Просьба: если вы здесь увидели какие-то ошибки или неточности то просьба сообщить об этом в комментариях или написать мне. Если вы хорошо разбираетесь в робототехникe или очень хорошо знакомы с RobotStudio свяжитесь со мной

ABB роботы

Все роботы компании ABB это манипуляторы, которые используются в основном на производствах, в лабораториях или на складах. В каталоге компании [ссылка удалена мод.] можно встретить такие типы роботов как: SCARA роботы, DELTA роботы, коллабративные роботы (коботы), индустриальные манипуляторы (5-6 осевые)

Интересный факт: к ABB обращаются множество клиентов чтобы использовать роботов для покраски. ABB пришлось сделать отдельную линейку роботов.

Это было небольшое вступление, идем дальше…

ABB RobotStudio, FlexPendant, IRC5

Для программирования роботов компании ABB используется их фирменное программное обеспечение RobotStudio. Программа платная и стоит целых 1500$/год за стандартный комплект. За каждое дополнение придется доплачивать отдельно, хотя стоит сказать, что ABB иногда проводят акции или предоставляют своим клиентам специальные предложения.

Но есть и хорошая новость, — это пробный период. Пробный период доступен всего 30 дней, после чего основной функционал RobotStudio будет заблокирован. Стоить еще сказать, что переустановка RobotStudio или установка на виртуальную машину не поможет, в этом случае «программа» не даст возможности выбрать пробную версию.

Любой робот ABB это просто корпус, сервомоторы и датчики (грубо говоря) и нуждается в том, чтобы им кто-то управлял. В этом случае нас спасает контроллер компании ABB — IRC5.

В комплекте с контроллером поставляется пульт управления роботом ABB FlexPendant. Он напрямую подключается к контроллерам (например IRC5). Точно такой же пульт в виде симуляции можно использовать в RobotStudio. Программу для роботов можно писать в RobotStudio (через RAPID редактор) или через FlexPendant. В этой статье рассмотрим именно базу для FlexPendant.

Создаем робота в RobotStudio

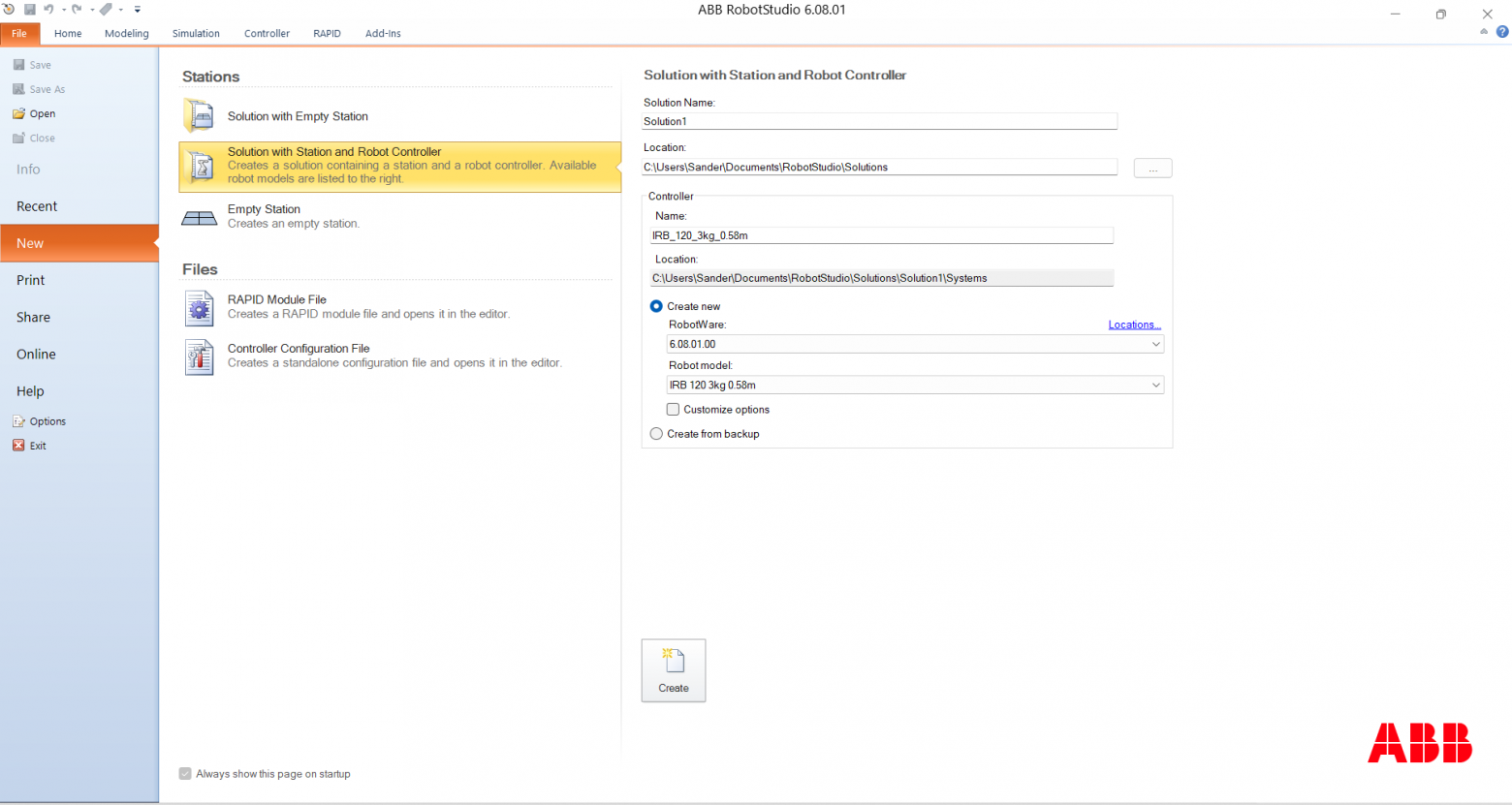

Итак, про RobotStudio поговорили, про IRC5 поговорили, о FlexPendant узнали. Теперь мы переходим к практике. Запускаем RobotStudio:

Выбираем Solution with Station and Robot Controller (создать робота, со станцией управления и контроллером). Заполняем необходимые поля, задаем имя для нашего проекта.

Обратите внимание, чтобы в Location не было слишком длинного пути до файлов, иначе RobotStudio не даст создать проект и будет показывать ошибки

Далее переходим к первым настройкам самого робота: RobotWare я выберу 6 версию (RobotWare — ОС для контроллера IRC5). В Robot model выбираем необходимого нам робота и оставляем пустым Customize options, так как дополнительные настройки нам пока не нужны.

