-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for Mindray DP-50

Summary of Contents for Mindray DP-50

-

Page 1

DP-50/DP-50T/DP-50 PT/DP-50Expert/DP-50 Pro/DP-50S/DP-50W/DP-70/DP-70T/D P-70 Pro/DP-70 Expert/DP-70C/DP-50 Vet/DP-70 Vet/DP-50 Exp Vet Digital Ultrasonic Diagnostic Imaging System Service Manual Revision 6.0… -

Page 3: Table Of Contents

Table of Content Table of Content……………………i Revision History ……………………I Intellectual Property Statement ………………II Applicable for……………………II Statement ……………………… III Responsibility on the Manufacturer Party …………… III Customer Service Department ………………III Preface……………………1-1 Meaning of Signal Words ………………..1-1 Meaning of Symbols ………………….

-

Page 4

Installing Peripherals ………………….. 3-8 3.4.1 Footswitch Installation ………………..3-8 3.4.2 Video Printer Installation………………. 3-8 3.4.3 Installing a Graph / Text Printer …………….3-9 3.4.1 Installing Printer Adapter ………………3-9 3.4.2 Installing External DVD-R/W ……………… 3-14 System Configuration ………………..3-14 3.5.1 Power ON / OFF ……………….. -

Page 5

6.5.1 Product Configuration ………………..6-7 6.5.2 Log Maintenance ………………… 6-7 Display Parameter Setting ………………..6-9 HDD Partition …………………… 6-10 Field Replacement Unit ……………….. 7-1 Explosive View …………………… 7-2 Assembly Explosive View ………………..7-3 7.2.1 Monitor Assembly (A0) ………………… 7-3 7.2.2 Operation Panel Assembly (B0) ……………. -

Page 6

10.1.2 Care and Maintenance Items …………….. 10-2 10.2 Cleaning ……………………10-3 10.2.1 Clean the System ………………..10-3 10.2.2 Content ……………………10-3 10.2.3 Clean the Peripherals ………………… 10-6 10.3 Checking ……………………10-6 10.3.1 General check ………………….10-6 10.3.2 System Function Check ………………10-7 10.3.3 Peripherals and Options Check ……………. -

Page 7: Revision History

Revision History Mindray may revise this publication from time to time without written notice. Revision Date Reason for Change 2019.06 Initial release 2019.08 Update the probe board FRU and add new FRUs in chapter 7. 2020.02 Update monitor assembly procedure and relevant FRUs.

-

Page 8: Intellectual Property Statement

Intellectual Property Statement SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the intellectual property rights to this Mindray product and this manual. This manual may referring to information protected by copyright or patents and does not convey any license under the patent rights or copyright of Mindray, or of others.

-

Page 9: Statement

Mindray or repairs by people other than Mindray authorized personnel.

-

Page 11: Preface

Preface This chapter describes important issues related to safety precautions, as well as the labels and icons on the ultrasound machine. Meaning of Signal Words In this operator’s manual, the signal words DANGER, WARNING, CAUTION and NOTE are used regarding safety and other important instructions. The signal words and their meanings are defined as follows.

-

Page 12: Warning Labels

1.2.2 Warning Labels Warning Labels Meaning Please carefully read this manual before use device. The following labels are a. Do not place the device on a sloped surface. Otherwise the available when the system device may slide, resulting in personal injury or the device works with the mobile malfunction.

-

Page 13

Symbol Meaning Location panel Battery indicator Standby indicator Lower right corner on the control panel Hard disk indicator Probe port A Rear panel Probe port B This product is provided with a CE marking in accordance with the regulations stated in Council Directive 93 / 42 / EEC concerning Medical Devices. -

Page 14: Safety Precautions

Do not use any cables other than the cables provided with the device by Mindray. 3. Use the cable provided with this system to connect the printer. Other cables may result in electric shock.

-

Page 15: Mechanical Safety

The user is not allowed to open the covers and panel of the system, neither NOTE: device disassemble is allowed. To ensure the system performance and safety, only Mindray engineers or engineers authorized by Mindray can perform maintenance. Only technical professionals from Mindray or engineers authorized by Mindray after training can perform maintenance.

-

Page 17: Product Specifications

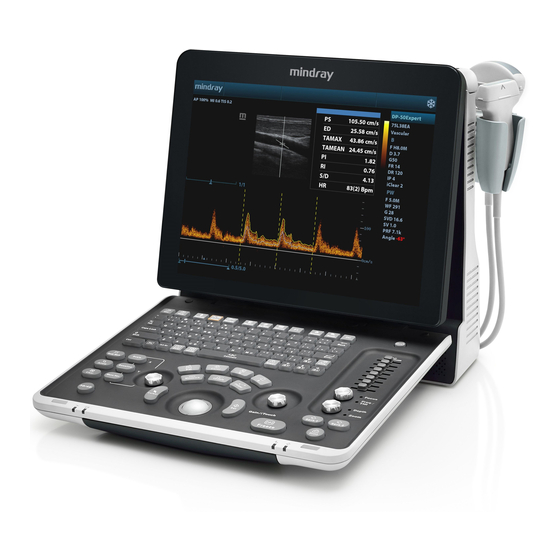

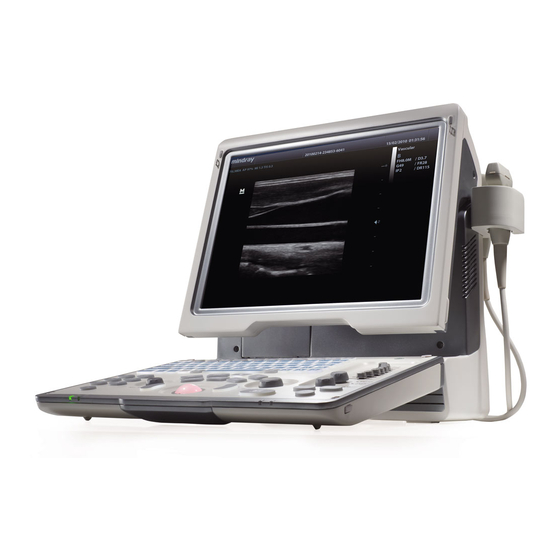

Product Specifications Overview 2.1.1 Intended Use The digital ultrasonic diagnostic imaging system is intended for use in clinical ultrasonic diagnosis. 2.1.2 Introduction of Each Unit Right View Product Specifications 2-1…

-

Page 18

Left View Rear View 2-2 Product Specifications… -

Page 19: I/O Panel

Bottom View Name Function Probe holder Used to place the probe Display Displays the image and parameters during scanning Control Panel Refer to the 2.1.5 Control Panel. USB ports Used to connect USB devices Handle Used to carry the machine Interface panel used for inputting and outputting signals, refer to I/O Panel 2.1.3 I/O Panel.

-

Page 20: Power Supply Panel

Symbol Function Network port USB ports Separate video output, connecting video printer or LCD Remote control port VGA signal output Composite video output Power indicator 2.1.4 Power Supply Panel Name Function Power inlet AC power inlet Used for equipotential connection, that balances the protective Equipotential terminal earth potentials between the system and other electrical equipment.

-

Page 21: Control Panel

2.1.5 Control Panel Name Description Function Off: when system is turned off; Power button Green: when system is turned on by pressing this button. Exit Press to exit the current status to the previous status. Press to display or hide the help information on Help screen.

-

Page 22

Name Description Function User-defined key You can assign a function to the key. Biopsy Press to show or hide the biopsy guide line. Setup Press to open/close the setup menu. Press to delete the comment, etc. Alphanumeric Same as on PC keys Press to enter Dual mode from non-Dual mode;… -

Page 23

Name Description Function Rotate: to adjust the gain Gain/ iTouch Press: to enter/ exit iTouch Move to adjust time gain compensation. Focus Press: to switch between Focus and Freq./THI; Freq./THI Rotate: to adjust corresponding parameter Depth Press: to switch between Depth and Zoom; Zoom Rotate: to adjust corresponding parameter Save 1… -

Page 24: Peripherals Supported

2.1.6 Peripherals Supported Item Model Graph / text printer HP OFFICEJET PRO 8100 Digital Color Video SONY UP-D25MD Printer MITSUBISHI P93W-Z Black and White Video Analog Printer SONY UP-X898MD Footswitch (1-pedal (not for CE region); 2-pedal; 3-pedal) LAN Accessory LPA11 (only for CE region) If the ultrasound system cannot recognize the SONY UP-X898MD printer automatically, you may need to change the settings on the printer: push <PUSH ENTER>…

-

Page 25: Monitor Specification

2.2.4 Monitor Specification Voltage Dimension 15 inch Resolution 1024×768 Adjustable angle ≤60 degree Product Specifications 2-9…

-

Page 27: System Installation

System Installation Preparations for Installation NOTE: Do not install the machine in the following locations: Locations near heat generators; Locations of high humidity; Locations with flammable gases. 3.1.1 Electrical Requirements 3.1.1.1 Requirement of Regulated Power Supply Requirement of power supply is referring to 2.2.2.Due to the difference of the power supply stability of different districts, please advise the user to adopt a regulator of good quality and performance such as an on-line UPS.

