Автосервис «Ралли»

МЕНЮ

Обновлено: 23.09.2023

Читайте также:

- Как собрать генератор ваз

- Ремонт рулевой рейки рено лагуна 2

- Р2188 ошибка киа рио

(Ocr-Read Summary of Contents of some pages of the KAMAZ 5490 Document (Main Content), UPD: 29 August 2023)

-

254, 1) Reference value (depends on vehicle type and vehicle data as well as the prevailing operating conditions). 2) To this end, also observe the ZF guidelines for installing manual transmissions (1203 765 110). 3) To a large extent, the connection for the turning-shaft shift control can be adapted to the vehicle’s installation conditions. 4) Option 5) For the required air pressure, observe the ZF guidelines for installing manual transmissions (1203 765 110). 6) Transmission inclina…

-

49, 4-26 The shape of seat back profile is selected at ro- tation of the handle 2 (see Fig. Passenger’s seat). At counterclockwise rotation the back convex camber in- creases, clockwise — decreases. The angle of armrest 3 inclination is smoothly adjusted at armrest regulator rotation. Back inclination angle With lever 4 shifting up the back is unfixed and inclines forward, with lever re- lease, the back is fixed in selected position. Seat heating (if a…

-

122, KAMAZ 5490 6-19 CHECKING THE OIL LEVEL IN ENGINE CRANKCASE 1. Place the vehicle on level horizontal surface. Engage the parking brake. 2. The level of oil is tested in 10 min. after en- gine stop. During that time, oil flows into crankcase sump. 3. Check the oil level with the help of dipstick (with the cab raised). The oil level should be between the lower and upper dipstick marks. 4. If necessary, add oil th…

-

288, 6085 758 102b — 2006-10 7 Table of Contents Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . 6 1 General Safety Instructions Intarder . . . . . . . . . 9 2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.1 Operation at Low…

-

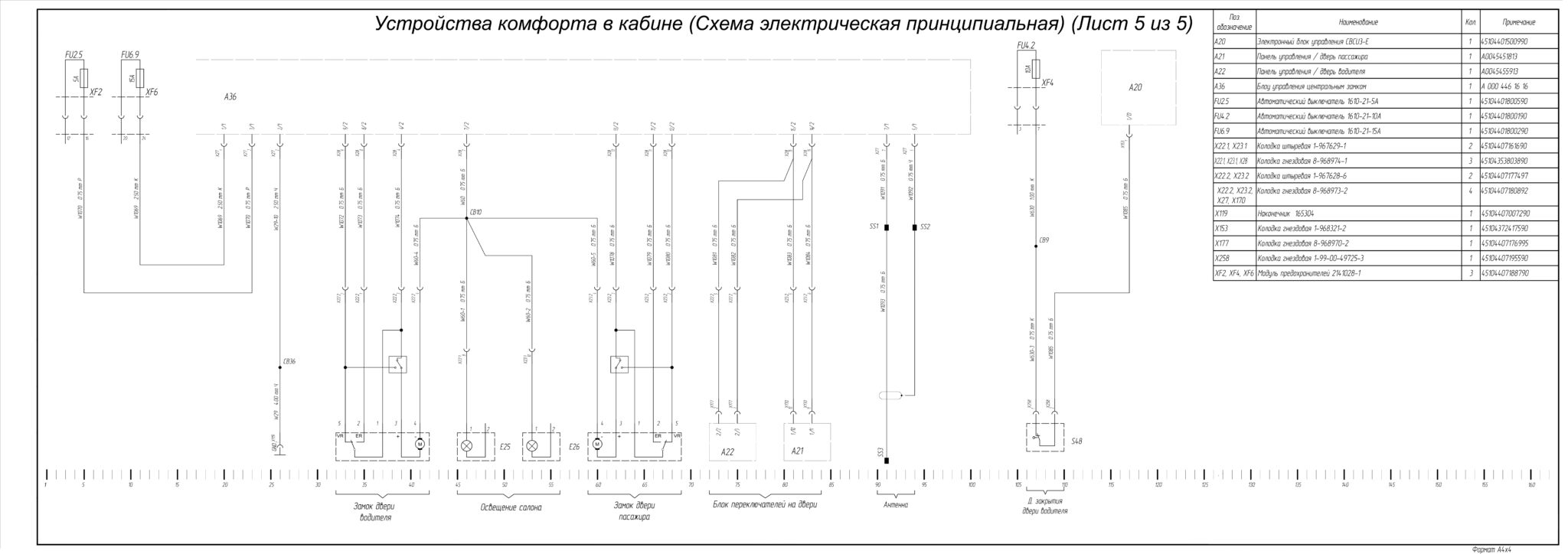

163, 7-32 Symbol Nominal value Consumer State of the main supply switch/ ignition switch key FU2.7 5A Hatch control actuator* ON/ACC FU2.8 20A Conditioner ON/ACC FU2.9 15A Driver’s side control panel ON/ACC FU2.10 15A Passengers’s side door control panel ON/ACC FU2.11 5A Audio system ON/ACC FU2.12 10A Cigar lighter ON/ACC FU3.1 15A EBS control unit ON/0 FU3.…

-

194, A3-2 TRANSMISSION OILS Attention! For ZF gearboxes, use oils approved by ZF, strictly. The complete information on oils (list, usage conditions and change intervals) for ZF units may be found in any ZF service center and on site www.zf.com. The site information is updated every 3 months. Each further revision substitutes all previous ones. For gearboxesZF 16S2220TD and ZF 16S2221TD use oils of class: 02Е, 02Н, 02L. For ZF gearbox 12АS2130TDand ZF 12АS2131TD oils of…

