-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

1. SPECIFICATIONS

MB-373

1

Sewing speed

2

Number of stitches

3

Amount of feed

4

Stitching pattern

5

Button size

6

Needle bar stroke

7

Needle

8

Automatic thread trimmer

9

Presser lifter

10

Stop-motion unit

11

Power supply

MB-377

1

Stitching pattern

2

Needle

Other specifications are same as those of MB-373.

Max. 1,500 rpm

8, 16, and 32 stitches

(6, 12 and 24 stitches are also possible by changing the cam.)

Crosswise feed

2.5 to 6.5 mm

Lengthwise feed 0, 2.5 to 6.5 mm

コ -shape, Z-shape, Π -shape, and X-shape

10 to 28 ø mm

48.6 mm

TQ x 7 #16 (#14 to #20)

Interlocked with the presser lifter.

Consists of a fixed knife and a moving knife.

Automatically operated (Pedal-system is also available.)

Automatically operated (equipped with speed slowing device)

200 W (1/4 HP) single- or three-phase

コ -shape, Z-shape, and X-shape

TQ x 1 #16 (In case of attachments for medium button (Z202) and

large button (Z201) TQ x 7 #16, #14 to #20)

1

1

−

−

−

−

Normal speed 1,300 rpm

Summary of Contents for JUKI MB-373

This manual is also suitable for:

Mb-377

File Specifications:1922/1922581-mb373.pdf file (02 Jul 2023) |

Accompanying Data:

JUKI MB-373 Series Sewing Machine PDF Manual (Updated: Sunday 2nd of July 2023 08:34:05 PM)

Rating: 4.9 (rated by 80 users)

Compatible devices: LZ-2290A Series, LBH-1790A Series, MB-1373, LK-980 Series, LH-4500C Series, MB-1800B, AP-874/IP-420, MF-7900 Series.

Recommended Documentation:

Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the JUKI MB-373 Series Document (Main Content), UPD: 02 July 2023)

-

14, −14 − (13) Positioning the needle driving pulley pressure applying lever The clearance at the stop-motion position (while the driving pulley is running idle) should be 0.2 to 0.3 mm. (14) Positioning the thread pull-off lever Adjust the position of thread pull-off lever 1 so that the dimension between thread guide pole 4 and thread pull-off lever 1 is 5 to 9 mm at the stop-motion position. Standard Adjustment Needle driving pull…

-

3, −3 − ™ Turn the hand wheel by hand and loosen screw 1 in the Fig. A in the thread take- up lever to adjust so that the upper engraved line of the two engraved lines on the needle bar aligns with the bottom of lower bushing 3 when the needle bar is at its lowest position. For the old type sewing machine, in addition, adjust the position so that needle clamp screw 4 enters the slot of lower bushing 3 as …

-

10, −10 − (8) Positioning the thread nipper The clearance between thread nipper 1 and nipper block 2 should be 0.8 to 1.2 mm while the machine is in operation. (In case of MB-377 : 0.4 to 0.8 mm) (9) Positioning the stitch adjusting cam The clearance between the roller and the recess of the cam should be 0.8 mm at the stop-motion position. Standard Adjustment 0.8 to 1.2 mm 0.8 mm A Rotating direction of cam 1 2

… -

19, JUKI MB-373 Series −19 − ™ Make adjustment after tilting the machine head by loosening two nuts 3 and moving connecting screw 4 back and forth. Loosen nuts 3 so that thread trimming connecting joint 5 becomes almost horizontal. ™ If the above distance is too large, the timing of the thread trimming will be delayed, and excessively long thread will remain on the wrong side of a fabric. On the contrary, if the distance is too small, thre…

-

33, iii R SINGLE THREAD, CHAINSTITCH BUTTON ATTACHING MACHINE WITH AUTOMATIC THREAD TRIMMER MB-373 MB-377 ENGINEER’S MANUAL 29231701 No.01 (WITH KNOT-TYING MECHANISM)

… -

8, −8 − (6) Lift and pressure of the button clamp 1) Lift of the button clamp A MB-372 : 12 mm MB-373 : 9 mm MB-377 : 8 mm for コ-shape 8 mm for Z -shape 10 mm for X -shape 2) Pressure of the button clamp Adjust the position of pressure adjusting nut 1 to 4 to 5 mm from the lower side of the screw section of pressure adjusting bar 2. (7) Thread tension disc No.1 Adjust so that the thread tension disc No.1 floats by 1 mm at the time of stop moti…

-

12, −12 − (10) Positioning the stop motion disc and the stop motion plunger 1) The clearance between the stop motion disc and the stop motion plunger should be 2.4 mm while the machine is in operation or at the position of 3 to 4 stitches from the position of stop-motion. 2) The clearance between the stop motion plunger lever and the stop motion plunger should be 8.5 mm. (12) Positioning the button clamp lifting link The clearance between button c…

-

29, − 29 − 7. THREAD TRIMMING TROUBLES AND THE CORRECTIVE MEASURES Troubles Causes Corrective measures 1. Thread is not trimmed. The needle does not come down into the correct point of a button hole. The final stitch is skipped. The height of the thread separating claw of the moving knife is not correct. Correct the position on the looper. Refer to the clause “2. (2) Positioning the needle and the looper” (pa…

-

17, −17 − ™ Perform adjustment so that the clearance between the end surface of button clamp lifting lever 1 and the adjusting screw 2 becomes 0.5 mm. Then tighten nut 3. Adjustment Procedures Results of Improper Adjustment

… -

15, −15 − ™ Loosen nut 1 of the screw of the needle driving pulley pressure applying lever and adjust by screwing in and out screw 2. The clearance will become larger by screwing it in. ™ Perform adjustment by loosening screw 2 of the nipper bar block (rear) and moving nipper bar block (rear) 3 to the right or left. ™ If the amount of movement of the nipper bar block (rear) is too large, at the beginn…

-

20, JUKI MB-373 Series −20 − (1) The mechanism and the name of each component of the knot-tying As shown in the figure below, when the machine is running, the stitch adjusting cam rotates and the thread bind arm roller rides over the thread bind notch attached to the stitch adjusting cam making the thread bind plate actuate by means of the respective links to hook thread. The slack portion of the hooked thread will be tightened by the thread wring lever at the time of stop motion. (2) Positioning…

-

28, JUKI MB-373 Series − 28 − 6. CORRECTIVE MEASURES FOR MECHANICAL FAILURES (1) Defective stop motion 1) The sound of the stop motion is low, and the machine stops before reaching the required position. ™ Decrease the clearance between the stitch adjusting cam and the roller. ™ Decrease the tension of the clamping pressure spring. ™ Reduce the axial play of the needle driving pulley at the time of stop motion. (2) The button clamp …

-

13, −13 − 1) Perform adjustment to provide the 2.4 mm clearance after loosening screw 1 of the stop motion tripping lever. Remove the stop motion disc pressure lever and the needle driving pulley, insert a 2.4 mm gauge or a 3 mm wrench between the stop motion plunger and the stop motion disc, and tighten srew 1 of the stop motion tripping lever since the stop motion lever shaft becomes loose. 2) Perform adjustment to provide the 8.5 mm clearance by the stop …

-

5, −5 − ™ For adjusting the timing of the travel of the yoke slide, align the engraved marks of the loop positioning finger cam and the triangle loop positioning finger cam with the engraved mark of the cam and looper sleeve after the adjustment of the looper so that the engraved marks are on a straight line. Then temporarily tighten the screws. 1) Adjust the crosswise travel timing of the yoke slide in the rotati…

-

21, −21 − ™ Loosen screw 1 and adjust so that the clearance between the outside periphery of the roller of the knot-tying arm and that of the stitch adjusting cam should be 1 to 1.5 mm at the time of stop-motion. ™ If the clearance is too large, the stroke of the thread bind plate will become short. ™ If the clearance is too small, the roller may come in contact with the outside periphery of the cam, or the thread bind plate may come in contact with the throat plate. A…

-

JUKI MB-373 Series User Manual

-

JUKI MB-373 Series User Guide

-

JUKI MB-373 Series PDF Manual

-

JUKI MB-373 Series Owner’s Manuals

Recommended: MHS550, DV 16540, 22-90830, 3300128

Links & Tools

Operating Impressions, Questions and Answers:

Single Thread, Chainstitch Button Sewing Machine

From the library of: Superior Sewing Machine & Supply LLC

w.ith

Automatic Thread

Trimmer

and Automatic Button Feeder

aJUKI

liiil11!;ftJifiliK11

(

1311.1

;tttJJBB,

:Ji’l

1311J

iK

~

~

:J

11

:Ji~MBIIi’l)

