-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Reference Manual

00809-0300-4408, Rev AA

June 2019

™

Rosemount

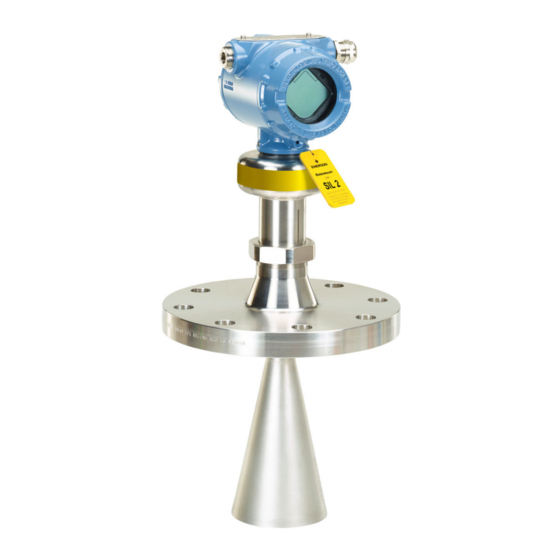

5408 Level Transmitter

™

Non-Contacting Radar with F

Fieldbus Protocol

OUNDATION

Related Manuals for Emerson Rosemount 5408

Summary of Contents for Emerson Rosemount 5408

-

Page 1

Reference Manual 00809-0300-4408, Rev AA June 2019 ™ Rosemount 5408 Level Transmitter ™ Non-Contacting Radar with F Fieldbus Protocol OUNDATION… -

Page 2

Equipment ratings and certifications are no longer valid on any products that have been damaged or modified without the prior written permission of Emerson. Any continued use of product that has been damaged or modified without the written authorization is at the customer’s sole risk and expense. -

Page 3

The products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified products in applications that require nuclear-qualified hardware or products may cause inaccurate readings. For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative. -

Page 5: Table Of Contents

5.5 Change device mode……………………76 5.6 Configure transmitter using Guided Setup………………77 5.7 Verify level……………………….78 5.8 Write protect a transmitter………………….79 Chapter 6 Operation……………………81 6.1 LCD display screen messages………………….81 6.2 Set up the LCD display……………………82 6.3 View measurement data…………………….83 Rosemount 5408 Level Transmitter…

-

Page 6

Contents Reference Manual June 2019 00809-0300-4408 6.4 Device status……………………..85 Chapter 7 Service and troubleshooting………………89 7.1 Safety messages……………………..89 7.2 Diagnostic messages……………………89 ™ 7.3 F Fieldbus error messages…………………96 OUNDATION 7.4 Troubleshooting guides……………………99 7.5 Service and troubleshooting tools………………..105 7.6 Application challenges……………………. -

Page 7

Reference Manual Contents 00809-0300-4408 June 2019 D.2 Analog Input block……………………239 D.3 Measurement Transducer block………………..248 D.4 Register Transducer block………………….252 D.5 Supported units……………………… 254 Rosemount 5408 Level Transmitter… -

Page 8

Contents Reference Manual June 2019 00809-0300-4408 viii Reference Manual… -

Page 9: Chapter 1 Introduction

FOUNDATION Fieldbus Block Information provides information regarding the function blocks. Product recycling/disposal Recycling of equipment and packaging should be taken into consideration and disposed of in accordance with local and national legislation/regulations. Rosemount 5408 Level Transmitter…

-

Page 10

Introduction Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 11: Chapter 2 Transmitter Overview

This signal is further processed to obtain fast, reliable, and highly accurate level measurements. See Figure 2-2 for a schematic overview of the signal processing. Figure 2-1: FMCW-method Δf≈d=distance A. Frequency (GHz) B. Time (s) C. Transmitted signal D. Reflected signal Rosemount 5408 Level Transmitter…

-

Page 12: Process Characteristics

Transmitter overview Reference Manual June 2019 00809-0300-4408 Figure 2-2: Flowchart of the Signal Processing A. Microwave module B. A/D converter C. Fast Fourier transform (FFT) D. Peak search E. Peak interpolation F. Echo tracker G. Echo identifier H. Distance filtering I.

-

Page 13

Grain silo — small kernel grains Grain silo — large kernel grains Lime stone silo Possible Cement — raw mill silo Cement — finished product silo Coal bin Saw dust High consistency — pulp stock Alumina Salt Rosemount 5408 Level Transmitter… -

Page 14: Vessel Characteristics

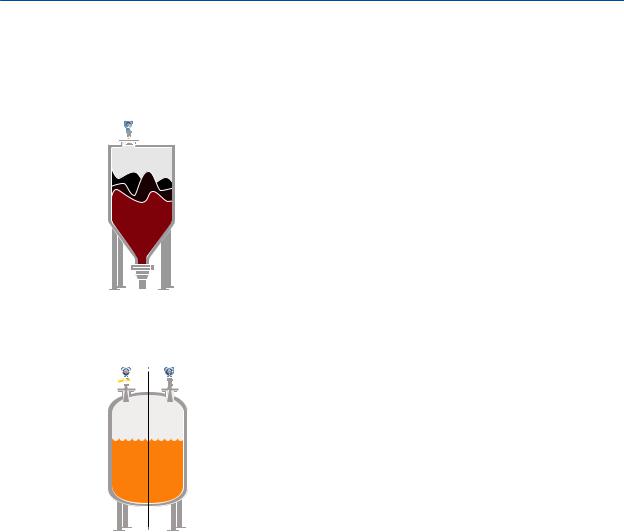

Application examples The Rosemount 5408 is ideal for level measurements over a broad range of liquid and solids applications. The transmitters are virtually unaffected by changing density, temperature, pressure, media dielectric, pH, and viscosity. Non-contacting radar level is ideal for harsh conditions such as corrosive and sticky media, or when internal tank obstructions are a limiting factor.

-

Page 15

00809-0300-4408 June 2019 Blenders and mixers The Rosemount 5408 can help you withstand the rigors of blenders and mixing tanks. Easy to install and commission, it is also unaffected by virtually any fluid property change. Open atmospheric applications The Rosemount 5408 measures reliably in open applications, from short range sumps or ponds to long range dams. -

Page 16: Components Of The Transmitter

Reference Manual June 2019 00809-0300-4408 Bulk solids The Rosemount 5408 is the ideal solution for small to medium sized silos with rapid level changes. The narrow beam avoids internal obstructions while still keeping good level measurement. Components of the transmitter Figure 2-3 shows the different components of the transmitter.

-

Page 17

J. Threaded process connection (NPT or BSPP (G)) K. Air purge ring (option code PC1 for cone antenna) L. Integrated air purge connection M. Parabolic antenna N. Parabolic antenna with swivel mount O. Process seal antenna ® P. Tri-Clamp process connection Rosemount 5408 Level Transmitter… -

Page 18: System Integration

Application), a handheld communicator, the AMS Device Manager, or any other Device Descriptor (DD) or Field Device Integration (FDI) compatible host system. The Rosemount 5408 is compliant with NAMUR NE 107 Field Diagnostics for standardized device diagnostic information. Figure 2-4: System Architecture A.

-

Page 19: Chapter 3 Mechanical Installation

Use the equipment only as specified in this manual. Failure to do so may impair the protection provided by the equipment. • For installations in hazardous locations, the transmitter must be installed according to the Rosemount 5408 and 5408:SIS Product Certifications document and System Control Drawing (D7000002-885).

-

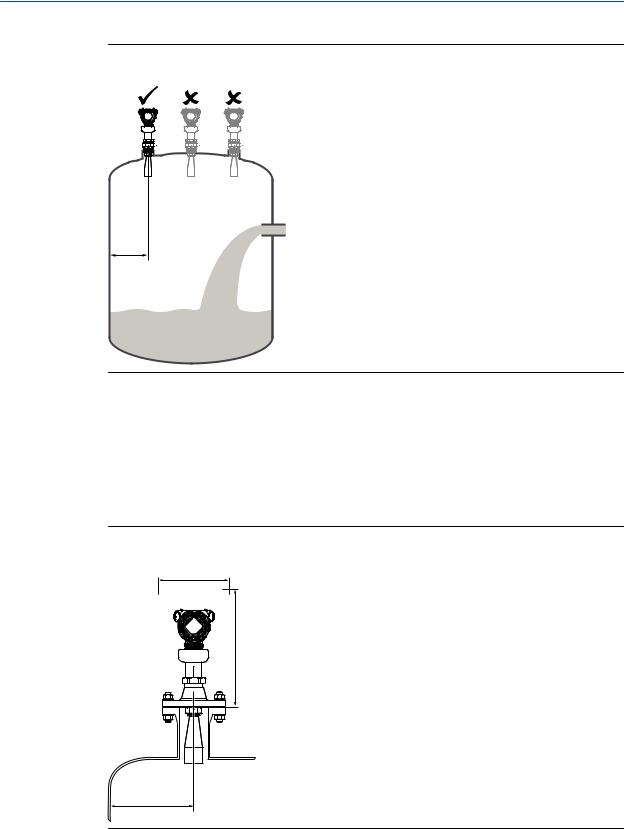

Page 20: Confirm Approval Type

Do not install the transmitter in the center of the tank. • Do not mount close to or above the inlet stream. • Multiple Rosemount 5408 Level Transmitters can be used in the same tank without interfering with each other. Reference Manual…

-

Page 21

Therefore the following minimum clearance, according to Table 3-1, must be maintained. For easy access to the transmitter, mount it with sufficient service space (see Table 3-2). Figure 3-3: Free Space Requirements Rosemount 5408 Level Transmitter… -

Page 22

Mechanical installation Reference Manual June 2019 00809-0300-4408 Table 3-1: Distance to Tank Wall (L) Application Minimum Recommended Liquids 8 in. (200 mm) ½ of tank radius Solids 8 in. (200 mm) ⅔ of tank radius Table 3-2: Free Space Requirements Description Distance Service space width (A) -

