Предложите, как улучшить StudyLib

(Для жалоб на нарушения авторских прав, используйте

другую форму

)

Ваш е-мэйл

Заполните, если хотите получить ответ

Оцените наш проект

1

2

3

4

5

|

Title |

File Size |

Download Links |

|

Wartsila (Sulzer) RT-FLEX82C — Operating Manual.pdf |

8.1Mb |

Download |

|

Wärtsilä 18V32 Instruction Manual.pdf |

21.2Mb |

Download |

|

Wartsila 18V32LN Spare Parts Catalogue.pdf |

9.2Mb |

Download |

|

Wartsila 18V32LND Operating Manual.pdf |

13Mb |

Download |

|

Wartsila 20 Project Guide.pdf |

5.5Mb |

Download |

|

Wartsila 20DF Project Guide.pdf |

4.5Mb |

Download |

|

Wartsila 32 Project Guide.pdf |

5.3Mb |

Download |

|

Wartsila 34DF Project Guide.pdf |

5.4Mb |

Download |

|

Wartsila 46 PG Project Guide 2007.pdf |

12.2Mb |

Download |

|

Wartsila 8L26 Product Manual.pdf |

8.2Mb |

Download |

|

Wartsila 8R22M Operations Manual.doc |

7.9Mb |

Download |

|

Wartsila RT-flex84T-D Marine Installation Manual.pdf |

13.8Mb |

Download |

|

Wärtsilä SG18V34 Instruction Manual.pdf |

16.1Mb |

Download |

|

Wartsila Tools Guide — TCSPC.pdf |

3.1Mb |

Download |

|

Wartsila Vasa W32DF Service Manual.pdf |

9.5Mb |

Download |

|

Wartsila W20 Project Guide 2005.pdf |

8.4Mb |

Download |

|

Wartsila W26 Workshop Manual.pdf |

8.5Mb |

Download |

|

Wartsila W32 engine manual.pdf |

11.2Mb |

Download |

|

Wartsila W8l20C3 Instruction Manual.pdf |

9.4Mb |

Download |

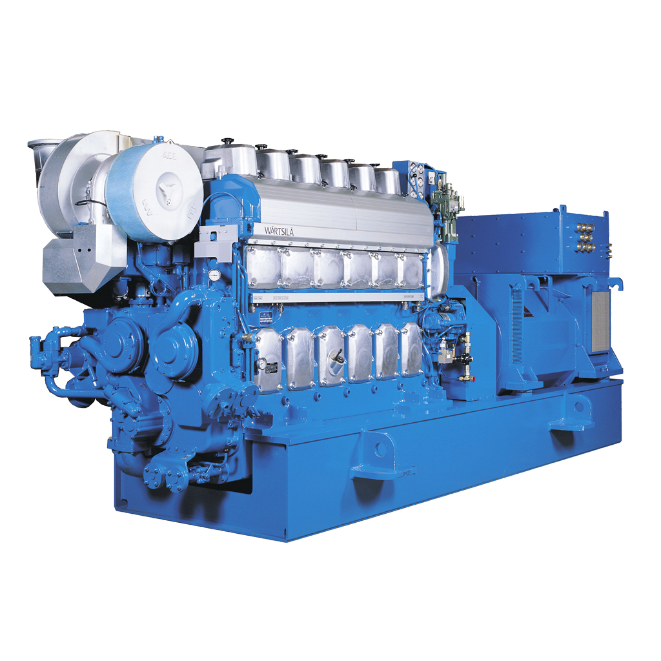

Wärtsilä Oyj Abp is a Finnish public engineering company that manufactures machinery and other equipment for gas, oil and other raw materials power plants.

Throughout its history, the company has worked in the field of shipbuilding, paper, locks, ceramics, glass. Large plants of the company are located in the cities of Vaasa, Turku (in 2004

production was moved to Trieste), Helsinki; Headquarters — in the city of Helsinki.

In 2016, due to the weak market conditions and the difficult competitive environment, the company reorganizes its structure and activities, including by reducing staff.

Wärtsilä is a Finnish concern that specializes in the manufacture of marine power plants, power plants, screw mechanisms, ship control systems and other equipment. Wärtsilä

Corporation is recognized as a world leader in the production and design of four-stroke piston engines with high power, which are installed on the largest cruise liners, tankers and container

ships.

Wärtsilä is a leading global manufacturer of marine and industrial power plants. The corporation manufactures four-stroke in-line and V-shaped engines, provides

a license for the manufacture of in-line two-stroke engines under the Sulzer brand. But still, the main product is medium-speed four-stroke engines, in the production of which the company is a

world leader.

The company is in third place in the production of low-speed two-stroke engines. Wärtsilä low-speed two-stroke engines are the optimal solution as propulsion engines for merchant ships with

direct screw drive. The Wärtsilä common rail electronic control system plays a key role in helping shipowners reduce fuel costs.

The first digit indicates the number of cylinders, the letter L — cylinders in a row (in older versions of R) and the letter V — for the V-shaped engine. The last digit is the cylinder diameter

in cm, the last letter means the power code, which is used only in ship engines, power plant engines do not have it.

For example: 12V46C means a 12-cylinder V-engine with a cylinder diameter of 46 cm and a power of 975 kW per cylinder.

File Specifications:1367/1367389-wrtsil32.pdf file (19 Feb 2023) |

Accompanying Data:

WÄRTSILÄ WÄRTSILÄ32 Engine PDF Product Manual (Updated: Sunday 19th of February 2023 06:40:59 AM)

Rating: 4.6 (rated by 6 users)

Compatible devices: WÄRTSILÄ 50DF, 46DF, WÄRTSILÄ 20, 31SG, RT-flex50-D, AL20, 34DF Series, ?31DF Series.

Recommended Documentation:

Product Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the WÄRTSILÄ WÄRTSILÄ32 Document (Main Content), UPD: 19 February 2023)

-

32, 3.3 Wärtsilä 8L32, 720 rpm DE SCR mode AE SCR mode DE IMO Tier 2 AE IMO Tier 2 Wärtsilä 8L32 720 560 720 560 720 560 720 560 RPM kW/cyl Engine speed Cylinder output 4480448044804480kWEngine output 2.92.92.92.9MPaMean effective pressure Combustion air system (Note 1) 8.068.068.068.06kg/sFlow at 100% load 45454545°CTemperature at turbocharger intake, max. 55555555°CAir temperature after air cooler (TE 601) Exhaust gas system (Note 2) 8.38.38.38.3kg/…

-

220, Fig 18-4 V engines, turbocharger in driving end (DAAE053931) AEngine 3700V-engine with filter/ silencer on turbochar- ger 3800V-engine with suction branches All dimensions in mm. 18-4 Wärtsilä 32 Product Guide — a21 — 7 September 2016 Wärtsilä 32 Product Guide18. Engine Room Layout

… -

175, NOTE The Dual Fuel engines fulfil the IMO Tier 3 NOx emission level as standard in gas mode operation without the need of a secondary exhaust gas emission control system. Sulphur Oxides, SO x emissions Marpol Annex VI has set a maximum global fuel sulphur limit of currently 3,5% (from 1.1.2012) in weight for any fuel used on board a ship. Annex VI also contains provisions allowing for special SOx Emission Control Areas (SECA) to b…

