-

Contents

-

Table of Contents

-

Bookmarks

Related Manuals for Siemens SINUMERIK 840D

Summary of Contents for Siemens SINUMERIK 840D

-

Page 1

Operator’s Guide 03/2004 Edition SINUMERIK 840D/840Di/810D HMI Advanced… -

Page 3

HMI Advanced Machine Parameters Operator’s Guide Program Services Diagnostics Startup Valid for Service Control Software version SINUMERIK 840D powerline SINUMERIK 840DE powerline (export version) SINUMERIK 840Di SINUMERIK 840DiE (export version) Appendix SINUMERIK 810D powerline SINUMERIK 810DE powerline (export version) 03.04 Edition… -

Page 4

, SINUMERIK and SIMODRIVE are registered trademarks of Siemens AG. The other designations in this publication may also be trademarks, the use of which by third parties may constitute copyright violation Additional information is available on the Internet under: http://www.siemens.com/motioncontrol Other functions not described in this documentation might be executable in the control. -

Page 5: Sinumerik 840D Powerline

More detailed information about other publications concerning SINUMERIK 840D and 810D and publications that apply to all SINUMERIK controls (e.g. Universal Interface, Measuring Cycles…) can be obtained from your local Siemens branch office.

-

Page 6

Synchronous actions step 2 Measurement level 2 Adaptive control Continuous dressing Using the compile cycles (OEM) Sag compensation, multi-dimensional — Function not possible 1) restricted functionality Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 7

For safety reasons some functions are disabled to protect them from unauthorized access. The machine manufacturer can customize or modify the described functionality. Please follow the instructions of the machine-tool manufacturer. Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 8

Cross-references to other documentation or sections Danger notes Additional notes or background information Ordering data supplement Explanation Description of syntax Programming examples Ó Siemens AG, 2004. All rights reserved viii SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 9

This symbol appears whenever specific information can be found in other documentation. A complete list of available literature is included in the Appendix of this Operator’s Guide. Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 10

(with a view to identifying externally visible defects and damage as well as changes in the operating behavior of the control). Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 11

Improper usage gives rise to unforeseen danger to: · Life and limb of personnel, · The control, machine or other assets of the owner and the user. Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 12

Preface 03.04 Structure of manual Notes Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 13: Table Of Contents

Editor help ……………………. 2-73 2.7.2 Quick help for program commands…………….2-74 2.7.3 Extended help for program commands…………..2-77 Job list ……………………2-78 Ó Siemens AG, 2004. All rights reserved xiii SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 14

Display system frames ……………….. 4-133 MDI mode…………………… 4-135 4.5.1 Function and main screen ………………4-135 4.5.2 Save program, file function………………4-137 4.5.3 Teach-in ……………………4-138 Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 15

Function ……………………5-232 5.4.2 Editing/deleting/finding R parameters …………..5-232 Setting data ………………….5-234 5.5.1 Working area limitation ………………. 5-234 5.5.2 Jog data ……………………5-235 Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 16

Free contour programming………………6-275 6.5.1 General……………………6-275 6.5.2 Program contour…………………. 6-276 6.5.3 Contour elements ………………..6-280 6.5.4 Graphic representation of the contour…………..6-281 Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 17

«Services» Operating Area 7-359 Function ……………………7-360 Directory structure………………..7-360 7.2.1 NC active data………………….7-360 7.2.2 Hard disk ……………………. 7-361 7.2.3 Directories ………………….. 7-363 Ó Siemens AG, 2004. All rights reserved xvii SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 18

8.3.12 Displaying loadable compile cycles (from SW 6.3) ……….8-422 PLC status ………………….. 8-424 8.4.1 General……………………8-424 8.4.2 Changing/deleting values ………………8-425 Ó Siemens AG, 2004. All rights reserved xviii SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 19

10-459 10.1 Operating data …………………. 10-460 10.2 Cleaning …………………… 10-461 Appendix A-463 Abbreviations………………….A-464 Terms ……………………A-474 References………………….A-497 Index ……………………I-511 Commands, identifiers ………………… I-516 Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 20

Contents 03.04 Ó Siemens AG, 2004. All rights reserved SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 21: Introduction

03.04 Introduction Introduction The SINUMERIK 840D/810D system …………… 1-22 Notes on handling ………………… 1-24 Activation/deactivation ………………..1-25 Ó Siemens AG, 2004. All rights reserved 1-21 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 22: The Sinumerik 840D/810D System

Set up communication links between 1 or more control units (m) or 1 or more NCs (n) (m:n, m control units and n NCK/PLC units). Ó Siemens AG, 2004. All rights reserved 1-22 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 23: Operator Components

Read Chapter 2 «Operator Components» carefully before proceeding with further chapters. All subsequent chapters are written on the assumption that you have done so! Ó Siemens AG, 2004. All rights reserved 1-23 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 24: Notes On Handling

Before operating any of the control elements on this operator panel front: Please first read the explanations supplied in this documentation! Ó Siemens AG, 2004. All rights reserved 1-24 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 25: Activation/Deactivation

Deactivation Please follow the instructions for switching off the control or the entire system! Machine manufacturer Please follow the machine manufacturer’s instructions! Ó Siemens AG, 2004. All rights reserved 1-25 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 26

By pressing the «Area switchover» key twice, you can toggle between the operating areas last selected, e.g. between the «Parameters» and «Machine» areas. Ó Siemens AG, 2004. All rights reserved 1-26 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 27: Operator Components/Sequence Of Operations

Example of a job list with multi-channel m:n connections ……..2-84 2.8.4 «Execute job list» operating sequence…………… 2-85 2.8.5 Rename workpieces with job lists …………….2-87 Ó Siemens AG, 2004. All rights reserved 2-27 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 28

Operator Components/Sequence of Operations 03.04 2.8.6 Copy workpieces with job lists …………….2-88 2.8.7 Archive workpieces with job lists in case of m:n…………. 2-88 Ó Siemens AG, 2004. All rights reserved 2-28 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 29: Operator Panels

3 Softkey bar (horizontal) 4 ETC key (menu extension) 5 Area switchover key 6 Softkey bar (vertical) All keys are described in the following sections. Ó Siemens AG, 2004. All rights reserved 2-29 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 30: Op 010S Operator Panel

1 Machine area key 2 Recall (return) 3 Softkey bar (horizontal) 4 ETC key (menu extension) 5 Area switchover key 6 Softkey bar (vertical) Ó Siemens AG, 2004. All rights reserved 2-30 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 31: Op 012 Operator Panel

(menu extension) 5 Area switchover key 6 Softkey bar (vertical) For further information about operator components, please see: /BH/ Operator Components Manual. Ó Siemens AG, 2004. All rights reserved 2-31 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