Page 23

Beam width and beam angle The transmitter should be mounted with as few internal structures as possible within the signal beam. Refer to Table 3-3 for beam angle and Table 3-4 for beam width at different distances. Rosemount 5408 Level Transmitter… -

Page 24

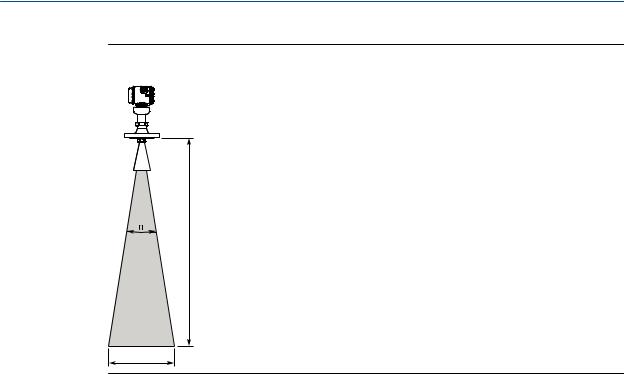

Mechanical installation Reference Manual June 2019 00809-0300-4408 Figure 3-5: Beam Angle and Beam Width Table 3-3: Beam Angle Antenna size Beam angle (α) 2-in. (DN50) cone/process seal 18° 3-in. (DN80) cone/process seal 14° 4-in. (DN100) cone/process seal 10° 8-in. (DN200) parabolic 4.5°… -

Page 25

Nozzle requirements for process seal antenna The antenna can be used on nozzles up to 4 ft. (1.2 m). Disturbing objects inside the nozzle may impact the measurement, and should therefore be avoided. Rosemount 5408 Level Transmitter… -

Page 26

Mechanical installation Reference Manual June 2019 00809-0300-4408 Figure 3-7: Mounting of the Process Seal Antenna Table 3-6: Nozzle Requirements for Process Seal Antenna Antenna size Minimum nozzle diameter (D) Recommended maximum nozzle height 2-in. (DN50) 1.77 in. (45 mm) 4 ft. (1.2 m) 3-in. -

Page 27

Minimum distance between holes is 6 in. (150 mm). • Holes should be drilled on one side only and deburred. • Drill one hole above maximum product surface. Antenna • All cone/process seal antenna sizes can be used for still pipe/chamber installations. Rosemount 5408 Level Transmitter… -

Page 28

Mechanical installation Reference Manual June 2019 00809-0300-4408 • The gap between the cone antenna and the still pipe should be maximum 0.2 in. (5 mm). If required, order a larger antenna and cut on location. See Table A-15 for antenna dimensions. Figure 3-9: Still Pipe Requirements A. -

Page 29

Ensure there is no edge between the ball valve and the nozzle or still pipe, the inside should be smooth. • Valves can be combined with still pipes. • The ball valve should have the same inner diameter as the still pipe. Rosemount 5408 Level Transmitter… -

Page 30: Mounting Preparations

Mechanical installation Reference Manual June 2019 00809-0300-4408 Mounting preparations 3.4.1 Assemble the segmented cone antenna This section applies to the segmented cone antenna (option code S2). Use only one segment; the total antenna length should not exceed 47.2 in. (1200 mm). To determine the antenna length, follow the guidelines in section Nozzle requirements.

-

Page 31

8. Update the transmitter configuration to the new Antenna Extension Length (L). • Rosemount Radar Master Plus: — Under Configure, select Level Setup → Antenna. • AMS Device Manager and handheld communicator: — Select Configure → Manual Setup → Level Setup → Antenna. Rosemount 5408 Level Transmitter… -

Page 32

Mechanical installation Reference Manual June 2019 00809-0300-4408 3.4.2 Shorten the extended cone antenna This section only applies to the extended cone antenna (option code S1). To determine the antenna length, follow the guidelines in section Nozzle requirements. Procedure 1. Mark where to cut the antenna. 2. -

Page 33

1. Remove the stop ring using a flat head screwdriver. Wear gloves to increase grip when using the tool! 2. Replace the transmitter head nut. 3. Mount the stop ring. Use the new stop ring supplied with the kit. Rosemount 5408 Level Transmitter… -

Page 34: Mount The Cone Antenna

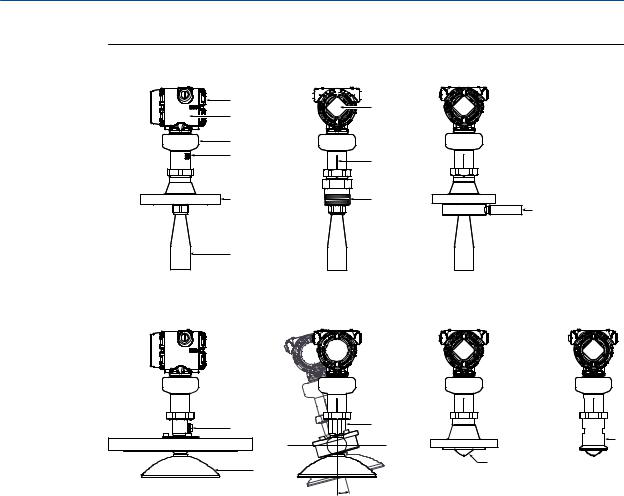

Mechanical installation Reference Manual June 2019 00809-0300-4408 Postrequisites Ensure to set the Antenna Type to Legacy (Rosemount 5402), and then set the User Defined Antenna Options parameters. Related information User defined antenna options Mount the cone antenna 3.5.1 Overview Figure 3-11: Overview A.

-

Page 35

Assemble the segmented cone antenna). Procedure 1. Place a suitable gasket on the tank flange. 2. Lower transmitter with antenna and flange into the nozzle. 3. Tighten bolts and nuts with sufficient torque for the flange and gasket choice. Rosemount 5408 Level Transmitter… -

Page 36

Mechanical installation Reference Manual June 2019 00809-0300-4408 Postrequisites Align the transmitter head (see Align transmitter head). 3.5.4 Flanged version with air purge ring (option code PC1) Prerequisites If applicable, assemble the segmented cone antenna (see Assemble the segmented cone antenna). Procedure 1. -

Page 37

5. Tighten bolts and nuts with sufficient torque for the flange and gasket choice. A. 1.0 in. (25.5 mm) 6. Connect the air purging system. Use thread sealant or suitable gasket according to your site procedures. A. G⅜-in. B. 0.4 in. (10 mm) Rosemount 5408 Level Transmitter… -

Page 38

Mechanical installation Reference Manual June 2019 00809-0300-4408 Table 3-8: Incoming Air Supply Specification Maximum pressure Recommended pressure 190 psi (13 bar) 100 to 115 psi (7 to 8 bar) Postrequisites Align the transmitter head (see Align transmitter head). 3.5.5 Threaded version, antenna diameter smaller than thread diameter Threaded tank connection Prerequisites… -

Page 39

3. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice. 4. Apply anti-seize paste or PTFE tape on threads according to your site procedures. Gasket may be used as a sealant for adapters with 1½- or 2-in. BSPP (G) threads. Rosemount 5408 Level Transmitter… -

Page 40

Mechanical installation Reference Manual June 2019 00809-0300-4408 5. Lower transmitter with antenna into the nozzle. A. Gasket (for 1½-in. and 2-in. BSPP (G) threads only) Postrequisites Align the transmitter head (see Align transmitter head). 3.5.6 Threaded version, antenna diameter larger than thread diameter Prerequisites If applicable, assemble the segmented cone antenna (see… -

Page 41

Gasket may be used as a sealant for adapters with 1½- or 2-in. BSPP (G) threads. 3. Mount the adapter on the customer supplied flange. A. Gasket (for 1½-in. and 2-in. BSPP (G) threads only) 4. Mount the antenna. Note Visually inspect the microwave launcher for damage and dirt. Rosemount 5408 Level Transmitter… -

Page 42

Mechanical installation Reference Manual June 2019 00809-0300-4408 Torque 5 in-lb (0.5 N-m) H2 mm Torque 250 in-lb (28 N-m) 38 mm 5. Place a suitable gasket on the tank flange. 6. Lower transmitter with antenna and flange into the nozzle. 7. -

Page 43: Bracket Mounting

B. Vertical pipe On wall: 2. Mount the holder to the bracket. 3. Unscrew and remove the antenna. H2 mm Note Be careful not to scratch the microwave launcher. The microwave launcher is sensitive to mechanical impacts. Rosemount 5408 Level Transmitter…

-

Page 44

Mechanical installation Reference Manual June 2019 00809-0300-4408 4. Screw the transmitter into the holder. 5. Mount the antenna. Torque 5 in-lb (0.5 N-m) H2 mm 38 mm Postrequisites Align the transmitter head (see Align transmitter head). 3.5.8 Align transmitter head Procedure 1. -

Page 45

Align the external ground screw toward the holes of the still pipe (see Figure 3-14). Chamber Align the external ground screw toward the process connections (see Figure 3-15). 3. Tighten the nut. Torque 355 in-lb (40 N-m) 60 mm Figure 3-13: Open Tank Figure 3-14: Still pipe Rosemount 5408 Level Transmitter… -

Page 46: Mount The Process Seal Antenna

Mechanical installation Reference Manual June 2019 00809-0300-4408 Figure 3-15: Chamber Mount the process seal antenna 3.6.1 Overview Figure 3-16: Overview A. Flanged version (see page ® B. Tri-Clamp version (see page 3.6.2 Mount the flanged version Procedure 1. Lower the transmitter into the nozzle. Reference Manual…

-

Page 47

The conditions used for the calculation are: Standard mating metal flange, A193 B8M Cl.2 / A4-70 bolt material, and a friction coefficient of μ=0.16. Low strength bolt and non-metallic mating flange may require lower tightening torque. Postrequisites Align the transmitter head (see Align transmitter head). Rosemount 5408 Level Transmitter… -

