Скачать бесплатно руководства по ремонту автомобилей в PDF формате

Электронные книги : Руководства по ремонту, советы по эксплуатации, ремонту двигателей и электрооборудования, технические характеристики различных марок автомобилей

Скачать бесплатно электронные книги , инструкции и руководства по ремонту автомобилей, книги по ремонту и эксплуатации автомобилей, и другие автокниги, а также автокаталоги, карты, атласы, учебные пособия для подготовки водителей, CD диски по автомобильной тематике, каталоги запчастей для автомобилей, автокниги по ремонту, эксплуатации и обслуживанию автомобилей, как российских, так и зарубежных производителей, издательств технической литературы, таких как Третий Рим, Арус, Монолит, Мир Автокниг, За рулем, Легион Автодата

Acura, Alfa Romeo, Audi, Beifan Benchi, BMW, Buick, BYD, Cadillac, Chery, Chevrolet, Chrysler, Citroen, Dacia, Dadi, Daewoo, DAF, Daihatsu, Derways, Dodge, Dong Feng, FAW, Fiat, Ford, Foton, Freightliner, Geely, GMC, Great Wall, Groz, Hania, Hino, Holden, Honda, HOWO, Hummer, Hyundai, Infiniti, International, Iran, Isuzu, Iveco, Jeep, Kenworth, Kia, Lancia, Land Rover, Range Rover, Lexus, Lifan, Lincoln, MAN, Maxus, Mazda, Mercedes-Benz, Mercury, Mini, Mitsubishi, Nissan, Oldsmobile, Opel, Peterbilt, Peugeot, Plymouth, Pontiac, Porsche, Renault, Rover, Saab, Samsung, Saturn, Scania, Scion, Seat, Setra, Shaanxi, Skoda, SsangYong, Subaru, Suzuki, TagAZ, Tata, Toyota, VolksWagen, Volvo, Vortex, ZAZ, АЗЛК, Москвич, ВАЗ, Lada, ГАЗ, Донинвест, ЗИЛ, Иж, КамАЗ, КрАЗ, ЛиАЗ, ЛуАЗ, МАЗ, МЗКТ, ПАЗ, УАЗ, УРАЛ

Книга: MAN TGX / TGS дизель с 2007 г.в., ремонт, эксплуатация, техническое обслуживание

Руководство по эксплуатации и техническому обслуживанию грузовых автомобилей Man TGX / TGS с 2007 года выпуска с дизельными двигателями D20; D26; D28.

Книга: MAN TGX / TGS дизель с 2007 г.в., эксплуатация, каталог деталей

Руководство по эксплуатации + каталог деталей MAN TGX / TGS с двигателями D2066 и D2676 EURO 4/5.

Книга: MAN TGL / TGM дизель с 2005 г.в., ремонт, эксплуатация, техническое обслуживание

Руководство по эксплуатации и техническому обслуживанию грузовых автомобилей Man TGL / TGM с 2005 года выпуска с дизельными двигателями D0834; D0836.

Книга: MAN TGA дизель с 2000 / 2005 г.в., ремонт, эксплуатация, техническое обслуживание

Руководство по эксплуатации и техническому обслуживанию грузовых автомобилей Man TGA с 2000 года выпуска с дизельными двигателями D2066; D2865; D2866; D2876.

Книга + CD: MAN TGA дизель с 2000 г.в., ремонт, эксплуатация, техническое обслуживание + каталог деталей

Подробный комплект материалов по ремонту и обслуживанию автомобиля MAN TGA с 2000 года выпуска с дизельными моторами: 6.9D, 10.5D, 12.0D, 12.4D, 12.8D, 18.3D л.

Книга: MAN L2000 / LE2000 / M2000L / M2000M / ME2000 / F90 / M90 / F2000 дизель ремонт, эксплуатация, техническое обслуживание

Самое подробное пособие по ремонту и техническому обслуживанию грузовых автомобилей Man L2000 / LE2000 / M2000L / M2000M / ME2000 / F90 / M90 / F2000 с дизельными двигателями D02, D08, D25, D28.

Книга: MAN 19 дизель ремонт, техническое обслуживание

Руководство по ремонту и техническому обслуживанию грузовых автомобилей Man модели 19.292, 19.332, 19.362 с двигателями объемом 12 литров.

Книга: MAN 19 дизель ремонт, техническое обслуживание

Руководство по ремонту и техническому обслуживанию грузовых автомобилей Man модели 19.292, 19.332, 19.362 с двигателями объемом 12 литров.

