- Manuals

- Brands

- Minsk Tractor Works Manuals

- Tractor

- Belarus 1221B.2

- Disassembly-assembly manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

BELARUS

1221.2/1221В.2

1221.3/1221.4

1221-0000010 РРС

DISASSEMBLY-ASSEMBLY MANUAL

Minsk Tractor Works 2010

Summary of Contents for Minsk Tractor Works Belarus 1221B.2

-

Page 1

BELARUS 1221.2/1221В.2 1221.3/1221.4 1221-0000010 РРС DISASSEMBLY-ASSEMBLY MANUAL Minsk Tractor Works 2010… -

Page 2

You can obtain more detailed information from your dealer of trade mark BELARUS. _______________________________________________________________________ Minsk Tractor Works RUE, 2010 All rights reserved. No part of this manual may be reproduced in any form whatsoever without written permission of Minsk Tractor Works RUE. -

Page 3: Table Of Contents

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 CONTENTS INTRODUCTION …………………………..7 1 SAFETY REQUIREMENTS……………………….8 2 GENERAL …………………………..10 3 DISMOUNTING AND MOUNTING OF ENGINE AND ITS SYSTEMS …………..12 3.1 DISMOUNTING-MOUNTING OF ENGINES MMZ AND DEUTZ …………….12 3.2 DISMOUNTING OF SUPERCHARGED AIR COOLER (SAC), MOUNTED ON TRACTORS BELARUS-1221.320 3.3 DISMOUNTING OF SUPERCHARGED AIR COOLER (SAC), MOUNTED ON TRACTORS BELARUS-1221.4 WITH ENGINE MMZ …………………………

-

Page 4

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3 CLUTCH …………………………..44 4.3.1 DISASSEMBLY-ASSEMBLY OF CLUTCH CONTROL UNITS BELARUS-1221.2/1221.3/1221.4 ….44 4.3.1.1 DISASSEMBLY-ASSEMBLY OF CLUTCH CONTROL UNITS FOR BELARUS-1221В.2 ……45 4.3.2 DISASSEMBLY-ASSEMBLY OF CLUTCH COUPLING ………………48 4.3.3 MOUNTING DISKS OF CLUTCH COUPLING ON ENGINE FLYWHEEL …………51 4.3.4 ADJUSTING POSITION OF SQUEEZE LEVERS ………………… -

Page 5

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.14 ADJUSTMENT OF FOOT BRAKE, VALVE AND REGULATOR OF PNEUMATIC SYSTEM PRESSURE .. 115 4.6.15 ADJUSTMENT OF PARKING BRAKE, BRAKE VALVE AND REGULATOR OF PNEUMATIC SYSTEM PRESSURE …………………………..116 4.6.16 MULTI-DISK FOOT AND PARKING BRAKES OPERATING IN OIL BATH ……….117 4.6.18 DISASSEMBLY OF LEFT-SIDE MULTI-DISK BRAKE OPERATING IN OIL BATH …….. -

Page 6

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 7.1.1 DISASSEMBLY-ASSEMBLY OF UNITS OF THE HYDROSTATIC STEERING CONTROLMOUNTED ON TRACTORS BELARUS-1221.4 WITH ENGINE DEUTZ» ………………201 7.1.2 DISASSEMBLY-ASSEMBLY OF UNITS OF THE HYDROSTATIC STEERING CONTROLMOUNTED ON TRACTORS BELARUS-1221В.2 ……………………..204 7.2 STEERING COLUMN ……………………….207 7.2.1 DISASSEMBLY-ASSEMBLY OF STEERING COLUMN …………….. -

Page 7

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 11.1.1 DISMOUNTING ELEMENTS OF ELECTRICAL EQUIPMENT OF ENGINE (MMZ) MOUNTED ON TRACTORS BELARUS-1221.2/1221В.2 ……………………261 11.1.2 DISMOUNTING ELECTRICAL EQUIPMENT ELEMENTS OF ENGINE (MMZ) MOUNTED ON TRACTORS BELARUS-1221.3 …………………………262 11.1.3 DISMOUNTING ELECTRICAL EQUIPMENT ELEMENTS OF ENGINES (MMZ OR DEUTZ) MOUNTED ON TRACTORS BELARUS-1221.4 …………………….. -

Page 8: Introduction

Data contained in this manual is accurate at the time of this manual compilation. As tractors BELARUS are continually updated, Minsk Tractor Works PA reserves the right to introduce design amendments without notifying the customers. All data given in this manual can be amended, and illustrative materials can differ from those describing tractors currently manufactured.

-

Page 9: Safety Requirements

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 SAFETY REQUIREMENTS For your safety purpose carefully study this manual before starting maintenance and repair works. Pay particular attention to all warnings and recommendations given in this manual. Always consult operating and maintenance manual issued by the manufacturer. 1.

-

Page 10

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 10. For washing parts and assembly units use special washing agents. When using kerosene or benzene for washing, observe fire safety regulations; make washing in ventilated premises. Keep tidy working place where dismounting-mounting works are underway. 11. -

Page 11: General

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 2 GENERAL Tractor BELARUS 1221 and its modifications belong to general purpose row-crop wheeled tractors of traction class 2 with axle arrangement 4 x 4. They are designed for various agricultural works with mounted, half-mounted, trailer machines and implements, loading-unloading mechanisms, driving stationary agricultural machinery, as well as transport works in different climatic regions.

-

Page 12

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Steering is hydrostatic (HSC); supply pump is of gear type, actuating mechanism – two hydraulic cylinders of two-way action. Wheels with pneumatic low-pressure tires. Rear wheels – driving, front wheels – driving and guiding. Size of main tires: front wheels — 420/70R24;… -

Page 13: Dismounting And Mounting Of Engine And Its Systems

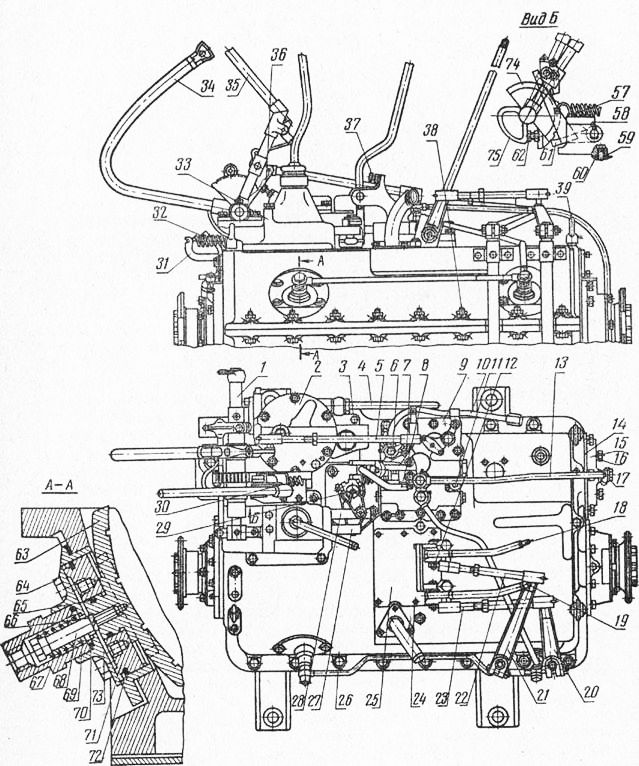

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3 DISMOUNTING AND MOUNTING OF ENGINE AND ITS SYSTEMS 3.1 Dismounting-mounting of engines MMZ and Deutz Dismounting-mounting engine MMZ, mounted on tractors BELARUS 1221.2/1221В.2/1221.3 Figure 3.1 Mounting engine (MMZ) on tractors BELARUS 1221.2/1221В.2/1221.3/1221.4 а) dismantle tractor facia, see section 8.2 “Dismounting-mounting of facia of tractor BELARUS 1221.2/1221В.2”;…

-

Page 14

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1) for tractors BELARUS 1221.2/1221В.2, see section 11.1.1 “Dismounting elements of engine electrical equipment (MMZ) mounted on tractors BELARUS 1221.2/1221В.2”; 2) for tractors BELARUS 1221.3, see sections: — 11.5.4 “Operations performed when replacing engine”; — 11.6.1 “Operations performed when replacing engine”; — 11.7.1 “Operations performed when replacing engine”;… -

Page 15

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 j) disconnect fuel lines from coarse fuel filter 6 (Figure 3.3), installed only on tractor BELARUS 1221.4 with engine MMZ; Figure 3.3 Mounting coarse fuel filter on MMZ. k) dismantle air purifier, as described in section 3.9 “Disassembly-assembly of air purifier unit installed on tractors BELARUS 1221.2/1221В.2/1221.3/1221.4 (with engine MMZ)”;… -

Page 16

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1- support fastening bolt; 2- adjustment bolt; 3- check nut; 4- support; 5- shock absorber Figure 3.4 Front engine support o) connect lifting mechanism to diesel, for slinging diagram see (Figures 3.5); 1 – eye bolt; 2 –steel rope (chain); 3 – beam; 4 – grip; Figure 3.5 Diagram of slinging diesel MMZ… -

Page 17

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 p) separate front driving axle together with spars and radiators from tractor and roll it away from diesel; ATTENTION! To prevent turning over of front axle take off ballast loads or put supports under them. q) unscrew bolts 10, 11 (Figure 3.1) that fasten rear diesel sheet to clutch body, disconnect diesel having pulled it forward until clutch coupling goes out of clutch body bell, and raise it using lifting mechanism;… -

Page 18

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 а) Dismantle tractor facia, see section 8.3 “Dismounting-mounting facia of tractor BELARUS 1221.3/1221.4”; b) drain cooling fluid from tractor cooling system; c) drain oil from engine, having unscrewed plug in lower section of engine casing; d) drain oil from HSC system, see section 7.1.1 “Disassembly-assembly of hydrostatic steering controlunits mounted on tractors BELARUS 1221.4 with engine Deutz”;… -

Page 19

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 i) dismantle air purifier, as described in section 3.10 “Disassembly-assembly of air purifier unit mounted on tractors BELARUS 1221.4 Deutz”; l) dismantle HSC oil lines 8, 5 (Figure 3.8) and undock from engine oil lines 10 by dismounting brace 9;… -

Page 20

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 3.9 Diagram of slinging engine Deutz р) undock FDA with front bar and radiators from tractor, and roll it aside from diesel; ATTENTION! To prevent FDA turning over remove ballast loads or put supports under them. q) unscrew bolts (Figure 3.6) that fasten rear diesel sheet to clutch body, disconnect diesel having pulled it forward until clutch coupling goes out of clutch body bell, and raise it using lifting mechanism;… -

Page 21

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.2 Dismounting of supercharged air cooler (SAC), mounted on tractors BELARUS-1221.3 а) loosen collars 2 (Figure 3.10) and shift heat-resistant silicon branch pipes 3 off air conduits 1 and cooler 8; b) unscrew bolts 4, 5, 7 that fasten cooler to water radiator and air conduit to inlet collector, remove cooler, air conduit and spacer 6. -

Page 22: With Engine Mmz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.3 Dismounting of supercharged air cooler (SAC), mounted on tractors BELARUS-1221.4 with engine MMZ а) loosen collars 10, 11, 12 (Figure 3.11); b) shift heat-resistant silicon branch pipes 13, 14, 15, 16 off air conduits 1, 2, 3 and supercharged air cooler 9;…

-

Page 23: Dismounting Of Supercharged Air Cooler (Sac), Mounted On Tractors Belarus-1221.4

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.4 Dismounting of supercharged air cooler (SAC), mounted on tractors BELARUS-1221.4 with engine Deutz а) loosen collars 12 (Figure 3.12) and shift heat-resistant silicon branch pipes 5, 14, 15 off air conduits 1, 2, 3 and supercharged air cooler 16; b) unscrew bolts fastening the cooler to water radiator and dismantle the cooler.

