Dani_O

Рег.

28.09.2014

Сообщ.

20

шатл, Здравствуйте. Заказала в инет магазине оверлок MO-654DE , а привезли MO-600 Series. Я отказалась, потому что про такой даже не читала нигде. Что это за оверлок, можете рассказать и стоит ли его брать вместо 654. У меня «чуйка» сработала, что мне он не нужен. Вы что скажите? Что за зверь? Спасибо.

шатл

Рег.

06.02.2013

Сообщ.

20393

Награды: 2

Dani_O Это,я так понимаю на коробке написано,а на белой бумажке,там -же на коробке,что написано.?

Trish

Рег.

14.01.2009

Сообщ.

4022

Dani_O

шатл, Здравствуйте. Заказала в инет магазине оверлок MO-654DE , а привезли MO-600 Series. Я отказалась, потому что про такой даже не читала нигде. Что это за оверлок, можете рассказать и стоит ли его брать вместо 654. У меня «чуйка» сработала, что мне он не нужен. Вы что скажите? Что за зверь? Спасибо.

О! Мне тоже в прошлый вторник привезли этот оверлок и крупная надпись на коробке MO-600 Series меня тоже смутила, но внизу была маленькая белая наклейка MO-654DE/CE3. Очень довольна. Сшила уже несколько вещей. Тоже долго читала тему и в дополнение Мэррилоку 11 (ну очень надоело перенастраивать, да и оверлочная строчка перестала устраивать в полной мере. Может, игольный блок пора менять) взяла Жука. Спасибо всем, и, в частности, Вам, Шатл.

Dani_O

Рег.

28.09.2014

Сообщ.

20

Trish, шатл, Да я и не смотрела, как увидела, что 600, сразу паника (( Завтра привезут, уже позвонила и извинилась. Сказали, что они и сами не знали (экспедиторы) им что дали на складе, то и повезли. Завтра посмотрим

Вам ОГРОМНОЕ СПАСИБО за разъяснения

Fraxine

Рег.

16.08.2014

Сообщ.

5013

Добрый день. Дозрела уже до заказа нового оверлока (бразер 1034) и вижу в магазине Джаноме 714 ненамного дороже. И хоть я джаномовские оверлоки сразу исключила, а тут на фоне такой цены думаю-а может зря.

Как 1034 и 714 в сравнении по работе на тонких материалах?

И еще-у бразера дифференциал 0,7-2,0, а у джаноме 0,5-2,25-на практике это большая разница в швах будет?

И еще вопрос-к модели 4234 идет сменный палец ширины строчки. Можно ли его к 1034 приделать и вообще-нужная это вещь?

шатл

Рег.

06.02.2013

Сообщ.

20393

Награды: 2

Fraxine Дубовей конечно,но 714 из Джаноме ,это не плохой вариант,в принципе можно приспособиться и к тонким тканям и трикотажу, а так все функции и удобства.На 1034 тоже есть этот палец или стежковый язычок,он убирается для закрутки рулика,но конструктивно они разные и не взаимозаменяемые.

Dani_O

Рег.

28.09.2014

Сообщ.

20

Trish, шатл, Приехал мой овер. Таки Вы были правы, спасибо! Есть стикер на котором указана модель овера. шатл, Вам огромное спасибо в помощи вывора овера. Еще не пробовала. Потом поделюсь впечатлениями.

Ляпс

Рег.

26.10.2009

Сообщ.

155

Dani_O

слово series вас никак не смутила? или увидели 600 и на series уже и не смотрели?

lenNM13

Рег.

21.12.2013

Сообщ.

1

Добрый день! Планирую приобрести оверлок. Почитав форум, определилась с моделью — Juki 654 DE.

Шатл, очень нужен Ваш совет!

Сделала запрос в ИМ, но пришел вот такой ответ:

Нарекания на Juki 654 DE идут волной. У кого ломается верхний петлитель,у кого треснуло «плечо»(деталь для верхнего петлителедержателя),а кто жалуется именно на DE -электронную,типа,педаль.Плато в педали не функционирует.

Альтернатива: Janome 60789 -с обычными натяжителями

Janome 60788 -с вертикальными натяжителями

Janome T-72 с японскими петлителями и толкателями

Например на оверлоке Janome 60788 работнику,при шитье,очень удобно,благодаря специальным «окошечкам» видеть и устанавливать нужный ему размер дифференциала и ширину строчки и т. д.

Также эти оверлоки выполняют знаменитый ролевый шов(он очень тонкий и красивый—только у Janome и Elna).

Ещё варианты: Elna 664, Elna 664 PRO

Помогите! Планирую шить для дома, друзей. Бюджет до 13 т.руб.

Ляпс

Рег.

26.10.2009

Сообщ.

155

lenNM13

Сделала запрос в ИМ, но пришел вот такой ответ:

Нарекания на Juki 654 DE идут волной. У кого ломается верхний петлитель,у кого треснуло «плечо»(деталь для верхнего петлителедержателя),а кто жалуется именно на DE -электронную,типа,педаль.Плато в педали не функционирует.

Озвучьте пожалуйста название магазина, страна должна знать своих героев и ничего у них не покупать из-за их вранья.. (хотя я примерно догадываюсь кто это)

шатл

Рег.

06.02.2013

Сообщ.

20393

Награды: 2

lenNM13 Это необъективная информация,никакой волны нет,петлители ,что верхние,что нижние ломаются на всех оверах и коверах,причем нельзя сказать на каких больше,насчет рычага привода петлителя,на Бразере и Джаноме такое встречал,на Джуки пока нет причем учитываю временную и количественную статистику нашего СЦ по Джуки,а это более 10 лет.Насчет педали,сразу не вспомню,не скажу,но в последнее время проблем с педалями не было,и имейте ввиду,что не обязательно,в случае поломки покупать фирменную педаль,к Джуки подходят педали,а они не дорогие,от некоторых моделей ШМ Ягуар.Про удобства и окошечки не скажу,это уже вам решать,это индивидуально,но никаких преимуществ Джаноме и Елна перед Джуки я не вижу,про закрутку рулика,тут даже писать не буду,здесь объективно лидеры Бернина и Джуки,а Джаноме,ну даже не на втором и третьем местах,здесь они не соперники.Насчет петлителей,видел я японские петлители от пром.оверов,поверьте Джаномовские,да и другие бытовые петлители и рядом не стоят,да и абсурд это,для других Джаноме петлители тайваньские,а для дешевого и простого Т72,их делают в Японии,смысл.

Fraxine

Рег.

16.08.2014

Сообщ.

5013

Ох, горе-горькое Металась-металась между 1034й и 654 (разница в цене 3200), все из-за шва двухниточного да ножей, ну и иголки у 654 крепятся отдельно. Прочитала тему заново и все же решила купить 1034. Думаю на пару лет ножей хватит (думаю от кулирок да интерлоков они не сильно затупятся).

Просмотрела в доме все вещи с руликами-на детских вообще двухнитки нет, на одном платке шифоновом есть такой, а другой тонкий платок вообще на ШМ подогнут на 1 мм вместо оверложки.

Думаю если делать рулик иламентными нитками, то и трехнитка будет не толстая.

Ну а по креплению иголок-буду развивать ловкость рук .

Ну в общем это себяя уговариваю, что 1034 не хуже 654.

И еще вопрос (а то в теме бразеров мне никто не ответил)-на обчных швах можно поставить длину стежка 1-1,5 мм? В инструкции написано, что мин. длина 2 мм, а при ролевом шве ставить надо на R-это я так понимаю и есть 1 мм?

шатл

Рег.

06.02.2013

Сообщ.

20393

Награды: 2

Fraxine На обычных швах в принципе 3 ,длинна стежка нормально,если длинну стежка ставить слишком маленькую,то шов будет не красивый да и расход ниток лишний,закрутка рулика на 1034 вполне хорошая,причём на R будет плотновато,визуально даже меньше миллиметра,лучше ставить немного больше.

Valentino4ka

Рег.

15.10.2014

Сообщ.

29

Доброго вечера осинкам! Освоила свою новую ШМ (спасибо Шатл и все-все-все!) и вернулась к выбору оверлока/коверлока… и вопрос такой: бернина 880 или джуки 735 — как именно оверлок, что лучше, удобнее? разница в цене у них небольшая..

Крокодительница

Рег.

31.10.2013

Сообщ.

8

Уважаемые форумчане! Годик назад с вашей помощью выбрала себе машинку, за что я вам глубоко признательна, а теперь вот хочу «апгрейднуться» до оверлока. Оверлок первый будет, в первую очередь хочу использовать для шитья трикотажа (детские трусы-спортивные штаны, шапочки и т.п.)

Как вы считаете, Смогу ли удовлетворить мои потребности какие-то из нижеперечисленных моделей? Вопрос цены стоит довольно принципиально, потому даже разница в цене в 30% уже откладывает покупку в долгий ящик.

рассматриваю такие варианты:

Janome T-34

Janome 205D

Janome ML 204D

Janome ML 9002D

может, другие модели в этой ценовой категории порекомендуете?

