-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

OPTISWIRL 4200

OPTISWIRL 4200

OPTISWIRL 4200

OPTISWIRL 4200

Vortex flowmeter

© KROHNE 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en

Handbook

Handbook

Handbook

Handbook

Related Manuals for KROHNE OPTISWIRL 4200

Summary of Contents for KROHNE OPTISWIRL 4200

-

Page 1

OPTISWIRL 4200 OPTISWIRL 4200 OPTISWIRL 4200 OPTISWIRL 4200 Handbook Handbook Handbook Handbook Vortex flowmeter © KROHNE 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 2

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without the prior written authorisation of KROHNE Messtechnik GmbH. Subject to change without notice. Copyright 2015 by KROHNE Messtechnik GmbH — Ludwig-Krohne-Str. 5 — 47058 Duisburg (Germany) www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 3: Table Of Contents

3.8.3 Installing devices in flange design ………………31 3.8.4 Mounting the field housing, remote version ……………. 32 3.9 Heat insulation…………………… 33 3.10 Turning the connection housing………………. 34 3.11 Turning the display ………………….. 35 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 4

6.8.1 Settings for free air delivery measurement — FAD…………… 81 6.8.2 Gross Heat Measurement………………… 82 6.8.3 Net Heat Measurement ………………….83 6.9 Status messages and diagnostic information…………..84 6.10 Plausibility Checks Menu A12 ………………89 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 5

8.2 Technical data……………………. 95 8.3 Dimensions and weights ………………..100 8.3.1 Flange versions……………………100 8.3.2 Sandwich version …………………… 107 8.3.3 Dimensions of remote version……………….. 109 8.4 Flow tables ……………………110 9 Notes 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 6: Safety Instructions

ER 1.0.0_ MA OPTISWIRL 4200 R01 2015-01-07 ER 1.0.1_ 1;2-H MA OPTISWIRL 4200 R01 2015-02-04 ER 1.0.2_ 1;3-PO MA OPTISWIRL 4200 R01 2015-03-04 ER 1.0.3_ 1;2-H MA OPTISWIRL 4200 R01 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 7: Intended Use

Primarily, volumetric flow and temperature are measured, with pressure measurement as an option. From these parameters the measuring device calculates the mass flow or standard volumetric flow using pre-programmed density data and then exports the measured values via various communication interfaces. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 8

2 Use the smaller value, according to the amount. INFORMATION! DN15C and DN25C have a robust flow sensor (signal pick-up) for harsh measuring conditions and higher maximum velocity compared to the standard version. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 9: Certifications

The manufacturer certifies successful testing of the product by applying the CE marking. DANGER! For devices used in hazardous areas, additional safety notes apply; please refer to the Ex documentation. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 10: Safety Instructions From The Manufacturer

The manufacturer reserves the right to alter the content of its documents, including this disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable in any way for possible consequences of such changes. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 11: Product Liability And Warranty

This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device. Special considerations and precautions are also described in the document, which appear in the form of icons as shown below. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 12: Warnings And Symbols Used

In general, devices from the manufacturer may only be installed, commissioned, operated and maintained by properly trained and authorized personnel. This document is provided to help you establish operating conditions, which will permit safe and efficient use of this device. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 13: Device Description

The following designs are available as options: • with pressure sensor — with or without shut-off valve • Flange version, measuring sensor with single reduction F1R • Flange version, measuring sensor with double reduction F2R 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 14: Devices With Connection Flange

Figure 2-3: Sandwich versions with display 1 Version with temperature sensor 2 Version with temperature sensor and optional pressure sensor 3 Version with temperature sensor, optional pressure sensor and shut-off valve www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 15: Dual Version And Twofold Reliability

With the remote version, the measuring sensor and signal converter are installed separately in different places. The 6-pin, shielded connection cable is available with a length up to 50 m / 164 ft. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 16: Devices With Integrated Nominal Diameter Reduction

1 Standard version 2.2.6 Device description Figure 2-5: Device description 1 Signal converter 2 Cable feed through 3 Pressure sensor, optional 4 Shut-off valve, optional 5 Measuring sensor 6 Centering ring www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 17: Free Air Delivery Measurement — Fad (Optional)

FAD measurement is an optional feature which can be unlocked in menu item C6.3 «Extras». Please contact the manufacturer to obtain the four-digit code required to enable this feature. Programming example: refer to Settings for free air delivery measurement — FAD on page 81 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 18: Gross Heat Quantity Calculation (Optional)

Gross heat quantity calculation is an optional feature, which can be unlocked in menu item C6.3 «Extras». Please contact the manufacturer to obtain the four-digit code required to enable this feature. Programming example: refer to Gross Heat Measurement on page 82 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 19: Net Heat Quantity Calculation (Optional)

Net heat quantity calculation is an optional feature which can be unlocked in menu item C6.3 «Extras». Please contact KROHNE to obtain the four-digit code required to enable this feature. Programming example: refer to Net Heat Measurement on page 83 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 20: Dual Seal

Even though there is no reason to expect the seal to fail, regular visual checks should still be carried out to detect any possible leak as early as possible. In the event of a leak, contact the manufacturer’s service department to service or replace the device. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 21: Nameplate

9 Tag no. — Measuring point identifier 10 Manufacturer’s website Figure 2-9: Example of nameplate 1 Serial number 2 Order number 3 Production order number 4 Type code 5 Item number 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 22: Installation

Non-secured devices can pose risk of injury. The centre of mass of the device is often higher than the point at which the lifting straps are attached. Prevent the measuring device from sliding or rotating accidentally. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 23: Installation Conditions

Suitable measures must be taken to avoid water cavitation if it is a possible risk. Sunshades Figure 3-2: Installation recommendations 1 Horizontal mounting 2 Vertical mounting The meter MUST be protected from strong sunlight. A sunshade is available from the manufacturer as an option. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 24: Prohibited Installation When Measuring Liquids