-

Page 24: Dismounting-Mounting Of Cooling System Mounted On Tractors Belarus-1221.4 With Engine Mmz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.5 Dismounting-mounting of cooling system mounted on tractors BELARUS-1221.4 with engine MMZ а) drain cooling fluid from tractor cooling system; b) untignten collars 2 (Figure 3.13) and disconnect hoses 7, 8; c) unscrew three bolts 18, 21 and dismantle expansion tank 14; d) dismantle SAC, as described in section 3.3 “Dismounting supercharged air cooler (SAC), mounted on tractors BELARUS-1221.4 with engine MMZ”;…

-

Page 25: Dismounting-Mounting Of Cooling System Mounted On Tractors Belarus-1221.4 With Engine Deutz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.6 Dismounting-mounting of cooling system mounted on tractors BELARUS-1221.4 with engine Deutz Figure 3.14 Cooling system a) drain cooling fluid from tractor cooling system; b) disconnect hose 10, sleeves 29, 30, 31 from radiator 24 (Figure 3.14); c) unscrew two bolts 15 and dismantle expansion tank 4;…

-

Page 26: 1221.2/1221В.2/1221.3 With Engine Mmz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting-mounting cooling system mounted tractors BELARUS- 1221.2/1221В.2/1221.3 with engine MMZ а) drain cooling fluid from tractor cooling system; b) untighten collars 7 (Figure 3.15) or 49, 48 and disconnect hoses 14, 16, 26; c) unscrew three bolts 31, 32, 33 and dismantle expansion tank ок 24; d) disconnect wires of terminal carrier socket, if installed, on fan diffuser 6;…

-

Page 27: Disassembly-Assembly Of Fuel Tank 1221-1101500, Mounted On Tractors Belarus

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.8 Disassembly-assembly of fuel tank 1221-1101500, mounted on tractors BELARUS- 1221.2/1221В.2/1221.3/1221.4 with engines MMZ and Deutz, with two cylinders of lift linkage (hydraulic lift of the hydraulic system) 1) drain diesel fuel out of tank 22 (Figure 3.16) via draing point 30; 2) dismantle draining point 30;…

-

Page 28

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 3.16 Fuel tank… -

Page 29: Disassembly-Assembly Of Air Purifier Unit Mounted On Tractors Belarus- 1221.2/1221В.2/1221.3/1221.4 (Mmz)

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.9 Disassembly-assembly of air purifier unit mounted on tractors BELARUS- 1221.2/1221В.2/1221.3/1221.4 (MMZ) а) dismount facia, as described in in section 8.3 “Dismounting-mounting facia of tractors BELARUS-1221.3/1221.4”; b) loosen collars 6 and 9 (Figure 3.17); c) dismantle branch pipes 7, 10 and air conduit 8; d) loosen collars 11;…

-

Page 30: Disassembly-Assembly Of Air Purifier Unit Mounted On Tractors Belarus-1221.4 Deutz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.10 Disassembly-assembly of air purifier unit mounted on tractors BELARUS-1221.4 Deutz а) dismount facia, as described in in section 8.3 “Dismounting-mounting of facia of tractors BELARUS-1221.3/1221.4”; b) unscrew bolts 15 (Figure 3.18); c) dismantle arms 16, 17; d) loosen collars 12;…

-

Page 31: Disassembly-Assembly Of Exhaust System Of Tractors Belarus-1221.4

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.11 Disassembly-assembly of exhaust system of tractors BELARUS-1221.4 а) unscrew bolts 4 (Figure 3.19); b) dismantle guarding 5; c) loosening fastening of collars 7; d) dismantle metal sleeve 6; e) loosening fastening of collars 20; f) dismantle metal sleeve 19;…

-

Page 32

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – outlet pipe; 2, 4, 10, 11, 13, 15, 18 – bolt; 3 – damper; 5 – guarding; 6 – metal sleeve; 7 – collar; 8 – nut; 9 – brace; 12 – support; 14 – cross piece; 16 – spacer; 17 – branch pipe; 19 – metal sleeve;… -

Page 33: Disassembly-Assembly Of Fuel Supply Control Mounted On Tractors Belarus-1221В.2

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.12 Disassembly-assembly of fuel supply control mounted on tractors BELARUS-1221В.2 а) dismantle manual control of fuel supply, and to do this dismantle cover of right side panel, see section 8.4 “Disassembly-assembly of facia panels of right side panel”; b) dismantle tie-rods 20, 22, 23 (Figure 3.20), having disconnected cotter pins 19 and pins 18;…

-

Page 34

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4… -

Page 35: Disassembly-Assembly Of Fuel Supply Control, Mounted On Tractors Belarus- 1221.2/1221.3

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.13 Disassembly-assembly of fuel supply control, mounted on tractors BELARUS- 1221.2/1221.3 а) Dismount cover of right side panel, see section 8.4 “Disassembly-assembly of facia panels of right side panel”; b) dismantle tie-rods 20, 22, 23, (Figure 3.21) having disconnected cotter pins 19 and pins 18; c) unscrew nuts 8;…

-

Page 36

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4… -

Page 37: Disassembly-Assembly Of Fuel Supply Control, Mounted On Tractors Belarus-1221.4

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3.14 Disassembly-assembly of fuel supply control, mounted on tractors BELARUS-1221.4 with engines MMZ и Deutz а) disconnect harness 33 (Figure 3.22); b) unscrew bolts 25, 29 and 32; c) dismantle pedal 24 and plate 28; d) dismantle cover of right side panel, see section 8.4 “Disassembly-assembly of facia panels of right side panel”;…

-

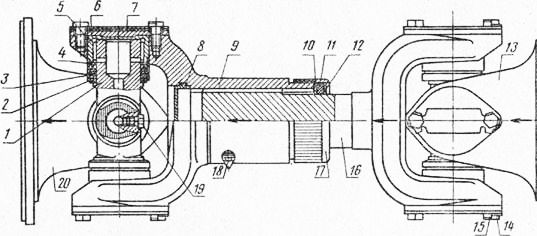

Page 38: Transmission

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4 TRANSMISSION Transmission is designed for transfer and conversion of torque from engine to rear drive wheels, drive of front driving axle and rear PTO shank, as well as for driving pump of hydraulic hinge system.

-

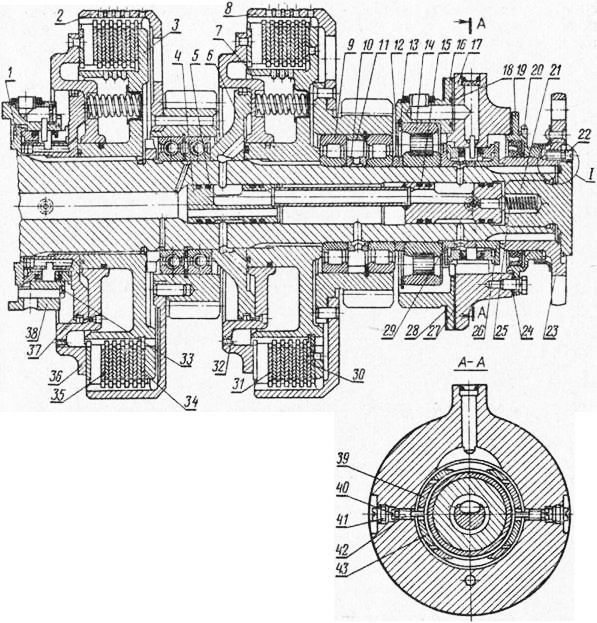

Page 39

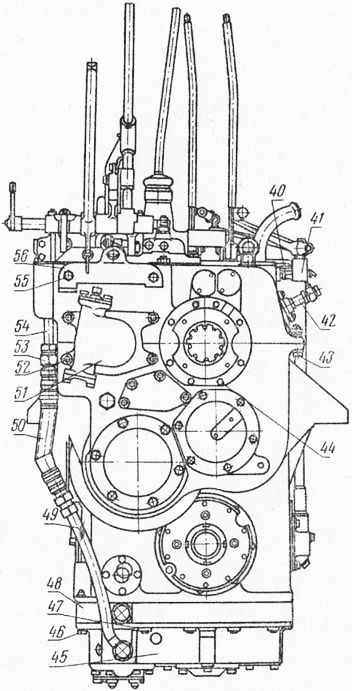

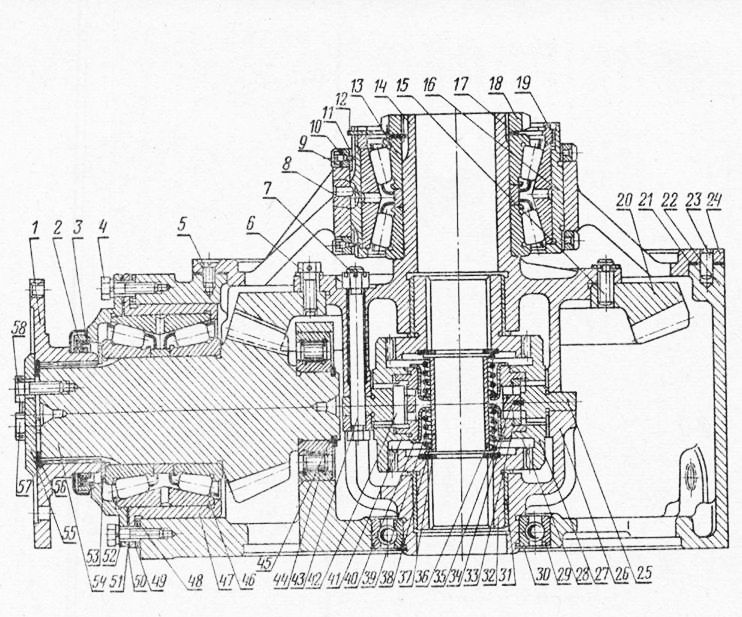

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 21 – tie-rod of clutch; 22 – shaft of FDA drive; 26 – bolts for fastening GB levers; 27 – cardan shaft of FDA. Figure 4.2 Technical data: Torque for tightening bolts of butt between clutch coupling body and GSB body is 320…400 N·m; butt of GSB body –… -

