Paccar MX-11/MX-13 Engines operators, electrical wiring diagrams, workshop, service and repair manuals, spare parts catalogues, error codes in PDF download

|

Title |

File Size |

Download Links |

|

Paccar 2005-2010 Multiplexed Electrical System Sevice Manual |

6.2Mb |

Download |

|

Paccar 2005-2010 Service Manual [PDF] |

6.2Mb |

Download |

|

Paccar 2010 Multiplexed Electrical System Sevice Manual [PDF] |

6.9Mb |

Download |

|

Paccar MX ECM Circuit Diagram [PDF] |

336.4kb |

Download |

|

Paccar MX-11 Operator’s Manual [PDF] |

6.5Mb |

Download |

|

Paccar MX-11 / MX-13 Programming Manual [PDF] |

3Mb |

Download |

|

Paccar MX-13 2013 Diagnostic Service Manual [PDF] |

8.9Mb |

Download |

|

PACCAR MX-13 Engines [PDF] |

4.2Mb |

Download |

|

Paccar MX-13 EPA13 Overhaul Service Manual [PDF] |

10.7Mb |

Download |

|

Paccar MX-13 Operator’s Manual [PDF] |

4.9Mb |

Download |

|

Paccar MX11-MX13 Engines 2019 Brochure [PDF] |

13Mb |

Download |

|

Paccar parts catalog 2022 [PDF] |

5Mb |

Download |

|

Paccar PX 8 Operator’s Manual [PDF] |

2.1Mb |

Download |

|

Paccar PX-7 Engine Operator’s Manual [PDF] |

3.3Mb |

Download |

|

Paccar PX-9 Operator’s Manual [PDF] |

2.9Mb |

Download |

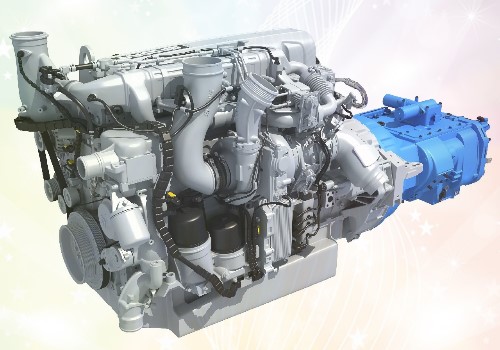

The PACCAR MX-13 Euro engine 6, with a volume of 12.9 litres, uses ultra-modern injection technology with a fuel distribution ramp, a turbocharger with variable geometry and an

optimized control system that provides maximum efficiency. Furthermore, to comply with the strict requirements of the ecological standard Euro 6, the engine is equipped with a recirculation

system for exhaust gases in conjunction with SCR technology and an active soot filter.

The engines provide additional torque at low speeds at the highest gear for gearboxes with direct high gear and on the two highest gearboxes with high gear, which reduces the car’s fuel

consumption.

A six-cylinder in a row diesel engine with turbocharges and intermediate cooling. Superflowing fuel combustion due to the use of a different processing system for exhaust gases with re-cycling of

OG (EGR), anti-dryer filter and selective catalytic neutralization (SCR), which ensure the content of toxic substances in emissions in the Euro 6 standard.

Advanced technologies, first-class materials and a comprehensive set of integrated functions increase the reliability and durability of the engine. Pipelines for supplying coolant and oil,

low-pressure fuel pipelines and the NTVD housing are built into the cylinder block. The cylinder block is designed without lateral covers to ensure maximum stiffness and low noise. In a whole

cylinder block, an intake manifold is built. The combined fuel pump and the moisture separator are installed directly on the engine to ensure the maximum simplicity of maintenance.

All Paccar MX-13 engines provide high performance in a wide range of engine speeds, as well as excellent indicators of torque at low rates. The optional powerful motor brake MX Engine Brake

provides optimal controllability on protracted slopes. MX Engine Brake brake integration into the working brake system increased driving safety and reduced brake pads’ wear.

A thoroughly controlled process of fuel combustion, in combination with other technologies aimed at achieving ultra-low emissions according to the Euro 6 standard, helps to increase fuel

efficiency.

The amount of fuel entering the total fuel distribution ramp is measured by the intellectual dosing system, which provides optimal efficiency by compressing only the required fuel mixture. This

reduces hydraulic losses to a minimum.