-

Page 28: Installation Condition

3.1.2 Installation Condition 3.1.2.1 Space Requirements Place the system with the necessary accessories at a proper position for convenient use. 1. Place the system in a room with good ventilation or having an air conditioning unit. 2. Leave at least 20cm clearance around the system to ensure effective cooling. 3.

-

Page 29: Unpacking

3.2.1 Unpacking Use the scissor to clip the 2 rubber belts as follows: Use a knife to open the tapes: Take out the operation manual: Take out the probe box 1: Take out the accessory box: System Installation 3-3…

-

Page 30

Take out the probe box2, as follows (the box is below the accessory box): Hold the handle tightly and pull the machine with the surrounding foam: Remove the surrounding protective foam to take out the main system. 3-4 System Installation… -

Page 31: Checking

3.2.2 Checking 1. After unpacking, check the objects in the container with the package list to see if anything is in short supply or is wrong. 2. Inspect and make sure there is no damage to the machine, no indentation, no cracks. Installation of Main Unit 3.3.1 Installing Battery…

-

Page 32: Display Adjusting

3.3.3 Display Adjusting 1. Open the display as described in 3.3.2. 2. Put the finger on the rim of the display and pull the display to tilt the display (60 degrees max.). 3. Tear off the screen protective film. Tilt the display Figure 3-3 Open and tilt the display Press <Fn>+ directional keys to adjust brightness and contrast.

-

Page 33: Installing Probe Holder

NOTE: On the monitor, the brightness adjustment comes before contrast. After readjusting the monitor’s contrast and brightness, adjust all preset and peripheral settings. 3.3.4 Installing Probe Holder Fix the probe holder hanger into the groove of the main unit, and push downwards to confirm the installation.

-

Page 34: Installing Peripherals

NOTE: Before inserting the connector into the probe port, inspect the connector pin. If the pin is bent, do not use the probe until it has been inspected / repaired / replaced. Installing Peripherals For the models of the supported peripherals, please refer to “2.1.3 Supported Peripherals”. 3.4.1 Footswitch Installation Connecting: Take 971-SWNOM as an example: insert the USB connector to the system…

-

Page 35: Installing A Graph / Text Printer

Video cable Remote port Figure 3-6 Installing Analog Video Printer Digital Video Printer Connect one terminal of the data cable of the video printer to the USB port of the ultrasound system and the other terminal to the video input port of the video printer; Insert the power cord to a power supply receptacle that is well grounded.

-

Page 36

Name Function 1. Power Button Powers on the printer adapter. 2. USB port Connects the printer to the printer adapter. 3. Network port Connects the printer adapter to the Ultrasound system. Power inlet Connects the printer adapter to power by using the auxiliary output port of the Ultrasound system. -

Page 37

System Connection Note: A maximum of 6 text/graph printers can be connected to the printer adapter at the same time. Before power on, perform the following steps: Connect the printer adapter to the ultrasound system using Shielded Ethernet cable; Connect the printer adapter to the ultrasound system using AC power cord together with the power adapter;… -

Page 38

Open the Network page via [Setup] [Network Preset] [Local TCP/IP]. Select Static; Set the IP Address to any value from 192.168.1.1 to 192.168.1.200 (192.168.1.10 is excluded, because it belongs to the printer adapter); Set the Subnet Mask to 255.255.255.0 and Gateway to 192.168.1.254; Click [Save]. -

Page 39

Printer Adapter Preset Open the Printer Adapter page via [Setup] [Print Preset] [Printer Adapter]. Set the IP Address to 192.168.1.10 and Port number to 6666. Click [Add], and the Printer Adapter name is displayed in the Service List. Print Preset … -

Page 40: Installing External Dvd-R/W

3.4.2 Installing External DVD-R/W Connect the USB cable connector of the external DVD recorder to the USB port in the ultrasound system. cable Figure 3-7 Installing External DVD System Configuration 3.5.1 Power ON / OFF Connect the system power cord to the AC power, and make sure the ultrasound system and other optional devices are correctly connected.

-

Page 41: System Preset

3.5.3 System Preset Press the <Setup> key to enter the [Setup] menu. Click <System Preset> to enter the screen as follows: Region System Installation 3-15…

-

Page 42

In the Region page, set the system language, date format, date, time and hospital related information, etc. General Click <System Preset> to enter: In this page, set the time of standby, brightness/contrast and color temperature of display,etc. Key Config 3-16 System Installation… -

Page 43

Function of keyboard keys <Print>, <Save>, F1 and the footswitch keys (left, mid, right) are user-defined. Key brightness, key volume, trackball backlight and trackball sensitivity can be adjusted. Image Preset Click [Image Preset] to enter: System Installation 3-17… -

Page 44: Print Preset

General image parameters can be set in this page. 3.5.4 Print Preset Press <Setup> and click [Print Preset] to set video printer, graph/text printer parameters: After connecting the local printer, Click “Printer Driver”, the system will display the printer name and status (Ready) automatically which already installed printer driver successfully.

-

Page 45

Return “Printer Service” page, Select the corresponding service from the printer list and increase the service. The system integrates drivers of HP printers, after HP printers are connected, drivers will be installed automatically (about 10s).If auto installation fails, icon will display on the right lower corner of the screen to warn you that manual installation is necessary. -

Page 46: Network Preset

After successful connection, the newly added network printer name will be shown in the printer driver list. NOTE: Before connect the network printer, make sure the ultrasound system and the printer are in the same network domain, and the network is working normally. The IP address and the server name should be valid, e.g.

-

Page 47

DICOM Setting Enter the AE Title of the ultrasound system, port and PDU according to the actual situation, and then click [OK] to exit the screen. NOTE: AE Title should be the same with the SCU AE Title preset in the server (PACS/RIS/HIS). -

Page 48

Only when the system is configured with DICOM basic function module, and installed DICOM Work list, MPPS, DICOM Structured Reporting and Query/ Retrieve modules, can the corresponding preset settings be found in DICOM Service screen. The DICOM Service Setting is used to set properties of DICOM services as Storage, Print, Work list, MPPS, Storage Commitment and Query/ Retrieve. -

Page 49: System Information

3.5.6 System Information In System Information screen, it displays the product configuration, software version, hardware & boards, and driver related information. You can check the product information here. 1. Press the <Setup> and click [System Info] to enter system information screen. 2.

-

Page 51: Hardware Principle

Hardware Principle General Structure of Hardware System Monitor Probe IO board board 4D drive board Main module board Control panel Hard disk Speaker Battery DC-DC connecting Charge/ Battery board discharge board Ultrasound signal AC-DC Power supply board Comm&control AC IN Figure 4-1 Schematic Diagram of System As a portable black-and-white ultrasonic product, the system supports two probe slots.

-

Page 52: Main Unit

Main Unit The main unit mainly involves 3 boards: Probe board (Two probe ports) Main board IO board 4D drive board (optional) 4.2.1 Probe Board A+5V LC filter A+95V +95V 3.3V/5V BOARD ID A-95V -95V PRB_A_VDD_EN, PRB_A_VCC_EN Power ON/OFF D+3V3…

-

Page 53: Main Board

Support 4D probe; recognize the probe via the ID code; switch the 4D drive signal via the electrical relay to make the 4D probe work normally. 4.2.2 Main board The main board could be divided into two parts: front-end of the main board and back-end of the main board.

-

Page 54

BF FPGA combines 64-channel echo signal to output to DSP FPGA, and DSP FPGA is sent to signal processing to a single image which is uploaded to CPU module by PCIE_PHY, then CPU module performs post processing. PCI_PHY implements PCIE interface switching. … -

Page 55: Io Broad

Back-end of the main board MUL FPGA implements display ports, it also supports display assembly, video and s-video interface of IO board. Multifunction FPGA on the back-end of the main board is to implement the REMOTE port on the IO panel. The CPU module implements interfaces including USB, Ethernet and VGA on the IO …

-

Page 56: Drive Board (Optional)

4.2.4 4D Drive Board (Optional) Communication & 4D Drive Board Ultrasonic si gnal Control Power supply Communication signal Voltage control Motor driving signal Power probe amplication 4D probe Hall return signal Amplifies 4D drive signal power and output signal matching the power requirement to drive the …

-

Page 57: Ultrasound System Indicator

Function: On the back-end of the main board, a special monitor IC is used to monitor signal voltages and clock battery power that are provided to the main board by the main unit box power supply module. The system temperature is detected in three positions: BF FPGA, CPU module and power …

-

Page 58: Display

4.2.7 Display Parameter High-voltage Inverter board board screen Display Brightness 3.3V 3.3V LVDS ON/OFF control IO board Brightness 3.3V control triode triode LVDS Control signal Brightness of switch Multifunction FPGA Main board Figure 4-8 Principle Diagram of Display Monitor mainly consists of the inverter board, LCD and the parameter board. Function describes as following: The inverter board produces high voltage to illuminate backlight of LCD which is adjusted …

-

Page 59: Control Panel

4.2.8 Control Panel Trackball TGC board Control panel PCBA ADC curcuit FPGA 5 status backlight Trackball indicators scan scan backlight Main driver curcuit board Main Interface Functional control Single- chip button encoder scan board +12V PWM generating Double- curcuit encoder board Buzzer driver curcuit Buzzer…

