40,4 Мб

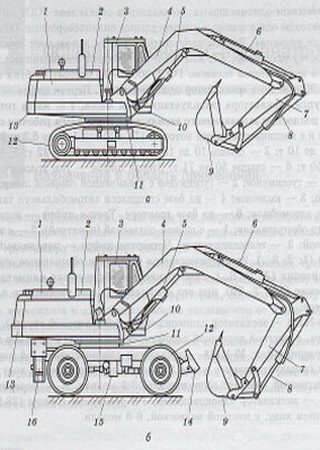

Экскаваторы Твэкс ЭО-3221, ЭО-3323, ЕТ-14, ЕТ-18, ЕТ-25,

Формат: pdf

-

Год:

2008

-

Страниц:

66

-

Язык:

русский

-

Размер:

40,4 Мб

-

Категории:

Экскаваторы

4,06 Мб

Руководство по эксплуатации экскаваторов УЗТМ ЭКГ-4, УЗТМ

Формат: djvu

-

Год:

1975

-

Страниц:

161

-

Язык:

русский

-

Размер:

4,06 Мб

-

Категории:

Экскаваторы

14,5 Мб

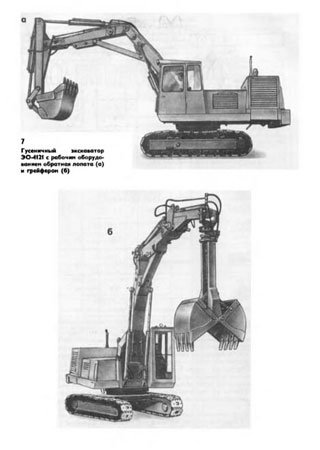

Экскаваторы Э-302 (303, 304, 625, 652), ЭО-2621 (3111,

Формат: djvu

-

Год:

1977

-

Страниц:

389

-

Язык:

русский

-

Размер:

14,5 Мб

-

Категории:

Экскаваторы

80,9 Мб

Экскаваторы Hitachi ZX200-3, ZX225-3, ZX240-3, ZX270-3:

Формат: pdf

-

Год:

2006

-

Страниц:

1826

-

Язык:

русский

-

Размер:

80,9 Мб

-

Категории:

Экскаваторы

5,14 Мб

Экскаваторы Hitachi ZX225US-3 (Zaxis 225US-3), ZX225USR-3

Формат: pdf

-

Год:

2006

-

Страниц:

309

-

Язык:

русский

-

Размер:

5,14 Мб

-

Категории:

Экскаваторы

12,1 Мб

Экскаваторы Hitachi ZX200-3 (Zaxis 200-3), ZX270-3 (Zaxis

Формат: pdf

-

Год:

2006

-

Страниц:

343

-

Язык:

русский

-

Размер:

12,1 Мб

-

Категории:

Экскаваторы

7,41 Мб

Экскаватор Hitachi ZX450 (Zaxis 450): Руководство по

Формат: pdf

-

Год:

2003

-

Страниц:

208

-

Язык:

русский

-

Размер:

7,41 Мб

-

Категории:

Экскаваторы

5,43 Мб

Экскаватор Caterpillar 345C: Руководство по эксплуатации и

Формат: pdf

-

Год:

2007

-

Страниц:

258

-

Язык:

русский

-

Размер:

5,43 Мб

-

Категории:

Экскаваторы

14,2 Мб

Руководство оператора экскаватора Volvo EC950E

Формат: pdf

-

Год:

2016

-

Страниц:

394

-

Язык:

русский

-

Размер:

14,2 Мб

-

Категории:

Экскаваторы

29,5 Мб

Экскаватор Hitachi EX1900-5: Руководство по ремонту и

Формат: pdf

-

Год:

2006

-

Страниц:

1060

-

Язык:

русский

-

Размер:

29,5 Мб

-

Категории:

Экскаваторы

93,8 Мб

Руководство по эксплуатации и обслуживанию экскаватора

Формат: pdf

-

Год:

2006

-

Страниц:

759

-

Язык:

русский, английский

-

Размер:

93,8 Мб

-

Категории:

Экскаваторы

51 Мб

Руководство по эксплуатации и обслуживанию экскаватора

Формат: pdf

-

Год:

2007

-

Страниц:

821

-

Язык:

русский, английский

-

Размер:

51 Мб

-

Категории:

Экскаваторы

9,06 Мб

Каталог запчастей экскаваторов Komatsu PC200-7, PC200LC-7,

Формат: pdf

-

Год:

2004

-

Страниц:

536

-

Язык:

английский

-

Размер:

9,06 Мб

-

Категории:

Экскаваторы

20,7 Мб

Руководство по эксплуатации и обслуживанию мини-экскаватора

Формат: pdf

-

Год:

2012

-

Страниц:

141

-

Язык:

русский

-

Размер:

20,7 Мб

-

Категории:

Экскаваторы

10,9 Мб

Каталог запчастей мини-экскаватора Hidromek HMK 62SS

Формат: pdf

-

Год:

2005

-

Страниц:

247

-

Язык:

турецкий, английский

-

Размер:

10,9 Мб

-

Категории:

Экскаваторы

15,9 Мб

Экскаваторы-погрузчики Hidromek HMK 102B и HMK 102S

Формат: pdf

-

Год:

2012

-

Страниц:

196

-

Язык:

русский

-

Размер:

15,9 Мб

-

Категории:

Экскаваторы

20,5 Мб

Гусеничные экскаваторы JCB JS130, JS160, JS180, JS200,

Формат: pdf

-

Год:

2001

-

Страниц:

152

-

Язык:

русский

-

Размер:

20,5 Мб

-

Категории:

Экскаваторы

5,7 Мб

Руководство по эксплуатации и обслуживанию гидравлического

Формат: pdf

-

Год:

2011

-

Страниц:

154

-

Язык:

английский

-

Размер:

5,7 Мб

-

Категории:

Экскаваторы

6,51 Мб

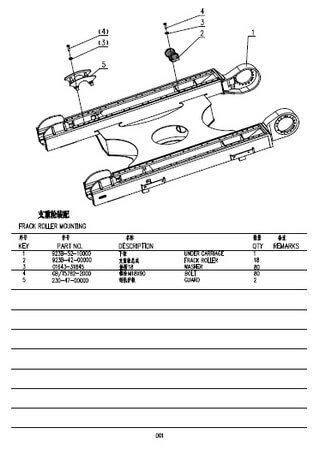

Каталог запчастей гидравлического экскаватора XCMG XE230

Формат: pdf

-

Год:

2006

-

Страниц:

102

-

Язык:

английский, китайский

-

Размер:

6,51 Мб

-

Категории:

Экскаваторы

15,3 Мб

Руководство по эксплуатации и обслуживанию гидравлических

Формат: pdf

-

Год:

2011

-

Страниц:

157

-

Язык:

испанский

-

Размер:

15,3 Мб

-

Категории:

Экскаваторы

1 2

-

Bookmarks

Quick Links

XE210C Hydraulic Excavator

Operating & Maintenance Manual

XUZHOU XUGONG EXCAVATOR

MACHINERY CO., LTD.

