Главная

/

Пользователям

/

Инструкции

/

Описание архитектуры и процесса решения типовых задач посредством пакета ANSYS CFX

1. Общая структура пакета

Пакет ANSYS CFX состоит из 5 приложений, между которыми происходит поток информации, возникающей в процессе постановки и решения задач гидродинамики.

Рис. 1Схема постановки и решения задачи с использованием пакета ANSYS CFX.

Рассмотрим, за какие этапы процесса постановки и решения задачи отвечает каждое приложение пакета.

CFX — Mesh, или другое приложение генерации сетки – это первый шаг постановки задачи. На данном этапе происходит следующее:

- определение геометрии области исследования;

- создание областей потоков жидкостей или газов, твердых областей и задание имен граничным областям;

- установка параметров сетки.

Система ANSYS CFX позволяет импортировать геометрические данные из большинства современных систем автоматизированного проектирования (CAD) и автоматически сгенерировать сетку на их основе. Таким образом, первый этап постановки задачи может быть выполнен во внешнем приложении (CAD-системе).

ANSYS CFX — Pre реализует процесс определения физики задачи. Физический препроцессор импортирует сетку, созданную на первом шаге. Это второй шаг постановки задачи, на котором определяются физические модели, на основе которых будет происходить симуляция процесса, а также их основные параметры и характеристики. CFX-Pre позволяет определить граничные условия процесса (входные, выходные параметры), модели теплообмена.

ANSYS CFX-Solver – это программа, реализующая процесс решения задачи вычислительной гидродинамики. Импортируется задача, поставленная посредством ANSYS CFX — Pre и производится поиск решения всех требуемых переменных:

- уравнения в частных производных интегрируются по всему объему задачи в области исследования, соответствует применению закона сохранения (масс или момента) к каждой исследуемой области;

- полученные интегральные уравнения преобразуются в систему алгебраических уравнений путем аппроксимирования членов в интегральных уравнениях;

- алгебраические уравнения решаются численным методом.

ANSYS CFX-Solver Manager – это надстройка над CFX-Solver. Она позволяет контролировать ход решения задачи:

- определять входные файлы решателя;

- запускать или приостанавливать CFX — Solver ;

- контролировать процесс решения задачи;

- устанавливать CFX — Solver для проведения параллельных вычислений.

ANSYS CFX-Post – это программа, предназначенная для анализа, визуализации и представления результатов, полученных в ходе решения задачи посредством ANSYS CFX-Solver. Для этого используются следующие средства:

- визуализация геометрии и исследуемых областей;

- векторные графики для визуализации направления и величины потоков;

- визуализация изменения скалярных величин (такие как температура, давление) внутри исследуемой области.

Графики, изображения и видео, полученные в результате анализа решения задачи можно сохранить в виде отдельных файлов.

2. Типы файлов ANSYS CFX

2.1 Общая схема обмена файлами

В процессе постановки, решения и анализа задачи, различные модули пакета ANSYS CFX обмениваются информацией посредством импорта/экспорта различных файлов.

Рис. 2Схема файлов, генерируемых в процессе постановки и решения задач программами из пакета ANSYS CFX.

Рассмотрим базовые файлы, посредством которых реализован процесс решения задач в пакете ANSYS CFX.

2.2 Файлы программы ANSYS CFX- Pre

Пакетный файл ANSYS CFX — Pre (*.cfx) содержит данные о физике процесса, и используется совместно с GTM -файлом, содержащем «базу данных» процесса симуляции. Эта пара файлов используется для сохранения и возобновления процесса постановки задачи в приложении ANSYS CFX — Pre. Пакетный файл – бинарный, вследствие чего непосредственное его редактирование невозможно.

Файлы GTM (» Geometry, Topology and Mesh» – «Геометрия, Топология и Сетка») содержат информацию о всех областях и сетках, требуемых для симуляции. Когда происходит импорт сетки в приложение ANSYS CFX — Pre, происходит формирование соответствующего GTM -файла. Таким образом, после импорта сетки, первоначальный файл, содержащий сетку, более не требуется. Эти файлы можно открывать непосредственно в среде ANSYS CFX — Post для детального анализа сеток.

Файл постановки задачи ANSYS CFX (*.def) содержит полную информацию о поставленной задаче, включая геометрию, сетку поверхности, граничные условия, параметры среды, параметры решателя и начальные переменные. Он создается ANSYS CFX — Pre и импортируется ANSYS CFX — Solver для запуска процесса решения задачи.

Файл CCL (» Command Language File» – «Файл языка команд») – это текстовый файл, описывающий постановку задачи решателю ANSYS CFX-Solver. Он может быть как сгенерирован отдельно, так и получен из файла постановки задачи, посредством применения утилиты cfx5cmds.

2.3 Файлы программы ANSYS CFX- Solver

Файл результатов ANSYS CFX — Solver (*.res) содержит полную информацию о результатах решения задачи, включая пространственную сетку и решения потоков жидкостей и газов. Он подобен файлу постановки задачи (*.def), но в дополнение к информации, содержащейся в файле постановки задачи, он еще содержит вычисленные значения каждой переменной в каждом узле сетки. Этот тип файлов может быть использован как входной файл ANSYS CFX — Pre, для определения начальных значений переменных для дальнейшего анализа.

Выходной файл ANSYS CFX — Solver (*.out) – это форматированный текстовый файл, содержащий информацию о настройках модели ANSYS CFX, состоянии решения в процессе работы ANSYS CFX — Solver и статистику выполнения задания.

2.4 Файлы программы ANSYS CFX- Post

ANSYS CFX-Post может обрабатывать файлы GTM (*.gtm) и файлы постановки задачи (*.def) (для детального изучения и выявления возможных проблемных сегментов сетки) а также файлы результатов (*.res) (для анализа и визуализации результатов решения поставленной задачи). В качестве результата работы, ANSYS CFX-Post генерирует различные графические файлы, содержащие графическое представление решения поставленной задачи.

3. Процесс постановки и решения типовой задачи посредством пакета ANSYS CFX

3.1 Постановка задачи

Рассмотрим одну из типовых задач, решаемых посредством пакета ANSYS CFX. В качестве примера, возьмем задачу смешения жидкостей с разными температурами, текущих по трубам. Пакет ANSYS CFX, по умолчанию, не содержит встроенных средств для построения геометрии. В качестве исходных данных могут быть использованы сетки, сгенерированными различными внешними приложениями генерации сеток (CAD -пакетами). В нашем случае есть 2 возможных пути получения сетки: либо использовать уже имеющуюся сетку, либо смоделировать новую сетку посредствам приложений, входящих в состав пакета ANSYS. Собственноручно создадим геометрию исследуемой области и сформируем сетку на ее основе.

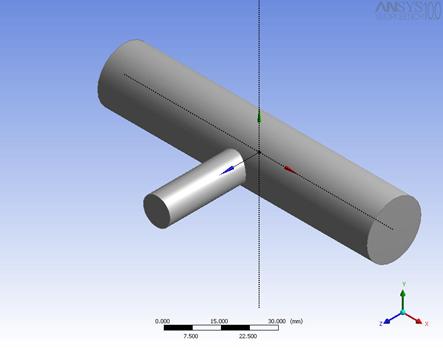

Для описания геометрии исследуемой области воспользуемся приложением ANSYS DesignModeler. Это приложение, входящее состав пакета ANSYS Workbench, предназначенное для создания и редактирования геометрии. Создадим простую систему, состоящую из пары соединенных труб: основной трубы, и побочной трубы, по которой подается подогретая вода. Для этого создадим систему из двух цилиндров: больший представляет собой участок основной трубы, а меньший – «впайку» (Рис. 3).

Рис. 3Постановка геометрии задачи.

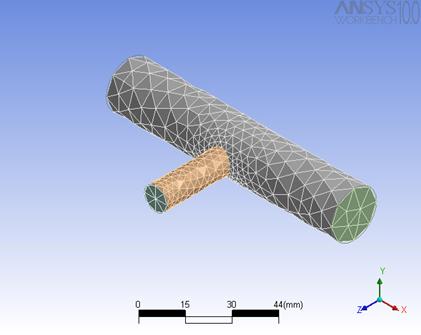

Созданный нами файл геометрии экспортируем в генератор сеток ANSYS CFX — Mesh. Устанавливаем требуемые параметры точности сетки и получаем следующее представление исследуемой области (Рис. 4).

Рис. 4Формирование сетки на основе геометрии.

Сформированная сетка относительно грубая, но, как можно заметить из рисунка, плотность ее узлов непостоянна и значительно увеличивается в точке сочленения труб, что позволяет более детально исследовать интересующий нас участок.

