 are just variants based on YMZ-536 design but their fuel injection systems are tuned up differently, by means of adjusting the parameters of their electronic control unit (E.C.U.).

-

Page 24: Main Parameters And Characteristics Of Engines

MAIN PARAMETERS AND CHARACTERISTICS OF ENGINES YMZ-536 FAMILY Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 Four-stroke, compression ignition, turbo- charging, liquid cooling, air–air type Engine type intercooling mounted on vehicle; rear gear drive of accessory units. Number of cylinders…

-

Page 25

Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 RPM at max. torque, min 1300–1600 Torque at RMP=1000 min at least (100) (85) (75) Torque at RMP= 800 min at least (66) (73) Idle speed, min — minimum 700±50 — maximum 2650 Specific fuel consumption at… -

Page 26

Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 Accumulator-type, with electronically Fueling System controlled high pressure injection Common Rail System with electronic Injection equipment control of fuel supply, injection pressure up to 180 MPa (1800 kgf/cm Microprocessor unit EDC7 UC31, model 0 Injection control system 281 020 111 from BOSCH, with gear-driven fuel supply pump CPN 2.2+… -

Page 27

Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 Electronic Control System Microprocessing unit, cooled Electronic Control Unit (ECU) circulating fuel, model EDC7UC31 model from BOSCH Electronic Control System sensors: Crankshaft RPM sensor 0 281 002 315, from «BOSCH Camshaft RPM sensor 0 281 002 315, from «BOSCH»… -

Page 28

Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 – at rated idel r.p.m., 100 (1,0) at least Full-flow filter built in the service module with replaceable filter cartridge Oil filters centrifugal fine purification filter with replaceable cartridge, W 11 102 from MANN+HUMMEL Gas turbine type, supercharge air is cooled in… -

Page 29

Carbon-black filter catalyst embodied in the Exhaust gas neutralizer silencer-neutralizer — for long-haul and 5361.1201010-01 or 536.1201010-02 or international vehicles 5340.1201010-03 for engines YMZ-536, YMZ-5361, YMZ-5363 — for dumpers and rigids 536.1201010-21 or 536.1201010-22 or 5340.1201010-23 for engines YMZ-536, YMZ-5361, YMZ-5363 —… -

Page 30

Main parameters YMZ- YMZ- and characteristics -5361 -5362 5363 -5364 One cylinder, piston-type, pinion-driven with reduction ratio 1,14:1, output 350 l/min at counter-pressure 0,8 MPa. On engines YMZ-5362 and YMZ-5364 Pneumatic brakes compressor destined to LiAZ — two-cylinders, piston- type, pinion-driven with reduction ratio 1,14:1, output 600 l/min at counter-pressure 0,8 MPa. -

Page 31

Fig. 2. Speed performance of YMZ-536 engine: М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 32

Fig. 2a. Speed performance of YMZ-5361 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 33

Fig. 2b. Speed performance of YMZ-5362 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 34

Fig. 2c. Speed performance of YMZ-5363 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 35

Fig. 2d. Speed performance of YMZ-5364 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 36

MAIN PARAMETERS AND CHARACTERISTICS OF ENGINES YMZ-536-10, YMZ-536-30, YMZ-536-40 YMZ- YMZ- YMZ- Main parameters and characteristics 536-10 536-30 536-40 Speed performance Fig.3 Fig.3a Fig.3b 229 (312) Rated power, kW (hp), at least 1226 (125) Maximum torque, min , at least Crankshaft r.p.m. -

Page 37

— linear, maximum — cross, maximum Total oil/Fuel consumption ratio, in % All remaining parameters and characteristics of engines YMZ-536- 10, YMZ-536-30 and YMZ-536-40 are similar to the corresponding engine modifications. MAIN PARAMETERS AND CHARACTERISTICS OF ENGINES YMZ-53602-10, YMZ-53622-10, YMZ-53642-10… -

Page 38

Max. hourly fuel consumption at rated power, kg/h Intermediary bunch of wires from 536.3724017 Engine ECU (EECU) to vehicle Turbcharger B2G from BORG WARNER, with radial centripetal turbine and Turbocharger centrifugal compressor; equipped with a bypass valve Supercharge air temperature at turbocharger outlet, at rated engine’s r.p.m. -

Page 39

Fig. 3. Speed performance of YMZ-536-10 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 40

Fig. 3a. Speed performance of YMZ-536-30 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 41

Fig. 3b. Speed performance of YMZ-536-40 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 42

Fig. 3c. Speed performance of YMZ-53602-10 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 43

Fig. 3d. Speed performance of YMZ-53622-10 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 44

Fig. 3e. Speed performance of YMZ-53642-10 engine. М — gross torque, N — gross specific power; е е — specific fuel consumption; n — crankshaft rpm… -

Page 45

Engine units’ arrangement and overall dimensions are shown in pictures 4–8 Fig. 4. YMZ-536 arrangement of engine units and overall dimensions (front view) 1 – oil filter; 2 – surcharge air pressure and temperature sensor; 3 – fan switching visco-coupling; 4 – AC compressor; 5 — generator; 6 – serial number… -

Page 46

Fig. 5. YMZ-536 arrangement of engine units and overall dimensions (left side view) 1 – fuel pressure and temperature sensor; 2 – manufacturer plate area; 3 — damper; 4 — generator; 5 – AC compressor; 6 – pre-heater relay; 7 – high pressure pipes; 8 — rail; 9 – E.C.U.; 10 – high pressure pump;… -

Page 47

Fig. 6. YMZ-536 arrangement of engine units and overall dimensions (rear view) 1 – camshaft RPM sensor; 2 – carter ventilation system; 3 – EGR flap pneumatic governor; 4 — flywheel… -

Page 48

Fig. 7. YMZ-536 arrangement of engine units and overall dimensions (right side view) 1 – crankshaft turning inspection eye; 2 – oil pressure and temperature sensor; 3 – exhausted gases recirculation flap governor; 4 – coolant temperature sensor; 5 – turbocharger; 6 – surcharge air pressure and temperature sensor;… -

Page 49

Fig. 7. YMZ-536 arrangement of engine units (top view) 1 – oil level indicator; 2 – EGR system; 3 – carter ventilation system; 4 – crankshaft RPM sensor; 5 – fuel pressure in the rail sensor; 6 – oil filler cap… -

Page 50: General Design And Operation

GENERAL DESIGN AND OPERATION Engine’s general design and construction is shown in cross- (Fig. 9) and longitudinal section (Fig. 10). Fig. 9. Cross-section…

-

Page 51

Fig. 10. Longitudinal section… -

Page 52

This page intentionally left blank… -

Page 53

BASIC PARTS CYLINDER BLOCK AND CYLINDER LINERS The six-cylinder block is made of grey cast iron. It serves as a mounting base for all engine parts and units. Each cylinder liner seat bore has a circular groove for the liner collar in the upper part and a cylinder-shaped hole in the lower part made coaxially. -

Page 54: Cylinder Head

The year of manufacture and the engine serial number are marked on a special flat area of the cylinder block located on its front, on the left, near the generator (See Fig. 4, item 6). In the top left part of the block there is a tunnel with seven seat bores for the camshaft.

