Инструкция по эксплуатации плоттера

Раздел 1

Обслуживание

Перед началом эксплуатации оборудования внимательно изучите следующие требования:

- Запрещается размещать вблизи плоттера (особенно рядом с кареткой) магнитные устройства.

- Избегайте попадания внутрь плоттера инородных тел (болты, небольшие шурупы и т.п.)

- При длительном неиспользовании оборудования вилка питания должна быть отключена от розетки.

- Запрещается подключать и отключать последовательный/параллельный/usb кабель при включенном питании

- Запрещается оставлять прижимные ролики прижатыми, если устройство не используется.

- Разрешается подключение шнура питания только к заземленной розетке.

- Запрещается перемещение каретки вручную.

- Запрещается дотрагиваться до каретки, металлического ролика, резца и любых подвижных частей при работающем устройстве.

- Установка оборудования производится на устойчивой поверхности, не подверженной вибрации, электромагнитному излучению. Не устанавливайте устройство в пыльных, влажных помещениях. Избегайте попадания на него прямых солнечных лучей.

Запрещается давить на верхнюю перекладину и поднимать черную перекладину.

Раздел 2

Установка

2-1 Упаковка

Внимательно проверьте все изделия после вскрытия упаковки. Оборудование поставляется в следующей комплектности:

- Плоттер.

- Комплектующие (в пакете).

- Комплект деталей для стенда.

2-2 Комплектация

| № | Наименование | Количество |

|

1 |

Сетевой шнур |

1 |

|

2 |

Инструкция по эксплуатации (на диске) |

1 |

|

3 |

Держатель для ножа |

1 |

|

4 |

Нож |

3 |

|

5 |

Стержень |

1 |

|

6 |

Шестигранный ключ |

1 |

|

7 |

Последовательный кабель (COM) |

1 |

|

8 |

Параллельный кабель (опционально) |

1 |

|

9 |

USB-кабель (опционально) |

1 |

|

10 |

Защитный чехол для плоттера |

1 |

|

11 |

Диск с драйвером для CorelDraw и USB порта |

1 |

|

12 |

ПО «Artcut 2009», на диске (опционально) |

1 |

2-3 Комплектация стенда

| № |

Наименование |

Кол-во |

№ |

Наименование |

Кол-во |

|

1 |

Левая стойка |

1 |

6 |

Ролики для пленки |

2 |

|

2 |

Правая стойка |

1 |

7 |

Держатель для пленки |

2 |

|

3 |

Поперечная перекладина |

1 |

8 |

Плита для крепления |

2 |

|

4 |

Опора |

2 |

9 |

Винт M4×20 |

10/12 |

|

5 |

Колесики опоры |

4 |

10 |

Винт M4×8 |

8 |

2-4 Сборка стенда

Примечания по чертежу:

— Подходит лишь для моделей, имеющих ширину не менее 780 мм

Шаг 1: Прикрепите винтами опоры к левой и правой стойке.

Шаг 2: Соедините правую и левую стойки поперечной перекладиной при помощи винтов.

Шаг 3: Присоедините держатели для пленки с внешнней части левой и правой стоек при помощи винтов.

Шаг 4: Присоедините плиту для крепления к верхней части левой и правой стойки при помощи винтов.

Шаг 5: Поместите плоттер на плиту крепления и вставьте опоры в панель для присоединения плоттера.

Шаг 6: Поместите ролики для рулонов на держатель.

Раздел 3 Основные операции

3-1 Установка и подключение

1 Установите плоттер на ровную поверхность, в просторном месте

2 Подключите сигнальный кабель к порту COM1,COM2 или USB компьютера

3 Проверьте напряжение питания и наличие заземления и убедитесь в соблюдении всех условий

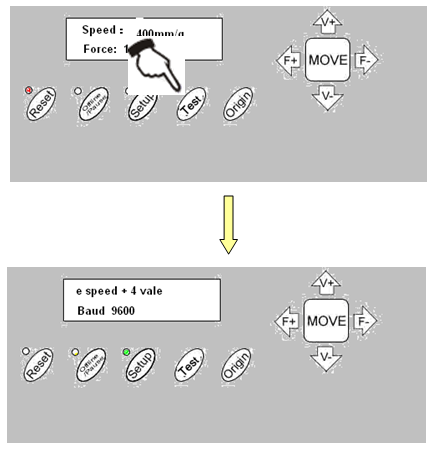

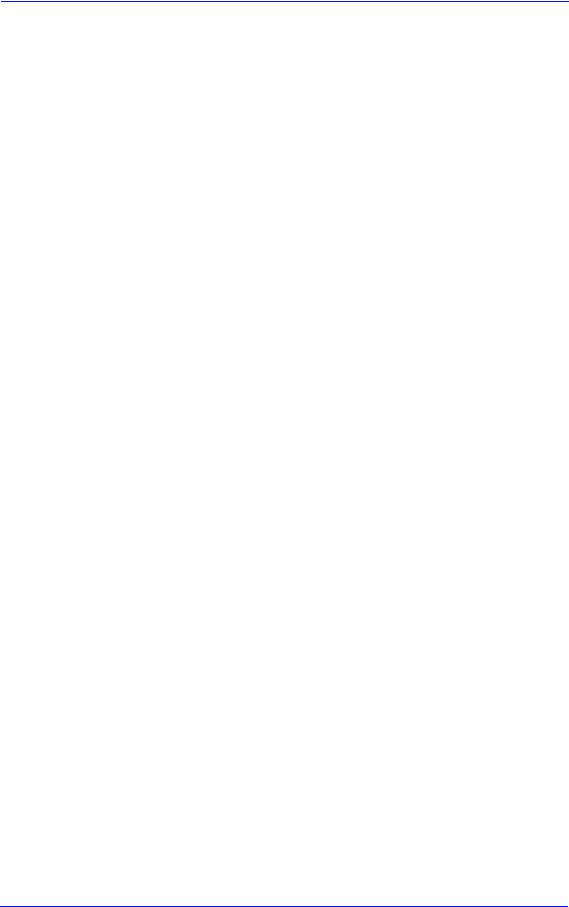

3-2 Установка ножа

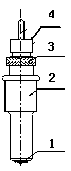

3-2.1 Части держателя ножа и комплектующие

Поворотом установочного винта отрегулируйте длину ножа таким образом, чтобы он не прорезал нижний слой.

- Нож (диаметр – 2 мм)

- Кожух держателя ножа

- Установочный винт

- Корпус держателя ножа

3-2.2 Установка и регулировка лезвия

1.Перед установкой ножа тщательно протрите корпус держателя ножа и руки. Даже незначительное загрязнение может сказаться на работе ножа. Для удобства держания ножа в руках используйте захваты из мягкого пластика или резины. Аккуратно вставьте нож в корпус держателя. Он должен примагнититься к нему.

2 Поверните кожух держателя ножа и выставьте такую длину ножа, чтобы длина лезвия не превышала толщину клейкого слоя

3. Во избежание травмы запрещается касаться лезвия пальцами

Закрепите шариковую ручку в стержне (см.рисунок).

- Поверните колпачок.

- Установите шариковую ручку на нужную длину.

- Закройте стержень при помощи колпачка. Вкрутите их в корпус

3-2.4 Установка

1. Отключите питание

2. Ослабьте крепежный болт суппорта, установите в него держатель ножа или стержень. По достижении нужного положения закрутите крепежный болт по часовой стрелке.

3-2.5 Максимальное использование ресурса ножа

Ресурс ножа ограничен, но его можно максимально использовать.

Примечание:

1. Выставление большей длины ножа приводит к сокращению его ресурса. В процессе резки избегайте прорезания нижнего слоя.

2. Большее усилие реза приводит к сокращению ресурса ножа.

3. Для разных материалов требуется разная степень остроты ножа.

4. Применяйте минимальное усилие реза, насколько это возможно; увеличение усилия необходимо лишь при затуплении ножа.

5. Ножи разных производителей имеют разный ресурс.

6. Производите своевременную замену ножа по мере его затупления или ухудшении производительности плоттера. При необходимости срочной замены для заточки ножа можно использовать кусочек кожи (аналогично тому, как затачивают бритву).

Раздел 4 Установка через USB-порт

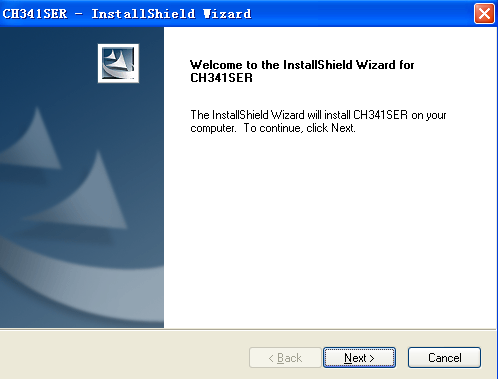

Установка 340 USB драйвера

- Установка USB-порта:

Внимание: Перед установкой диска не подключайте плоттер к ПК

Вставьте установочный CD с драйвером в привод CD-ROM. На диске найдите данный файл. Выберите его двойным нажатием мыши

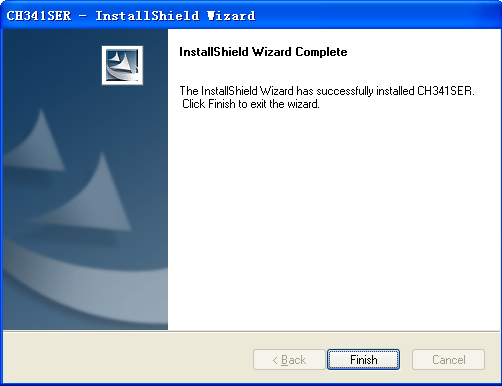

Выбрать «NEXT» (Далее) для автоматической установки драйвера.

Нажать «OK». Драйвер успешно установлен

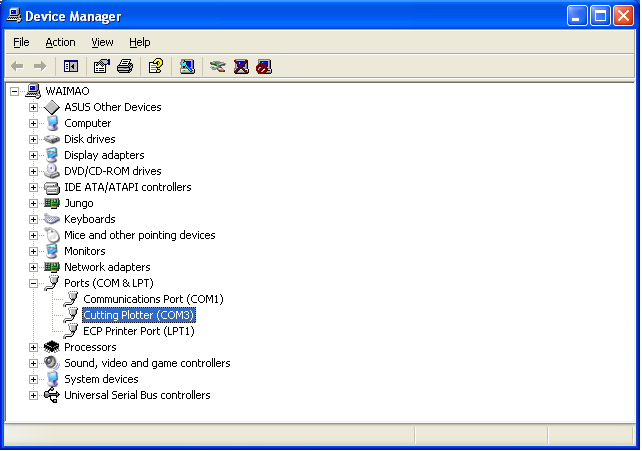

Теперь подключите USB-кабель режущего плоттера к USB-порту ПК. В «диспетчере утройств» USB-устройство будет определено как «COM3». Это свидетельствует об успешном подключении плоттера к ПК