-

164, WÄRTSILÄ WÄRTSILÄ32 The recommended flow velocity in the pipe is maximum 35…40 m/s at full output. If there are many resistance factors in the piping, or the pipe is very long, then the flow velocity needs to be lower. The exhaust gas mass flow given in chapter Technical data can be translated to velocity using the formula: where: gas velocity [m/s]v = exhaust gas mass flow [kg/s]m’ = exhaust gas temperature [°C]T = exhaust gas pipe diameter [m]D = The exhaust pipe must be insulated with insulatio…

-

59, WÄRTSILÄ WÄRTSILÄ32 ● exhaust gas to exhaust system ● cooling water from cylinder head to the return pipe 4.2.9 Camshaft and valve mechanism The cams are integrated in the drop forged shaft material. The bearing journals are made in separate pieces, which are fitted, to the camshaft pieces by flange connections. The camshaft bearing housings are integrated in the engine block casting and are thus completely closed. Th…

-

138, Fig 9-7 Example diagram for multiple main engines (3V76C5263C) System components: Circulating pump (evaporator)4P19Heat recovery (evaporator)4E03 Air venting4S01Heater (preheater)4E05 Drain tank4T04Central cooler4E08 Expansion tank4T05Preheating unit4N01 Temperature control valve (heat recovery)4V02Evaporator unit4N02 Temperature control valve (central cooler)4V08Circulating pump (preheater)4P04 T…

-

58, The connecting rods, at the same crank in the V-engine, are arranged side-by-side in order to achieve standardisation between the in-line and V-engines. The crankshaft is fully balanced to counteract bearing loads from eccentric masses. If necessary, it is provided with a torsional vibration damper at the free end of the engine. 4.2.3 Connecting rod The connecting rod is of forged alloy steel. All connecting rod studs are hydraulic…

-

55, ME SCR mode DE SCR mode AE SCR mode ME IMO Tier 2 DE IMO Tier 2 AE IMO Tier 2 Wärtsilä 16V32 750 580 750 580 750 580 750 580 750 580 750 580 RPM kW/cyl Engine speed Cylinder output 180181183179180182 g/kWhFuel consumption at 85% load, MDF 180181183179180182 g/kWhFuel consumption at 75% load, MDF 181189190179185189 g/kWhFuel consumption at 50% load, MDF 35.635.435.635.635.435.6 kg/hClean leak fuel quantity, MDF at 100% load 7.17.17.17.17.17.1 k…

-

38, 3.5 Wärtsilä 9L32, 720 rpm DE SCR mode AE SCR mode DE IMO Tier 2 AE IMO Tier 2 Wärtsilä 9L32 720 560 720 560 720 560 720 560 RPM kW/cyl Engine speed Cylinder output 5040504050405040kWEngine output 2.92.92.92.9MPaMean effective pressure Combustion air system (Note 1) 9.039.039.039.03kg/sFlow at 100% load 45454545°CTemperature at turbocharger intake, max. 55555555°CAir temperature after air cooler (TE 601) Ex…

-

70, WÄRTSILÄ WÄRTSILÄ32 Fig 5-1 Flexible hoses 5.9 Clamping of pipes It is very important to fix the pipes to rigid structures next to flexible pipe connections in order to prevent damage caused by vibration. The following guidelines should be applied: ● Pipe clamps and supports next to the engine must be very rigid and welded to the steel structure of the foundation. ● The first support should be located as close as possible to the fl…

-

226, Fig 18-10 Main engine arrangement, in-line engines (DAAE059183) Fig 18-11 Main engine arrangement, V-engines (DAAE059181A) Notes: All dimensions in mm. Intermediate shaft diameter to be determined case by case * Depending on type of gearbox ** Depending on type of shaft bearing 18-10 Wärtsilä 32 Product Guide — a21 — 7 September 2016 Wärtsilä 32 Product Guide18. Engine Room Layout

… -

145, where: total fresh water flow [m³/h]q = nominal LT pump capacity[m³/h]q LT = heat dissipated to HT water [kW]Φ = HT water temperature after engine (91°C)T out = HT water temperature after cooler (38°C)T in = Design data: see chapter Technical DataFresh water flow see chapter Technical DataHeat to be dissipated max. 60 kPa (0.6 bar)Pressure drop on fresh water side acc. to cooler manufacturer, normally 1.2 — 1.5 x the fresh water flow Sea-water flow acc.…

-

110, StandardPressure classSizePipe connections: ISO 7005-1PN16DN150Lubricating oil outlet (dry sump)202 ISO 7005-1PN16DN250Lubricating oil to engine driven pump (dry sump)203 ISO 7005-1PN16DN125Lubricating oil to priming pump (dry sump)205 ISO 7005-1PN16DN200Lubricating oil to el. driven pump (stand-by pump)207 ISO 7005-1PN16DN125Lubricating oil from el. driven pump (stand-by pump)208 ISO 7005-1PN40DN40Lubrica…

-

87, The surface temperature in the heater must not be too high in order to avoid cracking of the fuel. The temperature control must be able to maintain the fuel temperature within ± 2°C. Recommended fuel temperature after the heater depends on the viscosity, but it is typically 98°C for HFO and 20…40°C for MDF. The optimum operating temperature is defined by the sperarator manufacturer. The required minimum capacity of the heater i…

-

WÄRTSILÄ WÄRTSILÄ32 User Manual

-

WÄRTSILÄ WÄRTSILÄ32 User Guide

-

WÄRTSILÄ WÄRTSILÄ32 PDF Manual

-

WÄRTSILÄ WÄRTSILÄ32 Owner’s Manuals

Recommended: KE-P37XS1, Remote Aim Anywhere Adapter, BCD-159, toCharge, BTS-84

Links & Tools

Operating Impressions, Questions and Answers:

© Copyright by WÄRTSILÄ FINLAND OY

All rights reserved. No part of this booklet may be reproduced or copied in any form or by any means (electronic,

mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written

permission of the copyright owner.

THIS PUBLICATION IS DESIGNED TO PROVIDE AN ACCURATE AND AUTHORITATIVE INFORMATION WITH

REGARD TO THE SUBJECT-MATTER COVERED AS WAS AVAILABLE AT THE TIME OF PRINTING. HOWEVER,THE

PUBLICATION DEALS WITH COMPLICATED TECHNICAL MATTERS SUITED ONLY FOR SPECIALISTS IN THE

AREA, AND THE DESIGN OF THE SUBJECT-PRODUCTS IS SUBJECT TO REGULAR IMPROVEMENTS,

MODIFICATIONS AND CHANGES. CONSEQUENTLY, THE PUBLISHER AND COPYRIGHT OWNER OF THIS

PUBLICATION CAN NOT ACCEPT ANY RESPONSIBILITY OR LIABILITY FOR ANY EVENTUAL ERRORS OR

OMISSIONS IN THIS BOOKLET OR FOR DISCREPANCIES ARISING FROM THE FEATURES OF ANY ACTUAL ITEM

IN THE RESPECTIVE PRODUCT BEING DIFFERENT FROM THOSE SHOWN IN THIS PUBLICATION. THE PUBLISHER

AND COPYRIGHT OWNER SHALL UNDER NO CIRCUMSTANCES BE HELD LIABLE FOR ANY FINANCIAL

CONSEQUENTIAL DAMAGES OR OTHER LOSS, OR ANY OTHER DAMAGE OR INJURY, SUFFERED BY ANY

PARTY MAKING USE OF THIS PUBLICATION OR THE INFORMATION CONTAINED HEREIN.