Related Manuals for XCMG XE210C

Summary of Contents for XCMG XE210C

-

Page 1

XE210C Hydraulic Excavator Operating & Maintenance Manual XUZHOU XUGONG EXCAVATOR MACHINERY CO., LTD. -

Page 2

Preface Welcome you to use our XE210C hydraulic excavators. Before operating, maintaining and repairing these equipments, please read carefully and master this manual, and learn how to correctly operate, maintain and repair your machines while paying more attention to related safety warning. -

Page 3

XE210C Hydraulic Excavator Operating and Maintenance Manual Machine Number: Please record all numbers correctly for future maintenance. In addition, your distributors also need this information. If this manual is on the machine, please put the part of the machine numbers in the safe places except the machine for filing in order to search the machine after missing. -

Page 4

XE210C Hydraulic Excavator Operating and Maintenance Manual Swing motor No.:____________________ Hydraulic pump No.:____________________… -

Page 5

XE210C Hydraulic Excavator Operating and Maintenance Manual Content Preface Machine Number Safety Instruction of safety and warning signs ………………….7 Safety sign and other signs ……………………..9 Location of safety signs ……………………….9 Instruction of safety signs ……………………..10 Safety rules …………………………. 17 Safety equipment ………………………… -

Page 6

XE210C Hydraulic Excavator Operating and Maintenance Manual Road transport ………………………… 141 Removal of trailer ……………………….141 Storage and protection ………………………. 144 Daily and short-term storage and protection ………………..144 Long-term storage ……………………….144 Use preparation after storage …………………….. 144 Technical specifications Product specification ………………………. -

Page 7

XE210C Hydraulic Excavator Operating and Maintenance Manual Safety Instruction of safety and warning signs This is the sign of “ATTENTION ON SAFETY”. When you notice this warning , you should read carefully the following information and abide by it and inform other operators. -

Page 8

XE210C Hydraulic Excavator Operating and Maintenance Manual assignment, it is possible that the content, specification and icons etc. will have some change at any time, which will influence the maintenance and repair of machine. The pictures in the book is only used to describe the concerning part vividly, varying from the practical machine probably. -

Page 9

XE210C Hydraulic Excavator Operating and Maintenance Manual Safety sign and other signs On many part of this machine, there are safety sign and other signs, so the operator should fully understand the content and location of all signs and abide by the following requirements: … -

Page 10

XE210C Hydraulic Excavator Operating and Maintenance Manual 10 Instruction of safety signs (1) Warning on bucket lever away from operation scope Picture of lubrication and maintenance Operational instruction… -

Page 11

XE210C Hydraulic Excavator Operating and Maintenance Manual 11 Warning signs in the manual Sign for being away from the high voltage electricity Sign for locking the doors and windows Attention To prevent the injury due to the fall of front window, be sure to lock two sides of windows with lock pins. -

Page 12

XE210C Hydraulic Excavator Operating and Maintenance Manual 12 Machine starting sign Attention ● Before starting the engine or operator, sound the horn and check that there is no people around the machine. ● If the engine fails to start within 15 seconds, return the key to the position of “OFF”, and… -

Page 13

XE210C Hydraulic Excavator Operating and Maintenance Manual 13 (11) Sign for being away from the action radius (12) Battery sign Dangerous being flammable, steam of battery fluid should be far away from spark because the battery will explode or lead to fire disaster if collided with. -

Page 14

XE210C Hydraulic Excavator Operating and Maintenance Manual 14 (15) Warning on adjusting the crawler tension Warning The spring of adjuster bears great pressure, and the pressure in oil cylinder is very high, so an accident may caused by such high pressure when adjusting or dismantling. -

Page 15

XE210C Hydraulic Excavator Operating and Maintenance Manual 15 (18) Schematic drawing to lift the complete machine (19) Safety sign for locked machine (20) Hydraulic oil sign Attention ● Before dismantling the hydraulic oil tank cap, please shut off the engine first ●… -

Page 16

XE210C Hydraulic Excavator Operating and Maintenance Manual 16 (21) No stepping sign (22) Sign to prevent scolding the arm… -

Page 17

XE210C Hydraulic Excavator Operating and Maintenance Manual 17 Safety rules Only the personnel trained and guided can operate and maintain the machine. When operating and maintaining the machine, obey to all of the safety rules, notes and instructions. -

Page 18

XE210C Hydraulic Excavator Operating and Maintenance Manual 18 Safety equipment Ensure all shields and cover plates in the proper positions. If any damage for them, please repair immediately. Understand the use methods of the safety devices and use them correctly. -

Page 19

XE210C Hydraulic Excavator Operating and Maintenance Manual 19 When leaving the machine, be sure to lower the working devices down to the ground completely and then shut down the engine. Lock all equipment, take off the keys and put them in the safe places. -

Page 20

XE210C Hydraulic Excavator Operating and Maintenance Manual 20 Installation and dismantlement Do not jump up and off the machine. Do not climb up and down the machine when the machine is moving. If the machine moves suddenly without manual operations, it is banned to jump up the machine and attempt to stop the machine. -

Page 21

XE210C Hydraulic Excavator Operating and Maintenance Manual 21 Fire protection and explosion proof Prevent fire caused by the fuel oil or engine oil The fuel oil, engine oil, antifreeze and window washing are very flammable dangerous goods. To prevent the fire, the follow regulations must be followed: … -

Page 22

XE210C Hydraulic Excavator Operating and Maintenance Manual 22 Prevent the falling objects, flying objects and intrusive objects In the work place where the falling objects, flying objects and intrusive objects hit or enter the driver’ cab, install the necessary shields to protect the operators according to the operations. -

Page 23

XE210C Hydraulic Excavator Operating and Maintenance Manual 23 Installation for the accessories When installing the optional parts or accessories, please contact the Xugong excavator distributor in advance. Any injuries, accidents or product faults caused by using the accessories or parts without approval from Xugong Excavator Mechanical Co., Ltd. -

Page 24

XE210C Hydraulic Excavator Operating and Maintenance Manual 24 Working on the unconsolidated ground Avoid walking or operating the machine near the cliff side, road side and the deep ditch. Because the ground in these areas is very soft, if the ground is collapsed under the role of the weight or vibration of the machine, it will cause the machine to collapse or roll over. -

Page 25

XE210C Hydraulic Excavator Operating and Maintenance Manual 25 Ventilation in the closed area If it is necessary to start the engine or the treatment fuel oil, cleaning oil or paint in the closed area, open the doors and windows to ensure good ventilation to prevent gas poisoning. -

Page 26

XE210C Hydraulic Excavator Operating and Maintenance Manual 26 Safe Operation of Machine Start the engine If the warning label is hung on the operating lever of the operating device, do not start the engine or contact the operating lever. Inspection before starting… -

Page 27

XE210C Hydraulic Excavator Operating and Maintenance Manual 27 Operation Inspection after starting the engine When carrying out the inspection, move the machine to a wide area without any barrier to operate slowly. No one is allowed to approach the machine. -

Page 28

XE210C Hydraulic Excavator Operating and Maintenance Manual 28 Safety rules for moving Do not exceed the maximum permissible load when using the machine in order to prevent that the machine is unstable because of overload and avoid the damage of the working device. -