-

Page 60: Power System

Power System Power supply module DC-DC Main board boar POWER 14.8V,6600mAh drive board Display Battery in place ARM control signal MUL FPGA Control signal AC in place Restart automatically Power on/off signal control Battery connecting board CPU module Power 12V、5V Temperature signal management Battery in…

-

Page 61: System Power-On Control

Power Support circuit module or function Remarks description 3 +5V HDD, Control panel, Front-end of main board, Probe board 4 -5V Front-end of main board 5 5Vst CPU module 6 VDD Front-end of main board, Back-end of main board, Display 7 1V2 Back-end of main board (FPGA core voltage) 8 1V8A…

-

Page 62

Controlling signal Description Remarks SUS_S3_N CPU module output effectively represents that CPU system has been in the standby status, when 5VSTB which is controlled by power management FPGA is in the charging status. SUS_S4_N CPU module output effectively represents that CPU system has been in the dormancy status. -

Page 63

Pressing power button (Control panel) Receiving PWR_BTN_N effective (Power management FPGA) Is AC in place? (Ppower management FPGA) CPU_PWR_BTN_N is valid PWR_5VSTB_EN_N is valid (Power management FPGA) (Power management FPGA) SUS_S3_N and SUS_S4_N 5VSTB start-up is invalid(CPU module) (Power supply module) Indicating PWR_5VSTB_OK_N is valid 5VSTB_CPU… -

Page 65: Function And Performance Checking Method

The chapter supplies the method to verify main function and performance of product. This is only used for reference, not preventive execution. Function checking and testing of this part shall be carried out by Mindray service engineers and the user together.

-

Page 66: General Exam

General exam 5.3.1 Check Flow Check the control panel Check the monitor Check DVD Check peripherals Check I/O ports 5.3.2 Checking Content 5.3.2.1 Check Control Panel Procedure Standard Check the functions of all keys and knobs All keys and knobs are effective. Follow the direction: left to right, and up to down.

-

Page 67

5.3.2.2 Check the Display Procedure Standard Press “<Fn>+< >”, the brightness increases; and press Adjust LCD brightness “<Fn>+< >”, the brightness decreases. Adjust LCD contrast Press “<Fn>+< >”, the contrast increases; and press Display color temperature … -

Page 68: Function Checks

bar Code scanner: The bar code is correctly displayed on the screen. Perform code bar scanning when the ultrasound system is running normally. 5.3.2.5 Check IO Ports Procedure Standard Checking IO ports: The contents displayed on the VGA/LCD are the same …

-

Page 69: Checking Content

5.4.2 Checking Content 5.4.2.1 B Mode In B Mode scanning, the image parameter area in the right corner of the screen will display the real-time parameter values as follows: Display Image Parameters Frequency Depth Gain Frame Rate B Dynamic Range Parameters that can be adjusted to optimize the B Mode image are indicated in the following.

-

Page 70

Focus Position Adjustment The focus position will change in correspondence with the knob rotates. Press <Focus/Freq./THI.> light Focus indicator, rotate the knob Frequency adjustment Rotate clockwise to increase Press Rotate anticlockwise to decrease <Focus/Freq./THI.> light on the Freq./THI “FR” will be changed relevantly. indicator, rotate the knob iTouch iTouch sign will be displayed in the image area to activate image effect… -

Page 71

mode menu-> parameter. [Line Density] The higher the line density, the higher the resolution, and the lower the frame rate. iClear Click [iClear] to adjust, off represents no iClear is turned on, and the bigger the value the stronger the effect. The bigger the value the more clearly the mode menu->… -

Page 72

Menu Procedure Standard Speed Click [Speed], and rotate the multifunction knob to adjust the parameter. B mode menu-> [Speed] The lower the value the faster the refreshing. Display Format There are 4 formats available for image display: L/R, V1:1, V1:2, Full. M mode menu->… -

Page 73

5.4.2.4 PW Mode In PW Mode scanning, the image parameter area in the right corner of the screen will display the real-time parameter values as follows: Display Angle Pulse Sample Sample Image PW/CW Wall Frequency Repetition Volume Volume Angle Parameters Gain Filter… -

Page 74

Press <ESC> or <Cine> cine review. The images are still frozen but the system exits cine review. Auto Review Region Total frames Start mark Current frame Playback mark End mark 5.4.2.6 Measurement Procedure Standard In B mode Enter the application measurement mode. … -

Page 75: Performance Test

Performance Test 5.5.1 Test Process Resolution Detection depth Geometric Position Accuracy Blackout area test Record the exam images 5.5.2 Test Content The image used here is only for reference, stick to the image effect in the real NOTE: situation. Requirements: Display: set the contrast and brightness at the clinical application value (or the default status) Operation environment: dark room, simulating the clinical application environment.

-

Page 76

In condition that the transverse resolution testing targets are horizontally displayed, record the minimal distance of two targets that can be clearly recognized. Repeat the operation above for the transverse resolution testing targets at other depths. As shown in figure below. Axial resolution … -

Page 77

When using the convex probe, keep the transverse resolution testing targets to NOTE: be displayed near the midline. When using a linear probe with steer function, do not turn on the steer function when perform the transverse resolution test. Zoom in the region where the targets located if necessary. The diameter of the target point at a certain depth is equal to the transverse resolution at the depth. -

Page 78

5.5.2.3 Geometric positioning accuracy Longitudinal geometric positioning accuracy Test Step: Do adjustments as the way in testing the maximum depth. Record the distance by 20mm each segment on the longitudinal targets line using the measurement caliper; Select the value with the greatest error (to 20mm), calculate the accuracy using the formula below The measurement caliper should be positioned at the upper edge of the target, NOTE:… -

Page 79

Transverse geometric positioning accuracy Test Step: Cover the scan surface of the phantom with water or couple gel, gently contact the probe with the scan surface Adjust the depth, making the transverse targets to be displayed in the image. Adjust the focus point to be posited beside the transverse targets (the standard is not clear) Adjust parameters like gain, TGC, making each transverse targets to be clearly displayed. -

Page 80

5.5.2.4 Blackout Area Test Step: Cover the scan surface of the phantom with water or couple gel, gently contact the probe with the scan surface Adjust the depth at a lower value, and set the focus at the nearest place to the scan surface. Decrease the value of parameters like AP, Gain until the background noise just can be seen. -

Page 81: Software Upgrade And Maintenance

Software Upgrade and Maintenance WARNING: DO NOT directly remove a USB memory device; otherwise, the USB memory device and / or the system may be damaged. Enter the Maintenance Window NOTE: Log on the system with the identity of Service before perform system maintenance. To log on the system: When access control function has not been activated: press “Ctrl+/”…

-

Page 82: System Software Installation/ Restoration

System Software Installation/ Restoration Refer to recovery guide. Installation of Optional Devices Copy the optional devices to the U disk, then insert it to the USB port of the ultrasound system; Enter [Preset], click [Maintenance] to enter [Option] menu to select the option module to be installed.

-

Page 83

3. Click [Install]. Select key file from the dialog box, and then click [OK]. 4. The options become Installed after the key files are installed. The corresponding function is activated after returning from preset. Note: After all modules are installed, please go to the previous interface to confirm. Trial: select the corresponding software package, and then click [Trial]. -

Page 84

Note: the promotion function is only applied to the uninstalled key. If the optional key is installed, the promotion function is disabled. 2. Select the key to be promoted. 3. Click [OK] to complete the promotion. Note: it is unavailable to use promotion for multiple optional keys. For the optional key which is promoted, it can also be installed. -

Page 85: Data Backup And Storage

Return to the system preset interface. The option status changes into Uninstalled. The uninstalling function is exclusive to internal users. The service engineers must Note: log in the system with the account of Service, and then conduct the uninstallation. Data Backup and Storage 6.4.1 Manage Settings Press <Setup>…

-

Page 86: Patient Data Backup And Restore

6.4.1.1 Back up the Preset Data 1. On Manage Settings page, Click [Export] to open the [Export Data] dialogue box. 2. Select the path to save data. 3. Click [OK], a progress bar will appear and the preset data of the selected items will be exported to the specified path.

-

Page 87: Software Maintenance

Software Maintenance 6.5.1 Product Configuration NOTE: [Config] is available on the Maintenance menu only if the operator logged on the system as Service. Make the product configuration file—PCF file (generated by the production line or already archived PCF file) according to specific requirements and copy to the USB disk. Connect the USB disk to the machine, click [Config] and load the file in the popped up dialogue box.

