- Manuals

- Brands

- Yamaha Manuals

- Outboard Motor

- 40X

- Service manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

40X, E40X

SERVICE MANUAL

E

MANUEL D’ENTRETIEN

F

WARTUNGSHANDBUCH

D

MANUAL DE SERVICIO

ES

290301

Related Manuals for Yamaha 40X

Summary of Contents for Yamaha 40X

-

Page 1

40X, E40X SERVICE MANUAL MANUEL D’ENTRETIEN WARTUNGSHANDBUCH MANUAL DE SERVICIO 290301… -

Page 416

YAMAHA MOTOR CO., LTD. Printed in Japan Sep. 1997 – 2.6 × 1 CR 66T-28197-Z7-C1 (40XMH, 40XWH, 40XW, 40XWT, E40XMH, E40XWH, E40XW) Printed on recycled paper…

This manual is also suitable for:

E40x

Table of Contents

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

40

50

OWNER’S MANUAL

U.S.A.Edition

LIT-18626-06-58

63B-28199-1E

Related Manuals for Yamaha 40

Summary of Contents for Yamaha 40

-

Page 1

OWNER’S MANUAL U.S.A.Edition LIT-18626-06-58 63B-28199-1E… -

Page 2

EMU25060 ZMU01690 Read this owner’s manual carefully before operating your outboard motor. -

Page 3: Important Manual Information

EMU25110 tain maximum enjoyment from your new Yamaha. If you have any question about the operation or maintenance of your outboard motor, please consult a Yamaha dealer. 40, 50 In this Owner’s Manual particularly important…

-

Page 4: Table Of Contents

Table of contents General information ……1 Trim tab with anode……16 Trim rod (tilt pin) ……17 Identification numbers record… 1 Tilt support lever for power trim Outboard motor serial number ..1 and tilt or hydro tilt model….17 Key number……..

-

Page 5

Procedure for tilting up ….38 Connecting the battery ….58 Procedure for tilting down ….39 Disconnecting the battery….59 Cruising in shallow water ….40 Checking top cowling …… 59 Power trim and tilt models / Coating the boat bottom ….59 power tilt models…… -

Page 6: General Information

Record your outboard motor serial number in the spaces provided to assist you in ordering spare parts from your Yamaha dealer or for reference in case your outboard motor is sto- len. 1. Key number…

-

Page 7: Safety Information

General information should give you an understanding of the motor and its operation. Before operating the boat, read any own- EMISSION CONTROL INFORMATION er’s or operator’s manuals supplied with it ENGINE FAMILY : THIS ENGINE CONFORMS TO 2001 U.S. EPA REGULATIONS FOR MARINE SI ENGINES. REFER TO THE OWNERS MANUAL FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

-

Page 8: Important Labels

Never illegally discard (dump) the product. Attach the engine stop switch lanyard cord Yamaha recommends consulting the deal- to a secure place on your clothing, or your er on discarding the product. arm or leg while operating. If you acciden- Be informed about boating safety.

-

Page 9: Basic Boating Rules (Rules Of The Road)

General information EMU25401 These rules determine which vessel has the Label right-of-way, and what each vessel should EWM01260 WARNING Stand-on vessel Be sure shift control is in neutral before The vessel with the right-of-way has the duty starting engine. (except 2HP) to continue its course and speed, except to Do not touch or remove electrical parts avoid an immediate collision.

-

Page 10: Other Special Situations

General information sel head-on) Crossing When two power driven vessels are crossing Crossing: (you are traveling across the oth- each other’s path close enough to run the er vessel’s path) risk of collision, the vessel which has the oth- Overtaking: (you are passing or being er on the starboard (right) side must keep out passed by another vessel) of the way of the other.

-

Page 11

General information bend that may obstruct the view of other wa- er is going towards the port). This means that ter vessels, the operator should sound a pro- red buoys are passed on the starboard longed blast on the whistle (4 to 6 seconds). (right) side when proceeding from open wa- If another vessel is around the bend, it too ter into port, and black buoys are to port (left) -

Page 12: Fueling Instructions

General information ZMU01708 EMU25540 away from sparks, flames, or other Fueling instructions sources of ignition. EWM00010 Stop engine before refueling. WARNING Refuel in a well-ventilated area. Refuel GASOLINE AND ITS VAPORS ARE HIGH- portable fuel tanks off the boat. LY FLAMMABLE AND EXPLOSIVE! Take care not to spill gasoline.

-

Page 13: Gasoline

The performance of your outboard motor will the fuel meets minimum octane ratings. be critically affected by your choice of propel- Yamaha does not recommended gasohol ler, as an incorrect choice could adversely containing methanol because it can cause affect performance and could also seriously fuel system damage or engine performance damage the motor.

-

Page 14: Start-In-Gear Protection

53. on the engine. EMU25770 Start-in-gear protection Yamaha outboard motors are fitted with pro- Yamaha outboard motors or Yamaha-ap- pellers chosen to perform well over a range proved remote control units are equipped of applications, but there may be uses where with start-in-gear protection device(s).

-

Page 15: Basic Components

Basic components EMU25796 Main components NOTE: * May not be exactly as shown; also may not be included as standard equipment on all mod- els. 40, 50 ZMU05014 1. Battery cable 15. Fuel tank* 2. Anode(s) EMU25802 3. Propeller* Fuel tank 4.

-

Page 16: Fuel Joint

Basic components tions. ZMU03157 1. Power trim and tilt switch 2. Remote control lever 1. Fuel joint 3. Neutral interlock trigger 2. Fuel gauge 4. Neutral throttle lever 3. Fuel tank cap 5. Main switch / choke switch 4. Air vent screw 6.

-

Page 17: Neutral Interlock Trigger

Basic components 6. Throttle 7. Fully open EMU26201 Neutral interlock trigger To shift out of neutral, first pull the neutral in- terlock trigger up. 1. Fully open 2. Fully closed EMU25911 Tiller handle To change direction, move the tiller handle to the left or right as necessary.

-

Page 18: Throttle Grip

Basic components 1. Throttle indicator 1. Forward “ ” 2. Neutral “ ” EMU25970 3. Reverse “ ” Throttle friction adjuster A friction device provides adjustable resis- EMU25941 tance to movement of the throttle grip or the Throttle grip remote control lever, and can be set accord- The throttle grip is on the tiller handle.

-

Page 19: Engine Stop Lanyard Switch

Basic components NOTE: The engine cannot be started with the lock plate removed. When constant speed is desired, tighten the adjuster to maintain the desired throttle set- ting. EMU25990 Engine stop lanyard switch 1. Lanyard 2. Lock plate The lock plate must be attached to the en- gine stop switch for the engine to run.

-

Page 20: Main Switch

Basic components EMU26090 EMU26141 Main switch Power trim and tilt switch on remote The main switch controls the ignition system; control or tiller handle its operation is described below. The power trim and tilt system adjusts the “ ” (off) outboard motor angle in relation to the tran- With the main switch in the “…

-

Page 21: Power Trim And Tilt Switch On Bottom Engine Cowling

Basic components DOWN ZMU03096 EMU26151 NOTE: Power trim and tilt switch on bottom For instructions on using the power trim and engine cowling tilt switch, see page 37. The power trim and tilt switch is located on EMU26241 the side of the bottom engine cowling. Press- Trim tab with anode ing the switch “…

-

Page 22: Trim Rod (Tilt Pin)

Basic components ZMU03097 ZMU03194 EMU26372 1. Trim tab Top cowling lock lever(s) (turn type) 2. Bolt To remove the engine top cowling, turn the lock lever(s) and lift off the cowling. When in- EMU26261 Trim rod (tilt pin) stalling the cowling, check to be sure it fits The position of the trim rod determines the properly in the rubber seal.

-

Page 23: Tachometer

Basic components EMU26470 7. Engine trouble warning indicator Tachometer 8. Set button This gauge shows the engine speed and has 9. Mode button the following functions. NOTE: The water separator and engine trouble warning indicators only operate when the en- gine is equipped with the appropriate func- tions.

-

Page 24: Overheat Warning Indicator (Digital Type)

Basic components rious engine damage will occur. ZMU04581 NOTE: ZMU01867 Memorize the trim angles that work best for 1. Oil level indicator your boat under different conditions. Adjust the trim angle to the desired setting with the EMU26581 Overheat warning indicator (digital power trim and tilt switch.

-

Page 25: Warning System

Warning system ECM00090 CAUTION: Do not continue to operate the engine if a warning device has activated. Consult your Yamaha dealer if the problem can- not be located and corrected. EMU26814 Overheat warning ZMU03025 This engine has an overheat warning device.

-

Page 26: Oil Level Warning And Oil Filter Clogging Warning

Basic components ZMU03942 ZMU03026 The buzzer will sound (if equipped on the EMU26845 Oil level warning and oil filter tiller handle, remote control box, or main clogging warning switch panel). Oil injection models This engine has an oil level warning system. If the oil level falls below the lower limit, the warning system will activate.

-

Page 27

Basic components ZMU03366 1. Oil filter… -

Page 28: Operation

Operation EMU26901 specific boat and motor combination. Installation EWM00830 ECM00110 WARNING CAUTION: Improper mounting of the outboard mo- Incorrect engine height or obstructions tor could result in hazardous conditions to smooth water flow (such as the design such as poor handling, loss of control, or or condition of the boat, or accessories fire hazards.

-

Page 29: Clamping The Outboard Motor

Other- mine the optimum mounting height. Con- wise the engine could be completely lost sult your Yamaha dealer boat if it accidentally falls off the transom. manufacturer for further information on de- termining the proper mounting height.

-

Page 30: Breaking In Engine

Operation board (if packed). For details, consult EMU27060 Gasoline and engine oil mixing chart your Yamaha dealer. (50:1) EWM00650 WARNING Avoid using bolts, nuts or washers other than those contained in the engine pack- aging. If used, they must be of at least the same quality of material and strength and must be tightened securely.

-

Page 31: Preoperation Checks

Keep hands, hair, and clothes away Check fuel line connections to be sure they from the flywheel and other rotating are tight (if equipped Yamaha fuel tank or parts while the engine is running. boat tank). Be sure the fuel tank is positioned on a se-…

-

Page 32: Filling Fuel And Engine Oil

Fuel tank capacity (if equipped Yamaha Ring Free Fuel Additive, available from fuel tank): your Yamaha dealer. Ring Free Fuel Addi- 25 L (6.60 US gal) (5.50 Imp.gal) tive has repeatedly proven its ability to clean combustion deposits from inside the engine, notably the critical piston-ring-land area, and fuel system components.

-

Page 33: Filling Oil For Electric Start Models

EWM00530 WARNING Do not add gasoline into the oil tank. Fire or explosion could result. This engine uses the Yamaha oil injection system, which provides superior lubrication by ensuring the proper oil ratio for all operat- ZMU03370 ing conditions. No fuel premixing is needed.

-

Page 34: Oil Level Indicator Operation

450 No refilling necessary. (0.48 US qt, 0.40 Imp qt) Yellow from 450 cm (0.48 US qt, 0.40 Imp qt) down to Add oil; see page 28. 200 cm (0.21 US qt, 0.18 Imp qt) Buzzer sounds in…

-

Page 35: Starting Engine

Operation tank cap, loosen it 2 or 3 turns. zontally, otherwise fuel cannot be drawn from the fuel tank. Squeeze the primer pump with the outlet end up until you feel it become firm. ZMU02295 If there is a fuel joint on the motor, firmly connect the fuel line to the joint.

-

Page 36

Operation gine stop switch. Turn the main switch to “ ” (start), and hold it for a maximum of 5 seconds. EWM00120 WARNING Attach the engine stop switch lanyard to a secure place on your clothing, or your arm or leg while operating. Do not attach the lanyard to clothing that could tear loose. -

Page 37

Operation EMU27662 Electric start and remote control models Place the remote control lever in neutral. Turn the main switch to “ ” (on). Turn the main switch to “ ” (start), and hold it for a maximum of 5 seconds. NOTE: The start-in-gear protection device prevents the engine from starting except when in neu-… -

Page 38: Warming Up Engine

Place the throttle grip in the fully closed the lower case or the cooling water pilot position. hole is blocked. Consult your Yamaha dealer if the problem cannot be located and corrected. Move the gear shift lever quickly and…

-

Page 39: Reverse (Automatic Reverse Lock And Power Trim And Tilt Models)

Operation firmly from neutral to forward. Move the gear shift lever quickly and firmly from neutral to reverse. Remote control models Pull up the neutral interlock trigger (if equipped) and move the remote control lever quickly and firmly from neutral to forward.

-

Page 40: Procedure

Operation ping the engine immediately after operating at high speed is not recommended. EMU27844 Procedure Push and hold the engine stop button or turn the main switch to “ ” (off). ZMU02301 Remove the key if the boat will be left unattended.

-

Page 41: Adjusting Trim Angle

Operation Adjust the outboard motor trim angle using the power trim and tilt switch. ZMU03110 1. Power trim and tilt switch ZMU03109 1. Trim operating angle DOWN EMU27881 Adjusting trim angle ZMU03096 Power trim and tilt models EWM00750 1. Power trim and tilt switch WARNING Be sure all people are clear of the out- board motor when adjusting the tilt an-…

-

Page 42: Adjusting Boat Trim

Operation “ ” (down). the operator and passengers overboard. Make test runs with the trim set to different angles to find the position that works best for your boat and operating conditions. NOTE: To adjust the trim angle while the boat is moving, use the power trim and tilt switch lo- cated on the remote control device or tiller handle, if equipped.

-

Page 43: Procedure For Tilting Up

Operation sion with obstructions, and also to reduce salt corrosion. EWM00220 WARNING Be sure all people are clear of the out- board motor when tilting up and down, also be careful not to pinch any body parts between the drive unit and engine bracket.

-

Page 44: Procedure For Tilting Down

Operation ZMU01935 ZMU03115 EWM00260 WARNING After tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back down suddenly if oil in the power trim and tilt unit loses pres- sure.

-

Page 45: Cruising In Shallow Water

Operation ZMU02569 EMU28060 Push the power tilt / power trim and tilt Cruising in shallow water switch “ ” (down) to lower the outboard The outboard motor can be tilted up partially motor to the desired position. to allow operation in shallow water. EMU28090 Power trim and tilt models / power tilt models…

-

Page 46: Cruising In Other Conditions

ZMU01935 For cooling system flushing instructions, see page 43. Cruising in turbid water Yamaha strongly recommends that you use the optional chromium-plated water pump kit (not available for some models) if you use the outboard motor in turbid (muddy) water…

-

Page 47: Maintenance

Gear ratio: Full throttle operating range: 1.85 (24/13) 4500–5500 r/min Trim and tilt system: Maximum output: Power trim and tilt 40TR 29.4 kW@5000 r/min (40 Propeller mark: HP@5000 r/min) 50TR 36.8 kW@5000 r/min (50 Fuel and oil: HP@5000 r/min) Recommended fuel:…

-

Page 48: Transporting And Storing Outboard Motor

Maintenance Spark plug: sition using a motor support device such as 25.0 Nm (18.4 ft-lb) (2.55 kgf-m) a transom saver bar. Consult your Yamaha Propeller nut: dealer for further details. 35.0 Nm (25.8 ft-lb) (3.57 kgf-m) EMU28235 Clamp screw mounting models…

-

Page 49: Procedure

NOTE: Cooling system flushing is essential to prevent the cooling system from clog- The use of “Yamaha Fuel Conditioner and ging up with salt, sand, or dirt. In addi- Stabilizer” eliminates the need to drain the tion, fogging of the engine is mandatory fuel system.

-

Page 50: Lubrication (Oil Injection Models)

Seal replacement should be per- follow these preventive measures: formed by an authorized Yamaha dealer Charge batteries in a well-ventilated ar- prior to use. Grease all grease fittings. For further de- Keep batteries away from fire, sparks, tails, see page 49.

-

Page 51: Cleaning The Outboard Motor

EMU28510 Replacement parts If replacement parts are necessary, use only genuine Yamaha parts or parts of the same type and of equivalent strength and materi- als. Any part of inferior quality may malfunc- ZMU03223 tion, and the resulting loss of control could endanger the operator and passengers.

-

Page 52: Maintenance Chart

When operating in salt water, turbid or muddy water, the engine should be flushed with clean water after each use. The “ ” symbol indicates the check-ups which you may carry out yourself. The “ ” symbol indicates work to be carried out by your Yamaha dealer. Initial Every 50 hours Item…

-

Page 53

Maintenance Initial Every 50 hours Item Actions 10 hours hours (6 hours (1 (1 month) months) months) year) Inspection / replace- Water pump ment Oil pump Inspection / adjustment Oil tank water drain Inspection / cleaning Cleaning / adjustment / Spark plug(s) replacement… -

Page 54: Greasing

Maintenance EMU28931 Greasing Yamaha marine grease (Water resistant grease) 40, 50 ZMU03414 The spark plug is an important engine com- EMU28952 Cleaning and adjusting spark plug ponent and is easy to inspect. The condition EWM00560 of the spark plug can indicate something WARNING about the condition of the engine.

-

Page 55: Checking Fuel System

Improper repairs can make the outboard unsafe to operate. Check the fuel lines for leaks, crack, or mal- function. If a problem is found, your Yamaha dealer or other qualified mechanic should re- 1. Spark plug gap pair it immediately.

-

Page 56: Inspecting Fuel Filter

If any water is found in the If you have any question about properly fuel, the Yamaha portable fuel tank or doing this procedure, consult your other fuel tanks should be checked and Yamaha dealer.

-

Page 57: Inspecting Idling Speed

If you have difficulty ver- 1. Filter cup ifying the idle speed, or the idle speed re- 2. Filter element quires adjustment, consult a Yamaha dealer 3. Filter housing or other qualified mechanic. 4. O-ring Verify whether the idle speed is set to Reinstall the filter element in the cup.

-

Page 58: Exhaust Leakage

Never get under the lower unit while it NOTE: is tilted, even when the tilt support lever Consult your Yamaha dealer if any operation is locked. Severe injury could occur if is abnormal. the outboard motor accidentally falls.

-

Page 59: Removing The Propeller

Maintenance move the key, and remove the lanyard from the engine stop switch. Turn off the battery cut-off switch if your boat has one. Do not use your hand to hold the pro- peller when loosening or tightening the propeller nut. Put a wood block be- tween the anti-cavitation plate and the propeller to prevent the propeller from turning.

-

Page 60: Installing The Propeller

Apply Yamaha marine grease or a cor- Tilt the outboard motor so that the gear rosion resistant grease to the propeller oil drain screw is at the lowest point pos- shaft.

-

Page 61: Cleaning Fuel Tank

NOTE: Remove the fuel tank from the boat be- For disposal of used oil consult your Yamaha fore cleaning it. Work only outdoors in dealer. an area with good ventilation.

-

Page 62: Inspecting And Replacing Anode(S)

EMU29312 Inspecting and replacing anode(s) Yamaha outboard motors are protected from corrosion by sacrificial anodes. Inspect the ZMU03135 external anodes periodically. Remove scales from the surfaces of the anodes. Consult a Yamaha dealer for replacement of external anodes.

-

Page 63: Connecting The Battery

(for example: welding charge the battery when it is low. equipment, lighted cigarettes, and so NOTE: on.) Consult a Yamaha dealer when charging or DO NOT SMOKE when charging or han- re-charging batteries. dling batteries. EMU29331 KEEP BATTERIES AND ELECTROLYTIC Connecting the battery FLUID OUT OF REACH OF CHILDREN.

-

Page 64: Disconnecting The Battery

EMU29390 Checking top cowling Check the fitting of the top cowling by push- ing it with both hands. If it is loose have it re- paired by your Yamaha dealer. ZMU04678 EMU29400 Coating the boat bottom A clean hull improves boat performance. The boat bottom should be kept as clean of ma- rine growth as possible.

-

Page 65: Trouble Recovery

Q. Has fuel pump malfunctioned? If your outboard motor requires repair, bring A. Have serviced by a Yamaha dealer. it to your Yamaha dealer. If the engine trouble warning indicator is Q. Are spark plug(s) fouled or of incorrect flashing, consult your Yamaha dealer.

-

Page 66

Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is carburetor clogged? A. Have serviced by a Yamaha dealer. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Is fuel joint connection incorrect? A. -

Page 67

Trouble Recovery A. Have serviced by a Yamaha dealer. Q. Are weeds or other foreign matter tangled on gear housing? Q. Is load on boat improperly distributed? A. Remove foreign matter and clean lower A. Distribute load to place boat on an even unit. -

Page 68: Temporary Action In Emergency

EWM00630 Q. Is steering pivot loose or damaged? WARNING A. Tighten or have serviced by a Yamaha Be sure to use the specified fuse. An in- dealer. correct fuse or a piece of wire could allow EMU29432 excessive current flow.

-

Page 69: Power Trim And Tilt / Power Tilt Will Not Operate

NOTE: ate. Make sure the remote control lever Consult your Yamaha dealer if the new fuse is in neutral. Otherwise the boat could immediately blows again. unexpectedly start to move, which EMU29522 could result in an accident.

-

Page 70: Emergency Starting Engine

Trouble Recovery wheel or other moving parts when the main switch must be “ ” (on), if engine is running. Do not install the equipped. starter mechanism or top cowling after the engine is running. Do not touch the ignition coil, spark plug wire, spark plug cap, or other elec- trical components when starting or op- erating the motor.

-

Page 71: Engine Fails To Operate

Trouble Recovery NOTE: When the engine does not start with this pro- cedure, see page 66. EMU29670 Engine fails to operate EMU29704 Cold engine fails to start If the engine fails to start when it is cold, use the following procedure. ZMU03142 EWM00410 WARNING…

-

Page 72: Treatment Of Submerged Motor

Do not keep the starter motor turning If the outboard motor is submerged, immedi- for more than 5 seconds. If the starter ately take it to a Yamaha dealer. Otherwise motor is turned continuously for more some corrosion may begin almost immedi- than 5 seconds, the battery will be ately.

-

Page 73

Feed fogging oil or engine oil through the carburetor(s) and spark plug holes while cranking with the manual starter or emergency starter rope. ZMU01911 Take the outboard motor to a Yamaha dealer as soon as possible. ECM00400 CAUTION: Do not attempt to run the outboard motor… -

Page 74: Consumer Information

Consumer information EMU29811 Important warranty information for U.S.A. and Canada…

-

Page 75

Consumer information… -

Page 76: Yamaha Motor Corporation, U.s.a. Outboard Motor Two Year Limited Warranty

Consumer information EMU29820 YAMAHA MOTOR CORPORATION, U.S.A. OUTBOARD MOTOR TWO YEAR LIMITED WARRANTY…

-

Page 77

Consumer information… -

Page 78

Consumer information… -

Page 79: Important Warranty Information If You Use Your Yamaha Outside The Usa Or Canada

Consumer information EMU29841 IMPORTANT WARRANTY INFORMATION IF YOU USE YOUR YAMAHA OUTSIDE THE USA OR CANADA…

-

Page 80

Printed in Japan May 2005–0.8 × 1 ! Printed on raecycled paper… -

Page 81

(A l’usage du concessionnaire) MODÉLE ET NO. DE SÉRIE DU MOTEUR HORS-BORD (sur l’étiquette d’identification de la presse de fixation) YAMAHA DEALER NUMBER NO. DU CONCESSIONNAIRE YAMAHA DEALER NAME YAMAHA MOTOR CO., LTD. NOM DU MADE IN JAPAN CONCESSIONNAIRE PAYS D’ORIGINE JAPON USAGE… -

Page 82

PLACE POSTAGE HERE ATTN: WARRANTY DEPARTMENT…

This manual is also suitable for:

50

4-я Красноармейская, 2А

Санкт-Петербург, 190005

Email: info@lenmoto.ru

Телефон: +7 (921) 930-81-18

Телефон: +7 (911) 928-08-06

Компания ЛенМото

Запчасти, аксессуары, экипировка, тюнинг для мотоциклов, скутеров, квадроциклов, снегоходов, багги, гидроциклов, катеров и лодочных моторов.

