Mercedes-Benz Sprinter Mark II (W906, NCV3) с дизельными двигателями: OM651 2.1 л (2143 см³) 95-129-163 л.с./70-95-120 кВт, OM646 2.1 л (2148 см³) 88-109-150 л.с./ 65-80-110 кВт и OM642 3.0 л (2987 см³) 184-190 л.с./135-140 кВт; Руководство по ремонту, инструкция по эксплуатации, каталог запасных частей, характерные неисправности, 217 электросхем 71 система, характерные неисправности, проверка и замена, моменты затяжки, техобслуживание, периодичность, объемы и жидкости, диагностика, технические характеристики, устройство, особенности конструкции. Производственно-практическое издание малотоннажные микроавтобусы LCV класса Мерседес-Бенц Спринтер в исполнении: пассажирский микроавтобус, маршрутное такси (19+7 мест), междугородний микроавтобус (до 20 мест), грузовой фургон, бортовой грузовик задне- и полноприводные модели (209 CDI, 309 CDI, 509 CDI, 211 CDI, 311 CDI, 411 CDI, 511 CDI, 215 CDI, 315 CDI, 415 CDI, 515 CDI, 218 CDI, 318 CDI, 418 CDI, 518 CDI) второго поколения выпуска с 2006 по 2013 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео MB Sprinter 2 замена передних тормозных колодок и дисков, радиатора системы охлаждения (Мерседес-Бенц Спринтер 06-13)

Mercedes-Benz Sprinter Mark II общая информация (Мерседес-Бенц Спринтер 2006-2013)

Радиатор

Снятие и установка

1. Слейте охлаждающую жидкость с радиатора.

2. Отсоедините шланги охлаждающей жидкости от радиатора.

3.1. Отсоедините трубки охладителя рабочей жидкости АКПП от радиатора.

3.2. Отсоедините охладитель рабочей жидкости АКПП от радиатора и поверните его в сторону с подсоединенными шлангами.

а) Снимите передний бампер.

б) Снимите вентиляторы в сборе.

Выверните болт.

— Отсоедините трубки охладителя рабочей жидкости гидроусилителя рулевого управления.

— Отсоедините разъемы.

— Выверните болты.

— Отсоедините шланги рабочей жидкости АКПП от фиксаторов.

Поверните вентиляторы в сборе вверх, отсоедините охладитель рабочей жидкости АКПП и сдвиньте в сторону.

— Снимите вентиляторы в сборе.

в) Отсоедините охладитель рабочей жидкости АКПП от кронштейна.

г) Отсоедините шланги от охладителя и снимите охладитель.

4. Снимите диффузор вентилятора.

5. Снимите панель под решеткой радиатора.

6. Снимите решетку радиатора.

7. Отсоедините радиатор от передней панели.

8. Подайте радиатор с конденсатором назад в направлении двигателя.

9. Сожмите фиксаторы, отсоедините конденсатор от радиатора и поднимите до появления доступа к болтам

10. Снимите охладитель рабочей жидкости гидроусилителя с радиатора.

11. Выверните болты.

12. Отсоедините конденсатор от радиатора.

13. Снимите радиатор.

14. Установка осуществляется в последовательности, обратной снятию.