-

Page 55: Gear Housing

Fig. 11. Cylinder head gasket: 1 – cylinder head oil feed hole; 2 – cylinder head cooling liquid feed holes; 3 – cylinder head oil drain holes; 4 – cylinder head cooling liquid drain holes; 5 – cylinder head gasket marking place GEAR HOUSING The gear housing is installed directly on the rear face of the cylinder block, with a sealant, without a gasket.

-

Page 56

On the right side at the bottom there is a hole for the crankshaft manual turning tool and an inspection hole necessary to adjust valve expansion gaps. To ensure the engine/transmission interface, the rear face of the flywheel housing is designed according to SAE-1. CYLINDER BLOCK FRONT COVER The cylinder block front cover has a sealing collar to seal the crankshaft front butt. -

Page 57

Fig. 12 Crankshaft 1 – front collar; 2 – main bearing upper shell; 3 – crankshaft; 4 – crankshaft gear; 5 – rear collar; 6 – thrust bearing washer; 7 – main bearing lower shell The counterweight for the last crankshaft web has the following visible marks… -

Page 58

Table 1 Crankshaft journal sizes; Labeling on crankshaft, journals and semi-rings Main -0,019 -0,022 – Ш1 75,90 88,0 – К1 76,0 87,90 +0,062 – Ш1К1 75,90 87,90 repair 75,75 0,25 87,75 0,25 repair 75,50 0,50 87,50 0,50 repair 75,25 0,75 87,25 0,75 37,5… -

Page 59

«YMZ-536» mark. The flywheel is fixed to the rear end of the crankshaft with 10 bolts through the common hardened plate. As the bolts are not locked, they must be properly tightened to ensure a reliable connection. -

Page 60: Piston Rings

Fig. 13. Piston: 1 – piston; 2 – top compression ring; 3 – 2 compression ring; 4 – oil control ring; 5 – circlips; 6 – piston pin; 7 – connecting rod PISTON RINGS The split-type piston rings are made of special cast iron and installed into the corresponding piston grooves.

-

Page 61: Piston Pin

ATTENTION! WHEN INSTALLING THE PISTON RINGS, PAY SPECIAL ATTENTION TO THEIR PROPER POSITION. THE WORD «ТОР» MUST FACE THE BOTTOM OF THE PISTON. PISTON PIN The piston pin is hollow, floating-type, made of steel with а case-hardened surface. The pin is installed into the piston pin hole. The piston pin axial movement is limited by circlips installed into special grooves in the piston bosses.

-

Page 62: Bearing Shells

Fig. 14. Piston /Connecting rod unit 1 – piston; 2 – compression rings; 3 – oil control ring; 4 – piston pin; 5 – circlips; 6 – connecting rod; 7 – small end shell; 8 – connecting rod cap fixing bolts; 9 – marking place for the group number (А, В, С); 10 –…

-

Page 63: Piston Oil Cooling Jet

oil supply. Besides, due to the bronze coating, the most loaded lower shell has a higher load-bearing capacity. The upper and the lower shells of the connecting rod big end are also not interchangeable. The bronze coating of the upper shell, which is more loaded, has a higher load-bearing capacity.

-

Page 64

the connecting rods, to make sure the unit is assembled properly and the piston ring locks are in the correct position. Only the same weight group connecting rods can be installed on the engine. The group number: A, B or C is embossed on the connecting rod cap. -

Page 65

ACCESSORY DRIVE GEARS Accessories located in the rear part of the engine have a gear drive (See Fig.16). The gear on the crankshaft nose drives the camshaft gear. This pair of gears is assembled according to the marks on the teeth (See View A, Fig.16). -

Page 66

А Fig. 16. Accessory units gear drive 1 – drive gears housing; 2 – crankshaft gear; 3 – camshaft gear; 4 – fuel pump gear; 5 – pneumatic brakes compressor gear; 6 – compressor intermediate gear; 7 – oil pump gear; 8 –… -

Page 67: Accessory Drive Belts

ACCESSORY DRIVE BELTS Accessories located in the front part of the engine are driven by poly-V belts. The engine package comes in three options: Water pump, fan and generator (Fig. 17). Fig. 17 Accessory drive belts (first option): – crankshaft pulley damper;…

-

Page 68

Fig. 17а. Accessory drive belts (second option): 1 – crankshaft pulley and damper; 2 – tension roller; 3 – water pump pulley; 4 – belt; 5 – fan drive pulley; 6 – tension roller; 7 – belt; 8 – generator pulley; 9 –… -

Page 69

Fig. 17b Accessory drive belts (third option): 1 – crankshaft pulley and damper; 2 – tension roller; 3 – water pump pulley; 4 – belt; 8 – generator pulley The belts are tensioned by automatic rollers with springs inside; during operation no additional adjustment is required. All rollers are the same, with a smooth pulley, operating on the outer smooth belts surface. -

Page 70

During installation of a new belt, the mark on the rotating part must be within the area of the two neighboring marks on the fixed part. Fig. 18 Checking accessory drive belt tensioning: 1 – mark on the rotating part; 2 – marks on the fixed part During maintenance, check the cleanliness of the belts and pulleys;… -

Page 71: Valve Train

VALVE TRAIN The valve train controls admission of fresh air into the cylinders and release of exhaust gases out of the cylinders according to the cylinder firing order and engine strokes. The valve train is OHV type, with the camshaft below the cylinder head;…

-

Page 72

Each cylinder has four valves — two intake valves and two exhaust valves. The main valve train components are: a camshaft with a drive gear, rear bearing and a thrust flange; tappets; pushrods; rocker arms with adjusters; yokes; rocker arm shaft; rocker arm shaft supports; valves;… -

Page 73

Fig. 20 Camshaft tail end with a gear, supports and tappets. 1 – cylinder block; 2 – gear housing; 3 – camshaft; 4 – camshaft gear; 5 – camshaft bushing; 6 – camshaft rear bushing;7 – camshaft bearing housing; 8 – camshaft thrust flange; 9 –… -

