- Manuals

- Brands

- Claas Manuals

- Farm Equipment

- LEXION 540

Manuals and User Guides for Claas LEXION 540. We have 2 Claas LEXION 540 manuals available for free PDF download: Operator’s Manual, Repair Manual Supplement

Claas LEXION 540 Operator’s Manual (41 pages)

Brand: Claas

|

Category: Farm Equipment

|

Size: 1.58 MB

Advertisement

Claas LEXION 540 Repair Manual Supplement (21 pages)

Brand: Claas

|

Category: Farm Equipment

|

Size: 1.64 MB

Table of Contents

-

Table of Contents

3

-

1 Introduction

6

-

General Information

6

-

Validity of Manual

6

-

-

-

2 Feed Rake Conveyor

7

-

Replacing the HP Feed Rake Conveyor Anti-Slip Strips

7

-

-

3 Straw Discharge

8

-

Chaff Spreader

8

-

Overview of Chaff Spreader / Chaff Spreader Fan LEXION 600 — 560 (Type 589 — 584)

8

-

Overview of Radial Spreader LEXION 600 — 560 (Type 589 — 584)

10

-

-

Straw Spreader

12

-

Overview of Straw Spreader

12

-

-

-

4 Drives

14

-

Drive Belts / Drive Chains

14

-

Drive Diagram, Left Side (LEXION 600 with JET STREAM Cleaning System)

14

-

Drive Diagram, Right Side (LEXION 600 with JET STREAM Cleaning System)

16

-

Drive Diagram, Left Side (LEXION 580 with Standard Cleaning System)

17

-

Drive Diagram, Right Side (LEXION 580 with Standard Cleaning System)

19

-

Drive Diagram, Left Side (LEXION 570 with Standard Cleaning System)

21

-

-

Advertisement

Related Products

-

Claas LEXION 540 C

-

Claas LEXION 550

-

Claas LEXION 560

-

Claas LEXION 530

-

Claas TUCANO 500

-

Claas QUANTUM 5500 S-18

-

Claas QUANTUM 5500 S-16

-

Claas QUANTUM 5500 GT

-

Claas QUANTUM 5500 P

-

Claas LEXION 600

Claas Categories

Farm Equipment

Tractor

Tractor Accessories

Utility Vehicle

Engine

More Claas Manuals

3,66 Мб

Руководство по эксплуатации комбайнов Claas Lexion 510,

Формат: djvu

-

Год:

2013

-

Страниц:

104

-

Язык:

русский

-

Размер:

3,66 Мб

-

Категории:

Claas Lexion

|

Title |

File Size |

Download Links |

|

Claas Ag Belt Programme [PDF] |

16.2Mb |

Download |

|

Claas Agri Manual [PDF] |

836.2kb |

Download |

|

Claas ARES 546, 556, 566, 616, 656, 696 Operators and Maintenance Manual [PDF] |

9.2Mb |

Download |

|

Claas ARES 547, 557, 5342, 5352 Operators and Maintenance Manual [PDF] |

3.4Mb |

Download |

|

Claas Arion 510 / 520 / 530 / 540 / 610 / 620 / 630 / 640 Service & Parts Manual |

75.2kb |

Download |

|

Claas ARION PDF Service Manuals [PDF] |

29.1Mb |

Download |

|

Claas Axion 9 Series Service Manual [PDF] |

10.5Mb |

Download |

|

Claas C490-C370 Repair Manual [PDF] |

535.8kb |

Download |

|

Claas CELTIS 426, 436, 446, 456 Service Manual [PDF] |

5.7Mb |

Download |

|

Claas Columbus Series Service Manual [PDF] |

13.5Mb |

Download |

|

Claas Consul Harvest Belts [PDF] |

76.7kb |

Download |

|

Claas CROP TIGER 30 Operator / s Manual PDF [PDF] |

14.4Mb |

Download |

|

Claas DISCO, CORTO, VOLTO, LINER — Technical Systems, Hydraulic System PDF manual [PDF] |

4.8Mb |

Download |

|

Claas Dominator 140 150 — Technical Systems, Hydraulic System PDF manual [PDF] |

2.8Mb |

Download |

|

Claas Dominator 150-140-130 Operators manual PDF [PDF] |

19.8Mb |

Download |

|

Claas DOMINATOR 204 / 208 MEGA III Operator’s Manual [PDF] |

683.7kb |

Download |

|

Claas DOMINATOR 68 S Operator’s Manual [PDF] |

615kb |

Download |

|

Claas Dominator-58-48-38 Service Manual [PDF] |

7.1Mb |

Download |

|

Claas ELIOS 240-210 Repair Manual [PDF] |

3.9Mb |

Download |

|

Claas Jaguar 2 Service Manual [PDF] |

9.5Mb |

Download |

|

Claas Jaguar 830 / 850 / 860 / 870 [PDF] |

7.1Mb |

Download |

|

Claas JAGUAR 830-900 PDF Service Manuals [PDF] |

54.2Mb |

Download |

|

Claas Jaguar 830, 850, 860, 870 Information Basic Field Settings [PDF] |

7.1Mb |

Download |

|

Claas JAGUAR 930 Information And Basic Field Settings [PDF] |

6.7Mb |

Download |

|

Claas Jaguar Service Manual [PDF] |

7.9Mb |

Download |

|

Claas Lexion 470-420 Technical Systems, Hydraulic System PDF manual [PDF] |

7.2Mb |

Download |

|

Claas Lexion 480 Repair Manual PDF [PDF] |

34.1Mb |

Download |

|

Claas Lexion 480 Service Manual [PDF] |

10.3Mb |

Download |

|

Claas Lexion 480-405 Technical Systems, Hydraulic System PDF manual [PDF] |

8.4Mb |

Download |

|

Claas Lexion 500 R Service Manual [PDF] |

1.2Mb |

Download |

|

Claas Lexion 570 Technical Systems, Hydraulic System PDF manual [PDF] |

10.4Mb |

Download |

|

Claas LEXION 620 / 670 Manual [PDF] |

3.9Mb |

Download |

|

CLAAS Lexion 700 Series Steering Ready Combine — Installation Manual [PDF] |

1.2Mb |

Download |

|

Claas LEXION Repair Manual [PDF] |

541kb |

Download |

|

Claas Lexion Service Manual [PDF] |

5Mb |

Download |

|

Claas Liner 3000 with Communicator — Technical Systems, Hydraulic System PDF manual |

3Mb |

Download |

|

Claas Markant 650 [PDF] |

1.6Mb |

Download |

|

Claas OPTIMISING OUTPUT FROM YOUR COMBINE [PDF] |

554.3kb |

Download |

|

Claas QUADRANT 2100 RC — Technical Systems, Hydraulic System PDF manual [PDF] |

2.4Mb |

Download |

|

Claas QUADRANT 2200 RC- Technical Systems, Hydraulic System PDF manual [PDF] |

412.4kb |

Download |

|

Claas Quantum 3500-6800 Technical Systems [PDF] |

5.5Mb |

Download |

|

Claas Rollant 160 — Electric System, Hidraulic System — Service Repair Manual [PDF] |

609.6kb |

Download |

|

Claas Rollant 240-250 — Electric System, Hidraulic System — Service Repair Manual [PDF] |

3.2Mb |

Download |

|

Claas Rollant 250-255-254 Diagnosis PDF [PDF] |

661kb |

Download |

|

Claas ROLLANT 66 Repair Manual [PDF] |

481kb |

Download |

|

Claas Scorpion Manual PDF [PDF] |

5Mb |

Download |

|

Claas Targo C Service Manual [PDF] |

5.8Mb |

Download |

|

Claas Targo K50 K60 K70 — Electric System, Hidraulic System — Service Repair Manual |

