Note, when downloading a print driver, please select your operating system from the «Platform» drop down menu

User Documentation

Руководство пользователя

- Released: 04/16/2013

- Size: 6.82 MB

- Filename: WorkCentre_5020_guide_ru.pdf

- Tags: User Guides

Руководство пользователя WorkCentre 5020DN

- Released: 04/16/2013

- Size: 4.84 MB

- Filename: WorkCentre_5020DN_guide_ru.pdf

- Tags: User Guides

Quick Use Guide (Kazakh)

- Released: 03/12/2013

- Size: 2.25 MB

- Tags: Setup and Installation Guides, User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 741.70 KB

- Filename: XE3029EN0-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 873.09 KB

- Filename: XE3029DE0-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 766.67 KB

- Filename: XE3029ES0-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 781.36 KB

- Filename: XE3029FR0-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 715.93 KB

- Filename: XE3029IT0-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 671.90 KB

- Filename: XE3029PTB-1.pdf

- Tags: User Guides

Linux GDI User Guide

WorkCentre 5016, 5020B, and 5020DB Linux GDI Print Driver User Guide.

- Released: 03/04/2010

- Size: 720.59 KB

- Filename: XE3029RU0-1.pdf

- Tags: User Guides

WorkCentre 5020DN Systems Administrator Guide

- Released: 11/10/2008

- Size: 2.18 MB

- Filename: sag_en.pdf

- Tags: System Administration Guides

WorkCentre 5020DN User Guide

- Released: 11/10/2008

- Size: 3.26 MB

- Filename: 5020DN_ug_en.pdf

- Tags: User Guides

User Guide for WorkCentre 5020 / DN.

The user guide provides information on the installation, use, and care of your WorkCentre 5020/DN.

- Released: 11/10/2008

- Size: 2.76 MB

- Filename: ug_iw.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 06/03/2008

- Size: 6.26 MB

- Filename: ug_tr.pdf

- Tags: User Guides

Linux User Guide

Guía del usuario del controlador

de impresión para Linux

- Released: 05/21/2008

- Size: 1.30 MB

- Filename: LinuxUG_Spanish.pdf

- Tags: User Guides

Linux User Guide

WorkCentre 5020/DN

Linux Print Driver User Guide

- Released: 05/21/2008

- Size: 1.21 MB

- Filename: LinuxUG_English.pdf

- Tags: User Guides

Linux User Guide

Pilote d’imprimante Linux — Guide de l’utilisateur

- Released: 05/21/2008

- Size: 1.40 MB

- Filename: LinuxUG_French.pdf

- Tags: User Guides

Linux User Guide

Linux-Druckertreiber Benutzerhandbuch

- Released: 05/21/2008

- Size: 1.45 MB

- Filename: LinuxUG_German.pdf

- Tags: User Guides

Linux User Guide

Guida per l’utente del driver di stampa Linux

- Released: 05/21/2008

- Size: 1.29 MB

- Filename: LinuxUG_Italiano.pdf

- Tags: User Guides

Linux User Guide

Guia do Usuário do Driver de Impressão

WorkCentre 5020/DN para Linux

- Released: 05/21/2008

- Size: 1.18 MB

- Filename: LinuxUG_Portuguese.pdf

- Tags: User Guides

Linux User Guide

Руководство пользователя по драйверу

принтера для Linux

- Released: 05/21/2008

- Size: 1.17 MB

- Filename: LinuxUG_Russian.pdf

- Tags: User Guides

Instruction Poster — Install the Printer

Installation Guide for the WorkCentre 5016, 5020B, and 5020DB.

- Released: 05/20/2008

- Size: 1.20 MB

- Filename: Install_Guide_acommon.pdf

- Tags: Other Documentation, Setup and Installation Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.39 MB

- Filename: ug_auk.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB.

- Released: 05/20/2008

- Size: 5.85 MB

- Filename: ug_apt.pdf

- Tags: User Guides

Use Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB.

- Released: 05/20/2008

- Size: 6.32 MB

- Filename: ug_abg.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.86 MB

- Filename: ug_acs.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 4.63 MB

- Filename: ug_aen.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 5.90 MB

- Filename: ug_afr.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.57 MB

- Filename: ug_ahu.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.52 MB

- Filename: ug_apl.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.90 MB

- Filename: ug_aro.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 5.88 MB

- Filename: ug_aes.pdf

- Tags: User Guides

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5016, 5020B, and 5020DB..

- Released: 05/20/2008

- Size: 6.23 MB

- Filename: XE3006TR0-3_TR_5020_XC.pdf

- Tags: User Guides

Quick Use Guide

Reference guide to the use of the features and functions available on the WorkCentre 5016, 5020B, and 5020DB.

- Released: 05/20/2008

- Size: 520.67 KB

- Filename: Quick_Use_Guide_acommon.pdf

- Tags: User Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 4.03 MB

- Filename: sag_ru.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 4.20 MB

- Filename: sag_de.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 2.18 MB

- Filename: 5020_DN_SAG_EN_v2.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 3.71 MB

- Filename: sag_es.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 3.87 MB

- Filename: sag_fr.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 3.59 MB

- Filename: sag_it.pdf

- Tags: System Administration Guides

System Administrator Guide

Provides detailed instructions on the setup, administration, and use of your WorkCentre 5020DN.

- Released: 05/20/2008

- Size: 3.57 MB

- Filename: sag_ptbr.pdf

- Tags: System Administration Guides

Quick Use Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 369.62 KB

- Filename: quick_use_com.pdf

- Tags: User Guides

Instruction Poster — Install the Printer

- Released: 05/20/2008

- Size: 1.19 MB

- Filename: Install_Guide_com.pdf

- Tags: Other Documentation, Setup and Installation Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.65 MB

- Filename: ug_tr.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.81 MB

- Filename: ug_bg.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.73 MB

- Filename: ug_ca.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.91 MB

- Filename: ug_cz.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.89 MB

- Filename: ug_da.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.78 MB

- Filename: ug_de.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.85 MB

- Filename: ug_el.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.26 MB

- Filename: ug_en.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.54 MB

- Filename: ug_es.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.70 MB

- Filename: ug_fi.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.82 MB

- Filename: ug_fr.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.57 MB

- Filename: ug_hu.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.81 MB

- Filename: ug_it.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.82 MB

- Filename: ug_nl.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.66 MB

- Filename: ug_no.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.65 MB

- Filename: ug_pl.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.53 MB

- Filename: ug_ptbr.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 3.88 MB

- Filename: ug_ro.pdf

- Tags: User Guides

User Guide for the WorkCentre 5020DN

- Released: 05/20/2008

- Size: 2.48 MB

- Filename: ug_sv.pdf

- Tags: User Guides

User Guide

User Guide for the WorkCentre 5016, 5020B, and 5020DB.

- Released: 05/20/2008

- Size: 6.35 MB

- Filename: ug_ael.pdf

- Tags: User Guides

Read Me file

Contains information on installation, requirements, uninstallation, and limitations of the print driver, scan driver, and button manager utilities.