To comply with the strict requirements of Euro 6 in the content of toxic substances in the exhaust gases, DAF uses several technologies for additional processing of the exhaust gases, such as the

catalytic neutralizer of the SCR and an active soot filter. The correct composition of the mixture of the exhaust gases contributes to the optimum temperature in the filter necessary for

regenerating the collected soot particles.

The exhaust manifold and the most critical parts of the exhaust gas production system are isolated for maximum use of passive regeneration. In addition, higher temperatures positively affect the

operation of the CCR catalytic neutralizer, which increases efficiency and reduces ADBLUE fluid consumption.

Paccar MX-13 engines are also available in EURO 5 and Euro 3. The main difference between these versions is the system of additional processing of the exhaust gases. Compared to

the Euro 6 version, there is no DOC (diesel catalytic neutralizer) and DPF on the Euro 5 version. That is, there is no active soot filter on cars of the Euro 5 version. The Euro 3 version is not

equipped with a system of additional processing of exhaust gases and is supplied only with a silencer to reduce the noise level. Three versions of engines do not have significant differences in

working indicators.

Paccar Engines: owner’s, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

| Title | File Size | Download Links |

| Paccar 2005-2010 Multiplexed Electrical System Service Manual [PDF] | 5.7Mb | Download |

| Paccar 2005-2010 Service Manual [PDF] | 5.7Mb | Download |

| Paccar 2010 Multiplexed Electrical System Service Manual [PDF] | 6.9Mb | Download |

| PACCAR MX 13 engines DE 527061 [PDF] | 4.4Mb | Download |

| PACCAR MX 13 engines RU 527061 [PDF] | 4.4Mb | Download |

| Paccar MX ECM Circuit Diagram [PDF] | 320.9kb | Download |

| Paccar MX-11 Operator’s Manual [PDF] | 6.5Mb | Download |

| Paccar MX-11 / MX-13 Programming Manual [PDF] | 2.7Mb | Download |

| Paccar MX-13 2013 Diagnostic Service Manual [PDF] | 8.3Mb | Download |

| PACCAR MX-13 Engines [PDF] | 4.2Mb | Download |

| Paccar MX-13 EPA13 Overhaul Service Manual [PDF] | 10.5Mb | Download |

| Paccar MX-13 Operator’s Manual [PDF] | 4.7Mb | Download |

| Paccar MX11-MX13 Engines 2019 Brochure [PDF] | 12.9Mb | Download |

| Paccar parts catalog 2022 [PDF] | 4.8Mb | Download |

| Paccar PX 8 Operator’s Manual [PDF] | 2Mb | Download |

| Paccar PX-7 Engine Operator’s Manual [PDF] | 3.1Mb | Download |

| Paccar PX-9 Operator’s Manual [PDF] | 2.7Mb | Download |

American truck manufacturer Paccar is among the world’s top three. It also manufactures engines for use in DAF vehicles and other brands.

Motors having a displacement of 12.9 liters (generating 360–510 hp) fall under the MX classification. Torque ratings range from 1775 Nm to 2500 Nm, and they stand out for their dependability. Power units on the series have SMART injection and SCR technology, making them compatible with the Euro-5 environmental classification. In addition, the MX engine can meet EEV standards because of the existence of a particle filter.

The reliability of Paccar MX engines has increased due to their redesign. In addition, the designers successfully extended the maintenance interval to 90,000 kilometers.

If synthetic oil and a centrifugal filter element are used, the distance between maintenance stops climbs to 150,000 km.

One of the motor’s characteristics is a built-in motor brake, which can be used to gradually increase the engine’s output. From 1500 rpm, it can provide 200 kW of braking power, and at 2100 rpm, it can generate 325 kW.

Let’s quickly compare the characteristics of each candidate:

Whether you choose to call it “MX 265” or “360 horses,” that’s how much power you get from this beast of a generator. In order to reach the aforementioned specifications, a speed range of 1500–1900 rpm is required. At 1000-14,000 rpm, the torque is 1775 N * m. Compatible with DAF CF85 vehicles.

MX 300. The power output of 300 kW (410 hp; @ 1500–1900 rpm) with such an engine. Two thousand newton meters is equivalent to four thousand hundred revolutions per minute. Incorporating CF85 and XF105 upgrades.