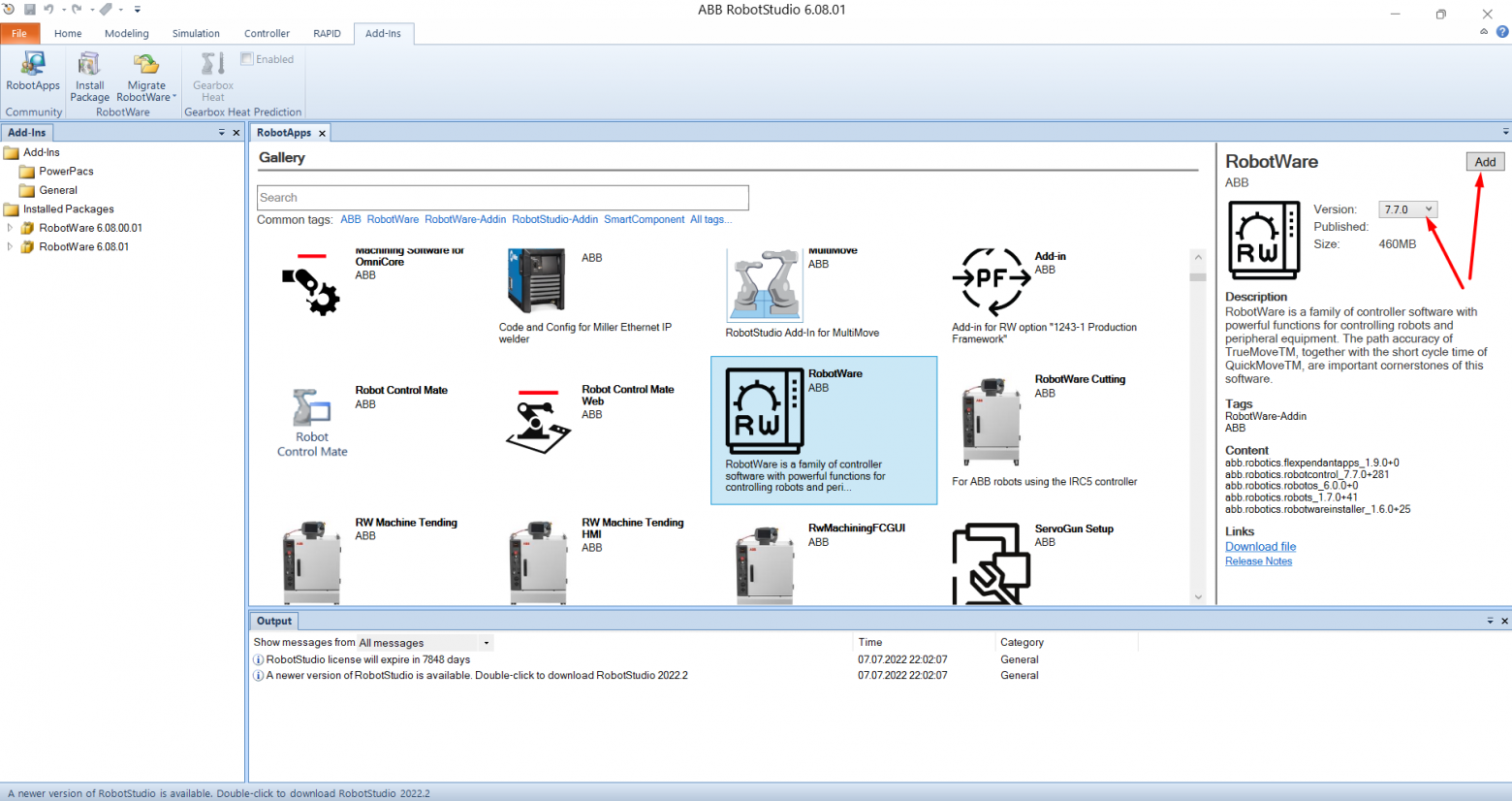

Может случиться, что нужно будет установить RobotWare необходимой версии вручную (хотя как правило в новых версиях RobotStudio он уже предустановлен). Добавить необходимую версию RobotWare можно перейдя во вкладку Add-ins и найти в галерее RobotWare, затем выбираем необходимую версию и нажимаем Add

При выборе разных версий (например 7) некоторые роботы пропадут из списка доступных. Это связанно с тем, что не все роботы поддерживают более новый RobotWare. В реальности ABB создает поддержку для новых версий, однако в RobotStudio не успевает быстро появится поддержка

После создания проекта программа может попросить нас выбрать более точную модель робота. Чтобы понять какой робот нам необходим нужно залезть в каталог роботов ABB и посмотреть на техническую документацию.

Робот создан! В данной статьи я не буду рассказывать подробно как ориентироваться в интерфейсе. Можно посмотреть это видео, где показывается как управлять роботом.

Запускаем FlexPendant и управление через пульт

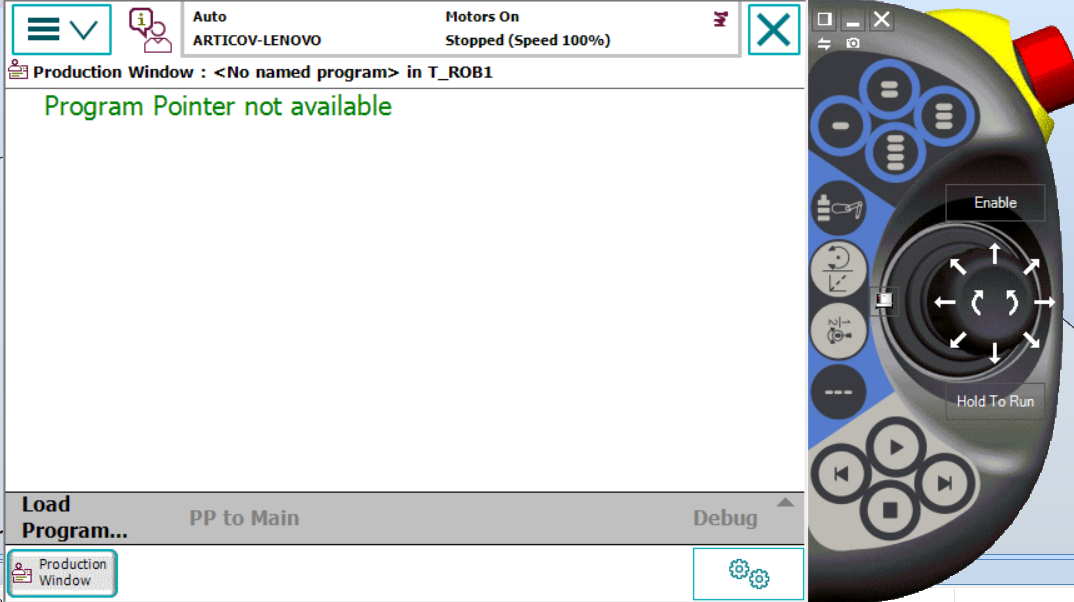

Итак. В RobotStudio мы выбираем вкладку Controller и ищем FlexPendant с изображением нашего пульта. После этого выбираем Virtual FlexPendant.

После чего перед вами в виде отдельного окна появится симуляция пульта FlexPendant, это окно независимо от RobotStudio и можно например переместить на второй монитор, чтобы на первом видеть RobotStudio.

Давайте подвигаем нашего робота. Для этого необходимо в Flexpendant открыть меню (левый верхний угол) и выбрать страницу Jogging.

Перед нами откроется страница для управления режимами, выбором степенями свободы робота и другой информации: нагрузка, рабочий объект, инструмент.

Окно Position показывает нам каждое звено и под каким углом оно в данный момент находится (0 — null позиция, она необходима для калибровки).

Окно Joystick directions показывает нам как нужно сам боковой джойстик повернуть чтобы задействовать необходимое нам звено.

Если мы сейчас попробуем подвигать нашего робота, то у нас ничего не получится. А все потому что, так как этот пульт в точности копирует настоящий нам необходимо переключиться на «ручной режим» управления. Для этого необходимо возле самого джойстика найти маленькое изображение контроллера IRC5 и нажать на него. После чего необходимо выбрать среднее положение «ключа».

Теперь необходимо включить сами сервомоторы. Для этого нажимаем на Enable и Hold To Run. Теперь попробуйте подвигать джойстиком и посмотрите как начинает себя вести робот.

Кликнув на Motion mode: Axis 1 — 3… мы можем выбрать какими степенями свободы мы хотим управлять. Кликнув на ROB_1 (это идентификатор нашего робота в RobotWare) мы можем открыть дополнительное окно настроек нашего робота. Тамже можно настраивать скорость движения, углы, возрастающую скорость и многое другое.

Выбрав самое верхнее изображение нашего робота мы увидим тот же самый Motion mode однако в добавок у нас будет возможность выбора системы координат и рабочего инструмента.

Создаем программу для ABB робота с помощью FlexPendant

Давайте в завершении создадим простую программу с 2 точками.

Что нам нужно?

-

Запустить RobotStudio ✔

-

Создать робота ✔

-

Запустить FlexPendant ✔

-

Открыть редактор программы

-

Создать программу

-

Обучить робота точкам

Точки — это наши пункты в разных системах координат для нашего робота. С помощью указаний этих пунктов и вида движения мы задаем роботу жесткий сценарий по которому он будет следовать. Например следовать дугой от точки А к точки Б, или следовать к точки А остановиться в точки Б и повернуть обратно.

Давайте перейдем к практике:

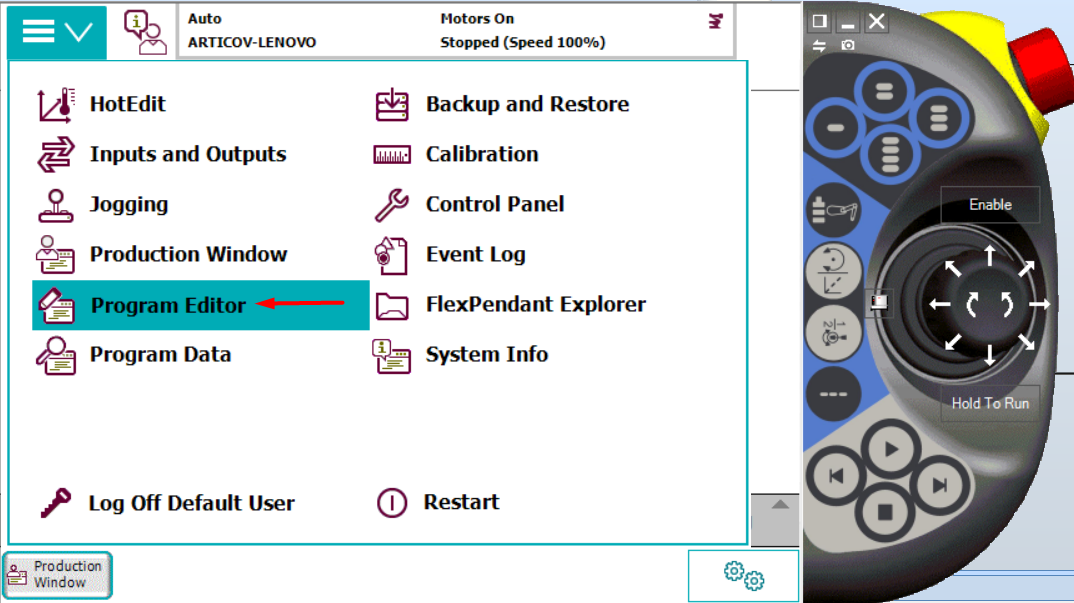

Находим в меню Program Editor. Именно там мы будем создавать нашу программу.