- Released: 10/02/2007

- Size: 6.05 KB

- Filename: Read_Me.zip

- Tags: Setup and Installation Guides

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 50.92 KB

- Filename: WC5020_FCL_Ukrainian.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 21.85 KB

- Filename: WC5020_FCL_BrPort.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 50.97 KB

- Filename: WC5020_FCL_Bulgarian.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 51.11 KB

- Filename: WC5020_FCL_Czech.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 21.10 KB

- Filename: WC5020_FCL_English.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 21.26 KB

- Filename: WC5020_FCL_French.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 50.98 KB

- Filename: WC5020_FCL_Hungarian.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 53.16 KB

- Filename: WC5020_FCL_Polish.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 51.96 KB

- Filename: WC5020_FCL_Romanian.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 50.45 KB

- Filename: WC5020_FCL_Russian.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 21.68 KB

- Filename: WC5020_FCL_Spanish.pdf

- Tags: Other Documentation

Fault Code List

Provides fault codes and instructions.

- Released: 10/01/2007

- Size: 60.70 KB

- Filename: WC5020_FCL_Turkish.pdf

- Tags: Other Documentation

Toner Replenishment Instructions

Provides directions on how to replenish depleted toner.

- Released: 10/01/2007

- Size: 210.80 KB

- Filename: WC5020_Toner_Replenish_Instructions.pdf

- Tags: Other Documentation

Instruction Poster — Install the 500-Sheet Feeder

How to install the 500 sheet paper tray.

- Released: 10/01/2007

- Size: 156.18 KB

- Filename: WC5020_500_Sheet_Tray_Install_Instructions.pdf

- Tags: Other Documentation, Setup and Installation Guides

Instruction Poster — Install the Drum Cartridge

- Released: 10/01/2007

- Size: 136.74 KB

- Filename: WC5020_Drum_Install_Instructions.pdf

- Tags: Other Documentation, Setup and Installation Guides

Instruction Poster — Install the Stand

How to install the stand for the WorkCentre 5020.

- Released: 10/01/2007

- Size: 157.09 KB

- Filename: WC5020_Stand_Instructions.pdf

- Tags: Setup and Installation Guides, Other Documentation

User Guide

The user guide provides information on the installation, use, and care of your WorkCentre 5020.

- Released: 10/01/2007

- Size: 3.37 MB

- Filename: XE3006HE0-2_HE_5020_XC.pdf

- Tags: User Guides

Customer Tips — English Only

Hints and Tips on installation and configuration of your Xerox WorkCentre, WorkCentre Pro, and Document Centre products.

- Released: 03/25/2007

- Tags: Other Documentation

- Digital Front End: built-in controller, built-in controller, EFI Fiery Controller, built-in controller

Service manual для принтера XEROX WC 5020DN

Данная подробная инструкция поможет вам в разборке и обслуживании принтера.

Соблюдайте правила безопасности при работе с электрооборудованием - отключайте принтер от источника питания перед началом ремонтных работ. Работа должна выполнятся квалифицированным персоналом с соответствующими знаниями. Руководство подготовлено производителем, ни сайт, ни производитель не несет никакой ответственности за ущерб вследствие любых неточностей при выполнении указанных в данном Руководстве действий. Вся документация по обслуживанию предоставляется только для информации. Вся документация по техническому обслуживанию предназначена только для использования обученным и сертифицированным сервисным персоналом. Обслуживание оборудования, модулей, элементов или частей самостоятельно может аннулировать гарантийные обязательства, в отношении обслуживания данного оборудования.

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

WorkCentre 5020

Service Documentation

WorkCentre 5020 Service Documentation

701P47442

Initial Issue

July, 2007

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product-trained service per-

sonnel only. Xerox does not warrant or represent that it will notify or provide to such customer

any future change to this documentation. Customer performed service of equipment, or mod-

ules, components, or parts of such equipment may affect whether Xerox is responsible to fix

machine defects under the warranty offered by Xerox with respect to such equipment. You

should consult the applicable warranty for its terms regarding customer or third-party provided

service.

If the customer services such equipment, modules, components or parts thereof, the customer

releases Xerox from any and all liability for the customer actions, and the customer agrees to

indemnify, defend and hold Xerox harmless from any third party claims which arise directly or

indirectly from such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising

out of any inaccuracies or omissions. Changes are periodically made to this document.

Changes, technical inaccuracies, and typographical errors will be corrected in subsequent edi-

tions.

©Copyright 2007 Xerox Corporation. All rights reserved.

Global Knowledge & Language Services

800 Phillips Road — Bldg. 845-17S

Webster, New York 14580-9791

USA

Printed in the United States of America.

XEROX®, The Document Company®, the stylized X and the identifying product names and

numbers herein are trademarks of XEROX CORPORATION.

All non-Xerox brands and product names are trademarks or registered trademarks of their

respective companies

WorkCentre 5020

This equipment generates, uses and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions documentation, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A comput-

ing device pursuant to subpart B of part 15 of FCC rules, which are designed to provide rea-

sonable protection against such interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause interference in which case

the user, at his own expense, will be required to correct the interference.

July, 2007

i

CAUTION

Chapters

Summary of Contents for Xerox WorkCentre 5020

701P48365June 2008

Work Center 5016, 5020Service Documentation

CAUTIONCertain components in the Work Center 5016/ 5020 are susceptible to damage from electrostatic dis-charge. Observe all ESD procedures to avoid com-ponent damage.

AcknowledgementsPrepared by Global Knowledge & Llanguage Services — North America800 Phillips Road — Building 0218-01AWebster, New York 14580-9791ISO9001 AND ISO27001 Certified© Copyright 2007-2008 by Xerox Corporation. All rights reserved.Xerox® and all product names and number names are trademarks of Xerox Corporation.Printed in the USA

While Xerox has tried to make this documentation accurate, Xerox will haveno liability arising out of any inaccuracies or ommissions. Changes are peri-odically made to this document. Changes, technical inaccuracies, and typo-graphical errors will be corrected in subsequent editions.

All service documentation is supplied to Xerox external customers for infor-mational purposes only. Xerox service documentation is intended for use by certified product trained service personal only. Xerox does not warrant or represent that such documentation is complete, nor does Xerox represent or warrant that it will notify or provide to such customer any future changes to this documentation. Customer performed service of equipment, or mod-ules, components or parts of such equipment may affect the warranty offered by Xerox with respect to such equipment. You should consult the applicable warranty for its terms regarding customer or third party provided service. If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third party claims which arise directly or indirectly from such service.

WorkCentre 5016, 5020

Reissue

WorkCentre 5016, 5020 Printed in the United States of America.

mentioned in this publication are trademarks of rademarks are also acknowledged.

tone, Inc.

ument. Changes, technical inaccuracies, and typo-nt editions.

AUTION

radiate radio frequency energy, and if not installed ns documentation, may cause interference to radio und to comply with the limits for a Class A comput- of FCC rules, which are designed to provide rea-ce when operated in a commercial environment. l area is likely to cause interference in which case d to correct the interference.

June, 2008i

Front Matter

Service Documentation

WorkCentre 5016, 5020 Service Documentation

701P48365

Reissue

June, 2008

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes only. Xerox service documentation is intended for use by certified, product-trained service per-sonnel only. Xerox does not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or mod-ules, components, or parts of such equipment may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with respect to such equipment. You should consult the applicable warranty for its terms regarding customer or third-party provided service.

If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer actions, and the customer agrees to indemnify, defend and hold xerox harmless from any third party claims which arise directly or indirectly for such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising out of any inaccuracies or omissions. Changes are periodically made to this document. Changes, technical inaccuracies, and typographical errors will be corrected in subsequent edi-tions.