Подпишитесь на наши новости

Подписаться

40X

E40X

290545

SERVICE MANUAL

66T-28197-5F-11

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

1

40X, E40X

SERVICE MANUAL

©2003 by Yamaha Motor Co., Ltd.

1st Edition, December 2003

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

Power unit

GEN

INFO

SPEC

CHK

ADJ

FUEL

POWR

1

2

3

4

5

Lower unit

Bracket unit

Electrical systems

Troubleshooting

Index

LOWR

BRKT

–+

ELEC

TRBL

SHTG

6

7

8

9

GEN

INFO

General information

How to use this manual………………………………………………………………………1-1

Manual format………………………………………………………………………………..1-1

Symbols………………………………………………………………………………………..1-2

Safety while working…………………………………………………………………………..1-3

Fire prevention……………………………………………………………………………….1-3

Ventilation……………………………………………………………………………………..1-3

Self-protection ……………………………………………………………………………….1-3

Parts, lubricants, and sealants …………………………………………………………1-3

Good working practices …………………………………………………………………..1-4

Disassembly and assembly ……………………………………………………………..1-4

1

2

Identification………………………………………………………………………………………1-5

Applicable models ………………………………………………………………………….1-5

Serial number ………………………………………………………………………………..1-5

Propeller selection……………………………………………………………………………..1-5

Propeller size…………………………………………………………………………………1-5

Selection……………………………………………………………………………………….1-6

Predelivery checks …………………………………………………………………………….1-6

Checking the fuel system ………………………………………………………………..1-6

Checking the gear oil level ………………………………………………………………1-6

Checking the battery (WH, W)………………………………………………………….1-6

Checking the outboard motor mounting height……………………………………1-7

Checking the remote control cables (remote control model) …………………1-7

Checking the steering system ………………………………………………………….1-8

Checking the gear shift and throttle operation…………………………………….1-8

Checking the engine start switch and engine stop lanyard switch …………1-9

Checking the cooling water pilot hole ………………………………………………..1-9

Test run ………………………………………………………………………………………..1-9

Break-in ………………………………………………………………………………………1-10

After test run ………………………………………………………………………………..1-10

3

4

5

6

7

66T5F11

8

9

GEN

INFO

General information

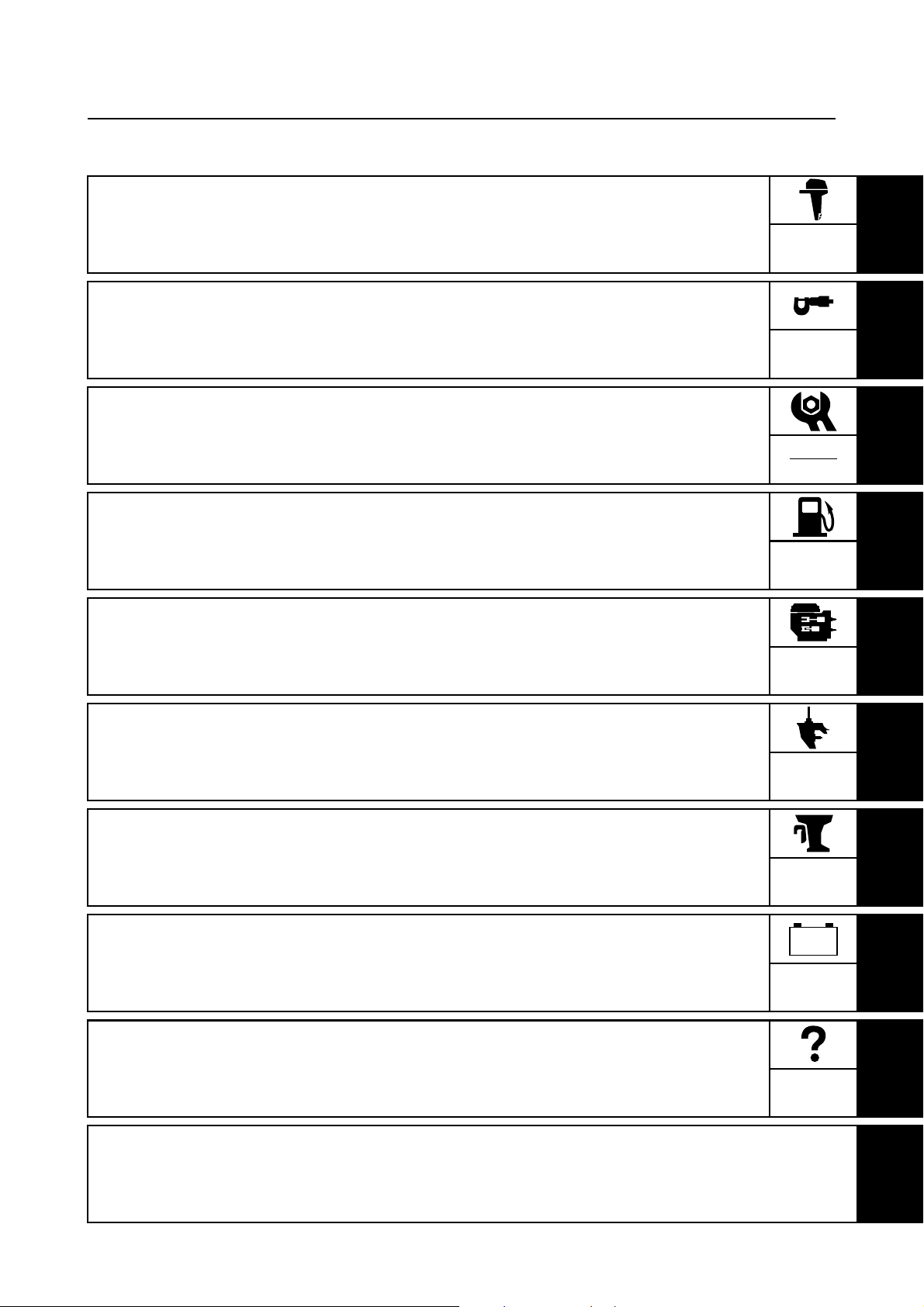

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the exploded diagrams and after a numbered

step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consists of part names and part quantities, as well as bolt and screw dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

NOTE:

For troubleshooting procedures, see Chapter 9, “Troubleshooting.”

1

LOWR

Lower unit

No. Part name Q’ty Remarks

1 Lower unit 1

2 Plastic tie 1

3Hose 1

4 Check screw 1

5 Gasket 2

6 Dowel pin 2

7 Bolt 4 M10 40 mm

8 Drain screw 1

9Grommet 1

10 Bolt 1 M10 45 mm

11 Bolt 1 M8 60 mm

12 Thrust washer 1

13 Propeller 1

14 Washer 1

15 Washer 1

16 Cotter pin 1

17 Propeller nut 1

18 Trim tab 1

6-5

Lower unit

Not reusable

Not reusable

Not reusable

3

4

2

62Y5A11

1

LOWR

Removing the drive shaft

1. Remove the drive shaft assembly and

pinion, and then pull out the forward

gear.

Disassembling the drive shaft

1. Install the pinion nut 1, tighten it finger

tight, and then remove the drive shaft

bearing 2 using a press.

CAUTION:

• Do not press the drive shaft threads

directly.

• Do not reuse the bearing, always

replace it with a new one.

Disassembling the forward gear

1. Remove the taper roller bearing from the

forward gear using a press.

Lower unit

S62Y6850K

Drive shaft holder 4 1: 90890-06518

Pinion nut holder 2: 90890-06505

Socket adapter 2 3: 90890-06507

Bearing inner race attachment 3:

90890-06639

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

Bearing separator 1: 90890-06534

2. Remove the needle bearing from the forward gear.

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

a

Stopper guide plate 2: 90890-06501

Stopper guide stand 3:

90890-06538

Bearing puller 4: 90890-06535

Bearing puller claw 1 5:

90890-06536

S62Y6740K

1-1

5

6-19

62Y5A11

66T5F11

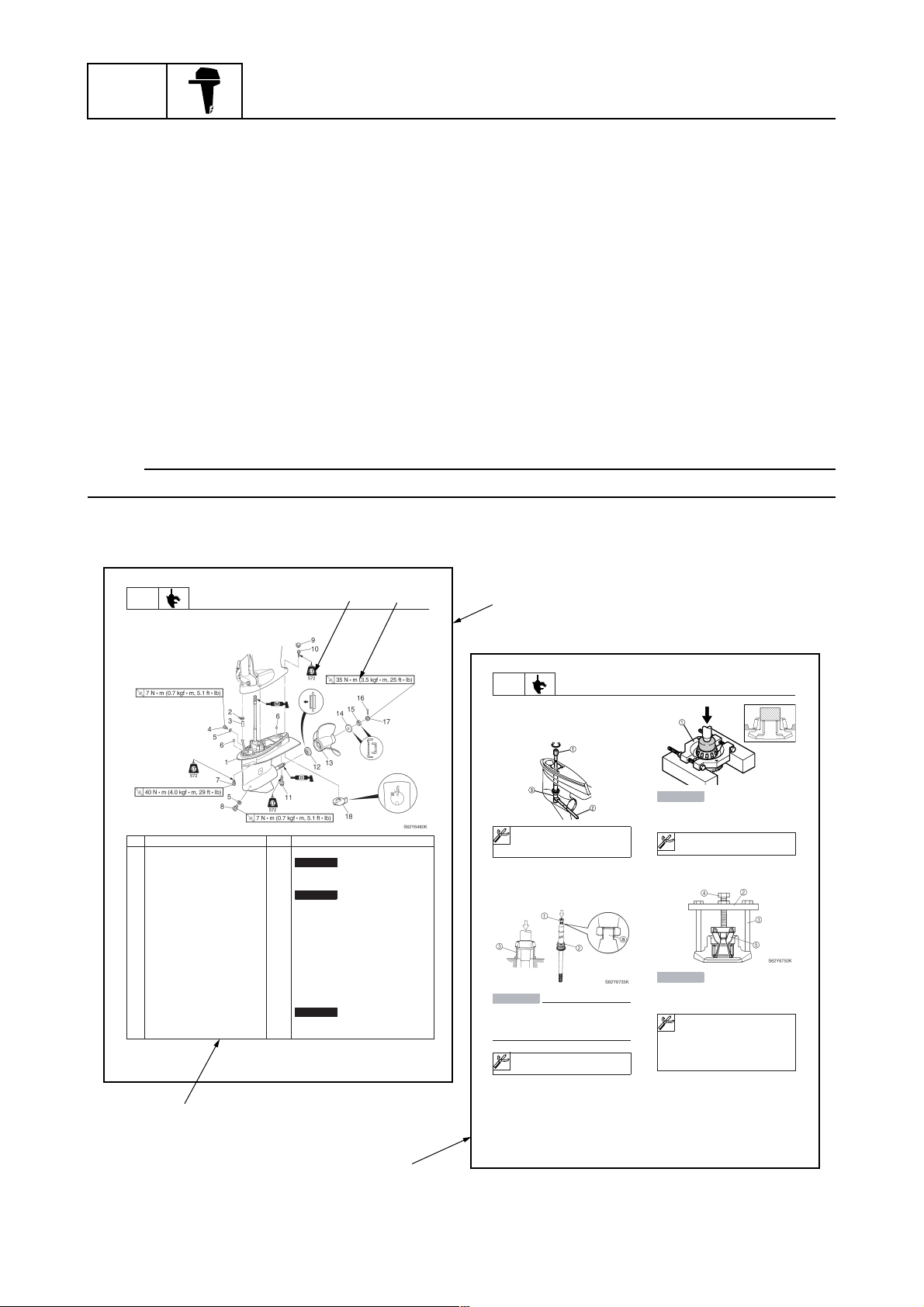

Symbols

The symbols below are designed to indicate the content of a chapter.

How to use this manual

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Symbols 1 to 6 indicate specific data.

123456

Fuel system

FUEL

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

Troubleshooting

– +

TRBL

SHTG

1

2

3

4

Special tool

1

Specified oil or fluid

2

Specified engine speed

3

Specified tightening torque

4

Symbols 7 to C in an exploded diagram indicate the grade of lubricant and the lubrication point.

7890ABC

A M

E G

Apply 2-stroke outboard motor oil

7

Apply gear oil

8

Apply water resistant grease (Yamaha grease A)

9

Apply molybdenum disulfide grease

0

Symbols D to I in an exploded diagram indicate the type of sealant or locking agent and the application point.

DEFGHI

GM

4

LT

271

Specified measurement

5

Specified electrical value

6

(resistance, voltage, electric current)

C I

Apply corrosion resistant grease

A

(Yamaha grease D)

Apply low temperature resistant grease

B

(Yamaha grease C)

Apply injector grease

C

LT

572

SS

5

6

7

8

9

Apply Gasket Maker

D

Apply Yamabond No. 4

E

Apply LOCTITE 271 (red)

F

66T5F11

Apply LOCTITE 242 (blue)

G

Apply LOCTITE 572

H

Apply silicon sealant

I

1-2

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety procedures provided below.

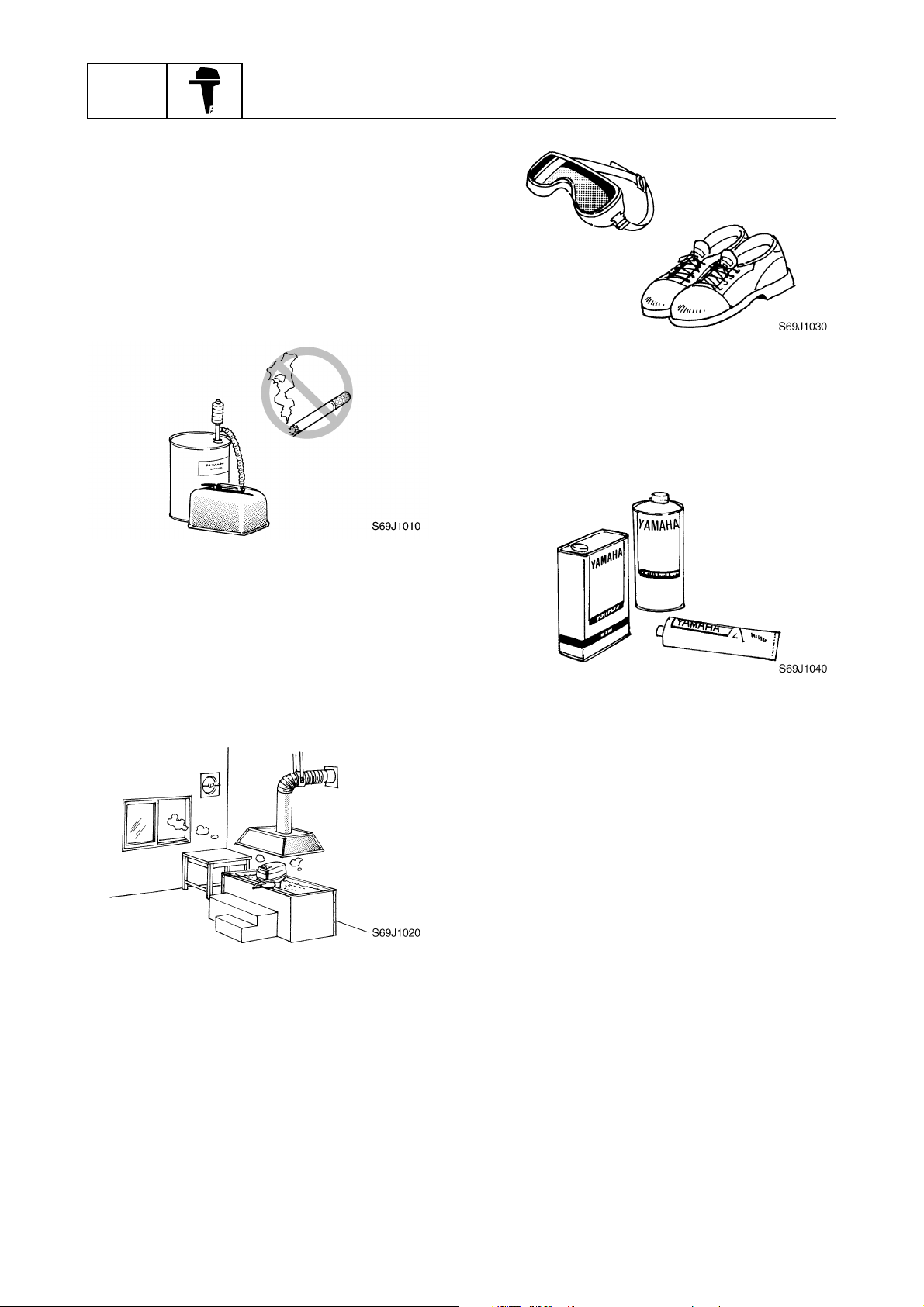

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where adequate ventilation can be maintained.

1

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the outboard motor.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involving drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1-3

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.

66T5F11

Safety while working

6. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

Good working practices

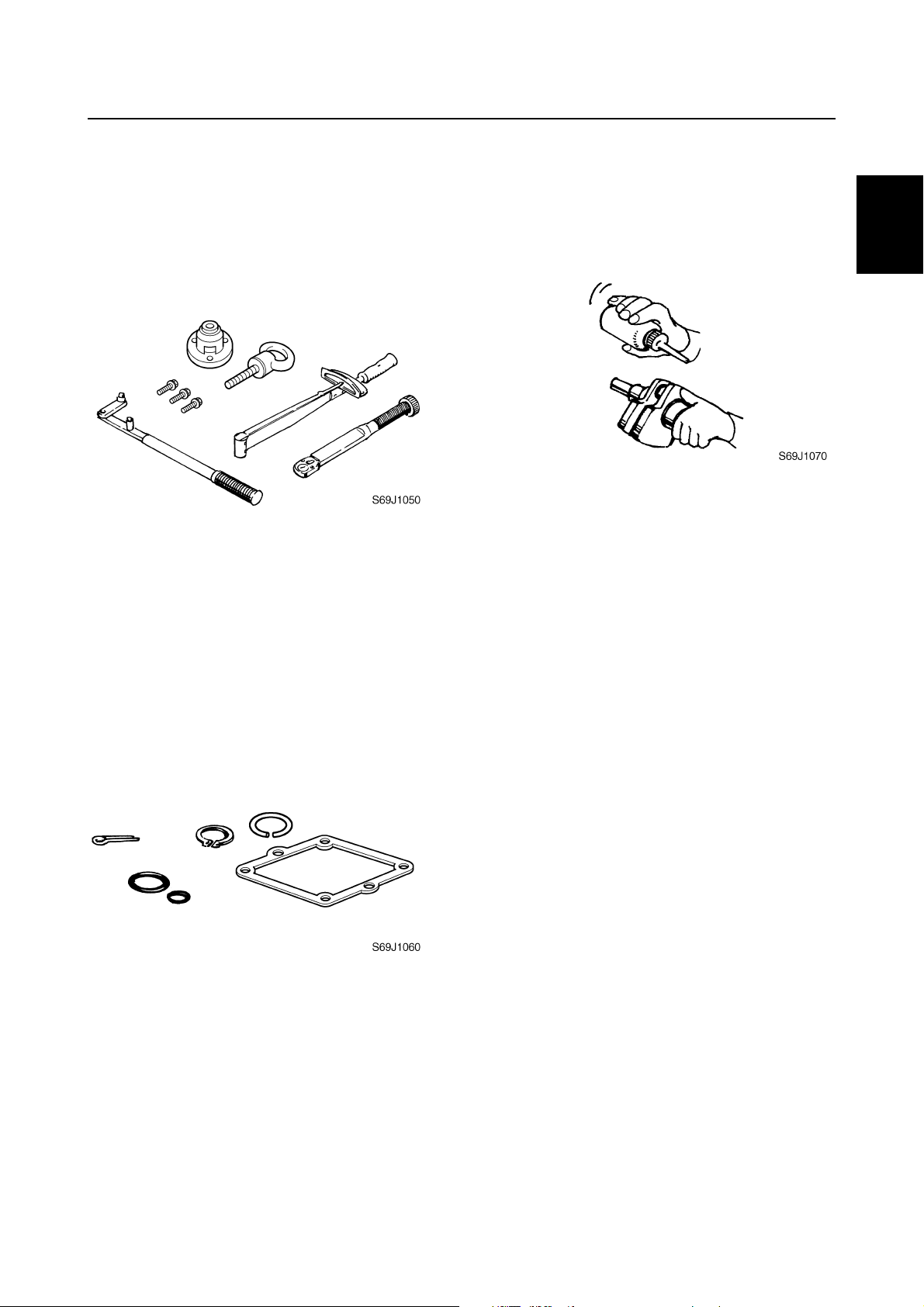

Special service tools

Use the recommended special service tools

to protect parts from damage. Use the right

tool in the right manner—do not improvise.

Tightening torques

Follow the tightening torque specifications

provided throughout the manual. When tightening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter pins, circlips, etc., when installing or

assembling parts.

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply engine oil to the contact surfaces

of moving parts before assembly.

3. Install bearings with the manufacture

identification mark in the direction indicated in the installation procedure. In

addition, be sure to lubricate the bearings

liberally.

4. Apply a thin coat of water-resistant

grease to the lip and periphery of an oil

seal before installation.

5. Check that moving parts operate normally after assembly.

1

2

3

4

5

6

7

8

9

66T5F11

1-4

GEN

INFO

General information

Identification

Applicable models

This manual covers the following models.