Page 74

The rocker arms are pressed to the shaft supports by a spacer spring installed on the shaft between neighboring rocker arms. Fig. 21 Valve drive system 1 – shaft with rocker arms and shaft supports; 2 – pushrod; 3 – tappet; 4 — yoke Intake valves are single-piece design, made of heat-resistant alloy steel and heat-treated. -

Page 75

The valves move in the guide bushings made of a sintered material and press-fitted into the cylinder head. The intake valve bushings have sealing collars. Fig. 22. Valve train (top view), located in the cylinder head: 1 – inlet valve; 2 – exhaust valve; 3 – stop ring; 4 – rocker arm shaft; 5 –… -

Page 76

LUBRICATION SYSTEM The engine lubrication system is a mixed-type wet-sump system. The oil pump sucks oil from the oil sump through the suction pipe intake and a safety valve and supplies it to the system through the in-line liquid-oil heat-exchanger (L/O HE) and the oil filter (OF). The L/O HE is installed in the service module housing which also incorporates the lubrication system differential valve, the water pump and the thermostat box. -

Page 77: Oil Filter

ATTENTION! THE HIGH-PRESSURE FUEL PUMP IS LUBRI- CATED BY THE OIL CIRCULATING INSIDE ITS HOUSING. OIL PUMP The oil pump is mounted on the rear side of the cylinder block and can only be accessed when the flywheel housing is removed. The oil pump safety valve is installed on the cylinder block lower flange in the oil pump feed pipe and can be accessed when the oil sump is removed.

-

Page 78

When installing the filter, screw on the replaceable filter by hand as far as it will go. LUBRICATION SYSTEM DIFFERENTIAL VALVE The lubrication system oil pump capacity is calculated with allowance for worn-out friction pairs of the engine which has been in operation until its scheduled overhaul, including low-speed operation mode. -

Page 79: Cooling System

COOLING SYSTEM The engine cooling system is a liquid circulation system consisting of a water pump, a liquid-to-oil heat exchanger (L/O HE), a fan, thermostats and an exhaust gas recirculation (EGR) heat exchanger. The cooling system also includes a vehicle-mounted water radiator and an air-to-air charge air cooler.

-

Page 80

The EGR heat exchanger is located above the cylinder head water distribution pipe. Part of the liquid from the pipe goes to the heat exchanger through the bushing with a rubber ring, cools down exhaust gases and is drained through the external pipe to the service module water collecting channel. -

Page 81

Fig. 24. Service module, front view: 1 – cooling liquid feed pipe from the vehicle radiator; 2 – cooling liquid feed flange to the thermostat box from the transmission heat exchanger; 3 – thermostat box; 4 – oil filter; 5 – L/O HE safety valve; 6 – service module housing;… -

Page 82: Water Pump

Fig. 24а. Service module, rear view: 1 – cooling liquid feed channel to the thermostat box from the block; 2 – L/O HE heat-transferring element; 3 – L/O HE oil feed channel from the block; 4 – oil filter outlet channel to the block; 5 – oil channel from the differential valve outlet to the oil sump WATER PUMP The centrifugal water pump is part of the service module.

-

Page 83

4 5 6 А Fig. 25 Water pump with thermostats: 1 – cooling liquid feed pipe from the vehicle radiator; 2 – suction cavity; 3 – thermostat; 4 – water pump volute; 5 – water pump impeller; 6 – water pump housing; 7 – water pump pulley; 8 –… -

Page 84

installed in the aluminum water pump housing 6. The bearing is closed and filled with grease. On the pump drive spindle the end seal 9 is mounted and the impeller 5 and the pulley 7 are press-fitted. To ensure leak proofness of the end seal, the pump housing has a drain hole 10. -

Page 85

Fig. 26. Installation of heat-transferring element: 1 – service module housing; 2 – heat-transferring element; 3 – heat-transferring element fixing bolt; 4 – joint; 5 – gasket; 6 – oil outlet channel… -

Page 86

Б Fig. 27. Arrangement of channels in the service module: 1 – cooling liquid feed pipe from the vehicle radiator; 2 – suction cavity; 3 – thermostat; 4 – oil outlet channel from the L/O HE element; 5 – L/O HE element oil feed channel;… -

Page 87

Installed in the oil filter housing is the L/O HE safety valve (Fig. 27). When the differential pressure before and after the heat- exchanger reaches 274 ± 40 kPa (2,8 ± 0,40 kgf/cm ), the valve opens and part of the oil is supplied uncooled directly to the oil filter. The valve design is shown in Fig. -

Page 88

Fig. 28. Thermostat arrangement in the service module: 1 – thermostats; 2 – cooling liquid feed channel from the transmission heat exchanger; 3 – cooling liquid feed channel from the water pump to the L/O HE; 4 – cooling liquid feed channel from the engine;… -

Page 89: Fuel System

The fan drive is installed on the front side of the cylinder block along the engine axis above the crankshaft axis. Fig. 29. Fan drive: 1 – spacer; 2 — bolt М10х1.25-6g×20-8.8 with a neck (6 pcs.); 3 – fan drive pulley; 4 — bolt М8×1.25-6g×25-8.8 with a neck (4 pcs.);…

-

Page 90

CRS BOSCH with an electronic control unit ensures the following: precise fuel injection rate for each operation mode as well as multi-stage injection; fuel injection advance angle control depending on the rpm, load and temperature; flexible control of fuel injection pressure over a wide range; … -

Page 91

three sections each of which is fed through a dosage device with an electric valve. The HP pump sends the fuel under pressure to the common fuel accumulator (rail) 9 from where the fuel is delivered to each injector via an individual line. The injectors deliver the fuel under pressure into the combustion chamber. -

Page 92

Fig. 31 Fuel system: 1 – injector; 2 – side union; 3 – rail; 4 – high-pressure pipes; 5 – HP fuel pump pipe; 6 – HP fuel pump with a low-pressure pump; 7 – priming pump fuel feed pipe; 8 – HP fuel pump feed pipe; 9 – engine fuel feed pipe;… -

Page 93

COARSE FUEL FILTER The coarse fuel filter is a full-flow sump-type filter. The coarse fuel filter is equipped with (see Fig. 32) a water separator 7 (water sump), a manual fuel priming pump 5, a fuel heater 6 and a level sensor 1. The coarse fuel filter is installed in the low-pressure fuel line between the fuel tank and the ECU fuel feed union. -

Page 94

1 – level sensor; 2 – replaceable filter; 3 — filter cover with a flange with 4 holes; 4 – vent hole threaded plug; 5 — manual fuel priming pump; 6 – fuel heater; 7 – water sump; 8 – drain hole plug A –… -