Page 29

XE210C Hydraulic Excavator Operating and Maintenance Manual 29 Equipment Protection Top. ROPS or FOPS If the machine is operated at the region with falling stores and aggregates, the machine should be provided with devices of the equipment protection top, ROPS or FOPS according to the potential dangerous situation. -

Page 30

XE210C Hydraulic Excavator Operating and Maintenance Manual 30 The machine directly moves on the slop upward and downwards, because it is very dangerous to make a turn or traverse on the slop. Do not make a turn and transverse on the slop. The machine should change the position of the machine at the flat area, and then, go up to the slope. -

Page 31

XE210C Hydraulic Excavator Operating and Maintenance Manual 31 Operation on the Slope When the machine operates on the slope, and the revolution or working device is operated, the machine will lost balance and incline so as to cause the serious damage or equipment breakdown. -

Page 32

XE210C Hydraulic Excavator Operating and Maintenance Manual 32 The dismantling operation is forbidden to carry out under the machine, and the dismantling operation will cause the unsteadiness of the machine and has the risk of roll-over. When the machine operates on the buildings and the upper part of other structures, the buildings will be seriously ruined or damaged. -

Page 33

XE210C Hydraulic Excavator Operating and Maintenance Manual 33 Operation in Snowy weather Do not put the bucket above the heads of other workers or seats of operators of other transporting equipment. Because the loaded stuffs maybe drop, the bucket can contact the dump trucks so as to cause serious ruin or damage. -

Page 34

XE210C Hydraulic Excavator Operating and Maintenance Manual 34 Transportation In order to conveniently transport the machine, the machine is divided to several parts. Therefore, please contact with the dealers of Xugong excavator to carry out the transportation work. Machine Transportation When the machine is transported by trailers, the following rules need to be obeyed: … -

Page 35

XE210C Hydraulic Excavator Operating and Maintenance Manual 35 Battery Prevention of the Danger caused by Battery The electrolyte of the battery includes sulfuric acid, so the inflammable and explosive hydrogen is generated by the battery. The operation error can cause serious damage or fire hazards, so the following items must be obeyed: … -

Page 36

XE210C Hydraulic Excavator Operating and Maintenance Manual 36 Starting engine with auxiliary cable If the auxiliary cable is connected in the error way, the battery may explode, and therefore, the following rules should be followed: When the engine is started with the auxiliary cable,… -

Page 37

XE210C Hydraulic Excavator Operating and Maintenance Manual 37 Traction Safety rules of traction If the fault machine is not correctly pulled, or the selection and check of wire ropes are wrong, serious injury or death will be resulted. When the wire ropes are used, leather gloves will be worn. -

Page 38

XE210C Hydraulic Excavator Operating and Maintenance Manual 38 Lifting objects by the bucket The safety rules for lifting objects The lifting operation should not be carried out on slopes, soft ground or other places where machines put unstably. … -

Page 39

XE210C Hydraulic Excavator Operating and Maintenance Manual 39 Optional component-Hydraulic hammer Main functions: — Crushing rocks — Demolishing — Road repair Hydraulic hammer is widely applied in demolishing buildings, crushing road surfaces, excavating tunnels, crushing cinders, and crushing or cutting rocks. -

Page 40

XE210C Hydraulic Excavator Operating and Maintenance Manual 40 The striking direction of the drill rod is slight deviated from the direction of the hammer. Therefore, the direction of oil cylinder of the bucket must be rectified to ensure the direction alignment. -

Page 41

XE210C Hydraulic Excavator Operating and Maintenance Manual 41 When striking, do not move the drill rod. Do not strike horizontally or upward. When punching on the ground, do not twist the drill rod. When lifting the machines, do not make the bucket oil cylinder to… -

Page 42

XE210C Hydraulic Excavator Operating and Maintenance Manual 42 Safety maintenance instructions Warning labels ‘No operation’ warning label must be hung on work device operating lever in the cab to warn that someone is maintaining the machine. If necessary, the warnings should also be published around the machine. -

Page 43

XE210C Hydraulic Excavator Operating and Maintenance Manual 43 When the engine is running, two persons carry out the maintenance. To prevent damage, when the engine is running, the maintenance should not be carried out. If the maintenance must be carried out when the engine is running, two persons operate at least, and do following rules:: … -

Page 44

XE210C Hydraulic Excavator Operating and Maintenance Manual 44 Energy container The energy container is filled with high pressure nitrogen. When operating on the energy container, the careless operation will cause explosion, and cause serious injury or damage. Therefore, the following matters need to be paid attention: … -

Page 45

XE210C Hydraulic Excavator Operating and Maintenance Manual 45 Noise If the noise of the machine is too loud, temporary or permanent hearing problems can be caused. When persons maintain the engine and suffer the noise for a long time, ear covers or earplugs should be worn. -

Page 46

XE210C Hydraulic Excavator Operating and Maintenance Manual 46 When the crawler belt tension is adjusted with high-pressure grease, the safety need be paid attention to. The grease is pressed into the crawler belt tension adjustment system under the condition of high pressure. -

Page 47

XE210C Hydraulic Excavator Operating and Maintenance Manual 47 Safe Operation of High Pressure Hose If the hose leaks, it may cause fire or faulty operation, resulting in serious injury or damage. If the bolt loose is found, stop operations and screw up/down the bolts to the specified tightening torque. -

Page 48

XE210C Hydraulic Excavator Operating and Maintenance Manual 48 Name of Parts General drawing Counter Engine Armrest weight Case Bucket Diesel Hydraulic Hydraulic Tool Boom Engine Bucket Chassis lever tank oil tank system case… -

Page 49

XE210/XE230/XE260C Hydraulic Excavator Operating and Maintenance Manual Seat Fig.1-27 layout of operational and indicating parts in cab 1 left operational lever 2 horn switch(above left operational lever) 3 left treading control lever 4 left treading pedal 5 right treading pedal 6 right treading control lever 7 boosting switch (above right operational lever) 8 right control lever 9 monitor… -

Page 50

XE210C Hydraulic Excavator Operating and Maintenance Manual 50 List 1-4 Illustrated signal Serial No. Name Signal Function Control the arm stretching and retracting and the Left operational lever rotation of the up carriage Horn switch (on top of left Enable the horn to sound after being pressed… -

Page 51

XE210C Hydraulic Excavator Operating and Maintenance Manual 51 Switch for radio Control the radio Control button Control the air conditioner conditioner Safe locking lever Control hydraulic guidance oil… -

Page 52

XE210/XE230/XE260C Hydraulic Excavator Operating and Maintenance Manual Monitor Fig. 1-28 Picture of monitor interface List 1-3 List of illustrated signals Serial Name Signal Function Screen indication or main menu catalogue(for Indication interface of screen details, see the latter introduction) Alarm hydraulic liquid On for a high temperature… -

Page 53

XE210C Hydraulic Excavator Operating and Maintenance Manual 53 Engine coolant high temperature On for high temperature of engine coolant alarm Oil pressure alarm On for low pressure of engine oil Engine preheat indicator On for the process of engine preheat… -