Page 48

Mechanical installation Reference Manual June 2019 00809-0300-4408 ® 3.6.3 Mount the Tri-Clamp version Procedure 1. Lower the transmitter into the nozzle. Note Be careful not to scratch or otherwise damage the PTFE sealing. 2. Tighten the clamp to the recommended torque (see the manufacturer’s instruction manual). -

Page 49: Mount The Parabolic Antenna

Reference Manual Mechanical installation 00809-0300-4408 June 2019 Mount the parabolic antenna 3.7.1 Overview Figure 3-17: Overview A. Flanged version (see page B. Threaded version (see page C. Welded version (see page Rosemount 5408 Level Transmitter…

-

Page 50

Mechanical installation Reference Manual June 2019 00809-0300-4408 3.7.2 Components of the parabolic antenna Components of the threaded version Figure 3-18: Components A. Antenna B. Purge plug kit C. Threaded sleeve D. M20 adapter E. Lock nut BSPP (G) 3½-in. F. Antenna adapter with ball joint G. -

Page 51

A. Antenna B. Purge plug kit C. Threaded sleeve D. M20 adapter E. Weld protection plate F. Flange ball G. O-ring H. Clamp flange I. Washer J. M8 screw K. Weld protection bar L. Ball joint Rosemount 5408 Level Transmitter… -

Page 52

Mechanical installation Reference Manual June 2019 00809-0300-4408 3.7.3 Mount the flanged version Procedure 1. Place a suitable gasket on the tank flange. 2. Lower the flange and antenna assembly into the nozzle. 3. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice. Postrequisites 1. -

Page 53

A. Ø 3.98 ± 0.02 in. (Ø 101 ± 0.6 mm) or G 3½-in. B. Max. 0.59 in. (15 mm) 4. Remove the M20 adapter and visually inspect the O-rings for damage and dirt. Rosemount 5408 Level Transmitter… -

Page 54

Mechanical installation Reference Manual June 2019 00809-0300-4408 5. Carefully insert the antenna. 6. Secure the antenna. Torque 180 in-lb (20 N-m) 27 mm 7. Tighten the set screw. Torque 5 in-lb (0.5 N-m) H2 mm 8. Place a suitable gasket on the tank flange. Reference Manual… -

Page 55

10. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice. Postrequisites 1. Adjust the inclination of the antenna (see Adjust the inclination of the antenna). 2. Connect the air purging system (see Connect the air purging). Rosemount 5408 Level Transmitter… -

Page 56

Mechanical installation Reference Manual June 2019 00809-0300-4408 3.7.5 Mount the welded version Procedure 1. Mount the protection plates to flange/manhole cover. These plates protect the internal surfaces of the flange ball from dust and sparks during welding. A. Ø 3.94 ± 0.02 in. (Ø 100 ± 0.5 mm) B. -

Page 57

Insert the ball joint and place the clamp flange with the “7 Nm” marking side b) Gradually tighten the M8 screws. Torque 65 in-lb (7 N-m) H6 mm 6. Remove the M20 adapter and visually inspect the O-rings for damage and dirt. Rosemount 5408 Level Transmitter… -

Page 58

Mechanical installation Reference Manual June 2019 00809-0300-4408 7. Carefully insert the antenna. 8. Secure the antenna. Torque 180 in-lb (20 N-m) 27 mm 9. Tighten the set screw. Reference Manual… -

Page 59

12. Tighten the bolts and nuts with sufficient torque for the flange and gasket choice. Postrequisites 1. Adjust the inclination of the antenna (see Adjust the inclination of the antenna). 2. Connect the air purging system (see Connect the air purging). Rosemount 5408 Level Transmitter… -

Page 60

Mechanical installation Reference Manual June 2019 00809-0300-4408 3.7.6 Adjust the inclination of the antenna Prerequisites WARNING Contents may be under pressure. • Do not loosen the M8 screws while in operation. Attempting to do so may release pressurized gases, resulting in serious injury or death. Procedure 1. -

Page 61

Reference Manual Mechanical installation 00809-0300-4408 June 2019 4. Adjust the inclination of the antenna. 5. Gradually tighten the M8 screws. Torque 65 in-lb (7 N-m) H6 mm 6. Remove the circular level. Rosemount 5408 Level Transmitter… -

Page 62

Mechanical installation Reference Manual June 2019 00809-0300-4408 7. Mount the transmitter head. Align the marking on the sensor module with the air purge connection. Torque 355 in-lb (40 N-m) 60 mm 36 mm Reference Manual… -

Page 63

D. Use thread sealant or gasket according to your site procedures. E. G⅜-in. F. 0.3-0.4 in. (8-10 mm) (gasket excluded) Table 3-10: Incoming Air Supply Specification Maximum pressure Recommended pressure 190 psi (13 bar) 100 to 115 psi (7 to 8 bar) Rosemount 5408 Level Transmitter… -

Page 64: Adjust Display Orientation (Optional)

Mechanical installation Reference Manual June 2019 00809-0300-4408 Adjust display orientation (optional) To improve field access to wiring or to better view the optional LCD display: Prerequisites Note In high vibration applications, the transmitter housing must be fully engaged into the sensor module to meet the vibration test specifications.

-

Page 65: Chapter 4 Electrical Installation

Use the equipment only as specified in this manual. Failure to do so may impair the protection provided by the equipment. • For installations in hazardous locations, the transmitter must be installed according to the Rosemount 5408 and 5408:SIS Product Certifications document and System Control Drawing (D7000002-885).

-

Page 66: Hazardous Areas

Electrical installation Reference Manual June 2019 00809-0300-4408 Hazardous areas When the transmitter is installed in hazardous areas, local regulations, and specifications in applicable certificates must be observed. Related information Product Certifications Prepare the electrical connections 4.3.1 Cable selection Recommended wiring is 18 AWG twisted shielded pair, referred to as Fieldbus type A cable.

-

Page 67

4.3.5 Power supply The transmitter operates on 9-32 Vdc (9-30 Vdc in Intrinsically Safe installations and 9-17.5 Vdc for FISCO) at the transmitter terminals. Rosemount 5408 Level Transmitter… -

Page 68: Wiring Diagram

Electrical installation Reference Manual June 2019 00809-0300-4408 4.3.6 Signal termination A terminator should be installed at the beginning and end of every Fieldbus segment. For transmitter with built-in terminator, connect a jumper wire between the «TERMINATE ON» terminals to activate the terminator. Refer to Cable selection for recommended wire size.

-

Page 69: Connect Wiring And Power Up

D. Daisy-chain connection to other devices E. Handheld communicator F. Fieldbus modem G. Power supply ™ H. Rosemount 2410 Tank Hub Connect wiring and power up Procedure Verify the power supply is disconnected. 2. Remove the cover. Rosemount 5408 Level Transmitter…

-

Page 70

Electrical installation Reference Manual June 2019 00809-0300-4408 3. Remove the plastic plugs. 4. Pull the cable through the cable gland/conduit. Identification of thread size and type: 5. Connect the cable wires (see Wiring diagram). Torque 7 in-lb (0.8 N-m) 6. Ensure proper grounding (see Grounding). 7. -

Page 71

Verify the cover jam screw is completely threaded into the housing. H2.5 mm b) Attach and tighten the cover. Make sure the cover is fully engaged. There should be no gap between the cover and the housing. Rosemount 5408 Level Transmitter… -

Page 72

Electrical installation Reference Manual June 2019 00809-0300-4408 c) Turn the jam screw counterclockwise until it contacts the cover. Required for explosion-proof/flameproof installations only. d) Turn the jam screw an additional ½ turn counterclockwise to secure the cover. 10. Connect the power supply. Note It may take up to 15 seconds before the LCD display lights up. -

Page 73: Chapter 5 Configuration

High voltage that may be present on leads can cause electrical shock. Overview This chapter provides information about configuration and configuration tools. Appendix Configuration parameters provides extended information about the configuration parameters. The menu trees can be found in Menu tree. Rosemount 5408 Level Transmitter…

-

Page 74: System Readiness

5-1, use the Device Revision number to find the correct DD or FDI Package. 2. Download the latest DD at Emerson.com/DeviceInstallKits. 3. Download the latest FDI Package at Emerson.com/RosemountRadarMasterPlus. Table 5-1: Identification and Compatibility According to NAMUR NE 53 Release…

-

Page 75

The Device Descriptor (DD) is a configuration tool that is developed to assist the user through the configuration. Prerequisites The Rosemount 5408 DD is typically installed together with AMS Device Manager. To download the latest DD, visit the Emerson Device Install Kit site at: Emerson.com/DeviceInstallKits… -

Page 76: Change Device Mode

Get the latest Device Descriptor (DD) If the DD is not installed in your handheld communicator, see the appropriate handheld communicator User’s Manual available at Emerson.com/FieldCommunicator instructions on how to update the handheld communicator with the latest DD. Change device mode 5.5.1…

-

Page 77: Configure Transmitter Using Guided Setup

The options available in the Guided Setup wizard include all items required for basic operation. Procedure 1. Turn on the handheld communicator and connect to the device. 2. Select Configure → Guided Setup. 3. Select Basic Setup and follow the on-screen instructions. Rosemount 5408 Level Transmitter…

-

Page 78: Verify Level

Configuration Reference Manual June 2019 00809-0300-4408 Verify level The Verify Level tool matches the product level reported by the device to a reference measurement (measured by using for example handgauging). If any difference, the Calibration Offset parameter will be adjusted. A minor adjustment using Calibration Offset is normal.