Книга: MAN M90 / M2000 дизель ремонт, эксплуатация, техническое обслуживание

Руководство по ремонту и эксплуатации грузовых автомобилей MAN M90 / M2000. Каталог деталей двигателей.

Книга: MAN M90 / M2000 дизель устройство каталог деталей

Руководство по устройству грузовых автомобилей MAN M90 / M2000. Каталог деталей.

Книга: MAN F90 / F2000 дизель устройство каталог деталей

Руководство по устройству грузовых автомобилей MAN F90 / F2000. Книга содержит каталог деталей и сборочных единиц автомобиля.

Книга: MAN F90 / F2000 дизель ремонт, эксплуатация, техническое обслуживание

Руководство по ремонту и эксплуатации грузовых автомобилей MAN F90 / F2000. Электросхемы.

Книга: MAN TGA дизель 2000-2008 г.в., ремонт, техническое обслуживание электросхемы

Руководство по ремонту и техническому обслуживанию грузовых автомобилей Man TGA 2000-2008 годы выпуска. В книге представлены подробные электрические схемы.

Книга: MAN TGL дизель эксплуатация, техническое обслуживание каталог деталей

Руководство по эксплуатации и техническому обслуживанию автомобилей MAN TGL. Книга содержит каталог деталей и сборочных единиц автомобиля, включая двигатели MAN D0834 и MAN D0836 различных модификаций.

Книга: MAN TGA дизель эксплуатация, каталог деталей

Руководство по эксплуатации и техническому обслуживанию автомобилей Man TGA. Книга содержит каталог деталей и сборочных единиц автомобиля. В книге представлена инструкция по эксплуатации Man TG-A, а также рекомендации по техническому обслуживанию автомобиля.

Книга: MAN L2000 дизель рем

Руководство по ремонту грузового автомобиля MAN L2000.

Книга: MAN M90 дизель эксплуатация,

Руководство по эксплуатации грузовых автомобилей MAN M90.

Книга: MAN M90 дизель ремонт, Часть 2

В издании описывается ремонт сцепления, КПП, мостов, рулевого управления, тормозной системы, подвесок, электрооборудования и кузова устанавливающихся на автомобили MAN M90.

Книга: MAN M90 дизель ремонт, Часть 1

В издании описывается ремонт дизельных двигателей серии DO 826 (F, FO1, TF, LF01, LF, LF02) устанавливающихся на автомобили MAN M90.

Книга: MAN F90 / F2000 дизель ремонт, техническое обслуживание

Руководство по ремонту грузовых автомобилей Man F 90 / F 2000 серий 19.273, 293, 323, 343, 373, 403, 423, 463, 23.343, 26.373, 403, 423, 463, с двигателями D2555, D2556, D2565, D2566, D2865, D2866, D2876 рабочим объемом 9,2; 9,5; 11,0; 11,4; 12,0; 12,8 л.

Книга: MAN TGA дизель рем

Руководство по ремонту грузовых автомобилей MAN TG-A.

Книга: MAN TGA дизель эксплуатация,

Руководство по эксплуатации и техническому обслуживанию грузовых автомобилей Man TGA.

Книга: MAN TGL дизель эксплуатация, техническое обслуживание

Руководство по эксплуатации и техническому обслуживанию грузовых автомобилей MAN TGL.

Книга: MAN F2000 дизель эксплуатация, техническое обслуживание

Руководство по эксплуатации и обслуживанию нескольких выпусков большегрузных автомобилей фирмы MAN третьего (и частично 4-го) поколения, тяжелой серии F-2000, подробно описано техническое обслуживание всех систем, даны рекомендации по поиску возможных неисправностей ряда систем.

Книга: MAN M2000 дизель рем

Руководство по ремонту грузовых автомобилей MAN M 2000 с двигателя D0824 LFL06, D0826 LFL03, LFL09, LF15, LF17 рабочим объемом 4,6 и 6,9 л

MAN F2000, L2000 & M2000 Trucks Operator’s & Service Manuals PDF

MAN TGA Truck Operator’s Manual & Wiring Diagram PDF

MAN TGE — VW Crafter — Self Study Manual PDF

MAN TGL & TGM Truck Operator’s Manuals PDF

MAN TGS Truck Operator’s Manual PDF

MAN TGX Truck Operator’s Manual PDF

Man Fault codes

Man Fault codes

Man Fault codes.pdf

Adobe Acrobat Document

491.4 KB

MAN Fehlercodes TVI und 1324

MAN Fehlercodes TVI und 1324

MAN Fehlercodes_TVI_und_1324.pdf

Adobe Acrobat Document

110.9 KB

Blink codes MAN

Blink codes MAN

Blink codes MAN.pdf

Adobe Acrobat Document

286.5 KB

Some MAN Truck Service Manuals & Electric Wiring Diagram PDF (TGA, TGE, TGL, TGM, TGS, TGX, M2000, L2000, F2000) are above the page.