Page 95

FINE FUEL FILTER The engines are equipped with a fine fuel filter 1 installed on the filter housing with its cap down (Fig. 31). The housing with the filter is mounted on the left side of the cylinder block. The replaceable filter (2 pcs.) is designed as a single-piece shell with a metal housing. -

Page 96

Fig. 33 High-pressure fuel pump… -

Page 97

INJECTOR The injectors are closed type, with a multi-hole nozzle, hydraulically controlled needle lift and a built-in fast-response fuel injection solenoid valve (Fig. 34). 1 — Nozzle assy 2 — Injector body 3 — Nozzle nut 4 — Rod 5 — Control piston 6 —… -

Page 98

The injector features an electro-hydraulic principle of operation Being under the pressure of fuel, the injector is closed as the area of the control piston 5 is larger than the nozzle differential area. When the solenoid 19 receives a 80V (18A) PWM signal, the pusher with the armature compresses the spring 18 and goes up by 0.05 mm. -

Page 99

Fig. 35. Injector control The injector installation in the cylinder head is shown in Fig. 36. -

Page 100

Fig. 36 Injector installation in the cylinder head: 1 – cylinder head; 2 – injector; 3 – injector union; 4 – injector union sealing ring; 5 – cap screw; 6 – rubber sealing ring 7 – injector sleeve; 8 – sealing washer; 9 – injector fixing bracket; 10 –… -

Page 101

has a tapered socket, and the union 3 has a tapered end. The joint is tightened by means of a cap screw 5 from the outer side of the cylinder head. The cap screw 5 is screwed into the cylinder head and presses the union through the thrust collar. -

Page 102

TURBOCHARGER SYSTEM GENERAL DESCRIPTION To ensure the required power output, the engine is equipped with a turbocharger that uses the energy of exhaust gases to force more air into the engine. By increasing the mass of the air entering the cylinders, the turbocharger contributes to more effective burning of higher amount of fuel thus increasing the engine power. -

Page 103

The heat released to the environment by the air-to-air type cooler of the YMZ-536 engine can reach the value up to 57 kW. The charge air cooler is not part of the engine supply kit and is mounted in the vehicle upstream the cooling system radiator. -

Page 104

CRANKCASE VENTILATION SYSTEM The crankcase ventilation system is a closed-type system (see Fig. 37). During the engine operation some amount of exhaust gases from the cylinders enter the crankcase where they are mixed with oil mist and sent to the turbocharger suction. To prevent oil coking in the turbocharger, crankcase gases are separated from oil in the breather 2. -

Page 105

А Б В Г Д Е-Е Fig. 37. Crankcase ventilation system: 1 – cylinder head cover; 2 – two-stage breather; 3 – 1 stage swirlers; 4 – 1 stage hydraulic lock; 5 – internal cylinder; 6 – external cylinder; 7 – drain pipe; 8 – 2 stage swirlers;… -

Page 106

Through the 2mm hole 13 in the cover 12 atmospheric pressure is applied onto the diaphragm. From below, on the crankcase gases side the diaphragm 14 is spring-loaded by the cylindrical spring The crankcase gases are removed via the circular slot between the diaphragm and the central outlet pipe 16. -

Page 107

EXHAUST BRAKE When it is necessary to use sustained braking (e.g. for a long- time downhill movement), the driver, without disengaging the clutch, cuts off the fuel supply and shifts to the lowest gear. In this case the engine starts operating as an air compressor, with the rpm depending on the vehicle movement speed. -

Page 108: Electrical Equipment

ELECTRICAL EQUIPMENT Electrical equipment operates in a single-wire DC system with 24V of rated voltage. The negative pole of the power source is connected to the vehicle body. STARTER The YMZ engines are equipped with an electric starter. Its specifications are listed below. Specifications Rated voltage, V Rated power, kWt…

-

Page 109: Engine Labeling

ENGINE LABELING The engine is labeled on the engine nameplate. An exemple of YMZ-536-01 engine nameplate is shown on picture 38. The nameplate is fitted in the middle of the left side of the cylinder block. The nameplate provides the following information: 1.

-

Page 110: Consumables

CONSUMABLES Trouble-free operation and long lifetime of the engine and power train is guaranteed only if fuels, oils and coolants recommended by the manufacturer are used. ATTENTION! IT IS FORBIDDEN TO USE FUELS, LUBRICANTS OR COOLANTS WHICH ARE NOT SPECIFIED IN THIS MANUAL. RECOMMENDED FUEL GRADES The diesel fuels to use should be as follows: BASIC DIESEL FUEL…

-

Page 111: Recommended Motor Oil Grades

RECOMMENDED MOTOR OIL GRADES Use the following oils: BASIC MOTOR OIL GRADES SHELL Shell Rimula Super (SAE 10W-40, API CI-4/CH-4/CG-4/ CF-4/CF); Shell Rimula Super FE (SAE 15W-40, API CI-4/CH-4/CG-4/ CF-4/CF). 2. ALTERNATIVE MOTOR GRADES ExxonMobil: Mobil Delvac MX Extra (SAE 10W-40, API CI-4/CH-4/ CG-4/CF-4/CF/CL/SJ);…

-

Page 112

MOTOR OIL CHANGE FREQUENCE First change after 500 hours, then after every 1000 hours or 30,000 km on dumpers, chassis and municipal buses; or 50,000 km for trucks on interurban or international roads, buses on inter-urban roads (See “MAINTENANCE”). ATTENTION! IF SULFUR CONTENT IN THE FUEL IS MORE THAN 0.2%;… -

Page 113

antifreeze (-65) «X-Freeze Carbox®» (Felix® Carbox®), TS 2422-068-36732629-2006. ATTENTION! NEVER USE THE CONCENTRATE AS A READY-TO-USE OPERATING LIQUID! If the coolant concentrate GlycoShell or Glacelf Auto Supra is used, to prepare the working solution the concentrate must be diluted with distilled (demineralized) water in the following proportion: … -

Page 114: Safety Requirements

SAFETY REQUIREMENTS While operating the engine, the following safety requirements must be observed. Please keep in mind that strict observance of safety requirements is, above all, in your interest. Before starting the engine, carefully read this Engine Operation Manual …

-

Page 115

Remember that ethylene glycol liquids and «Tosol» are toxic if swallowed. Use fire extinguishers to extinguish a burning fuel spill, throw sand onto the fire, cover it with asbestos blanket, felt or tarpaulin. Don’t pour water onto the flame. … -

Page 116: Starting, Running And Stopping

STARTING, RUNNING AND STOPPING PREPARATION FOR START-UP OF NEW ENGINE AND ENGINE START-UP AFTER LONG-TERM LAY-UP OR REPAIR The rules stated in this Section apply to initial powertrain and engine start-up in the following cases: new engine engine that has been out of operation for a long time (for 5 days and longer) …

-

Page 117: Engine Start

PREPARATION FOR DAILY START-UP 1. Make sure there is enough fuel in the tank. 2. Check the oil level in the engine sump; if necessary pour fresh oil up to the top level mark. 3. Check for the coolant level in the cooling system. 4.

