- Manuals

- Brands

- Yamaha Manuals

- Offroad Vehicle

- Raptor 700R YFM70RSPX

- Owner’s manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

READ THIS MANUAL CAREFULLY!

It contains important safety information.

OWNER’S MANUAL

YFM70RSPX

This A

WARNING

This ATV should not be ridden by anyone under 16 years of age.

LIT-11626-21-12

1S3-28199-15

Related Manuals for Yamaha Raptor 700R YFM70RSPX

Summary of Contents for Yamaha Raptor 700R YFM70RSPX

-

Page 1

READ THIS MANUAL CAREFULLY! It contains important safety information. OWNER’S MANUAL YFM70RSPX This A WARNING This ATV should not be ridden by anyone under 16 years of age. LIT-11626-21-12 1S3-28199-15… -

Page 2

EBU17091… -

Page 3

Yamaha experience in the production of fine sporting, touring, and pace-setting racing machines. With the purchase of this Yamaha, you can now appreciate the high degree of craftsmanship and reliability that have made Yamaha a leader in these fields. -

Page 4

EBU17330 IMPORTANT MANUAL INFORMATION EBU17341 FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THIS MANUAL CAN RESULT IN SERIOUS IN- JURY OR DEATH. Particularly important information is distinguished in this manual by the following notations: The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Failure to follow WARNING instructions could result in severe injury WARNING… -

Page 5

EBU17350 IMPORTANT NOTICE EBU17360 Welcome to the Yamaha world of motor sports! This ATV is designed and manufactured for OFF-ROAD use only. It is illegal and unsafe to operate this ATV on any public street, road or highway. This ATV complies with all applicable OFF-ROAD noise level and spark arrester laws and regulations in effect at the time of manufacture. -

Page 6: Table Of Contents

EWB00010 Clutch lever ……….4-6 WARNING Brake lever ……….4-6 Brake pedal ……….4-7 Indicates a potential hazard that could result in Parking brake lever ……..4-7 serious injury or death. Shift pedal ……….4-8 Reverse knob “REV” ……..4-9 Fuel tank cap ……….

-

Page 7

Starting the engine ……..6-1 Periodic maintenance chart for the emission control system ……8-3 Operating the reverse knob and driving in reverse ………… 6-2 General maintenance and lubrication chart …………8-4 Shifting …………6-3 Removing and installing the panel ….. 8-7 Engine break-in ……… -

Page 8

Checking and lubricating the brake and YAMAHA EXTENDED SERVICE shift pedals ……….8-37 (Y.E.S.) ……….11-7 Checking the wheel hub bearings … 8-37 Lubricating the swingarm pivots ….8-37 Lubricating the upper and lower arm pivots …………. 8-38 Battery …………. 8-39 Replacing a fuse …….. -

Page 9: Safety Information

EBU17430 SAFETY INFORMATION SAFETY INFORMATION EBU26661 – A child under 16 years old should never oper- ate an ATV with engine size greater than 90 cc. AN ATV IS NOT A TOY AND CAN BE HAZARD- Never allow a child under age 16 to operate an OUS TO OPERATE.

-

Page 10

that is proper for the terrain, visibility, operating before attempting larger hills. conditions, and your experience. Always follow proper procedures for climbing Never attempt wheelies, jumps, or other stunts. hills as described in this manual. Check the ter- Always inspect your ATV each time you use it to rain carefully before you start up any hill. -

Page 11

ing, use the proper gear and maintain a steady Always be sure there are no obstacles or people speed when climbing a hill. If you stall or roll behind you when you operate in reverse. When backwards, follow the special procedure for it is safe to proceed in reverse, go slowly. -

Page 12

EWB02320 HOW TO AVOID THE HAZARD WARNING If you should swallow some gasoline or in- POTENTIAL HAZARD hale a lot of gasoline vapor, or get some gas- Improper handling of gasoline. oline in your eyes, seek medical help WHAT CAN HAPPEN immediately. -

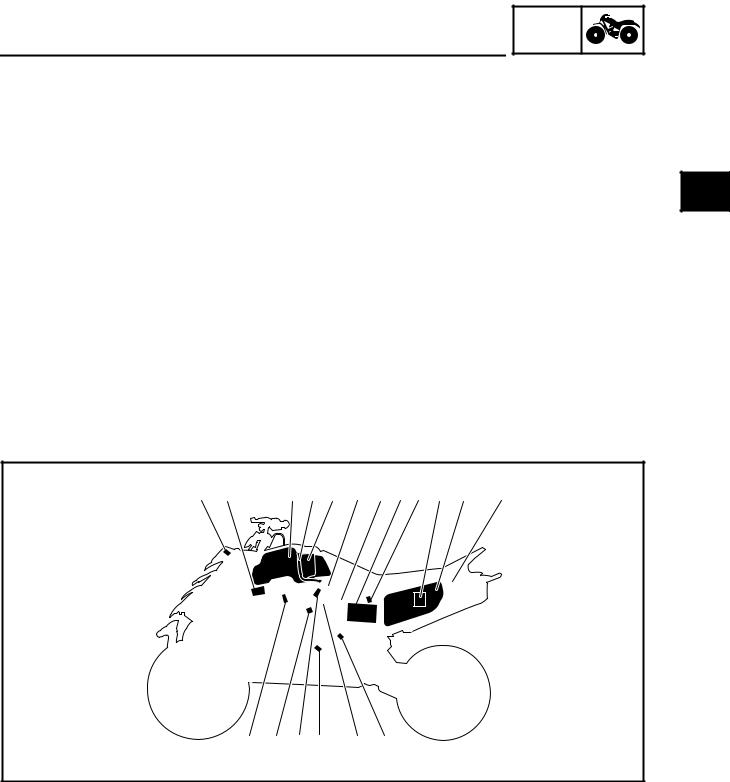

Page 13: Location Of The Warning And Specification Labels

EBU17660 LOCATION OF THE WARNING AND SPECIFICATION LABELS…

-

Page 14

Read and understand all of the labels on your ATV. These labels contain important information for safe and proper operation. Never remove any labels from your ATV. If a label becomes difficult to read or comes off, request a replace- ment label from your Yamaha dealer. -

Page 15

WARNING WARNING Improper ATV use can result in SEVERE INJURY or DEATH. UNDER ALWAYS USE NEVER USE NEVER CARRY NEVER USE AN APPROVED ON PUBLIC PASSENGERS WITH DRUGS HELMET AND ROADS OR ALCOHOL PROTECTIVE GEAR Operating this ATV if you are under NEVER operate : without proper training or instruction. -

Page 16

WARNING WARNING IMPROPER TIRE PRESSURE OR OVERLOADING CAN NEVER ride as a CAUSE LOSS OF CONTROL. LOSS OF CONTROL CAN RESULT IN SEVERE passenger. INJURY OR DEATH. OPERATING TIRE PRESSURE: Set with tires cold Passengers can cause Recommended : FRONT : 27.5 kPa, { 0.275 kgf/cm } 4.0 psi a loss of control, REAR : 27.5 kPa, { 0.275 kgf/cm… -

Page 17: Description

EBU17680 DESCRIPTION EBU17690 EBU17700 Left view Right view 1. Engine oil tank 1. Spark arrester 2. Coolant reservoir 2. Seat 3. Idle adjusting screw 3. Headlight 4. Tail/brake light 4. Brake pedal 5. Shift pedal…

-

Page 18: Controls And Instruments

EBU17712 from the figures shown in this manual. Controls and instruments 1. Clutch lever 2. Parking brake lever 3. Main switch 4. Brake lever 5. Throttle lever 6. Reverse knob 7. Fuel tank cap 8. Handlebar switches NOTE: The ATV you have purchased may differ slightly…

-

Page 19: Instrument And Control Functions

EBU17720 INSTRUMENT AND CONTROL FUNCTIONS EWB00010 WARNING Indicates a potential hazard that could result in serious injury or death. EBU17760 Main switch The positions of the main switch are as follows: All electrical systems are supplied with power. The headlights and taillight come on when the light switch is on, and the engine can be started.

-

Page 20: Indicator Lights And Warning Lights

The electrical circuit of the warning light can be checked by turning the key to “ON”. If the warning light does not come on, and then go off, have a Yamaha dealer check the electrical circuit. ECB00010 CAUTION: 1. Neutral indicator light “N”…

-

Page 21: Handlebar Switches

” This warning light comes on or flashes when an electrical circuit monitoring the engine is defective. When this occurs, have a Yamaha dealer check the self-diagnosis system. The electrical circuit of the warning light can be checked by turning the key to “ON”. If the warning 1.

-

Page 22: Throttle Lever

EBU18090 tle lever will increase the engine speed. Start switch “START” Regulate the speed of the ATV by varying the Push this switch to crank the engine with the start- throttle position. Because the throttle is spring- loaded, the ATV will decelerate, and the engine will ECB00050 return to an idle any time the hand is removed from CAUTION:…

-

Page 23: Speed Limiter

Check the operation of the throttle lever be- fore you start the engine. If it does not work smoothly, check for the cause. Correct the problem before riding the ATV. Consult a Yamaha dealer if you can’t find or solve the problem yourself. 1. Locknut EBU18311 2.

-

Page 24: Clutch Lever

EWB00190 off system.) WARNING POTENTIAL HAZARD Improper adjustment of the speed limiter and throttle. WHAT CAN HAPPEN The throttle cable could be damaged. Im- proper throttle operation could result. You could lose control, have an accident or be in- jured. HOW TO AVOID THE HAZARD Do not turn the adjusting screw out more than 12 mm (0.47 in).

-

Page 25: Brake Pedal

1. Brake lever 1. Brake pedal 2. Locknut 3. Brake lever position adjusting bolt EBU18510 4. Distance between brake lever and handlebar grip Parking brake lever Use the parking brake before starting the engine or EBU18432 Brake pedal parking the ATV, especially on a slope. To apply the parking brake, move the parking brake lever in The brake pedal is located on the right side of the direction (a).

-

Page 26: Shift Pedal

EWB00170 WARNING POTENTIAL HAZARD Improper use of the parking brake. WHAT CAN HAPPEN The ATV could start moving unexpectedly if the parking brake is not applied before start- ing the engine. This could cause loss of con- trol or a collision. The brake could overheat if you ride the ATV without releasing the parking brake.