MB-373/BR-1

PARTS LIST

BEBR01SOPJA

No.0089-07

HOW

From the library of: Superior Sewing Machine & Supply LLC

TO MAKE

,~-·~

IJ

A~

USE

(J)JL»jj

OF

THIS PARTS

LIST

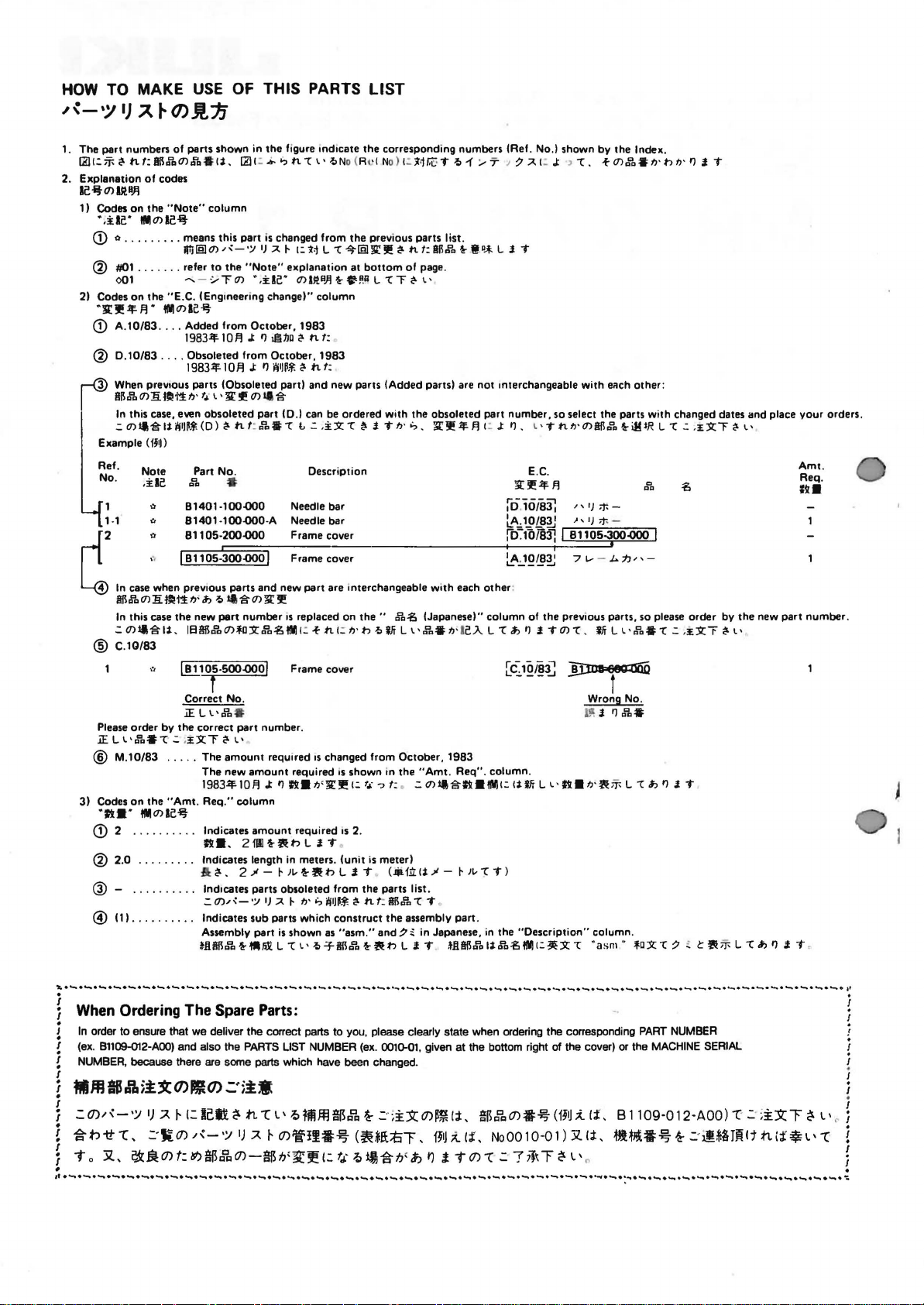

1. The part numbers of parts shown in

~t::-r-t!ont:Sll.ra11>.f’a.li,

2. Explanation

ae

-~t m ~

1) Codes

•

(!) o .

@ #01

2) Codes

·11r

(!) A.

@ D.10/83

r—@

I

Ref.

rr42

~

@ C.

Please

.iE L l•.ra•»l.:

@ M.10/83

3) Codes

·ft•·

of

codes

aJl

on

the

«Note»

.ile·

WJm

……..

…

. .

001

on

the «E.C. IEngeneering change)» column

!I!

.lf.

w

10/83

. . . . Added from October, 1983

….

When prev1ous parts (Obsoleted part) and new parts (Added parts) are not Interchangeable with

SB.ra

11>

!i

In

this case, even obsoleted

.:

mll.g.lii’jiJ~t.

EKample

No.

(fJ•Jl

Note

.

ile

»

1·1

0

0

,

.,

In

case when prev1ous parts and new part are interchangeable with each

&B.ra

11>

!i

In

this case

.:

11>!1-g.li,

10/83

order by the correct

on

the

111m1e~

column

le-it

means this part

Jllj[§JI1>,.;:-•;JIJ

..

refer

to

….. -‘/rl1>

W~m

ae

~

1983-lf.IOF!

Obsoleted from October,

1983-lf.

Je!i-:1

fJ•

t~

l •l!r !I!

(D)

Part No.

Q

a a

81401-100.000

81401-100.000-A

81105-200.000

I 811

05-JOO.OQO

tl1″1

fJ

‘ ~

~

the

new

part

J138li.Pa11>lc:SZ:.ra.S!NI

[hl105-SOO.OOOj

f

Correct No.

.iELl•.Pa

.

:~::SZ:T

…..

The

The new

1983-lf.lOF!

«Amt.

Req.» column

(!) 2 . . . . . . . . . . Indicates

ft

••

the

figure end1cate

~t:.b.’:>tl.cl•~N

is

changed from the previous parts list.

;;t. ~ 1::11

the

«Note»

eKplanation at

•,i:Be•

11>I~H}j~.;tP.B

J:

I’J

tli1.JD

t!-

tt

10

F!

J:

I’)

11>

II

part ID.J can be ordered with the obsoleted part number, so select the parts with changed dates and place

~

t1.

t:

.Pa.»l

~~~~*

~

t1.

.g.

L .:

Description

1983

•

Needle

Needle bar

Frame cover

Frame cover

I

II

.g.

11>

~

lJI!

number

IS

replaced on

1:

-t

Frame cover

•

part

number .

~

l’

amount

required

amount

J:

amount

2fll~fl(t:>LI.T

IS

required

I’J

ft.

n’~J!:

required is 2.

@ 2.0 . . . . . . . . . Indicates length in meters. (unit

@ —

…

…

@)

11)

. . . . . . . . . . Indicates

:fl: ~ • 2

.. .. lnd1cates parts obsoleted from

.::(]),,_’;I

Assembly part

*.!ISli.PaHJtAltL»ll·~-Tim.Pa~fl(t:>LI.T

-»

-~ ‘»

IJ

;;t.

sub

parts which

~

~

fJ’.,

is

shown as

ft

the

corresponding numbers (Ref. No.) shown by the lndeK.

o(RPINo)l:~<jr.(::»t~1:..-‘T

L

«(~[§Jl!r!JI!

f:

t:

.i:SZ:

«l

bar

bottom

L

«lr<?-l•

t!o

I.

T

t!-

ttf:8B.Pa

of page.

n·

i:>.

~!!:.iFF!

J

~@.•.t.

L

I.

t:

J:

r.—-~

ID

~A_,

iD-:-foi83J I

I I 4

~;;t.t:J:

T

I’J, l • T

E.

lll:!!:.lf.F!

.10/831

1JlL8;!! » IJ

~J.Q11~

other

:

the»

.ra~

tt

1

.:

n·

t> ~ Wi

changed from October, 1983

IS

shown in

1.:

t~-,

is

t:>

L I. T .

the

~~~~~

~

t1.

construct

«asm.»

(Japanese)» column of

L l •

.Po.

the

«Amt. Req»

f:. .:

11>11-g.ft.!NII:

meterl

(Jit

fti:.li-» — r

parts list .

t:

1m

.Po»(

T .

the

assembly part.

and~~

in Japanese,

trleJ…

L «l ~ I’J

. column.

li

WiLl’

‘»

«l T )

in

~.!ISll.rali.Pa.S!!IIII:~:SZ:»l

the «Description» column.

>

«l.

-tm.Pa•n·t>IJ•I’JI.T

eRch

other:

tt

n·

m&B.ra

~

iHtR L «l .:

C.

«IJ

;f.-

*-

81105-Joo.ooo

71..—J….jJn-

the

previous parts, so please order by

I.

T

11>

«l ,

WiLl· .Pa.»l

..

a a

I

.: ,i:SZ:T ~ l’

~

t

Wrong No.

ll’:

I.

I’J

a»L

•

ft.

n·ft

-r-L «l ~ I’J

·asm»

-tc:SZ:»l~

.

:~::SZ:T

~

I. T

~

cft

~

l’

the

new

-r-

Lc~I’J

part

I. T ,

your

Amt.

Req.

Ill.

number

orders .

.

~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·-·~·-·-·-·-·-·-·-·-·~·~·~·~·~’

i

! When Ordering The Spare Parts:

J

In

order to ensure that we deliver the correct parts to you, please clearly

.

I

(ex.

81109-012-AOO)

NUMBER, because

!

I

!

fiiM.Aii:X(1)1f1(1).:.

I

=-

(}).1 ~-·:;

i

.

I

~

h

1t

T 0

«(,

3C

~.61:

.

I

.

I

.

~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·~·

and

also the

PARTS

UST

there are some parts which have been changed.

·

~.t·

1

J A

~

1:

lc~

~

.n

«C

=.·ti

0)

0)

«‘-

t:

~~8′,

1

•:;

A

)

0)-~tJ;~J!

NUMBER

L’

~

nftffl

~Qc,

~

0)1f!l#~

(:

t.~-·

~

·~·~·~·~·~·~·~·~·~·~·~·~·~·-·-·-·-·-·-·-·~·-·~·-·-·-·-·-·-·-·-·-·-·-·-·~·~·~

(~*!:t::tiT,

~!I~

(ex.