Figure 3-4: Downstream pipe and outlet CAUTION! Installing the device in a downstream pipe 3 or upstream pipe of an outlet 4. There is the risk of partially filled pipes leading to inaccurate measurements. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 25: Prohibited Installation When Measuring Vapours And Gases

1 Recommended: installing the device before the control valve at a distance of ≥ 5 DN 2 Not recommended: Installing the flowmeter directly downstream of control valves, due to vortex formation. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 26: Preferred Mounting Position

3 On a vertical pipe 4 Horizontal pipeline with signal converter-orientation 90° to the side INFORMATION! Depending on the installation position, you may have to rotate the display and/or the connection housing. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 27: Minimum Inlet Sections

The nominal diameter of the flange is significant for the determination of the minimum inlet and outlet sections for the nominal diameter reduced versions of Vortex flowmeter F1R and F2R. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 28: Minimum Outlet Sections

1 Straight inlet section upstream of straightener ≥ 2 DN 2 Flow straightener 3 Straight pipe run between flow straightener and device ≥ 8 DN 4 Minimum straight outlet section ≥ 5 DN www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 29: Installation

Figure 3-11: Inner diameter 1 Inner diameter of connection pipe 2 Inner diameter of flange and gasket 3 Inner diameter of measuring sensor 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 30: Installing Devices In Sandwich Design

• Turn the centring ring 2 in a counter-clockwise direction and align the device. • Check that the gaskets 5 are concentric; they must not protrude into the pipe cross-section. • Now tighten all nuts bit by bit alternately across the diagonal. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 31: Installing Devices In Flange Design

• Install the gasket, bolts and fastening nuts on the other side of the flange. • Align the measuring device and the gaskets so they are concentric. • Now tighten all nuts bit by bit alternately across the diagonal. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 32: Mounting The Field Housing, Remote Version

Converters with a wall mounting rack have to be mounted with screws (ø 8mm), or with U- brackets (ø 8mm) in case of pole installation. In case of mounting directly to the wall, a mounting system suitable for the background has to be applied. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 33: Heat Insulation

2 Max. thickness of the insulation up to the bend of the pressure pipe 3 Insulation CAUTION! The heat insulation 3 may only extend as far as the bend of the pressure sensing line 2. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 34: Turning The Connection Housing

• Loosen the M4 hexagon socket screw 1 on the side of the connection housing. • Rotate the connection housing to the desired position (0…<360°). • Tighten the hexagon socket screw 1 again. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 35: Turning The Display

• Turn the cover with gasket 5 back onto the housing and tighten it by hand. INFORMATION! Before closing the housing cover refer to Maintaining the O-Rings on page 91 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 36: Electrical Connections

INFORMATION! Check the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 37: Connecting The Signal Converter

• Turn the housing cover and gasket back onto the housing and tighten it by hand. INFORMATION! Ensure that the housing gasket is properly fitted, clean and undamaged. Before closing the housing cover refer to Maintaining the O-Rings on page 91 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 38: Electrical Connections

Connect current loop 4..20mA to terminals C1+ and C2-. When connection cables are long, a shielded or twisted cable may be necessary. The cable shield may only be grounded at one place (e.g. on the power supply unit). www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 39: Current Input

The binary output is electrically separated from the current output and must be supplied with power separately. 4.3.5 Limit switch output Figure 4-4: Connection binary output 1 Power supply U ext. 2 Isolated switching amplifier 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 40

The upper limit of the signal current must not be exceeded as this may damage the transistor output. For selection of measurement variable and adjustable data of the limit switch please refer to chapter 6.7.6 Menu Description C, menu item C2.2.5 Limit Switch and appropriate sub-menus. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 41: Pulse Output / Frequency Output

6.7.6 Menu Description C, menu item C2.2.2 Pulse Output or menu item C2.2.3 Frequency Output and appropriate sub-menus. INFORMATION! Make sure the pulse width is in line with the pulse rate. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 42: Status Output

4.4 Connection of remote version The connections in the sensor and wall mount bracket connection boxes are identical in construction. Connection cable strand colour Terminals Strand colour blue black grey yellow green gnye Shielding www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 43

CAUTION! Please ensure that the shielding 4 has been properly connected to both terminals 3 and 5. The exterior shielding of the cable must not be connected to any terminal. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 44: Grounding Connections

1 Electrical grounding connection on measuring sensor 2 Electrical grounding connection on signal converter housing INFORMATION! In the remote version, the sensor as well as the signal converter must be grounded. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 45: Ingress Protection

• Align the measuring device so that the cable feedthrough is never facing up 3. • Close any unused cable feedthroughs using blind plugs 4 suitable for the protection category. • Do not remove the required cable bushing from the cable feedthrough. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 46: Start-Up

5.2 Operation INFORMATION! The measuring device is largely maintenance-free. Observe the application limits in respect of temperature and medium. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 47: Operation

4 1st measured variable in large representation 5 Indicates when a key has been pressed 6 Tag number (just shown if entered previously by the operator) 7 Indicates a possible status message in the status list 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 48: Display For Selection Of Submenu And Functions, 3 Lines

(_ _ _ signalise in this line the end of the list) 6 Current menu(s), submenu or function 7 Previous menu(s), submenu or function (_ _ _ signalise in this line the beginning of the list) www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 49: Display When Setting Parameters, 4 Lines

3 Denotes a changed parameter (simple check of changed data when browsing through lists) 4 Next parameter 5 Currently set data from 6 6 Current parameter (for selection press key >; then see previous chapter) 7 Factory setting of parameter 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 50: Basic Principles Of Operation

• Press the ^ button to save the settings, or to reject them. • Before returning to measuring mode, you are prompted «Save config? Yes». Switch between «Yes», «Back» and «No» by pressing the ↑ or ↓ keys. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 51: Character Selection In Change Mode

Volume Flow 6.2.4 Character selection in change mode Depending on the menu function, the following characters are available: Numbers Lower case letters Upper case letters Special characters ..08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 52: Units, Figures And Factors

Access Levels Access Levels Access Levels The OPTISWIRL 4200 features a multi-level security concept, which helps to prevent accidental or unauthorized configuration changes. To gain a specific access level you need to log into the device by entering a four-digit hexadecimal password associated with that access level (see menu C6.2 “Security”).

