-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

KA01136D/06/EN/06.16

71326673

Products

Brief Operating Instructions

Proline Prowirl F 200

Vortex flowmeter

These Instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Detailed information about the device can be found in the

Operating Instructions and the other documentation:

• On the CD-ROM supplied (not included in the delivery for all

device versions).

• Available for all device versions via:

– Internet:

www.endress.com/deviceviewer

– Smart phone/tablet: Endress+Hauser Operations App

Solutions

Services

Summary of Contents for Endress+Hauser Proline Prowirl F 200

Products Solutions Services

Operating Instructions

Proline Prowirl F 200

HART

Vortex flowmeter

BA01686D/06/EN/02.19

71442767

2019-07-01

Valid as of version

01.03.zz (Device firmware)

Proline Prowirl F 200 HART

2 Endress+Hauser

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the «Basic safety instructions» section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser Sales Center will supply you with current information and updates to

these instructions.

Proline Prowirl F 200 HART Table of contents

Endress+Hauser 3

Table of contents

1 About this document ……………. 6

1.1 Document function ………………… 6

1.2 Symbols ………………………… 6

1.2.1 Safety symbols ……………… 6

1.2.2 Electrical symbols ……………. 6

1.2.3 Communication symbols ……….. 6

1.2.4 Tool symbols ……………….. 7

1.2.5 Symbols for

certain types of information ……… 7

1.2.6 Symbols in graphics …………… 7

1.3 Documentation …………………… 8

1.3.1 Standard documentation ……….. 8

1.3.2 Supplementary device-dependent

documentation ……………… 8

1.4 Registered trademarks ………………. 8

2 Safety instructions ……………… 9

2.1 Requirements for the personnel ………… 9

2.2 Designated use …………………… 9

2.3 Workplace safety …………………. 10

2.4 Operational safety ………………… 10

2.5 Product safety …………………… 10

2.6 IT security ……………………… 11

2.7 Device-specific IT security ……………. 11

2.7.1 Protecting access via hardware write

protection ………………… 11

2.7.2 Protecting access via a password …. 11

2.7.3 Access via fieldbus …………… 11

3 Product description ……………. 12

3.1 Product design …………………… 12

4 Incoming acceptance and product

identification ………………… 14

4.1 Incoming acceptance ………………. 14

4.2 Product identification ………………. 14

4.2.1 Transmitter nameplate ……….. 15

4.2.2 Sensor nameplate …………… 16

4.2.3 Pressure measuring cells nameplate .. 19

4.2.4 Symbols on measuring device …… 19

5 Storage and transport …………. 20

5.1 Storage conditions ………………… 20

5.2 Transporting the product ……………. 20

5.2.1 Measuring devices without lifting

lugs ……………………. 20

5.2.2 Measuring devices with lifting lugs .. 21

5.2.3 Transporting with a fork lift …….. 21

5.3 Packaging disposal ………………… 21

6 Installation ………………….. 22

6.1 Installation conditions ……………… 22

6.1.1 Mounting position …………… 22

6.1.2 Environment and process

requirements ……………… 27

6.1.3 Special mounting instructions …… 28

6.2 Mounting the measuring device ……….. 29

6.2.1 Required tools ……………… 29

6.2.2 Preparing the measuring device ….. 29

6.2.3 Mounting the sensor …………. 29

6.2.4 Mounting the pressure measuring

unit ……………………. 30

6.2.5 Mounting the transmitter of the

remote version …………….. 32

6.2.6 Turning the transmitter housing …. 33

6.2.7 Turning the display module …….. 34

6.3 Post-installation check ……………… 34

7 Electrical connection ………….. 36

7.1 Connection conditions ……………… 36

7.1.1 Required tools ……………… 36

7.1.2 Connecting cable requirements ….. 36

7.1.3 Connecting cable for remote

version ………………….. 37

7.1.4 Terminal assignment …………. 38

7.1.5 Requirements for the supply unit …. 40

7.1.6 Preparing the measuring device ….. 41

7.2 Connecting the measuring device ………. 41

7.2.1 Connecting the compact version ….. 42

7.2.2 Connecting the remote version ….. 43

7.2.3 Connecting the connecting cable for

the pressure measuring cell …….. 48

7.2.4 Ensuring potential equalization ….. 48

7.3 Ensuring the degree of protection ………. 48

7.4 Post-connection check ……………… 48

8 Operation options …………….. 50

8.1 Overview of operation options ………… 50

8.2 Structure and function of the operating

menu ………………………… 51

8.2.1 Structure of the operating menu …. 51

8.2.2 Operating philosophy ………… 52

8.3 Access to the operating menu via the local

display ……………………….. 53

8.3.1 Operational display ………….. 53

8.3.2 Navigation view ……………. 54

8.3.3 Editing view ………………. 56

8.3.4 Operating elements ………….. 58

8.3.5 Opening the context menu ……… 58

8.3.6 Navigating and selecting from list … 60

8.3.7 Calling the parameter directly …… 60

8.3.8 Calling up help text ………….. 61

8.3.9 Changing the parameters ……… 62

Table of contents Proline Prowirl F 200 HART

4 Endress+Hauser

8.3.10 User roles and related access

authorization ……………… 63

8.3.11 Disabling write protection via access

code ……………………. 63

8.3.12 Enabling and disabling the keypad

lock ……………………. 64

8.4 Access to the operating menu via the

operating tool …………………… 64

8.4.1 Connecting the operating tool …… 64

8.4.2 Field Xpert SFX350, SFX370 ……. 65

8.4.3 FieldCare ………………… 66

8.4.4 DeviceCare ……………….. 67

8.4.5 AMS Device Manager ………… 67

8.4.6 SIMATIC PDM ……………… 68

8.4.7 Field Communicator 475 ………. 68

9 System integration ……………. 69

9.1 Overview of device description files ……… 69

9.1.1 Current version data for the device … 69

9.1.2 Operating tools …………….. 69

9.2 Measured variables via HART protocol …… 69

9.3 Other settings …………………… 71

10 Commissioning ……………….. 74

10.1 Function check ………………….. 74

10.2 Switching on the measuring device ……… 74

10.3 Setting the operating language ………… 74

10.4 Configuring the measuring device ………. 75

10.4.1 Defining the tag name ………… 75

10.4.2 Setting the system units ………. 76

10.4.3 Selecting and setting the medium … 80

10.4.4 Configuring the current input …… 83

10.4.5 Configuring the current output ….. 85

10.4.6 Configuring the pulse/frequency/

switch output ……………… 86

10.4.7 Configuring the local display ……. 91

10.4.8 Configuring the output

conditioning ………………. 93

10.4.9 Configuring the low flow cut off ….. 93

10.5 Advanced settings ………………… 95

10.5.1 Setting the medium properties …… 96

10.5.2 Performing external compensation . 109

10.5.3 Carrying out a sensor adjustment … 111

10.5.4 Configuring the totalizer ……… 114

10.5.5 Carrying out additional display

configurations …………….. 115

10.5.6 Configuration management ……. 118

10.5.7 Using parameters for device

administration ……………. 119

10.6 Configuration management …………. 119

10.6.1 Function scope of the «Configuration

management» parameter ……… 120

10.7 Simulation …………………….. 121

10.8 Protecting settings from unauthorized

access ……………………….. 123

10.8.1 Write protection via access code … 123

10.8.2 Write protection via write protection

switch ………………….. 124

10.9 Application-specific commissioning ……. 125

10.9.1 Steam application ………….. 125

10.9.2 Liquid application ………….. 126

10.9.3 Gas applications …………… 127

10.9.4 Calculation of the measured

variables ………………… 130

11 Operation ………………….. 135

11.1 Reading the device locking status ……… 135

11.2 Adjusting the operating language ……… 135

11.3 Configuring the display ……………. 135

11.4 Reading measured values …………… 135

11.4.1 Process variables …………… 136

11.4.2 «Totalizer» submenu …………. 139

11.4.3 Input values ……………… 139

11.4.4 Output values …………….. 140

11.5 Adapting the measuring device to the process

conditions …………………….. 141

11.6 Performing a totalizer reset …………. 141

11.6.1 Function scope of the «Control

Totalizer» parameter ………… 141

11.6.2 Function scope of the «Reset all

totalizers» parameter ………… 142

11.7 Showing data logging …………….. 142

12 Diagnostics and troubleshooting .. 145

12.1 General troubleshooting ……………. 145

12.2 Diagnostic information on local display ….. 147

12.2.1 Diagnostic message …………. 147

12.2.2 Calling up remedial measures ….. 149

12.3 Diagnostic information in FieldCare or

DeviceCare ……………………. 149

12.3.1 Diagnostic options ………….. 149

12.3.2 Calling up remedy information …. 151

12.4 Adapting the diagnostic information …… 151

12.4.1 Adapting the diagnostic behavior … 151

12.4.2 Adapting the status signal …….. 152

12.5 Overview of diagnostic information ……. 152

12.5.1 Operating conditions for displaying

the following diagnostics

information ……………… 156

12.5.2 Emergency mode in the event of

pressure compensation ………. 156

12.5.3 Emergency mode in event of

temperature compensation ……. 156

12.6 Pending diagnostic events ………….. 157

12.7 Diagnostic list ………………….. 157

12.8 Event logbook ………………….. 158

12.8.1 Reading out the event logbook ….. 158

12.8.2 Filtering the event logbook ……. 158

12.8.3 Overview of information events …. 159

12.9 Resetting the measuring device ………. 160

12.9.1 Function scope of the «Device reset»

parameter ……………….. 160

12.10 Device information ………………. 160

12.11 Firmware history ………………… 162

Proline Prowirl F 200 HART Table of contents

Endress+Hauser 5

13 Maintenance ……………….. 163

13.1 Maintenance tasks ……………….. 163

13.1.1 Exterior cleaning …………… 163

13.1.2 Interior cleaning …………… 163

13.1.3 Replacing seals ……………. 163

13.1.4 Adjusting the pressure measuring

cell ……………………. 163

13.2 Measuring and test equipment ……….. 164

13.3 Endress+Hauser services …………… 164

14 Repair ……………………… 165

14.1 General notes ………………….. 165

14.1.1 Repair and conversion concept ….. 165

14.1.2 Notes for repair and conversion …. 165

14.2 Spare parts ……………………. 165

14.3 Endress+Hauser services …………… 166

14.4 Return ……………………….. 166

14.5 Disposal ……………………… 166

14.5.1 Removing the measuring device …. 166

14.5.2 Disposing of the measuring device .. 167

15 Accessories …………………. 168

15.1 Device-specific accessories ………….. 168

15.1.1 For the transmitter …………. 168

15.1.2 For the sensor …………….. 169

15.2 Communication-specific accessories ……. 169

15.3 Service-specific accessories ………….. 170

15.4 System components ………………. 171

16 Technical data ………………. 172

16.1 Application ……………………. 172

16.2 Function and system design …………. 172

16.3 Input ………………………… 172

16.4 Output ………………………. 179

16.5 Power supply …………………… 182

16.6 Performance characteristics …………. 185

16.7 Installation ……………………. 189

16.8 Environment …………………… 189

16.9 Process ………………………. 191

16.10 Mechanical construction …………… 193

16.11 Operability ……………………. 202

16.12 Certificates and approvals ………….. 203

16.13 Application packages ……………… 204

16.14 Accessories ……………………. 205

16.15 Supplementary documentation ……….. 205

Index …………………………… 207

About this document Proline Prowirl F 200 HART

6 Endress+Hauser

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols

1.2.1 Safety symbols

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

1.2.3 Communication symbols

Symbol Meaning

Wireless Local Area Network (WLAN)

Communication via a wireless, local network.

Proline Prowirl F 200 HART About this document

Endress+Hauser 7

1.2.4 Tool symbols

Symbol Meaning

Flat blade screwdriver

Allen key

Open-ended wrench

1.2.5 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

Reference to page.

Reference to graphic.

Notice or individual step to be observed.

,

,

… Series of steps.

Result of a step.

Help in the event of a problem.

Visual inspection.

1.2.6 Symbols in graphics

Symbol Meaning

1, 2, 3, … Item numbers

,

,

, … Series of steps

A, B, C, … Views

A-A, B-B, C-C, … Sections

Hazardous area

Safe area (non-hazardous area)

Flow direction

About this document Proline Prowirl F 200 HART

8 Endress+Hauser

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• W@M Device Viewer (www.endress.com/deviceviewer): Enter the serial number

from nameplate

• Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2D matrix code (QR code) on the nameplate

Detailed list of the individual documents along with the documentation code

→ 205

1.3.1 Standard documentation

Document type Purpose and content of the document

Technical Information Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Sensor Brief Operating Instructions Guides you quickly to the 1st measured value — Part 1

The Sensor Brief Operating Instructions are aimed at specialists with

responsibility for installing the measuring device.

• Incoming acceptance and product identification

• Storage and transport

• Installation

Transmitter Brief Operating

Instructions

Guides you quickly to the 1st measured value — Part 2

The Transmitter Brief Operating Instructions are aimed at specialists with

responsibility for commissioning, configuring and parameterizing the

measuring device (until the first measured value).

• Product description

• Installation

• Electrical connection

• Operation options

• System integration

• Commissioning

• Diagnostic information

Description of Device Parameters Reference for your parameters

The document provides a detailed explanation of each individual

parameter in the Expert operating menu. The description is aimed at

those who work with the device over the entire life cycle and perform

specific configurations.

1.3.2 Supplementary device-dependent documentation

Additional documents are supplied depending on the device version ordered: Always

comply strictly with the instructions in the supplementary documentation. The

supplementary documentation is an integral part of the device documentation.

1.4 Registered trademarks

HART®

Registered trademark of the FieldComm Group, Austin, Texas, USA

KALREZ®, VITON®

Registered trademarks of DuPont Performance Elastomers L.L.C., Wilmington, DE USA

GYLON®

Registered trademark of Garlock Sealing Technologies, Palmyar, NY, USA

Proline Prowirl F 200 HART Safety instructions

Endress+Hauser 9

2 Safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

‣

Trained, qualified specialists must have a relevant qualification for this specific function

and task.

‣

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

supplementary documentation as well as the certificates (depending on the

application).

‣

Follow instructions and comply with basic conditions.

The operating personnel must fulfill the following requirements:

‣

Are instructed and authorized according to the requirements of the task by the facility’s

owner-operator.

‣

Follow the instructions in this manual.

2.2 Designated use

Application and media

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or where there is an

increased risk due to process pressure, are labeled accordingly on the nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

‣

Keep within the specified pressure and temperature range.

‣

Only use the measuring device in full compliance with the data on the nameplate and

the general conditions listed in the Operating Instructions and supplementary

documentation.

‣

Based on the nameplate, check whether the ordered device is permitted for the

intended use in the hazardous area (e.g. explosion protection, pressure vessel safety).

‣

Use the measuring device only for media to which the process-wetted materials are

sufficiently resistant.

‣

If the ambient temperature of the measuring device is outside the atmospheric

temperature, it is absolutely essential to comply with the relevant basic conditions as

specified in the device documentation. → 8

‣

Protect the measuring device permanently against corrosion from environmental

influences.

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage

caused by improper or non-designated use.

L

WARNING

Danger of breakage due to corrosive or abrasive fluids and ambient conditions!

‣

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Keep within the specified pressure and temperature range.

Safety instructions Proline Prowirl F 200 HART

10 Endress+Hauser

NOTICE

Verification for borderline cases:

‣

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance

in verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

L

WARNING

The electronics and the medium may cause the surfaces to heat up. This presents a

burn hazard!

‣

For elevated fluid temperatures, ensure protection against contact to prevent burns.

2.3 Workplace safety

For work on and with the device:

‣

Wear the required personal protective equipment according to federal/national

regulations.

For welding work on the piping:

‣

Do not ground the welding unit via the measuring device.

If working on and with the device with wet hands:

‣

Due to the increased risk of electric shock, gloves must be worn.

2.4 Operational safety

Risk of injury.

‣

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

‣

If, despite this, modifications are required, consult with Endress+Hauser.

Repair

To ensure continued operational safety and reliability,

‣

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EU

directives listed in the device-specific EU Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

Proline Prowirl F 200 HART Safety instructions

Endress+Hauser 11

2.6 IT security

Our warranty is valid only if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the settings.

IT security measures, which provide additional protection for the device and associated

data transfer, must be implemented by the operators themselves in line with their security

standards.

2.7 Device-specific IT security

The device offers a range of specific functions to support protective measures on the

operator’s side. These functions can be configured by the user and guarantee greater in-

operation safety if used correctly. An overview of the most important functions is provided

in the following section.

2.7.1 Protecting access via hardware write protection

Write access to the device parameters via the local display or operating tool (e.g. FieldCare,

DeviceCare) can be disabled via a write protection switch (DIP switch on the motherboard).

When hardware write protection is enabled, only read access to the parameters is possible.

2.7.2 Protecting access via a password

A password can be used to protect against write access to the device parameters.

This password locks write access to the device parameters via the local display or another

operating tool (e.g. FieldCare, DeviceCare) and, in terms of functionality, is equivalent to

hardware write protection. If the service interface CDI RJ-45 is used, read access is only

possible if the password is entered.

User-specific access code

Write access to the device parameters via the local display or operating tool (e.g. FieldCare,

DeviceCare) can be protected by the modifiable, user-specific access code (→ 123).

When the device is delivered, the device does not have an access code and is equivalent to

0000 (open).

General notes on the use of passwords

• The access code and network key supplied with the device should be changed during

commissioning.

• Follow the general rules for generating a secure password when defining and managing

the access code or network key.

• The user is responsible for the management and careful handling of the access code and

network key.

• For information on configuring the access code or on what to do if you lose the

password, see the «Write protection via access code» section → 123

2.7.3 Access via fieldbus

Cyclic fieldbus communication (read and write, e.g. measured value transmission) with a

higher-order system is not affected by the restrictions mentioned above.

Product description Proline Prowirl F 200 HART

12 Endress+Hauser

3 Product description

The device consists of a transmitter and a sensor.

Two device versions are available:

• Compact version – transmitter and sensor form a mechanical unit.

• Remote version — transmitter and sensor are mounted in separate locations.