8.5Mb |

Download |

|

Claas Tractor Parts Catalog [PDF] |

36.7Mb |

Download |

|

Claas TUCANO 2017 [PDF] |

2.8Mb |

Download |

|

Claas Tucano 3 and 4 Series Service Manual [PDF] |

5.1Mb |

Download |

|

Claas TUCANO 400-300 Information And Basic Field Settings [PDF] |

3.1Mb |

Download |

|

Claas TUCANO 500 [PDF] |

17.3Mb |

Download |

|

Claas UNIWRAP — Technical Systems, Hydraulic System PDF manual [PDF] |

2.8Mb |

Download |

|

Claas VARIANT 260 — 280- Technical Systems, Hydraulic System PDF manual [PDF] |

1.6Mb |

Download |

|

Claas XERION 3300 — Technical Systems, Hydraulic System PDF manual [PDF] |

3Mb |

Download |

|

Class Parts Doc EPC Agricultural 2022 [PDF] |

67.3kb |

Download |

Claas Axion 9 Series Service Manual [PDF, ENG, 13.8 MB]

Claas Axion 9 Series Service Manual [PDF

Adobe Acrobat Document

13.5 MB

Claas Dominator-58-48-38 Service Manual [PDF, ENG, 7.3 MB]

Claas Dominator-58-48-38 Service Manual

Adobe Acrobat Document

7.1 MB

Claas Columbus Series Service Manual [PDF, ENG, 13.7 MB]

Claas Columbus Series Service Manual [PD

Adobe Acrobat Document

13.5 MB

Claas Jaguar Service Manual [PDF, ENG, 9.3 MB]

Claas Jaguar Service Manual [PDF, ENG, 9

Adobe Acrobat Document

9.1 MB

Claas Lexion 480 Service Manual [PDF, ENG, 10.5 MB]

Claas Lexion 480 Service Manual [PDF, EN

Adobe Acrobat Document

10.3 MB

CLAAS Lexion 700 Series Steering Ready Combine — Installation Manual [PDF, ENG, 1.3 MB]

CLAAS Lexion 700 Series Steering Ready C

Adobe Acrobat Document

1.2 MB

Claas OPTIMISING OUTPUT FROM YOUR COMBINE [PDF, ENG, 563 KB]

Claas OPTIMISING OUTPUT FROM YOUR COMBIN

Adobe Acrobat Document

562.5 KB

Claas Lexion 500 R Service Manual [PDF, ENG, 1.2 MB]

Claas Lexion 500 R Service Manual [PDF,

Adobe Acrobat Document

1.2 MB

Claas Lexion Service Manual [PDF, ENG, 5.8 MB]

Claas Lexion Service Manual [PDF, ENG, 5

Adobe Acrobat Document

5.7 MB

Claas Tucano 3 and 4 Series Service Manual [PDF, ENG, 6.6 MB]

Claas Tucano 3 and 4 Series Service Manu

Adobe Acrobat Document

6.5 MB

1993

The powerful tractor CLAAS XERION 2000 was first introduced to the public. XERION as its own development CLAAS combines the requirements for a modern tractor with the

requirements for a system agricultural vehicle. The cab is installed in three different positions, providing different applications: first, as a classic tractor with a central position of the

cab, and secondly as a system vehicle with a 180 ° rotatable driver’s cabin with a middle and rear position in the middle and, thirdly , As a vehicle that has a cab above the engine and is

therefore convenient for transporting semi-trailers. The adapters offered for XERION further extend the scope of application. Another feature of the XERION is the award-winning and continuously

developed HM-8 gearbox developed by CLAAS specialists.

2003

With the purchase of a controlling stake in Renault Agriculture, CLAAS complements the range of products produced by standard tractors. In the same year, from the former Renault tractor plant in

Le Mans, France, the first green-painted CLAAS tractors, first presented to the public at the Agritechnica exhibition, are descending. The four models include a line of tractors

in the traditional CLAAS salad color: the universal model CELTIS, the top class ARES tractor, the large ATLES tractor, and the Harzwinkel «royal» class XERION.

2004

The new large XERION 3300 tractor is entering the market. The revised CLAAS XERION 3300 is a universal tractor in three versions. The XERION TRAC version with 335 hp, the

stepless ZF Eccom 3.5 gearbox, the RABA-controlled axles and the electronic all-wheel drive system with six control programs. Version of the XERION TRAC VC, which is distinguished primarily by

the turntable. And the version of the XERION SADDLE TRAC, the cabin of which is rigidly mounted on the front axles.

2006

Offered in five different versions from 163 to 260 hp. CLAAS AXION is the first tractor from the former Renault tractor plant in Le Mans, which from start to finish is the creation of CLAAS. Its

development began in late 2003, shortly after the CLAAS family was enlarged with tractors. The first place in the design of the new AXION was a high level of comfort, improved handling comfort,

as well as high power combined with economical fuel consumption and high reliability.

Installed on the CLAAS AXION, the 6.8 liter 6.8 liter DPS engine not only meets the TIER 3a exhaust emissions standards, but also thanks to modern technology it provides less

fuel consumption than the TIER 2 standard. As a result, CLAAS has got another modern tractor for large Agricultural enterprises, contractors and machine parks.

2007

In the tractors segment, CLAAS presented the new ARION 500 and 600 series at Agritechnica. Due to a wide range of power tractor from 112 to 155 hp. CLAAS has managed to reach a significant part

of the international clientele. CLAAS POWER MANAGEMENT in large models ARION 540 and ARION 640 allows you to release an additional 20 horsepower for the most difficult tasks. The new ARION series

is equipped with a convenient HEXASHIFT transmission, which automates the group change and is switched without the aid of a clutch. All ARION tractors develop a final speed of 40 km / h or 50 km

/ h (optional) at an economical 1900 rpm.

CLAAS AXION with infinitely variable transmission CMATIC. The AXION is offered in five different versions from 163 to 225 hp. (From 120 to 165 kW ECE R24) and fills a niche between ARES 600 and

ATLES. The main components of this modern tractor were developed from scratch. This is the first tractor, which from the beginning to the end is the creation of CLAAS. Its development began in

late 2003, shortly after the CLAAS family was enlarged with tractors.

A powerful XERION 3800 tractor is presented. The 378 horsepower XERION tractor equipped with the new CLAAS SEQUENCE MANAGEMENT, steering system for GPS coordinates and the ISOBUS connector, turns

into a true universal talent. Thanks to the already proven TRAC VC rotary cab, the driver retains the familiar perfect circular view.

2009

CLAAS presents the compact ARION 400 tractor. Six new engines of this new compact class cover the power range from 90 hp / 66 kW to 125 hp / 92 kW (according to ECE R24).

Features and dimensions allow the ARION 400 to purposefully fill a niche between the ARION 500 and the AXOS.

At the Agritechnica in 2009, CLAAS first introduced two new XERION 5000 and 4500. Along with the XERION 3800 and 3300 models in the class up to 400 hp. With these two models, CLAAS extends the

range of tractors up to 500 hp. and higher.

2011

In the pavilion 6 at the SIMA exhibition at the CLAAS booth the preliminary premiere of the new AXION 900 tractor is noted. Four models with a 280-400 hp capacity. Complemented the already

well-known series AXION 800 with 164-260 hp. And the XERION 3300-5000 with 330-530 hp. The AXION 900 is the first model of the CLAAS tractor, which complies with the TIER 4 exhaust emission

standards. The CLAAS POWER SYSTEMS (CPS) technology is first used in the AXION 900. CPS represents the optimal combination of innovative components and technologies in the drive.

2012

With the release of the ARION 500/600 series, CLAAS can offer customers the technology and comfort of powerful tractors also in the power range of 140-184 hp.