Applicable models

40XWH, 40XW, E40XMH, E40XW

Serial number

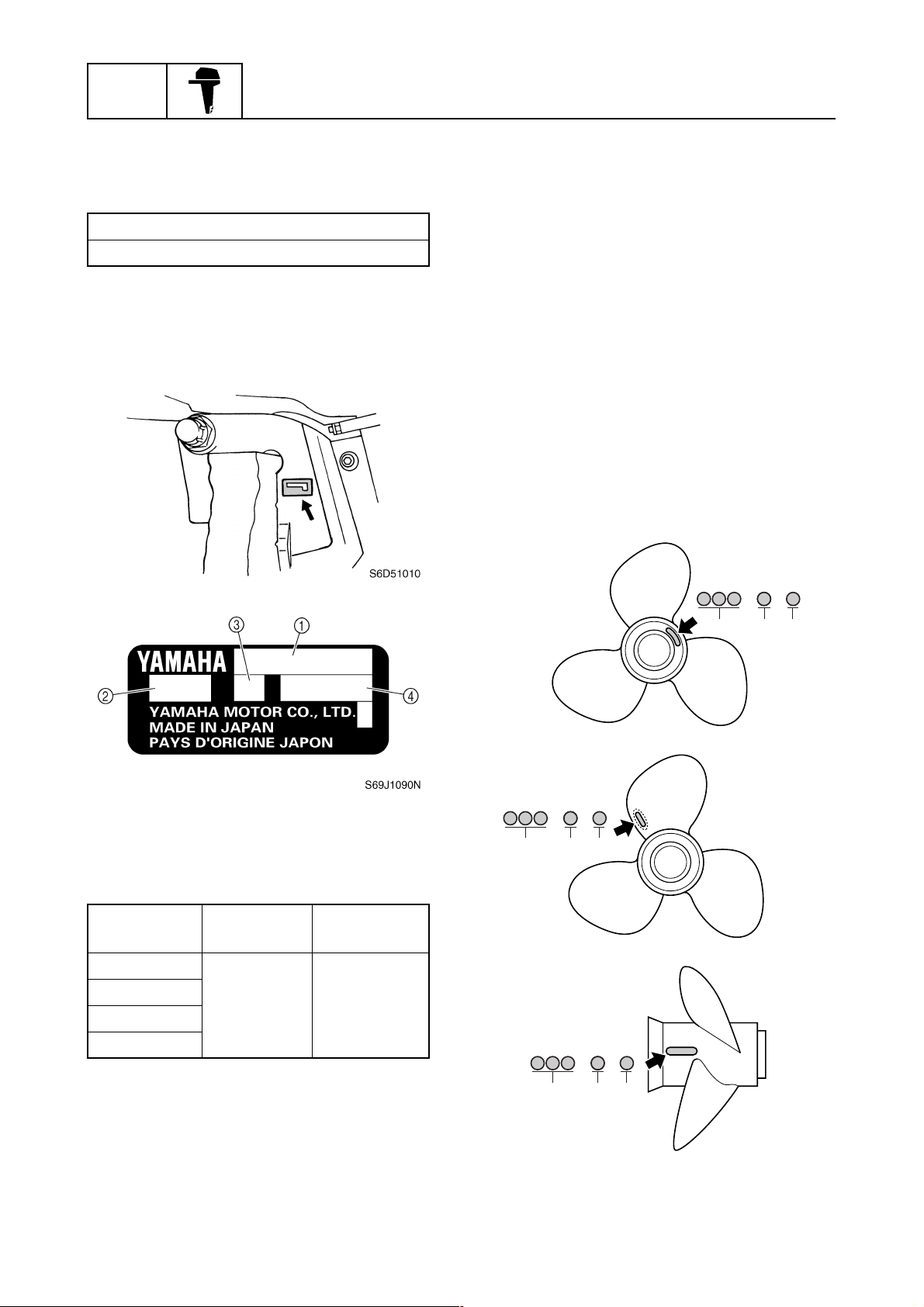

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

1

Propeller selection

1

The performance of a boat and outboard

motor will be critically affected by the size

and type of propeller you choose. Propellers

greatly affect boat speed, acceleration,

engine life, fuel economy, and even boating

and steering capabilities. An incorrect choice

could adversely affect performance and

could also seriously damage the engine.

Use the following information as a guide for

selecting a propeller that meets the operating

conditions of the boat and the outboard

motor.

Propeller size

The size of the propeller is indicated on a

propeller blade, on the propeller boss end, on

the side of the propeller boss.

Model name

1

Approved model code

2

Transom height

3

Serial number

4

Model name

40XWH

40XW

E40XMH

E40XW

Approved

model code

Starting

serial No.

66TK 1008141–

× —

a

bc

× —

× —

a

bc

S69W1030

S69W1040

1-5

a

bc

S69W1050

66T5F11

Identification / Propeller selection / Predelivery checks

Propeller diameter (in inches)

a

Propeller pitch (in inches)

b

Propeller type (propeller mark)

c

Selection

When the engine speed is at the full throttle

operating range (4,500–5,500 r/min), the

ideal propeller for the boat is one that provides maximum performance in relation to

boat speed and fuel consumption.

1

Propeller size (in) Material

10 1/4 × 14 — G

10 1/4 × 15 — G

10 1/4 × 16 — G

10 3/4 × 16 — G

10 3/4 × 17 — G

11 × 15 — G

11 1/8 × 13 — G

11 1/4 × 14 — G

Aluminum

11 3/8 × 12 — G

11 1/2 × 13 — G

11 5/8 × 11 — G

11 3/4 × 10 — G

11 3/4 × 12 — G

12 × 11 — G

12 1/4 × 8 — G

12 1/4 × 9 — G

CAUTION:

Use pre-mixed fuel only.

Fuel and oil mixing ratio is 50:1. For

break-in period, 25:1 mixture shall be

used.

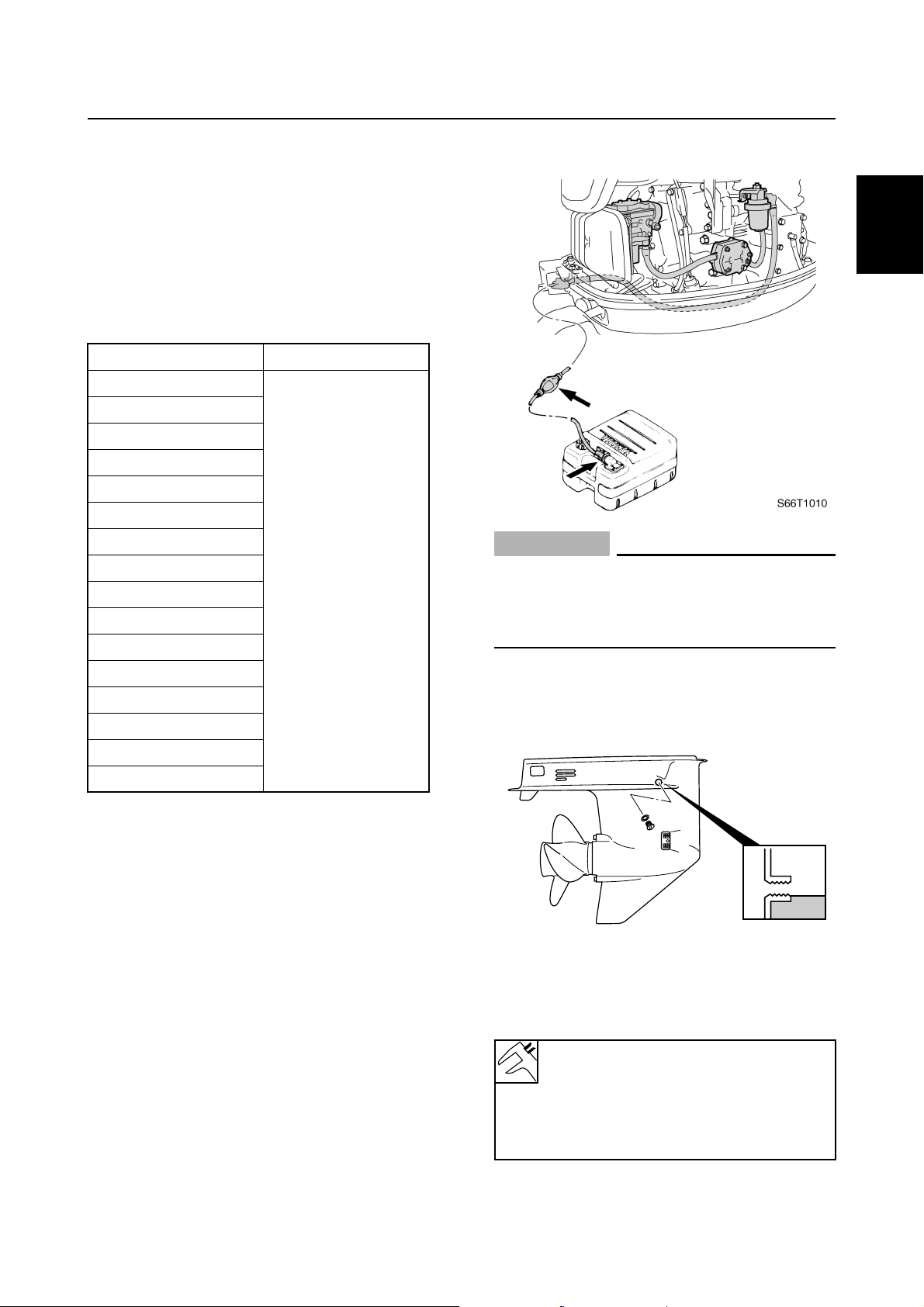

Checking the gear oil level

1. Check the gear oil level.

2

3

4

5

6

Predelivery checks

To make the delivery process smooth and

efficient, the predelivery checks should be

completed as explained below.

Checking the fuel system

1. Check that the fuel hoses are securely

connected and that the fuel tank is full

with fuel.

66T5F11

1

7

S60V1290

Checking the battery (WH, W)

1. Check the capacity, electrolyte level, and

specified gravity of the battery.

Recommended battery capacity:

CCA/EN: 430 A

20HR/IEC: 70 Ah

Electrolyte specified gravity:

1.280 at 20 °C (68 °F)

1-6

8

9

GEN

INFO

2. Check that the positive and negative battery leads are securely connected.

Checking the outboard motor

mounting height

1. Check that the anti-cavitation plate is

between the bottom of the boat and a

maximum of 25 mm (1 in) a below it. If

the mounting height is too high, cavitation will occur and propulsion will be

reduced. Also, the engine speed will

increase abnormally and cause the

engine to overheat. If the mounting

height is too low, water resistance will

increase and reduce engine efficiency.

General information

a

S6D51030

NOTE:

The optimum mounting height is affected by

the combination of the boat and the outboard

motor. To determine the optimum mounting

height, test run the outboard motor at different heights.

2. Check that the clamp brackets are

secured with the clamp screws.

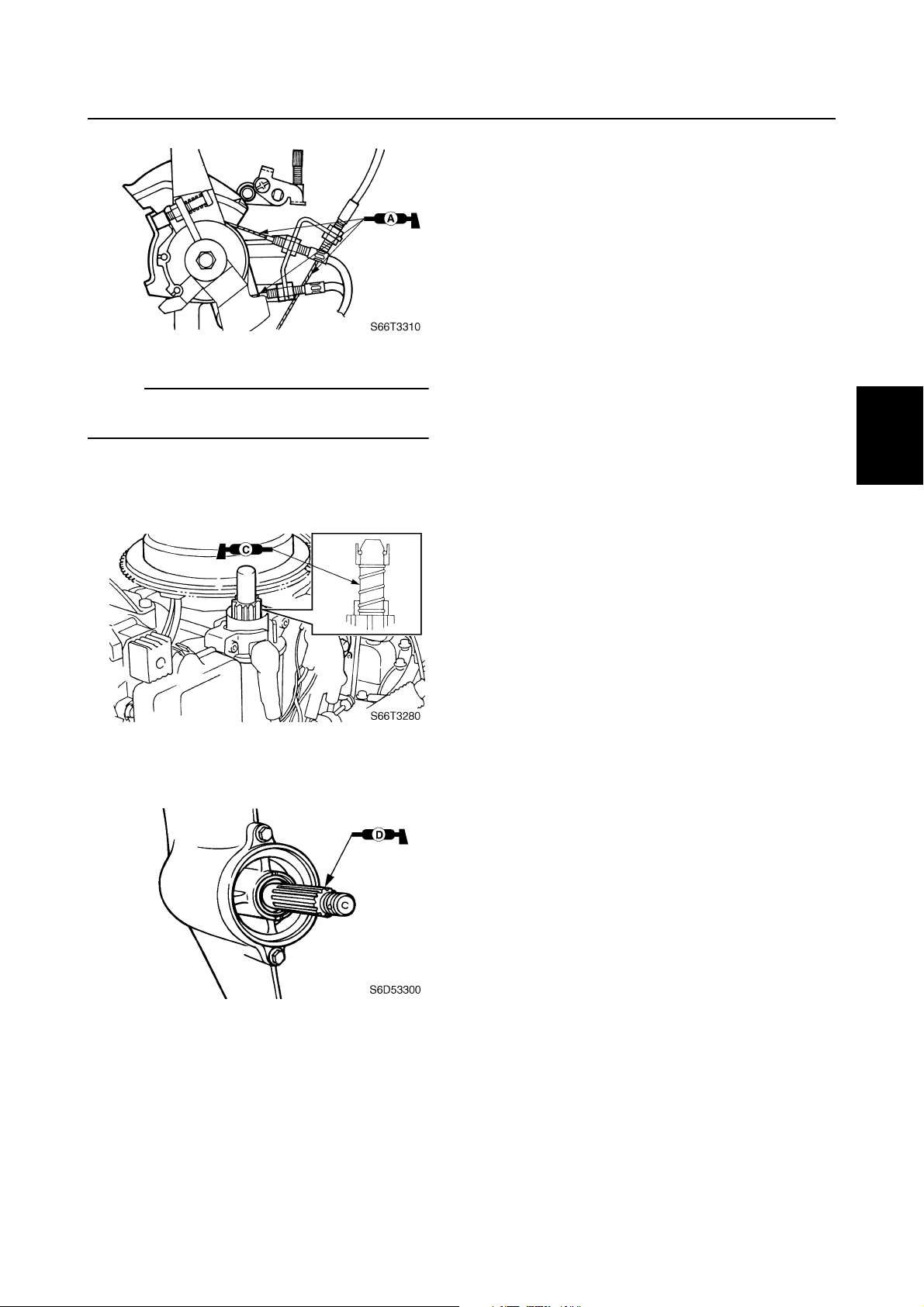

Checking the remote control cables

(remote control model)

1. Set the remote control lever to the neutral position and fully close the throttle

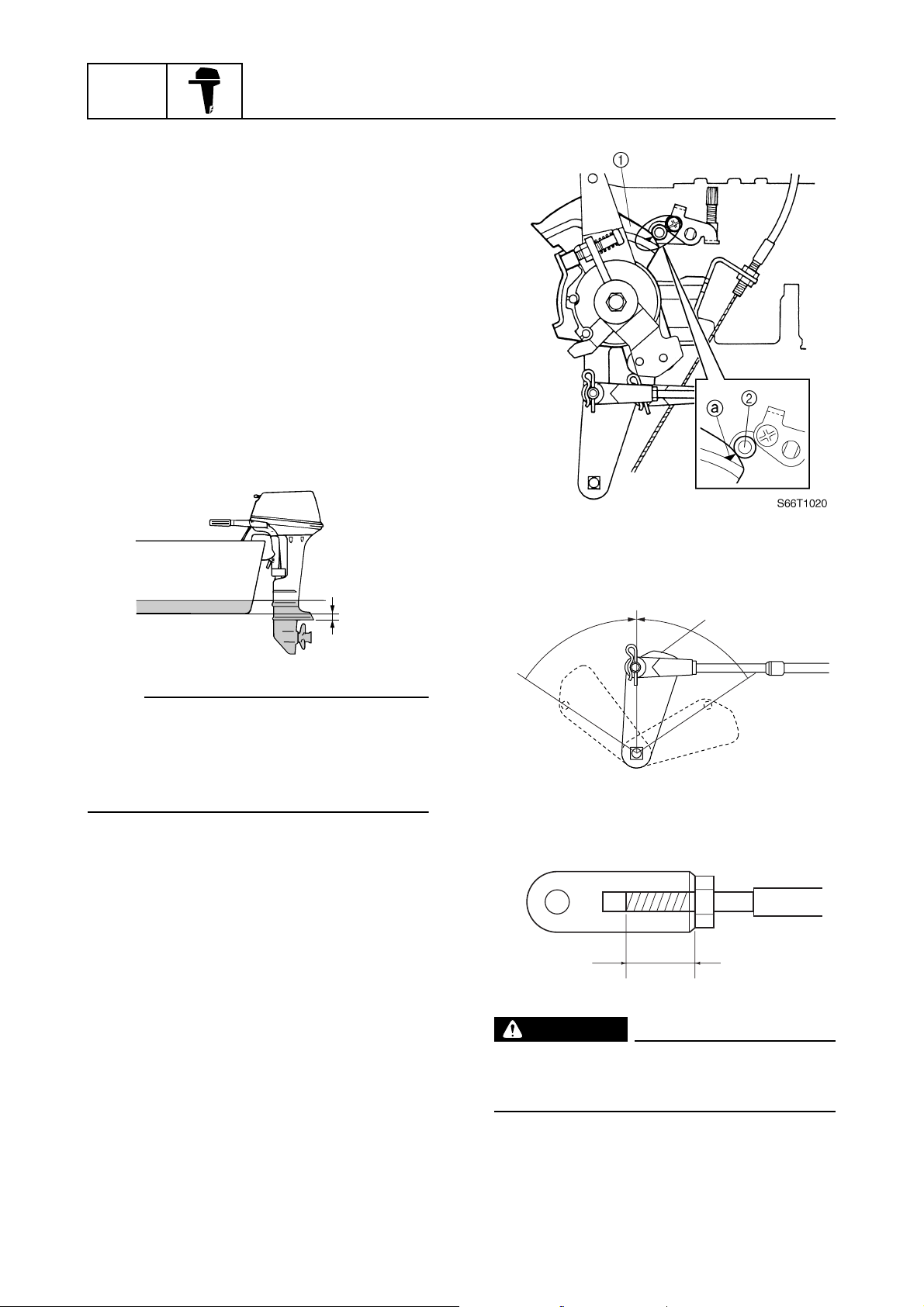

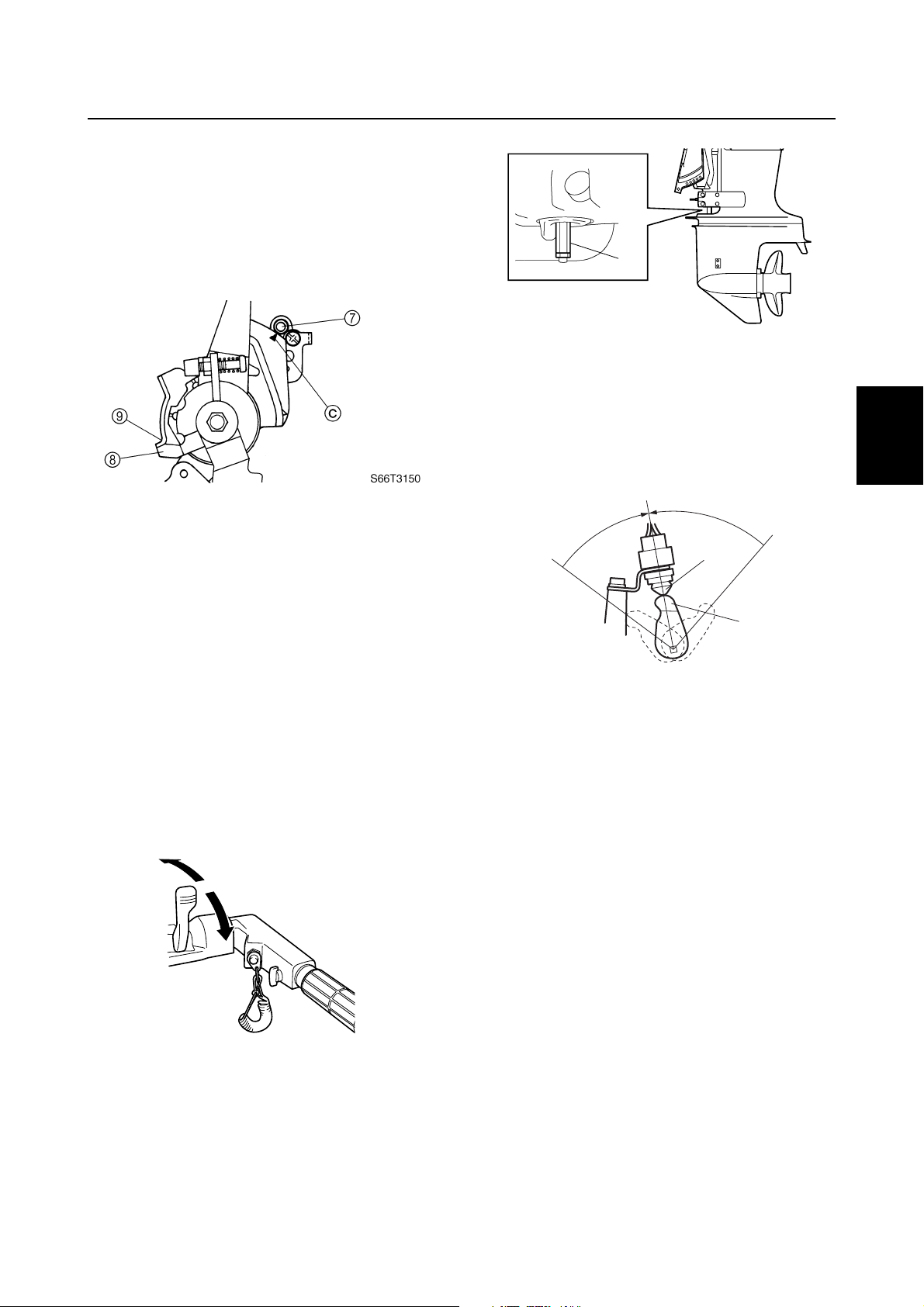

lever.

2. Check that the throttle cam 1 is in its

fully closed position and align the center

of the throttle cam roller 2 with the mark

a

on the throttle cam.

3. Check that the shift link lever 3 is in the

neutral position.

N

R

b

3

F

S66T1030

S66T1050

WARNING

The shift/throttle cable joint must be

screwed in a minimum of 8.0 mm (0.31 in)

b

.

1-7

66T5F11

Predelivery checks

Checking the steering system

1. Check the steering friction for proper

adjustment.

NOTE:

• To increase the friction, turn the friction

adjusting bolt in direction a.

• To decrease the friction, turn the friction

adjusting bolt in direction b.

2. Check that the steering operates

smoothly.

Checking the gear shift and throttle

operation

1. Check that the gear shift operates

smoothly when the remote control lever

or shift lever is shifted from neutral to forward or reverse.

2. Check that the throttle operates smoothly

when the throttle grip (tiller handle

model) is turned from the fully closed

position to the fully open position a.

Check that the throttle operates smoothly

when the remote control lever (remote

control model) is shifted from forward or

reverse to the fully open positions a.