The MX 340 has a 460-horsepower engine that can turn at speeds between 1500 and 1900 rpm, making it capable of producing 340 kW of power. Produces 2300 Nm of torque between 1000 and 1400 rpm. Equipped on the CF-85 and XF-105.

MX 375. 510 horsepower (or 375 kW) of power may be generated by the engine. The range of 1500–1900 rpm is optimal for achieving the necessary qualities. At a speed of 1000-1400 rpm, the torque is 2500 Nm. The CF 85 and XF 105 had the power plant mounted atop the aircraft.

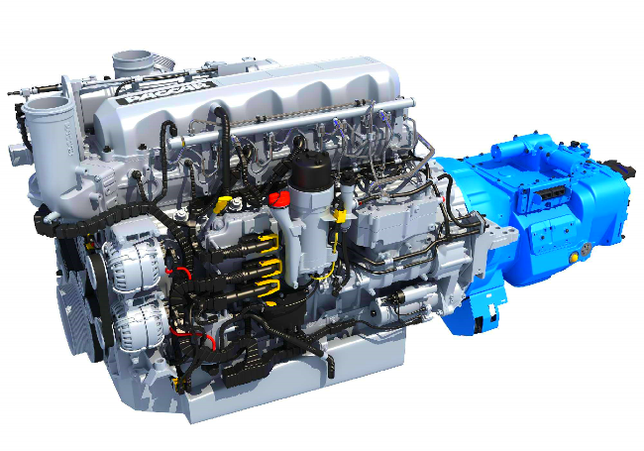

Paccar’s more widely used MX 11 and MX 13 engines deserve their own group because they are found in so many different types of vehicles. Below, we shall go deeper into their technical aspects and design nuance.

MX-13

Featuring a cutting-edge injection system and a variable geometry turbocharger, the Paccar MX-13 is a 12.9-liter Euro 6 engine. As an added bonus, the developers have included a new and better control system that ensures productivity without increasing expenses.

The Paccar engine is a cutting-edge innovation that satisfies present-day standards for reliability and environmental friendliness. Their durability, enhanced performance, and low fuel costs make them an excellent choice. They serve as the primary motive force for DAF trucks and other vehicles.

The manufacturer includes a recirculation system, particulate filter, and selective catalytic reduction (SCR) to ensure the lowest possible environmental impact. Extra torque at low RPM in top gear from the motors is a boon to fuel economy.

The MX-13 motor family features:

- There are 315 kilowatts (kW) or 428 horsepower (1600 rpm) available from this engine. This motor generates 355 kW, or 483 hp, at 1600 rpm and a torque of 2150 or 2300 N * m between 900 and 1365 rpm and between 900 and 1125 rpm.

- The engine produces maximum power at 1675 rpm when it produces 390 kW (530 hp), and the torque is 2350 or 2500 N * m (900 or 136 lb-ft, respectively).

- Two different speeds (1000-1425 and 1000-1460 rpm) produce torque values of 2500 and 2600 N * m, respectively.

The diesel turbocharged supercharged total combustion internal combustion engine is under consideration. SCR, EGR, and DPF systems are all available. The Euro-6 requirements have been met in full. The compression ratio is 18.5 to 1, the cylinder diameter is 13, and the piston stroke is 16.2 cm.

Components of the layout:

- A steel crankshaft with no counterweights and a cast iron cylinder block.

- Each cylinder has four valves.

- The drive is mounted in the back.

The fuel and air delivery system of the Pakkar MX-13 engine has been upgraded. The fuel is heated and prepared by a heater installed within the tank. The water is automatically drained and filtered. Nozzles capable of delivering an ignitable mixture at pressures up to 2500 bar are fitted at the output.

Paccar MX-13

A turbocharger and an air cooler are part of the system that draws in air. The turbocharger’s geometry can be adjusted as needed. A block houses the various components of the lubrication system: filters, an oil cooler, pipes, valves, and a thermostat.

A centrifugal bypass valve is included for long-term reliability. The oil-cleaning filter element is a full-flow type, and the cooler is managed by a thermostat in a stainless-steel heat exchanger.