The 4-cylinder models of the ARION 500 series feature versatility and potential power, especially when working with a power take-off shaft and a front loader. The 6-cylinder models of the ARION

600 series are convincing with high tractive effort and smooth running on the field and during transportation works on the roads.

2013

The new CLAAS AXION 800 is presented. This is a completely new development in the CLAAS family of tractors, equipped with engines from 200 to 270 horsepower. It is also the first

series produced at the Le Mans plant, the engine of which complies with the Stage IV (Tier 4f) standard, and thus already meets all future requirements for gas toxicity.

Successful basic concepts, embodied in the first 800 series, CLAAS remained true to the design of the new AXION 800: a compact design with a long wheelbase, as well as various components and

control systems CIS and CEBIS. At the first stage the tractor is equipped with a HEXASHIFT gearbox, a bit later the CMATIC continuously variable transmission will be added to it.

780 760 750 740 730(P) 730

670

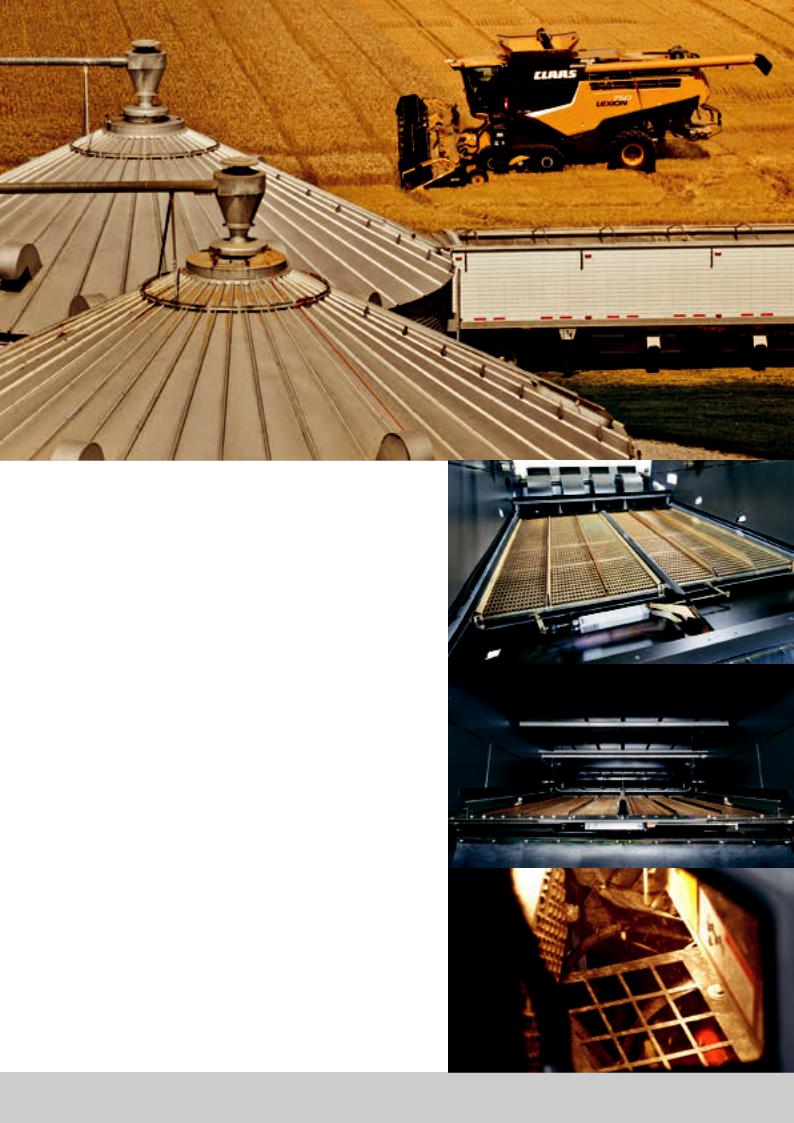

LEXION features.