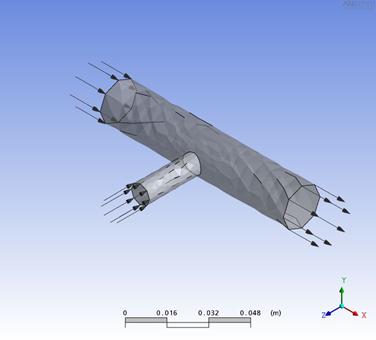

Созданную сетку импортируем в ANSYS CFX — Pre и определяем физику задачи. Устанавливаем, что в данной системе будет находиться вода, задаем ее скорости и температуры на входах труб, указываем выход основной трубы (Рис. 5).

Рис. 5Определение физики задачи.

3.2 Решение и анализ задачи

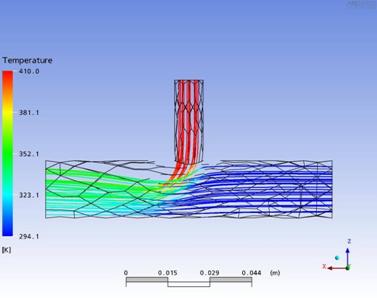

В результате действий, описанных в 3.1, мы получили файл постановки задачи, который передается в ANSYS CFX — Solver Manager. В нем мы задаем параметры решения поставленной задачи (решение будет производиться на локальной машине, без применения параллельных вычислений) и запускаем процесс решения задачи посредством ANSYS CFX — Solver.

Рис. 6Картина потока воды в трубах.

Решение задачи на кластере происходит несколько по-другому. Требуется скопировать сгенерированный файл постановки задачи (*.def) на кластер, и запустить решение задачи следующим образом:

cl-run -as cfx13 -np 32 cfx_test -def. /test-file.def (более подробно о запуске см. в инструкции)

После запуска приведенной выше команды, будет запущен процесс решения задачи, поставленной в файле test-file.def. Решение будет производиться на 32-и ядрах, что определяется параметром -np 32. Результаты расчетов (файл с расширением *.res) появятся в той же директории, из которой производился запуск расчета. Файл *.res требуется скопировать на локальный компьютер, где и будет производиться анализ решения задачи посредством программы ANSYS CFX — Post.

В результате решения задачи мы получаем файл результатов, в котором храниться вся информация о потоках воды в рассматриваемой задаче. Для визуализации и анализа результатов, воспользуемся приложением ANSYS CFX — Post. После импорта результатов в приложение создадим 2 потока, соответствующих течению воды в основной и побочной трубе. Цвет потока установим соответствующим температуре воды. В результате, получим наглядную картину течения воды в данной системе труб (Рис. 6).

Ansys CFX – NACA 4412 (Structured Mesh)

The NACA four-digit wing sections define the profile by:

First digit describing maximum camber as percentage of the chord.

Second digit describing the distance of maximum camber from the airfoil leading edge in tenths of the chord.

Post Views: 4,448

OpenFOAM vs ANSYS CFX

OpenFOAM is the free, open source CFD software developed primarily by OpenCFD Ltd since 2004. It has a large user base across most areas of engineering and science, from both commercial and academic organisations.

Post Views: 3,598

Ansys CFX – Compressible Flow

Compressibility effects are encountered in gas flows at high velocity and/or in which there are large pressure variations. When the flow velocity approaches or exceeds the speed of sound of the gas or when the pressure change in the system ( $\Delta p /p$) is large, the variation of the gas density with pressure has a significant impact on the flow velocity, pressure, and temperature.

Post Views: 5,674

Ansys CFX – Heat Transfer through a Pipe

Thermodynamics is a branch of physics that deals with the energy and work of a system. Thermodynamics deals only with the large scale response of a system that we can observe and measure in experiments. In aerodynamics, we are most interested in the thermodynamics of propulsion systems and high speed flows.

Post Views: 3,226

Ansys CFX – Heat Exchanger (Shell & Tubes)

A heat exchanger is a device used to transfer heat between two or more fluids. The fluids can be single or two phase and, depending on the exchanger type, may be separated or in direct contact.

Post Views: 3,860

Ansys CFX – Vortex Generator 3D

In fluid dynamics, a vortex is a region in a fluid in which the flow revolves around an axis line, which may be straight or curved. Vortices form in stirred fluids, and may be observed in smoke rings, whirlpools in the wake of a boat, and the winds surrounding a tropical cyclone, tornado or dust devil.

Post Views: 3,376

Ansys CFX – How to add new material?

By default, your local materials list will include a single fluid material (air) and a single solid material (aluminum). If the fluid involved in your problem is air, you can use the default properties for air or modify the properties.

Post Views: 3,908

Ansys CFX – Free Surface 3D

Free surface is the surface of a fluid that is subject to zero parallel shear stress, such as the interface between two homogeneous fluids, for example, liquid water and the air in the Earth’s atmosphere.

Post Views: 3,695

In these notes the basic steps in a CFD solution will be illustrated using the professionalsoftware ANSYS Workbench Version 11which includes the componentsDesignModeler, Meshing, and Advanced CFD (all trademarks of ANSYS).

-

ME 566Computational Fluid Dynamics for Fluids Engineering

DesignANSYS CFX STUDENT USER MANUAL Version 11

Gordon D. StubleyDepartment of Mechanical Engineering,

University of WaterlooG.D. Stubley 2008

January 30, 2008

1

-

Contents

Contents i

Preface iii

I Tutorial 1

1 Overview of CFD Process 21.1 Example Problem . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 21.2 Domain . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 21.3 Domain Descritization: Mesh . . . . . . . . . . . . . . .

. . . . . . . . . . 31.4 CFD Flow Solver . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . 41.5 Post-processing . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

82 Tutorial Commands 102.1 Introduction to the GUI . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 102.2 Commands for Duct

Bend Example . . . . . . . . . . . . . . . . . . . . . 13II Additional Notes 30

3 Geometry and Mesh Specification 313.1 Basic Geometry Concepts

and Definitions . . . . . . . . . . . . . . . . . 313.2 Geometry

Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 323.3 Mesh Generation . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 344 CFX-Pre: Physical Modelling 424.1 Domain . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434.2

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . 464.3 Output Control . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 474.4 Simulation Type

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

474.5 Solver Control . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 475 CFX Solver Manager: Solver Operation 495.1 Monitoring the

Solver Run . . . . . . . . . . . . . . . . . . . . . . . . . . .

49i

-

Contents ii

6 CFX-Post: Visualization and Analysis of Results 526.1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . 526.2 Objects . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 546.3 Tools . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 556.4 Controls . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . 567 Frequently Asked Questions 577.1 Where are the ANSYS-CFX

tutorial files? . . . . . . . . . . . . . . . . . . 577.2 How to

use an existing mesh after modifying the geometry? . . . . . 577.3

How to use an existing CFX-Pre model after modifying the mesh? .

577.4 How is heat conduction modelled in a single domain? . . . . .

. . . . . 577.5 Why is there only a few point values given when

exporting dataalong a line normal to a wall? . . . . . . . . . . . . . . . . .

. . . . . . . . . 587.6 How is a thin guide vane modelled? . . . .

. . . . . . . . . . . . . . . . . . 58 -

Preface

In these notes the basic steps in a CFD solution will be

illustrated using the pro-fessional software ANSYS Workbench

Version 11which includes the componentsDesignModeler, Meshing, and

Advanced CFD (all trademarks of ANSYS). Thesenotes include an

introductory tutorial and a mini users guide. In particular,

thenotes are pertinent to the simulation of two dimensional steady

incompressiblelaminar and turbulent fluid flows on stationary

meshes. They are not meant to re-place a detailed users guide. For

full information on these components refer to theon-line help

documentation provided with the software 1.These notes include sections on:

Overview of CFD Simulation An introductory section outlining the

componentsof a CFD simulation. Includes the description of an

example CFD analysisproblem;Commands for the Example Problem: A complete step-by-step list

of instructionsfor solving the example problem.Software Components: A description of the concepts and operation

involved inthe five software components: DesignModeler, Meshing,

CFX-Pre, CFX-Solver, and CFX-Post; andFrequently Asked Questions: Suggestions for further study and

for solving typi-cal flow cases.The following font/format conventions are used to indicate the

various com-mands that should be invoked:Menu/Sub-Menu/Sub-Sub-Menu Item chosen from the menu hierarchy

at the top of amain panel or window,Button/Tab Command Option activated by clicking on a button or

tab,Link description Click on the description to move by a link to

the next step/page;Name val ue Enter the val ue in the named box,

1Many of the features available in these software components

will not be explored in introductoryCFD courses.iii

-

PREFACE iv

Name selection Choose the selection(s) from the named list,Name

Panel or window name,Name On/off switch box, and Name On/off switch circle (radio

button). -

Part I

Tutorial

1

-

Chapter 1

Overview of CFD Process

1.1 Example Problem

To provide a context for these notes consider the application of

CFD to studyingthe flow in a short radius bend within the duct

system shown in Figure 1.1. Thereis a flow of water upwards into

the bend.The side view of the duct bend geometry is shown in Figure 1.2.