-

Page 27: Reverse Knob «Rev

when shifting. 1. Reverse knob “REV” 1. Shift pedal EBU18720 Fuel tank cap EBU18641 Reverse knob “REV” Remove the fuel tank cap by turning it counter- The reverse knob is used to shift into reverse. See clockwise. the “Operating the reverse knob and driving in re- verse”…

-

Page 28: Fuel

1. Filler tube 1. Fuel tank cap 2. Fuel level EBU18730 Fuel Recommended fuel: Make sure that there is sufficient fuel in the tank. UNLEADED GASOLINE ONLY Fill the fuel tank to the bottom of the filler tube as Fuel tank capacity: shown.

-

Page 29: Seat

WHAT CAN HAPPEN Fuel can spill, which can cause a fire and se- Your Yamaha engine has been designed to use vere injury. regular unleaded gasoline with a pump octane Fuel expands when it heats up. If the fuel…

-

Page 30: Adjusting The Front Shock Absorber Assemblies

1. Seat lock lever 1. Projection 2. Seat holder To install the seat EBU27892 Insert the projections on the front of the seat into Adjusting the front shock absorber the seat holders and push down on the seat at the assemblies rear.

-

Page 31

Do not dispose of a damaged or worn out shock absorber assembly yourself. Take NOTE: the shock absorber assembly to a Yamaha A special wrench can be obtained at a Yamaha dealer for any service. dealer to make this adjustment. The spring preload setting is determined by Spring preload measuring distance A, shown in the illustration. -

Page 32

adjusting nut, distance A is changed by 1.5 mm 3. Tighten the locknut to the specified torque. (0.06 in). Tightening torque: Locknut: Spring preload setting: 30 Nm (3.0 m·kgf, 22 ft·lbf) Minimum (hard): Distance A = 246.5 mm (9.7 in) ECB00080 Standard: CAUTION:… -

Page 33

Compression damping force Compression damping force (for fast compression damping) 1. To increase the compression damping force and thereby harden the compression damp- ing, turn the adjusting bolt in direction (a). To decrease the compression damping force and thereby soften the compression damping, turn the adjusting bolt in direction (b). -

Page 34

Compression damping setting (for fast com- pression damping): Minimum (soft): Adjusting bolt 3 turn(s) out from the fully turned in position Standard: Adjusting bolt 1 1/4 turn(s) out from the ful- ly turned in position Maximum (hard): Adjusting bolt fully turned in 1. -

Page 35: Specifications

the minimum and maximum settings. EWB00350 WARNING NOTE: POTENTIAL HAZARD Improper shock absorber assembly adjust- Although the total number of clicks of a damping ment. force adjusting mechanism may not exactly match WHAT CAN HAPPEN the above specifications due to small differences in Uneven adjustment can cause poor handling production, the actual number of clicks always rep- and loss of stability, which could lead to an…

-

Page 36

Do not dispose of a damaged or worn out shock absorber assembly yourself. Take NOTE: the shock absorber assembly to a Yamaha A special wrench can be obtained at a Yamaha dealer for any service. dealer to make this adjustment. The spring preload setting is determined by Spring preload measuring distance A, shown in the illustration. -

Page 37

adjusting nut, distance A is changed by 1.5 mm 3. Tighten the locknut to the specified torque. (0.06 in). Tightening torque: Locknut: Spring preload setting: 42 Nm (4.2 m·kgf, 30 ft·lbf) Minimum (hard): Distance A = 228 mm (8.98 in) ECB00080 Standard: CAUTION:… -

Page 38

damping) 1. To increase the compression damping force and thereby harden the compression damp- ing, turn the adjusting bolt in direction (a). To decrease the compression damping force and thereby soften the compression damping, turn the adjusting bolt in direction (b). 1. -

Page 39

Compression damping setting (for fast com- pression damping): Minimum (soft): Adjusting bolt 4 turn(s) out from the fully turned in position Standard: Adjusting bolt 2 turn(s) out from the fully turned in position Maximum (hard): Adjusting bolt fully turned in 1. -

Page 40

the minimum and maximum settings. EWB00010 WARNING NOTE: Indicates a potential hazard that could result in Although the total number of clicks of a damping serious injury or death. force adjusting mechanism may not exactly match the above specifications due to small differences in production, the actual number of clicks always rep- resents the entire adjusting range. -

Page 41: Pre-Operation Checks

Always follow the inspection and maintenance procedures and schedules described in the Own- er’s Manual. NOTE: The maintenance of some items in the table has to be performed by a Yamaha dealer. Refer to the periodic maintenance charts on page 8-3 to determine which service should be performed by a Yamaha dealer.

-

Page 42

Coolant specified level if necessary. 5-4, 8-14 Check cooling system for leakage. Correct if necessary. Check operation. If soft or spongy, have Yamaha dealer bleed hydraulic system. Check brake pads for wear, and replace if necessary. Front brake 5-5, 8-25, 8-26, 8-28 Check brake fluid level in reservoir, and add recommended brake… -

Page 43

ITEM ROUTINE PAGE Check wheel condition, and replace if damaged. Wheels and tires Check tire condition and tread depth. Replace if necessary. 5-6, 5-7, 5-8 Check air pressure. Correct if necessary. Make sure that operation is smooth. Lubricate pedal pivoting points Brake and shift pedals 8-37 if necessary. -

Page 44: Fuel

EBU19530 EBU19620 Fuel Coolant Make sure that there is sufficient fuel in the tank. Make sure that the coolant is at the specified level. (See page 4-10.) Add coolant as necessary. (See page 8-14.) EWB00500 NOTE: WARNING The coolant level must be checked on a cold en- POTENTIAL HAZARD gine since the level varies with engine tempera- Improper care when refueling.

-

Page 45: Front And Rear Brakes

Check that there is no free play in the brake le- make sure they are working properly. If the brakes ver. If there is free play, have a Yamaha dealer do not provide proper braking performance, check check the brake system.

-

Page 46: Drive Chain

HOW TO AVOID THE HAZARD The tires listed below have been approved EBU19770 by Yamaha Motor Co., Ltd. for this model. Drive chain Other tire combinations are not recom- Check the condition of the drive chain and check mended.

-

Page 47: Measuring The Tire Pressure

The tires should be set to the recommend- Maximum tire seating pressure: ed pressure: Front: Recommended tire pressure: 250 kPa (36 psi) (2.5 kgf/cm Front: Rear: 27.5 kPa (4.0 psi) (0.275 kgf/cm 250 kPa (36 psi) (2.5 kgf/cm Rear: Higher pressures and fast inflation may 27.5 kPa (4.0 psi) (0.275 kgf/cm cause a tire to burst.

-

Page 48: Tire Wear Limit

Recommended pressure: Front 27.5 kPa (4.0 psi) (0.275 kgf/cm Rear 27.5 kPa (4.0 psi) (0.275 kgf/cm Minimum: Front 24.5 kPa (3.5 psi) (0.245 kgf/cm Rear 24.5 kPa (3.5 psi) (0.245 kgf/cm 1. Low-pressure tire gauge Maximum: Front Set the tire pressure when the tires are cold. Set 30.5 kPa (4.4 psi) (0.305 kgf/cm the tire pressures to the following specifications: Rear…

-

Page 49: Chassis Fasteners

1. Tire wear limit EBU19840 Chassis fasteners Make sure that all nuts, bolts and screws are prop- erly tightened. EBU19850 Instruments, lights and switches Check that all instruments, lights and switches are working properly. Correct if necessary.

-

Page 50: Operation

See the “Engine break-in” section on page 6-5 a control or function you do not understand, prior to operating the engine for the first time. ask your Yamaha dealer. 1. Set the parking brake. 2. Turn the main switch to “ON” and the engine stop switch to “RUN”.

-

Page 51: Operating The Reverse Knob And Driving In Reverse

For maximum engine life, always warm the en- indicator light should come on, if it does not gine up before starting off. Never accelerate come on, have a Yamaha dealer check the hard when the engine is cold! electrical circuit.

-

Page 52: Shifting

If the indicator light does not come on, closed position, apply the clutch, and then repeat- have a Yamaha dealer check the electrical circuit. edly depress the shift pedal until it stops. 4. Check behind you for people or obstacles, When it stops, it will be in first gear.

-

Page 53

time, release the clutch lever slowly. 5. Once the ATV has attained adequate speed, release the throttle, and at the same time, quickly pull in the clutch lever. 6. Shift the transmission into second gear. (Make sure not to shift the transmission into neutral) 7. -

Page 54: Engine Break-In

tle and apply the brakes smoothly and evenly. As ning. Inadequate lubrication may damage you slow down, shift to a lower gear. Be sure that the transmission. the engine has sufficiently slowed before engaging Always use the clutch when changing gears. a lower gear.

-

Page 55: Parking

ECB00220 CAUTION: If any engine trouble should occur during the engine break-in period, immediately have a Yamaha dealer check the ATV. EBU26760 Parking When parking the ATV, stop the engine, shift into first gear, and then apply the parking brake.

-

Page 56: Parking On A Slope

EBU20870 4. With the front and rear brakes applied, pull the Parking on a slope clutch lever, shift into first gear, and then re- EWB00800 lease the clutch lever, brake lever and brake WARNING pedal. POTENTIAL HAZARD NOTE: Parking on a hill or other incline. Make sure that the neutral indicator light goes off.

-

Page 57

However, judgment as the stability and handling of an ATV it is not possible for Yamaha to test all non- can be changed. When adding accessories, keep Yamaha accessories, nor control over their qual- the following points in mind: ity or suitability. -

Page 58

Make sure the load does not interfere with con- HOW TO AVOID THE HAZARD trols or your ability to see where you are going. Never exceed the stated load capacity for Ride more slowly than you would without a load. this ATV. -

Page 59: Riding Your Atv

EBU21131 RIDING YOUR ATV…

-

Page 60: Getting To Know Your Atv

EWB00010 RIDE WITH CARE AND GOOD JUDGEMENT WARNING Get training if you are inexperienced. Indicates a potential hazard that could result in Beginners should get training from a certified in- serious injury or death. structor. Become familiar with this ATV at slow speeds first, EBU21591 even if you are an experienced operator.