3.1 Product design

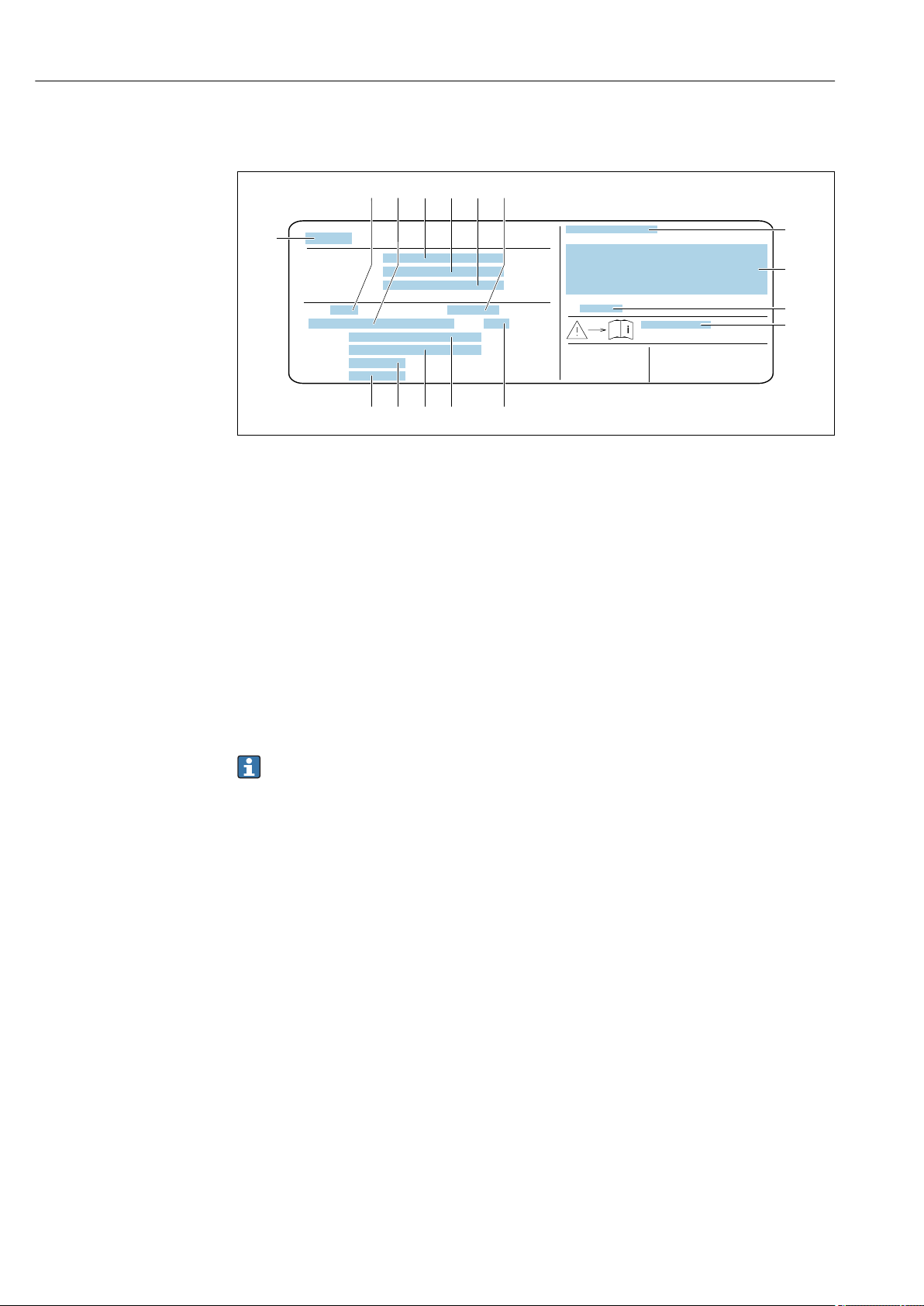

A0020649

1 Important components of a measuring device

1 Electronics compartment cover

2 Display module

3 Main electronics module

4 Cable glands

5 Transmitter housing (incl. HistoROM)

6 I/O electronics module

7 Terminals (spring loaded terminals, pluggable)

8 Connection compartment cover

9 Sensor

Proline Prowirl F 200 HART Product description

Endress+Hauser 13

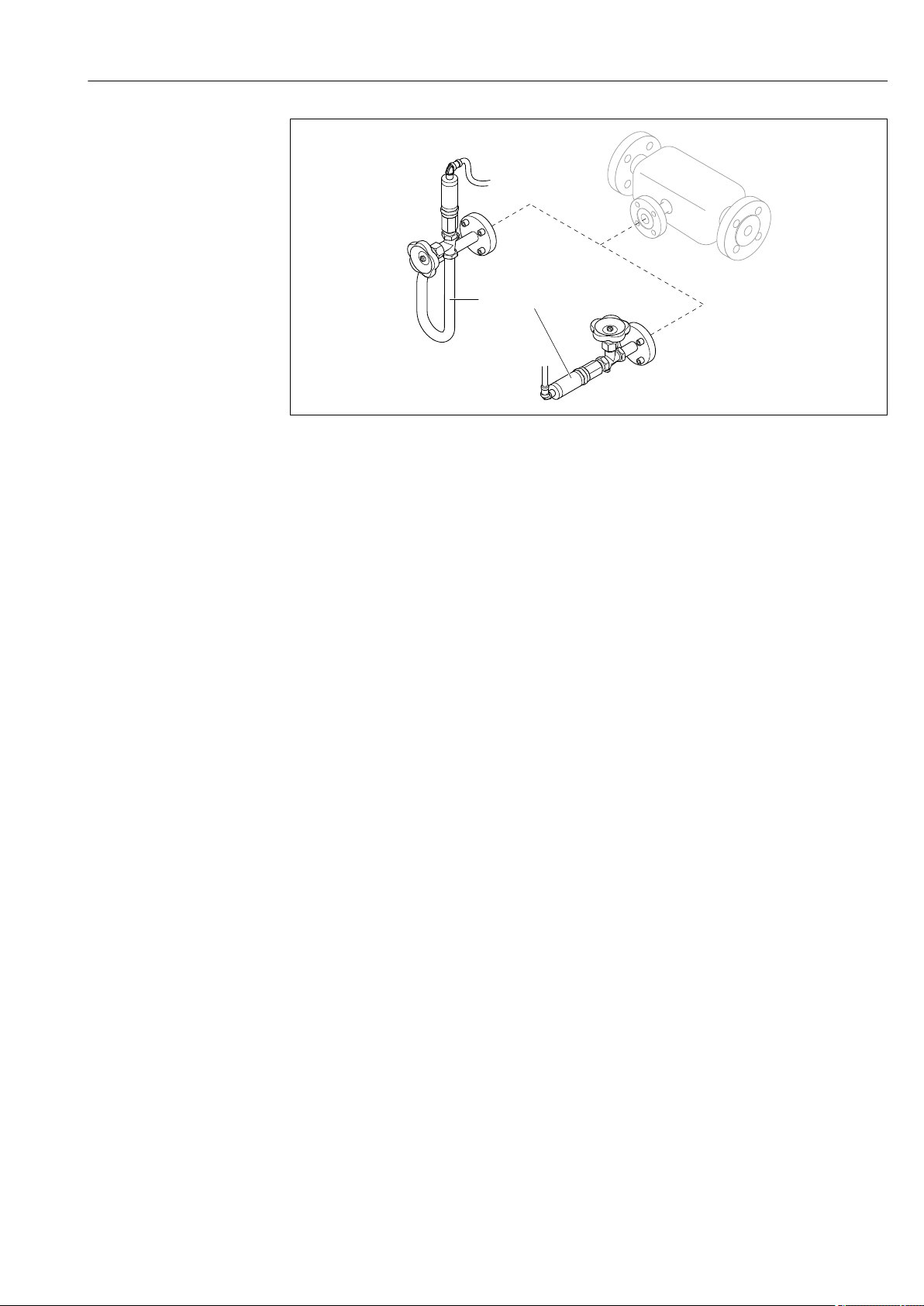

A0034152

2 Versions of pressure measuring unit

1 Order code for «Sensor version», option DA «mass steam»

2 Order code for «Sensor version», option DB «mass gas/liquid»

Incoming acceptance and product identification Proline Prowirl F 200 HART

14 Endress+Hauser

4 Incoming acceptance and product

identification

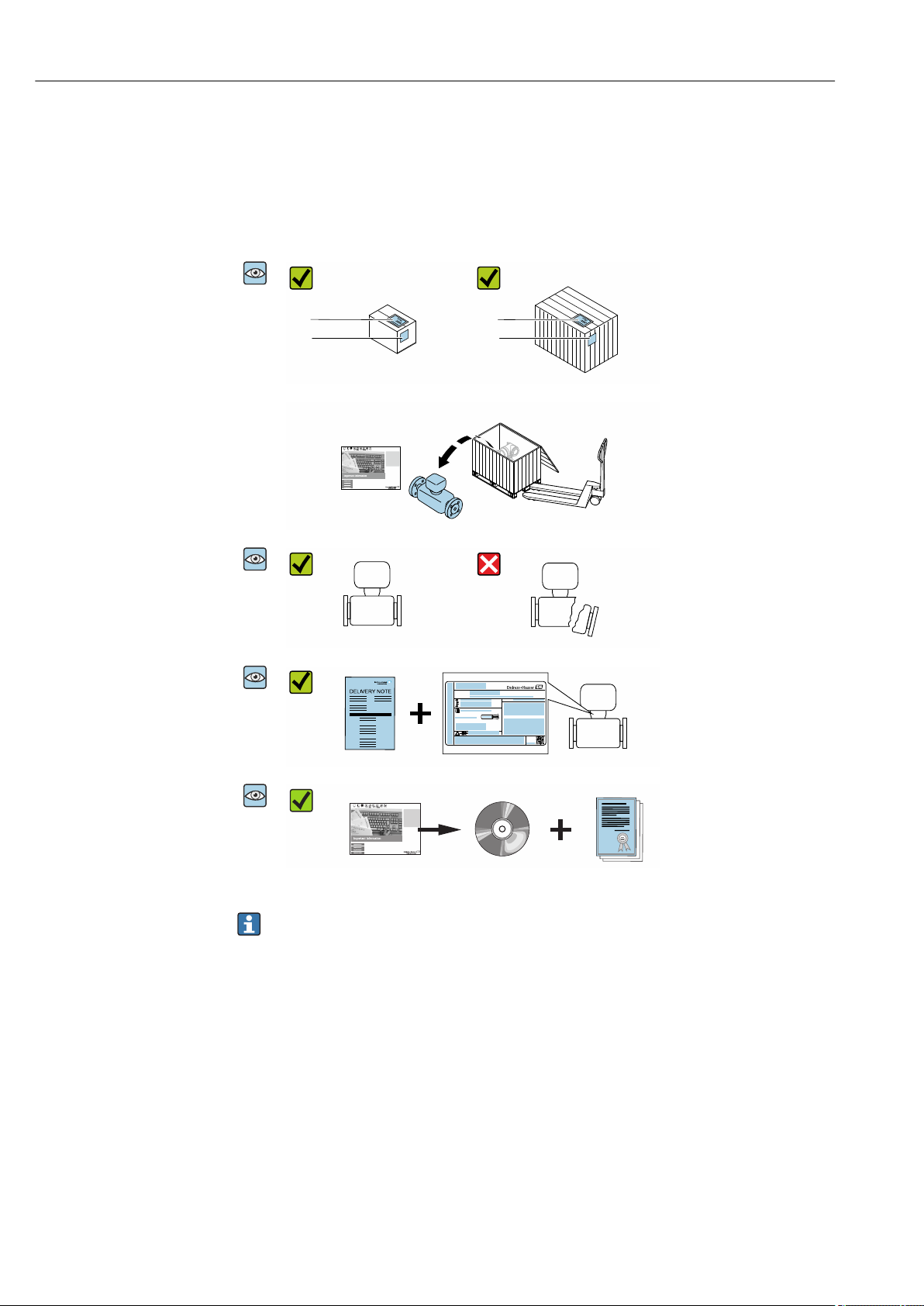

4.1 Incoming acceptance

Are the order codes on the

delivery note (1) and the

product sticker (2) identical?

Are the goods undamaged?

Order code:

Ser. no.:

Ext. ord. cd.:

i

i

Date:

Do the nameplate data

match the ordering

information on the delivery

note?

Is the document folder

present with accompanying

documents?

Is the optional CD-ROM with

the Technical

Documentation present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery!

The Technical Documentation is available via the Internet or via the Endress+Hauser

Operations App, see the «Product identification» section → 15.

4.2 Product identification

The following options are available for identification of the device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in the W@M Device Viewer

(www.endress.com/deviceviewer): All information about the device is displayed.

• Enter the serial number from nameplates in the Endress+Hauser Operations App or scan

the 2-D matrix code (QR code) on the nameplate using the Endress+Hauser Operations

App: All information about the device is displayed.

Proline Prowirl F 200 HART Incoming acceptance and product identification

Endress+Hauser 15

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The «Additional standard documentation on the device»→ 8 and «Supplementary

device-dependent documentation»→ 8 sections

• The W@M Device Viewer: enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

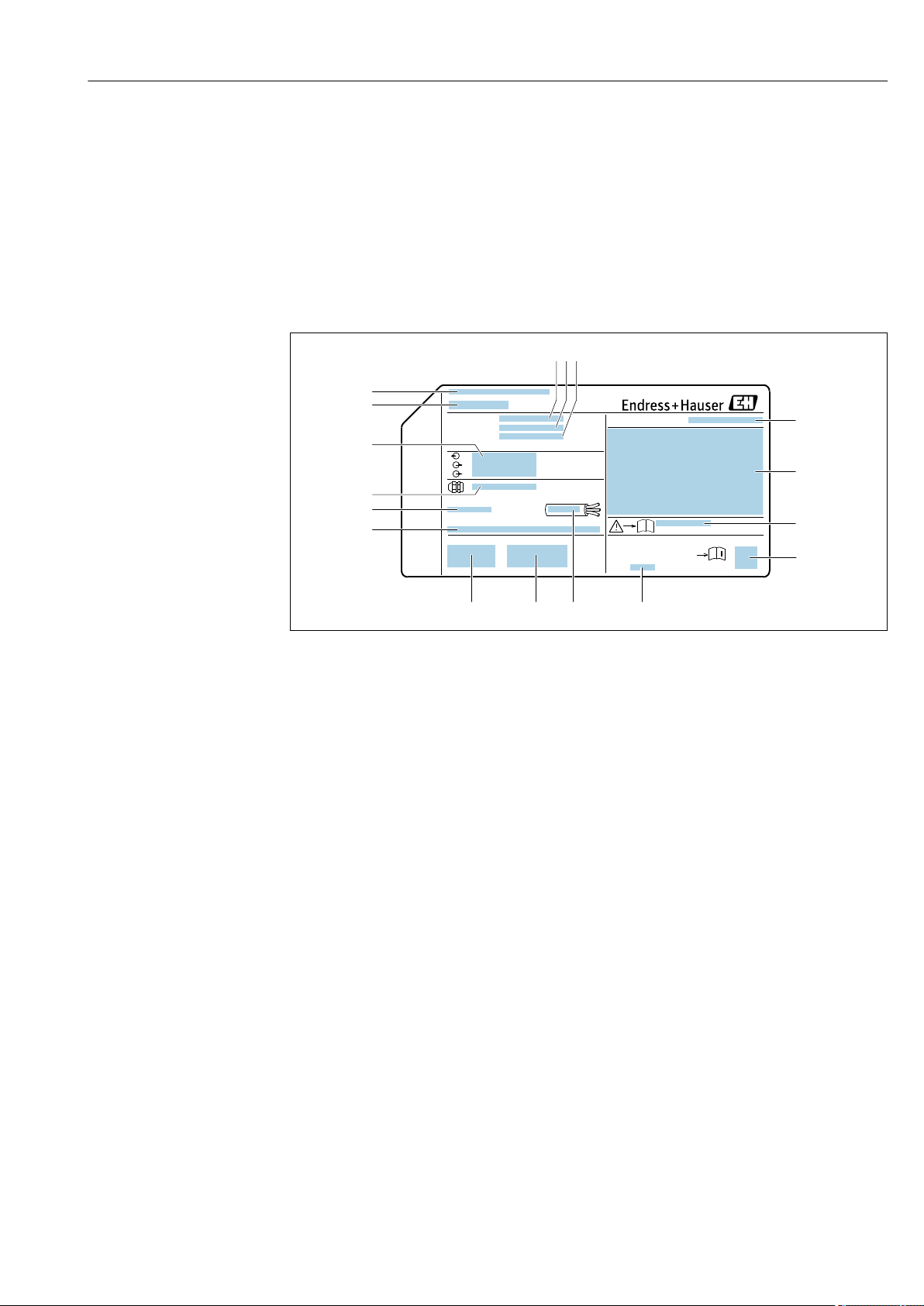

4.2.1 Transmitter nameplate

Order code:

Ext. ord. cd.:

Ser. no.:

Date:

i

i

Patents

322540-0001

1

2

3 4 5

6

7

8

9

10 11

12

14

15

16

17

13

A0032237

3 Example of a transmitter nameplate

1 Manufacturing location

2 Name of the transmitter

3 Order code

4 Serial number (ser. no.)

5 Extended order code (Ext. ord. cd.)

6 Electrical connection data, e.g. available inputs and outputs, supply voltage

7 Type of cable glands

8 Permitted ambient temperature (T

a

)

9 Firmware version (FW) and device revision (Dev.Rev.) from the factory

10 CE mark, C-Tick

11 Additional information on version: certificates, approvals

12 Permitted temperature range for cable

13 Manufacturing date: year-month

14 Degree of protection

15 Approval information for explosion protection

16 Document number of safety-related supplementary documentation

17 2-D matrix code

Incoming acceptance and product identification Proline Prowirl F 200 HART

16 Endress+Hauser

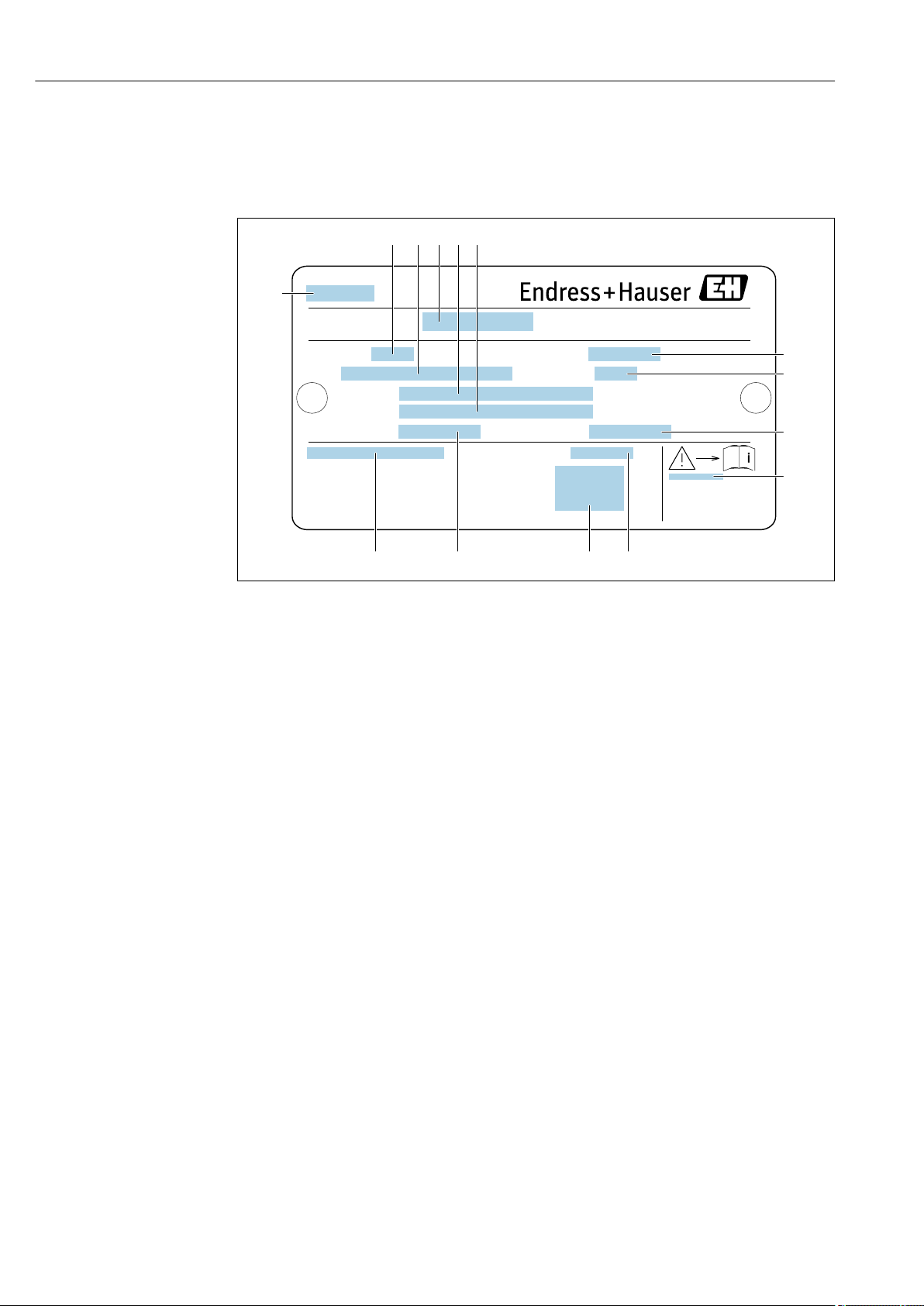

4.2.2 Sensor nameplate

Order code for «Housing» option B «GT18 dual compartment, 316L, compact» and

option K «GT18 dual compartment, 316L, remote»

Ser. no.:

Ptest:

Size:

Materials:

Gasket:

Tm:

Qmax(G):

Ta:

1

2 6

7

8

3

9

10

13 12

4 5

14 11

A0034423

4 Example of a sensor nameplate

1 Name of the sensor

2 Nominal diameter of sensor

3 Flange nominal diameter/nominal pressure

4 Serial number (ser. no.)

5 Measuring tube material

6 Measuring tube material

7 Maximum permitted volume flow (gas/steam): Q

max

→ 173

8 Test pressure of the sensor: OPL→ 192

9 Seal material

10 Document number of safety-related supplementary documentation → 205

11 Ambient temperature range

12 CE mark

13 Medium temperature range

14 Degree of protection

Proline Prowirl F 200 HART Incoming acceptance and product identification

Endress+Hauser 17

Order code for «Housing» option C «GT20 dual compartment, aluminum, coated,

compact»

Ser. no.:

Ptest:

Size:

Materials:

Tm:

Qmax(G):

Gasket:

Ta:

1

2

5 6 8

7

9

3

4

10

111213

A0034161

5 Example of a sensor nameplate

1 Nominal diameter of sensor

2 Flange nominal diameter/nominal pressure

3 Measuring tube material

4 Measuring tube material

5 Serial number (ser. no.)

6 Maximal permitted volume flow (gas/steam)

7 Test pressure of the sensor

8 Degree of protection

9 Approval information for explosion protection and Pressure Equipment Directive→ 205

10 CE mark

11 Seal material

12 Medium temperature range

13 Ambient temperature range

Incoming acceptance and product identification Proline Prowirl F 200 HART

18 Endress+Hauser

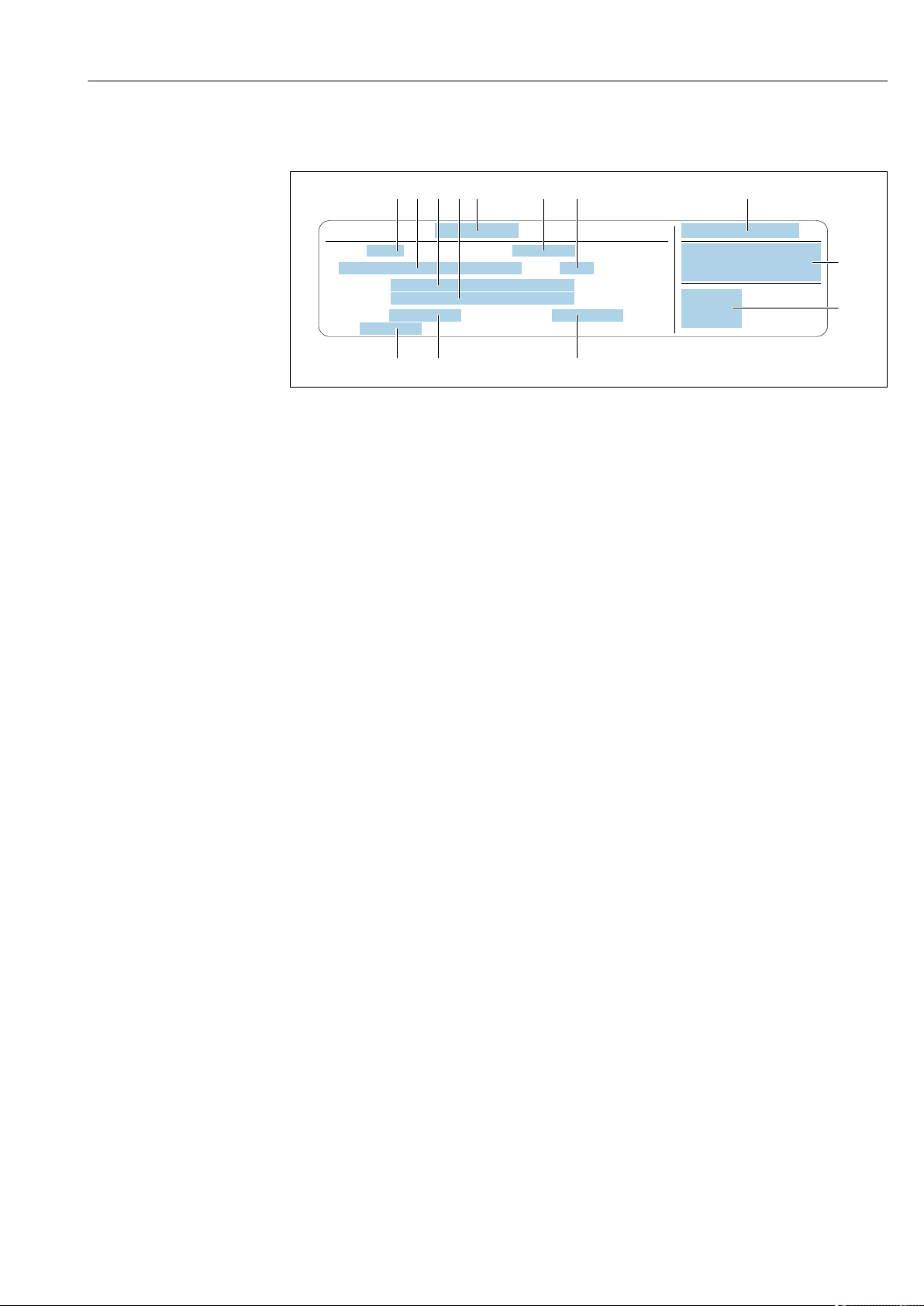

Order code for «Housing» option J «GT20 dual compartment, aluminum, coated,

remote»

Order code:

Ext. ord. cd.:

Ser. no.:

Ptest:

Size:

Ta:

Materials:

Gasket:

Tm:

Qmax(G):

4

1

5

8

12

2

7

9

10

11

13141516

3

6

A0034162

6 Example of a sensor nameplate

1 Name of the sensor

2 Nominal diameter of sensor

3 Flange nominal diameter/nominal pressure

4 Order code

5 Serial number (ser. no.)

6 Extended order code (Ext. ord. cd.)

7 Maximal permitted volume flow (gas/steam)

8 Degree of protection

9 Approval information for explosion protection and Pressure Equipment Directive

10 Ambient temperature range

11 Document number of safety-related supplementary documentation → 205

12 Test pressure of the sensor

13 Measuring tube material

14 Measuring tube material

15 Seal material

16 Medium temperature range

Order code

The measuring device is reordered using the order code.