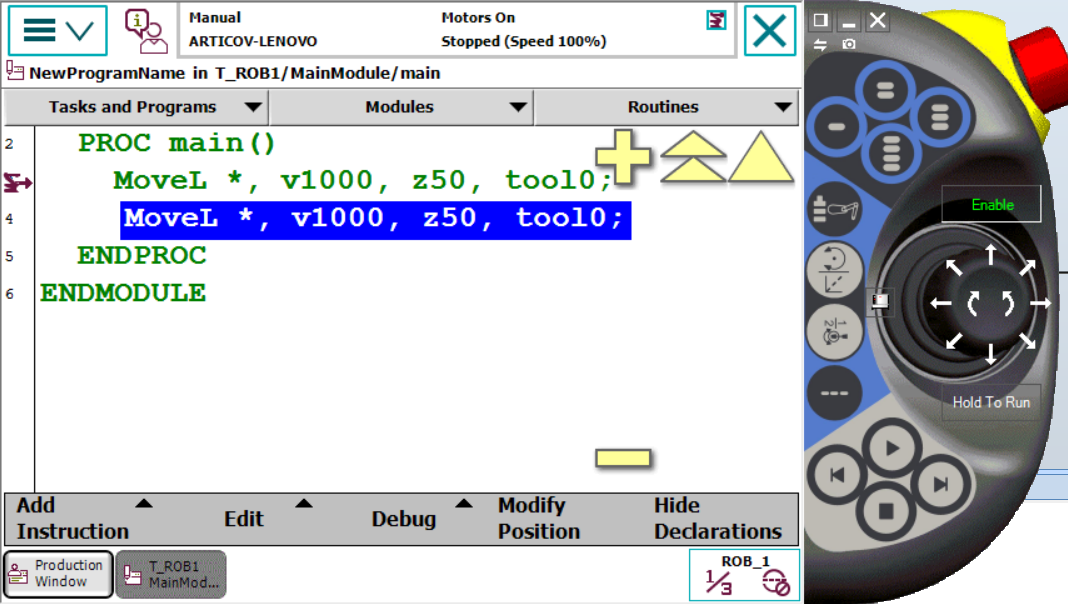

Если программы до этого не было, то пульт предложит создать новую программу с нуля. Мы соглашаемся с этим и попадаем в редактор. Если вы видите следующий код, то все сделано было правильно.

Ниже код представлен на языке программирования RAPID.

MODULE MainModule

PROC main()

<SMT>

ENDPROC

ENDMODULEВАЖНО: Чтобы начать создавать программу пульт должен быть переведен в «ручной режим» работы и при необходимости должны быть включены моторы для передвижения робота

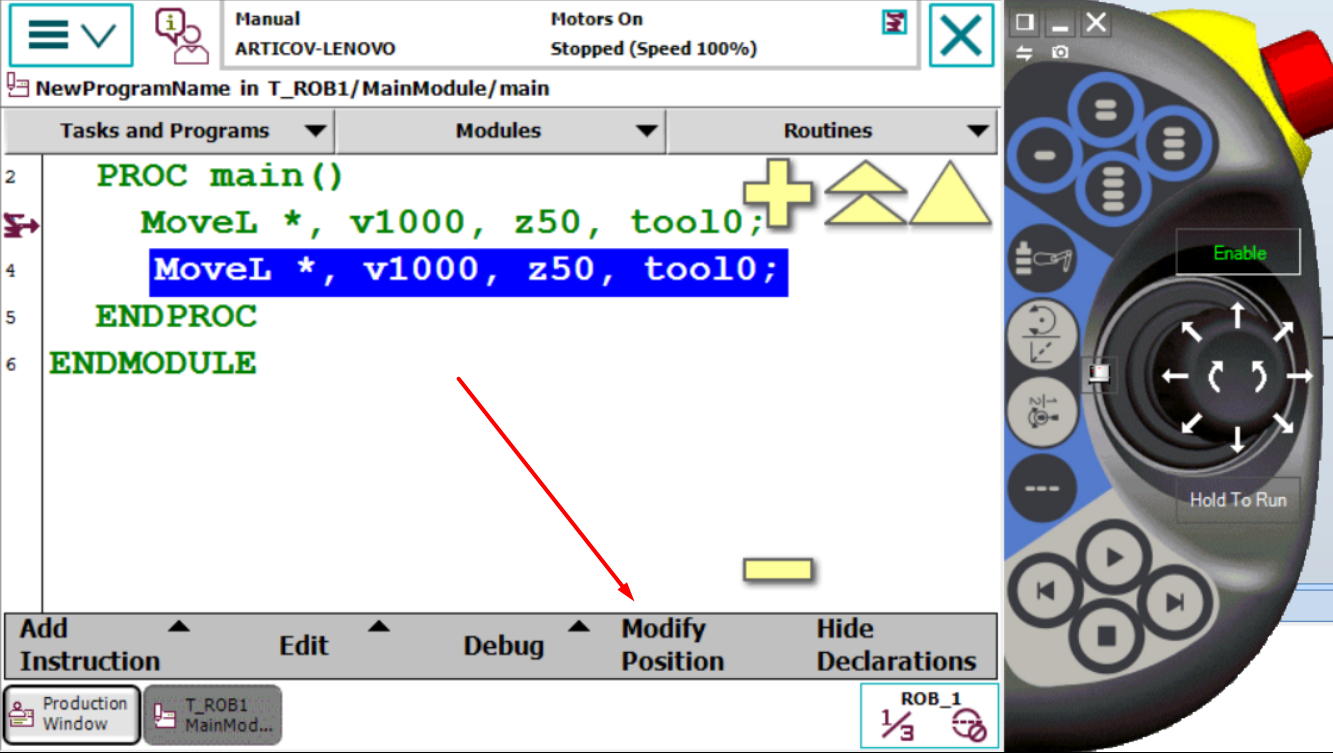

Теперь нам необходимо создать для робота первую точку. Пусть это будет его текущая позиция и назовем её «домашней». Для этого прожимаем на Add Instruction и сбоку появится окно с командами, где мы должны выбрать какую инструкцию добавить. Я добавлю MoveL. MoveL — это прямолинейное движение. Это значит, что робот к ЭТОЙ точке будет двигаться с помощью команды прямолинейного движения MoveL и никак иначе.

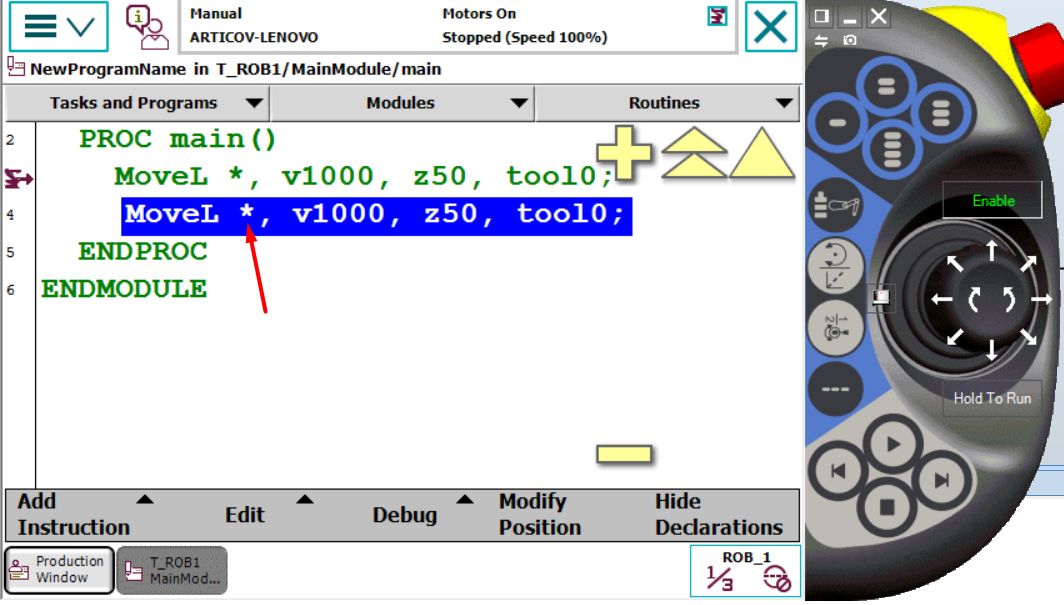

После того как создана первая точка необходимо создать еще одну. Попробуйте подвигать робота с помощью FlexPendant и задайте с помощью инструкции MoveL вторую точку.