-

Page 61

A child under 16 should never operate an should complete the certified training course ATV with engine size greater than 90 cc. offered by Yamaha. They should then regu- larly practice the skills learned in the course and the operating techniques described in this Owner’s Manual. -

Page 62

This ATV is designed to carry operator only – passengers prohibited. EWB00910 WARNING POTENTIAL HAZARD Carrying a passenger on this ATV. WHAT CAN HAPPEN Greatly reduces your ability to balance and control this ATV. Could cause an accident, resulting in harm to you and/or your passen- ger. -

Page 63

WHAT CAN HAPPEN Operating without an approved motorcycle helmet increases your chances of a severe head injury or death in the event of an acci- dent. Operating without eye protection can result in an accident and increases your chances of a severe injury in the event of an accident. -

Page 64

Pre-operation checks Always perform the pre-operation checks listed on page 5-1 before riding for proper care of the ATV and to ensure safety. EWB00940 WARNING POTENTIAL HAZARD Failure to inspect the ATV before operating. Failure to properly maintain the ATV. WHAT CAN HAPPEN Increases the possibility of an accident or EWB00930… -

Page 65

WHAT CAN HAPPEN HOW TO AVOID THE HAZARD Use of improper tires on this ATV, or opera- Always go at a speed that is proper for the tion of this ATV with improper or uneven tire terrain, visibility and operating conditions, pressure, may cause loss of control, increas- and your experience. -

Page 66

MAXIMUM LOADING LIMIT ATV loading limit (total weight of cargo, rider, accessories, and tongue): 100.0 kg (220 lb) EWB00970 WARNING POTENTIAL HAZARD Overloading this ATV or carrying or towing cargo improperly. 1. Locknut WHAT CAN HAPPEN 2. Adjusting screw Could cause changes in ATV handling which could lead to an accident. -

Page 67

During operation WHAT CAN HAPPEN Always keep your feet on the footboards during op- Removing even one hand or foot can reduce eration, otherwise they may contact the rear your ability to control the ATV or could cause wheels. you to lose your balance and fall off of the ATV. -

Page 68

Never modify this ATV through improper in- stallation or use of accessories. All parts and accessories added to this ATV should be genuine Yamaha or equivalent components designed for use on this ATV and should be installed and used according to instructions. -

Page 69: Be Careful Where You Ride

EWB01020 HOW TO AVOID THE HAZARD WARNING Do not operate, idle, or park the ATV in dry POTENTIAL HAZARD grass or other dry ground cover. Operating this ATV on paved surfaces. Keep the engine area free of dry grass, WHAT CAN HAPPEN brush, or other combustible material.

-

Page 70

HOW TO AVOID THE HAZARD Never operate this ATV on any public street, road or highway, even a dirt or gravel one. In many states it is illegal to operate ATVs on public streets, roads and highways. Do not ride on any public road, street, or highway. Riding on public roads can result in collisions with other vehicles. -

Page 71

EWB01040 WARNING POTENTIAL HAZARD Failure to use extra care when operating this ATV on unfamiliar terrain. WHAT CAN HAPPEN You can come upon hidden rocks, bumps, or holes, without enough time to react. Could result in the ATV overturning or going out of control. -

Page 72

EWB01050 WARNING POTENTIAL HAZARD Failure to use extra care when operating on excessively rough, slippery or loose terrain. WHAT CAN HAPPEN Could cause loss of traction or ATV control, which could result in an accident, including an overturn. HOW TO AVOID THE HAZARD Do not operate on excessively rough, slip- pery or loose terrain until you have learned and practiced the skills necessary to control… -

Page 73

mission. EWB01060 Select a large, flat area off-road to become familiar WARNING with your ATV. Make sure that this area is free of POTENTIAL HAZARD obstacles and other riders. You should practice Operating in areas where you might not be control of the throttle, brakes, shifting procedures, seen by other off-road vehicles. -

Page 74

do not allow skin or clothing to come in contact with WHAT CAN HAPPEN these components. The ATV could wheelie. This would increase With the engine idling, pull the clutch lever to dis- the chance of an accident, including over- engage the clutch and shift into 1st gear, and then turn. -

Page 75: Turning Your Atv

WHAT CAN HAPPEN HOW TO AVOID THE HAZARD The wheels could stop rotating. This could Always follow proper procedures for turning cause loss of control, an accident and injury. as described in this Owner’s Manual. Prac- It could also cause engine or drive train dam- tice turning at low speeds before attempting age.

-

Page 76: Climbing Uphill

be able to perform it at higher speeds or in tighter curves. Improper riding procedures such as abrupt throttle changes, excessive braking, incorrect body move- ments, or too much speed for the sharpness of the turn may cause the ATV to tip. If the ATV begins to tip over to the outside while negotiating a turn, lean more to the inside.

-

Page 77

WHAT CAN HAPPEN HOW TO AVOID THE HAZARD The ATV can overturn more easily on ex- Always follow proper procedures for climb- tremely steep hills than on level surfaces or ing hills as described in this Owner’s Manual. small hills. Always check the terrain carefully before you HOW TO AVOID THE HAZARD start up any hill. -

Page 78

WHAT CAN HAPPEN Could cause loss of control or cause the ATV to overturn. HOW TO AVOID THE HAZARD Never attempt to turn the ATV around on any hill until you have mastered the turning tech- nique as described in the Owner’s Manual on level ground. -

Page 79

EWB01251 WARNING POTENTIAL HAZARD Stalling, rolling backwards or improperly dis- mounting while climbing a hill. WHAT CAN HAPPEN Could result in the ATV overturning. HOW TO AVOID THE HAZARD Use the proper gear and maintain a steady speed when climbing a hill. If you lose all forward speed: Keep weight uphill. -

Page 80: Riding Downhill

braking may also cause a loss of traction. Whenever possible, ride your ATV straight down- hill. Avoid sharp angles which could allow the ATV to tip or roll over. Carefully choose your path and ride no faster than you will be able to react to ob- stacles which may appear.

-

Page 81: Crossing A Slope

HOW TO AVOID THE HAZARD Always follow proper procedures for going down hills as described in this Owner’s Man- ual. Note: a special technique is required when braking as you go down a hill. Always check the terrain carefully before you start down any hill.

-

Page 82: Crossing Through Shallow Water

steering when riding on loose surfaces by pointing When crossing the side of a hill: the front wheels slightly uphill. When riding on Always follow proper procedures as de- slopes, be sure not to make sharp turns either up scribed in the Owner’s Manual. or down hill.

-

Page 83

low water of up to a maximum of 35 cm (14 in) in depth. Before entering the water, choose your path carefully. Enter where there is no sharp drop off, and avoid rocks or other obstacles which may be slippery or upset the ATV. Drive slowly and care- fully. -

Page 84: Riding Over Rough Terrain

1. Air filter case check hose RIDING OVER ROUGH TERRAIN ECB00240 Riding over rough terrain should be done with cau- CAUTION: tion. Look out for obstacles which could cause damage to the ATV or could lead to an upset or ac- After riding your ATV in water, be sure to drain cident.

-

Page 85: Sliding And Skidding

WHAT CAN HAPPEN Could cause loss of control or a collision. Could cause the ATV to overturn. HOW TO AVOID THE HAZARD Before operating in a new area, check for ob- stacles. Never attempt to ride over large obstacles, such as large rocks or fallen trees. When you go over obstacles, always follow proper pro- cedures as described in the Owner’s Manual.

-

Page 86: What To Do If

HOW TO AVOID THE HAZARD Learn to safely control skidding or sliding by practicing at low speeds and on level, smooth terrain. On extremely slippery surfaces, such as ice, go slowly and be very cautious in order to re- duce the chance of skidding or sliding out of control.

-

Page 87

Steer in the direction of the slide if you have the you come out of the water. Do not continue to room. Applying the brakes or accelerating is not ride your ATV until you have regained adequate recommended until you have corrected the braking ability. -

Page 88: Periodic Maintenance And Minor Repair

Safety is an obligation of the owner. Periodic in- nance unless otherwise specified. Have a spection, adjustment and lubrication will keep your Yamaha dealer perform the service if you are ATV in the safest and best operating condition not familiar with maintenance work.

-

Page 89

If you have questions, consult an authorized additional tools such as a torque wrench may be Yamaha ATV dealer. necessary to perform certain maintenance work correctly. NOTE: If you do not have the tools or experience required for a particular job, have a Yamaha dealer perform… -

Page 90: Periodic Maintenance Chart For The Emission Control System

However, keep in mind that if the ATV isn’t used for a long period of time, the month maintenance intervals should be followed. Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical skills.

-

Page 91: General Maintenance And Lubrication Chart

EBU21864 General maintenance and lubrication chart INITIAL EVERY month Whichev- CHECK OR MAINTENANCE ITEM er comes 1300 2500 2500 5000 first (mi) (200) (800) (1600) (1600) (3200) hours Every 20–40 hours (more often in wet or Air filter element Clean and replace if necessary. dusty areas) √…

-

Page 92

INITIAL EVERY month Whichev- CHECK OR MAINTENANCE er comes ITEM 1300 2500 2500 5000 first (mi) (200) (800) (1600) (1600) (3200) hours Upper and lower √ √ √ 10 * Lubricate with lithium-soap-based grease. arm pivots Check chain slack and adjust if necessary. Check rear wheel alignment and correct if necess- √… -

Page 93

INITIAL EVERY month Whichev- CHECK OR MAINTENANCE er comes ITEM 1300 2500 2500 5000 first (mi) (200) (800) (1600) (1600) (3200) hours Moving parts and √ √ √ √ 20 * Lubricate. cables Check operation and correct if necessary. Throttle lever hous- Check throttle cable free play and adjust if neces- √… -

Page 94: Removing And Installing The Panel

EWB00010 EBU23100 Panel A WARNING To remove the panel Indicates a potential hazard that could result in Remove the bolts, and then take the panel off. serious injury or death. EBU23080 Removing and installing the panel The panel shown needs to be removed to perform some of the maintenance jobs described in this chapter.

-

Page 95: Checking The Spark Plug

Do not spark plug wrench included in the owner’s tool attempt to diagnose such problems yourself. In- kit. stead, have a Yamaha dealer check the ATV. 2. Check the spark plug for electrode erosion and excessive carbon or other deposits, and…

-

Page 96: Engine Oil And Oil Filter Element

replace it if necessary. and its mating surface, and then wipe off any grime from the spark plug threads. Specified spark plug: 3. Install the spark plug with the spark plug NGK/CR8E wrench, and then tighten it to the specified torque.