Extended order code

• The device type (product root) and basic specifications (mandatory features) are

always listed.

• Of the optional specifications (optional features), only the safety and approval-

related specifications are listed (e.g. LA). If other optional specifications are also

ordered, these are indicated collectively using the # placeholder symbol (e.g. #LA#).

• If the ordered optional specifications do not include any safety and approval-related

specifications, they are indicated by the + placeholder symbol (e.g. XXXXXX-ABCDE

+).

Proline Prowirl F 200 HART Incoming acceptance and product identification

Endress+Hauser 19

4.2.3 Pressure measuring cells nameplate

A0034354

7 Example of pressure measuring cell nameplate

1 Manufacturer address

2 Pressure range

3 Maximum permitted pressure

4 Ambient temperature range

5 Serial number or XPD structure

6 Degree of protection

7 CE mark, C-Tick mark

8 QR code

9 Manufacturing date

4.2.4 Symbols on measuring device

Symbol Meaning

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious

or fatal injury.

Reference to documentation

Refers to the corresponding device documentation.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Storage and transport Proline Prowirl F 200 HART

20 Endress+Hauser

5 Storage and transport

5.1 Storage conditions

Observe the following notes for storage:

‣

Store in the original packaging to ensure protection from shock.

‣

Do not remove protective covers or protective caps installed on process connections.

They prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

‣

Protect from direct sunlight to avoid unacceptably high surface temperatures.

‣

Store in a dry and dust-free place.

‣

Do not store outdoors.

Storage temperature: –50 to +80 °C (–58 to +176 °F)

5.2 Transporting the product

Transport the measuring device to the measuring point in the original packaging.

A0029252

Do not remove protective covers or caps installed on process connections. They

prevent mechanical damage to the sealing surfaces and contamination in the

measuring tube.

5.2.1 Measuring devices without lifting lugs

L

WARNING

Center of gravity of the measuring device is higher than the suspension points of the

webbing slings.

Risk of injury if the measuring device slips.

‣

Secure the measuring device against slipping or turning.

‣

Observe the weight specified on the packaging (stick-on label).

A0029214

Proline Prowirl F 200 HART Storage and transport

Endress+Hauser 21

5.2.2 Measuring devices with lifting lugs

L

CAUTION

Special transportation instructions for devices with lifting lugs

‣

Only use the lifting lugs fitted on the device or flanges to transport the device.

‣

The device must always be secured at two lifting lugs at least.

5.2.3 Transporting with a fork lift

If transporting in wood crates, the floor structure enables the crates to be lifted lengthwise

or at both sides using a forklift.

5.3 Packaging disposal

All packaging materials are environmentally friendly and 100 % recyclable:

• Outer packaging of device

Polymer stretch wrap that complies with EU Directive 2002/95/EC (RoHS)

• Packaging

• Wooden crate treated in accordance with ISPM 15 standard, confirmed by IPPC logo

• Cardboard box in accordance with European packaging guideline 94/62EC,

recyclability confirmed by Resy symbol

• Carrying and securing materials

• Disposable plastic pallet

• Plastic straps

• Plastic adhesive strips

• Filler material

Paper pads

Installation Proline Prowirl F 200 HART

22 Endress+Hauser

6 Installation

6.1 Installation conditions

6.1.1 Mounting position

Mounting location

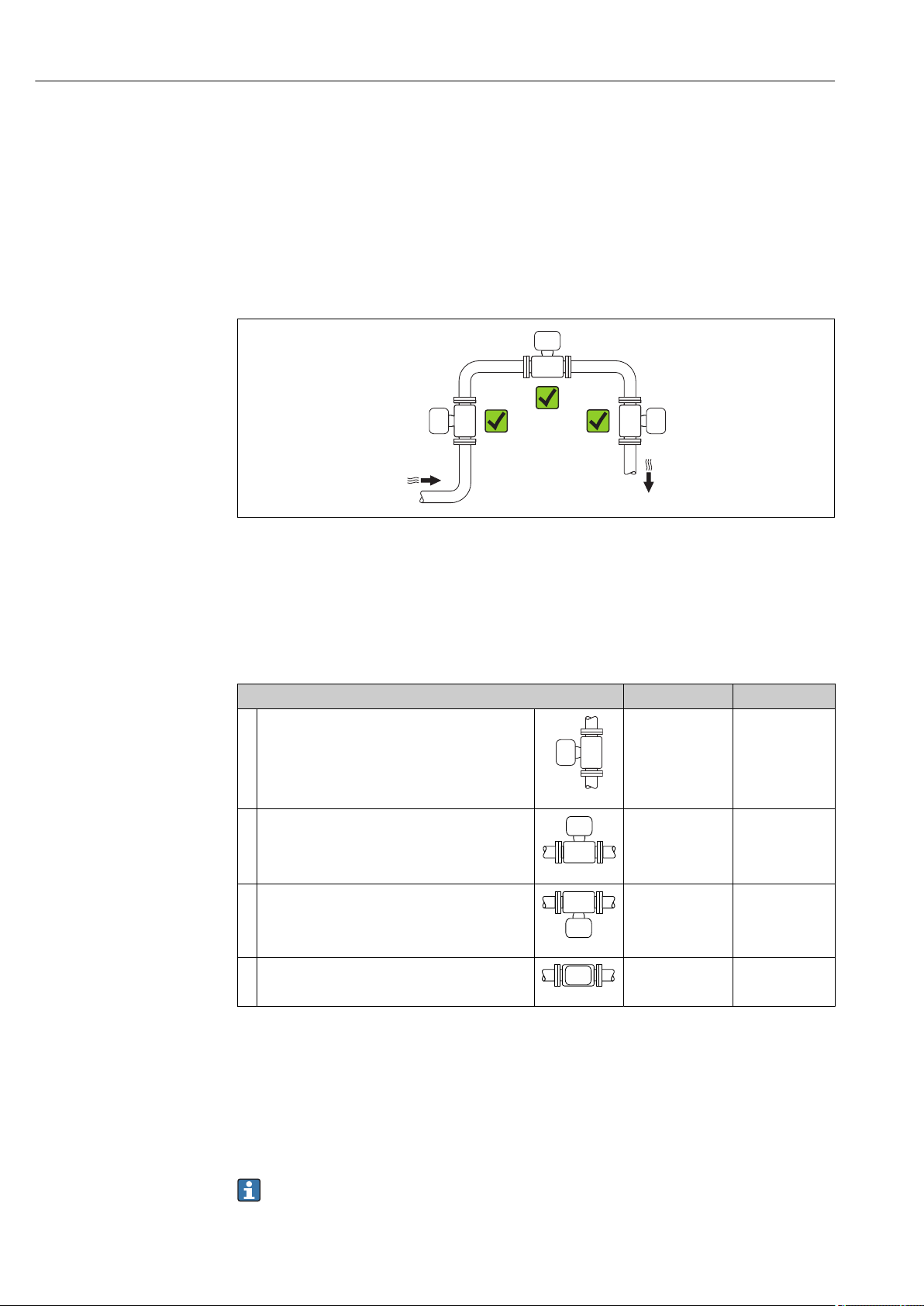

A0015543

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor

according to the flow direction (direction of medium flow through the piping).

Vortex meters require a fully developed flow profile as a prerequisite for correct volume

flow measurement. Therefore, please note the following:

Orientation Compact version Remote version

A Vertical orientation

A0015545

1)

B Horizontal orientation, transmitter head up

A0015589

2) 3)

C Horizontal orientation, transmitter head down

A0015590

4) 5)

D Horizontal orientation, transmitter head at side

A0015592

4)

1) In the case of liquids, there should be upward flow in vertical pipes to avoid partial pipe filling (Fig. A).

Disruption in flow measurement! In the case of vertical orientation and downward flowing liquid, the pipe

always needs to be completely filled to ensure correct liquid flow measurement.

2) Danger of electronics overheating! If the fluid temperature is ≥ 200 °C (392 °F), orientation B is not

permitted for the wafer version (Prowirl D) with nominal diameters of DN 100 (4″) and DN 150 (6″).

3) In the case of hot media (e.g. steam or fluid temperature (TM) ≥ 200 °C (392 °F): orientation C or D

4) In the case of very cold media (e.g. liquid nitrogen): orientation B or D

5) For «wet steam detection/measurement» option: orientation C

The «mass» sensor version (integrated pressure/temperature measurement) is

available only for measuring devices in the HART communication mode.

Proline Prowirl F 200 HART Installation

Endress+Hauser 23

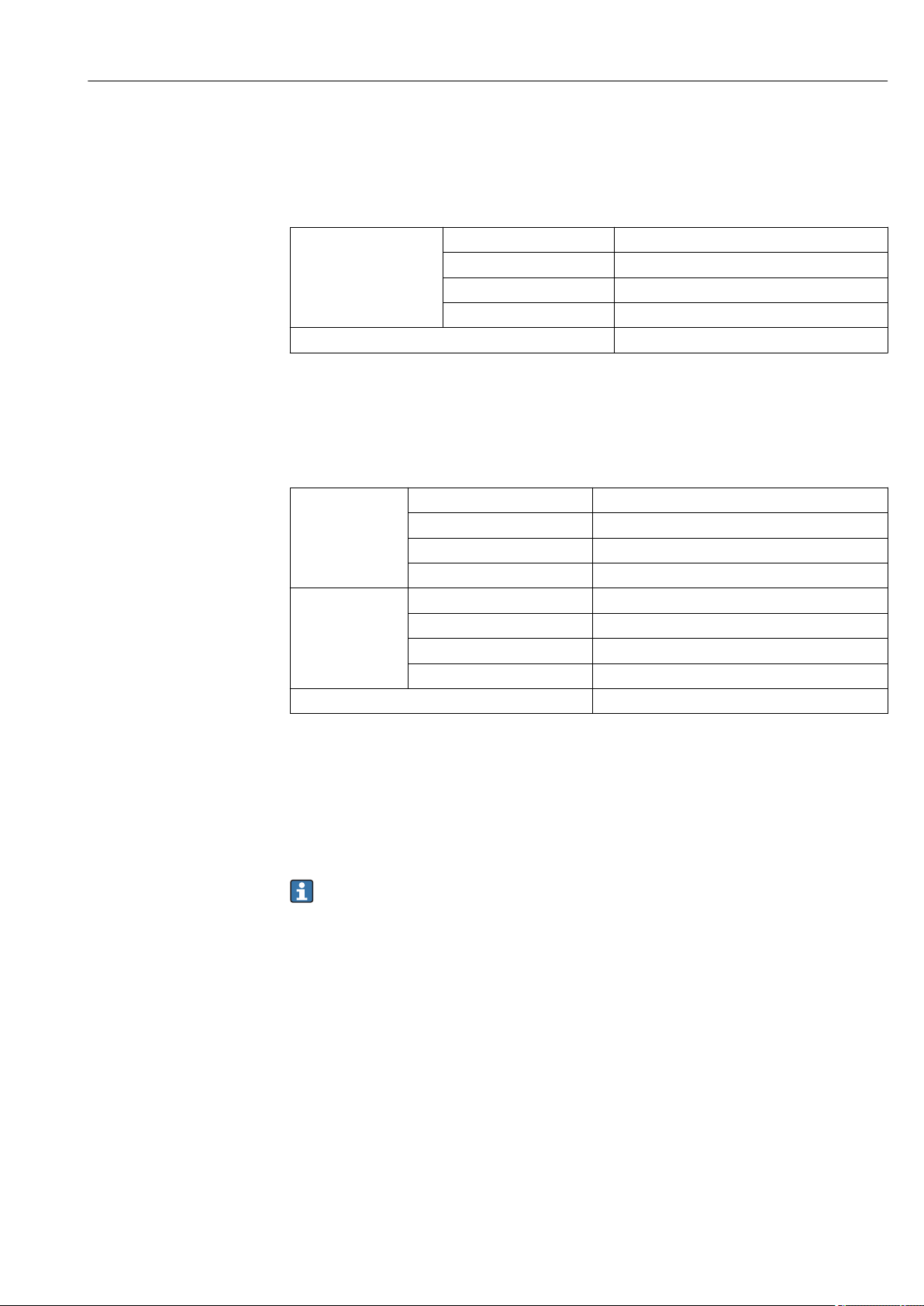

Pressure measuring cell

Steam pressure measurement Option DA

E • With the

transmitter

installed at the

bottom or at the

side

• Protection

against rising

heat

• Reduction in

temperature to

almost ambient

temperature due

to siphon

1)

A0034057

F

A0034058

Gas pressure measurement Option DB

G • Pressure

measuring cell

with shutoff

device above

tapping point

• Discharge of any

condensate into

the process

A0034092

Liquid pressure measurement Option DB

H Device with shutoff

device at the same

level as tapping

point

A0034091

1) Note max. permitted ambient temperature of transmitter→ 27.

Minimum spacing and cable length

Order code for «Sensor version», option «mass» DA, DB

The «mass» sensor version (integrated pressure/temperature measurement) is

available only for measuring devices in the HART communication mode.

A0019211

A Minimum spacing in all directions

L Required cable length

Installation Proline Prowirl F 200 HART

24 Endress+Hauser

The following dimensions must be observed to guarantee problem-free access to the device

for service purposes:

• A =100 mm (3.94 in)

• L = L + 150 mm (5.91 in)

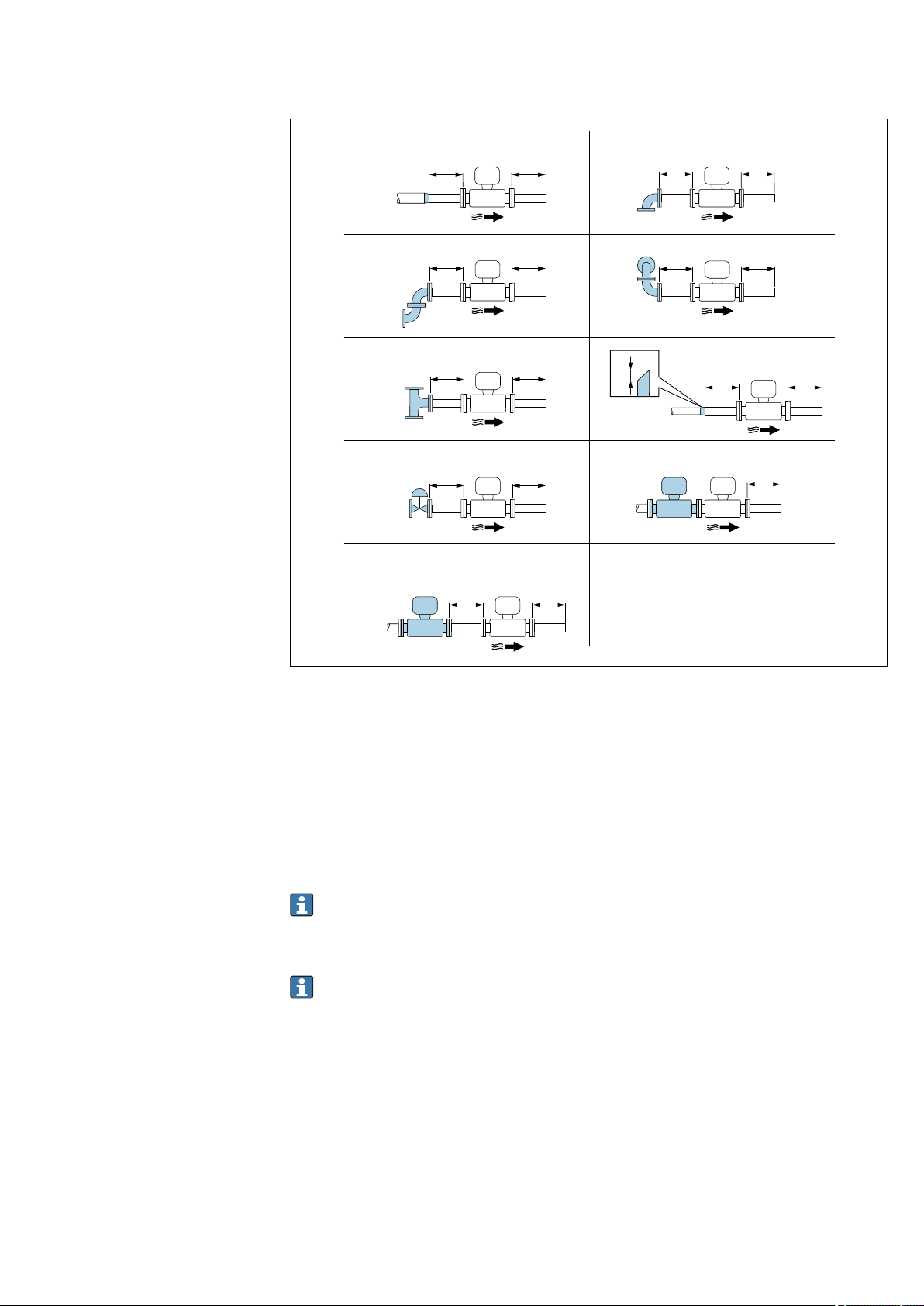

Inlet and outlet runs

To attain the specified level of accuracy of the measuring device, the inlet and outlet runs

mentioned below must be maintained at the very minimum.

Proline Prowirl F 200 HART Installation

Endress+Hauser 25

1

15 DN×

5 × DN

3

25 × DN

5 × DN

40 × DN

5 × DN

4

2

20 × DN

5 × DN

5

20 × DN

5 × DN

6

17 × DN + 8 × h

5 × DN

h

7

50 × DN

5 × DN

9

40 × DN

5 × DN

8

5 × DN

DN 25 (1″):≤

DN 40 (1½»):≥

A0019189

8 Minimum inlet and outlet runs with various flow obstructions

h Difference in expansion

1 Reduction by one nominal diameter size

2 Single elbow (90° elbow)

3 Double elbow (2 × 90° elbows, opposite)

4 Double elbow 3D (2 × 90° elbows, opposite, not on one plane)

5 T-piece

6 Expansion

7 Control valve

8 Two measuring devices in a row where DN ≤ 25 (1″): directly flange on flange

9 Two measuring devices in a row where DN ≥ 40 (1½»): for spacing, see graphic

• If there are several flow disturbances present, the longest specified inlet run must

be maintained.

• If the required inlet runs cannot be observed, it is possible to install a specially

designed flow conditioner → 25.

The inlet run correction function:

• Makes it possible to shorten the inlet run to a minimum length of 10 × DN in the

event of flow obstructions 1 to 4. An additional measuring uncertainty of ±0.5% o.r.

occurs here. → 111

• Cannot be combined with the wet steam detection/measurement application

package. If wet steam detection/measurement is used, the corresponding inlet runs

must be taken into consideration. It is not possible to use a flow conditioner for wet

steam.