R

N

F

0 100%

1

2

3

4

S66T1060

S66T1040

3. Check that there is no interference with

wires or hoses when the outboard motor

is steered.

a

S66T1070

a

5

N

F

R

a

S69J1210

6

7

8

9

66T5F11

1-8

GEN

INFO

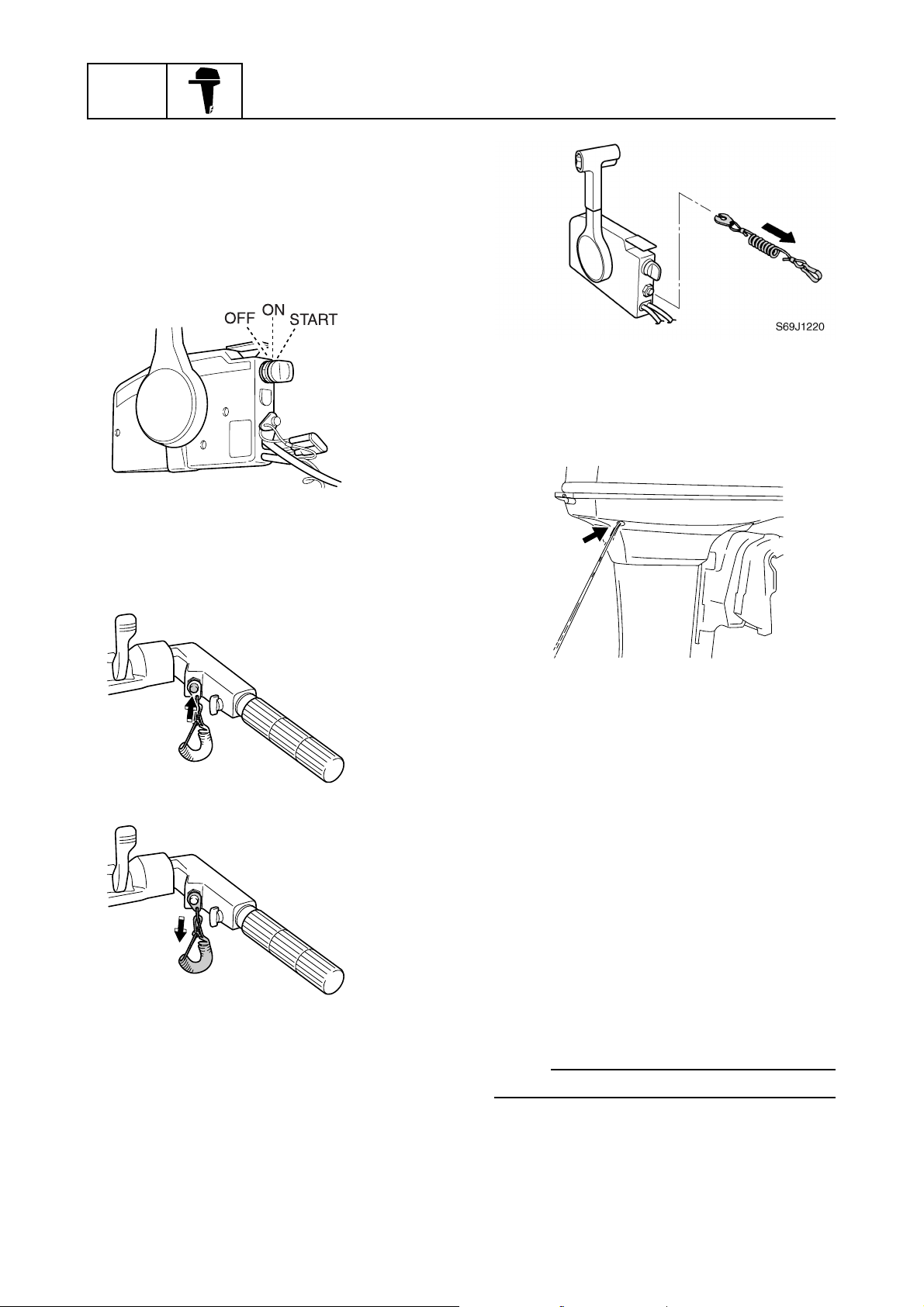

Checking the engine start switch and

engine stop lanyard switch

1. Check that the engine starts when the

engine start switch is turned to START.

2. Check that the engine turns off when the

engine start switch is turned to OFF.

3. Check that the engine turns off when the

engine stop lanyard switch is pushed or

the engine stop lanyard is pulled from the

engine stop lanyard switch.

General information

S60V1070

Checking the cooling water pilot

hole

1. Check that cooling water is discharged

from the cooling water pilot hole.

S66T1080

S66T1090

S66T3050

Test run

1. Start the engine, and then check that the

gear shift operates smoothly.

2. Check the engine idle speed after the

engine has been warmed up.

3. Operate at trolling speed.

4. Run the outboard motor for 1 hour at

3,000 r/min or at half throttle, then for

another hour at 4,000 r/min or at 3/4

throttle.

5. Check that the outboard motor does not

tilt up when shifting into reverse and that

water does not flow in over the transom.

NOTE:

The test run is part of the break-in operation.

1-9

66T5F11

Break-in

During the test run, perform the break-in

operation in the following four stages.

1. First 10 minutes a of operation at idle

Predelivery checks

2. Fifty minutes b at 3,000 r/min or less

3. One hour c at 4,000 r/min or less

4. Eight hours d at 5,000 r/min or less with

repeated wide-open-throttle operation for

5 minutes or less

cdaÈb

0

È

Hour

After test run

1. Check for water in the gear oil.

1

210

S60V1120

1

2

3

4

5

2. Check for fuel leakage in the cowling.

3. Flush the cooling water passage with

fresh water using the flushing kit and with

the engine running at idle.

6

7

8

9

66T5F11

1-10

GEN

INFO

General information

— MEMO —

1-11

66T5F11

SPEC

Specifications

General specifications………………………………………………………………………..2-1

Maintenance specification ………………………………………………………………….2-3

Power unit……………………………………………………………………………………..2-3

Lower unit ……………………………………………………………………………………..2-5

Electrical ……………………………………………………………………………………….2-5

Dimensions……………………………………………………………………………………2-7

Tightening torques……………………………………………………………………………..2-9

Specified torques……………………………………………………………………………2-9

General torques……………………………………………………………………………2-10

1

2

3

4

5

6

7

8

9

66T5F11

SPEC

Specifications

General specifications

Item Unit

40XWH 40XW E40XMH E40XW

Dimension

Overall length mm (in)

1,073 (42.2)

675 (26.6)

Overall width mm (in) 402 (15.8) 362 (14.3) 402 (15.8) 362 (14.3)

Overall height

(S) mm (in) — 1,237 (48.7) —

(L) mm (in)

1,364 (53.7)

(X) mm (in) —

Boat transom height

(S) mm (in) — 381 (15.0) —

(L) mm (in) 508 (20.0) — 508 (20.0)

(X) mm (in) — 635 (25.0) —

Weight

(with aluminum propeller)

(S) kg (lb) —

(L) kg (lb)

78.0 (172.0)

74.6 (164.5) 72.0 (158.8)

(X) kg (lb) —

Performance

Maximum output kW (hp) 29.4 (40) at 5,000 r/min

Full throttle operating range r/min 4,500–5,500

Maximum fuel consumption L (US gal,

20 (5.3, 4.4) at 5,500 r/min

Imp gal)/hr

Engine idle speed r/min 950–1,050

Power unit

Type 2-stroke

Cylinder quantity L2

Total displacement cm

3

(cu. in) 703 (42.9)

Bore × stroke mm (in) 80.0 × 70.0 (3.15 × 2.76)

Compression ratio 6.0

Intake system Reed valve

Scavenging system Loop charge

Control system Tiller

handle

Remote

control

Starting system Manual and electric Manual Manual and

Fuel system Carburetor

Ignition control system CDI

Maximum generator output V, A 12, 6.0 — 12, 6.0

Starting enrichment Choke valve

Spark plug B7HS (NGK), BR7HS (NGK)

Cooling system Water

Exhaust system Propeller boss

Lubrication system Pre-mixed fuel

Model

1,073 (42.2)

675 (26.6)

— 1,364 (53.7)

1,476 (58.1)

—

73.6 (162.3) 76.2 (168.0)

76.7 (169.1)

Tiller

handle

Remote

control

electric

2

—

—

—

2-1

66T5F11

General specifications

Item Unit

Fuel and oil

Fuel type Regular gasoline

Engine oil 2-stroke outboard motor oil

Engine oil grade

Fuel and oil mixing ratio 50:1

Gear oil type Hypoid gear oil

Gear oil grade

Gear oil quantity cm

Bracket unit

Tilt angle Degree 8, 12, 16, 20, 24

(at 12° boat transom)

Tilt-up angle Degree 68

Steering angle Degree 45 + 45

Drive unit

Gear shift positions F-N-R

Gear ratio 2.00 (26/13)

Reduction gear type Spiral bevel gear

Clutch type Dog clutch

Propeller shaft type Spline

Propeller direction (rear view) Clockwise

Propeller mark G

Electrical

Battery minimum capacity

CCA/EN A 430 — 430

20HR/IEC Ah 70 — 70

(*1)

Meeting both API and SAE requirements

(*2)

CCA: Cold Cranking Ampere

EN: European Norm (European standard)

IEC: International Electrotechnical Commission

(*1)

API

(*2)

NMMA-certified

SAE

3

Imp oz)

(US oz,

40XWH 40XW E40XMH E40XW

430 (14.54, 15.17)

Model

TC-W3

GL-4

90

1

2

3

4

5

6

7

66T5F11

8

9

2-2

SPEC

Specifications

Maintenance specification

Power unit

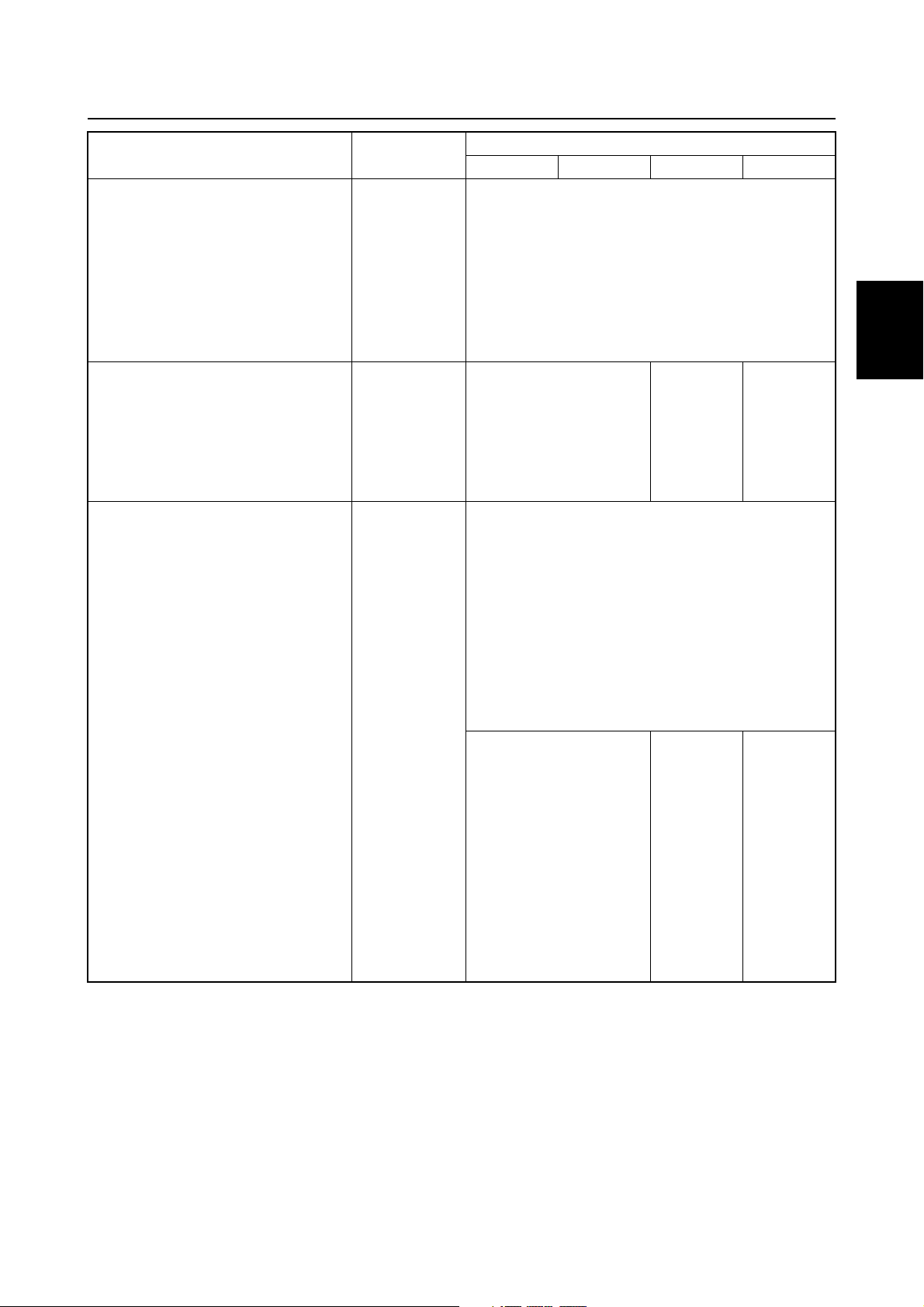

Item Unit

40XWH 40XW E40XMH E40XW

Power unit

Minimum compression

pressure

(*1)

kPa

(kgf/cm2, psi)

Cylinder heads

Warpage limit

mm (in) 0.1 (0.0039)

(lines indicate straightedge

position)

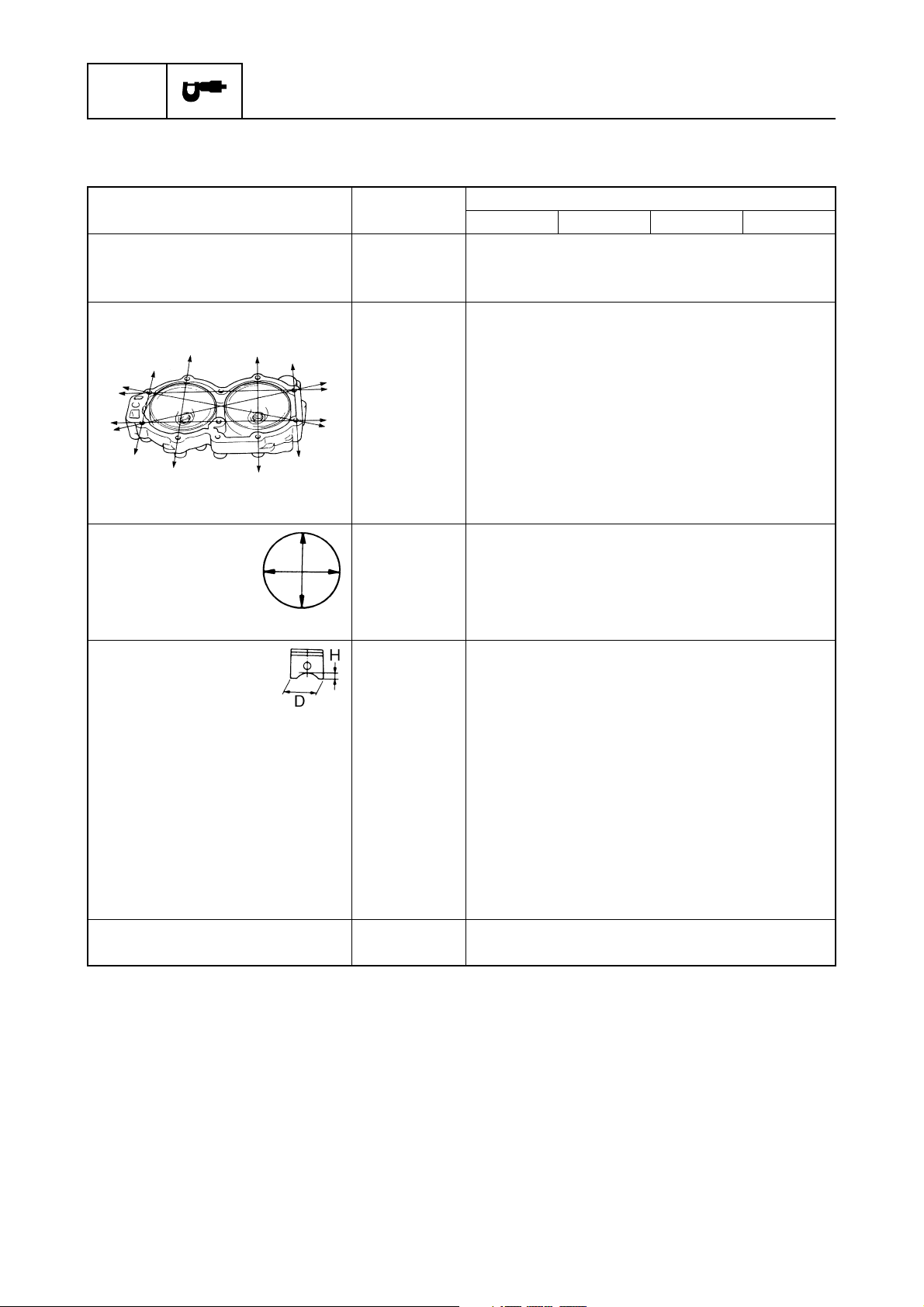

Cylinders

Bore size mm (in) 80.000–80.020 (3.1496–3.1504)

Bore size limit mm (in) 80.100 (3.1535)

Taper limit mm (in) 0.08 (0.0032)

Out-of-round limit mm (in) 0.05 (0.0020)

Pistons

Piston diameter (D) mm (in) 79.910–79.934 (3.1461–3.1470)

Measuring point (H) mm (in) 10 (0.39)

Piston-to-cylinder clearance mm (in) 0.085–0.090 (0.0033–0.0035)

(Limit) mm (in) 0.14 (0.0055)

Piston pin boss bore mm (in) 19.904–19.915 (0.7836–0.7841)

Oversize piston

1st mm (in) 0.25 (0.010)

2nd mm (in) 0.50 (0.020)

Oversize piston diameter

1st mm (in) 80.160–80.184 (3.1559–3.1568)

2nd mm (in) 80.410–80.434 (3.1657–3.1667)

Piston pins

Outside diameter mm (in) 19.895–19.900 (0.7833–0.7835)

(*1)

Measure conditions:

Ambient temperature 20 °C (68 °F), wide open throttle, with spark plugs removed from all cylinders.

The figures are for reference only.

Model

630 (6.3, 91)

2

2-3

66T5F11

Maintenance specification

Item Unit

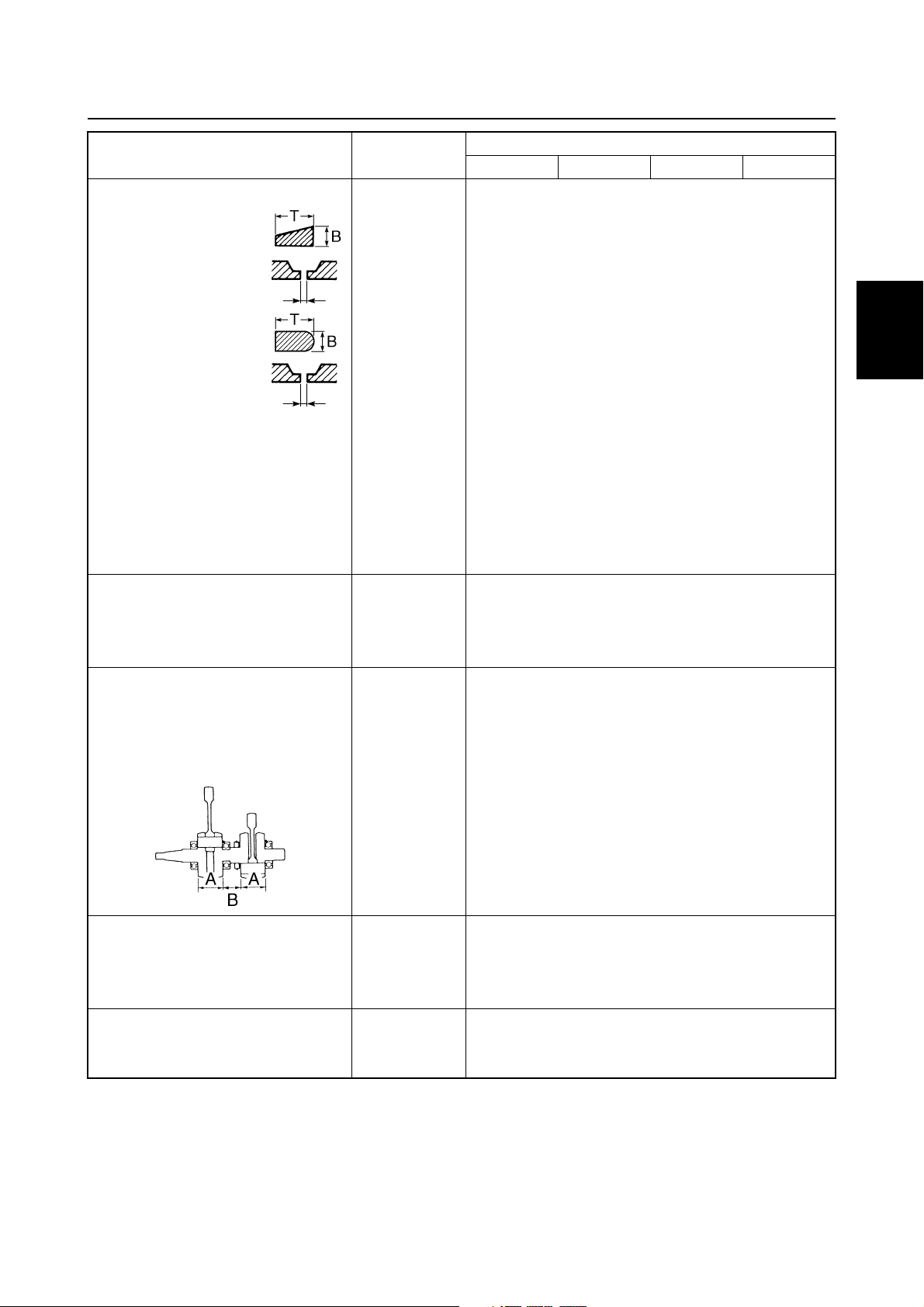

Piston rings

Top ring

Dimension B mm (in) 1.97–1.99 (0.0776–0.0783)

Dimension T mm (in) 2.40–2.60 (0.0945–0.1024)

End gap mm (in) 0.30–0.50 (0.0118–0.0197)

Side clearance mm (in) 0.04–0.08 (0.0015–0.0031)

Oversize diameter

1st mm (in) 80.250 (3.1594)

2nd mm (in) 80.500 (3.1693)

2nd piston ring

Dimension B mm (in) 1.97–1.99 (0.0776–0.0783)

Dimension T mm (in) 2.40–2.60 (0.0945–0.1024)

End gap mm (in) 0.30–0.50 (0.0118–0.0197)

Side clearance mm (in) 0.03–0.07 (0.0012–0.0028)

Oversize diameter

1st mm (in) 80.250 (3.1594)

2nd mm (in) 80.500 (3.1693)

Connecting rods

Small-end inside diameter mm (in) 24.900–24.912 (0.9803–0.9808)

Big-end side clearance mm (in) 0.200–0.700 (0.0079–0.0276)

Small-end axial play limit mm (in) 2.0 (0.08)

Crankshaft

Crankshaft width A mm (in) 63.90–63.95 (2.5157–2.5177)

Crankshaft width B mm (in) 40.88–41.10 (1.6094–1.6181)

Crankpin diameter mm (in) 26.995–27.000 (1.0628–1.0630)

Runout limit mm (in) 0.03 (0.0012)

40XWH 40XW E40XMH E40XW

Model

1

2

3

4

5

6

Thermostats

Opening temperature °C (°F) 48–52 (118–126)

Fully open temperature °C (°F) 60 (140)

Valve open lower limit mm (in) 3.0 (0.12)

Reed valves

Valve stopper height limit mm (in) 10.2–10.4 (0.40–0.41)

Valve bending limit mm (in) 0.2 (0.008)

66T5F11

7

8

9

2-4

SPEC

Specifications

Item Unit

Carburetor

ID mark 66T02 66T12 66T02 66T12

Main jet # 170

Main air jet # 160

Pilot jet # 70

Pilot air jet # 60

Pilot screw turns out 1 3/8–1 7/8

Float height mm (in) 16.5–18.5 (0.65–0.73)

40XWH 40XW E40XMH E40XW

Model

Lower unit

Item Unit

Gear backlash

Pinion-to-forward gear mm (in) 0.19–0.56 (0.0075–0.0220)

Pinion-to-reverse gear mm (in) 0.75–1.13 (0.0295–0.0445)

Pinion shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Forward gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

Reverse gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50

40XWH 40XW E40XMH E40XW

Model

Electrical

Item Unit

Ignition and ignition control

system

Ignition timing (cylinder #1) Degree

Degree

Spark plug gap mm (in) 0.6–0.7 (0.024–0.028)

Spark plug cap resistance

(with resister type)

Ignition coil resistance

Primary coil (B/W – B)

at 20 °C (68 °F)

Secondary coil

(B/W – spark plug wire)

at 20 °C (68 °F) kΩ 5.4–7.4

CDI unit output peak voltage

(B/O – B, B/W – B)

at cranking (loaded) V 180

at 1,500 r/min (loaded) V 180

at 3,500 r/min (loaded) V 170

kΩ 4.0–6.0

Ω

0.32–0.44

40XWH 40XW E40XMH E40XW

ATDC2 at engine idle speed

BTDC23 at 5,000 r/min

Model

2-5

66T5F11

Maintenance specification

Item Unit

Pulser coil output peak voltage

(W/R – W/B)

at cranking (unloaded) V 7.0

at cranking (loaded) V 4.0

at 1,500 r/min (loaded) V 10.0

at 3,500 r/min (loaded) V 17.0

Pulser coil resistance

Starter motor

Type Bendix — Bendix

Brushes

Length limit mm (in) 6.4 (0.25) — 6.4 (0.25)

Armature

Commutator undercut limit mm (in) 0.8 (0.03) — 0.8 (0.03)

Charging system

Fuse A 10

Charge coil output peak

voltage (Positive side: Br –

Negative side: L)

at cranking (unloaded) V 330

at cranking (loaded) V 190

at 1,500 r/min (loaded) V 190

at 3,500 r/min (loaded) V 190

Charge coil resistance (Br – L)

Lighting coil output peak

voltage

Lighting coil resistance

Rectifier output peak voltage

(*1)

The figures are for reference only.