-

RT-flex82C

Operating ManualMarine

Vessel:

Type:

Engine No.:Book No.:

Wrtsil Switzerland Ltd Tel. +41 52 262 49 22PO Box 414 Fax +41

52 212 49 17CH-8401 Winterthur

http://www.wartsila.comSwitzerland2008 Wrtsil Switzerland Ltd, Printed in Switzerland

-

01

2

3

4

5

6

7

8

9

O

M

/

R

T

f

l

e

x

/

R

e

g

i

s

t

e

r

Engine Control and Control Elements

Crankshaft, Connecting Rod and Piston

Cylinder Liner and Cylinder Cover

Bedplate and Tie Rod

Operating Descriptions

Supply Unit, Servo Oil Pump and Fuel Pump

Scavenge Air System

Cylinder Lubrication

Piping Systems

Engine Monitoring

-

Operation 00001/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 1

This manual is put at the disposal of the recipient solely for

use in connection withthe corresponding type of diesel engine.It

has always to be treated as confidential.The intellectual property

regarding any and all of the contents of this manual, par-ticularly

the copyright, remains with Wrtsil Switzerland Ltd. This

documentand parts thereof must not be reproduced or copied without

their written permis-sion, and the contents thereof must not be

imparted to a third party nor be used forany unauthorized

purpose.Before the operator intends to use the engine or before

maintenance work is un-dertaken, the Operating Instructions or the

Maintenance Manual respectively is tobe read carefully.To ensure

the best efficiency, reliability and lifetime of the engine and its

compo-nents, only original spare parts should be used.It is to be

ensured as well that all equipment and tools for maintenance are in

goodcondition.The extent of any supplies and services is determined

exclusively by the relevantsupply contract.The data, instructions

and graphical illustrations etc. in this manual are based

ondrawings made by Wrtsil Switzerland Ltd and correspond to the

actual stan-dard at the time of printing (year of printing is

indicated on title page).Those specifications and recommendations

of the classification societies whichare essential for the design

have been considered therein. It must be recognizedthat such data,

instructions and graphical illustrations may be subject to

changesdue to further development, widened experience or any other

reason.This manual is primarily intended for use by the engine

operating and maintenancepersonnel. It must be ensured that it will

always be at the disposal of such person-nel for the operation of

the engines and/or for the required maintenance work.This manual

has been prepared on the assumption that operation and mainte-nance

of the engines concerned will always be carried out by qualified

personnelhaving the special knowledge, training and qualifications

needed to handle in aworkman-like manner diesel engines of the

corresponding size, the associatedauxiliary equipment, as well as

fuel and other operating media.Therefore, generally applicable

rules, which may also concern such items asprotection against

danger, are specified in this manual in exceptional cases only.It

must be made sure that the operating and maintenance personnel are

familiarwith the rules concerned.This manual has been prepared to

the best knowledge and ability of its au-thors. However, neither

Wrtsil Switzerland Ltd nor their employees as-sume any liability

under any legal aspect whatsoever, including possiblenegligence in

connection with this manual, its contents, or modificationsto it or

in connection with its use.Claims relating to any damage whatsoever

or claims of other nature suchas, but not limited to, demands for

additional spares supplies, service orothers are expressly

excluded.Wrtsil Switzerland LtdWinterthurSwitzerland

For Particular Attention

2008

-

Operation 00101/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 3

1. Summary

The documentation for this diesel engine type comprises the

following books andpublications:1.1 Operating ManualThis contains information covering engine

operation, the required operating media(oil, water and fuel), as

well as a description of the function of specific systems.1.2 Maintenance ManualThis contains, in addition to the

maintenance diagrams, information covering spe-cific dismantling

and assembly work necessary for engine maintenance.It contains

furthermore a masses (weight) table of certain individual parts, a

clear-ance table, a list of rubber / O-rings, tightening values for

important screwed con-nections and a tools list.1.3 Code Book (spare parts catalogue)In this book all parts are

marked with a code number by which they can be orderedfrom Wrtsil

Switzerland Ltd or the engine supplier. Such spare parts are to

beordered exclusively from this book.1.4 Documentation for bought-out itemsSeparate publications are

provided for those items on the engine supplied by out-side

manufacturers, such as turbocharger, automatic filter, torsional

vibrationdamper, etc. In most cases these can also be used as a

spare parts catalogue.1.5 Records and drawingsWith the first delivery of the

documentation, the setting tables, shop trial docu-ments and

surveyors certificates of the engine concerned as well as

schematicdiagrams are also supplied.2. Structure of manuals

Generally the manuals have to be regarded as Basic Manuals. They

describeparticularly the standard engine with all cylinder numbers,

alternative designexecutions and special equipment.As a rule, in

the case of alternative design executions the descriptions have

beendivided in separate groups and clearly designated by the

respective alternativenames. This allows on one hand to quickly

find with certainty the respective pas-sages, on the other hand it

allows the later removal of sheets of not supplied alter-natives

and special executions.Further indications can be found under

Explanation on the Use of the OperatingManual 00401.GeneralPreface

2008

-

Operation00101/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 3

2.1 Structure and page designationsThe individual groups with

their illustrations are divided according to the designgroups

whenever possible.0peration 11321/A1TitleSubtitle

Wrtsil Switzerland Ltd 1 / 42008

XXX / 10.08Year of issue(or)

Modification dateInternal identification

Page numberTotal pages of group

Engine typeManual type

Group No.Design variant

Variantdescription

(Version)

RT-flex82C

2.2 Symbols

Remark: Refers to important details and recommendations

concerning operationand maintenance of the engine.Refers to checks which must be carried out for trouble-free

operation and duringmaintenance.2008

Preface

CHECK

-

Operation 00101/A1RT-flex82C

Wrtsil Switzerland Ltd 3/ 3

Attention! Risk of injury! or Risk of accident! Refers to

instructions for opera-tion and maintenance of the engine which

absolutely must be complied with.In case of non-observance high

risk of injury as well as damage to componentsmust be expected.Refers to activities which must not be carried out during

operation and mainte-nance of the engine. In case of non-observance

damage to components must beexpected.Sign for order of actions, activities to be carried out Sign for

observance of regulations Sign for enumerations3. Repeat-order of technical documentation

Remark: Corresponding to the continuing development of the

engines the docu-mentation is continually being updated.This means

that in a later ordered manual for the same engine, text and

designa-tions may no longer coincide in every way with the previous

version (see modifica-tion date on the relevant pages).Not

withstanding the foregoing, important information and improvements

arebrought to the customers notice by Service Bulletins so that the

relevant part ofany development should already be known.When

ordering documentation at a later stage for engines which have

alreadybeen in operation since several years, the following details

are basically required: Engine type, year of manufacture and engine

manufacturer Name of vessel or site of installation Cylinder or

engine number Special equipment Language of documentation (German

or English) Form of documentation (printed Manuals or CD-ROM)2008

Preface

-

Operation 00201/A1

Table of Contents

RT-flex82C

Wrtsil Switzerland Ltd 1/ 4 2008

Operating Descriptions Group 0For Particular Attention 00001/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .General Preface 00101/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . Subject Index 00301/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . Guide for Symbols and Abbreviations 00351/A1. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Explanations on

the Use of the Operating Manual 00401/A1. . . . . . . . . . . . . .

. . . . . . . . . Brief Description of the Engine 00501/A1. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. Working Principle of the Two-stroke Diesel Engine 00601/A1. . . .