-

Page 88

Select the path in the Browse page to save the log, and click [OK]. When the log is exported, the system prompts “Export succeed!” click [OK] to return to the Maintenance menu. The log can be exported to the external USB storage device only, make sure the NOTE: connection between U disk and ultrasound is normal before the exporting. -

Page 89: Display Parameter Setting

NOTE: Before uploading the log, make sure the ultrasound system has been connected to network, otherwise, the system may warn “could not connect to server” The server (smtp.163.com) is already specified by the system, the user doesn’t have to select it. Display Parameter Setting NOTE: In normal condition, when changing display assembly or main board assembly, the…

-

Page 90: Hdd Partition

3. Click the upper icon in the screen (prompts “Update” if you put the cursor on it), the update step is carried out, if fails, please send to R&D center. Figure 6-1 Main Monitor Maintenance Screen 4. After update is successful, restart the machine after power off to make the data effective. HDD Partition …

-

Page 91

structured report related data file and DICOM viewing software Report report template obd.bin OBD data file version.txt Version file Comment Comment file AnatomyImage Anatomical images Measurement Measurement library Doppler program and related boot configuration main file and plug-ins, remote desktop server Multilanguage string file \exe videoplay… -

Page 92

\selftest Self test log appmon_window_monitor.txt Appmon monitor log message.txt Warning message PeriLog.txt Peripheral log commentlog.txt Comment log burn_cd_msg.txt Burn log error.txt System error log \PATIENTDATA Main patient database path \Preset \Current User preset data \temporary Temporary file \PatientBack Patient back up data E drive Catalog Data… -

Page 93: Field Replacement Unit

Field Replacement Unit This chapter lists the details of the Field Replaceable Units (FRU) of the system. Please refer to the explosive view and the FRU table below. Level 0 represent the main Assembly of the system, and the whole system is divided into 4 Assembly. Level X represent the main parts of Level 0 Assembly.

-

Page 94: Explosive View

Explosive View 7-2 Field Replacement Unit…

-

Page 95: Assembly Explosive View

Assembly Explosive View 7.2.1 Monitor Assembly (A0) Order Number Part Name Qty. Remark 115-063844-00 Monitor Assembly(1117Vet/1116/1156/FRU) Field Replacement Unit 7-3…

-

Page 96

Order Number Part Name Qty. Remark 115-068553-00 Monitor Damper(FRU) 7-4 Field Replacement Unit… -

Page 97: Operation Panel Assembly (B0)

7.2.2 Operation Panel Assembly (B0) Order Number Part Name Qty. Remark 115-063914-00 Control Panel Assembly(1156/FRU) 115-063841-00 Dual Encodes Assembly(FRU) With trackball connecting line Field Replacement Unit 7-5…

-

Page 98

Order Number Part Name Qty. Remark 115-063842-00 Single Encode Assembly(FRU) With harness 801-1150-00015-00 optical trackball unit(FRU) With trackball connecting line 801-1150-00016-00 TGC Adjustment Board(FRU) With STC connecting line 115-063875-00 Bottom Cover of Control Panel(Vet) 115-063925-00 Bottom Cover of Control Panel(1156Human) 049-001795-00 keyboard Overlay With four pieces of encode knob and… -

Page 99: Core Assembly (C0)

Order Number Part Name Qty. Remark B1-1 049-001743-00 silcon keyboard 7.2.3 Core Assembly (C0) Field Replacement Unit 7-7…

-

Page 100

OS as well after replacement. 115-063913-00 is obsolete. Please use 115-063913-01 Probe Board Assy(1117/1156/Two Sockets) 115-063913-01 to order. 801-1150-00005-00 IO Board CE only. When applying, please 115-063916-00 HDD(DP-50/CE/FRU) remark: Software version, Serial number of unit. CE only. When applying, please 115-063917-00 HDD(DP-50T/CE/FRU) remark:… -

Page 101

Order Number Part Name Qty. Remark number of unit. CE only. When applying, please 115-063918-00 HDD(DP-50 PT/CE/FRU) remark: Software version, Serial number of unit. CE only. When applying, please 115-063919-00 HDD(DP-50Expert/CE/FRU) remark: Software version, Serial number of unit. CE only. When applying, please… -

Page 102

CE only. When applying, please 115-067388-00 HDD(DP-70C/CE/FRU) remark: Software version, Serial number of unit. CE only. When applying, please 115-068758-00 HDD(DP-50 Expert Vet/CE/FRU) remark: Software version, Serial number of unit. CE only. When applying, please 115-068756-00 HDD(DP-70 Vet/CE/FRU) remark: Software… -

Page 103

Order Number Part Name Qty. Remark number of unit. 115-063836-00 Power Supply Module(FRU) 115-063845-00 Main Unit Fan(FRU) 115-063886-00 Battery Connection Board(FRU) 115-063877-00 FrontCover Assy of MU(1117Vet/1116/1156) 043-011251-00 Handle 115-044346-00 4D Module Kit Optional 043-003940-00 Probe Holster Small 043-004917-00 large probe holster 115-011470-00 one-piece lithium-ion Battery Pack CE only… -

Page 104: Cable Set Of Main Unit (D0)

Order Number Part Name Qty. Remark C6-1 115-051844-00 AC-DC board( FRU) C6-2 115-051845-00 DC-DC Board( FRU) C6-3 115-063846-00 Power Supply Fan(FRU) 7.2.4 Cable Set of Main Unit (D0) Order Number Part Name Qty. Remark Include D2~D9, but only one piece for 115-063885-00 Cable Set of Main Unit(FRU) each of them.

-

Page 105: 台车(E0

Order Number Part Name Qty. Remark Control panel PCBA J7-TGC STC connecting line assembly J1 7.2.5 UMT-170 台车(E0) Order Number Part Number Qty. Remark 115-037617-01 Probe holder & cup bracket(FRU) Field Replacement Unit 7-13…

-

Page 106

Order Number Part Number Qty. Remark 115-070488-00 Bin(FRU) UMT-170 Trolley Caster 115-070487-00 Spanner(FRU) 7-14 Field Replacement Unit… -

Page 107: Structure And Assembly/Disassembly

Structure and Assembly/Disassembly Structure of the Complete System Figure 8-1 Overall Exploded View Name Name Holder Null turning axis of keyboard Rear cover assembly of main unit Control panel Assembly of main unit rack Bottom cover of control panel Display assembly Preparations 8.2.1 Tools Required…

-

Page 108: Engineers Required

8.2.2 Engineers Required Only technical professionals from Mindray or engineers authorized by Mindray after training can perform maintenance and check. 8.2.3 Assembly/Disassembly Required You should perform the following preparations before the disassembling of ultrasound equipment. When you stop the scanning and the image capture, you should power off the system and disconnect the system from the AC power supply, then pull out AC power cables.

-

Page 109: Battery Connecting Board

NOTE: The illustration of disassemble is provided for reference only, and the concrete picture depends on the actual model. 8.3.1 Battery Connecting Board Press the clasp of the battery cover, and then rotate the battery cover down to open it. Figure 8-2 Disassembly of Battery (1) Slide battery to the right side pressing it all the time, and then remove the battery when the battery pops on the recommended distance.

-

Page 110: Power Supply Module

Figure 8-5 Disassembly of Rear Cover Assembly of Main Unit (2) Remove panhead screws with washers (2 M3X6) fixed on the main unit box, and then take off the battery connecting board. Figure 8-6 Removing the Battery Connecting Board 8.3.2 Power Supply Module 1.

-

Page 111

Figure 8-8 Disassemble the Power Module Assembly (1) Figure 8-9 Disassemble the Power Module Assembly (2) Figure 8-10 Disassemble the Power Module Assembly (3) Remove panhead screws with washers (2 M3X6) fixed on power module assembly to take out the lower baffle and remove cables connecting the battery conversion board and the main board. -

Page 112

Remove three cables Figure 8-12 Disassemble the cables 8.3.2.1 Power module Fan After removing panhead screws with washers (5 M3X6) fixed on the power module assembly and pulling out the plug of the fan connecting cables and power input outlet connecting cables, you can take off the rear panel of power supply assembly. -

Page 113

Figure 8-15 Disassemble the Power Module Fan During the assembly, fan label must be pasted towards the surface of the machine, NOTE: and don’t confuse with fans of other products. 8.3.2.2 DC-DC Power Board Remove panhead screws with washers M3X6 (4) used to fix the DC-DC power board. Figure 8-16 Disassemble the DC-DC Power Board (1) Remove the plug of fan cable. -

Page 114: Io Broad

8.3.2.3 AC-DC Power Board Remove panhead screws with washers M3X6 (5) used to fix the AC-DC power board (one of the screws should be removed after the fan is removed). Figure 8-19 Disassemble the AC-DC Power Board (1) After removing the connecting plug between DC-DC power board and AC-DC power board, and the connecting plug between AC-DC power board and power input, you could take out the AC-DC power board.

-

Page 115: Probe Board

NOTE: Make sure that you could pull out and push into the IO board sockets vertically when pulling out and assembling the IO board assembly on the position of the handle. Remove panhead screws with washers M3X6 (4) used to secure the IO board, and then you could take out the IO board.

-

Page 116

Remove panhead screws with washers (2 M3X6) which are fixed on the main unit, take out the upper baffle and then pull out two cables connecting the main board to the power module assembly. Figure 8-24 Disassemble the Main Board Assembly (1) Remove the probe board assembly (referring to 8.3.4 the 2 step) and the IO assembly (referring to 8.3.3 step 3) -

Page 117: Control Panel Assembly

After replacing the CPU module, key file must be generated once again according to the new MAC address and written into HDD of the machine. Or else, the configuration function of the product will be lost. After removing the CPU module, Remove panhead screws with washers (12 M3X6) fixed on the main unit box, you can take off the board.