(*1)

(G – G)

at cranking (unloaded) V 6.0 — 6.0

at 1,500 r/min (unloaded) V 16.0 — 16.0

at 3,500 r/min (unloaded) V 33.0 — 33.0

at 1,500 r/min (unloaded) V 14.0 — 14.0

at 3,500 r/min (unloaded) V 32.0 — 32.0

(*1)

(W/R – W/B)

(*1)

(G – G)

(R – B)

Ω

311.4–380.6

Ω

684–836

Ω

0.31–0.37 — 0.31–0.37

40XWH 40XW E40XMH E40XW

Model

1

2

3

4

5

6

7

8

66T5F11

9

2-6

SPEC

Specifications

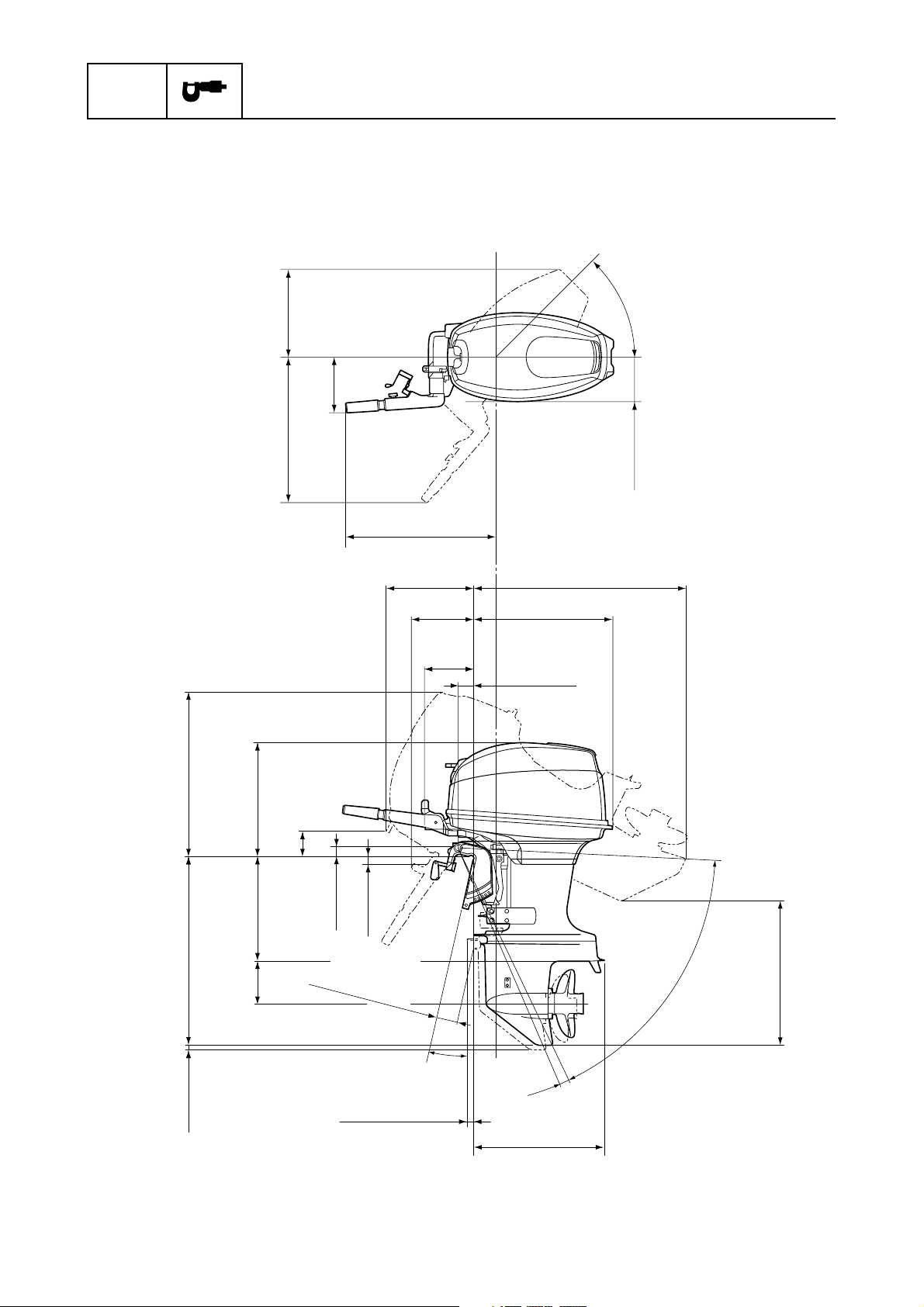

Dimensions

Exterior

* Tiller handle model only

mm (in)

45˚

221 (8.7)*

702 (27.6)

592 (23.3)* 369 (14.5)

159 (6.3)

523 (20.6)*

397 (15.6)

294 (11.6)*

118 (4.7)

190 (7.5)*

182 (7.2)

S: 826 (32.5)

L: 940 (37.0)

X:1,043 (41.1)

553 (21.8)

65 (2.6)

2-7

S: 424 (16.7)

X: 1,007 (39.7)

S: 767 (30.2)

L: 893 (35.2)

S: 25 (1.0)

L: 24 (0.9)

X: 24 (0.9)

L: 550 (21.7)

X: 664 (26.1)

175 (6.9) 471 (18.5)

43 (1.7)

38 (1.5)*

S: 65 (2.6)

L: 91 (3.6)

X: 91 (3.6)

S: 3 (0.1)

L: 8 (0.3)

X:16 (0.6)

12

˚

˚

4

522 (20.6)

64

˚

S: 626 (24.7)

L: 697 (27.4)

X: 761 (30.0)

S66T2010

66T5F11

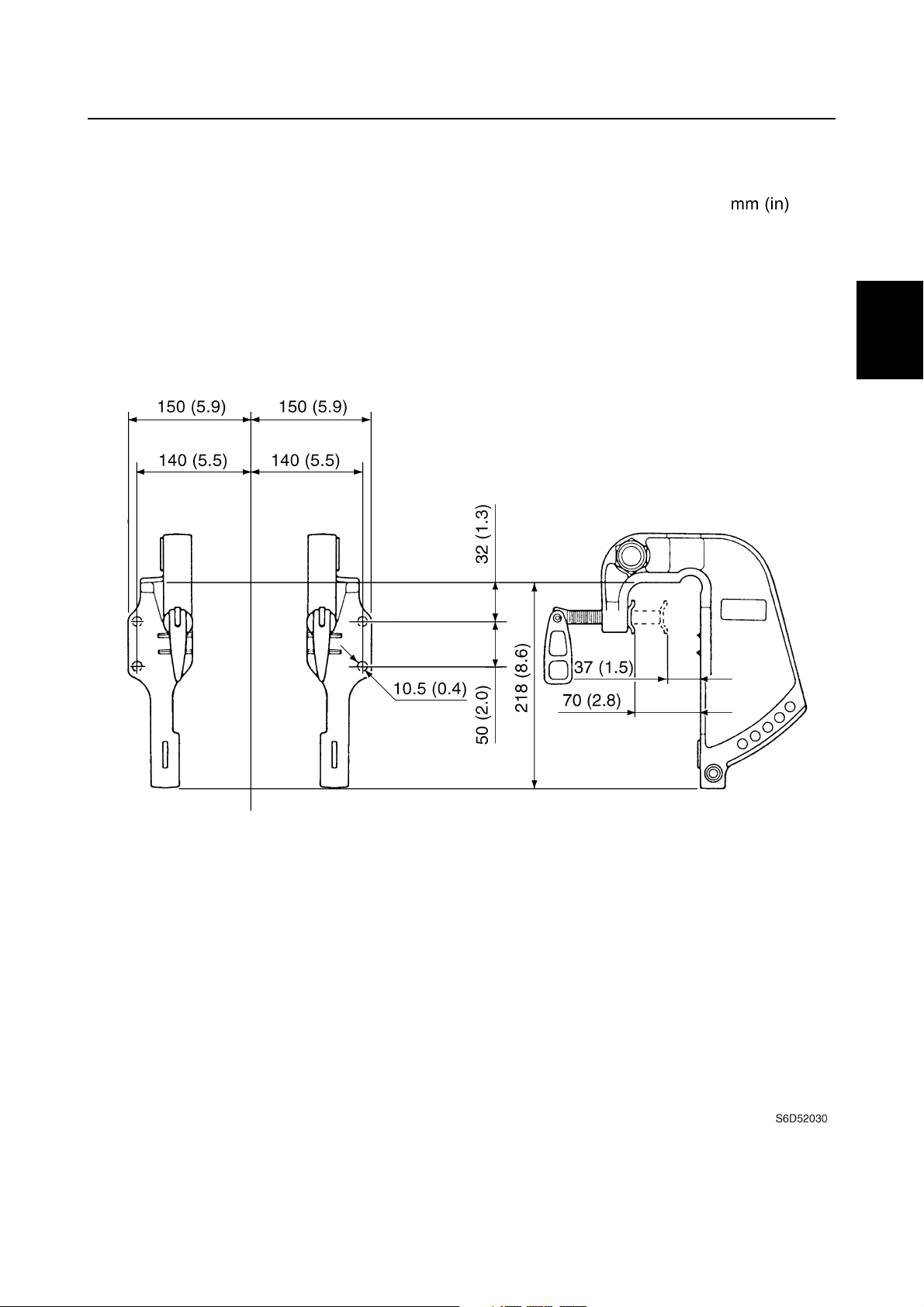

Clamp bracket

Maintenance specification

1

2

3

4

5

6

7

8

66T5F11

9

2-8

SPEC

Specifications

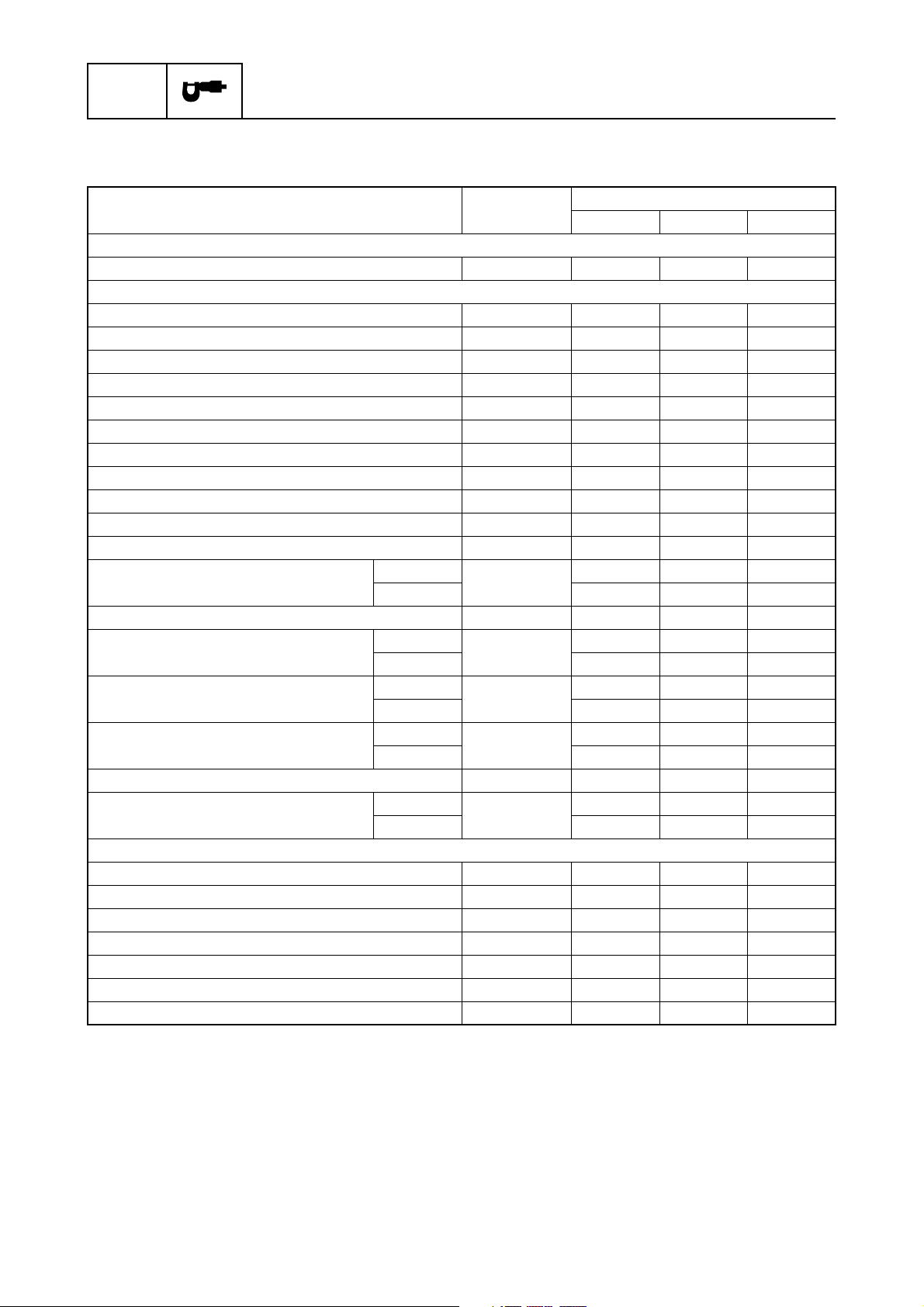

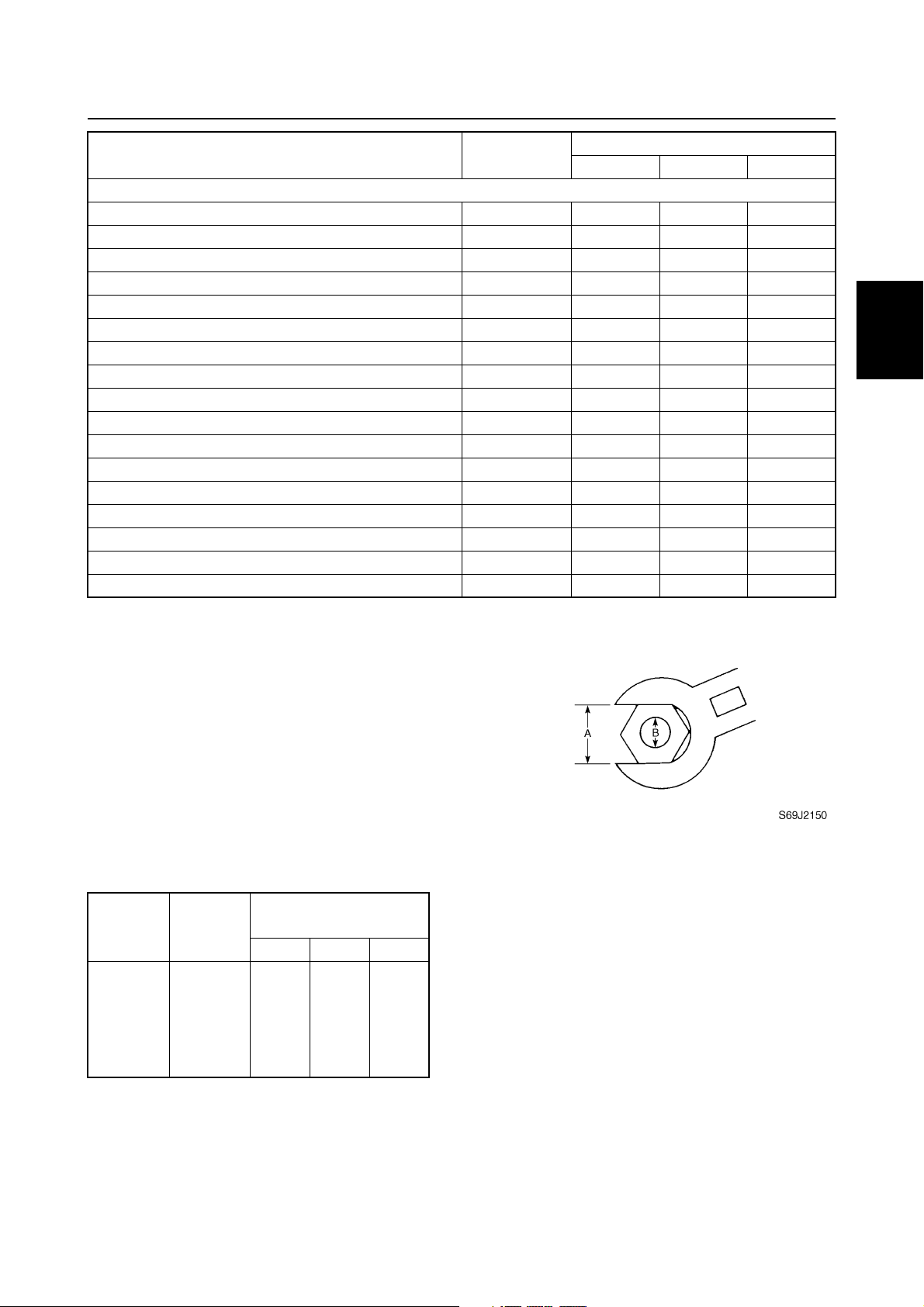

Tightening torques

2

Specified torques

Part to be tightened Thread size

Fuel system

Intake silencer screw M6 2 0.2 1.5

Power unit

Power unit mounting bolt M8 21 2.1 15.5

Engine start button nut M16 5 0.5 3.7

Starter rope guide bolt M6 8 0.8 5.9

Manual starter roller bolt M6 3 0.3 2.2

Sheave drum bolt M6 5 0.5 3.7

Flywheel magnet nut M20 157 15.7 115.8

Starter motor bolt M8 21 2.1 15.5

Starter motor terminal nut M8 7 0.7 5.2

Starter relay terminal nut M6 4 0.4 3.0

Ignition coil bolt M6 8 0.8 5.9

Rectifier screw M5 3 0.3 2.2

Intake manifold bolt

1st

2nd 12 1.2 8.9

M6

Reed valve screw M5 2 0.2 1.5

Cylinder head bolt

Cylinder head cover bolt

Exhaust cover bolt

1st

2nd 30 3.0 22.1

1st

2nd 12 1.2 8.9

1st

2nd 12 1.2 8.9

M8

M6

M6

Spark plug — 25 2.5 18.4

Crankcase bolt

1st

2nd 40 4.0 29.5

M10

Lower unit

Gear oil drain screw — 90.96.6

Gear oil check screw — 90.96.6

Lower case mounting bolt M10 40 4.0 29.5

Cooling water inlet cover screw M5 4 0.4 3.0

Propeller nut M16 40 4.0 29.5

Propeller shaft housing bolt M8 16 1.6 11.8

Pinion nut M12 74 7.4 54.6

Tightening torques

N·mkgf·mft·lb

60.64.4

15 1.5 11.1

60.64.4

60.64.4

20 2.0 14.8

2-9

66T5F11

Tightening torques

Part to be tightened Thread size

Bracket unit

Tiller handle bracket nut M10 10 1.0 7.4

Self-locking nut M10 41 4.1 30.2

Engine stop lanyard switch nut — 20.21.5

Battery lead holder screw M6 2 0.2 1.5

Throttle grip screw M5 3 0.3 2.2

Neutral switch nut — 70.75.2

Upper mounting nut M8 24 2.4 17.7

Upper mount bolt M8 27 2.7 20.0

Mount housing nut M10 54 5.4 39.8

Steering friction adjusting bolt M8 4 0.4 3.0

Upper case bolt M8 21 2.1 15.5

Exhaust manifold bolt M8 21 2.1 15.5

Self-locking nut M22 45 4.5 33.2

Tilt stopper plate nut M8 24 2.4 17.7

Grease nipple — 30.32.2

Clamp bracket nut M8 18 1.8 13.3

Tilt lever screw M5 4 0.4 3.0

Tightening torques

N·mkgf·mft·lb

1

2

3

4

General torques

This chart specifies tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifications

for special components or assemblies are

provided in applicable sections of this manual. To avoid warpage, tighten multi-fastener

assemblies in a crisscross fashion and progressive stages until the specified torque is

reached. Unless otherwise specified, torque

specifications require clean, dry threads.

Components should be at room temperature.