Flow conditioner

If the inlet runs cannot be observed, the use of a flow conditioner is recommended.

Installation Proline Prowirl F 200 HART

26 Endress+Hauser

The flow conditioner is fitted between two pipe flanges and centered by the mounting

bolts. Generally this reduces the inlet run needed to 10 × DN with full accuracy.

A0019208

1 Flow conditioner

The pressure loss for flow conditioners is calculated as follows: ∆ p [mbar] = 0.0085 ⋅ ρ

[kg/m

3

] ⋅ v

2

[m/s]

Example for steam Example for H

2

O condensate (80 °C)

p = 10 bar abs. ρ = 965 kg/m

3

t = 240 °C → ρ = 4.39 kg/m

3

v = 2.5 m/s

v = 40 m/s ∆ p = 0.0085 ⋅ 965 ⋅ 2.5

2

= 51.3 mbar

∆ p = 0.0085 ⋅ 4.394.39 ⋅ 40

2

= 59.7 mbar

ρ : density of the process medium

v: average flow velocity

abs. = absolute

For the dimensions of the flow conditioner, see the «Technical Information» document,

«Mechanical construction» section

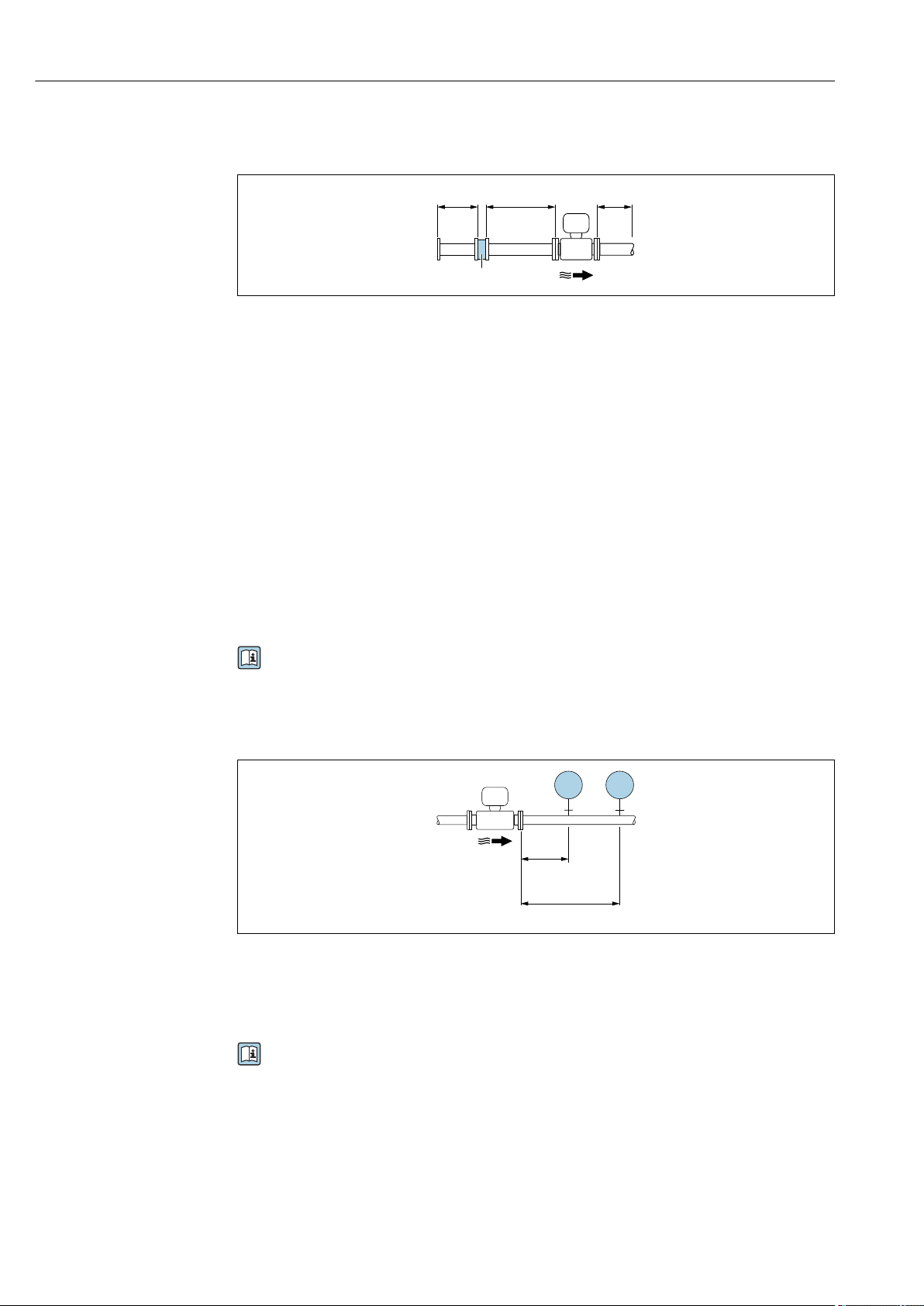

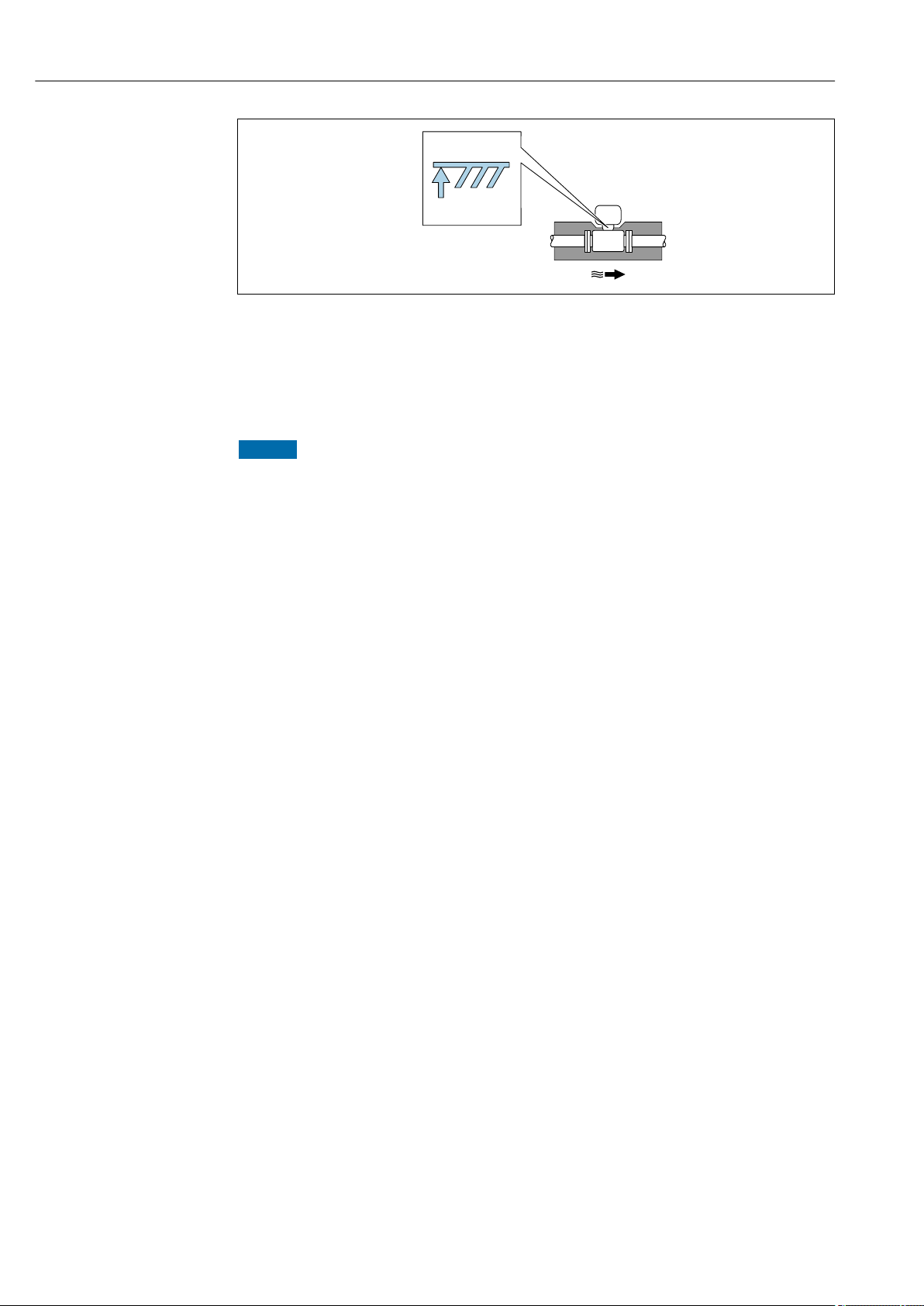

Outlet runs when installing external devices

If installing an external device, observe the specified distance.

A0019205

PT Pressure

TT Temperature device

Installation dimensions

For the dimensions and installation lengths of the device, see the «Technical

Information» document, «Mechanical construction» section.

Proline Prowirl F 200 HART Installation

Endress+Hauser 27

6.1.2 Environment and process requirements

Ambient temperature range

Compact version

Measuring device Non-hazardous area: –40 to +80 °C (–40 to +176 °F)

1)

Ex i, Ex nA, Ex ec: –40 to +70 °C (–40 to +158 °F)

1)

Ex d, XP: –40 to +60 °C (–40 to +140 °F)

1)

Ex d, Ex ia: –40 to +60 °C (–40 to +140 °F)

1)

Local display –40 to +70 °C (–40 to +158 °F)

2) 1)

1) Additionally available as order code for «Test, certificate», option JN «Transmitter ambient temperature –

50 °C (–58 °F)».

2) At temperatures < –20 °C (–4 °F), depending on the physical characteristics involved, it may no longer be

possible to read the liquid crystal display.

Remote version

Transmitter Non-hazardous area: –40 to +80 °C (–40 to +176 °F)

1)

Ex i, Ex nA, Ex ec: –40 to +80 °C (–40 to +176 °F)

1)

Ex d: –40 to +60 °C (–40 to +140 °F)

1)

Ex d, Ex ia: –40 to +60 °C (–40 to +140 °F)

1)

Sensor Non-hazardous area: –40 to +85 °C (–40 to +185 °F)

1)

Ex i, Ex nA, Ex ec: –40 to +85 °C (–40 to +185 °F)

1)

Ex d: –40 to +85 °C (–40 to +185 °F)

1)

Ex d, Ex ia: –40 to +85 °C (–40 to +185 °F)

1)

Local display –40 to +70 °C (–40 to +158 °F)

2) 1)

1) Additionally available as order code for «Test, certificate», option JN «Transmitter ambient temperature –

50 °C (–58 °F)».

2) At temperatures < –20 °C (–4 °F), depending on the physical characteristics involved, it may no longer be

possible to read the liquid crystal display.

‣

If operating outdoors:

Avoid direct sunlight, particularly in warm climatic regions.

You can order a weather protection cover from Endress+Hauser. → 168.

Thermal insulation

For optimum temperature measurement and mass calculation, heat transfer at the sensor

must be avoided for some fluids. This can be ensured by installing thermal insulation. A

wide range of materials can be used for the required insulation.

This applies for:

• Compact version

• Remote sensor version

The maximum insulation height permitted is illustrated in the diagram:

Installation Proline Prowirl F 200 HART

28 Endress+Hauser

A0019212

1 Maximum insulation height

‣

When insulating, ensure that a sufficiently large area of the housing support remains

exposed.

The uncovered part serves as a radiator and protects the electronics from overheating and

excessive cooling.

NOTICE

Electronics overheating on account of thermal insulation!

‣

Observe the maximum permitted insulation height of the transmitter neck so that the

transmitter head and/or the connection housing of the remote version is completely

free.

‣

Observe information on the permissible temperature ranges.

‣

Note that a certain orientation might be required, depending on the fluid temperature.

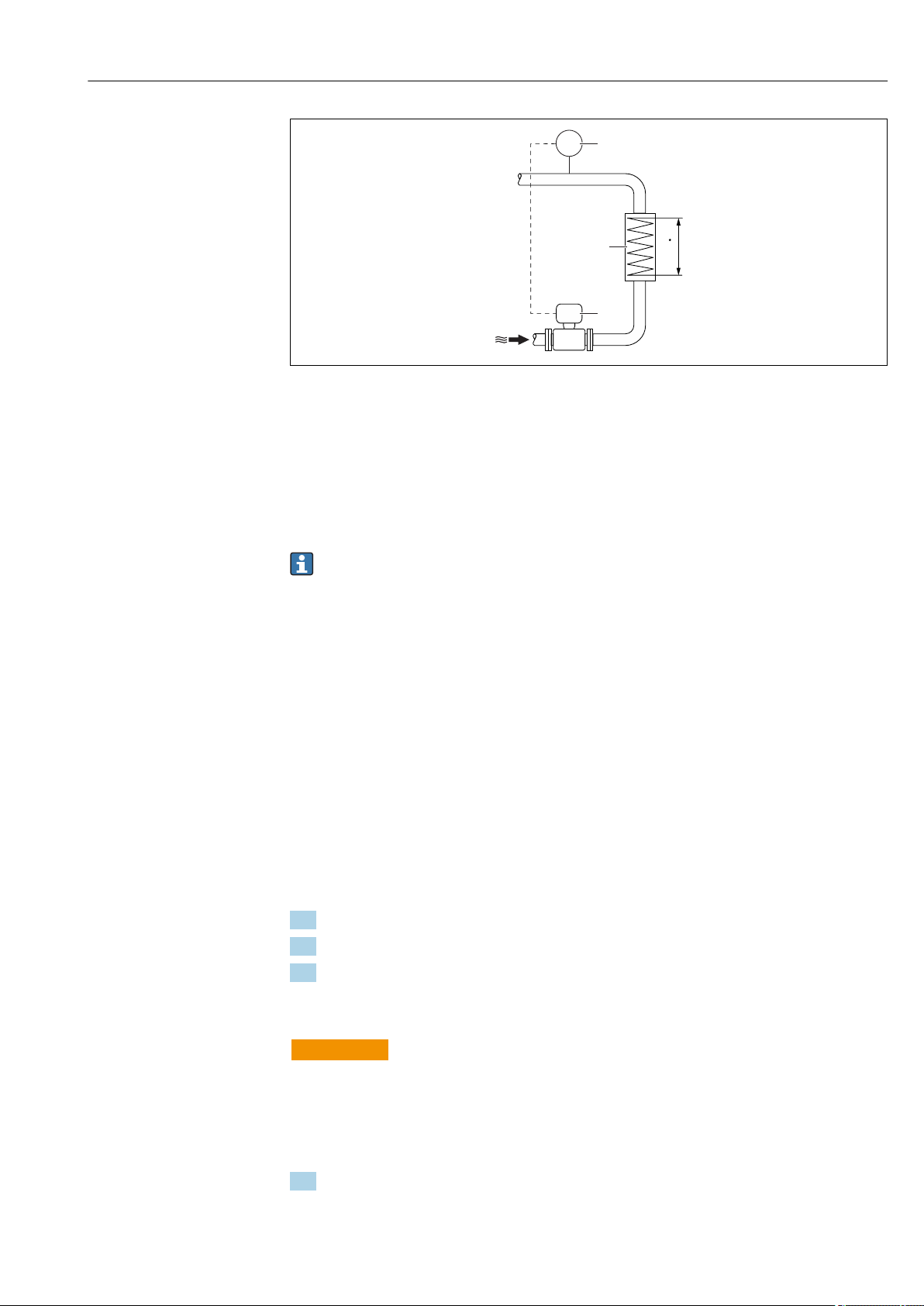

6.1.3 Special mounting instructions

Installation for delta heat measurements

• Order code for «Sensor version», option CA «mass; 316L; 316L (integrated temperature

measurement), –200 to +400 °C (–328 to +750 °F)»

• Order code for «Sensor version», option CB «mass; Alloy C22; 316L (integrated

temperature measurement), –200 to +400 °C (–328 to +750 °F)»

• Order code for «Sensor version», option CC «mass; Alloy C22; Alloy C22 (integrated

temperature measurement), –40 to +260 °C (–40 to +500 °F)»

• Order code for «Sensor version», option DA «mass steam; 316L; 316L (integrated

pressure/temperature measurement), –200 to +400 °C (–328 to +750 °F)»

• Order code for «Sensor version», option DB «mass gas/liquid; 316L; 316L (integrated

pressure/temperature measurement), –40 to +100 °C (–40 to +212 °F)»

The second temperature measurement is taken using a separate temperature sensor. The

measuring device reads in this value via a communication interface.

• In the case of saturated steam delta heat measurements, the measuring device must be

installed on the steam side.

• In the case of water delta heat measurements, the device can be installed on the cold or

warm side.

Proline Prowirl F 200 HART Installation

Endress+Hauser 29

A0019209

9 Layout for delta heat measurement of saturated steam and water

1 Measuring device

2 Temperature sensor

3 Heat exchanger

Q Heat flow

Protective cover

Observe the following minimum head clearance: 222 mm (8.74 in)

For information on the weather protection cover, see → 168

6.2 Mounting the measuring device

6.2.1 Required tools

For transmitter

• For turning the transmitter housing: Open-ended wrench8 mm

• For opening the securing clamps: Allen key3 mm

For sensor

For flanges and other process connections: Corresponding mounting tools

6.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove any protective covers or protective caps present from the sensor.

3. Remove stick-on label on the electronics compartment cover.

6.2.3 Mounting the sensor

L

WARNING

Danger due to improper process sealing!

‣

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

process connections and piping.

‣

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

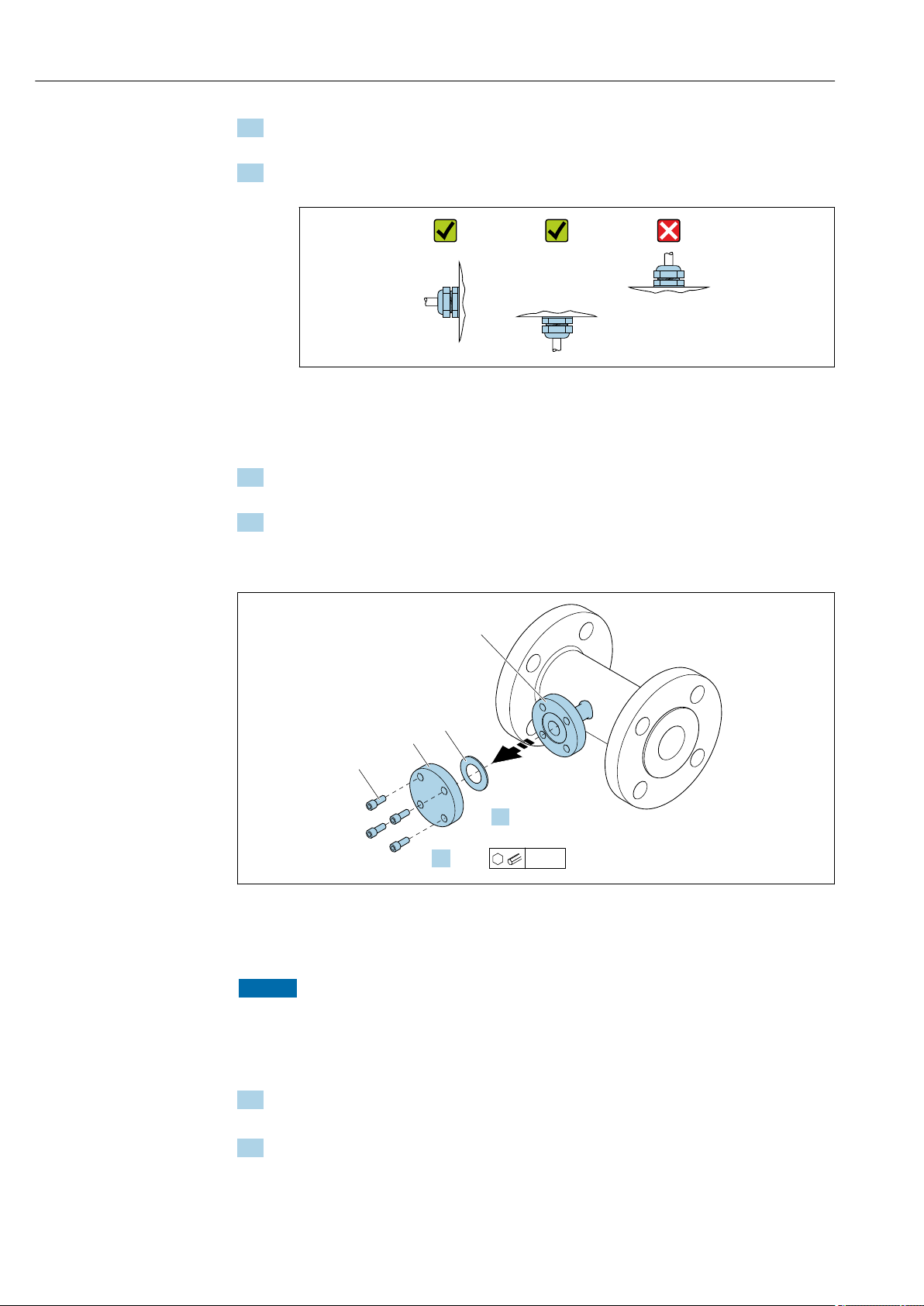

1. Ensure that the direction of the arrow on the sensor matches the flow direction of

the medium.

Installation Proline Prowirl F 200 HART

30 Endress+Hauser

2. To ensure compliance with device specifications, install the measuring device

between the pipe flanges in a way that it is centered in the measurement section.