Итак. Две точки созданы и при необходимости эти инструкции можно дополнительно настроить. Нужно кликнуть по символу звездочки и мы попадем в настройки нашей инструкции

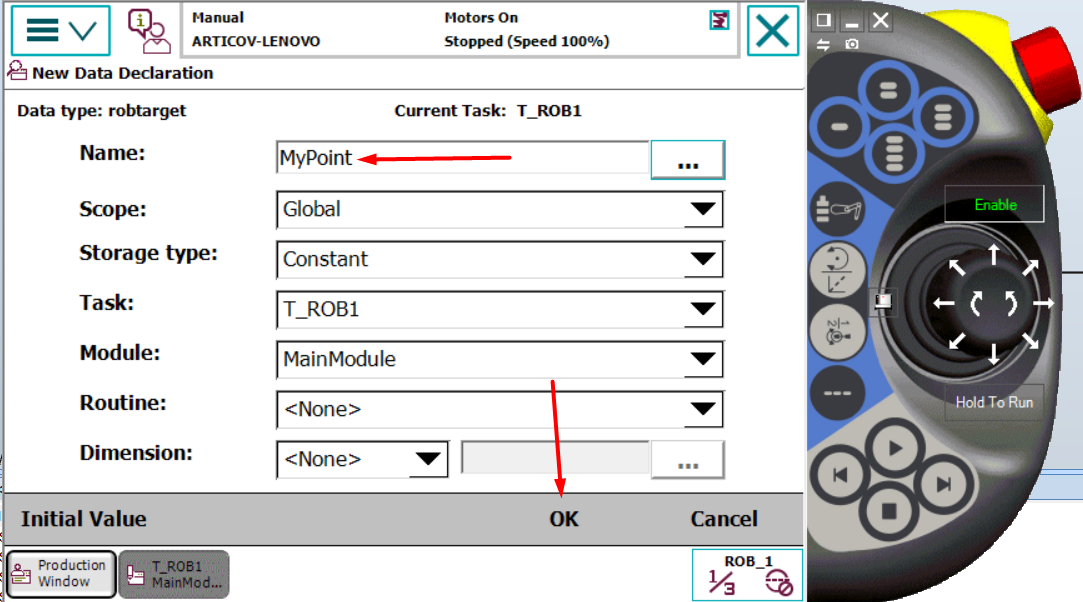

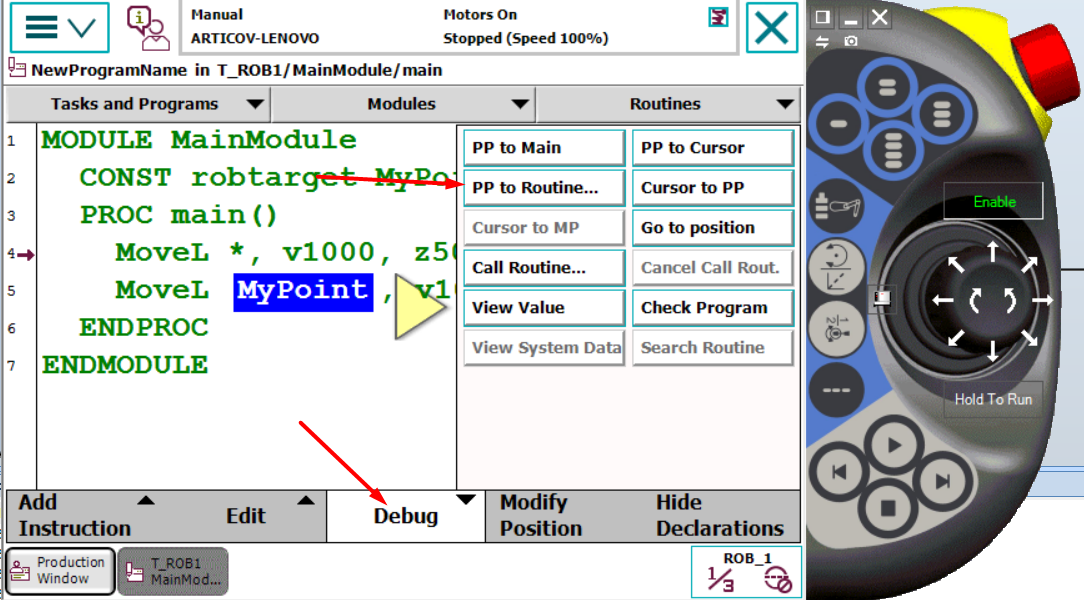

В меню настроек инструкции мы можем добавить «особое имя» для нашей точки, для этого во вкладке Data выбираем функцию new и после чего указываем имя для нашей точки

Советую всегда указывать имя для точек, ибо по дефолту пульт задает им значение Target_N или P_N (где N — номер точки) и потом очень трудно определить какая именно это точка и куда она ведет.

Обратите внимание, что имя должно быть уникальным и больше нигде не повторяться.

Помимо имени точки мы еще можем управлять такими настройками как скорость движения до точки (v1000), разрешение погрешность от точки (z50) и какой рабочий инструмент будет использоваться (tool0). Чтобы изменить эти параметры необходимо на них кликнуть и выбрать новые.

Изменение положения точки

С помощью функции Modify position мы можем изменить положение уже созданной точки. Например создав точку Target_10 мы поняли, что она должна быть на 1 сантиметр левее, то мы сначала двигаем робота левее куда нам необходимо и после чего используем Modify position

Запускаем программу в FlexPendant

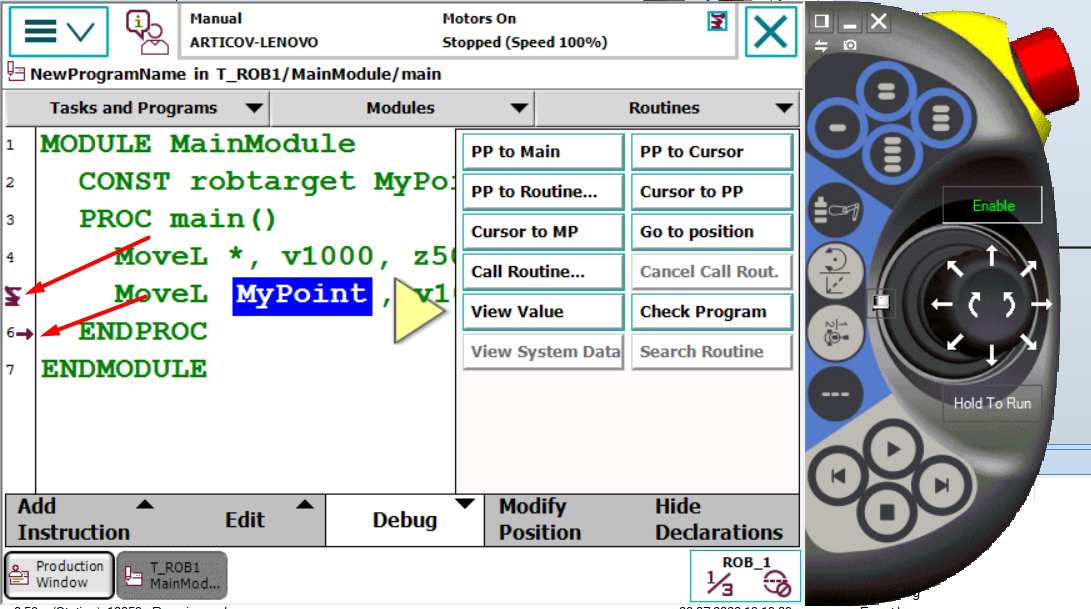

Наша простая программа создана и теперь мы хотим проверить как она работает. Для этого мы будем использовать встроенный дебагер. Нажав на кнопку Debug нам открывается меню выбора дебага. Что есть что:

-

PP to Main -робот будет выполнять программу от самого начала до самого конца. Весь MODULE

-

PP to Routine — робот будет выполнять программу только в определенной области PROC #имя

-

PP to Cursor — робот будет выполнять команду, на которую указывает стрелка возле номера строки

Остальные функции я не так часто использую, но все же расскажу о них:

Curstor to PP — переводим стрелку на нужную нам строку

Go to position — робот будет двигаться на определенную позицию (точку)

Check Programm — пульт проверит нашу программу

Call Routine — вызвать PROC

View Value — посмотреть данные (переменные, сигналы и т.д.)

Мы выбираем PP to Routine чтобы проверить как будет работать наша рутина main. После этого на пульте мы можем запустить нашу программу использую следующее управление:

Стрелка play — мы запускаем программу и она будет от начала до конца автоматически исполняться

Стрелка «перемотки» вперед — мы запускаем программу шаг за шагом (например нажав первый раз робот пойдет к точке А и будет ждать дальше разрешения на движение к точке Б)

Стрелка «перемотки» назад обратное стрелки вперед. Мы возвращаемся на шаг назад в программе.

Квадратик — кнопка STOP. Программа завершается и робот уходит в режим ожидания (Stand By)

Дебагер позволяет отслеживать на какой строчке кода находится робот и каким будет его следующим шагом

Всё! Мы научились с помощью FlexPendant и RobotStudio управлять роботами ABB (на самом деле это только базовые навыки правильного «пользования» всем этим. Здесь присутствует очень много функционала, а значит и подводных камней тоже не мало. Здесь я постарался представить представление как работать с этим)

Знаю, возможно этого материала полным полно в Интернете и на ютубе, но здесь я не видел чтобы развивали эту тему. В моей стране не сильно развита робототехника и в «нашем» русском сообществе не с кем поговорить на эту тему, поэтому было бы классно найти единомышленников здесь и узнать что-то новое для себя и поделиться чем-нибудь.

А так, надеюсь что всем вам понравилось и прошу прощения за свою грамматику! Это была моя первая статья и в будущем я хочу больше развивать тему RobotStudio и как там создавать различные решения и как обучать роботов. Жду вашего мнения и впечатлений в комментариях.

Спасибо!

Только зарегистрированные пользователи могут участвовать в опросе. Войдите, пожалуйста.

Продолжать тематику роботов ABB и RobotStudio?

Проголосовали 10 пользователей.

Воздержались 3 пользователя.