в вопросе оверлоков я полный профан

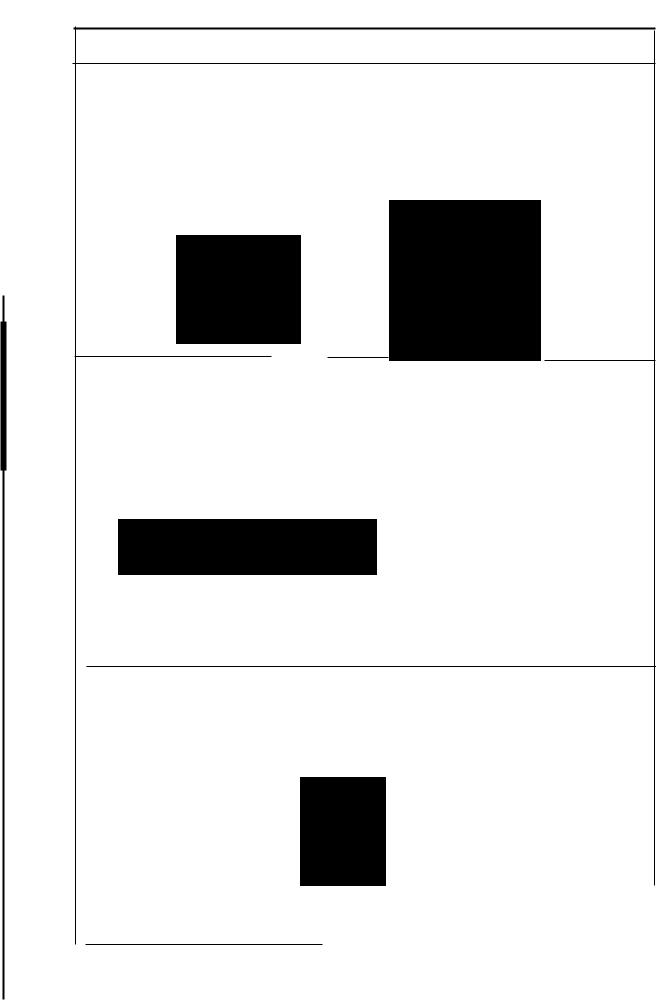

PREFACE

This Engineer’sManual is written for the technical personnel who are responsible for the service and maintenance of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel factory contains operating instructions in detail. And this manual describes «Standard Adjustment», «Adjustment Procedures», «Results of Improper Adjustment», and other important information which are not covered by the Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List described below together with this Engineer’s Manual when carrying out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or Engineer’sManual for the motor. And for the control panel, refer to the Instruction Manual for the control panel. This manual gives the «Standard Adjustment» on the former page under which the most basic adjustment value is described, and on the latter page «Results of Improper Adjustment» under which stitching errors and troubles arising from mechanical failures are described together with the CIAdjustment Procedures».

|

~ |

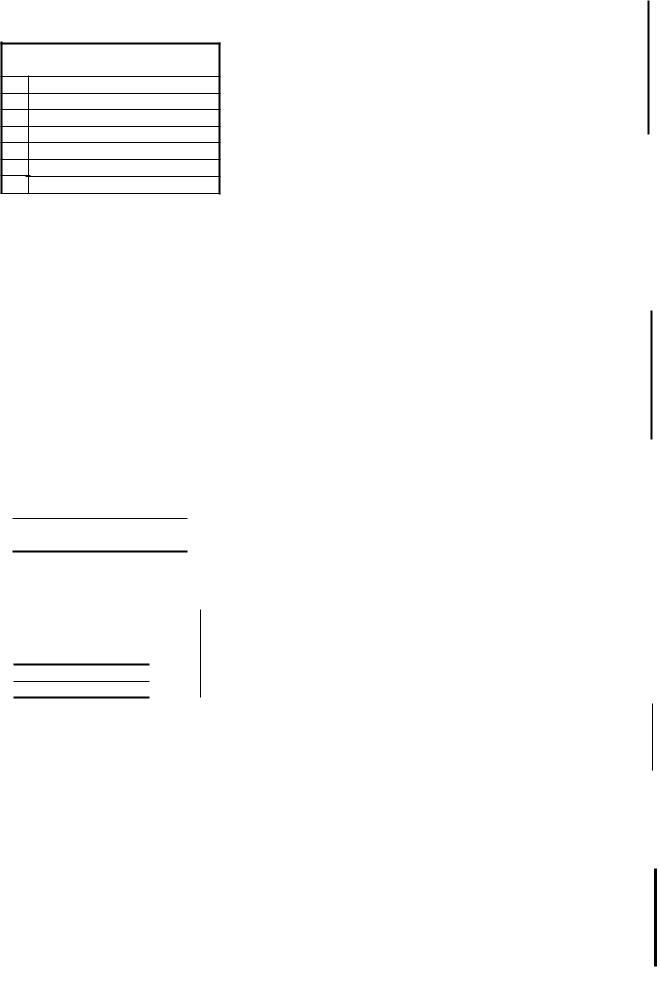

MO·6900S |

MO-6700S |

MO·6900G |

MO·6900R |

MO·6900J |

|

N |

|||||

|

Part No. |

Part No. |

Part No. |

Part No. |

Part No. |

|

|

Instruction Manual |

29351707 |

29351707 |

29351707 |

29356409 |

29363009 |

|

Parts List |

29351806 |

29352408 |

29352309 |

29356201 |

29362803 |

ii

ll

11

!

From the Library of Superior Sewing Machine & Supply LLC

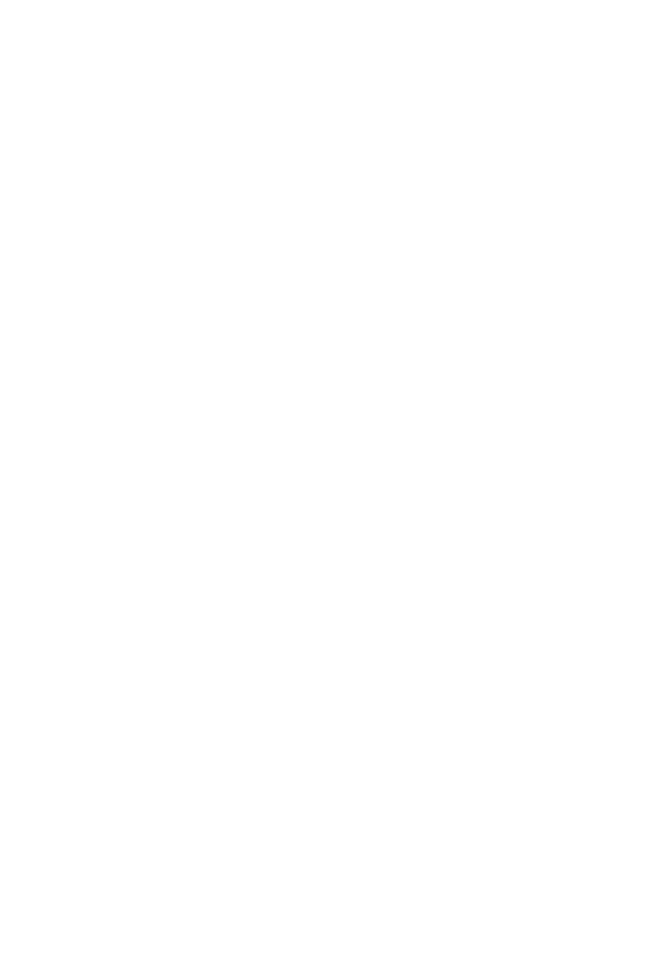

CONTENTS

|

1. SPECIFICATIONS ………. |

•….•..•••.•.••••…•••..••••.••.••••••..•.••… |

••..•…….. |

•..•••.•..•••.••.•… |

1 |

||||||

|

(1) MO-6700S SERIES …………………………………………………………………………………………….. |

1 |

|||||||||

|

(2) MO-6900S SERIES …………………………………………………………………………………………….. |

2 |

|||||||||

|

(3) MO-6900G SERIES •••••••..•••••••..•••••••… |

••••••..••••..••••.•••••.•.•••.•…. |

•.••… |

•••••… |

•.•••••.•.•.•.•••.•.•.•••.•. |

3 |

|||||

|

(4) MO-6900R SERIES •.••.•••••••••••.••••.•••.••••••••.•••••…….•.•..••..•••… |

•……. |

•.•.•••.•.••..•… |

•..••….. |

•.•.•… |

• |

4 |

||||

|

(5) MO-6900J SERIES………………………………………………………………………………………………. |

5 |

|||||||||

|

2. MODEL NUMBERING SYSTEM |

..••.••.•••..••••…••… |

•.•••••••.•••.•..•.••.•… |

•..•… |

••.•… |

•….. |

6 |

||||

|

3. STANDARD ADJUSTMENT ….••.•.•.•..•••..•.••••.••••••…. |

•…… |

•..•.•••.••…… |

•.•.••.••….. |

•.. |

8 |

|||||

|

(1) Adjusting the needle height……………………………………………………………………………….. |

8 |

|||||||||

|

(2) Positioning the throat plate ……………………………………………………………………………….. |

8 |

|||||||||

|

(3) Installing position of the needle Clamp …………………………………………………………….. |

10 |

|||||||||

|

(4) Adjusting the length of the lower looper holder |

||||||||||

|

(Applicable only to MO-6.616S / MO-6916R, G, J series) ……………………………………. |

10 |

|||||||||

|

(5) Adjusting the lower looper ._……………………………………………………………………………… |

12 |

|||||||||

|

1) Returning amount of the lower looper ………………………………………………………………………………………. |

12 |

|||||||||

|

2) Clearance between the lower looper and the needle ………………………………………………………………….. |

12 |

|||||||||

|

(6) Position of the upper looper guide ……………………………………………………………………. |

14 |

|||||||||

|

(7) Positioning the upper looper holder …………………………………………………………………. |

16 |

|||||||||

|

(8) Positioning the upper looper ……………………………………………………………………………. |

18 |

|||||||||

|

1) Height of the upper looper ……………………………………………………………………………………. |

~……………….. |

18 |

||||||||

|

2) Longitudinal position of the upper looper …………………………………………………………………………………… |

18 |

|||||||||

|

(9) Adjusting the double chain looper |

||||||||||

|

· (Applicable only to M0-6~16S/MO-6916R, G, J |

series) |

……………………………………….. |

20 |

|||||||

|

1) Returning amount of the double chain looper…………………………………………………………………………….. |

20 |

|||||||||

|

2) Longitudinal motion {Avoid motion) ………………………………………………………………………………………….. |

20 |

|||||||||

|

3) Clearance between the double chain looper and the needle ……………………………………………………….. |

20 |

|||||||||

|

(10) Adjusting the height and clearance of the needle guard ………….. |

~…………………….. |

22 |

||||||||

|

1) For 1-needle or 2-needle overlock machine ………………………………………………………………………………. |

22 |

|||||||||

|

2) For safely stitch machine ………………………………………………………………………………………………………… |

22 |

|||||||||

|

(11) Adjusting the height of the feed dog ………………………………………………………………. |

24 |

|||||||||

|

(12) Adjusting the tillt of the feed dog …………………………………………………………………….. |

24 |

|||||||||

|

(13) Adjusting the differential feed ratio ………………………………………………………………… |

26 |

|||||||||

|

(14) Longitudinal position of the feed dog …………………………………………………………….. |

26 |

|||||||||

|

(15) Adjusting the presser foot ……………………………………………………………………………… |

28 |

|||||||||

|

1) Adjusting the tilt of the presser foot ………………………………………………………………………………………….. |

28 |

|||||||||

|

2) Adjusting the micro-lifting mechanism of the presser foot |

……………………………………………………………. |

28 |

||||||||

|

(16) Positioning the upper knife arm shaft …………………………………………………………….. |

30 |

|||||||||

|

(17) Positioning the upper and lower knives, and available overedge widths ………….. |