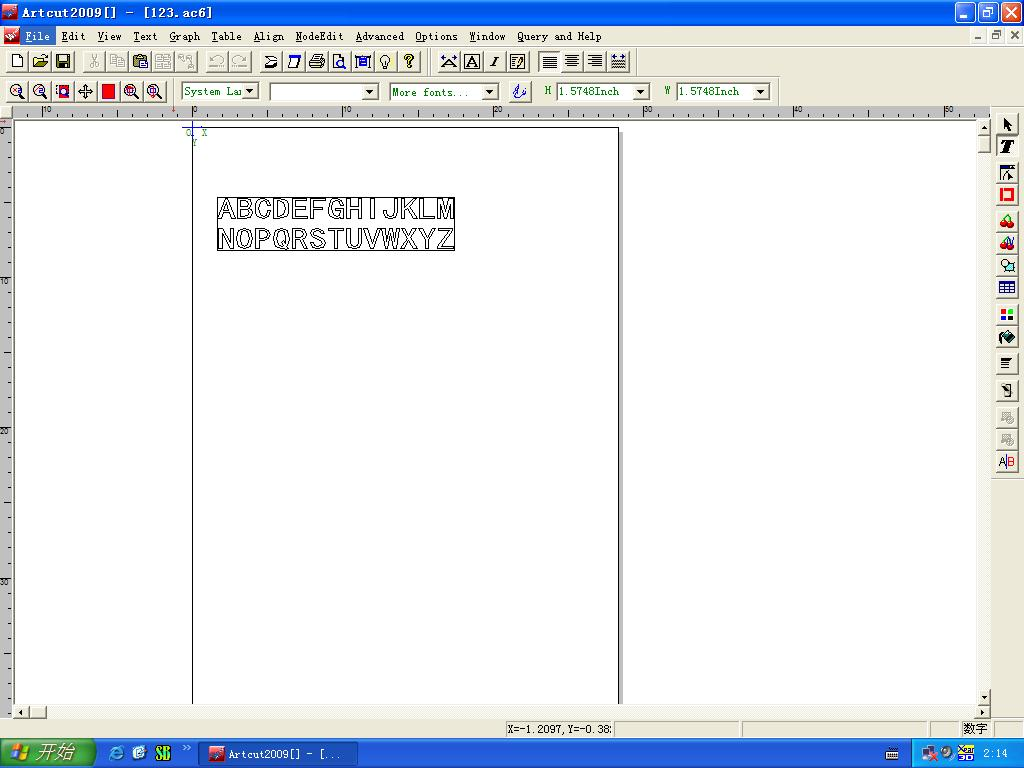

2. Установка порта в ПО «Artcut»

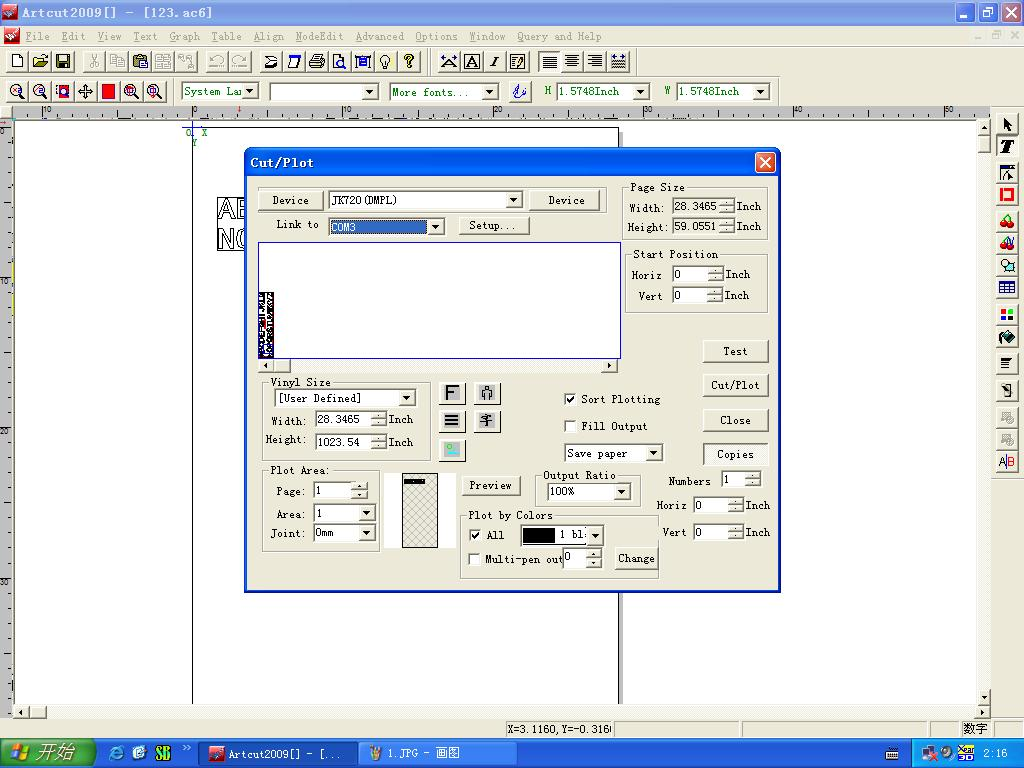

В окошке «Link to» выберите COM 3 для USB-порта

В “Sequential Control” отметьте DTR/DSR и RTS/CTS

3. По завершении настроек выполните перезагрузку компьютера

Раздел 5 Инструкция по эксплуатации

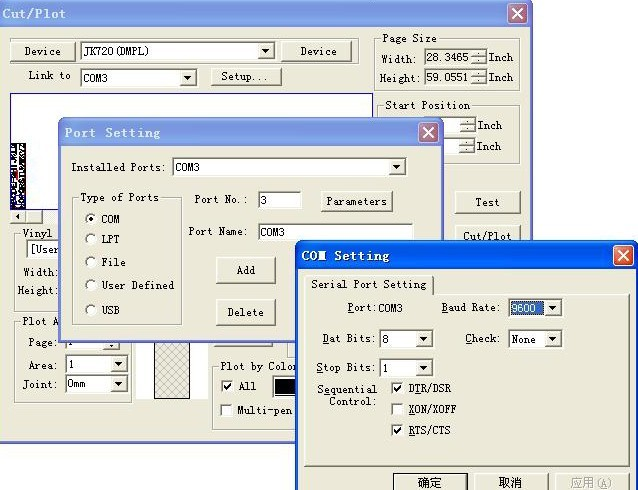

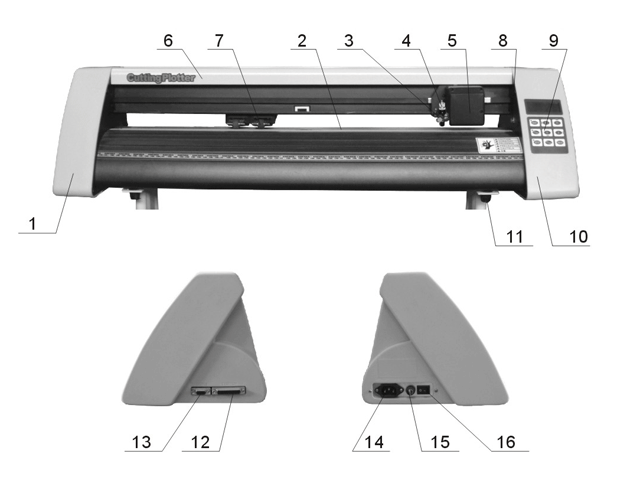

5-1 Названия и функции деталей

5-1.1 Составные части

Тип_0

1. Левая крышка

2. Металлический ролик

3. Скоба для ножа

4. Держатель ножа

5. Каретка

6. Крышка направляющей

7. Прижимной ролик

8. Ручка регулировки положения

9. Панель управления

10. Правая крышка

11. Опора

12. Параллельный порт (опция)

13. Последовательный порт

14. Разъем питания

15. Разъем с плавким предохранителем

16. Выключатель питания

Типы_1

1. Левая крышка

2. Металлический ролик

3. Скоба для ножа

4. Держатель ножа

5. Каретка

6. Крышка направляющей

7. Прижимной ролик

8. Панель управления

9. Ручка регулировки положения

10. Правая крышка

11. Опора

12. Разъем питания

13. Разъем с плавким предохранителем

14. Выключатель питания

15. Переходник USB/СОМ (опция)

16. Последовательный порт

17. Параллельный порт (опция)

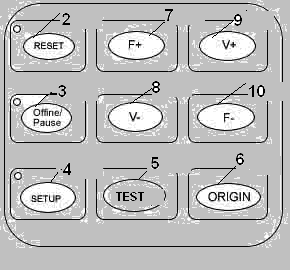

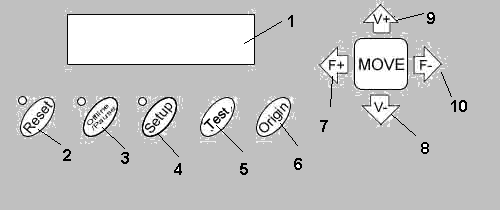

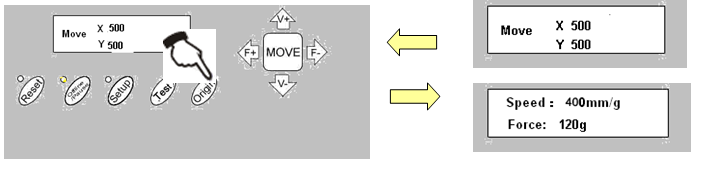

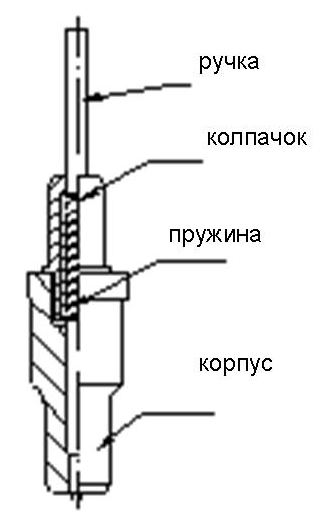

5-1.2 Панель управления

Тип_0

Тип_1

1. ЖК-дисплей

2. Сброс параметров

3. Автономный режим /Пауза

4. Настройка

5. Тестирование

6. Кнопка установки исходной точки

7. Увеличение усилия

8. Уменьшение скорости реза

9. Увеличние скорости реза

10. Уменьшение усилия

5-2 Основные операции

5-2.1 Включение плоттера

1. Выключатель питания должен находиться в положении OFF (выкл.);

2. Подключите сетевой шнур к разъему питания плоттера, включите питание выключателем;

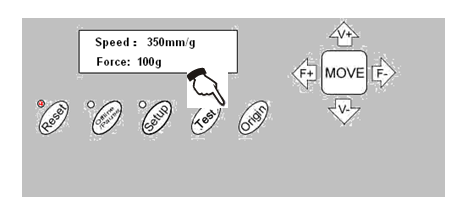

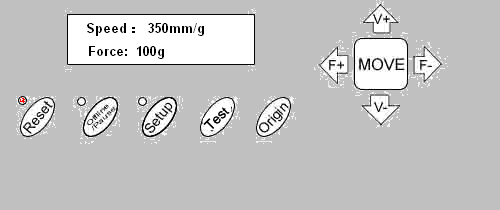

3. После включения ЖК-дисплея на нем отображается процесс подготовки и следующая информация:

4 По окончании подготовки загорается красная лампа. Плоттер находится в состоянии онлайн и может работать под управлением с ПК

5-2.2 Установка материалов

1 Загрузка материалов

1. Поднимите рукоятки прижимных роликов и уберите их с металлических роликов.

2. Вставьте рулон с виниловой пленкой между металлическими роликами и прижимными роликами по направлению от задней крышки плоттера к передней.