-

Page 118: Cold-Season Start

engine starts running, release the key so that it is back to the first (I) position. The duration of the starter non-stop operation must not exceed 10 seconds (20 seconds in cold season). If this duration is exceeded, the starter may fail. Wait for 1 or 2 minutes, then try again. If after three such tries the engine fails to run, find and eliminate the fault 6.

-

Page 119: Checking Engine Operation

CHECKING ENGINE OPERATION When operating the engine, follow the readings of the control instruments and alarm indicators: 1. The temperature of the engine cooling liquid must be within the range of 80-100 С. A short-term (up to 10 min) temperature increase up to 105 С…

-

Page 120: Stopping The Engine

7. When operating the engine, pay attention to any abnormal noise. STOPPING THE ENGINE Before stopping the engine allow it to idle for 2-3 minutes without any load, at minimal rpm 700 min To stop the engine, decrease the RPM to minimum and turn the ignition key to the “0”…

-

Page 121: Winter Operation

WINTER OPERATION To ensure failure-free engine operation in winter conditions, use antifreeze coolants (See Section Operational Substances) In case the coolant volume has decreased due to evaporation, and not due to leaking, add only distilled water into the cooling system as the amount of ethylene glycol remains unchanged due to its high boiling point.

-

Page 122: Maintenance

MAINTENANCE Timely maintenance of the engine and the power train ensures their trouble-free operation and long lifetime. As maintenance procedures are preventive, maintenance should be conducted according to the fixed schedule over the whole operating period. GENERAL MAINTENANCE GUIDANCE According to the time period and operations performed, maintenance is subdivided as follows: DAILY MAINTENANCE (DM) FIRST SCHEDULED MAINTENANCE (M-1) is conducted…

-

Page 123: Daily Maintenance (Dm)

One of the SMs must be conducted in parallel with the next regular maintenance. One-time maintenance operations DAILY MAINTENANCE (DM) 1. Check the engine operation. 2. Check the generator with an ampere meter. 3. After the engine stops, check the sound of the running turbocharger.

-

Page 124: Second Scheduled Maintenance (M-2)

SECOND SCHEDULED MAINTENANCE (M-2) 1. Examine the engine, clean off any dirt or dust, if necessary. 2. Change the oil in the engine lubrication system. 3. Change the oil filtering elements 4. Change the filtering elements of the fuel filter 5.

-

Page 125: One-Time Maintenance Operations

ONE-TIME MAINTENANCE OPERATIONS AFTER EVERY 200,000 km 1. Change the drive belts of the generator and the fan. AFTER EVERY 400,000 km 1. Change the tension pulley of the generator drive AFTER EVERY 800,000 km 1. Change the tension pulley of the fan drive EVERY THREE YEARS 1.

-

Page 126: Lubrication System

LUBRICATION SYSTEM MAINTENANCE CHECK OF ENGINE OIL LEVEL The oil level is to check after the marks of the oil level indicator which is located on the engine’s left-hand side. Check the oil not before than 15 minutes after the engine has stopped, with the vehicle standing on a flat horizontal surface.

-

Page 127: Fuel Supply System Maintenance

Fig. 39. Removal and installing of replaceable oil filter: 1 – replaceable oil filter element 5. Screw back the new filter by hand until the sealing ring touches the bearing surface of the service module housing, then tighten an additional 1/2 – 3/4 rev. 6.

-

Page 128: Coarse Fuel Filter Maintenance

COARSE FUEL FILTER MAINTENANCE DRAINING WATER FROM COARSE FILTER Draining collected water is necessary when the water sump is full, when the replaceable filter is changed, or before possible freezing in cold weather conditions. WARNING! RISK OF FREEZING. DRAIN THE WATER FROM THE SUMP IN ORDER TO AVOID IT.

-

Page 129

1. Switch off the engine 2. Drain water from the water sump 3. Unscrew the water sump 1 (Fig. 41) by means of the tools from the package of the new sump. While doing this, hold the replaceable filter in position so that it should not be unscrewed. -

Page 130

4. Lubricate the sealing gasket of the new filter with a few drops of motor oil. 5. Screw the filter by hand until the filter gasket touches the cover surface, then screw additionally (about 3/4 rev.) 6. Unscrew the plug of the vent hole 1 (Fig. 42) 7. -

Page 131

FUEL HEATER To install the heater (Fig. 43) do the following: 1. Unscrew the screws 3 (fixing the safety cap) and remove the safety cap 1 from the filter. Use these screws to fix the heater. 2. Insert the heater 2 with the gasket 5 into the opening in the filter. -

Page 132

Fig. 44. Removal of fuel filter replaceable elements: 1 – replaceable filtering elements; 2 – seal ring Fig. 44a. Mounting of fuel filter replaceable elements 1 – replaceable filter elements; 2 – seal ring… -

Page 133

5. Prime the fuel system using the manual pump of the coarse fuel filter. 6. Start the engine, check the junction for leaks. If necessary, additionally tighten the replaceable filters. 7. In case of leakage, unscrew the replaceable fuel filter; check the condition of the sealing ring and its bearing seat. -

Page 134: Cooling System Maintenance

COOLING SYSTEM MAINTENANCE Proper operation of the cooling system is critical for the engine efficiency, reliability, service life other performance characteristics. The cooling system maintenance procedure includes the following: 1. Replace the cooling liquid every three years of the vehicle operation.

-

Page 135: Valve Train Clearance Adjustment

VALVE TRAIN CLEARANCE ADJUSTMENT Expansion gaps in the valve train are essential to ensure leak- proof valve contact with the seat during thermal expansion of the valve train parts when the engine is in operation. If the clearances are too large, the valve lift is decreased which results in worse cylinder filling and cleaning, higher shock loads (valves start knocking) and increased wear of the valve train parts.