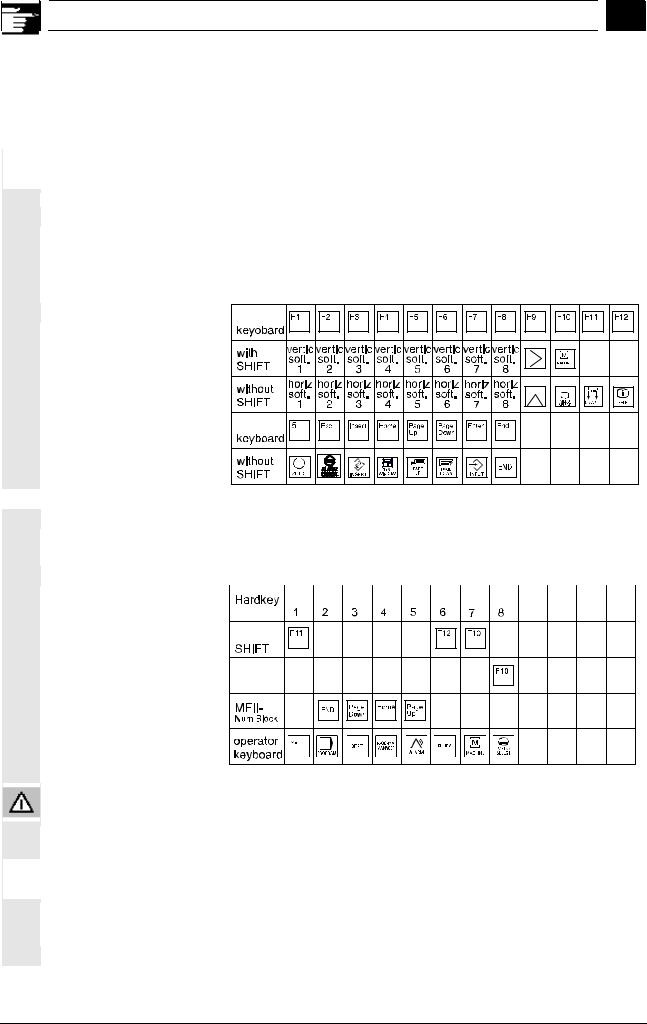

Page 32: Full Standard Keyboard

For further information about the configuration of operating keys, please see: /IAM/, IM4 Installation and Start-Up, Chapter 5 Functions/Parameters. Ó Siemens AG, 2004. All rights reserved 2-32 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 33

Direct access to the Machine operating area. Direct access to the last selected operating area: Machine, Parameters, Program, Services, Diagnostics or Startup Ó Siemens AG, 2004. All rights reserved 2-33 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 34: Operator Panel Keys

Recall key Return to the next higher menu. Recall closes a window. ETC key Expansion of the softkey bar in the same menu. Ó Siemens AG, 2004. All rights reserved 2-34 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 35

(the active window has a thicker border). Keyboard input e.g. the page keys, is possible only in the active window. Ó Siemens AG, 2004. All rights reserved 2-35 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 36

= UNDO). Ó Siemens AG, 2004. All rights reserved 2-36 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 37

A program can be opened in the text editor. Alarm Takes you directly to the Alarms screen User key Can be configured by the customer Ó Siemens AG, 2004. All rights reserved 2-37 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 38

NC. In the above cases, the operation is denied with alarms 1203xx. Ó Siemens AG, 2004. All rights reserved 2-38 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 39: Machine Control Panels

The machine tool can either be equipped with a standard machine control panel from SIEMENS (ordering data option) or with a specific machine control panel from the machine-tool manufacturer.

-

Page 40: Machine Control Panel Keys

Control of machine through execution of a block or a sequence of blocks. The blocks are entered on the operator panel front. Ó Siemens AG, 2004. All rights reserved 2-40 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 41: Machine Control Panel Keys

Repositioning Repos Reposition, re-approach contour in «JOG» mode. Approaching a reference point Ref Point Approach the reference point (Ref) in «JOG» mode. Ó Siemens AG, 2004. All rights reserved 2-41 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 42: Feed Control

Press these keys to traverse the selected axis (X…Z) in a positive +X +Z direction. Press these keys to traverse the selected axis (X…Z) in negative direction. Ó Siemens AG, 2004. All rights reserved 2-42 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 43

You can switch between the machine and workpiece coordinate WCS MCS systems in the Machine operating area using softkeys (WCS)/(MCS) or the corresponding key on the machine control panel. Ó Siemens AG, 2004. All rights reserved 2-43 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 44: Spindle Control

— The maximum spindle speed and the values for the spindle speed override position are defined in the machine data and setting data (see information supplied by the machine-tool manufacturer). Ó Siemens AG, 2004. All rights reserved 2-44 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 45: Keyswitch

2.4 Machine control panel keys 2.4.5 Keyswitch SIEMENS keyswitch The keyswitch on the SINUMERIK 840D, 810D has 4 settings to which protection levels 4 to 7 are assigned. Functions can be assigned to keyswitch positions by the machine Machine manufacturer manufacturer.

-

Page 46: Program Control

— The control is in its initial state and ready for a new program run. See also /FB/, K1, Description of Functions Mode Group, Channel, Program Operation Mode Ó Siemens AG, 2004. All rights reserved 2-46 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 47: Screen Layout

You can display information by pressing the i key Recall: Return to higher-level menu > ETC.: Expansion of the softkey bar in the same menu. Ó Siemens AG, 2004. All rights reserved 2-47 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 48: Global Machine Status Display

Parameters, Program, Services, Diagnosis, Start-Up). 2 Channel status The current channel status is displayed: — Channel reset — Channel interrupted — Channel active Ó Siemens AG, 2004. All rights reserved 2-48 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 49

24 Wait: For tool change acknowledgement 25 Wait: For gear stage change 26 Wait: For position control 27 Wait: For thread cut Ó Siemens AG, 2004. All rights reserved 2-49 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 50

61 Wait: For axis replacement: Axis is currently coupled- motion axis 62 Wait: For axis replacement: Axis is currently coupled slave axis Ó Siemens AG, 2004. All rights reserved 2-50 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 51

9 Program control display Functions that have been activated are visible can be set via «Program control», see Section 4.6 Automatic mode, «Program control» Ó Siemens AG, 2004. All rights reserved 2-51 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 52: Program Control Display

Traverse movements are performed with the feedrate value set in the Dry run feedrate setting data «Dry run feedrate». This dry run feedrate function replaces the programmed motion commands. Ó Siemens AG, 2004. All rights reserved 2-52 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 53

This function is not set/deactivated under Program Control, but via the Feed Start/Feed Stop keys on the machine control panel. Ó Siemens AG, 2004. All rights reserved 2-53 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 54: General Sequence Of Operation

The function of the keys and menus is the same in all operating areas. This identical functionality applies only if the operating areas are left intact as supplied by Siemens AG and no modifications have been configured by the user.