3. Install the measuring device or turn the transmitter housing so that the cable entries

do not point upwards.

A0029263

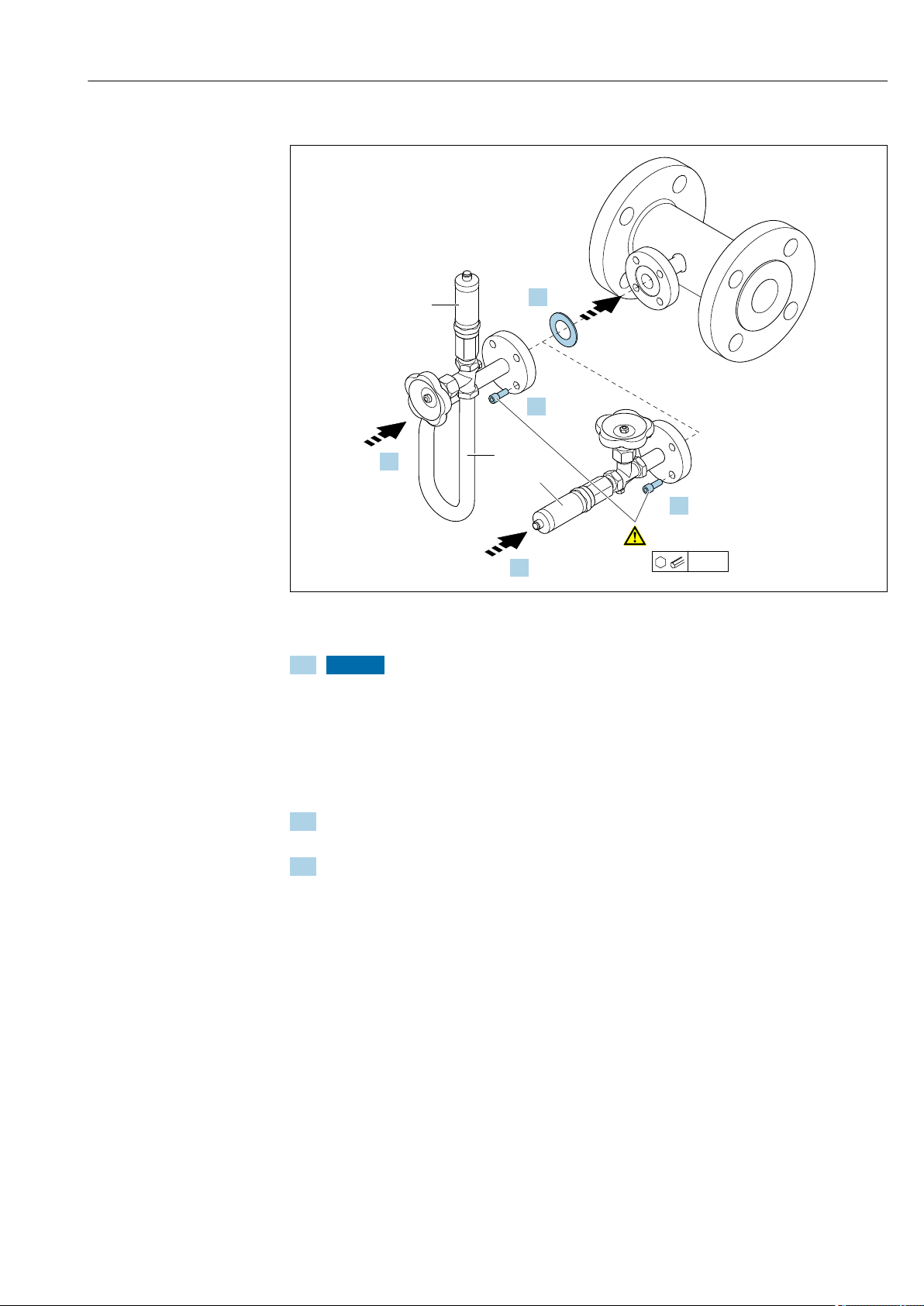

6.2.4 Mounting the pressure measuring unit

Preparation

1. Prior to mounting the pressure measuring unit, install the measuring device in the

pipe.

2. When mounting the pressure measuring unit, use only the seal provided. The use of a

different sealing material is not permitted.

Removing the blind flange

A0034355

1 Mounting screws

2 blind flange

3 Seal

4 Flange connection on sensor side

NOTICE

When replacing the seal following commissioning, fluid may escape when the flange

connection is opened!

‣

Ensure that the measuring device is not under pressure.

‣

Ensure that there is no fluid in the measuring device.

1. Release the mounting screws on the blind flange.

The screws are needed again to mount the pressure measuring unit.

2. Remove the internal seal.

Proline Prowirl F 200 HART Installation

Endress+Hauser 31

Mounting the pressure measuring unit

A0035442

5 Siphon

6 Pressure measuring cell

3. NOTICE

Damage to seal!

The seal is made of expanded graphite. It can therefore be used only once. If a

coupling is released, a new seal must be installed.

‣

Use the additional seals provided. If necessary, these can be ordered as separate

spare parts at a later stage.

Insert the enclosed seal into the groove of the flange connection on the sensor side.

4. Align the flange connection on the pressure measuring unit and tighten the screws

by hand.

5. Tighten the screws with a torque wrench in three steps.

1. 10 Nm in criss-cross sequence

2. 15 Nm in criss-cross sequence

3. 15 Nm in circular sequence

Installation Proline Prowirl F 200 HART

32 Endress+Hauser

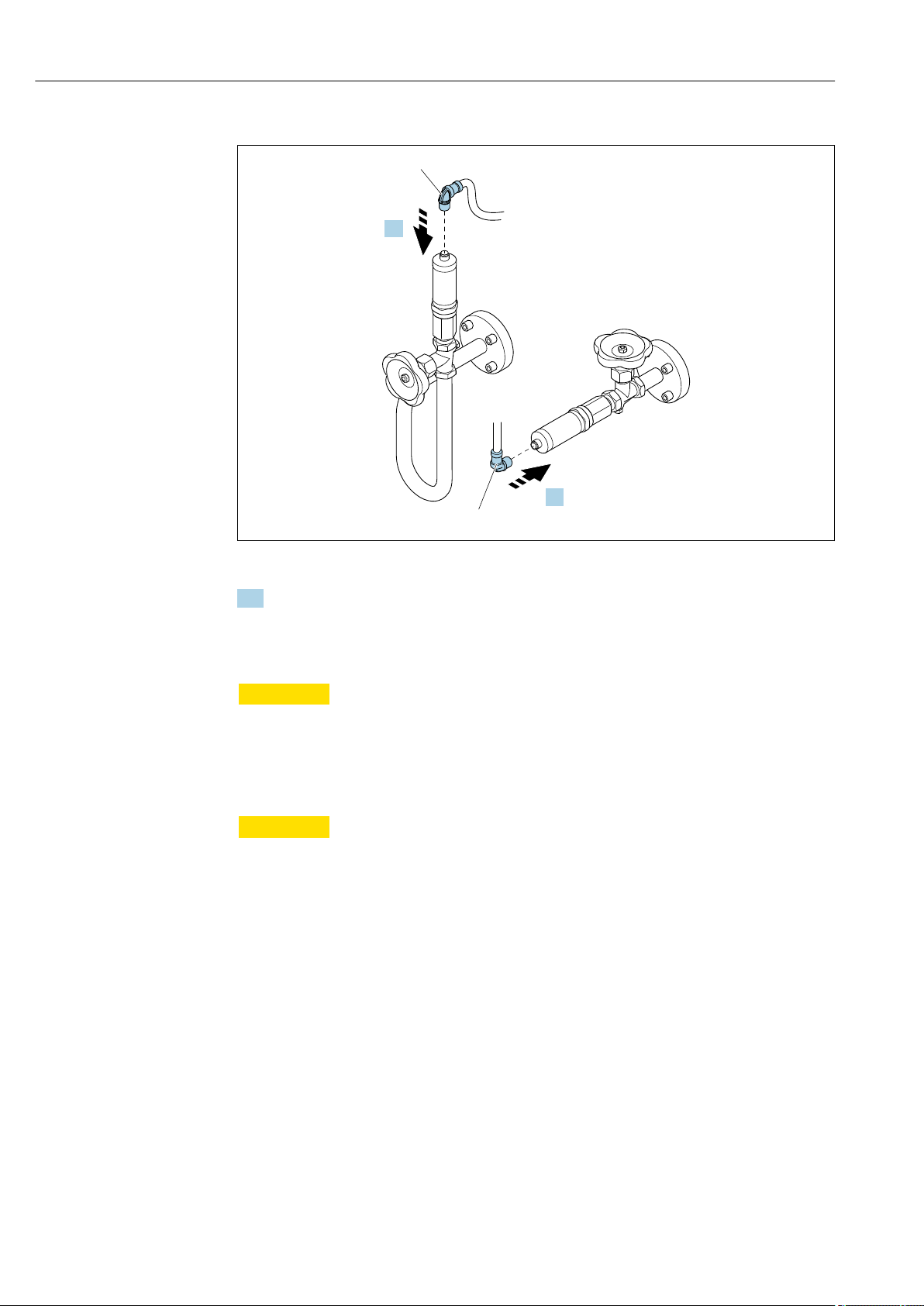

Connecting the pressure measuring unit

A0035443

7 Device plug

6. Insert the plug for electrical connection of the pressure measuring cell and screw into

place.

6.2.5 Mounting the transmitter of the remote version

L

CAUTION

Ambient temperature too high!

Danger of electronics overheating and housing deformation.

‣

Do not exceed the permitted maximum ambient temperature .

‣

If operating outdoors: Avoid direct sunlight and exposure to weathering, particularly in

warm climatic regions.

L

CAUTION

Excessive force can damage the housing!

‣

Avoid excessive mechanical stress.

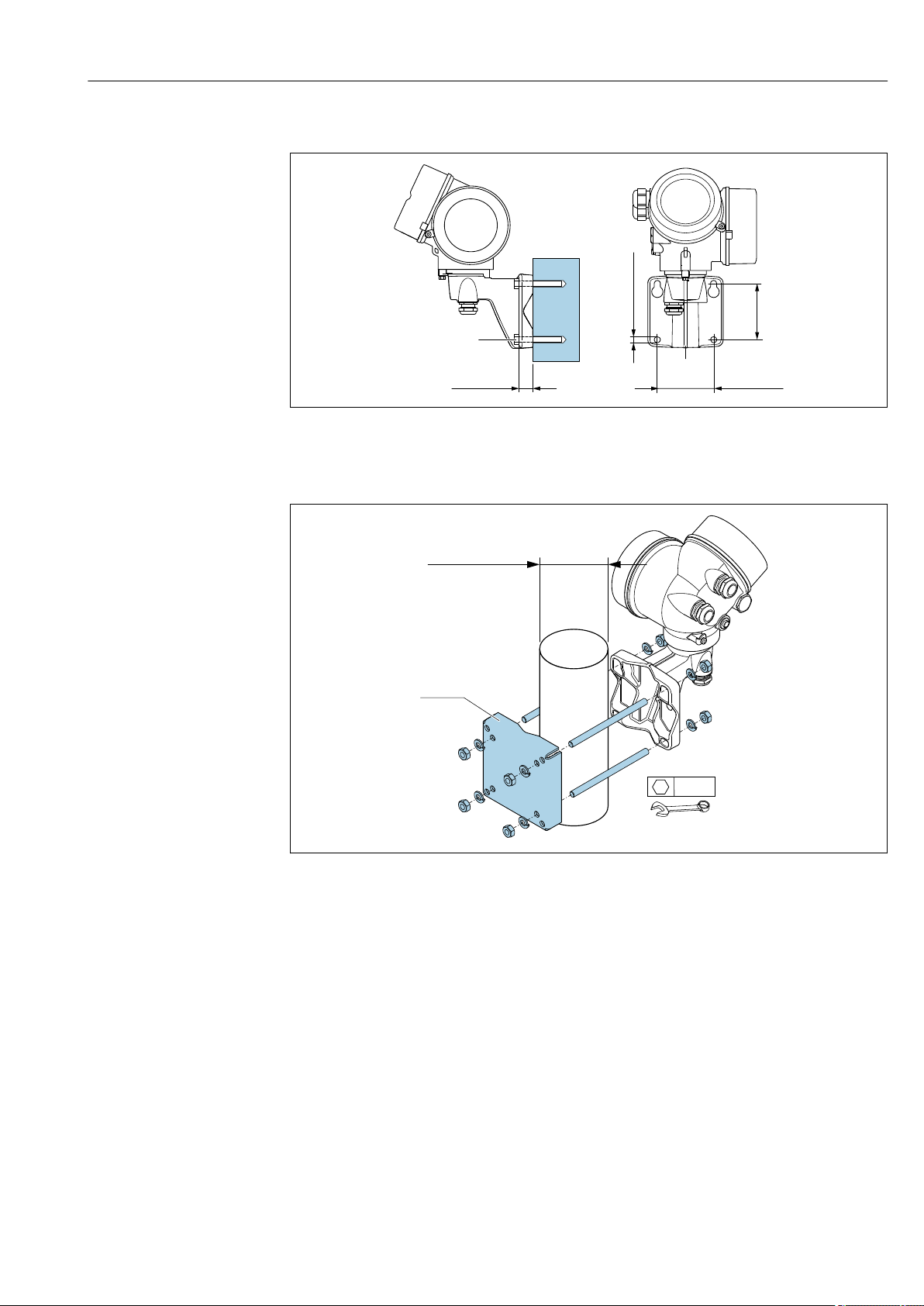

The transmitter of the remote version can be mounted in the following ways:

• Wall mounting

• Pipe mounting

Proline Prowirl F 200 HART Installation

Endress+Hauser 33

Wall mounting

80 (3.15)

80 (3.15)

19 (0.6)

! 8.6 (0.39)

M8

A0033484

10 mm (in)

Post mounting

! …20 70

(! 0.79 to 2.75)

4 x

SW 13

A0033486

11 mm (in)

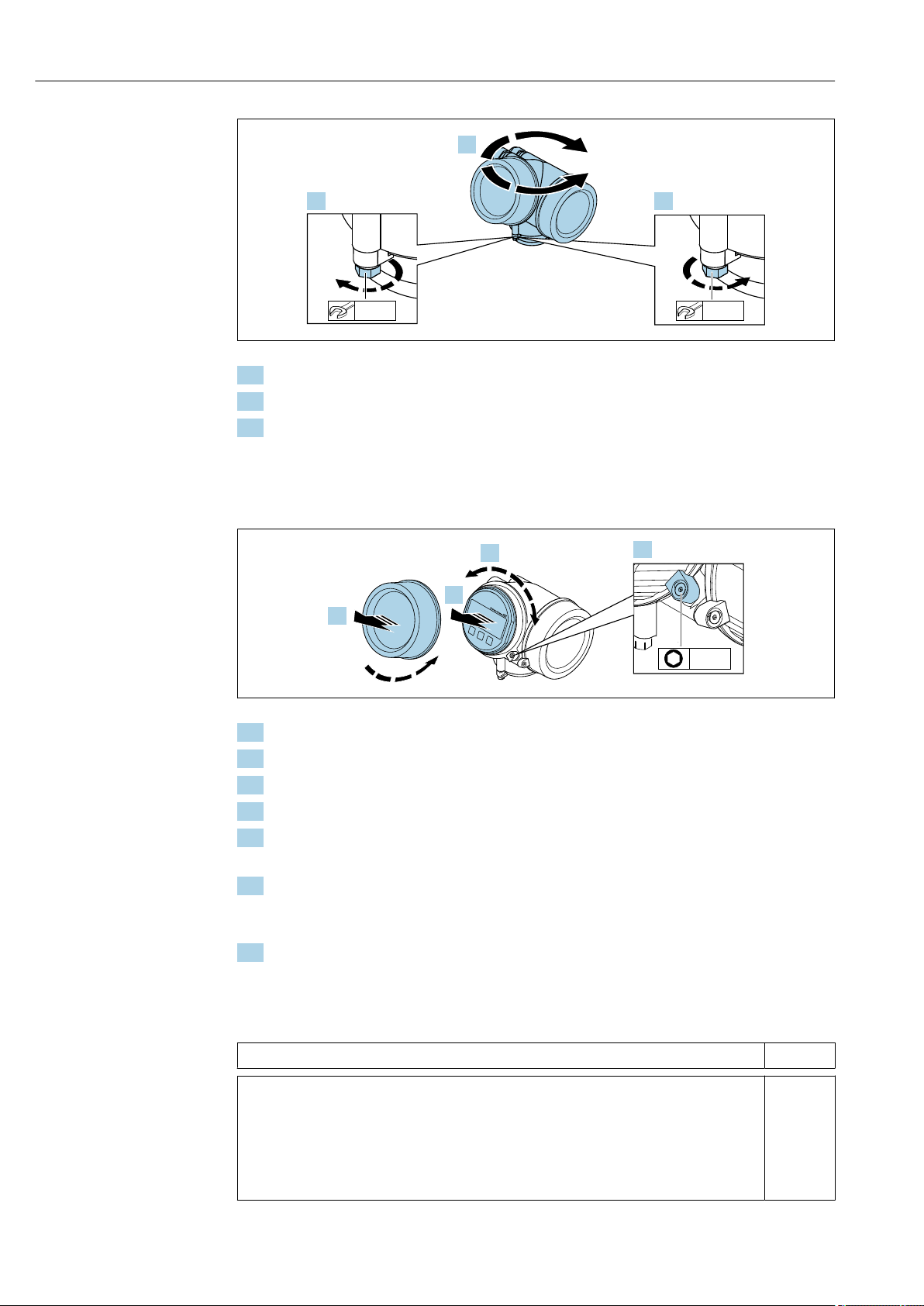

6.2.6 Turning the transmitter housing

To provide easier access to the connection compartment or display module, the transmitter

housing can be turned.

Installation Proline Prowirl F 200 HART

34 Endress+Hauser

A0032242

1. Release the fixing screw.

2. Turn the housing to the desired position.

3. Firmly tighten the securing screw.

6.2.7 Turning the display module

The display module can be turned to optimize display readability and operability.

A0032238

1. Loosen the securing clamp of the electronics compartment cover using an Allen key.

2. Unscrew cover of the electronics compartment from the transmitter housing.

3. Optional: pull out the display module with a gentle rotational movement.

4. Turn the display module to the desired position: max. 8 × 45° in every direction.

5. Without display module pulled out:

Allow display module to engage at desired position.

6. With display module pulled out:

Feed the cable into the gap between the housing and main electronics module and

plug the display module into the electronics compartment until it engages.

7. Reverse the removal procedure to reassemble the transmitter.

6.3 Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature → 191

• Process pressure (refer to the section on «Pressure-temperature ratings» in the «Technical

Information» document → 205)

• Ambient temperature

• Measuring range → 173

Proline Prowirl F 200 HART Installation

Endress+Hauser 35

Has the correct orientation for the sensor been selected → 22?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the direction of flow of the fluid through the

piping → 22?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected against precipitation and direct sunlight?

Are the securing screw and securing clamp tightened securely?

Has the maximum permitted insulation height been observed?

• Has the pressure range been observed→ 192?

• Was the correct orientation selected→ 23?

• Is the pressure unit mounted correctly→ 30?

• Have the pressure gauge valve and the siphon with pressure sensor been mounted using the

prescribed seal and the specified torque→ 30?

Electrical connection Proline Prowirl F 200 HART

36 Endress+Hauser

7 Electrical connection

7.1 Connection conditions

7.1.1 Required tools

• For cable entries: Use corresponding tools

• For securing clamp: Allen key 3 mm

• Wire stripper

• When using stranded cables: Crimper for wire end ferrule

• For removing cables from terminal: Flat blade screwdriver ≤ 3 mm (0.12 in)

7.1.2 Connecting cable requirements

The connecting cables provided by the customer must fulfill the following requirements.

Electrical safety

In accordance with applicable federal/national regulations.

Permitted temperature range

• The installation guidelines that apply in the country of installation must be observed.

• The cables must be suitable for the minimum and maximum temperatures to be

expected.

Signal cable

Current output 4 to 20 mA HART

A shielded cable is recommended. Observe grounding concept of the plant.

Current output 4 to 20 mA

Standard installation cable is sufficient.

Pulse/frequency/switch output

Standard installation cable is sufficient.

Current input

Standard installation cable is sufficient.