3. Перед началом работы внимательно проверьте правильность расположения пленки во избежание отклонений при резке. Если пленка расположена неровно, поднимите прижимные ролики с одной стороны, поправьте пленку и опустите ролики. Перед началом работы необходимо выполнить несколько пробных прогонов для минимизации отклонений.

2 Регулировка прижимных роликов по ширине пленки

Режущий плоттер имеет 2-4 прижимных ролика, которые можно передвигать по направляющей. Перед началом перемещения прижимных роликов поднимите их рукоятки, держа заднюю часть ролика потяните его вправо или влево. Во избежание ухудшения точности не тяните ролики вперед.

3 Требования к положению роликов:

1.Прижимные ролики не должны находиться в пределах области рисунка.

2.Прижимные ролики должны находиться на расстоянии 10-50 мм от краев бумаги.

3.Прижимные ролики не должны находиться в зоне сопряжения двух металлических роликов.

5.2.3 Пробный запуск (проверка усилия и ножа)

1 Пробная резка

По завершении установки ножа и пленки выполните предварительный пробный запуск для проверки усилия реза ножа. Для этого нажмите кнопку TEST. На дисплее отобразится следующая информация, после чего плоттер автоматически произведет резку.

2 Регулировка усилия реза

Снимите вырезанный рисунок. Если сделать это не получается, рисунок нуждается в дальнейшей резке из-за слишком низкого давления ножа или из-за слишком маленькой длины ножа. Прорезание основы говорит о слишком большой длине ножа и слишком большом давлении ножа. Длина выступающей части ножа должна составлять не более 0,5 мм или 2/3 толщины виниловой пленки. Отрегулируйте длину и давление ножа по результатам пробного реза. Давление ножа увеличивается/уменьшается на один уровень при помощи кнопок F+ или F-.

Внимание:

Выполняйте пробную резку каждый раз при использовании нового типа пленки, для проверки давления ножа.

5-3 Инструкция по эксплуатации

5-3.1 Функция «Сброс параметров» (Reset)

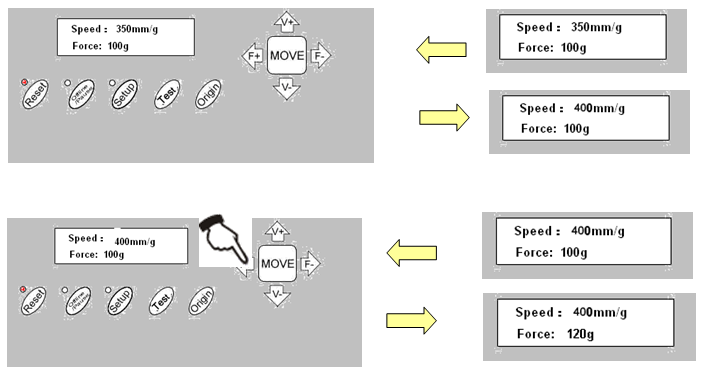

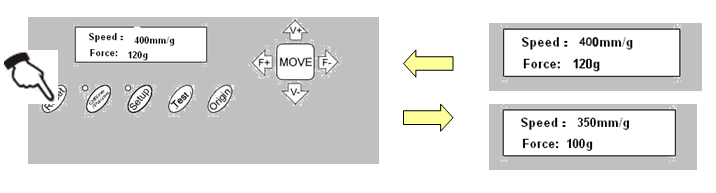

При включении плоттера происходит его автоматическое обнуление (сброс параметров). Загорается красный индикатор и плоттер переходит в режим готовности получения данных с ПК. При этом на ЖК-дисплее отображается следующее:

Заводские параметры:

·Скорость передачи данных: 9600

·Скорость резки: 350мм/сек

·Давление ножа: 100г

·Исходная точка резки – согласно заводским настройкам

Вышеуказанная информация может быть изменена в ходе работы.

При нажатии кнопки RESET в режиме работы плоттер отменяет текущее задание и выполняет переход к заводским настройкам.

5-3.2 Функция «Под управлением ПК» (Online)

После перезагрузки светится красный индикатор. Если плоттер получает данные с компьютера, он находится в онлайн режиме.

Теперь Вы можете изменить скорость резки при помощи кнопок V+ или V- и отрегулировать давление ножа кнопками F+ или F

При нажатии кнопки RESET в рабочем режиме, плоттер возвращается к заводским настройкам и переходит в режим сброса параметров (удаляет заданную информацию) и выполняет подготовку к новому заданию.

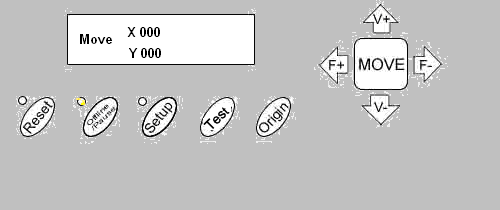

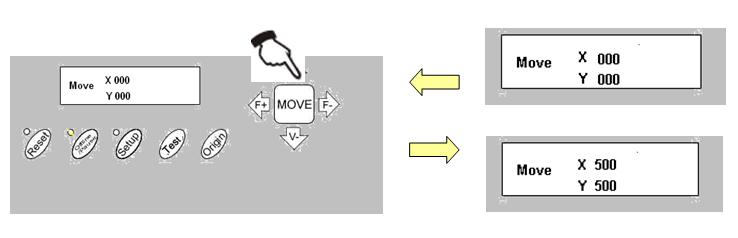

5-3.3 Функция «Автономный режим/Пауза» (Offline /Pause)

Для перехода в автономный режим нажмите кнопку OFFLINE. Включится желтый индикатор. При этом, на дисплее появится сообщение «Motion, X= xxx, Y= yyy», указывающее на текущее местоположение (координаты) ножа.

Перемещение каретки влево/вправо производится нажатием кнопок V+ или V-. Перемещение пленки вперед/назад выполняется кнопками F+ или F-. В данном режиме Вы можете выполнить перемещение ножа в исходную позицию. При этом будет пошагово изменяться значение координат «X, Y» на ЖК-дисплее.

При нажатии кнопки «Pause» в режиме работы происходит остановка плоттера. Для возобновления работы необходимо повторно нажать кнопку «Pause».

5-3.4 Установка исходной точки

При перемещении ножа в исходную позицию нажмите кнопку «Origin». Новая исходная точка задана – плоттер начнет построение с новой исходной точки.

5-3.5 Функция настройки (Setup)

В режиме «ONLINE» при нажатии кнопки «SETUP» загорается зеленый индикатор и Вы можете изменить скорость передачи через серийный порт. Повторное нажатие кнопки SETUP приводит к сохранению в онлайн-режиме.

Внимание:

Изменение данных настроек непрофессиональными техниками не рекомендуется.

5-3.6 Функция повторного резания (Copy)

При нажатии кнопок OFFLINE, SETUP и ORIGIN плоттер выполнит повторное резание последнего задания. При мигающем зеленом индикаторе RESET повторное резание невозможно, так как это свидетельствует о превышении емкости оперативной памяти. Для повторного запуска задания нажмите кнопку RESET.

Внимание:

При появлении признаков сбоя и невозможности отключения плоттера, выключите его питание или выдерните вилку из розетки

5-3.7 По завершении работы

По завершении работы:

1.Уберите бумагу

2.Снимите держатель ножа или стержень, протрите его мягкой тканью и поместите на хранение

3.Отключите питание и выдерните шнур питания (если не планируете использовать плоттер длительное время)

4.Накройте плоттер тканью или чехлом

5-4 Таблица параметров

|

Технические характеристики ( тип_0) |

|||||

|

Модель |

360 |

720 |

870 |

1100 |

1350 |

|

Макс.ширина материала |

365мм |

720мм |

870мм |

1100мм |

1350мм |

|

Макс.область резки |

275мм |

630мм |

780мм |

1010мм |

1260мм |

|

Скорость резки |

50-800мм/сек 50-800mm/s |

||||

|

Давление ножа |

50-500г 50-500g |

||||

|

Объем памяти |

1M 1M |

||||

|

ЖК-дисплей |

Опционально Optional |

||||

|

Процессор |

8-bit CPU |

||||

|

Полоска плоттера |

Пластиковый лист |

||||

|

Двигатель |

Шаговый |

||||

|

Мин.матрица знаков |

Высота ~5 мм [0.2»] |

||||

|

Тип лезвия |

Особая сталь [1,2 мм и 2,0 мм] |

||||

|

Материалы |

Самоклеящаяся виниловая пленка, флуоресцентная пленка, отражающая пленка, бумага |

||||

|

Панель дисплея |

8 символов X 2 строки, ЖК |

||||

|

Интерфейсы |

Параллельный, последовательный, USB (опционально) |

||||

|

Напряжение |

90-260В |

||||

|

Точность повтора |

0,0127мм |

||||

|

Разрешение |

0.0254мм/шаг |

||||

|

Набор команд |

DMPL / HPGL |

||||

|

Рабочая температура |

0-350С |

||||

|

Влажность |

5%-65%, без конденсации |

|

Технические характеристики ( тип_1 ) |

|||||

|

Модель |

361 |

721 |

871 |

1101 |

1351 |

|

Макс.ширина материала |

365мм |

720мм |

870мм |

1100мм |

1350мм |

|

Макс.область резки |

275мм |

630мм |

780мм |

1010мм |

1260мм |

|

Скорость резки |

50-800мм/сек |

||||

|

Давление ножа |

50-500г |

||||

|

Объем памяти |

1-4M |

||||

|

ЖК-дисплей |

Имеется |

||||

|

Процессор |

8-bit |

||||

|

Специальные настройки |

Двухпозиционное крепление ножа |

||||

|

Полоска плоттера |

Пластиковый лист |

||||

|

Двигатель |

Пошаговый |

||||

|

Мин.матрица знаков |

Примерно 5 мм [0.2»] в высоту |

||||

|

Тип лезвия |

Особая сталь [1,2мм и 2,0мм] |

||||

|

Материалы |

Самоклеящаяся виниловая пленка, флуоресцентная пленка, отражающая пленка, бумага |

||||

|

Панель дисплея |

8 символов X 2 строки, ЖК |

||||

|

Интерфейсы |

Параллельный, последовательный, USB |

||||

|

Напряжение |

90-260В |

||||

|

Точность повтора |

0.0127мм |

||||

|

Разрешение |

0.0254мм/шаг |

||||

|

Набор команд |

DMPL / HPGL |

||||

|

Рабочая температура |

0-350С |

Раздел 6 Неисправности и их устранение

Рисунок деформирован или незавершен

- Слишком высокое давление ножа, слишком большая длина лезвия, загрязненный стол, слишком мягкая пленка – все это может стать причиной сопротивляемости двух сторон пленки, вследствие чего она попадает за вращающийся ролик – это приводит к деформации рисунка.

- Неправильно установленное ПО.

- Ослаблен ремень каретки, или металлический ролик не совмещается с электрическим механизмом

- Двигатель не выполняет все шаги.

- Слишком малое значение коррекции может привести к незавершению резки при нормальном рисунке.

Плоттер вычерчивает несоответствующим образом

- Несовместимость программного обеспечения – необходимо установить верный набор команд или указать надлежащее значение коррекции на инструмент.

- Сбой в работе программного обеспечения плоттера.

- Повреждение ПО или наличие вирусов в ПК.

Отклонения материала

- Пленка установлена ненадлежащим образом.

- Слишком грязный стол – сопротивление с двух сторон не может быть сбалансировано при перемещении материала.

- Деформация или несоответствие прижимных роликов.

- Слишком низкое усилие прижима прижимных роликов, материал слишком чувствителен к прилагаемому усилию.