The history of the famous automobile brand begins in 1840, from the time of the opening of the Ludwig Zander machine factory in Augsburg.

In 1893, the factory in Augsburg created the first experienced diesel engine, and in 1897 the world’s first efficient diesel engine.

In 1908, after the transformation of the name of the factory into the Machinery factory Augsburg Nuremberg AG, as a consequence, the name MAN arises.

In 1924, at the automobile exhibition in Berlin, the first serviceable truck with a diesel direct injection engine with a capacity of 40 hp was introduced.

In 1980, there are 39 company-owned sales offices in Germany with 700 employees. In 19 countries of Europe, there are 299 MAN

truck dealers.

1982 year. The joint program MAN / Volkswagen introduces an off-road truck 8.136 FAE with all-wheel drive and divided tires.

- Manuals

- Brands

- Man Manuals

- Engine

- D 2866 E

- Operating instructions manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Operating Instructions

Diesel Engine

D 2866 E

D 2866 TE

D 2866 LE

D 2866 LXE

Related Manuals for Man D 2866 E

Summary of Contents for Man D 2866 E

-

Page 1

Operating Instructions Diesel Engine D 2866 E D 2866 TE D 2866 LE D 2866 LXE… -

Page 3

It is imperative and in your own interest to entrust your MAN Local Service Centre with the removal of any disturbances and with the performance of checking, setting, and re- pair work. -

Page 4: Table Of Contents

Index Declaration …………. . . Nameplates .

-

Page 5: Declaration

In accordance with Article 4, paragraph 2, in conjunction with Appendix II, section B, of Directive 89/392/EEC, version 93/44/EEC MAN Nutzfahrzeuge Aktiengesellschaft, hereby declares that the engine described below is destined for installation in a machine as defined in the EC directive on machines.

-

Page 6: Nameplates

In all your correspondence please always quote engine model, serial number and job number (Order number). Enter 14-digit serial number (is used in the MAN Nutzfahrzeuge Aktiengesellschaft spare parts catalog to distinguish between spare parts). Motor-Nr. / Engine No. NI/II Enter 14-digit engine serial number.

-

Page 7: Safety Regulations

D Do not touch the engine with bare hands when it is warm from operation – risk of burns. D Exhaust gases are toxic. Comply with the instructions for the installation of MAN Die- sel engines which are to be operated in enclosed spaces. Ensure that there is ad- equate ventilation and air extraction.

-

Page 8

Safety regulations During maintenance and care D Always carry out maintenance work when the engine is switched off. If the engine has to be maintained while it is running, e.g. changing the elements of change-over filters, remember that there is a risk of scalding. Do not get too close to rotating parts. D Change the oil when the engines is warm from operation. -

Page 9

If faults occur, find the cause immediately and have it eliminated in order to prevent more serious damage. Use only genuine MAN spare parts. MAN will accept no responsibility for damage result- ing from the installation of other parts which are supposedly “just as good”. -

Page 10

Safety regulations D Comply with instructions for operation of the alternator. See “Commissioning and oper- ation”. D Do not let the raw water pump run dry. If there is a risk of frost, drain the pump when the engine is switched off. Regulations designed to prevent pollution Engine oil and filter elements / cartridges, fuel/fuel filter D Take old oil only to an old oil collection point. -

Page 11

Safety regulations D After washing apply a fatty skin cream to the skin. D Change oil-soaked clothing and shoes. D Do not put oily rags into your pockets. Ensure that used engine oil is disposed of properly – Engine oil can endanger the water supply – For this reason do not let engine oil get into the ground, waterways, the drains or the sewers. -

Page 12: Technical Information

Technical information Engine views D 2866 E…

-

Page 13

Technical information 1 Tensioning pulley 2 Water pump 3 Oil filler neck 4 Tandem fuel filter 5 Oil separator valve for crankcase breather 6 Fuel lift pump with prestrainer 7 Injection pump 8 Oil drain plug 9 Oil dipstick 10 Alternator 11 Oil cooler 12 Oil filter 13 Starter motor… -

Page 14

Technical information Engine views D 2866 TE… -

Page 15

Technical information 1 Tensioning pulley 2 Water pump 3 Oil filler neck 4 Oil separator valve for crankcase breather 5 Tandem fuel filter 6 Fuel lift pump with prestrainer 7 Injection pump 8 Oil drain plug 9 Oil dipstick 10 Oil cooler 11 Oil filter 12 Turbocharger 13 Starter motor… -