-

Page 55: Switch Menu Window

Position cursor in menu window: You can position the cursor at the desired point in the menu window with the «Direction keys». Ó Siemens AG, 2004. All rights reserved 2-55 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 56: Select Directory/File

The subsequent files are selected continuously until you press «Cursor up» or «Cursor down» (without «Shift») key. Deselects a selected file. Cancels all selections. Ó Siemens AG, 2004. All rights reserved 2-56 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 57: Edit Input/Values

Press the «Edit» key to open a complete list of possible or existing values. Position the cursor on the value of your choice using the «Direction» keys. Ó Siemens AG, 2004. All rights reserved 2-57 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 58: Confirm/Cancel Input

The cursor remains positioned in the currently selected field. Switch from the horizontal menu level back to the call menu level. Ó Siemens AG, 2004. All rights reserved 2-58 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 59: Editing Part Programs In The Ascii Editor

You have selected the file you wish to edit in the directory and pressed the «Input» key, the vertical softkey bar changes. Your selected file is opened in the text editor. Ó Siemens AG, 2004. All rights reserved 2-59 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 60

The softkey pastes the cut or copied block from the buffer into the text Paste block in front of the cursor position. Ó Siemens AG, 2004. All rights reserved 2-60 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 61

Installation and Start-up of HMI Advanced (PCU 50). The function «Replace all texts» is only enabled for files located on the hard drive (i.e. not in the NC memory). Ó Siemens AG, 2004. All rights reserved 2-61 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 62

The part program block is inserted in the part program with the appropriate parameters. Example: CYCLE81 (110, 100, 2, 35) /PGC/, Programming Guide Cycles Ó Siemens AG, 2004. All rights reserved 2-62 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 63

«Renumber» function. · Number of first block · Incrementation of block numbers (e.g. 1, 2, 10) Ó Siemens AG, 2004. All rights reserved 2-63 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 64

· The coordinate system and the technology to be used are set via the machine data; see /IAM/ Installation and Start-Up Guide IM4. · Edited programs are automatically enabled after saving. Ó Siemens AG, 2004. All rights reserved 2-64 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 65: Switch Channel

1. Switch to next channel. 2. Switch over configured channel group/channels (1 NC). 3. Switch to another NC (with m:n link involving several NCs). Ó Siemens AG, 2004. All rights reserved 2-65 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 66: M:n Communication Links

All current communication links and associated symbol names are listed in display «Channel menu». Important Only two links may be active simultaneously on one NCU. Ó Siemens AG, 2004. All rights reserved 2-66 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 67

NC) only takes place upon activation of a vertical softkey. NC switchover You can change to another NC via the vertical softkeys if the channel is not on the current NC. Ó Siemens AG, 2004. All rights reserved 2-67 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 68

· If an application (e.g. processing from external source) disables switchover to the selected NC, then only the channels of the current NC are displayed in the channel menu. Ó Siemens AG, 2004. All rights reserved 2-68 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 69

After setting up a link to another NCU, the operating area selected last is always available for this (as for the NCU whose link was separated). Ó Siemens AG, 2004. All rights reserved 2-69 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 70: Pocket Calculator

· Enter the letter «I» (convert to inches) or «M» (convert to metric) · Press the «input» key, the value is converted. Ó Siemens AG, 2004. All rights reserved 2-70 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 71: Help

Zoom + Zoom — decrease the zoom factor in the document view, with «Exit help» you return to the editor. Exit help Ó Siemens AG, 2004. All rights reserved 2-71 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 72

«ETC.» key the function «MMC help» is directly invoked (corresponds to HMI MMC help Help). Ó Siemens AG, 2004. All rights reserved 2-72 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 73: Editor Help

From the context-sensitive help you can jump to the corresponding page in the documentation with the «information» key, e.g. jump to the Programming Guide, Fundamentals. Ó Siemens AG, 2004. All rights reserved 2-73 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 74: Quick Help For Program Commands

· If there is no match, a full overview (see below) is displayed. Ó Siemens AG, 2004. All rights reserved 2-74 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 75

If a heading is selected and you press «Input» or the softkey «Show heading», the instructions belonging to the selected heading are displayed. Show heading Ó Siemens AG, 2004. All rights reserved 2-75 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 76

«info» key, if the symbol for the info key is displayed on the bottom right part of the screen (see Fig. below). Ó Siemens AG, 2004. All rights reserved 2-76 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 77: Extended Help For Program Commands

You call the help function in the editor with the «information key». Press the «information» key once more to open the Programming Guide (pdf file) with the Adobe Acrobat Reader. Ó Siemens AG, 2004. All rights reserved 2-77 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 78: Job List

· Backup (in preparation for the next software version) Notes Parallel setup, preparations for NC Start, parallel cleanup and backup can also be executed from the PLC. Ó Siemens AG, 2004. All rights reserved 2-78 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 79

Manufacturer directory, and finally the Siemens directory. Job list templates can be stored according to language and system. See Programming operating area: 6.1.5 Templates. Ó Siemens AG, 2004. All rights reserved 2-79 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 80: Syntax Description For Job Lists

(loads all files from one directory, here e.g. all files from part programs (MPF.DIR)) LOAD PART1.MPF (loads one file, e.g. PART1.MPF from the currently selected workpiece directory of the job list) Ó Siemens AG, 2004. All rights reserved 2-80 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 81

(PART2 is selected in the 2nd channel of NCU_2) SELECT /shaft1.wpd/side1.mpf CH=2 DISK (Part program PAGE1.MPF of workpiece SHAFT1.WPD is executed from hard disk in the 2nd channel) Ó Siemens AG, 2004. All rights reserved 2-81 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 82

NETNAMES.INI) COPY PART12.MPF NC=NCU_2 (Copies one file from the workpiece of the job list to the NC «NCU_2») Ó Siemens AG, 2004. All rights reserved 2-82 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 83: Example Of A Job List With Two-Channel 1:1 Connections

SELECT /WCS.DIR/Part1.WPD/Channel1.MPF CH=1 SELECT /WCS.DIR/Part1.WPD/Channel2.MPF CH=2 The destination is not specified for loading in a 1:1 link, the current NC is the default. Ó Siemens AG, 2004. All rights reserved 2-83 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 84: Example Of A Job List With Multi-Channel M:n Connections

COPY /WORK.DIR/Part1.WPD/Channel3.MPF NC=NCU2 (or CH=CHANNEL3) COPY /WORK.DIR/Part1.WPD/Channel3.INI NC=NCU2 (or CH=CHANNEL3) COPY /WORK.DIR/Part1.WPD/Ch32.MPF NC=NCU2 (or CH=CHANNEL3) SELECT /WORK.DIR/Part1.WPD/Channel1.MPF CH=CHANNEL1 SELECT /WORK.DIRPart1.WPD/Channel2.MPF CH=CHANNEL2 SELECT /WORK.DIR/Part1.WPD/Channel3.MPF CH=CHANNEL3 Ó Siemens AG, 2004. All rights reserved 2-84 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 85: Execute Job List» Operating Sequence

If the files have different time stamps or are of different lengths, the identifier is «!X!». Ó Siemens AG, 2004. All rights reserved 2-85 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 86

With «Unload» only files are transferred from the passive file system of the NC. If, for example, modifications have been made to the active data in parameters, these must be saved beforehand. Ó Siemens AG, 2004. All rights reserved 2-86 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 87: Rename Workpieces With Job Lists

Place the cursor on the workpiece directory that you want to rename. The «Rename» dialog window opens. Rename Enter the new name. Ó Siemens AG, 2004. All rights reserved 2-87 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 88: Copy Workpieces With Job Lists