-

Page 53

“Reset Passwords” command available in the C6.2.3 submenu. However to prevent unauthorized use this command itself is protected by a non-changeable unique password available by contacting KROHNE. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 54: Overview Of The Most Important Functions And Units

Francais in preparation: Italiano Portugues Nederlands Espanol Svensk Russian Norwegian Finnish Slovenian Czech Hungarian Slovak Albanian Bulgarian Romanian Moldavian Danish Polish Lithuanian Chinese Estonian Latvian Turkish Table 6-4: Menu languages www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 55: Gas Options For Gas Measurement

↑. Change between the digits by pressing the rightwards button →. After reaching the last digit the cursor will jump again to the first digit. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 56: Units

Units for standard volume flow Units for standard volume flow Units for standard volume flow Liquids, vapours, gases /min Customised standard volume flow Table 6-6: Flow measurements and their units www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 57

Mcal g/ml kg/cm temperature Mcal/h lb/gal g/cm torr Btu/h Customised lb/ft energy Mbtu/s lb/in psi (abs) Mbtu/h Customised density Mbtu/d b/ft Customised power Customised pressure Table 6-9: Units additional measurements 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 58: Menu Structure

A9.21 Density A9.22 Cst. Density A10 Meter Type A11 Application A11.1 Liquids assistant A11.2 Saturated Steam A11.3 Superheated Steam A11.4 Heat Measurement A11.5 Gas A11.6 FAD A12 Cluster Cluster 1…12 Checks www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 59: Menu Overview B — Test

B2.4 Mass Flow B2.5 Gross Power B2.6 Net Power B2.7 FAD B2.8 Volume B2.9 Norm. Volume B2.10 Mass B2.11 Gross Energy B2.12 Net Energy B2.13 Density B2.14 Temperature1 B2.15 Temperature2 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 60: Menu Overview C — Setup

C1.6.1 Temp. Source1 C1.6.2 Temp. Source2 C1.7 Pressure Sensor C1.8 Time Constant C1.9 Low Flow Cutoff C1.10 Operating C1.10.1 Oper. Temperature Values C1.10.2 Oper. Pressure C1.10.3 Oper. Density C1.10.4 Min/Max Oper. Dens. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 61

C4.1.4 Set Value C4.1.5 Start Totalizer? C4.1.6 Stop Totalizer? C4.1.7 Information C4.2 Energy C4.2.1 Measurement C4.2.2 Preset Value C4.2.3 Reset Totalizer? C4.2.4 Set Value C4.2.5 Start Totalizer? C4.2.6 Stop Totalizer? C4.2.7 Information 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 62

C6.1.9 Device Revision C6.1.10 Software Revision C6.1.11 Hardware Revision C6.1.12 Electronic Serial No. C6.1.13 CG-Number C6.1.14 Production Date C6.1.15 Calibration Date C6.2 Security C6.2.1 Login C6.2.2 Change Password C6.2.3 Reset Passwords www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 63

C6.6 Factory Default C6.6.1 Reset to Fact. Def.? 1 All even-numbered menu items e.g. C6.5.2 are appropriate customised units. It is followed by submenu items with prompts for text, offset and factor. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 64: Menu Description A — Quick Setup

FAD functionality Application Assistant Details see next tables Plausibility Checks Menu A12 Cluster Checks refer to on page 89 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 65

OPTISWIRL 4200 A11 Application Assistant The factory settings of your OPTISWIRL 4200 have been made in accordance with your order specifications. Nonetheless it can be necessary to make additional settings for the use of some functionalities. For an easy operation the device is equipped with an application assistant for each type of application. -

Page 66

One Value / Two Values / Three Values / One Value & Bargraph / Two values & Bargraph 2. Meas. Page One Value / Two Values / Three Values / One Value & Bargraph / Two values & Bargraph www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 67

Flow Totalizer Same options as in A11.1.11 Energy Totalizer Same options as in A11.1.12 1. Meas. Page Same options as in A11.1.13 2. Meas. Page Same options as in A11.1.14 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 68

Flow Totalizer Same options as in A11.1.11 Energy Totalizer Same options as in A11.1.12 1. Meas. Page Same options as in A11.1.13 2. Meas. Page Same options as in A11.1.14 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 69

Same options as in A11.1.8 Status Output Same options as in A11.1.9 Limit Switch Same options as in A11.1.10 Flow Totalizer Same options as in A11.1.11 Energy Totalizer Same options as in A11.1.12 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 70

Same options as in A11.1.6 Pulse Output Same options as in A11.1.7 Frequency Output Same options as in A11.1.8 Status Output Same options as in A11.1.9 Limit Switch Same options as in A11.1.10 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 71

Same options as in A11.1.6 Pulse Output Same options as in A11.1.7 Frequency Output Same options as in A11.1.8 Status Output Same options as in A11.1.9 Limit Switch Same options as in A11.1.10 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 72: Menu Description B — Test

Enter gas mixture as percentage share of gas options refer to Gas options for gas measurement on page 55 C1.3.2 Relative Humidity This menu item is available if fluid = Wet Gas. Enter 0…100% www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 73

C1.10.4.1 Function Select: On / Off If function = On, min./max. operating density can be defined in C1.10.4.2 and C1.10.4.3 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 74

Enter measured value for 20 mA point. Reset to 20 mA restores the factory calibration. Binary output C2.2 Binary Output For possible functions of the binary output refer to on page 39 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 75