Page 54

XE210C Hydraulic Excavator Operating and Maintenance Manual 54 Displaying interface of main screen: 1 Trademark 2 Working hour meter 3 Moving speed low/high indicator 4 Alarm and switch blink 5 Water thermometer 6 Automatic idle indicator 7 Time and information prompt 8 Instantaneous reinforcement indicator… -

Page 55

XE210C Hydraulic Excavator Operating and Maintenance Manual 55 When the key switch is turned to ON, the interface of the instrument is as follows: Date time and information display area Button instructions: The two buttons are respectively corresponding to functions of the instruction area between positive display liquid crystal to realize power mode switch. -

Page 56

XE210C Hydraulic Excavator Operating and Maintenance Manual 56 Date time and information display area When the key is pressed again, the moving electromagnetic valve loses electricity, and the machine moves slowly. The interface is as follows: Date time and information display area … -

Page 57

XE210C Hydraulic Excavator Operating and Maintenance Manual 57 Choose use information in the main menu and press the confirmation key , the use information menu is entered as follows: Use information Detail information Host information Date time and information display area … -

Page 58

XE210C Hydraulic Excavator Operating and Maintenance Manual 58 Choose in the main menu press the confirmation key , the maintenance information menu is entered, which shows maintenance details in each time period, and users can keep maintenance accurately and timely. -

Page 59

XE210C Hydraulic Excavator Operating and Maintenance Manual 59 Language setup Chinese Date time and information display area Choose in the user setting menu and press the confirmation key , the language setting menu is entered as follows: Brightness control Date time and information display area … -

Page 60

XE210/XE230/XE260C Hydraulic Excavator Operating and Maintenance Manual Control panel of Air Conditioner Control Button of Air-out (Foot direction) When this button is pressed, the motor of foot direction part of air conditioning unit is started and the ventilation door is opened to have the air blown out from the lower air duct. Control Button of Air-out (Face direction) When this button is pressed, the motor of face direction part of air conditioning unit is started, the ventilation door is opened to have the air blown out from the upper air duct. -

Page 61

XE210C Hydraulic Excavator Operating and Maintenance Manual 61 Radio (1) Power/mode switch ◇Press the button to switch on power; hold the button under the working state to turn off the radio. ◇When the radio is powered on, press the button to toggle between FM MP3 (IN Optional). -

Page 62

XE210C Hydraulic Excavator Operating and Maintenance Manual 62 Seat 1. Adjustable back and forth 2. Adjustable on weight 3. Adjustable back cushion 4. Adjustable armrests Warning! The seat is designed for one person at a time. Do not adjust the seat during digging actions. -

Page 63

XE210C Hydraulic Excavator Operating and Maintenance Manual 63 Switches Lighting switch Rocker Switch 1# Press this switch (1#), the illuminating lamps for the movable arm and the platform are turned on. Switch for the windshield wiper Rocker Switch 2#. Press this switch (2#), the windshield wiper for the front glass Swing continuously. -

Page 64

XE210C Hydraulic Excavator Operating and Maintenance Manual 64 Switch for the horn When pressing the button switch on top of the operating lever of right working device, and the horn honks. Pressure-up switch The button switch on the operating lever of the left working device is used to start the contact-mode strength function. -

Page 65

XE210C Hydraulic Excavator Operating and Maintenance Manual 65 Operation General principle This machine can only be operated by those qualified, experienced operator with excavator operating certificate, who is allowed to inspect and maintain this machine. Pay attention to: Read carefully and command this book before the starting or the first operation of machine. -

Page 66

XE210C Hydraulic Excavator Operating and Maintenance Manual 66 Operating procedure Operating environment Operating lever 1. Left control handle 3. Right control handle for the crawler 2. Left control handle for the crawler 4. Right control handle Traveling pedal Warning! … -

Page 67

XE210C Hydraulic Excavator Operating and Maintenance Manual 67 Operating lever for the working device The operating lever (1) of the left working device is used to operate the bucket rod and the rotation of the upper part of the machine. -

Page 68

XE210C Hydraulic Excavator Operating and Maintenance Manual 68 Open the windows Put the auxiliary devices on the ground, and then shut down the engine. Hold two handles (A), heave outwards and pull upwards, the front window can be opened. Put the window in the locking position after opening them. -

Page 69

XE210C Hydraulic Excavator Operating and Maintenance Manual 69 Dismantle the front window For opening the front window, see the “open the windows”. Hold the upper part with two hands and pull upwards. Store the windows dismantled in the inner side behind the driver’… -

Page 70

XE210C Hydraulic Excavator Operating and Maintenance Manual 70 The preparation and operation of starting Follow the safety regulation Read carefully and abide by all the safety signs as well as all the safety-related information in this book. If necessary, please install, maintain or replace safety signs. -

Page 71

XE210C Hydraulic Excavator Operating and Maintenance Manual 71 Don’t put the lighter in the cab casually, which may explode if the temperature in the cab is very high. To ensure the safety, don’t wear earphone to tune in the radio or music to avoid of a severe accident. -

Page 72

XE210C Hydraulic Excavator Operating and Maintenance Manual 72 Repeated inspection surrounding the machine should be done in earnest. While doing the repeated check, it is necessary to check all the items described latter in “checking the engine before the start”. -

Page 73

XE210C Hydraulic Excavator Operating and Maintenance Manual 73 The preparation and operation of starting Adjust the seat Any seat position unsuitable to the operator or operation will lead to the fatigue of the operator very soon even an operational error. -

Page 74

XE210C Hydraulic Excavator Operating and Maintenance Manual 74 safety:Keep all the people away from the machine and remove the obstacle. Check the cab before starting the engine Confirm the safe locking lever in LOCK position and all the control levers in middle position. -

Page 75

XE210C Hydraulic Excavator Operating and Maintenance Manual 75 As the preheat indicator goes out, turn the key switch to START position again, and release it as soon as the engine is started. Warm up the engine after the start. Important: the best working temperature for hydraulic oil is 50℃~80℃. If the temperature is below 30℃, overwork of the machine will damage it and hydraulic parts seriously. -

Page 76

XE210C Hydraulic Excavator Operating and Maintenance Manual 76 Operation procedure of running Confirm the treading direction of machine Guidance wheel Operational errors on treading pedal and control lever will lead to a severe casualty. Fig.1-44 Before driving this machine, confirm the relation between the positions of machine’s low body and the operator. -

Page 77

XE210C Hydraulic Excavator Operating and Maintenance Manual 77 (Rotate at original point) (Turn right) Fig.1-48 Fig.1-49 Note: during a long journey, you can relax your feet by stepping on continuously the protruding part of pedal (D in picture). To achieve the smooth operation, a damper has been installed on treading guidance valve. -

Page 78

XE210C Hydraulic Excavator Operating and Maintenance Manual 78 Notes on travel Note: when moving, rotating or operating the machine in narrow area, one signaler is sure to be employed. Before starting the machine, hand signs should be coordinated. Before moving the machine, the operator should be clear how to operate the treading pedal/control lever towards the desired direction. -

Page 79

XE210C Hydraulic Excavator Operating and Maintenance Manual 79 In frozen weather, before loading and unloading the machine, make sure to remove the deposited snow and ice on crawler board to guard against the slip. Operation on soft land Avoid running on very soft ground when there is no enough strength to support the machine. -

