Issue 09/2013

Art. No. 7001-0026

Инструкция по эксплуатации

APT.line™ BD (E2)

Инкубаторы с естественной конвекцией

APT.line™ ED (E2)

Сушильные/сухожаровые шкафы с естественной

конвекцией

APT.line™ FD (E2)

Сушильные/сухожаровые шкафы с

принудительной конвекцией

с микропроцессорным контроллером

BINDER GmbH

Адрес

Post office box 102

D-78502 Tuttlingen

Тел.

+49 7462 2005 0

Факс

+49 7462 2005 100

Internet

http://www.binder-world.com

info@binder-world.com

Сервис – Горячая линия

+49 7462 2005 555

Сервис — Факс

+49 7462 2005 93 555

Сервис E-Mail

service@binder-world.com

Сервис – Горячая линия, США

+1 866 885 9794 или

+1 631 224 4340 x3

Сервис – Горячая линия, Азия и Океания +852 39070500 или +852 39070503

Сервис – Горячая линия

+7 495 98815 17

- Manuals

- Brands

- Binder Manuals

- Laboratory Equipment

- FD 115

Manuals and User Guides for Binder FD 115. We have 4 Binder FD 115 manuals available for free PDF download: Operating Manual

Binder FD 115 Operating Manual (117 pages)

Brand: Binder

|

Category: Accessories

|

Size: 13.98 MB

Table of Contents

-

Table of Contents

2

-

Safety

5

-

Personnel Qualification

5

-

Operating Manual

5

-

Legal Considerations

5

-

Intellectual Property

6

-

Structure of the Safety Instructions

6

-

Signal Word Panel

6

-

Safety Alert Symbol

7

-

Pictograms

7

-

Word Message Panel Structure

8

-

Localization / Position of Safety Labels on the Chamber

8

-

Type Plate

9

-

General Safety Instructions on Installing and Operating the Chambers

10

-

Intended Use

12

-

Foreseeable Misuse

13

-

Residual Risks

14

-

Chamber Description

15

-

Chamber Overview

16

-

Triangular Instrument Panel

17

-

Main Power Switch ED, FD, FED 720

17

-

Completeness of Delivery, Transportation, Storage, and Installation

18

-

Unpacking, and Checking Equipment and Completeness of Delivery

18

-

Guidelines for Safe Lifting and Transportation

18

-

Storage

19

-

Location of Installation and Ambient Conditions

19

-

Installation

21

-

Mounting the Tilt Protection Holders (Chambers with Window)

21

-

Electrical Connection

22

-

Connection to an Exhaust/Ventilation System (Optional)

24

-

Inserting the Racks

24

-

Start up

25

-

Behavior When Opening the Door

25

-

Performance During and after Power Failures

25

-

Loading

25

-

Overview and General Settings on the R4 Controller

26

-

Controller Overview

26

-

Normal Display

26

-

Setting the Menu Language

27

-

Setting Date and Time

28

-

Selecting the Temperature Unit

30

-

Set-Point Entry for Temperature and Fan Speed

31

-

Set-Point Entry for Temperature in Two-Door Chambers (ED, FD, FED 720)

32

-

Adjusting the Air Flap Position

33

-

Changing the Passwords for User Level and General Controller Functions

34

-

Overtemperature Protection

36

-

Overtemperature Protective Device (Class 1)

36

-

Safety Controller

37

-

Setting the Safety Controller Set-Point

38

-

Alarm Message and Proceeding in Case of an Alarm

39

-

Function Check

39

-

Disconnectable Audible Over-Temperature Alarm (Option)

40

-

Timer Functions

41

-

Selecting the Timer Function

41

-

Timer Function «Delayed off

42

-

Entry and Activation of the Timer Run-Time and Fan Setting

42

-

Turning off the Timer Function or Changing the Settings

44

-

Timer Function «Temperature Dependent Delayed Off» (BF, FED)

46

-

Entry and Activation of the Timer Run-Time, Fan Setting and Set-Point Entry

46

-

Turning off the Timer Function or Changing the Settings

48

-

Timer Function «Delayed On» (BF, FED)

49

-

Entry and Activation of the Timer Run-Time and Fan Setting

49

-

Changing the Settings

51

-

Temperature Programming Example (BF, FED)