~

OOlQ-01

.:·

;

i::>c

1.1

;

.n

state

, given

0)~

i91J

I’)

1.

when ordering

at

the bottom right of

l;t,

gBJ>,

0)#~

~

(;t’,

NoOO

T

0)

«(

.:·?

the

(i91J

10-0 1) :X.I;t,

7l~T

~

corresponding

the

cover) or the

~

li

L \

PART

MACHINE

.. B 1109 -0 12-AOO) «(-

~lll#~

NUMBER

SERIAL

!-

.:

·if*3

Jill

It

.:

-;

i::>cT

.tL

(;t ~

~

L’

I

.

!

I

.

L’

I

.

I

«(

.

I

I

.

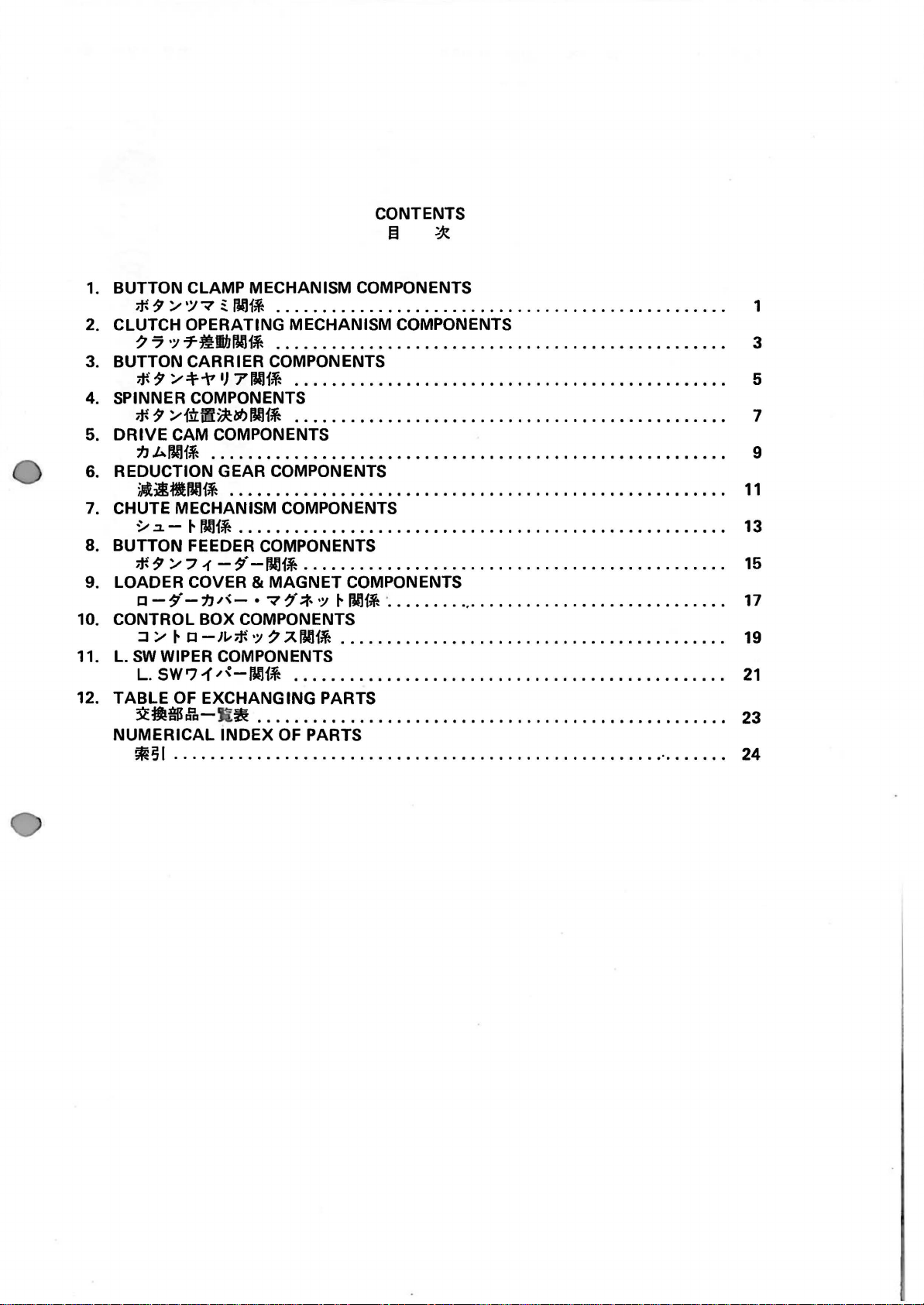

CONTENTS

From the library of: Superior Sewing Machine & Supply LLC

~

.;x

1. BUTTON CLAMP MECHANISM COMPONENTS

* 9

::..-

‘:1-:t

~

001*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. CLUTCH

7 7

3. BUTTON CARRIER COMPONENTS

;f.

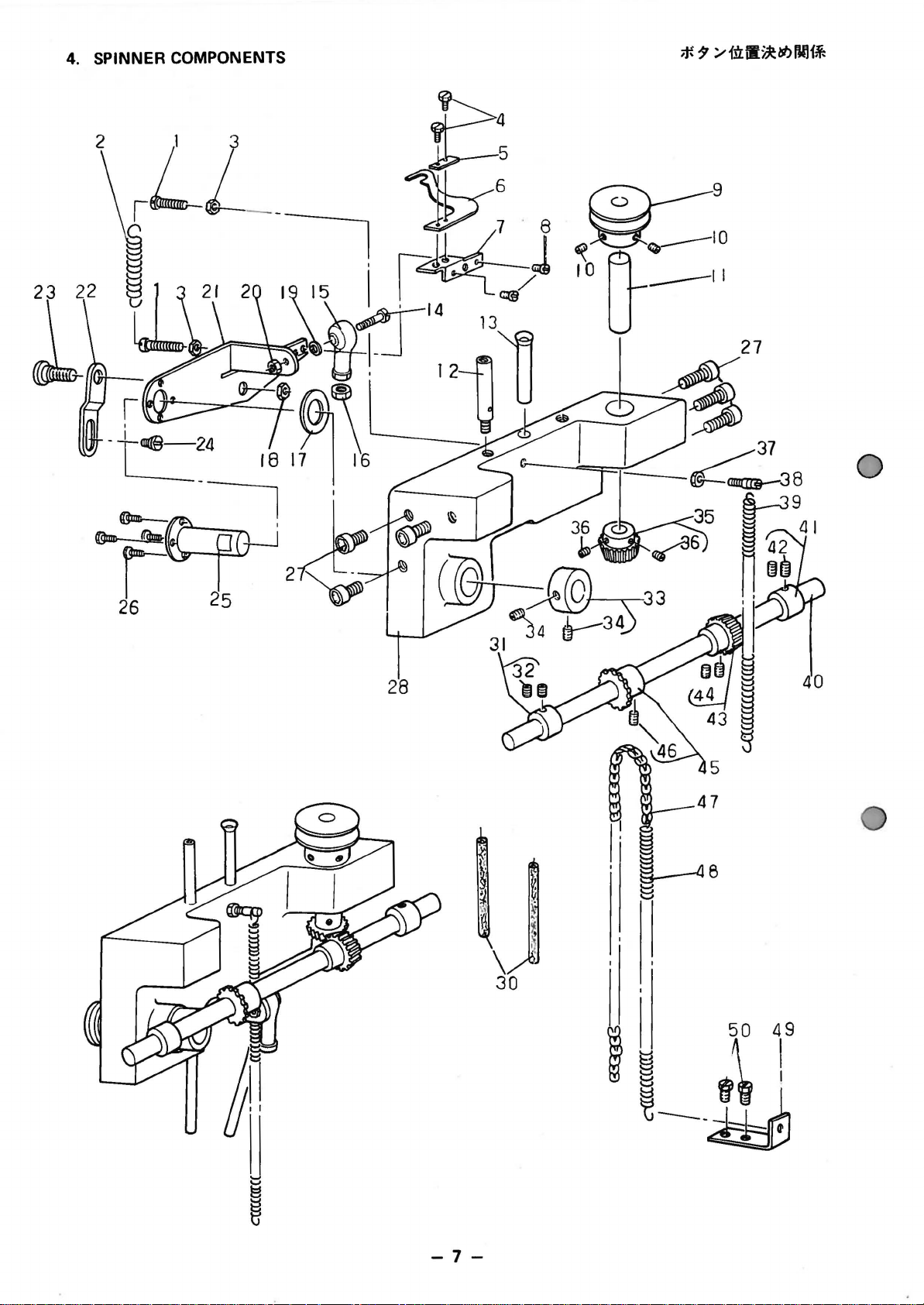

4. SPINNER COMPONENTS

* 9

5.

DRIVE

1J

REDUCTION GEAR COMPONENTS

6.

ilitll~IVJ1j

7. CHUTE MECHANISM COMPONENTS

~

8. BUTTON FEEDER COMPONENTS

;f-9 ::..-7-(

9. LOADER COVER & MAGNET COMPONENTS

o-‘)1—JJ/’-

10. CONTROL BOX COMPONENTS

::J

11.

L.

SW

L.

12.

TABLE

3CMB6

NUMERICAL

*51

OPERATING MECHANISM COMPONENTS

·:;

71i:lb001j . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

9

:,.-.:f—\7

::..-itr!i~l!f.>001j

CAM COMPONENTS

.L-001*

IJ

71VJ1j

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.:L-

~

!V11~

. . . . . . . . . . . . • . . . . . • • . . . • . . . . • . • . . . . . . • • • . . . • • • . . . . . . • 13

-‘>’-IJil1j……………………………………….