General torque

Nut (A) Bolt (B)

8 mm M5 5 0.5 3.6

10 mm M6 8 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 25

17 mm M12 43 4.3 31

specifications

N·mkgf·mft·lb

5

6

7

8

9

66T5F11

2-10

SPEC

Specifications

— MEMO —

2-11

66T5F11

CHK

ADJ

Periodic checks and adjustments

Special service tools ………………………………………………………………………….3-1

Maintenance interval chart………………………………………………………………….3-2

Top cowling ……………………………………………………………………………………….3-3

Checking the top cowling…………………………………………………………………3-3

Fuel system ……………………………………………………………………………………….3-3

Checking the fuel joint and fuel hoses (fuel joint-to-carburetor) …………….3-3

Checking the fuel filter …………………………………………………………………….3-3

Power unit………………………………………………………………………………………….3-3

Checking the spark plugs ………………………………………………………………..3-3

Checking the thermostat………………………………………………………………….3-4

Adjusting the start-in-gear protection…………………………………………………3-4

Checking the cooling water passage…………………………………………………3-5

Control system…………………………………………………………………………………..3-5

Adjusting the ignition timing……………………………………………………………..3-5

Adjusting the throttle cables (MH, WH) ……………………………………………..3-6

Adjusting the throttle cable (W) ………………………………………………………..3-7

Checking the gear shift operation (MH, WH)………………………………………3-8

Checking the gear shift operation (W) ……………………………………………….3-8

Checking the engine idle speed ……………………………………………………….3-9

Checking the ignition timing……………………………………………………………3-10

1

2

3

4

5

Bracket…………………………………………………………………………………………….3-10

Checking the tilt operation ……………………………………………………………..3-10

Lower unit………………………………………………………………………………………..3-11

Checking the gear oil level …………………………………………………………….3-11

Changing the gear oil ……………………………………………………………………3-11

Checking the lower unit for air leakage ……………………………………………3-12

Checking the propeller…………………………………………………………………..3-12

General…………………………………………………………………………………………….3-12

Checking the anodes…………………………………………………………………….3-12

Checking the battery……………………………………………………………………..3-12

Lubricating the outboard motor……………………………………………………….3-13

6

7

8

9

66T5F11

CHK

ADJ

Periodic checks and adjustments

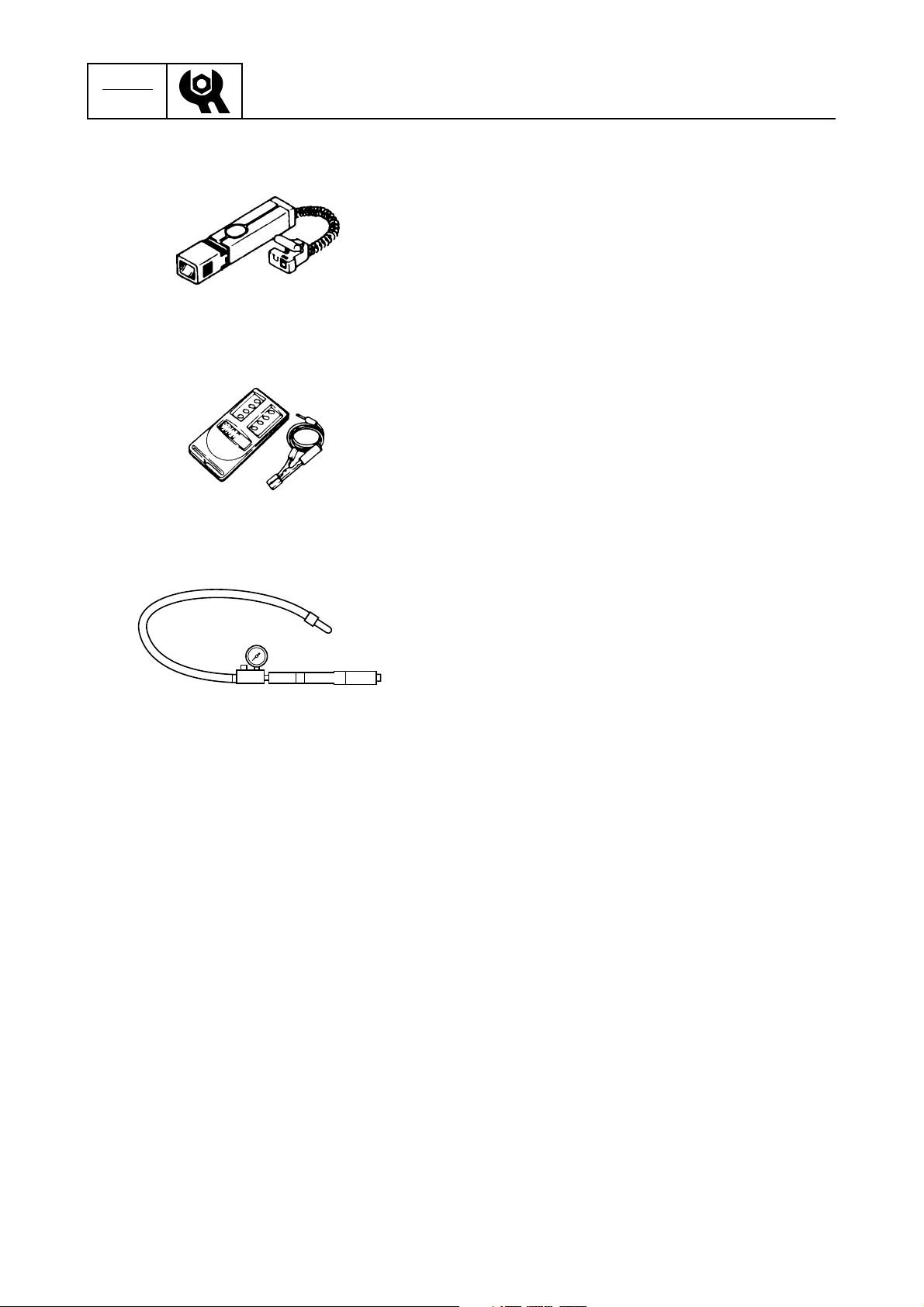

Special service tools

Timing light

90890-03141

Digital tachometer

90890-06760

3

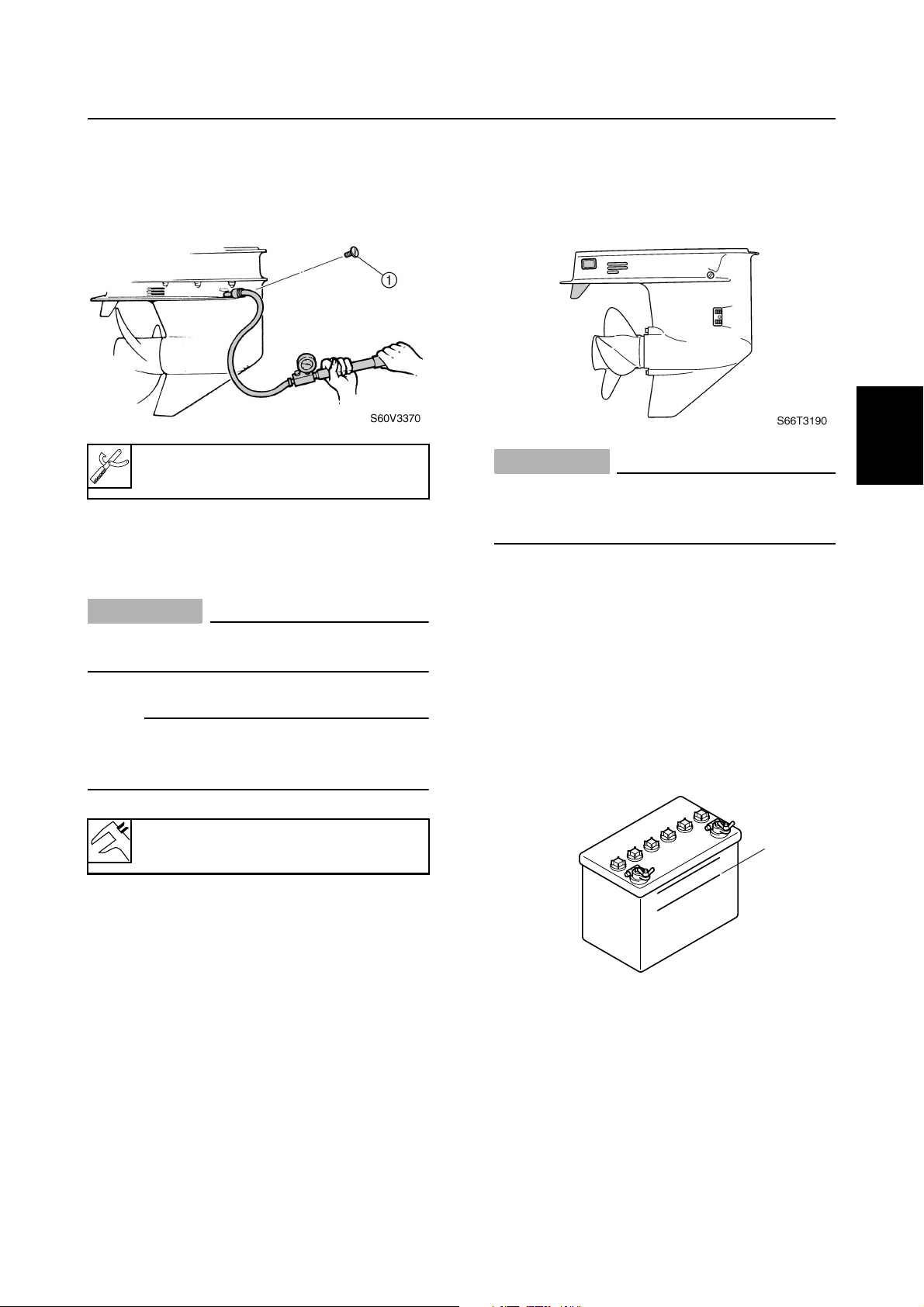

Leakage tester

90890-06840

3-1

66T5F11

Special service tools / Maintenance interval chart

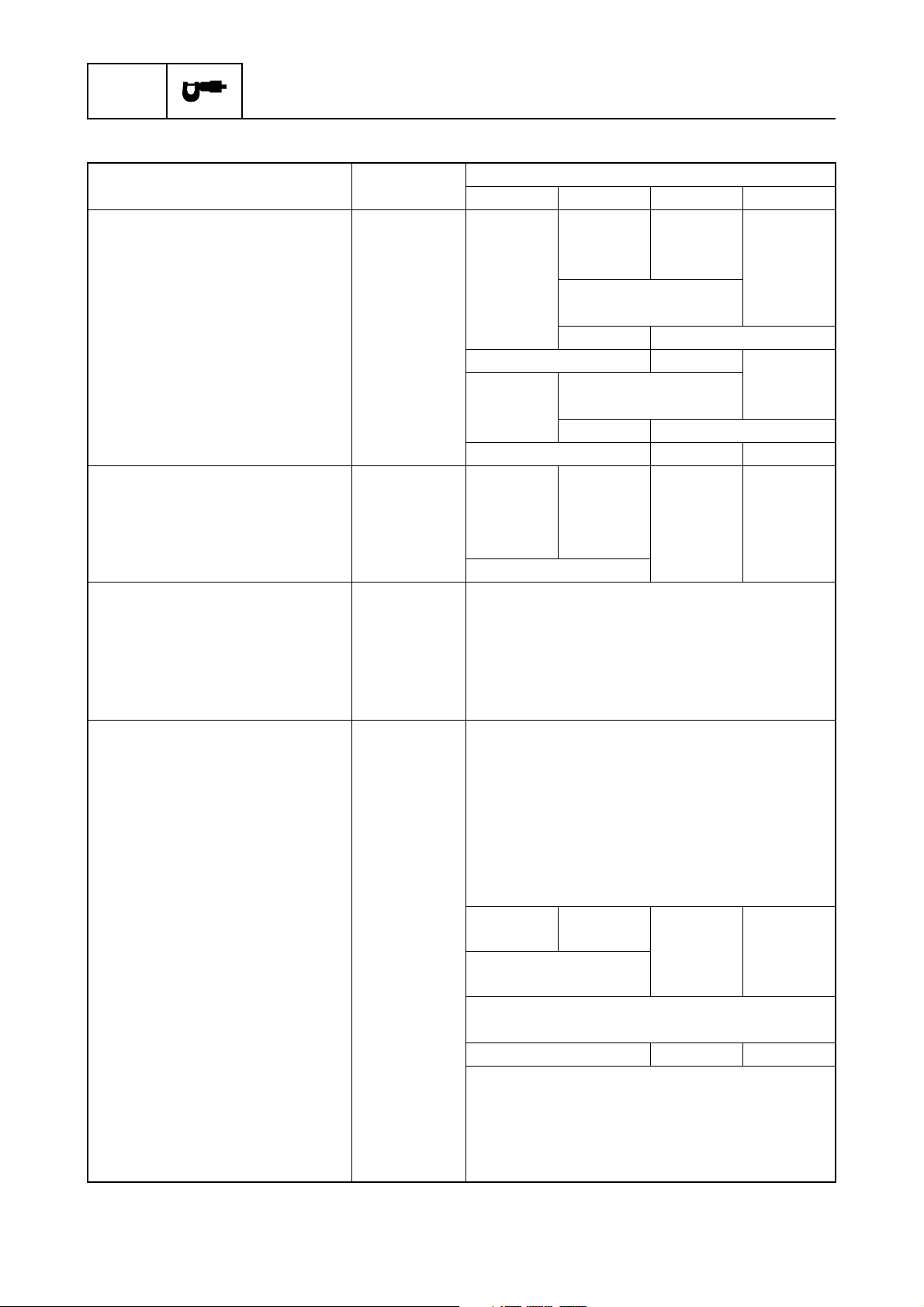

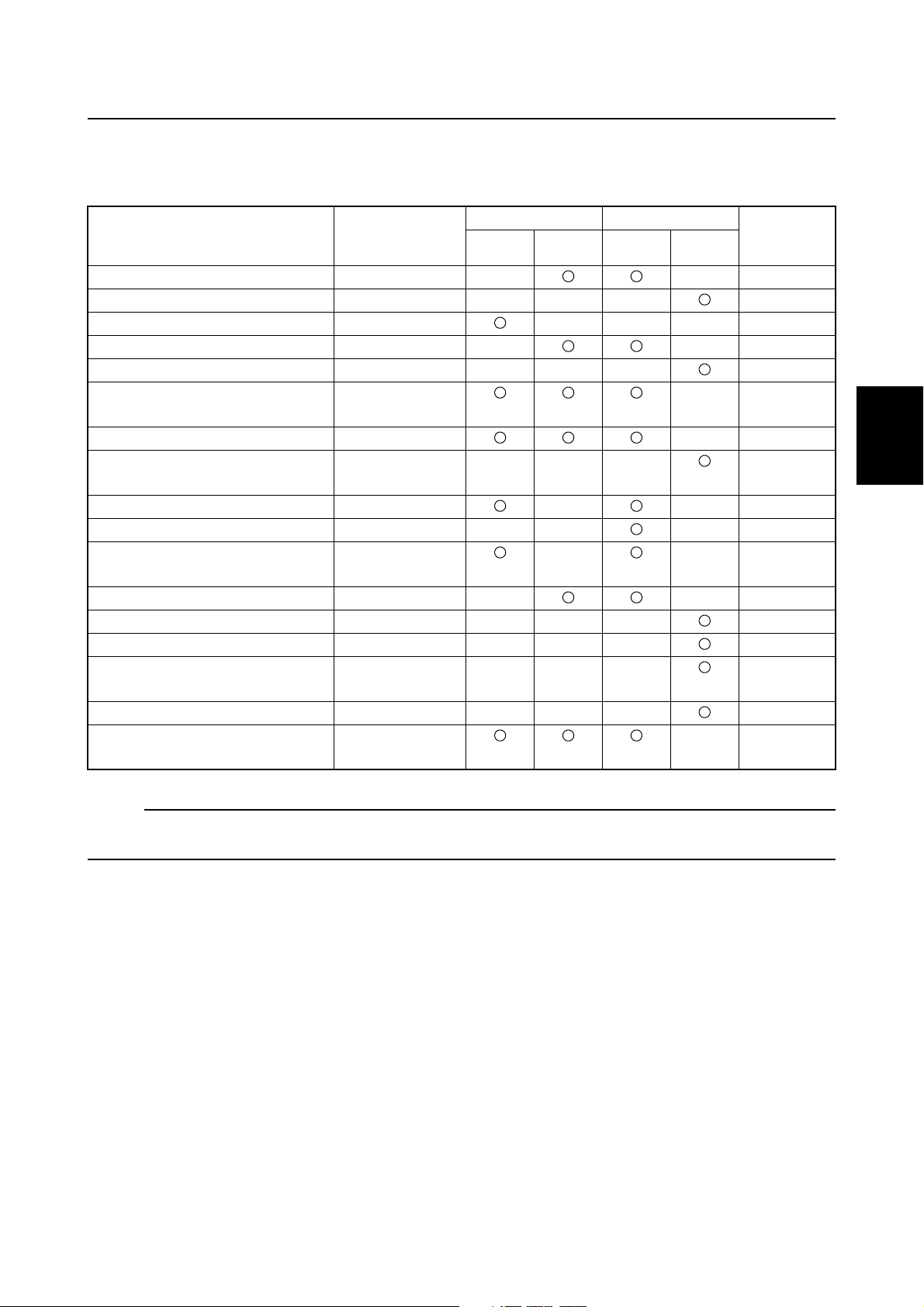

Maintenance interval chart

Use the following chart as a guideline for general maintenance.

Adjust the maintenance intervals according to the operating conditions of the outboard motor.

Item Remarks

Anodes (external) Check/replace

Anodes (internal) Check/replace

Battery Check/charge

Cooling water passages Clean

Top cowling Check

Fuel filter

(can be disassembled)

Fuel system Check

Fuel tank

(Yamaha portable tank)

Gear oil Change

Lubrication points Lubricate

Engine idle speed

(carburetor models)

Propeller and cotter pin Check/replace

Shift link/shift cable Check/adjust

Thermostat Check

Throttle link/throttle cable/

throttle pick-up timing

Water pump Check

Spark plugs Clean/adjust/

Check/replace

Check/clean

Check/adjust

Check/adjust

replace

Initial Every

10 hours

(1 month)

50 hours

(3 months)

100 hours

(6 months)

200 hours

(1 year)

Refer to

page

3

1

2

3

4

5

6

NOTE:

When operating in salt water, turbid or muddy water, the engine should be flushed with clean water

after each use.

66T5F11

3-2

7

8

9

CHK

ADJ

Periodic checks and adjustments

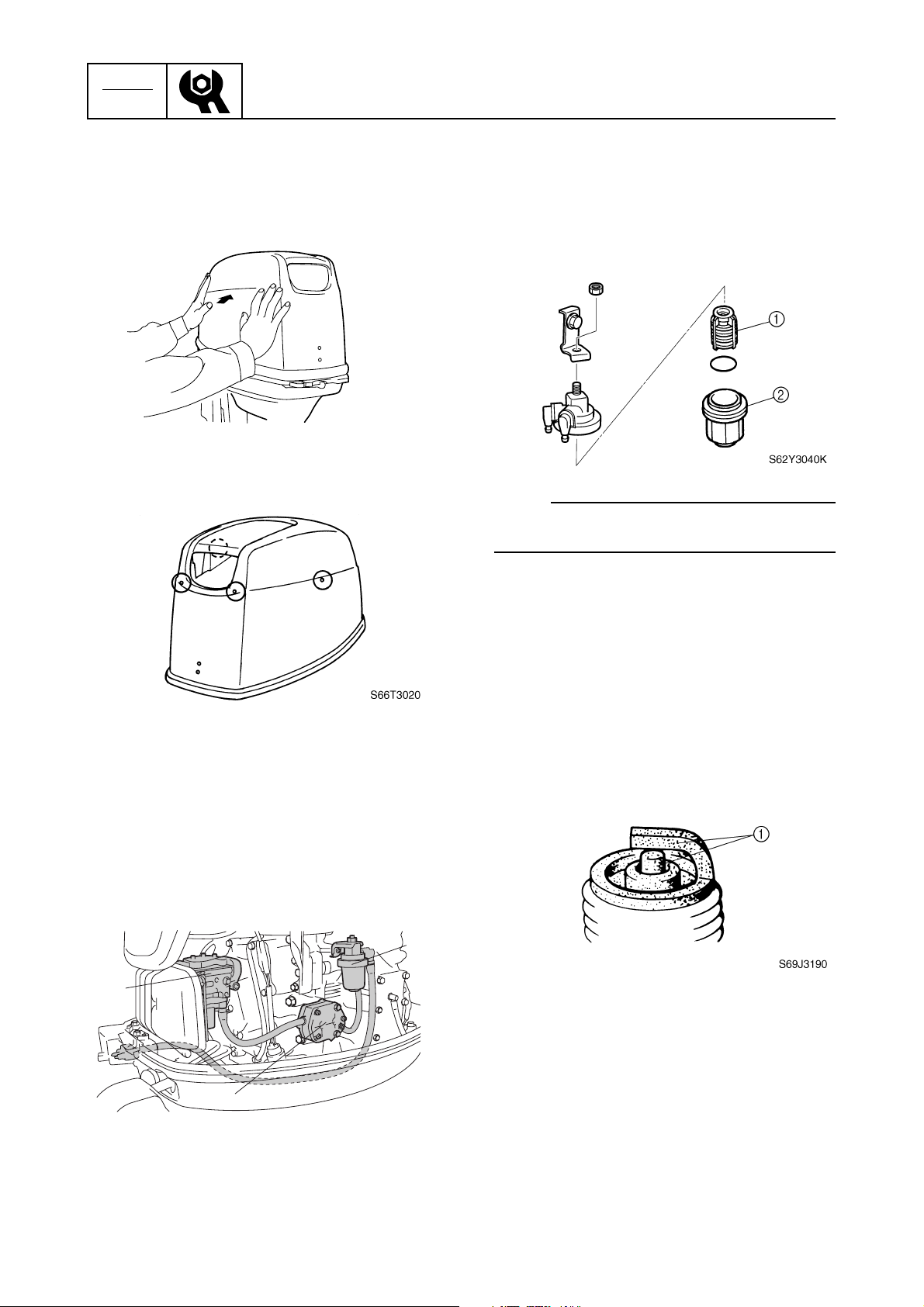

Top cowling

Checking the top cowling

1. Check the fitting by pushing the cowling

with both hands.

S66T3010

2. Check the water separator drain holes for

obstructions. Clean if necessary.

3

Checking the fuel filter

1. Check the fuel filter element 1 for dirt

and residue and check the fuel filter cup

2

for foreign substances and cracks.

Clean the cup with straight gasoline and

replace the element if necessary.

NOTE:

Be sure not to spill any fuel when removing

the fuel filter cup.