| № | Спецификация / Specs | Данные |

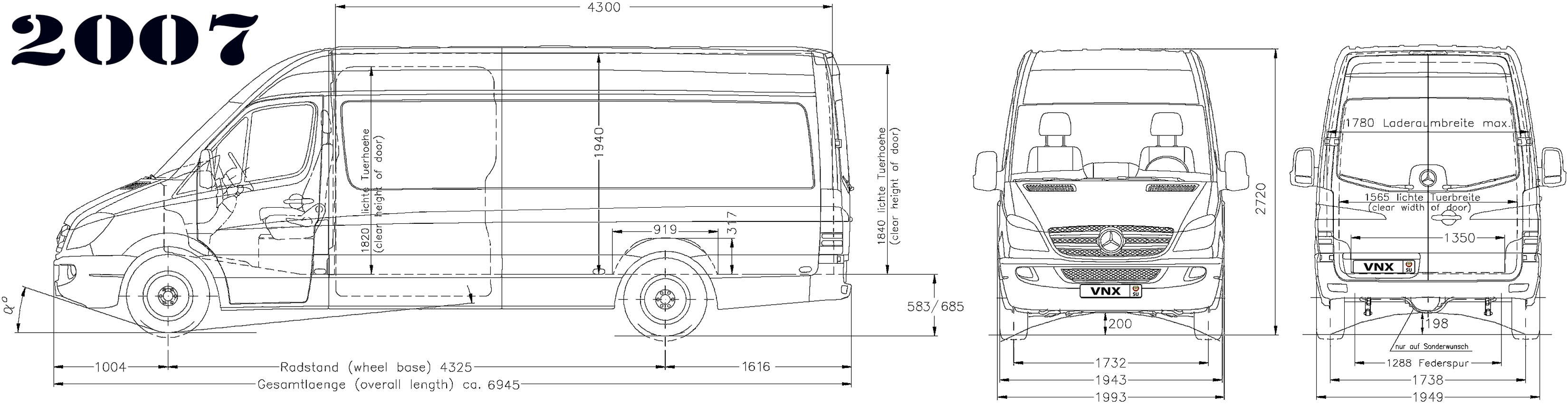

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 6945 |

| 2 | Ширина (без/с зеркалами) / Width | 1993/2425 |

| 3 | Высота (загружен/пустой) / Height | 2715-2720 |

| 4 | Колёсная база / Wheelbase | 4325 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 200⇒198 |

| 6 | Снаряжённая масса / Total (curb) weight | 2320–2410 |

| Полная масса / Gross (max.) weight | 3500 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Дизельный, жидкостного охлаждения, четырехтактный, OM 646 DE22LA |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, рядный, 16V, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 88.0 мм |

| 10 | Ход поршня / Stroke | 88.3 мм |

| 11 | Объём / Engine displacement | 2148 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Прямой впрыск «коммон рейл» с ЭБУ |

| Турбонаддув и промежуточное охлаждение наддувочного воздуха | ||

| 13 | Степень сжатия / Compression ratio | 18.0:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 110 кВт (150 л.с.) при 3800 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 330 Нм при 1800–2400 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Однодисковое, сухое, с диафрагменной нажимной пружиной и гасителем крутильных колебаний, постоянно замкнутого типа |

| 17 | КПП / Transmission type | 711.6 NSG400 МКПП 6 шестиступенчатая механическая, двухвальная, с синхронизаторами на всех передачах переднего хода |

О Книге

- Название: Mercedes-Benz Sprinter (W906) Руководство по ремонту и техническому обслуживанию

- Дизельные двигатели: OM651 2.1 л (2143 см³) 95-129-163 л.с./70-95-120 кВт, OM646 2.1 л (2148 см³) 88-109-150 л.с./ 65-80-110 кВт и OM642 3.0 л (2987 см³) 184-190 л.с./135-140 кВт

- Выпуск с 2006 года

- Серия: «Профессионал»

- Год издания: 2015

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 541

- Размер: 636.67 МБ

- Язык: Русский

- Количество электросхем: 217

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

New Generation of 4-Cylinder

Inline Engines, OM 651

Introduction into Service Manual

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Related Manuals for Mercedes-Benz OM 651

Summary of Contents for Mercedes-Benz OM 651

-

Page 1

New Generation of 4-Cylinder Inline Engines, OM 651 Introduction into Service Manual – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 2

Mercedes-Benz Service Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 Daimler AG · Technical Information and Workshop Equipment (GSP/OI) · D-70546 Stuttgart – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 3

Information and copyright Ordering workshop information All printed workshop information from GSP / OI, such as Introduction into Service Manuals, System Descriptions, Function Descriptions, Technology Guides, Tech- nical Data Manuals and adhesive labels, can be ordered as follows: Within Germany Through our GSP / OI Shop on the Internet Link: http: / / gsp-ti-shop.de… -