30 |

|||||||||

|

1) lower knife …………………………………………………………………………………………………………………………… |

30 |

|||||||||

|

2) Upper knife …………………………………………………………………………………………………………………………… |

30 |

|||||||||

|

3) Overdging width …………………………………………………………………………………………………………………….. |

30 |

|||||||||

|

(18) Resharpening of the knife ……………………………………………………………………………… |

32 |

|||||||||

|

(19) Position of the thread cam (Applicable only to MO-6~16~ series) …………………… |

32 |

|||||||||

|

1) Adjustment of the thread cam ……………………………………… |

:…………………………………………………………. |

32 |

||||||||

|

2) Adjusting looper thread cam thread guides A and B and the looper thread cam nail ……………………….. |

32 |

From the Library of Superior Sewing Machine & Supply LLC

rl!~

11

1·

I

I

l~i11

I

,,11

1~

I

I

!I

•l

!I~

I

|

(20) Adjusting the throat plate support ………………………………………………………………….. |

34 |

|

(21) Adjusting the feed mechanism cover presser …………………………………………………. |

34 |

|

(22) Adjusting the looper cover …………………………………………………………………………….. |

36 |

|

(23) Adjusting the cloth chip cover ……………………………………………………………………….. |

36 |

|

(24) Adjusting the needle mechanism ……………………………………………………………………. |

38 |

|

(25} Position of the upper looper lubrication pin ……………………………………………………. |

40 |

|

1) Orientation of the lubricating pin ………………………………………………………………………………………………. |

40 |

|

2) Setting the lubricating pin ……………………………………………………………………………………………………….. |

40 |

|

(26) Longitudinal momentum of the top feed dog (Top feed amount) ……………………… |

42 |

|

(27) Vertical momentum of the top feed dog ………………………………………………………….. |

44 |

|

(28) Adjusting the height of the top feed dog …………………………………………………………. |

46 |

|

(29) Locus cut of the top feed dog ………………………………………………………………………… |

48 |

|

(30) Adjusting the longitudinal position of the top feed dog …………………………………… |

48 |

|

(31) Adjusting the lateral position of the top feed dog ……………………………………………. |

50 |

|

(32) Position of the motion of the top feed dog ……………………………………………………… |

52 |

|

(33) Adjusting the feed bar guides A and B ……………………………………………………….. |

~.•.. 54 |

|

(34) Adjusting the top feed dog pressure ………………………………………………………………. |

56 |

|

(35) Lifting amount of the top feed dog (when operating the pedal)••….••..••..••……. |

•..••.• 56 |

|

(36) Height of the presser (pedal operation) …………………………………………………………… |

58 |

(37} Lifting amount of the top feed dog (when the presser lifting lever is operated) .•• 60

|

(38) Position of the thread guides and the looper thread take-ups ………………………….. |

62 |

|

|

(39) Adjusting soft chain making mechanism ………………………………………………………… |

64 |

|

|

1) Replacing·the parts with those exclusively designed for making soft chains ………………………………….. |

64 |

|

|

2) Adjustment value …………………………………………………………………………………………………………………… |

64 |

— |

|

3} Important points in adjustment ………………………………………………………………………………………………… |

65 |

|

|

(40) Position of the thread guides and the looper thread take-ups of MO-6900G (J) … |

66 |

|

4. ADDITIONAL INFORMATION AND PRECAUTIONS ………………………………. |

68 |

|

|

(1) Thread tension ………………………………………………………………………………………………… |

68 |

|

|

1) Strength of tension spring ……………………………………………………………………………………………………….. |

68 |

|

|

2) Springs used for each model. ………………………………………………………………………………………………….. |

68 |

|

|

(2) Upper looper·…………………………………………………………………………………………………… |

69 |

|

|

(3) Center-to-center distance of the upper looper holder ……………………………………….. |

69 |

|

|

(4) Caution in assembly ………………………………………………………………………………………… |

69 |

|

|

1) Application of sealant …………………………………………………………………………………………………………….. |

69 |

|

|

2) Precautions to be taken with respect to the lubricating components ……………………………………….. |

~…… 71 |

|

|

(5) Kinds of motor pulleys, belts and frame support plate bolts ……………………………… |

72 |

|

|

1) Motor pulleys and belts …………………………………………………………………………………………………………… |

72 |

|

|

2) Pat No. of frame support plate bolt …………………………………………………………………………………………… |

73 |

|

|

(6) Inspection and replacement of the cartridge filter …………………………………………….. |

73 |

|

|

5. ADJUSTMENT OF THE NEEDLE HEIGHT AND LOOPER TIMMING ……….. |

74 |

|

|

(1) MO-60006. SERIES ………………………………………………………………………………………….. |

74 |

|

|

6. TROUBLES AND CORRECTIVE MEASURES ……………………………………….. |

75 |

|

|

7. DIMENSIONS OF TABLE ••… |

••.••..••••….•.•..•.•.••••.•..•••.•..••••..••.••••••..•••.•••.••..••.•.. |

87 |

|

(1) Semi-sunken type ……………………………………………………………………………………………. |

87 |

|

|

(2) Fully-suken type ……………… |

u ……………………………………………………………………………. |

88 |

From the Library of Superior Sewing Machine & Supply LLC

1.. SPECIFICATIONS

(1) MO-6700S SERIES

|

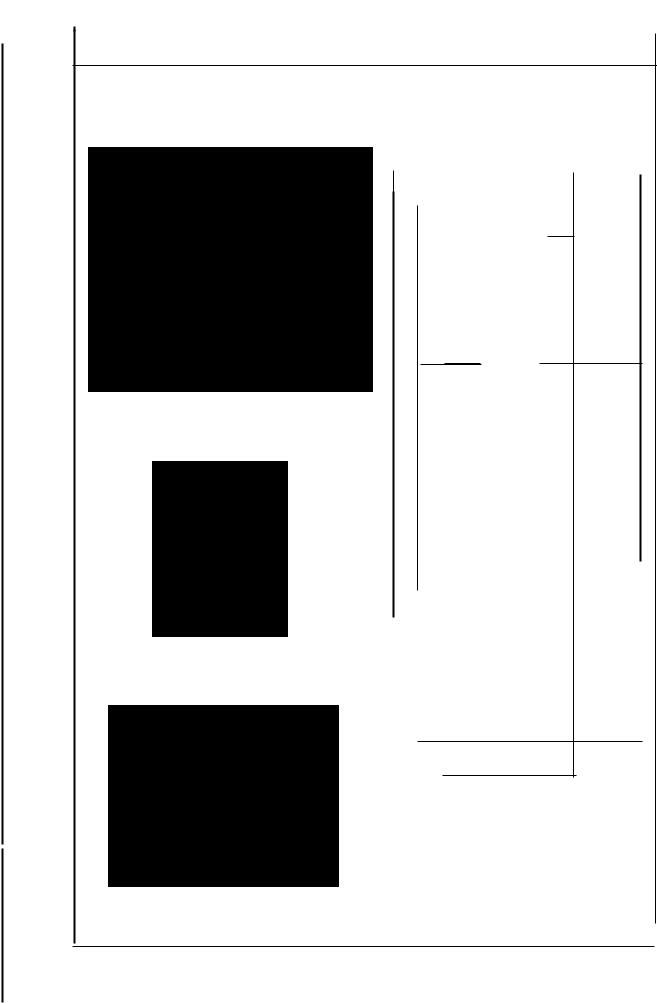

No. |

Item |

Specifications |

||||||||||||||||||||

|

1 |

Model |

M0-67048 |

M0-67148 |

. M0-6716$ |

||||||||||||||||||

|

2 |

Description |

1-neecile Overlock |

2-needle Overlock |

2-needle Safety stitch |

||||||||||||||||||

|

machine |

machine |

machine |

||||||||||||||||||||

|

3 |

Stitch type F. S. T. |

JISE13 |

JISE24 |

JISE13+D12 |

||||||||||||||||||

|

(USA standard : 504) |

(USA standard: 514) |

(USA standard =516) |

||||||||||||||||||||

|

4 |

Sewing speed |

7,000,pm |

||||||||||||||||||||

|

5 |

Stitch length |

. 0.8to4mm |

1.5to4mm |

|||||||||||||||||||

|

6 |

Needle gauge |

— |

2, 2.4, 3.2 mm |

2. 3.2, 4, 4.8 mm |

||||||||||||||||||

|

7 |

Overedging width |

1.6, 3.2, 4, 4.8 mm |

32,4,4.Bmm |

3.2, 4, 4.8, 6.4 mm |

||||||||||||||||||

|

8 |

Differential feed ratio |

Gathering 1 =2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6) |

||||||||||||||||||||

|

9 |

Needle bar stroke |

24.5mm |

||||||||||||||||||||

|

10 |

Needle tilt angfe |

20· |

||||||||||||||||||||

|

11 |

Needle |

ORGAN DC X 27 (Standard) (DC X 1can be used as well.) |

||||||||||||||||||||

|

12 |

Presser lifting amount |

7.0mm |

6.5nm |

7.0mm |

||||||||||||||||||

|

13 |

Presser foot pressure |

49N (5Kg) |

||||||||||||||||||||

|

14 |

Stitch acfJUstlng method |

By pushbutton |

||||||||||||||||||||

|

15 |

Upper knife |

FlatknHe |

||||||||||||||||||||

|

16 |

Differential feed adjustment |

By lever with micro adjustment medlanism |

||||||||||||||||||||

|

17 |

Weight |

28kg |

||||||||||||||||||||

|

18 |

Lubrication |

Gear-type automatic lubrication |

||||||||||||||||||||

|

19 |

Lubricating oil |

• JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

||||||||||||||||||||

|

20 |

Needle cooler |

Optional |

||||||||||||||||||||

|

21 |

Needle thread heat remover |

Optional |

||||||||||||||||||||

|

22 |

Micro presser lifting device |

Provided as standard |

||||||||||||||||||||

|

23 |

Motor |

2P 550W (In case of 7,000 rpm) |

||||||||||||||||||||

|

2P 400W (in case of less than 7,000 rpm) |

||||||||||||||||||||||

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m g )

-1 —

111

11

11

I’

·I

11

II

11

ij

L‘I’

I

r·!I

·1

j

~i

I:

11i.