-

Page 136

5. Place the piston of the 1st cylinder at the top dead centre (TDC) of the compression stroke by turning the crankshaft with the turning gear in the clockwise direction (if looking from the fan side) using one of the two methods described below: Remove plug 3 of the inspection hole located METHOD 1: below the crankshaft turning gear hole. -

Page 137

6. Check or adjust the valve clearance. 7. To adjust the clearance, do the following (see Fig. 46): release the lock nut 3 of the adjusting screw 2 of the intake or exhaust valve rocker arm 1; insert a feeler gauge of the required thickness between the rocker arm cup 5 and the yoke 4;… -

Page 138

Fig. 46. Valve mechanism adjustment: 1 – rocker arm; 2 – rocker arm setscrew; 3 – lock nut; 4 – yoke; 5 – rocker arm cap 13. Start the engine and make sure that there is no leakage on the junction of the cylinder head cover and the crankcase gas discharge hose pipe… -

Page 139

AUXILIARY UNITS DRIVE MAINTENANCE In course of operation, tension of the generator and other auxiliaries’ drive belts is adjusted automatically, no need of extra adjustments. To remove the belt from the generator, compress the spring of the automatic belt tensioning system. To remove the belt from other driven units, press the spring of the automatic belt tensioning system. -

Page 140: Checking Intake And Exhaust System For Likeage

CHECKING INTAKE AND EXHAUST SYSTEM FOR LIKEAGE 1. Let the engine run at minimum idle speed at 700 min Check the air filter / turbocharger link for leakage. For that purpose, spray the «Start Pilot» liquid (ether based) at the connections. In case of leakage the rpm increases.

-

Page 141: E.c.s. Diagnostics

A full list of failures with interpretation of each blink-code is given in the YMZ document ref. 5340.3902250 IS specially devoted to the diagnostics of YMZ-5340 and YMZ-536, their modifications and assembly sets. For elimination of faults detected please call a service center.

-

Page 142: Sealants

SEALANTS The engine sealing materials (sealants) by Russian and foreign manufacturers are listed below in Table 2. Table 2 Designation of junction or component Sealant brand Cylinder block, threaded hole for tapered plug – 1/4″ Anaherm-100 tapered plug. Anakrol-2051, Cylinder block, threaded hole for tapered plug – 1/2″ Unifix-An17M tapered plug.

-

Page 143

Designation of junction or component Sealant brand Fitting of the cooling liquid supply pipe from the Anaherm-100, Distribution pipe to the air break compressor (ABC) , Anakrol-2051, fitting thread – distribution pipe thread Anaherm-100, Coolant supply elbow pipe from ABC to the cylinder Anakrol-2051 block, elbow pipe thread –… -

Page 144: Engine Preservation And Depreservation

Note: The sealants must be applied to cleaned and degreased surfaces. ATTENTION! SEALANTS ARE FIRE-HAZARDOUS SUBSTANCES. WHEN WORKING WITH SEALANTS, OBSERVE CORRESPONDING SAFETY RULES. THE WORKING SPACE MUST HAVE PROPER VENTILATION. ENGINE PRESERVATION AND DEPRESERVATION 1. Engine preservation is performed in order to protect the engine interior and exterior surfaces against corrosion during transportation and storage in the Client’s warehouse by means of applying a protective corrosion inhibitor film onto these surfaces.

-

Page 145

media; thermometers and hydrometers to control the temperature and humidity in the room. 5. The engines coming for preservation must be clean. The coolant and the oil must be drained from the engine. 6. The engine temperature must be equal to or higher than the temperature in the preservation room. -

Page 146: Engine Exterior Preservation

the foaming stops completely; the moisture is removed from the fuel by settling. 12. Wooden plugs, stoppers and planks used during preservation must be made of dry wood and impregnated with preservation oil at 105-120°С until foaming stops. ENGINE EXTERIOR PRESERVATION 1.

-

Page 147: Engine Packing

ENGINE PACKING Put the preserved engine onto a wooden pallet, fix it and pack. The engines packing must allow for their storage in warehouses mechanical loading/unloading from containers and covered wagons. Preservation and packing procedure for each engine must be documented in a special report (Act) as shown below: DEED of preservation and packing…

-

Page 148: Engine Depreservation

The components used during installation of the vehicle engine systems must be preserved and packed into a separate box as per GOST 2991-85. Engine tools, spare parts and accessories must be preserved, marked and packed in sets into a separate box as per GOST 2991-85 according to the manufacture’s established procedure.

-

Page 149: Manufacturer’swarranty And Claiming Procedure

MANUFACTURER’S WARRANTY AND CLAIMING PROCEDURE DEAR OWNER! AVTODIZEL JSC (YMZ) (HEREINAFTER REFERRED TO AS MANUFACTURER) THANKS YOU FOR YOUR CHOICE AND GUARANTEES HIGH QUALITY AND TROUBLE-FREE OPERATION OF THE ENGINE/POWERTRAIN PURCHASED BY YOU PROVIDED THAT THE OPERATION RULES STATED IN THIS MANUAL ARE STRICTLY FOLLOWED.

-

Page 150: Warranty Period

Note: The list of service centres is provided in the Service Book for the product, or at www.service.powertrain.ru and www.gazgroup.ru. Conducted maintenance must be confirmed by the corresponding records in the Service Book (form, service card) for the engine and the vehicle except the cases when the Service Book (form, card) is not included in the engine or vehicle delivery package.

-

Page 151

The warranty service life runtime powertrains/engines to be used by the Ministry of Defense of the Russian Federation (MOD RF) are established according to the warranty service life and runtime of the end product, but not more than 10 years. For the engines which are supplied for spare parts to the MOD RF and which have undergone complete preservation the warranty service life starts on the date when the engine was installed into the end product provided that the time elapsed after… -

Page 152

Upon expiration above-mentioned periods, Engine/Powertrain must be put into operation or subjected to re- preservation according to «Preservation and Depreservation» section of this Operation Manual. All repair operations conducted within the warranty scope, as well all parts, components and units which have been replaced during these operations are covered by warranty until the warranty period for the new engine is expired. -

Page 153: How To Use The Warranty

be raised against the service centre where the maintenance or repair has been conducted; any defects caused by using operational materials (oils, fuels, coolants, etc.) which are not recommended by the manufacturer, or by operating the Engine/Powertrain with insufficient amount of operational materials (coolant, oil, etc.) due to late detection of the leakage or high consumption level;…

-

Page 154

all the relative information on the equipment and conducted maintenance. b) Vehicle Registration Certificate and/or other documents confirming the user’s right to raise the warranty claim; c) a Warranty Letter in which the user undertakes to reimburse the dealer/SC for the expenses in case the claim is declared void. -

Page 155

Note: Any risks and expenses related to the Engine/Powertrain defects and breakdowns caused by operating the Engine/Powertrain which is out of order shall be born by the owner. CONCLUSION In case no dealer or SC of «Powertrain – GAZ Group» LLC is available in your area, the notification (claim) on behalf of the product owner should be sent by wire or by post to the Warranty and Service Maintenance Department of «Powertrain –… -

Page 156: Disposal

DISPOSAL Disposal is a process of destruction or liquidation of machinery and equipment by means of their disassembly, recycling, burial and other methods, including preparation procedures preceding disposal process. During disposal the personnel must follow safety requirements for mechanical operations. The personnel must have appropriate training and qualification.