Page 40: Transmission Disassembly (General Provisions)

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.1 Transmission disassembly (general provisions) a) drain oil from transmission, having unscrewed two draining plugs; b) put transmission with engine on supports; c) disconnect and dismantle pipelines of control system and transmission lubrication system passing through bodies’ butts; d) disconnect transmission from engine and dismantle tractor parts and units that hinder further disassembly;…

-

Page 41: Dismounting (Disconnection) Of Clutch Coupling Body

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 g) dismantle HSC metal oil lines by having disconnected them from high-pressure sleeves: 1) for tractors BELARUS-1221.2/1221.3/1221.4 (MMZ) see section 7.1 “Disassembly-assembly of hydrostatic steering controlunits mounted on tractors BELARUS-1221.2/1221.3/1221.4 with engine MMZ”; 2) for tractors BELARUS-1221В.2, see section 7.1.2 “Disassembly-assembly of hydrostatic steering controlunits mounted on tractors BELARUS-1221В.2”;…

-

Page 42

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) disconnect oil line 2 for lubrication of the shell of FDA drive cardan shaft (Figure 4.1); g) disconnect harness of FDA control, see section: 1) for tractors BELARUS-1221.3: — 11.5.3 “Control of DI and FDA 1221-8700410 (electrical part), mounted on tractors BELARUS- 1221.3”;… -

Page 43: Dismounting (Disconnection) Of Gear Box Body

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 n) dismantle oil tank, see section 9.1.1 “Disassembly-assembly of hydraulic system units. Dismounting of oil tank from tractor with cabin dismantled (for hydraulic system with distributor RP 70-1221); or Dismounting of oil tank from tractor with cabin dismantled (for hydraulic system with distributor RS 213 Mita)”;…

-

Page 44: Transmission Assembly

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) bring under gear box (GB) body screwed support Р 7010-00 (or identical to it) (Figure 4.6) until it fully touches GB body; g) to disconnect butt “GB body – RA body” remove GB cover 19 (Figure 4.1) and cover of FDA 9 to get access to bolts to be unscrewed, then unscrew ten bolts (М18) 17 and two nuts 11, and take the units apart.

-

Page 45: Clutch

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3 Clutch 4.3.1 Disassembly-assembly of clutch control units BELARUS-1221.2/1221.3/1221.4 а) unscrew bolt 4 (Figure 4.7), remove rod 2 and strap 1; b) disconnect tie-rod 22, having pulled out pins 13; c) unscrew yokes 24 and nuts 23 off tie-rod 22; d) remove washer (20) and spring (21);…

-

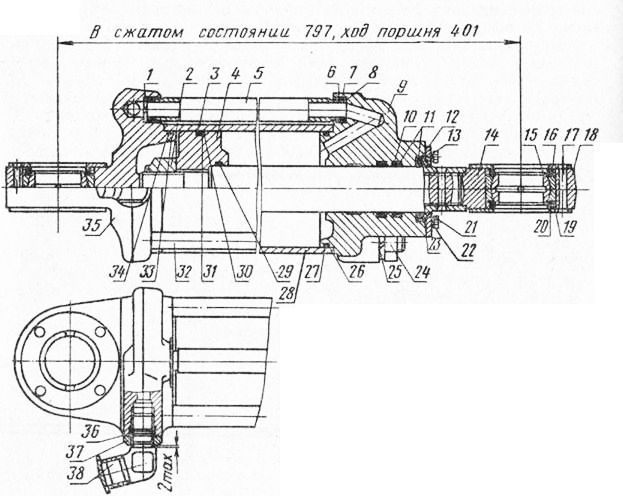

Page 46: Disassembly-Assembly Of Clutch Control Units For Belarus-1221В.2

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3.1.1 Disassembly-assembly of clutch control units for BELARUS-1221В.2 Observe the following sequence of disassembly of clutch control units (Figure 4.8): Figure 4.8 Clutch control…

-

Page 47

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.9 Working cylinder а) drain brake fluid from the system, and to do it: 1) remove protective cap 8 (Figure 4.9) from the working cylinder; 2) put on pipe connection 9 one end of hose and put another end in clean vessel; 3) unscrew pipe connection 9 by half turn: 3.1) keep pressing pedal 39 (Figure 4.8) until fluid is released from hydraulic system on reversal;… -

Page 48

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 3) unscrew nut 11 and tie-rod 12; 4) unscrew cover 10, remove ring 15; 5) make assembly of working cylinder in sequence reverse to disassembly; Figure 4.10. Main cylinder of clutch control on reversal e) disassembly hydraulic booster (Figure 4.11); to do this; 1) remove covers 3, having unscrewed bolts 8, 10;… -

Page 49: Disassembly-Assembly Of Clutch Coupling

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Make assembly and mounting of parts and assemblies of clutch control in sequence reverse to disassembly. Before assemblying main and working cylinders hydraulic boosters must be clean. Presence of foreign particles (dust, paint, chips, pile) is not allowed. Before assembly of main cylinder and working cylinder on reversal grease friction surfaces with thin layer of braking fluid NEVA-M under Specification TU 2451-053-36732629-2003.

-

Page 50

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.13 f) remove second driven disk 7 (Figure 4.14); Figure 4.14 g) install squeezing device 1 on disks as an assembly (Figure 4.15);… -

Page 51

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.15 h) unscrew technological bolts 2 (Figure 4.15) (М12х40); i) dismantle retaining plates 3 by unscrewing six bolts 5 and pull out adjustment nuts 4; j) unscrew nut of squeezing device and dismount supporting disk; l) unpin pin and dismount axles of squeeze levers and squeeze levers. -

Page 52: Mounting Disks Of Clutch Coupling On Engine Flywheel

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3.3 Mounting disks of clutch coupling on engine flywheel Perform mounting of clutch coupling disks on engine flywheel in the following order: а) mount first driven disk with hub long end facing flywheel; b) mount middle disk as an assembly inside flywheel along three grooves; c) mount second driven disk with hub short end facing middle disk;…

-

Page 53

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.19 c) adjust position of squeeze levers by adjustment nuts 1, having set distance from supporting surfaces of levers to end face of supporting disk hub equal to 13.5…14.5 mm. Figure 4.20 Variation of dimension for individual leverов must not exceed 0.3 mm. After adjustment secure nuts 4 (Figure 4.20) against turning through by retaining plates 5. -

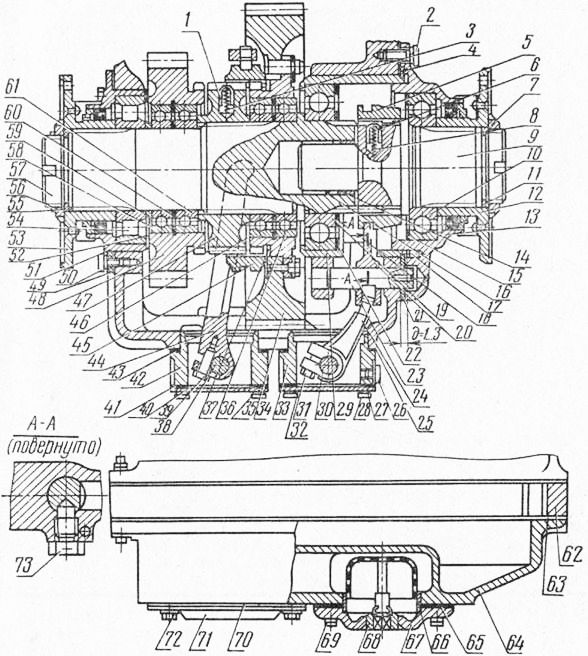

Page 54: Reduction Gear Section Of Clutch Coupling Body

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3.5 Reduction gear section of clutch coupling body Drive shaft 6 (Figure 4.21) of stand-alone PTO, mounted on two bearings 3 and 5, has two gear rings. Smaller gear ring is permanently engaged with gear 2 of pump drive for hydraulic hinge system, and gear 14 of the first stage of PTO reduction gear;…

-

Page 55: Disassembly Of The Reduction Gear Section Of Clutch Coupling Body

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3.6 Disassembly of the reduction gear section of clutch coupling body 1 – shaft; 2 – bolt; 3 – yoke; 4 – bearing; 5 – tap; 6 – nut; 7 – arm; 8 – spacer; 9 – sealing ring; 10 –…

-

Page 56

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 а) first drain oil from clutch coupling body. b) disconnect tractor skeleton in plane “diesel”- “clutch body” — «gear box c) disconnect and remove meshed filler neck, side and bottom covers, covers’ spacers. To dismount lever of switching clutch coupling and tie-rod, do the following: а) unpin pin and pull out pin 2 (Figure 4.23), disconnect tie-rod 1. -

Page 57

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.25 c) press bearing 1 from shaft (Figure 4.26); Figure 4.26 d) unscrew crown nut 1 (Figure 4.27) of PTO drive driven shaft; Figure 4.27 e) knock driven shaft 1 (Figure 4.28) of PTO drive outwards and extract it from clutch body together with gear of stage II;… -

Page 58

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.28 h) remove ring 1 (Figure 4.29) that locks gear 2 on shaft 4; i) remove washer 3 and gear 2; Figure 4.29 j) remove bearing 1 (Figure 4.30) from shaft 2; Figure 4.30 k) remove locking wire, unscrew bolt 3 (Figure 4.31) for fastening yoke 2;… -

Page 59

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.31 m) unscrew bolt 5 (Figure 4.32) and remove plate 6; n) knock roller 4 inside clutch body; o) extract yoke 2 (Figure 4.31) and gear 7 (Figure 4.33) of I stage of reduction gear. Figure 4.32 Figure 4.33 To dismount pump driving gears of transmission hydraulic system do the following:… -

Page 60

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.34 b) press out gear 1 (Figure 4.35) together with axle, bearingом and locking ring; c) remove washer 2; Figure 4.35 d) remove locking ring 3 (Figure 4.36 а); e) press axle 1 (Figure 4.36 а) with bearing 2 off gear 4 (Figure 4.36 б); f) press bearing off axle;… -