MX-11

This vehicle is powered by a PaccarMX-11-10.8-liter engine, which may generate 290–440 horsepower, differences in size, profitability, weight, and noise level. DAF Trucks of the Netherlands developed and began manufacturing this model in the fall of 2013.

Peculiarities:

- Improved rigidity characteristics and integrated systems for the cylinder block of the 6-cylinder variant;

- Top-mounted double camshaft in the cylinder head; variable-geometry turbocharger; high-pressure fuel delivery system; cutting-edge engineering for optimal performance.

The developers have included an improved double camshaft. Manufacturers employed advanced construction techniques that included adding graphite and a vertical rib to boost rigidity and quietness. The cylinder block has been outfitted with as many features as possible to extend its useful life. Pipelines, for instance, can take the form of channels, and pressure-generating pumps can be embedded directly into the concrete itself.

The fuel delivery system utilizes a pre- and post-injection device and a common frame that provides a pressure of 2500 bar. This layout makes it possible to cut back on fuel use and ensures that it gets distributed evenly.

Several improvements have been made to the engine as well, such as the elimination of the need for a separate drive for the fan by mounting it directly to the crankshaft. This results in lower operating and fuel expenses. The motor features a water pump, a combined generator/compressor unit, and an oil block with a filter integrated into its design.

Paccar FR

Paccar FR engines are a subset of this larger category; they are 4-cylinder power units that are vertically arranged; they are turbocharged, and they use clean combustion to power the vehicle. To be seen as a row of the following prototypes:

- engine producing 118-160 hp at its peak RPM of 1900, with the torque of 550 Nm; engine producing 103-140 hp at its peak RPM of 1900, with the torque of 550 Nm;

- 136 – 185 hp engine at 200 rpm with 700 Nm of torque; 152-207 hp unit with peak power at 2100-2300 rpm and 760 Nm of torque.

The FR has a working volume of 4.5 liters, a cylinder diameter of 10.7 cm, and a piston stroke of 12.4 cm. The motor has the following features: Features a cast-iron ladder-type frame, a cylinder head with separate channels for starting and releasing the engine, aluminum pistons with symmetrical concave chambers and a cooling channel, a forged camshaft with induction hardening, a common-rail fuel injection system, an adjustable starter, and electronic control.

Standards and technologies for SCR and EEV Paccar engines ensure that they operate at peak efficiency. The most important ones are as follows:

- The EEV is a benchmark for a low-emission vehicle. SRC technology and smart injection are used to regulate the combustion process. Many models of DAF trucks use the FR, PR, and MX variations of this class of motor.

- SCR refers to a method of selective catalytic breakdown. Its purpose is to purify exhaust fumes to conform to Euro 5 and EEV standards. Particulate filters and enhanced fuel delivery support the system’s fundamental feature—the afterburning of spent exhaust gases.

PACCAR MX-13 Engine Fault Codes DTC

PACCAR MX-13 Engine Fault Codes DTC

PACCAR MX-13 Engine Fault Codes DTC

PACCAR MX-13 Fault Codes DTC.pdf

Adobe Acrobat Document

41.4 KB

PACCAR Engine Aftertreatment Systems — Operator’s Manual

PACCAR Engine Aftertreatment Systems — Operator’s Manual

PACCAR Engine Manuals_PACCAR Engine Afte

Adobe Acrobat Document

1.3 MB

PACCAR PX-8 Engine Operator’s Manual

PACCAR PX-8 Engine Operator’s Manual

PACCAR Engine Manuals_PACCAR PX-8 Engine

Adobe Acrobat Document

2.1 MB

PACCAR PX-7 Engine Operator’s Manual

PACCAR PX-7 Engine Operator’s Manual

PACCAR Engine Manuals_PACCAR PX-7 Engine

Adobe Acrobat Document

3.3 MB

PACCAR MX Engine Operator’s Manual

PACCAR MX Engine Operator’s Manual

PACCAR Engine Manuals_PACCAR MX Engine O

Adobe Acrobat Document

2.9 MB

PACCAR PX-9 Engine Operator’s Manual

PACCAR PX-9 Engine Operator’s Manual

PACCAR Engine Manuals_PACCAR PX-9 Engine

Adobe Acrobat Document

3.5 MB

PACCAR MX-13 Engine Operator Manual

PACCAR MX-13 Engine Operator Manual

PACCAR Engine Manuals_PACCAR_MX-13_Engin

Adobe Acrobat Document

5.0 MB

Some PACCAR Engine Service Manuals PDF above the page — MX, PX; PACCAR MX-13 Engine Fault Codes DTC.