«Programs/Data» file tree is displayed. The vertical softkey bar changes. Please refer to Chapter «Reading out data» in «Services» operating area for additional sequences of operation. Ó Siemens AG, 2004. All rights reserved 2-88 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 89: Example Of Operation

Insert tool and run machining program Store the program · 6.10 Save a part program · To hard disk 7.5.3/7.5.4 · Read in/out via RS-232 interface Ó Siemens AG, 2004. All rights reserved 3-89 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 90

Example of Operation 03.04 3.1 Typical sequence of operation Notes Ó Siemens AG, 2004. All rights reserved 3-90 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 91: Machine Operating Area

Executing programs from the hard disk …………4-145 4.6.6 Access to external network drive …………..4-146 4.6.7 Program editing ………………..4-148 4.6.8 Block search/setting the search destination………… 4-150 Ó Siemens AG, 2004. All rights reserved 4-91 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 92

Block search in program testing mode, multi-channel ……..4-156 4.6.11 Overstore ………………….4-158 4.6.12 Program control ………………..4-160 4.6.13 DRF offset………………….4-164 Ó Siemens AG, 2004. All rights reserved 4-92 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 93: Data Structure Of The Nc Control

Only one copy exists of programs that are loaded from the hard disk to the NC memory. The program memory in the NC is limited (see memory display). Ó Siemens AG, 2004. All rights reserved 4-93 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 94: Operating Modes And Machine Functions

In operating mode «Jog» you can select the following machine functions via the machine control panel or softkeys in the basic menu: Inc (traverse in preset increments) Ó Siemens AG, 2004. All rights reserved 4-94 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 95: Data Structure Of The Nc Control

2. Traverse the tools/workpiece to the start position specified in the setup plan, 3. Download the part program to the control memory, 4. Check/enter the work offsets, 5. Check/enter the tool offsets. Ó Siemens AG, 2004. All rights reserved 4-95 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 96: Mode Groups And Channels

Channel status Channel interrupted Channel active Channel RESET Channel operational messages Stop: Action is required (e.g. cancel feedrate disable). Ó Siemens AG, 2004. All rights reserved 4-96 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 97: Channel-Wide Status Display With Symbols (Sw 6.2 And Higher)

Feedrate is not enabled Spindle status Spindle turning left or right Spindle is not enabled Spindle stop Application example with 4 channels and 2 spindles: Ó Siemens AG, 2004. All rights reserved 4-97 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 98: Dual-Channel Display (Sw 6.4 And Higher)

For selecting and changing operating modes, please refer to the following chapter. Ó Siemens AG, 2004. All rights reserved 4-98 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 99: Operating Mode Selection/Change

An error message is output if a mode change request is rejected by the system. The error message will indicate the error cause and possibly the remedy. Ó Siemens AG, 2004. All rights reserved 4-99 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 100: Services

When a mode is selected, the LED next to the selection key on the MCP lights up. The same status is signaled in the mode field on the screen. Ó Siemens AG, 2004. All rights reserved 4-100 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 101

To provide this type of protection, the control system offers a facility for disabling or enabling mode changes. /FB/, K1, Description of Functions Ó Siemens AG, 2004. All rights reserved 4-101 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 102: General Functions And Displays

Select «Jog» mode. Press the «Repos» key to reposition the tool on the contour. Repos Turning machine: Press the «+X» or «-X» key. Ó Siemens AG, 2004. All rights reserved 4-102 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 103: Display Program Level

When you press softkey «Current block», the «Current block» window Current block containing the program blocks of the current part program is displayed again. Ó Siemens AG, 2004. All rights reserved 4-103 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 104: Toggling Between Machine/Work (Mcs/Wcs)

Cartesian coordinate system. All geometry axes and special axes are displayed in the workpiece coordinate system. Work position Repos offset Ó Siemens AG, 2004. All rights reserved 4-104 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 105

· The number of places displayed after the decimal point and units of measure can be set in machine data. /PA/, Programming Guide, Fundamentals Ó Siemens AG, 2004. All rights reserved 4-105 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 106: Display Axis Feeds

Using the «Page» keys you can scroll up and down to display other G functions. Ó Siemens AG, 2004. All rights reserved 4-106 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 107: Display Auxiliary Functions

The «Auxiliary functions» window appears on the screen. Display Aux. fct. Up to 5 M functions and 3 H functions can be displayed. Ó Siemens AG, 2004. All rights reserved 4-107 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 108: Display Spindles

· «Spindle Stop» · «Spindle not enabled» · «Spindle CCW direction of rotation» or «… CW» (=Spindle running) Ó Siemens AG, 2004. All rights reserved 4-108 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 109: Handwheel

The machine-tool manufacturer is responsible for the design of handwheels. Operation may therefore differ from the explanation above. Please refer to the machine-tool manufacturer’s documentation! Ó Siemens AG, 2004. All rights reserved 4-109 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 110: Status Of Synchronized Actions

The programmed synchronized actions are listed block by block with block number (static/modal actions are listed together with the number of the synchronized action) Ó Siemens AG, 2004. All rights reserved 4-110 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 111

If the control finds matching program blocks, the associated condition and instruction parts are output with the other basic display data. Press RECALL to return to the «Automatic» basic display. Ó Siemens AG, 2004. All rights reserved 4-111 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 112: Preset

Other information Machine manufacturer The «Preset» function can be disabled by means of protection levels (keyswitch position). Ó Siemens AG, 2004. All rights reserved 4-112 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 113: Setting The Actual Value

The new actual value is displayed in the «Position» column. Using «Abort», you can undo the entire offset entered up to now and Abort exit the input screen. Ó Siemens AG, 2004. All rights reserved 4-113 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 114: Inch/Metric Switchover

The display resolution for the inch system of measurement is defined by machine data. Actions such as part program start or mode change are disabled for the duration of the switchover. Ó Siemens AG, 2004. All rights reserved 4-114 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 115

NCUs whereby the interpolations can provide correct results only if the same unit systems are used. References: /FB/, B3, Distributed Systems Ó Siemens AG, 2004. All rights reserved 4-115 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 116: Reference Point Approach

Press the «Axis» keys. Milling machine: Select the axis to be traversed and 9th Axis then press the «+» or «-» key. Ó Siemens AG, 2004. All rights reserved 4-116 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 117

· All axes of a mode group can approach the reference point simultaneously (depending on the PLC program of the machine- tool manufacturer). · The feedrate override is active. Ó Siemens AG, 2004. All rights reserved 4-117 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 118

The NC cannot be started in automatic mode until all axes with a defined reference point (see machine data MD) have actually reached this point. Ó Siemens AG, 2004. All rights reserved 4-118 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 119: Jog Mode

0.000 % feedrate Power [%] Feedrate mm/min Act. 7000.000 0.000% Zoom 7000.000 Act. val. Tool Act. val. Preselected tool: Scratch Preset Handwheel Ó Siemens AG, 2004. All rights reserved 4-119 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 120

If the axes are traversed in the «Program interrupted» status in «Jog» mode, the path traversed by every axis with respect to the point of interruption is displayed in the REPOS offset. –0.1 Ó Siemens AG, 2004. All rights reserved 4-120 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 121