-

Page 118

Figure 8-29 Disassemble the Control Panel Assembly (1) Hold the upper edge of control panel assembly, and open up the control panel. Figure 8-30 Disassemble the Control Panel Assembly (2) After removing one countersunk head self-tapping screw PT3X10 fixed on the control panel and take out the plug of the keyboard and the main unit connecting cables, you could remove the control panel assembly. -

Page 119

Figure 8-32 Disassemble the Encoder Board (1) After removing the connecting cable plug on the control panel and taking out countersunk head self-tapping screw PT3X10(7) used to secure the encoder board, you could remove the encoder boards. Figure 8-33 Disassemble the Encoder Board (2) 8.3.6.2 Trackball Remove the connecting cable plug of trackball, and countersunk head self-tapping screw… -

Page 120

Figure 8-35 Disassembly of the TGC Board (1) After removing the connecting cable plug of TGC board and removing screws PT3X10 (4) fixed on the TGC board, you could remove the TGC board. Figure 8-36 Disassembly of the TGC Board (2) 8.3.6.4 Buzzer After removing the connecting cable plug of buzzer on the control panel and taking out the… -

Page 121: Display Assembly

Remove 18 PT3X10 self-tapping screws fixed on the control panel. Figure 8-38 Disassemble the Control Panel (1) Pull out the control panel and silicon key from the keyboard cover and then dispatch them apart. Take out the silicon key. Silicon key (upper) Control panel PCBA (lower)

-

Page 122: Hard Disk

Cut off cable ties connecting the main unit on the display by diagonal cutting pliers, and then pull out the corresponding cable plugs. Figure 8-41 Disassemble the Display assembly Pull the display assembly upwards to make it separated from the main unit. Figure 8-42 View of Display Assembly 8.3.8 Hard Disk…

-

Page 123: Speaker

Tilt the display Figure 8-43 Disassembly of HDD (1) Remove panhead screw with washer (1 M3X8 ) which is installed on the rack of the main unit front cover, then remove the HDD cover assembly (including HDD cover, HDD cover metal part and conductive foam ).

-

Page 124

2. Remove 4 combination screws M3X8 used to fix the monitor assembly by using the cross screwdriver. Figure 8-46 Disassembly of Speaker (1) 3. Remove cables connecting the speaker and cables connecting the control panel from machine core unit, and cut the cable ties by using wire cutters. Figure 8-47 Disassembly of Speaker (2) 4. -

Page 125: Printer Adapter (Optional)

5. Remove 4 panhead screws with washers (M3X6) used to fix the speaker assembly from the front cover of the main unit to take out the speaker assembly. Figure 8-49 Disassembly of Speaker (4) 6. Remove 4 panhead screws (M2X8) from the speaker assembly to disassemble the speaker assembly.

-

Page 126

Type-2 screwdriver screws. 8.3.10.3 Engineers Required Only technical professionals from Mindray or engineers authorized by Mindray after training can perform the maintenance and the check. 8.3.10.4 Requirements You should perform the following preparations before disassembling the ultrasound device. Power off the printer adapter, and disconnect all the AC power. -

Page 127

Structure and Assembly/Disassembly 8-21… -

Page 129: System Diagnosis And Support

System Diagnosis and Support General Status Indicator 9.1.1 Status Indicators of the Control Panel Status Icon Status definition and indicators Position indicators Power-on The indicator is not on when the system is turned off; The Control Panel status Press the key, the indicator blinks green at power on. indicator on the upper After power on, the indicator is green.

-

Page 130: Status Indicator Of The Power Supply On The Io Board

Screen-saver default is and the backlight of the freezing status automatically. “mindray” showing on the control panel both monitor. restore to the previous 9-2 System Diagnosis and Support…

-

Page 131: Starting Process Of The Whole System

The system is frozen. status. Ultrasound imaging hardware system is in the dormancy mode The system is on the power-off status: when Press the power switch for a connected the AC power short time, and then the system Starting the system by Power-off supply the AC indicator is is turned off by choosing from…

-

Page 132: Start Process Of Complete System

9.2.1 Start Process of Complete System 9.2.1.1 Powered on by AC Basic Procedures Phenomenon The original status: no indication Finishing loading The AC status indicator on the control panel lights on, but the 3.3VSTB,Finishing loading indicators of HDD and standby are off. 5VSTB Press the power button, The Power-on status indicator flashes continuously on the control…

-

Page 133: Start-Up Process Of Bios

9.2.2 Start-up Process of BIOS The start-up process of BIOS is a black-box operation, and the primary description is as following: Basic Procedures Basic phenomenon Self-test after the system power-on The LCD is blank screen in a short time. Initialization& The settings of record system & BIOS start-up display Providing the resident programmer library &…

-

Page 134: Start-Up Of Doppler

9.2.4 Start-up of Doppler 9.2.4.1 Procedure of Startup Linux app initialization Initialize Related PC HDD peripherals along with PC initialization PC software initialization Initialize ultrasonic Ultrasonic HDD initialization Finish related Ultrasonic startup ,operation and software application of ultrasonic initialization software Finish initialization 9.2.4.2…

-

Page 135

Platform Initializing gui… initialization Ultrasonic software Peripheral Initializing ultrasound peripheral… The total initialization initialization increment is 1 Imaging Initializing ultrasound image… The total initialization increments are 2 Application Initializing ultrasound application… The total initialization increment is 1 Finishing Initialization completed… The total initialization increment is 1… -

Page 136: Alarming And Abnormal Information

Initializing Set related information of the zoom, languages, font In increments of 1. locale… library and input Construct widget factory Configure the GUI layer Set menu items Initialize function library Construct UICenter Initializing Configure the application layer In increments of 1. gui……

-

Page 137: Turning On The System Configuration File Is Abnormal

9.3.1 Turning on the System Configuration File is Abnormal Alarming tips LOG record Suggestion Fail to open the file none Reinstall the system software. «SystemConfiguration.ini», and please check HDD data. 9.3.2 The voltage of system power is abnormal Alarming tips LOG record Suggestion ×××: System Monitor: Power supply alert! [VBAT], Current…

-

Page 138: Fan Alarming

[VVV] represents the current value, and [LLL] represents the first limit of CPU temperature. Temperature The log records are the same The second alarming, XX temperature of CPU [VVV] represents the current value, and [LLL] Shut down represents the second limit of CPU temperature. Suggestion as above (XX means inversion timing,…

-

Page 139: Phv Related Alarming

replace with new battery please change the battery Replace battery and confirm Battery I2C error, the malfunction module. Shutdown State Stop the illegal operation. Battery Hot Plug, Shutdown State 9.3.6 PHV Related Alarming Alarming tips LOG record Potential reason Alarm! Something is wrong with the programmed High-voltage voltage of power module, which make…

-

Page 141: Care And Maintenance

Care and Maintenance 10.1 Overview These procedures in this chapter are recommended. 10.1.1 Tools, Measurement Devices and Consumables Table 10-1 Tools and Measurement Devices Tool/Measurement Devices Qty. Remarks Resin or plastic container 1 pcs Can accommodate two probes Soft brush 1 pcs About a toothbrush size Small plastic basin…

-

Page 142: Care And Maintenance Items

10.1.2 Care and Maintenance Items Table 10-3 Maintenance Items and Frequency Maintain content Frequency Method Clean display Monthly Referring to 9.2.1 Clean trackball Monthly Same as the above Clean control panel Monthly Same as the above Clean probes (the head) Every time after using Same as the above Clean probe cable and the surface of…

-

Page 143: Cleaning

10.2 Cleaning 10.2.1 Clean the System 10.2.1.1 Flow of Cleaning Power off and pull out the power cables Clean display Clean trackball Clean control panel Clean probe Clean holders Clean cover Figure 10-1 View of Cleaning Maintenance Before cleaning the system, be sure to turn off the power and WARNING: disconnect the power cord from the outlet.

-

Page 144

Trackball is one of important interface parts, which are embedded into the main unit keyboard, and part of which is exploded to be operated by users in order to implement variety of module’s control functions. Trackball is one of the most using frequency of input assemblies on the whole operation panel, and the trackball similar to a multi-directory caster can rotate in every direction drived manually, due to the feature, gas or dust can enter into module internal easily, as a result, contamination of lens would lead to the failure of the trackball. -

Page 145

Clean control panel Tools: dry soft cloth, mild soapy water Method: Use dry soft cloth to clean the surface of the system. If the system is dirty, moisten the soft cloth with mild soapy water and wipe off any stains. Use dry soft cloth to remove any moisture and allow all hard surfaces to completely air-dry. -

Page 146: Clean The Peripherals

10.2.3 Clean the Peripherals Do the cleaning maintenance according to your actual peripheral configuration; items which are not configured can be skipped. Table 10-4 Peripherals Cleaning List Content Description First wipe off dust or stain attached to the cover of printer with Color and B/W video soft dry cloth, then clean the inside of printer.

-

Page 147: System Function Check

Content Method Check the battery periodically : a) Check if battery can be charged normally when power-on: That the current capacity is 100% or capacity increases after a short time indicates that the battery can be charged normally. It takes less than 2 minutes to increase 1% capacity when the total Battery capacity is less than 90% and it takes more time when the…

-

Page 148: Peripherals And Options Check

10.3.3 Peripherals and Options Check If the system is not configured with any module or peripheral, the corresponding items checking can be skipped. Table 10-7 Options, Peripherals and Accessories Check list Content Method Color and B/W video Check if the output of video printer is normal. printer Graph / text printer Check if the output of graph / text printer is normal.