- Неуравновешенный вес пленки.

Пропуски при прорезании букв

- Слишком тяжелая виниловая пленка, слишком большое натяжение пленки. На металлический ролик попали инородные вещества или виниловые обрезки.

- Слишком высокая скорость резки, слишком высокое давление ножа, слишком большая длина лезвия.

- Слишком большое натяжение синхронизирующего ремня, или слишком высокое давление на прижимной ролик.

- Поломка металлического ролика. Обратитесь к местному дистрибьютору по вопросу ремонта и замены.

Разные буквы в одной строке имеют разную глубину реза

- Держатель ножа не закреплен. Необходимо закрепить его

- Лезвие ножа не закреплено в держателе.

Волнистость букв

- Слишком большая скорость резки. Скорость не должна превышать значения 480мм/сек (кроме случаев резки крупных букв и знаков)

- Низкое качество или повреждение лезвия ножа. Требуется замена

- Держатель ножа не закреплен. Требуется его затягивание

Резка букв малого размера

При резке букв небольшого размера установите скорость резки и давление ножа на минимальное значение. Аналогичным образом, длина лезвия ножа должна быть минимальной, насколько это возможно.

Резка букв большого размера

Чем больше размер букв, тем большее значение выставляют для давления ножа. При резке букв большого размера функцию Sharp Angle в программе «Artcut» можно не применять.

Инструкция по эксплуатации плоттера

Раздел 1

Обслуживание

Прежде чем начать пользоваться плоттером, необходимо знать следующие требования:

1. Недопустимо располагать рядом с плоттером любые магнитные устройства.

2. Недопустимо попадание в оборудование инородных тел (болты, шурупы и т.д.).

3. Если вы знаете, что не будете пользоваться аппаратом длительное время, вытащите вилку питания из сети.

4. Запрещено при включенном питании плоттера подключать или отключать дополнительные USB кабеля.

5. Прижимные ролики не должны оставаться прижатыми, когда устройство не находится в рабочем состоянии.

6. Шнур питания аппарата подключается к розетке с заземлением.

7. Недопустимо перемещать каретку ручным способом.

8. Запрещено любое прикосновение к любым подвижным частям плоттера (каретка, резец, металлический ролик) во время его работы.

9. Устанавливать плоттер следует на ровной, устойчивой, не подверженной электромагнитным излучениям и вибрациям поверхности. Помещение, в котором будет находиться плоттер, не должно быть перенасыщено влагой или пылью. Также нежелательно для устройства попадание на него прямых солнечных лучей.

10. Категорически запрещено оказывать любое давление на верхнюю перекладину и поднимать черную перекладину плоттера.

Раздел 2

Установка

2-1 Упаковка

Внимательно проверьте все изделия после вскрытия упаковки. Оборудование поставляется в следующей комплектности:

• Плоттер.

• Комплектующие (в пакете).

• Комплект деталей для стенда.

2-2 Комплектация

| Номер | Наименование | Количество |

| 1 | Сетевой шнур | 1 |

| 2 | Инструкция по эксплуатации (на диске) | 1 |

| 3 | Держатель для ножа | 1 |

| 4 | Нож | 3 |

| 5 | Стержень | 1 |

| 6 | Шестигранный ключ | 1 |

| 7 | Последовательный кабель (COM) | 1 |

| 8 | Параллельный кабель (опционально) | 1 |

| 9 | USB-кабель (опционально) | 1 |

| 10 | Защитный чехол для плоттера | 1 |

| 11 | Диск с драйвером для CorelDraw и USB порта | 1 |

| 12 | ПО «Artcut 2009», на диске (опционально) | 1 |

2-3 Комплектация стенда

| Номер | Наименование | Кол-во | Номер | Наименование | Кол-во |

| 1 | Левая стойка | 1 | 6 | Ролики для пленки | 2 |

| 2 | Правая стойка | 1 | 7 | Держатель для пленки | 2 |

| 3 | Поперечная перекладина | 1 | 8 | Плита для крепления | 2 |

| 4 | Опора | 2 | 9 | Винт M4х20 | 10/12 |

| 5 | Колесики опоры | 4 | 10 | Винт M4х8 | 8 |

2-4 Сборка стенда

Примечания по чертежу:

Подходит лишь для моделей, имеющих ширину не менее 780 мм

Шаг 1: Прикрепите винтами опоры к левой и правой стойке.

Шаг 2: Соедините правую и левую стойки поперечной перекладиной при помощи винтов.

Шаг 3: Присоедините держатели для пленки с внешнней части левой и правой стоек при помощи винтов.

Шаг 4: Присоедините плиту для крепления к верхней части левой и правой стойки при помощи винтов.

Шаг 5: Поместите плоттер на плиту крепления и вставьте опоры в панель для присоединения плоттера.

Шаг 6: Поместите ролики для рулонов на держатель.

Раздел 3 Основные операции

3-1 Установка и подключение

1. Установите плоттер на ровную поверхность, в просторном месте.

2. Подключите сигнальный кабель к порту COM1,COM2 или USB компьютера.

3. Проверьте напряжение питания и наличие заземления и убедитесь в соблюдении всех условий.

3-2 Установка ножа

3-2.1 Части держателя ножа и комплектующие

Поворотом установочного винта отрегулируйте длину ножа таким образом, чтобы он не прорезал нижний слой.

• Нож (диаметр — 2 мм)

• Кожух держателя ножа

• Установочный винт

• Корпус держателя ножа

3-2.2 Установка и регулировка лезвия

1. Перед установкой ножа тщательно протрите корпус держателя ножа и руки. Даже незначительное загрязнение может сказаться на работе ножа. Для удобства держания ножа в руках используйте захваты из мягкого пластика или резины. Аккуратно вставьте нож в корпус держателя. Он должен примагнититься к нему.

2. Поверните кожух держателя ножа и выставьте такую длину ножа, чтобы длина лезвия не превышала толщину клейкого слоя.

3. Во избежание травмы запрещается касаться лезвия пальцами.

3-2.3 Компоненты и структура стержня

Закрепите шариковую ручку в стержне (см.рисунок).

• Поверните колпачок.

• Установите шариковую ручку на нужную длину.

• Закройте стержень при помощи колпачка. Вкрутите их в корпус

3-2.4 Установка

1. Отключите питание

2. Ослабьте крепежный болт суппорта, установите в него держатель ножа или стержень. По достижении нужного положения закрутите крепежный болт по часовой стрелке.

3-2.5 Максимальное использование ресурса ножа

Ресурс ножа ограничен, но его можно максимально использовать.

Примечание:

1. Помните, что при повышенных усилиях реза сокращаются ресурсы ножа. В процессе резки избегайте прорезания нижнего слоя.

2. Исходя из вышеупомянутого, следует применять рез с минимально возможными усилиями. Только при затуплении ножа, увеличение усилия реза оправдано.

3. Нож нужно менять вовремя. Тогда когда он затупился или производительность оборудования упала. Если требуется срочная замена ножа, можно его заточить с помощью небольшого кусочка кожи (наподобие того, как затачивается бритва).

4. Выставляя большую длину ножа, вы значительно сокращаете его ресурс. По возможности в процессе резке не допускайте прорезывания нижних слоев.

5. Помните, что разные материалы требуют разной остроты ножа.

6. Ресурс ножей также зависит и от их производителя.

Раздел 4 Установка через USB-порт

Установка 340 USB драйвера

1. Установка USB-порта:

Внимание: Перед установкой диска не подключайте плоттер к ПК.

Вставьте установочный CD с драйвером в привод CD-ROM. На диске найдите данный файл. Выберите его двойным нажатием мыши.

Выбрать «NEXT» (Далее) для автоматической установки драйвера.

Нажать «OK». Драйвер успешно установлен.

Теперь подключите USB-кабель режущего плоттера к USB-порту ПК. В «диспетчере утройств» USB-устройство будет определено как «COM3». Это свидетельствует об успешном подключении плоттера к ПК.

2. Установка порта в ПО «Artcut»:

В окошке «Link to» выберите COM 3 для USB-порта.

В «Sequential Control» отметьте DTR/DSR и RTS/CTS.

3. По завершении настроек выполните перезагрузку компьютера.

Раздел 5 Инструкция по эксплуатации

5-1 Названия и функции деталей

5-1.1 Составные части

Тип_0

1. Левая крышка

2. Металлический ролик

3. Скоба для ножа

4. Держатель ножа

5. Каретка

6. Крышка направляющей

7. Прижимной ролик

8. Ручка регулировки положения

9. Панель управления

10. Правая крышка

11. Опора

12. Параллельный порт (опция)

13. Последовательный порт

14. Разъем питания

15. Разъем с плавким предохранителем

16. Выключатель питания

Типы_1

1. Левая крышка

2. Металлический ролик

3. Скоба для ножа

4. Держатель ножа

5. Каретка

6. Крышка направляющей

7. Прижимной ролик

8. Панель управления

9. Ручка регулировки положения

10. Правая крышка

11. Опора

12. Разъем питания

13. Разъем с плавким предохранителем

14. Выключатель питания

15. Переходник USB/СОМ (опция)

16. Последовательный порт

17. Параллельный порт (опция)

5-1.2 Панель управления

Тип_0

Тип_1

1. ЖК-дисплей

2. Сброс параметров

3. Автономный режим /Пауза

4. Настройка

5. Тестирование

6. Кнопка установки исходной точки

7. Увеличение усилия

8. Уменьшение скорости реза

9. Увеличние скорости реза

10. Уменьшение усилия

5-2 Основные операции

5-2.1 Включение плоттера

1. Выключатель питания должен находиться в положении OFF (выкл.);

2. Подключите сетевой шнур к разъему питания плоттера, включите питание выключателем;

3. После включения ЖК-дисплея на нем отображается процесс подготовки и следующая информация:

4. По окончании подготовки загорается красная лампа. Плоттер находится в состоянии онлайн и может работать под управлением с ПК.

5-2.2 Установка материалов

1 Загрузка материалов

1. Необходимо приподнять рукоять прижимных роликов. Затем убрать их с металлических роликов.

2. Взять рулон виниловой пленки и вставить его между прижимными и металлическими роликами. Направление пленки должно быть от задней части крышки плоттера к передней.

3. Прежде чем преступить к работе, еще раз тщательно осмотрите пленку на предмет ее правильного расположения в плоттере. В случае ошибочной установки произойдет отклонение в процессе резки. Если вы обнаружили, что виниловая пленка расположена неровно, плавно поднимите прижимный ролик и поправьте ее, отпустите ролик в начальное положение. Рекомендуется перед началом основной работы сделать несколько проверочных прогонов. Таким образом, вы минимизируете возможные неточности и отклонения.

2 Регулировка прижимных роликов по ширине пленки

Любой режущий плоттер укомплектован, как правило, 2-4 прижимными роликами. Такие ролики можно двигать по направляющей. Прежде чем вы начнете их двигать, поднимите рукоятки прижимных роликов. Затем возьмитесь за их заднюю часть и плавно потяните влево или вправо. Не следует тянуть ролики вперед, может ухудшиться точность.

3 Требования к положению роликов:

1. Прижимные ролики всегда должны быть расположены на расстоянии от 10 до 50 мм от краев бумажного полотна.

2. Недопустимо располагать прижимные ролики в одной зоне с сопряжением двух металлических роликов.

3. Не следует располагать прижимные ролики в области рисунка.