Cable diameter

• Cable glands supplied:

M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• Plug-in spring terminals for device version without integrated overvoltage protection:

wire cross-sections 0.5 to 2.5 mm

2

(20 to 14 AWG)

• Screw terminals for device version with integrated overvoltage protection: wire cross-

sections 0.2 to 2.5 mm

2

(24 to 14 AWG)

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 37

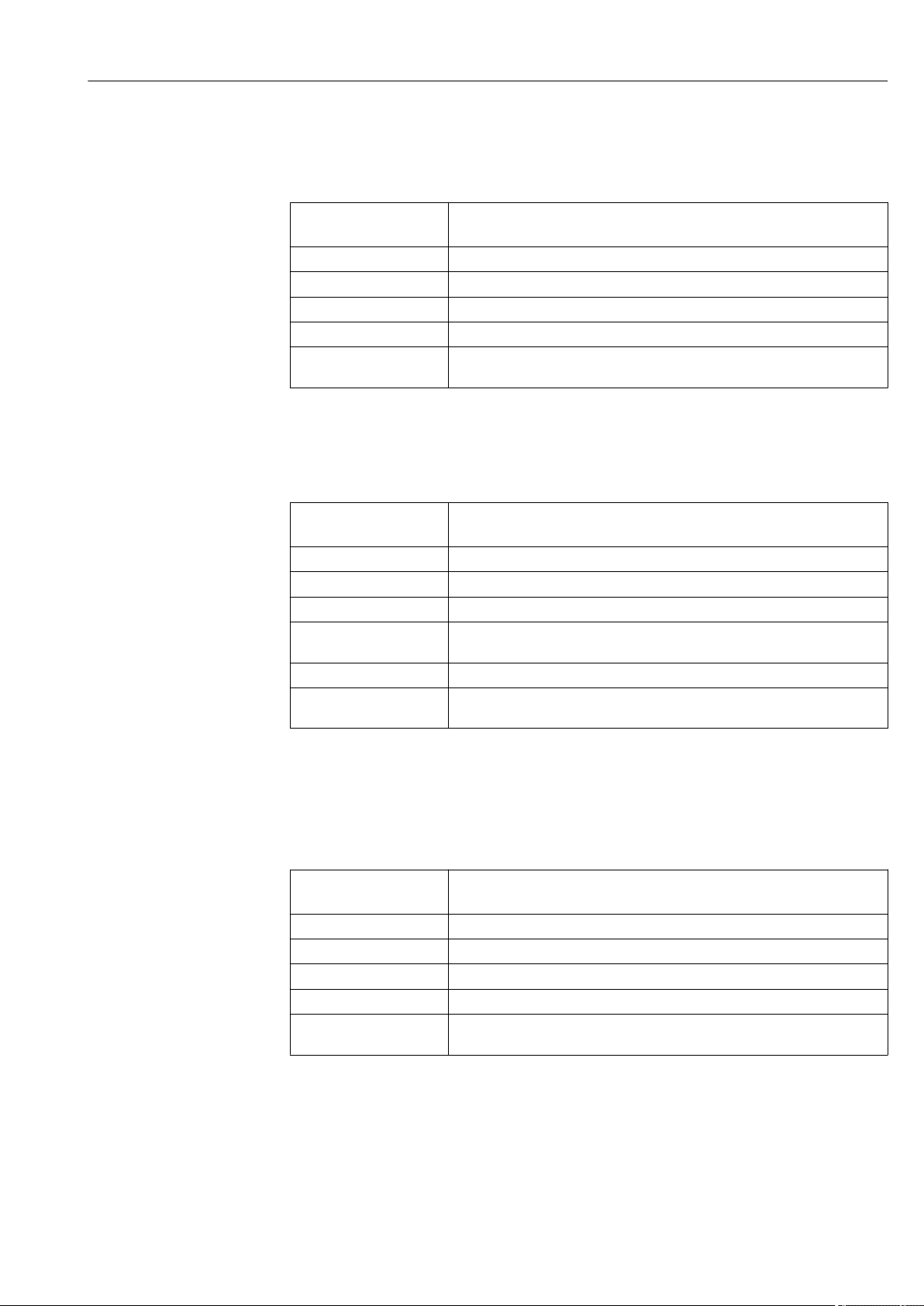

7.1.3 Connecting cable for remote version

Connecting cable (standard)

Standard cable

2 × 2 × 0.5 mm

2

(22 AWG) PVC cable with common shield (2 pairs, pair-

stranded)

1)

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx.85 %

Cable length 5 m (16 ft), 10 m (32 ft), 20 m (65 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

can move freely: –25 to +105 °C (–13 to +221 °F)

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

Connecting cable (reinforced)

Cable, reinforced

2 × 2 × 0.34 mm

2

(22 AWG) PVC cable with common shield (2 pairs, pair-

stranded) and additional steel-wire braided sheath

1)

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx. 85%

Strain relief and

reinforcement

Steel-wire braid, galvanized

Cable length 5 m (16 ft), 10 m (32 ft), 20 m (65 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

can move freely: –25 to +105 °C (–13 to +221 °F)

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

Connecting cable (option «mass pressure-/temperature-compensated»)

Order code for «Sensor version; DSC sensor; measuring tube», option DA, DB

Standard cable

[(3 × 2) + 1] × 0.34 mm

2

(22 AWG)PVC cable with common shield (3 pairs, pair-

stranded)

1)

Flame resistance According to DIN EN 60332-1-2

Oil-resistance According to DIN EN 60811-2-1

Shielding Galvanized copper-braid, opt. density approx. 85%

Cable length 10 m (32 ft), 30 m (98 ft)

Operating temperature When mounted in a fixed position: –50 to +105 °C (–58 to +221 °F); when cable

can move freely: –25 to +105 °C (–13 to +221 °F)

1) UV radiation may cause damage to the outer jacket of the cable. Protect the cable from exposure to sun as

much as possible.

Electrical connection Proline Prowirl F 200 HART

38 Endress+Hauser

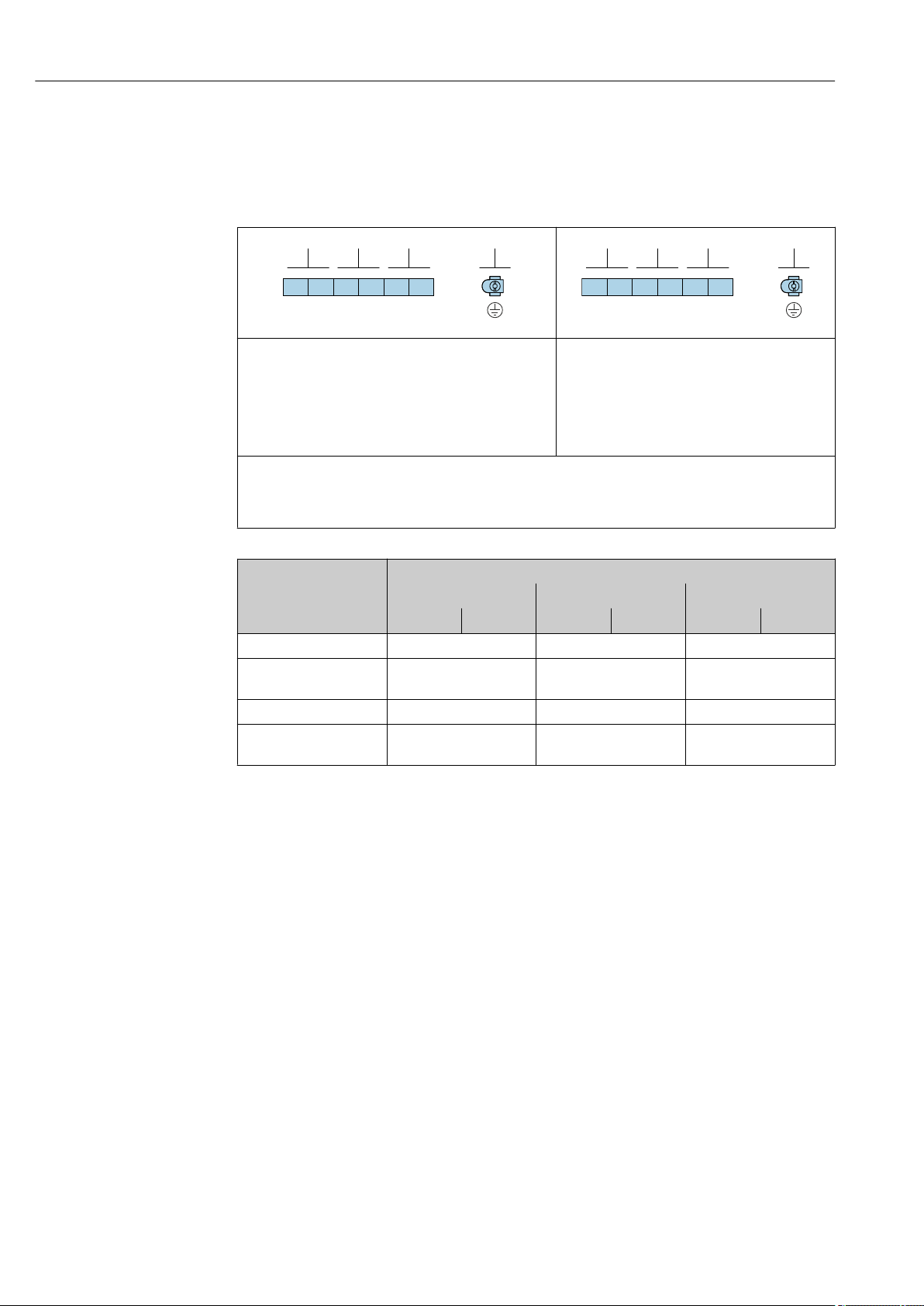

7.1.4 Terminal assignment

Transmitter

4-20 mA HART connection version with additional inputs and outputs

A0033475

A0033475

Maximum number of terminals

Terminals 1 to 6:

Without integrated overvoltage protection

Maximum number of terminals for order code for

«Accessory mounted», option NA «Overvoltage

protection»

• Terminals 1 to 4:

With integrated overvoltage protection

• Terminals 5 to 6:

Without integrated overvoltage protection

1

2

3

4

Output 1 (passive): supply voltage and signal transmission

Output 2 (passive): supply voltage and signal transmission

Input (passive): supply voltage and signal transmission

Ground terminal for cable shield

Order code for «Output» Terminal numbers

Output 1 Output 2 Input

1 (+) 2 (-) 3 (+) 4 (-) 5 (+) 6 (-)

Option A 4-20 mA HART (passive) — —

Option B

1)

4-20 mA HART (passive)

Pulse/frequency/switch

output (passive)

—

Option C

1)

4-20 mA HART (passive) 4-20 mA analog (passive) —

Option D

1) 2)

4-20 mA HART (passive)

Pulse/frequency/switch

output (passive)

4-20 mA current input

(passive)

1) Output 1 must always be used; output 2 is optional.

2) The integrated overvoltage protection is not used with option D: Terminals 5 and 6 (current input) are not

protected against overvoltage.

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 39

Connecting cable for remote version

Transmitter and sensor connection housing

In the case of the remote version, the sensor and transmitter are mounted separately from

on another and connected by a connecting cable. Connection is performed via the sensor

connection housing and the transmitter housing.

How the connecting cable is connected in the transmitter housing depends on the

measuring device approval and the version of the connecting cable used.

In the following versions, only terminals can be used for connection in the transmitter

housing:

• Certain approvals: Ex nA, Ex ec, Ex tb and Division 1

• Use of reinforced connecting cable

• Order code for «Sensor version; DSC sensor; measuring tube», option DA, DB

In the following versions, an M12 device connector is used for connection in the

transmitter housing:

• All other approvals

• Use of connecting cable (standard)

Terminals are always used to connect the connecting cable in the sensor connection

housing (tightening torques for screws for cable strain relief: 1.2 to 1.7 Nm).

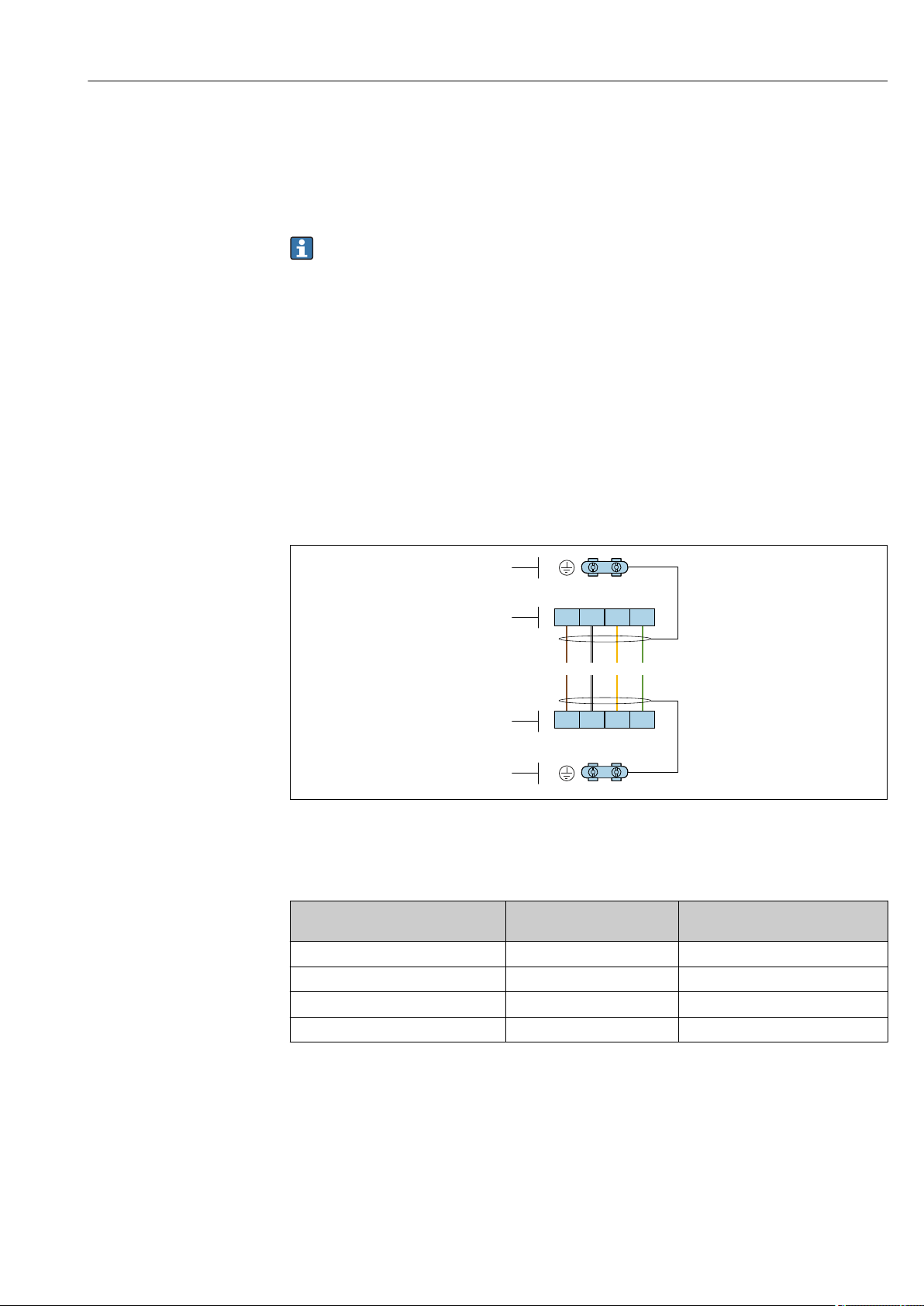

Connecting cable (standard, reinforced)

+ –

+ –

2

1

1

2

1 2 3 4

1 2 3 4

GNYEWHBN

A0033476

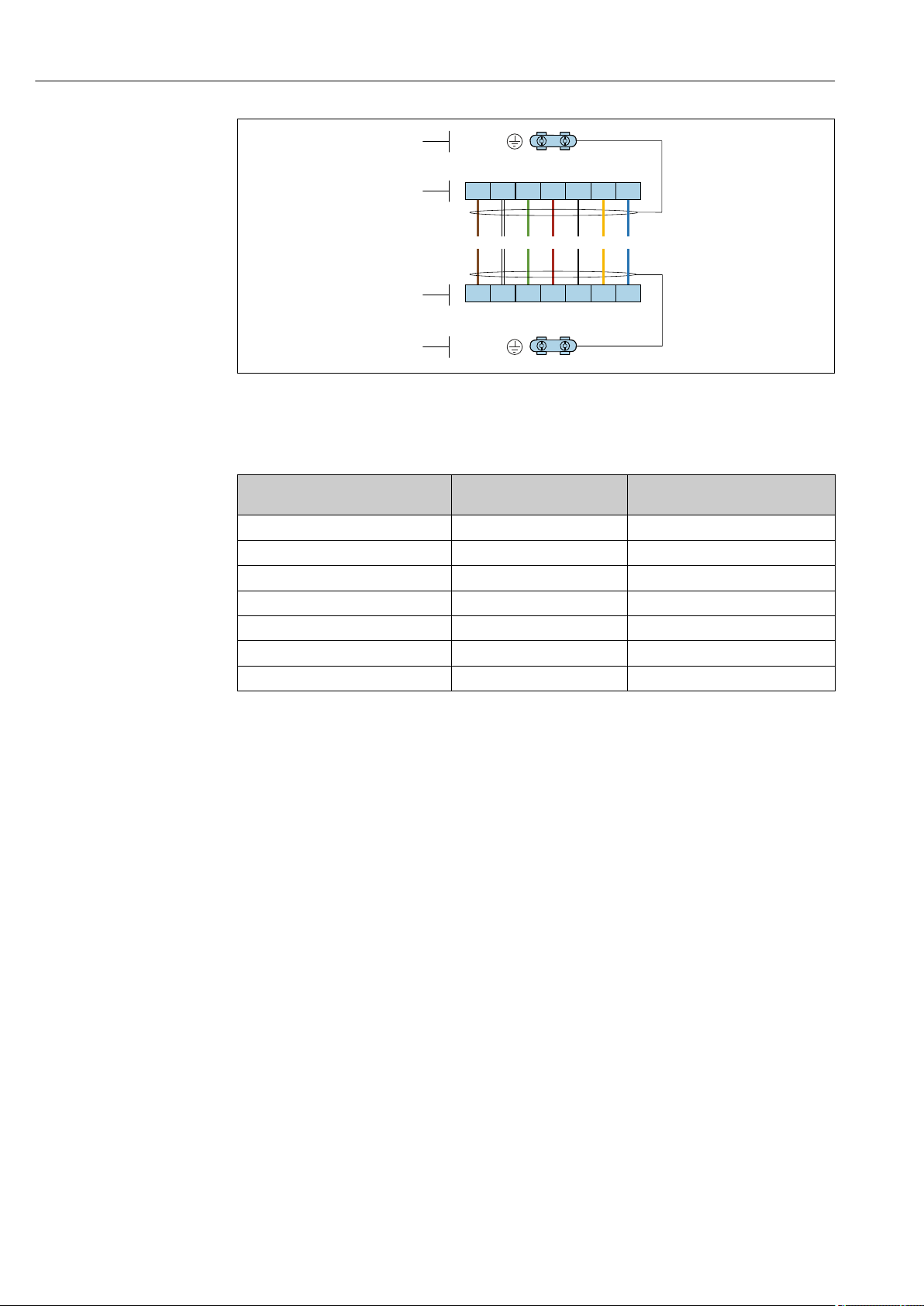

12 Terminals for connection compartment in the transmitter wall holder and the sensor connection housing

1 Terminals for connecting cable

2 Grounding via the cable strain relief

Terminal number Assignment Cable color

Connecting cable

1 Supply voltage Brown

2 Grounding White

3 RS485 (+) Yellow

4 RS485 (–) Green

Connecting cable (option «mass pressure-/temperature-compensated»)

Order code for «Sensor version; DSC sensor; measuring tube», option DA, DB

Electrical connection Proline Prowirl F 200 HART

40 Endress+Hauser

+–

+ –

2

1

1

2

1 2 3 4

1 2 3 4

5

5

6

6

7

7

RDGNWHBN BK YE BU

+–

+ –

RES

VCC

GND

RES

VCC

GND

A0034571

13 Terminals for connection compartment in the transmitter wall holder and the sensor connection housing

1 Terminals for connecting cable

2 Grounding via the cable strain relief

Terminal number Assignment Cable color

Connecting cable

1 RS485 (-) DPC Brown

2 RS485 (+) DPC White

3 Reset Green

4 Supply voltage red

5 Grounding Black

6 RS485 (+) Yellow

7 RS485 (–) Blue

7.1.5 Requirements for the supply unit

Supply voltage

Transmitter

An external power supply is required for each output.