51

-

Ramp Function

52

-

General Information

52

-

Setting and Displaying the Ramp Function

53

-

Displaying the Effective Ramp Set-Point and Changing the Target Ramp Set-Point

54

-

Turning off the Ramp Function

55

-

Data Recording Via Usb Interface

56

-

Starting Data Recording

56

-

Terminating Data Recording

57

-

Network Configuration for Chambers with Ethernet Interface

58

-

Options

61

-

APT-COM™ 4 Multi Management Software (Option)

61

-

Object Temperature Display with Additional Pt100 Temperature Sensor (Option)

61

-

Analog Output for Temperature (Option)

61

-

HEPA Fresh Air Filter (Option for FD, FED)

61

-

Water Protected Disconnectable Internal Socket (Option BD, BF)

62

-

Mostly Gas-Tight Version (Option for BF, FD, FED)

62

-

Inert Gas Connection with Mostly Gas-Tight Version (Option for BF, FD, FED)

63

-

Cleaning and Decontamination

65

-

Cleaning

65

-

Decontamination / Chemical Disinfection

67

-

Maintenance and Service, Troubleshooting, Repair, Testing

68

-

General Information, Personnel Qualification

68

-

Maintenance Intervals, Service

68

-

Simple Troubleshooting

69

-

Sending the Chamber Back to BINDER Gmbh

70

-

Disposal

71

-

Disposal of the Transport Packing

71

-

Decommissioning

71

-

Disposal of the Chamber in the Federal Republic of Germany

71

-

Disposal of the Chamber in the Member States of the EU Except for the Federal Republic of Germany

72

-

Disposal of the Chamber in Non-Member States of the EU

73

-

Technical Description

74

-

Factory Calibration and Adjustment

74

-

Definition of Usable Volume

74

-

Over Current Protection

74

-

BD Technical Data

75

-

BF Technical Data

76

-

ED Technical Data

78

-

FD Technical Data

80

-

FED Technical Data

81

-

Equipment and Options (Extract)

83

-

Accessories and Spare Parts (Extract)

84

-

Dimensions Size 56

86

-

Dimensions Size 115

88

-

Dimensions Size 260

90

-

Dimensions Size 720

92

-

Certificates and Declarations of Conformity

95

-

EU Declaration of Conformity for BD

95

-

EU Declaration of Conformity for BF

97

-

EU Declaration of Conformity for ED

99

-

EU Declaration of Conformity for FD

101

-

EU Declaration of Conformity for FED

103

-

Certification Institute of the Association for Electrical, Electronic and Information Technologies)

105

-

Certificate of Compliance for the UL Certification Mark from Underwriters Laboratories

110

-

Contamination Clearance Certificate

111

-

For Chambers Located Outside the USA and Canada

111

-

For Chambers Located in the USA and Canada

114

Advertisement

Binder FD 115 Operating Manual (99 pages)

Model version: BD056-230V;BD056UL-120V;BD115-230V;BD115UL-120V;BD260-230V;BD260UL-120V;BF056-230V;BF056UL-120V;BF115-230V;BF115UL-120V;BF260-230V;BF260UL-120V;ED056-230V;ED056UL-120V;ED115-230V;ED115UL-120V;ED260-230V;ED260UL-240V;FD056-230V;FD056UL-120V;

Brand: Binder

|

Category: Laboratory Equipment

|

Size: 10.74 MB

Table of Contents

-

Table of Contents

2

-

1 Safety

5

-

Legal Considerations

5

-

Structure of the Safety Instructions

5

-

Signal Word Panel

5

-

Safety Alert Symbol

6

-

Pictograms

6

-

Word Message Panel Structure

7

-

-

Localization / Position of Safety Labels on the Chamber

7

-

Type Plate

8

-

General Safety Instructions on Installing and Operating the Chambers

9

-

Intended Use

11

-

-

2 Chamber Description

12

-

Chamber Overview

12

-

Triangular Instrument Panel

13

-

-

3 Completeness of Delivery, Transportation, Storage, and Installation

14

-

Unpacking, and Checking Equipment and Completeness of Delivery

14

-

Guidelines for Safe Lifting and Transportation

14

-

Storage

15

-

Location of Installation and Ambient Conditions

15

-

-

4 Installation

16

-

Mounting the Tilt Protection Holders (Chambers with Window)

16

-

Electrical Connection

17

-

Connection to a Suction Plant (Optional)