The radiusof the inner wall bend is R1= 0.025[m]. The spacing

between the duct inner walland outer wall is H3= 0.1[m]. The duct

has a width (into the page) of 1[m]. Theaverage speed of the water

flow through the duct is 3[m/s].The purpose of the CFD analysis is to determine if and where

flow separation isan issue. CFD is well suited to this task because

it can provide a detailed representa-tion of the velocity and

pressure fields throughout the flow domain. By examiningthe

velocity field it will be possible to identify regions where the

flow separates andreverses direction and by examining the pressure

field it will be possible to identifyregions where flow reversal is

likely to occur. In this chapter a brief description ofhow these

field properties are determined is presented.1.2 Domain

The CFD simulation is restricted to a specific three dimensional

region known asthe domain. For the duct bend example, the domain,

shown in Figures 1.1 and 1.2,is a thin volume that is bounded by

the outer wall, the inner wall, by planes per-pendicular to the

flow upstream and downstream of the bend, and by surfaces inthe x y

plane on the front and back sides. The domain extends V 2= 0.1[m]

up-stream from the bend and H4= 0.25[m] downstream from the bend.

The domainis 0.02[m] wide.The geometry of the domain is represented in digital form by

solid modellingsoftware. The resulting geometric model is known as

a solid or solid-body for his-torical reasons. The volume of the

solid geometric model is the volume where thefluid flow is

modelled.2

-

CHAPTER 1. OVERVIEW OF CFD PROCESS 3

xz

y

CFD Domain

Figure 1.1: Schematic of the region near a short radius bend in

a duct system. Wateris flowing upwards into the bend and to the

right out of the bend. A wireframerepresentation of the CFD flow

domain is also shown.1.3 Domain Descritization: Mesh

It is not possible to analytically determine mathematical

functions for the variationof velocity and pressure throughout

complex domains. Therefore approximate val-ues of the velocity

components, Ui , i = 1,2,3,1 and pressure, p, are generated onlyat discrete points or nodes

throughout the domain. The locations of the nodes arebased on a

mesh. A mesh for the duct bend geometry is shown in Figure 1.3.The mesh is comprised of a set of relatively simple three

dimensional polyhedralelements. The example mesh is comprised of

hexahedral elements. For all meshes,the set of elements is

non-overlapping, fills the domain, and fits the boundaries ofthe

domain. For CFX meshes, the nodes are located at the vertices of

the elements.The example mesh is only one element thick in the z

direction and the surfacemeshes on the front and back surfaces are

identical. This is suitable for this flowbecause there is no

significant variation of flow properties in the z direction.1Index notation is used in these notes, where the x,y, and z

directions are indicated by indices 1,2,and 3 respectively. -

CHAPTER 1. OVERVIEW OF CFD PROCESS 4

Figure 1.2: Solid body model of the duct bend geometry included

in the CFD flowdomain.1.4 CFD Flow Solver

CFD software assumes that each node is surrounded by a finite

control volumebounded by planar faces as illustrated in Figure 1.3.

By applying the principles ofconservation of momentum and mass to

each control volume, a set of finite volumeequations are formed

which can be solved to provide nodal values of velocity

andpressure.After a mesh has been generated, there are three major steps to

create a simula-tion of the velocity and pressure fields on the

mesh:Flow Model Specification: identify all significant flow

processes (such as advectiveflows and stress tensor forces) and

their appropriate models;Finite Volume Equation Generation: apply a set of numerical

approximations toestimate all control volume flow processes in

terms of the nodal field propertyvalues. When applied to the

conservation principles, this leads to a set of finitevolume

equations; andFinite Volume Equation Solution: use a nonlinear matrix solution

algorithm tosolve the equation set for estimates of the nodal

values of velocity and pres-sure. -

CHAPTER 1. OVERVIEW OF CFD PROCESS 5

Figure 1.3: Mesh of hexahedral elements for the duct bend

geometry showing atypical node and finite control volume.By convention the software that performs these three steps is

referred to as the CFDflow solver.Flow Model Specification

The first step of the CFD flow solver requires input from the

CFD analyst to iden-tify the relevant flow processes and to choose

suitable models for these processes.For the example problem of flow through the duct bend:

Type of Flow: the flow is modelled as turbulent, non-buoyant,

steady in themean flow properties, and doesnt involve heat

transfer;Fluid Type and Properties: the fluid, water, is modelled as a

constant propertyNewtonian liquid, with a density of = 1000[k g/m3]

and dynamic viscosityof = 0.001[Pas];Flow Domain Properties: the domain is modelled as

stationary;Turbulence Model: the mean action of the turbulent eddying

motion onthe mean velocity field is accounted for with the

k-epsilon (k «) model. In -

CHAPTER 1. OVERVIEW OF CFD PROCESS 6

this model, the turbulent Reynolds stresses, u i u j , are

related to the meanvelocity strain rate byu i u j t Ui x j

+ Uj xi

!where the turbulent viscosity, t , is proportional to the fluid

density, thevelocity scale (intensity) of the turbulent eddies, and

the length scale of theeddies. The scales of the turbulent eddying

motion are estimated from twofield properties of the turbulence

which are calculated at each node: k, meanturbulent kinetic energy

(i.e. kinetic energy associated with swirling turbu-lent eddies)

and «, the rate at which k is dissipated by molecular action;

andBoundary Conditions: modelling the influence of the surroundings

on theflow domain are specified for each surface on the flow domain

and are mod-elled as:[Inflow Surface:] with a uniform normal velocity of Vin =

3[m/s],turbulent intensity, I pk

Vin= 5%, and turbulent length scale, l k 32

«=

0.01[m]; [Outflow Surface:] with a uniform relative pressure of

0[Pa]; [Inner and Outer Walls:] modelled as smooth no-slip walls.

The tur-bulent wall shear stress is estimated with the Law of the Wall

for equi-librium turbulent boundary layers;[Front and Back Surfaces:] modelled as symmetry surfaces

implyingno mass flow across these surfaces and all normal gradients

are zero.Finite Volume Equation Generation

As mentioned above, a finite control volume surrounds each node

in the mesh.Once calculated the nodal field values are

representative average values for theirrespective control volumes.

To calculate the nodal field values a set of discrete alge-braic

equations based upon conservation principles are formed. For the

duct bendexample, these equations are based on conservation of

mass, momentum in 3 direc-tions, x, y, and z, turbulent kinetic

energy, and its dissipation rate.The finite volume methodology can be illustrated with a

simplified discussionof the generation of the discrete mass

conservation equation. Consider mass conser-vation for the control

volume surrounding the P node shown in Figure 1.3. Withthe

specified steady incompressible flow model, mass conservation

implies that thesum of mass flows across the faces of the P control

volume must balance or0=faces

~Vface nAface (1.1)

where ~Vface is the face average velocity, n is the face

outwards pointing unit normalvector, and Aface is the face area.

Notice that Equation 1.1 provides a relationship in -

CHAPTER 1. OVERVIEW OF CFD PROCESS 7

terms of face velocities and not one in terms of the nodal

velocities. However, eachinterior face separates two neighbour

nodes. If numerical interpolation functionsare used to estimate the

face velocities in terms of the neighbour nodal values thena useful

discrete mass conservation equation can be formed in terms of the

nodalvalues.Typically the interpolation functions assume some form of linear

interpolation.While largely prescribed by the CFD software, the

choice of certain interpolationfunctions can be set by the CFD

analyst.For the duct bend example the following interpolation functions

are specified:Mass flows: linear-linear-linear interpolation;

Diffusive flows: linear-linear-linear interpolation;

Advective flows: upwind weighted linear interpolation based on

nodal values andgradient estimates (high resolution scheme)Pressure forces: linear-linear-linear interpolation; and

Stress tensor forces: linear-linear-linear interpolation.

Finite Volume Equation Solution

For the duct bend example, there are five unknown field

properties at each node,pressure, three velocity components,

turbulent kinetic energy, and its dissipationrate. As explained

above, five corresponding discrete algebraic equations can

begenerated for each node based on conservation of mass, momentum

in three di-rections, turbulent kinetic energy, and its dissipation

rate. Therefore, once finitevolume equations are generated for each

node there is a set of equations which canbe solved to determine

estimates of the nodal field properties.This equation set is highly coupled, both linearly and

nonlinearly. Therefore aniterative solution algorithm is

implemented in the CFD solver to obtain estimatesof the nodal field

properties. The essence of the algorithm:1. Make an initial guess for each field property at each

node;2. Determine the imbalance, residual, in each finite volume

conservation equa-tion. If the residual imbalance values are

sufficiently small stop the iteration.If not continue with the

following:3. Use the residual values to estimate improved values for the

nodal field prop-erty values;4. Return to Step 2.