. . . . . . . . . . . . . . . . . . . Interrelationship between

Engine and Propeller 00701/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . Engine Numbering and Designations 00801/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .Preparation before Taking into Service Preparations before

Starting after a Short Shut-down (One or More Days) 01101/A1. .

Prepare the Fuel Oil System for Operation 01201/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . Prepare the Servo Oil

System 01301/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . Prepare the Cylinder Lubricating System

01401/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.Operation under Normal Conditions Summary 02001/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . Safety Precautions and Warnings

(General Information) 02101/A1. . . . . . . . . . . . . . . . . .

Slow Turning 02201/A1. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 02301/A1. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. Normal Running 02401/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Operating Data Sheet Pressure and Temperature Ranges at

Continuous Service Power MCR 02501/A1. . . . . Alarms and

Safeguards at Continuous Service Power 02502/A1. . . . . . . . . .

. . . . . . . . . .Operation Manoeuvring 02601/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . Changing Over from Diesel Oil to Heavy Fuel Oil and Vice

Versa 02701/A1. . . . . . . . . . Viscosity — Temperature Diagram

02702/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . Operation at Low Load 02801/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . Operation at Overload 02901/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Shutting Down General 03101/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . Measures to be Taken after Stopping 03201/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Table of Contents

-

Operation00201/A1

Table of Contents

RT-flex82C

2/ 4 Wrtsil Switzerland Ltd2008

Special Measures in Operation Running-in of New Cylinder Liners

and Piston Rings 04101/A1. . . . . . . . . . . . . . . . . . . . .

Indicator Diagrams 04201/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measures against Fouling and Fires in the Scavenge Air Spaces

04501/A1. . . . . . . . . . Instructions Concerning the Prevention

of Crankcase Explosions 04601/A1. . . . . . . . . .Operation under Abnormal Conditions General Information

05001/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . Operation with Injection Cut

Out (One or More Cylinders) 05101/A1. . . . . . . . . . . . . . . .

. Faults in High Pressure Fuel System 05151/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . Operation with

Exhaust Valve Control Unit Cut Out 05201/A1. . . . . . . . . . . .

. . . . . . . . . . Faults in Servo Oil System 05251/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . Operation with Running Gear Partially or Totally Removed

05401/A1. . . . . . . . . . . . . . . . Operation with Water

Leakage into the Combustion Chamber 05451/A1. . . . . . . . . . . .

. Scavenge Air Cooler Out of Service / Failure of Auxiliary Blowers

05501/A1. . . . . . . . . . Defective Remote Control 05601/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Defect in Speed Control System 05701/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger Out of Service 05901/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .Special Measures before and after Operation Preparations before

Starting after a Prolonged Shut-down Periodor an Overhaul 06101/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measures to be taken before Putting Out of Service for Extended

Period 06201/A1. . .Operating Media Diesel Engine Fuels 07101/A1. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . Fuel Treatment, Fuel Oil System 07201/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scavenge

Air and Compressed Air 07401/A1. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . Lubricating Oils 07501/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Cooling Water / Cooling Water

Treatment 07601/A1. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .Operating Troubles General 08001/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Troubles during Starting and Stopping

08101/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . Irregularities during Operation 08201/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubles and Damages with Engine Parts 08401/A1. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . Failures and Defects of

WECS Components 08501/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . -

Operation 00201/A1

Table of Contents

RT-flex82C

Wrtsil Switzerland Ltd 3/ 4 2008

Bedplate and Tie Rod Group 1Main Bearing 11321/A1. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Thrust Bearing 12031/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . Tie Rod 19031/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .Cylinder Liner and Cylinder Cover Group 2Cylinder Liner

21241/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . Lubricating

Quills on Cylinder Liner 21381/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Piston Rod Gland

23031/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . Injection Valve

27221/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . Starting

Valve 27281/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust

Valve 27511/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Crankshaft, Connecting Rod and Piston Group 3Axial Damper

31461/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . Connecting

Rod and Connecting Rod Bearing 33031/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . Crosshead and Guide Shoe 33261/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . Piston 34031/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . Crosshead Lubrication and Piston Cooling

36031/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .Engine Control and Control Elements Group 4

Engine Control Engine Control System WECS9520 40021/A1. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . User

Parameters and Maintenance Settings 40023/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . Regular Checks and Recommendations

for WECS9520 40024/A1. . . . . . . . . . . . . . . . . Engine

Control 40031/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .Control Diagram Designations (Description to 40031, 40032 and

40033) 40032/A0. . . . . . . . . . . . . . . Control Diagram (6 to

8 Cylinders) 40032/A1. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . Control Diagram (9 to 12 Cylinders)

40032/A2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .Control and Auxiliary Systems Detailed Control Diagrams with

Interfaces to the Plant 40033/A1. . . . . . . . . . . . . . . . . .

.Drive Supply Unit 41041/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. Shut-off Valve for Starting Air 43251/A1. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Air Supply 46051/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Control Panel 46181/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pick-up for Speed Measurement 46281/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . -

Operation00201/A1

Table of Contents

RT-flex82C

4/ 4 Wrtsil Switzerland Ltd2008

Supply Unit, Servo Oil Pump and Fuel Pump Group 5Fuel Pump

55561/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cutting

Out and Cutting In of the Fuel Pump 55562/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . Fuel Pressure Control Valve

3.06 55621/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . Fuel Pump Unit 55811/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . Fuel Pump Actuator 55831/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Servo Pump Unit 55911/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .Scavenge Air System Group 6Scavenge Air Receiver 64201/A1. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Turbocharging 65001/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .Cleaning the Turbocharger in Operation Turbocharger TPL Type

65101/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Turbocharger MET Type 65101/A2. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .Auxiliary Blower and Switch Box 65451/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scavenge

Air Cooler, Operating Instructions and Cleaning 66061/A1. . . . . .

. . . . . . . . . . . . .Cylinder Lubrication Group 7Cylinder Lubrication 72181/A1. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . Instructions Concerning Measurementof

Cylinder Lubricating Oil Consumption 72182/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .Piping Systems Group 8Lubricating Oil System 80161/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . Cooling Water System 80171/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Starting Air Diagram 80181/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . Fuel Oil System 80191/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . Drainage System and Wash-water Piping System 83451/A1. .

. . . . . . . . . . . . . . . . . . . . . . . .Engine Monitoring Group 9Instrument Panel 92151/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . Crank Angle Sensor Unit 92231/A1. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . Pressure Switches and Pressure Transmitters

92581/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Mist Detector 93141/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location of flex Electronic Components 93621/A1. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . -

Operation 00301/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 5

AAbbreviations 00351/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Abnormal

operating condition 05001/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . Air flaps in the scavenge air receiver

64201/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms and safeguards at continuous service power 02502/A1. . . . .

. . . . . . . . Auxiliary blower and switch box 65451/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Auxiliary blower,

failure of… 05501/A1. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . Axial damper 31461/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . Auxiliary systems 40033/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .BBrief description of the engine 00501/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .CChangeover, diesel oil heavy fuel oil operation 02701/A1. . . .

. . . . . . . . . . . . . Checking engine controls 40031/A1. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the cooling system 07601/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . Cleaning the scavenge air

cooler in operation 66061/A1. . . . . . . . . . . . . . . . . . .

Cleaning exhaust gas turbocharger (TPL type) in operation 65101/A1.