Page 16

Technical information Engine views D 2866 LE, LXE… -

Page 17

Technical information 1 Oil filler neck 2 Oil separator valve for crankcase breather 3 Tandem fuel filter 4 Fuel lift pump with prestrainer 5 Injection pump 6 Oil dipstick 7 Alternator 8 Water pump 9 Tensioning pulley 10 Oil filter 11 Water drain plug 12 Oil drain plug 13 Turbocharger… -

Page 18: Engines

Technical information Engines The engines D 2866 E / TE / LE / LXE are in-line vertical liquid-cooled 6-cylinder four- stroke Diesel engines with direct injection. D 2866 E is a naturally aspirated engine. D 2866 TE is turbocharged, and D 2866 LE / LXE are turbocharged and intercooled.

-

Page 19

Technical information Engine timing Camshaft, oil pump and injection pump are driven by a gear train arranged at the fly- wheel end. 1 Crankshaft gear 4 Camshaft drive gear 2 Oil pump drive gear 5 Idler gear 3 Oil pump impeller gears 6 Injection pump drive gear The crankshaft gear and camshaft gear are match-marked by “1”… -

Page 20: Engine Lubrication

Technical information Engine lubrication The engine is equipped with force-feed lubrication. The pressure is produced by a gear pump whose drive gear is in direct mesh with the crankshaft gear at the flywheel end. The oil pump draws the oil from the oil sump and delivers it through the oil cooler and oil filter to the main distributor gallery and from there to the main bearings, big-end bearings and camshaft bearings as well as to the small-end bearings and the rocker arms.

-

Page 21

Technical information The injection pump and the turbocharger are also connected to the engine lubricating system. The cylinder walls and timing gears are splash-lubricated. Each cylinder has an oil jet provided for cooling the underside of the pistons. The lube oil is cleaned in a full-flow oil filter. Depending on the agreed extent of delivery and the design of the engine, the lube oil cir- cuit can be equipped with oil pressure monitors (advance warning and cut-off function) which shut the engine down in the event of a sudden loss of pressure. -

Page 22: Fuel System

Technical information Fuel system The fuel is delivered by the fuel lift pump via the fuel filter to the injection pump and from there to the injectors. The fuel is sprayed into the cylinder through four-hole nozzles fitted in screw-fit injectors in the cylinder heads.

-

Page 23: Turbocharger

Technical information Fuel filters Before entering the suction chamber of the injection pump, the fuel is cleaned in a two- stage, parallel or changeover filter. Turbocharger (D 2866 TE, LE, LXE) The exhaust gases of the engine are passed through the turbine rotor of the turbochar- ger.

-

Page 24: Intercooler

Technical information Intercooler (D 2866 LE, LXE) Before entering the cylinders the combustion air compressed in the turbocharger is passed through a heat exchanger (intercooler). Heat removal in the cooler is either by air (air-to-air intercooler) or, in case of the marine application, by means of seawater (air-to-water intercooler) delivered by the raw water pump.

-

Page 25: Electrical Equipment

Technical information Electrical equipment Alternator The alternator is fitted with integral silicon rectifiers. A transistorized regulator mounted on the alternator limits the alternator voltage. The al- ternator should not be operated except with the regulator and battery connected in circuit to avoid damage to the rectifier and regulator.

-

Page 26: Commissioning And Operation

“Technical Information down lever to “stop” at the same time for the installation of MAN Diesel en- until the oil pressure warning light goes gines”. out and the oil pressure gauge shows a pressure.

-

Page 27: Starting

Commissioning and operation Raw water pump Running in Do not let raw water pump run dry. It is recommended that new or overhauled Make sure that all valves / cocks in the engines should not be operated at a load raw water circuit are open.

-

Page 28: Shutting Down

Temporary anti-corrosion protection ac- into contact! cording to MAN works norm M 3069 is re- D Do not operate the alternator without quired for engines which are to be put out battery connection! of service for fairly long periods.