-

CHAPTER 1. OVERVIEW OF CFD PROCESS 8

Figure 1.4: Vector plot of the simulated flow field through a

duct bend showingseparated flow on the inner wall downstream of the

bend.1.5 Post-processing

The CFD flow solver provides estimates of fundamental field

properties at eachnode. Often this information is insufficient. For

example, in the duct bend flow itis necessary to know the extent of

the possible separated flow regions and the dropin total pressure

through the bend. This information is found by post-processingthe

nodal values to provide graphic images or to calculate secondary

values of directrelevance to evaluating the flow.Figure 1.4 shows a vector plot of the simulated flow through the

duct bend. Aseparated flow region adjacent to the inner wall

downstream of the bend is clearlyseen. Regions of high speed and

low speed flow are also seen in this visualization.A summary of the complete CFD model including meshing details is

shown inFigure 1.5. -

CHAPTER 1. OVERVIEW OF CFD PROCESS 9

Figu

re1.

5:Su

mm

ary

ofth

eC

FDm

odel

for

flow

thro

ugh

adu

ctbe

nd.

-

Chapter 2

Tutorial Commands

2.1 Introduction to the GUI

Windows XP/NEXUS

The CFD software is available on the workstations in the

Engineering Comput-ing labs, Fulcrum (E2-1313), Wedge (E2-1302B),

Helix (RCH-108), and WEEF (E2-1310), and the Mechanical Engineering

4th year computing room, E3-3110. Theworkstations use the Windows

XP operating system on Waterloo NEXUS. Youshould be familiar with

techniques to create new folders (or directories), to deletefiles,

to move through the folder (directory) system with Windows

Explorer, toopen programs through the Start menu on the Desktop

toolbar, to move, resize,and close windows, and to manage disk

space usage with tools like WinZip.Introduction to Workbench

The ANSYS Workbench environment provides an interface to manage

the filesand databases associated with the individual software

components. These files anddatabases are organized into a

particular project. To get a feel for this environ-ment and the

GUIs associated with the software components, we will look at

apre-prepared project on flow through a pipe bend.1. Create a working directory called CFDTest on your N

drive.2. Use a web browser to visit the UW-ACE ME 566 course page

(uwace.uwaterloo.ca).Under the Lessons tab and open the Student

User Manual folder. Click on thelink to PipeBend.zip and follow the

instructions to download the archive con-taining the working

files.3. Use WinZip to extract the files in the PipeBend archive into

your workingdirectory.4. Open ANSYS Workbench fromStart/Programs/Engineering/ANSYS

11.0/ANSYS Workbench.10

-

CHAPTER 2. TUTORIAL COMMANDS 11

5. Open the project file. Check that Open: Workbench Project is

selected be-fore using the Browse button below the Open: Workbench

Projects panel areato find and selecting the file PipeBend.wbdb

from your working directory.6. There are three main areas on the screen: command menus,

buttons, and tabsat the top, a list of potential Project Tasks on

the left, and a list of the fileslinked to the project.7. On-line help for Workbench, DesignModeler, and CFX-Mesh is

available inweb-page format similar to other Windows programs.

Choose Help/ANSYSWorkbench Help to open the ANSYS Workbench

Documentation. Search forkeyword Tutorials and select CFX-Mesh

Help. Follow the Tutorials link to seethe list of available

tutorials.Introduction to DesignModeler/CFX-Mesh GUI

1. In the Workbench file area click on the item name PipeBend

just to the rightof the DesignModeler button ( DM ). Notice that

the Project Tasks area atthe left adjusts to reflect your choice.

Under DesignModeler Tasks chooseOpen to open the geometry file.2. A new page for DesignModeler will open. Go back to the

Project page byclicking on the PipeBend [Project] tab at the top

left of the screen. Click onthe PipeBend [DesignModeler] tab to return to the DesignModeler

page.3. There are four major areas on the page: command menus and

buttons atthe top, a Tree View and Sketch Toolbox on the left, a

Details View at thebottom left, and a Model View window. Place the

mouse cursor over oneof the command buttons in the top row. A brief

description of the buttonsaction should appear (you may need to

click in the window once to make itactive). Visit each button with

the mouse cursor to see its action.4. One method of controlling the view is with the coordinate

system triad inthe lower right corner of Model View. Click on the Z

axis of the triad to seea back view of the pipe bend. Click on the

cyan sphere to select the isometricview.5. Another method of controlling the view is with the mouse left

button inconjunction with a mouse action selection. From the upper

row of buttons,select the Pan action. Holding the left mouse button

down, drag the mouseover the Model View to translate the view. Select the Zoom

action andrepeat with an up-down mouse action to change the size of

the view.6. Select the Rotate action. The rotate action is context

sensitive in that itdepends upon the position of the mouse cursor.

With the mouse cursor closeto the pipe bend, press the left mouse

button to get free 3D rotation. The point -

CHAPTER 2. TUTORIAL COMMANDS 12

of rotation can be changed by clicking the left button while the

cursor is onthe pipe bend surface (this may take some

experimentation). With the mousecursor in a corner of the Model

View, press and hold the left mouse buttonto get a roll action in

which there is 2D rotation about an axis perpendicularto the Model

View window. Move the cursor to either the left or right ofthe

Model View and hold the left button to get a yaw action in which

thereis 2D rotation about the vertical axis. Move the cursor to

either the top orbottom of the Model View and hold the left button

to get a pitch action inwhich there is 2D rotation about the

horizontal axis.7. Rotate, zoom, and pan actions can be achieved directly by

pressing the middlemouse key alone, with the Shift key, and with

the Ctrl key, respectively.8. The Tree View on the left shows the geometric entities that

were used togenerate the cylinder. Expand the 1 Part, 1 Body entity

and click on Solid tosee some properties of the cylinder in the

Details View. The pipe bend wasgenerated from two entities:a) Sketch1: which can be found in the Plane4 entity. Click on

Sketch1 tohighlight the circle that the pipe bend is based upon

with yellow.b) Sketch2:. which can be found in the YZPlane entity. Click on

the Sketch2to highlight the path that is swept out by Sketch1 to

generate the pipebend.9. In the help page search for keywords rotation modes and

select «Rotation Cur-sors in the Rotate Mode» to find more

information on changing the view.10. Click the X button on the PipeBend [DesignModeler] tab to

close the De-signModeler page. You can click No to quit without

saving changes.Introduction to the Advanced CFD GUI

The tasks associated with CFD simulation in Workbench are

referred to as Ad-vanced CFD Tasks. For historical reasons, the GUI

for the three Advanced CFDTasks is slightly different from that of

the other Workbench components. We willuse CFX-Post to look at the

completed simulation of flow through a pipe bend toget a feel for

these differences.1. In the Workbench file area click on the item name

PipeBend_001. Under Ad-vanced CFD Tasks, choose Open in CFX-Post to

open the results file (PipeBend_001.res).All of the pertinent CFD

model data (mesh, flow attributes, and boundarycondition

information) for this problem is stored in this file.2. A new page for CFX-Post will open.

3. There are three major areas on the screen: Command menus and

buttons atthe top, outline and detail panels on the left, and 3D

Viewer window. Wire-frame models of the pipe inlet and outlet

should be in the Viewer. To see the -

CHAPTER 2. TUTORIAL COMMANDS 13

pipe bend click the Domain 1 Default object on in the tree under

PipeBend_OO1and Domain 1 in the Outline panel.4. The mouse button action for controlling the view is similar

to that in Design-Modeler.5. The coordinate system triad is shown in the lower right

corner. Unlike inDesignModeler, the triad cannot be used to change

the view. To set standarddirectional views type x, y, or z while

the Viewer window is active to getviews in the positive axis

directions and type X, Y, or Y to get views in thenegative axis

directions. Other standard key mappings can be seen by clickingon

the Show Help Dialog icon at the right of the lower row of icon

buttons.6. On-line help is available, Help. Open the main table of

contents, Help/MasterContents. Context-sensitive help is also

available. Right click on Default Legend View 1object and choose

Edit. Position the mouse pointer in the Details of DefaultLegend

View 1 panel and press to bring up the help page for that

panel.7. This should give a sense of the operation of the Advanced CFD

GUI. Whenyou have finished, return to the Workbench Project page.