• -:r/f.:t-·:;

::..-

~

c

-JL-;f.

WIPER COMPONENTS

SW?

;f

OF EXCHANGING PARTS

.fb-

·:;

7

.AIVH~

/~-001~

~

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

INDEX

OF

~IVHj

·

………………………………..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS

……………………………………………..

·

…….

11

15

17

21

24

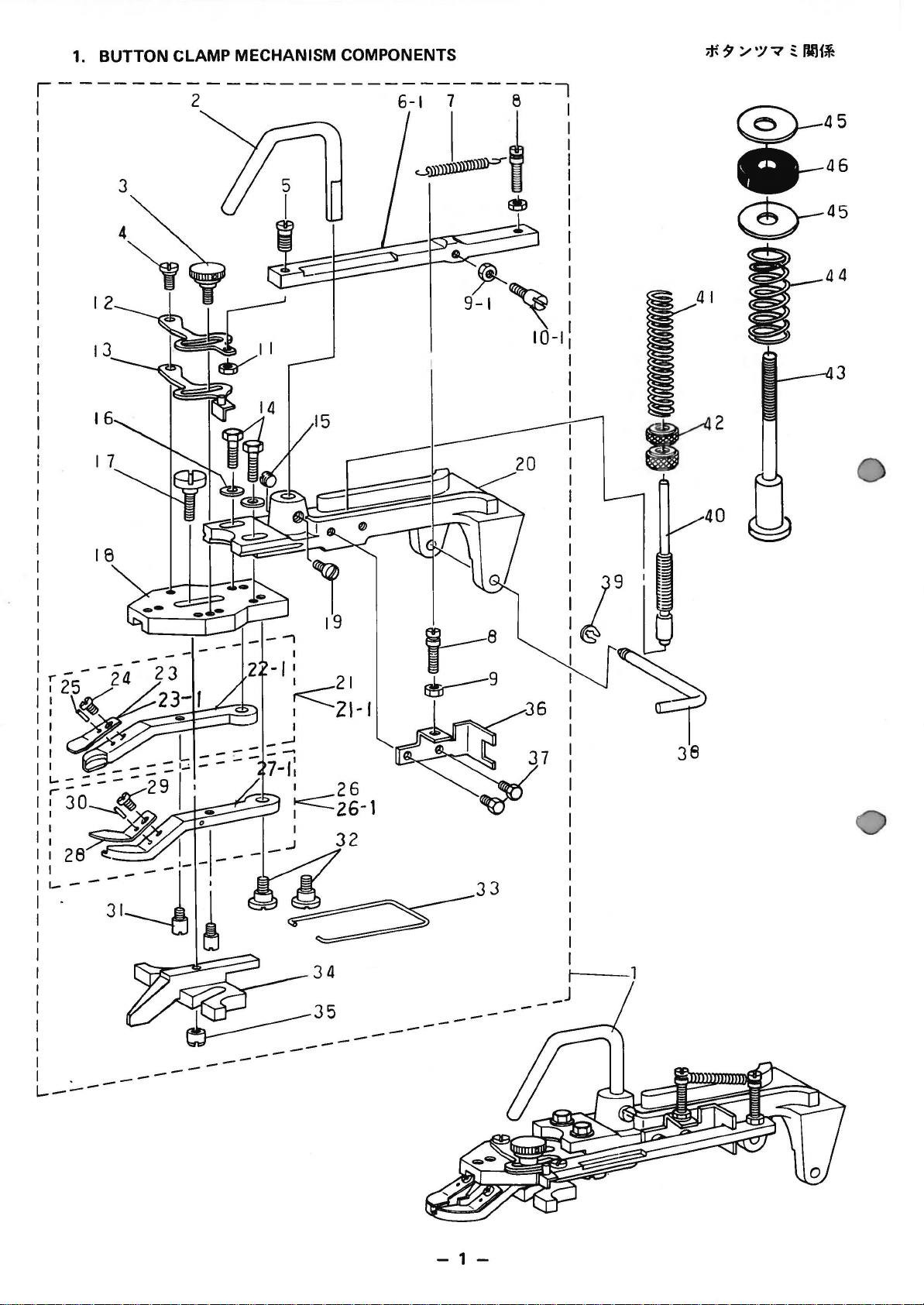

1. BUTTON CLAMP MECHANISM COMPONENTS

From the library of: Superior Sewing Machine & Supply LLC

~—————————-,

1 2

6-1

7 e

@—45

i

1

I

I

I

I

I

I

I

I

I

I

~-

—46

®—-45

2

0

L—:..—

—

—

—

-II

—

I

I

21

:<===z1-1

34

35

—

—

7

__

t—1

J

—

1-

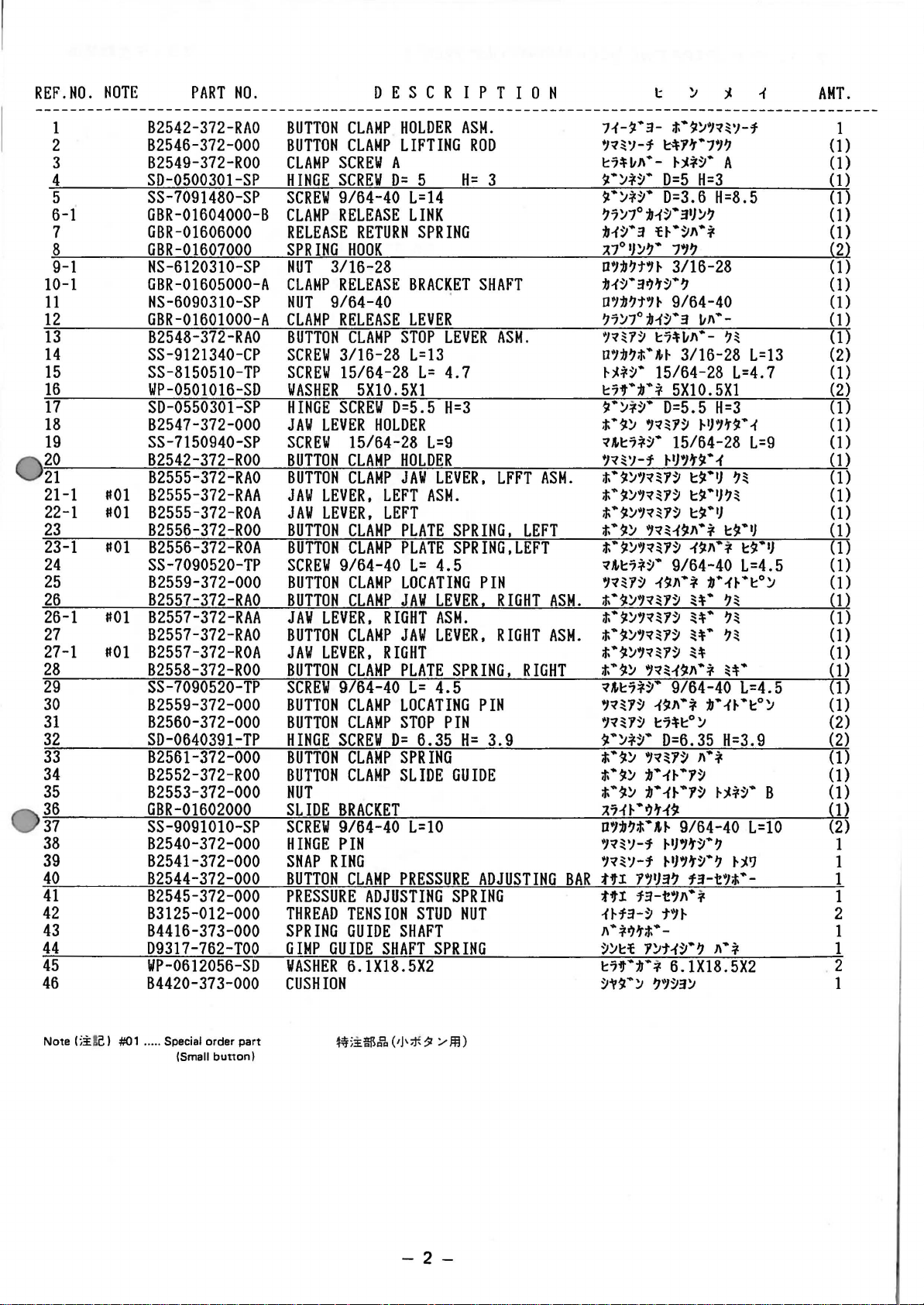

REF.NO.

From the library of: Superior Sewing Machine & Supply LLC

NOTE

PART

NO.