-

Page 1

ROBOTICS Operating manual IRC5 with FlexPendant… -

Page 2

Trace back information: Workspace R18-2 version a9 Checked in 2018-10-09 Skribenta version 5.3.008… -

Page 3

Operating manual IRC5 with FlexPendant RobotWare 6.08 Document ID: 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. Specifications subject to change without notice. -

Page 4

The information in this manual is subject to change without notice and should not be construed as a commitment by ABB. ABB assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damages to persons or property, fitness for a specific purpose or the like. -

Page 5: Table Of Contents

Quickset ………………….3.5.1 The Quickset menu …………….. 3.5.2 Quickset menu, Mechanical unit …………..3.5.3 Quickset menu, Increment ……………. 3.5.4 Quickset menu, Run Mode ……………. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 6

5.3.3 Handling of routines …………….5.3.4 Handling of instructions …………….5.3.5 Example: Add movement instructions …………5.3.6 About the Program and Motion Pointers …………Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 7

Switching to manual full speed mode …………Modifying positions ………………. 6.4.1 Modifying and tuning positions …………..6.4.2 Modifying positions in the Program Editor or Production Window ….Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 8

Important when performing backups! …………..Restore the system ……………….. 10 Calibrating 10.1 How to check if the robot needs calibration …………10.2 Updating revolution counters …………….Index Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 9: Overview Of This Manual

Be familiar with the concepts described in Operating manual — Getting started, IRC5 and RobotStudio. • Be trained in robot operation. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 10

Added a warning note regarding load data in the sections Before you start programming on page147, Tools on page175, Payloads on page200, Service routines on page 217. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 11

Updated the section Changing programmable keys on page 116. • Added information and code example to the section Brake check for MultiMove systems on page 234. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 12: Product Documentation

Product documentation Categories for user documentation from ABB Robotics The user documentation from ABB Robotics is divided into a number of categories. This listing is based on the type of information in the documents, regardless of whether the products are standard or optional.

-

Page 13

The operating manuals describe hands-on handling of the products. The manuals are aimed at those having first-hand operational contact with the product, that is production cell operators, programmers, and troubleshooters. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 14

This page is intentionally left blank… -

Page 15: Safety

These topics are covered in the Product Manuals supplied with the robot. Note The integrator is responsible for the safety of the final application. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 16: Applicable Standards

Terminology and general principles EN 574:1996 + A1:2008 Safety of machinery — Two-hand control devices — Functional aspects — Principles for design Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 17

Safety requirements for industrial robots and robot systems ANSI/UL 1740 Safety standard for robots and robotic equipment CAN/CSA Z 434-14 Industrial robots and robot Systems — General safety require- ments Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 18: Safety Actions

The plant designer may have placed additional emergency stop devices in convenient places. Consult your plant or cell documentation to find out where these are placed. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 19: Extinguishing Fires

Always use carbon dioxide extinguishers when extinguishing fires in electrical equipment such as the robot or the controller. Do not use water or foam. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 20: Make Sure That The Main Power Has Been Switched Off

Note Switch off all main power switches in a MultiMove system. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 21: Moving Robots Are Potentially Lethal

The hold-to-run function is used in manual mode, not in automatic mode. Make sure no personnel are present within the working range of the robot before pressing the start button. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 22: Recover From Emergency Stops

Locate and reset the device or devices that gave the emergency stop condition. Press the Motors On button to recover from the emergency stop condition. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 23: Enabling Device And Hold-To-Run Functionality

How to operate the hold-to-run function for IRC5 is described in Operating manual — IRC5 with FlexPendant. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 24: Working In A Safe Manner

A disconnected FlexPendant should be stored in such a way that it cannot be mistaken for being connected to the controller. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 25

When releasing and then pressing the three-position enabling device again, make sure to wait for the system to go to Motors Off state before pressing again. Otherwise you will receive an error message. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 26: Safety Tools

The robot’s working range can be restricted by means of mechanical stops or software functions, or by a combination of both. See your plant or cell documentation to see how your robot system is configured. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 27: About The Automatic Mode

All remedial actions must be performed by personnel with good knowledge of the entire production line, not only the malfunctioning manipulator. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 28

Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 29: About The Manual Mode

WARNING Wherever possible, the manual mode of operation shall be performed with all persons outside the safeguarded space. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 30

Creating and editing RAPID programs • Starting, stepping, and stopping program execution, for example while testing a program • Tuning programmed positions Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 31

Setting program pointer (to Main, to routine, to cursor, to service routine, etc.) The following tasks cannot be performed in the manual full speed mode: • Changing system parameter values • Editing system data Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 32: Safety Terminology

ELECTROSTATIC Warns for electrostatic hazards which could result DISCHARGE (ESD) in severe damage to the product. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 33

Designation Significance NOTE Describes important facts and conditions. Describes where to find additional information or how to do an operation in an easier way. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 34: Protective Stop And Emergency Stop

1.5.2 Protective stop and emergency stop 1.5.2 Protective stop and emergency stop Overview The protective stops and emergency stops are described in the product manual for the controller. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 35: Welcome To Irc5

This manual describes a basic robot without options. However, in a few places, the manual gives an overview of how options are used or applied. Most options are described in detail in their respective application manual. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 36: The Irc5 Controller

Product manual — IRC5 Panel Mounted Controller, IRC5 of design 14. Product manual — IRC5 Compact, IRC5 of design M2004. Product manual — IRC5 Compact, IRC5 of design 14. Application manual — MultiMove. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 37: The Flexpendant

The hot plug button option makes it possible to disconnect the FlexPendant in automatic mode and continue running without it. Main parts These are the main parts of the FlexPendant. xx1400001636 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 38

If the FlexPendant freezes during operation, press the reset button to restart the FlexPendant. The reset button resets the FlexPendant, not the system on the controller. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 39

START button. Starts program execution. Step FORWARD button. Executes one instruction forward as button is pressed. STOP button. Stops program execution. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 40

A left-hander, however, can easily rotate the display through 180 degrees and use his right hand to support the device. en0400000913 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 41

Production Window • Program Editor • Program Data • Backup and Restore • Calibration • Control Panel • Event Log Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 42

The task bar displays all open views and is used to switch between these. Quickset menu The quickset menu provides settings for jogging and program execution. This is described in section The Quickset menu on page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 43: The T10

Prerequisites The RobotWare option 976-1 T10 Support is necessary to run the T10 with the IRC5 robot controller. Overview xx1400002068 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 44

2 Welcome to IRC5 2.4 The T10 Continued Display Joystick Emergency stop button Three-position enabling device Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 45: Robotstudio Online

Manage is a tool to manage IRC5 controllers on a network. xx1400002047 Calibrate is a tool for calibration and defini- tion of frames with IRC5 controllers. xx1400002049 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 46

YuMi, IRB 14000, from ABB. It will help the users to get a fast introduction to robot programming using lead-thru and graphical programming. xx1500000832 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 47: Robotstudio

2.6 RobotStudio Overview of RobotStudio RobotStudio is an engineering tool for the configuration and programming of ABB robots, both real robots on the shop floor and virtual robots in a PC. To achieve true offline programming, RobotStudio utilizes ABB VirtualRobot™ Technology.

-

Page 48: When To Use Different Jogging Devices

Apps. Transfer files between the controller and net- RobotStudio, FlexPendant or the RobotStu- work drives dio Online Apps. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 49

Install a system on a controller from The FlexPendant. a USB memory Calibration To… Use… Calibrate base frame etc. The FlexPendant or the RobotStudio Online Apps. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 50

Document number FlexPendant Operating manual — IRC5 with Flex- 3HAC050941-001 Pendant RobotStudio Operating manual — RobotStudio 3HAC032104-001 Operating manual — IRC5 with T10 3HAC050943-001 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 51: Buttons And Ports On The Controller

Service outlet 115/230 V, 200 W (option) Hot plug button (option) Connector for FlexPendant or T10 Related information Product manual — IRC5, IRC5 of design 14. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 52

Product manual — IRC5 Panel Mounted Controller, IRC5 of design 14. Product manual — IRC5 Compact, IRC5 of design 14. Operating manual — Troubleshooting IRC5. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 53: Navigating And Handling Flexpendant

Main menu but not described in this manual. All options are detailed in their respective application manual. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 54: The Main Menu

Saves and loads selections of positions to be tuned. If your system uses UAS, this may be the only way to select positions for HotEdit. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 55

Tuning positions with HotEdit on page 268. Technical reference manual — RAPID Instructions, Functions and Data types. Technical reference manual — System parameters, section TopicController — TypeModPos Settings. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 56: Flexpendant Explorer

New folder. Tap to create a new folder in current folder. Up one level. Tap to change to parent folder. Refresh. Tap to refresh files and folders. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 57: Inputs And Outputs, I/O

The I/O signal configuration defines the specific system parameters for the I/O signal that will control the behavior of the I/O signal. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 58: Jogging

135. Payload Select payload, described in section Selecting tool, work object, and payload on page 135. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 59

Move the robot to a selected position/target. See section Moving the robot to a programmed position on page 274. Activate Activate a mechanical unit. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 60: Production Window

The Visual Step mode icon indicates that the Step Into mode is not selec- ted. This means that if the step mode is Step Out, Step Over, or Next Move the Visual Step mode icon is displayed. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 61: Program Data

168. Show Data Shows all instances of the selected data type. View Shows all or only used data types. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 62

Edits the selected instances, see Editing data instances on page 171. Refresh Refreshes the list of instances. View Data Types Returns to the Program Data menu. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 63: Program Editor