-

Page 79: Write Protect A Transmitter

Write protect a transmitter using AMS Device Manager and handheld communicator The transmitter can be write protected to prevent unauthorized changes. Procedure 1. Select Configure → Manual Setup → Device Setup → Security. 2. Select Change Write Protection and follow the on-screen instructions. Rosemount 5408 Level Transmitter…

-

Page 80

Configuration Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 81: Chapter 6 Operation

The following screens are shown on the LCD display when the transmitter is switched on: Figure 6-2: Startup Screen Sequence 1. All segments on 2. Device type and 3. Software revision 4. Serial number communication protocol Variable screens The transmitter can display the following variables: Rosemount 5408 Level Transmitter…

-

Page 82: Set Up The Lcd Display

Operation Reference Manual June 2019 00809-0300-4408 Table 6-1: LCD Display Variables Parameter Presentation on display Description Level LEVEL The current level measurement value. Distance DIST Distance from the upper reference point to the product surface. Level Rate The current velocity at which the level is moving.

-

Page 83: View Measurement Data

Current measurement data of the primary variables are presented on the Overview screen together with a graphical representation of the tank. Procedure Select All Variables to view a complete list of all variables within the transmitter. Rosemount 5408 Level Transmitter…

-

Page 84

Operation Reference Manual June 2019 00809-0300-4408 Figure 6-3: Rosemount Radar Master Plus — Overview Screen 6.3.2 View measurement data in AMS Device Manager and handheld communicator Current measurement data of the primary variables are presented on the Overview screen. To view all current measurement values, do the following: Procedure 1. -

Page 85: Device Status

High/low user defined alert 6.4.1 Check device status Follow this procedure to check device status and see whether there are any active alerts reported. Procedure 1. Go to the Overview screen to view the overall device status. Rosemount 5408 Level Transmitter…

-

Page 86

Operation Reference Manual June 2019 00809-0300-4408 2. If status is anything than Good, click the button in the device status image to open a window with active alerts. The different device status images are shown in Table 6-2 Table 6-3. Active Alerts can also be obtained via Service Tools →… -

Page 87

At least one Out of Specification Specification alert is active (and no Failure or Function Check alerts). Maintenance At least one Maintenance Required Required alert is active (and no Failure, Function Check, or Out of Specification alerts). Rosemount 5408 Level Transmitter… -

Page 88

Operation Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 89: Service And Troubleshooting

Make sure the mains power to the transmitter is off and the lines to any other external power source are disconnected or not powered while wiring the transmitter. Diagnostic messages Diagnostic messages per NAMUR NE 107 are listed in Table 7-1 Table 7-5. Rosemount 5408 Level Transmitter…

-

Page 90

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-1: Status — Failed LCD display Host diagnostic Description Recommended actions message message ELEC Electronics Failure, An electronics error has occurred. 1. Restart the device. Transmitter FAILUR The device measurement reading is 2. -

Page 91

ERROR multiple (see Table 7-2 for details). 2. Correct the parameter causing the error. DD4: 1. Check ALERT_CONFIG_DETAILS parameter for details. 2. Correct the issue causing configuration error. 3. Restore default settings and reconfigure device. Rosemount 5408 Level Transmitter… -

Page 92

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-2: Configuration Error Details Host diagnostic message Description Recommended actions Volume Configuration Error The volume cannot be calculated correctly 1. If strapping table is used, check that with the current configuration. level-volume values are entered in increasing order. -

Page 93

Upgrade function. Note 2. If condition persists, contact your Start codes are unique for individual local Emerson representative to get a devices and cannot be copied from one valid start code. device to another. Table 7-3: Status — Function Check… -

Page 94

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-3: Status — Function Check (continued) LCD display Host diagnostic Description Recommended actions message message OUTOF Device Not in Service One or more blocks in the device • Change block mode to Auto to are not in service. -

Page 95

1. Check configuration of Bottom Estimation Degraded degraded. Product Dielectric Constant. DEGRAD 2. Check configuration of Accuracy of level measurement may Reference Height and Bottom be degraded. Offset. 3. If not needed, disable Tank Bottom Projection. Rosemount 5408 Level Transmitter… -

Page 96: Foundation ™ Fieldbus Error Messages

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 ™ Fieldbus error messages OUNDATION 7.3.1 Resource block errors Table 7-6 lists conditions reported in the BLOCK_ERR parameter. Table 7-6: Resource Block BLOCK_ERR Conditions Condition Condition name Description number Other A device specific error has occurred. Block Configuration Error There is a configuration error in resource block such as wrong…

-

Page 97

Check XD_SCALE parameter. correct. If using Indirect mode, scaling • Check OUT_SCALE parameter. (see could be wrong XD_SCALE and OUT_SCALE). OUT parameter status reads Out_ScaleEU_0 and EU_100 settings are XD_SCALE and OUT_SCALE. UNCERTAIN and substatus incorrect. reads EngUnitRangViolation Rosemount 5408 Level Transmitter… -

Page 98

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-8: Troubleshooting the AI Block (continued) Symptom Possible causes Recommended actions Mode will not leave OOS Target mode not set Set target mode to something other than OOS. Configuration error BLOCK_ERR will show the configuration error bit set. -

Page 99: Troubleshooting Guides

(especially the Reference Height). • Run Verify Level to adjust level measurement, see Verify level. • Analyze the echo curve and check amplitude thresholds, see Amplitude thresholds. • Restore default settings and Time reconfigure the device. Rosemount 5408 Level Transmitter…

-

Page 100

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-11: Incorrect Level Readings (continued) Symptom Possible causes Recommended actions Level is stuck in measuring range. Incorrect alignment of the • Verify the transmitter head is correctly transmitter. aligned, see Align transmitter head. -

Page 101

Analyze the echo curve and check tank with the amplitude amplitude thresholds, see Amplitude threshold set too low. thresholds. The product surface is close If possible, remove the disturbing object. to a suppressed false echo. Time Rosemount 5408 Level Transmitter… -

Page 102

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Table 7-11: Incorrect Level Readings (continued) Symptom Possible causes Recommended actions Measured level lags during rapid level Damping value too high. If there is a problem with lag during rapid changes. level changes, consider decreasing the Damping value, see Damping value. -

Page 103

Empty Tank Detection Area, see Empty tank handling. • Verify the Bottom echo visible when tank is empty parameter is disabled, Enable bottom echo visible when tank is empty. Time = actual level = reported level Rosemount 5408 Level Transmitter… -

Page 104

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 ™ 7.4.2 Troubleshooting the F Fieldbus output OUNDATION Table 7-12: Troubleshooting the F Fieldbus Output OUNDATION Symptom Possible causes Recommended actions Transmitter does not show up on No power to transmitter • Ensure the transmitter is segment connected to the segment. -

Page 105: Service And Troubleshooting Tools

Service and troubleshooting tools This section briefly describes tools and functions in the Rosemount Radar Master Plus, AMS Device Manager, and handheld communicator, which may be useful for service and troubleshooting of the Rosemount 5408 Level Transmitter. 7.5.1 Using the echo curve The Rosemount Radar Master Plus software includes functions for viewing and recording single instances or movies of the echo curve.

-

Page 106

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Figure 7-1: Echo Curve Measurement problems can be understood by studying the position and amplitude of the different peaks. Additionally, the recorded echo curves give insight into unexpected and intermittent measurement behaviors, for instance, at the time of the triggered alert. Read the echo curve To read the echo curve in Rosemount Radar Master Plus: Procedure… -

Page 107

You can zoom in to a specific area of the echo curve. Procedure • To zoom in, drag a rectangle around the area you want to magnify. • To zoom out, in the upper right corner of the echo curve, select Reset Zoom. Rosemount 5408 Level Transmitter… -

Page 108

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 View level trends and historical echo curves Procedure • To go to a desired point in the displayed part of the timeline, drag the slider, or click anywhere in the timeline. • To move the timeline forward or backward, click the left or right arrow, or drag anywhere in the timeline. -

Page 109

To set the resolution of the level trend timeline: Procedure 1. Under Service Tools, select Echo Curve. 2. Select Options. 3. In the Timeline Resolution list, select the desired length (in hours) of the timeline. 4. Select Save. 5. Select Back. Rosemount 5408 Level Transmitter… -

Page 110

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 7.5.2 Managing disturbance echoes There are two general methods for managing disturbance echoes: • Set amplitude thresholds to filter out weak disturbance echoes and noise. • Use the suppress false echoes function to manage strong disturbance echoes. Amplitude thresholds The amplitude thresholds are used to filter out noise and disturbing echoes from the product surface echo. -

Page 111

A. Amplitude threshold point Set the endpoint of a threshold segment Procedure 1. In the echo curve, drag the endpoint up or down, or type the desired value (Figure 7-5). 2. Select Save. Figure 7-5: Endpoint A. Endpoint Rosemount 5408 Level Transmitter… -

Page 112

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Add or delete an amplitude threshold point Procedure 1. In the echo curve, select the desired amplitude threshold point, and select Split threshold or Merge with threshold below. 2. Click again on one of the amplitude threshold points and select Save. Suppressing false echoes Stationary objects with horizontal surfaces may generate strong false echoes. -

Page 113

2. In the echo curve, click at the unknown echo peak, and then select Suppress. Figure 7-7: Add False Echo Suppression Delete a false echo suppression Procedure 1. In Rosemount Radar Master Plus, under Service Tools, select Echo Curve. Rosemount 5408 Level Transmitter… -

Page 114

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 2. In the echo curve, click at the left end of the false echo suppression, and then select Delete. Figure 7-8: Delete False Echo Suppression Suppress a false echo manually The false echo may also be suppressed manually if the position of the false echo is known. Procedure 1. -

Page 115

5. Optional: Select the Create and save report (.pdf) check box. 6. Select Save. 7.5.4 Download configuration from file to device Procedure 1. In Rosemount Radar Master Plus, under Service Tools, select Maintenance → Backup . Rosemount 5408 Level Transmitter… -

Page 116

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 2. Select Restore Configuration. 3. Browse to the backup file and select Open. 7.5.5 Restore to default settings Restore to default settings using Rosemount Radar Master Plus This function restores the transmitter to default settings (user configuration is overwritten). -

Page 117

Procedure 1. Under Configure, select Level Setup → Advanced. 2. Under More Advanced Options, select Expert Options. 3. Select the Input Registers tab. 4. Under Show registers by, do one of the following: Rosemount 5408 Level Transmitter… -