D E S C R I P T I 0 N

AMT.

t

2

3

4

5

6-t

7

8

9-t

tO-t

tt

t2

t3

t4

t5

t6

t7

t8

t9

20

2t

2t-t

22-t

23

23-t

24

25

26

26-t

27

27-t

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

B2542-372-RAO

B2546-372-000

B2549-372-ROO

SD-050030t-SP

SS-709t480-SP

GBR-Ot604000-B

GBR-Ot606000

GBR-Ot607000

NS-6t203t0-SP

GBR-Ot605000-A

NS-60903t0-SP

GBR-Ot601000-A

B2548-372-RAO

SS-9t2t340-CP

SS-8t505t0-TP

WP-050t0t6-SD

SD-055030t-SP

B2547-372-000

SS-7t50940-SP

B2542-372-ROO

B2555-372-RAO

not

B2555-372-RAA

not

B2555-372-ROA

B2556-372-ROO

not

B2556-372-ROA

SS-7090520-TP

B2559-372-000

B2557-372-RAO

not

B2557-372-RAA

B2557-372-RAO

not

B2557-372-ROA

B2558-372-ROO

SS-7090520-TP

B2559-372-000

B2560-372-000

SD-064039t-TP

B2561-372-000

B2552-372-ROO

B2553-372-000

GBR-01602000

SS-9091010-SP

B2540-372-000

B2541-372-000

B2544-372-000

B2545-372-000

B3t25-0t2-000

B4416-373-000

D93t7-762-TOO

WP-06t2056-SD

B4420-373-000

BUTTON

BUTTON

CLAMP

HINGE

SCREW

CLAMP

RELEASE

SPRING

NUT

CLAMP

NUT

CLAMP

BUTTON

SCREW

SCREW

WASHER

HINGE

JAW

SCREW

BUTTON

BUTTON

JAW

JAW

BUTTON

BUTTON

SCREW

BUTTON

BUTTON

JAV

BUTTON

JAW

BUTTON

SCREW

BUTTON

BUTTON

HINGE

BUTTON

BUTTON

CLAMP

CLAMP

SCREW

SCREW

9/64-40

RELEASE

RETURN

HOOK

3/t6-28

RELEASE

9/64-40

RELEASE

CLAMP

3/t6-28

t5/64-28

5X10.5Xt

SCREW

LEVER

t5/64-28

CLAMP

CLAMP

LEVER,

LEVER,

CLAMP

CLAMP

9/64-40

CLAMP

CLAMP

LEVER.

CLAMP

LEVER,

CLAMP

9/64-40

CLAMP

CLAMP

SCREW

CLAMP

CLAMP

NUT

SLIDE

SCREW

HINGE

SNAP

BUTTON

PRESSURE

THREAD

SPRING

GIMP

WASHER

BRACKET

9/64-40

PIN

RING

CLAMP

ADJUSTING

TENSION

GUIDE

GUIDE

6.1X18.5X2

CUSHION

HOLDER

LIFTING

A

D=

5

L=14

LINK

SPRING

BRACKET

LEVER

STOP

L=t3

L=

D=5.5

HOLDER

L=9

HOLDER

JAW

LEVER,

LEFT

ASM.

LEFT

PLATE

PLATE

L=

4.5

LOCATING

JAW

LEVER.

RIGHT

JAW

ASM.

LEVER.

RIGHT

PLATE

L=

4.5

LOCATING

STOP

PIN

D=

6.35

SPRING

SLIDE

L=10

PRESSURE

STUD

SHAFT

SHAFT

SPRING

ASM.

ROD

H=

3

SHAFT

LEVER

ASM.

4.7

H=3

LFFT

ASM.

SPRING,

LEFT

SPRING,LEFT

PIN

RIGHT

RIGHT

SPRING,

RIGHT

PIN

H=

3.9

GUIDE

ADJUSTING

SPRING

NUT

ASM.

ASM.