Exit by File/CloseProject and choose No: do not save any items.8. Clean up by deleting the CFXTest directory.

2.2 Commands for Duct Bend Example

To set-up the project files and options:

Create a new folder N:/Ductbend1 to be the working directory for

the projectfiles.Open ANSYS Workbench fromStart/Programs/Engineering/ANSYS

11.0/ANSYS Workbench. To open a new project:1. In the Start window, select Empty Project in the New

panel,2. From the menu bar choose File/Save As … to create a project

file in yourworking directory, and3. In the Save As window fill in File name: Ductbend.wbdb and

click theSave button.

From the menu bar choose Tools/Options … to set the length

units and meshingtool options:In the Options window expand the + DesignModeler entity and

1When NEXUS network traffic is high, it is better to make the

working directory on your localmachine, i.e. C:/Temp/Ductbend. -

CHAPTER 2. TUTORIAL COMMANDS 14

* Select Units in the tree view on the left to set Length Unit

Meter ;and* Select Grid Defaults (Meters) in the tree view on the left to

setMinimum Axes Length 0.5 and Major Grid Spacing 0.1 .Expand the + Meshing entity and select Meshingto Set Show

Mesh-ing Options Panel at Startup No , Default Physics Preference

CFD , andDefault Method Automatic (Patch Conforming/Sweeping) .

Expand the + Common Setting entity and select Geometry Import

to:* set Named Selection Processing Yes ; and

* set Named Selection Prefixes (i.e. leave blank).

Click OK to save the options and close the window,

Geometry Model

The commands listed below will use DesignModeler to create a

solid body geometrythat will represent the flow domain.Under Create DesignModeler Geometry, choose New Geometry,

Check that the desired length unit is Meter is selected and

click Ok in theunits window that appears,In the Tree View, select the XYPlane entity and then click the

New Sketchicon to create the Sketch1 entity as a component of the

XYPlane.To start the sketching , select the Sketching tab and click on

the Z coordinateof the triad in the lower right corner of the Model

View, and draw in the 2Dsketch of the flow path;1. Select the Draw toolbox and use the Arc by Center tool to

sketch theinner wall bend shape:a) Place the cursor over the origin (watch for the P constraint

symbol)and left mouse button click.b) Move the cursor to the left along the X axis. With the C

constraintvisible click the left mouse button to put the start

point of the arcon the X axis.c) Sweep the cursor clockwise until the C constraint appears at

the Yaxis. Click the left mouse button.22. Switch to the Dimensions toolbox to size the inner wall bend

radius:2Notice that the drawing instruction steps are provided in the

lower left corner. -

CHAPTER 2. TUTORIAL COMMANDS 15

a) Select the Radius tool;b) Select a point on the arc. Then

move the cursor to the inside of thearc near the origin. Click to complete a dimension which is

labelledR1.c) In the Details View notice that R1 is shown under the

Dimensionstitle.d) Change the value of R1 to 0.025 [m]. Notice the arc radius

changesautomatically. If the dimension is poorly placed on your

sketch youcan use the Move tool to correct the placement.3. Switch back to the Draw toolbox to sketch the inner entrance

wall:a) With the Line tool selected, place the cursor in the lower

left quad-rant of the XY plane near the arc. Click the left mouse

button.Move the mouse cursor down to create a vertical line. Look

for theV constraint symbol and click the left mouse button;b) Switch to the Dimensions toolbox to size the inner entrance

walllength:i. Select the General tool;ii. Select a point near the centre of

the line. Click and drag thecursor to the right to form the dimension lines. Release

themouse button where the label, V2, is to be placed.iii. In the Details View change the value of V2 to 0.10 [m].c)

To join the inner entrance wall and the inner wall bend switch

tothe Constraints toolbox;

i. Select the Coincident tool;ii. Select the upper end of the

entrance inner wall with a leftmouse button click. The square end marker should be yellow;iii.

Select the square end marker of the arc that lies on the X axiswith a left mouse button click. The inner entrance wall

shouldjoin the inner wall bend.4. To draw a line across the inflow (entrance):

a) Use the Line tool in the Draw toolbox;b) Place the cursor

over the bottom end point of the entrance innerwall and notice that a P constraint symbol appears. Left

mousebutton click to select this point and then move the cursor to

theleft and click while the H constraint symbol is visible.c) Use the General tool in the Dimensions toolbox:d) Select a

point near the centre of the line. Click and drag the cur-sor to the bottom to form the dimension lines. Release the

mousebutton where the label, H3, is to be placed.e) In the Details View change the value of H3 to 0.1 [m].

-

CHAPTER 2. TUTORIAL COMMANDS 16

5. Repeat the procedure used for the entrance inner wall to draw

the exitinner wall:a) Draw a horizontal line in the upper right XY quadrant near

the endpoint of the inner wall bend;b) Set the length of the line to 0.25 [m] with the General tool

fromthe Dimensions toolbox;

c) Join the exit inner wall to the inner wall bend with the

Coincidenttool from the Constraints toolbox.

6. Draw the outer entrance wall with the Line tool. Start at the

outer(left) end point of the inflow edge (look for the P constraint

symbol)and draw a vertical line that is coincident (C) with the X

axis;7. Draw the outer bend wall with the Arc by Center tool. Put the

centreat the origin, make the start point at approximately 20 above

the X axisin the upper left quadrant, and make the end point

coincident (C) withthe Y axis. Use the Coincident constraint tool

to join the start pointof the arc to the end point of the outer

entrance wall;8. Draw the outer exit wall with the Line tool. Draw a

horizontal (H)line coincident (C) with the Y axis above its final

desired location. Usethe Coincident constraint tool to join this

line to the end of the outerbend wall. Use the Equal Length constraint tool to make the

outer exitwall the same length as the inner exit wall; and9. Draw a line from the end of the outer exit wall to the end of

the innerexit wall to form the outflow edge. Make sure that the end

points arecoincident (P).The sketch should now be an enclosed contour on the XYPlane.

To create the three dimensional solid body:

1. Switch to the Tree View by selecting the Modeling tab;

2. Click on the Extrude button to create the Extrude1 feature .

In theDetails View:Check Base Object Sketch1 ,

Select Operation Add Material , Select Direction Vector None

(Normal) , Set FD1, Depth (> 0) 0.02 ,Select As Thin/Surface? No , and Select Merge Topology? No .

-

CHAPTER 2. TUTORIAL COMMANDS 17

3. Click on the Generate button to create a Solid. Use the

isometric viewin the Model View to check that you have a three

dimensional solid greybody.Name the faces of the solid body to make it easy to apply

boundary condi-tions:Choose Tools/Named Selection.

In the Details panel set Named Selection Outflow ;

In the Graphics View select the outflow face (or surface) and

then clickGeometry Apply in the Details View;Click on the Generate button to complete the named selection

process;Repeat for surfaces named Front, Back, InnerWall, OuterWall, and

In-flow. Some faces, like InnerWall and OuterWall, may be composed

ofthree primitive surfaces. To select a set of faces hold the

«Ctrl»key downwhile clicking on the component faces in the Graphics

View.Save an image of the geometry by clicking on the Image Capture

(camera)button. Set File name: Geometry to save the png format file.

Choose File/Save As … and set File name: Ductbend.agdb in the

Save As win-dow. Click Save to close window.

Return to the Project page by clicking on the Ductbend [Project]

tab at thetop left corner of the window.ANSYS Mesh Generation

The commands listed below use ANSYS swept mesher3 to generate a

discrete hexa-hedral mesh in the flow domain:Choose the New Mesh DesignModeler Tasks; Notice the three

primary areas:Geometry View, Outline View, and Details View, in the

Meshing window.In the outline view, right click on the Mesh entity and select

Generate Mesh.Notice that a simple hexahedral mesh is generated

with automatic settings.To achieve a realistic CFD simulation this

mesh is modified by:1. Ensure that a structured hexahedral mesh is produced by:

a) Select the Face Selection Filter icon from the button

commandsat the top of the meshing window;b) Right click on the Mesh entity and select Insert/Mapped Face

Meshing;3For CFX-Meshing tools see the section on CFX Mesh Generation,

page 27. -

CHAPTER 2. TUTORIAL COMMANDS 18

c) On the Geometry View select the Front face; and

d) then click Geometry Apply in the Details View.