Prepared by:

Xerox Corporation

Global Knowledge and Language Services

800 Phillips Road, Bldg. 0218-01A

Webster, New York 14580-9791

USA

©2007 — 2008 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and infor-mation now allowed by statutory judicial law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen such as icons, screen displays, looks, etc.

XEROX® and all Xerox product names XEROX CORPORATION. Other company t

PANTONE is a registered trademark of Pan

Changes are periodically made to this docgraphic errors will be corrected in subseque

C

This equipment generates, uses and can and used in accordance with the instructiocommunications. It has been tested and foing device pursuant to subpart B of part 15sonable protection against such interferenOperation of this equipment in a residentiathe user, at his own expense, will be require

WorkCentre 5016, 5020

Reissue

June, 2008ii

Front Matter

Introduction

Introduction

June, 2008iWorkCentre 5016, 5020

Reissue

How To Use This Manual…………………………………………………………………………………… iii

WorkCentre 5016, 5020

Reissue

June, 2008ii

Introduction

Introduction

How To Use This Manual Chain 1 Standby Power

tion

Symbolsout this service manual are described as follows:

ARNINGrating or maintenance procedure, practice, or ould result in personal injury or loss of life.

AUTION

g or maintenance procedure, practice, or condition damage to, or destruction of, equipment.

ating or maintenance procedure, practice, or condi-efficiently.

nt and troubleshooting.

re for reference.

rence.

ic-sensitive IC chips, which could be damaged if not arding Safety Critical Components set by XEROX

June, 2008iiiWorkCentre 5016, 5020

Reissue

This manual is used as the standard service manual for the WorkCentre 5016, 5020.

Enter any comments and/or corrections regarding the WorkCentre 5016, 5020 Service Docu-mentationl on the Publication Comment Sheet, and send it to the Technical Support Center SDEG.

This manual describes the standard procedures for servicing the WorkCentre 5016, 5020. Refer to Section 1 Service Call Procedure for efficient and effective servicing during mainte-nance calls.

Contents of ManualThis manual is divided into nine sections as described below.

Section 1 Service Call Procedures

This section describes the structured process for determining the type and sequence of actions that are performed during a service call.

Section 2 Status Indicator RAPs

This section contains the Repair Analysis Procedures (RAPs) necessary to repair all faults other than image quality faults.

Section 3 Image Quality RAPs

This section contains the Repair Analysis Procedures (RAPs) that are used to diagnose image quality defect problems.

Section 4 Removal/Replacement and Adjustment Procedures

This section contains the removal, replacement, and adjustment procedures for components of WorkCentre 5016, 5020.

Section 5 Parts List

This section contains a list of spare parts list for the WorkCentre 5016, 5020.

Section 6 General Procedures/Information

This section contains frequently used procedures that relate to the diagnosis, setup, or opera-tion of the machine. It also contains pertinent information that will not be found in any other part of the service documentation.

Section 7 Wiring Data

This section contains the wiring information for the WorkCentre 5016, 5020. It contains a con-nector list/locator, wirenet diagrams, and Block Schematic Diagrams (BSDs) for the following chains:

Chain 2 Mode Selection

Chain 3 Machine Run Control

Chain 4 Start Print Power

Chain 6 Imaging

Chain 7 Paper Supplying

Chain 8 Paper Transportation

Chain 9 Marking

Chain 10 Fusing and Copy Transporta

Description of Terminology and The terminology and symbols used through

WA Warning statement indicates an opecondition that, if not strictly observed, c

C

A Caution statement indicates an operatinthat, if not strictly observed, could result in

NOTE: A Note statement indicates an opertion that is necessary to accomplish a task

Reference:

Used when other explanations are given.

Purpose:

Used to describe the purposes of adjustme

REP:

Indicates the removal/replacement procedu

ADJ:

Indicates the adjustment procedure for refe

PL:

Indicates the parts list for reference.

ASSY:

Means Assembly.

Safety Critical Components (SCC):

These are components, such as electrostathandled properly. Follow the regulations regCorp.

WorkCentre 5016, 5020

Reissue

June, 2008iv

Introduction

Service Call Procedures

vice Call Procedures

June, 20081-1WorkCentre 5016, 5020

Reissue

1 Ser1.1 Before Starting Service ………………………………………………………………………………… 1-31.2 Service Call Procedure ………………………………………………………………………………… 1-41.3 Service Call Details ……………………………………………………………………………………… 1-41.4 TRIM Checklist ……………………………………………………………………………………………. 1-51.5 Periodic Replacement Parts/Consumables List ……………………………………………….. 1-5

WorkCentre 5016, 5020

Reissue

June, 20081-2

Service Call Procedures

1.1Service Call Procedures

1.1 Before Starting Service 1.1.2Things to Note When Handling Customer Dataata.

the purpose of investigation/analysis, always obtain ure you assure them that the data will not be used

changed during diagnostics.

ch as polling, were set for test purposes, make sure s after the test.

stomer data.

ed within the OpCo and ensure that customer data e.

service, observe the following:

on, so that you can take a systematic approach.

dition of the machine before removing parts or dis-

omplete, check that no parts or tools are left inside

ables

consumables, as well as the packaging materials,

WARNINGridges into a fire. Always keep them away from gniting and causing a fire.

methods for replaced parts or consumables, refer 2-138 for all machines.

g consumables, affix the «U-TAG» so that the recy-priately.

essary items on the «U-TAG.»

mer’s daily work.

to a trash bag and bring it to the service office.

ation in the Machine Service Log:

laced

June, 20081-3WorkCentre 5016, 5020

Reissue

1.1.1SafetyTo prevent any accident that may occur during maintenance service, any warning or any cau-tion regarding the service must be strictly observed. Do not perform any hazardous operation.

1. Power Supply

To prevent electrical shocks, burns, or injury, etc., be sure to switch OFF the machine and disconnect the plug before starting the maintenance service. If the machine has to be switched ON, such as when measuring a voltage, take extra care to avoid an electrical shock.

2. Drive Area

Never inspect, clear or lubricate the drive components, such as chain belts, chain wheels or gears, when the machine is in operation.

3. Heavy Parts

When removing or installing heavy parts, keep your back straight and lift with your legs. Some parts should not be lifted by one person:

IOT (Platen): 31.5kg (requires 3 persons)

2 Tray Modules: 8.6kg (requires 2 persons)

Take extra care of your working posture to prevent backache.

4. Safety Devices

See that safety devices for preventing accidents, such as fuses, circuit breakers, interlock switches, etc., and those for protecting customers from injury, such as panels and covers, function properly. Modifications that hinder the function of any safety devices are strictly prohibited.

5. Installing and Removing Parts

The edges of parts and covers may be sharp, so take care not to touch them. Be careful not to touch those parts, and wipe off any oil that may have adhered to your fingers or hands before servicing. When pulling out parts, cables, etc., do it gently. Do not use excessive force.

6. Specified Tools

Follow the instructions when a particular tool is specified.

7. Cleaning Up Toner Spills

Since toner can be explosive, sweep or brush any spilled toner into a container to collect it. To clean away the remaining toner using a vacuum cleaner, always use an FX standard vacuum cleaner that is toner-tolerant. Never use the customer’s vacuum cleaner.

8. Earthquake Preparedness Measures

If the customer requests earthquake proofing, an earthquake preparedness kit is avail-able.