The following supply voltage values apply for the outputs available:

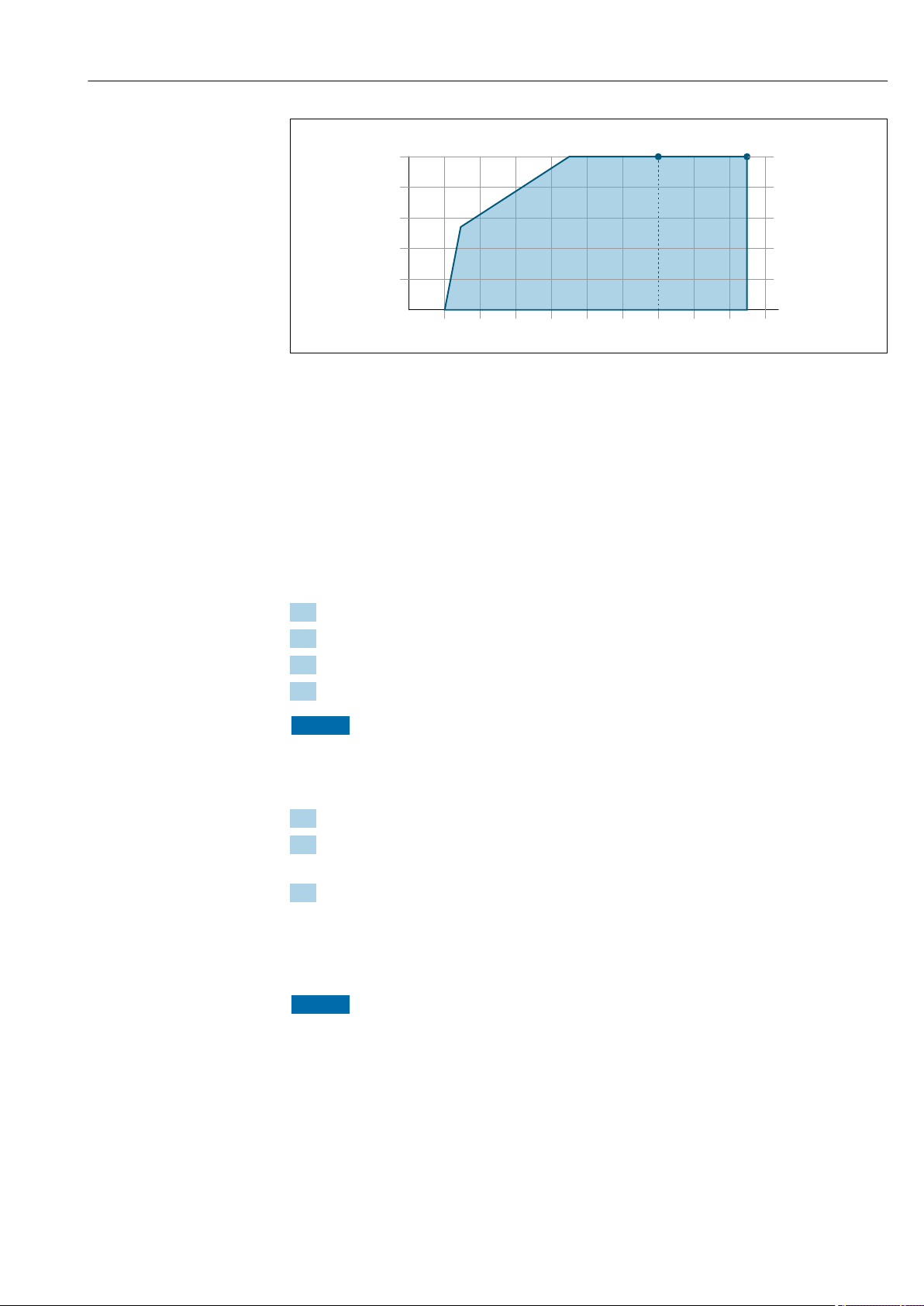

Load

Load for current output: 0 to 500 Ω, depending on the external supply voltage of the power

supply unit

Calculation of the maximum load

Depending on the supply voltage of the power supply unit (U

S

), the maximum load (R

B

)

including line resistance must be observed to ensure adequate terminal voltage at the

device. In doing so, observe the minimum terminal voltage

• For U

S

= 17.9 to 18.9 V: R

B

≤ (U

S

— 17.9 V): 0.0036 A

• For U

S

= 18.9 to 24 V: R

B

≤ (U

S

— 13 V): 0.022 A

• For U

S

= ≥ 24 V: R

B

≤ 500 Ω

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 41

0

100

200

300

400

500

16 18 20

22 24

26 28 30 32

U [V]

S

R

B

[Ω]

34 36

A B

A0013563

A Operating range for order code for «Output», option A «4-20 mA HART»/option B «4-20 mA HART, pulse/

frequency/switch output» with Ex i and option C «4-20 mA HART + 4-20 mA analog»

B Operating range for order code for «Output», option A «4-20 mA HART»/option B «4-20 mA HART, pulse/

frequency/switch output» with non-Ex and Ex d

Sample calculation

Supply voltage of power supply unit: U

S

=19 V

Maximum load: R

B

≤ (19 V — 13 V): 0.022 A = 273 Ω

7.1.6 Preparing the measuring device

Carry out the steps in the following order:

1. Mount the sensor and transmitter.

2. Connection housing, sensor: Connect connecting cable.

3. Transmitter: Connect connecting cable.

4. Transmitter: Connect signal cable and cable for supply voltage.

NOTICE

Insufficient sealing of the housing!

Operational reliability of the measuring device could be compromised.

‣

Use suitable cable glands corresponding to the degree of protection.

1. Remove dummy plug if present.

2. If the measuring device is supplied without cable glands:

Provide suitable cable gland for corresponding connecting cable.

3. If the measuring device is supplied with cable glands:

Observe requirements for connecting cables → 36.

7.2 Connecting the measuring device

NOTICE

Limitation of electrical safety due to incorrect connection!

‣

Have electrical connection work carried out by appropriately trained specialists only.

‣

Observe applicable federal/national installation codes and regulations.

‣

Comply with local workplace safety regulations.

‣

Always connect the protective ground cable before connecting additional cables.

‣

For use in potentially explosive atmospheres, observe the information in the device-

specific Ex documentation.

Electrical connection Proline Prowirl F 200 HART

42 Endress+Hauser

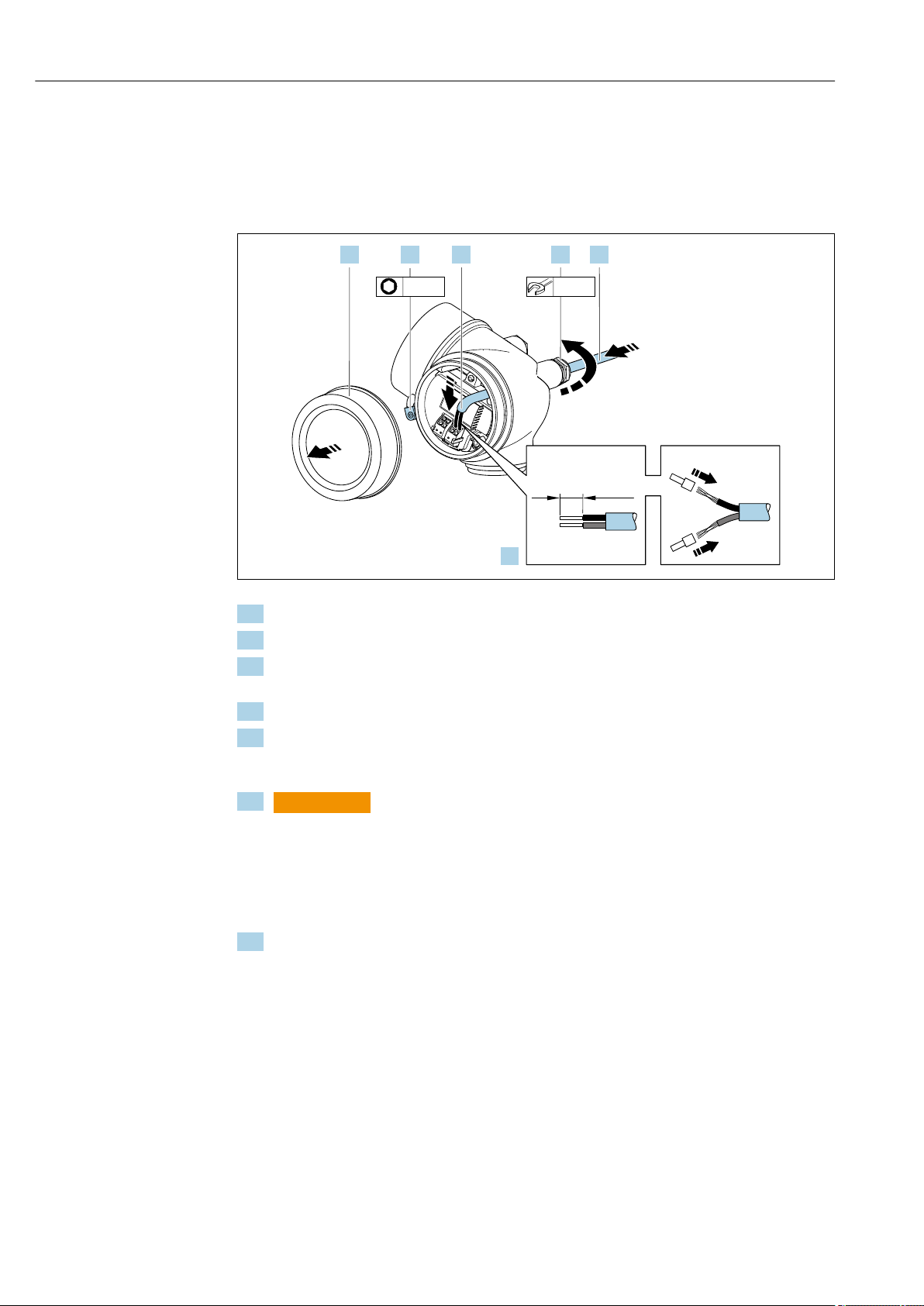

7.2.1 Connecting the compact version

Connecting the transmitter

Connection via terminals

10 (0.4)

mm (in)

20 mm3 mm

1.2. 3.

4.

5. 6.

A0032239

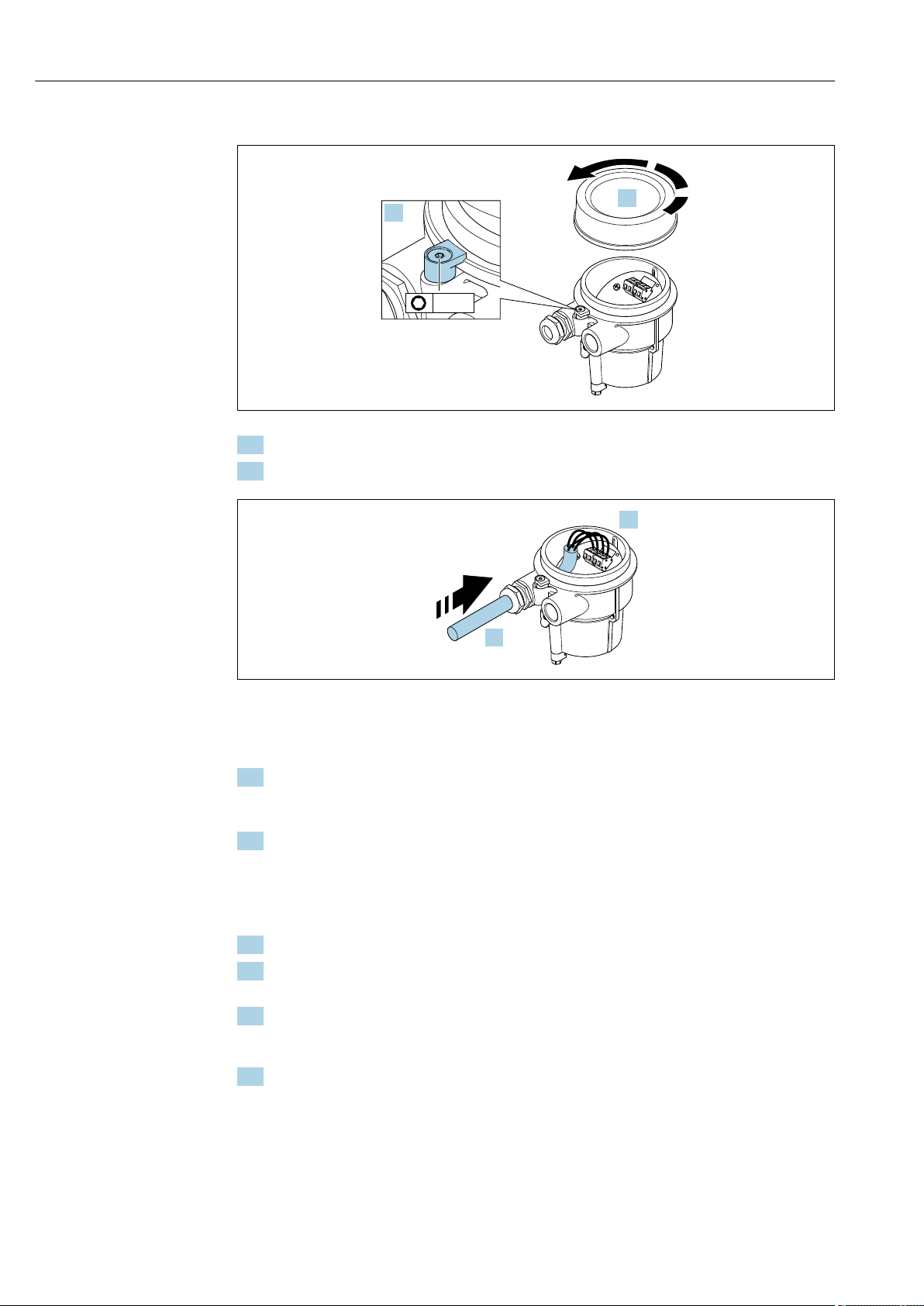

1. Loosen the securing clamp of the connection compartment cover.

2. Unscrew the connection compartment cover.

3. Push the cable through the cable entry . To ensure tight sealing, do not remove the

sealing ring from the cable entry.

4. Strip the cable and cable ends. In the case of stranded cables, also fit ferrules.

5. Connect cable in accordance with terminal assignment → 38. For HART

communication: when connecting the cable shielding to the ground clamp, observe

the grounding concept of the facility.

6.

L

WARNING

Housing degree of protection may be voided due to insufficient sealing of the

housing.

‣

Screw in the screw without using any lubricant. The threads on the cover are

coated with a dry lubricant.

Firmly tighten the cable glands.

7. Reverse the removal procedure to reassemble the transmitter.

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 43

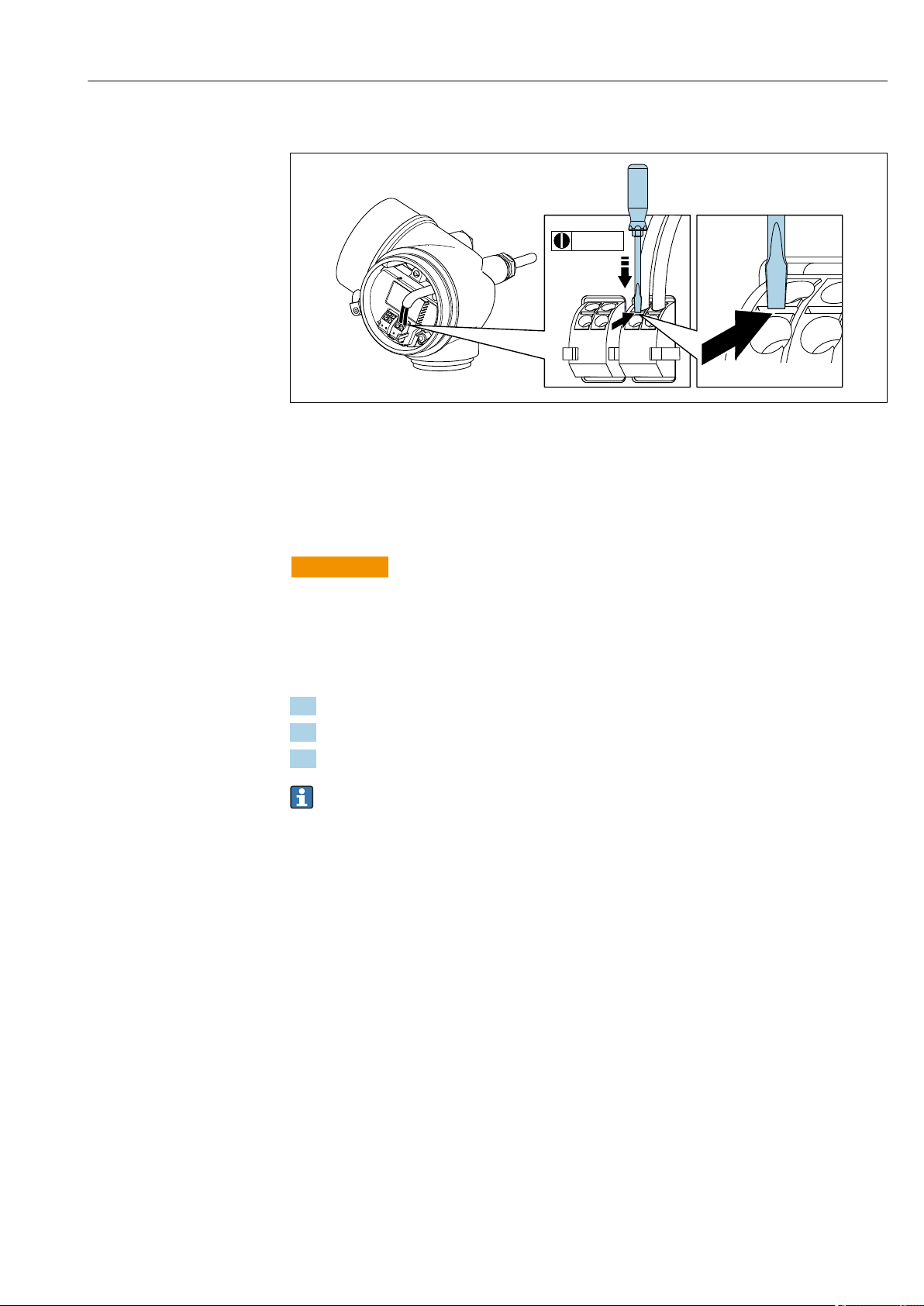

Removing a cable

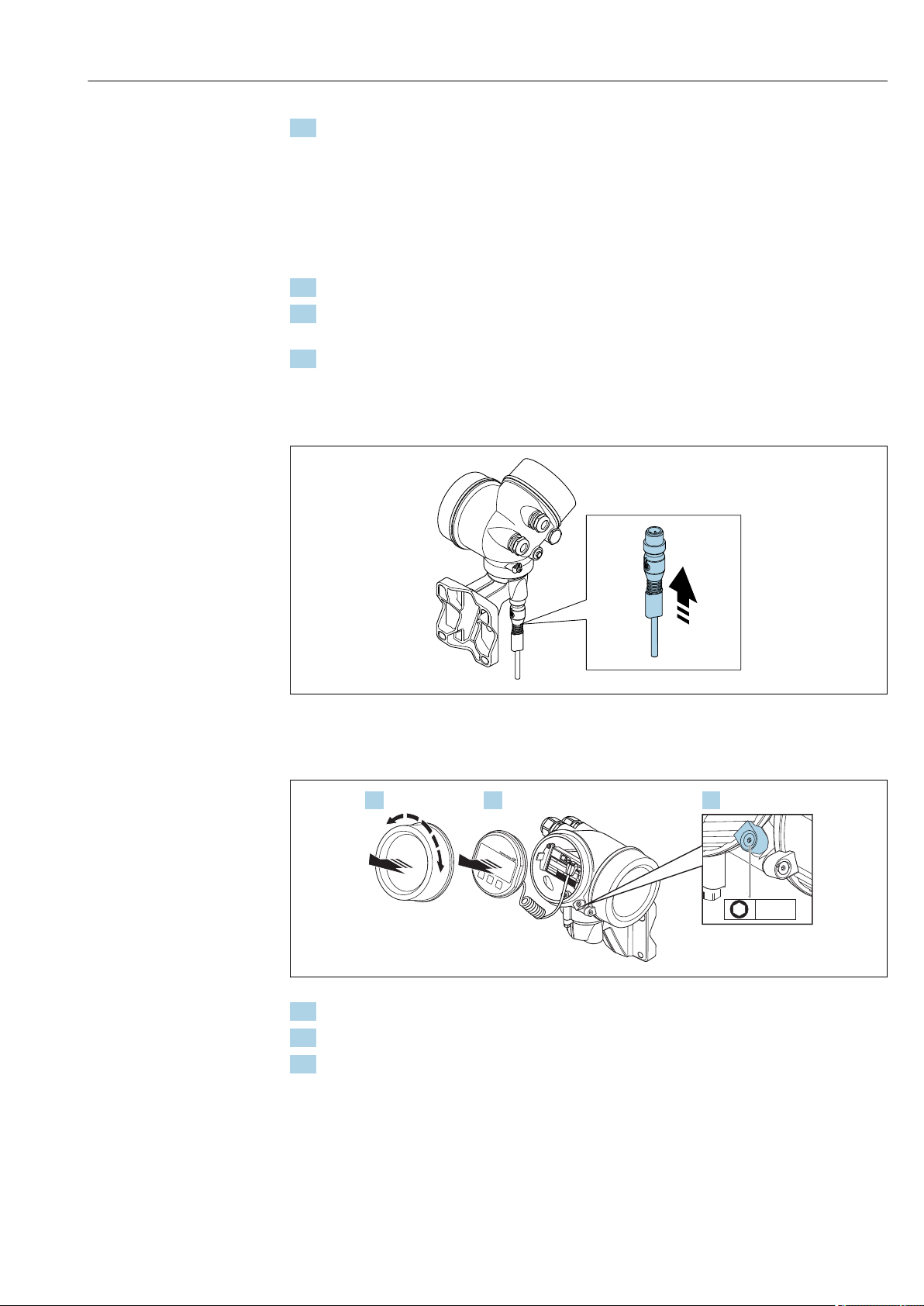

A0032240

‣

To remove a cable from the terminal, use a flat-blade screwdriver to push the slot

between the two terminal holes while simultaneously pulling the cable end out of the

terminal.

7.2.2 Connecting the remote version

L

WARNING

Risk of damaging the electronic components!

‣

Connect the sensor and transmitter to the same potential equalization.

‣

Only connect the sensor to a transmitter with the same serial number.

The following procedure (in the action sequence given) is recommended for the remote

version:

1. Mount the sensor and transmitter.

2. Connect the connecting cable for the remote version.

3. Connect the transmitter.

How the connecting cable is connected in the transmitter housing depends on the

measuring device approval and the version of the connecting cable used.

In the following versions, only terminals can be used for connection in the transmitter

housing:

• Certain approvals: Ex nA, Ex ec, Ex tb and Division 1

• Use of reinforced connecting cable

• Order code for «Sensor version; DSC sensor; measuring tube», option DA, DB

In the following versions, an M12 device connector is used for connection in the

transmitter housing:

• All other approvals

• Use of connecting cable (standard)

Terminals are always used to connect the connecting cable in the sensor connection

housing (tightening torques for screws for cable strain relief: 1.2 to 1.7 Nm).