-

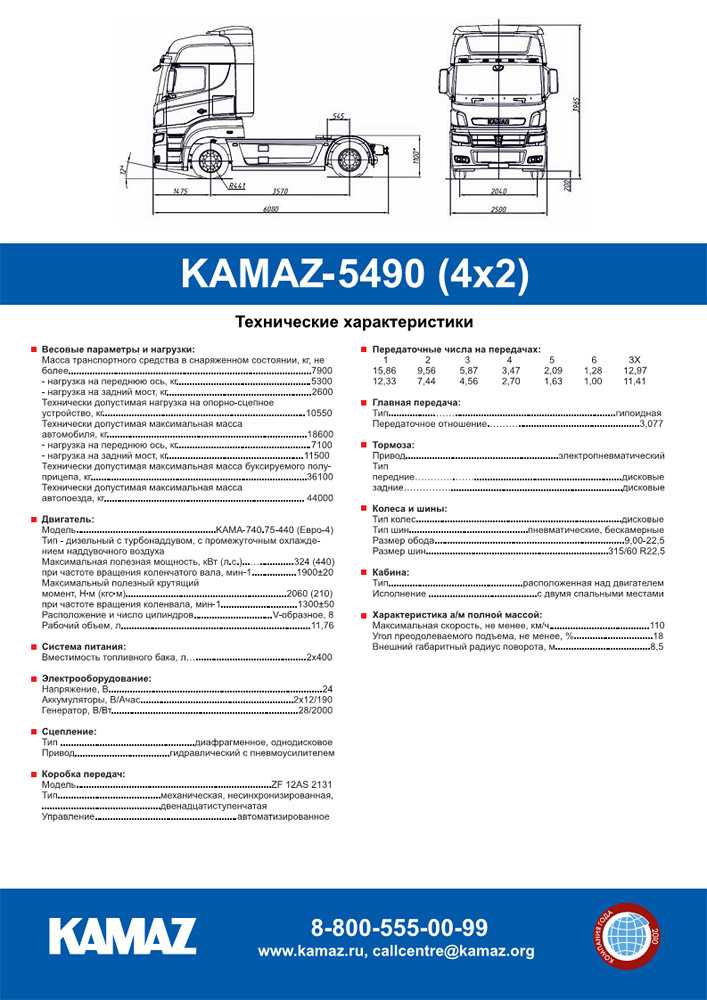

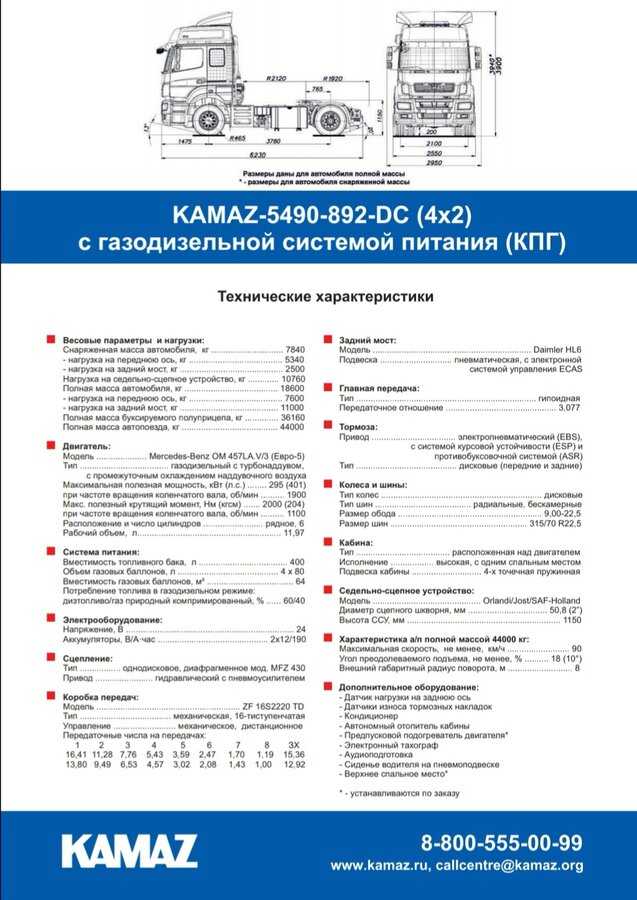

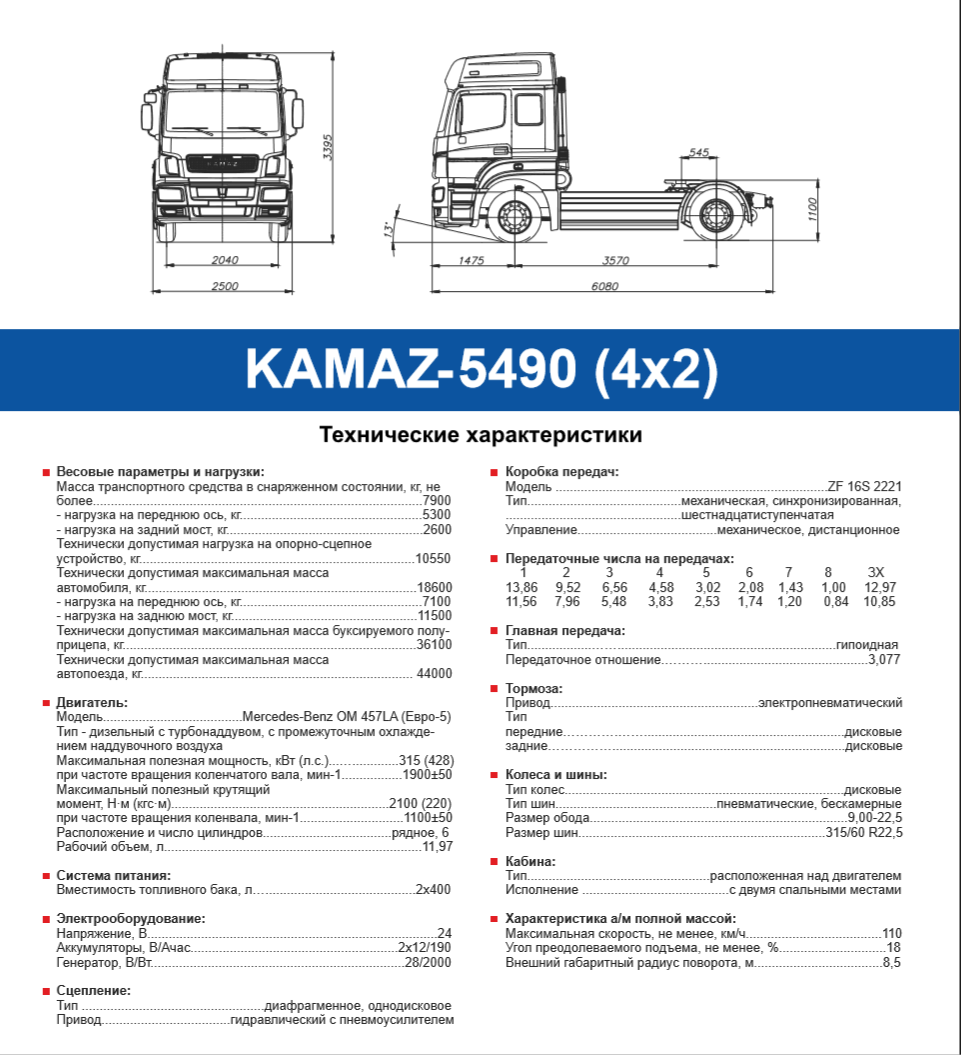

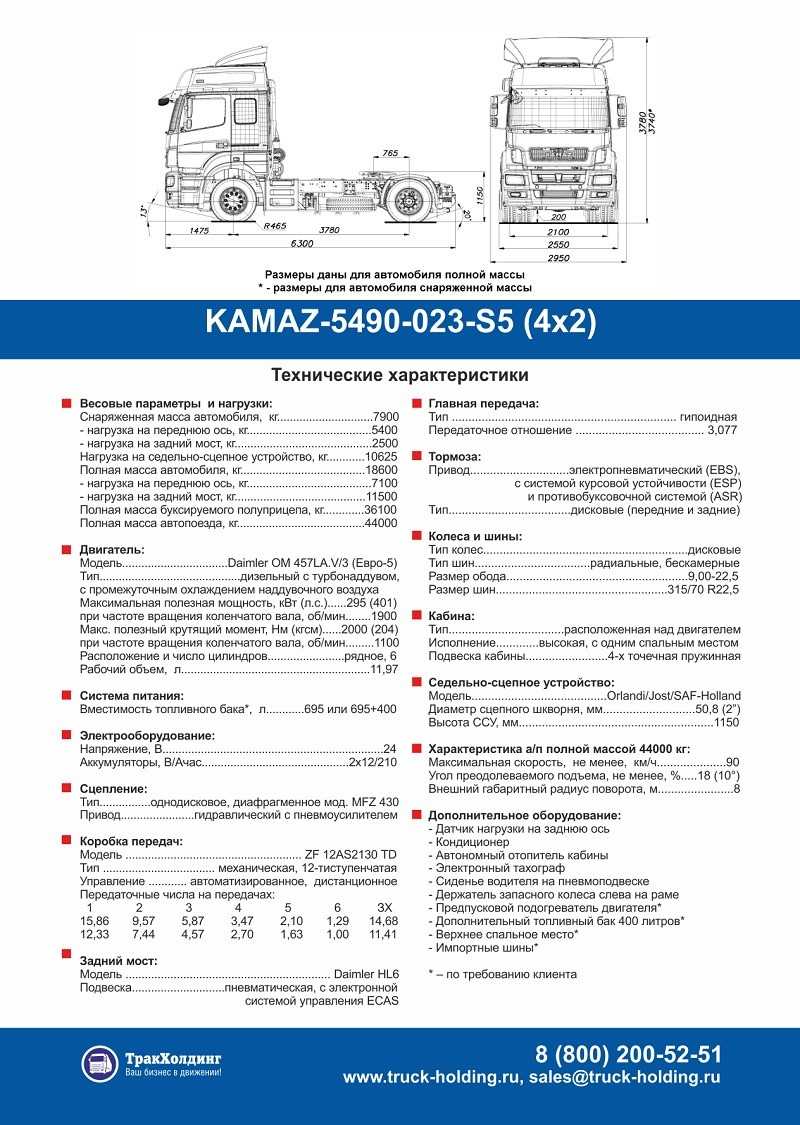

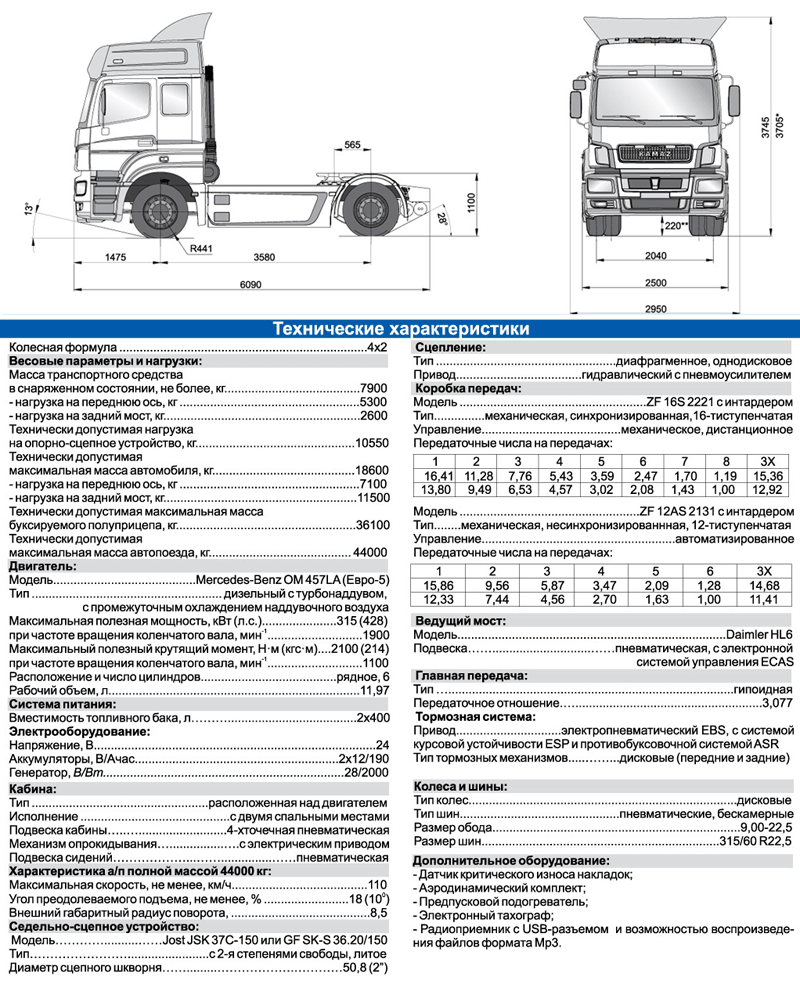

21, 3-1 3 BRIEF DESCRIPTION OF VEHICLE SYSTEMS AND MECHANISMS ENGINE Vehicle is equipped with engine Mercedes-Benz OM457LA. Operation manual for Mercedes-Benz engine is supplied with vehicle. TRANSMISSION Clutch Clutchis single-plate, diaphragm, pull-type model MFZ 430 «SACHS». Clutch control actuator is hydraulic with air- hydraulic booster «WABCO». Gearbox In accord with configuration, vehicles are equ…

-

152, 7-21 Trouble of all rear left marker lights Trouble of all rear right marker lights Trouble of the rear left direction indicator Trouble of the rear right direction indicator Trouble of tail fog lamps, located on both sides of the vehicle Trouble of brake lights of the rear lamps located on both sides of the vehicle