-

Page 97

To check the engine oil level 1. Place the ATV on a level surface. 2. Start the engine, warm it up until the engine oil has reached a normal temperature of 60 °C (141 °F), let it continue to idle for ten seconds or more, and then turn the engine off. -

Page 98

NOTE: When adding oil, be careful not to overfill the en- gine oil tank; the oil level rises faster starting from the half-level-portion on the dipstick. 6. Insert the dipstick into the engine oil tank filler hole, and then tighten the engine oil tank filler cap. -

Page 99

5. Remove the engine oil tank filler cap and the engine oil tank drain bolt. 1. Oil filter element cover 2. Bolt 1. Engine oil tank drain bolt 8. Check the O-rings for damage, and replace them if necessary. 6. Check the washers for damage, and replace if necessary. -

Page 100

11. Install the crankcase engine oil drain bolt and the engine oil tank drain bolt, and then tighten them to the specified torques. Tightening torques: Crankcase engine oil drain bolt: 23 Nm (2.3 m·kgf, 16.6 ft·lbf) Engine oil tank drain bolt: 19 Nm (1.9 m·kgf, 13.7 ft·lbf) 12. -

Page 101: Coolant

16. Install and tighten the engine oil tank filler cap. is leaking, immediately turn the engine off and check for the cause. Recommended oil: 18. Turn the engine off, and then check the oil lev- See page 10-1. el and correct it if necessary. Oil quantity: Without oil filter element replacement: EBU23470…

-

Page 102

If water has been added to the coolant, have a Yamaha dealer check the antifreeze con- tent of the coolant as soon as possible, oth- erwise the effectiveness of the coolant will be reduced. -

Page 103

4. Remove the radiator cap. WHAT CAN HAPPEN You could be burned by hot fluid and steam blown out under pressure. HOW TO AVOID THE HAZARD Wait for the engine to cool before removing the radiator cap. Always place a thick rag over the cap. -

Page 104

voir to the maximum level mark, and then in- stall the reservoir cap. 11. Pour the recommended coolant into the radia- tor until it is full. Antifreeze/water mixture ratio: Recommended antifreeze: High-quality ethylene glycol antifreeze con- taining corrosion inhibitors for aluminum en- gines Coolant quantity: 1. -

Page 105: Cleaning The Air Filter Element

14. Start the engine, and then check for coolant leakage. NOTE: If any leakage is found, have a Yamaha dealer check the cooling system. 15. Install the panel. 1. Air filter case check hose EBU26791 1.

-

Page 106

1. Wing bolt 1. Air filter case cover 2. Air filter element 2. Air filter case cover holder 5. Remove the wing bolt and washer from the air 3. Loosen the wing bolt. filter element. 4. Remove the air filter element together with the 6. -

Page 107

WHAT CAN HAPPEN 9. Check the sponge material and replace it if Low-flash-point solvents or gasoline can damaged. catch fire or explode. 10. Apply Yamaha foam air filter oil or other qual- ity foam air filter oil to the sponge material. 8-20… -

Page 108

13. Insert the air filter element into the air filter NOTE: case, and then tighten the wing bolt. The sponge material should be wet but not drip- 14. Install the air filter case cover by hooking the ping. holders onto the air filter case. 11. -

Page 109: Cleaning The Spark Arrester

will affect the fuel injection system with sub- brush to remove any carbon deposits from the sequent poor performance and possible en- spark arrester portion of the tailpipe and inside gine overheating. of the tailpipe housing. EBU23872 Cleaning the spark arrester Select a well-ventilated area free of combustible materials and make sure the exhaust and muffler are cool.

-

Page 110: Adjusting The Engine Idling Speed

WHAT CAN HAPPEN Could injure the eyes. Could cause burns. Could cause carbon monoxide poisoning, possibly leading to death. Could start a fire. HOW TO AVOID THE HAZARD When purging the exhaust system: Always let the exhaust system cool prior to touching exhaust components.

-

Page 111: Adjusting The Throttle Cable Free Play

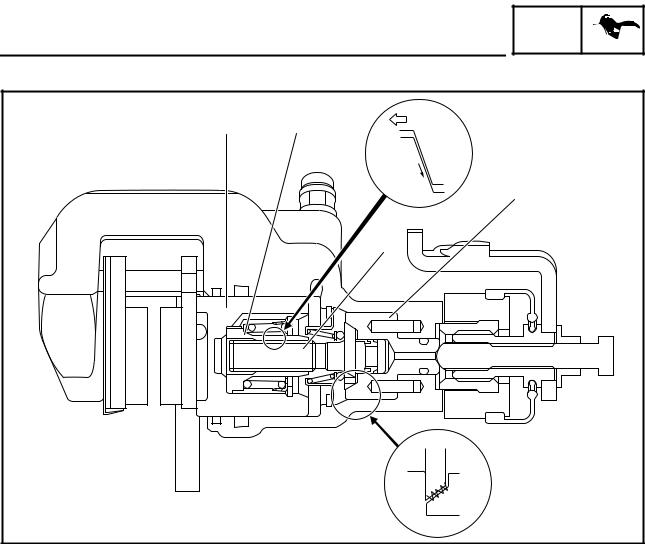

If the specified idling speed cannot be obtained as 2. Attach the tachometer to the spark plug lead. described above, have a Yamaha dealer make the 3. Check the engine idling speed and, if neces- adjustment. sary, adjust it to specification by turning the idle adjusting screw.

-

Page 112: Valve Clearance

The valve clearance changes with use, resulting in improper air-fuel mixture and/or engine noise. To prevent this from occurring, the valve clearance must be adjusted by a Yamaha dealer at the inter- 1. Wear indicator groove vals specified in the periodic maintenance and lu-…

-

Page 113: Checking The Brake Fluid Level

Front brake 1. Minimum level mark 1. Wear indicator groove Rear brake EBU26821 Checking the brake fluid level Insufficient brake fluid may allow air to enter the brake system, possibly causing it to become inef- fective. Before riding, check that the brake fluid is above the minimum level mark and replenish if neces- sary.

-

Page 114

NOTE: To check the rear brake fluid level, remove the seat. (See page 4-11.) If the rear brake fluid level is low, replenish as fol- lows. 1. Remove the cowling bolt and quick fastener. 1. Cowling 2. Brake fluid reservoir cap 3. -

Page 115: Changing The Brake Fluid

(zero in) as shown. If the free result in vapor lock. play is incorrect, have a Yamaha dealer check the Brake fluid may deteriorate painted surfaces or brake system.

-

Page 116: Checking The Brake Pedal Position

EWB02010 shown. If the brake pedal is not positioned as spec- WARNING ified, have a Yamaha dealer adjust it. POTENTIAL HAZARD Operating with improperly serviced or ad- justed brakes. WHAT CAN HAPPEN You could lose braking ability, which could lead to an accident.

-

Page 117: Adjusting The Parking Brake Free Play

Make sure the brakes are not spongy. All air must be bled from the brake system. Replacement of brake components requires professional knowledge. These procedures should be performed by a Yamaha dealer. 1. Cable length “A” EBU26840 Adjusting the parking brake free play 1.

-

Page 118: Brake Light Switches

Yamaha dealer. The brake light switch for the brake pedal can be adjusted as follows, but the other brake light 4. Tighten the locknut on the brake cable. switches should be adjusted by a Yamaha dealer. EWB02030 WARNING NOTE:…

-

Page 119: Adjusting The Clutch Lever Free Play

switch in place. To make the brake light come on earlier, turn the adjusting nut in direction (a). To make the brake light come on later, turn the adjust- ing nut in direction (b). 1. Locknut 2. Clutch lever free play adjusting bolt 3.

-

Page 120: Drive Chain Slack

Drive chain slack: clutch lever. 25.0–35.0 mm (0.98–1.38 in) NOTE: If the specified free play cannot be obtained as de- scribed above or if the clutch does not operate cor- rectly, have a Yamaha dealer check the internal clutch mechanism. 8-33…

-

Page 121

To adjust the drive chain slack NOTE: 1. Loosen the rear axle pinch bolts. A rod can be obtained at a Yamaha dealer to make 2. Insert a rod of a diameter of 8 mm (0.3 in) and this adjustment. -

Page 122: Lubricating The Drive Chain

ECB00541 EBU24880 Lubricating the drive chain CAUTION: The drive chain must be cleaned and lubricated at Improper drive chain slack will overload the en- the intervals specified in the periodic maintenance gine as well as other vital parts of the ATV and and lubrication chart, otherwise it will quickly wear can lead to drive chain slippage or breakage.

-

Page 123: Checking And Lubricating The Cables

If a cable is damaged or does not move smoothly, have a Yamaha dealer check or replace Recommended lubricant: Engine oil 8-36…

-

Page 124: Shift Pedals

If there is play in a wheel hub or if a wheel does not turn smoothly, Recommended lubricants: have a Yamaha dealer check the wheel hub bear- Brake lever: ings. Silicone grease Clutch lever: EBU24992 Lubricating the swingarm pivots…

-

Page 125: Lubricating The Upper And Lower Arm Pivots

1. Grease nipple EBU25030 Lubricating the upper and lower arm pivots The upper and lower arm pivots must be lubricated at the intervals specified in the periodic mainte- nance and lubrication chart. Lubricate the pivoting points using a grease gun. Recommended lubricant: Lithium-soap-based grease 1.

-

Page 126: Battery

Left side Right side 1. Upper grease nipple 1. Upper grease nipple 2. Lower grease nipple 2. Lower grease nipple EBU25212 Battery This model is equipped with a sealed-type (MF) battery, which does not require any maintenance. There is no need to check the electrolyte or to add distilled water.

-

Page 127

EWB02140 To charge the battery WARNING Have a Yamaha dealer charge the battery as soon as possible if it seems to have discharged. Keep in POTENTIAL HAZARD mind that the battery tends to discharge more Failure to handle batteries or battery electro- quickly if the ATV is equipped with optional electri- lyte carefully. -

Page 128: Replacing A Fuse

To charge a sealed-type (MF) battery, a spe- cial constant-voltage battery charger is re- quired. Using a conventional battery charger will damage the battery. If you do not have access to a constant-voltage battery charg- er, have a Yamaha dealer charge your bat- tery. 8-41…

-

Page 129

fuse. 2. Remove the blown fuse, and then install a new fuse of the specified amperage. Specified fuses: Main fuse: 20.0 A Headlight fuse: 15.0 A Ignition fuse: 10.0 A Signaling system fuse: 1. Signaling system fuse 10.0 A 2. Headlight fuse Fuel injection system fuse: 3. -

Page 130: Replacing A Headlight Bulb

2. Bolt circuits to check if the devices operate. 4. If the fuse immediately blows again, have a 2. Disconnect the headlight coupler. Yamaha dealer check the electrical system. 3. Remove the headlight bulb holder cover. EBU25430 Replacing a headlight bulb If a headlight bulb burns out, replace it as follows.