5.2.3 Пробный запуск (проверка усилия и ножа)

1. Пробная резка

После того, как вы установили нож и поместили в аппарат пленку, сделайте проверочный тест, с целью посмотреть, каким будет усилие реза ножа. Для этого нужно нажать кнопку, расположенную на корпусе прибора, ?TEST?. После, на дисплее плоттера отобразится следующая информация, и прибор начнет тестовую резку.

2. Регулировка усилия реза

Необходимо снять вырезанный рисунок. Если вы не можете его снять, значит нужно продолжить его резку. Судя по всему, длина или давление ножа были недостаточными. Если же повреждена (прорезана) основа, то наоборот давление и длинна ножа были избыточными. Нужно запомнить, что выступающая длина ножа должны быть не более 0,5 мм или две третьих от толщины пленки. Следует регулировать давление и длину ножа после тестового среза. Степень давления настраивается с помощью кнопок «F-«, «F+». Каждое нажатие той или иной кнопки увеличивает или уменьшает давление ножа на 1 уровень.

Внимание:

Обязательно выполняйте тестовую резку для проверки давления ножа при каждом использовании нового вида пленки.

5-3 Инструкция по эксплуатации

5-3.1 Функция «Сброс параметров» (Reset)

При включении плоттера происходит его автоматическое обнуление (сброс параметров). Загорается красный индикатор и плоттер переходит в режим готовности получения данных с ПК. При этом на ЖК-дисплее отображается следующее:

Заводские параметры:

• Скорость передачи данных: 9600

• Скорость резки: 350мм/сек

• Давление ножа: 100г

• Исходная точка резки — согласно заводским настройкам

Вышеуказанная информация может быть изменена в ходе работы.

При нажатии кнопки RESET в режиме работы плоттер отменяет текущее задание и выполняет переход к заводским настройкам.

5-3.2 Функция «Под управлением ПК» (Online)

После перезагрузки светится красный индикатор. Если плоттер получает данные с компьютера, он находится в онлайн режиме.

Теперь Вы можете изменить скорость резки при помощи кнопок V+ или V- и отрегулировать давление ножа кнопками F+ или F.

При нажатии кнопки RESET в рабочем режиме, плоттер возвращается к заводским настройкам и переходит в режим сброса параметров (удаляет заданную информацию) и выполняет подготовку к новому заданию.

5-3.3 Функция «Автономный режим/Пауза» (Offline/Pause)

Для перехода в автономный режим нажмите кнопку OFFLINE. Включится желтый индикатор. При этом, на дисплее появится сообщение «Motion, X= xxx, Y= yyy», указывающее на текущее местоположение (координаты) ножа.

Перемещение каретки влево/вправо производится нажатием кнопок V+ или V-. Перемещение пленки вперед/назад выполняется кнопками F+ или F-. В данном режиме Вы можете выполнить перемещение ножа в исходную позицию. При этом будет пошагово изменяться значение координат «X, Y» на ЖК-дисплее.

При нажатии кнопки «Pause» в режиме работы происходит остановка плоттера. Для возобновления работы необходимо повторно нажать кнопку «Pause».

5-3.4 Установка исходной точки

При перемещении ножа в исходную позицию нажмите кнопку «Origin». Новая исходная точка задана — плоттер начнет построение с новой исходной точки.

5-3.5 Функция настройки (Setup)

В режиме «ONLINE» при нажатии кнопки «SETUP» загорается зеленый индикатор и Вы можете изменить скорость передачи через серийный порт. Повторное нажатие кнопки SETUP приводит к сохранению в онлайн-режиме.

Внимание:

Изменение данных настроек непрофессиональными техниками не рекомендуется.

5-3.6 Функция повторного резания (Copy)

При нажатии кнопок OFFLINE, SETUP и ORIGIN плоттер выполнит повторное резание последнего задания. При мигающем зеленом индикаторе RESET повторное резание невозможно, так как это свидетельствует о превышении емкости оперативной памяти. Для повторного запуска задания нажмите кнопку RESET.

Внимание:

При появлении признаков сбоя и невозможности отключения плоттера, выключите его питание или выдерните вилку из розетки.

5-3.7 По завершении работы

1. Уберите бумагу.

2. Снимите держатель ножа или стержень, протрите его мягкой тканью и поместите на хранение.

3. Отключите питание и выдерните шнур питания (если не планируете использовать плоттер длительное время).

4. Накройте плоттер тканью или чехлом.

5-4 Таблица параметров

| Технические характеристики (тип_0) | |||||

| Модель | 360 | 720 | 870 | 1100 | 1350 |

| Макс.ширина материала | 365мм | 720мм | 870мм | 1100мм | 1350мм |

| Макс.область резки | 275мм | 630мм | 780мм | 1010мм | 1260мм |

| Скорость резки | 50-800мм/сек 50-800mm/s 50-800mm/s 50-800mm/s |

||||

| Давление ножа | 50-500г 50-500g 50-500g 50-500g |

||||

| Объем памяти | 1M 1M 1M 1M |

||||

| ЖК-дисплей | Опционально Optional Optional Optional |

||||

| Процессор | 8-bit CPU | ||||

| Полоска плоттера | Пластиковый лист | ||||

| Двигатель | Шаговый | ||||

| Мин.матрица знаков | Высота ~5мм [0.2»] | ||||

| Тип лезвия | Особая сталь [1,2 мм и 2,0 мм] | ||||

| Материалы | Самоклеящаяся виниловая пленка, флуоресцентная пленка, отражающая пленка, бумага | ||||

| Панель дисплея | 8 символов X 2 строки, ЖК | ||||

| Интерфейсы | Параллельный, последовательный, USB (опционально) | ||||

| Напряжение | 90-260В | ||||

| Точность повтора | 0,0127мм | ||||

| Разрешение | 0.0254мм/шаг | ||||

| Набор команд | DMPL / HPGL | ||||

| Рабочая температура | 0-350С | ||||

| Влажность | 5%-65%, без конденсации |

| Технические характеристики (тип_1 ) | |||||

| Модель | 361 | 721 | 871 | 1101 | 1351 |

| Макс.ширина материала | 365мм | 720мм | 870мм | 1100мм | 1350мм |

| Макс.область резки | 275мм | 630мм | 780мм | 1010мм | 1260мм |

| Скорость резки | 50-800мм/сек | ||||

| Давление ножа | 50-500г | ||||

| Объем памяти | 1-4M | ||||

| ЖК-дисплей | Имеется | ||||

| Процессор | 8-bit | ||||

| Специальные настройки | Двухпозиционное крепление ножа | ||||

| Полоска плоттера | Пластиковый лист | ||||

| Двигатель | Пошаговый | ||||

| Мин.матрица знаков | Примерно 5 мм [0.2»] в высоту | ||||

| Тип лезвия | Особая сталь [1,2мм и 2,0мм] | ||||

| Материалы | Самоклеящаяся виниловая пленка, флуоресцентная пленка, отражающая пленка, бумага | ||||

| Панель дисплея | 8 символов X 2 строки, ЖК | ||||

| Интерфейсы | Параллельный, последовательный, USB | ||||

| Напряжение | 90-260В | ||||

| Точность повтора | 0.0127мм | ||||

| Разрешение | 0.0254мм/шаг | ||||

| Набор команд | DMPL / HPGL | ||||

| Рабочая температура | 0-350С |

Раздел 6 Неисправности и их устранение

Если рисунок не завершен или деформирован:

1. Давление ножа не отрегулировано, чрезмерная длина лезвия, грязный стол, слишком мягкая пленка — все это влияет на сопротивляемость двух сторон пленки, поэтому она попадает за вращающийся ролик, что приводит к деформации рисунка.

2. Неправильно установлено программное обеспечение.

3. Ремень каретки ослаблен. Металлический ролик и электрический механизм не совмещаются.

4. Двигатель не делает все нужные шаги.

5. Установлено слишком маленькое значение коррекции, которое может привести к незавершению резки при нормальном рисунке.

Если плоттер вычерчивает неправильно:

1. Программное обеспечение несовместимо. Важно установить правильный набор команд. Указать соответствующее значение коррекции на инструмент.

2. Сбой программного обеспечения плоттера.

3. ПО повреждено либо ПК заражен вирусами.

Если происходят отклонения материала:

1. Неправильно установленная пленка.

2. Грязная рабочая поверхность (стол) — сопротивление с обеих сторон не может быть сбалансированным при перемещении материала.

3. Прижимные ролики деформированы, не соответствуют рабочим параметрам.

4. Недостаточно усилия прижима прижимных роликов, материал слишком чувствителен к прилагаемому усилию прижима.

5. Вес пленки неуравновешен.

Если происходят пропуски при прорезании букв:

1. Вероятно, пленка имеет чрезмерное натяжение, или она слишком тяжелая.

2. Металлический ролик засорен. На него попало какое-либо инородное вещество, например, виниловые обрезки.

3. Чрезмерная длина лезвия ножа, чрезмерное давление ножа, завышенная скорость резки.

4. Из-за высокого давления на прижимный ролик или сверхвысокого натяжения синхронизирующего ремня.

5. Металлический ролик сломан, неисправен. Для того чтобы отремонтировать или заменить вышедший из строя металлический ролик вам следует обратиться к местному поставщику по вопросу ремонта и замены.

Если буквы в одной строке имеют разную глубину реза:

1. Держатель ножа не закреплен. Требуется его закрепить.

2. Лезвие ножа не закреплено в держателе.

Если присутствует волнистость букв:

1. Чрезмерная скорость резки. Она не должна превышать 480мм/сек (за исключением случаев резки букв и знаков большого размера).

2. Нож поврежден, требует замены.

3. Держатель ножа не закреплен. Необходимо его затянуть.

Резка букв малого размера

Чем меньше буквы вам нужны, тем минимальней должны быть выставлены значения давления и длины лезвия ножа.

Резка букв большого размера

Для очень больших букв выбираем предельное значение давления ножа. При резке букв большого размера функцию Sharp Angle в программе «Artcut» можно не применять.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

6000 SERIES

CE

CUTTING PLOTTER

USER’S MANUAL

MANUAL NO.CE6000U-UM-151

Related Manuals for GRAPHTEC CE6000 SERIES

Summary of Contents for GRAPHTEC CE6000 SERIES

-

Page 1

6000 SERIES CUTTING PLOTTER USER’S MANUAL MANUAL NO.CE6000U-UM-151… -

Page 2: To Ensure Safe And Correct Use

TO ENSURE SAFE AND CORRECT USE • To ensure the safe and correct use of your plotter, read this manual thoroughly prior to use. • After reading this manual, keep it in a handy location for quick reference as necessary. •…

-

Page 3

Use of the plotter in such a condition may result in a fire hazard or electric shock. • After confirming that smoke is no longer being emitted, contact your sales representative or nearest Graphtec vendor for repairs. • Never attempt to perform repairs yourself. -

Page 4

Use of a damaged cord may result in electric shock or a fire hazard due to current leakage. • Contact your sales representative or nearest Graphtec vendor for repairs. Unplug the power Prohibited cord from the socket… -

Page 5

Safety Precautions CAUTION Do not attempt to lubricate the cutting-plotter Do not clean the plotter using volatile solvents such mechanisms. as thinner or benzene. • • Such action may cause it to break down. Such action may impair its performance. Prohibited Prohibited Provide sufficient space around the plotter so that… -

Page 6: Preface

In addition to cutting marking film and other media, an CE6000 series plotter can also be used as a pen plotter. To ensure high cutting quality and optimal productivity, be sure to read this User’s Manual thoroughly prior to use.