Page 4: Table Of Contents

Gear drive Belt drive Combustion Common rail injection Charging Air supply Exhaust system Exhaust system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 5

Vacuum control Environmental protection Emission reduction Service information New features Special tools Engine Abbreviations Index Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 6: Preface

Daimler AG Technical Information and Workshop Equipment (GSP / OI) Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 7: Brief Description

System Description for engine 651. Order number: 6516 1363 02 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 8: Engine Data

Maximum rpm 4,900 5,200 Engine 646.821 EVO Engine 651.911 Engine speed M Torque Output Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 9: Highlights

System (WIS). without the use of welding consumable. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 10: Engine Views

Engine views Engine 651: Side view from left Engine 651: Side view from right Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 11: System Comparison

Oil pump – drive Simplex chain Gear drive Alternator – current rating Engine weight DIN (dry) approx. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 12: At A Glance

Shutoff-capable coolant pump and shutoff-capable oil spray nozzles Exhaust system with oxidation catalytic converter and diesel particulate filter Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 13: Crankcase

• Universal timing case cover for adaptation to various transmission models Crankcase Crankcase Oil spray nozzle shutoff valve Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 14: Cylinder Head

Main bearing bridge Exhaust valve Valve spring Cylinder head cover Piezo injector Valve clearance compensation Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 15: Oil Pan

This prevents unnecessary warning messages e.g. triggered by cornering. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 16: Crankshaft Assembly

There is therefore no differentiation between A, B or X sizes on this engine. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 17

Exhaust camshaft with sensor wheel Drive gear Exhaust camshaft Sensor wheel with orifice plate Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 18: Valve Assembly

Hydraulic valve clearance compensator Intake camshaft Chain tensioner Exhaust camshaft Timing chain drive gear Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 19: Gear Drive

Oil and vacuum pump drive gear Crankshaft gear Drive sprocket Lanchester drive gears High-pressure pump drive gear Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 20: Belt Drive

8 Guide pulley 3 Guide pulley 6 Belt tensioner with tensioner pulley 9 Major assembly carrier Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 21: Common Rail Injection

• Higher engine output • Minimized combustion noise • Reduced emissions • Smoother engine running Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 22

250 V is applied to the piezo injectors. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 23

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 24

Fuel filter housing Pressure line Quantity control valve Rail Piezo injector Pressure regulator valve Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 25: Charging

• Low-pressure turbocharger is designed to build up high boost pressure with high gas flow at medium and high engine speeds Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 26

Charging Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 27

13 EGR cooler 3 Boost pressure control flap (LRK) 9 Intake manifold 14 EGR bypass flap Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 28

13 EGR cooler 3 Boost pressure control flap (LRK) 9 Intake manifold 14 EGR bypass flap Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 29

13 EGR cooler 3 Boost pressure control flap (LRK) 9 Intake manifold 14 EGR bypass flap Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 30: Air Supply

Air filter housing Clean air line Throttle valve Charge air cooler Charge air manifold Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 31

Charge air manifold Actuator motor Tangential intake port Adjustment flap Charge air manifold Spiral intake port Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 32

Throttle valve Throttle valve Throttle valve actuator Charge air manifold Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 33: Exhaust System

Exhaust gas recirculation EGR pre-cooler Charge air manifold EGR cooler Exhaust manifold Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 34

EGR path EGR actuator EGR cooler Vacuum unit EGR pipe EGR bypass EGR pre-cooler Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 35: Exhaust System

Nitrogen Oxygen Nitrogen oxide HC Hydrocarbon PM Particulate matter CO Carbon monoxide O Water Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 36

If DPF regeneration is not possible during normal operation, the engine diagnosis warning lamp lights up on the instrument cluster. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 37: Engine Cooling

More detailed information on this can be found in the Workshop Information System (WIS). Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 38

Engine cooling Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 39: Engine Lubrication And Oil Circuit

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 40

Engine lubrication and oil circuit Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 41: Oil Pump

Cross-section of oil pump Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 42: Coolant Pump