In 1905, in Seattle, Sir William Pigot created the company «Seattle Car Mfg Co.» for the production of equipment for the maintenance of railways, as well as hoists for the timber

industry.

After a few years of «Seattle Car» merged with «Twohy Brothers» from Portland, and the new company is named «Pacific Car and Foundry Company«, a name that will

remain unchanged for 55 years.

In 1924, William Pigott sells controlling stake in «American Car and Foundry Company». With the onset of the Great Depression, and the general economic downturn in 1929, the

production technology is fully terminated and the business is waning.

Paul Pigott, son of the founder, in 1934, bought the remaining assets of the company and equipment in «American Car«. Under the leadership of the company Paul literally rises

from the ashes and begin to produce powerful winches and hoists «Carco» for track-type tractors.

The first production was the basis for the subsequent development of the PACCAR Empire. Until today, at the plant has successfully operated a small assembly line for winches,

sleeves, collars and planetary gears used in the timber industry. The plant is called PACCAR’s Winch Division Renton there are production and integrates directly 3 small

companies: «Braden«, «Carco» and «Gearmatic«.

In 1941, America is entering into a world war. The company receives a large government order. The plant in Renton starts production of heavy tanks «Sherman» and emergency repair army vehicles.

Throughout the war, «Pacific Car and Foundry» building a ship repair docks and tugs for the Navy.

With the purchase of «Kenworth Motor Truck Company» in 1945, the company enters into the industry production of trucks and

special-purpose machinery. Pacific Car and Foundry has significantly increased its production capacity and raised its stock rating immediately after the acquisition of the

ownership of Peterbilt Motors Company in 1958.

In the fall, Pacific Car manages to buy another well-known company — Dart Truck, producing dump trucks and trucks for work in the mines.

In 1962, the opening of the world trade fair, one of the production units PACCAR titled «Structural Steel Division» has won the tender and by special order manufactured metal

special strength for the construction of the TV tower in Seattle «Space Needle».

Somewhat later, «Structural Steel Division» Perform the following order — delivered steel elements for the construction of the framework of the World Trade Center in New York.

In 1960, PACCAR buys a number of factories outside the United States and become a transnational concern. A significant part of

production lines Kenworth transferred to Mexico and soon formed a new division called «Kenworth Mexicana«.

In 1966, PACCAR is entering the fight for the Australian market and is building near Melbourne plant to assemble tractors 7-8 class.

In 1960, the department «Carco Acceptance Corporation«, now known as PACCAR Financial

Corp. appointed responsible for the distribution of products of concern in the United States.

In 1967 it created a wholly owned subsidiary «Dynacraft«, responsible for the production of belts, pumps, adapters, and other truck

accessories for Kenworth and Peterbilt plants. Assuming that the old name

of «Pacific Car and Foundry Company» did not accurately correspond to the genus of the company, in 1972 the Board of Directors and major

shareholders decide to rename the group to PACCAR.

However, the name «Pacific Car and Foundry Company» is still one of the auxiliary units of PACCAR.

In 1973, the Group improved the structure and create two parallel operating units:

«PACCAR International» becomes responsible for the sale, warranty and post warranty maintenance of machinery outside the United States.

PACCAR Parts Division, headquartered in Renton, for the supply of spare parts and aggregates all service centers and dealerships.

In 1980 he produced PACCAR Leasing Corporation, responsible for the development of leasing schemes for the organization of delivery of

equipment in long-term leases and working with dealerships.

A year later, c buy truck manufacturer of the oldest in the world — the British company Foden, PACCAR Concern becoming an international

manufacturer.

PACCAR is investing tens of millions of dollars in the construction of the largest US service center Peterbilt and Kenworth car brands. In July 1982, put into operation a modern complex,

located 65 miles north of Seattle.

In 1987, PACCAR bought the company «Al’s Auto Supply» in Washington, a major player

in the automotive market and one of the largest wholesale center for the sale of commercial vehicles and car accessories.