-

Page 7: Special Precautions On Handling Blades

Special Precautions on Handling Blades Sharp cutter blades are used with this plotter. Handle the cutter blades and holders with care to prevent bodily injury. Cutter Blades Cutter blades are very sharp. While handling a cutter blade or cutter pen, be careful to avoid cutting your fingers or other parts of your body.

-

Page 8: After Turning On The Plotter

The machine’s Caution Label is located on the top cover. Be sure to observe all the cautions on the label. Notes on the Stand Be sure to use only the stand designed for the CE6000 Series with your CE6000 Series plotter. The use of a different stand may cause a plotter malfunction or bodily injury.

-

Page 9: About The Words And Phrases In This Text

Proper cables and connectors are available from GRAPHTEC’s authorized dealers or manufacturers of computers or peripherals. GRAPHTEC is not responsible for any interference caused by using cables and connectors other than those recommended or by unauthorized changes or modifications to this equipment.

-

Page 10: Selecting A Power Cable

Selecting a Power Cable Be sure to refer to the following tables if you wish to use a cable other than the one supplied as an accessory. Table 1. 100 V to 120 V Power Supply Voltage Range Supply Voltage Reference Plug Configuration Plug Type…

-

Page 11: Table Of Contents

CONTENTS TO ENSURE SAFE AND CORRECT USE……… . . Preface .

-

Page 12

2-27 Contents of Operation from Menu Screen……. . . 2-28 Contents of Operation from [COND/TEST] Key . -

Page 13

Positioning of the Media and the Registration Mark ……Position of the Origin Point and the Registration Mark ……Media That Registration Mark Cannot be Detected . -

Page 14

Chapter 9: Setting Regarding Interface Setting Interface…………USB Interface . -

Page 15: Chapter 1 Product Summary

Chapter 1 Product Summary This chapter explains how to connect this device your computer. PRODUCT SUMMARY Checking the Accessories Nomenclature Assembling Connecting to the Computer…

-

Page 16: Checking The Accessories

Checking the Accessories Accessories Item Q’ty Item Q’ty Power cable 1 pc USB cable 1 pc 1 pc SETUP MANUAL, 1 of TO ENSURE SAFE AND CORRECT USE each • Various software • User’s Manual (pdf) Cutter holder (PHP33-CB09N-HS) 1 pc Cutter blades (CB09UB-1) 1 pc Water-based fiber pen adapter (PHP31-FIBER)

-

Page 17: Nomenclature

Nomenclature Front View: CE6000-40 Tool carriage Control panel Tool holder Grit roller position guide Media set lever Cutting mat USB interface connector Cutting groove Push roller RS-232C interface connector Media sensor Grit roller Control panel ……Used to access various plotter functions. Push rollers ……Rollers that push the media against the grit rollers.

-

Page 18: Rear View: Ce6000-40

Rear View: CE6000-40 Power switch AC line inlet Roll-medium tray Roll-medium tray guide rail Roll-medium tray …..A tray to set media in. Roll-medium tray guide rail ..A rail to set the roll media tray in. Power switch ……Used to turn the plotter on and off. AC line inlet ……Inlet where the power cable is connected.

-

Page 19: Front View: Ce6000-60

Front View: CE6000-60 Tool holder Control panel Tool carriage Grit roller position guide Cutting mat Media set lever Cutting groove Media stopper Push roller USB interface connector Media sensor Grit roller RS-232C interface connector Control panel ……Used to access various plotter functions. Push rollers ……Rollers that push the media against the grit rollers.

-

Page 20: Rear View: Ce6000-60

Rear View: CE6000-60 Power switch Stopper AC line inlet Stock shaft Stopper Media stocker Stand Power switch ……Used to turn the plotter on and off. AC line inlet ……Inlet where the power cable is connected. Media stocker ……A stock to set roll media in. Stock shaft …….A roller that takes in roll media.

-

Page 21: Front View: Ce6000-120

Front View: CE6000-120 Grit roller position guide Tool holder Tool carriage Cutting mat Control panel Cutting groove Media set lever Media stopper Grit roller Push roller USB interface connector Media sensor Media guide bar RS-232C interface connector Control panel ……Used to access various plotter functions. Push rollers ……Rollers that push the media against the grit rollers.

-

Page 22: Rear View: Ce6000-120

Rear View: CE6000-120 Power switch AC line inlet Stock shaft Stopper Media stocker Stand Power switch ……Used to turn the plotter on and off. AC line inlet ……Inlet where the power cable is connected. Media stocker ……A stock to set roll media in. Stock shaft …….A roller that takes in roll media.

-

Page 23: Assembling

Assembling Assemble the stand. The stand is made up of the following parts. CE6000-60 Stand side bar × 2 Stand foot × 2 Center bar × 1 Allen wrench (for M5 Socket head cap screw screws) × 1 (M5) × 12 Stopper ×…

-

Page 24

Assembly (CE6000-60) CAUTION Please assemble with two or more people. People can be accidentally injured by the machine’s edges. Please be very careful. Please be careful not to get your hands pinched or stuck when you secure the machine. 1 Assemble the left and right stand sides. -

Page 25

3 Attach a media stocker to each of the left and right stand side bars with two socket head cap screws, using the Allen wrench. Mount the media stockers so that each one of media stockers of long side to be rear side. Socket head cap screw Media stocker Media stocker… -

Page 26

Assembly (CE6000-120) CAUTION Please assemble with two or more people. People can be accidentally injured by the machine’s edges. Please be very careful. Please be careful not to get your hands pinched or stuck when you secure the machine. 1 Assemble the left and right stand sides. -

Page 27

3 Attach a media stocker to each of the left and right stand sides with Five socket head cap screws, using the Allen wrench. Mount the media stockers so that each one protrudes directly above the longer of the two stand foot lengths. -

Page 28: Mounting The Roll-Medium Tray

Mounting the Roll-medium tray Mounting (CE6000-40 and the CE6000-60 without stand) 1 Set the roll media tray in using the roll media tray guide rail. Make sure the rollers on the roll media tray are on the outside on both sides. Roll-medium tray guide rail Roll-medium trays…

-

Page 29

Mounting (CE6000-120) 1 Set one stopper in the stock shaft. (Keep the stopper screws slightly loose.) Stock shafts Stoppers 2 Slide the stock shaft into the media stocker. Stock shafts Roller 1-15… -

Page 30: Connecting To The Computer

Please install driver software before connecting. Depending on the port used, use either the USB cable, the RS-232C cable (CB0023C-HS: sold separately) to connect. Use the cables specified by Graphtec, matching the computer that is to be connected. This will be explained in CE6000-120.

-

Page 31: Chapter 2: Preparing To Cut

Chapter 2: Preparing to Cut This chapter describes how to prepare to start the cutting. PRODUCT SUMMARY Preparation of Cutter Plunger Attaching a Tool Loading Media (Paper or Marking Film) Aligning the Push Rollers About the Default Screen Connecting to the Power How to Use Control Panel Setting Feeding Method Pre Feed of Media (Paper or Marking Film)

-

Page 32: Preparation Of Cutter Plunger

Preparation of Cutter Plunger This chapter describes the structures and types of the putter plungers (cutter pens). Cutter Plunger Nomenclature The plotter cuts using a cutter blade mounted in a plunger. There are two different plungers to suit the diameter of the cutter blade to be mounted (the φ0.9 mm cutter plunger is provided as a standard accessory).

-

Page 33: Blade Application And Features

Blade Application and Features Referring to the blade application and features in the table below, select the optimal cutter blade and medium to be cut. Blade part no. and type Diameter Plunger part no. Applications and features CB09UB Φ0.9mm PHP33-CB09N-HS Standard blade for cutting color adhesive media.

-

Page 34: Attaching A Tool

Attaching a Tool Attach a tool (cutter plunger, plotter pen) to the plotter. Attaching a Tool When mounting the tool in the tool holder, please note the following. • Push the tool all the way into the holder until its flange contacts the upper part of the holder and then tighten the screw firmly.

-

Page 35: Removing The Tool

3 Make sure that the tool bracket is engaged on the tool’s flange, and then tighten the screw. Flange Bracket to hold tool Removing the tool When removing the tool, turn it counterclockwise to remove the tool.

-

Page 36: Loading Media (Paper Or Marking Film)

Loading Media (Paper or Marking Film) Both roll media and sheet media can be used with the CE6000. Load the media according to the instructions given for each type. Use the grit roller on the right side of the media (looking from the front) as a guide when setting it in the media sensor.

-

Page 37

3 Pulled from the front, the roll media should be long enough so that its tip completely covers the sensor. If you pull it too long, wind the roll and adjust the length. Push roller Media sensor 4 Position the media and the push rollers to correspond with Supplement the width of the media. -

Page 38

5 Pull the media taut to make sure that there is no slack in the conveyance path, and then raise the media set lever to lower the push rollers. Media set lever Create the same amount of slack in the media as will be used for the back of the machine. -

Page 39: Loading Roll Media (Ce6000-60/120)

Loading Roll Media (CE6000-60/120) This will be explained in CE6000-120. Operation 1 Lower the media set lever to raise the push rollers. Push roller Media set lever Media sensor 2 Set the roll media on top of the stock shaft, and then insert the roll media into the stopper.

-

Page 40

3 Push the tip of the roll media forward from the back of the CE6000. Make sure to pull it so that there is no slackening across the roll media’s route. 4 Press the media lock to engage it, and then pull the leading Supplement edge out of the front of the plotter, making sure that it When actually cutting, please release the… -

Page 41

5 Position the media and the push rollers to correspond with the width of the media. When the CE6000-60 The push rollers push down on either side of the media. Use Supplement the grit roller position guide to make sure the push rollers are The media must always be positioned over set on top of the grit rollers. -

Page 42

When Feeding Long-axis Media (at exceeds 2 meters) Position the push rollers at least 15 mm inside the edges of the media. Push roller 15 mm 15 mm Media When Feeding Long-axis Media (at least 2 meters) Position the push rollers at least 5 mm inside the edges of the media. -

Page 43

8 When the set lever is up (and the media is held down by the Supplement push rollers) and the media stopper is unlocked, pull out the Dirt from the floor may stick to the media when roll media and give it slack. giving it slack, so please be careful. -

Page 44: Loading Sheet Media (Ce6000-40/60)

Loading Sheet Media (CE6000-40/60) This will be explained in CE6000-60. Operation 1 Lower the media set lever to raise the push rollers. Push roller Media set lever Media sensor 2 Set the sheet media so that the paper’s edges line up with the guideline on the front side.

-

Page 45

3 Position the media and the push rollers to correspond with Supplement the width of the media. The media must be at least 125 mm in length. The push rollers push down on either side of the media. Use The media must always be positioned over the grit roller position guide to make sure the push rollers are the media sensor. -

Page 46: Loading Sheet Media (Ce6000-120)

Loading Sheet Media (CE6000-120) Operation 1 Lower the media set lever to raise the push rollers. Push roller Media set lever Media sensor 2 Make sure that the sheet media completely covers the media sensor. Media sensor 2-16…

-

Page 47

3 Position the media and the push rollers to correspond with Supplement the width of the media. The media must always be positioned over Use the 3 push rollers to push down the sides and center of the media sensor. the media. -

Page 48

5 You can set the media straight by stacking media you pull out and matching the edges up together. After you check to make sure there’s no slack, raise the media set lever and fixate the sheet media in the push roller. Media set lever Line up Media guide bar… -

Page 49: Aligning The Push Rollers

Aligning the Push Rollers This section describes how to alignment of the push rollers. Aligning the Push Roller Position the left and right push rollers to correspond with the width of the media. Adjust the push rollers so that they are positioned above both the media and the grit rollers. Position the push rollers within the grit roller position guides ensures that they are above the grit rollers.