18

-

-

5 Start up

18

-

Behavior When Opening the Door

18

-

-

6 Overview and General Settings on the R4 Controller

19

-

Controller Overview

19

-

Normal Display

19

-

Setting the Menu Language

20

-

Setting Date and Time

21

-

Selecting the Temperature Unit

23

-

Set-Point Entry for Temperature and Fan Speed

24

-

Adjusting the Air Flap Position

25

-

Changing the Passwords for User Level and General Controller Functions

26

-

-

7 Overtemperature Protection

28

-

Overtemperature Protective Device (Class 1)

28

-

Safety Controller

29

-

Setting the Safety Controller Set-Point

30

-

Alarm Message and Proceeding in Case of an Alarm

31

-

Function Check

31

-

Disconnectable Audible Over-Temperature Alarm (Option)

32

-

-

8 Timer Functions

33

-

Selecting the Timer Function

33

-

Timer Function «Delayed off

34

-

Entry and Activation of the Timer Run-Time and Fan Setting

34

-

Turning off the Timer Function or Changing the Settings

36

-

-

Timer Function «Temperature Dependent Delayed Off» (BF, FED)

38

-

Entry and Activation of the Timer Run-Time, Fan Setting and Set-Point Entry

38

-

Turning off the Timer Function or Changing the Settings

40

-

-

Timer Function «Delayed On» (BF, FED)

41

-

Entry and Activation of the Timer Run-Time and Fan Setting

41

-

Changing the Settings

43

-

-

Temperature Programming Example (BF, FED)

43

-

-

9 Ramp Function

44

-

General Information

44

-

Setting and Displaying the Ramp Function

45

-

Displaying the Effective Ramp Set-Point and Changing the Target Ramp Set-Point

46

-

Turning off the Ramp Function

47

-

-

10 Data Recording Via Usb Interface

48

-

Starting Data Recording

48

-

Terminating Data Recording

49

-

-

11 Network Configuration for Chambers with Ethernet Interface

50

-

12 Options

53

-

Communication Software APT-COM™ 3 Datacontrolsystem (Option)

53

-

Data Logger Kits (Option)

53

-

Object Temperature Display with Additional Pt100 Temperature Sensor (Option)

53

-

Analog Output for Temperature (Option)

54

-

Water Protected Disconnectable Internal Socket (Option BD, BF)

54

-

HEPA Fresh Air Filter (Option for FD, FED)

55

-

Mostly Gas-Tight Version (Option for BF, FD, FED)

55

-

Inert Gas Connection with Mostly Gas-Tight Version (Option for BF, FD, FED)

55

-

-

13 Maintenance, Cleaning, and Service

57

-

Maintenance Intervals, Service

57

-

Cleaning and Decontamination

58

-

Cleaning

58

-

Decontamination

59

-

-

Sending the Chamber Back to BINDER Gmbh

60

-

-

14 Disposal

61

-

Disposal of the Transport Packing

61

-

Decommissioning

61

-

Disposal of the Chamber in the Federal Republic of Germany

61

-

Disposal of the Chamber in the Member States of the EU Except for the Federal Republic of Germany

62

-

Disposal of the Chamber in Non-Member States of the EU

63

-

-

15 Troubleshooting

64

-

16 Technical Description

65

-

Factory Calibration and Adjustment

65

-

Definition of Usable Volume

65

-

Over Current Protection

65

-

BD Technical Data

66

-

BF Technical Data

67

-

ED Technical Data

69

-

FD Technical Data

70

-

FED Technical Data

72

-

Equipment and Options (Extract)

74

-

Accessories and Spare Parts (Extract)

75

-

Dimensions Size 56

77

-

Dimensions Size 115

79

-

Dimensions Size 260

81

-

-

17 Certificates and Declarations of Conformity

83

-

EU Declaration of Conformity for BD

83

-

EU Declaration of Conformity for BF

85

-

EU Declaration of Conformity for ED

87

-

EU Declaration of Conformity for FD

89

-

EU Declaration of Conformity for FED

91

-

-

18 Product Registration

93

-

19 Contamination Clearance Certificate

94

-

For Chambers Located Outside the USA and Canada

94

-

For Chambers Located in the USA and Canada

97

-

Binder FD 115 Operating Manual (69 pages)