A year later, due to the purchase of another major wholesaler from California — «Grand Auto», PACCAR significantly strengthens the

position of his unit PACCAR Automotive.

Каталог товаров

Двигатели PACCAR MX13. Руководство по ремонту.

Артикул: NPAC002

Изд. «СпецИнфо»

Год издания: 2021

Кол-во страниц: 106

Переплет: Мягкий

Язык: Русский

Цветность: Ч/б

Иллюстрации: Картинки

НОВИНКА!!! 100% В НАЛИЧИИ!!! ОПТ И РОЗНИЦА!!! ЦЕНА ИЗДАТЕЛЬСТВА!!!

Руководство по ремонту двигателя PACCAR MX13. Контрольные параметры и моменты затяжки. Рекомендации по выполнения ремонтных операций.

Двигатели Паккар МХ13 — это 12.9 литровый двигатель, который устанавливается на грузовые автомобили DAF XF105 и DAF XF106, Kenworth T680, Peterbilt 579 и другие.

Книга по ремонту двигателя Паккар МХ 13 PACCAR предназначена для широкого круга читателей – водителей, специалистов и техников, работающих в области авторемонта; также может использоваться в качестве учебного пособия для персонала автосервисов, автомастерских и станций технического обслуживания.

Содержание книги

ОБЩИЕ СВЕДЕНИЯ 3

ТИПЫ ДВИГАТЕЛЕЙ 3

ИДЕНТИФИКАЦИЯ ДВИГАТЕЛЕЙ 3

РАЗБОРКА/СБОРКА ДВИГАТЕЛЯ 5

РАЗБОРКА 5

СБОРКА 25

снятие И УСТАНОВКА КОМПОНЕНТОВ 55

быстроразъемные соединения ТРУБОПРОВОДОВ 55

датчики, ЛЕВАЯ СТОРОНА ДВИГАТЕЛЯ 55

подшипники распределительного ВАЛА 56

СНЯТИЕ 56

СНЯТИЕ ПОДШИПНИКА № 7 РАСПРЕДВАЛА 56

СНЯТИЕ ПОДШИПНИКОВ № 2 — № 6 РАСПРЕДВАЛА 57

СНЯТИЕ ПОДШИПНИКА № 1 РАСПРЕДВАлА 58

УСТАНОВКА 58

УСТАНОВКА ПОДШИПНИКА № 1 РАСПРЕДВАлА 58

УСТАНОВКА ПОДШИПНИКОВ № 2 — № 6 РАСПРЕДВАЛА 60

УСТАНОВКА ПОДШИПНИКА № 7 РАСПРЕДВАЛА 60

распределительный ВАЛ 61

СНЯТИЕ 61

УСТАНОВКА 61

ГИЛьзы цилиндров 62

СНЯТИЕ 62

УСТАНОВКА 63

ИЗМЕРЕНИЕ ВЫСТУПАНИЯ ГИЛЬЗ ЦИЛИНДРОВ ОТНОСИТЕЛЬНО ПОВЕРХНОСТИ БЛОКА ЦИЛИНДРОВ 63

Шатуны 64

СНЯТИЕ 64

СБОРКА 64

УСТАНОВКА 64

МАСЛОРАСПыЛИТЕЛИ ОхЛАжДЕНИЯ поршней 64

СНЯТИЕ 64

УСТАНОВКА 65

ТОЛКАТЕЛИ КЛАПАНОВ 66

СНЯТИЕ 66

УСТАНОВКА 66

МАСЛЯНый АвтоБуква ПОДДОН 66

СНЯТИЕ 66

УСТАНОВКА 66

ТОЛКАТЕЛИ НАСОСНых БЛОКОВ ТОПЛИВА ВыСОКОГО ДАВЛЕНИЯ 67

СНЯТИЕ 67

УСТАНОВКА 67

ТРУБКА МАСЛОМЕРНОГО ЩУПА 67

КРОНшТЕйН ГЕНЕРАТОРА 67

ПЕРЕДНЯЯ КРышКА ДВИГАТЕЛЯ 67

УСТАНОВКА 67

передний сальник КОЛЕНВАЛА, ПЕРЕДНЯЯ крышка 68