Page 61

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 g) press out shaft-gear 1 (Figure 4.37) together with bearingом and locking ring; h) pull out gear 2; Figure 4.37 i) remove locking ring 1 (Figure 4.38); j) press out bearing 2; Figure 4.38 k) press bearing 1 (Figure 4.39) off clutch body. Figure 4.39… -

Page 62

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 To dismount driving gear of hinge hydraulic system pump do the following: а) unscrew bolt 2 (Figure 4.40) and remove thrust washer 3; b) unscrew two bolts 1 and remove bar 4; Figure 4.40 c) using knocker 1 (Figure 4.41) press gear axle off clutch body; Figure 4.41 d) pull out gear 2 (Figure 4.42) with two bearings and two rings through upper hatch of clutch body;… -

Page 63

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) turn gear over and press our the second bearing; Figure 4.43 g) press out bushing 1 (Figure 4.44); Figure 4.44 To dismount shaft of driving PTO drive, tap arm do the following: а) unscrew three nuts 1 (Figure 4.45); b) inside threaded openings of tap arm 2 screw technological bolts (М10 х30) 3 and using them press tap arm off clutch body;… -

Page 64

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 d) press off clutch body driving shaft of PTO drive 1 (Figure 4.46) with two bearings; Figure 4.46 e) press sealing ring off tap arm (Figure 4.47); Figure 4.47 f) press bearing 1 off driving shaft of PTO drive (Figure 4.48); Figure 4.48… -

Page 65

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 g) remove locking ring 1 from the shaft (Figure 4.49); Figure 4.49 h) press the second bearing 2 off the shaft (Figure 4.50); Figure 4.50 g) press sealing ring 1 (Figure 4.51) off the shaft of PTO drive. Figure 4.51… -

Page 66: Assembly Of Clutch Coupling Body

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.3.7 Assembly of clutch coupling body Make assembly in sequence reverse to disassembly, and while doing so,: а) lubricate with consistent grease cavities of sealing rings pressed inside tap arm and driving shaft of PTO drive, as well as friction surfaces of tap arm, surface of roller 4 (Figure 4.32). b) gears and shafts must freely and without jams rotate in bearings.

-

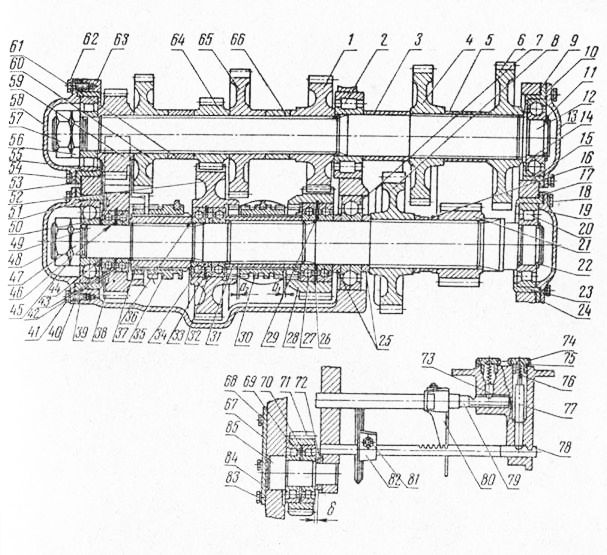

Page 67: Gear Box

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.4 Gear box 4.4.1 Disassembly of gear box. Dismounting gear box а) unscrew bolts 1 (Figure 4.52), remove cover 2 of GB control; Figure 4.52 b) remove small collars 12 (Figure 4.53) anf disconnect hoses 13 of rear PTO drive; c) unscrew bolts 5, 9 and dismantle pipelines: 4 lubrications of FDA bushing, pipeline 2 –…

-

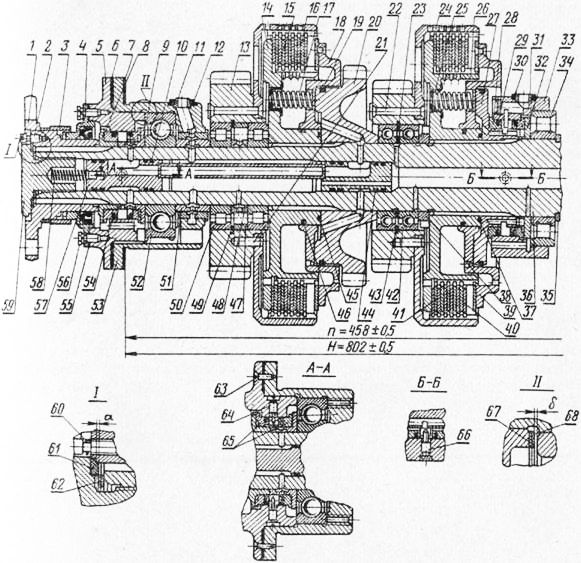

Page 68: Dismounting Hydraulic System Units, Gears’ Assembly And Gear Shifting Yokes

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.54 4.4.2 Dismounting hydraulic system units, gears’ assembly and gear shifting yokes а) unscrew bolts 1 (Figure 4.55) and dismount left side cover 2; Figure 4.55 b) move lever for switching on transmission pump 1 (Figure 4.56) clockwise to the end; Figure 4.56 c) unscrew fastening bolts 2 (Figure 4.56), using dismounting bolts 3 remove pump drive 4 (Figure 4.57) as an assembly;…

-

Page 69

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.57 d) unscrew bolts 2 (Figure 4.58), dismantle filter-distributor 1, meshed filter 3 and spacers; Figure 4.58 e) unscrew bolts 1 (Figure 4.59) and dismount yokes’ body 2 as an assembly with yokes;… -

Page 70

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.59 f) extract driving shaft of rear power-take-off 6 (Figure 4.60); g) remove collars 5 and disconnect pipe 3 for lubrication supply to primary shaft 2; h) unscrew bolts 1 and nut 7 for fastening cup 4 to GB body, screw two bolts in technological openings “А”… -

Page 71

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 j) remove springs 6, 11, fixing elements 1, 10, pin 5, balls 2, 4, 9, 18, and axle 3; Figure 4.61 k) unpin and unscrew bolts 2 (Figure 4.62) of yokes 1 on leads 3, knock leads out of body and pull out yokes;… -

Page 72: Disassembly Of Gears’ Assembly

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.63 4.4.3 Disassembly of gears’ assembly а) unscrew bolts 1 (Figure 4.64) and remove bushing of lubricant conduit 3 , cover 2 , cup 4; b) unscrew nuts 5, dismount thrust washers; Figure 4.64 с) press cup 9 (Figure 4.65) together with bearings 6 off shafts 7 and 8;…

-

Page 73

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.65 Disassembly of primary shaft: а) remove washer 1 (Figure 4.66), gear 3, bearing 2, synchronizer 6; Figure 4.66 b) remove locking ring 4, press bushing of synchronizer 5, remove gear 7 and bearing 8; с) press bearing 19 (Figure 4.68) off shaft 9 (Figure 4.67), bearing 17 (Figure 4.68), gear 16, synchronizer 13. -

Page 74

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 d) remove locking ring 15, bushing of synchronizer 14, bearing 11, gear 12. Figure 4.68 Disassembly of intermediate shaft: а) press off intermediate shaft 5 (Figure 4.69) gears 1, 2, 3, 4; Figure 4.69 b) dismantle bushings 1 (Figure 4.70); Figure 4.70 с) press off bearing 1 (Figure 4.71);… -

Page 75

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.71 d) press off cup 3 (Figure 4.72) bearings 1 and 2. Figure 4.72 4.4.4 Disassembly of reduction gear section. Secondary shaft Figure 4.73… -

Page 76

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 To Figure 4.73: 1 – nut; 2 – washer; 3 – bearing; 4 – ring; 5 – washer; 6 – washer; 7 – bearing; 8 – gear; 9 – clutch; 10 – bushing; 11 — gear; 12 — gear; 13 — seat; 14 — washer; 15 — bolt; 16 — bearing; 17 — shaft; 18 — spacer;… -

Page 77

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.75 e) press off cup 1 (Figure 4.76) external bearing shell; Figure 4.76 f) press off shaft 1 (Figure 4.77) internal shell of bearing 2. Figure 4.77… -

Page 78: Disassembly Of Reduced Gears’ Shaft

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.4.5 Disassembly of reduced gears’ shaft 1 — pipe; 2 – pipe connection; 3 — cup; 4 — bolt; 5 — washer; 6 — throttle; 7 — nut; 8 — washer; 9 — bearing; 10 — washer; 11 — gear; 12 — gear; 13 — ring; 14 — bushing; 15 — bearing; 16 — gear; 17 — clutch;…

-

Page 79

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 с) unscrew nut 1 (Figure 4.81) and remove cup 2; Figure 4.81 d) unscrew bolts 1 (Figure 4.82) and remove locking bars 2; Figure 4.82 e) knock out shaft 1 (Figure 4.83) so that to remove locking ring 2; Figure 4.83 f) knock out shaft with bearings, bushing and nut, as shown in figure 4.84;… -

Page 80

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.84 g) extract from GB body gears, bushings and tooth clutch (Figure 4.85); Figure 4.85 h) unscrew nut 1 (Figure 4.86); i) press bearing 2 off shaft; j) remove bushing 3, bearing 4. Figure 4.86… -

Page 81: Disassembly Of Gear Train Shaft

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.4.6 Disassembly of gear train shaft 1 – shaft; 2 – ring; 3 – bearing; 4 – gear; 5 – ring; 6 – gear; 7 – bearing; 8 – bushing; 9 – bearing; 10 – gear; 11 – bushing; 12 – bearing; 13 – bar; 14 – washer; 15 – bolt; 16 – bushing; 17 – impeller; 18 –…

-

Page 82

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.89 с) press bearing 1 (Figure 4.90) off gear 2; Figure 4.90 d) through opening in gear 1 (Figure 4.91) press external shell of bearing 2 off gear boring, extract bushing 4 and bearing 3; Figure 4.91… -

Page 83

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) using puller press off shaft 1 (Figure 4.92) gear 2 with internal bearing shell; Figure 4.92 f) remove locking ring 1 (Figure 4.93), knock out shaft 2, extract gear 3; Figure 4.93 Dismount FDA drive in accordance with recommendations of section “Disassembly of FDA drive”… -

Page 84

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 b) unpin washer 2 (Figure 4.95) and unscrew bolt 3, dismantle yoke 1; Figure 4.95 с) unscrew bolt 11 (Figure 4.96) and extract washer 12, spring 10, guide 9, ball 8 and lead 7; Figure 4.96 d) remove locking ring 5, unscrew bolt 1 and remove plate 2;… -