. . . . . . Cleaning exhaust gas turbocharger (MET type) in

operation 65101/A2. . . . . . . Compressed air, starting air,

control air 07401/A1. . . . . . . . . . . . . . . . . . . . . . . .

. Control air supply 46051/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . Control diagram,

designations 40032/A0. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . Control diagram (6 to 8 cylinders) 40032/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . Control

diagram (9 to 12 cylinders) 40032/A2. . . . . . . . . . . . . . . .

. . . . . . . . . . . . Connecting rod, connecting rod bearing

33031/A1. . . . . . . . . . . . . . . . . . . . . . . . Cooling

water system 80171/A1. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . Cooling water treatment 07601/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . Crank angle sensor unit 92231/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . Crankcase explosions,

prevention of… 04601/A1. . . . . . . . . . . . . . . . . . . . .

. . . . Crosshead and guide shoe 33261/A1. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Crosshead lubrication

and piston cooling 36031/A1. . . . . . . . . . . . . . . . . . . .

. . . Cutting out and cutting in of the fuel pump 55562/A1. . . . .

. . . . . . . . . . . . . . . . . Cut out an exhaust valve control

unit 05201/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder liner 21241/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Cylinder liner,

running-in of new… 04101/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . Cylinder lubrication 72181/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder lubricating oil consumption, Instructions … 72182/A1. .

. . . . . . . . . . . . Cylinder lubricating system, control

72181/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder lubricating system, preparation before taking into service

01401/A1.DDamage to engine parts 08401/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Defective remote

control system 05601/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . Detailed control diagrams with interfaces to the

plant 40033/A1. . . . . . . . . . . . . Determination of cylinder

lubricating oil consumption 72182/A1. . . . . . . . . . . . .

Drainage system and wash-water piping system 83451/A1. . . . . . .

. . . . . . . . . . Drive supply unit 41041/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.Subject IndexAlphabetical Table of Contents

2008

-

Operation00301/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 5

EEmergency operation with exhaust valve closed / opened

05201/A1. . . . . . . . . Engine, brief description of… 00501/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine control 40031/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . Engine control

system WECS9520 40021/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . Engine numbering and designations 00801/A1. . . . . . . .

. . . . . . . . . . . . . . . . . . . Exchange of defective exhaust

valve control unit 05201/A1. . . . . . . . . . . . . . . . Exchange

of filter element (cylinder lubrication) 72181/A1. . . . . . . . .

. . . . . . . . . Exchange of defective hydraulic piping 05201/A1.

. . . . . . . . . . . . . . . . . . . . . . . . Exhaust valve

27511/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Explanations on the use of the

Operating Manual 00401/A1. . . . . . . . . . . . . . . .FFailure of auxiliary blower 05501/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Failures and defects of

WECS components 08501/A1. . . . . . . . . . . . . . . . . . . . .

Faults in HP fuel system 05151/A1. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . Faults in servo oil system

05251/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . Filling and pressure relief of servo oil rail 80161/A1.

. . . . . . . . . . . . . . . . . . . . . . Finding group and page

numbers 00401/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . Fires in scavenge air spaces, prevention of… 04501/A1. .

. . . . . . . . . . . . . . . . . For particular attention

00001/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . Fuels for diesel engines 07101/A1. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel

leakage system 80191/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . Fuel oil system 80191/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . Fuel oil system, prepare for… 01201/A1. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel

pressure control valve 3.06 55621/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . Fuel pump, cutting out and in

55562/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . Fuel pump 55561/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel pump

actuator 55831/A1. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . Fuel pump unit 55811/A1. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Fuel treatment 07201/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GGeneral indications for operation 02101/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . Guide shoe on crosshead

33261/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .HHeavy fuel oil, quality requirements 07101/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . Heavy fuel oil, treatment

07201/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .IIndicator diagrams 04201/A1. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Injection valve

27221/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Interfaces to the plant, …

control diagrams 40033/A1. . . . . . . . . . . . . . . . . . . . .

. Instructions concerning measurement of thecylinder lubricating

oil consumption 72182/A1. . . . . . . . . . . . . . . . . . . . . .

. . . . . . Instrument panel 92151/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated axial damper 31461/A1. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . Interrelationship between

engine and propeller 00701/A1. . . . . . . . . . . . . . . . . .

Irregularities during operation 08201/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .2008

Alphabetical Table of Contents

-

Operation 00301/A1RT-flex82C

Wrtsil Switzerland Ltd 3/ 5

LLeakage and wash-water piping system 83451/A1. . . . . . . . .

. . . . . . . . . . . . . . . Leakage oil pipe of exhaust valve

80161/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED indications on ALM20 module 72181/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . LED indications on FCM20 module 08501/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . Local control

panel 46181/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . Location of flex electronic

components 93621/A1. . . . . . . . . . . . . . . . . . . . . . . .

. Lubricating oils 07501/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Lubricating oil

system 80161/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . Lubricating quills 21381/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . Lubrication of cylinder liner 72181/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .MMain bearing 11321/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Manoeuvring

02601/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . Measures to be taken before

putting out of servicefor extended period 06201/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measures against fouling and fires in the scavenge air spaces

04501/A1. . . . . Measure to be taken after shutting down 03201/A1.

. . . . . . . . . . . . . . . . . . . . . . Measures to be taken

before starting 01101/A1. . . . . . . . . . . . . . . . . . . . . .

. . . .NNormal running 02401/A1. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .OOil mist detector 93141/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Operating data

sheet, alarms and safeguards 02502/A1. . . . . . . . . . . . . . .

. . . . Operating data sheet, pressure and temperature ranges

02501/A1. . . . . . . . . . Operating medium, air 07401/A1. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating medium, oil 07501/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . Operating medium, water

07601/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Operating troubles, general 08001/A1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Operating with

defective turbocharger 05901/A1. . . . . . . . . . . . . . . . . .

. . . . . . . . Operation at low load 02801/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Operation

at overload 02901/A1. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Operation under normal conditions,

general information 02101/A1. . . . . . . . . . Operation under

normal conditions, summary 02001/A1. . . . . . . . . . . . . . . .

. . . Operation interruption, measures before extended standstill

06201/A1. . . . . . . Operation under abnormal conditions, general

information 05001/A1. . . . . . . . Operation under breakdown

conditions 05001/A1 . . . . . . . . . . . . . . . . . . . . . . .

.to 05901/A1Operation with injection cut out (one or more

cylinders) 05101/A1. . . . . . . . . . . Operation with a running

gear removed 05401/A1. . . . . . . . . . . . . . . . . . . . . . .

. Operation with cut out exhaust valve control unit 05201/A1. . . .

. . . . . . . . . . . . Operation with scavenge air cooler out of

service 05501/A1. . . . . . . . . . . . . . . . Operation with

water leakage into the combustion chamber 05451/A1. . . . . . .2008

Alphabetical Table of Contents

-

Operation00301/A1 RT-flex82C

Wrtsil Switzerland Ltd 4/ 5

PParticular attention, for your… 00001/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Pick-up for speed

measurement 46281/A1. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Piping systems Group 8. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston 34031/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . Piston and

piston rings, running-in of cylinder liner 04101/A1. . . . . . . .

. . . . . . . Piston rod gland 23031/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautionary measures for operation 02101/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . Preface 00101/A1. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . Prepare the fuel oil system for operation 01201/A1. .