-

Page 149: Electrical Safety Inspection

10.3.5 Electrical Safety Inspection Only technical professionals from Mindray or engineers authorized by Mindray after training can perform electric safety inspection. Please refer to appendix A: Electrical Safety Inspection for details. Care and Maintenance 10-9…

-

Page 151: Troubleshooting Of Regular Malfunctions

Troubleshooting of Regular Malfunctions 11.1 System cannot be powered on 11.1.1 Module or Board Related Descriptions Remarks Battery Li-ion 14.8V 6600mAh LI34I002A Power supply module CPU module 11.1.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks AC power indicator Located on control panel Power-on status indicator Backlight of the power button…

-

Page 152: System Cannot Start Up Normally

The AC input is normal ,AC power indicator Power supply module fails Replace power remains off; supply module Power indicators: off AC power indicator: ON; Power supply module fails Replace power supply module Power-on status indicator: off after power button pressed Power indicators: off AC power indicator: ON;…

-

Page 153: Image Fault

interface BIOS start-up graphics is normally CPU module failure Replace CPU module displayed, but it cannot be kept on Enters BIOS start-up graphics. Cannot find operating system, Find the failure cause the HDD or OS in HDD may by entering BIOS No LINUX start-up graphics be damaged.

-

Page 154: Key Points Supporting Troubleshooting

4D drive board IO board 11.3.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks Image feature, including dark strips and noise Images appearance when contact occurs between different types of probe in different interface of probe socket. 11.3.3 Troubleshooting Fault Cause Analysis Measure…

-

Page 155: Probe Socket System Malfunction

probe. The image abnormality may be caused by Replace the probe, or the swivel of the 4D probe or the 4D drive replace the 4D drive board board. It is suggested to replace the probe first, and then replace the 4D drive board. 11.4 Probe Socket System Malfunction 11.4.1 Module or Board Related Descriptions…

-

Page 156: Io Interface System

11.5 IO Interface System 11.5.1 Module or Board Related Descriptions Remarks Main board CPU module IO board Speaker 11.5.2 Key Points Supporting Troubleshooting Key Points Supporting Troubleshooting Remarks Working condition of the control panel Confirm if the USB main device is functional since the control panel is connected by internal USB cable Working condition of each USB port…

-

Page 157: Control Panel

11.6 Control Panel 11.6.1 Module or Board Related Descriptions Remarks Silicon key Control panel Dual encoder module Single encoder module Trackball module TGC module 11.6.2 Key Points Supporting Troubleshooting Points Supporting Remarks Troubleshooting Backlight of control panel To confirm if the control panel is powered on normally; Key sound of the control panel.

-

Page 158: Lcd Display

speed in system preset; Degenerated trackball Replace the trackball module performance All key of control panel are Single encoder malfunction Replace the encoder board normal, Single encoder failed. All key of control panel are TGC board malfunction Replace TGC board normal, Single key of TGC failed.

-

Page 159

The color of some mode key turns on orange. monitor board or monitor malfunction assembly No display (blank screen) on the LCD, with backlight only; or, disordered screen. Replace CPU module Control panel powered on normally and no key CPU module indicator turns on orange. -

Page 160: Printer Adapter Related Troubleshooting

11.8 Printer Adapter Related Troubleshooting Failure Description Cause Analysis Measure The ultrasound system Connect the ultrasound and the printer adapter system to the printer are not properly adapter again using connected. Ethernet cables. Check whether the indicator on the printer adapter flashes The following icon is displayed at the normally after power-on, bottom right corner of the ultrasound…

-

Page 161

The indicator on the printer Errors occur when the adapter turns orange, and the printing printer adapter runs. Disconnect and connect the fails. power adapter, power on the printer adapter again, and verify whether the printing is normal after 1 minute. -

Page 163: Electrical Safety Inspection

Appendix A ELECTRICAL SAFETY INSPECTION The following electrical safety tests are recommended as part of a comprehensive preventive maintenance program. They are a proven means of detecting abnormalities that, if undetected, could prove dangerous to either the patient or the operator. Additional tests may be required according to local regulations.

-

Page 164

ELECTRICAL SAFETY INSPECTION 1- Power Cord Plug TEST PROCEDURE The Power Plug The Power Plug Pins No broken or bent pin. No discolored pins. The Plug Body No physical damage to the plug body. No physical damage to the strain relief. No plug The Strain Relief warmth for device in use. -

Page 165

ELECTRICAL SAFETY INSPECTION Device Enclosure And Accessories TEST PROCEDURE Visual Inspection No physical damage to the enclosure and accessories. No physical damage to meters, switches, connectors, etc. No residue of fluid spillage (e.g., water, coffee, The Enclosure and Accessories chemicals, etc.). -

Page 166

ELECTRICAL SAFETY INSPECTION Device Labeling TEST PROCEDURE Check the labels provided by the manufacturer or the healthcare facility is present and legible. Main Unit Label Integrated Warning Labels Slope and High Voltage Caution Label Don’t Stress Label … -

Page 167

ELECTRICAL SAFETY INSPECTION 4- Protective Earth Resistance VOERVIEW Protective Earth Resistance is measured using the RED test lead attached to the DUT Protective Earth terminal or Protective Earth Metal enclosure or equipotential terminal. Select the test current by pressing SOFT KEY 3 to toggle between 1AMP, 10AMP, and 25AMP. The front panel outlet power is turned off for this test. -

Page 168

ELECTRICAL SAFETY INSPECTION 4- Protective Earth Resistance metal area. Press shortcut key 3. The Protective Earth Resistance test is displayed. Press SOFT KEY 3 to select a test current (1AMP, 10AMP, or 25AMP). The selected test current is displayed in the upper right corner of the display. Press START TEST to start the test. -

Page 169

ELECTRICAL SAFETY INSPECTION Earth Leakage Test OVERVIEW Run an Earth Leakage test on the device being tested before performing any other leakage tests. Leakage current is measured the following ways: ♦ Earth Leakage Current, leakage current measured through DUT outlet Earth ♦… -

Page 170

ELECTRICAL SAFETY INSPECTION Earth Leakage Test Figure 1 Earth leakage test Failure Check any short-circuits of the Y capacitor on power unit. Replace a new one if any portion defective. Check any broken of the Power Unit. Replace a new one if any portion defective. Inspect mains wiring for bad crimps, poor connections, or damage. -

Page 171

ELECTRICAL SAFETY INSPECTION Patient Leakage Current OVERVIEW Patient leakage currents are measured between a selected applied part and mains earth. All measurements may have either a true RMS or a DC-only response. TEST PROCEDURE Prepare Perform a calibration from the Mains on Applied Part menu. The following outlet conditions apply when performing this test: Normal Polarity, Earth Open, Outlet ON Normal Polarity, Outlet ON… -

Page 172

ELECTRICAL SAFETY INSPECTION Patient Leakage Current 601PRO. Press the print data key at any time to generate a printout of the latest measurement. Figure 2 patient leakage Current Note 1, In addition to Probes ,Patient leakage current test should be perform if ECG or PCG parts used;… -

Page 173

ELECTRICAL SAFETY INSPECTION Patient Leakage Current LIMITS All countries For BF ECG input and transducer 100μA Normal Condition 500μA Single Fault Condition Electrical Safety Inspection A-11… -

Page 174

ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage OVERVIEW The Mains on Applied Part test applies a test voltage, which is 110% of the mains voltage, through a limiting resistance, to selected applied part terminals. Current measurements are then taken between the selected applied part and earth. Measurements are taken with the test voltage (110% of mains) to applied parts in the normal and reverse polarity conditions as indicated on the display. -

Page 175

ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage Attach the applied parts to the 601PRO applied part terminals. Attach the red terminal lead to a conductive part on the DUT enclosure. Press shortcut key 7. The Mains on Applied Part test is displayed. Select the desired outlet configuration and applied part to test using the appropriate SOFT KEYS: Press START TEST (SOFT KEY 1) to begin the test. -

Page 176

ELECTRICAL SAFETY INSPECTION Mains on Applied Part Leakage user or owner to correct any deviations. As a work around, check the other outlets to see if they could be used instead. Change another probe to confirm if the fail is caused by console. Inspect wiring for bad crimps, poor connections, or damage. -

Page 177

ELECTRICAL SAFETY INSPECTION FORM (Class I equipment) Overall assessment: □ Scheduled inspection Test item: 1, 2, 3, 9 □ Unopened repair type Test item: 1, 2, 3, 9 □ Opened repair type, not modify the power part Test item: 1, 2, 3, 4, 5, 9 including transformer or patient circuit board □… -

Page 179: Appendix B Phantom Usage Illustration

Appendix B Phantom Usage Illustration Note: The use of Phantom is not required during Preventive Maintenance. Customer may use it as part of their Quality Assurance Program tests。 Note: Best storage and operating temperature of phantom is 10℃~35℃,do not use phantom beyond the specified temperature range, otherwise tested performance indicators may be affected.