Page 80

XE210C Hydraulic Excavator Operating and Maintenance Manual 80 only for towing light-weight object.(refer to the introduction about how to use hook hole correctly). Operate in water or mud Only when the groundwork of construction site is strong enough to prevent the going-down of… -

Page 81

XE210C Hydraulic Excavator Operating and Maintenance Manual 81 Operation of cutoff The procedure of stopping the engine Land the machine on even ground. Lower the bucket down the ground. Turn the engine speed knob to low-speed idling position and run the engine for 5 min. to cool it. -

Page 82

XE210C Hydraulic Excavator Operating and Maintenance Manual 82 Without load, run the engine 5 min. at low idling speed to cool the engine. Stop the engine and withdraw the key from switch. Pull the safe locking lever to LOCK position. -

Page 83

XE210C Hydraulic Excavator Operating and Maintenance Manual 83 Getting on and off the machine Use railing and ladder Falling off is one of the major causes for person’s Injury. When getting on or off the machine, make sure to keep three touching points (two feet and one hand or two hands and one foot) with railing, pedal and crawler all the Fig.1-63… -

Page 84

XE210C Hydraulic Excavator Operating and Maintenance Manual 84 Operating procedure Control lever Caution: Don’t extend any part of your body out of the right window frame of the cab. If touching the right control lever due to careless collision or other reason, you may be injured by moving arm. -

Page 85

XE210C Hydraulic Excavator Operating and Maintenance Manual 85 3) Always verity the following cases to ensure safe locking lever has been pulled to LOCK position. When transporting the machine; When leaving the machine after the duty. The operation of safe locking lever:… -

Page 86

XE210C Hydraulic Excavator Operating and Maintenance Manual 86 Attention: always verity the brightness of self-idling indicator before the operation. If it is on, showing the self-idling is functioning. Self-idling function is on: self-idling indicator is on. Self-idling function is off: self-idling indicator goes out. -

Page 87

XE210C Hydraulic Excavator Operating and Maintenance Manual 87 machine will be damaged. Note: after the start of machine, the default working mode is S. Operation of counter-shoveling Let the bottom of bucket be 45°with ground, and place the bucket teeth on ground. -

Page 88

XE210C Hydraulic Excavator Operating and Maintenance Manual 88 When digging, don’t let the bucket knock the crawler. Try to place the machine on level ground, don’t use the bucket as a hammer or pile driver, and don’t try to Wrong move stone or crash wall through rotation. -

Page 89

XE210C Hydraulic Excavator Operating and Maintenance Manual 89 List 1-9 Parameter list Hook hole Machine type Chassis bodyframe XE210C 73600N(7.5T) XE210C3Ⅶ 73600N(7.5T) Steel cable XE210C2 73600N(7.5T) Hook XE210C2Ⅶ 73600N(7.5T) Fig.1-77 Hook must be used. Make sure that steel cable is towed horizontally and in the same direction of crawler. -

Page 90

XE210C Hydraulic Excavator Operating and Maintenance Manual 90 rear. In this way, even the wall collapses, the machine can withdraw easily. If it is necessary to work on cliff or under high bank, make sure to check working site at first and confirm there is no possibility that cliff or bank will collapse, if there is, don’t work in this area. -

Page 91

XE210C Hydraulic Excavator Operating and Maintenance Manual 91 him in your visual field and using the hand signs in accordance with local rules. Only when the signaler and operator understand the signals very well, can the machine be moved. Understand the meaning of all the banners, signals and signs used in the work and confirm who should be responsible for issuing the signals. -

Page 92

XE210C Hydraulic Excavator Operating and Maintenance Manual 92 You mustn’t undercut a high bank Undercutting a high bank may lead to the collapse of edge or landslide, causing a severe casualty. Dig with care Accidentally cutting off underground electric cable or gas pipe may lead to a explosion or fire, causing a severe casualty. -

Page 93

XE210C Hydraulic Excavator Operating and Maintenance Manual 93 Operation under special conditions Attention on operation If the front working equipments of machine or other part collide with high objects such as overpass, both the machine and overpass will be damaged even the person will be injured. -

Page 94

XE210C Hydraulic Excavator Operating and Maintenance Manual 94 Refilling method Park the machine on even ground. Lower the bucket on the ground. Run the engine for 5 min. at low-speed idling speed without load. Turn off the engine; withdraw the key from key switch. -

Page 95

XE210C Hydraulic Excavator Operating and Maintenance Manual 95 Refilling quantity XE series:XE210C/ XE210C3Ⅶ/ XE210C2/ XE210C2Ⅶ are 25 L Driving equipment Gear oil brand and name recommended List 1-15 Gear oil brand and name list -20~40℃ Supplier Travel reducer Swing reducer… -

Page 96

XE210C Hydraulic Excavator Operating and Maintenance Manual 96 with the mixed fluid composing of anti-freeze fluid and soft water. The mixing rate of anti-freeze fluid refers to List 1-19, normally between 30% and 50%. If the rate is less than 30%, the system will be rusted;… -

Page 97

XE210C Hydraulic Excavator Operating and Maintenance Manual 97 Safe operating procedure against fire Treat the liquid safely Handle the fuel with care, since it is highly flammable. If fuel is ignited, it will explode and cause a fire and person’s casualty. -

Page 98

XE210C Hydraulic Excavator Operating and Maintenance Manual 98 disadvantage to putting out the fire. So before operating the machine everyday, always check the function of key switch: Start the engine and run it at low idling speed. Turn the key switch to OFF and confirm if the engine has stopped. -

Page 99

XE210C Hydraulic Excavator Operating and Maintenance Manual 99 Avoid heating near the high-pressure hydraulic pipe Flammable sprayer will be produced by heat near the high-pressure hydraulic pipe, leading to a severe burning injury for you and the surrounding people. -

Page 100

XE210C Hydraulic Excavator Operating and Maintenance Manual 100 Other operating procedures Lift or move objects Attention: When using the machine to lift or move objects, you must abide by all the local regulations. Since the steel cable, strap or rope may be broken and lead to a severe casualty, so don’t use damaged chain, broken steel cable or strap or rope to lift heavy thing. -

Page 101

XE210C Hydraulic Excavator Operating and Maintenance Manual 101 Releasing Locking Positioning screw Fig.1-101 Fig.1-102 1-operating pedal 1-operating pedal 2-pedal lock Choose knapping hammer mode (mode B) through working mode switch, the indicator of mode B will shine. Move the pedal lock and release the operating pedal. -

Page 102

XE210C Hydraulic Excavator Operating and Maintenance Manual 102 equipment and machine’s upper structure may be shattered. Before operating the knapper, always move (lower down) the knapper slowly and put it on broken object. Wrong Don’t use the knapper to rotate and move something, or the moving arm, bucket lever and knapper will be damaged. -

Page 103

XE210C Hydraulic Excavator Operating and Maintenance Manual 103 Don’t rotate the upper machine structure to the side to Wrong operate the knapper. This action will make the machine unstable and even shorten the lifespan of lower machine Correct Correct parts. -