BAR

7~-~·3-

1~~~-f

t7UJ\·-

1·~-1~·

1·~-1~·

~7~7°~~~-3~~~

i~~·3

l7°~~~·

D’~~t’~

~~~·3~~~·~

o’t~t’~

~7~7°~~~·3

1~~1~

o’t~t.·~~

~~-1~·

t7t•t•-1

~·~-1~·

t.·1~

~~t7-1~·

7~~~-f

t-·1~,~~1~

t-·1~,~~1~

t.·~~1~~1~

t-·1~

t-·~~,~~1~

~~t7-1~·

‘~~1~

t-·1~,~~1~

t-·~~,~~1~

t-·~~,~~1~

t.·1~’~U~

t.·1~

~~t?-1~·

‘~~1~

7~~1~

1·~-1~·

t-·1~

t.·1~

t.·1~

l7~~

D7~~t.·~~

7~~~-f

7~~~-f

ttl

ttl

~~f3-~

1\·i~~t.·-

~~tt

t7t•:JJ•-1

~11·~ ~7~3~

t.·~~,~~~-f

~1~·1,~

~~-1~·

D=5

D=3.6

t~·~J\·-1

7’~

A

H=3

H=8.5

3/16-28

9/64-40

~J\·-

t7*~J\·-

t5/64-28

~~

3/t6-28

L=4.7

L=t3

5Xt0.5Xt

D=5.5

‘~~1~

~~’~9·~

‘~~~91\•-1

~~J\·-1

‘~~~11\•*

~11\

t7*to~

D=6.35

7~~1~

~·~~·1~

~-~~·y~

·~H9

~~,~~·~

~~,~~·~

17~3~

f3-t,J\•-1

t’~

1~t~~·;

H=3

~~1~1·~

15/64-28

t9·~

~~

t9·~~~

1

t1

…

J

t9·~

~11\·-1

9/64-40

~·~~·to~

~~·

~~

~*·

~~

~*·

~~

H

~~·

9/64-40

…

*

~·~~·to~

H=3.9

J\•*

~~-1~·

9/64-40

~~?

f3-t7t.•-

J\·-1

L=9

t1·~

L=4.5

L=4.5

L=lO

6.tX18.5X2

B

t

(1)

(1)

(1)

(1)

(1)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(2)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(2)

(2)

(1)

(1)

(1)

(1)

(2)

1

1

1

t

2

t

1

2

t

Note

(;i:!c I #01 ….. Special order

(Small

part

button

I

-2-

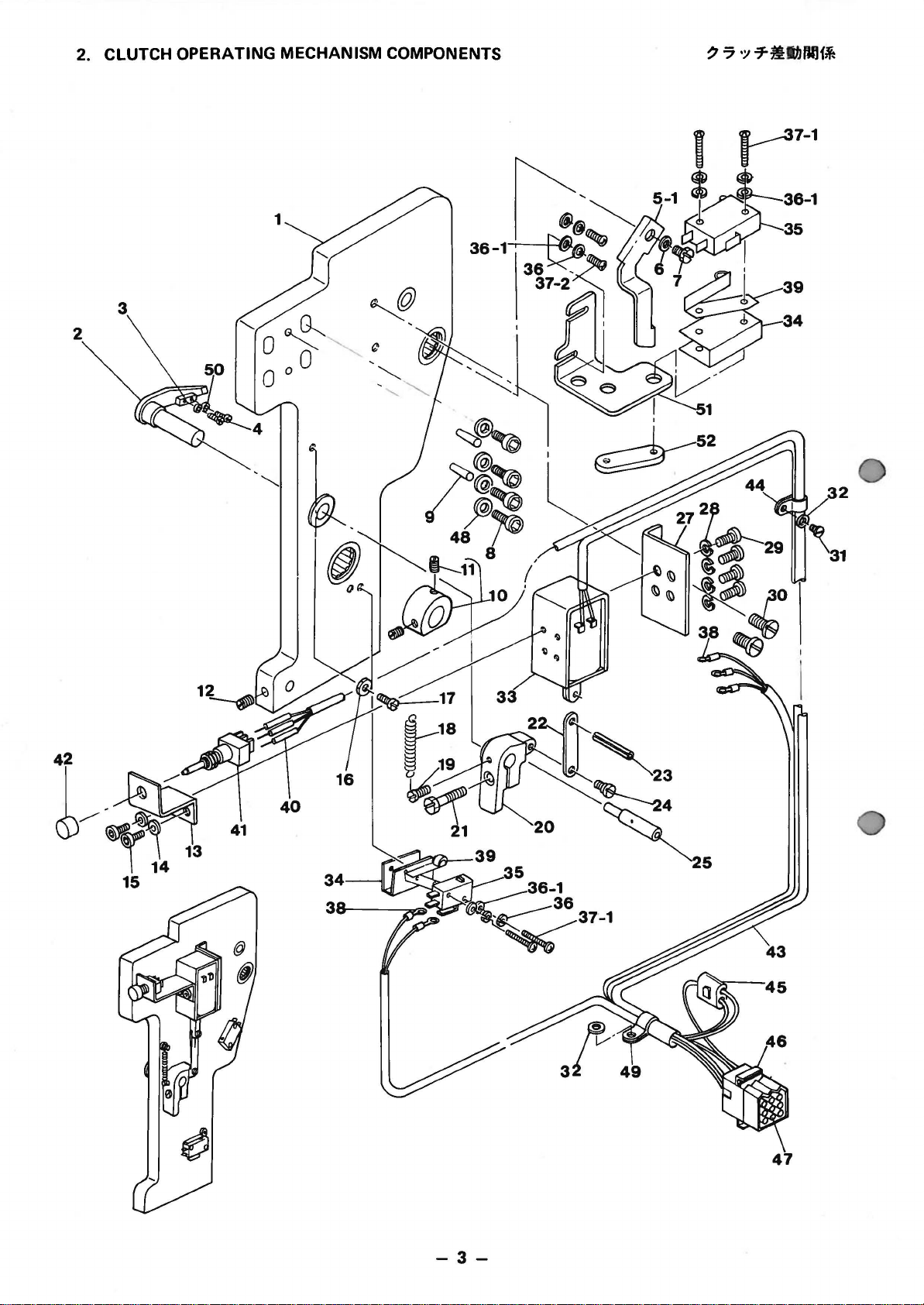

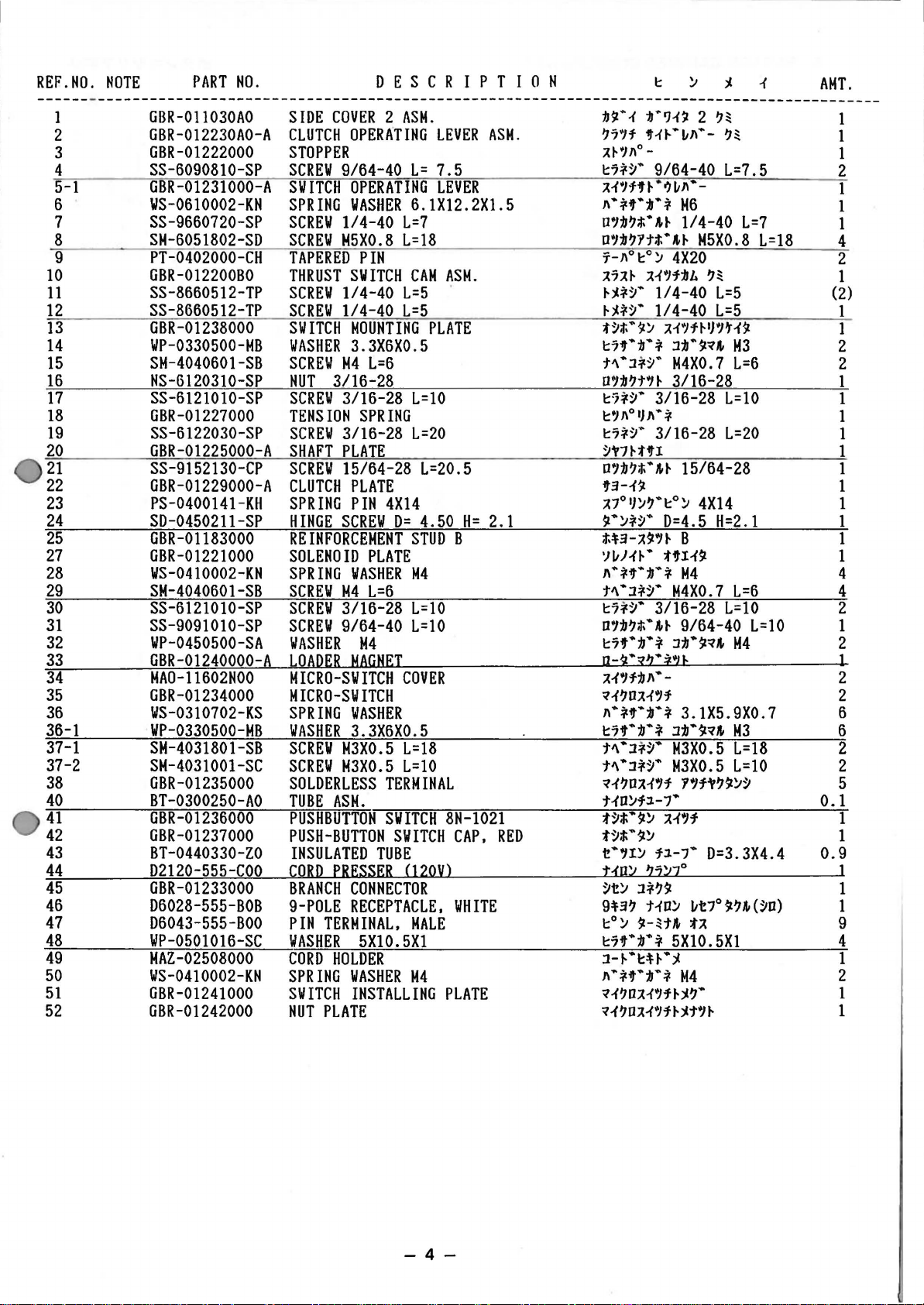

2. CLUTCH OPERATING MECHANISM COMPONENTS

From the library of: Superior Sewing Machine & Supply LLC

-3-

47

REF.HO.

From the library of: Superior Sewing Machine & Supply LLC

1

2

3

4

5-1

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

34

35

36

36-1

37-1

37-2

38

40

41

42

43

44

45

46

47

48

49

50

51

52

NOTE

PART

GBR-011030AO

GBR-012230AO-A

GBR-01222000

SS-6090810-SP

GBR-01231000-A

WS-0610002-KH

SS-9660720-SP

SM-6051802-SD

PT-0402000-CH

GBR-01220080

SS-8660512-TP

SS-8660512-TP

GBR-01238000

WP-0330500-MB

SM-4040601-SB

NS-6120310-SP

SS-6121010-SP

GBR-01227000

SS-6122030-SP

GBR-01225000-A

SS-9152130-CP

GBR-01229000-A

PS-0400141-KH

SD-0450211-SP

GBR-01183000

GBR-01221000

WS-0410002-KH

SM-4040601-SB

SS-6121010-SP

SS-9091010-SP

WP-0450500-SA

GBR-01240000

MA0-11602HOO

GBR-01234000

WS-0310702-KS

WP-0330500-MB

SM-4031801-SB

SM-4031001-SC

GBR-01235000

BT-0300250-AO

GBR-01236000

GBR-01237000

BT-0440330-ZO

D2120-555-COO

GBR-01233000

D6028-555-BOB

D6043-555-BOO

WP-0501016-SC

MAZ-02508000

WS-0410002-KN

GBR-01241000

GBR-01242000

NO.

D E S C R I P T I 0 N

SIDE

COVER 2 ASH.

CLUTCH

OPERATING

STOPPER

SCREW

SWITCH

SPRING

SCREW

SCREW

TAPERED

THRUST

SCREW

SCREW

SWITCH

WASHER

SCREW

HUT

SCREW

TENSION

SCREW

SHAFT

SCREW

CLUTCH

SPRING

HINGE

9/64-40

OPERATING

WASHER

1/4-40

M5X0.8

PIN

SWITCH

1/4-40

1/4-40

MOUNTING

3.3X6X0.5

M4

L=6

3/16-28

3/16-28

SPRING

3/16-28

PLATE

15/64-28

PLATE

PIN

SCREW

REINFORCEMENT

SOLENOID

SPRING

SCREW

SCREW

SCREW

WASHER

A

LOADER

PLATE

WASHER

M4

L=6

3/16-28

9/64-40

M4

MAGNET

MICRO-SWITCH

MICRO-SWITCH

SPRING

WASHER

SCREW

SCREW

WASHER

3.3X6X0.5

M3X0.5

M3X0.5

SOLDERLESS

TUBE

ASH.

PUSHBUTTON

PUSH-BUTTON

INSULATED

CORD

BRANCH

9-POLE

PIN

TERMINAL,

WASHER

CORD

SPRING

SWITCH

NUT

PLATE

TUBE

PRESSER

CONNECTOR

RECEPTACLE,

5X10.5Xl

HOLDER

WASHER

INSTALLING

LEVER

L=

7.5

LEVER

6.1X12.2X1.5

L=7

L=18

CAM

ASM.

L=5

L=5

PLATE

L=lO

L=20

L=20.5

4X14

D=

4.50

H=

STUD

B

M4

L=10

L=10

COVER

L=18

L=lO

TERMINAL

SWITCH

SWITCH

8N-1021

CAP,

(120V)

WHITE

MALE

M4

PLATE

ASM.

2.1

RED

:b$!

…

1

t•’J1’J.

~71f

iJ’-f~-~~—

;H’:I~o-

~7*~

..

A-i’1f’H·o)~~·-

~·*iJ’•;IJ•i

0′:/:b~t.·~~

0’1:11~Ytt.·,~

1″-~o~o~

A7A~

A-i’1f:bJ.

~~*~·

~~*~·

-~t.·$1~

~7iJ’•t•*

t~·l*~·

U1:11~t»‘J~

~7*~·

~’}\OJ}~•*

~7*~·

~’\’7~tiJ’l

O’:b~;t.·~~

2

~~

~~

9/64-40

L=7.5

M6