Electrical connection Proline Prowirl F 200 HART

44 Endress+Hauser

Connecting the sensor connection housing

A0034167

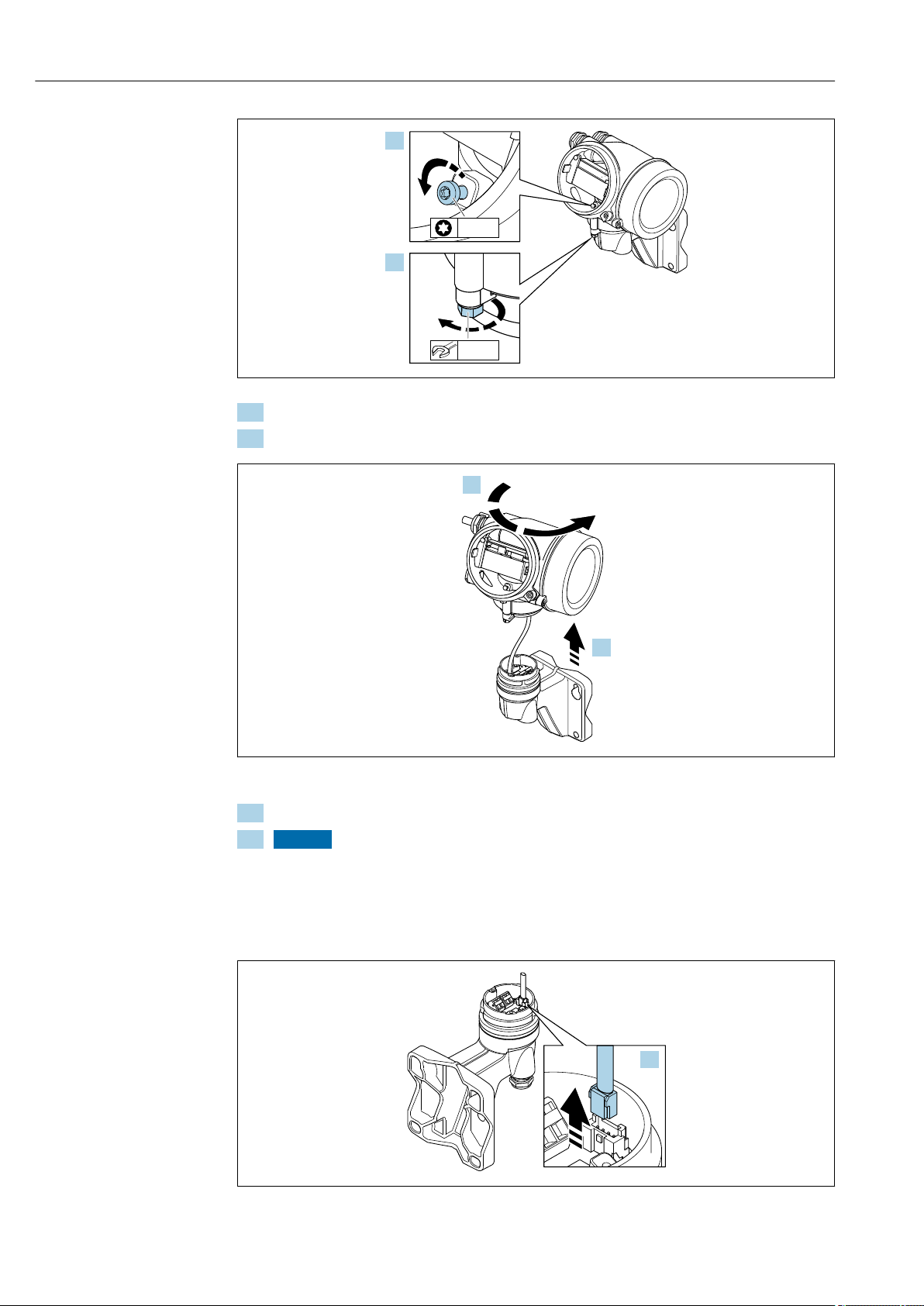

1. Loosen the securing clamp.

2. Unscrew the housing cover.

A0034171

14 Sample graphic

Connecting cable (standard, reinforced)

3. Guide the connecting cable through the cable entry and into the connection housing

(if using a connecting cable without an M12 device plug, use the shorter stripped end

of the connecting cable).

4. Wire the connecting cable:

Terminal 1 = brown cable

Terminal 2 = white cable

Terminal 3 = yellow cable

Terminal 4 = green cable

5. Connect the cable shield via the cable strain relief.

6. Tighten the screws for the cable strain relief using a torque in the range of

1.2 to 1.7 Nm.

7. Reverse the removal procedure to reassemble the connection housing.

Connecting cable (option «mass pressure-/temperature-compensated»)

3. Guide the connecting cable through the cable entry and into the connection housing

(if using a connecting cable without an M12 device plug, use the shorter stripped end

of the connecting cable).

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 45

4. Wire the connecting cable:

Terminal 1 = brown cable

Terminal 2 = white cable

Terminal 3 = green cable

Terminal 4 = red cable

Terminal 5 = black cable

Terminal 6 = yellow cable

Terminal 7 = blue cable

5. Connect the cable shield via the cable strain relief.

6. Tighten the screws for the cable strain relief using a torque in the range of

1.2 to 1.7 Nm.

7. Reverse the removal procedure to reassemble the connection housing.

Connecting the transmitter

Connecting transmitter via plug

A0034172

‣

Connect the plug.

Connecting transmitter via terminals

A0034173

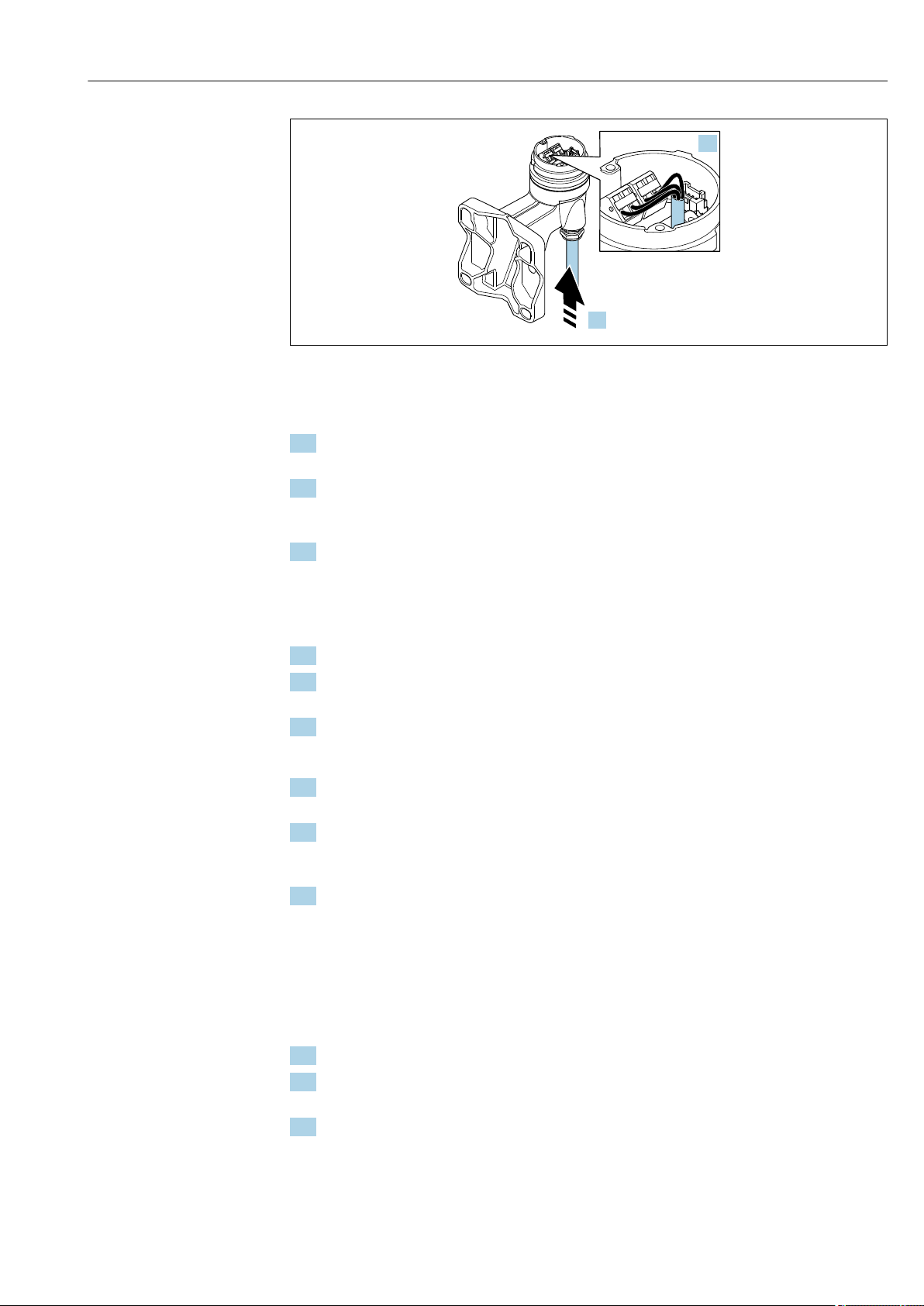

1. Loosen the securing clamp of the electronics compartment cover.

2. Unscrew the electronics compartment cover.

3. Pull out the display module with a gentle rotational movement. To make it easier to

access the lock switch, attach the display module to the edge of the electronics

compartment.

Electrical connection Proline Prowirl F 200 HART

46 Endress+Hauser

A0034174

4. Loosen the locking screw of the transmitter housing.

5. Loosen the securing clamp of the transmitter housing.

A0034175

15 Sample graphic

6. Turn the transmitter housing to the right until it reaches the marking.

7. NOTICE

The connection board of the wall housing is connected to the electronics board

of the transmitter via a signal cable!

‣

Pay attention to the signal cable when lifting the transmitter housing!

Lift the transmitter housing.

A0034176

16 Sample graphic

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 47

A0034177

17 Sample graphic

Connecting cable (standard, reinforced)

8. Disconnect the signal cable from the connection board of the wall housing . by

pressing in the locking clip on the connector. Remove the transmitter housing.

9. Guide the connecting cable through the cable entry and into the connection housing

(if using a connecting cable without an M12 device plug, use the shorter stripped end

of the connecting cable).

10. Wire the connecting cable:

Terminal 1 = brown cable

Terminal 2 = white cable

Terminal 3 = yellow cable

Terminal 4 = green cable

11. Connect the cable shield via the cable strain relief.

12. Tighten the screws for the cable strain relief using a torque in the range of

1.2 to 1.7 Nm.

13. Reverse the removal procedure to reassemble the transmitter housing.

Connecting cable (option «mass pressure-/temperature-compensated»)

8. Disconnect both signal cables from the connection board of the wall housing. by

pressing in the locking clip on the connector. Remove the transmitter housing.

9. Guide the connecting cable through the cable entry and into the connection housing

(if using a connecting cable without an M12 device plug, use the shorter stripped end

of the connecting cable).

10. Wire the connecting cable:

Terminal 1 = brown cable

Terminal 2 = white cable

Terminal 3 = green cable

Terminal 4 = red cable

Terminal 5 = black cable

Terminal 6 = yellow cable

Terminal 7 = blue cable

11. Connect the cable shield via the cable strain relief.

12. Tighten the screws for the cable strain relief using a torque in the range of

1.2 to 1.7 Nm.

13. Reverse the removal procedure to reassemble the transmitter housing.

Electrical connection Proline Prowirl F 200 HART

48 Endress+Hauser

7.2.3 Connecting the connecting cable for the pressure measuring

cell

When delivered to the customer, the connecting cable is connected as follows:

• Compact version: to transmitter housing

• Remote version: to sensor connection housing

For connection to sensor and pressure measuring cell:

‣

Insert M12 plug of connecting cable into pressure measuring cell and screw into place.

7.2.4 Ensuring potential equalization

Requirements

Please consider the following to ensure correct measurement:

• Same electrical potential for the fluid and sensor

• Remote version: same electrical potential for the sensor and transmitter

• Company-internal grounding concepts

• Pipe material and grounding

7.3 Ensuring the degree of protection

The measuring device fulfills all the requirements for the IP66/67 degree of protection,

Type 4X enclosure.

To guarantee IP66/67 degree of protection, Type 4X enclosure, carry out the following

steps after the electrical connection:

1. Check that the housing seals are clean and fitted correctly.

2. Dry, clean or replace the seals if necessary.

3. Tighten all housing screws and screw covers.

4. Firmly tighten the cable glands.

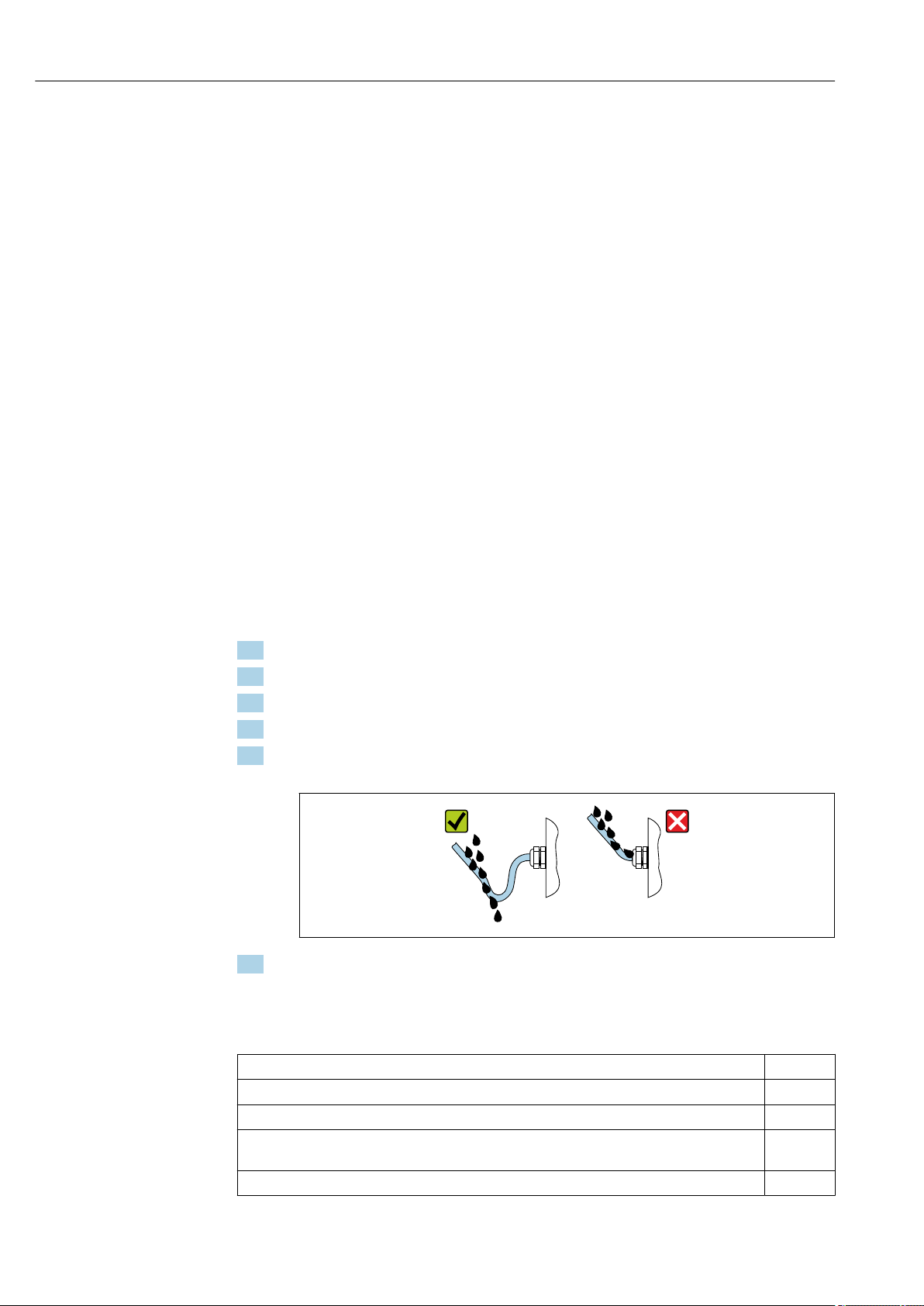

5. To ensure that moisture does not enter the cable entry:

Route the cable so that it loops down before the cable entry («water trap»).

A0029278

6. Insert dummy plugs into unused cable entries.

7.4 Post-connection check

Are cables or the device undamaged (visual inspection)?

Do the cables used meet the requirements→ 36?

Do the mounted cables have adequate strain relief?

Are all cable glands installed, securely tightened and leak-tight? Cable run with «water trap»

→ 48?

Depending on the device version, are all the device plugs firmly tightened→ 42?

Proline Prowirl F 200 HART Electrical connection

Endress+Hauser 49

Only for remote version: is the sensor connected to the right transmitter?

Check the serial number on the nameplate of the sensor and transmitter.

Does the supply voltage match the specifications on the transmitter nameplate?

Is the terminal assignment correct ?

If supply voltage is present, do values appear on the display module?

Are all the housing covers installed and tightened?

Is the securing clamp tightened correctly?

Have the screws for the cable strain relief been tightened using the correct torque→ 43?

Has the M12 plug of the connecting cable been correctly connected to the pressure measuring

cell→ 48?

Operation options Proline Prowirl F 200 HART

50 Endress+Hauser

8 Operation options

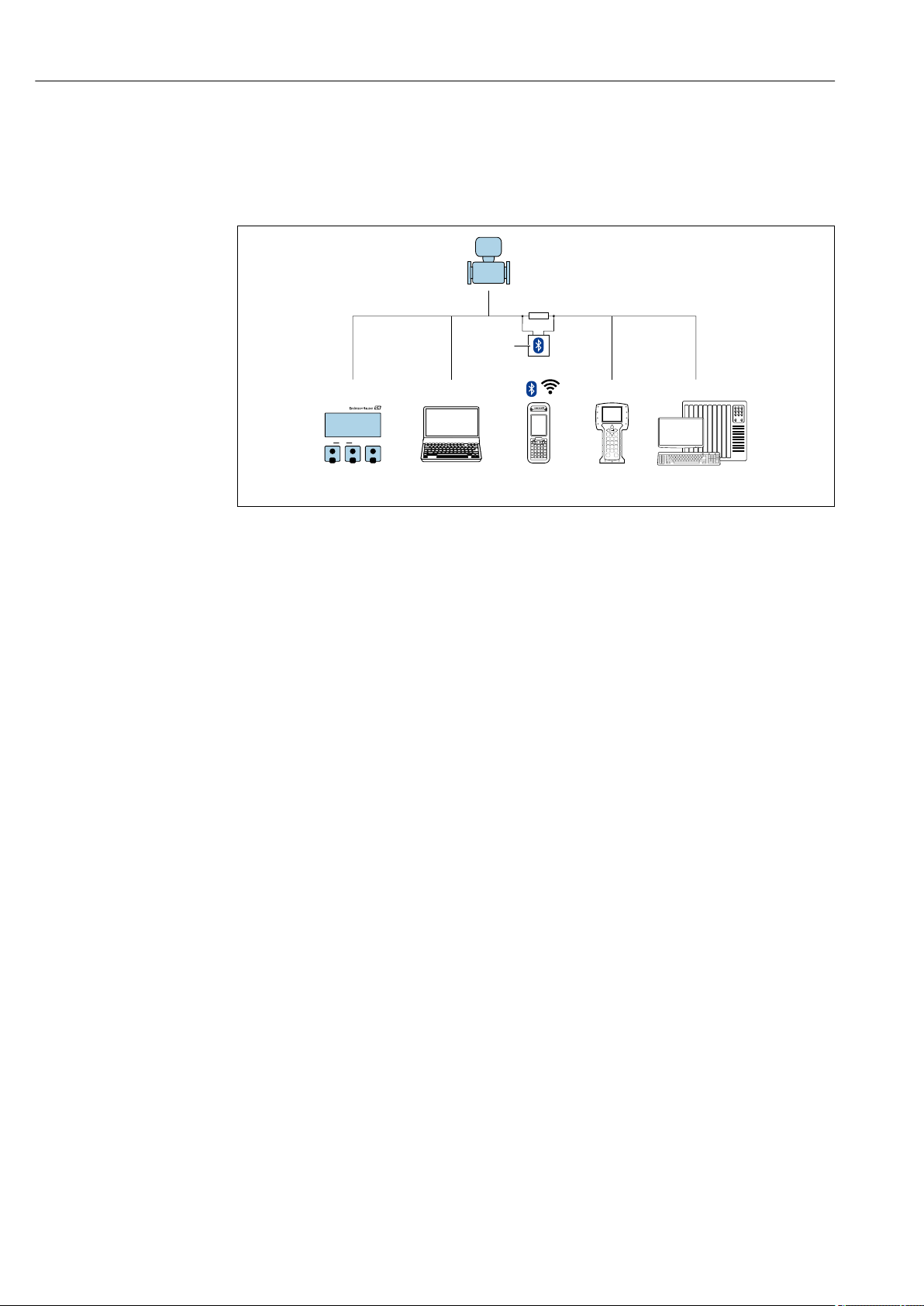

8.1 Overview of operation options

A0032226

1 Local operation via display module

2 Computer with operating tool (e.g. FieldCare, DeviceCare, AMS Device Manager, SIMATIC PDM)

3 Field Xpert SFX350 or SFX370

4 Field Communicator 475

5 Control system (e.g. PLC)

6 VIATOR Bluetooth modem with connecting cable

Цена по запросу

DN 15 … 300

- Описание

- Тех.характеристики

- Документация

Описание

Prowirl F 200