Brand: Binder

|

Category: Climate chamber

|

Size: 9.4 MB

Table of Contents

-

Table of Contents

2

-

Safety

4

-

Legal Considerations

4

-

Structure of the Safety Instructions

4

-

Signal Word Panel

4

-

Safety Alert Symbol

5

-

Pictograms

5

-

Word Message Panel Structure

6

-

Localization / Position of Safety Labels on the Chamber

6

-

Type Plate

7

-

General Safety Instructions on Installing and Operating the Chambers

8

-

Intended Use

10

-

Operating Instructions

11

-

Measures to Prevent Accidents

11

-

Chamber Description

12

-

Chamber Overview

13

-

Installation

13

-

Unpacking, and Checking Equipment and Completeness of Delivery

13

-

Guidelines for Safe Lifting and Transportation

14

-

Storage

14

-

Location of Installation and Ambient Conditions

15

-

Installation of the Equipment

16

-

Electrical Connection

16

-

Connection to a Suction Plant (Optional)

17

-

Start up

17

-

Turning on the Chamber

17

-

Heating Operation Display

17

-

Air Change

18

-

Operating the Controller

18

-

Display / Entry of Temperature Set-Point (Without Ramp Function)

18

-

Display / Entry of Temperature Set-Point (with Selected Temperature Ramp)

19

-

Time Functions: Continuous Operation and Timer Operation

20

-

Switching between «Continuous Operation» and «Timer Operation

21

-

Continuous Operation

21

-

Timer Operation: Setting the Tempering Time

22

-

User Level Settings

23

-

Temperature Unit Change between Degrees Celsius °C and Degrees Fahrenheit °F

23

-

Entering a Temperature Ramp

24

-

Chamber Addressing

24

-

General Notes

25

-

Temperature Safety Devices

26

-

Temperature Safety Device Class 2 (DIN 12880) ED, FD

26

-

Temperature Safety Device Class 3.1 (DIN 12880) BD (Option for ED, FD)

27

-

Options

29

-

Disconnectable Audible Over-Temperature Alarm (Option)

29

-

APT-COM™ 4 Multi Management Software (Option for BD and ED)

29

-

Data Logger Kit (Option)

29

-

Additional Pt100 Temperature Sensor (Option for BD)

30

-

Analog Output for Temperature (Option)

30

-

Water Protected Internal Socket (Option for BD)

31

-

Maintenance, Cleaning, and Service

32

-

Maintenance Intervals, Service

32

-

Cleaning and Decontamination

32

-

Cleaning

33

-

Decontamination

34

-

Sending the Chamber Back to BINDER Gmbh

35

-

Disposal

36

-

Disposal of the Transport Packing

36

-

Decommissioning

36

-

Disposal of the Chamber in the Federal Republic of Germany

36

-

Disposal of the Chamber in the Member States of the EU Except for the Federal Republic of Germany

37

-

Disposal of the Chamber in Non-Member States of the EU

38

-

Troubleshooting

39

-

Technical Description

40

-

Factory Calibration and Adjustment

40

-

Definition of Usable Volume

40

-

Over Current Protection

40

-

BD Technical Data

41

-

ED Technical Data

42

-

FD Technical Data

44

-

Equipment and Options BD (Extract)

47

-

Equipment and Options ED (Extract)

48

-

Equipment and Options FD (Extract)

49

-

Accessories and Spare Parts (Extract)

50

-

Certificates and Declarations of Conformity

51

-

EU Declaration of Conformity for BD

51

-

EU Declaration of Conformity for ED

54

-

EU Declaration of Conformity for FD

57

-

Certificate for the GS Mark of Conformity of the «Deutsche Gesetzliche Unfallversicherung E.V.» (German Social Accident Insurance) DGUV

60

-

Product Registration

62

-

Contamination Clearance Certificate

63

-

For Chambers Located Outside the USA and Canada

63

-

For Chambers Located in the USA and Canada

66

Advertisement

Binder FD 115 Operating Manual (55 pages)

Incubators with gravity (natural) convection Heating ovens with gravity convection Heating ovens with forced convection with R3 Controller

Brand: Binder

|

Category: Accessories

|

Size: 1.28 MB

Table of Contents

-

Table of Contents

8

-

1 Safety

10

-

Legal Considerations

10

-

Structure of the Safety Instructions

10

-

Signal Word Panel

10

-

Safety Alert Symbol

11

-

Pictograms

11

-

Word Message Panel Structure

12

-

-

Localization / Position of Safety Labels on the Unit

12

-

Type Plate

13

-

General Safety Instructions on Installing and Operating the Incubators BD and Heating Ovens ED and FD