… -

38, KAMAZ 5490 4-15 LIGHT SHIFTER Vehicle light is switched on and off by light shifter. Prior light energizing, rotate the ignition key to position «ON» (motion position). LIGHT FOR MOVEMENT IN THE DAYTIME Daytime running lights switch on automatically when ignition key is shifted to «ON» position. Light shifter is in « 0» position. Daytime running lights are switched off when low or high beams or auxiliary illumination headlamps are engaged in …

-

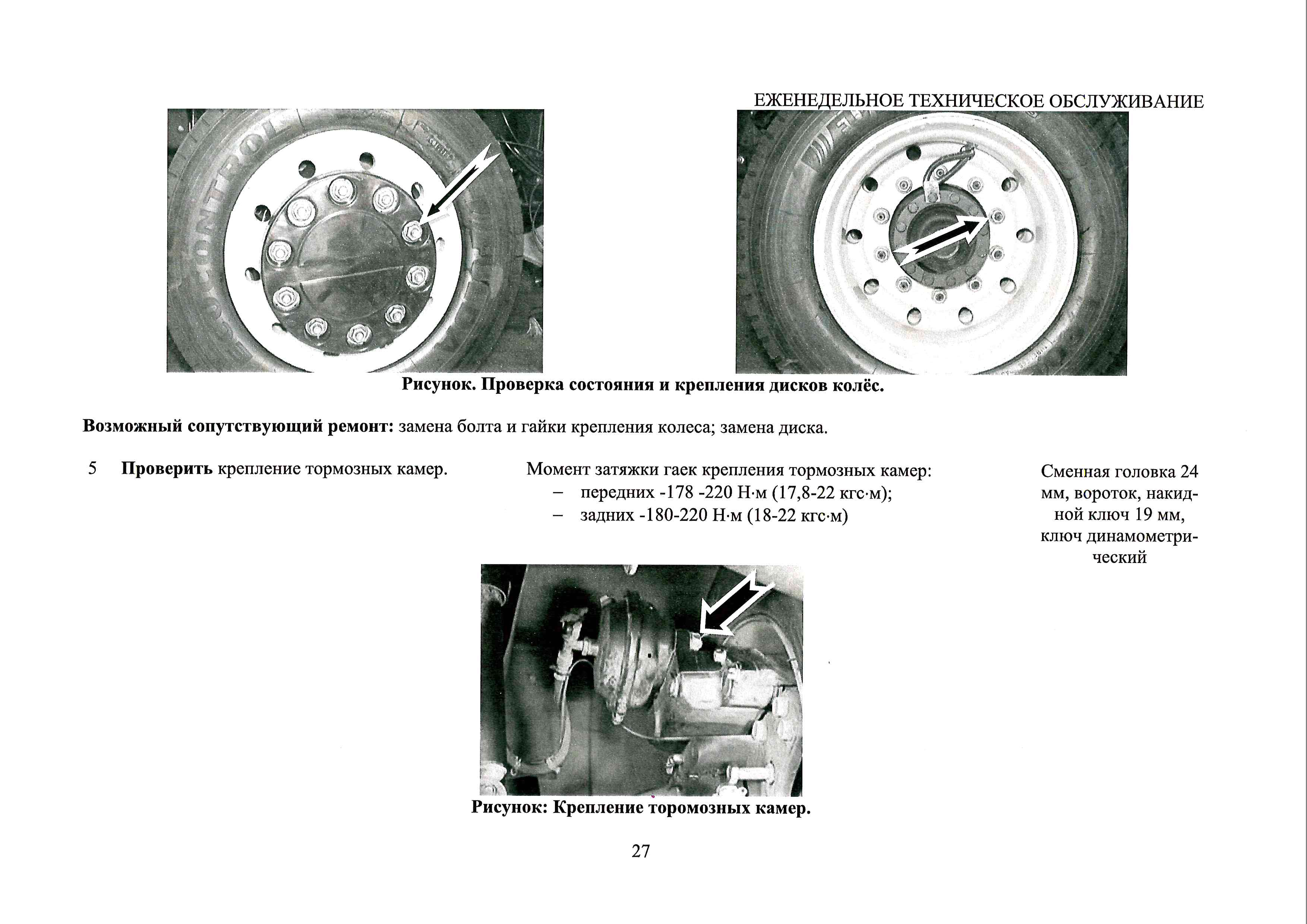

178, 7-47 DISASSEMBLY AND ASSEMBLY OF WHEELS IN VEHICLES Wheel dismantle 1. Apply the parking brake. 2. Place the chocks under the wheels. 3. When disassembling the tire, release air from the tire completely. 4. Undo the disk attachment nuts, remove disk (if any). 5. Slacken the wheel nuts. 6. To install the jack: — for the front shaft of the thrust journal (see Fig. Lifting the front wheel); — for the rear shaft of…

-

241, 8 6.2 HEATNG OPERATION IN HIGH GROUND • Heating operation is possible at a height up to 1500 m above sea level. Otherwise, adjustment of device is necessary. Heating operation at a height of 1500-3000 m above sea level without adjustment of the heater is possi- ble for a short time (for example, during a pass crossing or a stop). If you stay for a long time at these altitudes above the sea…

-

248, 15 9.9 ERROR CODES, THEIR DESCRIPTION AND REMEDIAL PROCEDURE Error code Description Remedial procedure/ customer INIT Function of machine recognition is switched on. Timing device EasyStart was switched off, and then it was switched on again. Wait until the machine recognition finishes, then set the exact time and day of the week. NO SIGNAL The device does not respond to commands. Check the heater fuse, replace if necessary. Contact the serv…

-

188, A2-2 Table 2 Lubrication chart for KAMAZ 5490 vehicle Lubrication points Name & Designation of Fuel, Oil and Grease Grease, qnt. (per item) Maintenance Name of works main specifications 1 2 3 4 5 6 Vehicle power sup- ply system Daimler OM457 Diesel fuel EURO GOST Р 52368-2005 (ЕН 590:2009) grade III; Diesel fuel EURO complant with the standards of the environmental class K5 according to GOST 32511-2013 (ЕН 590:200…

-

85, 4-62 INTERWHEEL DIFFERENTIAL LOCK Differential is to be locked when there is a differ- ence in values of wheel adhesive forces between which it is set. The lock is to be engaged directly before overcom- ing of hard track sections (sticky ground, hindrances, slippery dirty road). Attention! Lock engagement and disengagement are to be done with the coupling disengaged and only after full vehicle stop. For vehicles equipped with automatic gearbox …