Search Routine: Searches all routines across all the modules (except hidden routines). • View System Data: Displays all the tasks. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 64

Mechanical units are manually activated for jogging in the Jogging window or in the Quickset menu, see Selecting mechanical unit for jogging on page 132. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 65: Backup And Restore

This is the Backup and Restore menu. xx0300000440 Backup Current System Back up the system on page 287. Restore System Restore the system on page 291. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 66: Calibration

This illustration shows the Calibration menu. All mechanical units are listed and their calibration status is displayed in the Status column. en0400001146 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 67

3 Navigating and handling FlexPendant 3.2.9 Calibration Continued Calibration menu options This illustration shows the Calibration menu options after selecting mechanical unit. en0400000771 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 68: Control Panel

3.2.10 Control Panel 3.2.10 Control Panel Control Panel The Control Panel contains functions for customizing the robot system and the FlexPendant. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 69

Authorization System. See Defining a view to be shown during operating mode change or startup on page 101. Configuration Configuration of the system parameters configuration. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 70: Event Log

284. Save the log Saving log entries on page 285. Close the log Accessing the event log on page 283. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 71

Acknowledge or OK button. Related information about logs Event log messages and more information about the event log are described in Operating manual — Troubleshooting IRC5. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 72: System Info

Drive Module x options, with type of robot and so on. Additional options Any RobotWare options and Process application options. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 73

Software used by the controller. RAPID memory Memory allocated for RAPID programs. RAPID performance Shows the execution load. Communication Contains information about Remote Service Embedded. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 74: Restart

3.2.13 Restart 3.2.13 Restart Restart A running system normally does not need to be restarted. Tap the ABB menu and then Restart to restart the system. en0500001557 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 75: Log Off

The Log Off menu This section details the Log Off menu. More about using this menu is described Logging on and off on page Log Off is available under the ABB menu. en0400000947 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G…

-

Page 76: Operator Window

The operator window is opened by tapping the icon to the right of the ABB logo in the status bar. The illustration shows an example of an operator window:…

-

Page 77: Status Bar

Mechanical units. The selected unit (and any unit coordinated with the selected) is marked with a border. Active units are displayed in color, while deactivated units are grey. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 78: Quickset

Quickset menu, Run Mode on page Step Mode, see Quickset menu, Step Mode on page Speed, see Quickset menu, Speed on page Tasks, see Quickset menu, Tasks on page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 79: Quickset Menu, Mechanical Unit

Show details, further settings are described in Illustration Show Details on page Note The Mechanical unit menu is only available in manual mode. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 80

134. en0300000540 Select motion mode setting: • Axis 1-3 • Axis 4-6 • Linear • Reorient Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 81

These settings are also available in the Jogging window, see Selecting tool, work object, and payload on page 135. en0400000989 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 82

Select a coordinate system setting: • World coordinate system • Base coordinate system • Tool coordinate system • Work object coordinate system Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 83

To re-enable the button you must setup coordination again manually. For information about coordination between MultiMove robots, see Application manual — MultiMove. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 84: Quickset Menu, Increment

User defined movements Show/Hide Values Displays/hides increment values Angle unit Defines the unit for the angles. Note The Increment menu is available only in manual mode. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 85: Quickset Menu, Run Mode

MultiMove, see Application manual — MultiMove, section User interface specific for Multimove. Illustration Run mode en0300000472 Single Cycle Runs one cycle then stops execution. Continuous Runs continuously. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 86: Quickset Menu, Step Mode

If you select the Step Out/Step Over/Next Move step modes, an arrow icon ) is also displayed in the QuickSet menu indicating that the selected mode is not a Step Into step mode. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 87: Quickset Menu, Speed

Increase running speed in steps of 5% Set speed to 0% Run at quarter speed (25%) Run at half speed (50%) 100% Run at full speed (100%) Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 88: Quickset Menu, Tasks

You can define if all tasks or only normal tasks should be displayed. See section Defining which tasks should be selectable in the tasks panel on page 107. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 89: Basic Procedures

All western characters can be used, also in usernames and passwords. To access international characters, tap the Int’l button on the soft keyboard. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 90

Deleting 1 Tap the Backspace key (top right) to delete characters to the left of the insertion point. xx0300000494 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 91: Messages On The Flexpendant

RAPID programs can send out messages to the Operator window, see section Operator window on page How to generate program messages is described in Technical reference manual — RAPID Instructions, Functions and Data types. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 92: Scrolling And Zooming

Scroll up (the height of one line) Scroll left Scroll right Zoom out (smaller text) Scroll down (the height of one page) Scroll down (the height of one line) Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 93: Filtering Data

See Illustration of automatic filter display on page Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 94

Depending on type of data, there may be one or several ways to filter data, e.g. numeric, alphabetic. Filter Applies the filter. Opens and closes the Active filter menu. en1100000506 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 95

Enter a new number defining the upper limit for not using the filter. Then tap Done. Tap Virtuals to select if all, or only virtual, or only non virtual signals should be listed. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 96: Process Applications

3.6.5 Process applications 3.6.5 Process applications Process applications Custom process applications are started from the ABB menu. Each application is listed as a menu item together with the FlexPendant views. Start a process application Use this procedure to start a process application.

-

Page 97: Granting Access For Robotstudio

For a system connected to T10, users in RobotStudio can request write access by pressing the enabling device twice and logging in as a local client. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 98: Logging On And Off

3.6.7 Logging on and off Logout procedure Use this procedure to log off the system. Action On the ABB menu, tap Log Off. Tap Yesto confirm. Login procedure Use this procedure to log on to the controller, using the User Authorization System, UAS.

-

Page 99

How to edit what views or functions are hidden for certain users is described in Defining a view to be shown during operating mode change or startup on page 101. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 100: Changing Flexpendant Settings

RobotStudio. See Operating manual — RobotStudio. Setting default paths Use this procedure to set a default path. Action On the ABB menu, tap Control Panel and then FlexPendant. Tap File System Default Path. en0500002361 Tap the File type menu to choose type of default path: •…

-

Page 101: Defining A View To Be Shown During Operating Mode Change Or Startup

Use the following procedure to configure the FlexPendant to automatically show a specified view during a change in operating mode or during startup. Action On the ABB menu, tap Control Panel and then tap FlexPendant. Tap View on System Event. The View on System Event window is displayed.

-

Page 102: Changing The Background Image

Format gif Changing background image Use this procedure to change background image on FlexPendant. Action On the ABB menu, tap Control panel. Tap FlexPendant and then Background Image. en0500001547 Tap Browse to locate another picture on the controller hard disk.

-

Page 103: Defining Visibility Level For Uas Protected Functions

RobotStudio. See Operating manual — RobotStudio. Defining visibility level for UAS protected functions Action On the ABB menu, tap Control Panel and then tap FlexPendant. Tap User Authorization System. en0400001153 Tap to select the level of visibility for UAS protected functions: •…

-

Page 104: Defining An Additional Test View

Defining an additional test view Use this procedure to define an additional test view. Action On the ABB menu, tap Control Panel and then FlexPendant. Tap Additional Test View. The displayed screen might look like this: en0600003110 Usually only the Program Editor and the Production Window are allowed test views.

-

Page 105: Defining Position Programming Rule

Defining position programming rule Use this procedure to define a naming rule for new robot positions. Action On the ABB menu, tap Control Panel and then FlexPendant. Tap Position Programming Rule. en0500002415 Tap to select the preferred position programming rule.

-

Page 106

“*” will always be used. This can be replaced by an existing target at a later stage. For example: MoveJ p10 will be followed by MoveJ *. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 107: Defining Which Tasks Should Be Selectable In The Tasks Panel

Use this procedure to define which tasks should be selectable in the tasks panel in the Quickset menu. Action On the ABB menu, tap Control Panel and then tap FlexPendant. Tap Task Panel Settings. Select Only Normal tasks or All tasks.

-

Page 108: Managing The Display Of Controller And System Name

Use the following procedure to manage the display of controller and system name in the status bar. Action On the ABB menu, tap Control Panel and then tap FlexPendant. The FlexPendant Configuration Properties window is displayed. Navigate and tap Controller and System Name.

-

Page 109: Basic Settings

Changing brightness and contrast Use this procedure to change brightness and contrast of the screen. Action On the ABB menu, tap Control Panel. Tap Appearance. Tap the Plus or Minus button to adjust the levels. Tap Set Default to return to default.

-

Page 110: Adapting The Flexpendant For Left-Handed Users

Rotating the FlexPendant screen Use this procedure to adapt the FlexPendant to suit a left-handed user. Action Tap the ABB menu, then tap Control Panel. Tap Appearance. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G…

-

Page 111

Emergency stop No effect. Differently located, at the bot- tom instead of at the top. Three-position enabling No effect device Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 112: Controller Settings

Date and time settings Use the following procedure to configure date and time. Step Action On the ABB menu, tap Control Panel. Tap Controller Settings. The Date and Time settings window is displayed. In the Settings section, select Network Time or Manual Time.

-

Page 113

3 Navigating and handling FlexPendant 3.7.2.3 Controller settings Continued Step Action Tap OK. The name of the controller is saved. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 114: Configuring Most Common I/O

Configuring Most Common I/O Use this procedure to configure the list Most Common I/O. Action On the ABB menu, tap Control Panel. Tap I/O. A list of all I/O signals defined in the system is listed with check boxes. Tap the names of the signals to select for the Most Common I/O list.