Coolant outlet Regulating valve Power diaphragm Evacuation chamber Rod seal Vacuum fitting Compression spring Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 43: Engine Control Unit

CDI control unit on air filter housing CDI control unit Air filter housing Cooling fins Air filter Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 44: Glow System

CDI control installed. unit. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 45: Vacuum Control

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 46

Vacuum control Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 47: Emission Reduction

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 48

The exhaust flow produced by the engine is reduced. Oil pump volume-controlled at clean oil side This reduces the drive resistance. Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 49: New Features

Seal with installation checking pin (arrow) on charge air manifold Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 50

Further information on repairing and maintaining engine 651 can be found in the Workshop Informa- tion System (WIS). Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 51: Engine

Part number W 651 589 04 63 00 FG 05 Set C Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 52

Part number W 651 589 01 91 00 FG 07 Set B Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 53

Use For knocking out fuel injectors. Part number W 651 589 00 33 00 FG 07 Set B Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 54

Use For inserting front radial shaft sealing ring of crankshaft. Part number W 651 589 00 61 00 FG 03 Set B Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 55

/ / gotis.aftersales.mercedes-benz.com Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –… -

Page 56: Abbreviations

Physical Vapor Deposition Euro NCAP European New Car Assessment Program Vibration damper Hydrocarbon Workshop Information System Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 57: Index

….13 Cylinder head Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –…

-

Page 58

..23 Zero quantity calibration Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q – This printout will not be recorded by the update service. Status: 09 / 2008 –…

Table of Contents for Mercedes-Benz OM 651:

-

Daimler AG · Technical Information and Workshop Equipment (GSP/OI) · D-70546 Stuttgart Mercedes-Benz Service Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status: 09 / 2008 –

-

Overview 7 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine data Comparison Engine 646.821 EVO Engine 651.911 Difference Displacement cm 3 2,148 2,143 –0.2% Rated output kW at rpm 125 3,800 150 4,200 +20% Rated torque Nm at rpm 400 2,000 500 1,600…1,800 +25% Maximum rpm rpm 4,900 5,200 +6% Engine 646.821 EVO Engine 651.911 n Engine speed M Torque POutput – This printout will not be recorded by the update service.

-

Engine 50 Special tools Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q l Socket wrench Use For removing shift valve for controlling piston cooling. Part number W 651 589 00 09 00 FG 18 Set B Hold-down device Use Fixing camshaft in place when tightening or loosening camshaft sprockets. Part number W 651 589 01 40 00 FG 05 Set C Assembly inserts Use For pressing on and riveting outer link plates of bush chain. Part number W 651 589 04 63 00 FG 05 Set C – This printout will not be recorded by

-

Charging Combustion 25 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Dual stage turbocharging 108 Exhaust manifold 110 High-pressure turbocharger (HD-Lader) 110 / 1 HD-Lader compressor impeller 110 / 2 HD-Lader turbine wheel 111 Vacuum unit (boost pressure control flap) 112 Adjustment rod (boost pressure control flap) 113 Boost pressure control flap 120 Low-pressure turbocharger (ND-Lader) 120 / 1 ND-Lader compressor impeller 120 / 2 ND-Lader

-

10 Overview Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q System comparison Comparison Engine 646.821EVO C 220 CDI Engine 651.911 C 250 CDI Market launch 06 / 2006 10 / 2008 Combustion system Diesel direct injection No. of cylinders 4 Engine configuration Inline Bore mm 88.3 83.0 Stroke mm 88.3 99.0 Compression ratio e 16.5:1 16.2:1 Camshafts – drive Duplex chain Simplex

-

Cooling and lubrication 37 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine cooling Cooling circuit 1 Coolant pump 2 Oil / water heat exchanger 3Crankcase 4 Cylinder head 5 Coolant collector 6Chain case housing 7 Bypass housing 8EGR cooler 9Radiator 10 Coolant expansion reservoir 11 Heat exchanger for vehicle heater B Filling line E Vent line KK Radiator circuit KS Short-circuited circuit MEngine R Engine retu