Check the Service Guide for more information on the earthquake preparedness kit.

9. Modifications to the Machine

Before altering the machine, submit an irregular use license application.

10. Other Safety Precautions

Follow the recommendations in WORKING PRACTICES FOR ENGINEERS issued by FXAP EH&S (Environmental Health and Safety).

1. Handling of copied/printed customer d

Before you bring back any sample for permission from the customer. Make sfor any other purpose.

2. Security-related NVM values that were

If any security-related NVM values, suyou restore them to their original value

3. Other things to note when handling cu

Follow the safety guidelines establishdo not get compromised during servic

1.1.3 Other PrecautionsTo avoid performing wrong or unnecessary

1. Reference Materials

Read all relevant service documentati

2. Disassembling

Make sure to note the assembled conassembling it.

3. Installation and Adjustment

After the installation or adjustment is cthe machine.

4. Handling of replaced parts and consum

Make sure that any replaced parts orare taken back to the Service Center.

Never discard the Drum/Toner Cartopen flames to prevent them from i

NOTE: For separation and processingto Common Technical Information No.

• If you have replaced the followinclable parts will be handled appro

a. Drum Cartridge

b. Toner Cartridge

• For recyclable parts, fill in the nec

5. General Precautions

• Take care not to disturb the custo

• Place any service-related trash in

• Clearly record the following inform

– Details of the service call

– Parts and consumables rep

WorkCentre 5016, 5020

Reissue

’s condition.

paper jams

he machine.

e Log from the last call.

f Problemtatus Indicator RAPs.

2 Status Indicator RAPs.

leshoot by referring to the BSD in Section 7 Wiring

ttern (499T247), then check the quality.

rform the applicable RAP in Section 3 Image Qual-

ance call.

ing the TRIM Checklist.

c cleaning/replacement by referring to the TRIM ent Parts/Consumables List. Clean them if neces-nters of the corresponding items in the Chain Func-

June, 20081-41.2, 1.3

Service Call Procedures

1.2 Service Call Procedure1.2.1 Initial Actions1. Ask the operator(s) about the machine’s condition.

2. Record the billing meter readings.

3. Inspect any faulty copies, then check the machine.

4. Check the Service Log.

1.2.2 Actions to Take During UM (Unscheduled Maintenance)1. Perform the service flow in Section 2 Status Indicator RAPs.

2. Perform the applicable RAP in Section 2 Status Indicator RAPs.

If there are no applicable RAPs, troubleshoot by referring to the BSD in Section 7 Wiring Data.

3. Check the copy quality.

Make several copies using the Test Pattern (499T247), then check the quality.

4. Look at the last 20 error codes in order to understand the machine status.

• Enter Diagnostic Mode. Enter [40-01] (Display Error History How to Enter the Diag-nostic Mode).

• When the last error code is displayed, press the [Start] key to return to the Function input screen.

• Pressing the [Stop] key during the display will stop it and return you to the Function input screen.

5. Repair all the secondary problems.

6. Perform TRIM servicing.

1.2.3 Actions to Take During SM (Scheduled Maintenance)1. Check the copy quality.

Make several copies using the Test Pattern (499T247), then check the quality.

2. Look at the last 20 error codes in order to understand the machine status.

• Enter Diagnostic Mode. Enter [40-01] (Display Error History How to Enter the Diag-nostic Mode).

• When the last error code is displayed, press the [Start] key to return to the Function input screen.

• Pressing the [Stop] key during the display will stop it and return you to the Function input screen.

3. Perform TRIM servicing.

1.2.4 Final Actions1. Check overall machine operation/features.

2. Check the machine exterior and consumables.

3. Train the operator as required.

4. Complete the Service Log and Service Report.

5. Keep the copy samples with the Service Log.

1.3 Service Call Details1.3.1 Initial Actions1. Ask the operator(s) about the machine

• Frequency and location of recent

• Copy quality

2. Record the billing meter readings.

3. Inspect any faulty copies, then check t

4. Check the copy sample and the Servic

1.3.2 Checking Reproducibility o1. Perform the service flow in Section 2 S

2. Perform the applicable RAP in Section

3. If there are no applicable RAPs, troubData.

1.3.3 Checking Copy Quality1. Make several copies using the Test Pa

2. If there is a problem in copy quality, peity.

1.3.4 TRIM ServicingPerform TRIM servicing during the mainten

1. Perform the necessary TRIM items us

2. Check for parts that require periodiChecklist and the Periodic Replacemsary. If replaced, always clear the coution.

1.4, 1.5Service Call Procedures

1.4 TRIM Checklist 1.5 Periodic Replacement Parts/Consumables Listmber of copies and the replacement interval for the ical cleaning/replacement. Clean or replace them if d at Chain-Function > NVRAM R/W, while the IIT er to Diagnostic Mode in Section 2 Status Indicator in the Diagnostic Mode, clean or replace them dard PV).

AUTION

our car for long periods of time.

Table 1

nt pies) Counters Check

[29/34] [29/24] [29/14] [29/4]Count up 1 for every feed. Replace both at the same time.

[29/25] [29/15] [29/5]Count up 1 for every feed. Replace both at the same time.

[29/39] [29/29] [29/19] [29/9]Count up 1 for every feed. Replace both at the same time.

[21/39] [21/29] [21/19] [21/9]Count up 1 for every feed.

31,000 (Warning)36,000 (Machine Stops)

June, 20081-5WorkCentre 5016, 5020

Reissue

A: Check. Clean, replace, or replenish if necessary.

B: Always check and clean.

*: Always replace at the specified interval.

CAUTION

Do not touch the Drum of the Drum Cartridge.

When servicing the machine, check the nuconsumables and parts that require periodnecessary. The IOT history can be checkehistory can be checked in the Counters (refRAPs). For items that cannot be checkedaccording to the replacement intervals (stan

C

Do not keep toner and drum cartridges in y

Table 1

No. Service ItemsEvery time Service Details

1.1 Check before servicing(check machine operation)

A Turn on the machine, and make sure that there are no abnormal sounds.

1.2 Check before Servicing(copy the Test Pattern)

A Make several copies using the Test Pattern (499T247), then check the image quality.

2 Clean the interior of the machine (paper transport system)

A Clean the paper dust and toner residue in the paper path and on the jam sensor.

3 Clean the IIT A • Clean the Platen Glass surface and the Platen Cushion with the optical cleaning cloth.

• Clean the Reflector, back of the Platen Glass, mirrors and lens with the optical cleaning cloth.

5 Safety Precautions B • Make sure that the power cord is plugged in properly.

• Make sure that there are no cracks in the power plug and no holes or cuts in the power cord insulation.

• If an extension cord or power strip is used, make sure it is of sufficient capacity to handle the power requirements of the machine.

• Make sure that no more than one power plug is connected to a single socket.

6.1 Check after servicing(copy quality check)

A Make several copies using the Test Pattern (499T247), then check the image quality.

6.2 Check after servicing(check machine operation)

A • Check the paper feed.

• Make sure that there are no abnormal sounds.

6.3 Check after servicing(check the meter)

A Create the Service Log and Service Report.

NoParts/Consumables Name/PL No.