Page 85: Disassembly Of Control Mechanism

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.4.7 Disassembly of control mechanism а) unscrew bolts 4 (Figure 4.97), remove cover 6 and spacer 5; b) dismantle clamps 9 and sheathes 8; с) unpin pin and knock out pins 2, 7; d) pull out levers 1, remove yokes 17, 18 and springs 16; e) extract spherical joints 3;…

-

Page 86: Assembly Of Gear Box

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.4.8 Assembly of gear box Assembly GB in reverse order. Parts must be washed. Bearings, balls and friction bushings must be lubricated with oil. Torques of boltов: 8 – 1.4…1.7 kgf m; 16 — 12.. .14 kgf m; 10 — 3…3.5 kgf m;…

-

Page 87

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.98… -

Page 88: Rear Axle

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.5 Rear axle 4.5.1 Disassembly of rear axle а) unscrew cap nut 1 of oil line 5 (Figure 4.99); b) unscrew bolts 2 for fastening housing 3 of interlock clutch of differential and foot brake; с) dismantle housing 3 with adapter 4;…

-

Page 89

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 А – dismounting opening; 1 – left-side sleeve of half-axle; 2 – bolt; 3 – left-side cup; 4 – bushing; 5 – driven gear; 6 – cover; 7 – differential as an assembly; 8 – bearing; 9 – driven gear; 10 – right-side cup;… -

Page 90

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Differential а) fix differential as an assembly in bench vice or special device; b) unscrew bolts 2 (Figure 4.102), disconnect cover 3 of differential and remove it; с) remove washer 4, gear 5; d) pull out cross-piece 6 with satellites 7, washers 8 and rollers 17; e) extract gear 15 and washer 14;… -

Page 91

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Differential interlocking clutch а) unscrew bolts 12 (Figure 4.104); b) remove cover 13, diaphragm 14, squeeze disk 15, shaft 16, disks 17, 18, 19, 20; 1 – body; 2 – ring; 3 – bushing; 4 – spring; 5 – ring; 6 – connection pipe; 7 – adapter; 8 – sealant; 9 –… -

Page 92

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Final drive а) fix half-axle 3 (Figure 4.106) to prevent turning through; b) remove locking washer 14, unscrew 15 and dismount carrier as an assembly; с) remove crown gear 11; d) unbend locking plates 18 and unscrew bolts 17; e) screw two bolts Ml8 inside dismounting openings of hub flange 10;… -

Page 93

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 i) using inertion hammer press external shell of bearing 2 off sleeve 3, pull out ring 1 (Figure 4.108). Figure 4.108 Carrier а) using knocker knock out build-up pins 5 aiming to centre (Figure 4.109), via spacer of soft metal press out axles 6 of satellites;… -

Page 94

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – bearing; 2 – gear; 3 – bearing; 4 – cup; 5 – ring; 6 – shell; 7 – shaft; 8 – sealing ring; 9 – locking ring; 10 – sealing ring; 11 – thrust ring; 12 – external shell of bearing. Figure 4.110 с) press out shell 6 with sealing ring as an assembly using puller and two dismountin threaded openining in shell;… -

Page 95: Assembly Of Rear Axle

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.112 g) using gear 2 (Figure 4.113) and stand press off shaft 3 internal shell 1 of bearing; Figure 4.113 4.5.2 Assembly of rear axle Differential а) put differential body 13 (Figure 4.114) in vertical position using bench vice or a device; b) put on differential body 13 gear 10, secure it with bolts 11, nuts 9 with locking plates 16;…

-

Page 96

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 in oil. Check quality of assembly: insert in differential drive gear shaft of main drive and also check half- axle gear 5 which must turn through with satellites 7 and gear 15 without jams. ATTENTION! Before starting the assembly lubricate washers 4 and 14, gears 5 and 15, pins of cross-piece 6, rollers 17, satellites 7 and washers 8 with transmission oil. -

Page 97

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) install on half-axle splines carrier 3 as an assembly, washer 12 and torque 10 to 200…220 N m (20…22 kgf/l) without spacers 11, while turning half-axle for rollers of bearings to take proper position; g) release bolt 10 and tighten it again by hand;… -

Page 98

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Shaft-torsion а) mount bushing 3 (Figure 4.116) on splines of torsion 4 to the end on collar; b) mount on splines of torsion 4 gear 2 and secure it locking ring 1. Figure 4.116 Carrier, cup, clutch of differential interlock Make assembly of carrier, cup in sequence reverse to disassembly. -

Page 99

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 ATTENTION! Total thickness of diametrically opposite stacks of spacers must be identical. d) insert bearings 6 inside borings of body 3 to the end; e) press bearings 8 (Figure 4.118) inside seats of cups 7; 7 –… -

Page 100

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 7 – top cover; 8, 13 – sleeve; 9 – locking bolt; 10 – PTO crown gear; 11 — PTO drive clutch; 12 – bolt. Figure 4.120 j) install sleeves 8 and 13 (Figure 4.120) as an assembly with planetary mechanisms and tighten them with bolts 12 (М=18…22 kgf/l);… -

Page 101: Adjusting Rear Axle

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 m) mount foot and parking-reserve brakes, differential imtelock clutch, see section 4.6 “Brakes”; n)mount top cover of rear axle and secure it with bolts; o) mount hubs for fastening rear wheels, and to do this: 1) mount hub 2 (Figure 4.122) on half-axle;…

-

Page 102

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 b) unscrew bolts for fastening cup 2 (Figure 4.124) and screwing them inside dismounting openinings in flange, press out the cup to extent allowing free dismantling of adjustment shims 4; с) by reducing thickness of stack of spacers 4 under flange of left cup 2, obtain such tension of differential bearings, that effort applied to external end face of driven gear teeth of main drive in order to turn through differential in bearings was in the range of 3..5 kgf (30…50 N). -

Page 103

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 b) fix gear 2 (Figure 4.126) against turning through and, while swinging driven gear 4, measure lateral clearance in the engagement. Measure clearance at least in three positions of driven gear 4 in every 120°. 1 –… -

Page 104

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 If tooth contact doesn’t correspond to the above-mentioned conditions, adjust engagement following recommendations given in table. Table 4.1 Position of tooth contact on driven gear The way to obtain correct engagement Diagram of gears Forward Back run Correct gears’… -

Page 105: Brakes

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6 Brakes Tractors are equipped with foot-driven working brakes and separate parking stand-by brake with manually driven lever. Left- and right-side foot brakes are engaged for simultaneous braking of both wheels with interlocked pedals, or separately for brake left or right wheel. Separate braking is used in performing some works when enhanced tractor, or tractor aggregate manoevrability is required with minimum turning radii through inside wheel braking.

-

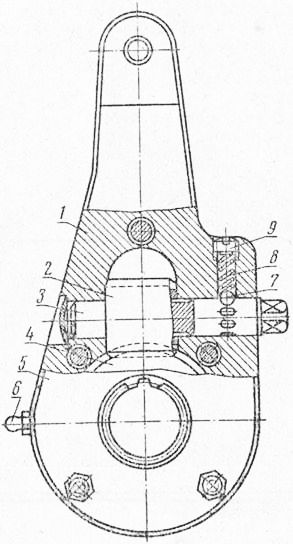

Page 106: Dismounting Of Parking And Right-Side Foot Brake As An Assembly

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.1 Dismounting of parking and right-side foot brake as an assembly 1.- brake shaft; 2 – braking disk; 3 – tie-rod; 4 – yoke; 5 – pin; 6 – pin; 7 – sheath; 8 – lever; 9 – spherical washer;…

-

Page 107: Disassembly Of Lever For Parking Brake Control

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.3 Disassembly of lever for parking brake control а) remove lever 2 (Figure 4.129) as an assembly with tie-rod 11 from axle 15 by unscrewing nut 8; b) remove sector (5) from cabin side plate, by unscrewing nuts (7); с) loosen check nut 12 and unscrew yoke 13 from yie-rod 11;…

-

Page 108: Dismounting Of Brakes’ Levers

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.4 Dismounting of brakes’ levers а) unscrew bolts 25 (Figure 4.130) and remove pedals with rods 1, 2; b) remove return springs 24 of brakes levers 3, 4, remove cotter pin 26 and washer 27 from roller 18, unscrew bolt 5, remove right-side lever 3, unscrew bolt 7 and remove left-side lever 4;…

-

Page 109: Disassembly Of Differential Interlock Clutch

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – fastening bolt; 2 – adjustment bolt; 3 – oil line of rear axle DI; 4 – cap nut; 5 – adapter; 6 – DI housing; 7 – housing of left-side brake. Figure 4.131 4.6.6 Disassembly of differential interlock clutch а) unscrew bolts 9 (Figure 4.132) and remove 7, diaphragm 6 and pressure disk 5;…

-

Page 110: Dismounting Of Left-Side Foot Brake

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 During subsequent assembly: а) disks 2 (Figure 4.132) must move along splines of interlock shaft (4) under its own weight; b) disks’ facia should have no traces of oil or grease; c) bolts 9 must be torqued to 14…18 N•m. 4.6.7 Dismounting of left-side foot brake Unpin checknut and unscrew adjustment bolt-tie-rod 17 (Figure 4.133), remove spherical washer.