· The «delay time» can only be displayed if you have set «Punching with delay time». Increases the size of the actual-value display. Zoom act. val. Ó Siemens AG, 2004. All rights reserved 4-121 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 122: Traverse The Axes

Feedrate and rapid traverse override switches can be operative. One or several axes can be selected at the same time (depending on PLC program). Ó Siemens AG, 2004. All rights reserved 4-122 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 123: Inc: Incremental Dimensions

(see also Section «Traversing axes»). Increment keys with preset increment sizes are temporarily inoperative. Ó Siemens AG, 2004. All rights reserved 4-123 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 124: Repos (Repositioning)

The rapid traverse override switch is active. Non-compensated Repos offsets are compensated with programmed feedrate and linear interpolation on switchover to Automatic mode and selection of NC start. Ó Siemens AG, 2004. All rights reserved 4-124 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 125: Si (Safety Integrated): User Agreement

Check whether the axis is referenced. If not, error message «Please reference axis first» is output. User agreement cannot be activated for the axis until it has been referenced. Ó Siemens AG, 2004. All rights reserved 4-125 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 126: Scratching (Sw 6 Or Higher)

· The active NV is displayed and can be changed. · The active tool is displayed. No tool is displayed if none is active (message). Ó Siemens AG, 2004. All rights reserved 4-126 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 127

«Approach direction» column on the axis to be altered and press the «Toggle key» so that the desired approach direction is visible. Ó Siemens AG, 2004. All rights reserved 4-127 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 128

If a toolholder is active in the present system, it is displayed in the G function window as «TCARR=n» (n = 1 or 2). Ó Siemens AG, 2004. All rights reserved 4-128 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 129

If an error occurs, e.g. the channel is in «active» state or the connection with the NC is disrupted, «Swiveling: adjustment not possible» is displayed in the message line. Ó Siemens AG, 2004. All rights reserved 4-129 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 130: Scratching (Sw 5 And Lower)

2. Use the cursor to select the first axis to be moved in the «Scratch» display. Selected axes are automatically marked in parallel in the actual value window. Ó Siemens AG, 2004. All rights reserved 4-130 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 131

«Toggle key» to define how the tool offset must be included in the calculation. Example 1 Set «+R» with toggle key. Approach direction Ó Siemens AG, 2004. All rights reserved 4-131 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 132

«scratching» function cannot be used for G54 to G599. · Any rotation, mirroring or scale modification included in the offset to be measured remains valid. Ó Siemens AG, 2004. All rights reserved 4-132 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 133: Display System Frames

You can choose between the system frames and basic frames by scrolling through the desired section. The following figure shows sample screen contents Ó Siemens AG, 2004. All rights reserved 4-133 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 134

As of SW 6.3: Workpiece reference corresponds to $P_WPFR) Cycles corresponds to $P_CYCFR) See also the figure at the end of 4.4.6 Ó Siemens AG, 2004. All rights reserved 4-134 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 135: Mdi Mode

«Channel Reset» or «Channel interrupted» state. The program generated in MDI mode can be stored · in the part programs directory (MPF.DIR) Ó Siemens AG, 2004. All rights reserved 4-135 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 136

Press this softkey to access vertical softkeys providing editing Editor functions functions: Overwrite, Mark, Copy, Paste, Delete, Find, Find Next, Position. Ó Siemens AG, 2004. All rights reserved 4-136 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 137: Save Program, File Function

MDI buffer. The program is saved/stored as a part program (MPF) under the name you have entered in the Part Programs directory. Ó Siemens AG, 2004. All rights reserved 4-137 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 138: Teach-In

«Teach In program» window. The axis name and axis positions are transferred to the MDI program as values referred to the workpiece coordinate system. Ó Siemens AG, 2004. All rights reserved 4-138 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 139

· When using special kinematics or robots, the positions of the STAT machine and rotary axis TU are displayed in addition to the positions in the workpiece coordinate system. Ó Siemens AG, 2004. All rights reserved 4-139 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 140: Automatic Mode

Explanation of basic Like the Jog display, the Automatic display contains actual value, display spindle window, feedrate and tool windows. Ó Siemens AG, 2004. All rights reserved 4-140 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 141

Unlike with function «Current block», the program created by the programmer is displayed. Other information The other softkeys are described in the sections below. Ó Siemens AG, 2004. All rights reserved 4-141 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 142: Program Overview

All programs of a particular type are displayed via the horizontal softkeys: Display of all workpiece directories Work- pieces Display of all existing part programs Part programs Ó Siemens AG, 2004. All rights reserved 4-142 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 143: Loading And Unloading The Workpiece/Part Program

The highlighted workpiece/part program is loaded from the NC Upload NC->HD memory to the hard disk. The workpiece/program is erased from the NC memory. Ó Siemens AG, 2004. All rights reserved 4-143 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 144: Log: Loading List Of The Programs

The «Program overview» is open. Program overview The softkey bars change. Select softkey «Log». The «Job log for program overview» is opened. Ó Siemens AG, 2004. All rights reserved 4-144 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 145: Executing Programs From The Hard Disk

(softkey program run) or the larger multi-block display (softkey program blocks) can be selected during automatic operation. The setting made applies for the single block or NC stop status. Ó Siemens AG, 2004. All rights reserved 4-145 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 146: Access To External Network Drive

Select the program that you want to execute with the cursor and then Execute fr. hard disk press the softkey «Execute from hard disk». The program starts when you press «NC Start». Cycle Start Ó Siemens AG, 2004. All rights reserved 4-146 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 147

For further information about the EXTCALL command, please refer to: /PGA/ Programming Guide, Advanced, Chapter 2. /FB/, K1 Description of Functions «Processing programs from external» Ó Siemens AG, 2004. All rights reserved 4-147 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 148: Program Editing

«Level +». This is only possible if the NC has a correction block. After you have corrected the error, you can continue the program run by pressing «NC Start». Cycle Start Ó Siemens AG, 2004. All rights reserved 4-148 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 149

«Correct block» softkey is pressed. In this case, program execution must be aborted with «NC Reset». The part program can then be edited under Programming. Ó Siemens AG, 2004. All rights reserved 4-149 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 150: Block Search/Setting The Search Destination

· by specifying a block number, a label, a program name or any character string. References For further information about block search, please refer to: /FB/ K1, BAG, Channel, Program control Ó Siemens AG, 2004. All rights reserved 4-150 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 151

· When you press NC start the program is started and the process resumes at this destination block. Block search can be aborted with Reset. Reset Ó Siemens AG, 2004. All rights reserved 4-151 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 152

Preset search destination to last program interruption point: The search pointer is assigned the data of the last program Interrup. point interruption point. Ó Siemens AG, 2004. All rights reserved 4-152 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 153: Accelerated External Block Search

The following search destinations are entered in the Block search menu: Search target 1 ………………Search target 2 ………………Search target 3 ………………Ó Siemens AG, 2004. All rights reserved 4-153 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 154

SUBPRG3.SPF; the previous statements are skipped, and the search stops. On NC Start, the subroutine SUBPRG3.SPF is processed starting at the destination line. Ó Siemens AG, 2004. All rights reserved 4-154 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 155