СНЯТИЕ 68

УСТАНОВКА 69

ПЕРЕДНИЙ КРОНШТЕЙН ДВИГАТЕЛЯ 69

БОКОВОЙ КРОНшТЕйН ДВИГАТЕЛя 70

промежуточный шкив АвтоБуква.ру ПОЛИКЛИНОВОГО РЕМНЯ 70

УСТАНОВКА 70

ЛЕВый промежуточный шкив ПОЛИКЛИНОВОГО РЕМНЯ 70

УСТАНОВКА 70

правый натяжитель ПОЛИКЛИНОВОГО РЕМНЯ 70

демпфер КРУТИЛьных колебаний 71

УСТАНОВКА 71

шестерни механизма ГАЗОРАСПРЕДЕЛЕНИЯ 71

КАРТЕР маховика 71

УСТАНОВКА 71

ЗАДНИй сальник КОЛЕНВАЛА (КАРТЕР маховика 72

УСТАНОВКА 72

Маховик 72

УСТАНОВКА 72

ГОЛОВКА БЛОКА цИЛИНДРОВ 72

СНЯТИЕ 72

УСТАНОВКА 73

кронштейн системы EGR 74

УСТАНОВКА 74

ТРУБКИ охлаждающей жидкости ТУРБОНАГНЕТАТЕЛЯ 74

ТРУБКА ПОДАЧИ ОХЛАЖДАЮЩЕЙ ЖИДКОСТИ 74

ТРУБКА ВыПУСКА ОХлАжДАющЕй жИДКОСТИ 74

масляные ТРУБКИ ТУРБОНАГНЕТАТЕЛЯ 74

турбонагнетатель С VGT 75

УСТАНОВКА 75

АКТюАТОР ТУРБОНАГНЕТАТЕЛЯ С VGT 75

Снятие 75

УСТАНОВКА 75

ТРУБКИ охлаждающей жидкости ТУРБОНАГНЕТАТЕЛЯ 76

ОТСОЕДИНЕНИЕ 76

ПОДСОЕДИНЕНИЕ 76

охладитель системы EGR 76

СНЯТИЕ 76

ОЧИСТКА 77

ГИБКАЯ ТРУБКА СИСТЕМы EGR 77

УСТАНОВКА 77

ПЕРЕПУСКНОй КлАПАН СИСТЕМы EGR (BPV 78

ТРУБКА ВЕНТУРИ 78

ТРУБКА ДАТчИКА ДАВЛЕНИЯ ДО ТУРБОНАГНЕТАТЕЛЯ 79

ТРУБКА ДАТчИКА ДАВЛЕНИЯ ПОСЛЕ ПЕРЕПУСКНОГО КЛАПАНА СИСТЕМы EGR (BPV)79

УСТАНОВКА 79

ТРУБКИ охлаждающей жидкости системы EGR 79

УСТАНОВКА 79

перепускной клапан системы очистки выхлопных ГАЗОВ

С изогнутой трубкой выпуска отработавших ГАЗОВ 80

КРЕПЛЕНИЕ ТРУБОК, БЛОК ДОЗАТОРА, СИСТЕМА ОчИСТКИ ВыхЛОПНых ГАЗОВ 81

ТРУБА 01 КОМПРЕССОРА (СТОРОНА ВСАСыВАНИЯ 81

УСТАНОВКА 81

ТРУБКА подачи воздуха ОТ ВОЗДУшНОГО фильтра К турбонагнетателю 81

УСТАНОВКА 81

ВЫПУСКНОЙ КОЛЛЕКТОР 81

УСТАНОВКА 81

ТРУБКА ВОЗВРАТА ТОПЛИВА ОТ ФОРСУНОК 82

УСТАНОВКА 82

ОПОРА коромысла МОТОРНОГО ТОРМОЗА 82

УСТАНОВКА 82

запирающая ПЛАСТИНА НА КАРТЕРЕ маховика 82

УСТАНОВКА 82

БЛОК УПРАВЛЕНИЯ ДВИГАТЕЛЯ 83

УСТАНОВКА 83

модуль фильтрации ТОПЛИВА В СБОРЕ 83

УСТАНОВКА 83

питающая ТРУБКА МОДУЛЯ ДОЗИРОВАНИЯ ТОПЛИВА 83

ПОДСОЕДИНЕНИЕ 83

МАСЛОЗАЛИВНАЯ ГОРЛОВИНА 84

УСТАНОВКА 84

ТОЛКАТЕЛИ НАСОСНых БЛОКОВ ТОПЛИВА ВыСОКОГО ДАВЛЕНИЯ 84

УСТАНОВКА 84

насосные БЛОКИ common RAIL ТОПЛИВА высокого ДАВЛЕНИЯ 84

УСТАНОВКА 84

модуль ВПУСКА ТОПЛИВА 85

УСТАНОВКА 85

топливопроводы высокого давления от насосных БЛОКОВ К ТОПЛИВНОй РАМПЕ common rail 85