-

Page 131

1. Headlight bulb holder 1. Headlight bulb holder cover 2. Headlight coupler EWB02180 WARNING 4. Remove the headlight bulb holder by pushing POTENTIAL HAZARD it in and turning it counterclockwise, and then A headlight bulb is hot when it is on and im- remove the defective bulb. -

Page 132: Adjusting A Headlight Beam

EBU25560 Adjusting a headlight beam ECB00690 CAUTION: It is advisable to have a Yamaha dealer make this adjustment. To raise a headlight beam, turn the adjusting bolt in direction (a). 1. Do not touch the glass part of the bulb.

-

Page 133: Tail/Brake Light

Rear Tail/brake light This model is equipped with an LED type of tail/ brake light. If the tail/brake light does not come on, have a Yamaha dealer check it. EBU25650 Removing a wheel 1. Loosen the wheel nuts. Front 1. Nut 2.

-

Page 134

Front Rear 1. Arrow mark 1. Arrow mark 2. Lower the ATV to the ground. 3. Tighten the wheel nuts to the specified torques. Tightening torques: Front wheel nut: 45 Nm (4.5 m·kgf, 33 ft·lbf) Rear wheel nut: 45 Nm (4.5 m·kgf, 33 ft·lbf) 8-47… -

Page 135: Troubleshooting

However, should your ATV re- quire any repair, take it to a Yamaha dealer, whose skilled technicians have the necessary tools, expe- rience, and know-how to service the ATV properly.

-

Page 136: Troubleshooting Charts

EBU27680 Troubleshooting charts Starting problems or poor engine performance 1. Fuel 2. Compression 3. Ignition 4. Battery 8-49…

-

Page 137

Start the engine. If the engine overheats again, have a The coolant level Yamaha dealer check and repair the cooling system. is OK. NOTE: If coolant is not available, tap water can be temporarily used instead, provided that it is changed to the rec- ommended coolant as soon as possible. -

Page 138: Cleaning And Storage

EBU25860 CLEANING AND STORAGE EBU25890 ed from improper high-pressure detergent Cleaning applications such as those available in coin- Frequent, thorough cleaning of your ATV will not operated car washers. only enhance its appearance but will improve its 4. Once most of the dirt has been hosed off, general performance and extend the useful life of wash all surfaces with warm water and mild, many components.

-

Page 139: Storage

EWB02300 nia) and areas where strong chemicals are WARNING stored. POTENTIAL HAZARD Operation with wet brakes after washing. Long-term WHAT CAN HAPPEN Before storing your ATV for several months: Wet brakes may have reduced stopping abil- 1. Follow all the instructions in the “Cleaning” ity, increasing the chance of an accident.

-

Page 140

plug, and then place the spark plug on the 8-39. cylinder head so that the electrodes are NOTE: grounded. (This will limit sparking during Make any necessary repairs before storing the the next step.) ATV. d. Turn the engine over several times with the starter. -

Page 141: Specifications

EBU25960 SPECIFICATIONS EBU2597A Compression ratio: Dimensions: 9.20 :1 Overall length: Starting system: 1845 mm (72.6 in) Electric starter Overall width: Lubrication system: 1170 mm (46.1 in) Dry sump Overall height: Engine oil: 1130 mm (44.5 in) Type: Seat height: YAMALUBE 4, SAE5W30 or SAE10W30 or SAE20W40 815 mm (32.1 in) Wheelbase: 0˚…

-

Page 142

Engine oil quantity: Spark plug (s): Without oil filter element replacement: Manufacturer/model: 1.75 L (1.85 US qt) (1.54 Imp.qt) NGK/CR8E With oil filter element replacement: Spark plug gap: 1.85 L (1.96 US qt) (1.63 Imp.qt) 0.7–0.8 mm (0.028–0.031 in) Cooling system: Clutch: Coolant reservoir capacity (up to the maximum level mark): Clutch type:… -

Page 143

Reverse gear: Rear: 24/13 × 29/12 (4.462) 27.5 kPa (4.0 psi) (0.275 kgf/cm Chassis: Minimum: Front: Frame type: 24.5 kPa (3.5 psi) (0.245 kgf/cm Aluminum die-cast and steel tube frame Rear: Caster angle: 24.5 kPa (3.5 psi) (0.245 kgf/cm 5.0 ° Maximum: Trail: Front:… -

Page 144

Rear brake: Headlight: Type: Bulb type: Single disc brake Krypton bulb Operation: Bulb voltage, wattage x quantity: Right foot operation Headlight: 12 V, 30.0/30.0 W × 2 Recommended fluid: DOT 4 Neutral indicator light: Front suspension: Type: Fuel level warning light: Double wishbone Spring/shock absorber type: Reverse indicator light:… -

Page 145: Consumer Information

Yamaha dealer or for ref- erence in case the ATV is stolen. KEY IDENTIFICATION NUMBER: VEHICLE IDENTIFICATION NUMBER: 1.

-

Page 146: Model Label

EBU26050 Model label The model label is affixed at the location in the il- lustration. Record the information on this label in the space provided. This information will be need- ed when ordering spare parts from a Yamaha deal- 11-2…

-

Page 147: Noise Regulation

EBU26060 Noise regulation TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED: Federal law prohibits the following acts or the causing thereof: (1) The removal or rendering inoperative by any person other than for purposes of maintenance, repair, or replacement of any device or element of de- sign incorporated into any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use or (2) the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person.

-

Page 148: Maintenance Record

EBU26080 Maintenance record Copies of work orders and/or receipts for parts you purchase and install will be required to document main- tenance done in accordance with the warranty. The chart below is printed only as a reminder to you that the maintenance work is required.

-

Page 149: Yamaha Motor Corporation, U.s.a. Atv Limited Warranty

(6) months from the date of purchase. appropriate owner’s manual; YAMAHA MOTOR CORPORATION, U.S.A. MAKES NO 2. Give notice to an authorized Yamaha ATV dealer OTHER WARRANTY OF ANY KIND, EXPRESSED OR of any and all apparent defects within ten (10) days DURING THE PERIOD OF WARRANTY any authorized IMPLIED.

-

Page 150

Attention: Warranty Department 3. Each Yamaha ATV dealer is held responsible for his setup, service and war- ranty repair work. This will ensure that Yamaha Motor Corporation, U.S.A. has an up-to-date registration record in accordance with federal law. -

Page 151

Yamaha people who handle your warranty – and it Y.E.S. coverage is transferable to a new owner if you shows in the comprehensive coverage benefits. There sell or trade in your ATV. That can make your Yamaha are no mileage limitations. Coverage isn’t limited to much more valuable! “moving par ts”… -

Page 152

Y.E.S. costs less within the first 90 days after you buy your Yamaha. See your dealer today! A special note: If visiting your dealer isn’t convenient, contact Yamaha with your Primar y ID number (your frame number). We’ll be happy to help you get the Y.E.S. coverage you need. -

Page 153

EBU26132 11-9… -

Page 154

INDEX Drive chain, lubricating……….8-35 Drive chain slack …………8-33 Accessories and loading ……….6-7 Air filter element, cleaning……….8-18 Engine break-in ………….. 6-5 Engine idling speed…………8-23 Battery…………….8-39 Engine oil …………… 5-4 Brake and clutch levers, checking and lubricating ..8-36 Engine oil and oil filter element …….. -

Page 155

Shift pedal …………..4-8 Shock absorber assemblies, adjusting the front ..4-12 Label locations …………..2-1 Shock absorber assembly, adjusting the rear….4-17 Light switch …………..4-4 Spark arrester, cleaning……….8-22 Spark plug, checking…………8-7 Main switch …………..4-1 Specifications…………… 10-1 Maintenance and lubrication chart ……..8-4 Speed limiter ………….. -

Page 156

LOCATE AND READ OWNER’S MANUAL. FOLLOW ALL INSTRUCTIONS AND WARNINGS. (For replacement manual, call 1-800-532-1558) YAMAHA MOTOR CO., LTD. PRINTED IN JAPAN PRINTED ON RECYCLED PAPER 2007.04-1.6×1 ! -

Page 157

8 TAKE THE FREE HANDS-ON TRAINING COURSE OFFERED BY YAMAHA – ASK YOUR DEALER FOR DETAILS OR CALL 1-800-887-2887 If you have any questions about these points, or if you purchased your ATV from an authorized Yamaha dealership and were not informed of the age recommendation for your ATV by the dealership, please fill out the information below and mail this card to yamaha today. -

Page 158

NO POSTAGE NECESSARY IF MAILED IN THE UNITED STATES FIRST CLASS PERMIT NO. 4 CYPRESS, CA POSTAGE WILL BE PAID BY ADDRESSEE YAMAHA MOTOR CORPORATION U.S.A. P.O. BOX 6555 CYPRESS, CALIFORNIA 90630-9989 ATTN: SALES ADMINISTRATION…

|

LIT-11616-19-13 |

1S3-28197-10 |

EBS00001

YFM700RV

SERVICE MANUAL

©2005 by Yamaha Motor Corporation, U.S.A. First Edition, May 2005

All rights reserved.

Any reproduction or unauthorized use without the written permission of Yamaha Motor Corporation, U.S.A. is expressly prohibited.

Printed in U.S.A.

LIT-11616-19-13

EBS00002

NOTICE

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on Yamaha vehicle has a basic understanding of the mechanical ideas and the procedures of vehicle repair. Repairs attempted by anyone without this knowledge are likely to render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EBS00003

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

CAUTION:

NOTE:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death to the vehicle operator, a bystander or a person checking or repairing the vehicle.

A CAUTION indicates special precautions that must be taken to avoid damage to the vehicle.

A NOTE provides key information to make procedures easier or clearer.

EBS00004

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “symbols”)

1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2: This title indicates the section of the chapter and only appears on the first page of each section. It is located in the upper left corner of the page.

3rd title 3: This title indicates a sub-section that is followed by step-by-step procedures accompanied by corresponding illustrations.

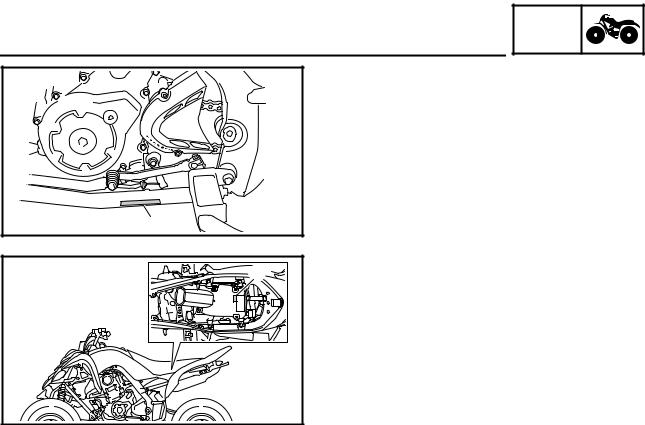

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

1.An easy-to-see exploded diagram 4 is provided for removal and disassembly jobs.