Automatic Machine Optimization by CRUISE PILOT and CEMOS AUTOMATIC

Spacious, Quiet, and Comfortable Cab

In-Cab Hydraulic HP Feederhouse

Pitch Adjustment

Standard Power Folding Grain Tank

Latest Tier 4 final Engine Systems

DYNAMIC COOLING System

JET STREAM High Performance

Cleaning System

CLAAS TERRA TRAC

CLAAS Exclusive APS Threshing System

|

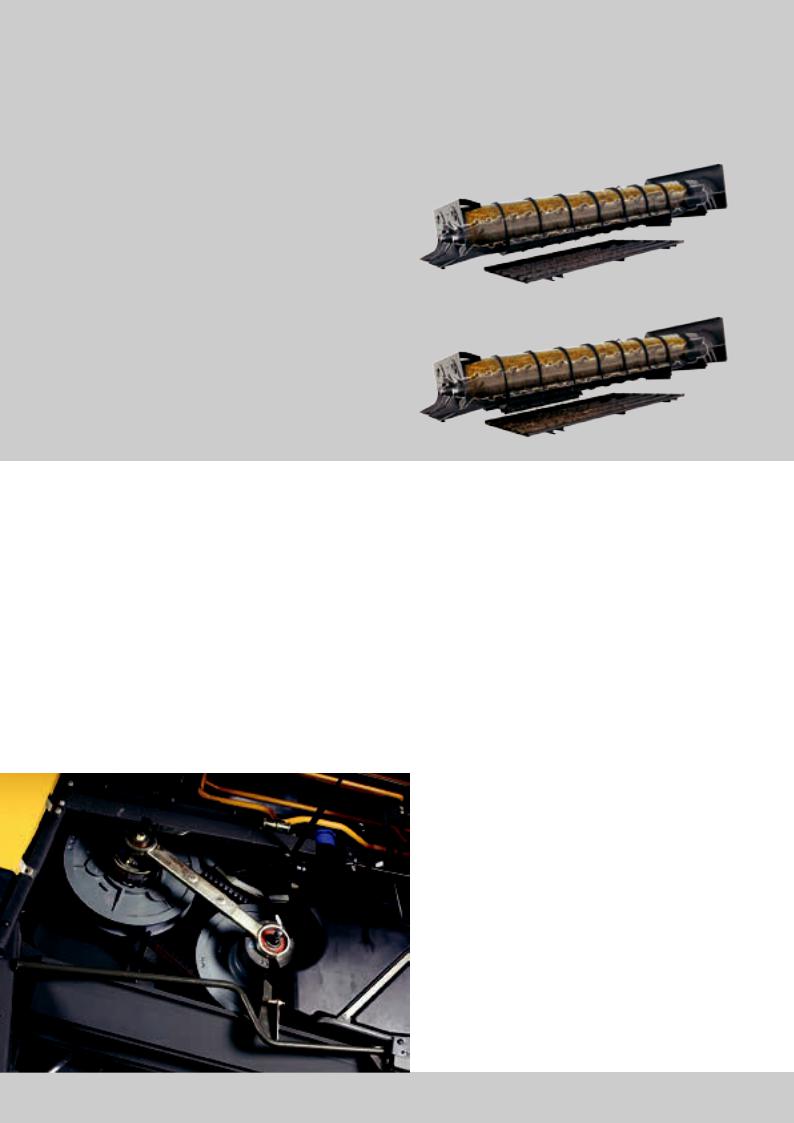

Standard feederhouse. |

HP feederhouse. |

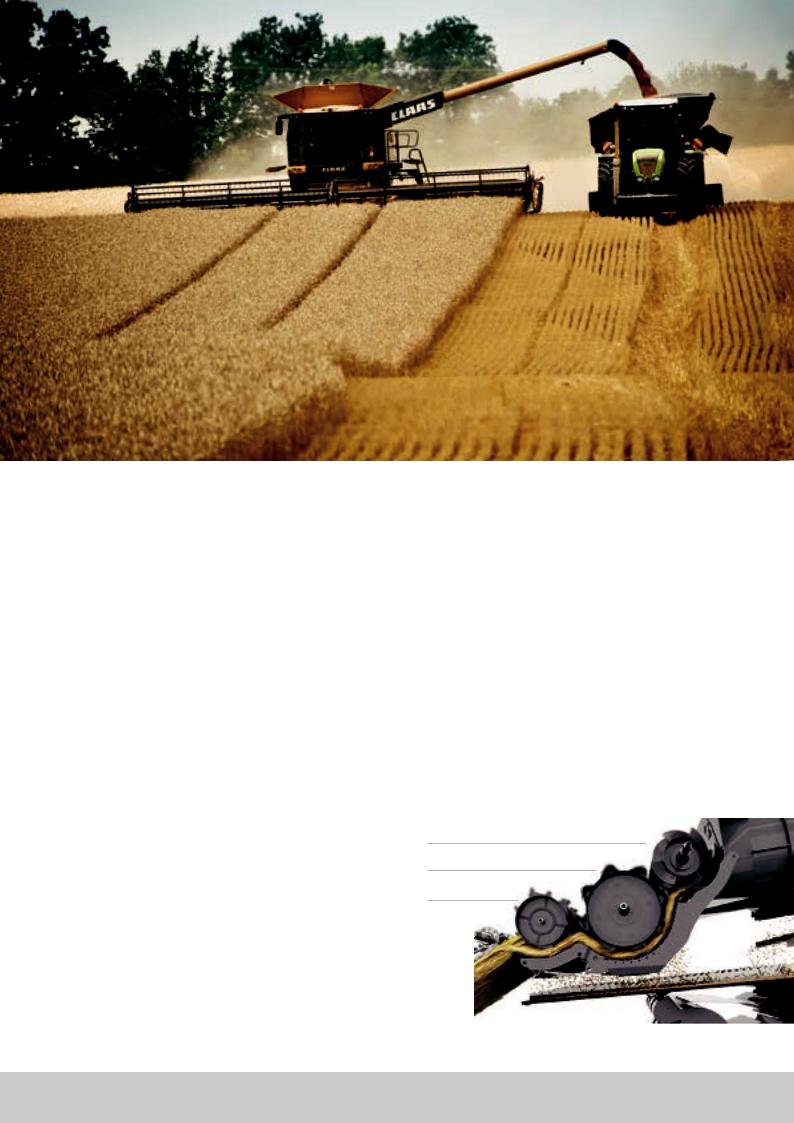

The standard feederhouse is designed for all crops and features an extra large channel with a shallow angle that provides a smooth transition for the crop into the APS system for threshing.

A heavy duty 4-chain, 3-slat conveyor provides reliable transfer of the crop through the feederhouse. The conveyor chain rides on an adjustable front drum, and when it is in a down position, provides added protection against rocks and foreign debris.

Dual heavy-duty AUTO CONTOUR cylinders not only carry the header, they also provide lateral tilt compensation when operating in changing terrain.

Compatible with:

•All corn heads

•All rigid heads (VARIO, MAXFLO)

•F750 and F900 flex heads

•SWATH UP heads

The HP feederhouse includes all of the same features as the standard feederhouse, plus an added header pitch (HP) adjustment to more easily adapt to changing field conditions along with a hydraulic chain tensioning system.

The HP feederhouse is equipped with the exclusive optional hydraulic top-link that allows the operator to make adjustments when desired from the cab to the header’s pitch by simply adjusting the faceplate’s exclusive top-link. The cutting angle offers 19 degrees of adjustability

(11 degrees forward, 8 degrees back), and AUTO CONTOUR cylinders fitted within the HP faceplate provide 9 degrees of lateral tilt.

Compatible with:

• All header types

4

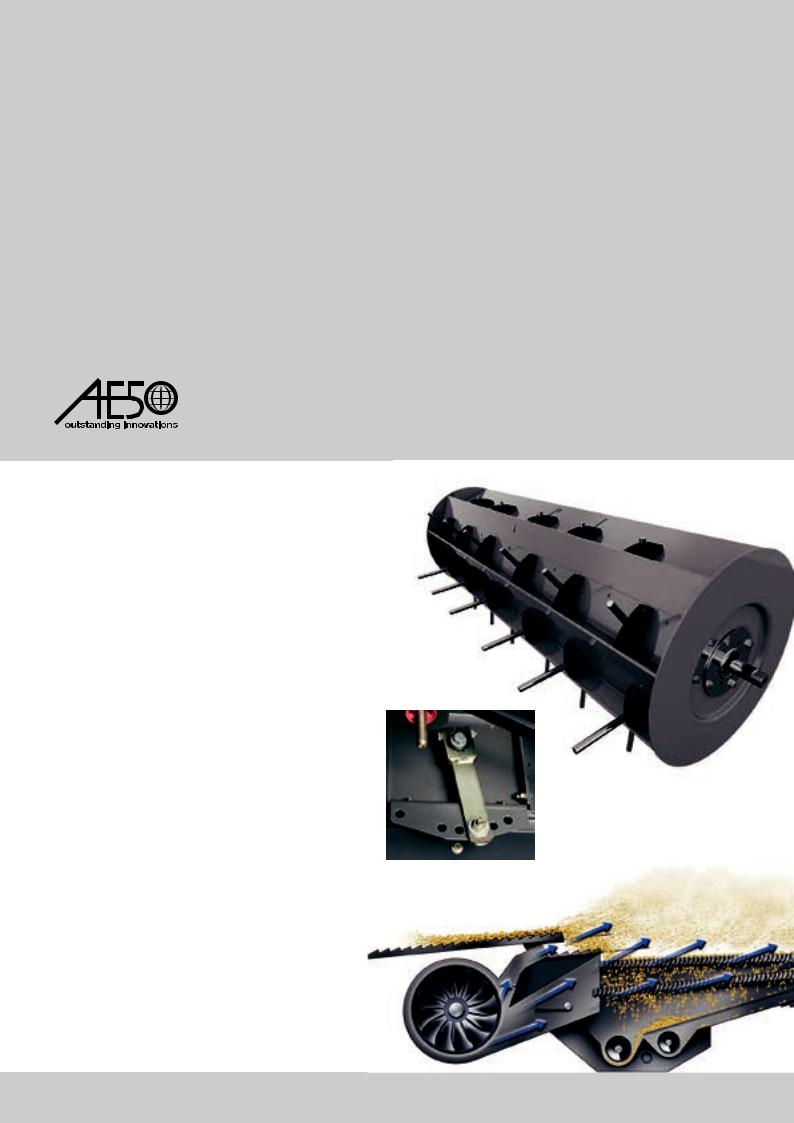

Unrivalled intake.

Dust suction fan.

An optional dust suction fan can be fitted to both the Standard or HP feederhouse to help prevent dust from obstructing the view of the operator. The turbine fan has a removable shroud for easy clean out and inspection of the fan unit.

Hydraulic reverser.

Reversing the feederhouse (and header) is done by a powerful hydraulic motor that can be engaged electronically from the cab without having to turn the separator off. When operating with a platform head, the reel will also reverse when the feederhouse reverser is engaged in order to prevent any expelled material from building up on the cutterbar.

The header’s vertical and lateral position is displayed in CEBIS.

Multi-Link Connector.

Make all seven electrical and hydraulic connections in one easy step with the Multi-Link Connector. The self-sealing hydraulic connections allow mess-free connection and disconnection, even while under pressure.

Header lock.

A single lever securely locks all platform heads to the combine feederhouse.

5

Consistent results in any field.

Header drive.