. . . . . . . . . . . . . . . . . . . . . . Prepare the servo oil

system 01301/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . Preparation before taking into service 01101/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . Preparations before

starting after a prolonged shut-down periodor an overhaul 06101/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Pressure and temperature ranges 02501/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Pressure switch

and pressure transmitter 92581/A1. . . . . . . . . . . . . . . . .

. . . . . . Prevention of crankcase explosions 04601/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . Propeller curve

00701/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .QQuality requirements for heavy fuel oil 07101/A1. . . . . . . .

. . . . . . . . . . . . . . . . .RRegular checks and recommendations for WECS9520 40024/A1. . . .

. . . . . . Remote control system defective 05601/A1. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . Running gear, operation

with removed… 05401/A1. . . . . . . . . . . . . . . . . . . . . .

. . Running-in of new cylinder liner, piston and piston rings

04101/A1. . . . . . . . . .SSafety measures and warnings (general information) 02101/A1. .

. . . . . . . . . . . Scavenge air 07401/A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. Scavenge air cooler, operating instructions and cleaning

66061/A1. . . . . . . . . . Scavenge air cooler out of service,

failure of auxiliary blower 05501/A1. . . . . . Scavenge air

receiver 64201/A1. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . Servo oil leakage system 80161/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. Servo pump unit 55911/A1. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . Servo oil service

pump 80161/A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . Shutting down, general 03101/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutting down, measures to be taken after the … 03201/A1. . . . .

. . . . . . . . . . . Shut off the injection control unit 05101/A1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shut-off valve for starting air 43251/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . Slow turning 02201/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Speed control system defective 05701/A1. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . Speed

measurement, pick-up for… 46281/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . Starting 02301/A1. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . Starting air system, schematic diagram 80181/A1. . . . .

. . . . . . . . . . . . . . . . . . . . Starting valve 27281/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . Structure of the manuals 00101/A1. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 00101/A1. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .2008

Alphabetical Table of Contents

-

Operation 00301/A1RT-flex82C

Wrtsil Switzerland Ltd 5/ 5

TTable of contents 00201/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Thrust bearing

12031/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . Tie rod 19031/A1. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . Troubles, during operation 08201/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubles

when starting and shutting down 08101/A1. . . . . . . . . . . . . .

. . . . . . . . Troubles with engine parts (damage) 08401/A1. . . .

. . . . . . . . . . . . . . . . . . . . . . . Turbocharger (TPL

type), cleaning in service 65101/A1. . . . . . . . . . . . . . . .

. . . . Turbocharger (MET type), cleaning in service 65101/A2. . .

. . . . . . . . . . . . . . . . Turbocharger out of service

05901/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . Turbocharger surging 08201/A1. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . Turbocharging

65001/A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .UUser parameters and maintenance settings 40023/A1. . . . . . .

. . . . . . . . . . . . . .VVenting and leak test of fuel oil system on engine 01201/A1. .

. . . . . . . . . . . . . . Venting the lubricating pump (cylinder

lubrication) 72181/A1. . . . . . . . . . . . . . . .

Viscosity-temperature diagram 02702/A1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .WWarnings and safety measures (general) 02101/A1. . . . . . . .

. . . . . . . . . . . . . . . Wash-water piping system 83451/A1. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water, operating medium… 07601/A1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . WECS9520 components, failures

and defects of… 08501/A1. . . . . . . . . . . . . . WECS9520

engine control system 40021/A1. . . . . . . . . . . . . . . . . . .

. . . . . . . . WECS9520 manual control panel 46181/A1. . . . . . .

. . . . . . . . . . . . . . . . . . . . . Working principle of

two-stroke diesel engine 00601/A1. . . . . . . . . . . . . . . . .

. . .2008

Alphabetical Table of Contents

-

Operation 00351/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

1. Symbols

These stand for control components (valve units etc.) used for

engine control.Symbols ExplanationsA Control air supply unitB Fuel supply

C Fuel injectionD Servo oil supplyE Valve unit for start

F Exhaust valve driveH Instrument panelI Pressure switches and

pressure transmittersK Local control panel2. Abbreviations

2.1 GeneralThe abbreviations used in the manuals are arranged

alphabetically in this guide,however, unit of measures are not

listed.Remark: Identical abbreviations e.g. MCR can be

distinguished in the corre-sponding context.Abbreviations ExplanationsAHD AheadALM AlarmAST AsternBDC Bottom

Dead CenterBFO Bunker Fuel OilBN Base NumberCCAI Calculated Carbon

Aromaticity IndexCMCR Contract Maximum Continuous RatingCOC

Cleveland Open CupHFO Heavy Fuel OilIMO International Maritime

OrganisationISO International Standard OrganisationJIS Japanese

Industrial StandardsMCR Maximum Continuous RatingMCR Micro Carbon

ResidueMDO Marine Diesel Oilmep mean effective pressureMGO Marine

Gas OilPMCC Pensky Martens Closed Cup methodGuide for Symbols and Abbreviations

2008

-

Operation00351/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 2

Abbreviations ExplanationsRCS Remote Control SystemSCR Selective

Catalytic ReductionSIPWATP Sulzer Integrated Piston ring Wear detecting

Arrangementwith Trend ProcessingSHD SHut DownSHF Sediment by Hot FiltrationSLD SLow DownTDC Top

Dead CenterWHR Waste Heat Recovery system2.2 Concerning engine control system WECS9520

ALM20 Advanced Lubrication Module20AMS Alarm and Monitoring

SystemCANBus Controller Area NetworkCAN M CAN Modul busCAN S CAN

System busCOMFN COMon FuNction (engine-related control

functions)CYLFN CYLinder FuNction (cylinder-related control

functions)DENIS9520 Diesel Engine CoNtrol and OptImizing

Specification forWECS9520ECR Engine Control RoomFCM20 Flex Control

Module20FQS Fuel Quality SettingLED Light Emitting DiodeSCS Speed

Control SystemModbus GouldModicon FieldbusOPI OPerator Interface

(user interface in control room)PCS Propulsion Control SystemRCS

Remote Control SystemSIB Shipyard Interface Box (engine / remote

control interface)SSI Synchron Serial InterfaceVEC Variable Exhaust

valve ClosingVEO Variable Exhaust valve OpeningVIT Variable

Injection TimingWECS Wrtsil Engine Control SystemWECS9520

Computerized control system for all flex-specific functionsGuide for Symbols and Abbreviations

2008

-

Operation 00401/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 3

1. Contents

The Operating Manual, called Operation for short, mainly

contains descriptionsand indications on: Servicing of the engine in

operation. Required operating media (oil, water, air, fuel).

Explanations of the function of specific components and

systems.Remark: The instructions on maintenance and overhauls are

found in a separatebook, the Maintenance Manual.2. Where to find what

When looking for group descriptions consult first of all the

Table of Contents00201. The Subject Index 00301 is also very

useful.In the cross section and longitudinal section illustrations,

important componentshave been marked with the group number where

they can quickly be found withtheir description. The sections

further provide a general view of the design of theengine, which,

depending on specific executions, may differ slightly.Cross section and longitudinal section see pages 2 and 3.