-

Page 115: Changing Language

Changing language Use this procedure to change language on the FlexPendant. Action On the ABB menu, tap Control Panel. Tap Language. A list of all installed languages is displayed. Tap the language that you want to change to.

-

Page 116: Changing Programmable Keys

They can also be used to activate menus on the FlexPendant. Change programmable keys Use the following procedure to set the programmable keys: Action On the ABB menu, tap Control Panel. Tap ProgKeys. en0400001154 Select key to set, Key 1-4 in the upper selection list.

-

Page 117

Tap the Allow in auto menu to select if the function is also allowed in automatic operating mode Set the other keys as described in steps 3 to 7 above. Tap OK to save the settings. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 118: Calibrating The Touch Screen

Calibrating the touch screen Use this procedure to calibrate the touch screen. Action Information On the ABB menu, tap Control Panel. Tap Touch Screen. Tap Recalibrate. The screen will go blank for a few seconds. A series of symbols will appear on the screen, one at a time.

-

Page 119

The best way to avoid this problem is to tap the symbol for only one second and then release. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 120

This page is intentionally left blank… -

Page 121: Jogging

How to jog multiple manipulators is de- can be jogged simultaneously. This re- tailed in section Coordinated jogging on quires the option MultiMove. page 131. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 122

Read more about coordinate systems in section Coordinate systems for jogging on page 123. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 123: Coordinate Systems For Jogging

Reorient mode For each mechanical unit the system will by default use the tool coordinate system for the reorientation motion mode. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 124

Please check your plant or cell documentation to determine the physical orientation of any additional axes. The illustration shows the movement patterns for each manipulator axis. xx0300000520 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 125

X axis, while moving the joystick to the sides will move the robot along the Y axis. Twisting the joystick will move the robot along the Z axis. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 126

For example, you are determining the positions of a number of holes to be drilled along the edge of the work object. You are creating a weld between two walls in a box. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 127

Examples of use Use the tool coordinate system when you need to program or adjust operations for threading, drilling, milling or sawing. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 128

If you jog in the base coordinate system for the inverted robot, movements will be very difficult to predict. Choose the shared world coordinate system instead. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 129: Joystick Directions

Jog axis by axis on page 137. en0300000537 Reorient Reorient mode is described in section Setting the tool orientation on page 136. en0400001131 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 130: Restrictions To Jogging

If the weight of tools and payloads is not set, then overload errors might occur when jogging. Loads for additional axes controlled by specific software (dynamic models) can only be set in programing. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 131: Coordinated Jogging

Coordinating robots Coordinating robots, so that when jogging one robot another robot will follow, requires the option MultiMove. See Application manual — MultiMove. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 132: Basic Settings For Jogging

There are three ways to select mechanical unit: • Using the Select mechanical unit button. • Using the Jogging window on the ABB menu. • Using the Quickset menu Mechanical unit, see Quickset menu, Mechanical unit on page Any changes you make to jogging properties only affects the currently selected mechanical unit.

-

Page 133

Program Editor windows. See section Program Editor on page Mechanical units can be activated or deactivated with the Activate function in the Jogging window. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 134: Selecting Motion Mode

Motion mode There are three ways to select motion mode: 1 Using the Toggle motion mode button. 2 Using the Jogging window on the ABB menu. 3 Using the Quickset menu Mechanical unit, see Quickset menu, Mechanical unit on page Selecting motion mode using the toggle button Press the Toggle motion mode reorient/linear button to switch motion mode.

-

Page 135: Selecting Tool, Work Object, And Payload

Selecting tool, work object, and payload Action On the ABB menu, choose Jogging to view jogging properties. Tap Tool, Work object, or Payload to display the lists of available tools, work objects or payloads.

-

Page 136: Setting The Tool Orientation

Press and hold the three-position enabling device to activate the mechanical unit’s motors. Move the joystick and the tool’s orientation changes. Use the QuickSet menu to select jogging mode faster. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 137: Jog Axis By Axis

There are three ways to select axis for jogging. • Using the Toggle motion mode axis group button. • Using the Jogging window on the ABB menu. • Using the Quickset menu Mechanical unit, see Quickset menu, Mechanical unit on page In manual mode, the Quickset menu button displays which axis group is selected.

-

Page 138: Selecting Coordinate System

Coordinate systems for jogging on page 123, for more information. There are two ways to select coordinate system: • Using the Jogging window on the ABB menu. • Using the Quickset menu Mechanical unit, see Quickset menu, Mechanical unit on page Prerequisites Select motion mode suitable for the intended jogging.

-

Page 139: Locking The Joystick In Specific Directions

This section describes how to see which joystick directions are locked Action On the ABB menu, tap Jogging to view jogging properties. Tap Joystick lock to check the joystick properties, or check the Joystick directions area properties in the right hand corner of the window.

-

Page 140

This section describes how to unlock all axes from the joystick directions lock. Action On the ABB menu, tap Jogging. Tap Joystick lock. Tap None, then tap OK. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 141: Incremental Movement For Precise Positioning

There are three ways to select the increment size: • Using the Toggle increments button. • Using thee Jogging window on the ABB menu. • Using the Quickset menu Increments, see Quickset menu, Increment on page To use the toggle button you must first select an increment size in the Jogging window or Quickset menu.

-

Page 142

Choose between small, medium or large increments. You can also define your own increment movement sizes. Increment Distance Angular Small 0.05 mm 0.005° Medium 1 mm 0.02° Large 5 mm 0.2° User Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 143: Reading The Exact Position

Reading the exact position This procedure describes how to read the exact position. Action On the ABB menu tap .Jogging. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 144

Euler angles The Position angle format can be set to: • Angles The Presentation angle unit can be set to: • Degrees • Radians Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 145: Aligning Tools

Select a coordinate system to align the selected tool to. Press and hold the three-position enabling device and then tap and hold Start Align to start aligning the tool. Tap Close when completed. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 146

This page is intentionally left blank… -

Page 147: Programming And Testing

For more details about the RAPID language and structure, see Technical reference manual — RAPID Overview and Technical reference manual — RAPID Instructions, Functions and Data types. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 148: Using Rapid Programs

When starting program execution, you may Described in section Quickset menu, Run choose between running the program once, Mode on page or running it continuously. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 149

245. After program execution is completed, the Proceed as detailed in section Stopping program may be stopped. programs on page 244. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 150: Programming Concept

Creating a new program This section describes how to create a new program. Action On the ABB menu, tap Program Editor. Tap Tasks and Programs. Tap File, then New Program. If there was already a program loaded, a warning dialog appears.

-

Page 151

Loading an existing program This section describes how to load an existing program. Action On the ABB menu, tap Program Editor. Tap Tasks and Programs. Tap File, then Load Program. If there was already a program loaded, a warning dialog appears. -

Page 152

Continued Renaming a loaded program This section describes how to rename a loaded program. Action On the ABB menu, tap Program Editor. Tap Tasks and Programs. Tap File and select Rename Program. A soft keyboard is displayed. Use the soft keyboard to enter the new name of the program. Then tap OK. -

Page 153: Handling Of Modules

Creating a new module This section describes how to create a new module. Action On the ABB menu, tap Program Editor. Tap Modules. Tap File, then tap New Module. en0400000688 Tap ABC… and use the soft keyboard to enter the new module’s name. Then tap OK to close the soft keyboard.

-

Page 154

5.3.2 Handling of modules Continued Loading an existing module This section describes how to load an existing module. Action On the ABB menu, tap Program Editor. Tap Modules. Tap File, then Load Module. en0400000689 Locate the module to be loaded. See section FlexPendant Explorer on page 56. -

Page 155

The module is saved. Renaming a module This section describes how to rename a module. Action On the ABB menu, tap Program Editor. Tap Modules. Tap File, then Rename Module… The soft keyboard is displayed. Use the soft keyboard to enter the module’s name. Then tap OK. -

Page 156

This section describes how to delete a module from memory. If the module has been saved to disk, it will not be erased from the disk. Action On the ABB menu, tap Program Editor. Tap Modules and tap to select the module you want to delete. Tap File, then Delete Module… -

Page 157: Handling Of Routines

This section details how to create a new routine, set the declaration, and add it to a module. Action On the ABB menu, tap Program Editor. Tap Routines. Tap File, then New Routine. A new routine is created and displayed with default declaration values.

-

Page 158

This section describes how to define parameters in a routine. Action In the routine declaration, tap … to define parameters. A list of defined parameters is displayed. en0400000693 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 159

The new parameter is displayed in the list. en0400000696 Tap to select a parameter. To edit values, tap the value. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 160

Tap OK to return to the routine declaration. Creating a copy of a routine This section describes how to create a copy of a routine. Action On the ABB menu, tap Program Editor. Tap Routines. Highlight the routine by tapping it. Tap File, then Copy Routine. -

Page 161

Continued Action Tap: • OK to delete the routine without saving any changes made to it. • Cancel to revert without deleting the routine. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 162: Handling Of Instructions

Adding instructions This section describes how to add instructions. Action On the ABB menu, tap Program Editor. Tap to highlight the instruction under which you want to add a new instruction. Tap Add instruction. A category of instructions is displayed.