li

111

Ii

1′

Ii~

i

ii

‘I

I i

I

l

.I

I

I

From the Library of Superior Sewing Machine & Supply LLC

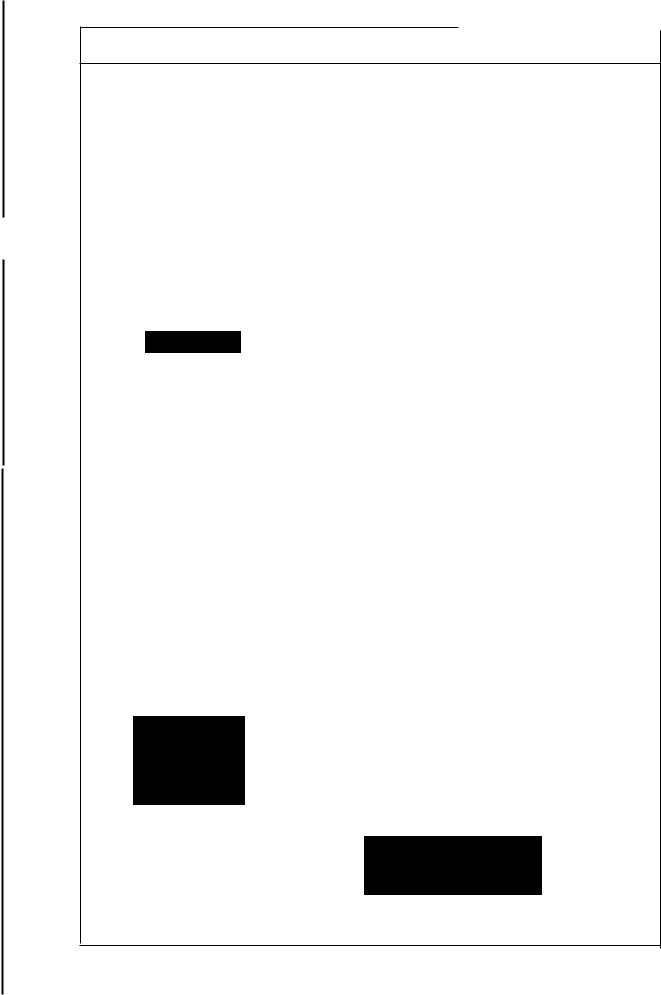

(2) MO-6900S SERIES

|

No. |

Item |

Specifications |

|||||||||||||||||||

|

1 |

Model |

MD-69045 |

M0-6914$ |

MQ-69168 |

|||||||||||||||||

|

2 |

Description |

1-needle Over1ock |

2-neeclle Over1ock |

2-needfe Safety stitch |

|||||||||||||||||

|

machine |

machine |

machine |

|||||||||||||||||||

|

3 |

Stitch type F. S. T. |

JIS E13 |

JIS E24 |

JISE13+ D12 |

|||||||||||||||||

|

(USA standard : 504) |

(USA standard: 514) |

(USA standard : 516) |

|||||||||||||||||||

|

4 |

Sewing speed |

8,500rpm |

8,000rpm |

||||||||||||||||||

|

5 |

Stitch length |

0.8to4mm |

1.5to4mm |

||||||||||||||||||

|

6 |

Needle gauge |

— |

2, 2.4, 3.2 mm |

2, 3.2. 4, 4.8 mm |

|||||||||||||||||

|

7 |

Overedging width |

1.6, 3.2, 4, 4.8 mm |

3.2, 4, 4.8 mm |

3.2, 4, 4.8, 6.4 mm |

|||||||||||||||||

|

8 |

Differential feed ratio |

Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 {Max.1 : 0.6) |

|||||||||||||||||||

|

9 |

Needle bar stroke |

24.5mm |

|||||||||||||||||||

|

10 |

Needle tilt angle |

20· |

|||||||||||||||||||

|

.. 11 |

Needle |

ORGAN DC X 27 (Standard) (DC X 1 |

can be used as |

weil.) |

|||||||||||||||||

|

Presser lifting amount |

7.0mm |

6.5mm |

7.0mm |

||||||||||||||||||

|

12 |

|||||||||||||||||||||

|

13 |

Presser foot pressure |

49N (5Kg) |

|||||||||||||||||||

|

14 |

Stitch adjusting method |

By pushbutton |

|||||||||||||||||||

|

15 |

Upper knife |

Flat knife |

|||||||||||||||||||

|

16 |

Differential feed adjustment |

By lever with micro adjustment mechanism |

|||||||||||||||||||

|

17 |

Weight |

28kg |

|||||||||||||||||||

|

18 |

Lubrication |

Gear-type automatic lubrication |

|||||||||||||||||||

|

19 |

Lubricatina oil |

» JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

|||||||||||||||||||

|

20 |

Needle cooler |

Provided as standard (Exduding some of subclass machines) |

|||||||||||||||||||

|

21 |

Needle thread heat remover |

Provided as standard {Excluding some of subdass machines) |

|||||||||||||||||||

|

22 |

Micro presser lifting device |

Provided as standard |

|||||||||||||||||||

|

23 |

Motor |

2P 550W (In case of not less than 7,000 rpm) |

|||||||||||||||||||

|

2P 400W (In case of less than 7,000 rpm) |

|||||||||||||||||||||

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m ! )

-2-

From the Library of Superior Sewing Machine & Supply LLC

(3) MO-6900G SERIES

|

No. |

· Item |

Specifcations |

|||||||||||||||||||

|

1 |

Model |

M0-6904G |

M0-6914G |

M0-6916G |

|||||||||||||||||

|

2 |

Description |

1-needle Overlock |

2-needle Overlock |

2-needle Safety stitch |

|||||||||||||||||

|

machine |

machine |

machine |

|||||||||||||||||||

|

3 |

Stitch type F. S. T. |

JIS E13 |

JISE24 |

JIS E13+ 012 |

|||||||||||||||||

|

(USA standard : 504) |

(USA standard : 514) |

(USA standard: 516) |

|||||||||||||||||||

|

4 |

Sewing speed |

6,000rpm |

|||||||||||||||||||

|

5 |

Stitch length |

2.5to5mm |

2.5to4mm |

2.5to5mm |

|||||||||||||||||

|

6 |

Needle gauge |

— |

2.6mm |

4.8mm |

|||||||||||||||||

|

7 |

Overeclging width |

4.8, 10mm |

6.4mm |

4.8,6.4mm |

|||||||||||||||||

|

8 |

Differential feed ratio |

Gathering 1: 1.75 (Max.1 : 3.8) |

Gathering 1:2(Max.1 : 3.8) |

Gathering 1:1.75{Max.1 :3.8) |

|||||||||||||||||

|

Stretchirg 1:0.6 |

Stretching 1 :0.7 (Max.1 : 0.6) |

Stretching 1:0.6 |

|||||||||||||||||||

|

9 |

Needle bar stroke |

28.8mm |

|||||||||||||||||||

|

10 |

Needle tilt angle |

20· |

|||||||||||||||||||

|

11 |

Needle |

ORGAN DO XS |

|||||||||||||||||||

|

12 |

Presser frfting amount |

Max.Bmm |

|||||||||||||||||||

|

13 |

Presser foot pressure |

49N(5Kg) |

|||||||||||||||||||

|

14 |

Stitch acfjUSting methcxJ |

By pushbutton |

|||||||||||||||||||

|

15 |

Upperknife |

Flat knife |

|||||||||||||||||||

|

16 |

Differential feed adjustment |

By lever with micro adjustment mechanism |

|||||||||||||||||||

|

17 |

Weight |

28kg |

|||||||||||||||||||

|

18 |

Lubrication |

Gear-type automatic lubrication |

· |

— |

|||||||||||||||||

|

19 |

Llbricating oil |

* JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

|||||||||||||||||||

|

·- |

|||||||||||||||||||||

|

20 |

Needle cooler |

Provided as standard (Excluding some of subclass machines) |

|||||||||||||||||||

|

21 |

Needle thread heal remover |

Provided as standard (Excluding some of subclass machines} |

|||||||||||||||||||

|

22 |

Micro presser lifting device |

Provided as standard |

|||||||||||||||||||

|

23 |

Motor |

2P400W |

•JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m 2 )

-3-

From the Library of Superior Sewing Machine & Supply LLC

t

I

l1

I~

~l

11

II

-!

II

I

I

11

I,!11\·

‘I

l

fi

11

11

II

·I

i

11

!i

(4) MO-6900R SERIES

|

No. |

Item |

Specifications |

|||||||||||||||||||||

|

1 |

Model |

M0-6904R |

M0-6914R |

M0-6916R |

|||||||||||||||||||

|

2 |

Feed type |

Vertical amount of top feed dog |

|||||||||||||||||||||

|

3 |

Description |

1-needle Overlock |

2-needle Over1ock |

2-needle Safety stitch |

|||||||||||||||||||

|

r:nachine |

machine |

machine |

|||||||||||||||||||||

|

4 |

Stitch type F. S. T. |

JIS E13 |

JIS E24 |

JISE13+D12 |

|||||||||||||||||||

|

(USA standard : 504) |

(USA standard : 514) |

{USA standard : 516) |

|||||||||||||||||||||

|

5 |

Sewing speed |

7,000 rpm (longitudinal amount of top feed less than 6 rrm) |

|||||||||||||||||||||

|

6,000 rpm (longitudinal amount of top feed 6 to 8.5 mm) |

|||||||||||||||||||||||

|

6 |

Stitch length |

0.8to4mm |

1.5to4mm |

||||||||||||||||||||

|

7 |

Needle gauge |

— |

2mm |

32,4.Bmm |

|||||||||||||||||||

|

8 |

Overedaina width |

3.21 4, 4.8, 5.6 mm |

3.2.4nm |

3.2, 4, 4.8, 6.4 mm |

|||||||||||||||||||

|

9 |

Differential feed ratio |

Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6) |

|||||||||||||||||||||

|

10 |

Needle bar stroke |

24.5mm |

|||||||||||||||||||||

|

11 |

Needle tilt angle |

20· |

|||||||||||||||||||||

|

12 |

Needle |

ORGAN DC X 27 (Standard) (DC X 1 can be used as well.) |

|||||||||||||||||||||

|

13 |

Presser lifting amount |

7.0mm |

6.5mm |

5.5mm |

|||||||||||||||||||

|

14 |

Presser foot pressure |

49N (5Kg) |

|||||||||||||||||||||

|

15 |

Stitch adjusting method |

By pushbutton |

|||||||||||||||||||||

|

16 |

Upper knife |

Rat knife |

|||||||||||||||||||||

|

17 |

Vertica! amount of top feed dog |

3.5to8.5mm |

|||||||||||||||||||||

|

18 |

Lonaitudnal amountof top feed dog |

1 to 7.5 mm (deoending on the ~ifications of the respective machines) |

|||||||||||||||||||||

|

19 |

Top feed adjusting type |

By lever |

|||||||||||||||||||||

|

20 |

Differential feed adjustment |

By lever with micro adjustment mechanism |

|||||||||||||||||||||

|

21 |

Weight |

29kg |

|||||||||||||||||||||

|

22 |

Lubrication |

Gear-~,pe automatic lubrication |

|||||||||||||||||||||

|

23 |

Lubricating oil |

* JUKJ MACHINE OIL 18 (Equivalent to ISO VG 18) |

|||||||||||||||||||||

|

24 |

Needle cooler |

Provided as standard (Exduding some of subclass machines) |

|||||||||||||||||||||

|

25 |

Needle thread heat remover |

Provided as standard (Excluding some of subclass machines) |

|||||||||||||||||||||

|

26 |

Micro presser lifting device |

Provided as standard |

|||||||||||||||||||||

|

27 |

Motor |

2P 55DW (In case of not less than 7,0CYJ rpm) |

|||||||||||||||||||||

|

2P 400W (In case of less than 7,000 rpm) |

|||||||||||||||||||||||

•JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m f )