Type 1 (block number) and type 5 (line number) are possible as search target types. Start search without calculation for external programs. Ext. without calc. Ó Siemens AG, 2004. All rights reserved 4-155 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 156: Block Search In Program Testing Mode, Multi-Channel

The channel in which the destination block is searched for or the program pointer set is the destination channel. Other channels are started according to the setting in the «machine.ini» file. Ó Siemens AG, 2004. All rights reserved 4-156 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 157

JOG mode, before program processing is continued via NC Start at the point in the program reached by the block search. Ó Siemens AG, 2004. All rights reserved 4-157 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 158: Overstore

Cycle Stop The «Overstore» window is opened. Overstore In this window you can now enter the NC blocks that are to be processed. Ó Siemens AG, 2004. All rights reserved 4-158 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 159

«AUTO» mode when you press «NC Start» again. · Overstore does not alter the programs stored in the part program memory. Ó Siemens AG, 2004. All rights reserved 4-159 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 160: Program Control

When you select the DRY function «dry run feedrate» in «AUTOMATIC» mode, the feedrate entered in setting data SD 42100: DRY_RUN_FEED is applied in the program instead of the programmed feedrate. Ó Siemens AG, 2004. All rights reserved 4-160 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 161

This allows you to see from the top window which level · is selected, but not yet active, · selected and active, · deselected and active, · deselected and not active. Ó Siemens AG, 2004. All rights reserved 4-161 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 162

The program control display is output irrespective of the selected menu. For further information about how to program skip levels, please see: References: /PG/, Programming Guide, Fundamentals Ó Siemens AG, 2004. All rights reserved 4-162 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 163

Blocks which are too long for the display window (approx. 65 characters) are truncated and the truncated code is replaced by «…». Ó Siemens AG, 2004. All rights reserved 4-163 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 164: Drf Offset

Traverse the required axes using the handwheel. Using the same operating sequence, you can also return the DRF offset to the value «0». Ó Siemens AG, 2004. All rights reserved 4-164 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 165: Parameters» Operating Area

Display active work offset external…………….5-249 5.6.7 Display sum of the active work offsets…………..5-249 5.6.8 Immediately activate work offset and basic frame ……….5-250 Ó Siemens AG, 2004. All rights reserved 5-165 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 166

Changing/finding user data/user variables………….. 5-252 Display system variables………………5-254 5.8.1 Creating/editing variable views …………….5-255 5.8.2 Manage variable views……………….. 5-257 5.8.3 Log system variables………………..5-257 Ó Siemens AG, 2004. All rights reserved 5-166 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 167: Tool Data

(drill, milling cutter, turning tools with cutting edge position etc.). Ó Siemens AG, 2004. All rights reserved 5-167 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 168

Other values must Radius in Z/X be set to zero F — Toolholder Length1 in X G19: reference point Radius in Y/Z Ó Siemens AG, 2004. All rights reserved 5-168 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 169

Length 1 in Z reference point Other values must G18: Length 1 in Y be set to zero G19: Length 1 in X Ó Siemens AG, 2004. All rights reserved 5-169 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 170

Radius in Z/X Other values must Length 1 in Z be set to zero G19: Length 2 in Y Radius in Y/Z Ó Siemens AG, 2004. All rights reserved 5-170 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 171

Radius Radius in Z/X Length 1 in Z G19: Length 2 in Y Radius in Y/Z Base Length 2 Geometry Length 2 Siemens AG, 2004. All rights reserved 5-171 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 172

Length 2 in Z Radius Radius in Z/X Length 1 in Z G19: Length 2 in Y Length 2 (Z) Radius in Y/Z Ó Siemens AG, 2004. All rights reserved 5-172 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 173

R: Tool nose radius (tool radius) S: Tool nose center position Length 2 (Z) Tool tip P (Cutting edge 1 = D Ó Siemens AG, 2004. All rights reserved 5-173 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 174

Length 1 in Z G19: Length 2 in Y Radius Group type 7xy (special tools) · Slotting saw 3D probe Edge probe Fixed stop Ó Siemens AG, 2004. All rights reserved 5-174 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 175

Type 730 The stop is used to position the material in turning machines with bar feed. Only tool length compensation is important. Ó Siemens AG, 2004. All rights reserved 5-175 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 176

Reserved Reserved Reserved Wear Length and radius compensation Radius compensation Length 1 Length 2 Length 3 Radius Reserved Reserved Reserved Reserved Reserved Ó Siemens AG, 2004. All rights reserved 5-176 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 177

Other values must be set to zero Length 1 in X G19: Length 2 in Z Length 3 in Y Radius in Z/X Ó Siemens AG, 2004. All rights reserved 5-177 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 178

Length 1 in X be set to zero Length 2 in Z F: Toolholder Length 1 in Z G19: reference point Length 2 in Y Ó Siemens AG, 2004. All rights reserved 5-178 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 179

F´: Tool base reference point Other values must Length 1 in Z F: Toolholder be set to zero reference point Length 2 in Y Ó Siemens AG, 2004. All rights reserved 5-179 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 180

Basic length 2 Basic length 2 *(2 21 =2097152) $TC_DP23 Basic length 3 Basic length 3 Basic length 3 *(2 22 =4194304) Ó Siemens AG, 2004. All rights reserved 5-180 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 181

The tool lengths are not automatically compensated when the angle is altered. With inclined axis machines, the same angle must be used for the inclined axis and the inclined grinding wheel. Ó Siemens AG, 2004. All rights reserved 5-181 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 182: Tool Offsets

The number of parameters shown in the window is that for the tool type. The maximum number of offset parameters (T and D numbers) can be set by means of machine data. Ó Siemens AG, 2004. All rights reserved 5-182 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 183

Find any tool or the active tool Go to… List of all available tools Overview… New cutting edge or a new tool New … Ó Siemens AG, 2004. All rights reserved 5-183 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 184: New Tool

Sets up another cutting edge for the tool you have just set up. OK + new cutting edge The window remains open. Ó Siemens AG, 2004. All rights reserved 5-184 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 185: Display Tool

T No. T No. – Other information Input of the geometry and wear data of the tool can be disabled using the keyswitch. Ó Siemens AG, 2004. All rights reserved 5-185 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 186: Delete Tool

The tool and all its edges are deleted. The tool offsets of the tool number preceding the deleted tool are displayed. Ó Siemens AG, 2004. All rights reserved 5-186 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 187: New Cutting Edge

Another new cutting edge can be set up. A new cutting edge is set up. OK + new tool Another new tool can be set up. Ó Siemens AG, 2004. All rights reserved 5-187 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 188: Delete Cutting Edge

Tool offset, absolute dimension Tool mounting point Machine reference point Workpiece zero Ó Siemens AG, 2004. All rights reserved 5-188 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 189

If «Jog» mode is selected, it is also possible to change the position by traversing the axes. The control automatically calculates the value from the reference value and the new position. Ó Siemens AG, 2004. All rights reserved 5-189 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 190: Activate Tool Offset Immediately

The offset is applied after NC Start of the Reset in response to the next programmed axis movement in the part program. Ó Siemens AG, 2004. All rights reserved 5-190 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 191: Tool Management