-

251, 3 1341 758 101 — 2012-05 NOTE As a result of type variety, images shown in these operating instructions are not always identical with your transmission. Consequently, only one variant is displayed on an exemplary basis. Subject to technical changes. First edition: 2006 Your vehicle is equipped with a mechanical synchromesh transmission of the ZF-Ecosplit model range. The more familiar you are with the ZF transmis…

-

212, KAMAZ 5490 14 8.2 Other faults are listed in Table 2. Table 2 Number of LED blinks Fault Notes/ Troubleshooting 1 Overheating The risk of overheating. Temperature difference between the readings of the overheating sensor and heat sensor is too big. Heat/ overheating sensor indicates temperature higher 102 °C. Thoroughly check the complete liquid circuit and circulation pump operation. …

-

25, 4-2 DRIVER’S WORKING PLACE Driver’s working place 1 – switch block on driver’s door; 2,10,17 – ventilation and heat deflectors; 3 – smoke detector; 4 – cab heat control console panel (if available); 5 – tachograph; 6 – terminal for radio receiver energizing ; 7 – switch block; 8, 27 – clothes compartment; 9 – glove box; 11 — switch block on passen- ger’s door; 12 – light sw…

KamAZ operator’s, electrical wiring diagrams, workshop, service and repair manuals, spare parts catalogs, error codes in PDF download

|

Title |

File Size |

Download Links |

|

KamAZ 16s151 (1315051712) Spare Parts Catalog [PDF] |

1.7Mb |

Download |

|

Kamaz 5490 Operation Manual [PDF] |

8.1Mb |

Download |

|

KamAZ 6х6 Operation and Maintenance Manual rus [PDF] |

115.7Mb |

Download |

|

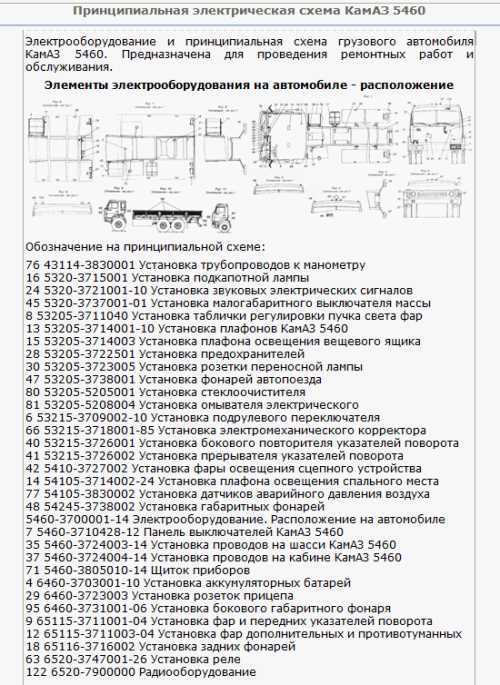

KamAZ Electrical Wiring Diagrams [PDF] |

32.4Mb |

Download |

|

KamAZ Repair Manual rus [PDF] |

35.9Mb |

Download |

|

KamAZ Spare Parts Catalog — Transfer Case [PDF] |

549.8kb |

Download |

|

KamAZ-4310 Repair Manual [PDF] |

58.7Mb |

Download |

|

KamAZ-4310 Textbook for cadets of educational institutions rus |

47.6Mb |

Download |

|

KamAZ-5320 Hydraulic steering [PDF] |

935.8kb |

Download |

|

KamAZ-5460 Electrical Wiring Diagrams [PDF] |

720.9kb |

Download |

Kamaz is a Russian company founded in 1969 and specializing in the manufacture of diesel trucks, bus and motors. Kamaz produced 38,192 vehicles in 2017, 11% more than in 2016 (34,432 units).

Kamaz is one of the car manufacturers to have survived the fall of the Soviet Union, in a profitable way.

The catalog now has around thirty models, both for civilian and professional or military use. In 2006, Kamaz produced 47,937 vehicles, including 89.4 % heavy goods vehicles2. In the heavyweight

segment, Kamaz represented that same year 54.4 % of Russian production, but only 6.6 % of European production and 1.46 % of world production.

In addition to its Russian factories of Naberejnye Tchelny, Tatarstan, and Neftekamsk, in Bachkirie, Kamaz has production lines in Poland, Kazakhstan, Azerbaijan, Ukraine, Ethiopia, Iran (in

partnership with Rakhsh Khodro) and Vietnam.

The Russian state agency Rosoboronexport, by which 30 % of Kamaz exports pass, envisaged in 2006 a takeover of the manufacturer. The Russian government’s goal was to bring together the national

automotive industry5, but this project has not emerged.

Since 2008, Daimler AG has been Kamaz’s strategic industrial partner, having acquired 11 % of its capital alongside the BERD, taking 4 % in 20106, from the Russian investment bank Troika Dialog

which held 21.1 %.

Опубликовано: | 23 марта, 2022

-

Версия

-

Скачать

109 -

Размер файла

2.17 MB -

Количество файлов

1 -

Дата создания

23.03.2022 -

Последнее обновление

24.03.2022

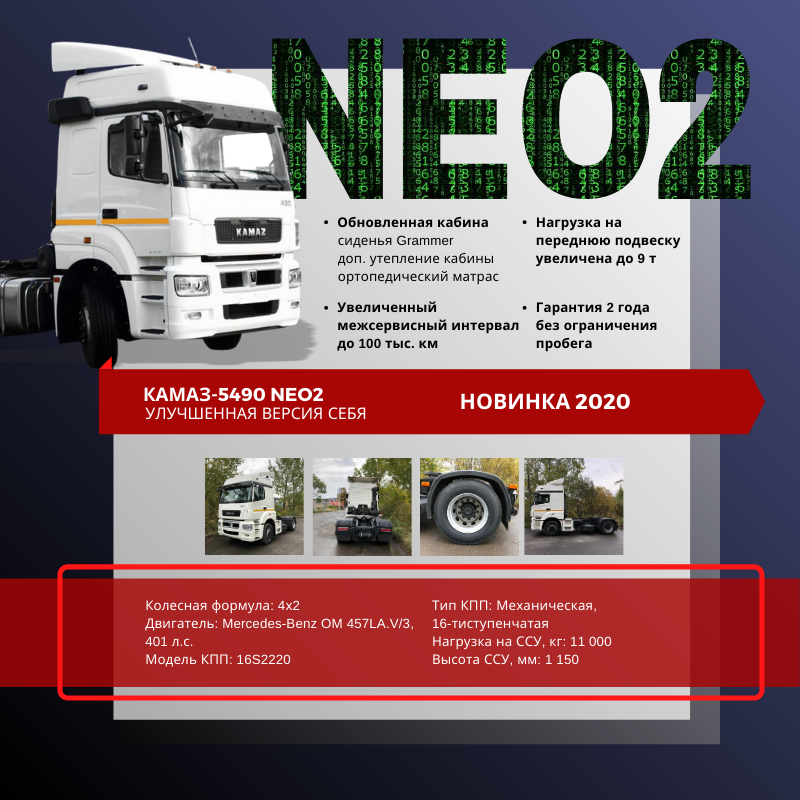

КамАЗ 5490 NEO. Инструкция по техническому обслуживанию и ремонту

Содержание:

- Инструмент и принадлежности.