-

Mechanical system 19 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Belt drive Belt routing The ancillary assemblies are driven by a single-piece, low-maintenance poly-V belt. The poly-V belt is tensioned by an automatic belt tensioner with tensioner pulley. Belt routing 1Alternator 2 Belt pulley 3 Guide pulley 4 Coolant pump 5Power steering pump 6 Belt tensioner with tensioner pulley 7 Refrigerant compressor

-

Oil pan 14 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Special design features • Two-piece design • Lower section of oil pan made of plastic •Noise-optimized • Service-optimized and cost-optimized replacement parts • Bolts secured to prevent them being lost • Installation can be checked via special pins on seal Oil pan 1 Upper section of oil pan 2Seal with pins 3 Lower section of oil pan (plastic) 4 Bolts with retainer (anti-loss) i Note Temporary level fluctuations are balanced out by

-

New features 48 Service information Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Dual stage turbocharging The vacuum units of the turbocharger can be replaced individually with the turbocharger installed. Attention must be paid to t he following important points: • The color coding on the control lines • The nuts secured with temperature-resistant paint Oil spray nozzles The oil spray nozzles can be replaced individually. The exact seating is defined by a posi

-

Mechanical system 15 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Crankshaft assembly Crankshaft The forged crankshaft with eight counterweights is supported by five bearings for effective vibration damping. The radiuses of the crank pins are rolled to give them high strength. In addition, the connection between the drive gear and crankshaft is friction welded. The vibration damper is fixed

-

8 Overview Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Highlights New features Based on the use of the latest innovative technologies, engine 651 sets a new standard in terms of output and torque characteristics, economy, exhaust emission levels and smooth running. The engine features a number of new developments which cannot be found in this combination in any other series-produced passenger car diesel engine. Technology The most important technical features of the new engine are: • Dual

-

Common rail injection 22 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Advantages of the new injection technology The advantages gained with the new technology include a larger available injection volume as well as particularly fine and rapid metering of injection quan- tities due to finely tuned switching times. In combina- tion with direct actuation of the piezo inje

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Mercedes-Benz OM 651 device using right now.

(Ocr-Read Summary of Contents of some pages of the Mercedes-Benz OM 651 Document (Main Content), UPD: 18 July 2023)

-

14, Mechanical system 13 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Cylinder head General The cylinder head is made of high-strength aluminum. It is equipped with two camshafts and four valves per cylinder. The cylinder head cover is made of plastic with integrated ventilation. The cylinder head is char- acterized by the following new features: • Maximum ignition pressure of 200 bar (previously 160 bar) …

-

22, Common rail injection Combustion 21 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Piezo injectors An important component of the new Common Rail technology are the piezo injectors, which are an entirely new development. The injector needle is actu- ated directly by a piezo-ceramic actuator, instead of being moved by a hydraulic supp ort system. Compared to a conventional fuel injector, the piezo injector injects fuel into the combustion chamber more rapidly, with be…

-

24, Common rail injection Combustion 23 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Injection quantity correction Injection quantity correction consists of two proce- dures: • Main injection quantity correction • Zero quantity calibration Main injection quantity correction With main injection quantity correction, the injected fuel quantity is corrected using the oxygen sensor upstream of the catalytic c…

-

54, Special tools 53 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine Rear radial shaft sealing ring insertion tool Use For inserting rear radial shaft sealing ring of crankshaft. Part number W 651 589 01 61 00 FG 03 Set B Assembly tool Use For fixing balance shafts in place when disassembling and assembling drive gears. Part number W 651 589 02 63 00 FG 03 Set C Front radial shaft sealing ring insertion tool Use For inserting front radial shaft s…

-

55, Mercedes-Benz OM 651 Engine 54 Special tools Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Counterholder Use For fixing crankshaft belt pulley in place when loosening mounting screws. Part number W 651 589 00 40 00 FG 03 Set B P58.20-2241-00 i Note For more information on workshop equipment, commercially available tools and special tools, see the following website: http: / / gotis.aftersales.merced…