Page 118

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 • Select Block, and then in the list, select the desired register group. • Select Number, and then type the desired register number and the number of registers. 5. Select Refresh. View input registers using AMS Device Manager and handheld communicator Measured data is continuously stored in the input registers. -

Page 119: Application Challenges

Select Write Holding Register and follow the on-screen instructions. Application challenges 7.6.1 Handling disturbances at top of tank There are two general methods for managing disturbance echoes at the top of the tank: • Set amplitude threshold section • Extend the Upper Null Zone Rosemount 5408 Level Transmitter…

-

Page 120

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Set amplitude threshold section If necessary, a customized amplitude threshold section can be used to block out disturbing echoes (e.g. from the tank nozzle or bypass well inlet). Refer to Amplitude thresholds for general guidelines. -

Page 121

Under Configure, select Level Setup → Antenna. b) Under Advanced, type desired Upper Null Zone, and then select Save. Figure 7-10: Upper Null Zone A. Upper Null Zone B. Disturbance echo C. Amplitude threshold D. Product surface echo Rosemount 5408 Level Transmitter… -

Page 122

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 7.6.2 Tracking of weak surface echoes close to tank bottom Use tank bottom projection The Tank Bottom Projection function can be used to enhance measurement performance in the tank bottom region. If the product surface echo is weak in the tank bottom region and the bottom echo is strong (typical for flat tank bottoms), the transmitter may lock on the bottom echo and report a false level measurement (empty tank). -

Page 123

F. Echo peak from tank bottom (at the electrical distance when product in the tank) Prerequisites Note Only enable this parameter if a bottom echo is visible when tank is empty. To verify this, use the echo curve function. Rosemount 5408 Level Transmitter… -

Page 124

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Procedure 1. In Rosemount Radar Master Plus, under Configure, select Level Setup → Advanced. 2. Under More Advanced Options, select Empty Tank Handling. 3. In the Empty Tank Handling list, select User Defined. 4. -

Page 125

A double bounce echo occurs when a radar signal bounces back and forth between the product surface and tank roof (or other object within the tank) before it is detected by the transmitter. Normally, these signals have a low amplitude and are ignored by the transmitter. Rosemount 5408 Level Transmitter… -

Page 126

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 Figure 7-14: Double Bounce Echoes A. Distance to surface B. Distance to first double bounce C. Actual level D. Virtual level (first double bounce) E. Signal amplitude F. Distance Prerequisites Note The Double Bounce Handling function should only be used if the problem of double bounces cannot be solved by changing the mounting position. -

Page 127: Replace The Transmitter Head

1. Disconnect the power supply. 2. If applicable, remove the external ground cable from the transmitter head. 3. Turn the jam screw clockwise until it is completely threaded into the housing. H2.5 mm 4. Remove the cover. Rosemount 5408 Level Transmitter…

-

Page 128

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 5. Remove all electrical leads and disconnect conduit. 6. Loosen the nut that connects the transmitter head to the process seal. 60 mm 7. Carefully lift the transmitter head. Do not attempt to loosen it by rotating the transmitter head. If it is stuck, then it may need to be replaced with a new process connection and transmitter head, by following all plant safety rules and procedures. -

Page 129: Cleaning Or Replacing The Ptfe Sealing

Remove from service Be aware of the following: • Follow all plant safety rules and procedures. • In Explosion Proof/Flameproof and Non-Incendive/Type n installations, do not remove the transmitter covers when power is applied to the unit. Rosemount 5408 Level Transmitter…

-

Page 130

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 • Do not remove the process connection while in operation. Removing while in operation may cause process gas leaks. Cleaning To avoid electrostatic charges, use only a damp cloth to clean the PTFE surfaces. Clean the PTFE sealing with care. -

Page 131

3. Gently insert the PTFE sealing until it stops, and then firmly push it all the way in. ® 7.8.2 Tri-Clamp version Disassembly procedures Procedure 1. Insert a wide flathead screwdriver into the groove at the base of the PTFE sealing. Rosemount 5408 Level Transmitter… -

Page 132

Service and troubleshooting Reference Manual June 2019 00809-0300-4408 2. Gently wiggle the screwdriver back and forth. Note Be careful not to scratch or depress the PTFE surfaces (facing the process). 3. Repeat Step 1-Step 2 at different positions until the PTFE sealing is loose. 4. -

Page 133: Service Support

2. Verify the O-ring on the PTFE sealing is in place. 3. Gently insert the PTFE sealing until it stops, and then firmly push it all the way in. Service support To expedite the return process outside of the United States, contact the nearest Emerson representative. Rosemount 5408 Level Transmitter…

-

Page 134

Reference Manual June 2019 00809-0300-4408 Within the United States, call the Emerson Instrument and Valve Response Center using the 1-800-654-RSMT (7768) toll-free number. This center, available 24 hours a day, will assist you with any needed information or materials. The center will ask for product model and serial numbers, and will provide a Return Material Authorization (RMA) number. -

Page 135: Appendix A Specifications And Reference Data

Refers to inaccuracy according to IEC 60770-1 when excluding installation dependent offset. See the IEC 60770-1 standard for a definition of radar specific performance parameters and if applicable corresponding test procedures. Ambient temperature effect specification valid over temperature range -40 °F to 176 °F (-40 °C to 80 °C). Rosemount 5408 Level Transmitter…

-

Page 136

June 2019 00809-0300-4408 A.1.2 Measuring range Maximum measuring range Rosemount 5408: 130 ft. (40 m) Note that a combination of adverse process conditions, such as heavy turbulence, foam, and condensation, together with products with poor reflection may affect the measuring range. -

Page 137

In challenging applications where the dynamic of the transmitter sensitivity is utilized by multiple factors such as small aperture antenna, very low product dielectric constant and/or turbulent surface, the margin for additional influence due to extreme EMC may be limited. Rosemount 5408 Level Transmitter… -

Page 138: Functional Specifications

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Pressure Equipment Directive (PED) Complies with 2014/68/EU article 4.3 Built-in lightning protection EN 61326, IEC 61000-4-5, level 6kV Radio approvals • Radio Equipment Directive (2014/53/EU): ETSI EN 302 372, ETSI EN 302 729 and EN 62479 •…

-

Page 139

Product Data Sheet for more information. Configuration tools • Rosemount Radar Master Plus for Rosemount 5408 Series (accessible through any Field ™ Device Integration (FDI) based tool, e.g Instrument Inspector Application • Device Descriptor (DD) based systems, e.g. AMS Device Manager, 475 Field ™… -

Page 140: Cable Selection

Specifications and reference data Reference Manual June 2019 00809-0300-4408 • Volume: ft , in. , yd , US gal, imperial gal, barrel (bbl), m • Temperature: °F, °C • Signal strength: mV Output variables Table A-2: Output Variables Variable Digital output LCD display ✓…

-

Page 141

Tools and logging in Rosemount Radar Master Plus • Echo curve • Measurement and alert log Rosemount Radar Master Plus, embedded in Instrument Inspector, enables easy and powerful troubleshooting with the echo curve tool as well as the measurement and alert log. Rosemount 5408 Level Transmitter… -

Page 142

Specifications and reference data Reference Manual June 2019 00809-0300-4408 The measurement and alert log holds records of the last seven days of level readings and echo curve profiles, as well as the 50 last alert events. The logs can be transferred from the transmitter’s internal memory to a local computer and be presented in a graphical time line, enabling analysis of historical behaviors. -

Page 143

(-30) (-15) (-1) (-60) (-25) (170) (200) (220) (250) A. Pressure psig (bar) B. Temperature °F (°C) C. Code CBF (FVMQ) ® D. Code CBV (Viton E. Code CBM (FKM) ® F. Code CBK (Kalrez 6375) Rosemount 5408 Level Transmitter… -

Page 144

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Figure A-5: Process Seal Antenna 363 (25) 232 (16) -7 (-0.5) (200) (-60) (-25) A. Pressure psig (bar) B. Temperature °F (°C) C. Tri-Clamp Figure A-6: Parabolic Antenna 43 (3) -7 (-0.5) (200) (-55) A. -

Page 145

1.4404 according to EN 1092-1 material group 13E0 • 316 SST according to JIS B2220 material group No. 2.2 (10) • 316L SST according to JIS B2220 material group No. 2.3 (for protective plate design) (10) Flange rating according to backing flange. Rosemount 5408 Level Transmitter… -

Page 146

Specifications and reference data Reference Manual June 2019 00809-0300-4408 A.2.8 Conditions used for flange strength calculations Table A-4: 316/316L SST (EN 1.4404) Flanges Item ASME EN, JIS ® Bolting material SA193 B8M CL.2, SA193 B7 , or SA320 EN 1515-1/2, ISO 3506 A4-70, or Bumax Gasket Soft (1a) with min. -

Page 147

An air purge connection is also available for cone antennas with flanged connection by selecting option code PC1. This option consists of an antenna with purge holes and a separate air purge ring (see Figure A-9). Rosemount 5408 Level Transmitter… -

Page 148: Physical Specifications

Emerson is not in a position to evaluate or guarantee the compatibility of the process fluid or other process parameters with the product, options, configuration or materials of construction selected.

-

Page 149

All PTFE wetted parts ideal for use in corrosive and hygienic applications (11) Fully functional transmitter with sensor module, housing, terminal block, LCD display, and covers (12) The transmitter meets IP 68 at 9.8 ft. (3 m) for 30 minutes. Rosemount 5408 Level Transmitter… -

Page 150

This declaration is applicable to Tri-Clamp connections. Emerson certifies no process wetted components used in hygienic seal products contain substances of animal origin. Materials used in the production or processing of wetted components for hygienic seals meet the requirements stated in EMA/410/01 Rev. 3 and ISO 22442-1:2015. -

Page 151: Ordering Information

Ordering Information A.4.1 Rosemount 5408 Level Transmitter Table A-8: Rosemount 5408 Level Transmitter Ordering Information The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to additional delivery lead time.