- Расходные материалы.

- Комплектующие для ТО.

- Средства индивидуальной защиты (СИЗ).

- Подготовка автомобиля.

- Проверка на герметичность.

- Замена фильтрующего элемента в фильтре высокого давления.

- Замена фильтрующего элемента в фильтре низкого давления.

- Замена редуктора высокого давления.

- Замена блока газовых форсунок.

- Замена РТИ комплекта ГДС.

- Справочник нормо-часов.

- Приложения.

Attached Files

| Файл | |

|---|---|

| kamaz-5490-neo-instrukciya-po-tekhnicheskomu-obsluzhivaniyu-i-remontu-komponentov-sistemy-gazodizelnogo-pitaniya-ecomotive-solutions-emer.pdf |

© 1999-2022: ООО «АльфаАвтоГаз», Все права защищены. Копирование материалов с письменного разрешения администратора!

Изд. «КАМАЗ»

Год издания: 2013

Переплет: Мягкий

Язык: Русский

Цветность: Ч/б

Иллюстрации: Картинки + фотографии + 3D виды

100% В НАЛИЧИИ!!! ОТЛИЧНАЯ ЦЕНА!!!

Руководство по ремонту КАМАЗ 5490, 65206, 65207 EURO-5, эксплуатации и техническому обслуживанию. Устройство.

Книга КАМАЗ 5490, 65206, 65207 предназначена для широкого круга читателей – водителей, специалистов и техников, работающих в области авторемонта, а также может использоваться в качестве учебного пособия для персонала автосервисов, автомастерских и станций технического обслуживания.