-

1, New Generation of 4-Cylinder Inline Engines, OM 651 Introduction into Service Manual Daimler AG, GSP/OI, HPC R 822, D-70546 Stuttgart Order No. 6516 1364 02 – Printed in Germany – 08/08 – This printout will not be recorded by the update service. Status: 09 / 2008 –

… -

15, Oil pan 14 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Special design features • Two-piece design • Lower section of oil pan made of plastic •Noise-optimized • Service-optimized and cost-optimized replacement parts • Bolts secured to prevent them being lost • Installation can be checked via special pins on seal Oil pan 1 Upper section of oil pan 2Seal with pins 3 Lower section of oi…

-

48, Environmental protection 47 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Emission reduction Thermal management Along with optimization of the warm-up and cooling processes, the newly designed thermal management system incorporates the following function sequences: • Maximum heating combustion • Overheating protection • Post-start phase Exhaust emissions are reduced by the extended therm al management system. The table below shows the new measures…

-

8, Overview 7 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine data Comparison Engine 646.821 EVO Engine 651.911 Difference Displacement cm 3 2,148 2,143 –0.2% Rated output kW at rpm 125 3,800 150 4,200 +20% Rated torque Nm at rpm 400 2,000 500 1,600…1,800 +25% Maximum rpm rpm 4,900 5,200 +6% Engine 646.821 EVO Engine 651.911 n Engine speed M Torque POutput – This printout will not be recorded by the update service. Status: 09 / 2008 –

… -

35, Mercedes-Benz OM 651 Exhaust system 34 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Oxidation catalytic converter The oxidation catalytic converter is part of the exhaust system and is located in the exhaust tract down- stream of the turbocharger. The ceramic body is made of highly temperature resis- tant magnesium-aluminum-alumosilicate and has several thousand sm all passages running all the way though it…

-

56, Mercedes-Benz OM 651 55 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Abbreviations AGR Exhaust gas recirculation (EGR) CAN Controller Area Network CDI Common rail Direct Injection CO Carbon monoxide CO 2 Carbon dioxide DAS Diagnosis Assistance System DPF Diesel Particulate Filter EOBD European On-Board-Diagnosis Euro NCAP European New Car Assessment Program HC Hydrocarbon HFM Hot film mass air flow sensor H 2…

-

50, Service information 49 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q New features Piezo injector The piezo injectors are marked with a 24-digit I2C code. The I2C coding permits even more accurate tuning (injection quantity and injection period) of the indi- vidual piezo injectors when new. If a piezo injector is replaced, the CDI control unit must be supplied with this coding via …

-

36, Exhaust system Combustion 35 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q DPF regeneration The exhaust back pressure increases as the soot load of the DPF increases. A sensor measures the pressure differential upstream of and downstream of the DPF and forwards this information to the engine control unit. Regeneration of the DPF is initiated when the threshold value stored …

-

26, Mercedes-Benz OM 651 Charging Combustion 25 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Dual stage turbocharging 108 Exhaust manifold 110 High-pressure turbocharger (HD-Lader) 110 / 1 HD-Lader compressor impeller 110 / 2 HD-Lader turbine wheel 111 Vacuum unit (boost pressure control flap) 112 Adjustment rod (boost pressure control flap) 113 Boost pressure control flap 120 Low-pressure turbocharger (ND-Lader) 120 / 1 ND-Lader compressor impeller 120 / 2…

-

57, Index 56 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q A Air ducting . . . . . . . . . . . . . . . . . 29 Air supply . . . . . . . . . . . . . . . . . 29 B Balance shaft . . . . . . . . . . . . . . . . 15 Belt drive . . . . . . . . . . . . . . . . . 19 Belt routing . . . . . . . . . . . . . . …

-

37, Engine cooling 36 Cooling and lubrication Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine lubrication and cooling circuit The coolant pump pumps coolant through two sepa- rate ducts. The lower duct supplies the crankcase and the oil-water heat exchanger with coolant and the upper duct supplies the cylinder head with coolant. The EGR path runs parallel to the upper duct. The following components of the EGR path are supplied with coolant: •EGR v…