-4-

From the Library of Superior Sewing Machine & Supply LLC

(5) MO-6900J SERIES

|

No. |

Item |

. Specifications |

||||||||||||||||||

|

1 |

Model |

M0-6904J |

M0-6914J |

M0-6916J |

||||||||||||||||

|

2 |

Feed type |

Vertical amount of top feed dog |

||||||||||||||||||

|

3 |

Description |

1-needle Orerlock |

2-needle Overlock |

2-needle Safety stitch |

||||||||||||||||

|

machine |

machine |

machine |

||||||||||||||||||

|

4 |

Stitch type F. S. T. |

JIS E13 |

JISE24 |

JIS E13+ 012 |

||||||||||||||||

|

(USA standard: 504) |

(USA standard: 514) |

(USA standard : 516} |

||||||||||||||||||

|

5 |

Sewing speed |

6,000rpm |

||||||||||||||||||

|

6 |

Stitch length |

2.5to5mm |

2.5to4mm |

2.5to5mm |

||||||||||||||||

|

7 |

Needle gauge |

— |

2.6mm |

4.8mm |

||||||||||||||||

|

8 |

Overedging width |

4.8mm |

6.4mm |

4.8,6.4mm |

||||||||||||||||

|

9 |

Differential feed ratio |

Gathering 1: 1.75 (Max.1 : 3.8) |

Gathering 1 : 2 (Max.1 : 3.8) |

Gathering 1: 1.75 (Max.1: 3.8) |

||||||||||||||||

|

Stretching 1 : 0.6 |

Stretching 1: 0.7 (Max.1 : 0.6) |

Stretching 1 : 0.6 |

||||||||||||||||||

|

10 |

Needle bar stroke |

28.8mm |

||||||||||||||||||

|

11 |

Needle tilt angle |

20· |

||||||||||||||||||

|

12 |

Needle |

ORGAN DOX5 |

||||||||||||||||||

|

13 |

Presser lifting amount |

Max.8mm |

||||||||||||||||||

|

14 |

Presser foot pressure |

49N (5Kg) |

||||||||||||||||||

|

15 |

Stitch acfJUsting method |

By pushbutton |

||||||||||||||||||

|

16 |

Upper knife |

Square knife |

||||||||||||||||||

|

17 |

Vertical amount of top feed doa |

3.5to8.5mm |

||||||||||||||||||

|

18 |

Longitudinal amount of top feed dog |

2.7 to 7.0 mm (depending on the specifications of the respective machines) |

||||||||||||||||||

|

19 |

Top feed adjusting type |

By lever |

||||||||||||||||||

|

20 |

Differential feed adjustment |

By lever with micro adjustment mechanism |

||||||||||||||||||

|

21 |

Weight |

29kg |

||||||||||||||||||

|

22 |

Lubrication |

Gear-type automatic lubrication |

||||||||||||||||||

|

23 |

Lubricating oil |

*JUKI MACHINE OIL 18 (Equivalent to |

ISO VG |

18} |

||||||||||||||||

|

24 |

Needle cooler |

Provided as standard (Exduding some of subclass machines) |

||||||||||||||||||

|

25 |

Needle thread heat remover |

Provided as standard (Excluding some of subclass machines) |

||||||||||||||||||

|

26 |

Micro presser lifting device |

Provided as standard |

||||||||||||||||||

|

27 |

Motor |

2P400W |

||||||||||||||||||

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m £ )

From the Library of Superior Sewing Machine & Supply LLC

!j~’.

i

I

I

I

~I

1

11

II

I

ll

I

~

I

11

·I

11

ri! i

I

11:

11

I

2. MODEL NUMBERING SYSTEM

MO-6000 SERIES MODEL NUMBERING SYSTEM

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 14 15 |

16 |

17 |

18 |

19 20 |

21 |

22 |

M06666DDD6666/D666-DO6

4 Machine code

7 ·6700 series

9 6900 series

7 Basic specification code

|

s |

Standard |

|||

|

* |

G |

Extra heavy-weight materials |

||

|

* |

A |

Variable top feed type |

||

|

,I |

J |

Variable top feed type for |

||

|

extra heavy-weight materials |

||||

|

* 6900only |

5. 6 Seam code

|

03 |

Splicing |

|

|

04 |

1-needle 3-threa~ overtock (504) |

|

|

05 |

For blind hemmong (505) |

|

|

12 |

2-neeclle 4-thread mock safety stitch (512) |

|

|

14 |

2-needle 4-thread overtock (514) |

|

|

16 |

2-needle S.thread safety stitch (516) |

|

|

43 |

3-needle 6-thread safety stitch |

|

|

45 |

2-needle double chainstitch |

|

8 Needle gauge code

0 1-needle

B2.0mm

C2.4mm,

26 mm (for extra- heavy-weight materials)

|

D |

32mm |

|

|

E |

4.0mm |

|

|

F |

4.8mm |

|

|

1 |

4.8 mm+ 2.0 mm |

|

9 Overedging width code |

1O Feed dog code |

11 Material code |

||||||||||||||

|

A |

1.6mm |

4 |

2-row |

Classification based on materials to be used |

||||||||||||

|

D |

3.2mm |

5 |

1-row |

1 |

Extra light-weight to light- |

For light-weight materials such as |

||||||||||

|

E |

4.0mm |

6 |

3-row |

weight materials |

shirts or the Uke |

|||||||||||

|

F |

4.8mm |

7 |

4-row |

2 |

Light-weight to medium- |

Knit wear only |

||||||||||

|

——3 |

||||||||||||||||

|

H |

6.4mm |

weight materials |

General fabrics |

|||||||||||||

|

M |

10.0mm |

4 |

Medium-weight to heavy- |

Knit wear only such as sweater or |

||||||||||||

|

—5 |

weight materials |

the fike |

||||||||||||||

|

N |

18.0mm |

|||||||||||||||

|

Medium·weightto heavy-weight |

||||||||||||||||

|

—— |

materials such as denim or the like |

|||||||||||||||

|

For heavy-weight materials |

||||||||||||||||

|

6 |

||||||||||||||||

|

7 |

Heavy-weight to extra |

Heavy-weight materials for jeans, car |

||||||||||||||

|

heavy-weight materials |

mattress, etc. |

|||||||||||||||

12 Application code

Classification based on type of operation

and process

0 Standard

1For blind stitching

2Forgathering

4For attaching tape

5For binding

6For binding tape

DSplicing•

ECar mattress

FSoft chain

•In case of the splicing, 13th figure is (1).

— 6 —

From the Library of Superior Sewing Machine & Supply LLC

13 Special machine code

Special classification of machine, structure and specification other than gauge set

0 Standard

6Feed dog provided w~h a lip

7Upper looper high throw type

F For swim suits

H Upper looper extra high throw type

M For zipper

1 For splicing

15 to 18 Device and attachment code

|

G0’2/O141 |

Presser fo(?Vtape guide for attaching tape |

|

|

G39/Q141 |

Presser foot (for sharp curve)/tape guide for |

|

|

attaching tape |

||

|

L121 |

Blind hemming ruler |

|

|

S159 |

Swing type ruffler (pedal-intertocking type for safety |

|

|

stitch} |

||

|

S161 |

Swing type ruffler (Manual lever type for safety |

|

|

stitch) |

||

|

S162 |

Swing type ruffler (Manual lever type for over1ock) |

|

|

N077 |

Four-fold binder |

20 Machine head code

AStandard machine head (Common to all specifications)

21 Accessory code

|

A |

Fa general export * |

|

B |

ForJE |

|

G |

For China |

22 Machine head code

0Fully-sunken type

Semi-sunken type

The numberings after-..!'(hyphen) of 19th figure will be used on

and after Apnl 1, 2002. They are not described on the catalogue or the fike.

• The general export s~ification is for Hong Kong, U.SA, Japan and Singapore.

.. 7 —

I

J

l

j

I

I

11

lj

I,

\

I

i

I

II

·1

~

j:

11

I

11

11

I

,j

,,

ij!11

11

I

ll

I~

!

I

I

I

From the Library of Superior Sewing Machine & Supply LLC

i’

!