2.Numbers 5 are given in the order of the jobs in the exploded diagram. A number that is enclosed by a circle indicates a disassembly step.

3.An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks 6. The meanings of the symbol marks are given on the next page.

4.A job instruction chart 7 accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

5.For jobs requiring more information, the step-by-step format supplements 8 are given in addition to the exploded diagram and the job instruction chart.

|

1 |

2 |

|||

|

GEN |

SPEC |

|||

|

INFO |

||||

|

3 |

4 |

|||

|

CHK |

ENG |

|||

|

ADJ |

||||

|

5 |

6 |

|||

|

COOL |

FI |

|||

|

7 |

8 |

|||

|

CHAS |

ELEC – |

+ |

||

|

9 |

0 |

|||

|

TRBL |

||||

|

SHTG |

||||

|

A |

B |

|||

|

C |

D |

|||

|

T |

||||

|

. |

||||

|

R |

||||

|

. |

||||

|

E |

F |

G |

||

|

H |

I |

J |

||

|

E |

G |

M |

||

|

K |

L |

M |

||

|

B |

LS |

M |

||

|

N |

O |

|||

|

LT |

New |

|||

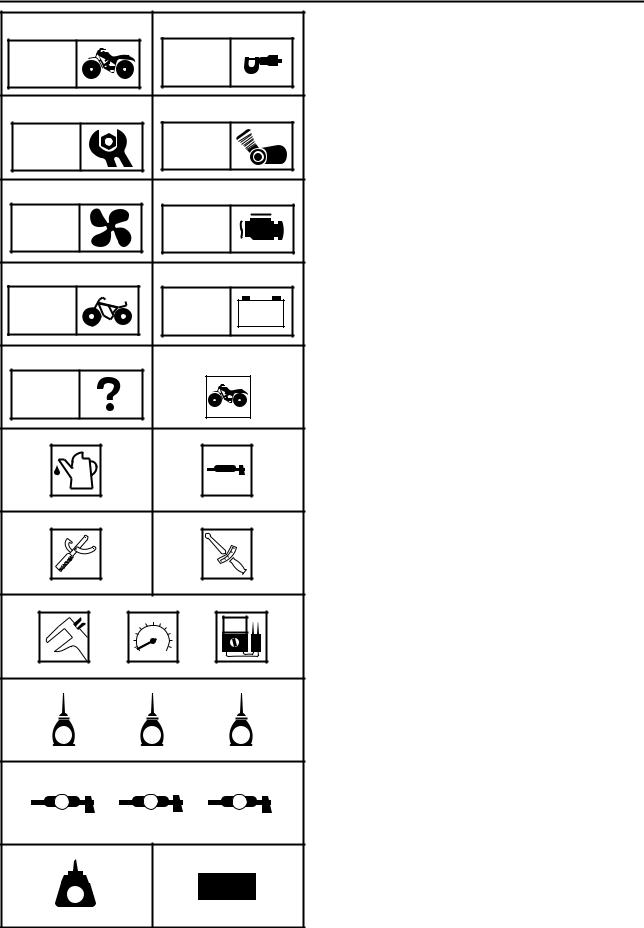

EBS00006

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 9 indicate the subject of each chapter.

1 General information

2Specifications

3Periodic checks and adjustments

4Engine

5Cooling system

6Fuel injection system

7Chassis

8Electrical

9Troubleshooting

Symbols 0 to G indicate the following.

0 Serviceable with engine mounted A Filling fluid

BLubricant

CSpecial tool

DTightening torque

EWear limit, clearance

FEngine speed

GElectrical data (Ω, V, A)

Symbols H to M in the exploded diagrams indicate the types of lubricants and lubrication points.

H Apply engine oil I Apply gear oil

J Apply molybdenum disulfide oil K Apply wheel bearing grease

LApply lithium-soap-based grease

MApply molybdenum disulfide grease

Symbols N to O in the exploded diagrams indicate where to apply a locking agent N and when to install a new part O.

NApply the locking agent (LOCTITE®)