Page 104

XE210C Hydraulic Excavator Operating and Maintenance Manual 104 It is possible to damage the front working equipment by relying on pressing down the knapper to prop up the lower Propping up Pressing 100mm-150 down machine body. Though it is permitted to prop up the front edge of lower body within 150mm, but normally this method is not Fig.1-115… -

Page 105

XE210C Hydraulic Excavator Operating and Maintenance Manual 105 Lubrication, maintenance and repair General principle Warning:Only those trained and qualified can repair and maintain this machine. Attention:Before any maintenance, read carefully the related content in this book. Attention:If diesel engine is running indoors, ensure good ventilation condition. -

Page 106

XE210C Hydraulic Excavator Operating and Maintenance Manual 106 Lubrication of equipment Attention: High-quality lubricant should be added according to appointed quantity. Excessive lubricant or grease may lead to overheating and even speed up the abrasion. The kinds of lubricant List 2-1 List of lubricant varieties used for this machine… -

Page 107

XE210C Hydraulic Excavator Operating and Maintenance Manual 107 Serial Position Quantity number Bucket, bucket lever and pin of Connection points of connection rod working equipments Others Swing reducer Swing bearing Rotation device oil-bath Tension device Connection points of working equipments Bucket, bucket lever and pin of connection rod Fig.2-2… -

Page 108

XE210C Hydraulic Excavator Operating and Maintenance Manual 108 Bottom of moving-arm hydraulic cylinder Fig.2-5 Pin of moving-arm hydraulic cylinder and bottom pin of bucket-lever hydraulic cylinder Fig.2-6 Rotary support area Fig.2-7 2 lubrication points for rotary support Rotation device oil-bath Fig.2-8… -

Page 109

XE210C Hydraulic Excavator Operating and Maintenance Manual 109 Oil inlet plug Travel reducer Oil-level inspection plug Drain plug Fig.2-10 ――2 lubrication points for treading gearbox Rotary speed reducer Oil filling cover Oil gauge Specified range Fig.2-11… -

Page 110

XE210C Hydraulic Excavator Operating and Maintenance Manual 110 Lubrication Period Schematic of lubrication and maintenance 图 2-12 —Grease —Engine oil —Gear oil —Engine oil filter —Hydraulic oil filter —Hydraulic oil —Engine coolant —Fuel filter —Air filter Table of lubrication periods:… -

Page 111

XE210C Hydraulic Excavator Operating and Maintenance Manual 111 Safety points for attention and precautionary measures Summarize the working hours correctly to determine the lubrication time. Stop in case of filling the grease, and don’t apply any lubrication work if not parked as per the requirements of this manual. -

Page 112

XE210C Hydraulic Excavator Operating and Maintenance Manual 112 Maintenance and repair Safety rules Safety maintenance In order to avoid any accident: Learn of the maintenance regulations before the work. Keep the work area clean and dry. Don’t spray water or steam in the cab. -

Page 113

XE210C Hydraulic Excavator Operating and Maintenance Manual 113 Use the safety goggles or safety glasses to avoid the injuries of splashed metal pieces or fragments. In case of hitting the object, prevent others from entering into the working place. … -

Page 114

XE210C Hydraulic Excavator Operating and Maintenance Manual 114 Pressure exists in the hydraulic oil tank. Ensure the pressure is released before removing the cover. High-temperature fluid and surface. During the operation, engine oil, gear oil and hydraulic oil may become hot; engine, hose, pipe and other parts will also become hot. -

Page 115

XE210C Hydraulic Excavator Operating and Maintenance Manual 115 In case of treating the accumulator, wear the safety goggles and protective gloves. The high-pressure hydraulic oil will stab the skin or cause the injury. Safety maintaining air-conditioning system The splash of refrigerant on skin will cause the frost injury. -

Page 116

XE210C Hydraulic Excavator Operating and Maintenance Manual 116 Maintenance Check and maintenance of hydraulic device Note: during the operation, the parts of hydraulic system will become very hot, and cool the machine before starting the check or maintenance. During the maintenance of hydraulic device, ensure that the machine shall be placed on the flat or hard ground. -

Page 117

XE210C Hydraulic Excavator Operating and Maintenance Manual 117 Open the access door at the hydraulic pump, check the liquid-level meter on hydraulic oil tank. The oil level must be between the marks on the level meter, otherwise add in the hydraulic oil. -

Page 118

XE210C Hydraulic Excavator Operating and Maintenance Manual 118 the tank: XE210C:220L. XE230,XE260C:240L. Remove the drain plug to make the hydraulic oil discharged. Take out the components of oil suction filter and hanger rod. Clean inner sides of filter and oil tank. In case of replacing the filter, attach a new filter to the hanger rod as shown in right figure. -

Page 119

XE210C Hydraulic Excavator Operating and Maintenance Manual 119 supercharger may be damaged. Pull the safety locking rod to LOCK (lock). Open the drain ball valve in the bottom of fuel tank for several seconds to discharge the water and deposits, and then close the ball valve. -

Page 120

XE210C Hydraulic Excavator Operating and Maintenance Manual 120 Hang “No Operation” nameplate to the control lever. Pull the safety locking rod to LOCK (lock). Check the hydraulic system for leaks. Replacement of fuel filter Replace the fuel filter every 250 hours. -

Page 121

XE210C Hydraulic Excavator Operating and Maintenance Manual 121 or safety glasses. Attach the outer filter element. Attach the end cover, and tighten the fixing clip. Start the engine, and run it at low speed and empty load. Check the warning indicator of air filter element on the monitor. If the indicator goes on, stop the engine immediately and replace the outer filter element. -

Page 122

XE210C Hydraulic Excavator Operating and Maintenance Manual 122 Close the engine, open the drain cock, and flush the cooling system with fresh water until the drained water becomes clean so as to remove the dirt and deposits. Close the drain cock, add the fresh water, and add the antirust agent and antifreeze agent into the radiator as per the specified mixing ratio. -

Page 123

XE210C Hydraulic Excavator Operating and Maintenance Manual 123 There are two 12V batteries on the machine. If one battery of 24V system fails negative grounded but the other is still good, replace the failed battery with the battery of the same type. For example, replace the failed and maintenance-free battery with new battery. -

Page 124

XE210C Hydraulic Excavator Operating and Maintenance Manual 124 Replace the bucket Note: avoid the injury caused by the flyout of metal filling or fragments in case of hitting out or Movement of O-ring in the connecting pin, and wear the safety goggles or safety glasses and safety appliances applicable for operation. -

Page 125

A between frame bottom and track plate back from middle part of chassis frame. Requirements of crawler sag: XE210C, XE230, XE260C: A=300 to 335mm. Note: check the slag of crawler after removing the soil on the track plate. -

Page 126

XE210C Hydraulic Excavator Operating and Maintenance Manual 126 ● Adjust the sag of crawler. Points for attention for adjusting the crawler sag If the crawler sag is not within the desired range, loosen or tighten the crawler as per the steps below. -

Page 127

XE210C Hydraulic Excavator Operating and Maintenance Manual 127 are found near to the connections of pipes, the air leak may occur to these connections. Check of refrigerant amount: after running the engine at 1500r/min for 1 to 3 minutes, check the amount of refrigerant through a sight glass on the liquid reservoir. -