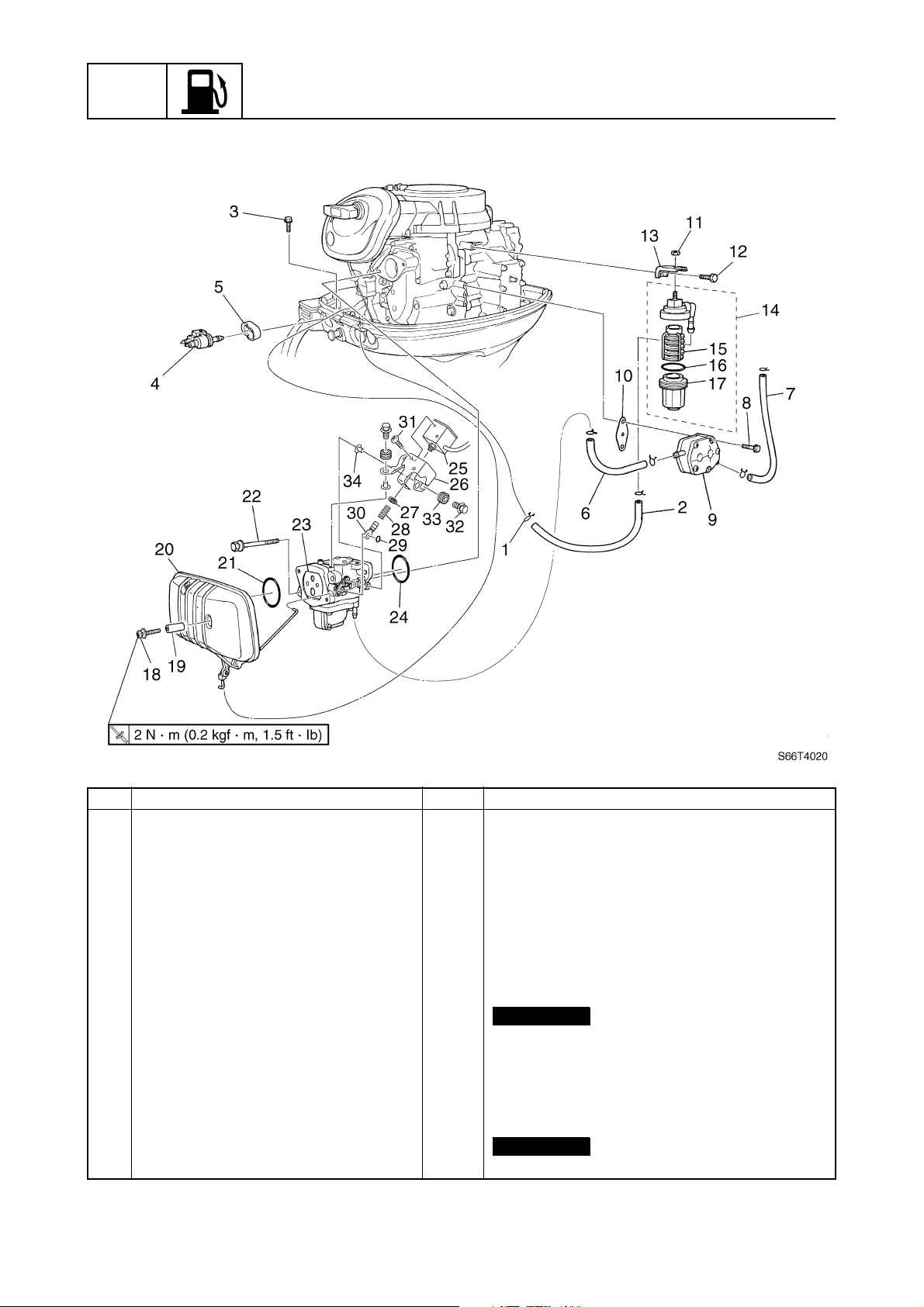

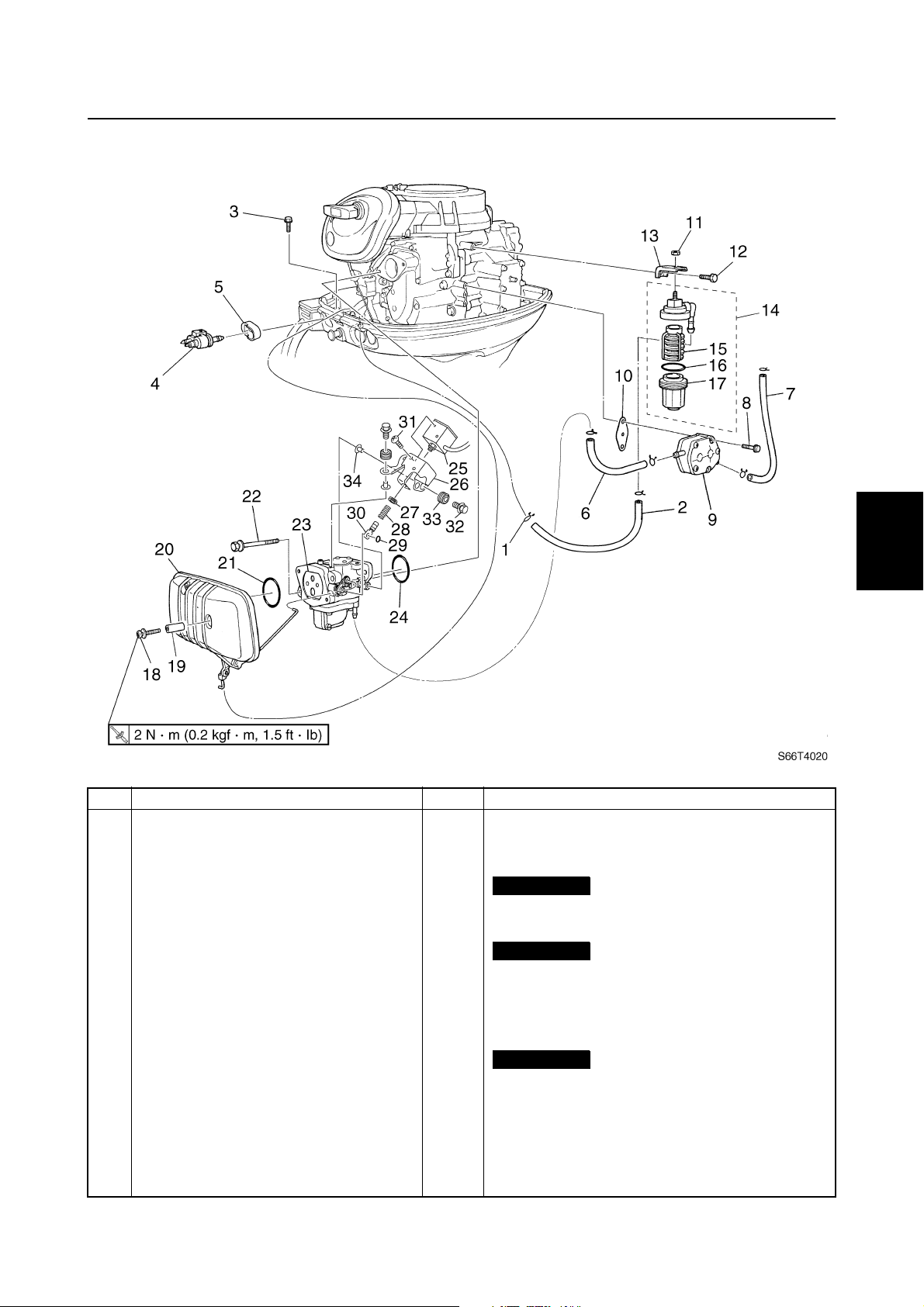

Fuel system

Checking the fuel joint and fuel

hoses (fuel joint-to-carburetor)

1. Check the fuel hose connections and fuel

joints for leaks. Replace if necessary.

Also, check the fuel filter 1, fuel pump

2

, and carburetor 3 for leaks or deterio-

ration. Replace if necessary.

1

3

Power unit

3

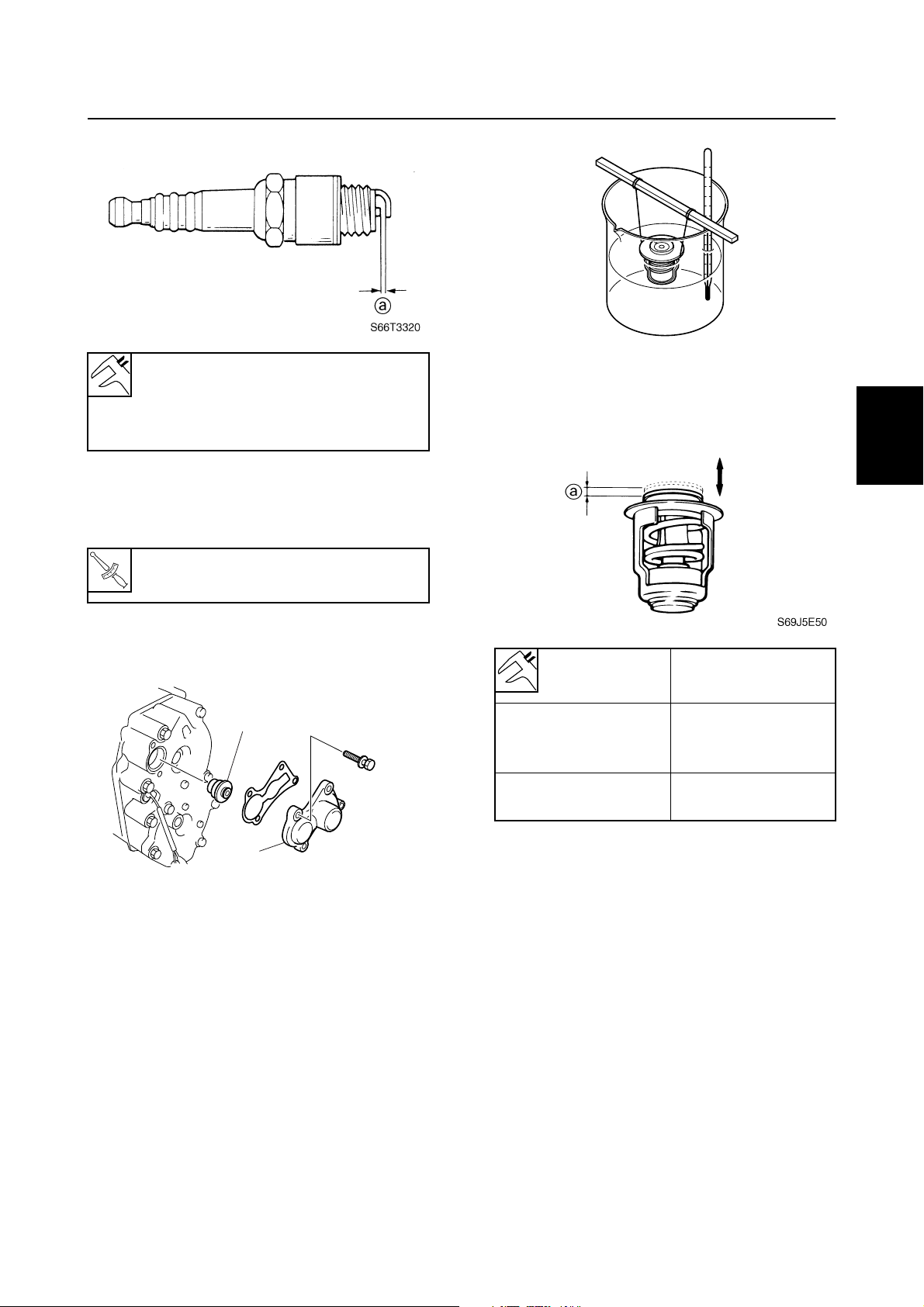

Checking the spark plugs

1. Disconnect the spark plug caps, and then

remove the spark plugs.

2. Clean the electrodes 1 with a spark plug

3

cleaner or wire brush. Replace the spark

plug if necessary.

3. Check the electrodes for erosion and

excessive carbon or other deposits, and

the gasket for damage. Replace the

spark plug if necessary.

3-3

2

S66T3030

4. Check the spark plug gap a. Adjust if out

of specification.

66T5F11

Specified spark plug:

B7HS (NGK), BR7HS (NGK)

Spark plug gap a:

0.6–0.7 mm (0.024–0.028 in)

5. Install the spark plugs, tighten them finger tight, then to the specified torque

using a spark plug wrench.

Top cowling / Fuel system / Power unit

1

S69J5E40

2

4. Check the thermostat valve opening at

the specified water temperatures.

Replace if out of specification.

3

Spark plug:

T

.

R

.

25 N·m (2.5 kgf·m, 18.4 ft·lb)

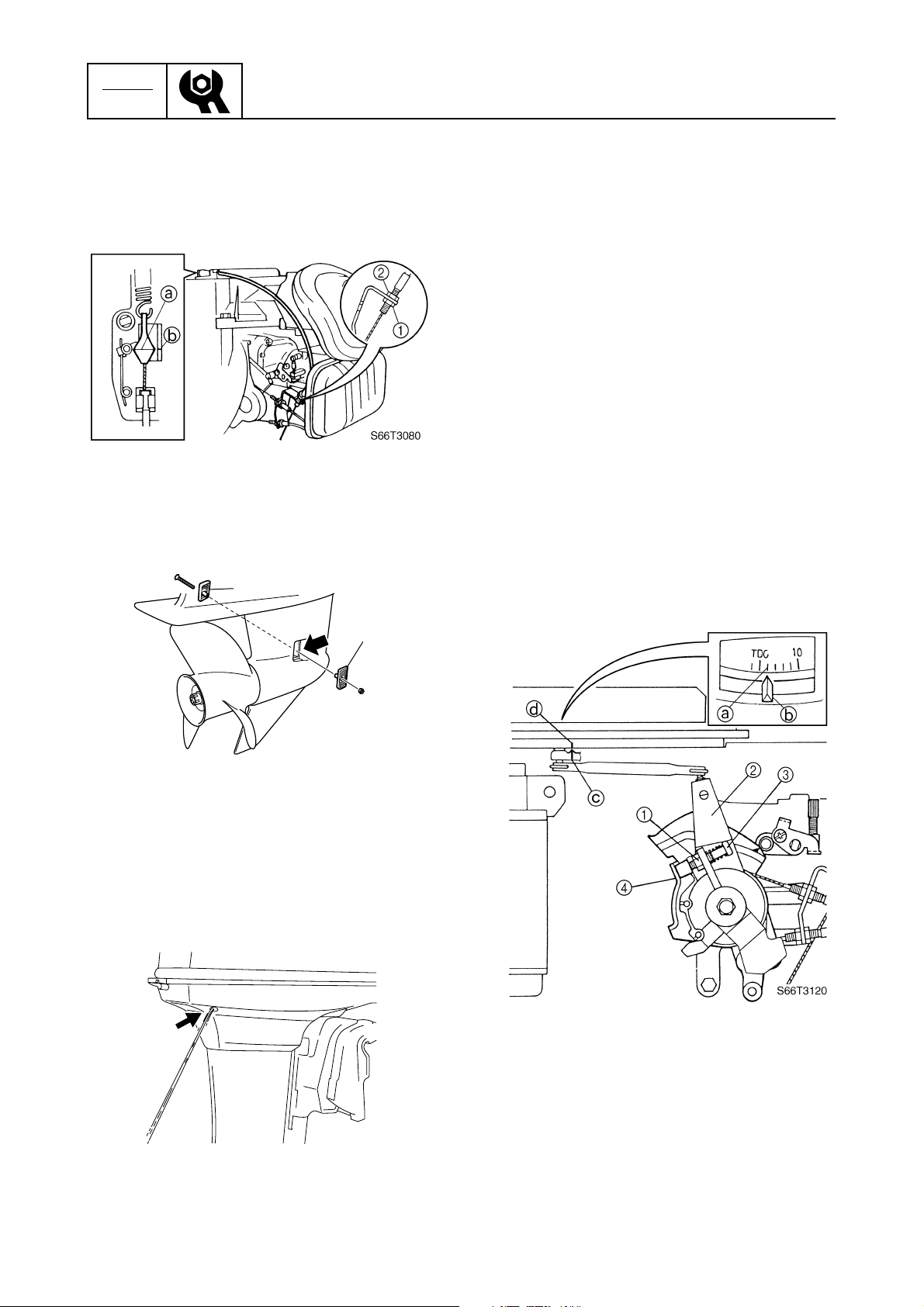

Checking the thermostat

1. Remove the cover 1 and thermostat 2.

2

1

2. Suspend the thermostat in a container of

water.

3. Place a thermometer in the water and

slowly heat the water.

S66T3040

Water

temperature

48–52 °C

(118–126 °F)

above

60 °C (140 °F)

5. Install the thermostat and cover, and

then tighten the cover bolts.

Adjusting the start-in-gear

protection

1. Set the gear shift to the neutral position.

Valve lift a

0.05 mm

(0.0020 in)

(valve begins to lift)

more than

3.0 mm (0.12 in)

4

5

6

7

8

66T5F11

9

3-4

CHK

ADJ

Periodic checks and adjustments

2. Loosen the lock nut 1, and then adjust

the start-in-gear protection adjusting nut

2

until the point a on the wire connector

aligned with the mark b on the manual

starter case.

Checking the cooling water passage

1. Check the cooling water inlet cover

and cooling water inlet for clogs. Clean if

necessary.

1

1

Control system

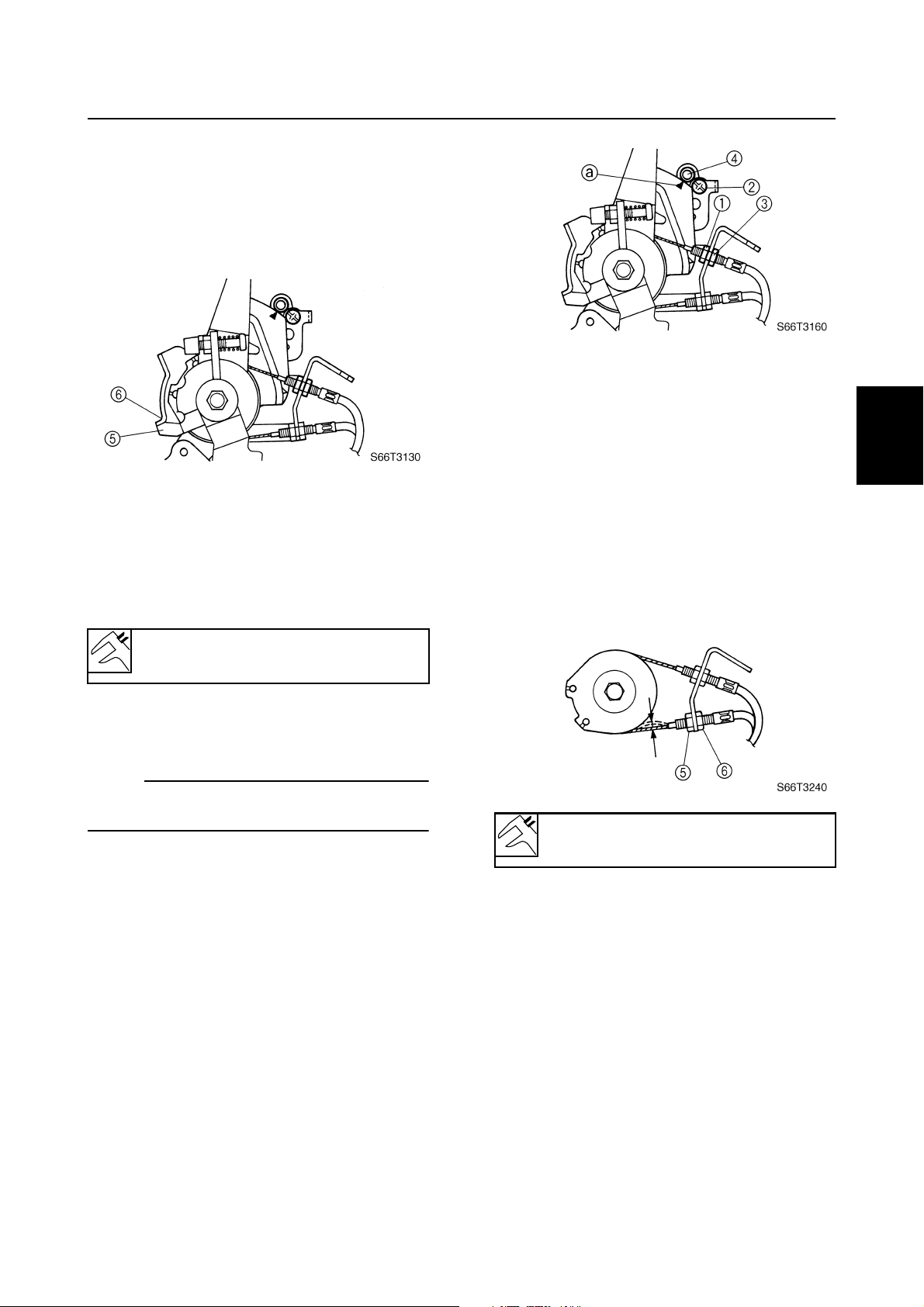

Adjusting the ignition timing

1. Make sure that the engine is stopped

before adjusting the ignition timing.

2. Loosen the throttle cables or remove the

remote control cable.

3. Turn the flywheel magnet clockwise so

that ATDC 2° line a aligns with the mark

b

on the manual starter case.

4. Loosen the locknut 1.

5. Turn the throttle control lever 2 so that

the full-retard screw 3 contacts the stopper 4.

6. Adjust the full-retard screw 3 so that the

timing indicator c aligns with the mark

d

on the flywheel magnet.

7. Tighten the locknut 1.

3

1

S66T3230

2. Place the lower unit in water, and then

start the engine.

3. Check for water flow at the cooling water

pilot hole. If there is no water flow, check

the cooling water passage inside the outboard motor.

8. Adjust the throttle cables or remote control cable.

3-5

S66T3050

66T5F11

9. Shift the remote control lever or shift

lever to forward or reverse, and then

check that the stopper 5 on the throttle

control lever contacts the stopper 6 on

the throttle cable bracket when the throttle is fully open.

10. Start the engine and warm it up for 5 minutes.

11. Check the ignition timing with a timing

light and, if necessary, repeat steps 1–

10.

Power unit / Control system

1

2

6. Turn the throttle grip to the fully closed

position.

7. Loosen the locknut 5.

3

8. Contact the full-retard screw 7 to the

stopper 8, and then turn the adjusting

nut 6 in or out until the specified throttle

cable free play is obtained.

4

9. Tighten the locknut 5.

Ignition timing at engine idle speed:

ATDC 2°

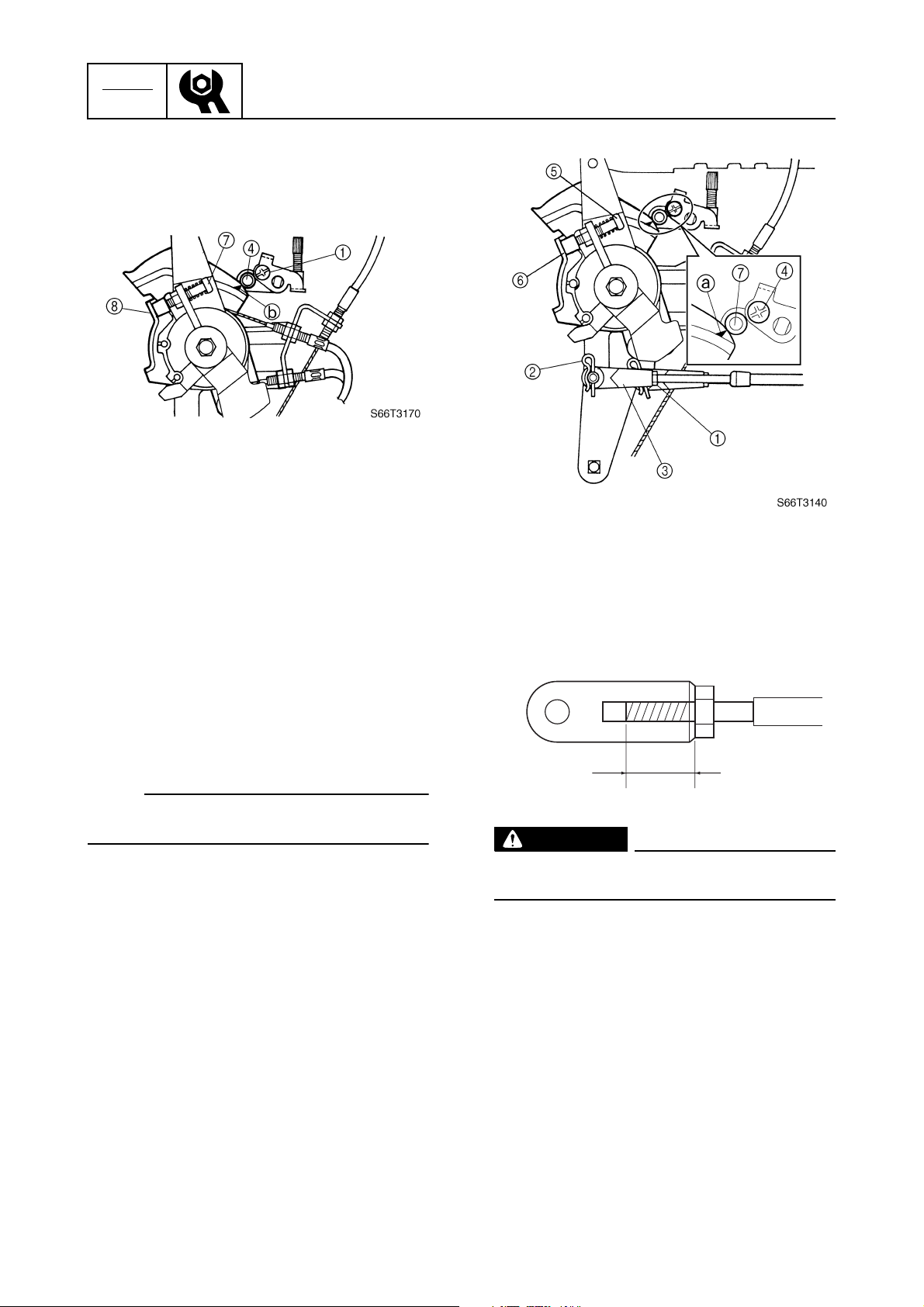

Adjusting the throttle cables

(MH, WH)

NOTE:

Before adjusting the throttle cables, the throttle stop screw should be properly adjusted.