2. Set the mesh one unit wide in the z direction by:

a) Select the Edge Selection Filter icon from the button

commandsat the top of the meshing window;b) Right click on the Mesh entity and select Insert/Sizing;c) On

the Geometry View select one of edges between the front andback faces at the outflow and then click Geometry Apply in

theDetails View;d) In the Details View set

Type Number of Divisions

Number of Divisions 1

Edge Behaviour Hard

Bias Type No Biase) right click on the Mesh entity and select

Generate Mesh.3. Set the mesh spacing in the cross-stream direction so that it

is fine nearthe walls and coarse in the core by:a) Right click on the Mesh entity and select Insert/Sizing;b) On

the Geometry View select the front edge at the inflow betweenouter and inner walls and the front edge oat the outflow

betweenthe walls (remember to use the «Ctrl» key) and then click

GeometryApply in the Details View;

c) In the Details View set

Type Number of Divisions

Number of Divisions 25

Edge Behaviour Hard Bias Type

Bias Factor 50d) right click on the Mesh entity and select

Generate Mesh.4. Set a uniform mesh spacing in the streamwise direction

direction in theentrance region by:a) Right click on the Mesh entity and select Insert/Sizing;b) On

the Geometry View select the front edges of the inner and outerwalls in the entrance region and then click Geometry Apply in

theDetails View;c) In the Details View set

Type Element Size

-

CHAPTER 2. TUTORIAL COMMANDS 19

Element Size 0.01

Edge Behaviour Hard

Bias Type No Biasd) right click on the Mesh entity and select

Generate Mesh.5. Set uniform mesh spacing in the streamwise direction

direction in thebend region by:a) Right click on the Mesh entity and select Insert/Sizing;b) On

the Geometry View select the front edge of the inner bend walland then click Geometry Apply in the Details View;

c) In the Details View set

Type Number of Divisions

Number of Divisions 20

Edge Behaviour Hard

Bias Type No Biasd) right click on the Mesh entity and select

Generate Mesh.6. Set an expanding mesh spacing in the stream direction of the

exit regionby:a) Right click on the Mesh entity and select Insert/Sizing;b) On

the Geometry View select the front edges of the inner and outerwalls in the exit region and then click Geometry Apply in the

De-tails View;c) In the Details View set

Type Element Size

Element Size 0.01

Edge Behaviour Hard Bias Type

Bias Factor 5d) right click on the Mesh entity and select

Generate Mesh.7. Save an image of the mesh by selecting New Figure or Image

Image to Filefrom the icons above the graphics window. Set File

name: Mesh to savethe png format file.8. Save the mesh with File/Save and set File name: Ductbend.cmdb

;9. Return to the Project page by clicking on the Ductbend

[Project] tab atthe top left corner of the window. -

CHAPTER 2. TUTORIAL COMMANDS 20

Pre-processing

In this phase the complete CFD model (mesh, fluids, flow

processes, boundaryconditions, etc.) is defined and saved in a

hierarchical database.To accomplish these steps execute the following commands:

Highlight the Mesh Model, Ductbend.cmdb, in the Project page and

selectCreate CFD Simulation with Mesh under Advanced CFD Tasks;After a short wait the CFX-Pre page will open. This page is

similar to the CFX-Post page. There are three main areas: the menus

and command buttons atthe top, the Viewer window at the right, and

the Outline view of the databasetrees at the left;To create a new material with the required water properties,

right mouseclick on the Materials entity in the Outline tree and

select Insert/Material. Inthe Insert Material panel, fill in Name

Water nominal and click OK to open apanel with two tabs:Click the Basic Settings tab and set:

Option Pure Substance , Material Group Constant Property Liquids

, Material Description off, Thermodynamic State on and

Thermodynamic State Liquid . Click the Material Properties tab and

set:Option General Material , in the Equation of State area set,

Option Value , Density 1000 k gm3 , expand Transport Properties

+ ,Dynamic Viscosity on and Dynamic Viscosity 0.001 Pa s ,and then

click Ok .In the Outline view, right mouse click the Simulation Type

entity and select Editto open the Simulation Type panel. Check that Option Steady

State is setand then click Ok .In the Outline view, double left mouse click the Default Domain

entity to openthe Domain: Default Domain panel which will have

several tabbed sub-panels. -

CHAPTER 2. TUTORIAL COMMANDS 21

On the General Options sub-panel, set:

* Location B28 and notice that the geometry is highlighted

ingreen in the Viewer window,* Domain Type Fluid Domain ,* Fluids List Water nominal ,*

Particle Tracking off,* Reference Pressure 1 atm ,* Buoyancy Option

Non Buoyant , and* Domain Motion Option Stationary .on the Fluid Models sub-panel set:

* Heat Transfer Model Option None ,* Turbulence Model Option

k-Epsilon ,* Turbulent Wall Functions Option Scalable ,* Reaction

or Combustion Model Option None , and* Thermal Radiation Model

Option None ,on the Initialization sub-panel ensure that Domain

Initialization is offand then click Ok to close the panel.To prepare for implementing the boundary conditions, expand the

expand+ Ductbend.cmdb mesh model to see the Principal 2D Regions of

the geometry.Check that all 2D regions are highlighted.

Right mouse click Back and select Insert/Boundary to open the

boundary de-tails panel. In this panel:under the Basic Settings tab set:

* Boundary Type Symmetry , and* Location Back ,

and then click Ok to close the panel and create the new boundary

object.Notice that perpendicular red arrows appear on the back

surface in the Viewerwindow and the boundary object is listed in

the Default Domain entity. Clickingon back surface object in the

Default Domain database causes the back surfacemesh to be outlined

with green in the Viewer window. A double mouse clickwill re-open

the boundary details panel.Right mouse click Front and select Insert/Boundary to open the

boundary de-tails panel. In this panel: -

CHAPTER 2. TUTORIAL COMMANDS 22

under the Basic Settings tab set:

* Boundary Type Symmetry , and* Location Front ,

and then click Ok to close the panel.

Right mouse click Inflow and select Insert/Boundary to open the

boundary de-tails panel. In this panel:under the Basic Settings tab set:

* Boundary Type Inlet , and* Location Inflow ,

and under the Boundary Details tab set:

* Flow Regime Option Subsonic ,* Mass and Momentum Option Normal

Speed ,* Normal Speed 3 ms1 ,* Turbulence Option Intensity and Length

Scale ,* Value 0.05 ,* Eddy Length Scale 0.01 m ,

and then click Ok to close the panel and create the new boundary

object.Right mouse click inner wall and select Insert/Boundary to open

the boundarydetails panel. In this panel:under the Basic Settings tab set:

* Boundary Type Wall , and* Location InnerWall ,

and under the Boundary Details tab set:

* Wall Influence on Flow Option No Slip ,* Wall Velocity off,*

Wall Roughness Option Smooth Wall ,and then click Ok to close the panel.

Right mouse click OuterWall and select Insert/Boundary to open

the boundarydetails panel. In this panel: -

CHAPTER 2. TUTORIAL COMMANDS 23

under the Basic Settings tab set:

* Boundary Type Wall , and* Location OuterWall ,

and under the Boundary Details tab set:

* Wall Influence on Flow Option No Slip ,* Wall Velocity off,*

Wall Roughness Option Smooth Wall ,and then click Ok to close the panel.

Right mouse click Outflow and select Insert/Boundary to open the

boundarydetails panel. In this panel:under the Basic Settings tab set:

* Boundary Type Outlet , and* Location Outflow ,

and under the Boundary Details tab set:

* Flow Regime Option Subsonic ,* Mass and Momentum Option Static

Pressure ,* Relative Pressure 0 Pa ,and then click Ok to close the panel.

Right mouse click on Solver Control entity and select Edit to

open the Detailsof Solver Control panel. Under the Basic Settings

tab set:Advection Scheme Option High Resolution , Max No. Iterations 75

,Timescale Control Auto Timescale , Length Scale Option

Conservative ,Timescale Factor 1. ,

Residual Type MAX , Residual Target 1.0e-3 ,

and then click Ok .

-

CHAPTER 2. TUTORIAL COMMANDS 24

Right mouse click on Output Control entity and select Edit to

open the Detailsof Output Control panel. Under the Results tab set:

Option Standard , Output Variable Operators on and choose All ,

and Output Boundary Flows on and choose All ,and then click Ok .