Page 128

XE210C Hydraulic Excavator Operating and Maintenance Manual 128 XE260C Fixing bolt of rail clamp Supporting bolt and nut of working device pin shaft XE210C 3000 Counterweight mounting bolt XE230C/XE260C 3000 Low-pressure pipe adapter and T-shape bolt clip Tightening Torques Table 2-5 Tightening Torques… -

Page 129

XE210C Hydraulic Excavator Operating and Maintenance Manual 129 Table 2-7 Maintenance under Special Environment Conditions Operating Maintenance cautions conditions Pre-operation: check if the screw plug and all the drain plugs are tightened. Mud field, rainy or After-operation: clean the machine, and check if there are broken, damaged, loose or missed nut and snowy bolt, and lubricate all the required parts immediately. -

Page 130

XE210C Hydraulic Excavator Operating and Maintenance Manual 130 List of Maintenance Periods Table 2-8 List of Maintenance Periods Intervals (hours) Item Maintenance point 500 1000 1500 2000 √ Check the level of hydraulic oil. √ Drain the oil reserve of oil tank. -

Page 131

XE210C Hydraulic Excavator Operating and Maintenance Manual 131 Trouble shooting Correct procedures of maintenance and check In order to maintain and repair the machine correctly, follow the correct maintenance and check procedures described in this manual. Check the machine before starting it every day. -

Page 132

XE210C Hydraulic Excavator Operating and Maintenance Manual 132 fuel tank. Low compression ratio of engine Contact with the assigned dealer of XEM excavator. Dirty nozzle or incorrect operation Contact with the assigned dealer of XEM excavator. Trouble of fuel cutoff linkage Adjust or repair the linkage. -

Page 133

XE210C Hydraulic Excavator Operating and Maintenance Manual 133 cooling water Trouble of thermometer or transfer Contact with the assigned dealer of XEM excavator. unit Trouble of engine oil pump or pump Contact with the assigned dealer of XEM excavator. drive Low level of engine oil Add in engine oil. -

Page 134

XE210C Hydraulic Excavator Operating and Maintenance Manual 134 Disengagement of starting motor Contact with the assigned dealer of XEM excavator. pinion with the flywheel gear starting motor Seizure or trouble of pinion shift rotates but it can’t be Contact with the assigned dealer of XEM excavator. -

Page 135

XE210C Hydraulic Excavator Operating and Maintenance Manual 135 Electric system Table 2-10 Trouble shooting of electric system Trouble Cause Remedy Current leakage of battery or it can’t hold Replace the battery. the charge capacity. “Draggle” of starting motor Slow starting of engine Contact with the assigned dealer of XEM excavator. -

Page 136

XE210C Hydraulic Excavator Operating and Maintenance Manual 136 Damaged fuse Replace the fuse. Contact with the assigned dealer of XEM Damaged fuel meter The fuel meter can’t work. excavator. Contact with the assigned dealer of XEM Trouble of electric circuit excavator. -

Page 137

XE210C Hydraulic Excavator Operating and Maintenance Manual 137 Blockage of filter Attach a new filter Wear of hydraulic pump Contact with the assigned dealer of XEM excavator. Blockage of radiator or oil cooler Clean and straighten the blade. Bypass of oil cooler Contact with the assigned dealer of XEM excavator. -

Page 138

XE210C Hydraulic Excavator Operating and Maintenance Manual 138 Leakage of hydraulic cylinder seal Contact with the assigned dealer of XEM excavator. Damage of hydraulic cylinder lever Contact with the assigned dealer of XEM excavator. hydraulic cylinder fails to Damage of pilot pipeline… -

Page 139

XE210C Hydraulic Excavator Operating and Maintenance Manual 139 Periodic replacement of parts In order ensure the safety of operation, be sure to check the machine at regular intervals. If any of the following parts is damaged, it may cause a severe accident or fire. The deterioration or damage of these parts… -

Page 140

XE210C Hydraulic Excavator Operating and Maintenance Manual 140 Transport, storage and protection Transport Cautions of transport During the attachment of machine to the platform of truck or trailer, or removal of machine from them During the transport of machine on the road, be sure to follow the local laws and regulations. -

Page 141

XE210C Hydraulic Excavator Operating and Maintenance Manual 141 Road transport During the transport of machine on the road, learn of and follow all the local laws and regulations. During the transport of trailer, verify the length, width, height and weight of trailer for loading the machine. -

Page 142

XE210C Hydraulic Excavator Operating and Maintenance Manual 142 Note: in the cold weather, be sure to heat the machine before loading/unloading it. Transport Note: tie the chain or rope to the frame of machine, and don’t make the chain or rope pass through or pressed on the hydraulic pipe or hose. -

Page 143

XE210C Hydraulic Excavator Operating and Maintenance Manual 143 machine. For the bucket rod and bucket hydraulic cylinder that are fully extended, fall the movable arm until the bucket contacts the ground. Supporting lever Pull the safety locking rod to LOCK (lock). -

Page 144

XE210C Hydraulic Excavator Operating and Maintenance Manual 144 Storage and protection Daily and short-term storage and protection Check the machine, repair the worn and damaged parts. If necessary, attach new parts. Clean the air filter element. If possible, retract all the hydraulic cylinders; if impossible, apply the grease to the exposed rod of hydraulic cylinder. -

Page 145

XE210C Hydraulic Excavator Operating and Maintenance Manual 145 Technical specifications Product specification Model XE210C XE210C3Ⅶ XE210C2 Item XE210C2Ⅶ Operation configuration under 2.91m 2.91m 2.91m 2.91m Bucket lever Bucket lever Bucket lever standard configuration Bucket lever 20850~21450 Kerb mass, kg 20850~21450 20850~21450… -

Page 146

XE210C Hydraulic Excavator Operating and Maintenance Manual 146 Operation range Model XE210C/XE210C3Ⅶ/XE210C2/XE210C2Ⅶ 2.53m 2.91m Item Bucket Lever Bucket Lever H1: maximum digging radius, 9680 9925 H2: maximum digging depth, 6280 6655 H3: maximum digging height, 9745 9640 H4: maximum unloading… -

Page 147

XE210C Hydraulic Excavator Operating and Maintenance Manual 147 Hydraulic System Schematic… -

Page 148

XE210C Hydraulic Excavator Operating and Maintenance Manual 148 Appendix Crawler type and application Choosing the track shoe meet the operating requirements. According to the floatability and grounding pressure to choose the width of the track shoe, choosing the narrowest track shoe possibly. If the used track shoe is wider than needed, it will increase the load of the track shoe, and lead the track bend, link broken pin-axis broken, loosen of the track shoe and other kinds of problems. -

Page 149

XE210C Hydraulic Excavator Operating and Maintenance Manual 149 Bucket type and application List 4-5 Bucket application table XE210C/XE210C3Ⅶ/XE210C2/XE210C2Ⅶ Bucket capacity Bucket type (Pileup) 2.52m 2.91m Bucket Lever Bucket Lever Strengthened △ △ bucket Strengthened △ △ 0.91 bucket Strengthened △… -