-

Page 29: Maintenance And Care

Maintenance and care Engine lubrication Oil level Check the oil level in the engine sump daily with a dipstick. The level should be between the two notches cut into the dip- stick and should never be allowed to drop below the lower notch. Caution: Do not add so much engine oil that the 1 Oil filler neck on valve cover…

-

Page 30

Maintenance and care Observe positions of selector lever! Continuous operation (both filter halves in operation) Right-hand filter cut out Left-hand filter cut out 1 Oil drain plug 2 Oil filter bowl Caution: 3 Tie screw Do not leave selector lever in any in- 4 Filter cartridge termediate position because this 5 Gasket… -

Page 31: Fuel System

Maintenance and care Fuel system Fuel lift pump The fuel lift pump is operated by the injec- Fuel tion pump camshaft via the roller tappet. If Diesel fuel which contains moisture is used the injection system and the cylinder Strainer liners / pistons will be damaged.

-

Page 32

Maintenance and care Two-stage fuel filter Parallel fuel filter with filter cartridges (replaced by parallel fuel filter) (replaced by parallel filter with inter- changeable filter) In two filter housings connected in series the fuel first passes through a felt tube el- The fuel passes through two filter el- ement and then through a paper element. -

Page 33

Maintenance and care Parallel fuel filter with interchangeable Change-over fuel filter with filter car- filter tridges (replaced by change-over fuel filter with The fuel flows through two parallel filters. interchangeable filter) Where the changeover-type filter is in- stalled, the servicing procedure is for the filter side requiring to be shut off with the engine running. -

Page 34

Maintenance and care Change-over fuel filter with inter- Caution: changeable filter Do not leave selector lever in any in- termediate position because this would be liable to interfere with fuel supply. If in doubt stop the engine to change the fuel filter. Continuous operation (both filter halves in operation) -

Page 35

Maintenance and care Injector maintenance Removal, dismantling and cleaning (by authorized specialist personnel) Unscrew delivery pipe at nozzle holder and at the injection pump. Remove leak-off pipe. Release union screw of nozzle holder with special wrench. Remove nozzle holder with gasket from the cylinder head. -

Page 36

Maintenance and care Before reassembly thoroughly wash Caution: nozzle body and needle in clean test oil. Do not hold your hands under the fuel jet, as there is a risk of injury. Do not Hold the needle at the pintle end only; to inhale the atomised fuel. -

Page 37: Cooling

See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines”. Filling-in of coolant (only when engine has cooled down) D Fill in the coolant slowly…

-

Page 38

HENKEL a) Drain coolant P3-begesol. This cleansing agent is avail- b) Open thermostats positively (use short- able from MAN in 10-kg cans under Part circuit inserts), so that the entire cool- No. 09.21002-0164. ant circuit is flushed in the cleaning… -

Page 39

Maintenance and care d) Warm up engine under load. After a D Drain the pickling fluid, fill the system temperature of 60°C is reached, run with tap water, and run the engine at engine for a further 15 minutes idle for 5 minutes to flush out all fluid; e) Drain cleaning fluid then drain the water f) Repeat steps c) and d) -

Page 40

Maintenance and care D Fill the container with undiluted original Filler caps and working valves of cool- pickling fluid at room temperature (Lith- ing system solventsäure or engine pickling fluid The rubber gaskets of the filler caps and RB-06) until the tube bundle is com- working valves (negative pressure and pletely immersed positive pressure valves) of the cooling… -

Page 41: Turbocharger

Maintenance and care Turbocharger This precaution will enable any wear of the bearings to be detected in good time before serious damage is caused to the Maintenance rotor and bearings. (by authorized specialist personnel) The turbochargers do not call for any spe- Measuring of axial clearance cific maintenance.

-

Page 42: Intercooler

Maintenance and care Intercooler Maintenance (by authorized specialist personnel) In order to maintain the heat transfer effi- ciency of the intercooler, it is necessary to clean it at regular intervals which depend on the quality of the coolant used. For this purpose, dismantle the inter- cooler.

-

Page 43: Air Cleaner

Maintenance and care Air cleaner Fouling Indicator As the degree of clogging increases the Dry air cleaner red indicator becomes more and more vis- ible in the transparent section of the air cleaner. If the fouling indicator remains engaged, i.e. it still shows completely red even with the engine shut down, the filter cartridge must be cleaned or replaced.