Save an image of the model by choosing File/Print … and in the

Print panel set:File model.png , and

Format PNG

followed by Print . The plot will printed to the file model.png

in yourworking directory.On the row of buttons below the menu bar above the Viewer

window, clickthe Write Solver File icon (last one in the row) to

open the panel. Accept thedefault filename, Ductbend.def and Operation Start Solver

Manager .Solver Manager

The CFX-Solver window will open after CFX-Pre closes. In the

Define Run panelset:Definition File ductbend.def (NOTE: If restarting a partially

converged run,you would enter the name of the most current results

file),Type of Run Full , and

Run Mode Serial ,

and then click Start Run .After a few minutes execution should

begin. Diagnostics will scroll on the ter-minal output panel and the equation RMS residuals will be

plotted as a function oftime step. After the first few time steps,

the residuals should fall monotonically. Ex-ecution should stop

within 50 time steps. In the ANSYS CFX Solver Finished

Normallywindow click Process Results Now . -

CHAPTER 2. TUTORIAL COMMANDS 25

Post-processing

To create and save a vector plot:

Choose Insert/Vector, accept Name Vector 1 , and click OK to

define a vectorobject and open an edit panel. In the panel set:Locations Front , Reduction Reduction Factor ,

Factor 1 (plots vector at every mesh point),

Variable Velocity , Hybrid on, Projection None ,

and click Apply . The vector plot should appear in the 3D Viewer

window andthe vector object is listed in the User Locations and

Plots database tree. Turn Default Legend View 1 off and back on to

remove and then replace the scalelegend. Turn Wireframe off and on.

Orthographic projection (type «ShiftZ» while in Graphics window)

will work best for two-dimensional views.Notice that if you

double-click on an object in the database tree then a detailspanel

opens up for that object.Choose File/Print … and in the Print panel set:

File vectorplot.png , and

Format PNG

followed by Print .

To create and plot the vorticity field:

Choose Insert/Variable and in the New Variable definition window

set NameVorticity and click OK . In Vorticity edit panel (lower

left):set Method Expression , set Scalar on, fill in Expression

Velocity v.Gradient X — Velocity u.Gradient Y , andclick Apply .

Choose Insert/Contour, accept Name Contour 1 , and click OK to

define afringe/contour plot object and open an edit panel. In the

panel set: -

CHAPTER 2. TUTORIAL COMMANDS 26

Locations Front , Variable Vorticity

and click Apply . The fringe plot should appear in the 3D Viewer

window.To output the velocity values along a straight line across the

duct:Choose Insert/Location/Line, accept Name Line 1 , and click OK

to define aline object and open an edit panel. Use Method Two Points , set

Point 1 to(0.0,0.1,0.01), set Point 2 to (0.0,0.025,0.01), set the

number of samples to 25,and click Apply to see the line (make sure

that the visibility of the contourplot, etc. is turned off).Choose File/Export … to open the Export panel where you

can:set File velocity.csv ,

select Line 1 from the Locations list,

set Export Geometry Information on, select (Ctrl key plus click)

Velocity u and Velocity v from the Select Vari-able(s) list, and

click Save to write the data to a file in a comma-separated

format thatcan be imported into a conventional spreadsheet program

for plottingor further analysis. Notice that this file includes x,

y, and z values.To export the inner wall pressure and wall shear stress

distribution:Choose Insert/Location/Plane, accept Name Plane 1 , and click OK

to definea plane object and open an edit panel. Use Method XY Plane with

Z =0[m] and click Apply (turn highlighting off to avoid clutter in

the view).Choose Insert/Location/Polyline, accept Name Polyline 1 , and

click OK todefine a polyline object. In the edit panel use Method Boundary

Intersectionwith Boundary List InnerWall and Intersect With Plane 1

and then clickApply . This creates a line that follows the inner

wall. You can follow thesteps for export along a line to export the values of the

pressure, total pressure,and wall shear (stress) along this line

into the data file wall.csv.To probe the velocity field at a point:

Choose Insert/Location/Point, accept Name Point 1 , and click OK

to definea point object. Use Method XYZ and initialize the point to

(0.10,0.04,0) -

CHAPTER 2. TUTORIAL COMMANDS 27

before clicking Apply . Choose Tools/Function Calculator to open

the Func-tion Calculator panel. Use Function probe , Location Point 1 ,

Variable Velocity u.Gradient X (Note: Use the … to get a list of

all possible variables.)before clicking on the Calculate button. The result with units

appears in theResult box. Move the point around to probe other

regions in the flow.To save the visualization state:

Choose File/Save State and enter tutorial1.cst for the file name

to saveall of the information associated with the visualization and

post-processingobjects you have created in this session. You can

load this state file (File/LoadState) to recreate these objects and

images in later sessions. This facility allowseasy comparison of

results between simulations.Return to the Project page and choose File/Exit. Select Yes to

save highlightedfiles.Clean Up

The last step is to remove unnecessary files created by CFX.

This step is necessaryto ensure that you do not exceed your disk

quota. At the end of each session4 deleteall files except:*.agdb, *.cmdat, *.cmdb, *.wbdb, *.def and *_*.res files.

If you no longer need your results but would like to be able to

replicate themthen you should delete all files except:*.def files.

After removing all unnecessary files, use the WinZip utility to

compress thecontents of your directory.CFX Mesh Generation

The commands below replace those in the section ANSYS Mesh

Generation. Thesenew commands generate an unstructured mesh with

the CFX-Meshing tools:Choose the New Mesh DesignModeler Tasks; Notice the three

primary areas:Graphics View, Outline View, and Details View, in the

Meshing window.In the outline view, right click on the Mesh entity and select

Generate Mesh.Notice that a simple hexahedral mesh is generated

with automatic settings.To achieve a realistic CFD simulation

continue;Switch the meshing method by:

4If you have used a local temp drive, remember to copy your work

to your N: drive -

CHAPTER 2. TUTORIAL COMMANDS 28

1. Select the Body Selection Filter icon from the button

commands at thetop of the meshing window;2. Right click on the Mesh entity and select Insert/Method;

3. On the Geometry View select the solid body; and in the

Details View:click Geometry Apply and

set Method CFX-Mesh ;

4. Right click on the Mesh entity and select Edit in CFX-Mesh.

Notice that anew tab, CFX-Mesh opens. Select this tab.In the Tree View, select Options to see the mesh options in the

Details View:Set Surface Meshing Advancing Front , Set Meshing Strategy

Extruded 2D Mesh , Set 2D Extrusion Option Full , and Set Number of

Layers 1 ;In the Tree View, expand the + Spacing entity;

Select the Default Body Spacing entity to open the Body Spacing

Details View.Set Maximum Spacing [m] 0.01 .

Left mouse click on the Extruded Periodic Pair entity;

In the Graphics View select the front surface and then click

Location 1Apply in the Details View;In the Graphics View select the back surface (remember to use

the loca-tion planes in the lower left corner of the Graphics View)

and then clickLocation 2 Apply in the Details View; andSet Periodic Type Translational ; In the Tree View, click on

Inflation entity and in the Details View set Numberof Inflated Layers 10 .

In the Tree View, right mouse click on Inflation and select

Insert/Inflated Bound-ary to create an Inflated Boundary entity.

Select the three surfaces of theinner wall in the Graphics View for

the Location and set Maximum Thickness[m] 0.03 ;Repeat to create an Inflated Boundary of Maximum Thickness [m]

0.03 onthe outer wall; -

CHAPTER 2. TUTORIAL COMMANDS 29

In the Tree View right mouse click on + Preview entity and

select GenerateSurface Meshes. Progress is shown in the lower left

corner. After a short timeyou should see a mesh of triangles and

rectangles on the surfaces of the solid;Click the Generate the volume mesh for the current problem icon

on the toprow of icons/buttons. Again, progress is shown in the

lower left corner.When this process is completed, go to the Tree

View and select Errors to ensurethat no errors are reported in the

Details View.Return to the Meshing page by clicking on the Ductbend [Meshing]

tab.Save an image of the mesh by selecting New Figure or Image Image

to Filefrom the icons above the graphics window. Set File name:

Mesh to save thepng format file.To close this phase, select File/Save As … and set File name:

Ductbend.cmdb .Return to the Project page by clicking on the Ductbend [Project]

tab at thetop left corner of the window.Instructions for creating the CFX simulation continue in the

section Pre-processingon page 20. -

Part II

Additional Notes

30

-

Chapter 3

Geometry and Mesh Specification

In the first steps of the CFD computer modelling, the solution

domain is created ina digital form and then subdivided into a large

number of small finite elements orvolumes.3.1 Basic Geometry Concepts and Definitions

Vertex: Occupies a point in space. Often other geometric

entities like edges con-nect at vertices.Edge: A curve in space. An open edge has beginning and end

vertices at distinctpoints in space. A straight line segment is an

open edge. A closed edge hasbeginning and end vertices at the same

point is space. A circle is a closededge.Face: An enclosed surface. The surface area inside a circle is a

planar face and theouter shell of a sphere is a non-planar face. An

open face has all of its edges atdifferent locations in space. A

rectangle makes an open face. A closed face hastwo edges at the

same location in space. The cylindrical surface of a pipe is

aclosed face.Solid: The basic unit of three dimensional geometry

modelling:is a space completely enclosed in three dimensions by a set of

faces (vol-ume);the surface faces of the solid are the the external surface of

the flowdomain; andholes in the solid represent physical solid bodies in the flow

domain suchas airfoils.Part: One or more solids that form a flow domain.