3. Guide for symbols and abbreviations

The symbols and abbreviations used in the Operating Manual are

explained in theguide 00351. Abbreviations used in the

illustrations are listed in the correspond-ing keys.GeneralExplanations on the Use of the Operating Manual

2008

-

Operation00401/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 3

Cross Section:

65451

27281

27511

65001

64201

66061

83451

80171

36031

80161

016.899/08

27221

3403121241

8016180191

19031

80181

43251

72181

23031

33261

33031559115556155831

55811

41041

Explanations on the Use of the Operating Manual

2008

-

Operation 00401/A1RT-flex82C

Wrtsil Switzerland Ltd 3/ 3

Longitudinal Section:

27511

12031

19031

34031

016.900/08

21241

21381

41041

23031

33261

33031

31461

92231

11321

Explanations on the Use of the Operating Manual

2008

-

Operation 00501/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

1. General

The RTflex engine is a single acting two-stroke diesel engine of

crossheaddesign with exhaust gas turbocharging and uniflow

scavenging.For direct coupled propeller drive it is reversible. The RTflex

concept is based on the Wrtsil Common Rail, with full electron-ic control of fuel injection and exhaust valve actuation. The

engine control is devised in such a way that remote controls of

recom-mended manufacturers which correspond to our specifications can

be builton, because the locations of interfaces are exactly

defined.In case of failure of the remote control the engine can be

controlled with emer-gency control from the local control

panel.Tie rods bind the bedplate, columns and cylinder jacket

together. Crankcase and cylinder jacket are separated from each

other by a partitionwhich incorporates the sealing gland boxes for the piston rods.

The thrust bearing and turning gear are situated at the engine

driving end. The exhaust valve actuation and the electronic

injection are controlled by theengine control system WECS9520. Lubricating oil, cooling water,

fuel feed and booster pumps as well as air com-pressors are parts of the engine room installation (ancillary

systems).2. Systems

The exhaust valves are opened hydraulically by the servo oil

system andclosed pneumatically. The oil supply is ensured from the

bearing oil systemthrough a fine filter. Servo oil pumps in the

servo pump unit provides the servooil rail with the required

pressure via three rising pipes.The pistons are cooled by bearing oil.

Fuel pumps in the fuel pump unit deliver fuel under high

pressure into the fuelrail via rising pipes and subsequently

through the injection control units toeach injection valves.The injection control units are activated via the servo oil

system.The cylinders and cylinder covers are fresh water cooled. For

cooling the scavenge air a single-stage cooler is used with central

freshwater cooling (closed circuit).

The engine is started by compressed air entering into the

cylinders via startingvalves, controlled by the WECS9520.2008

GeneralBrief Description of the Engine

-

Operation00501/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 2

The exhaust gases flow from the cylinders through the exhaust

valves into anexhaust gas manifold.The turbochargers work on the constant pressure charging

principle. The scavenge air delivered by the turbochargers flows

through air cooler andwater separator into the air receiver.It enters the cylinders

via air flaps through the scavenge ports when the pis-tons are

nearly at their BDC.At low loads independently driven auxiliary blowers supply

additional air to thescavenging air space.2008

Brief Description of the Engine

-

Operation 00601/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 1

First Stroke: (Compression) Piston in BDC (Bottom Dead Centre).

Scavenge ports and exhaust valve open. Scavenge air flows into the

cylinder and presses the exhaust gases throughthe exhaust valve into the exhaust gas manifold and from there

to the turbo-charger.Piston moves upwards.Point ES:

Scavenge ports are being closed by the piston.Point AS:

Exhaust valve shuts, compression begins.

Second Stroke: (Ignition Combustion Expansion Exhaustion

Scavenging) At around the TDC (Top Dead Centre) fuel is injected

into the cylinder. The fuel ignites in the compressed, heated air =

ignition. With ignition com-bustion begins. The gases expand and press the piston downwards

(working stroke).Point AO: The exhaust valve opens, exhaust gases flow out of the

cylinder into the ex-haust gas manifold and from there to the turbocharger.Point

EO:Scavenge ports are being uncovered by the downward moving

piston. Scavenge air flows into the cylinder and presses the

exhaust gases outthrough the exhaust valve into the exhaust gas manifold and from

there to theturbocharger.(See schematic diagram of Turbocharging 65001)

TDC

BDC

AO

EOES

AS

2008

GeneralWorking Principle of the Two-stroke Diesel Engine

-

Operation 00701/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

1. General

There is a defined relationship between the propeller speed and

the absorbedpower in ships equipped with fixed pitch

propellers.With a given propeller this relationship mainly depends

on its rotational speed.The following formula provides us with an

approximation which is adequate for thegeneral consideration of

conventional vessels:=

P1P2

n1

n2

3

Its graph is called the propeller characteristic.

If an engine is in good condition and properly supplied with air

(i.e. turbocharger(s)in good order and the air and exhaust lines

have low additional resistance) and thefuel injection quantity is

properly adjusted (see setting table), the mean effectivepressure

developed under service condition according to the specific reading

ofthe load indication corresponds approximately with the mean

effective pressureestablished for this particular position on the

test bed.In the diagram, the propeller characteristic line through the

point of CMCR (Con-tract Maximum Continuous Rating), i.e. nominal

power at nominal engine speed(100% power at 100% engine speed) is

called the nominal propeller characteristic.Engines which are to be

employed for the propulsion of vessels with fixed propel-lers are

loaded on the test bed according to this propeller characteristic.

However,the power requirement of a new ship with a smooth and clean

hull should be lessand correspond to the range D.With increasing resistance, changes in wake flow conditions, due

to marine growthand ageing of the vessels hull, a rough or

mechanically damaged propeller, unfa-vourable sea and weather

conditions or operation in shallow water, the propellerwill require

a higher torque to maintain its speed than it did at the time of

sea trial.The mean effective pressure of the engine (and thus the

fuel injection quantity) willincrease accordingly. In such a case,

the operating point will then be located to theleft of the original

propeller curve which was established during sea trials.Although cleaning and re-painting will help to reduce the

increased resistance ofthe ships hull, the original condition can

no longer be attained.Whereas the thermal loading of an engine depends chiefly on the

mean effectivepressure, the position of the operating point is also

important; the farther left it issituated from the propeller curve

in the diagram (page 2), the poorer the air supplyto the engine and

the more unfavourable the engines operating conditions will

be-come.In order to attain optimum working conditions, the operating

point of the engine forcontinuous service should lie in range A on

the right side of the nominal propellercharacteristic.Explanations:CMCR = Contract Maximum Continuous RatingP = Powern

= speedmep = mean effective pressureSee also Guide for Symbols and Abbreviations 00351.

GeneralInterrelationship between Engine and Propeller

2008

-

Operation00701/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 2

120

110

90

80

70

60

50

40

35

100

70 75 80 85 90 95 100 110ENGINE SPEED

[%CMCR]

[%CMCR]

104 108

E

N

G

I

N

E

P

O

W

E

R

CMCR

60 65

B D A C

A’

93.7060

E

2. Load ranges

A The portion on the right of the nominal propeller

characteristic is the ser-vice range without continuous operating

restrictions related to the se-lected CMCR point.The portion on the

left of the nominal propeller characteristic is the servicerange

for transient operating conditions (acceleration) and should

beavoided for continuous operation.A Maximum permissible engine power 40% CMCR from approx. 50% up

to67% of CMCR speed.B Service range with operational time limit, follows a

characteristic:P n 2.45.This characteristic originates from the

reference point 95% CMCR powerand 95% CMCR speed. With longer

operating time in this range, thermaloverloading and possible

resulting engine damage may be expected.C Service range with overspeed of 104 to 108% of CMCR speed,

only per-missible during sea trials to demonstrate the CMCR power

in presence ofauthorized representatives of engine builder.