-

Page 180

Targets disposal of Phantom KS107BD A1——A4 Axial resolution target group B1——B4 Lateral resolution target group Longitudinal target group Horizontal target group E1——E3 Mimic sacs with diameters of 2, 4, 6mm 4. Line Target System There are 8 groups of line targets disposed in TM material as shown in the figure. 1.A1——A4:… -

Page 181

Phantom Usage Illustration B-3… -

Page 183

P/N: 046-017661-00 (6.0)

(Ocr-Read Summary of Contents of some pages of the Mindray DP-50 Document (Main Content), UPD: 10 May 2023)

-

38, 3-12 System Installation 1. Open the Network page via [Setup] [Network Preset] [Local TCP/IP]. 2. Select Static; 3. Set the IP Address to any value from 192.168.1.1 to 192.168.1.200 (192.168.1.10 is excluded, because it belongs to the printer adapter); 4. Set the Subnet Mask to 255.255.255.0 and Gateway to 192.168.1.254; 5. Click [Save].

… -

141, Care and Maintenance 10-1 10 Care and Maintenance 10.1 Overview These procedures in this chapter are recommended. 10.1.1 Tools, Measurement Devices and Consumables Table 10-1 Tools and Measurement Devices Tool/Measurement Devices Qty. Remarks Resin or plastic container 1 pcs Can accommodate two probes Soft brush 1 pcs About a toothbrush size Small plastic basin 1 pcs Used to fill the soapy water Safety test analyzer 1 pcs R…

-

76, 5-12 Function and Performance Checking Method 4. In condition that the transverse resolution testing targets are horizontally displayed, record the minimal distance of two targets that can be clearly recognized. 5. Repeat the operation above for the transverse resolution testing targets at other depths. As shown in figure below. Axial resolution Test Step: 1. Cover the scan surface of the phantom with water or couple gel, gently contact the probe wi…

-

35, Mindray DP-50 System Installation 3-9 Figure 3-6 Installing Analog Video Printer Digital Video Printer 1. Connect one terminal of the data cable of the video printer to the USB port of the ultrasound system and the other terminal to the video input port of the video printer; 2. Insert the power cord to a power supply receptacle that is well grounded. 3. Please refer to 3.5.4 for the driver installation. And you need not install …

-

111, Structure and Assembly/Disassembly 8-5 Figure 8-8 Disassemble the Power Module Assembly (1) Figure 8-9 Disassemble the Power Module Assembly (2) Figure 8-10 Disassemble the Power Module Assembly (3) 5. Remove panhead screws with washers (2 M3X6) fixed on power module assembly to take out the lower baffle and remove cables connecting the battery conversion board and the main board. F…

-

91, Mindray DP-50 Software Upgrade and Maintenance 6-11 DCM structured report related data file and DICOM viewing software Report report template obd.bin OBD data file version.txt Version file Comment Comment file AnatomyImage Anatomical images Measurement Measurement library \exe main Doppler program and related boot configuration file and plug-ins, remote desktop server nls Multilanguage string file videoplay Video play exe fi…

-

9, III Statement This service manual describes the product according to the most complete configuration; some of the content may not apply to the product you are responsible for. If you have any questions, please contact Mindray Customer Service Department. Do not attempt to service this equipment unless this service manual has been consulted and is understood. Failure to do so may result in personnel injury …

-

72, 5-8 Function and Performance Checking Method 2. Menu Procedure Standard Speed B mode menu-> [Speed] Click [Speed], and rotate the multifunction knob to adjust the parameter. The lower the value the faster the refreshing. Display Format M mode menu-> [Display Format] There are 4 formats available for image display: L/R, V1:1, V1:2, Full. Tips: a) During M Mode scanning, frequency and acoustic power of the probeare synchronous with that of …

-

137, System Diagnosis and Support 9-9 9.3.1 Turning on the System Configuration File is Abnormal 9.3.2 The voltage of system power is abnormal 9.3.3 Temperature Alarming Alarming tips LOG record Suggestion Fail to open the file «SystemConfiguration.ini», and please check HDD data. none Reinstall the system software. Alarming tips LOG record Suggestion The real-time battery will be out…

-

136, 9-8 System Diagnosis and Support Initializing locale… Set related information of the zoom, languages, font library and input Construct widget factory Configure the GUI layer Set menu items Initialize function library Construct UICenter In increments of 1. Initializing gui… Configure the application layer Initialize the keyboard. Construct the user account control management, and remote desktop management In increments of 1. Initializing ultrasound peripheral… Co…

-

134, 9-6 System Diagnosis and Support 9.2.4 Start-up of Doppler 9.2.4.1 Procedure of Startup Linux app initialization PC HDD initialization Ultrasonic HDD initialization Finish initialization PC software initialization Ultrasonic software initialization Initialize Related peripherals along with PC Finish related startup ,operation and application of ultrasonic software Initialize ultrasonic HDD 9.2.4.2 Details of Procedures Now, DOPPLER starting is in in…

-

69, Function and Performance Checking Method 5-5 5.4.2 Checking Content 5.4.2.1 B Mode In B Mode scanning, the image parameter area in the right corner of the screen will display the real-time parameter values as follows: Display F D G FR DR Image Parameters Frequency Depth Gain Frame Rate B Dynamic Range Parameters that can be adjusted to optimize the B Mode image are ind…

-

173, Electrical Safety Inspection A-11 ELECTRICAL SAFETY INSPECTION 6- Patient Leakage Current LIMITS All countries For BF ECG input and transducer 100μA Normal Condition 500μA Single Fault Condition

… -

12, Mindray DP-50 1-2 Preface 1.2.2 Warning Labels No. Warning Labels Meaning 1. Please carefully read this manual before use device. 2. The following labels are available when the system works with the mobile trolley. a. Do not place the device on a sloped surface. Otherwise the device may slide, resulting in personal injury or the device malfunction. Two persons are required to move the device over a sloped surface. b. Do not sit …

-

125, Structure and Assembly/Disassembly 8-19 5. Remove 4 panhead screws with washers (M3X6) used to fix the speaker assembly from the front cover of the main unit to take out the speaker assembly. Figure 8-49 Disassembly of Speaker (4) 6. Remove 4 panhead screws (M2X8) from the speaker assembly to disassemble the speaker assembly. Figure 8-50 Disassembly of Speaker (5) 8.3.10 Printer Adapter (…

-

95, Mindray DP-50 Field Replacement Unit 7-3 7.2 Assembly Explosive View 7.2.1 Monitor Assembly (A0) No. Order Number Part Name Qty. Remark A1 115-063844-00 Monitor Assembly(1117Vet/1116/1156/FRU) 1 / A2 A1

… -

166, A-4 Electrical Safety Inspection ELECTRICAL SAFETY INSPECTION 3- Device Labeling TEST PROCEDURE Check the labels provided by the manufacturer or the healthcare facility is present and legible. Main Unit Label Integrated Warning Labels Slope and High Voltage Caution Label Don’t Stress Label

… -

36, 3-10 System Installation No. Name Function 1. Power Button Powers on the printer adapter. 2. USB port Connects the printer to the printer adapter. 3. Network port Connects the printer adapter to the Ultrasound system. 4. Power inlet Connects the printer adapter to power by using the auxiliary output port of the Ultrasound system. Specification Power Supply Environment Input: 100-240 [email protected] Frequency: 50/60Hz Output: …

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

DP-50 Vet/DP-70 Vet/DP-50 Exp Vet

Digital Ultrasonic Diagnostic

Imaging System

Operator’s Manual

[Basic Volume]

Related Manuals for Mindray DP-50 Vet

Summary of Contents for Mindray DP-50 Vet

-

Page 1

DP-50 Vet/DP-70 Vet/DP-50 Exp Vet Digital Ultrasonic Diagnostic Imaging System Operator’s Manual [Basic Volume]… -

Page 3: Table Of Contents

Contents Intellectual Property Statement ………………….I Responsibility on the Manufacturer Party ………………II Warranty ……………………….II Exemptions ……………………… II Customer Service Department ………………..III Important Information ……………………IV About This Manual ……………………..V Notation Conventions ……………………V Operator’s Manuals ……………………… V Manuals on Paper ……………………..

-

Page 4

2.6.3 Control Panel …………………… 2-9 Symbols ……………………..2-12 System Preparation ………………..3-1 Moving / Positioning the System ………………3-1 Power Supply ……………………3-1 3.2.1 Connecting External Power Supply …………….3-1 3.2.2 Powered by Battery …………………. 3-1 Powering ON/ OFF ………………….. 3-2 3.3.1 Powering ON …………………… -

Page 5

Image Optimization ………………..5-1 Switching Between Image Modes ………………5-1 Basic Operations ……………………5-1 Quickly Saving Image Setting (QSave) …………….5-2 B Mode ……………………..5-2 5.4.1 B Mode Exam Protocol ………………..5-2 5.4.2 B Mode Parameters …………………. 5-3 5.4.3 B Mode Image Optimization ………………5-3 M Mode …………………….. -

Page 6

Cine Review ……………………. 6-3 6.2.1 Entering/ Exiting Cine Review ………………6-4 6.2.2 Cine Review in 2D Mode ………………..6-4 6.2.3 Cine Review in M/PW Mode ………………6-5 6.2.4 Linked Cine Review …………………. 6-5 Image Compare ……………………6-6 6.3.1 Image Compare in Review Mode …………….. 6-6 6.3.2 Frame Compare …………………. -

Page 7

9.1.2 Animal Information Setting ………………. 9-1 Image File Management …………………. 9-2 9.2.1 Storage Media………………….. 9-2 9.2.2 Image File Formats ………………….. 9-2 9.2.3 Image Storage Preset ………………..9-2 9.2.4 Saving Images to the System ………………9-3 9.2.5 Quickly Saving Images to USB Flash Drive …………..9-3 9.2.6 Quickly Saving Full Screen Image to the System ………… -