OReplace

EBS00008

TABLE OF CONTENTS

|

GENERAL INFORMATION |

|||

|

INFOGEN |

1 |

||

|

SPECIFICATIONS |

|||

|

SPEC |

2 |

||

|

PERIODIC CHECKS AND |

|||

|

ADJUSTMENTS |

CHKADJ |

3 |

ENGINE

ENG 4

COOLING SYSTEM

COOL 5

FUEL INJECTION SYSTEM

FI 6

CHASSIS

CHAS 7

TROUBLESHOOTING SHTGTRBL 9

CONTENTS

CHAPTER 1

GENERAL INFORMATION

|

VEHICLE IDENTIFICATION…………………………………………………………………. |

1-1 |

|

VEHICLE IDENTIFICATION NUMBER …………………………………………….. |

1-1 |

|

MODEL LABEL……………………………………………………………………………… |

1-1 |

|

FEATURES………………………………………………………………………………………… |

1-2 |

|

OUTLINE OF THE FI SYSTEM……………………………………………………….. |

1-2 |

|

FI SYSTEM…………………………………………………………………………………… |

1-3 |

|

SELF-ADJUSTING PARKING BRAKE MECHANISM…………………………. |

1-4 |

|

IMPORTANT INFORMATION ………………………………………………………………. |

1-7 |

|

PREPARATION FOR REMOVAL AND DISASSEMBLY……………………… |

1-7 |

|

REPLACEMENT PARTS………………………………………………………………… |

1-7 |

|

GASKETS, OIL SEALS AND O-RINGS ……………………………………………. |

1-7 |

|

LOCK WASHERS/PLATES AND COTTER PINS ………………………………. |

1-8 |

|

BEARINGS AND OIL SEALS ………………………………………………………….. |

1-8 |

|

CIRCLIPS …………………………………………………………………………………….. |

1-8 |

|

CHECKING THE CONNECTIONS…………………………………………………… |

1-9 |

|

SPECIAL TOOLS ……………………………………………………………………………… |

1-10 |

|

CHAPTER 2 |

|

|

SPECIFICATIONS |

|

|

GENERAL SPECIFICATIONS ……………………………………………………………… |

2-1 |

|

ENGINE SPECIFICATIONS …………………………………………………………………. |

2-4 |

|

CHASSIS SPECIFICATIONS ……………………………………………………………… |

2-12 |

|

ELECTRICAL SPECIFICATIONS ……………………………………………………….. |

2-14 |

|

TIGHTENING TORQUES …………………………………………………………………… |

2-16 |

|

ENGINE TIGHTENING TORQUES ……………………………………………….. |

2-16 |

|

CHASSIS TIGHTENING TORQUES ……………………………………………… |

2-19 |

|

HOW TO USE THE CONVERSION TABLE………………………………………….. |

2-22 |

|

GENERAL TIGHTENING TORQUE SPECIFICATIONS…………………………. |

2-22 |

|

LUBRICATION POINTS AND LUBRICANT TYPES ……………………………… |

2-23 |

|

ENGINE……………………………………………………………………………………… |

2-23 |

|

COOLANT FLOW DIAGRAMS …………………………………………………………… |

2-24 |

|

OIL FLOW DIAGRAMS ……………………………………………………………………… |

2-28 |

|

CABLE ROUTING …………………………………………………………………………….. |

2-33 |

|

CHAPTER 3 |

|

|

PERIODIC CHECKS AND ADJUSTMENTS |

|

|

INTRODUCTION…………………………………………………………………………………. |

3-1 |

|

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL |

|

|

SYSTEM …………………………………………………………………………………………… |

3-1 |

|

GENERAL MAINTENANCE AND LUBRICATION CHART………………………. |

3-2 |

|

SEAT, FENDERS AND FUEL TANK …………………………………………………….. |

3-3 |

|

REMOVING THE FUEL TANK ………………………………………………………… |

3-9 |

|

REMOVING THE FUEL PUMP ……………………………………………………….. |

3-9 |

|

INSTALLING THE FUEL PUMP…………………………………………………….. |

3-10 |

|

INSTALLING THE FUEL HOSE …………………………………………………….. |

3-10 |

|

ENGINE …………………………………………………………………………………………… |

3-11 |

|

ADJUSTING THE VALVE CLEARANCE ………………………………………… |

3-11 |

|

ADJUSTING THE ENGINE IDLING SPEED ……………………………………. |

3-13 |

|

ADJUSTING THE THROTTLE LEVER FREE PLAY ………………………… |

3-14 |

|

ADJUSTING THE SPEED LIMITER……………………………………………….. |

3-15 |

|

CHECKING THE SPARK PLUG ……………………………………………………. |

3-16 |

|

CHECKING THE IGNITION TIMING………………………………………………. |

3-17 |

|

MEASURING THE COMPRESSION PRESSURE……………………………. |

3-18 |

|

CHECKING THE ENGINE OIL LEVEL……………………………………………. |

3-20 |

|

CHANGING THE ENGINE OIL ……………………………………………………… |

3-22 |

|

ADJUSTING THE CLUTCH CABLE……………………………………………….. |

3-25 |

|

CLEANING THE AIR FILTER ELEMENT………………………………………… |

3-25 |

|

CHECKING THE THROTTLE BODY JOINT……………………………………. |

3-27 |

|

CHECKING THE FUEL HOSE ………………………………………………………. |

3-28 |

|

CHECKING THE BREATHER HOSES …………………………………………… |

3-28 |

|

CHECKING THE COOLANT LEVEL………………………………………………. |

3-29 |

|

CHANGING THE COOLANT…………………………………………………………. |

3-29 |

|

CHECKING THE COOLING SYSTEM ……………………………………………. |

3-32 |

|

CHECKING THE COOLANT TEMPERATURE WARNING LIGHT……… |

3-33 |

|

CHECKING THE EXHAUST SYSTEM……………………………………………. |

3-34 |

|

CLEANING THE SPARK ARRESTER ……………………………………………. |

3-34 |

|

CHASSIS …………………………………………………………………………………………. |

3-36 |

|

ADJUSTING THE FRONT BRAKE ………………………………………………… |

3-36 |

|

ADJUSTING THE REAR BRAKE…………………………………………………… |

3-36 |

|

ADJUSTING THE PARKING BRAKE……………………………………………… |

3-37 |

|

CHECKING THE BRAKE FLUID LEVEL…………………………………………. |

3-38 |

|

CHECKING THE FRONT BRAKE PADS ………………………………………… |

3-39 |

|

CHECKING THE REAR BRAKE PADS ………………………………………….. |

3-39 |

|

ADJUSTING THE REAR BRAKE LIGHT SWITCH …………………………… |

3-40 |

|

CHECKING THE BRAKE HOSES………………………………………………….. |

3-40 |

|

BLEEDING THE HYDRAULIC BRAKE SYSTEM …………………………….. |

3-41 |

|

ADJUSTING THE SHIFT PEDAL…………………………………………………… |

3-43 |

|

ADJUSTING THE REVERSE CONTROL CABLE ……………………………. |

3-43 |

|

ADJUSTING THE DRIVE CHAIN SLACK ……………………………………….. |

3-44 |

|

CHECKING THE STEERING SYSTEM ………………………………………….. |

3-46 |

|

ADJUSTING THE TOE-IN…………………………………………………………….. |

3-46 |

|

CHECKING THE FRONT AND REAR SHOCK ABSORBERS …………… |

3-48 |

|

ADJUSTING THE FRONT SHOCK ABSORBERS …………………………… |

3-48 |

|

ADJUSTING THE REAR SHOCK ABSORBER ……………………………….. |

3-49 |

|

CHECKING THE TIRES……………………………………………………………….. |

3-52 |

|

CHECKING THE WHEELS …………………………………………………………… |

3-54 |

|

CHECKING AND LUBRICATING THE CABLES ……………………………… |

3-54 |

|

LUBRICATING THE LEVERS AND PEDALS ………………………………….. |

3-55 |

|

ELECTRICAL SYSTEM……………………………………………………………………… |

3-56 |

|

CHECKING AND CHARGING THE BATTERY………………………………… |

3-56 |

|

CHECKING THE FUSES ……………………………………………………………… |

3-62 |

|

ADJUSTING THE HEADLIGHT BEAMS…………………………………………. |

3-64 |

|

REPLACING A HEADLIGHT BULB ……………………………………………….. |

3-64 |

|

CHAPTER 4 |

|

|

ENGINE |

|

|

ENGINE REMOVAL ……………………………………………………………………………. |

4-1 |

|

MUFFLER AND EXHAUST PIPES ………………………………………………….. |

4-1 |

|

INSTALLING THE EXHAUST PIPES AND MUFFLER ……………………….. |

4-2 |

|

OIL TANK …………………………………………………………………………………….. |

4-3 |

|

LEADS, CABLES AND HOSES ………………………………………………………. |

4-4 |

|

ENGINE MOUNTING BOLTS …………………………………………………………. |

4-6 |

|

INSTALLING THE ENGINE…………………………………………………………….. |

4-8 |

|

CYLINDER HEAD……………………………………………………………………………….. |

4-9 |

|

REMOVING THE CYLINDER HEAD………………………………………………. |

4-11 |

|

CHECKING THE CYLINDER HEAD ………………………………………………. |

4-12 |

|

CHECKING THE TAPPET COVERS AND CAMSHAFT SPROCKET |

|

|

COVER……………………………………………………………………………………… |

4-13 |

|

CHECKING THE TIMING CHAIN TENSIONER……………………………….. |

4-13 |

|

CHECKING THE CAMSHAFT SPROCKET…………………………………….. |

4-13 |

|

INSTALLING THE CYLINDER HEAD …………………………………………….. |

4-13 |

|

ROCKER ARMS AND CAMSHAFT …………………………………………………….. |

4-17 |

|

REMOVING THE ROCKER ARMS AND CAMSHAFT………………………. |

4-19 |

|

CHECKING THE CAMSHAFT……………………………………………………….. |

4-19 |

|

CHECKING THE DECOMPRESSION SYSTEM………………………………. |

4-20 |

|

CHECKING THE ROCKER ARMS AND ROCKER ARM SHAFTS …….. |

4-21 |

|

INSTALLING THE CAMSHAFT AND ROCKER ARMS …………………….. |

4-22 |

|

VALVES AND VALVE SPRINGS………………………………………………………… |

4-24 |

|

REMOVING THE VALVES AND VALVE SPRINGS …………………………. |

4-25 |

|

CHECKING THE VALVES AND VALVE SPRINGS ………………………….. |

4-26 |

|

INSTALLING THE VALVES AND VALVE SPRINGS ………………………… |

4-31 |

|

CYLINDER AND PISTON…………………………………………………………………… |

4-33 |

|

REMOVING THE PISTON ……………………………………………………………. |

4-34 |

|

CHECKING THE CYLINDER AND PISTON ……………………………………. |

4-34 |

|

CHECKING THE PISTON RINGS………………………………………………….. |

4-36 |

|

CHECKING THE PISTON PIN ………………………………………………………. |

4-37 |

|

INSTALLING THE PISTON AND CYLINDER ………………………………….. |

4-38 |

|

A.C. MAGNETO………………………………………………………………………………… |

4-41 |

|

REMOVING THE A.C. MAGNETO ROTOR…………………………………….. |

4-43 |

|

CHECKING THE STATOR COIL |

|

|

AND CRANKSHAFT POSITION SENSOR …………………………………….. |

4-43 |

|

CHECKING THE STARTER CLUTCH ……………………………………………. |

4-44 |

|

CHECKING THE TORQUE LIMITER……………………………………………… |

4-45 |

|

INSTALLING THE A.C. MAGNETO ROTOR …………………………………… |

4-45 |

|

CLUTCH ………………………………………………………………………………………….. |

4-47 |

|

REMOVING THE CLUTCH …………………………………………………………… |

4-51 |

|

REMOVING THE PRIMARY DRIVE GEAR |

|

|

AND BALANCER DRIVEN GEAR …………………………………………………. |

4-52 |

|

CHECKING THE FRICTION PLATES…………………………………………….. |

4-52 |

|

CHECKING THE CLUTCH PLATES ………………………………………………. |

4-53 |

|

CHECKING THE CLUTCH SPRINGS…………………………………………….. |

4-53 |

|

CHECKING THE CLUTCH HOUSING ……………………………………………. |

4-54 |

|

CHECKING THE CLUTCH BOSS………………………………………………….. |

4-54 |

|

CHECKING THE PRESSURE PLATE ……………………………………………. |

4-54 |

|

CHECKING THE PULL LEVER SHAFT AND PULL ROD …………………. |

4-54 |

|

CHECKING THE PRIMARY DRIVE GEARS …………………………………… |

4-55 |

|

CHECKING THE BALANCER DRIVE GEARS ………………………………… |

4-55 |

|

INSTALLING THE PRIMARY DRIVE GEAR |

|

|

AND BALANCER DRIVEN GEARS ………………………………………………. |

4-55 |

|

INSTALLING THE CLUTCH………………………………………………………….. |

4-56 |

|

OIL PUMP………………………………………………………………………………………… |

4-59 |

|

CHECKING THE OIL PUMP …………………………………………………………. |

4-61 |

|

ASSEMBLING THE OIL PUMP……………………………………………………… |

4-62 |

|

SHIFT SHAFT…………………………………………………………………………………… |

4-63 |

|

CHECKING THE SHIFT SHAFT ……………………………………………………. |

4-65 |

|

CHECKING THE STOPPER LEVER ……………………………………………… |

4-65 |

|

CHECKING THE SHIFT GUIDE…………………………………………………….. |

4-65 |

|

CHECKING THE SHIFT DRUM SEGMENT ……………………………………. |

4-65 |