Value defines the sensitivity of transition detection. Enter value between -1.0 (to decrease sensitivity) and +1.0 (to increase sensitivity). C2.2.5 Limit Switch Only available, if Limit Switch is selected in C2.2.1 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 76

Primary HART variable; identical with current output measurement variable C3.1.4.2 Frequency Out. Meas. Secondary HART variable; identical with frequency output measurement variable C3.1.4.3 Current Input Meas. Tertiary HART variable; identical with current input measurement variable www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 77

Enter current value in selected unit. Start value has to be confirmed with ‘Yes’ or refused with ‘No’. C4.2.5 Start Totalizer? Select: Yes / No C4.2.6 Stop Totalizer? Select: Yes / No 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 78

Display of meter type as activated in A10 or C6.3.2 — C6.3.4. (read-only) C6.1.4 Serial number Individual device ID (read-only) C6.1.5 Manufacturer ID HART Manufacturer ID = 00069 [KROHNE] (read-only) www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 79

Heat & Dens. & FAD C6.4 Errors C6.4.1 Message View Display of NAMUR messages F S M C I Status messages and diagnostic information Explanations: refer to on page 84 C6.5 Units 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 80

Press → and confirm reset to factory default with `Yes’ or refuse with ‘No’. 1 In all even numbered menu items C6.5.2 to .22 Cst. Units (Custom Units) there is a sub menu with the prompt for «Text», «Offset» and «Factor». www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 81: Setting Examples

C5.3.3 / 4 0% / 100% Range Enter bargraph range limits (0% / 100%) in selected unit INFORMATION! This is an example setup for basic FAD measurement. Other setup options are feasible. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 82: Gross Heat Measurement

Two Values C5.3.2 Measurement 1. Line Gross Power C5.3.6 Measurement 2. Line Gross Energy INFORMATION! This is an example setup for basic gross heat measurement. Other setup options are feasible. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 83: Net Heat Measurement

Two Values C5.3.2 Measurement 1. Net Power Line C5.3.6 Measurement 2. Net Energy Line INFORMATION! This is an example setup for basic net heat measurement. Other setup options are feasible. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 84: Status Messages And Diagnostic Information

Check the connection of the available or invalid pressure sensor. Perform a communication hard reset. If the message recurs, contact KROHNE. Corrupt Sensor Sensor parameters are Check sensor parameters. inconsistent www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 85

Perform a hard reset. If the parameter memory message recurs, contact KROHNE. Disp. NVRAM Layout Error Incompatible data after Perform a hard reset. If the firmware update message recurs, contact KROHNE. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 86

Make sure that the device is pressure sensor out of operated within the specification permissable temperature range. Elec. Temp. Out Of Spec. The electronic temperature of the sensor module is out of specification. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 87

(maintenance the SIL mode according to mode 2) has to be performed the instructions of the safety by the operator. manual and confirm the correctness with the SIL jumper. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 88

Failed Piezo Test The continuous self test of Perform a hard reset. If the the sensor electronic failed. message recurs, contact Failed Sensor Input Test KROHNE. Failed Sensor MCU Test www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 89: Plausibility Checks Menu A12

100%. HART Catch If temperature or pressure data input is provided by HART, the device checks if the «Slot Variable Number“ fits in with the «Capture Command“. (Temperature / Pressure) 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 90: Service

• Tighten the two screws 6. • Attach the measuring sensor cable 5 • Attach display 1 in desired position, apply even pressure to the entire surface. • Screw on cover by hand. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 91: Maintaining The O-Rings

Operational temperature range (-30 C …130 C at permanent lubrication) • ° ° Free from silicone • Good adhesive capability • • Lithium saponified Water resistant • Compatible with material of O-ring • 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 92: Spare Parts Availability

• such dangerous substances, to enclose a certificate with the device confirming that is safe to handle and stating the • product used. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 93: Form (For Copying) To Accompany A Returned Device

The user must dispose of the WEEE to a designated collection point for the recycling of WEEE or send them back to our local organisation or authorised representative. 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 94: Technical Data

: S . v The vortex frequency is recorded at the sensor and evaluated at the converter. Figure 8-1: Functional principle www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 95: Technical Data

Flange version with double reduction of nominal diameter, measuring sensor: F2R Display and user interface Local display Graphic display Interface and display languages German, English, French, 23 further languages in preparation 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 96

Gases and vapours 2.0…80 m/s / 6.6…262.5 ft/s DN15: 3.0…45 m/s / 9.8…148 ft/s; DN25: 2.0…70 m/s / 6.6…230 ft/s Intended use For further information refer to on page 7. www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 97

All inputs and outputs are electrically isolated from one another. Time constant The time constant corresponds to 63% of the elapsed time of a processor procedure. 0…100 s (rounded up to 0.1 s) 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 98

VDI/VDE 2188 (category 2) Temperature coefficient 50 ppm/K Residual current < 0.2 mA at 32 V (Ri = 180 kOhm) Pulse width 0.5…2000 ms www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 99: Pulse Output

QPS IS Class I Div 1 — in preparation QPS XP Class I Div 1 — in preparation QPS NI Class I Div 2 — in preparation QPS DIP Class II, III Div 1 — in preparation 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 100: Dimensions And Weights

380.3 380.3 368.3 169.3 169.5 169.5 396.8 380.3 380.3 171.5 169.3 169.5 396.8 380.3 380.3 171.5 169.3 169.5 396.8 396.8 380.3 171.5 169.3 169.5 396.8 396.8 380.3 171.5 169.3 169.5 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 101

492.8 468.8 468.8 229.5 202.8 492.8 468.8 468.8 229.5 202.8 492.8 492.8 468.8 229.5 202.8 492.8 492.8 468.8 229.5 202.8 1 F1R — single reduction 2 F2R — double reduction 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 102