NC Start, ensure that the correct channel is selected for this tool. Ó Siemens AG, 2004. All rights reserved 5-191 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 192

/FBW/ Description of Functions Tool Management or /FBS/ Description of Functions ShopMill Ó Siemens AG, 2004. All rights reserved 5-192 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 193: Basic Tool Management Functions

Wzg3 0.0000 0.0000 D check Buffer locations Search and position Next magazine Magazine Tool Load Unload Working Relocate offset list list list Ó Siemens AG, 2004. All rights reserved 5-193 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 194

E = Tool has been used R = Unloading marking («radius») B = Loading marking S = Master tool Wear group assigned to the tool. Ó Siemens AG, 2004. All rights reserved 5-194 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 195

All other tool types are preset to a value of 0. Geo – Len 1 Tool offsets such as length, radius, wear, monitoring data, etc. Radius … Ó Siemens AG, 2004. All rights reserved 5-195 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 196

If you display transformed data and want to create a new tool in the magazine list (loading mode), the transformed data display is activated exclusively for input of this data block. Ó Siemens AG, 2004. All rights reserved 5-196 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 197

Only automatically accessible magazines are considered for processing. Any previously active tools are disabled by the activation of tools, especially if the wear group is changed. Ó Siemens AG, 2004. All rights reserved 5-197 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 198

The tool data are read from a code carrier and entered in the tool list Tool from (you can then edit the data). Ó Siemens AG, 2004. All rights reserved 5-198 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 199

Once you have set up a new tool, the cursor automatically jumps to the line containing the new tool when you return to the tool list. This gives you feedback about your operation. Ó Siemens AG, 2004. All rights reserved 5-199 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 200

The D number of the current tool is determined and displayed. Current D number Ó Siemens AG, 2004. All rights reserved 5-200 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 201: Modifying/Changing Tool Data

· Create new cutting edges · Modify cutting edge data · Modify monitoring data · Modify location-dependent offsets (DL numbers) · Delete cutting edges Ó Siemens AG, 2004. All rights reserved 5-201 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 202

Press the «<<» softkey to return to the Tool details input screen form. The new cutting edge is defined. The display color changes. Ó Siemens AG, 2004. All rights reserved 5-202 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 203

— Tool point direction (for turning tools) — Tool clearance angle (for turning tools) You can define the value of Length1, Length2, Length3 and Radius1 for every parameter. Ó Siemens AG, 2004. All rights reserved 5-203 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 204

The D number is removed from the table and can be reallocated. Terminates input of the tool data and returns to the table displayed << previously. Ó Siemens AG, 2004. All rights reserved 5-204 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 205: Change Of Meaning/Representation Of Tool Wear Data

The current tool for channel «REV2» is indicated in row 1. The current value of G56 on channel «REV2» deviates from the G56 reset value Ó Siemens AG, 2004. All rights reserved 5-205 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 206

Row 11 displays the current tool for channel «HAND». There the current value of G56 is equal to the reset value ( Ó Siemens AG, 2004. All rights reserved 5-206 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 207: Grinding Parameters Extension In Sw 6.2 Or Later

· Tool details basic screen · Tool details cutting edge data (secondary) screen · Tool details monitoring data (secondary) screen Ó Siemens AG, 2004. All rights reserved 5-207 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 208

$TC_TPG6 Maximum peripheral speed [m/s, ft/s] $TC_TPG7 Angle of inclined wheel [degrees] $TC_TPG8 Parameter number for radius $TC_TPG9 calculation/compensation parameter for GWPS Ó Siemens AG, 2004. All rights reserved 5-208 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 209

— They are not saved in the tool cabinet/tool catalog. — They are not transferred via code carrier/SINCOM. — The extension is available in HMI Advanced Version 6.2 or later. Ó Siemens AG, 2004. All rights reserved 5-209 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 210: Loading

The magazine location is selected either by searching for an empty location or by entering a magazine number and location number in the corresponding columns of the list. Ó Siemens AG, 2004. All rights reserved 5-210 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 211

Position the cursor on the location of your choice in the magazine list. Search via user-defined location (example) The assignment of the softkeys is configured by the machine manufacturer. Ó Siemens AG, 2004. All rights reserved 5-211 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 212

The loading operation is initiated. If the tool has not yet been created, Start it is created automatically. Ó Siemens AG, 2004. All rights reserved 5-212 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 213

The loading operation is initiated. If the tool has not yet been created, Start it is created automatically. «Load directly to spindle» is possible if the cursor is positioned on the spindle buffer location. Ó Siemens AG, 2004. All rights reserved 5-213 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 214: Unload

You can unload a tool from the «Magazine list» or the «Tool list». The sequence of operations is the same for both methods. Ó Siemens AG, 2004. All rights reserved 5-214 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 215

If a host computer is connected, the data are transferred to the host computer each time a tool is deleted or unloaded. Ó Siemens AG, 2004. All rights reserved 5-215 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 216: Relocation

· Enter the magazine and location numbers in the «Relocate tool» window. · Select softkey «Find empty location» and select the desired data in the window. Ó Siemens AG, 2004. All rights reserved 5-216 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 217: Tool Master Data In The Tool Catalog

«Ideal» tools are characterized by the relevant tool «master data» (i.e. with ideal tool dimensions, no wear, etc.). An «ideal» tool is uniquely defined by its «Tool name». Ó Siemens AG, 2004. All rights reserved 5-217 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 218

(e.g. cutting edge data, user data). You can change this data later. Duplo number 0 is allocated to the tool. Ó Siemens AG, 2004. All rights reserved 5-218 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 219

Switches to the input screen «Tool user data». Up to 10 user-specific tool data are displayed here. Enter the required settings in the table. Ó Siemens AG, 2004. All rights reserved 5-219 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 220: Tool Offset Data In The Tool Cabinet

A «real» tool is uniquely defined by its «tool name» and the associated «Duplo number». It is the «Duplo number» that assigns actual data to a «real» tool. Ó Siemens AG, 2004. All rights reserved 5-220 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 221

The defined tool data can be edited at any time. You can overwrite the data for the current tool or allocate a new Duplo number to create a replacement tool. Ó Siemens AG, 2004. All rights reserved 5-221 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 222

· Select «Abort» to discard the settings. Abort The data retain their old values. · Press «OK» to accept the changes. The data are updated. Ó Siemens AG, 2004. All rights reserved 5-222 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 223

A tool entered in the cabinet can be loaded to a magazine location via softkey «Tool from cabinet». Ó Siemens AG, 2004. All rights reserved 5-223 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 224: Batch Processing Of Tools

The function is available within the tool management. The parameters and other settings for the filter criteria are made in the paramtm.ini file without a separate operator interface. Ó Siemens AG, 2004. All rights reserved 5-224 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 225

Country-specific sections are parameterized in the «language\patm_xx.ini» file in the [BatchTools] section; «xx» stands for the 2 letters user for the country code. Ó Siemens AG, 2004. All rights reserved 5-225 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 226

If the situation is the same when coming from the tool list, the preset value is «All magazines». Ó Siemens AG, 2004. All rights reserved 5-226 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 227