1·

I

I

j

I:

II’

I

I

I·

1;

ii

I

.I

I! i

I

I

I

I

3. STANDARD ADJUSTMENT

Standard Adjustment

(1) Adjusting the needle height

When the needle(s) is in the highest position,

the needle height from the throat plate surface should be as shown below.

|

(Unit: mm) |

||||||||||||||||||||||||||||

|

6~046 |

— |

Model |

1-needle/ |

2-needle : right |

||||||||||||||||||||||||

|

·· |

||||||||||||||||||||||||||||

|

2-needle : left |

||||||||||||||||||||||||||||

|

30 — |

MO6l!.04S(R) -l!.66 |

·l!..60 |

10.5 |

— |

||||||||||||||||||||||||

|

11 z,z 1 ,inJ,a |

-Lib.6 |

|||||||||||||||||||||||||||

|

SD |

~ |

:I |

MO6604S |

-D.D.D. |

·66H |

11.3 |

— |

|||||||||||||||||||||

|

Cl) |

:II,» |

Cl) |

||||||||||||||||||||||||||

|

~ |

n |

::i., |

CD |

SOM |

||||||||||||||||||||||||

|

g: R |

~ |

|||||||||||||||||||||||||||

|

66146 |

MO- 6/\05S |

-606 |

-66.H |

11.3 |

— |

|||||||||||||||||||||||

|

fl) |

507 |

11 :0 |

9.4 |

|||||||||||||||||||||||||

|

::, |

MO- 6.6.125 |

-D.D.D. |

SOF |

|||||||||||||||||||||||||

|

3 Cl) |

||||||||||||||||||||||||||||

|

Cl) |

||||||||||||||||||||||||||||

|

e: |

||||||||||||||||||||||||||||

|

.,[!~zzma |

I» |

MOSD.12S |

-CE4 |

-40H |

11.3 |

9.9 |

||||||||||||||||||||||

|

n |

a, |

|||||||||||||||||||||||||||

|

0 |

MO· 6614S (R) -B66 — |

0H |

||||||||||||||||||||||||||

|

2:o |

MOSb14S (R) -8~6 |

-3c7 |

10.5 |

9.1 |

||||||||||||||||||||||||

|

:, |

< |

|||||||||||||||||||||||||||

|

CD |

Cl> |

2 |

11.3 |

9.9 |

||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||

|

::i. |

40H |

|||||||||||||||||||||||||||

|

‘:,t: |

||||||||||||||||||||||||||||

|

66166 |

||||||||||||||||||||||||||||

|

MO- 6b16S(R)-D.D.b |

-.t.60 |

10.5 |

— |

|||||||||||||||||||||||||

|

n |

en |

MO- Sil16S(R)-b.66 |

-l!..6H |

11.3 |

— |

|||||||||||||||||||||||

|

3 e. |

||||||||||||||||||||||||||||

|

II> |

a, |

MO- 6Li16S(R)-A.6.L’l |

-60H |

13 |

— |

|||||||||||||||||||||||

|

g.~ |

||||||||||||||||||||||||||||

|

-· en |

MO6943R |

-6.D.6 |

-b.l::,7 |

10.5 |

9.9 |

|||||||||||||||||||||||

|

i~ |

||||||||||||||||||||||||||||

|

MO66.43S |

-61::J.{:j, |

·6.D.H |

11.3 |

9.9 . — |

||||||||||||||||||||||||

|

::r |

||||||||||||||||||||||||||||

|

C2’Z2222Z]n |

MO- 6/\45S |

-D.b.l:l |

-360 |

9.8 |

— |

|||||||||||||||||||||||

|

:i5: |

MO· 6903G |

-ON6 |

-3D1 |

15.4 |

— |

|||||||||||||||||||||||

|

0 |

MO· 6904GCJl-OF6 |

-700 |

14.4 |

— |

||||||||||||||||||||||||

|

0, |

||||||||||||||||||||||||||||

|

CD |

MO6905G |

·OM6 |

-760 |

15.4 |

— |

|||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||

|

p |

MO- 6914G(Jl-CH6 |

-700 |

14.1 |

12.6 |

||||||||||||||||||||||||

|

<- |

||||||||||||||||||||||||||||

|

MO- 6916G(J)-F.0.6 |

-700 |

14.1 |

— |

|||||||||||||||||||||||||

The adjustment of needle height for the 2-needle overlock machine should be made in reference to the left needle.

(2) Positioning the throat plate

The needle entry point should be such that the distances listed below are provided between the needle slot edge of the throat plate and the center of needle.

|

Over1ock side A |

1.3 |

|

|

(Unit: mm) |

||

|

Double·chainstitchside B |

1.0 |

|

|

Note that «A:=1.8» and «8=1.5″‘ |

A |

|

|

for M0-6~16S (R) -n6.6-60H, |

||

|

«A=1.6» and «8=1.3» for M0-69~6G, J |

-8-

From the Library of Superior Sewing Machine & Supply LLC

|

Adjustment Procedures |

Results of Improper Adiustment |

|

|

1) Take off the upper cover, loosen setscrew 8. of needle driving |

o Any other needle height than |

|

|

forked crank O and move needle driving forked crank O up or |

specified here will badly affect |

|

|

down to adjust the needle height. |

the action of the lower looper. |

|

|

the timing for.catching the upper |

||

|

looper thread, etc. |

|

(Caution) Do not fully loosen the setscrew 8 of the needle |

o |

Improper lateral position of the |

||

|

driving forked crank 0. |

needle driving forked crank will |

|||

|

If the needle driving forked crank has got out of position |

cause seizure, play, or other |

|||

|

laterally when its setscrew was loosened, fully loosen the |

troubles. |

|||

|

setscrew and turn pulley to allow the forked crank to tum |

||||

|

until it settles by itself. Then tighten the setscrew to fix the |

||||

|

forked crank at that position. |

||||

|

1} Loosen setscrews 8 of throat plate base O and move throat |

o |

Improperly positioned throat |

||

|

plate base 8 back and forth to adjust dimension A or B. |

plate will |

cause |

needle |

|

|

breakage, |

contact |

of the |

||

|

needles will the throat plate, or |

other troubles.

-9-

From the Library of Superior Sewing Machine & Supply LLC

,11

!I

:-1

;ii

II

I

1l

Ii

I

‘I

!1

‘I

11

‘!i~

I

Standard Adjustment

(3) Installing position of the needle clamp

Needle clamp connecting stud O should fit with the bottom end of needle bar 8 or spaced within oto

0.5mm.

Oto 0.5 mm

|

Butt the needle clamp with the |

0 |

|

bottom end of the needle bar. |

(4) Adjusting the length of the lower looper holder (Applicable only to M0-6~16S / M0-6916R, G, J series)

The center-to-center distance should be 26 mm.

At this time, the clearance between the end surface of the arm and the neck of the ball should be

3.5mm.

26mm

-10 —

From the Library of Superior Sewing Machine & Supply LLC

|

Adjustment Procedures |

Results of Improper Adjustment |

||

|

1) Loosen setscrew O and adjust, by slightly turning needle clamp |

o If the clearance provided |

||

|

8. the clearance provided between the right-hand side needle |

betw~en the needle and the |

||

|

and the lower looper (for 2-needle overlock machine) and the |

looper is excessive, the needle |

||

|

clearance provided between the needle hole in the throat plate |

thread will be likely to skip at the |

||

|

and the needle (for safety stitch machine). |

time of tucking. |

||

|

o If the clearance provided |

|||

|

between the needle and the |

|||

|

looper is insufficient, the needle |

|||

|

will break or the looper blade |

|||

|

point will be damaged causing |

|||

|

thread breakage. |

|||

1)Loosen setscrew O of the lower looper holder from the rear of the frame.

Since it is difficult to accurately measure the center-to-center distance. perform adjustment to provide a 3.5 mm distance between the end surface of the arm and the neck of the ball as illustrated.

oIncreasing the center-to-center distance will give a smaller stroke of the duble chain looper or lower looper, and decreasing the distance will give larger stroke.

II ll

·I’

I

I

I

I

·1

I

-11 —

From the Library of Superior Sewing Machine & Supply LLC

Standard Adjustment

(5) Adjusting the lower looper

1) Returning amount of the lower looper

The distance between the blade point of the lower looper and the center of the needle should be as follows when the lower looper is at the extreme left of its stroke.

|

(Unit: mm) |

||||||||||||||||||||||||||||||||||||||

|

Model |

Dimension8 |

|||||||||||||||||||||||||||||||||||||

|

6604S{R) |

OAS |

156 |

— |

|||||||||||||||||||||||||||||||||||

|

4.0 |

||||||||||||||||||||||||||||||||||||||

|

.:.:: |

MO- SD.OSS |

·OA4to OE4 |

·210 |

|||||||||||||||||||||||||||||||||||

|

8 |

006 |

3t).~ |

||||||||||||||||||||||||||||||||||||

|

~ (D |

OF4 |

3t).O |

||||||||||||||||||||||||||||||||||||

|

> |

C: |

MO· 6604S{R)- |

||||||||||||||||||||||||||||||||||||

|

o:c |

OF6 |

3.7 |

||||||||||||||||||||||||||||||||||||

|

Cl> |

u |

500 |

||||||||||||||||||||||||||||||||||||

|

— |

«‘ |

OH4 |

SOM |

|||||||||||||||||||||||||||||||||||

|

ie |

||||||||||||||||||||||||||||||||||||||

|

Cl> |

||||||||||||||||||||||||||||||||||||||

|

c;= |

0D4 toOE4 |

. |

46H |

|||||||||||||||||||||||||||||||||||

|

MO- 6604S • |

OF6 |

3.8 |

||||||||||||||||||||||||||||||||||||

|

50H |

||||||||||||||||||||||||||||||||||||||

|

8 |

B04 to BE4 |

-3lH |

3.8 |

|||||||||||||||||||||||||||||||||||

|

MO- 6‘°’14 S(R) • B06 to BES |

||||||||||||||||||||||||||||||||||||||

|

.:.:: |

||||||||||||||||||||||||||||||||||||||

|

ii |

||||||||||||||||||||||||||||||||||||||

|

(D |

||||||||||||||||||||||||||||||||||||||

|

> |

C |

MO- 6614S(R) — 806 to BFS |

20H |

|||||||||||||||||||||||||||||||||||

|

o·- |

||||||||||||||||||||||||||||||||||||||

|

..92 |

‘g |

BE7 |

4uH |

3.8 |

||||||||||||||||||||||||||||||||||

|

je |

MO66125 |

-CE4 |

·40H |

4.0 |

||||||||||||||||||||||||||||||||||

|

C |

||||||||||||||||||||||||||||||||||||||

|

(\I |

MO- 6612S |

·DF6 |

50F |

|||||||||||||||||||||||||||||||||||

|

507 |

2.2 |

|||||||||||||||||||||||||||||||||||||

|

MO· 6616S(A) -66.0. |

360 |

|||||||||||||||||||||||||||||||||||||

|

500 |

3.7 |

|||||||||||||||||||||||||||||||||||||

|

~ |

||||||||||||||||||||||||||||||||||||||

|

~ <D |

BE4 |

|||||||||||||||||||||||||||||||||||||

|

. : |

C |

. |

46.H |

|||||||||||||||||||||||||||||||||||

|

~~ |

MO- 6.t).16S(R) |

-00/.\ |

3.8 |

|||||||||||||||||||||||||||||||||||

|

-e |

F66 |

56H |

||||||||||||||||||||||||||||||||||||

|

QI |

«‘ |

|||||||||||||||||||||||||||||||||||||

|

t8 |

||||||||||||||||||||||||||||||||||||||

|

MO· |

6616S(R) |

·F66 |

-60H |

2.8 |

||||||||||||||||||||||||||||||||||

|

MO6943R |

-666 |

-6.67 |

3.8 |

|||||||||||||||||||||||||||||||||||

|

MO6643S |

-6.6.6 |

-.ti.6.H |

3.8 |

|||||||||||||||||||||||||||||||||||

|

,. |

MO6903G |

-ON6 |

-301 |

1.4 |

||||||||||||||||||||||||||||||||||

|

MO6904G(J) |

·OF6 |

-700 |

3.5 |

|||||||||||||||||||||||||||||||||||

|

• |

C, |

|||||||||||||||||||||||||||||||||||||

|

Og |

||||||||||||||||||||||||||||||||||||||

|

MO6905G |

-OM6 |

-760 |

1.3 |

|||||||||||||||||||||||||||||||||||

|

:E a, |

.. |

|||||||||||||||||||||||||||||||||||||

|

MO- 6914G(J) |

-CHS |

-700 |

3.3 |

|||||||||||||||||||||||||||||||||||

|

U) |

||||||||||||||||||||||||||||||||||||||

|

MO6916G(J) |

-F66 |

-700 |

3.5 |

|||||||||||||||||||||||||||||||||||

2) Clearance between the lower looper and the needle

The clearance should be Oto 0. 1 mm.