Reduce fuel consumption without reducing power – the direct header drive delivers maximum power to the header for the ever-increasing volume of material being passed through the feederhouse.

New feederhouse drive technology offers stronger, more efficient header drive output to meet the demands of larger heads:

Fixed speed: 107hp (80kW)

Variable speed (standard): 160hp (120kW)

Automatic soft start system.

Improved controlled engagement of the header drive system. The new drive system allows for part of the system to engage with the separator system to allow for softer starts and decreased load limits when the feederhouse is engaged.

6

CLAAS CONTOUR:

Consistency matters.

CLAAS CONTOUR is standard on all LEXION combines. It allows automatic vertical response to changing terrain via an exclusive combine ground pressure sensor. This programmable cutting height feature helps to ensure that you automatically return to your set cutting position every time.

AUTO CONTOUR:

Faster and more accurate than ever.

Optional equipment for both combine and header, the CLAAS AUTO CONTOUR combines automatic vertical and lateral compensation for changing terrain and ground conditions. With advanced CLAAS on demand hydraulic and MACH 5 electrical technology, the AUTO CONTOUR system is the leader in terrain compensation performance.

The system records four pre-set cutting heights to ensure optimal performance in all crops and conditions, allowing you to focus on other harvesting tasks. AUTO CONTOUR simplifies harvest by reducing operator fatigue, especially with larger heads, and increases efficiency by maintaining a consistent crop height.

7

CLAAS Threshing & Separation

APS + ROTO PLUS

|

Only CLAAS integrates both systems into one combine to |

Models |

|

|

achieve what other combines cannot. |

||

|

780 |

||

|

• |

Independent threshing and separation speed control |

760 |

|

• |

More adaptable to changing crops and conditions |

750 |

|

• |

Maintains greater throughput optimization |

740 |

|

730(P) |

||

|

730 |

APS + Multi-Finger Separation System

The same leading threshing technology of the LEXION 700 Series is combined with advanced straw walker separation technology from CLAAS to provide the greatest separation performance possible without compromising straw quality.

•Extra-long straw walkers with the exclusive Multi-Finger Separation System drum provide unmatched straw walker separation.

|

“The APS SYSTEM lets me get in the field earlier and stay out later, giving me the largest output |

APS threshing technology |

|

|

per day during our limited harvest window.” |

||

APS: Separation starts up front.

The exclusive APS system is the heart of every LEXION combine, and is what gives all LEXION combines their in-field advantage.

•Up to 30% of all grain is pre-separated by the APS cylinder and concave (ahead of the threshing cylinder) to reduce the load on the main concave for more effective and thorough threshing performance.

•During pre-separation, the APS cylinder optimizes crop flow by accelerating the crop and distributing it evenly over the full width of the threshing cylinder. The distributed material enters the threshing cylinder at the same speed, width, thickness and angle for maximum threshing efficiency

•Reduces wear and tear on the combine

•More efficient use of power for greater fuel economy

Several different APS grate options are available.

Up-time is critical to getting maximum productivity from your combine, so spending an hour or more reconfiguring concaves to achieve quality threshing performance can significantly reduce productivity. In a LEXION, the only grates to change between crops are easily accessible from the rock trap. These APS concave grates are located under the APS cylinder, which can be changed easily and quickly (as needed).

Rasp bar threshing drum.

The APS threshing cylinder features a completely enclosed drum with raised rasp bars (24 inch tip diameter) to provide solid threshing in all conditions. The raised rasp bars allow greater expansion of the crop between them to enhance performance without compromising efficiency. All rasp bars are constructed using extremely durable material for extended wear life.

Impeller

Threshing drum

Accelerator (APS)

10

APS provides good results faster.

Synchronized concave adjustment with overload protection.

Our exclusive hydro-mechanical concave adjustment ensures precision finger-tip adjustment when fine-tuning performance. Hydraulic cylinders attached to the mechanical adjustment linkages on each side of the concave adjust the pre-concave and main concave simultaneously. Each concave moves in and out from its respective cylinder to prevent any bottle neck in the crop flow. This exclusive movement reduces wear and tear on the crop and the elements of the threshing system.

If a foreign object or extremely dense slug of material is ingested into the concave area, the hydro-mechanical adjustment linkage is equipped with a relief valve that will automatically drop the concave open (and reset automatically) to help avoid damage to the system and make clean-out easier.

Dis-awning plates.

Dis-awning plates are an exclusive lever-operated blanking plate system under the APS grates that can be used to enhance threshing performance. Because they are lever operated, the operator can engage or dis-engage them in seconds without tools and without having to access the inside of the machine.

Synchronized threshing speeds.

To maintain consistent material flow, each change made to the speed of the threshing cylinder will simultaneously change the speed of the APS cylinder and rear impeller. This maximizes efficiency while at the same time protects the crop.

11

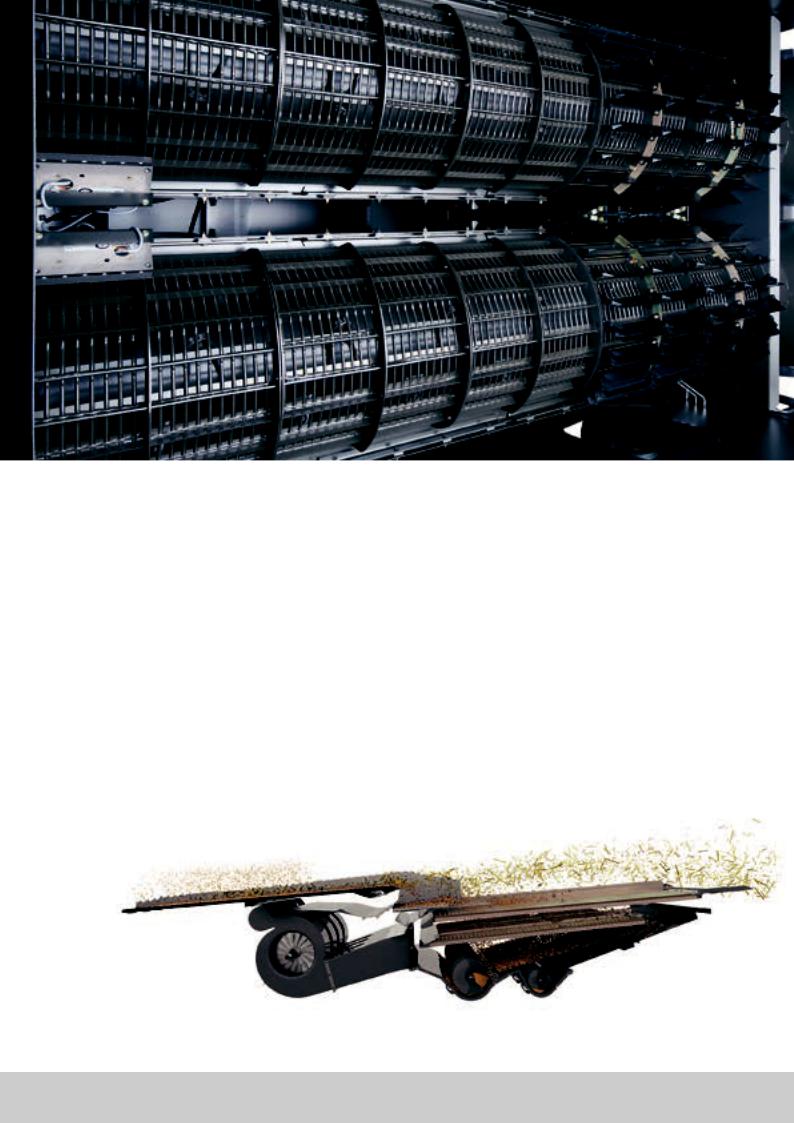

ROTO PLUS. A superior concept.