However, the specified tor-sional vibration limits must not be

exceeded.D Recommended layout range for fixed pitch propeller, valid for

the maxi-mum draught, clean hull under contractual weather and sea

conditions.E Overload range permissible only for maximum one hour during

seatrialsin presence of authorized representatives of engine

builder.Interrelationship between Engine and Propeller

2008

-

Operation 00801/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

General:

EXHAUST SIDEFUEL SIDE

FREE END

Thrust Bearing Pads

Turbocharger 1

DRIVING END

Main Bearing Numbering

65432 87

Turbocharger 2

9 10

1 2 3 4 5 6 7 8

016.833/08

1

Rail Unit

Fuel Pump Unit

Clockwise Rotation

CylinderNumbering

Servo Pump Unit

GeneralEngine Numbering and Designations

2008

-

Operation00801/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 2

flex Parts:

DRIVINGEND

FUEL SIDE

FREE END

FUEL SIDE

Fuel Pump B1Fuel Pump B2Fuel Pump B3

013.150/05

Fuel Pump A1Fuel Pump A2Fuel Pump A3

Actuator A1Actuator A2Actuator A3

Servo Oil Pump 3Servo Oil Pump 2Servo Oil Pump 1

EXHAUST SIDE

016.834/08

Actuator B3Actuator B2Actuator B1

Crank Angle Sensors

Sensor 2(GT5127C)

Sensor 1(GT5126C)

DRAWN FOR 9 TO 12CYLINDERS

Engine Numbering and Designations

2008

-

Operation 01101/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

1. Starting position

It is assumed that: all components on which overhaul work was

carried out have previously beencorrectly re-assembled and fitted and checked as to their

perfect function. all devices and tools which were used have been

removed from the engineand that no cleaning rags or other items have been left behind.

The setting of the fuel pumps and the connection of the actuators

with theregulating linkage are in order.Attention! Up to point where the

venting valves 2.21 and 2.27 must be closed, theshut-off valve for

starting air 2.03 remains in position CLOSED (closed by hand),the

venting valve 2.21, and the venting valve 2.27 in the starting air

main must beopen (see Control Diagram 40032).2. Checks and preparations

Check the fluid levels of all the tanks in the engine systems

(including the leak-age drain tanks).Check that all the shut-offs for the engine cooling water and

lubricating oil sys-tems are in the correct position.Check that the lubricating device (tool 94844 provided for

additional lubrica-tion of the fuel pump drive during overhaul

works) is removed and the oil pipeis properly closed by means of

the blank flange (see Maintenance Manual55814).Open the air supply from the shipboard system to the control air

supply A . Open the shut-off cock at connection A1 and put air

spring venting 4.08 tooperating position (see Control Air Supply 46051). Preheat the

lubricating oil to about 35 C (via separating circuit or heating in

oildrain tank). Preheat the cylinder cooling water to min. 60 C.

Switch on the engine and remote control system WHENS9520.Switch on all breakers in the power supply box E85. Check that

both green indication LETS light up on all FCC20 modules.The FCC20 modules are able to function if no red LETS light up

after thecountdown process.Prepare the servo oil system (see 01301). Start up the pumps for

cylinder cooling water, bearing oil and set the pres-sures to their normal values (see Operating Data Sheet 02501).

Switch on control box for automatic filter (see documentation of

the automaticfilter manufacturer). Switch on main switch of the servo oil

service pumps. Prepare the cylinder lubricating system (see 01401).

Prepare the fuel oil system (see 01201). Ensure that all systems

are correctly vented. After ensuring air spring supply, check

whether all exhaust valves are closed.Preparation before Taking into ServicePreparations before

Starting after a Short Shut-down (One or More Days)2008

-

Operation01101/A1 RT-flex82C

Wrtsil Switzerland Ltd 2/ 2

Open and shut each exhaust valve 4.01 few times manually in

remote controlin order to ensure thorough venting of the hydraulic

actuators of the exhaustvalves (user parameter, function Ex. A/M

Mc).Remark: The engine can not be started if the exhaust valves are

not fully closed. Open each cylinder covers indicator valve. With

the aid of the turning gear,turn the engine through at least one full revolution to check

that all the runninggears are in order. Neither water, oil nor fuel

may spray out of the indicatorvalves. If so, depending on the

liquid, check cylinder liner, cylinder cover, pis-ton or injection

valves.With this the cylinder lubrication must be switched on.Shut indicator valves. Check to ensure that all the crankcase

doors are locked with all the clamps. Check that the fuel pump

regulating linkage moves freely. Check the pressure in the starting

air bottles and open their drains until anycondensate has been drained. Open the drain and test valve 2.06

until no more water comes out. Close venting valves 2.21 and 2.27

and open the main shut-off valves on thestarting air bottles 9.01. Bring the shut-off valve for starting

air 2.03 to position AUTOMAT. Open the shut-off cock at connection

A2 (see Control Air Supply 46051). The pressure gauges on the

instrument panel must now show starting air andcontrol air pressure. A pressure must also be indicated on the

pressure gauges for the control airsupply.The different circuits are: Air spring air Control air

Air supply from the board system and back-up supply from the

starting air sys-tem via the pressure reducing valve 19HA.Required pressures see

Operating Data Sheet 02501). Set the switches on the control panels

for the auxiliary blowers to AUTOMAT. Switch off the servo oil

service pump. Disengage the turning gear and secure the lever. Open

the test valve 2.06 of the shut-off valve for starting air 2.03 for

a shorttime and listen if the valve opens (can be heard distinctly).

Close the test valveagain.Press SLOW TURNING button in WHENS9520 manual control panel on

thelocal control panel (46181). The engine will perform one slow

revolution (seealso Slow Turning 02201).Depending from where the engine will be started (either bridge,

control roomor local control panel), the corresponding button in

WECS9520 manual con-trol panel (local control panel) and the

corresponding takeover buttons of theremote control must be

activated.Check again to ensure that no personnel are near the flywheel.

Inform readiness to the bridge.Preparations before Starting after a Short Shut-down (One or

More Days)2008

-

Operation 01201/A1RT-flex82C

Wrtsil Switzerland Ltd 1/ 2

1. For diesel oil operation

(see 07201 Layout of the fuel oil system) Set three-way valve 21

in the suction line of low pressure feed pump 23 so thatdiesel oil flows from daily tank 3 to the pump and to mixing

unit 24. Check to ensure that the shut-off valves before and after

engine are open. Start up pumps 23 and 25. Drain daily tanks and

mixing unit. Set pressure in fuel oil system using pressure

regulating valve 31. When run-ning with diesel oil (and low fuel temperature) a slight

over-pressure is suffi-cient. If later a change-over to heavy fuel

oil is required, setting of normal pres-sure is recommended from

the beginning.Set fuel oil pressure at fuel pump inlet using pressure

retaining valve 31a(3.53) (pressure difference before/after

pressure retaining valve see Operat-ing Data Sheet 02501).2. For heavy fuel oil operation

(see 07201 Layout of the fuel oil system)Remark: The fuel oil

system is not ready for service until the heavy fuel oil beforethe

fuel pumps has reached the required temperature (see

Viscosity-TemperatureDiagram 02702).The high pressure circuit on

the engine must be preheated for at least four to sixhours after a

prolonged shut-down period (more than 24 hours).Before that, the

engine may not be started on heavy fuel oil! Turn on the heating

for heavy fuel oil daily tank 2, mixing unit 24, end-heater26 and filter 27.