128.1 127.5 132.0 131.4 143.2 142.6 Weight specifications for version with two signal converters + 3.2 kg / 7.05 lb 1 F1R — single reduction 2 F2R — double reduction www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 103

396.8 380.3 368.3 171.5 169.3 169.5 396.8 380.3 368.3 171.5 169.3 169.5 416.3 396.8 380.3 191.5 171.1 169.3 416.3 396.8 380.3 191.5 171.1 169.3 416.3 396.8 380.3 191.5 171.1 169.3 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 104

75.4 74.8 72.2 71.6 78.1 77.5 75.0 74.4 75.2 74.6 73.9 73.3 107.0 106.4 112.4 111.8 113.5 112.9 107.0 106.4 109.8 109.2 120.4 119.8 152.0 151.4 165.4 155.8 171.7 171.1 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 105

15.7 15.0 14.5 6.76 6.67 6.67 15.7 15.0 14.5 6.76 6.67 6.67 16.4 15.6 15.0 7.54 6.76 6.67 16.4 15.6 15.0 7.54 6.76 6.67 16.4 15.6 15.0 7.54 6.76 6.67 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 106

166.3 165.0 159.2 157.9 172.2 171.0 165.4 164.1 165.9 164.5 163.0 161.7 236.0 234.7 247.9 246.6 250.3 249.0 236.0 234.7 242.2 240.8 265.5 264.2 335.2 333.9 364.8 343.6 378.7 377.4 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 107: Sandwich Version

Specified weight + 2.8 kg / 6.2 lb Sandwich version EN Nominal size Pressure Dimensions [mm] Weight [kg] rating with without Pressure sensor 174.25 174.25 174.5 174.5 174.25 176.5 10.1 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 108

19.4 18.08 2.91 5.31 2.56 11.42 6.82 19.4 18.08 3.82 6.22 2.56 12.21 6.95 22.27 20.94 3.82 6.22 2.56 12.21 6.95 22.27 20.94 3.82 6.22 2.56 12.21 6.95 22.27 20.94 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 109: Dimensions Of Remote Version

1 F1R — single reduction — 2 F2R — double reduction Dimensions b…n b…n b…n b…n [mm] [«] 5.46 4.25 10.9 7.53 4.14 3.82 2.84 4.25 0.35 2.84 3.82 8.90 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 110: Flow Tables

1086 14478 286870 3824929 1577 21028 416638 5555167 Values based on air at 20°C / 68°F and 1.013 bar abs / 14.696 psig and density 1.204 kg/m / 0.0751 lb/ft www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en…

-

Page 111

1093 31715 1210 35334 1288 37737 1808 52054 2053 59574 2273 66371 2419 70884 2890 83215 3282 95237 3634 106102 3867 113318 4197 120858 4767 138318 5279 154099 5617 164578 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 112

2424 70309 2687 78419 2799 82006 4011 115455 4553 132068 5048 147302 5258 154041 6412 184569 7279 211127 8069 235481 8406 246254 9313 268060 10571 306632 11720 342002 12209 357649 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 113: Notes

NOTES OPTISWIRL 4200 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com…

-

Page 114

NOTES OPTISWIRL 4200 www.krohne.com 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en… -

Page 115

NOTES OPTISWIRL 4200 08/2015 — 4003930801 — MA OPTISWIRL 4200 R01 en www.krohne.com… -

Page 116

• Process Analysis • Services Head Office KROHNE Messtechnik GmbH Ludwig-Krohne-Str. 5 47058 Duisburg (Germany) Tel.: +49 203 301 0 Fax: +49 203 301 10389 info@krohne.com The current list of all KROHNE contacts and addresses can be found at: www.krohne.com…

KROHNE OPTISWIRL 4200 Measuring Instruments PDF User Guides and Manuals for Free Download: Found (4) Manuals for KROHNE OPTISWIRL 4200 Device Model (Supplementary Instructions Manual, Quick Start Manual)

More Measuring Instruments Device Models:

-

Klein Tools

VDV501-090

www.kleintools.comInstruction ManualFor Professionals…Since 1857®Ranger™ TDRVDV501-090ENGLISHEspañol pág. 15Français page 29• MEASURES CABLE LENGTH• CABLE FAULT FINDER• TONE GENERATOR• CABLE MANAGER …

VDV501-090 Measuring Instruments, 44

-

HydroPoint

WaterCompass FM300

Introduction This document covers installation for the WC-FM300-US Ultrasonic Flow Monitor for pipe sizes of 1/4 — 2”. The WaterCompass FM300 Ultrasonic Flow Monitor is a customized product made up of an integrated WT2W-H20 Flow Decoder, a clamp-on flow monitor and a 30 V power supply. The monitor sends real-time flo …

WaterCompass FM300 Measuring Instruments, 27

-

Hydro Instruments

TH-4000

1TH-4000 TurbidimeterOperation and Maintenance ManualTH-4000 Rev. 4/29/2022 v2The information contained in this manual was current at the time of printing. The most current versions of all Hydro Instruments manuals can be found on our website: www.hydroinstruments.com …

TH-4000 Measuring Instruments, 12

-

HOKUYO AUTOMATIC

UXM-30LAH-EWA

Title Approved by Checked by Designed by Symbol Amended Reason Date Amended by DWG.NO 1/51 Drawn by C-41-02495 Date: 2014.5.27 Area Designer Instruction Manual Drawing No. KristouKristouKristouKristou FukudaFukudaFukudaFukuda AokiAokiAokiAoki AokiAokiAokiAoki Area Designer UXM-30LAH-EWA configuration to …

UXM-30LAH-EWA Tools, 51

Recommended Documentation:

-

Sony FDDR-7000

MULTI-CHANNEL DIGITAL DISK RECORDERFDDR-7000INSTALLATION MANUAL1st Edition (Revised 1)BKFD-7800HDD UNITBKFD-7009/7009AHDD EXTENSION BOXVIDEO CHANNEL BOARD SETBKFD-7110VIDEO PROCESS BOARDBKFD-7120SCSI BOARDBKFD-7500AUDIO BOARDBKFD-7600OPERATION SOFTWAREBZFD-7010/7020 …