1/4-40

L=7

M5X0.8

L=18

4X20

~~

1/4-40

1/4-40

~1’1f~~’1t1$Z

L=5

L=5

l:ll

..

$1~’

M4X0.7

M3

L=6

3/16-28

3/16-28

3/16-28

L=lO

L=20

15/64-28

iJ’3-1$Z

~7°l}~~·~o~

$!·~*~·

t.H-~$!’1~

‘JltN~·

~

…

*,.

..

11

t~·l*~·

~7*~·

D1:11~t.·~~

~7f•11•*

n-~·x2·=1n

~1’1f:b~·

q-{~OA1’1f

~·*,.:b.*

~7iJ’·:b·*

t~·l*~·

t~·l*~·

q-{~D~1’1f

ND~fl.-7•

-~;J;·$!~

t~;r;·$!~

t·,l~

N!]:.t 2j:.t7°

~t~

l*~$!

9~3~

t1D~

~o~

$!-~t~

~7iJ’·:b·*

J-t-·~u·~

~·*iJ'»‘:II

q1~D~1’H~~·

q1~DM$H~~t’~

4X14

D=4.5

H=2.1

B

tiJ’I1$Z

…

*

M4

M4X0.7

3/16-28

9/64-40

l:II•$Zq~

3.1X5.9X0.7

l:b•$Zq~

M3X0.5

M3X0.5

Y’f’\’~$!~~

~1,1

f:J.-7.

5X10.5X1

.. * H4

L=6

L=lO

L=10

M4

M3

L=18

L=lO

D=3.3X4.4

ltt7°$Z~~(~D)

fA

AHT.

1

1

1

2

1

1

1

4

2

1

(2)

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

4

4

2

1

2

1

2

2

6

6

2

2

5

0.1

1

1

0.9

1

1

1

9

4

1

2

1

1

—

4-

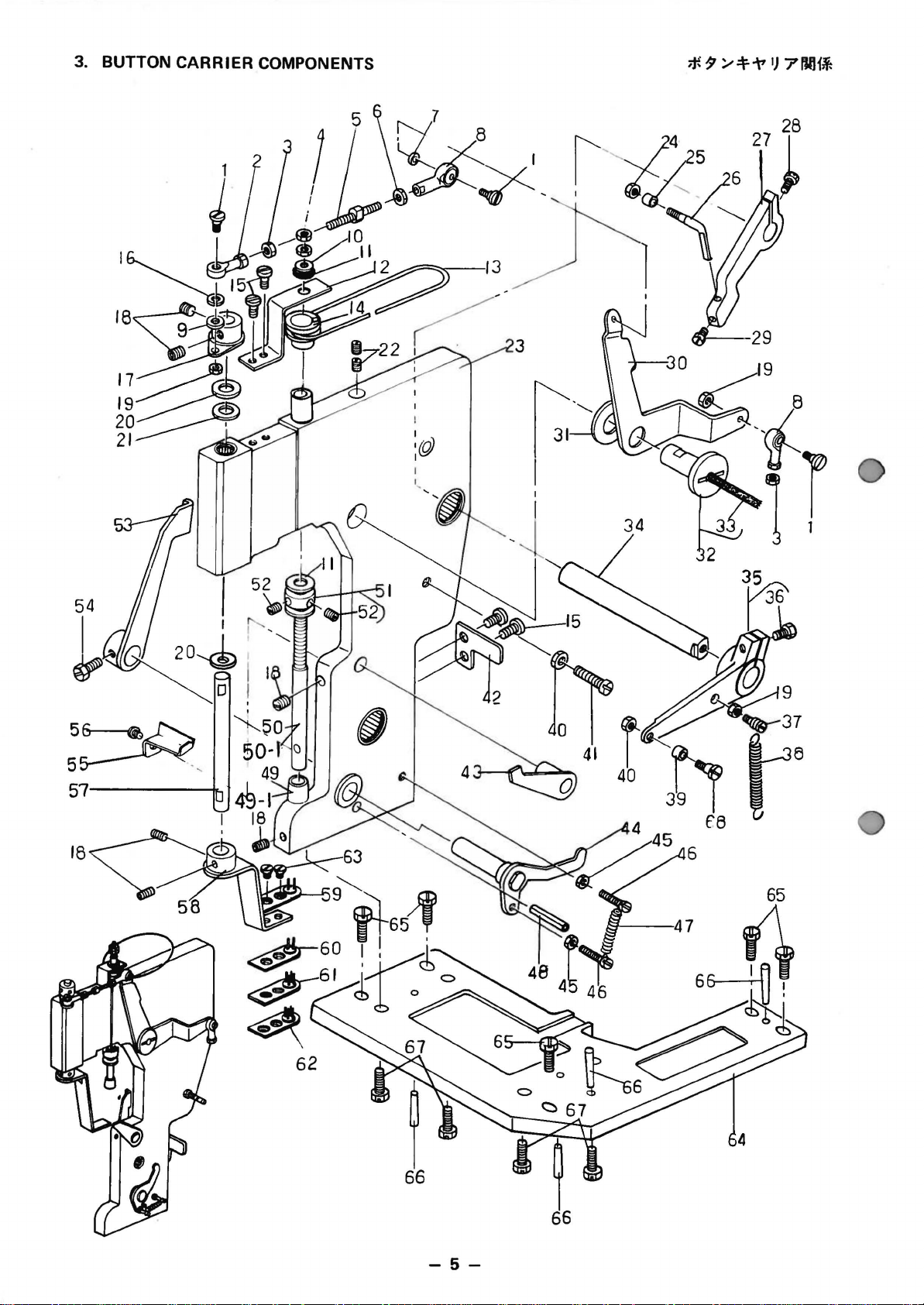

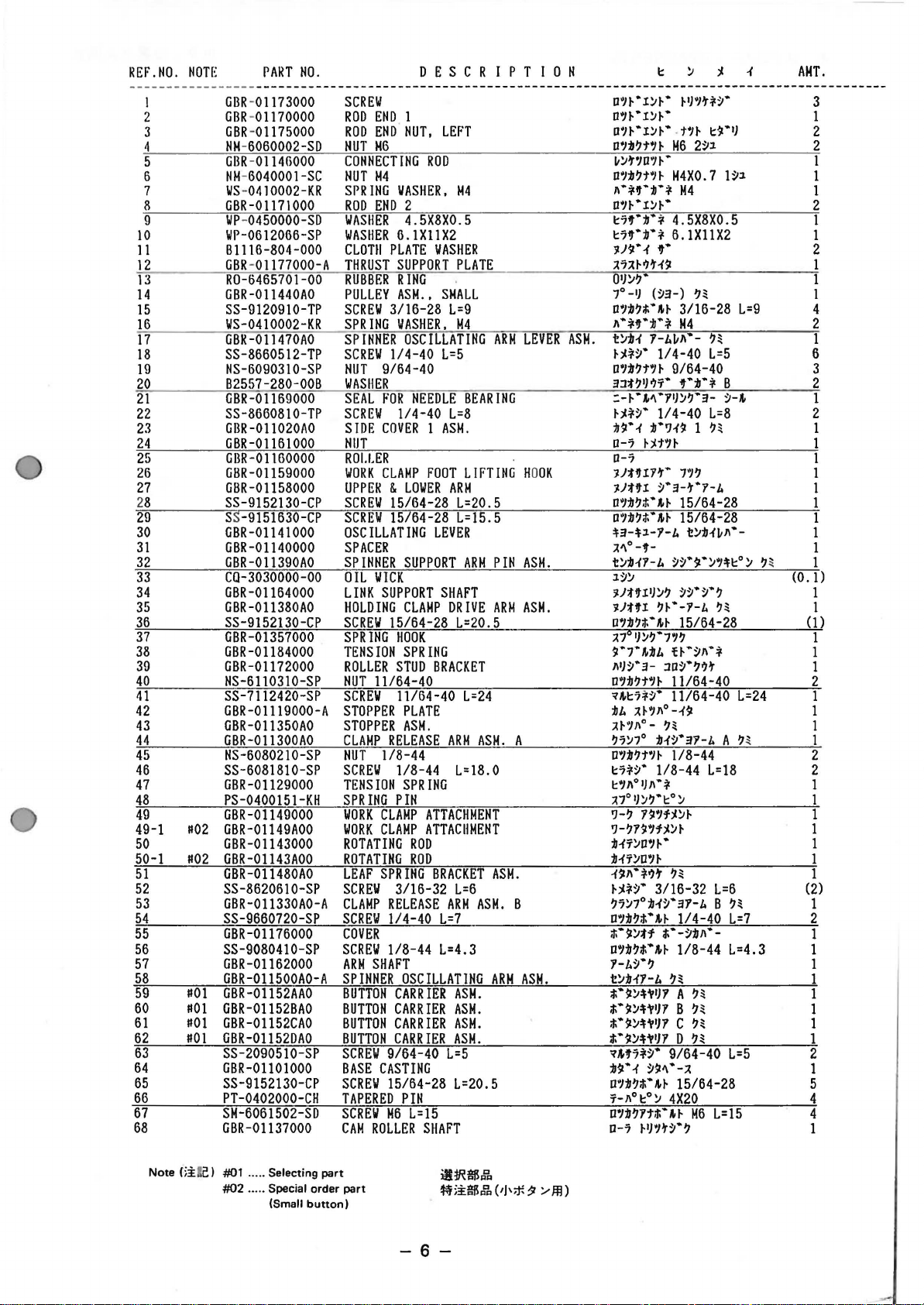

3. BUTTON CARRIER COMPONENTS

From the library of: Superior Sewing Machine & Supply LLC

56-t%~

5~

57——-n.

-5-

REF.NO.

From the library of: Superior Sewing Machine & Supply LLC

I

2

3

4

5

6

7

R

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

49-1

50

50-1

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

NOTE

PART

GBR-01173000

GBR-01170000

GBR-01175000

NH-6060002-SD

GBR-01146000

NM-6040001-SC

WS-0410002-KR

GBR-01171000

IIP-0450000-SD

WP-0612066-SP

B1116-804-000

GBR-01177000-A

R0-6465701-00

GBR-011440AO

SS-9120910-TP

WS-0410002-KR

GBR-011470AO

SS-8660512-TP

NS-6090310-SP

B2557-280-00B

GBR-01169000

SS-8660810-TP

GBR-011020AO

GBR-01161000

GBR-01160000

GBR-01159000

GBR-01158000

SS-9152130-CP

SS

-9151630-CP

GBR-01141000

GBR-01140000

GBR-011390AO

CQ-3030000-00

GBR-01164000

GBR-011380AO

SS-9152130-CP

GBR-01357000

GBR

-01184000

G

BR

-01172000

NS-6110310-SP

SS-7112420-SP

GBR-01119000-A

GBR-011350AO

GBR-011300AO

NS-6080210-SP

SS-6081810-SP

GBR-01129000

PS-0400151-KH

GBR-01149000

«02

GBR-01149AOO

GBR-01143000

«02

GBR-01143AOO

GBR-011480AO

SS-8620610-SP

GBR-011330AO-A

SS-9660720-SP

GBR-01176000

SS-9080410-SP

GBR-01162000

GBR-011500AO-A

«01

GBR-01152AAO

«01

GBR-01152BAO

«01

GBR-01152CAO

«01

GBR-01152DAO

SS-2090510-SP

GBR-01101000

SS-9152130-CP

PT-0402000-CH

SM-6061502-SD

GBR-01137000

NO.

SCREW

ROD

ROD

NUT

CONNECTING

NUT

SPRING

ROD

WASHER

WASIIER

CLOTII

THRUST

RUBBER

PULLEY

SCREW

SPRING

SPINNER

SCREW

NUT

WASHER

SEAL

SCREW

SIDE

NIJT

ROLLER

WORK

UPPER & LOWER

SCREW

SCREW

OSCILLATING

SPACER

SPINNER

OIL

LINK

HOLDING

SCREW

SPRING

TENSION

ROLLER

NUT

SCREW

STOPPER

STOPPER

CLAMP

NUT

SCREW

TENSION

SPRING

WORK

WORK

ROTATING

ROTATING

LEAF

SCREW

CLAMP

SCREW

COVER

SCREW

ARM

SPINNER

BUTTON

BUTTON

BUTTON

BUTTON

SCREW

BASE

SCREW

TAPERED

SCREW

CAM

D E S C R I P T I 0 N

END

1

END

NUT,

LEFT

H6

ROD

H4

WASHER,

END

2

H4

4.5X8X0.5

6.1XllX2

PLATE

WASHER

SUPPORT

PLATE

RING

ASH.,

3/16-28

SHALL

L=9

WASHER.

M4

OSCILLATING

1/4-40

L=5

9/64-40

FOR

NEEDLE

1/4-40

BEARING

L=8

COVER 1 ASH.

CLAMP

FOOT

LIFTING HOOK

ARM

15/64-28

15/64-28

L=20.5

L=15.5

LEVER

SUPPORT

ARM

WICK

SUPPORT

15/64-28

SHAFT

CLAMP

DRIVE

L=20.5

HOOK

SPRING

STUD

BRACKET

11/64-40

11/64-40

L=24

PLATE

ASH

.

RELEASE

ARM

ASH.

1/8-44

1/8-44

L=18.0

SPRING

PIN

CLAMP

ATTACHMENT

CLAMP

ATTACHMENT

ROD

ROD

SPRING

BRACKET

3/16-32

RELEASE

1/4-40

1/8-44

ARM

L=7

L=4.3

L=6

ASH.

SHAFT

OSCILLATING

CARRIER

CARRIER

CARRIER

CARRIER

9/64-40

ASH.

ASH.

ASH.

ASH

L=5

.

CASTING

15/64-28

L=20.5

PIN

M6

L=15

ROLLER

SHAFT

ARM

PIN

ARM

A

ASH.

B

ARM

LEVER

ASH.

ASH.

ASM.

n•H

·1~~ • pJ•H*~·

D~~·l~~·

D7~·l~~·-t~~

D~:IJ?t~~