ReplacemeInterval (co

1 Tray 1 Feed Roll/ Retard Pad

50,000

2 Tray 2 Feed Roll/Retard Roll

100,000

3 MSI Feed Roll/Retard Pad

50,000

4 Fuser Unit 100,000

5 Toner Cartridge 6,000

6 Drum Cartridge 36,000

WorkCentre 5016, 5020

Reissue

June, 20081-61.4, 1.5

Service Call Procedures

Status Indicator RAPS

tatus Indicator RAPS

June, 20082-1WorkCentre 5016, 5020

Reissue

2 S Error CodesFault Repair Overview and List of Error Codes……………………………………………………… 2-3

RAPsU0-1 Main Motor Stop Error ……………………………………………………………………………….. 2-25U1-1 Main Motor Rotation Error ………………………………………………………………………….. 2-25U2-1 Carriage Module Fail …………………………………………………………………………………. 2-26U3-5 Laser Power Or ROS Motor Fail ………………………………………………………………… 2-26U4-1 Fuser On Time Fail…………………………………………………………………………………… 2-27U4-2 Over Heat Temp Fail ………………………………………………………………………………… 2-27U4-3 FS1 Thermistor Defect ……………………………………………………………………………… 2-28U4-9 Fuser Fan Defect……………………………………………………………………………………… 2-28U6-2 RAM Read/Write Check Error ……………………………………………………………………. 2-29U6-3 NVM Data Defect …………………………………………………………………………………….. 2-29U6-4 NVM Read/Write Cannot Be Executed ……………………………………………………….. 2-30U6-5 CPU Power To Access NVM Is Not Enough ………………………………………………… 2-30U7-0 UI Communication TimeOut ………………………………………………………………………. 2-31U7-1 UI Communication Error……………………………………………………………………………. 2-31U8-1 Billing Counter Defect……………………………………………………………………………….. 2-32U9-0 HVPS Fail ……………………………………………………………………………………………….. 2-32062-300 Platen Interlock Open …………………………………………………………………………… 2-33062-345 IISS EEPROM Failure…………………………………………………………………………… 2-33062-360 Carriage Position Fail……………………………………………………………………………. 2-34062-371 Lamp Illumination Fail …………………………………………………………………………… 2-34062-380 AGC Failure ………………………………………………………………………………………… 2-35062-386 AOC Failure ………………………………………………………………………………………… 2-35062-392 IPS PWB Memory Fail ………………………………………………………………………….. 2-36062-393 IPS PWB Fail ………………………………………………………………………………………. 2-36005-170 DADF Feed Failure ………………………………………………………………………………. 2-37005-171 DADF Regi / Exit Failure………………………………………………………………………. 2-38005-172 DADF Inverted Document Jam ………………………………………………………………. 2-39005-198 Short Scan Jam …………………………………………………………………………………… 2-40005-199 Long Scan Jam ……………………………………………………………………………………. 2-40005-305 Feeder Top Cover Open ……………………………………………………………………….. 2-41005-920 Static Jam …………………………………………………………………………………………… 2-41

WorkCentre 5016, 5020

Reissue

June, 20082-2

Status Indicator RAPS

Status Indicator RAPS

June, 20082-3WorkCentre 5016, 5020

Reissue

Fault Repair Overview and List of Error CodesFault Repair OverviewThe fault repair operation proceeds in the following flow. After performing the pre-check, verify the symptoms and refer to the Error Code List and Section 7 Wiring Data to effectively repair the fault:

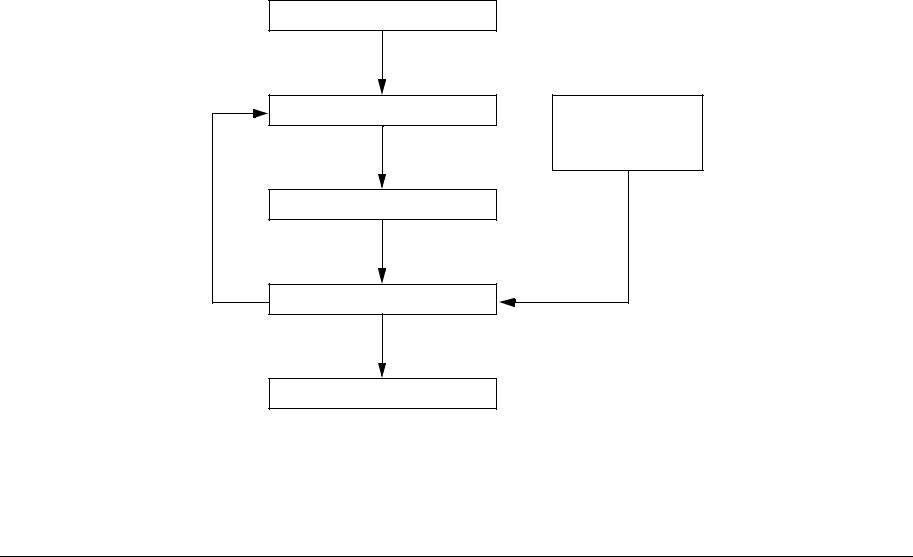

.

Figure 1 Troubleshooting Procedure

Check the status of Installation

Check the problem status

Perform RAP

Check if the fault is repaired

Completed

Diagnostic ModeOperating PrinciplesWiring Data

Reference Information

WorkCentre 5016, 5020

Reissue

expressed as follows: “P/J12″ -> The connector (P/ The plug side when the connector (P/J12) is in the directly connected to a board). «J12» -> The jack the disconnected state (except when it is directly

t all the opposing pins between «P/J1» and «P/J12» d be measured.

e measured using a special tool. Handle the tool

RAPs are for reference only. Approximate values

e RAP, you must check the references for the parts ures.

the parts that are considered to be the cause of the and, if necessary, the assembly that contains those

supply is called «Tray 1,» and the one below it is

cribed separately for each specification. Follow the e faults.

ing a failure. RAPs guide you through the trouble-nce of error codes and other types of problematic d to image quality, refer to Section 3 Image Quality

June, 20082-4

Status Indicator RAPS

Check the Status of Installation

Before starting to troubleshoot, always check the following items:

• The voltage of the power supply (measure the voltage at the power outlet to see if it is within specification).

• The power cord for damage, short circuits, open circuits, and wrong internal connections.

• The machine for proper grounding.

• The machine is not installed in a place with high temperature, high humidity, low tempera-ture, low humidity, or a place with drastic changes in temperature.

• The machine is not installed near a water outlet, humidifier, heater or fire source, dusty areas, or under the direct draft of an air conditioner.

• The machine is not installed in a place where volatile or flammable gas is generated.

• The machine is not installed in a place exposed to direct sunlight.

• The machine is installed in a well-ventilated place.

• The machine is installed on a stable level surface.

• The paper is within specification (standard paper is recommended).

• The machine for any improper handling.

• The Periodic Replacement Parts are replaced at the proper intervals.

Safety Considerations

• Before servicing, always unplug the power cord unless required otherwise. When the power is turned ON, never touch a current-carrying part unless required otherwise. Also, since current is carried in the LVPS power switch/inlet even when the power is turned OFF, never touch this area.

• When turning the power ON to perform a check while the Interlock Switch or Security Switch is also turned ON and the covers are removed, always disconnect the connector ( P/J140) that is connected to the ROS, unless required otherwise, because a laser beam might be emitted from the ROS.

• When connecting the connector ( P/J520) on the HVPS according to the instructions in the RAP, never touch the HVPS and high-voltage output parts.