FDDR-7000 Measuring Instruments, 64

-

Microlife BP A200 AFIB

Microlife BP A200 AFIB Microlife AGEspenstrasse 1399443 Widnau / Switzerlandwww.microlife.comIB BP A200 AFIB_3G S-V10 2518EN 1ES 10FR 18IT 26DE 34PT 42NL 50GR 58AR 68FA 76 …

BP A200 AFIB Blood Pressure Monitor, 85

-

Desco 19290

DESCO EUROPE — 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UKPhone: +44 (0) 1462 672005 • E-mail: [email protected], Website: DescoEurope.comTB-3076.E Page 1 of 8© 2018 DESCO INDUSTRIES INCEmployee OwnedDigital Surface Resistance Meter KitInstallation, Operation and MaintenanceDescriptionThe Desco 192 …

19290 Measuring Instruments, 8

-

PCB Piezotronics 356B41/NC

Model 356B41/NCTriax ICP® Seat Pad Accelerometer per ISO 10326-1Installation and Operating ManualFor assistance with the operation of this product,contact PCB Piezotronics, Inc.Toll-free: 800-828-884024-hour SensorLine: 716-684-0001Fax: 716-684-0987E-mail: [email protected]: www.pcb.com …

356B41/NC Measuring Instruments, 15

-

Fine Offset Electronics WH0280

Instruction Manual 1 Wireless Thermo-Hygro Monitor Model: WH0280 Content 1. Introduce ……………………………………………………………………………………… 2 2. Get Started …………………………………………………………………………………… 2 2.1 Packag …

WH0280 Measuring Instruments, 15

-

ICP DAS USA PMD-2201

August 2017, Version 1.0.2 Thank you for purchasing PMD-x201 – the Power Meter Concentrator with Display for power monitoring and management system. This Quick Start will provide you with minimum information to get started with PMD-x201. It is intended for use only as a quick reference. For more detailed …

PMD-2201 Measuring Instruments, 7

-

Anritsu Company VectorStar ME7838A4

Quick Start GuideVectorStar™ ME7838A4 Multiport Broadband/Banded Millimeter-Wave SystemHigh Performance Modular Broadband/Banded Millimeter-Wave Vector Network Analyzer (VNA) Multiport Measurement SystemME7838A4, 70 kHz to 110 (125) GHzAnritsu Company490 Jarvis DriveMorgan Hill, CA 95037-2809USAhttp://www.anritsu.com …

VectorStar ME7838A4 Measuring Instruments, 24

Vortex flowmeter

Electronic revision: ER 1.0.5_

© KROHNE 03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en

|

1 |

Safety instructions |

3 |

|

|

2 |

Installation |

4 |

|

|

2.1 |

Intended use ……………………………………………………………………………………………………… |

4 |

|

|

2.2 |

Scope of delivery………………………………………………………………………………………………… |

6 |

|

|

2.3 |

Storage …………………………………………………………………………………………………………….. |

6 |

|

|

2.4 |

Transport ………………………………………………………………………………………………………….. |

7 |

|

|

2.5 |

Installation conditions ………………………………………………………………………………………… |

8 |

|

2.5.1 Prohibited installation when measuring liquids ………………………………………………………….. |

9 |

|

|

2.5.2 Prohibited installation when measuring steam and gases………………………………………….. |

10 |

|

|

2.5.3 Pipelines with control valve…………………………………………………………………………………….. |

10 |

|

|

2.5.4 Preferred mounting position …………………………………………………………………………………… |

11 |

|

|

2.6 |

Minimum inlet sections …………………………………………………………………………………….. |

12 |

|

2.7 |

Minimum outlet sections…………………………………………………………………………………… |

13 |

|

2.8 |

Flow straightener …………………………………………………………………………………………….. |

13 |

|

2.9 |

Installation………………………………………………………………………………………………………. |

14 |

|

2.9.1 General installation notes……………………………………………………………………………………….. |

14 |

|

|

2.9.2 Installing devices in sandwich design ………………………………………………………………………. |

15 |

|

|

2.9.3 Installing devices in flange design …………………………………………………………………………… |

16 |

|

|

2.9.4 Mounting the field housing, remote version ……………………………………………………………… |

17 |

|

|

2.10 Heat insulation……………………………………………………………………………………………….. |

18 |

|

|

2.11 Turning the connection housing……………………………………………………………………….. |

19 |

|

|

2.12 Turning the display …………………………………………………………………………………………. |

20 |

|

|

3 Electrical connections |

21 |

|

|

3.1 |

Safety instructions……………………………………………………………………………………………. |

21 |

|

3.2 |

Connecting the signal converter ………………………………………………………………………… |

22 |

|

3.3 |

Electrical connections ………………………………………………………………………………………. |

23 |

|

3.3.1 Power supply…………………………………………………………………………………………………………. |

23 |

|

|

3.3.2 Current output ………………………………………………………………………………………………………. |

23 |

|

|

3.3.3 Current input…………………………………………………………………………………………………………. |

24 |

|

|

3.3.4 Binary output…………………………………………………………………………………………………………. |

24 |

|

|

3.3.5 Limit switch output ………………………………………………………………………………………………… |

25 |

|

|

3.3.6 Pulse output / Frequency output ……………………………………………………………………………… |

27 |

|

|

3.3.7 Status output…………………………………………………………………………………………………………. |

28 |

|

|

3.4 |

Connection of remote version ……………………………………………………………………………. |

28 |

|

3.5 |

Grounding connections……………………………………………………………………………………… |

30 |

|

3.6 |

Ingress protection ……………………………………………………………………………………………. |

31 |

|

2 |

www.krohne.com |

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

OPTISWIRL 4200

SAFETY INSTRUCTIONS 1

Warnings and symbols used

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to serious health problems and even death. There is also the risk of seriously damaging the device or parts of the operator’s plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems. There is also the risk of damaging the device or parts of the operator’s plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator’s plant.