Multiple Solids: May be used in each part:

31

-

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 32

the solid volumes cannot overlap;

the solids must join at common surfaces or faces; and

the faces where two solids join can be thin surfaces

Thin Surface: A thin solid body in a flow like a guide vane or

baffle can be mod-elled as an infinitely thin surface with no-slip

walls on both sides.Units: To keep things simple and to minimize errors, use metric

units throughout.Advanced Concepts: See the Geometry section of the CFX-Mesh Help

for furtherinformation on geometry modelling requirements. To

develop improved skillfollow the tutorials given in CFX-Mesh

Help/Tutorials.3.2 Geometry Creation

The basic procedure for creating a three dimensional solid

geometry is to make a2D sketch of an enclosed area (possibly with

holes) on a flat plane. The resulting 2Dsketch is a profile which

is swept through space to create a 3D solid feature. Thisprocess

can be repeated to either remove portions of the 3D solid or to add

portionsto the solid.Each sketch is made on a Plane:

There are three default planes, XYPlane, XZPlane, and YZPlane,

which co-incide with the three planes of the Cartesian coordinate

system;Each plane has a local X-Y coordinate system and normal vector

(the planeslocal Z axis);New planes can be defined based on: existing planes, faces,

point and edge,point and normal direction, three points: origin,

local X axis, and anotherpoint in plane, and coordinates of the

origin and normal; andPlane transforms such as translations and rotations can be used

to modify thebase definition of the plane.The creation of a sketch is similar to the creation of a drawing

with moderncomputer drawing software:A sketch is a set of edges on a plane. A plane can contain more

than onesketch;The sketching toolbox contains tools for drawing a variety of

common twodimensional shapes;Dimensions are used to set the lengths and angles of edges;

Constraints are used to control how points and shapes are

related in a sketch.Common constraints include: -

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 33

Coincident (C): The selected point (or end of edge) is

coincident with an-other shape. For example, the end point of a new

line segment can beconstrained to lie on the line extending from an

existing line segment.Note that the two line segments need not

touch;Coincident Point (P): The selected points are coincident in

space;Vertical (V): The line is parallel to the local planes Y

axis;Horizontal (H): The line is parallel to the local planes X

axis;Tangent (T): The line or arc is locally tangent to the existing

line or arc;Perpendicular (): The line is perpendicular to the existing

line; andParallel (): The line is parallel to the existing line.As

a sketch is drawn the symbols for each relevant constraint will

appear. Ifthe mouse button is clicked while a constraint symbol is

on the sketch thenthe constraint will be applied. Note that near

the X and Y axes it is oftendifficult to distinguish between

coincident and coincident point constraints;andAuto-Constraints are used to automatically connect points and

edges. Forexample, if one edge of a square is increased in length

the opposite edge lengthis also increased so that the shape remains

rectangular.Features are created from sketches by one of the following

operations:Extrude: Sweep the sketch in a particular direction (i.e. to

make a bar);Revolve: Sweep the sketch through a revolution about a

particular axis of rotation(i.e. to make a wedge shape);Sweep: Sweep the sketch along a sketched path (i.e. to make a

curved bar); andSkin/Loft: Join up a series of sketches or profiles to form the

3D feature (likeputting a skin over the frame of a wing).Features are integrated into the existing active solid with one

of the followingBoolean operations:Add Material: Merge the new feature with the active solid;

Cut Material: Remove the material of the new feature from the

active solid;Slice Material: Remove a section from an active solid; and

Imprint Face: Break a face into two parts. For example, this

will open a hole on acylindrical pipe wall.Sometimes it is necessary to use multiple solids in a single

part. These solidsmust share at least one common face. This common

face might be used to model athin surface in the flow solver. In

this case: -

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 34

1. Select active solid with the body selection filter turned

on;2. Freeze the solid body to stop the Boolean merge or remove

operations (Tools/Freeze).This will form a new solid body as a

component of a new part; and3. Select all solids and choose Tools/Form New Part.

The geometry database contains a list of primitive faces and

edges that areformed in the generation processes. It is often

cumbersome to work directly withthese primitive entities.

Therefore, there is a facility for naming selected surfaces.These

named selections are passed on to the meshing tools and to

CFX-Pre.When the solid model is completed an .agdb file is created and

saved in order tostore the geometry database.3.3 Mesh Generation

The mesh generation phase can be broken down into the following

steps:1. Read in or update the .agdb file with the solid body geometry

database;2. Set the properties of the mesh;

3. Cover the surfaces of the solid body with a surface mesh of

triangular orquadrilateral elements; and4. Fill the interior of the solid body with a volume mesh of

tetrahedral, hexahe-dral, or prism elements (see Figure 3.1) that

are based on the surface meshes.A .cmdb file containing all of the

mesh information and named selection in-formation is written at the

end of this step.Tetrahedral Prism Hexahedral

Figure 3.1: Shapes of common three dimensional elements.

Two strategies suitable for simulating two-dimensional flow

fields are discussedhere: mapped meshing and free tetrahedral (tet)

meshing with surface inflation. Ex-amples of these meshes are shown

in Figure 3.2. In both example meshes, the frontand back surfaces

have identical surface meshes which are swept through space

tocreate volume meshes that are one element thick in the direction

of negligible flowchanges. However, the example surface meshes

differ in the shape and topology of -

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 35

their surface elements. The mapped mesh is comprised solely of

quadrilateral ele-ments, Figure 3.3. The free tet mesh with surface

inflation has triangular elementswell away from the inner and outer

walls and quadrilateral elements adjacent to thewalls.Figure 3.2: Example meshes showing a mapped mesh and a free

tetrahedral meshwith surface inflation.Generally speaking mapped meshing strategies provide better

meshes for CFDsimulations than provided by free tet meshing

strategies. However, for a mappedmeshing strategy to work on a

surface it must be possible to:decompose the surface into a set of sub-surfaces each of which

are enclosedby four edges; andimpose the same number of mesh intervals, N , on pairs of

opposing edges foreach sub-surface.Isotropic Anisotropic

Quadrilateral

Triangle

Figure 3.3: Shapes of common two dimensional elements.

-

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 36

Figure 3.2 shows three sub-surfaces outlined in blue and shows

the number of meshintervals for each edge on the mapped mesh.For complex surfaces and volumes it is often difficult or

impossible to meetthe requirements for mapped meshing. In this case

free tet meshing is a viablealternative strategy except in boundary

layer regions. In these layers the need fora fine mesh scale normal

to the wall leads to triangular (3D) or quadrilateral (2D)prisms as

shown in Figure 3.2. These special mesh layers are referred to as

inflationlayers.Notes on controlling these two meshing meshing strategies are

given in the nexttwo sections.ANSYS: Mapped Meshing

The ANSYS meshing tools include a number of strategies and have

been highly au-tomated. They have been developed to provide

reasonable meshes for stress/failureanalysis simulations in solid

members. In stress/failure analysis a reasonable meshcan often be

established based on the geometry of the solid member. This is

nottrue for fluid flow simulations where special attention is

required for flow featureslike separation zones which do not

directly follow the domain geometry. Therefore,the user should

expect to provide a lot of input into the mesh design.As mentioned above, mapped meshing is applied to sub-surfaces

that are en-closed by four edges with opposing edge pairs having

the same number of meshelements. The quadrilateral mesh vertices

within a sub-surface are determined byinterpolating the vertex

locations on the edges. The overall mapped mesh proper-ties are

controlled by:Blocking: the decomposition of surfaces into sub-surfaces;

andEdge Sizing: the placement of vertices along edges.

While the blocking process in ANSYS meshing is highly automated,

it can be con-trolled by creating edges in the geometry which will

naturally lead to desired sub-surfaces and by ensuring that edge

element counts are the same on opposing edgesof desired

sub-surfaces.Figure 3.4 shows how blocking is influenced by edge sizing and

available geom-etry edges. In the left mesh, edge sizing is set on

the two left vertical edges. Theblocking is established so that the

mesh spacing is uniform on the single right ver-tical edge. In the

mesh on the right, the right vertical edge is composed of

twoun-merged edges and the edge sizing is set on opposing pairs of

upper and lowervertical edges.The meshing software creates a Mesh entity which can have the

following con-trols associated with it to control the mesh:Mapped Face Meshing: applied to a surface ensures that a mapped

or structuredquadrilateral mesh is created on the surface;(Edge) Sizing: applied to an edge or set of edges controls the

vertex location alongan edge by setting: -

CHAPTER 3. GEOMETRY AND MESH SPECIFICATION 37

Figure 3.4: Meshes showing the influence of edge sizing

specification on mesh block-ing. The mesh on the left has edge