• When performing a high voltage output check using the Input Diagnostics or Output Diag-nostics in Diagnostic Mode, make sure that all covers are installed unless specified other-wise. Also, never touch any high voltage output section when performing the high voltage output check.

• When operating the Drive Section using the Input Diagnostics or Output Diagnostics in Diagnostic Mode, make sure that all covers are installed unless specified otherwise. Also, never touch the Drive Section while operating it.

• Be careful not to burn yourself when touching parts that can get very hot.

• When servicing, use a grounded wrist band to remove static electricity from your body.

Things to Note When Using RAPs

• When troubleshooting using RAPs, prepare normally working parts such as the AIOC PWB, LVPS, HVPS and Fuser in advance because they might be required to identify a failure. In addition, if the fault cannot be repaired, replace the «parts considered to be the cause» and related parts in sequence and check the operation.

• When servicing, always disconnect the power cord unless required otherwise. When the power cord is connected, never touch any current-carrying part unless absolutely neces-sary.

• Descriptions related to connectors areJ12) is in the connected state. «P12» ->disconnected state (except when it isside when the connector (P/J12) is inconnected to a board).

• In a RAP, «P/J1 <=> P/J2» means tha(refer to Section 7, Wiring Data) shoul

• The voltages on small connectors arcarefully because it has a sharp tip.

• The numerical values described in theare considered to be the same.

• Note that for the checks specified in ththat must be removed and their proced

• «Replacement» in the RAPs indicates problem. Check by replacing the partsparts.

• In the RAPs, the highest level papercalled «Tray 2.»

• In the RAPs, some procedures are desinstructions for your model to repair th

RAP Flow

RAPs are a good place to start in diagnosshooting process by checking for the presesymptoms. To troubleshoot problems relateTroubleshooting.

Status Indicator RAPS

orm the

June, 20082-5WorkCentre 5016, 5020

Reissue

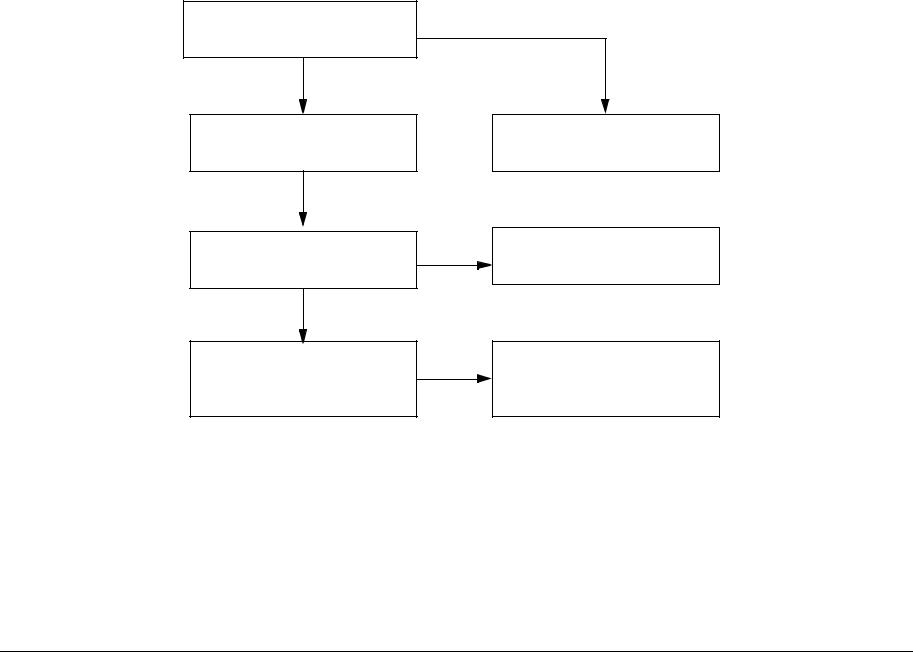

Figure 2 RAP Flow

Ask the operator about the problemDid the operator operate the machine correctly?

Turn the Power Switch OFF then ON

Does the error recur when operating the machine in the same way as before (when the problem originally occurred)?

Does the Control Panel display an Error Code?

Explain how to operate the machine

Procedure is complete

Refer to the Error Code List and perfrelevant troubleshooting

Yes

No

Yes

No

Yes

WorkCentre 5016, 5020

Reissue

Record in Error Log RAP BSD

eed Sensor

O -CH8.1

Figure 1

June, 20082-6

Status Indicator RAPS

Error Code List

NOTE: In the “Record in Error Log” column, “O” = yes and “X” = no.

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

C1-1

Error NameTray1 F/O#1 SNR on JAM

ExplanationTimeout between Tray1 Feed Clutch ON and Tray1 Feed Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-07] Tray1 Feed Sensor

• [08-12] Tray1 Feed Clutch

Check Items• Feed Roll or Retard Pad dirty, contaminated with paper dust, worn, or faulty

• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Tray1 Feed Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 F(PL 2.5)(REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Replace the Tray1 Feed Clutch (PL 2.2) (REP 2.2.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Status Indicator RAPS

eed Sensor

stration Sen-

O —

CH8.1Figure 1CH8.4

Figure 4

Error Record in Error Log RAP BSD

June, 20082-7WorkCentre 5016, 5020

Reissue

C1-2

Error NameTray1 Regi SNR on JAM

ExplanationTimeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-07] Tray1 Feed Sensor

• [08-05] IOT Registration Sensor

• [08-10] IOT Registration Clutch

Check Items• Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty

• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 F(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Regisor (PL 2.9).

— Wire between IOT Registration Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

— Wire between IOT Registration Sensor J156-2 and LVPS J503-2

— Wire between IOT Registration Sensor J156-1 and LVPS J503-3

• Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

Sensor (PL

.5) (REP

O -CH8.2

Figure 2

Record in Error Log RAP BSD

June, 20082-8

Status Indicator RAPS

C2-1

Error NameSTM F/O#2 SNR on JAM

ExplanationTimeout between STM Feed Motor ON and STM Feed Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-06] STM Feed Sensor

• [08-11] STM Feed Clutch

• [08-13] STM Feed Motor

Check Items• Tray2 Feed Roll or Tray2 Retard Roll dirty, contaminated with paper dust, worn, or faulty

• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• STM Feed Clutch faulty

• STM Feed Motor faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed11.5) (REP 11.5.1 ).

– — Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– — Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– — Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Replace the STM Feed Clutch (PL 11.6) (REP 11.6.1), the STM Feed Motor (PL 11.6) (REP 11.6.2), and the STM PWB (PL 1111.5.2 ) in that order.

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

Sensor (PL

eed Sensor

.5) (REP

O —

CH8.1Figure 1CH8.2

Figure 2

Error Record in Error Log RAP BSD

June, 20082-9WorkCentre 5016, 5020

Reissue

C2-2

Error NameTray1 F/O#1 SNR on JAM from STM feed

ExplanationTimeout between STM Feed Out Sensor ON and Tray 1 Feed Out Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-06] STM Feed Sensor

• [08-07] Tray1 Feed Sensor

• [08-11] STM Feed Clutch

• [08-13] STM Feed Motor

Check Items• Take Away Roll 2 dirty, contaminated with paper dust, worn, or faulty

• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• STM Feed Clutch faulty

• STM Feed Motor faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed11.5) (REP 11.5.1).

– Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 F(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7

– Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8

• Replace the STM Feed Clutch (PL 11.6) (REP 11.6.1), the STM Feed Motor (PL 11.6) (REP 11.6.2), and the STM PWB (PL 1111.5.2) in that order.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

eed Sensor

stration Sen-

O —

CH8.1Figure 1CH8.4

Figure 4

e job).

Paper Sen-

X -CH7.1

Figure 1

Record in Error Log RAP BSD

June, 20082-10

Status Indicator RAPS

C2-3

Error NameSTM Regi SNR on JAM

Explanation• When feeding paper from the STM, timeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-05] IOT Registration Sensor

• [08-10] IOT Registration Clutch

Check Items• Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty

• IOT Registration Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 F(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J502)

– Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7

– Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Regisor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

C5-0

Error NameNo paper in the selected paper tray (Tray1)

Explanation• No paper is detected in Tray1 when ATS function is disabled and Tray1 is selected during a copy job.

• No paper is detected in Tray1 when Tray1 is selected during a print job (the paper size setting matches the one specified for th

I/O Diagnostic Codes[07-07] Tray1 No Paper Sensor

Check Items• Press the [Stop] button on the Control Panel.

• Check the tray to see if it is empty; if it is, add paper specified by the job.

• Tray1 No Paper Sensor dirty and Sensor Actuator deformed or damaged

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Nosor (PL 2.7) (REP 2.7.1).

– Wire between Tray1 No Paper Sensor J157-3 ( P/J157) and LVPS J501-3 ( P/J501)

– Wire between Tray1 No Paper Sensor J157-2 and LVPS J501-4

– Wire between Tray1 No Paper Sensor J157-1 and LVPS J501-5

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

X — —

the job).

Paper Sen-

X -CH7.2

Figure 2

b.X — —

.X — —

Error Record in Error Log RAP BSD

June, 20082-11WorkCentre 5016, 5020

Reissue

C5-1

Error NameTray1 Paper Size Mismatch

Explanation• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in Tray1 is different from the paper size specification of the job when Tray1 is selected during a print job.

Check Items• Press the [Stop] button on the Control Panel.

• Change the paper size of Tray 1 to the one specified by the job.

C6-0

Error NameNo paper in the selected paper tray (Tray2)

Explanation• No paper is detected in the STM when ATS function is disabled and STM is selected during a copy job.

• No paper is detected in the STM when STM is selected during a print job (the paper size setting matches the one specified for

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[07-08] STM No Paper Sensor

Check Items• Press the [Stop] button on the Control Panel.

• Load the correct paper into the STM.

• STM No Paper Sensor dirty and Sensor Actuator deformed or damaged.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Nosor (PL 11.7) (REP 11.7.1).

– Wire between STM No Paper Sensor J171-3 ( P/J171) and STM PWB J542-3 ( P/J542)

– Wire between STM No Paper Sensor J171-2 and STM PWB J542-4

– Wire between STM No Paper Sensor J171-1 and STM PWB J542-5

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1).

C6-1

Error NameTray2 Paper Size Mismatch

Explanation• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in the STM is different from the paper size specification of the job when STM is selected during a print jo

Check Items• Press the [Stop] button on the Control Panel.

• Change the paper size of STM to the one specified by the job.

C7-1

Error NameMSI Paper Size Mismatch

Explanation• Paper that is different from the one in the Tray Settings is detected when feeding.

• Or, paper size setting in the MSI is different from the paper size specification of the job when MSI is selected during a print job

Check Items• Press the [Stop] button on the Control Panel.

• Change the paper size of Bypass to the one specified by the job.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

g a copy job.

uring a print X -CH3.2

Figure 2

stration Sen-

there is no

O —

CH8.3Figure 3CH8.4

Figure 4

Record in Error Log RAP BSD

June, 20082-12

Status Indicator RAPS

C0-1

Error NameAPS NG Unselected

Explanation• Either Tray 1 or STM is in one of the «paper settings is of a size that causes missing image» states when APS is selected durin

• Or, either Tray 1 or STM is «set with paper size that is different from the one specified for the job» when Auto Tray is selected djob.

Check Items• Press the [Stop] button on the Control Panel.

• Change the paper size of Tray 1 or STM to the one specified by the job.

C9-3

Error NameMSI Regi SNR on JAM

ExplanationTimeout between Bypass Solenoid ON and IOT Registration Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-05] IOT Registration Sensor

• [08-17] Bypass Solenoid

Check Items• Bypass Feed Roll, Retard Pad, or Bypass Take Away Roll dirty, contaminated with paper dust, worn, or faulty

• IOT Registration Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged, not within specification, or not loaded correctly

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Bypass Solenoid faulty

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Regisor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Check that the Bypass Solenoid and the LVPS J502-1/3 ( P/J502) pins are connected securely with good electrical contact. If problem, replace the Bypass Solenoid (PL 7.5).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

eed Sensor

O -CH8.1

Figure 1

Sensor (PL

O -CH8.2

Figure 2

eleted. O — —

Error Record in Error Log RAP BSD

June, 20082-13WorkCentre 5016, 5020

Reissue

C8-1

Error NameF/O#1 SNR Static JAM

ExplanationTray1 Feed Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[08-07] Tray1 Feed Sensor

Check Items• Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 F(PL 2.5) (REP 2.5.1).

– Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501)

– Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7

– Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

C8-2

Error NameF/O#2 SNR Static JAM

ExplanationSTM Feed Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[08-06] STM Feed Sensor

Check Items• STM Feed Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed11.5) (REP 11.5.1).

– Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542)

– Wire between STM Feed Sensor J172-2 and STM PWB J542-7

– Wire between STM Feed Sensor J172-1 and STM PWB J542-8

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

E0-1

Error NameCPM Image Lost

ExplanationDuring a copy job in CMP Priority Mode, it is detected that the paper containing an image cannot be output after the image is d

Check ItemsPress the [Stop] button on the Control Panel.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

stration Sen-

O -CH8.4

Figure 4

t Sensor (PL

O -CH10.2Figure 2

Record in Error Log RAP BSD

June, 20082-14

Status Indicator RAPS

E1-6

Error NameRegi SNR Static JAM

ExplanationIOT Registration Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[08-05] IOT Registration Sensor

Check Items• Sensor dirty

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Regisor (PL 2.9).

– Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503)

– Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2

– Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3

• Replace the AIOC PWB (PL 8.1)(REP 8.1.1).

E3-6

Error NameExit SNR JAM

ExplanationFuser Exit Sensor ON is detected during standby.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[10-23] Fuser Exit Sensor

Check Items• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

• Foreign matter, burrs, or paper in the paper path

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exi6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

r Interlock

X -CH1.2

Figure 2

ver Interlock

X -CH1.2

Figure 2

terlock

X -CH7.1

Figure 1

Error Record in Error Log RAP BSD

June, 20082-15WorkCentre 5016, 5020

Reissue

E5-1

Error NameIOT L/H Cover open

ExplanationThe Left Hand Cover is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[01-01] LH Cover Interlock Switch

Check Items• Check that the Left Hand Cover closes correctly.

• Check that the LH Cover Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the LH CoveSwitch (PL 8.2).

– Wire between LH Cover Interlock Switch FS151 ( FS151) and LVPS J506-4 ( P/J506)

– Wire between LH Cover Interlock Switch FS152 ( FS152) and LVPS J506-3

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

E5-2

Error NameIOT Front Cover open

ExplanationThe Front Cover is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[01-12] Front Cover Interlock Switch

Check Items• Check that the Front Cover closes correctly.