-

Page 111: Disassembly Of Right-Side Three-Disk Brake

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Assembly of right-side two-disk brake (dry) а) put thin coating of grease LITOL-24 on surface of profile grooves of disks 3 (Figure 4.133), put five balls inside them 5; b) mount second pressure disk 3 with grooves on balls and tighten them with springs 4; с) mount tie-rods 10, naving connected them with disks 3 by means of pins 14, and with yoke 12 –…

-

Page 112: Assembly Of Right-Side Three-Disk Brake (Dry Type)

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – housing; 2 – brake disk; 3 – pressure disk; 4 – tightening spring; 5 – pin; 6 – tie-rod; 7 – yoke; 8 – pin; 9 – checknut; 10 – spherical washer; 11 – adjustment bolt; 12 – cotter pin; 13 – nut; 14 – steel ball (5 pcs.);…

-

Page 113: Assembly Of Left-Side Foot Brake And Differential Interlock Clutch

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.11 Assembly of left-side foot brake and differential interlock clutch а) make assembly and installation of the left-side brake in a way similar to assembly and installation of the right-side foot brake; b) align, using shaft 1 of final drive driving gear, disks 3, interlock clutches and secure them with two diametrally located riveted rods 4 (screwdriver type);…

-

Page 114

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 b) mount brake shaft 7, having first lubricated with consistent grease its mounting neck “А” and sealing rings 10 of shaft 6; с) mount on splines of shaft 7 brake disk 3, and then subassembled set “Housing with disks (item 1)”;… -

Page 115: Assembly Of Parking Brake Control Lever

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.13 Assembly of parking brake control lever а) press handle 1 on lever 2 (Figure 4.138); b) insert tie-rod 17 inside lever handle 2, connect it to fixing element 3 and fix with cotter pinом 16; с) from upper end insert inside handle 1 of lever 2 washer 18, spring 19, press tie-rod 17 from below, and screw button 20 on it;…

-

Page 116: Adjustment Of Foot Brake, Valve And Regulator Of Pneumatic System Pressure

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 i) adjust control of parking brake, see section 4.6.15 “Adjustment of parking brake, brake valve and regulator of pneumatic system pressure”; 1 – handle; 2 – sector; 3 – fixing element; 4 – tie-rod; 5 – checknut; 6 – pin;7,9 – lever; 8 — bolt Figure 4.139 4.6.14 Adjustment of foot brake, valve and regulator of pneumatic system pressure 1 –…

-

Page 117: Adjustment Of Parking Brake, Brake Valve And Regulator Of Pneumatic System Pressure

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 2 – adjustment bolt; 3 – checknut Figure 4.141 b) screw bolts 2 inside adjustment yokes or unscrew them to an extent that full travel of brakes’ right-side pedal was in the range of 115…125 mm upon effort 120…130 N, and braking distance was no more than 6 m at speed of 20 km/hour with effort no more than 600 N on pedals interlocked with bar, and also non-simultaneity of wheels braking start no more than 1 m (by impression).

-

Page 118: Multi-Disk Foot And Parking Brakes Operating In Oil Bath

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.142 Note. For tractors equipped (optional) with multi-disk brakes, that operate in oil bath, operations of adjusting foot brakes and parking brakes are identical to described above for tractors with dry type brakes. 1 – lever for parking brake control; 2 – lever; 3 – lever; 4 – lever; 5 – pin; 6 – yoke; 7 – checknut; 8 –…

-

Page 119

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Attention! Pressure disks of dry and “wet” brakes have identical overall and mounting dimensions, but they are not interchangeable. It is strictly forbidden to install disks of dry brakes on “wet” brakes, and visa versa, as it affects safety of tractors operation Intermediate disks 3 are secured against turning through in bodies 1, 13 by means of shoulders, made on the external contour. -

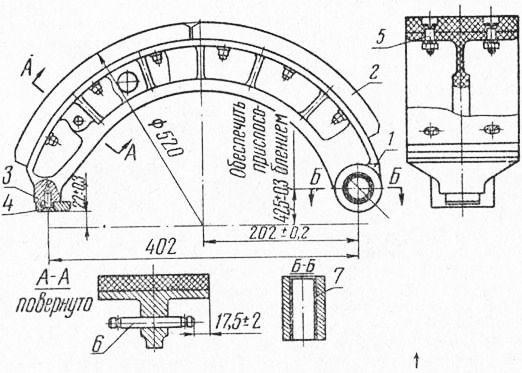

Page 120: Disassembly Of Left-Side Multi-Disk Brake Operating In Oil Bath

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.18 Disassembly of left-side multi-disk brake operating in oil bath а) put tractor on even horizontal terrain and block wheels with wedges from front and rear sides to exclude accidental tractor movement; b) jack up left rear section of tractor until the wheel is lifted from support ground, and put secure support under the left-side sleeve of rear axle;…

-

Page 121

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 i) dismount body (1) with foot brake as an assembly, having screwed two bolts in disassembly threaded openings “А” of brake body; k) remove body from mounting pins and pedals’ roller 4; l) put body with brake as an assembly 1 on the bench, see (Figure 4.146), (with cup cover “А” upwards);… -

Page 122: Assembly Of Left-Side Brake

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – body; 2 – nut; 3 – pin; 4 – tie-rod; 5 – brake disk (8 pcs.); 6 – intermediate disk (6 pcs.); 7 – pin; 8 – screw; 9 – washer; 10 – sheath; 11 – screw; 12 – plate; 13 – spacer; 14 – cotter pin; 15 – cup cover;…

-

Page 123

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Number Thickness S, mm Without number ‐0.1 1 ‐0.12 2 ‐0.12 3 3.6‐0.12 4 3.8‐0.12 5 4.0‐0.12 6 4.2‐0.12 7 4.4‐0.12 3) visually check quality of spacer 13 (Figure 4.150) and if damaged, install new poronyte 1 mm thick spacer;… -

Page 124

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.151 А-А (2:1) Figure 4.152 Adapter for assembly and installation of brake Spline parameters Module Number of teeth Angle of initial а contour profile Misalignment of Хm +1.125 initial contour Roller diameter Roller size 61.157 М… -

Page 125

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4… -

Page 126

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Material — steel Hardness – 255-302 НВ 7) mount brake (Figure 4.153) on tractor by performing the following operations: 7.1 bring brake together with aligning mandrel “А” to the end face of shank of final drive gear ‘С”; 7.2) ) insert shank of mandrel “В”… -

Page 127: Disassembly Of Right-Side Foot Brake

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.6.20 Disassembly of right-side foot brake а) make necessary preparatory operations described in section 4.6.20 “Disassembly of left-side multi-disk foot brake operating in oil bath”; b) for tractors BELARUS-1221.2/1221.3 with hydromechanical drive of rear PTO (Figure 4.154 а, с) make the following operations: 1) disconnect tie-rod of rear PTO control 7 from lever of control valve 8;…

-

Page 128

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – pedals roller; 2,4 – pin; 3 – PTO lever; 5 – washer; 6 – cotter pin; 7 – parking brake lever ; 8 – adjustment bolt of parking brake Figure 4.155 1) remove cotter pin 6 and washer 5 from pedals’ roller (1); 2) unpin and remove pins 2, 4 and disconnect control tie-rods from levers 3, 7;… -

Page 129

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – cup; 2 – friction disk; 3 – intermediate disk; 4 – pedals’ roller; 5 – sealing sheath; 6 – pressure disk; 7 – ball; 8 – parking brake; 9 – cover; 10 –spacer; 11 – parking brake shaft; 12 – drain plug; 13 –… -

Page 130

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – 1 – cup; 2 – friction disk; 3 – intermediate disk; 4 – pedals’ roller; 5 – sealing sheath; 6 – pressure disk; 7 – ball; 8 – parking brake; 9 – cover; 10 –spacer; 11 – parking brake shaft; 12 – drain plug;… -

Page 131: Assembly Of Right-Side Foot Brake

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 14) put body with brake as an assembly on the bench, with cup cover 2 upwards (Figure 4.159) and disassembly the brake, having first unscrewed three screws 1 15) remove cover 2 and spacer 3. Brake disassembly is similar to disassembly made in item “н”…

-

Page 132

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 2 – brake disk; 3 – intermediate disk; 11 – parking brake shaft; 13 – brake body; “А”. Plane. “В”. Parking brake shaft neck. “С”. Opening of drive gear (right-side). “Е”. Final drive gear. Figure 4.160 d) install spacer 10 and cover 9, (Figure 4.161);… -

Page 133

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) mount on tractor all dismounted parts for control of foot and parking brakes, as well as parts for rear PTO control; g adjust travel of right-side brake pedal using bolt 19, (Figure 4.163), as described above, see item “b”… -

Page 134

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – parking brake lever; 2 — clamp; 3 – sector Figure 4.164 If the tractor is equipped with pneumatic brake and operates with trailer equipped with pneumatic brakes, adjust travel of parking brake lever in the following way: а) shift lever 1, (Figure 4.164), to extreme forward (disengaged) position;… -

Page 135

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) by turning adjustment bolt 18, (Figure 4.163), adjust travel of lever (1) so that parking brake was fully engaged on the 2 or 3 tooth of sector 3 (Figure 4.164); f) tighten check nut 8 (Figure 4.165) and 21а (Figure 4.163); g) mount back in place right-side rear wheel, torque wheel fixing nuts to 200…250 N·m. -

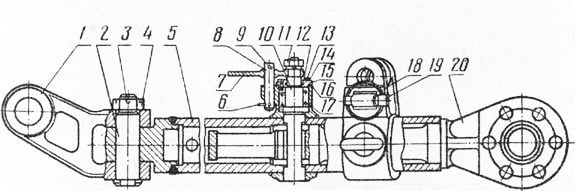

Page 136: Disassembly-Assembly Of Brakes Control On Reversal Of Belarus-1221В.2

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.7 Disassembly-assembly of brakes control on reversal of BELARUS-1221В.2 Observe the following sequence of brakes control on reversal (Figure 4.166): а) drain braking fluid from the system, and to do this: 1) take off sheath 1 of reverse 2 main cylinder, remove protective cap from by-pass valve 3 of reverse 4 working brake cylinder;…

-

Page 137

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.166… -

Page 138

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.167… -

Page 139: Dismounting Of Components Of One-Wire Pneumatic Drive Of Trailer Brakes On Tractors Belarus-1221.2/1221.3

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.8 Dismounting of components of one-wire pneumatic drive of trailer brakes on tractors BELARUS-1221.2/1221.3 Attention: Before starting disassembly of components of trailer brakes’ pneumatic drive, release compressed air from the system. To do this, pull upwards ring for condensate release valve 6 (Figure 4.168).

-

Page 140

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of connection head 1 (Figure 4.170): а) unscrew cap nut 3 and disconnect from connection head 1 pipeline 4; b) unscrew connection pipe 2 and remove connection head 1. Figure 4.170 Make assembly of components of the pneumatic drive of tractor trailer brakes in order reverse to disassembly. -

Page 141: Dismounting Of Components Of Two-Wire Pneumatic Drive Of Trailer Brakes On Tractors Belarus-1221.2/1221.3

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.9 Dismounting of components of two-wire pneumatic drive of trailer brakes on tractors BELARUS-1221.2/1221.3 Attention: Before starting disassembly of components of trailer brakes’ pneumatic drive, release compressed air from the system. To do this, pull upwards ring for condensate release valve 6 (Figure 4, item 6).

-

Page 142

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of connection heads 1 and 5 (Figure 4.173): а) unscrew cap nuts 3 and 7; b) disconnect from connection heads 1 and 5 pipelines 4 and 8; and then unscrew connection pipes 2and 6 c) remove connection heads 1 and 5. -

Page 143: Dismounting Of Components Of Combined Pneumatic Drive Of Trailer Brakes For Tractor Belarus-1221.4 With Engine Deutz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.10 Dismounting of components of combined pneumatic drive of trailer brakes for tractor BELARUS-1221.4 with engine Deutz Attention: Before starting disassembly of components of trailer brakes pneumatic drive, release compressed air from the system. To do this, pull upwards ring for condensate release valve 6 (Figure 4.174).