INFORMATION!

These instructions contain important information for the handling of the device.

HANDLING

•This symbol designates all instructions for actions to be carried out by the operator in the specified sequence.

iRESULT

This symbol refers to all important consequences of the previous actions.

Safety instructions for the operator

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately trained personnel. The regional occupational health and safety directives must always be observed.

LEGAL NOTICE!

The responsibility as to the suitability and intended use of this device rests solely with the user. The supplier assumes no responsibility in the event of improper use by the customer. Improper installation and operation may lead to loss of warranty. In addition, the «Terms and Conditions of Sale» apply which form the basis of the purchase contract.

INFORMATION!

•Further information can be found on the supplied CD-ROM in the manual, on the data sheet, in special manuals, certificates and on the manufacturer’s website.

•If you need to return the device to the manufacturer or supplier, please fill out the form contained on the CD-ROM and send it with the device. Unfortunately, the manufacturer cannot repair or inspect the device without the completed form.

|

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

www.krohne.com |

3 |

|

2 INSTALLATION |

OPTISWIRL 4200 |

2.1 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and corrosion resistance of the used materials against the measured fluid lies solely with the operator.

INFORMATION!

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in industrial environment. There may be potential difficulties in ensuring electromagnetic compatibility in other environments, due to conducted as well as radiated disturbances.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than the intended purpose.

The vortex flowmeters are used for flow measurement of gases, vapours and liquids.

The devices are particularly suitable for the measurement of:

•Clean liquids with low viscosity (< 10 cP)

•Hydrocarbons with low viscosity (< 10 cP)

•Water

•Chemicals with low corrosiveness

•Saturated steam

•Superheated steam, including CIP and SIP applications in the food industry

•The flow sensors are made from stainless steel 316 L (1.4404) or Hastelloy® C22.

•In your project planning, please observe the data given in the corrosion tables.

•The pressure-bearing parts have been designed and rated for stationary operation taking into account the maximum pressure and temperature.

•Observe the data indicated on the nameplate for PS, TS and PT (PED 97/23/EC).

•External forces and moments, caused e.g. by pipe stresses, have not been taken into account.

Primarily, volumetric flow and temperature are measured, with pressure measurement as an option. From these parameters the measuring device calculates the mass flow or standard volumetric flow using pre-programmed density data and then exports the measured values via various communication interfaces.

|

4 |

www.krohne.com |

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

|

INSTALLATION 2 |

||

|

OPTISWIRL 4200 |

||

The devices are rated for the following flow velocities:

|

Liquids: |

Vmin: 0.25 m/s |

0.8 ft/s |

1 |

||

|

DN15…DN300 |

|||||

|

Vmax: 10 m/s |

32 ft/s |

2 |

|||

|

Gases and |

DN15 |

Vmin: 3 m/s |

10 ft/s |

1 |

|

|

steam: |

|||||

|

Vmax: 45 m/s |

147 ft/s |

2 |

|||

|

DN15C |

Vmin: 3 m/s |

10 ft/s |

1 |

||

|

Vmax: 55 m/s |

180 ft/s |

2 |

|||

|

DN25 |

Vmin: 2 m/s |

6.6 ft/s |

1 |

||

|

Vmax: 70 m/s |

229 ft/s |

2 |

|||

|

DN25C |

Vmin: 2 m/s |

6.6 ft/s |

1 |

||

|

Vmax: 80 m/s |

262 ft/s |

2 |

|||

|

DN40… |

Vmin: 2 m/s |

6.6 ft/s |

1 |

||

|

DN300 |

|||||

|

Vmax: 80 m/s |

262 ft/s |

2 |

|||

1Use the larger value, according to the amount.

2Use the smaller value, according to the amount.

INFORMATION!

DN15C and DN25C have a robust flow sensor (signal pick-up) for harsh measuring conditions and higher maximum velocity compared to the standard version.

|

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

www.krohne.com |

5 |

|

2 INSTALLATION |

OPTISWIRL 4200 |

2.2 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order. Check for the correct supply voltage printed on the nameplate.

Figure 2-1: Scope of delivery

1Measuring device in ordered version

2Product documentation

3Certificates, calibration report and parameter data sheet

4CD with complete documentation

5Bar magnet

6Centering rings (only for sandwich devices)

7Handle to pull off the display

8Key for opening the front and rear cover

2.3Storage

•Store the device in a dry, dust-free location.

•Avoid extended direct exposure to the sun.

•Store the device in the original packaging.

•The permissible storage temperature for standard devices is -40…+85°C / -40…+185°F.

|

6 |

www.krohne.com |

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

|

INSTALLATION 2 |

||

|

OPTISWIRL 4200 |

||

2.4Transport

•Use lifting straps wrapped around both process connections for transport.

•Do not lift measuring devices by the signal converter housing for transport.

•Never lift the measuring device by the pressure sensor.

•Do not use lifting chains as they may damage the housing.

Figure 2-2: Transport instructions

CAUTION!

Non-secured devices can pose risk of injury. The centre of mass of the device is often higher than the point at which the lifting straps are attached.