1. Loosen the locknut 1.

2. Loosen the throttle-cam-roller adjusting

screw (left-hand threads) 2.

3. Turn the throttle grip to the fully open

position.

4. Adjust the throttle cable adjusting nut

until the center of the throttle cam roller

4

aligns with the mark a on the throttle

cam.

3

5

6

Throttle cable free play:

1 mm (0.04 in)

7

8

9

5. Tighten the locknut.

66T5F11

3-6

CHK

ADJ

10. Align the center of the throttle cam roller

4

with the mark b on the throttle cam,

and then tighten the throttle-cam-roller

adjusting screw 1.

11. Check that the center of the throttle cam

roller 4 aligns with the mark a on the

throttle cam when the throttle grip is

turned to the fully open position.

12. Check that the full-retard screw 7 contacts the stopper 8 and that the center of

the throttle cam roller 4 is aligned with

the mark b on the throttle cam when the

throttle grip is turned to the fully closed

position.

Periodic checks and adjustments

5. Adjust the position of the throttle cable

joint until its hole is aligned with the set

pin on the throttle control lever.

13. If necessary, repeat steps 1–12.

Adjusting the throttle cable (W)

NOTE:

Before adjusting the throttle cable, the throttle stop screw should be properly adjusted.

1. Loosen the locknut 1, remove the clip

2

, and then disconnect the throttle cable

joint 3.

2. Set the remote control lever to the neutral position.

3. Loosen the throttle-cam-roller adjusting

screw (left-hand threads) 4.

4. Check that the full-retard screw 5 contacts the stopper 6 and that the center of

the throttle cam roller 7 is aligned with

the mark a on the throttle cam.

b

S66T1050

WARNING

The throttle cable joint must be screwed

in a minimum of 8.0 mm (0.31 in) b.

6. Connect the cable joint, install the clip,

and then tighten the locknut.

7. Align the center of the throttle cam roller

7

with the mark a on the throttle cam,

and then tighten the throttle-cam-roller

adjusting screw 4.

3-7

66T5F11

8. Check that the stopper 8 on the throttle

control lever contacts the stopper 9 on

the throttle cable bracket and that the

center of the throttle cam roller 7 is

aligned with the mark c on the throttle

cam when the remote control lever is

fully open position.

Control system

1

S66T3290

2. Set the gear shift to the neutral position.

3. Check that the neutral switch lever 2 on

the shift lever assembly is pushing the

neutral switch 3. (WH)

N

1

2

3

9. Check that the full-retard screw 5 contacts the stopper 6 and that the center of

the throttle cam roller 7 is aligned with

the mark a on the throttle cam when the

remote control lever is fully closed position.

10. If necessary, repeat steps 1–9.

Checking the gear shift operation

(MH, WH)

1. Check that the gear shift operates

smoothly when shifting it from neutral to

forward or reverse. Adjust the adjusting

nut 1 if necessary.

R

N

F

R

F

Checking the gear shift operation

(W)

1. Check that the gear shift operates

smoothly when shifting it from neutral to

forward or reverse. Adjust the shift cable

length if necessary.

2. Set the gear shift to the neutral position.

3

2

S66T3260

4

5

6

7

8

66T5F11

S66T3250

9

3-8

CHK

ADJ

3. Loosen the locknut 1, remove the clip

2

, and then disconnect the shift cable

joint 3.

4. Set the shift lever 4 to the neutral position.

Periodic checks and adjustments

N

R

F

6

23

R

N

F

1

4

S66T3220

5. Adjust the position of the shift cable joint

until its hole is aligned with the set pin.

a

S6D53190

5

S66T3270

Checking the engine idle speed

1. Start the engine and warm it up for 5 minutes.

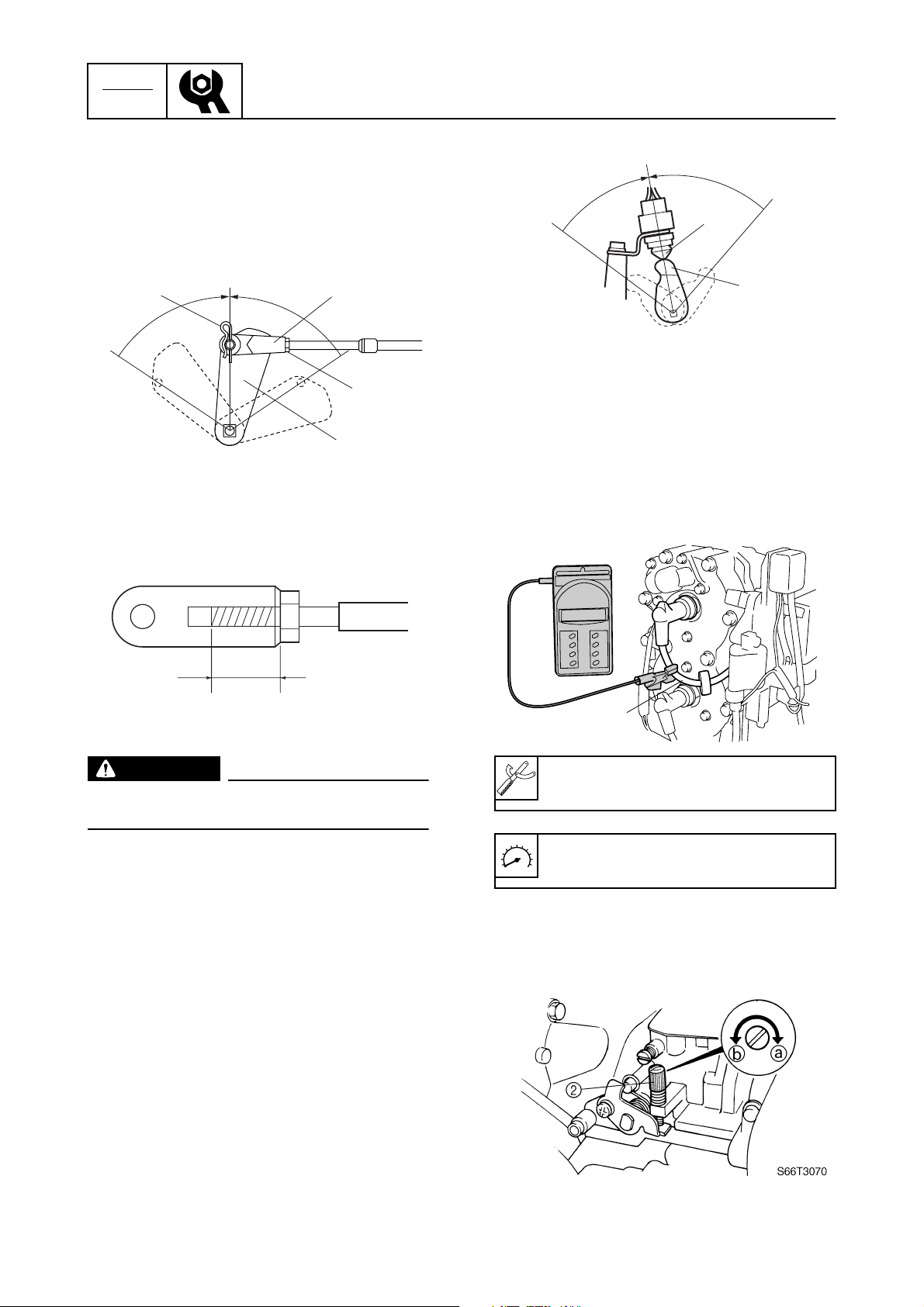

2. Attach the special service tool to spark

plug wire #1 1, and then check the

engine idle speed. Adjust if out of specification.

1

S66T3060

WARNING

The shift cable joint must be screwed in a

minimum of 8.0 mm (0.31 in) a.

6. Connect the cable joint, install the clip,

and then tighten the locknut.

7. Check the gear shift for smooth operation

and, if necessary, repeat steps 2–6.

8. Check that the neutral switch lever on the

shift lever assembly 5 is pushing the

neutral switch 6. (if equipped)

Digital tachometer: 90890-06760

Engine idle speed: 950–1,050 r/min

3. Turn the throttle stop screw 2 in direction a or b until the specified engine

idle speed is obtained.

3-9

66T5F11

Control system / Bracket

NOTE:

• To increase the idle speed, turn the throttle

stop screw in direction a.

• To decrease the idle speed, turn the throttle

stop screw in direction b.

4. If the specified engine idle speed cannot

be obtained, adjust the throttle cable(s).

Checking the ignition timing

1. Start the engine and warm it up for 5 min-

utes.

2. Attach the special service tool to spark

plug wire #1 1, and then check the

engine idle speed.

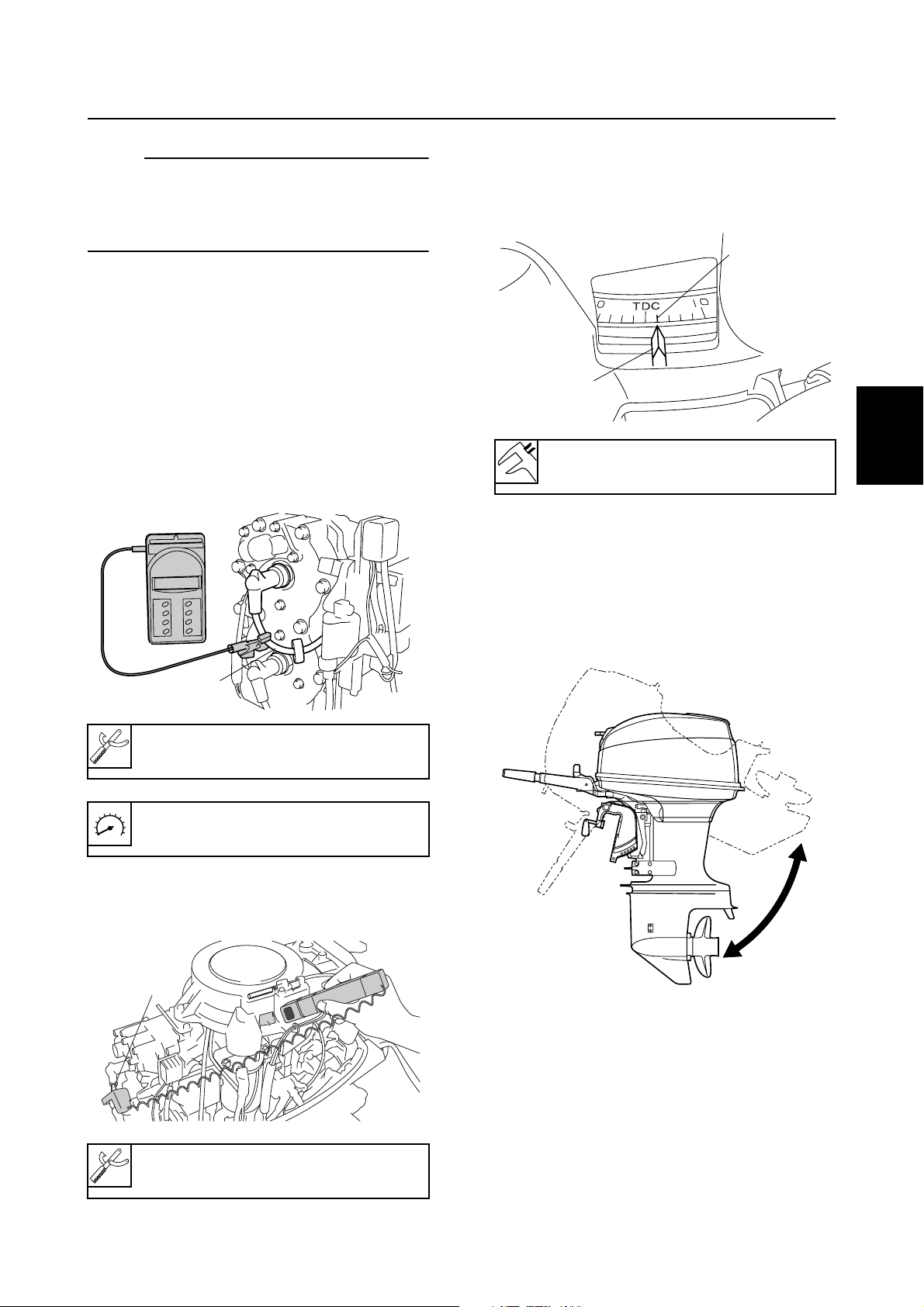

4. Check that the ATDC 2° line a on the

flywheel magnet is aligned with the mark

b

on the manual starter case. Adjust if

out of specification.

a

b

S66T3100

Ignition timing at engine idle speed:

ATDC 2°

Bracket

Checking the tilt operation

1. Fully tilt the outboard motor up and down

a few times and check the entire tilt

range for smooth operation.

1

2

3

3

4

1

S66T3060

Digital tachometer: 90890-06760

Engine idle speed: 950–1,050 r/min

3. Attach the special service tool to spark

plug wire #1 1.

1

S66T3090

5

6

7

8

S66T3300

9

66T5F11

Timing light: 90890-03141

3-10

CHK

ADJ

Periodic checks and adjustments

Lower unit

Checking the gear oil level

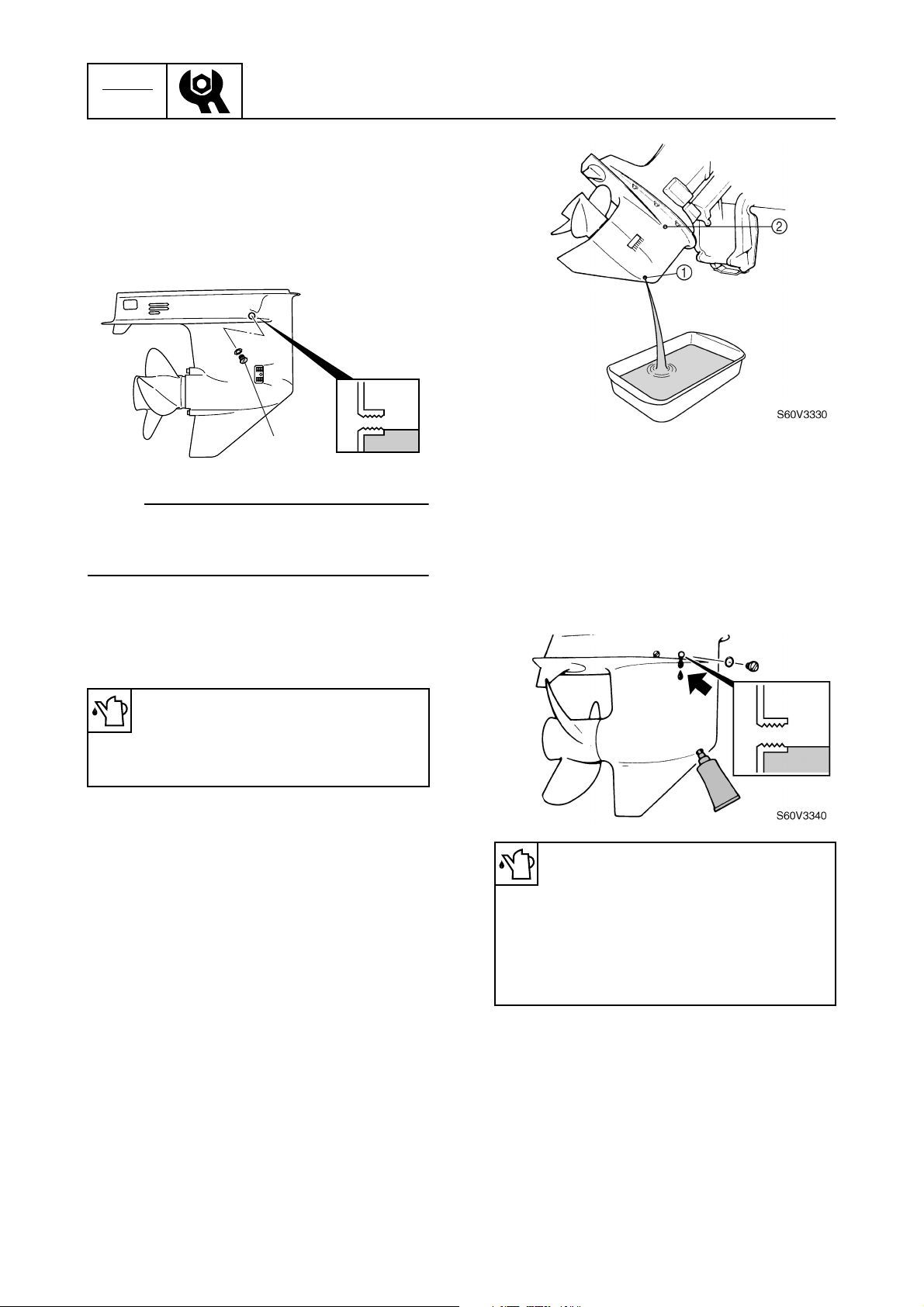

1. Fully tilt the outboard motor down.

2. Remove the check screw 1, and then

check the gear oil level in the lower case.

1

S60V3320

NOTE:

If the oil is at the correct level, the oil should

overflow out of the check hole when the

check screw is removed.

3. If necessary, add sufficient gear oil of the

recommended type until it overflows out

of the check hole.

3

3. Check the oil for metal and discoloration,

and its viscosity. Check the internal parts

of the lower case if necessary.

4. Insert a gear oil tube or gear oil pump

into the drain hole and slowly fill the gear

oil until oil flows out of the check hole and

no air bubbles are visible.

Recommended gear oil:

Hypoid gear oil

API: GL-4

SAE: 90

4. Install the check screw.

Changing the gear oil

1. Tilt the outboard motor up slightly.

2. Place a drain pan under the drain screw

1

, remove the drain screw, then the

check screw 2 and let the oil drain completely.

Recommended gear oil:

Hypoid gear oil

API: GL-4

SAE: 90

Oil quantity:

430 cm

3

(14.54 US oz, 15.17 Imp oz)

5. Install the check screw and quickly install

the drain screw.

3-11

66T5F11

Lower unit / General

Checking the lower unit for air

leakage

1. Remove the check screw 1, and then

install the special service tool.

Leakage tester: 90890-06840

2. Apply the specified pressure to check

that the pressure is maintained in the

lower unit for at least 10 seconds.

CAUTION:

Do not over pressurize the lower unit, otherwise the oil seals can be damaged.

NOTE:

Cover the check hole with a rag when removing the special service tool from the lower

unit.

General

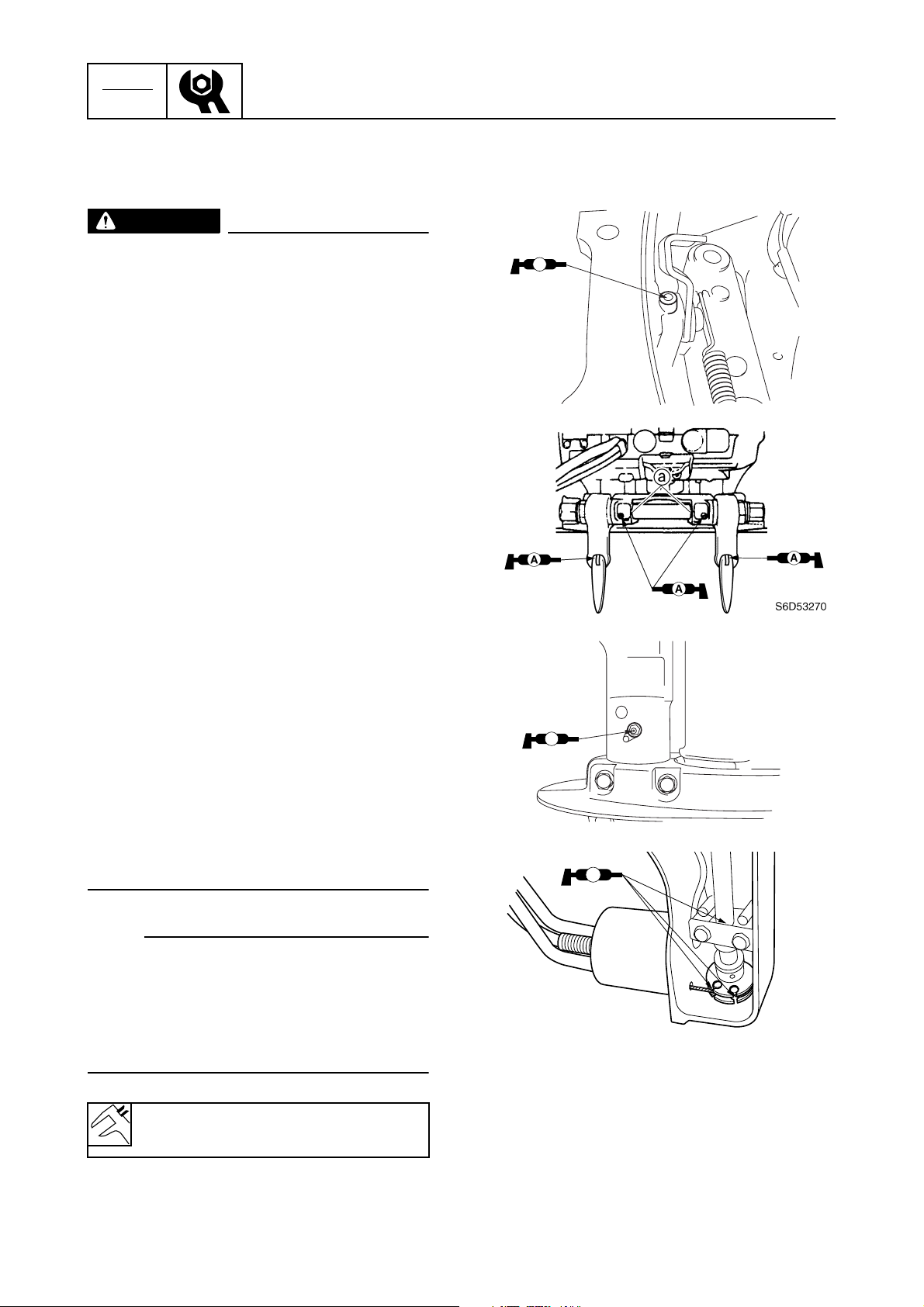

Checking the anodes

1. Check the anodes and trim tab for

scales, grease, or oil. Clean if necessary.

CAUTION:

Do not oil, grease, or paint the anodes or

the trim tab, otherwise they will be ineffective.

2. Replace the anodes or trim tab if excessively eroded.

Checking the battery

1. Check the battery electrolyte level. If the

level is at or below the minimum level