-

Page 144

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.175 Dismounting connection head 1 (Figure 4.176): а) unscrew cap nut 3 and disconnect from connection head 1 pipeline 4; b) unscrew connection pipe 2 and remove connection head 1. Figure 4.176 Dismounting connection heads 1 and 8 (Figure 4.177): а) unscrew cap nuts 3 and 6;… -

Page 145

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.177 Make assembly of components of the pneumatic drive of tractor trailer brakes in order reverse to disassembly. Attention: After assembly check air tightness of the system, parameters of pressure regulator and brake valve actuation. Design and principle of operation, procedure of check and adjustment are described in operating manual enclosed with each tractor. -

Page 146: Dismounting Of Components Of One-Wire Pneumatic Drive Of Trailer Brakes For Tractor Belarus-1221.4 With Engine Mmz

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.11 Dismounting of components of one-wire pneumatic drive of trailer brakes for tractor BELARUS-1221.4 with engine MMZ Attention: Before starting disassembly of components of trailer brakes’ pneumatic drive, release compressed air from the system. To do this, pull upwards ring for condensate release valve 9 (Figure 4.178).

-

Page 147

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of connection head 1 (Figure 4.180): а) unscrew cap nut 3 and disconnect from connection head 1 pipeline 4; b) unscrew connection pipe 2 and remove connection head 1. Figure 4.180 Make assembly of components of the pneumatic drive of tractor trailer brakes in order reverse to disassembly. -

Page 148: Dismounting Of Components Of Two-Wire Pneumatic Drive Of Trailer Brakes

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.12 Dismounting of components of two-wire pneumatic drive of trailer brakes Attention: Before starting disassembly of components of trailer brakes’ pneumatic drive, release compressed air from the system. To do this, pull upwards ring for condensate release valve 9 (Figure 4.181).

-

Page 149

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of connection heads 1, 5 (Figure 4.183): а) unscrew cap nuts 3and 7 and disconnect from connection heads 1 and 5 pipelines 4 and 8; b) unscrew connection pipes 2, 6 and remove connection heads 1, 5. Figure 4.183 Make assembly of components of the pneumatic drive of tractor trailer brakes in order reverse to disassembly. -

Page 150: Disassembly-Assembly Of Rear Pto

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.13 Disassembly-assembly of rear PTO Dismounting of hatch cover and rear axle cover: а) unscrew four bolts 2 (М8х16) and one bolt М12х20 (Figure 4.184), dismount access hatch cover (1) and spacer; b) unscrew nineteen bolts (3) (М12х30), dismount cover of rear axle body (4) and spacer. 1 –…

-

Page 151

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) unscrew nuts 1 and take off guarding 2; f) unscrew six boltов 4 (М10х35 – 5 pcs.шт., М10х40 – 1 pc.); g) ) screw two disassembly bolts inside cover 5 and dismount planetary PTO reduction gear off rear axle body;… -

Page 152

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Disassembly-assembly of planetary PTO reduction gear 1 – bearing; 2 – bushing; 3 – nut; 4 – lever; 5 – arm; 6 – lever; 7 – pin; 8 – shaft; 9 – ring, 10 – axle;… -

Page 153

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 22 – nut Figure 4.188; b) press out bearing 21 and carrier 18 together with satellites 19 (figures 4.187, 4.189); During subsequent assembly bearing (21) pust be pressed in carrier (18) to the end of shoulder (Figure 4.189);… -

Page 154

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 9, 10 – brake band; 31- eccentric shaft; 35 – check ring; 41 – axle Figure 4.190 ATTENTION! When tractor is equipped with planetary PTO reduction gear having wider brake band on driven drum (sun drum), make subsequent assembly in a way for wider band (В=56 mm) to be on the side of PTO cover 3 –… -

Page 155

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 16 – axle; 17 – pin; 19 — satellite; 20 – bearing. Figure 4.192 During subsequent assembly: а) lubricate openings matching satellites’ bearings with consistent grease; b) openings in satellites’ axles must be aligned with carrier openings for pressing in pins. Radial lubrication openings must face from centre outwards;… -

Page 156

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 During subsequent assembly press bearings in a way to provide installation of check rings; с) remove lock ring 13 (Figure 4.195) and disconnect from drum 14 sun gear 15; 13 – lock ring; 14 – drum; 15 – sun gear Figure 4.195 d) remove lock ring 8 (Figure 4.196) and press bearing 7 with collar 6 off cover 3;… -

Page 157

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of control roller and shift clutch: а) remove safety wire and unscrew locking bolt 2 (Figure 4.198); b) remove lead 3 and control roller 1; с) remove shift clutch лючения 4; 1 – control roller; 2 – locking bolt; 3 – lead; 4 – shift clutch Figure 4.198 During subsequent assembly: Tighten locking screw and securely lock with wire. -

Page 158

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – crown gear; 3 – cup; 8 – check nut; 9 – locking screw Figure 4.200 b) knock out crown gear shaft 7 as an assembly with gear 1, cup 3 and bearing 4 (Figure 4.199); с) dismount shift clutch (if it is still in place) (Figure 4.201);… -

Page 159

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 4.203 e) remove locking ring 2 (Figure 4.202), and disconnect crown gear from shaft 7; f) remove locking ring 6 (Figure 4.204) and press ball bearing 4 off cup 3; 3 – cup; 4 – bearing; 6 – locking ring Figure 4.204 During subsequent assembly: а) before mounting crown gear inside rear axle body, align opening «А»… -

Page 160: Disassembly-Assembly Of Rear Pto Control

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.13.1 Disassembly-assembly of rear PTO control Control of rear PTO 1221М-4216005 – electrohydraulic and mounted on tractors equipped with brakes operating in oil bath (wet brakes). ATTENTION: Disassembly-assembly of rear PTO control 1221M-4216005 must be made on shut- off tractor 1-arm;…

-

Page 161

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 а) to dismount sleeves 11, 12, 13 (Figure 4.206) unscrew bolts 15 and remove rings 16 and sleeves 11, 12, 13; b) to dismount hydraulic cylinder 5, remove cotter pina 25 и 29 and washers 17 and 22. с) to dismount lever 6, unscrew bolt 20. -

Page 162

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 с) dismount lever 2, having unscrewed bolt 17; d) dismount tie-rod 9 with handle 14, and to do this remove cotter pin 25 (view “А”) and washer e) remove valve 7 and arm 8,to which it is fastened, having unscrewed two bolts 18 with washers 20 and 28. -

Page 163: Adustment Of Pto

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4.13.2 Adustment of PTO Note: Make adjustment of PTO control in special workshop. During subsequent assembly: а) during factory assembly or repair eccentric axle 5 (Figure 4.209) is installed in extreme right position (the flat is vertically on the right side) and fastened with locking plate 3 and bolt 4; b) install lever 1 in neutral position, having aligned openings in lever and rear axle body by means of rod 8 mm in diameter, or bolt (2) М10х60;…

-

Page 164

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Make adjustment of PTO brake bands during tractor operations in the following cases: а) PTO slips; b) value of dimension “А” (Figure 4.210) in position “PTO off” (rod is drawn in) is less than 38 mm, or in position “PTO on”… -

Page 165: Front Driving Axle (Fda)

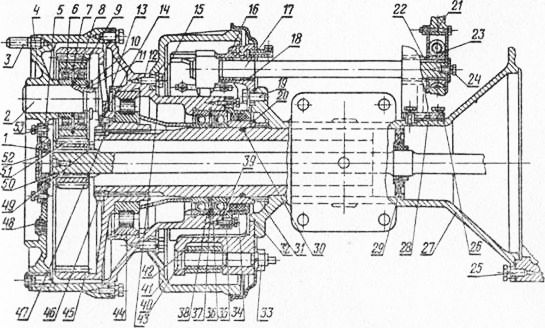

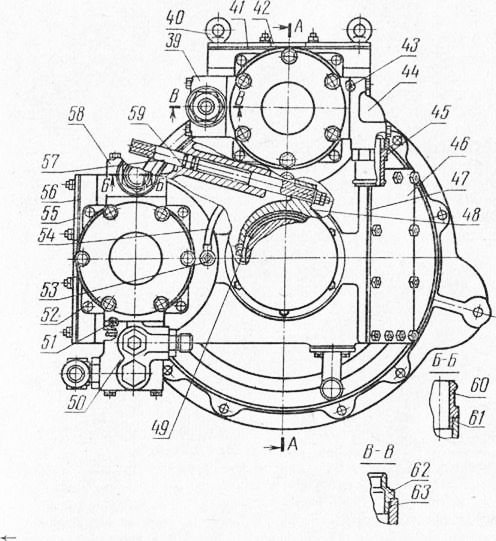

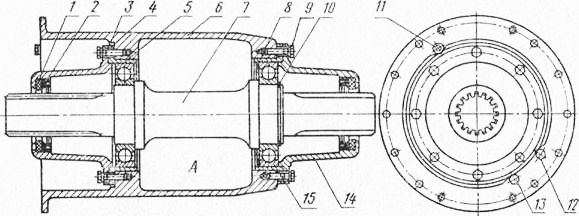

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5 FRONT DRIVING AXLE (FDA) 5.1 Drive of front driving axle FDA drive is designed for transfer of torque from gear box to FDA. It includes reduction gear with multi-disk friction hydraulically driven clutch, torsion, cardan shaft and drive control system. Drive friction clutch is located inside GB body on the right side of tractor movement.

-

Page 166: Disassembly Of Fda Drive

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 When tractor travels forward without slippage shaft (5), connected to FDA wheels, has greater rotation speed than gear (1) and drum (3), connected to gear (1) via stack of disks (2), turns against shaft (5). Knuckles of drum (3) move half-clutch across splines of shaft (5) in axial direction, squeezing spring (7).