0to0.1 mm

J

— 12 —

From the Library of Superior Sewing Machine & Supply LLC

|

Adjustment Procedures |

Results of Improper Adjustment |

|

|

1) Returning amount of the lower looper |

o |

Excessive return of the lower |

|

CD Loosen setscrew • of lower looper support arm 8 and adjust |

looper tends to cause·stitch |

|

|

lower looper 8 to make adjustment of the returning amount. |

skipping when filament thread is |

|

|

(Referential information) |

used. |

|

|

1. Radius 8 of lower looper 8 will be 66.9 mm when the lower |

o |

Insufficient return of the lower |

|

looper is inserted into lower looper support arm O until it |

looper tends to cause needle |

|

|

contacts with stopper pin O and then is fixed. |

thread stitch skipping when |

|

|

2. The rocking angle of the lower looper will be 2s·. |

spun thread is used. |

(M0-66665, R)

The rocking angle of the lower looper will be 32·.

(M0-6966G, J)

|

2) Clearance between the lower looper and the needle |

o |

Excessive clearance will often |

|

MO-6700S Series |

cause needle thread stitch |

|

|

CD Loosen setscrew 8 of lower looper support arm O to the extent |

||

|

skipping. |

||

|

that it is temporarily tightened. Now, make the adjustment by |

o |

Insufficient clearance will cause |

|

moving lower looper support arm 8 back and forth. |

needle breakage due to the |

|

|

MO-6900S, R, G, J Series. |

contact of the looper with the |

|

|

CD Loosen setscrew 8 of lower looper support arm 8 to the extent |

needle, or produce scratches on |

|

|

that it is temporarily tightened. Then finely adjust the longitudinal |

the blade point of the looper. |

|

|

position of the looper using fine adjustment screw O. |

leading to needle thread |

|

|

® Turn fine adjustment screw 8 clockwise to move lower looper |

breakage or other troubles. |

|

|

G away from the needle. |

||

|

Tum the screw counterclockwise to move lower looper 8 closer |

||

|

to it. |

-13-

From the Library of Superior Sewing Machine & Supply LLC

Standard Adjustment

(6) Position of the upper looper g~ide

Vertical position :

To be in close contact with the frame guide surface. Laternal position :

To be pressed against the upper looper guide support gauge 8.

0

Frame guide surface

(Unit: mm)

|

(Unit: mm) |

||||||||||

|

&St |

5.8~7 |

|||||||||

|

Upper |

||||||||||

|

looper |

||||||||||

|

13131909 |

13132006 |

|||||||||

|

guide |

||||||||||

|

support |

11 |

|||||||||

|

gauge |

~ |

|||||||||

|

11545100 |

12375606 |

|||||||||

(Unit: mm)

|

Model |

Dimension Ci) |

Modef |

Dimension(B |

|||||||||||||||||||||||||||||||||||||||||||

|

Q) |

OAS |

15A |

a-i |

|||||||||||||||||||||||||||||||||||||||||||

|

c:: |

360 |

3 |

||||||||||||||||||||||||||||||||||||||||||||

|

£ |

MO·S.604S(R) -OA4 lo OE4 |

-210 |

MO- 6.6.16S{R) |

-6.Ab. |

||||||||||||||||||||||||||||||||||||||||||

|

500 |

E@ |

|||||||||||||||||||||||||||||||||||||||||||||

|

co |

6.605S |

|||||||||||||||||||||||||||||||||||||||||||||

|

E |

006 |

3.6A |

a, |

|||||||||||||||||||||||||||||||||||||||||||

|

~ |

C |

|||||||||||||||||||||||||||||||||||||||||||||

|

:E |

||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

OF4 |

360 |

0 |

BE4 |

46H |

~y |

||||||||||||||||||||||||||||||||||||||||

|

‘C |

MO- 66.04S(A)-OF6 |

-500 |

~-3 |

co |

MO· 6/\16S(R) |

-00.6. |

||||||||||||||||||||||||||||||||||||||||

|

~ |

E |

— |

||||||||||||||||||||||||||||||||||||||||||||

|

OH4 |

SOM |

..c:; |

F.6..6. |

SOH |

||||||||||||||||||||||||||||||||||||||||||

|

a, |

004 to0E4 |

4AH |

@~ |

g |

||||||||||||||||||||||||||||||||||||||||||

|

‘g |

~ |

MO· 6A16S{R) |

-F.6.6 |

-60H |

r,s.s |

|||||||||||||||||||||||||||||||||||||||||

|

M0-6.l!:.045 |

·OF6 |

|||||||||||||||||||||||||||||||||||||||||||||

|

a, |

?:- |

[iliJ |

||||||||||||||||||||||||||||||||||||||||||||

|

~ |

50H |

.S! |

||||||||||||||||||||||||||||||||||||||||||||

|

co |

||||||||||||||||||||||||||||||||||||||||||||||

|

BD4toBE4 |

[f] |

|||||||||||||||||||||||||||||||||||||||||||||

|

-3.6.7 |

Cl) |

MO. 6943R |

-61.).A |

-D.D.7 |

||||||||||||||||||||||||||||||||||||||||||

|

0 |

MO·6614S(R)·sosto BEG |

~ |

||||||||||||||||||||||||||||||||||||||||||||

|

a, |

||||||||||||||||||||||||||||||||||||||||||||||

|

C |

||||||||||||||||||||||||||||||||||||||||||||||

|

:c |

!…;6 |

|||||||||||||||||||||||||||||||||||||||||||||

|

t’G |

,~ |

|||||||||||||||||||||||||||||||||||||||||||||

|

MQ. |

S(R}-806 to BF6 |

0 |

MO· 6.6.43S |

.,6_1.),,6, |

-6D.H |

i |

||||||||||||||||||||||||||||||||||||||||

|

E |

||||||||||||||||||||||||||||||||||||||||||||||

|

6614 |

20H |

|||||||||||||||||||||||||||||||||||||||||||||

|

~ |

BE7 |

4.llH |

||||||||||||||||||||||||||||||||||||||||||||

|

‘C |

||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

||||||||||||||||||||||||||||||||||||||||||||||

|

a, |

||||||||||||||||||||||||||||||||||||||||||||||

|

MO- |

6612S |

-CE4 |

-40H |

|||||||||||||||||||||||||||||||||||||||||||

|

> |

~7 |

MO. 6903G |

-ON6 |

-301 |

[iJ |

|||||||||||||||||||||||||||||||||||||||||

|

=o |

||||||||||||||||||||||||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||||||||||||||||||||