-

Page 44

Maintenance and care Changing the filter cartridge Blowing out (wear goggles) To do this fit a pipe to the compressed air Caution: gun. The end of the pipe should be bent No dust must get to the clear air end. by approx. -

Page 45

Maintenance and care Viscous air cleaner On no account re-use damaged car- tridges. If in doubt fit a new cartridge. Safety cartridge The maintenance intervals for filters de- When the main cartridge is being serviced pend on the respective operating condi- the safety cartridge remains in the filter tions. -

Page 46: Checking And Setting

Checking and setting To check and set the start of deliv- The pointer should then be aligned such that its measuring edge exactly coincides ery with start of delivery marker with the “OT” mark on the scale disc. on injection pump hub (by authorized specialist personnel) In order to enable the engine to be rotated manually during adjustments, there is a…

-

Page 47

Checking and setting Setting start of delivery To check and set the start of deliv- ery with start of delivery indicator Correct start of delivery by turning the in the governor housing pump hub in the slotted holes of the drive (by authorized specialist personnel) gear. -

Page 48

Checking and setting The pointer should then be aligned such Connect up power supply of light signal that its measuring edge exactly coincides transmitter (red terminal = +). Turn engine with the “OT” mark on the scale disc. by hand so that piston in cylinder no. 1 in the compression stroke comes close to In order to enable the engine to be rotated the start of delivery. -

Page 49

Checking and setting Setting start of delivery Note: If only lamp (B) comes on during this test the engine has been turned past the start of delivery. In this case turn the engine back and repeat the proce- dure. b. Sleeve If a light signal transmitter is not available, good measurement results can also be achieved with a plug-in receptacle. -

Page 50: To Check And Adjust Valve Clearance

Checking and setting To check and adjust valve clear- ance (by authorized specialist personnel) The valve clearance for new and over- hauled engines should be checked after the first 10 to 20 hours of operation. Then it should be adjusted every 400 hours of operation.

-

Page 51

Checking and setting Retightening cylinder head bolts Remove the sticker “First retightening of cylinder head bolts …” and attach the on new engines sticker “Second retightening of cylinder (engine cold or warm) head bolts …” to show that the cylinder by authorized specialist personnel head bolts have been retightened for the second time. -

Page 52

Checking and setting Tightening cylinder head bolts Retightening cylinder head bolts after a repair after repairs (engine cold) (engine cold or warm) by authorized specialist personnel by authorized specialist personnel Before inserting the cylinder head bolts oil After the first 10 to 20 hours of operation them with engine oil on the thread (not to after a repair turn the cylinder head bolts the bore) and coat the contact face of the… -

Page 53: V-Belts

Checking and setting Re-using old cylinder head bolts V-belts Checking The tension of the V-belts should be Before re-using old cylinder head bolts checked after every 200 hours of oper- check them as follows: ation. Length Change the V-belts if necessary During tightening the bolts are intention- If, in the case of a multiple belt drive, wear ally stressed beyond the yield point and…

-

Page 54

Checking and setting Tension and / or replace V-belts D Slowly depress pad  until the spring can be heard to disengage. This will Water pump – Alternator cause the indicator to move upwards D Remove fixing bolts À If pressure is maintained after the spring D Remove lock-nut Á… -

Page 55

Notes …………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………… -

Page 56: Technical Data

Technical data Model D 2866 E Design in-line vertical Cycle 4-stroke Diesel Combustion system Direct injection Number of cylinders Bore 128 mm Stroke 155 mm Swept volume 11 967 cm Compression ratio 17.5 : 1 Rating see engine nameplate Firing order 1–5–3–6–2–4…

-

Page 57

Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Deep 12 l 18 l Shallow 14 l 20 l For 30° tilt 12 l 18 l Oil pressure during operation (depend- monitored by oil pressure monitors or dis- ing on oil temperature, oil viscosity plays class and engine rpm) -

Page 58

Technical data Model D 2866 TE Design in-line vertical Cycle 4-stroke Diesel with turbocharger Combustion system Direct injection Turbocharging Turbocharger Number of cylinders Bore 128 mm Stroke 155 mm Swept volume 11 967 cm Compression ratio 15.5 : 1 Rating see engine nameplate Firing order 1–5–3–6–2–4… -

Page 59

Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Deep 12 l 18 l Shallow 14 l 20 l For 30° tilt 12 l 18 l Oil pressure during operation (depend- monitored by oil pressure monitors or dis- ing on oil temperature, oil viscosity plays class and engine rpm) -

Page 60

Technical data Model D 2866 LE, LXE Design in-line vertical Cycle 4-stroke Diesel with turbocharger and in- tercooler Combustion system Direct injection Turbocharging Turbocharger with intercooler Number of cylinders Bore 128 mm Stroke 155 mm Swept volume 11 967 cm Compression ratio D 2866 LE 15.5 : 1… -

Page 61

Technical data Injection timer Automatic centrifugal type in camshaft drive gear Injectors 4-orifice nozzles Opening pressure of injector Injector + injection nozzle New nozzle holder: Used nozzle holder: 51.10101-7274 220 + 8 bar 220 + 8 bar 51.10101-7290 235 + 8 bar 220 + 8 bar 51.10101-7338 295 + 8 bar… -

Page 62: Index

Index Air cleaner ……22, 41–43 Nameplates ……. Alternator .