УСТАНОВКА 85

двухцилиндровый воздушный КОМПРЕССОР 86

УСТАНОВКА 86

ТАНДЕМНЫй НАСОС 87

УСТАНОВКА 87

фиксирующая ПЛАСТИНА 87

УСТАНОВКА 87

МАСЛЯНЫй НАСОС 88

УСТАНОВКА 88

МАСЛОЗАБОРНАЯ ТРУБКА 88

УСТАНОВКА 88

фильтрующий элемент МАСЛЯНОГО фильтра 88

фильтрующий элемент центрифужного МАСЛЯНОГО фильтра 88

ТРУБКА ВПУСКА ВОЗДУхА ВПУСКНОГО КОЛЛЕКТОРА 88

УСТАНОВКА 88

ТРУБКА ВПУСКА ВОЗДУхА ОТ ВОЗДУшНОГО фИЛьТРА К турбонагнетателю 88

МАСЛЯНЫй модуль 89

УСТАНОВКА 89

заглушки МАСЛЯНОГО МОДУЛЯ 89

МАСЛЯНЫй ТЕРМОСТАТ 90

МАСЛОРАСПЫЛИТЕЛь ОхЛАжДЕНИЯ поршня 90

КЛАПАННАЯ КРЫшКА 90

кронштейны СИСТЕМЫ ВЫПУСКА отработавших ГАЗОВ 90

ТОПЛИВНЫй фильтр 91

демпфер крутильных колебаний 91

крышки коренных подшипников 91

шестерня КОЛЕНВАЛА 91

промежуточная шестерня 91

КАРТЕР МАхОВИКА 91

МАхОВИК 92

жГУТ J3 ДВИГАТЕЛЯ 92

НАСОС ОхЛАжДАюЩЕй жИДКОСТИ 92

СТАРТЕР 92

ПРОВЕРКИ И РЕГУЛИРОВКИ 93

УСТАНОВКА поршней цИЛИНДРОВ В ВМТ 93

проверка выступания гильз цилиндров относительно поверхности БЛОКА цилиндров 93

распределительный ВАЛ 95

коленчатый ВАЛ 95

гильза цилиндра 96

ПРОВЕРКА СОСТОЯНИЯ ГИБКОй ТРУБКИ АвтоБуква СИСТЕМы EGR ОТ управляющего КЛАПАНА К охладителю EGR 97

ПРОВЕРКА И РЕГУЛИРОВКА ЗАЗОРОВ КЛАПАННОГО МЕхАНИЗМА 97

ПРОВЕРКА ГОЛОВКИ БЛОКА цИЛИНДРОВ ДАВЛЕНИЕМ 98

РЕГУЛИРОВКА НАТЯжЕНИЯ ПОЛИКЛИНОВых РЕМНЕй 99

ПОЛИКЛИНОВОй РЕМЕНЬ 12PK 99

ПОЛИКЛИНОВОй РЕМЕНЬ 8PK 99

выпуск воздуха ИЗ топливной системы 100

выпуск воздуха ИЗ системы охлаждения 100

ПРОВЕРКА шестерен ГАЗОРАСПРЕДЕЛЕНИЯ 100

заправочный объем АвтоБуква МОТОРНОГО МАСЛА 101

ПРОВЕРКА ДАВЛЕНИЯ МОТОРНОГО МАСЛА 101

проверка биения лицевой поверхности маховика 102

Дополнительные изображения:

Различные Товары

2,88 Мб

Руководство оператора двигателей DAF-Paccar MX (MX265,

Формат: pdf

-

Год:

2011

-

Страниц:

100

-

Язык:

английский

-

Размер:

2,88 Мб

-

Категории:

Двигатели Paccar