|

Q) |

||||||||||||||||||||||||||||||||||||||||||||||

|

a, |

||||||||||||||||||||||||||||||||||||||||||||||

|

ffil |

||||||||||||||||||||||||||||||||||||||||||||||

|

Q) |

0 507 |

MO- 6904G(J) -OF6 |

-700 |

|||||||||||||||||||||||||||||||||||||||||||

|

C |

~~~ |

|||||||||||||||||||||||||||||||||||||||||||||

|

«‘ |

MO· 6.6.12S |

·DF6 |

SOF |

|||||||||||||||||||||||||||||||||||||||||||

|

«»‘) |

||||||||||||||||||||||||||||||||||||||||||||||

|

cj |

||||||||||||||||||||||||||||||||||||||||||||||

|

MO• 6905G |

-OM6 |

-1.6.0 |

ff: |

|||||||||||||||||||||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

||||||||||||||||||||||||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||||||||||||||||||||

|

CJ) |

||||||||||||||||||||||||||||||||||||||||||||||

|

CD |

||||||||||||||||||||||||||||||||||||||||||||||

|

::E |

||||||||||||||||||||||||||||||||||||||||||||||

|

MO· 6914G(J) |

-CHS |

-700 |

||||||||||||||||||||||||||||||||||||||||||||

|

u~ |

||||||||||||||||||||||||||||||||||||||||||||||

|

MO6916G(J) |

-f66 |

-700 |

||||||||||||||||||||||||||||||||||||||||||||

|

u~ |

||||||||||||||||||||||||||||||||||||||||||||||

-14-

From the Library of Superior Sewing Machine & Supply LLC

Adjustment Procedures

1)Fit upper looper guide support gauge 8 over gauge fixing pin

0 which has been driven in frame 8 and secure the gauge with an O ring.

Then position the gauge taking the marker dot engraved on it or the chamfering direction as reference.

2)When installin upper looper guide support 8 1 press it against the gauge while keeping the upper looper guide support into close contact with the frame guide surface, then tighten the screws.

(Caution) Refer to «4- (4) -1) — (J) Various sealants» for the

various sealants.

Results of Improper Adjustment

oIf the upper looper guide has improperly positioned vertically, it will cause oil leakage or disturbed path of the upper looper with resultant stitch skipping.

oIf the upper looper guide has been inaccurately positioned laterally. it will cause stitch skipping, or contact with the looper.

-15-

From the Library of Superior Sewing Machine & Supply LLC

Standard Adjustment

(7) Positioning the upper looper holder

The distance between the bottom surface of the frame and the upper end of the upper looper holder pin 8 should be as shown below when the upper looper holder O is at the highest point of its stroke.

53mm t

0

l llt(tllfl(llltltl((l/1

Bottom surface of frame

•

|

(Unit: mm) |

|||||||||||||||||||

|

Model |

|||||||||||||||||||

|

Dimension& |

|||||||||||||||||||

|

-~ |

OAS |

156 |

45.0 |

||||||||||||||||

|

MOSLl.04S(R) |

-OA4 to OE4 |

·210 |

|||||||||||||||||

|

6Ll.05S |

|||||||||||||||||||

|

006 |

3All. |

||||||||||||||||||

|

1 |

OF4 |

3ll.O |

— |

||||||||||||||||

|

8 |

462 |

||||||||||||||||||

|

‘C |

MO- M04S(A)· OF6 |

-500 |

|||||||||||||||||

|

CS) |

|||||||||||||||||||

|

{:; |

OH4 |

SOM |

|||||||||||||||||

|

~ |

|||||||||||||||||||

|

m |

004 toOE4 |

46H |

482 |

||||||||||||||||

|

J |

MO- 6.!i.04S • |

OF6 |

|||||||||||||||||

|

50H |

|||||||||||||||||||

|

CS) |

B04 loBE4 |

||||||||||||||||||

|

~ |

MO· 6614S(R)· |

·3ll.7 |

47.3 |

||||||||||||||||

|

u |

B06toBE6 |

~BO~ to BFLi. 20H

|

.g |

MO· 6614S(R)· BE7 |

• 4.ll.H |

48.4 |

|||||||||||||||||||||||||||

|

~ |

||||||||||||||||||||||||||||||

|

a, |

||||||||||||||||||||||||||||||

|

MO- |

6.ll.125 |

-CE4 |

·40H |

|||||||||||||||||||||||||||

|

> |

46.8 |

|||||||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||||

|

Cl> |

||||||||||||||||||||||||||||||

|

=a |

||||||||||||||||||||||||||||||

|

G) |

||||||||||||||||||||||||||||||

|

—507 |

||||||||||||||||||||||||||||||

|

Cl> |

MO- |

6ll.12S |

-DFG |

46.9 |

||||||||||||||||||||||||||

|

~ |

||||||||||||||||||||||||||||||

|

(\I |

SOF |

|||||||||||||||||||||||||||||

|

MO- |

66.16S(R)-6/\l\ |

3l:.O |

||||||||||||||||||||||||||||

|

46.2 |

||||||||||||||||||||||||||||||

|

500 |

||||||||||||||||||||||||||||||

|

GI |

BE4 |

|||||||||||||||||||||||||||||

|

C |

4.ll.H |

|||||||||||||||||||||||||||||

|

:c |

MO- |

6Ll.16S(R)- 006 |

48.2 |

|||||||||||||||||||||||||||

|

u |

5Ll.H |

|||||||||||||||||||||||||||||

|

as |

||||||||||||||||||||||||||||||

|

E |

Fll.D. |

|||||||||||||||||||||||||||||

|

.c |

6616S{R) ·FD.6 |

|||||||||||||||||||||||||||||

|

.B |

MO- |

-60H |

4B.4 |

|||||||||||||||||||||||||||

|

«,ID |

||||||||||||||||||||||||||||||

|

en |

||||||||||||||||||||||||||||||

|

2:- |

||||||||||||||||||||||||||||||

|

.S! |

MO- |

6943R |

-D.bD. |

·6.D.7 |

47.3 |

|||||||||||||||||||||||||

|

a, |

||||||||||||||||||||||||||||||

|

(/) |

. — |

|||||||||||||||||||||||||||||

|

MO- |

6643S |

-D.66 |

-6.ti.H |

48.4 |

||||||||||||||||||||||||||

|

— |

||||||||||||||||||||||||||||||

|

MO- |

-ON6 |

-301 |

||||||||||||||||||||||||||||

|

6903G |

512 |

|||||||||||||||||||||||||||||

|

Cl> |

||||||||||||||||||||||||||||||

|

-~ |

||||||||||||||||||||||||||||||

|

MO- |

6904G(J)-OF6 |

-700 |

50.7 |

|||||||||||||||||||||||||||

|

GI |

||||||||||||||||||||||||||||||

|

Ill |

||||||||||||||||||||||||||||||

|

-,_ |

||||||||||||||||||||||||||||||

|

(!J |

||||||||||||||||||||||||||||||

|

MO- |

6905G |

-OM6 |

·1/:J.O |

|||||||||||||||||||||||||||

|

0 |

51.7 |

|||||||||||||||||||||||||||||

|

0 |

||||||||||||||||||||||||||||||

|

en |

||||||||||||||||||||||||||||||

|

C0 |

||||||||||||||||||||||||||||||

|

6 |

MO- |

6914G(J)-CH6 |

-700 |

|||||||||||||||||||||||||||

|

:E |

49.3 |

|||||||||||||||||||||||||||||

|

,-. |

||||||||||||||||||||||||||||||

|

MO- |

6916G(J)·FD.6 |

-700 |

48.B |

|||||||||||||||||||||||||||

-16-

From the Library of Superior Sewing Machine & Supply LLC

|

Adjustment Procedures |

Results of Improper Adjustment |

||||

|

1) Loosen the setscrew of upper looper ball arm O and setscrew |

o Inaccurately positioned upper |

||||

|

0 of the upper looper holder. |

looper |

holder will cause |

|||

|

2) Adjust the clearances between upper looper bracket 8 and |

excessive projection of the |

||||

|

upper looper holder Oto approximately 0.2 mm respectively, |

upper looper, resulting in stitch |

||||

|

and tighten setscrew O of the upper looper holder. |

skipping, or other troubles. |

||||

|

(Make sure that the upper looper holder smoothly moves |

(Caution) To adiust the upper |

||||

|

together with upper looper shaft O.) |

|||||

|

looper |

ball arm, take |

||||

|

3) Then determine dimension O from the bottom surface of the |

|||||

|

dimension O as standard. |

|||||

|

frame to the top surface of upper looper holder pin 8 before |

|||||

|

Remember that the projecting |

|||||

|

tightening the setscrew of upper looper ball arm 8. |

|||||

|

amount and the height of the |

|||||

|

(Caution) Replace upper looper holder 8 according to the |

|||||

|

upper |

looper |

should |

|||

|

needle gauge size. |

eventually be |

properly |

|||

|

adjusted. So, confirm the |

|||||

|

dimensions related to the |

|||||

|

upper looper. |

|||||

-17-

From the Library of Superior Sewing Machine & Supply LLC

I

II;.

~‘

F

II

I

I

I

I!

ii

II

i

j

I

j

II

‘1·ii

!

t

l

Standard Adjustment

(8)Positioning the upper looper

1)Height of the upper looper

The distance between the throat plate surface and the blade point of the looper should be as follows when the upper looper is at the extreme left of its travel.

|

{Unit: mm) |

|||||||||||||||||||||||||||||||||||

|

Model |

Dimension |

Ci) |

|||||||||||||||||||||||||||||||||

|

«g |

MO- |

660 |

|||||||||||||||||||||||||||||||||

|

6804S(R)-L\L\L\ |

-6.66 |

||||||||||||||||||||||||||||||||||

|

«im |

11.0 |

||||||||||||||||||||||||||||||||||

|

is |

SOM |

||||||||||||||||||||||||||||||||||

|

a> |

ti |

||||||||||||||||||||||||||||||||||

|

MO- |

6604S |

-L\l::.l::. |

-l::.l::.H |

11.3 |

|||||||||||||||||||||||||||||||

|

‘g~ |

|||||||||||||||||||||||||||||||||||

|

Q) |

|||||||||||||||||||||||||||||||||||

|

:r |

|||||||||||||||||||||||||||||||||||

|

MO- |

6/\05S |

-!:l.66 |

-6illi |

11.3 |

|||||||||||||||||||||||||||||||

|

MO- |

B04 to8E4 |

10.3 |

|||||||||||||||||||||||||||||||||

|

~ |

Bli145lR)·sosto BES |

·307 |

|||||||||||||||||||||||||||||||||

|

u |

|||||||||||||||||||||||||||||||||||

|

0 |

|||||||||||||||||||||||||||||||||||

|

BO6 to BF.6. 20H |

|||||||||||||||||||||||||||||||||||

|

«C |

11.0 |

||||||||||||||||||||||||||||||||||

|

Q) |

11) |

MO6614S(R)- E |

|||||||||||||||||||||||||||||||||

|

l> ~ |

|||||||||||||||||||||||||||||||||||

|

8 7 |

4!::.H |

||||||||||||||||||||||||||||||||||

|

Q) |

u |

||||||||||||||||||||||||||||||||||

|

— |

co |

MO- |

6612S |

-CE4 |

-40H |

||||||||||||||||||||||||||||||

|

alE |

11.B |

||||||||||||||||||||||||||||||||||

|

Q) |

|||||||||||||||||||||||||||||||||||

|

C |

|||||||||||||||||||||||||||||||||||

|

«‘ |

MO- |

6L\12S |

-DF6 |

507 |

11.0 |

||||||||||||||||||||||||||||||

|

— |

50F |

||||||||||||||||||||||||||||||||||

|

Cl> |

MO- |

6616S(R) |

-666 |

-L\60 |

11.0 |

||||||||||||||||||||||||||||||

|

C |

|||||||||||||||||||||||||||||||||||

|

:E |

BE4 |

4/\H |

|||||||||||||||||||||||||||||||||

|

u |

MO- |

~16S(A) — D06 |

11.3 |

||||||||||||||||||||||||||||||||

|

t’O |

5~H |

||||||||||||||||||||||||||||||||||

|

E |

F6A |

||||||||||||||||||||||||||||||||||

|

.c |

|||||||||||||||||||||||||||||||||||

|

j:1 |

MO· |

6616S(R) -Fb.6 |

-60H |

12.8 |

|||||||||||||||||||||||||||||||

|

—C/l= |

|||||||||||||||||||||||||||||||||||

|

~~ |

MO- |

6943R |

-/\~6 |

·L\L\7 |

10.3 |

||||||||||||||||||||||||||||||

|

tU |

|||||||||||||||||||||||||||||||||||

|

Cl) |

MO- |

6643S |

·L\L\6 |

||||||||||||||||||||||||||||||||

|

·L\L\H |

11.0 |

||||||||||||||||||||||||||||||||||

|

0 |

MO- |

6903G |

-ON6 |

-3D1 |

13.6 |

||||||||||||||||||||||||||||||

|

c:J |

|||||||||||||||||||||||||||||||||||

|

·c: |

MO- |

||||||||||||||||||||||||||||||||||

|

CD |

6904G{J) |

-OF6 |