14

-

Intended Use

15

-

Incubators BD

15

-

Heating Ovens ED and FD

15

-

-

-

2 Unit Description

16

-

Equipment Overview BD/ED/FD

16

-

-

3 Completeness of Delivery, Transportation, Storage, and Installation

17

-

Unpacking, and Checking Equipment and Completeness of Delivery

17

-

Guidelines for Safe Lifting and Transportation

17

-

Storage

18

-

Location of Installation and Ambient Conditions

18

-

-

4 Installation of the Equipment

19

-

Electrical Connection

19

-

Connection to a Suction Plant (Optional)

20

-

-

5 Start up

21

-

Turning on the Unit

21

-

Heating Operation Display

21

-

Air Change

21

-

-

6 Controller Setting

22

-

Display / Entry of Temperature Set-Point (Without Ramp Function)

22

-

Display / Entry of Temperature Set-Point (with Selected Temperature Ramp)

22

-

Time Functions: Continuous Operation and Timer Operation

23

-

Switching between Continuous Operation and Timer Operation

24

-

Continuous Operation

24

-

Timer Operation: Setting the Tempering Time

25

-

-

User Level Settings

26

-

Temperature Unit Change between Degrees Celsius °C and Degrees Fahrenheit °F

26

-

Enter a Temperature Ramp

27

-

Chamber Addressing

27

-

-

General Notes

28

-

-

7 Safety Devices

29

-

Temperature Safety Device Class 2 (DIN 12880) ED, FD

29

-

Temperature Safety Device Class 3.1 (DIN 12880) BD (Option ED, FD)

30

-

-

8 Options

31

-

Disconnectable Audible Over-Temperature Alarm (Option)

31

-

Communication Software APT-COM™ 3 Datacontrolsystem (BD, Option ED)

32

-

Analog Output for Temperature (Option)

32

-

Additional Pt100 Temperature Sensor (Option BD)

32

-

Water Protected Internal Socket (Option BD)

33

-

-

9 Maintenance, Cleaning, and Service

33

-

Maintenance Intervals, Service

33

-

Cleaning and Decontamination

34

-

Sending the Unit Back to BINDER Gmbh

35

-

-

10 Disposal

36

-

Disposal of the Transport Packing

36

-

Decommissioning

36

-

Disposal of the Unit in the Federal Republic of Germany

36

-

Disposal of the Unit in the Member States of the EC Except for the Federal Republic of Germany

38

-

Disposal of the Unit in Non-Member States of the EC

39

-

-

11 Troubleshooting

39

-

12 Technical Description

40

-

Factory Calibration and Adjustment

40

-

Definition of Usable Volume

40

-

Over Current Protection

41

-

BD Technical Data

41

-

ED Technical Data

43

-

FD Technical Data

44

-

Equipment and Options Series BD

46

-

Equipment and Options Series ED

47

-

Equipment and Options Series FD

48

-

Spare Parts

49

-

-

13 Contamination Clearance Certificate

52

Advertisement

Related Products

-

Binder FD 56

-

Binder FD 260

-

Binder FD 23 Series

-

Binder FD 53 Series

-

Binder FD 240 Series

-

Binder FED 56

-

Binder FP 720

-

Binder APT.line FP 56

-

Binder FED 400E2

-

Binder APT.line FP 260-UL

Binder Categories

Accessories

Climate chamber

Laboratory Equipment

Oven

Media Converter

More Binder Manuals

Сушильные / сухожаровые шкафы Binder ED и FD применяются для сушки и термической обработки твердого или размельченного загружаемого вещества, а также сыпучего материала при помощи подвода тепла. Содержащийся раствор не должен быть взрывоопасным или воспламеняющимся.

Смесь любого компонента загружаемого материала с воздухом не должна быть взрывоопасной. Рабочая температура должна быть ниже температуры воспламенения или точки сублимации загружаемого материала. Автоклавы могут быть использованы для сушки например, стекло.

Инкубаторы Binder BD

Инкубаторы Binder BD предназначены для точного термостатирования безопасных материалов. Вследствие высокой точности контроля температуры, данные устройства особенно эффективны для инкубации культур при стандартной температуре в 37°С. Содержащийся в материале раствор не должен быть взрывоопасным или воспламеняющимся. Смесь любого компонента загружаемого материала с воздухом не должна быть взрывоопасной. Рабочая температура должна быть ниже температуры воспламенения или точки сублимации загружаемого материала.