-

Page 163

Editing instruction arguments This section describes how to edit instruction arguments. Action Tap the instruction to edit. en0400000699 Tap Edit. en0400000701 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 164

A number of options are displayed. en0400000703 Tap an existing data instance to select and then tap OK to complete, or tap Expression Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 165

Instruction rows can be commented, i.e. skipped in the program execution. The comment/uncomment command is found under the Edit menu in the Program Editor. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 166: Example: Add Movement Instructions

MoveL *, v50, fine, tool0; MoveL *, v50, z50, tool0; MoveL *, v50, z50, tool0; MoveL *, v50, z50, tool0; MoveL *, v50, fine, tool0; End Proc; Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 167: About The Program And Motion Pointers

The same behavior applies to the Production Window. Related information Production Window on page Program Editor on page Stepping instruction by instruction on page 214. Starting programs on page 241. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 168: Data Types

It is possible to view selections of data types by selecting a specific scope. Viewing data in specific tasks, modules, or routines This section details how to view data instances in specific modules or routines. Action On the ABB menu, tap Program Data. Tap Change Scope. The following screen is displayed: en0400000661 Select the required scope by selecting: •…

-

Page 169: Creating New Data Instance

This section details how to create new data instances of data types. Action On the ABB menu, tap Program Data. A list of all available data types is displayed. Tap the data instance type to be created, i.e. bool and then tap Show data.

-

Page 170

5 Programming and testing 5.4.2 Creating new data instance Continued Action Tap OK. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 171: Editing Data Instances

This section details how to view the available instances of a data type. Action On the ABB menu, tap Program Data. Tap the data type you want view and then tap Show Data. Tap the data instance you want to edit, and then tap Edit.

-

Page 172

If you delete a tool you cannot continue the program from the current position. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 173

How to define the tool frame or work object frame is described in the sections Defining the tool frame on page 180 Defining the work object coordinate system on page 193. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 174

Make sure that the correct work object and tool are selected when modifying positions in the Program Data window. This is not verified automatically by the system. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 175: Tools

The controller continuously monitors the load and writes an event log if the load is higher than expected. This event log is saved and logged in the controller memory. Illustration en0400000803 Tool side Robot side Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 176: What Is The Tool Center Point

In some applications a stationary TCP is used, for example when a stationary spot welding gun is used. In such cases the TCP can be defined in relation to the stationary equipment instead of the moving manipulator. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 177: Creating A Tool

Tool center point, TCP, for tool0 Action On the ABB menu, tap Jogging. Tap Tool to display the list of available tools. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 178

Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 179

See Editing the tool data on page 184 LoadIdentify, load identification service routine on page 224 to learn more about how to do it. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 180: Defining The Tool Frame

Tap Tool to display a list of available tools. Select the tool you want to define. In the Edit menu, tap Define Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 181

How to proceed with tool frame definition on page 182 for information on how to gather positions and perform the tool frame definition. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 182

If, for some reason, you want to redo the calibration procedure described in step 1- 4, tap Positions and then Reset All. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 183

Verify that the tool tip stays very close to the selected reference point as the robot moves. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 184: Editing The Tool Data

The data that defines the tool appears. Green text indicates that the value can be changed. Proceed with changing the data as described below. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 185

Editing the tool definition Action Instance Unit Enter the cartesian coordinates of the tool [mm] tframe.trans.x center point’s position. tframe.trans.y tframe.trans.z Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 186

If necessary, enter the tool’s moment of inertia. [kgm tload.ix tload.iy tload.iz Tap OK to use the new values, Cancel to leave the definition unchanged. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 187: Editing The Tool Declaration

If you change the name of a tool after it is referenced in any program you must also change all occurrences of that tool. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 188: Deleting A Tool

5.5.7 Deleting a tool 5.5.7 Deleting a tool Deleting a tool For more information about deleting a tool, see Deleting a data instance on page 172. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 189: Setup For Stationary Tools

(no change) user coordinate system world coordinate system robot’s mounting plate tool coordinate system robot’s mounting plate world coordinate system Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 190

You should enter the reference tip’s tool definition manually to minimize errors when calculating the stationary tool’s coordinate system. You may enter the stationary tool’s definition manually. en0400000990 Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 191: Work Objects

Payloads are important when working with grippers. In order to position and manipulate an object as accurate as possible its weight must be accounted for. You must choose which one to use for jogging. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 192: Creating A Work Object

Work object variables must the storage type always be persistent. the module select the module in which this work object should be declared from the menu Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 193: Defining The Work Object Coordinate System

Select method from the User method and/or the Object method menu. See How to define the user frame on page 194 How to define the object frame on page 195 en0400000893 Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 194

Select the point in the list. Tap Modify Position to define the point. Repeat steps 2 to 4 for the remaining points. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 195

In the Save Modified Points dialog, tap Yes. Tap ABC to change the name of the program module, tap OK to accept the name. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 196

Tap each point in the list to assign the positions manually from the drop down list. Tap If necessary, use Modify Position to define any remaining points that could not be loaded. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 197: Editing The Work Object Data

The user frame orientation uframe.rot.q1 uframe.rot.q2 uframe.rot.q3 uframe.rot.q4 Note Editing work object data can also be done from the Program Data window. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 198: Editing The Work Object Declaration

If you change the name of a work object after it is referenced in any program you must also change all occurrences of that work object. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 199: Deleting A Work Object

5.6.6 Deleting a work object Deleting a work object For more information about deleting a work object, see Deleting a data instance on page 172. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 200: Payloads

The controller continuously monitors the load and writes an event log if the load is higher than expected. This event log is saved and logged in the controller memory. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 201

Setting the value for ModalPayLoadMode This procedure describes how to modify the value of ModalPayLoadMode: 1 On the ABB menu, tap Control Panel and then Configuration. 2 Select Controller. 3 Select the type System Misc and tap. -

Page 202: Editing The Payload Data

TCP or work object. Thus it is possible to use the same payload loaddata for any robhold or stationary tool being active. This saves the time (for example, during commissioning). Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 203

Continued For more information about PayLoadsInWristCoords, see Technical reference manual — System parameters and Technical reference manual — RAPID Instructions, Functions and Data types. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 204: Editing The Payload Declaration

If you change the name of a payload after it is referenced in any program you must also change all occurrences of that payload’s name. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 205: Deleting A Payload

5.7.4 Deleting a payload 5.7.4 Deleting a payload Deleting a payload For more information about deleting a payload, see Deleting a data instance on page 172. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 206: Testing

All remedial actions must be performed by personnel with good knowledge of the entire production line, not only the malfunctioning manipulator. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 207

Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 208: About The Manual Mode

WARNING Wherever possible, the manual mode of operation shall be performed with all persons outside the safeguarded space. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 209

Creating and editing RAPID programs • Starting, stepping, and stopping program execution, for example while testing a program • Tuning programmed positions Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 210

Setting program pointer (to Main, to routine, to cursor, to service routine, etc.) The following tasks cannot be performed in the manual full speed mode: • Changing system parameter values • Editing system data Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 211: Using The Hold-To-Run Function

If the three-position enabling device is released, intentionally or by accident, the complete procedure must be repeated to enable running. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 212: Running The Program From A Specific Instruction

Make sure that the robot with TCP does not risk running into any obstacles! Running the program from a specific instruction Action On the ABB menu, tap Program Editor. Tap on the program step where you want to start, then tap Debug and then PP to Cursor. DANGER Make sure that no personnel are in the robot working area.

-

Page 213: Running A Specific Routine

This procedure describes how to run a specific routine by moving the program pointer. Action On the ABB menu, tap Program Editor. Tap Debug and then PP to Routine to place the program pointer at the start of the routine.

-

Page 214: Stepping Instruction By Instruction

Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 215

(MoveL p50). The motion pointer will indicate p40 and the program pointer will move up to MoveL p20. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 216

(MoveL p20). pressing the Forward the robot will move to p20 with the speed v1000. button again Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 217: Service Routines

This section describes how to execute a service routine or another routine in the task scope using Call Routine. Action On the ABB menu tap Program Editor. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G…

-

Page 218

Tap a service routine and then tap Go to. The Program Editor will be displayed with the program pointer moved to the beginning of the selected routine. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 219

LoadIdentify, load identification service routine on page 224. Service Information System, ServiceInfo service routine on page 223. Calibration Pendulum, CalPendulum service routine on page 222. Continues on next page Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 220

5.9.1 Running a service routine Continued For more information about StorePath and RestoPath, see Technical reference manual — RAPID Instructions, Functions, and Data types. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved. -

Page 221: Battery Shutdown Service Routine

How to start a service routine is described in Running a service routine on page 217. How to update the revolution counters is described in Updating revolution counters on page 296. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-

Page 222: Calibration Pendulum, Calpendulum Service Routine

When to use this service routine CalPendulum is a service routine used with Calibration Pendulum, the standard method for calibration of ABB robots. This is the most accurate method for the standard type of calibration, and it is also the recommended method in order to achieve proper performance.

-

Page 223: Service Information System, Serviceinfo Service Routine

Running a service routine on page 217. Operating manual — Service Information System. The system parameters for SIS are described in Technical reference manual — System parameters, chapter Motion. Operating manual — IRC5 with FlexPendant 3HAC050941-001 Revision: G © Copyright 2018 ABB. All rights reserved.

-