Further ahead of the others.

Two counter-rotating 17.5 inch diameter rotors generate more separation force, more efficiently than combines with a single-rotor processor. When you combine that force with their near 14 ft. length, you end up with the industry‘s highest capacity separation system – per class.

Take advantage of the unbeatable combination of APS + ROTO PLUS.

Rotor covers shown in closed position.

ROTO PLUS separation.

ROTO PLUS separation is a simple process. The rear impeller of the APS System divides the crop into two smaller, more manageable swaths and feeds them into the rotors.

The ROTO PLUS system is made up of twin elliptical tubes that are each fitted with a 17.5 in (445 mm) diameter by 13.75 ft long multi-crop paddle rotor, anchored just below the center of the tube — which is ideal placement for optimizing separation performance.

Adjustable rotor covers.

All 700 series combines can be equipped with the hydraulic rotor cover plate option. The purpose of rotor cover plates is to hold material longer within each rotor cage to improve separation performance (as needed). The covers are fitted on the outside of the front two rotor grates of each rotor to maintain consistent crop flow without any drag on power.

Rotor Cover Positions:

1.All grates open

2.First set of grates closed

3.First and second grates closed

4.Third and fourth grates closed (780 Small Grains combines only)

Variable rotor speed adjustment.

Rotor speed adjustments are made easily using the CEBIS dial. Separation speed can be adjusted independently of the threshing system from 400 to 1000 rpm to provide more efficient and practical adjustments on the go as field and conditions change.

12

JET STREAM.

The JET STREAM cleaning system is specially designed to handle the leading throughput of the APS Hybrid system.

•Removable poly preparation floor segments

•Dual-step cascade pre-cleaner with exclusive JET STREAM

•Large sieves (6 ft long top sieve and 5 ft long bottom sieve)

•Eight turbine fans (LEXION 780/760)

•Six turbine fans (LEXION 750/740/730)

•GRAINMETER

Cascade pre-cleaner.

The dual ventilated cascade step ensures intensive pre-cleaning. An extra wind tunnel from the turbine fans directly supplies this area an intense stream of air over the full width of the pre-cleaner enabling the lighter chaff to be blown free of the grain.

13

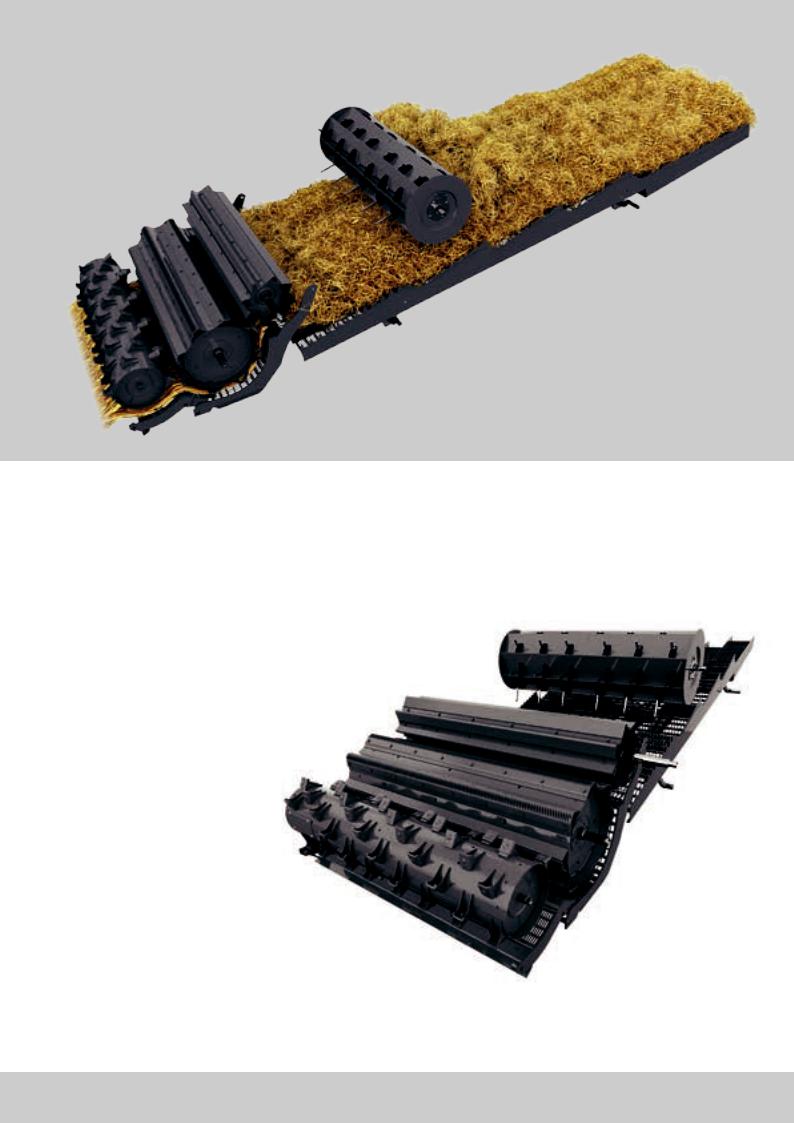

Get it all. Straw walker separation.

The APS threshing system on all LEXION combines works so efficiently that most of the grain is separated out during the pre-separation and threshing process. This efficiency means there is less grain that needs to be separated from the straw by a machine separation system.

Straw walker separation of the class 7 LEXION 670 is enhanced by the Multi-Finger Separation System (MSS) for extremely effective separation action while maintaining high-quality balable straw.

Each walker is 14.4 ft (4400 m) long and comprised of four aggressive steps fitted with fish-back risers for more

aggressive separation action. Large perforations allow grain to be shaken through the walkers onto a pan beneath that delivers the material to the cascade pre-cleaner.

Thorough agitation of the crop mat is critical for high separation efficiency, particularly under difficult field conditions such as wet straw or green straw. The LEXION 670 is equipped with the Multi-Finger Separation System (MSS) to ensure effective residual grain separation under all conditions.

14

Effective straw walker technology.

Multi-Finger Separation System (MSS) increases output.

MSS actively fluffs the crop with multiple controlled tines which dig into the straw. The tines reach into the mat of straw from above and aerate it while simultaneously speeding it up. The straw mat is thinned, making it easier for the remaining grains to separate out. The available length of the straw walkers is used more effectively, while the structure and quality of the straw is optimized. The operation speed of the tines can be adapted to changing harvest conditions.

Fast and easy tine adjustment makes fine-tuning your

LEXION 670 combine‘s walker performance a breeze.

Standard cleaning system (LEXION 670 only).

The standard cleaning system is tuned specifically for use with straw walker separation, maintaining balanced airflow and efficient cleaning. Extra-long sieves are controlled electrically from the cab.

15

Preparation pan.

Located below the APS System, the preparation pan starts the cleaning process using its exclusive shaking action to stratify the heavier grain to the bottom and the lighter chaff to the top. Using this method to transfer grain to the sieves eliminates the need for shoe augers that not only complicate the cleaning process by keeping the grain and chaff mixed together but can result in added damage to the crop caused by the augers. Once material travels to the end of the preparation pans, the material flows over the dual ventilated cascade step allowing the chaff to be blown out of the sieve area. This decreases the work load on the sieves, allowing for increased cleaning capacity.

In-cab visual returns monitoring.