• Check that the Front Cover Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Front CoSwitch (PL 8.2).

– Wire between Front Cover Interlock Switch FS153 ( FS153) and LVPS J506-2 ( P/J506)

– Wire between Front Cover Interlock Switch FS154 ( FS154) and LVPS J506-1

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

E6-1

Error NameL/H Low Cover open

ExplanationAccess Cover 1 is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[01-11] Tray1 Interlock Switch

Check Items• Check that Access Cover 1 closes correctly.

• Check that the Tray 1 Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 InSwitch (PL 2.5).

– Wire between Tray 1 Interlock Switch J161-2 ( P/J161) and LVPS J501-9 ( P/J501)

– Wire between Tray 1 Interlock Switch J161-1 and LVPS J501-10

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

rlock Switch

t order.

X -CH7.2

Figure 2

X -CH3.2

Figure 2

X -CH3.2

Figure 2

Record in Error Log RAP BSD

June, 20082-16

Status Indicator RAPS

E6-2

Error NameSTM L/H Cover open

ExplanationAccess Cover 2 is open.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[01-10] STM Interlock Switch

Check Items• Check that Access Cover 2 closes correctly.

• Check that the STM Interlock Switch is correctly installed and that the electrical connection is good.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Inte(PL 11.5).

– Wire between STM Interlock Switch J173-2 ( P/J173) and STM PWB J542-9 ( P/J542)

– Wire between STM Interlock Switch J173-1 and STM PWB J542-10

• Replace the STM PWB (PL 11.5) (REP 11.5.2), the LVPS (PL 8.1) (REP 8.1.2), and the AIOC PWB (PL 8.1) (REP 8.1.1) in tha

E8-1

Error NameNup NG Out Of Range

ExplanationThe magnification is not within the range of 50 to 200% during Nup.

Check Items• Press the [Stop] button on the Control Panel.

• Press the [Paper Supply] button on the Control Panel.

• Press the [Special Copy] button on the Control Panel.

• Press the [Original Size Input] button on the Control Panel.

• Press the [Clear All] button on the Control Panel.

E8-2

Error NameNup Paper direction mismatch

ExplanationThe paper orientation of the document and the tray are not aligned during Nup.

Check Items• Press the [Stop] button on the Control Panel.

• Press the [Paper Supply] button on the Control Panel.

• Press the [Special Copy] button on the Control Panel.

• Press the [Original Size Input] button on the Control Panel.

• Press the [Clear All] button on the Control Panel.

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

ct. If there is

t Sensor (PL

O -CH10.2Figure 2

t Sensor (PL

O -CH10.2Figure 2

Error Record in Error Log RAP BSD

June, 20082-17WorkCentre 5016, 5020

Reissue

E1-2

Error NameExit SNR on JAM

ExplanationTimeout between IOT Registration Clutch ON and Fuser Exit Sensor ON.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)• [08-10] IOT Registration Clutch

• [10-23] Fuser Exit Sensor

Check Items• Registration Roll dirty, contaminated with paper dust, worn, or faulty

• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged or not within specification

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• IOT Registration Clutch faulty

• Check that the IOT Registration Clutch and the LVPS J503-4/5 ( P/J503) pins are connected securely with good electrical contano problem, replace the IOT Registration Clutch (PL 2.9).

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exi6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

E3-1

Error NameExit SNR off JAM

ExplanationTimeout between Fuser Exit Sensor ON and Fuser Exit Sensor OFF.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[10-23] Fuser Exit Sensor

Check Items• Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged

• Paper damaged or not within specification

• Foreign matter, burrs, or paper in the paper path

• Drive gear worn or damaged

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exi6.2).

– Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505)

– Wire between Fuser Exit Sensor J153-2 and LVPS J505-2

– Wire between Fuser Exit Sensor J153-1 and LVPS J505-3

• Replace the LVPS (PL 8.1) (REP 8.1.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

O -CH3.1

Figure 1

X -CH3.2

Figure 2

If there is no

X — —

t. If there is

O -CH9.2

Figure 2

Record in Error Log RAP BSD

June, 20082-18

Status Indicator RAPS

H9-7

Error Name• MCU-STM comm. error

ExplanationA communication failure has occurred between the MCU and the Tray Module.

Check Items• Turn the power OFF then ON.

• Check for any open circuit or short circuit between the STM connectors.

• Replace the STM PWB (PL 11.5) (REP 11.5.2) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

L9-0

Error NameCopy Counter Full

ExplanationThe user that is logged in has reached the allotted copy limit in the Account Mode.

Check ItemsPress the [Stop] button on the Control Panel.

J1-0

Error NameToner Cartridge was PRENEAR empty

ExplanationThe toner cartridge is low.

Check Items• Refill the toner.

• Foreign matter on the sensor.

• Check that the Toner Empty Sensor and the LVPS J509-1-4 ( P/J509) pins are connected securely with good electrical contact. problem, replace the Toner Empty Sensor (PL 4.2).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

J1-2

Error NameToner Empty

ExplanationThe Toner Cartridge is empty.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[09-07] Toner Empty Sensor

Check Items• Refill the toner.

• Foreign matter on the sensor.

• Check that the Toner Empty Sensor and the LVPS J509 ( P/J509) 1-4 pins are connected securely with good electrical contacno problem, replace the Toner Empty Sensor (PL 4.2).

• Replace the AIOC PWB (PL 8.1) (REP 8.1.1).

Error Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

Status Indicator RAPS

rtridge (PL O -CH9.2

Figure 2

X — —

O — —

Error Record in Error Log RAP BSD

June, 20082-19WorkCentre 5016, 5020

Reissue

J3-1

Error NameNo Drum Cartridge

ExplanationUnable to detect the Drum Cartridge.

I/O Diagnostic Codes (How to Enter the Diagnostic Mode)[09-02] Drum Cartridge

Check Items• Turn the power OFF then ON.

• Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Drum Ca4.1) (REP 4.1.1).

– Wire between Drum Cartridge P610-7 ( P610) and AIOC PWB J402-1 ( P/J402)

– Wire between Drum Cartridge P610-3 and AIOC PWB J402-4

– Wire between Drum Cartridge P610-2 and AIOC PWB J402-5

– Wire between Drum Cartridge P610-5 and AIOC PWB J402-2

– Wire between Drum Cartridge P610-4 and AIOC PWB J402-3

– Wire between Drum Cartridge P610-1 and AIOC PWB J402-6

• Replace the Drum Cartridge (PL 4.1) (REP 4.1.1) and the AIOC PWB (PL 8.1) (REP 8.1.1) in that order.

J6-0

Error NameDrum near end of life

ExplanationThe Drum Cartridge is near the end of its life.

Check ItemsReplace the Drum Cartridge (PL 4.1) (REP 4.1.1).

J6-1

Error NameDrum cartridge life end

ExplanationThe Drum Cartridge has reached the end of its life.

Check ItemsReplace the Drum Cartridge (PL 4.1) (REP 4.1.1).

Code Error Name/Explanation/I/O Diagnostic Codes/Check Items

WorkCentre 5016, 5020

Reissue

rtridge (PL O -CH9.2

Figure 2

O -CH9.2

Figure 2

O -CH9.2

Figure 2

O — —

Record in Error Log RAP BSD

June, 20082-20

Status Indicator RAPS