|

INSTALLING THE SHIFT LEVER ………………………………………………….. |

4-65 |

|

INSTALLING THE SHIFT SHAFT ………………………………………………….. |

4-66 |

|

CRANKCASE …………………………………………………………………………………… |

4-67 |

|

CRANKCASE BEARINGS…………………………………………………………….. |

4-69 |

|

SEPARATING THE CRANKCASE…………………………………………………. |

4-70 |

|

CHECKING THE OIL STRAINER ………………………………………………….. |

4-70 |

|

CHECKING THE TIMING CHAIN AND GUIDE………………………………… |

4-71 |

|

CHECKING THE BEARINGS AND OIL SEALS……………………………….. |

4-71 |

|

CHECKING THE CRANKCASE …………………………………………………….. |

4-71 |

|

ASSEMBLING THE CRANKCASE…………………………………………………. |

4-72 |

|

CRANKSHAFT …………………………………………………………………………………. |

4-74 |

|

CRANKSHAFT AND BALANCER ………………………………………………….. |

4-74 |

|

REMOVING THE CRANKSHAFT ………………………………………………….. |

4-75 |

|

CHECKING THE CRANKSHAFT …………………………………………………… |

4-75 |

|

INSTALLING THE CRANKSHAFT …………………………………………………. |

4-76 |

|

TRANSMISSION……………………………………………………………………………….. |

4-77 |

|

MAIN AXLE ………………………………………………………………………………… |

4-79 |

|

DRIVE AXLE ………………………………………………………………………………. |

4-80 |

|

COUNTER AXLE…………………………………………………………………………. |

4-82 |

|

CHECKING THE SHIFT FORKS……………………………………………………. |

4-83 |

|

CHECKING THE SHIFT DRUM ASSEMBLY…………………………………… |

4-83 |

|

CHECKING THE TRANSMISSION ………………………………………………… |

4-83 |

|

ASSEMBLING THE MAIN AXLE AND DRIVE AXLE ………………………… |

4-84 |

|

INSTALLING THE TRANSMISSION ………………………………………………. |

4-85 |

|

CHAPTER 5 |

|

|

COOLING SYSTEM |

|

|

RADIATOR ………………………………………………………………………………………… |

5-1 |

|

CHECKING THE RADIATOR………………………………………………………….. |

5-3 |

|

INSTALLING THE RADIATOR………………………………………………………… |

5-4 |

|

THERMOSTAT …………………………………………………………………………………… |

5-5 |

|

CHECKING THE THERMOSTAT…………………………………………………….. |

5-6 |

|

INSTALLING THE THERMOSTAT…………………………………………………… |

5-6 |

|

WATER PUMP……………………………………………………………………………………. |

5-7 |

|

DISASSEMBLING THE WATER PUMP……………………………………………. |

5-9 |

|

CHECKING THE WATER PUMP …………………………………………………….. |

5-9 |

|

ASSEMBLING THE WATER PUMP……………………………………………….. |

5-10 |

CHAPTER 6

FUEL INJECTION SYSTEM

|

FUEL INJECTION SYSTEM…………………………………………………………………. |

6-1 |

|

CIRCUIT DIAGRAM ………………………………………………………………………. |

6-2 |

|

ECU’S SELF-DIAGNOSTIC FUNCTION…………………………………………… |

6-4 |

|

SELF-DIAGNOSTIC FUNCTION TABLE ………………………………………….. |

6-5 |

|

TROUBLESHOOTING CHART ……………………………………………………….. |

6-6 |

|

DIAGNOSTIC MODE …………………………………………………………………….. |

6-7 |

|

TROUBLESHOOTING DETAILS …………………………………………………… |

6-11 |

|

CHECKING THE SPEED SENSOR ……………………………………………….. |

6-25 |

|

CHECKING THE INTAKE AIR PRESSURE SENSOR ……………………… |

6-26 |

|

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ……………….. |

6-27 |

|

THROTTLE BODY…………………………………………………………………………….. |

6-28 |

|

CHECKING THE INJECTOR ………………………………………………………… |

6-31 |

|

CHECKING THE THROTTLE BODY ……………………………………………… |

6-31 |

|

INSTALLING THE THROTTLE BODY ASSEMBLY………………………….. |

6-31 |

|

CHECKING THE FUEL PUMP |

|

|

AND PRESSURE REGULATOR OPERATION……………………………….. |

6-32 |

|

CHECKING AND ADJUSTING THE THROTTLE POSITION |

|

|

SENSOR …………………………………………………………………………………… |

6-33 |

|

CHAPTER 7 |

|

|

CHASSIS |

|

|

FRONT AND REAR WHEELS ……………………………………………………………… |

7-1 |

|

FRONT WHEELS ………………………………………………………………………….. |

7-1 |

|

REAR WHEELS ……………………………………………………………………………. |

7-3 |

|

CHECKING THE WHEELS …………………………………………………………….. |

7-4 |

|

CHECKING THE WHEEL HUBS……………………………………………………… |

7-4 |

|

CHECKING THE BRAKE DISCS …………………………………………………….. |

7-5 |

|

INSTALLING THE FRONT WHEEL HUB BEARINGS ………………………… |

7-6 |

|

INSTALLING THE FRONT BRAKE DISCS……………………………………….. |

7-6 |

|

INSTALLING THE FRONT WHEELS……………………………………………….. |

7-6 |

|

INSTALLING THE FRONT WHEEL HUBS ……………………………………….. |

7-7 |

|

INSTALLING THE REAR WHEEL HUBS………………………………………….. |

7-7 |

|

REAR AXLE AND REAR AXLE HUB ……………………………………………………. |

7-8 |

|

REMOVING THE REAR BRAKE CALIPER …………………………………….. |

7-10 |

|

REMOVING THE REAR AXLE………………………………………………………. |

7-10 |

|

CHECKING THE REAR AXLE ………………………………………………………. |

7-11 |

|

CHECKING THE DRIVEN SPROCKET ………………………………………….. |

7-11 |

|

CHECKING THE BRAKE DISC……………………………………………………… |

7-12 |

|

INSTALLING THE DRIVEN SPROCKET ………………………………………… |

7-12 |

|

INSTALLING THE REAR AXLE …………………………………………………….. |

7-12 |

|

FRONT AND REAR BRAKES…………………………………………………………….. |

7-14 |

|

FRONT BRAKE PADS …………………………………………………………………. |

7-14 |

|

REAR BRAKE PADS……………………………………………………………………. |

7-15 |

|

REPLACING THE FRONT BRAKE PADS ………………………………………. |

7-16 |

|

REPLACING THE REAR BRAKE PADS…………………………………………. |

7-18 |

|

FRONT BRAKE MASTER CYLINDER……………………………………………. |

7-20 |

|

REAR BRAKE MASTER CYLINDER ……………………………………………… |

7-22 |

|

REMOVING THE FRONT BRAKE LIGHT SWITCH …………………………. |

7-25 |

|

CHECKING THE MASTER CYLINDERS………………………………………… |

7-25 |

|

ASSEMBLING THE FRONT BRAKE MASTER CYLINDER ………………. |

7-26 |

|

ASSEMBLING THE REAR BRAKE MASTER CYLINDER…………………. |

7-26 |

|

INSTALLING THE FRONT BRAKE MASTER CYLINDER…………………. |

7-27 |

|

INSTALLING THE REAR BRAKE MASTER CYLINDER …………………… |

7-29 |

|

FRONT BRAKE CALIPERS ………………………………………………………….. |

7-31 |

|

REAR BRAKE CALIPER ………………………………………………………………. |

7-33 |

|

REMOVING THE REAR BRAKE CALIPER …………………………………….. |

7-36 |

|

DISASSEMBLING THE FRONT BRAKE CALIPERS………………………… |

7-36 |

|

DISASSEMBLING THE REAR BRAKE CALIPER ……………………………. |

7-37 |

|

CHECKING THE FRONT AND REAR BRAKE CALIPERS ……………….. |

7-37 |

|

ASSEMBLING THE FRONT BRAKE CALIPERS……………………………… |

7-38 |

|

ASSEMBLING THE REAR BRAKE CALIPER …………………………………. |

7-39 |

|

INSTALLING THE FRONT BRAKE CALIPERS ……………………………….. |

7-40 |

|

INSTALLING THE REAR BRAKE CALIPER……………………………………. |

7-41 |

|

STEERING SYSTEM …………………………………………………………………………. |

7-44 |

|

HANDLEBAR………………………………………………………………………………. |

7-44 |

|

REMOVING THE FRONT BRAKE LIGHT SWITCH |

|

|

AND CLUTCH SWITCH ………………………………………………………………. |

7-46 |

|

REMOVING THE HANDLEBAR GRIPS………………………………………….. |

7-46 |

|

CHECKING THE HANDLEBAR …………………………………………………….. |

7-46 |

|

INSTALLING THE HANDLEBAR …………………………………………………… |

7-47 |

|

INSTALLING THE HANDLEBAR GRIPS ………………………………………… |

7-47 |

|

INSTALLING THE CLUTCH LEVER ………………………………………………. |

7-48 |

|

INSTALLING THE BRAKE MASTER CYLINDER …………………………….. |

7-48 |

|

STEERING STEM ……………………………………………………………………….. |

7-49 |

|

REMOVING THE BEARING RETAINER ………………………………………… |

7-51 |

|

CHECKING THE STEERING STEM ………………………………………………. |

7-51 |

|

INSTALLING THE BEARING RETAINER ……………………………………….. |

7-51 |

|

INSTALLING THE LOCK WASHER……………………………………………….. |

7-51 |

|

INSTALLING THE PITMAN ARM…………………………………………………… |

7-52 |

|

TIE-RODS AND STEERING KNUCKLES ……………………………………….. |

7-53 |

|

REMOVING THE STEERING KNUCKLES ……………………………………… |

7-54 |

|

CHECKING THE TIE-RODS …………………………………………………………. |

7-54 |

|

CHECKING THE STEERING KNUCKLES………………………………………. |

7-54 |

|

INSTALLING THE TIE-RODS ……………………………………………………….. |

7-54 |

|

FRONT ARMS AND FRONT SHOCK ABSORBER ASSEMBLIES …………. |

7-55 |

|

REMOVING THE FRONT ARMS …………………………………………………… |

7-57 |

|

CHECKING THE FRONT ARMS……………………………………………………. |

7-57 |

|

CHECKING THE FRONT SHOCK ABSORBER ASSEMBLIES …………. |

7-57 |

|

CHECKING THE BALL JOINTS…………………………………………………….. |

7-58 |

|

INSTALLING THE FRONT ARMS………………………………………………….. |

7-59 |

|

REAR SHOCK ABSORBER AND RELAY ARM …………………………………… |

7-60 |

|

HANDLING THE REAR SHOCK ABSORBER AND GAS CYLINDER…. |

7-62 |

|

DISPOSING OF A REAR SHOCK ABSORBER |

|

|

AND GAS CYLINDER …………………………………………………………………. |

7-62 |

|

REMOVING THE REAR SHOCK ABSORBER ………………………………… |

7-63 |

|

CHECKING THE REAR SHOCK ABSORBER…………………………………. |

7-63 |

|

CHECKING THE RELAY ARM AND CONNECTING ARM………………… |

7-63 |

|

INSTALLING THE RELAY ARM AND CONNECTING ARM………………. |

7-64 |

|

INSTALLING THE REAR SHOCK ABSORBER……………………………….. |

7-64 |

|

SWINGARM AND DRIVE CHAIN………………………………………………………… |

7-65 |

|

REMOVING THE SWINGARM………………………………………………………. |

7-67 |

|

CHECKING THE SWINGARM ………………………………………………………. |

7-67 |

|

CHECKING THE DRIVE CHAIN ……………………………………………………. |

7-68 |

|

INSTALLING THE SWINGARM …………………………………………………….. |

7-70 |

|

INSTALLING THE DRIVE SPROCKET…………………………………………… |

7-70 |

|

CHAPTER 8 |

|

|

ELECTRICAL |

|

|

ELECTRICAL COMPONENTS……………………………………………………………… |

8-1 |

|

CHECKING SWITCH CONTINUITY………………………………………………………. |

8-2 |

|

CHECKING THE SWITCHES……………………………………………………………….. |

8-3 |

|

CHECKING THE BULBS AND BULB SOCKETS …………………………………… |

8-5 |

|

TYPES OF BULBS ………………………………………………………………………… |

8-5 |

|

CHECKING THE CONDITION OF THE BULBS ………………………………… |

8-5 |

|

CHECKING THE CONDITION OF THE BULB SOCKETS ………………….. |

8-7 |

|

IGNITION SYSTEM …………………………………………………………………………….. |

8-8 |

|

CIRCUIT DIAGRAM ………………………………………………………………………. |

8-8 |

|

TROUBLESHOOTING …………………………………………………………………… |

8-9 |

|

ELECTRIC STARTING SYSTEM ………………………………………………………… |

8-14 |

|

CIRCUIT DIAGRAM …………………………………………………………………….. |

8-14 |

|

STARTING CIRCUIT CUT-OFF SYSTEM OPERATION …………………… |

8-15 |

|

TROUBLESHOOTING …………………………………………………………………. |

8-16 |

|

STARTER MOTOR……………………………………………………………………………. |

8-20 |

|

CHECKING THE STARTER MOTOR …………………………………………….. |

8-22 |

|

ASSEMBLING THE STARTER MOTOR…………………………………………. |

8-23 |

|

CHARGING SYSTEM………………………………………………………………………… |

8-25 |

|

CIRCUIT DIAGRAM …………………………………………………………………….. |

8-25 |