Page 8

11 Setup……………………11-1 11.1 System Preset ……………………11-1 11.1.1 Region ……………………11-1 11.1.2 General ……………………11-3 11.1.3 Image …………………….. 11-4 11.1.4 Application ……………………11-5 11.1.5 Key Config ……………………11-5 11.1.6 Biopsy ……………………. 11-6 11.1.7 Admin …………………….. 11-6 11.2 Exam Preset ……………………11-6 11.3 Measure Preset …………………… -

Page 9

12.2.8 Removing the Needle-guided Bracket …………..12-34 12.2.9 Clean and Sterilize the Needle-guided Bracket …………12-37 12.2.10 Storage and Transportation ………………12-39 12.2.11 Disposal ……………………12-39 12.3 Middle Line ……………………12-39 13 Battery ……………………13-1 13.1 Overview ……………………..13-1 13.2 Precautions ……………………13-2 13.3 Installing and Removing the Batteries ……………. -

Page 10

Appendix B Transducer Maximum Surface Temperature ……..B-1 Appendix C Acoustic Output Reporting Table (60601-2-37) ……..C-1 Appendix D Printer Adapter ………………D-1 viii… -

Page 11: Intellectual Property Statement

Intellectual Property Statement SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the intellectual property rights to this Mindray product and this manual. This manual may refer to information protected by copyright or patents and does not convey any license under the patent rights or copyright of Mindray, or of others.

-

Page 12: Responsibility On The Manufacturer Party

Contents of this manual are subject to change without prior notice. All information contained in this manual is believed to be correct. Mindray shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this manual.

-

Page 13: Customer Service Department

Customer Service Department Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd. Address: Mindray Building, Keji 12th Road South, High-tech industrial park, Nanshan, Shenzhen 518057, P.R. China Website: www.mindray.com E-mail service@mindray.com Address: Tel: +86 755 81888998 Fax: +86 755 26582680 Shanghai International Holding Corp. GmbH (Europe) Representative: Eiffestraβe 80, Hamburg 20537, Germany…

-

Page 14: Important Information

7. Important data must be backed up on external memory media. 8. Mindray shall not be liable for loss of data stored in the memory of this system caused by operator error or accidents. 9. This manual contains warnings regarding foreseeable potential dangers, but you shall always be alert to dangers other than those indicated as well.

-

Page 15: About This Manual

About This Manual This operator’s manual describes the operating procedures for this diagnostic ultrasound system DP-50 Vet/DP-70 Vet/DP-50 Exp Vet and the compatible probes. To ensure safe and correct operations, carefully read and understand the manual before operating the system.

-

Page 16: Conventions

[Dyn Rng (Value)]: Indicates menu items with parameter, (value) shows the current value of the item. Product Differences B-Profile B-Hist Double Dist Trace Length √ √ √ √ DP-50 Vet × √ √ √ DP-70 Vet √ × √ √ DP-50…

-

Page 17: Safety Precautions

Safety Precautions Safety Classification According to the type of protection against electric shock: Externally Powered Class I Equipment + Internally powered equipment According to the degree of protection against electric shock: Type-BF applied part According to the degree of protection against harmful ingress of water: Main unit: IPX0 Probes: IPX7 Footswitch: IP68…

-

Page 18: Meaning Of Signal Words

Meaning of Signal Words DANGER WARNING ”, “ ”, “ ”, CAUTION In this manual, the signal words» “NOTE” and «Tips» are used regarding safety and other important instructions. The signal words and their meanings are defined as follows. Please understand their meanings clearly before reading this manual.

-

Page 19: Safety Precautions

You must use the power adapter provided with the system; otherwise electric shock may result. You can only adopt the power supply method provided by Mindray, other power supply modes (e.g. using a UPS) may result in electric shock. Connect the protective grounding conductor before turning ON the system.

-

Page 20

DO NOT touch the Signal I/O ports if in contact with the animal; otherwise animal injury may result. Do not use an aftermarket probe other than those specified by Mindray. The probes may damage the system causing a profound failure, e.g. a fire in the worst case. -

Page 21

The ultrasound system use a mains plug as isolation means to the mains power supply. Please do not set the ultrasound system in a place difficult to operate the mains plug. Do not modify this equipment without authorization of the manufacture. Safety Precautions 1-5… -

Page 22

If the circuit protector is tripped, it indicates that the system or a peripheral device was improperly shut down and the system is unstable. You cannot repair the system under this circumstance and must call the Mindray Customer Service Department or sales representative. 1-6 Safety Precautions… -

Page 23

There is no risk of high-temperature burns during normal ultrasound examinations. It is possible for the surface temperature of the transducer to exceed the body temperature of an animal due to environmental temperature and exam type combinations. Do not apply the transducer to the same region on the animal for a long time. -

Page 24

If the system is used in a small room, the room temperature may rise. Please provide proper ventilation and free air exchange. To dispose of the system or any part, contact Mindray Customer Service Department or sales representative. Mindray is not responsible for any system content or accessories that have been discarded improperly. -

Page 25

Please read the following precautions carefully to ensure the safety of the animal and the operator when using the probes. The ultrasonic probe is only for use with the specified ultrasonic diagnostic system. Please refer to the “2.5.2 WARNING: Probes Available” to select the proper probe. The ultrasonic probe must be used only by qualified professionals. -

Page 26

Mindray will not be liable for damage caused by other solutions. If you have any questions, please contact Mindray Customer Service Department or sales representative. The probe sheath contains natural rubber that can cause allergic reactions in some individuals. -

Page 27: Latex Alert

Latex Alert When choosing a probe sheath, it is recommended that you directly contact CIVCO for obtaining probe sheath, pricing information, samples and local distribution information. For CIVCO information, please contact the following: CIVCO Medical Instruments Tel: 1-800-445-6741 WWW.civco.com Allergic reactions in latex (natural rubber) sensitive animals may WARNING: range from mild skin reactions (irritation) to fatal anaphylactic shock, and may include difficulty in breathing (wheezing),…

-

Page 28: Warning Labels

Warning Labels The warning labels are attached to this system in order to call your attention to potential hazards. The warning labels use the same signal words as those used in the operator’s manual. Read operator’s manual carefully before using the system. The name, pattern and meaning of each warning label are described as follows: No.

-

Page 29: System Overview

System Overview Intended Use The Digital Ultrasonic Diagnostic Imaging System is intended for veterinary use in ultrasound examination and diagnosis. Contraindication None. Product and Model Code Model code Product code The functions described in the operator’s manual may vary depending upon the NOTE: specific system you purchased.

-

Page 30: Power Supply

2.4.2 Power supply Voltage 100-240V~ Frequency 50/60Hz Input Power 1.5-0.8A 2.4.3 Environmental Conditions Operational Conditions Storage and Transportation Conditions Ambient 0° C-40° C -20° C-55° C temperature Relative 30%-85% (no condensation) 30%-95% (no condensation) humidity Atmospheric 700hPa-1060hPa 700hPa-1060hPa pressure Do not use this system in the conditions other than those WARNING: specified.

-

Page 31

Probe Model Category Region Applied 65C15EA Convex Body surface 65EB10EA Convex Transrectal Linear 75L38EA Body surface array Linear 75L53EA Body surface array Linear 10L24EA Body surface array 35C20EA Convex Body surface 65EC10ED Convex Transrectal 75LT38EA Linear Body surface 65EL60EA Linear Transrectal Linear 50L60EAV… -

Page 32: Options

Needle-guided Biopsy Angle/ Probe Model Applicable Biopsy Needle Bracket Model Depth (± 1° ) NGB-007 Plastic/needle Metal: 14G, 16G, 18G, 20G, 22G 75L53EA 40° , 50° , 60° detachable; Plastic: 13G, 15G, 16G, 18G, 20G Metal/needle detachable NGB-009 65EL60EA 0º 20G, 18G, 16G, 15G, 13G Metal/needle detachable…

-

Page 33: Peripherals Supported

Item Color Power Ultrasound gel (optional configuration in the CE region) 2.5.4 Peripherals Supported Item Model Graph / text printer HP OFFICEJET PRO 8100 Digital Color Video SONY UP-D25MD Printer MITSUBISHI P93W-Z Black and White Video Analog Printer SONY UP-X898MD Footswitch (1-pedal (not for CE region);…

-

Page 34: Introduction Of Each Unit

Introduction of Each Unit Right View Left View 2-6 System Overview…

-

Page 35

Rear View Bottom View Name Function Probe holder Used to place the probe Display Displays the image and parameters during scanning Control Panel Refer to 2.6.3 Control Panel USB ports Used to connect USB devices Handle Used to carry the machine Interface panel used for inputting and outputting signals, refer I/O Panel to 2.6.1 I/O Panel. -

Page 36: I/O Panel

2.6.1 I/O Panel <1> <2> <3> <4> <5> <6> <7> 3.3V <8> Symbol Function Network port USB ports Separate video output, connecting video printer or LCD Remote control port VGA signal output video output Composite Power indicator 2.6.2 Power Supply Panel Name Function Power inlet…

-

Page 37: Control Panel