16

Clean work for brilliant results.

|

3-D cleaning system. |

Returns window. |

|

|

• |

Dynamic slope compensation actively controls the |

Actually seeing what is in the returns elevator allows the |

|

pitch of the top sieve |

operator to make smarter settings adjustments for improved |

|

|

• |

Operating range up to 20% side slope |

performance. All LEXION combines allow the operator to |

|

• |

Maintenance free with no additional moving parts |

look directly into the returns cross auger through the |

|

• |

Fast, simple retrofitting |

exclusive returns window located in the lower right hand |

|

• |

Together with the AUTO CONTOUR, it is the ideal |

rear corner of the cab. |

|

“hillside package” |

||

|

All LEXION models also have the option to be equipped |

||

|

with the electronic returns monitoring system with a digital |

||

|

read out displayed on the CEBIS monitor. |

GRAINMETER (optional).

And, for those who prefer the ultimate in returns monitoring, the exclusive GRAINMETER displays on CEBIS the amount of grain being carried within the volume of returns.

17

Up to 385 bushels of the highest quality grain.

Power folding grain tank extensions.

Introduced as an industry-first and standard on all LEXION combines are the power folding grain tank extensions. The operator simply pushes a button inside the cab for fast, reliable hydraulics to open and close the grain tank extensions without having to enter the grain tank.

Fast unloading.

The high performance, robust auger system delivers up to 3.8 bushels of grain per second unloading rate (3.2 bu/sec for LEXION 670, 2.8 bu/sec for rice combines). Four unloading auger lengths (24.2 ft., 26.2 ft., 28.2 ft., and 29.2 ft.) are available to ensure extra clearance needed for large heads.

Heavy-duty grain tank.

The heavy-duty grain tank was further improved, now featuring extended-wear grain tank floor, auger troughs, augers, and vertical unloading tube and housing.

18

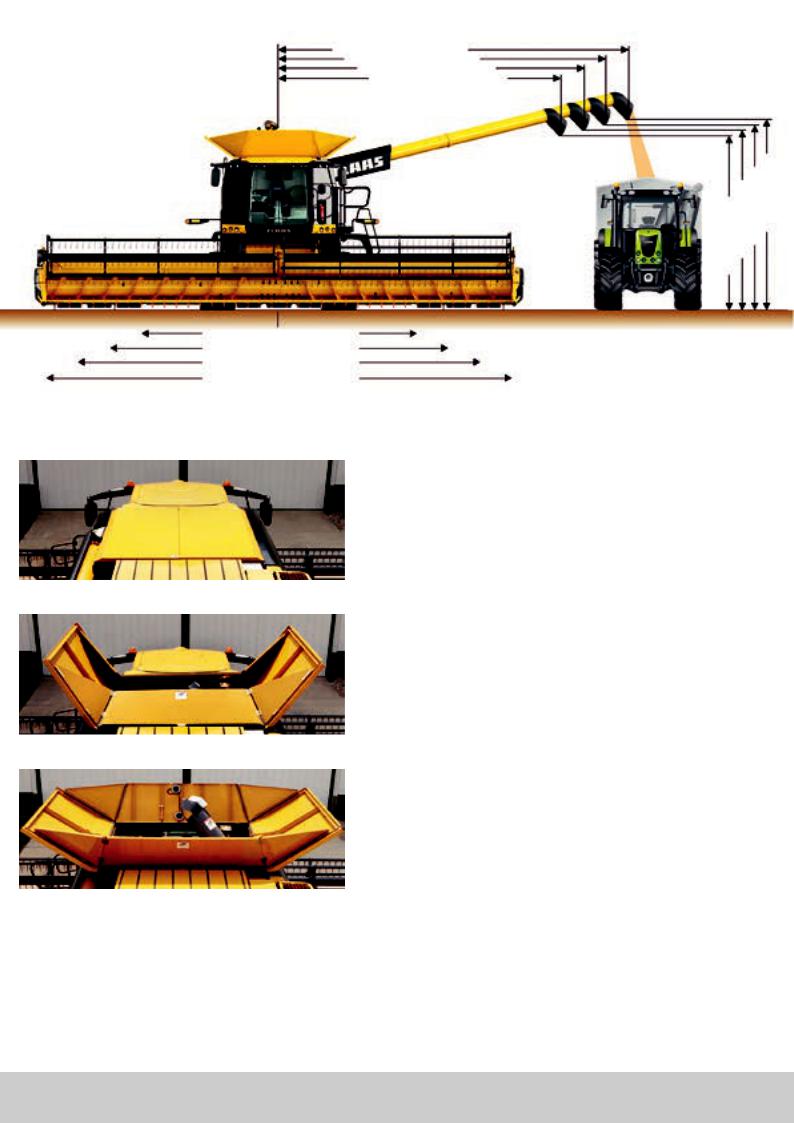

29.2ft (8.8 m) 4XL

28.2ft (8.5 m) 3XL

26.2ft (7.9 m) XXL

24.2ft (7.3 m) XL

m) 9.(4 ft 16 m) 8.(4 ft 8.15 m) 7.(4 ft 3.15 m) 5.(4 ft 8.14

25 ft (7.5 m)

30 ft (9 m)

35 ft (10.5 m)

40 ft (12 m)

4XL Unloading auger.

An even longer unloading auger is now available on the LEXION combine line. The new 4 XL unloading tube reaches out 29.2 ft. from the center of the combine, which is perfect for harvesting with heads over 40 ft wide.

LEXION 670 with up to 330 bu grain tank capacity and 4XL unloading auger.

The LEXION 670 straw walker combine has an increased grain tank volume of 300 bu standard and an optional capacity of 330 bu, and is available with an unloading rate of 3.3 bu/sec and the new 4XL (29.2 ft) unloading auger.

19

After harvest is before harvest.

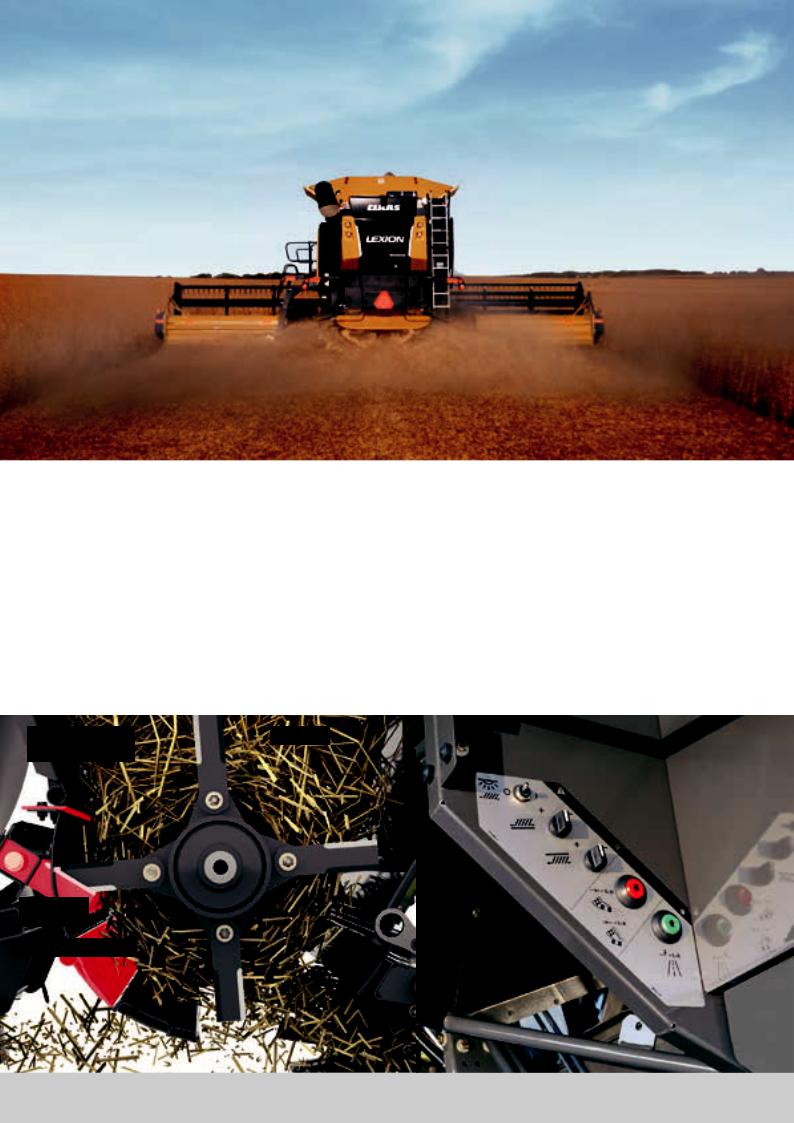

As yields increase, the amount of residue (straw and chaff) to manage also increases. How the residue exits is just as important as how it enters. Rapid, complete residue decomposition will improve next year’s planting season and yields. Residue chopped to a uniformly short length and spread evenly across the full width of the field is a decisive factor in next year’s success. Several different residue management solutions are available.