-

Page 50

When Feeding Long-axis Media (at least 2 meters) Position the push rollers at least 5 mm inside the edges of the media. Push roller 5 mm 5 mm Media For minimum width media Make sure that all push rollers are on the long right grit roller.Use the left side of the grit roller as a starting point and then set the push rollers so that they’re on both sides of the media. -

Page 51: Changing The Hold-Down Force

Changing the Hold-down Force The CE6000-120 requires the center push roller hold-down force to be set based on the media’s width and material type in order to keep the media in place. (This only applies to the CE6000-120) Switching (1) Lower the media set lever to raise the push rollers. (2) Use the push roller hold-down force switching lever on the back of the push roller to adjust the center push roller’s hold-down force.

-

Page 52: About The Default Screen

About the Default Screen The Initial Setup Screen appears only when powering up the machine for the first time after purchase. Here, you can set the display language and length unit. You can also enter the menu select from the READY status after a setup. P.10-2 Display Language Settings (LANGUAGE SELECTION) Display Length Unit Settings (LENGTH UNIT)

-

Page 53: Connecting To The Power

Connecting to the Power Turning on the power of the plotter. Operation 1 Check that the power switch is turned off. (the » » side is pressed down) 2 Connect one end of the provided power cord to the CE6000 AC line inlet and the other end to an electrical socket of the rated supply voltage.

-

Page 54: How To Use Control Panel

How to Use Control Panel This section explains the function of lamps and keys on the control panel. [2] key [1] key [SIMPLE] lamp [SIMPLE] key [MENU] lamp [PAUSE/MENU] key [ORIGIN] key [COPY] key [ENTER] key Screen (LCD) [3] key [4] key [FAST] key POSITION (…

-

Page 55: Indicator Lamp

Indicator Lamp SIMPLE lamp ….. A green light indicates Simple mode is on. MENU lamp ….A green light indicates MENU mode is on. Reading the Screen (LCD) Information reflecting the status will be displayed in the screen of the control panel. Name of the button and corresponding function is displayed on the screen when a function is allocated to the button on the control panel.

-

Page 56

Screen to set the corresponding conditions is displayed when the [PAUSE/MENU] key or [COND/TEST] key are pressed. [PAUSE/MENU] [COND/TEST] [PAUSE/MENU] [COND/TEST] It will return to default screen It will return to default screen It will return to default screen It will return to default screen when [PAUSE/MENU] key when [COND/TEST] key is when [PAUSE/MENU] key… -

Page 57: Contents Of Operation From Menu Screen

Contents of Operation from Menu Screen You can use the [SIMPLE] key on the default screen to switch between Simple mode and Normal mode. Switching will reset the CE6000. In Simple mode you can change easy settings from the menu screen. In Normal mode, you will be able to change more detailed settings.

-

Page 58: Contents Of Operation From [Cond/Test] Key

Contents of Operation from [COND/TEST] Key Simple mode CONDITION screen (1-5): (Simple mode) The [COND/TEST] key brings up the SETTING screens, where you can change the media type and tool conditions. The preset cutting condition is used when the media type is selected. [COND/TEST]: This will clear the CONDITION screen and return to default screen.

-

Page 59: Setting Feeding Method

Setting Feeding Method Feeding method for the loaded media is set. Operation 1 If you have already loaded the media, the MEDIA TYPE CAUTION menu appears. Select the media type to suit the loaded Before doing the media set selection, make sure media.

-

Page 60

2 After the media is detected, the plotter is ready to receive Supplement data for cutting or plotting. This status is called «READY The screen below shows a machine currently status» of the default screen. detecting media. When setting is finished, the tool carriage’s location will become the initial point. -

Page 61: Pre Feed Of Media (Paper Or Marking Film)

Pre Feed of Media (Paper or Marking Film) The PRE FEED function is used to prevent the loaded media from slipping by automatically advancing the media the specified length and imprinting it with grit roller marks. This function can also be used to acclimate long media lengths to the operating environment in order to minimize media expansion and contraction, and to ensure stable media feed operations.

-

Page 62: Selecting Tool Condition

2.10 Selecting Tool Condition In Simple mode, you can change tool conditions for five different types of media. Normal mode can remember up to 8 settings. Changing these settings allows you to make the proper settings for each different type of media. The [SIMPLE] key allows you to switch between Simple mode and Normal mode.

-

Page 63

Normal mode Operation 1 Press the [COND/TEST] key in the default screen. Supplement CONDITION setting screen (1/3) is displayed. Name of the media assigned in «Cutting Plotter controller» is displayed as the CONDITION No. name. CONDITION No. can also be changed from READY status. -

Page 64: Setting The Tool Condition

Setting the Tool Condition This section describes how to make the tool, speed, force, Supplement acceleration, and tool number settings. Before cutting media, the See the appropriate references for details following five cutter-pen conditions must be specified. about the «Setting the Tangential Emulation» (1) Cutter-blade length ..Adjust the blade length by referring to the , «Setting Length of the Overcut» P.7-3 media thickness table below. , «Setting the Distance Adjust» P.7-4 (2) FORCE …… Set the FORCE by referring to the table , and «Setting of the Initial Down P.7-14 Force» P.7-6 below. For method to manually adjust the blade (3) SPEED …… Set the SPEED by referring to the table length, see «Adjust the Blade Length below. Manually» and «Adjust the Blade P.2-44 (4) ACCELERATION .

-

Page 65

Reference Pen Conditions for Plotting Pen Pen type Part no. Force Speed (cm/s) Acceleration 10 to 12 Water-based fiber-tip pen KF700 series To prolong the pen life, set the FORCE to the lowest setting, and set the SPEED after checking to confirm that there are no faint lines or other problems during plotting. -

Page 66: Setting The Speed And Force (Simple Mode)

Setting the Speed and Force (Simple mode) In Simple mode, set the speed and force to be used with each tool condition. Setting range (SPEED) : 5 to 60 (in 5cm/s increment) Setting range (FORCE) : Standard Value + Adjusted Value When the value (standard value + adjusted value) is as follows;…

-

Page 67

5 When you want to change the force, press the [3] key (FORCE). The screen below will appear. 6 Press the POSITION ( ) keys to change the current value. Supplement The force setting can be modified with the ± adjusted value. Press the [ENTER] key (SET) to confirm the settings and return to the READY screen. -

Page 68: Setting The Tool

Setting the Tool Set the type and offset value of the tool that is used in each of the tool condition numbers. Operation 1 Press the [COND/TEST] key in the default screen. Supplement CONDITION setting screen (1/3) is displayed. Perform the settings in Normal mode. In Simple mode, CB09U is locked.

-

Page 69

7 Press the [3] key (OFFSET). Supplement OFFSET setting screen is displayed. What is Offset It will adjust the difference between the tip of the blade in the plunger and the center of the plunger. There are standard adjustment values for each cutter blades. Fine adjustment will be made to that standard values here. -

Page 70: Setting The Speed

Setting the Speed Set the speed of the tool that is used in each of the condition numbers. Setting range : CE6000-40 1 to10 (in 1 cm/s increment), 10 to 60 (in 5 cm/s increment) : CE6000-60 1 to10 (in 1 cm/s increment), 10 to 60 (in 5 cm/s increment), 64 : CE6000-120 1 to10 (in 1 cm/s increment), 10 to 70 (in 5 cm/s increment), 71 Supplement On the CE6000-60, if you set speed as 64 and acceleration as 3, they will both appear as «*».

-

Page 71: Setting The Force

Setting the Force Set the cutting force that is used in each of the condition numbers. Setting range : CE6000-40 : 1 to 31 : CE6000-60 : 1 to 31 : CE6000-120 : 1 to 38 Operation 1 Press the [COND/TEST] key in the default screen. Supplement CONDITION setting screen (1/3) is displayed.

-

Page 72: Setting The Acceleration

Setting the Acceleration Set the acceleration of the tool that is used in each of the tool condition numbers. Setting range : CE6000-40 : 1 to 3 : CE6000-60 : 1 to 3 : CE6000-120 : 1 to 2 Supplement On the CE6000-60, if you set speed as 64 and acceleration as 3, they will both appear as «*».

-

Page 73

5 Press the POSITION ( ) key and increase or decrease the Supplement setting value. Guideline to set acceleration See «Setting the Tool Condition» P.2-32 6 Confirm the setting and press the [ENTER] key (SET). Setting will be set, and it will return to CONDITION screen (2/3). 7 Press the [COND/TEST] key. -

Page 74: Adjust The Blade Length Manually

Adjust the Blade Length Manually Optimal cut is not achieved unless the blade length is adjusted in accordance to the used media and the cutter blade. Perform further adjustment by performing cutting test after adjusting the blade length manually. CAUTION To avoid bodily injury, handle cutter blades with care.

-

Page 75: Running Cutting Tests

2.11 Running Cutting Tests Test cutting can be performed after making the tool, speed, force, and acceleration settings to ensure that the selected cutting conditions actually produce the desired cutting results. Check how far the blade cuts into the media and how the corners are being cut. If the cutting results are not satisfactory, adjust the various settings and repeat the test cutting until the optimal settings are achieved.

-

Page 76

To make 3 cuts with set value and ±1 of set value Operation 1 Load the media for test cutting in the plotter. 2 Press the [COND/TEST] key in the default screen. In Normal mode, CONDITION screen (1/3) is displayed. In Simple mode, CONDITION screen (1/5) is displayed. -

Page 77: Confirm The Results Of The Cutting Test

Confirm the Results of the Cutting Test Confirm the cutting test results, and adjust to optimal setting. Repeat cutting test and adjustment until optimal cut is achieved. Adjustment of Offset Check the corners of the triangles and rectangles. See «Setting the Supplement Tool»…

-

Page 78: Adjust The Blade Length (Automatic Height Adjust)

Adjust the Blade Length (Automatic Height Adjust) Test cutting must be performed several times in order to confirm the optimal blade length setting. However, if the blade length adjustment function is used, the optimal length can be easily set. Operation 1 Load the media for test cutting in the plotter.

-

Page 79

7 Set the cutter Plunger in Tool Holder 1 (Backward). Supplement Adjustment is only possible for the cutter pen set in Tool Holder 1 (Backward). It does not apply to Tool Holder 2 (Forward) . See «Attaching a Tool» for instructions on P.2-2 setting. -

Page 80

Turn the blade-length adjustment knob and adjust the cutter CAUTION blade length. Depending on the loaded media, the blade [2] Current blade length is displayed by pressing the [2] key might sink in to the media, making accurate (CHECK) , so adjust the blade length until it matches the measurement impossible. -

Page 81: About Simple Mode

2.12 About Simple mode Simple settings can be made from the menu in Simple mode. Five different tool conditions can be switched on for different media. Copying can also be done from Simple mode. The green Simple Lamp will come on when Simple mode is activated. Simple mode and Normal mode are independent from each other.