-

Page 152

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Table A-8: Rosemount 5408 Level Transmitter Ordering Information (continued) ★ Canadian Intrinsically Safe; Nonincendive ★ Canadian FISCO Intrinsic Safety ★ IECEx Flameproof, Dust Ignition-proof ★ IECEx Intrinsic Safety ★ IECEx Type n ★… -

Page 153

Reference Manual Specifications and reference data 00809-0300-4408 June 2019 Table A-8: Rosemount 5408 Level Transmitter Ordering Information (continued) ASME flanges ★ ASME B16.5 Class 150 ★ ASME B16.5 Class 300 ★ ASME B16.5 Class 600 EN flanges Note ★ EN1092-1 PN6 ★… -

Page 154

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Table A-8: Rosemount 5408 Level Transmitter Ordering Information (continued) (7)(8) Purging connection (see Figure A-9) ★ Purging Connector (Purge Ring) Display ★ LCD Display Diagnostic functionality (see Smart Diagnostics Suite) ★… -

Page 155

Reference Manual Specifications and reference data 00809-0300-4408 June 2019 Table A-8: Rosemount 5408 Level Transmitter Ordering Information (continued) ★ WPQR/WPQ/WPS (10) Dye penetration test certificate ★ Certificate of Liquid Penetrant Inspection Positive material identification certificate ★ Positive Material Identification Certificate of Conformance… -

Page 156: Availability Of Process Connections

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Availability of process connections Table A-9: Cone Antenna — 316/316L SST/EN 1.4404 (Type vs. Size and Rating) Process Process connection rating connection Thread ASME B16.5 flanges EN1092-1 flanges JIS B2220 size flanges Class Class…

-

Page 157: Spare Parts And Accessories

W = Welded connection (process connection type code W) R = Raised Face face (process connection type code R) F = Flat Face face (process connection type code F) Spare parts and accessories Table A-13: Rosemount 5408 Series Spare Parts List — Transmitter Head Model Product Description 5408…

-

Page 158

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Table A-13: Rosemount 5408 Series Spare Parts List — Transmitter Head (continued) Performance class Standard Signal output ™ Fieldbus OUNDATION Housing material Aluminum Stainless Steel (SST) Conduit/cable threads ½-14 NPT M20 x 1.5 G½… -

Page 159

Reference Manual Specifications and reference data 00809-0300-4408 June 2019 Table A-13: Rosemount 5408 Series Spare Parts List — Transmitter Head (continued) Process connection rating None (Spare Transmitter Head) Antenna type None (Spare Transmitter Head) Antenna size None (Spare Transmitter Head) -

Page 160

Rosemount 5408 is backward compatible with the full range of Rosemount 5402 antennas manufactured after September 2013, when ordered with the appropriate adapter (option code A1). The Rosemount 5408 transmitter head can also be ordered with a Rosemount 5402 antenna, or pre-configured to an existing Rosemount 5402 antenna. -

Page 161

Reference Manual Specifications and reference data 00809-0300-4408 June 2019 Table A-14: Rosemount 5408 Series Spare Parts List — Antenna (continued) Ring Type Joint (RTJ) Flange Process connection size (see Table A-9, Table A-10, Table A-11, and Table A-12) Available antenna types 1½-in. -

Page 162

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Table A-14: Rosemount 5408 Series Spare Parts List — Antenna (continued) Cone Antenna (PEEK seal, FKM) -15 to 754 psig (-1 to 52 bar) -13 to 428 °F (-25 to 220 °C) -

Page 163

Reference Manual Specifications and reference data 00809-0300-4408 June 2019 Table A-14: Rosemount 5408 Series Spare Parts List — Antenna (continued) Welder Performance Qualification (WPQ) Welding Procedure Specification (WPS) WPQR/WPQ/WPS Dye penetration test certificate Certificate of Liquid Penetrant Inspection Positive material identification certificate… -

Page 164: Dimensional Drawings

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Dimensional drawings Figure A-10: Cone Antenna with Flanged Process Connection 5.16 (131) 4.21 4.51 (107) (114.5) 4.21 (106.9) 8.27 (210) 10.83 11.02 (275) (280) 0.39 (10) A. See Table A-15 for dimensions. B.

-

Page 165

1.85 in. (47 mm) 5.39 in. (137 mm) 3-in. (DN80) 6.02 in. (153 mm) 2.64 in. (67 mm) 6.77 in. (172 mm) 4-in. (DN100) 6.93 in. (176 mm) 3.62 in. (92 mm) 7.80 in. (198 mm) Rosemount 5408 Level Transmitter… -

Page 166

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Figure A-12: Extended Cone Antenna 23.6 (600) 47.2 (1200) A. Option code S1 B. Option code S2 Dimensions are in inches (millimeters). Reference Manual… -

Page 167

B. ½-14 NPT, M20 x 1.5, or G½; optional adapters: eurofast and minifast C. s60 D. 3-, 4-in. process seal style ® E. 2-in. Tri-Clamp F. 3-in. Tri-Clamp G. 4-in. Tri-Clamp Dimensions are in inches (millimeters). Rosemount 5408 Level Transmitter… -

Page 168

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Figure A-14: Parabolic Antenna 5.16 (131) 4.21 4.51 (107) (114.5) 4.21 (106.9) 8.27 (210) 11.34 (288) 2.46 (62.4) 7.40 (188) 10.35 10.35 (263) (263) 1.14 (29) 1.14 (29) Ø 3.90 (99) 3.43 3.43 (87) (87) -

Page 169

(57) A. Pipe mounting (vertical pipe) B. Pipe diameter, max 2.52 in. (64 mm) C. Pipe mounting (horizontal pipe) D. Wall mounting E. Hole pattern for wall mounting F. NPT 1½-in. Dimensions are in inches (millimeters). Rosemount 5408 Level Transmitter… -

Page 170

Specifications and reference data Reference Manual June 2019 00809-0300-4408 A.7.1 Standard flanges Figure A-16: Cone Antenna Flange Connection A. Forged one-piece B. Welded construction C. Protective plate design D. Weld E. Backing flange F. Protective plate Table A-16: Standard Flanges for Cone Antenna Standard Face type Face surface finish, R… -

Page 171

Table A-18: Standard Flanges for Parabolic Antenna Standard Face type Face surface finish ASME B16.5 Raised face 125-250 µin EN 1092-1 Type A flat face 3.2-12.5 µm JIS B2220 Raised face 3.2-12.5 µm Face gasket surface is serrated per mating standard. Rosemount 5408 Level Transmitter… -

Page 172

Specifications and reference data Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 173: Appendix B Product Certifications

5408 and 5408:SIS Product Certifications document. The most recent revision of the EU Declaration of Conformity can be found at Emerson.com/Rosemount. Ordinary location certification As standard, the transmitter has been examined and tested to determine that the design meets the basic electrical, mechanical, and fire protection requirements by a nationally recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and Health Administration (OSHA).

-

Page 174

Product Certifications Reference Manual June 2019 00809-0300-4408 and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:… -

Page 175: Radio Equipment Directive (Red) 2014/53/Eu

B.8.1 E5 Explosionproof (XP), Dust-Ignitionproof (DIP) Certificate FM-US FM16US0010X Standards FM Class 3600 – 2018; FM Class 3615 – 2018; FM Class 3810 – 2005; ANSI/ISA 60079-0 – 2013; ANSI/UL 60079-1 – 2015; ANSI/UL 60079-26 – Rosemount 5408 Level Transmitter…

-

Page 176

Product Certifications Reference Manual June 2019 00809-0300-4408 ® 2017; ANSI/ISA 60079-31 – 2015; ANSI/NEMA 250 – 1991; ANSI/IEC 60529 – 2014, ANSI/ISA 12.27.01:2011 Markings XP CL I, DIV 1, GRPS A, B, C, D T6…T2 DIP CLII/III, DIV 1, GRPS E, F, G; T6…T3 CL I Zone 0/1 AEx db IIC T6…T2 Ga/Gb Zone 21 AEx tb IIIC T85 °C…T250 °C Db (14) -

Page 177

I5 Intrinsic Safety (IS), Non-Incendive (NI) Certificate FM-US FM16US0010X Standards FM Class 3600 – 2018; FM Class 3610 – 2018; FM Class 3611 – 2018; FM Class 3810 – 2005; ANSI/ISA 60079-0 – 2013; ANSI/UL 60079-11 – 2014; Rosemount 5408 Level Transmitter… -

Page 178

Product Certifications Reference Manual June 2019 00809-0300-4408 ® ANSI/UL 60079-26 – 2017; ANSI/NEMA 250 – 1991; ANSI/IEC 60529 – 2014; ANSI/ISA 12.27.01:2011 Markings IS CL I, ll, lll DIV 1, GRPS A-G T4…T2 NI CL I, DIV 2, GRPS A-D T4…T2 S CL Il, lll DIV 2, GRPS E-G T4…T3 CL l Zone 0 AEx ia IIC T4…T2 Ga CL l Zone 0/1 AEx ib IIC T4…T2 Ga/Gb… -

Page 179

250 – 1991; ANSI/IEC 60529 – 2014; ANSI/ISA 12.27.01:2011 Markings IS CL I, ll, lll DIV 1, GRPS A-G T4…T2 NI CL I, DIV 2, GRPS A-D T4…T2 S CL Il, lll DIV 2, GRPS E-G T4…T3 Rosemount 5408 Level Transmitter… -

Page 180

Product Certifications Reference Manual June 2019 00809-0300-4408 CL l Zone 0 AEx ia IIC T4…T2 Ga CL l Zone 0/1 AEx ib IIC T4…T2 Ga/Gb Zone 20 AEx ia IIIC T85°C…T250°C Da -55 °C ≤ Ta ≤ +70°C When installed per Control Drawing D7000002-885 SINGLE SEAL Safety parameter FISCO… -