-

Page 64

MAN Nutzfahrzeuge Aktiengesellschaft Vogelweiherstraße 33 D–90441 Nürnberg Printed in Germany 51.99493–8264…

Замена масла в КПП и раздаточной коробке для МАН ТГА

От

evgenich

Замена масла в КПП и раздаточной коробке для МАН ТГА

Комплект файлов ,по технологическим процессам замены и контроля уровня масла в КПП и раздаточной коробке.

316 раз скачали

Отправлено

Руководство по эксплуатации TGX

От

FullThrottle

Руководство по эксплуатации TGX + мультируль

222 раза скачали

Обновлено

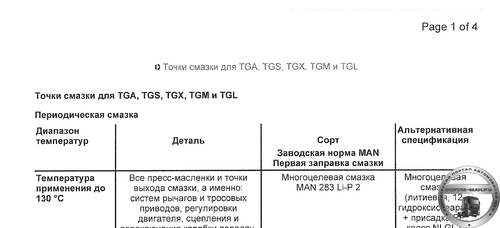

Точки смазки МАН

От

evgenich

Точки смазки МАН при проведении ТО

200 раз скачали

Обновлено

Регулировка клапанов D20

От

evgenich

Регулировка клапанов D20 двигатель

149 раз скачали

Отправлено

Руководство по эксплуатации TGS

От

FullThrottle

Руководство по эксплуатации TGS c обычным рулевым колесом

129 раз скачали

Обновлено

Регулировка клапанов D2866 76

От

evgenich

Регулировка клапанов D2866 76

128 раз скачали

Отправлено

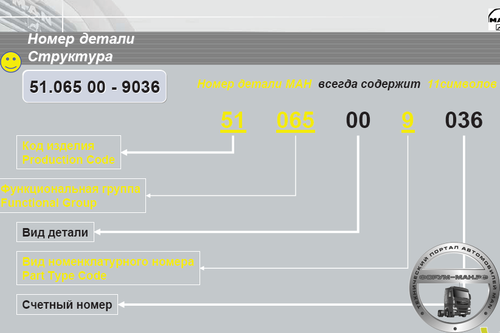

Структура и порядок маркировки автомобилей и з/ч МАН

От

evgenich

Структура и порядок маркировки автомобилей и з/ч МАН

115 раз скачали

Обновлено

Интервалы и периодичность регулировки клапанных зазоров на МАН.

От

evgenich

Интервалы и периодичность регулировки клапанных зазоров на МАН.

107 раз скачали

Отправлено

Руководство по ремонту D2676.

От

Витамин

Руководство по ремонту D2676.

106 раз скачали

Отправлено

Замена топливных фильтров ТГА

От

evgenich

Замена топливных фильтров ТГА

102 раза скачали

Отправлено

Замена антифриза TGA-TGS

От

evgenich

Замена антифриза TGA-TGS

72 раза скачали

Отправлено

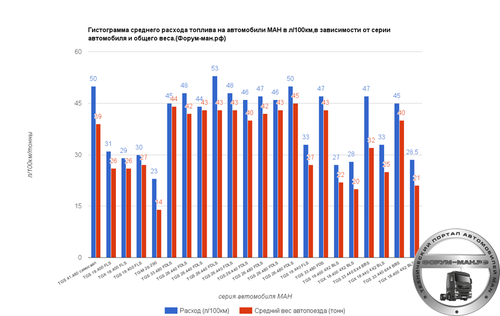

Гистограмма среднего расхода топлива на МАН по сериям.

От

evgenich

Один из вариантов, статистических данных по расходу топлива на МАН.

Данные , усредненные , и конечно, для разных регионов РФ, необходима существенная коррекция показателей.

Обсуждение на форуме здесь:

71 раз скачали

Обновлено

Замена фильтров мочевины

От

evgenich

Замена фильтров мочевины

62 раза скачали

Отправлено

Замена приводных ремней

От

evgenich

Замена приводных ремней

62 раза скачали

Отправлено

Замена приводных ремней d2866 76

От

evgenich

Замена приводных ремней d2866 76

52 раза скачали

Отправлено

Замена приводных ремней

От

evgenich

Замена приводных ремней

42 раза скачали

Отправлено

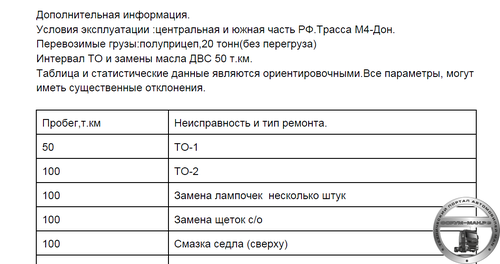

Статистика затрат на ТО и ТР для МАН ТГС 4*2

От

evgenich

Статистика затрат на ТО и ТР для МАН ТГС 4*2

Хороший статистический перечень работ по ТО и ТР, для тягача МАН ТГС, с 0 идо 650 т.км. пробега