MAV® (Maximum Air Velocity) Chopper.

The MAV system features 60 knives paired over the rotating drum with 31 stationary knives that can be engaged/ disengaged according to crop type. The MAV drum also includes 6 winged fan blades on both ends to pressurize the MOG for an accelerated exit velocity and assure a uniform spreading width of up to 35 ft.

TURBO CHOP / PRO CHOP

Long straw

Adjustable counter knife

Adjustable floor segment

20

(Ocr-Read Summary of Contents of some pages of the Claas LEXION 770 2016 Document (Main Content), UPD: 12 April 2023)

-

17, Claas LEXION 770 2016 16 HOTKEY HOTKEY The HOTKEY (2) is used to adjust the more frequently changing settings on the Combine for example straw chopper or LASER PILOT bias. To adjust any of the HOTKEY values turn the rotary switch (2) and the HOTKEY dial will appear on CEBIS which is shown in the picture below. Turn the dial to select the required icon to make any adjustments. After 5 seconds the HOTKEY dial will disappear from CEBIS and the settings will be displayed in the window shown below. To ch…

-

47, 46 8. Some dirt can usually be removed from both the cross auger covers, and the bottom covers on both the clean grain and returns elevators. 9. When unloading wet grain, reduce the flow into the unloading auger by shutting down the slides on both the cross augers in the grain tank. This will reduce the load on the unloading system, bringing it down to a ‘normal’ level. 10. If wet and dirty grain is being unloaded it is als…

-

48, CLAAS U.K. Ltd Saxham Bury St. Edmunds Suffolk IP28 6QZ Tel: 01284 763100 Fax: 01284 769839 www.claas.co.uk

… -

4, 3 Introduction This quick reference guide has been produced to aid operators with familiarisation and settings of CLAAS LEXION combine harvesters. CLAAS combines are designed for output and efficiency but this can only be achieved with correct operation and maintenance of the machine. This guide is not designed to replace the Operators Manual but merely as a reference document. More in depth information is available in the Operators Manual. ALWAYS READ TH…

-

5, 4 Safety Safety is of the utmost importance whilst you are operating and maintaining your combine harvester. Make sure that all of the risks are assessed to reduce the likelihood of an accident. Make sure you are familiar with the controls and operation of the machine and have read the operators manual. The combine harvester has many moving parts, guards are designed to keep you safe, please ensure that all guards are ke…

-

42, 41 Maintenance A full maintenance schedule is provided in the operators book and this should be followed to ensure reliable operation of the combine. When checking belt tensions there are three main types of tensioner that are fitted to LEXION Combines: 1. End to end guides – Correct tension is achieved when the ends of “D” are end to end. To tension the belt, slacken nut K from M and wind M in a clockwise direction until the ends of D are met then re lock n…

-

19, 18 HOTKEY Symbols LASER PILOT adjustment Hectolitre weight adjustment Flagging function for yield mapping Left / Right chopper bias, Working width, Central overlap, (only with power spreader) and crosswind compensation if fitted Favourite crop settings CRUISE PILOT Automatic Reel speed, Reel height, Reel fore & aft position Cutting height, VARIO length, End snapping plate adjustment Partial working width adjustment …

-

32, 31 De-awning De-awning can be carried by out operating the lever by the right hand front wheel of the machine, which in turn installs a set of plates under the APS concave. This gives the crop an extra ‘rub’ which in turn threshes it harder. They must only be installed when threshing is stopped. It is recommended that these plates are only engaged when there is a difficulty in threshing or when excess amounts of short straw are in the grain tank. If…

-

38, 37 Settings aid The following pages are designed as quick reference flow chart to aid with settings should you encounter problems during harvest. For further and more detailed instruction refer to the operators manual

… -

37, 36 Straw & Chaff management Chaff spreader The chaff spreader is situated at the back of the top sieve, the speed of the discs should be adjusted so that the material is spread evenly and over the full working width of the combine (if fitted). Straw chopper The straw chopper can be engaged and disengaged from work by operating the buttons on the rear of the machine. When the buttons are operated the chopper must be stopped. On LEXION fitted with …

-

20, Claas LEXION 770 2016 19 CEBIS Menu Navigation To navigate through the CEBIS menu turn the switch (3) shown below and the different icons at the top of the CEBIS screen will be highlighted in black (8). When the desired menu is highlighted push switch (3) to enter it, with any menu turn switch (3) to select the required section and push it to enter it. If a value needs to be changed within a menu push the switch (3) to display the + — sign…

-

9, Claas LEXION 770 2016 8 Roof console 1. Hazard warning lights 2. Road travel switch 3. Not used 4. Not used 5. Front attachment folding 6. Not used 7. Not used 8. Track tension/Montana brake warning 9. Emergency steering indicator

… -

1, Information and Basic Field Settings for LEXION version 14 Information and Basic Field Settings for LEXION 2016

… -

13, 12 CEBIS Road travel display Mercedes 1. Main menu 2. Engine RPM 3. Speedometer 4. Time 5. Operating hours 6. Ground speed 7. Ground speed units 8. Vehicle control display 9. Drive status 10. Message fields 11. Coolant temperature 12. Fuel (pointer)/ urea level*(green bar) *Engine HP is reduced if urea tank is below 20%

… -

28, 27 CEMOS CONTROLS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1 – 5 Menu-dependent function keys 6 Play button (Iso-bus only) 7 Stop button (Iso-bus only) 8 On/off button 9 ESC button 10 Select menu button 11 Incremental encoder 12-16 Menu-dependant function keys

… -

12, 11 Steering column Mercedes 7. Engine fault indicator 8. Urea level 9. Not used 10. Engine de-rate 11. Not used 12. Not used 13. Brake pressure warning 14. Track tension warning 15. Right indicator 16. 24v charging light 17. Emergency steering pump 18. Main beam 19. Trailer indicator 20. 12v charging light 21. Left indicator 22. Stop engine light

… -

8, 7 Right Hand Console 1. CEBIS rotary switch 2. HOTKEY rotary switch 3. Main menu rotary switch 4. Value select rotary switch 5. ESC button 6. Information button 7. Quick access button 8. Front Attachment Engagement 9. Threshing Engagement 10. Front Attachment reverser 11. Left hand rape knife switch 12. Front attachment cross levelling / VARIO length adjustment/Hotkey 13. Gear Selection switch 14. Not Used 15. Park Brake 16. LASER PILOT left & right selector switch 17. Not Used 18.…

-

22, Claas LEXION 770 2016 21 CEBIS Calibration Working Position Don’t forget to learn the working position of the cutterbar within CEBIS to avoid inaccurate yield measurements. This may also need to be changed when combining different crops. If a problem occurs involving the AUTO CONTOUR response, always try learning the cutting height limits before contacting the service department of your preferred CLAAS dealer.

…