-

Page 167

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 5.3 2) unstake corbel of nut (2) (figure 5.4), fix shaft (1) to prevent rotation, unscrew nut (2) and remove locking washer 3; Figure 5.4 3) using spacer made of soft metal (brass, etc.), knock out shaft (1) (figure 5.5) as an assembly forward in tractor movement direction;… -

Page 168

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 4) pull hydraulically squeezed clutch (1) out of GB body, (figure 5.6), as an assembly with gear 2; Figure 5.6 5 press out of gear box body bearing (2) (figure 5.7) and bushing (1) back as tractor travels; Figure 5.7 6) dismount from shaft (3) (figure 5.56) bushing (1), half-clutch (2), spring 4;… -

Page 169

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 5.9 11) press bearings (1) out of gear 2 (Figure 5.10); Figure 5.10 12) remove locking ring (1), (figure 5.11), and pull out of drum (10) a stack of friction disks (9), guides (6) and springs (7); 13) remove locking ring (3), cup (4) and spring 5;… -

Page 170: Assembly Of Fda Drive

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1) remove locking rings (4), avoiding their deformation; 2) press out needle bearings 5; 3) disconnect flange (1) and sliding yoke 6; 4) remove cross-pieces 2; 5) remove end face sealings of cross-pieces 3. Perform assembly in sequence reverse to disassembly. Figure 5.12 5.1.2 Assembly of FDA drive Perform assembly in sequence reverse to disassembly, and in doing this:…

-

Page 171

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Figure 5.14 с) while mounting shaft (3) (figure 5.15) see that its splines were alighed with splines of half-clutch (2) and drum (1). After clutch is installed in gear box body torque nut (4) to 80… 100 N•m. (8…10 kgf m) and centre- pop in shaft grooves;… -

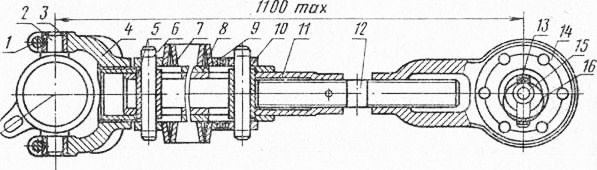

Page 172

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) before mounting cardan shaft grease external surface of sliding yoke (1) (figure 5.17) with oil that is filled in transmission body; Figure 5.17 f) torque nuts (2) for fastening flange (3) of cardanshaft to 35…45 N·m. (3.5…4.5 kgf m); g) to install cover (2) on transmission (2) (figure 5.18) as an assembly, unscrew plug (3) and align bushing (1) with cover opening using rod of 5…6 mm;… -

Page 173: Adjustment And Tesing Fda Drive

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5.1.3 Adjustment and tesing FDA drive Adjusting free travel of the stack of disks of hydraulically squeezed clutch Measure free travel “А” (figure 5.20) of the stack. If free travel exceeds allowable value add one driven disk or replace stack of disks.

-

Page 174

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 b) put under end face of switch (5), (figure 5.21) initial number (5-6 pcs) of adjusting shims (4); с) by removing one adjusting shim after another, obtain such position of switch when its contacts are closed; d) put half-clutch to position “II”, when knuckles of halg-clutch and drum are fully taken apart and pusher is recessed in extreme position;… -

Page 175

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – oil tank; 2 – metering vessel; 3 — hydraulically squeezed clutch; 4 – pressure gauge; 5 — throttle; 6 — filter; 7 – safety valve; 8 – oil pump Figure 5.23… -

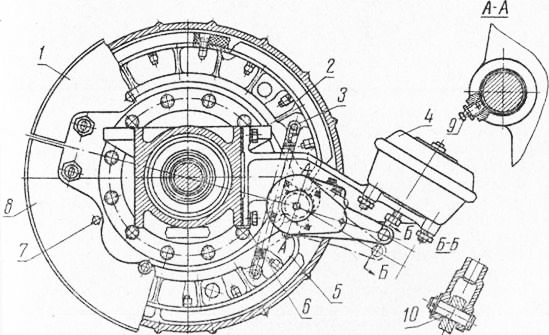

Page 176: Disassembly Of Fda With Planetary-Cylindrical Reduction Gears

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5.2 Disassembly of FDA with planetary-cylindrical reduction gears 5.2.1 Disassembly of FDA final drive Dismounting and disassembly of driving gear of the final drive: а) unscrew bolts 2 for fastening final drive body 3; b) screw two disassembly bolts (1) in threaded openings of body and dismount driving gear as an assembly (Figure 5.24);…

-

Page 177

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 To figure 5.25: 1 – driving gear of the final drive; 2, 5 – conical roller earings;3 – driving gear body; 4 – adjusting rings; 6 – oil retaining ring; 7 – sealing rings; 8 – plug; 9 – flange; 10 – washer; 11 – crown nut; 12 – cotter pin. -

Page 178

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1- bolt; 2 – disassembly bolt; 3- cover; 4 — differential Figure 5.28 с) using extractor press off internal shells of conical roller bearings 3. d) unlock and unscrew nut 2, (Figure 5.29). 1 – differential as an assembly; 2 – nut; 3 – bearing Figure 5.29 e) using special extractor press driven conical gear (2) off differential body as an assembly 1, (Figure 5.30). -

Page 179

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 f) unbend locking plates (1), unscrew nuts (2) and take differential boxes apart 3 and 4, (Figure 5.31). 1 – locking plate; 2 – nut; 3, 4 – differential box. Figure 5.31 g) remove satellites’ axles (6) together with satellites 5, (Figure 5.32); h) pull out of boxes (1) and (8) half-axle gears (4), pressure cups (3), drive disks (2) and driven disks (7). -

Page 180: Assembly And Adjustment Operations

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5.2.2 Assembly and adjustment operations а) adjust pretension in bearings 2, 3 of final drive driving gear 4, which must nor exceed 0.04 mm (Figure 5.33). Adjust tension by grinding oone one adjusting rings 5 and tightening crown nut 7. b) torque crown nut 7 to 120…150 N m.

-

Page 181

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) mount differential 5 with conical roller bearingами 6 inside body 3 of FDA, (Figure 5.35). f) put set pf spacers 2 with total thickness 2.0…2.5 mm on the right side between FDA body 3 and sleeve 9. -

Page 182

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – flange; 2 – body of final drive gear as an assembly; 2 – stack of spacers; 4 – driving gear of final drive; 5 – driving gear of final drive; 6 – body of FDA; 2 – filler plug. Figure 5.36 IMPORTANT! Lateral clearance and tooth contact are adjusted after adjusting pretension of bearings of the gear of final drive and differential (Figure 5.33). -

Page 183

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Table 5.1 Tooth contact on How to adjust gears’ engagement Adjustment driven gear diagram Correct gears engagement under small load Bring driving gear towards the driven one Shift driving gear aside from the driven one. Shift driven gear (differential) aside from the driving one Bring driven gear (differential) closer to… -

Page 184: Disassembly Of Planetary-Cylindrical Reduction Gear

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5.3 Disassembly of planetary-cylindrical reduction gear Dismounting of steering rod and joint of hydraulic cylinder rod а) unlock and unscrew crown nut 3 (Figure 5.38); b) press ball pin (1) out of swivel lever (2) and disconnect steering rod; с) press pin of hydraulic cylinder rod (4) out of arm (5);…

-

Page 185

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – nut; 2 – body bushing; 3 – hydraulic cylinder arm; 4 – swivel lever; 5 – reduction gear body. Figure 5.39 Dismounting of reduction gear а) to make dismounting of reduction gear easier, wrap steel rope around reduction gear body, and using lifting mechanism pull the rope to balance mass of reduction gear, (Figure 5.40) Figure 5.40 b) unscrew four bolts (1), screw two disassembly bolts in threaded openings (2) of pivot axle (3) -

Page 186

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – bolt; 2 – disassembly threaded openings; 3 – upper pivot axle; 4 – adjustment spacers; 5 – lower pivot axle; 6 – swivel knuckle. Figure 5.41 NOTE: Adjusting shims (4) are installed only under flange of upper swivel axle (3). Disassembly of wheel reduction gear а) unscrew bolts (3) and remove cover (2) together with spacer 1, (Figure 5.42) 1 –… -

Page 187

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 NOTE: To fasten cover to cup use bolts М8 1 – cup; 2 – nut; 3 – flange shank Figure 5.43 с) unscrew bolts (2) for fastening cover (3). Screw two disassembly bolts (1) in cover threaded openings and dismount cover together with flange (4), (Figure 5.44). -

Page 188

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1 – flange; 2 — bearing; 3 — carrier; 4 – distance ring; 5 – block of gears; 6, 7 – locking rings; 8 – spherical bearing Figure 5.45 e) unbend corners of washer (2) from corner of bolt head (1); unscrew bolt (1) and remove washers (2), (3);… -

Page 189

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 Dismounting of bearings of pivot axles а) pull cup of bearing (1) out of FDA sleeve using suitable tool, (Figure 5.47). 1 – bearing cup; 2 – bearing; 3 – FDA sleeve Figure 5.47 b) using suitable extractor (2) press out of sleeve external shell of conical roller bearing (1), and in a similar way press out lower shell, (Figure 5.48). -

Page 190

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 5.4 Assembly and adjustment operations а) adjust axial play in conical roller bearings (2) of drive cylindrical gear (3) using spacers (4) between cup (6) and body (5). Clearance or tension should not exceed 0.05 mm, (Figure 5.49). Torque bolt (1) to 120…140 N•m.and lock with bending washer 2, (Figure 5.46) 1 –… -

Page 191

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 с) bearings 2, 4 (figure 5.51) must be adjusted without clearance, make adjustment by torquing nut (2) to 180…200 N•m. with its subsequent unscrewing by angle 15…20; during tightening rotate body of wheel reduction gear so that rollers of bearings were correctly positioned in shells. After adjustment lock the nut by deformation of nut gorbel inside the cut of flange shaft. -

Page 192

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 1) put upper and lower bearings 2 and cup of bearing (1) inside half-axle sleeve (3), (Figure 5.53) 1 – bearing cup; 2 – bearing; 3 – FDA sleeve Figure 5.53 2) match borings in sleeve (6) and body (5) and mount upper axle (3) together with spacers (4) and ring (3) inside opening of bodyand sleeve, having first lubricated sealing ring with grease LITOL-24, (Figure 5.54). -

Page 193

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 turn axle by 180 , so that the second good lug coinsided with axis of pusher, sensor of wheel turning angle. 1 – extension; 2 – bottom left-side axle of pivot Figure 5.55 7) Adjust preload in conical roller bearings of pivot axles. Tension is considered correct if effort of knucle turn applied to flange (5), is 60…80 N. -

Page 194

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 e) check and, if necessary, adjust maximum allowable angles of knuckle turn (1), which must be within 39…40 (figure 5.57) when measured from position corresponding to straight movement. Make adjustment of maximum permissible turn to the left or right by means of adjustment screw (2), which is locked with checknut (3). -

Page 195: Wheels And Hubs

Disassembly-assembly manual for tractor BELARUS-1221.2/1221В.2/1221.3/1221.4 6 WHEELS AND HUBS 6.1 Mounting-dismounting works on wheel dismantled from tractor Mounting and dismounting tires are dangerous operations, hence they must be carried out only by competent persons who have corresponding professional knowledge and skills, and relevant equipment.

-

Page 196