Page 181: Canada

No. 60079-1:2016 Ed. 3, C22.2 No. 60079-26:2016; CAN/CSA-C22.2 No. 60079-31:2015, C22.2. 60529:2016, ANSI/ISA 12.27.01:2011 Markings XP CL I, DIV 1, GRPS A-D T6…T2 DIP CLII/III, DIV 1, GRPS E-G; T6…T3 Ex db IIC T6…T3 Gb Ex tb IIIC T85°C…T250°C Db Rosemount 5408 Level Transmitter…

-

Page 182

Product Certifications Reference Manual June 2019 00809-0300-4408 (15) (-40 °C ≤ Ta ≤ +70 °C) ; Type 4X/IP6X SINGLE SEAL Specific Conditions of Use (X): 1. Flamepath joints are not for repair. Contact the manufacturer. 2. Plastic wire-on tag, Plastic part of Process Seal Antenna and Non-standard paint options (paint options other than Rosemount Blue) may cause risk from Electrostatic discharge. -

Page 183

-60 °C ≤ Ta ≤ 70 °C -60 °C to 80 °C B.9.2 I6 Intrinsically Safe and Non-Incendive Systems Certificate FM-C FM16CA0011X Standards C22.2 NO. 0.4-17:2017, C22.2 NO. 0.5-16:2016, C22.2 No. 25-17:2017, C22.2 No.94-M91:1991 (R:2011), C22.2 No. 213-16:2016, C22.2 No. Rosemount 5408 Level Transmitter… -

Page 184

Product Certifications Reference Manual June 2019 00809-0300-4408 61010-1:2004, CAN/CSA C22.2 No. 60079-0:2015 Ed. 3, CAN/CSAC22.2 No. 60079-11:2014 Ed. 2, CAN/CSAC22.2 No. 60079-15:2016 Ed.2, C22.2 No. 60079-26:2016, C22.2. 60529:2016, ANSI/ISA 12.27.01:2011 Markings IS CL I, ll, lll DIV 1, GRPS A-G T4…T2 NI CL I, DIV 2, GRPS A-D T4…T2 S CL Il, lll DIV 2, GRPS E-G T4…T3 Ex ia IIC T4…T2 Ga… -

Page 185

61010-11:2004, CAN/CSA C22.2 No. 60079-0:2015 Ed. 3, CAN/CSAC22.2 No. 60079-11:2014 Ed. 2, CAN/CSAC22.2 No. 60079-15:2016 Ed.2, C22.2 No. 60079-26:2016, C22.2. 60529:2016; ANSI/ISA 12.27.01:2011 Markings IS CL I, ll, lll DIV 1, GRPS A-G T4…T2 NI CL I, DIV 2, GRPS A-D T4…T2 Rosemount 5408 Level Transmitter… -

Page 186

Product Certifications Reference Manual June 2019 00809-0300-4408 S CL Il, lll DIV 2, GRPS E-G T4…T3 Ex ia IIC T4…T2 Ga Ex ib IIC T4…T2 Ga/Gb Ex ia IIIC T85°C…T250°C Da -55 °C ≤ Ta ≤ +70°C When installed per Control Drawing D7000002-885 SINGLE SEAL Safety parameter FISCO… -

Page 187: Europe

B.10 Europe B.10.1 E1 ATEX Flameproof Certificate FM15ATEX0055X Standards EN 60079-0:2012+A11:2013, EN 60079-1:2014, EN 60079-26:2015, EN 60079-31:2014, EN 60529+A1+A2:2013 Markings II 1/2G Ex db IIC T6…T2 Ga/Gb II 2D Ex tb IIIC T85°C… T250°C Db, IP6X Rosemount 5408 Level Transmitter…

-

Page 188

Product Certifications Reference Manual June 2019 00809-0300-4408 -60 °C ≤ Ta ≤ +70 °C Specific Conditions of Use (X): 1. Flamepath joints are not for repair. Contact the manufacturer. 2. Plastic wire-on tag, Plastic part of Process Seal Antenna and Non-standard paint options (paint options other than Rosemount Blue) may cause risk from Electrostatic discharge. -

Page 189

-55 °C ≤ Ta ≤ 70 °C -55 °C to 195 °C -55 °C ≤ Ta ≤ 70 °C -55 °C to 130 °C Dust groups: T250°C -55 °C ≤ Ta ≤ 70 °C -55 °C to 250 °C Rosemount 5408 Level Transmitter… -

Page 190

Product Certifications Reference Manual June 2019 00809-0300-4408 Temperature class / Ambient temperature range Process temperature range Maximum surface temperature T200°C -55 °C ≤ Ta ≤ 70 °C -55 °C to 195 °C T135°C -55 °C ≤ Ta ≤ 70 °C -55 °C to 130 °C T100°C -55 °C ≤… -

Page 191

Module to be fully tightened and PTFE tape or pipe dope is required for cable entries and blanking plugs. See Instruction Manual on application requirements. 4. The applicable temperature class, ambient temperature range and process temperature range of the equipment is as follows: Rosemount 5408 Level Transmitter… -

Page 192: International

Product Certifications Reference Manual June 2019 00809-0300-4408 Temperature class Ambient temperature range Process temperature range -34 °C ≤ Ta ≤ 70 °C -34 °C to 250 °C -34 °C ≤ Ta ≤ 70 °C -34 °C to 195 °C -34 °C ≤ Ta ≤ 70 °C -34 °C to 130 °C B.11 International…

-

Page 193

4. The Transmitter can be installed in the boundary wall between EPL Ga and EPL Gb. In this configuration, the process connection is EPL Ga, while the transmitter housing is EPL Gb. Refer to Control Drawing D7000002-885. Rosemount 5408 Level Transmitter… -

Page 194

Product Certifications Reference Manual June 2019 00809-0300-4408 5. Using the box provided on the nameplate, the User shall permanently mark the type of protection chosen for the specific installation. Once the type of protection has been marked it shall not be changed. 6. -

Page 195

V ≤ 32V, I ≤ 22 mA Specific Conditions of Use (X): 1. The Model 5408 Level Transmitter will not pass the 500Vrms dielectric strength test between the circuits and the earth ground. This must be taken into account during installation. Rosemount 5408 Level Transmitter… -

Page 196: Additional Certifications

Product Certifications Reference Manual June 2019 00809-0300-4408 2. Plastic wire-on tag, Plastic part of Process Seal Antenna and Non-standard paint options (paint options other than Rosemount Blue) may cause risk from Electrostatic discharge. Avoid installation that could cause electrostatic build-up, and only clean with a damp cloth.

-

Page 197: Installation Drawings

KazInMetr No. 15466 Russia Pattern Approval Certificate VNIIMS No. SE.C.29.004.A No 70968 B.13 Installation drawings The installation guidelines presented by the System Control Drawing must be followed in order to maintain certified ratings for installed transmitters. Rosemount 5408 Level Transmitter…

-

Page 198

Product Certifications Reference Manual June 2019 00809-0300-4408 Figure B-1: D7000002-885 — System Control Drawing Reference Manual… -

Page 199

Reference Manual Product Certifications 00809-0300-4408 June 2019 Rosemount 5408 Level Transmitter… -

Page 200

Product Certifications Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 201

Reference Manual Product Certifications 00809-0300-4408 June 2019 Rosemount 5408 Level Transmitter… -

Page 202

Product Certifications Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 203

Reference Manual Product Certifications 00809-0300-4408 June 2019 Rosemount 5408 Level Transmitter… -

Page 204

Product Certifications Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 205

Reference Manual Product Certifications 00809-0300-4408 June 2019 Rosemount 5408 Level Transmitter… -

Page 206

Product Certifications Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 207: Appendix C Configuration Parameters

Menu tree ™ The menu tree structure in Figure C-1 is applicable for Rosemount Radar Master Plus. For AMS Device Manager and the handheld communicator, see Figure C-2. Figure C-1: Menu Tree for Rosemount Radar Master Plus Rosemount 5408 Level Transmitter…

-

Page 208: Device Setup

Configuration parameters Reference Manual June 2019 00809-0300-4408 Figure C-2: Menu Tree for AMS Device Manager and Handheld Communicator Device setup ™ C.2.1 Fieldbus protocol OUNDATION Variables Select the variables you want to appear on the Overview screen and to be included in the Guided Setup.

-

Page 209

Click Change to set all blocks (except resource block) into Out of Service mode or to set all At least one block in the device blocks into Auto mode. is in Out of Service mode. Rosemount 5408 Level Transmitter… -

Page 210: Write Protection

Software write protection The transmitter can be software write protected to prevent unauthorized configuration changes. Hardware write protection Contact your local Emerson representative for instructions on how to enable the hardware write protection. C.2.5 Device information Device tag Identifier of up to 32 characters for the transmitter used by host system.

-

Page 211: Level Setup

Expert users will use classic view to review all block parameters, and to perform some configuration or service tasks. Emerson does not recommend classic view to anyone who ™…

-

Page 212

Configuration parameters Reference Manual June 2019 00809-0300-4408 Figure C-3: Tank Geometry, Basic Dimensions A. Device Reference Point B. Reference Height C. Zero Level D. Vertical cylinder E. Cubical Tank F. Horizontal cylinder G. Spherical tank Reference Manual… -

Page 213

End Shape Length*/End Length** Bottom Offset Length of Tank*/Length** Device Reference Point Vertical cylinder Reference Offset Cubical cylinder Top Shape Height*/Top Height** Horizontal cylinder Width of Tank*/Width** Spherical cylinder AMS Device Manager and handheld communicator Rosemount Radar Master Plus Rosemount 5408 Level Transmitter… -

Page 214: Tank Shape

Configuration parameters Reference Manual June 2019 00809-0300-4408 Mounting type Select option best describing how transmitter is mounted on the tank. There are four options to choose from: Nozzle, Still pipe, Chamber, and Bracket. The Bracket option should be used for measurements in open air installations such as sumps or ponds, or when measuring through a plastic tank roof.