Активная тема на форуме здесь:http://форум-ман.рф/index.php?/topic/10710-man-tgs-42statistika-po-remontu-3goda650tkm/

41 раз скачали

Обновлено

Смазка тормозных валов барабанные тормоза TGA TGS TGX

От

evgenich

Смазка тормозных валов барабанные тормоза TGA TGS TGX

39 раз скачали

Отправлено

MAN M 2000- руководство по ремонту

От

4WDvod

MAN M 2000- руководство по ремонту. Взято из энциклопедии autogeriko.com

6 раз скачали

Отправлено

MAN L 2000- руководство по ремонту.

От

4WDvod

MAN L 2000- руководство по ремонту. Взято из энциклопедии autogeriko.com

6 раз скачали

Отправлено

Contents

Preface

Instructions

Engine type classification

Safety instructions

General notes on engine overhaul

Commissioning After Engine Overhaul

Fault table

Troubleshooting chart

Engine views

Engine lubrication schedule

Fuel System Diagram

Cooling System Diagram

Engine management schedule

Fuel system

Checking and adjusting start of fuel delivery

Removing and Installing Injection Pump

Removing and Installing Injection Nozzles

Checking Injection Nozzles

Fuel Prefilter

Removing and attaching fuel filter, exchanging filter cartridge

Flame starter sheathed−element glow plug,removing and installing

Cooling system

Draining and filling coolant

Removing and Installing Thermostats

Removing and installing the engine coolant pump

Repairing engine coolant pump

Repairing coolant pump with high-temperature and low-temperature parts

Cleaning cooling system

Lubrication

Changing the oil filter

Removing and installing the oil cooler

Removing and installing the oil pan

Removing and Installing / Repairing Oil Pump

Removing and Installing Oil Spray Nozzle

Intake / exhaust system

Removing and installing the intake manifold

Removing and installing the exhaust manifold

Removing and fitting exhaust-gas recirculation (EGR) module

Turbocharger, troubleshooting

Checking charging pressure

Removing and installing the turbocharger

Measuring the axial / radial clearance or the turbocharger shaft

Cylinder Head

Removing and installing the cylinder head

Setting the valve clearance

Disassembling and Assembling Rocker Arm Mechanism

Removing and installing valves

Removing and Installing Valve Guides

Replacing valve seat insert

Reworking valve seat

Refacing Valves

Checking Compression

Download Euro4, Euro5 and EEV MAN Engine Technology

Download MAN L2000 M2000 F2000 construction period 1992-2005

Download MAN Diesel Engine D2866E, D2866TE, D2866LE, D2866LXE Operating Instructions

MAN TGA — Schematic diagram of the instr

Adobe Acrobat Document

5.9 MB

EDC7 MAN fault codes list PDF.pdf

Adobe Acrobat Document

197.4 KB

MAN L2000 Repair Manual.rar

compressed file archive

53.1 MB

TGA+EWD.pdf

Adobe Acrobat Document

9.5 MB

MAN is one of the oldest German engineering companies that produce trucks, buses and diesel engines. Previously existed under the name

Maschinenfabrik Augsburg-Nürnberg AG. Formed in 1758, this company continues to occupy high positions on the world arena.

TGX truck series. These are classic truck tractors, characterized by maximum comfort for the driver and capable of pulling from 15 to 70 tons. These

trucks are driven by engines ranging from 360 to 680 hp.

TGS truck series. The series is represented by truck tractors, classic «loners», dump trucks and various construction equipment. They can carry a

payload from 18 to 70 tons with engine power from 360 to 680 hp

TGM truck series. The family consists of medium-tonnage trucks, dump trucks and classic «loners», capable of carrying from 7 to 20 tons of cargo.

Models are equipped with motors with power from 240 to 380 hp.

TGL truck series. Minicar for everyday exploitation in the city. They carry a payload of 5 to 7 tons and are driven by motors with a power of 150 to

250 hp.

MAN TGA ELECTRICAL WIRING DIAGRAMS Download

MAN Electrical System – Common-rail Injection System EDC7 Download