Page 150

XE210C Hydraulic Excavator Operating and Maintenance Manual 150 Hammer-type Knapper (Optional) Relief valve Front Operational Bucket Moving Knapper Excavator pedal lever Body frame Pump Left front Right front Relief valve Hydraulic oil tank Off: not used Control valve On: used Fig. -

Page 151

XE210C Hydraulic Excavator Operating and Maintenance Manual 151 Before installing hydraulic hammer-style knapper, make sure to take the controlling ability of the knapper into consideration and refer to the following list to choose hammer-style knapper. List 1-1 Permitted weight of hammer-style knapper… -

Page 152

XE210C Hydraulic Excavator Operating and Maintenance Manual 152 List 1-3 Specification List of Hammer-style Knapper (2) Type of Excavator XE230, XE260C Korea Japan Knapper Producer Korea Shuishan Japan Guhe Germany KRUPP Gongbing Dongkong Type of Knapper SB81 GB220E TNB-150LU HM960CS Weight,kg… -

Page 153

XE210C Hydraulic Excavator Operating and Maintenance Manual 153 Weight of work load Note: the weight is an approximate value of estimated average volume and capacity. Table 4-6 Table of Material Desity Low density Intermediate density High density Material ≤1100kg/m ≤1600kg/m ≤2000kg/m… -

Page 154

XE210C Hydraulic Excavator Operating and Maintenance Manual 154 XUGONG EXCAVATOR MACHINERY CO., LTD ADD : No.28 Donghuan Industrial Area, Xuzhou Economic Development Zone, Jiangsu, China Postcode:221004 Sale tel:0516-87870116 Fax:0516-87870118 Service tel:0516-87870111 Fax:0516-87870117 Spare parts tel:0516-87870133 http://www.xcmg.com First version in 2011…

Вы здесь

Руководства по эксплуатации и ремонту экскаваторов

Нажмите, чтобы скрыть

Перейти к полной версии/Вернуться

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- »

- конец

пт, 13.01.2012 — 00:27

#1

Регистрация: 29.09.2010 — 20:52

: 2114

Не в сети

Заходил: 1 год 11 месяцев назад

В этой теме предлагаю размещать руководства по эксплуатации, обслуживанию, ремонту экскаваторов. Каталоги запчастей.

Руководство по эксплуатации экскаватора Амкодор-702 ЕМ

Руководство по эксплуатации экскаватора Амкодор-702 ЕА

Руководство по эксплуатации экскаватора-погрузчика ПЭ-82

Руководство по эксплуатации экскаватора ЭО-2621А

пт, 13.01.2012 — 00:52

#2

Регистрация: 29.09.2010 — 20:52

: 2114

Не в сети

Заходил: 1 год 11 месяцев назад

пт, 13.01.2012 — 18:21

#3

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

вс, 29.01.2012 — 19:03

#4

Регистрация: 29.09.2010 — 20:52

: 2114

Не в сети

Заходил: 1 год 11 месяцев назад

чт, 16.02.2012 — 14:18

#5

Регистрация: 10.12.2011 — 20:24

: 97

Не в сети

Заходил: 3 года 4 месяца назад

ЗДРАВСТВУЙТЕ ЕСТЬ-ЛИ У КОГО НИБУДЬ ССЫЛКА НА РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ ЭКСКАВАТОРА ЭО 2628 БОРЕКС ИЛИ КАКАЯ ДРУГАЯ ЛИТЕРАТУРА ПО ДАННОМУ ЭКСКАВАТОРУ ЗАРАНЕЕ ВАМ БЛАГОДАРЕН

пт, 09.05.2014 — 19:03

#6

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Каталоги запчастей для экскаваторов YANMAR/

пт, 09.05.2014 — 20:00

#7

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

пт, 26.12.2014 — 18:45

#8

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Каталоги для AIRMAN и KUBOTA. После закачки названия моделей отображаются неправильно. 152-это 15-2, 172-это 17-2 и т.д….

сб, 17.01.2015 — 18:09

#9

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

сб, 17.01.2015 — 20:00

#10

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

сб, 17.01.2015 — 20:17

#11

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

сб, 17.01.2015 — 20:24

#12

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

вт, 17.02.2015 — 08:24

#13

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануалы на двигатели Yanmar.

вс, 18.01.2015 — 12:51

#14

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для двигателя Mitsubichi S3L и L3C.

пн, 19.01.2015 — 19:16

#15

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

ср, 13.04.2016 — 17:24

#16

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

вт, 20.10.2015 — 06:03

#17

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для TAKEUCHI TB035, TB025

пн, 26.01.2015 — 04:27

#18

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

| Вложение |

|---|

ср, 28.01.2015 — 10:30

#19

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануалы для двигателей KUBOTA D905-B, D1005-B, V1205-B, V1205-T-B, V1305-B. и D1403-B, D1703-B, V1903, V2203, F2803.

ср, 28.01.2015 — 17:50

#20

Регистрация: 29.09.2010 — 20:52

: 2114

Не в сети

Заходил: 1 год 11 месяцев назад

avsheff пишет:

Мануалы для двигателей

сб, 31.01.2015 — 08:33

#21

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

NiK 61

пт, 06.02.2015 — 09:31

#22

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Руководство по эксплуатации Bobcat 325. 328

| Вложение |

|---|

пт, 06.02.2015 — 17:23

#23

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для двигателей ISUZU 3KC1, 3KR1, 3KR2.

| Вложение |

|---|

пн, 09.02.2015 — 07:41

#24

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

инструкция и сервис мануал для двигателей ISUZU 3LA1, 3LB1, 3LD1.

вт, 17.02.2015 — 08:30

#25

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

вт, 17.02.2015 — 18:36

#26

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

| Вложение |

|---|

вт, 17.02.2015 — 19:42

#27

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал KOMATSU РС25-1, РС30-7, РС40-7, РС45-1

ср, 18.02.2015 — 12:31

#28

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануалы для Komatsu PC05-6F

ср, 18.02.2015 — 12:37

#29

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для Komatsu РС12R-8, PC12R-8-HS, PC15R-8, PC15R-8-HS

ср, 18.02.2015 — 12:40

#30

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для Komatsu PC14R-2

| Вложение |

|---|

ср, 18.02.2015 — 12:42

#31

Регистрация: 12.02.2010 — 06:07

: 1560

Не в сети

Заходил: 3 месяца 7 часов назад

Мануал для Komatsu PC16R-2

| Вложение |

|---|

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- »

- конец

Самые популярные темы

- ПЛАЗМОРЕЗЫ. ПЛАЗМЕННАЯ РЕЗКА МЕТАЛЛОВ. ДУГОВАЯ СВАРКА. АРГОННАЯ СВАРКА. РАСХОДНИКИ. НОВЫЕ ТЕХНОЛОГИИ

- Руководства по эксплуатации зерноуборочных комбайнов.

- Руководства по эксплуатации и ремонту тракторов

- РУКОВОДСТВО ПО ПРЕСС ПОДБОРЩИКАМ

- Навигация в поле — параллельное вождение.

- Комбайн CLAAS Consul

- Руководства по эксплуатации и ремонту экскаваторов

- Сеялки.

- Каталоги инструкции к сельхоз технике

- Разбрасыватели удобрений