Раздел 1. Введение………. 1-3

Техническое описание устройства и работы систем и механизмов автомобиля

Раздел 2. Двигатель…….. 2-1

Силовой агрегат… 2-1

Подвеска силового агрегата…. 2-1

Двигатель………. 2-2

Система питания двигателя воздухом…. 2-3

Система выпуска отработавших газов……. 2-6

Система охлаждения двигателя…….. 2-7

Система питания топливом………… 2-7

Система нейтрализации отработавших газов.. 2-10

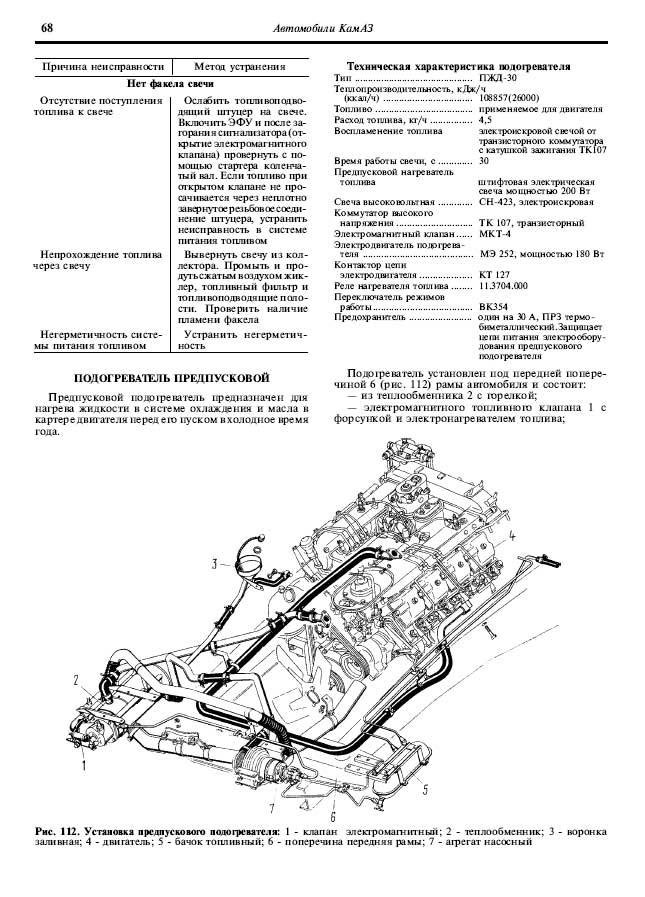

Система облегчения пуска холодного двигателя с предпусковым подогревателем2-12

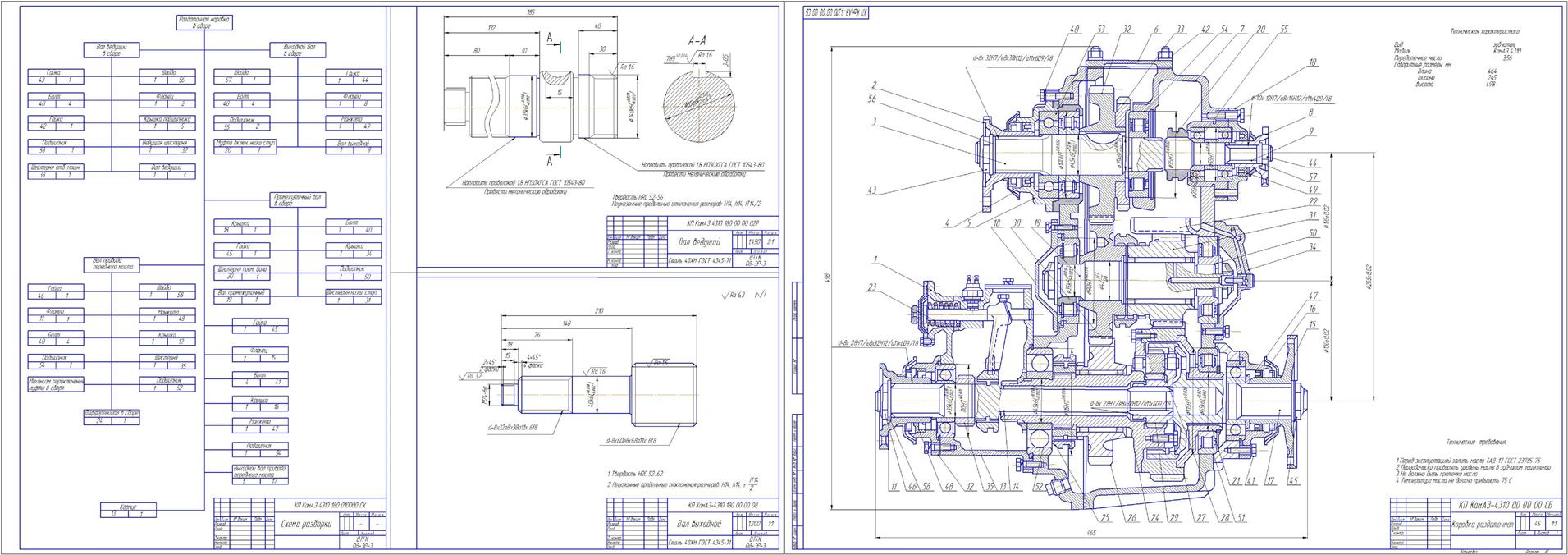

Раздел 3. Трансмиссия……………. 3-1

Сцепление………………………………………. 3-1

Привод управления сцеплением……………………. 3-3

Техническое обслуживание……………………….. 3-5

Ремонт……………………………………….. 3-7

Возможные неисправности сцепления……………….. 3-9

Коробка передач………………………………. 3-10

Техническое обслуживание………………………. 3-10

Ремонт………………………………………. 3-12

Карданная передача……………………………… 3-13

Техническое обслуживание………………………. 3-13

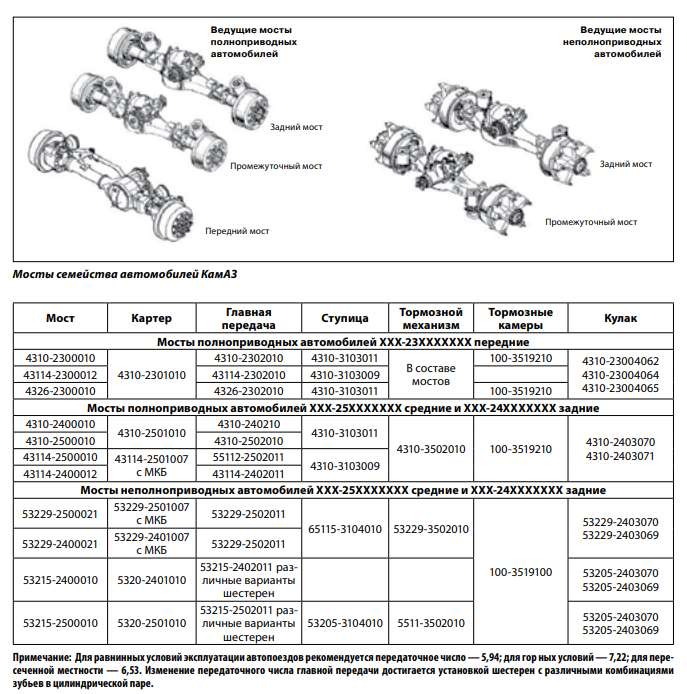

Ведущий мост…………………………………… 3-14

Техническое обслуживание………………………. 3-14

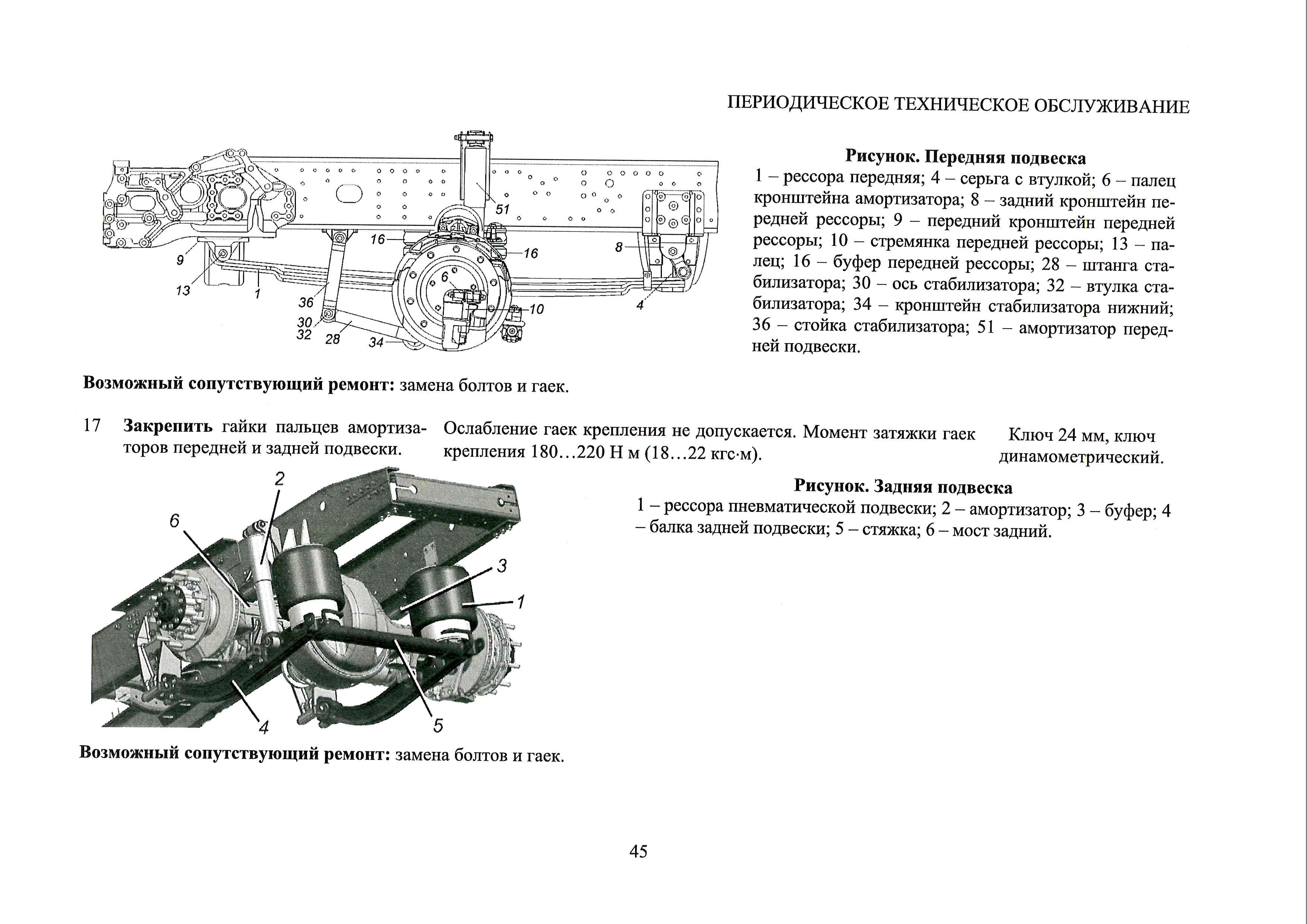

Раздел 4. Рама, седельно-сцепное устройство, подвеска, передняя ось, колеса, шины 4-1

Рама…………… 4-1