~~~~·Jn•H

D7:1J?t7~

11·*11·:1J·*

D7~·l~~·

~7f·:IJ·*

~711·:1J·*

«J.Jt•-t

~7::H~~1t

01}~?·

1°-1)

D7:1J?t.·~~

11·*-,·:IJ·*

t~:IJ1

ASM.

~~*~

o•J:IJ?t~

3:J:f?IJ~T·

=-~·~~-1~~?·3-

~~*~

1Jt•-t

M6

•

M4X0.7

M4

4.5X8X0.5

6.1X11X2

,.

(~3-)

3/16-28

M4

1-J.J,J\

..

1/4-40

~

9/64-40

,.:IJ

..

1/4-40

:IJ•’J-tt

2~:t

?~

..

—

..

1

D-7

:;tJ:tHr~·

;,tJHl

D7:1J?t.·~~

D7:1J?t.·~~

~3-~:1-1-J.

~~0-·-

t~:IJ-{1-J.

:1~~

«J.1Hl1J~?

«J.J:tn

D~:IJ?t.·~~

~70

t·1·u~.

J\1)~·3-

D~:b?t•J~

~~~7*~·

:IJJ.

~~711°-

?7~7°

u•J:IJ?t·J~

~7*~·

~~11ol}11•*

~7o1J~?·~o~

‘1-?

‘1-?1t~f~~~

:IJ17~D~~·

:IJ17~D7~

1tJI

~~*~·

?7~7°:1J1~·37-J.

D~:IJ?t.·~~

;t.•t~:tf t.•-~:IJII•-

D7:1J?;J;

1-J.~·?

t~:b11-J.

;~;·t~~’\1

;t;•t~H1JY B ?~

;t;·t~~’\1

t.·t~~’\1

~~f7*~·

:llt•-t

D7:11?;t.·~~

7-11°

D~:IJ?1t;t;·,~

D-7

7~?

~·3-~·1-1.

15/64-28

15/64-28

t~:IJ-{1!11·-

~~·t·~,~~o~ ?~

~~·~·?

?~·-1-1.

15/64-28

1)~?·7~?

u·~11·*

:ID~·?’)~

11/64-40

11/64-40

~~711°—ft

?~

:IJ1~·31-J.

118-44

1/8-44

1t·Jt~~~

..

*’)~

?~

3/16-32

1/4-40

..

~~

1/8-44

?~

1

11 A ?~

1

JY c ?~

1

JY D ?~

9/64-40

~t~·-~

15/64-28

~o

~

4X20

M6

~I)•J~~·?

~t·~

1~:1

L=9

?~

L=5

* B

~-~

L=8

?~

?~

L=24

A

?

L=l8

L=6

B

?~

L=7

L=4.3

L=5

L=15

~

AMT.

3

1

2

2

1

1

1

2

1

1

2

1

1

1

4

2

1

6

3

2

1

2

1

1

1

1

1

1

1

1

1

1

(0.

1)

1

1

(1)

1

1

1

2

1

1

1

1

2

2

1

1

1

1

1

1

1

(2)

1

2

1

1

1

1

1

1

1

1

2

1

5

4

4

1

Note ()i:

ft

e)

#01 ….. Selecting

#02

….. Special

(Small

part

order

button)

part

iJltRM.ff,

~ii.M.ff,(‘l’*:il

;..-If!)

-6-

4.

From the library of: Superior Sewing Machine & Supply LLC

SPINNER

2

—

COMPONENTS

to@

-24

-~

I B

17 16

I p 0 /

27

0

I

26

-7-

Adjustment Procedures

™ Turn the hand wheel by hand and loosen

screw 1 in the Fig. A in the thread take-

up lever to adjust so that the upper

engraved line of the two engraved lines

on the needle bar aligns with the bottom

of lower bushing 3 when the needle bar

is at its lowest position.

For the old type sewing machine, in

addition, adjust the position so that

needle clamp screw 4 enters the slot of

lower bushing 3 as illustrated in Fig. B

when the needle bar is at its highest

position.

Following needles are equipped at the

time of delivery.

MB-373 : Standard needle TQ x 7 #16

MB-377 : Standard needle TQ x 1 #16

MB-377 / Z201 : TQ x 7 #20

MB-377 / Z202 : TQ x 7 #18

1) Adjusting the looper timing

7

™ Loosen two screws 5 in the looper and cam sleeve and

adjust in the rotating direction of the looper and cam sleeve

so that the looper’s blade point aligns with the center of

the needle when the lower engraved line of the needle

bar is aligned with the bottom of the lower bushing. Then

tighten the screws.

2) Clearance between the needle and looper

Loosen two screws 7 in the looper suppot ring and adjust

in the longitudinal position of the looper when the looper’s

blade point is aligned with the center of the needle. Then

tighten the screws.

3) Clearance between the needle guide and needle

Loosen screw 8 in the needle guide and adjust in the

longitudinal position of the needle guide so that the clearance

between needle guide 6 and needle should become 0 to

0.1 mm when the needle bar is at its lowest position.

1

2

3

Fig. B

3

5

3

−

Results of Improper Adjustment

™ If needle bar 2 is too high, skipped

Fig. A

stitches will be produced.

If the needle bar is too low, the

needle will come in contact with the

looper.

4

4

™ If the clearance between the needle

and looper is too excessive, it is

likely to produce skipped stitches.

If the clearance is too small, in

accordance with the material used,

the needle will come in contact with

the looper resulting in needle

breakage and looper’s blade point

breakage.

™ For thick materials and overlapped

sections, adjust the clearance

between the needle guide and

needle so that the needle guide

touches the needle by 0.1 to 0.2

mm.

−

1. SPECIFICATIONS

MB-373

MB-377

Other specifications are same as those of MB-373.

−1 −−1 −

1

2

3

4

5

6

7

8

9

10

11

Sewing speed

Number of stitches

Amount of feed

Stitching pattern

Button size

Needle bar stroke

Needle

Automatic thread trimmer

Presser lifter

Stop-motion unit

Power supply

Max. 1,500 rpm Normal speed 1,300 rpm

8, 16, and 32 stitches

(6, 12 and 24 stitches are also possible by changing the cam.)

Crosswise feed 2.5 to 6.5 mm

Lengthwise feed 0, 2.5 to 6.5 mm

コ -shape, Z-shape, Π -shape, and X-shape

10 to 28 ø mm

48.6 mm

TQ x 7 #16 (#14 to #20)

Interlocked with the presser lifter.

Consists of a fixed knife and a moving knife.

Automatically operated (Pedal-system is also available.)

Automatically operated (equipped with speed slowing device)

200 W (1/4 HP) single- or three-phase

1

2

Stitching pattern

Needle

コ -shape, Z-shape, and X-shape

TQ x 1 #16 (In case of attachments for medium button (Z202) and

large button (Z201) TQ x 7 #16, #14 to #20)