-

Page 157

documentation. The main disposal method is mechanical disassembly. The article should be completely disassembled; its parts should be sorted out depending on the material. All non-metal parts should be pressed and sent to a disposal facility. There are no other requirements for disposal of powertrains, engines, clutches and gear boxes. -

Page 158: Appendices

APPENDICES APPENDIX 1 TIGHTENING REQUIREMENTS FOR MAIN THREADED CONNECTIONS FIXING CYLINDER HEAD The cylinder head is fixed on the block with 20 mm and 14 mm bolts. Fig. 48 shows the bolt tightening sequence: first install bolts and tighten them moderately. Further tightening of the cylinder head fixing bolts is performed in three steps: Step 1 –…

-

Page 159

Tightening needed Final tightening Preliminary Fixing elements to angle in tightening torque, degrees or torque Nm (kgf m) in Nm (kgf m) Crankshaft, conrods and pistons Crankshaft bearing cap 135 ± 15 (13.5 ± 1,5) 120º ± 2º securing .bolts Flywheel securing bolts. -

Page 160

Tightening needed Final tightening Preliminary Fixing elements to angle in tightening torque, degrees or torque Nm (kgf m) in Nm (kgf m) Timing mechanism Tightening is performed in three steps: 1. Preliminary tighten (2–3 revolutions) 2. Start middle, Bolts fixing rocker arm shaft successively moving toward and supports both sides, tighten to torque of… -

Page 161

Tightening needed Final tightening Preliminary Fixing elements to angle in tightening torque, degrees or torque Nm (kgf m) in Nm (kgf m) 22 – 25 (2.2 – 2.5) with application of Oil sump securing bolts Loctite 518 anaerobic gasket maker Oil sump bleeding plug 70 ±… -

Page 162

Tightening needed Final tightening Preliminary Fixing elements to angle in tightening torque, degrees or torque Nm (kgf m) in Nm (kgf m) Nuts attaching the turbo- charger to the exhaust 50 – 55 (5,0 – 5,5) manifold Nuts attaching the exhaust 50 –… -

Page 163: Engine Delivery Set For In-Vehicle Integration

APPENDIX 2 ENGINE DELIVERY SET FOR IN-VEHICLE INTEGRATION The Engine Delivery Set for in-vehicle integration comprises operation documents, spare parts, tools and accessories, as well as parts and products which are used for final mount into a truck or autobus. The Delivery Set is composed as follows (see Table 7). Table 7 Quantity for one engine D e s c r i p t i o n…

-

Page 164

Quantity for one engine D e s c r i p t i o n YMZ- YMZ- YMZ- YMZ- YMZ- 5361 5362 5363 5364 Spare Parts (SP), Tools & Accessories 1. Driver tools & accessories 5340.3901010 . One-time warranty spare parts kit 536.3906012 . -

Page 165

APPENDIX 3. BOSCH DIESEL SERVICE CENTERS IN RUSSIA WARRANTY MAINTENANCE & SALE OF DIESEL COMPONENTS BOSCH COMMON RAIL SYSTEM The table below is a list of authorized guarantee maintenance centers of Bosch Diesel Service in Russian Federation, specialized in servicing of Bosch Common Rail System. BOSCH №… -

Page 166: Table Of Contents

CONTENTS WARNING APPLICATION RANGE & PARTICULARITIES OF ENGINE ASSEMBLY SETS TECHNICAL SPECIFICATIONS MAIN PARAMETERS AND CHARACTERISTICS OF ENGINES YMZ-536 FAMILY GENERAL DESIGN AND OPERATION GEAR HOUSING FLYWHEEL HOUSING PISTON RINGS PISTON PIN CONNECTING ROD PISTON OIL COOLING JET PISTON/CONNECTING ROD UNIT ASSEMBLY…

-

Page 167

MAINTENANCE GENERAL MAINTENANCE GUIDANCE DAILY MAINTENANCE (DM) FIRST SCHEDULED MAINTENANCE (M-1) SECOND SCHEDULED MAINTENANCE (M-2) SEASONAL MAINTENANCE (SM) ONE-TIME MAINTENANCE OPERATIONS LUBRICATION SYSTEM ENGINE OIL CHANGE CHANGING THE REPLACEABLE FUEL SUPPLY SYSTEM MAINTENANCE COARSE FUEL FILTER MAINTENANCE DRAINING WATER FROM COARSE FILTER COOLING SYSTEM MAINTENANCE VALVE TRAIN CLEARANCE ADJUSTMENT CHECKING INTAKE AND EXHAUST SYSTEM FOR LIKEAGE 140… -

Page 168

NOTES…

диагностика неисправностей компонентов,как при помощи тестера выявить неисправность,описание принципа работы и характеристики параметров

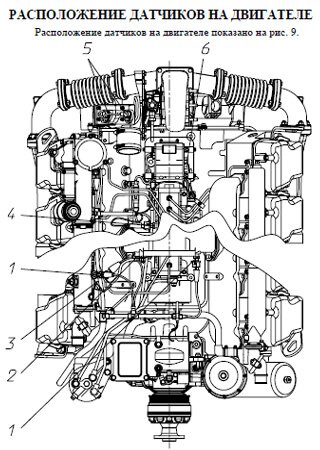

УСТРОЙСТВО И ПРИНЦИП РАБОТЫ ДАТЧИКА ЧАСТОТЫ ВРАЩЕНИЯ ДВИГАТЕЛЯ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик частоты вращения коленчатого вала, также называемый датчиком скорости двигателя или датчиком синхронизации, установлен в верхней части картера маховика с правой стороны, если смотреть со стороны маховика. С помощью датчика частоты вращения коленчатого вала определяется частота вращения и угловое положение коленчатого вала (положение поршня) относительно верхней мёртвой точки (ВМТ) в цилиндрах двигателя. Используя информацию с датчика, ЭБУ двигателя рассчитывает начало подачи и количество впрыскиваемого топлива для каждого отдельного цилиндра.

УСТРОЙСТВО И ПРИНЦИП РАБОТЫ ДАТЧИКА ЧАСТОТЫ ВРАЩЕНИЯ РАСПРЕДЕЛИТЕЛЬНОГО ВАЛА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик частоты вращения распределительного вала, также называемый датчиком фазы, аналогичен датчику частоты вращения коленчатого вала и установлен на картер маховика с левой стороны, если смотреть со стороны маховика. Частота вращения распределительного вала в два раза меньше частоты вращения коленчатого вала. ЭБУ.