Сушильные шкафы Binder fd описание

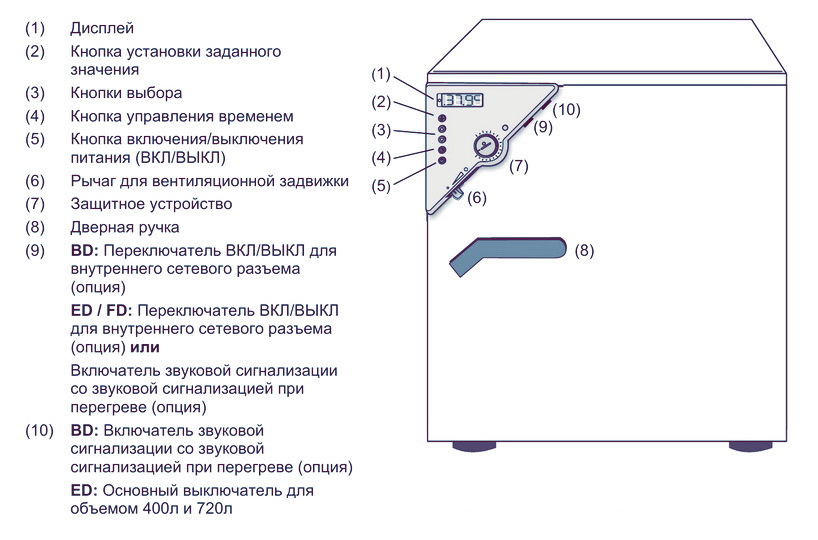

Инкубаторы Binder BD и шкафы Binder ED и FD оснащены электронным контролером со светодиодным цифровым дисплеем.

Инкубаторы Binder BD и сушильные / сухожаровые шкафы Binder ED нагреваются электрическим способом и вентилируются естественным образом (естественная конвекция). Автоклавы вентилируются принудительной циркуляцией, посредством вентилятора.

Внутренняя камера, камера предварительного нагрева и внутренняя сторона дверей выполнены из нержавеющей стали (материал №.1.4301 в Германии). При работе сушильных / сухожаровых шкафов Binder FD и ED при температуре выше 150 °C в результате воздействия кислорода, находящегося в воздухе, возможно окрашивание металлических поверхностей (коричнево-желтый или голубой) в результате естественного процесса окисления. Такое окрашивание безвредно и нив коем случае не влияет на качество функционирования оборудования.). На корпус нанесено порошковое покрытие RAL 7035.

Инкубаторы Binder BD и сушильные / сухожаровые шкафы Binder ED оснащены последовательным интерфейсом RS 422 для соединения с компьютером, например, с помощью программного обеспечения APT-COM™ 3 DataControlSystem.

Модели объемом 720л оснащаются четырьмя роликовыми колесами. Оба передних роликовых колеса ставятся на тормоза.

Диапазон температур Binder fd 53

- Инкубаторы Binder BD: от 5 °C выше комнатной до 100 °C.

- Сушильные / сухожаровые шкафы Binder ED и FD: от 5 °C выше комнатной до 300 °C.

Сушильные шкафы Binder fd обзор

Функция линейного нагрева

Температурные диапазоны устанавливаются для увеличения времени нагрева. Это может быть необходимо в некоторых случаях для предотвращения температурных стрессов в материале во время нагрева. Температурные диапазоны должны использоваться только в случае необходимости. Использование температурных диапазонов может привести к замедлению времени нагрева. Ввод °C/мин или °F/мин означают номинальное значение градиента и ограничивает максимальное температурное увеличение этим значением.

Благодаря нагреву и выпариванию энергия, приобретенная материалом, может привести к меньшим температурным градиентам. Линейный нагрев выполняется из ранее введенного к новому установленному значению. Температура должна быть отрегулирована к стартовому установленному значению.

Скачать инструкцию на сушильные шкафы Binder fd, bd, ed

Скачать инструкцию и другую документацию на сушильные шкафы Binder fd можно здесь.

Руководство пользователя ( user manual ) скачать.

Руководство пользователя ( user manual ) краткое скачать.

Сервисная инструкция ( service manual ) скачать.

Регистрационное удостоверение скачать.

Сертификат соответствия скачать.

Обзор продукции Binder скачать.

Так же смотрите низкотемпературный плазменный стерилизатор STERRAD 100 NX.