-

Page 82

Changing Mode When pressing the [SIMPLE] key, the following screen appears. The [1] key (Yes) allows you to change the mode after resetting the CE6000. The [2] key (No) allows you to return to the previous screen without changing the mode. 2-52… -

Page 83

* Please be sure to use the basket (option) when cutting something over 2 m long. Page ejection quality assurance goes up to 2 m for the CE6000-40 and up to 5m for the CE6000-60/120. (It depends on the media specified by Graphtec and setting conditions.) • Use the basket (option). -

Page 84

4 Press the POSITION ( ) keys to change the current setting. Supplement Press the [FAST] key to change the setting digits. You can enter any digit between 20.0cm and 5000.0cm. 5 Confirm the setting and press the [ENTER] key (SET). Supplement Setting will be set, and it will return to MEDIA SETTING screen. -

Page 85

2.12.2 Origin Point Settings When configuring HP-GL (Simple mode) When using the HP-GL command, the origin point is set to either the lower left of the cutting area or the center. When using the GP-GL command, this setting does not affect the operation. Command settings are automatic in Simple mode. -

Page 86

2.12.3 GP-GL Step Size (Simple mode) Here you can change the distance of 1 Step. Match it to the software you are using. «Command setting» is only for GP-GL commands. Operation 1 In default screen, press [PAUSE/MENU] key. MENU screen is displayed. 2 Press [2] key (I/F) . -

Page 87

2.12.4 Display Language Settings (Language) (Simple mode) Here you can change the display language. You can choose from 10 languages: English, Japanese, German, French, Italian, Spanish, Portuguese, Russian, Korean, and Chinese. This can be changed in Normal mode. Operation 1 In default screen, press [PAUSE/MENU] key. -

Page 88

2.12.5 Display Length Unit Settings (Length Unit) (Simple mode) You can choose to have length units displayed in either meters or inches. This can be changed in Normal mode. Operation 1 In default screen, press [PAUSE/MENU] key. MENU screen is displayed. 2 Press [3] key (ADV.). -

Page 89: Chapter 3: Basic Operations

Chapter 3: Basic Operations This chapter describes the basic methods to operate the plotter manually. All the operations described in this chapter is to start from the READY status (media is set) as a general condition. Perform the operation described in this chapter after making the plotter in READY status referring to previous chapter.

-

Page 90: Raise Or Lower The Tool

Raise or Lower the Tool This is a function to raise or lower the tool (pen). Operation 1 Press the [PAUSE/MENU] key. Supplement MENU screen is displayed. Perform the settings in Normal mode. 2 Press the [1] key (TOOL). TOOL SETTING (1/3) screen is displayed. 3 Tool is raised or lowered every time the [1] key (TOOL UP/ DOWN) is pressed.

-

Page 91: Move The Tool Carriage And Media

Move the Tool Carriage and Media Tool carriage and media can be moved manually using the POSITION key. It also can move the tool carriage and media to the origin, or move it certain distance to keep it away. Move in Steps Manually It can manually move in steps when the screen is displaying «READY», or when the POSITION ( ) key is displayed.

-

Page 92: Setting Of Step Movement Distance

Setting of Step Movement Distance The parameters when setting the cutting direction are determined by the distance of the cutting direction. Operation 1 Press the [PAUSE/MENU] key. Supplement MENU screen is displayed. Perform the settings in Normal mode. 2 Press the POSITION ( ) key (ADV). ADV.

-

Page 93: Move Away The Tool Carriage

Move Away the Tool Carriage It is possible to move the tool carriage 100 mm toward upper right. It makes it easier to confirm the cutting results if you perform this operation after the cutting is completed. <When using Roll Media>: Seen from above Standby position of the pen carriage Position of the pen carriage before moving away To the bottom of the cutting area…

-

Page 94: Change The Cutting Condition (Condition No.)

Change the Cutting Condition (Condition No.) Go through the following steps to change the Cutting Condition (Condition No.): Operation 1 Press the [ENTER] key in READY status. Supplement CONDITION No. selection screen is displayed. Perform the settings in Normal mode. 2 Press the [1] key (No.1), the [2] key (No.2), the [3] key (No.3), Supplement…

-

Page 95: Setting The Origin Point

Setting the Origin Point Point where the cutting starts is called origin point. The origin point can be set at any location. New origin point Original origin point Operation 1 Move the tool to the new origin point by pressing the POSITION ( ) key when it is in READY status.

-

Page 96: When Coordinate Axes Rotation Are Set

When Coordinate Axes Rotation are Set If the origin point is moved while the coordinate axes are rotated, the origin point will move as shown below. Supplement See «Setting the Cutting Direction» about the rotation of the coordinate axes. P.3-10 Original origin point New origin point…

-

Page 97: Setting Origin Point When Hp-Gl Is Set

Setting Origin Point When HP-GL is Set When using the HP-GL command, the origin point is set to either the lower left of the cutting area or the center. Supplement When using the GP-GL command, this setting does not affect the operation. See «Settings of Controls from Computer»…

-

Page 98: Setting The Cutting Direction

Setting the Cutting Direction Rotate the coordinate axes to change the cutting direction. Reference The rotation settings will be saved even if the power is shut off. Coordinate axes rotation settings on Coordinate axes rotation settings off Operation 1 Press the [PAUSE/MENU] key. Supplement MENU screen is displayed.

-

Page 99

5 Confirm the setting and press the [ENTER] key (SET). Supplement Setting will be set, and it will return to AREA PARAMETERS screen (1/2). It will return to AREA PARAMETERS setting screen (1/2) without changing the settings when you press the POSITION ( ) key 6 Press the [PAUSE/MENU] key. -

Page 100: Stop Cutting

Stop Cutting It will stop cutting when the [PAUSE/MENU] key is pressed while cutting. Operation selection menu is displayed on the screen of the control panel while it is stopped. It is possible to choose either to continue or stop the operation.

-

Page 101

Stop Cutting Operation 1 Press the [PAUSE/MENU] key. Operation will stop and following screen is displayed. 2 Press the [2] key (QUIT JOB). Supplement Following screen is displayed. It will resume cutting by pressing [1] (CONTINUE JOB) key. See «Pause and Resume Cutting» P.3-12 3 Confirm if the data transfer from the computer is stopped and… -

Page 102: Chapter 4: Convenient Functions

Chapter 4: Convenient Functions This chapter describes about the convenient functions of the plotter. PRODUCT SUMMARY Settings for Cutting Copy (Duplicate Cutting) Panel Cutting…

-

Page 103: Settings For Cutting

Settings for Cutting Settings such as area and width of cutting, page length, mirrored, enlarged, shrunk, etc., can be set. Setting Cutting Area Origin point will be set at lower left of the AREA once the AREA is Supplement set. It is possible to set the origin point at the center when the HPGL See «Setting the Origin Point»…

-

Page 104

4 Press the [1] key (AREA). Supplement SET LOWER LEFT screen is displayed. Coordinate value displayed here is the distance to the tool carriage from the origin point. Press [1] key (DEFAULT) if the cutting are is not to change. 5 Press the POSITION ( ) key and move the tool carriage… -

Page 105: Setting Cutting Width (Expand)

Setting Cutting Width (EXPAND) Set the cutting width. It is possible to set that it will cut to the area outside of the push rollers, or not to cut at the ends of the media. Default setting is to the internal edge of the push rollers. It can be set up to 10 mm outside (positive value) or 10 mm inside (negative value) from the default position.

-

Page 106: Setting Length Of The Page

* Please be sure to use the basket (option) when cutting something over 2 m long. Page ejection quality assurance goes up to 2 m for the CE6000-40 and up to 5m for the CE6000-60/120. (It depends on the media specified by Graphtec and setting conditions.) • Use the basket (option).

-

Page 107

2 Press the [4] key (MEDIA) in Normal mode, or press the [1] key (MEDIA) in Simple mode. MEDIA SETTING screen is displayed. MEDIA SETTING screen MEDIA SETTING screen (Normal mode) (Simple mode) 3 Press the [3] key (PAGE LENGTH) in Normal mode, or press the [1] key (PAGE LENGTH) in Simple mode. -

Page 108: Setting Mirror

Setting Mirror There is a function to mirror the cutting by reversing the origin point and coordinate axes. Set the MIRROR setting on to do mirroring. Reference This setting will be saved even if the power is shut off. MIRROR mode on MIRROR mode off Operation 1…

-

Page 109: Set The Enlarge/Shrink Scale (Scale)

4 Press the [1] key (ON). Supplement Press the [2] key (OFF) to turn off the mirror. 5 Confirm the setting and press the [ENTER] key (SET). Supplement Setting will be set, and it will return to AREA PARAMETERS setting It will return to AREA PARAMETERS setting screen (1/2).

-

Page 110

4 Press the POSITION ( ) key and increase or decrease the Supplement setting value. Values that can be set are 1/8, 1/4, 1/2, 1, 2, 3, 4, 5, 6, 7, and 8 (multiplications). 5 Confirm the setting and press the [ENTER] key (SET). Supplement Setting will be set, and it will return to AREA PARAMETERS setting It will return to AREA PARAMETERS setting… -

Page 111: Copy (Duplicate Cutting)

Copy (Duplicate Cutting) The function to cut specified numbers of cutting data stored in the buffer memory is called COPY. Supplement Do not send new data to plotter while copying. Cutting data in the buffer memory will be cleared. Previous cutting data will be cleared and newly sent data will be stored as cutting data if you send new data with 10 seconds or more interval from the time it finished cutting.

-

Page 112

It will copy in following order when COORDINATE AXES ROTATION is set. Copy origin Second point copy Third First cut First copy Fourth copy copy Origin point Copy space Copy space Fifth copy Sixth copy Operation 1 Create one data you want to copy. Cutting data is stored in the buffer memory. -

Page 113

6 Press the [2] key (NUMBER OF COPIES). NUMBER OF COPIES setting screen is displayed. Supplement 7 Press the POSITION ( ) key and increase or decrease the Number of copies can be set from 1 to 100, setting value. as much as it can fit in the media set on the printer. -

Page 114

When Media Change mode is on The Change Media message appears each time when ending a single cut in Media Change mode. Choosing to change media will instantly detect the media and proceed to a copy area (cut). Media switch copies can be made up to the set copy number (designated number). Operation 1 Create one data you want to copy. -

Page 115

7 Confirm the setting and press the POSITION ( ) key Supplement (PREVIOUS). «CANNOT COPY CUT AREA TOO SMALL!» is Copy space will be selected, and it will return to COPY MODE screen. displayed if the cutting area is smaller than the copy data. -

Page 116: Panel Cutting

Panel Cutting To prevent long skew, utilize partition length when cutting. Supplement When Partition Pastern is on, the machine will begin by dividing up partition length and continue cutting until one of the following data breaks appears. When the first partitioned area cut is finished, the machine will move to the next area, and repeat this until all areas have been cut.

-

Page 117

3 Press the POSITION ( ) key MEDIA SETTING screen (2/2) is displayed. 4 Press the [2] key (PANEL CUTTING). PANEL CUTTING screen is displayed. 5 Press the [1] key (OFF). PANEL CUTTING setting screen is displayed. 6 Press the [1] key (ON), or the [2] key (OFF). Confirm the settings and return to the PANEL CUTTING screen. -

Page 118: Chapter 5: Arms

Chapter 5: ARMS (Advanced Registration Mark Sensing System) ARMS (Advanced Registration Mark Sensing System) is a function to scan the registration mark written on the media using sensors. Tilt of the axes and distance can be adjusted with 2POINTS or 3 POINTS. 2 axes warp adjustment can be adjusted in addition to axes adjustment (tilt) and distance adjustment with 4POINTS.

-

Page 119: Outline Of Arms