ОТКАЗ ДАТЧИКА ДАВЛЕНИЯ И ТЕМПЕРАТУРЫ НАДДУВОЧНОГО ВОЗДУХА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик давления наддува со встроенным датчиком температуры DS-S3-TF, рисунок 16, служит для оценки абсолютного давления и температуры наддувочного воздуха на выходе из турбокомпрессора, а также используется для контроля системы рециркуляции ОГ. Датчик расположен на впускном патрубке (после ОНВ).

ОТКАЗ ДАТЧИКА ДАВЛЕНИЯ И ТЕМПЕРАТУРЫ МАСЛА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик давления и температуры масла DS-K-TF, служит для измерения и соответствующего контроля абсолютного давления и температуры масла в системе смазки двигателя. Кроме того, показания датчика температуры масла используются в работе устройства облегчения пуска (например, предпусковой подогреватель воздуха на входе в двигатель). Датчик расположен в масляном канале корпуса шестерен с правой стороны,

ОТКАЗ ДАТЧИКА ДАВЛЕНИЯ И ТЕМПЕРАТУРЫ ТОПЛИВА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик давления и температуры топлива DS-K-TF аналогичен датчику давления и температуры масла и контролирует давление и температуру топлива, подаваемого топливо- подкачивающим насосом (в контуре низкого давления). Оба датчика взаимозаменяемы. Датчик расположен сверху на корпусе фильтра тонкой очистки топлива на входе в фильтр.

ОТКАЗ ДАТЧИКА ТЕМПЕРАТУРЫ ОХЛАЖДАЮЩЕЙ ЖИДКОСТИ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик температуры охлаждающей жидкости TF-W, контролирует температуру охлаждающей жидкости двигателя. Датчик расположен на водяной рубашке блока цилиндров с правой стороны: для четырехцилиндровых двигателей рядом с сервисным модулем, а для шестицилиндровых – ближе к стартеру.

ОТКАЗ ДАТЧИКА ДАВЛЕНИЯ В ТОПЛИВНОЙ РАМПЕ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик давления топлива в рампе (аккумуляторе) DS-HD-RDS4.2, установлен в торец рампы и поставляется только с рампой в сборе. Датчик измеряет мгновенное значение давления топлива в рампе (контуре высокого давления) с высокой точностью и быстродействием. Диапазон измерений датчика составляет 0 – 200 МПа

ОТКАЗ ДОЗИРУЮЩЕГО УСТРОЙСТВА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Дозирующее устройство с электромагнитным клапаном (MeUn – Metering Unit – дозатор или MProp — «Magnet Proportional» или solenoid-controlled proportional valve – пропорциональный клапан с электромагнитным управлением или устройство пропорциональной подачи топлива), установлен на корпусе насоса высокого давления.

ОТКАЗ КЛАПАНА ЗАСЛОНКИ EGR ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Для выполнения нормативов по выбросам вредных веществ экологического класса 4 (показатели Евро-4) двигатели семейства ЯМЗ-530 оснащаются системой рециркуляции отработавших газов (РОГ или EGR – Exhaust Gas Recirculation) с внешним регулированием.

ОТКАЗ ЭЛЕКТРОННОЙ ПЕДАЛИ АКСЕЛЕРАТОРА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

На двигателях с механическим регулированием подачей топлива водитель, изменяя положение педали акселератора, через механический привод воздействует на положение рейки ТНВД и изменяет рабочие режимы двигателя. На двигателях с электронной системой управления электрический сигнал, образующийся на потенциометре педали аксе… Читать дальше »

ОТКАЗ ДАТЧИКА ПОЛОЖЕНИЯ ПЕДАЛИ ТОРМОЗА И СЦЕПЛЕНИЯ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик положения педали тормоза – это контактный датчик, определяющий положе-ние педали рабочего тормоза (педаль нажата или не нажата). Функцию датчика может выполнять как отдельный датчик, устанавливаемый под педаль тормоза, так и выключатель стоп-сигнала («лягушка»), устанавливаемый в контуре низкого давления пневматической тормозной системы.

ОТКАЗ КНОПКИ МОТОРНОГО ТОРМОЗА ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Моторный тормоз – это вспомогательная тормозная система, ограничивающая скорость движения автомобиля на длительных спусках. Выполняется она не зависимой от рабочей тормозной системы и в конечном итоге увеличивает срок службы тормозных накладок, так как отсутствует их износ и разогрев. В качестве тормоза-замедлителя на каждом ТС можно использовать двигатель, работающий как воздушный компрессор.

ОТКАЗ ДАТЧИКА ВОДЫ В ТОПЛИВЕ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ

Датчик воды в топливе (код Mann-Hummel 5902070772 для фильтров PreLine 270/420) – это двухконтактный датчик, измеряющий сопротивление. При появлении воды конт… Читать дальше »

ТОПЛИВНАЯ СИСТЕМА COMMON RAIL SYSTEM (CRS) ДВИГАТЕЛЯ ЯМЗ Топливная система аккумуляторного типа – Common Rail System (CRS) с электронным управлением подачей топлива производства фирмы Robert Bosch (Германия). CRS BOSCH с электронным блоком управления обеспечивает: • точную дозировку цикловой подачи топлива для каждого рабочего режима; • регулировку углов опережения впрыска топлива в зависимости от оборотов, нагрузки, температуры; • легкий пуск двигателя с минимальным выбросом вредных веществ в атмосферу при любых температурных условиях; • корректировку процесса топливоподачи в зависимости от условий окружающей среды с целью снижения выбросов вредных веществ; • совместимость с электронным блоком управления автомобиля (ABS, ASR, круиз-контроль и др.).

ЭЛЕКТРИЧЕСКАЯ СХЕМА БЛОКА УПРАВЛЕНИЯ ДВИГАТЕЛЕМ ЯМЗ 53601

ОПИСАНИЕ СИСТЕМЫ БОРТОВОЙ ДИАГНОСТИКИ ДВИГАТЕЛЕЙ СЕМЕЙСТВА ЯМЗ-530

ОПИСАНИЕ ЭЛЕКТРОННОГО БЛОКА УПРАВЛЕНИЯ ДВИГАТЕЛЕЙ ЯМЗ 530 СЕРИИ ЕВРО 4

ОПИСАНИЕ ДВИГАТЕЛЕЙ ЯМЗ 5340 / 536 И ИХ МОДИФИКАЦИЙ