Prevent the measuring device from sliding or rotating accidentally.

|

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

www.krohne.com |

7 |

|

2 INSTALLATION |

OPTISWIRL 4200 |

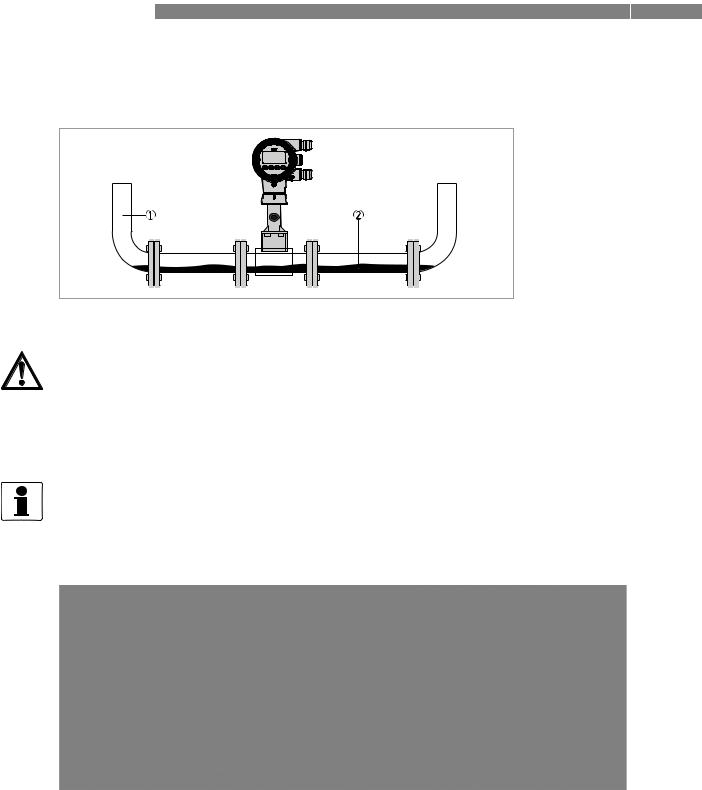

2.5 Installation conditions

INFORMATION!

For accurate volumetric flow measurement the measuring device needs a completely filled pipe and a fully developed flow profile.

CAUTION!

Any vibration will distort the measuring result. That is why any vibrations in the pipeline must be prevented through suitable measures.

CAUTION!

Procedures to carry out before installing the device:

•Nominal diameter of connection pipe flange = nominal flange diameter of pipe!

•Use flanges with smooth holes, e.g. welding neck flanges.

•Align carefully the holes of the connecting flange and the flowmeter flange.

•Check the compatibility of the gasket material with the process product.

•Make sure that the gaskets are arranged concentrically. The flange gaskets must not project into the pipe cross-section.

•The flanges have to be concentric.

•There must not be any pipe bends, valves, flaps or other internals in the immediate inlet run.

•Devices in sandwich version may only be installed using centering rings.

•Never install the device directly behind piston compressors or rotary piston meters.

•Do not lay signal cables directly next to cables for the power supply.

INFORMATION!

If there is a risk of water hammers in steam networks, appropriate condensate separators must be installed. Suitable measures must be taken to avoid water cavitation if it is a possible risk.

Sunshades

Figure 2-3: Installation recommendations

1Horizontal mounting

2Vertical mounting

The meter MUST be protected from strong sunlight.

A sunshade is available from the manufacturer as an option.

|

8 |

www.krohne.com |

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

|

INSTALLATION 2 |

||

|

OPTISWIRL 4200 |

||

2.5.1 Prohibited installation when measuring liquids

Figure 2-4: Upper pipe bend

CAUTION!

Prohibited: Installing the device in an upper pipe bend 1, because there is a risk of gas bubbles 2 forming. Gas bubbles can lead to pressure surges and inaccurate measurement.

Figure 2-5: Downstream pipe and outlet

CAUTION!

Installing the device in a downstream pipe 3 or upstream pipe of an outlet 4. There is the risk of partially filled pipes leading to inaccurate measurements.

|

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

www.krohne.com |

9 |

|

2 INSTALLATION |

OPTISWIRL 4200 |

2.5.2 Prohibited installation when measuring steam and gases

1Lower pipe bends

2Condensate

DANGER!

Prohibited: Installing the device in a lower pipe bend 1, because there is a risk of condensate forming 2.

Condensate can lead to cavitation and inaccurate measurement. Under certain circumstances the device can be destroyed and the measured product can leak.

2.5.3 Pipelines with control valve

INFORMATION!

To ensure smooth and correct measurement, the manufacturer recommends not installing the measuring device downstream from a control valve. This would run the risk of vortex formation, which would distort the measuring result.

Figure 2-6: Pipeline with control valve

1Recommended: installing the device before the control valve at a distance of ≥ 5 DN

2Not recommended: Installing the flowmeter directly downstream of control valves, due to vortex formation.

|

10 |

www.krohne.com |

03/2016 — 4003931402 — QS OPTISWIRL 4200 R02 en |

- Home

- Brands

- KROHNE Manuals

- Measuring Instruments

- KROHNE OPTISWIRL 4200

4 docs – User Manuals, Help Guides and Specs – for the KROHNE OPTISWIRL 4200 product are present in our data base.

|

Related Products:

Product Types:

|

Tips for Finding Manuals:

This web-page provides a list of 4 accessible operating manuals and information books describing KROHNE OPTISWIRL 4200.

All manuals and instructions for KROHNE OPTISWIRL 4200 are introduced in an easy-to-use PDF format and may be gratuitously downloaded or looked through directly from the site.

The page offers the following types of manuals: Measuring Instruments.

Helpful hints: While selecting a necessary guide for KROHNE OPTISWIRL 4200 one should pay special attention to the type of the document.

We try to supply you with the fullest possible set of papers we or our users are able to find. These may be overviews and specifications of the device, mounting and installing instructions, the unit operating rules and maintenance regulations and much more.

Haven’t found a required manual for your KROHNE OPTISWIRL 4200?

Check in a while. We update our guides collection and add new documents on a daily basis for you to be always able to find the very paper you need on our web-site. In case you own a directory or an instruction for KROHNE OPTISWIRL 4200, which is absent on our site, and you’d like to share it with the public, please send it to us as a scanned copy or a PDF file, and we’ll definitely place it on our page while providing your name as a supplier of the doc. Lots of our users will be grateful for your assistance!