«Cursor» and for «Selected for job processing» is identical and corresponds to the general selection display. When selection of the tools is completed, press the softkey to start the batch function. Ó Siemens AG, 2004. All rights reserved 5-227 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 228

«on request» with magazine positioning. Depending on the setting, the dialog box prompts for positioning and the load point as appropriate to the setting. Ó Siemens AG, 2004. All rights reserved 5-228 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 229

If batch processing has been started and the necessary entries have been made, the display switches to the 3rd screen «Batch execution». Ó Siemens AG, 2004. All rights reserved 5-229 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 230

This softkey can only be used while job processing is halted. Any job processing that has been halted is continued. Continue This softkey can only be used while batch processing is halted. Ó Siemens AG, 2004. All rights reserved 5-230 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 231

Job processing continues running in the background when you switch from your operator interface to other tool management screens or to other operating areas. Ó Siemens AG, 2004. All rights reserved 5-231 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 232: R Parameters (Arithmetic Parameters)

You can page up and down using the «Page» keys. Change parameters: Position the cursor bar on the appropriate input field and enter the new values. Ó Siemens AG, 2004. All rights reserved 5-232 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 233

When you press the «Input key», the cursor is automatically positioned on this parameter if it exists. Other information Input and deletion of parameters can be disabled via the keyswitch. Ó Siemens AG, 2004. All rights reserved 5-233 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 234: Setting Data

NC program until a «WALIMON» command is set. Other information The «Working area limitation» function can be disabled by means of the keyswitch. Ó Siemens AG, 2004. All rights reserved 5-234 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 235: Jog Data

Select softkey «Setting data». Setting data The vertical softkey bar changes. Select softkey «Jog data». Jog data The «Jog data» window is opened. Ó Siemens AG, 2004. All rights reserved 5-235 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 236: Spindle Data

· The limit values for the maximum and minimum permissible values are defined in the machine data. · The «Spindle data» function is displayed only if a spindle is configured. Ó Siemens AG, 2004. All rights reserved 5-236 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 237: Dry Run Feedrate For Dry Run Dry

The vertical softkey bar changes. Select softkey «Feedrate DRY». Feedrate The «Dry run feedrate» window is opened. Change the dry run feedrate: Enter a new value. Ó Siemens AG, 2004. All rights reserved 5-237 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 238: Starting Angle For Thread Cutting

The vertical softkey bar changes. Change starting angle: Starting angle Select softkey «Starting angle». The «Starting angle for thread» window opens. Enter a new value. Ó Siemens AG, 2004. All rights reserved 5-238 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 239: Other Types Of Setting Data

«Find next». Change setting data: Position the cursor bar on the appropriate input field and enter a new value. Ó Siemens AG, 2004. All rights reserved 5-239 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 240: Protection Zones

Select the plane in which the relevant protection zone is located: · Plane G17 (X,Y; Infeed direction Z) · Plane G18 (Z,X; Infeed direction Y) · Plane G19 (Y,Z; Infeed direction X) Ó Siemens AG, 2004. All rights reserved 5-240 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 241: Electronic Gears (Sw 6.3 And Higher)

The motion component of the following axis is derived from the coupling factors of the individual leading axes. Ó Siemens AG, 2004. All rights reserved 5-241 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 242: Work Offset

Workpiece reference point Effective WO The work offset effective in an axis $P_ACTFRAME=.. resulting from the sum of the following work offsets: Ó Siemens AG, 2004. All rights reserved 5-242 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 243

· Rotation, ROT, AROT · Scale, SCALE, ASCALE · Mirroring, MIRROR, AMIRROR In the part program, all work offsets can be deselected non-modally with G53. Ó Siemens AG, 2004. All rights reserved 5-243 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 244: Changing The Settable Work Offset (G54 …)

Use the 3rd basic offset onwards for your own applications. The 1st and 2nd basic offsets are reserved for setting the actual value and the external work offset. Ó Siemens AG, 2004. All rights reserved 5-244 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 245

· or a list of individual values, split into components for rotation, scale and mirror. You can select and, if necessary, change the individual values of the work offsets in both display modes. Ó Siemens AG, 2004. All rights reserved 5-245 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 246

· Settable WO;Coarse and fine (G57) · Programmable WO;G58 (TRANS), G59 (ATRANS) · T number and D number of active tool · G17 (geometry, wear, base). Ó Siemens AG, 2004. All rights reserved 5-246 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 247: Display Active Settable Work Offset

Ebene Längen 100.000 000.000 100.000 Radius 0.000 0.000 Istwert [WKS] 500.000 400.000 200.000 Work Setting Zero User offset data variable offset data Ó Siemens AG, 2004. All rights reserved 5-247 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 248: Display Active Programmable Work Offset

Select softkeys «Work offset» and «Go to …». Work Go to… offset The vertical softkey bar changes. The «Active progr. WO» window opens. Active progr. WO Ó Siemens AG, 2004. All rights reserved 5-248 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 249: Display Active Work Offset External

Sum WO = active settable WO + active programmable WO The values can be changed only in the «Settable work offsets» menu. (see Section «Settable work offsets» menu) Ó Siemens AG, 2004. All rights reserved 5-249 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 250: Immediately Activate Work Offset And Basic Frame

(settable zero offset system) is to be displayed in the actual value display. For configuring instructions see /IAM/ IM4: Installation/Start-Up Functions HMI, Section Work Offset Ó Siemens AG, 2004. All rights reserved 5-250 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 251: Service

For more information on how to protect global user data in the part program, please refer to /PGA/, Programming Guide, Advanced Section: File and Program Management Ó Siemens AG, 2004. All rights reserved 5-251 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 252: Changing/Finding User Data/User Variables

The selected data are displayed in the «Global user data» window. Other information Up to 200 characters can be entered/displayed for GUD of type String. Ó Siemens AG, 2004. All rights reserved 5-252 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 253

Other information A description of how to define and activate user data can be found · in Chapter «Services» Operating Area. Ó Siemens AG, 2004. All rights reserved 5-253 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 254: Display System Variables

With «Select view» a dialog is started in which the user can select Select view individual views or a file with several views. Ó Siemens AG, 2004. All rights reserved 5-254 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 255: Creating/Editing Variable Views

The NCK does not assign a $ as initial character. The softkey «Properties» opens a dialog box in which the text Properties displayed with a variable can be altered. Ó Siemens AG, 2004. All rights reserved 5-255 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 256

You can delete the entire contents of the display with «Delete all», Delete which does not affect a stored view on which the screen contents are based. Ó Siemens AG, 2004. All rights reserved 5-256 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 257: Manage Variable Views

This is done by writing the values selected for a log definition to a log file of defined size in the specified cycle. Ó Siemens AG, 2004. All rights reserved 5-257 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition…

-

Page 258

You can stop logging by pressing the button «Stop log» or with the Stop system variable $A_PROTO=0. $A_PROTO=0 After stopping, the log memory is automatically downloaded to a file. Ó Siemens AG, 2004. All rights reserved 5-258 SINUMERIK 840D/840Di/810D Operator’s Guide HMI Advanced (BAD) – 03.04 Edition… -

Page 259