Седельно-сцепное устройство………………………. 4-3

Подвеска……………………………………….. 4-5

Передняя ось………………………………….. 4-7

Колеса, шины……………………………………. 4-8

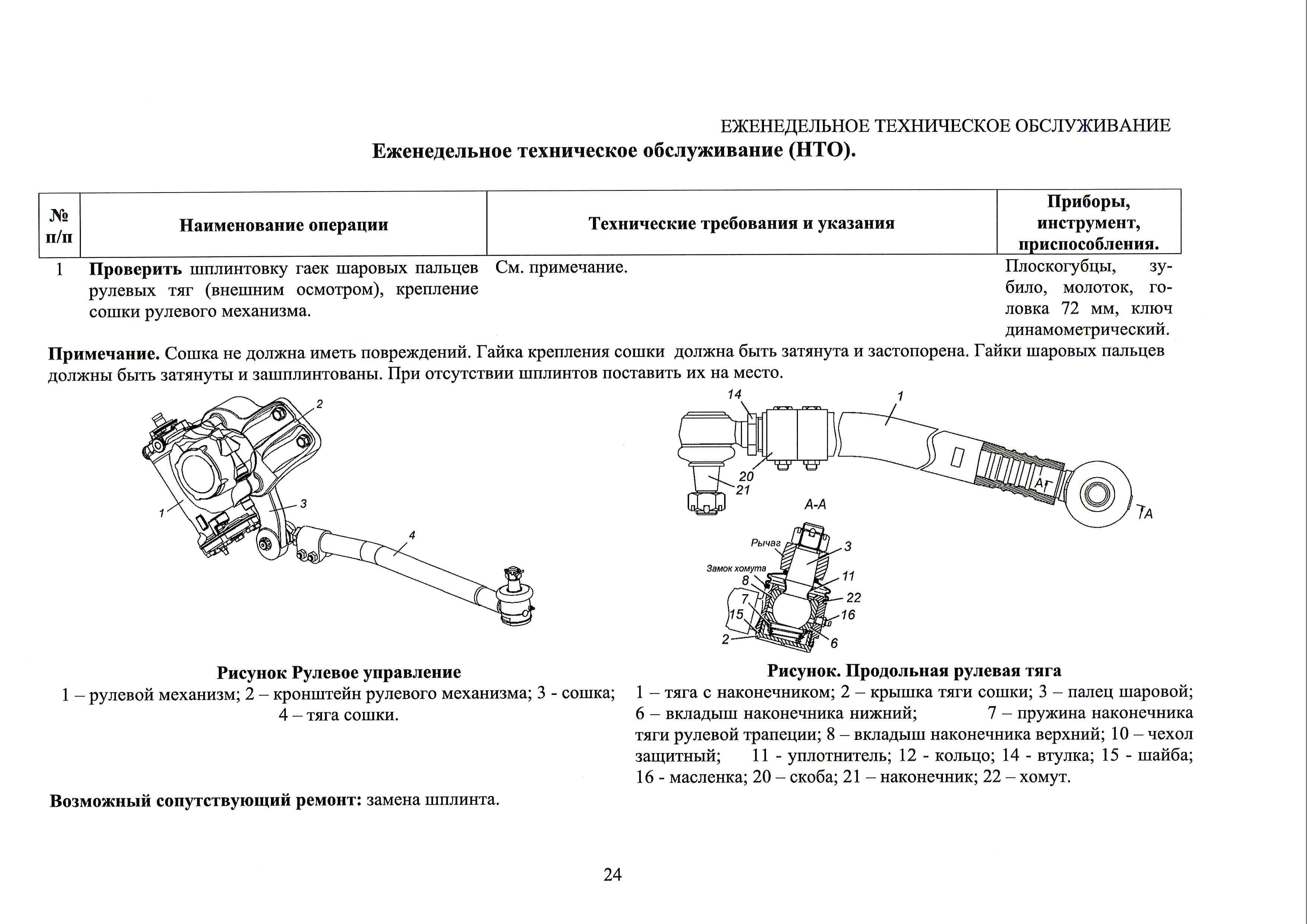

Раздел 5. Рулевое управление……………………….. 5-1

Раздел 6. Тормозная система………………………… 6-1

Пневмопривод тормозных систем…………………….. 6-4

Техническое обслуживание………………………… 6-19

Ремонт………………………………………… 6-28

Возможные неисправности пневмопривода…………….. 6-28

Раздел 7. Электрооборудование………………………. 7-1

Приложения

- Подогреватели предпусковые дизельные 14ТС-10.

Руководство по эксплуатации…………………….. 8-1

Б. Подогреватель жидкостный малогабаритный ПРАМОТРОНИК-16ЖД-24.

Руководство по эксплуатации……………………. 8-19

Руководство по ремонту коробок передач ZF 16S2221 …. 8-34

Г. Руководство по ремонту. Опорно-сцепное устройство JSK 37 фирмы JOST 8-262

Д. ECAS в грузовых автомобилях. Описание системы и инструкции по установке.. 8-293 Е. Рулевые механизмы фирмы RBL.

Руководство по техническому обслуживанию……….. 8-409

Ж. Рулевые механизмы фирмы RBL.

Руководство по ремонту…….. 8-420

3. ZF-Servocom типа 8090, 8095, 8097 и 8098. Конструкция, действие, техническое обслуживание, проверки……. 8-445

И. Особенности выполнения ремонтных работ…… 8-494