-

Page 215

D. Flat, inclined (for vertical cylinder) E. Flat, inclined (for cubical tank) Tank end shape For a horizontal tank, form of the tank ends. Same shape is assumed at both ends. Figure C-8: Tank End Shape A. Dome B. Flat Rosemount 5408 Level Transmitter… -

Page 216

Configuration parameters Reference Manual June 2019 00809-0300-4408 Reference height Distance between the Tank Reference Point (typically same as Device Reference Point) and zero level. Ensure the Reference Height is set as accurate as possible. The transmitter measures the distance to the product surface and subtracts this value from the Reference Height to determine the level. -

Page 217

If the Zero Level is not located at the tank bottom, then enter a Bottom Offset. It is needed for the transmitter to know the position of the tank bottom echo and for correct volume calculations. Rosemount 5408 Level Transmitter… -

Page 218

Configuration parameters Reference Manual June 2019 00809-0300-4408 Figure C-13: Bottom Offset A. Tank Reference Point B. Reference Offset C. Device Reference Point D. Reference Height E. Zero Level F. Bottom Offset Height of tank The vertical distance between tank bottom and tank roof. For a horizontal cylinder or spherical tank, this is the diameter of the tank. -

Page 219

Product dielectric range Select the range of the dielectric constant for the product in the tank. If the range is not known, or if the product in the tank is changed on a regular basis, then select Default. Rosemount 5408 Level Transmitter… -

Page 220

Configuration parameters Reference Manual June 2019 00809-0300-4408 C.3.3 Volume Select if the volume measurement should be calculated from the configured tank dimensions or a strapping table. Strapping tables can be used for irregularly shaped tanks, to eliminate errors due to bulging when product is added to a tank, or if a pre-defined tank type does not provide sufficient accuracy. -

Page 221

These antenna parameters are applicable to customized antennas only. The settings are typically provided by factory. When a Rosemount 5408 transmitter head is mounted on a Rosemount 5402 antenna, then select the Legacy (Rosemount 5402) antenna type and specify the antenna… -

Page 222

Configuration parameters Reference Manual June 2019 00809-0300-4408 Table C-5: Legacy (Rosemount 5402) Antenna Parameters, Free Propagation Antenna type Tank connection length Antenna Nearzone Nearzone range Upper null zone gain threshold (mV) 2-in. cone, 316L SST (EN 0.509 0.155 2.45 4500 5.09 1.55 0.541… -

Page 223

A positive Calibration Offset value will increase the presented level value. It is recommended to run the Verify Level tool to match the product level reported by the transmitter to a reference measurement. Related information Verify level Rosemount 5408 Level Transmitter… -

Page 224

Configuration parameters Reference Manual June 2019 00809-0300-4408 User defined variable setup This section applies only to transmitters ordered with Smart Diagnostics Suite (option code D01). Name Name of the user defined variable. It is recommended to enter a short name to fit into the LCD display area. -

Page 225

(e.g. oil), the transmitter may lock on the bottom echo and report a false level measurement (empty tank). This problem can be solved by using the Tank Bottom Projection function. Rosemount 5408 Level Transmitter… -

Page 226

Configuration parameters Reference Manual June 2019 00809-0300-4408 Table C-9: Tank Bottom Projection Parameter Description Bottom product dielectric constant Enter the product dielectric constant for the product in the bottom of the tank. Maximum projection distance This defines the range where the function is active. -

Page 227

The Overfill Prevention Range defines the lower end of the range in which the function operates. The range is configurable. See Figure C-16 for default factory settings. Rosemount 5408 Level Transmitter… -

Page 228: Alert Setup

Configuration parameters Reference Manual June 2019 00809-0300-4408 Figure C-16: Overfill Prevention Range 20 in. (500 mm) A. Device Reference Point B. Overfill Prevention Range Expert options Use the expert options to view input registers, and to view and edit holding registers. Note Instructions for how to use Expert options are typically provided by factory and should only be modified if required.

-

Page 229

The Signal Quality Alert limit should be at least 1, but a better guideline is 2-3. (16) Signal strength fluctuations are common when measuring solids, so Signal Quality alerts may not be appropriate in this case. Rosemount 5408 Level Transmitter… -

Page 230

Configuration parameters Reference Manual June 2019 00809-0300-4408 Figure C-17: Signal Quality Alert A. Signal quality B. Time C. Alert ON D. Deadband E. Limit F. The Signal Quality drops below the alert limit and an alert message is triggered. G. The alert message is reset once the Signal Quality value rises above the Deadband range. Limit The Signal Quality value that will trigger the alert. -

Page 231

B. Time C. Low Alert ON D. Deadband E. Limit F. The alert is active when the level value falls below the alert limit. G. The alert turns off when the value rises above the deadband. Rosemount 5408 Level Transmitter… -

Page 232

Configuration parameters Reference Manual June 2019 00809-0300-4408 Reference Manual… -

Page 233: Foundation

Manufacturer’s model number associated with the resource — used by interface devices to locate the DD file for the resource. DEV_REV Manufacturer revision number associated with the resource — used by an interface device to locate the DD file for the resource. Rosemount 5408 Level Transmitter…

-

Page 234

Identifies the block execution methods available for this resource. CYCLE_SEL Used to select the block execution method for this resource. The Rosemount 5408 supports the following: Scheduled: Blocks are only executed based on the function block schedule. Block Execution: A block may be executed by linking to another blocks completion. -

Page 235

Active status, if the subcode has changed. ALARM_SUM The current alarm status, unacknowledged states, unreported states, and disabled states of the alarms associated with the function block. Rosemount 5408 Level Transmitter… -

Page 236

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Table D-1: Resource Block Parameters (continued) Index Parameter Description Number ACK_OPTION Selection of whether alarms associated with the function block will be automatically acknowledged. WRITE_PRI Priority of the alarm generated by clearing the write lock. WRITE_ALM This alert is generated if the write lock parameter is cleared. -

Page 237

Indicates which miscellaneous device licensing options are enabled. OUTPUT_BOARD_SN Output board serial number. For the Rosemount 5408 this is the same as Main Label Device ID which can be found on the main label that is attached to the housing. -

Page 238

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Table D-1: Resource Block Parameters (continued) Index Parameter Description Number FAILED_ENABLE Enabled FAILED_ALM alarm conditions. Corresponds bit for bit to the FAILED_ACTIVE. A bit on means that the corresponding alarm condition is enabled and will be detected. -

Page 239: Analog Input Block

Alarm detection is based on the OUT value and user specified alarm limits. Table D-3 lists the AI block parameters and their units of measure, descriptions, and index numbers. Rosemount 5408 Level Transmitter…

-

Page 240

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Figure D-2: Analog Input Function Block Schematic A. Analog Measurement B. Access Analog Measurement C. CHANNEL D. SIMULATE E. Convert F. OUT_SCALE; XD_SCALE G. FIELD_VAL H. L_TYPE I. IO_OPTS J. PV_FTIME K. -

Page 241

If percentage value of transducer input fails below this, PV = 0. PV_FTIME Seconds The time constant of the first-order PV filter. It is the time required for a 63 percent change in the IN value. Rosemount 5408 Level Transmitter… -

Page 242

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Table D-3: Definitions of Analog Input Function Block System Parameters (continued) Index Number Parameter Units Description FIELD_VAL Percent The value and status from the transducer block or from the simulated input when simulation is enabled. UPDATE_EVT None This alert is generated by any change to the static data. -

Page 243

A minimum of four parameters are required to configure the AI block. The parameters are described below with example configurations shown at the end of this section. CHANNEL Select the channel that corresponds to the desired sensor measurement: Rosemount 5408 Level Transmitter… -

Page 244

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Table D-4: AI Block Channels AI block TB channel value Process variable Level CHANNEL_LEVEL Distance CHANNEL_DISTANCE Level Rate CHANNEL_LEVEL_RATE Signal Strength CHANNEL_SIGNAL_STRENGTH Volume CHANNEL_VOLUME Signal Quality CHANNEL_SIGNAL_QUALITY Scaled Variable CHANNEL_SCALED_VARIABLE Auxiliary Percent of CHANNEL_AUX_PERC_OF_RANGE Range… -

Page 245

Meter per hour CHANNEL_SIGNAL_STRENGTH Direct CHANNEL_ELECTRONICS_TEMPERATURE Direct deg C CHANNEL_VOLUME Direct Configuration examples Level and percentage of range are to be measured using a Rosemount 5408. The maximum level of the tank is 33 ft. (10 m). Rosemount 5408 Level Transmitter… -

Page 246

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Figure D-3: Tank A. 100% B. 33 ft. (10 m) C. 0% Table D-6 lists the appropriate configuration settings for the level measurement. Table D-6: Analog Input Function Block Configuration, Level Value Parameter Configured values L_TYPE… -

Page 247

(such as diagnostics and system alerts). Alarm conditions of priority 3 to 7 are advisory alarms of increasing priority. 8-15 Alarm conditions of priority 8 to 15 are critical alarms of increasing priority. Rosemount 5408 Level Transmitter… -

Page 248: Measurement Transducer Block

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 D.2.4 Status options Status Options (STATUS_OPTS) supported by the AI block are shown below. Propagate fault If the status from the sensor is Bad, Device failure or Bad, Sensor forward failure, propagate it to OUT without generating an alarm.

-

Page 249

A directory that specifies the number, starting indices, and DD Item ID’s of the data collections in each transducer within a transducer block. LENGTH_UNITS Length Unit VELOCITY_UNITS Level Rate Unit VOLUME_UNITS Volume Unit TEMPERATURE_UNITS Temperature Unit Rosemount 5408 Level Transmitter… -

Page 250

™ Fieldbus Block Information Reference Manual OUNDATION June 2019 00809-0300-4408 Table D-9: Measurement Transducer Block Parameters (continued) Index Parameter Description Number LEVEL Distance from the zero level (tank bottom) to the product surface. DISTANCE Distance from the upper reference point to the product surface. -

Page 251