-

17, Crankshaft assembly 16 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Camshafts The gear drive drives the camshaft sprockets and the connected camshafts via a timing chain. The mainte- nance free timing chain is tried and tested and has proven longevity. The cams are fixed to the camshaft by means of internal high-pressure forming (IHU). Camshaft sprocket The camshaft sprocket is connecte…

-

18, Mechanical system 17 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Valve assembly Valve assembly with hydraulic valve clearance compensation The valve assembly was modified with the aim of opti- mizing friction and reducing the moved masses. The camshafts control two intake valves and two exhaust valves per cylinder. This valve timing system uses low-friction roller-type cam followers with hydraulic valve c…

Summary of Contents:

|

[Page 1] Mercedes-Benz OM 651 New Generation of 4-Cylinder Inline Engines, OM 651 Introduction into Service Manual Daimler AG, GSP/OI, HPC R 822, D-70546 Stuttgart Order No. 6516 1364 02 – Printed in Germany – 08/08 – This printout will not be recorded by the update serv… |

|

[Page 2] Mercedes-Benz OM 651 Daimler AG · Technical Information and Workshop Equipment (GSP/OI) · D-70546 Stuttgart Mercedes-Benz Service Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 – This printout will not be recorded by the update service. Status:… |

|

[Page 3] Mercedes-Benz OM 651 Information and copyright Ordering workshop information All printed workshop information from GSP / OI, such as Introduction into Service Manuals, System Descriptions, Function Descriptions, Technology Guides, Tech- nical Data Manuals and adhesive l… |

|

[Page 4] Mercedes-Benz OM 651 3 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Contents Preface 5 Overview Brief description 6 Engine data 7 Highlights 8 Engine views 9 System comparison 10 At a glance 11 Mechanical system Crankcase 12 Cylinder head… |

|

[Page 5] Mercedes-Benz OM 651 Contents 4 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Cooling and lubrication Engine cooling 36 Engine lubrication and oil circuit 38 Oil pump 40 Coolant pump 41 Electrical and electronic systems Engine control unit 42… |

|

[Page 6] Mercedes-Benz OM 651 5 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Preface Dear Reader, This Introduction into Service Manual presents the new 4-cyli nder inline diesel engine 651 from Mercedes-Benz. It allows you to familiarize yourself with… |

|

[Page 7] Mercedes-Benz OM 651 6 Overview Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Brief description Engine model series 651 The new generation of the 4-cylinder diesel engine 651 equipped with the second-generation Common Rail Direct Injection (CDI… |

|

[Page 8] Mercedes-Benz OM 651 Overview 7 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine data Comparison Engine 646.821 EVO Engine 651.911 Difference Displacement cm 3 2,148 2,143 –0.2% Rated output kW at rpm 125 3,800 150 4,200 +20% Rated torque … |

|

[Page 9] Mercedes-Benz OM 651 8 Overview Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Highlights New features Based on the use of the latest innovative technologies, engine 651 sets a new standard in terms of output and torque characteristics, economy,… |

|

[Page 10] Mercedes-Benz OM 651 Overview 9 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine views Engine 651: Side view from right Engine 651: Side view from left – This printout will not be recorded by the update service. Status: 09 / 2008 – |

|

[Page 11] Mercedes-Benz OM 651 10 Overview Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q System comparison Comparison Engine 646.821EVO C 220 CDI Engine 651.911 C 250 CDI Market launch 06 / 2006 10 / 2008 Combustion system Diesel direct injection No. of cy… |

|

[Page 12] Mercedes-Benz OM 651 Overview 11 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q At a glance Objective Measures on engine 651 Optimized comfort Stiffer crankcase with full-length crankshaft bearing bridge Wide crankshaft main bearing; friction-opt… |

|

[Page 13] Mercedes-Benz OM 651 Crankcase 12 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q General When engine 651 was developed, the design of the crankcase was based on an overall concept with opti- mized spatial features. Accordingly, … |

|

[Page 14] Mercedes-Benz OM 651 Mechanical system 13 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Cylinder head General The cylinder head is made of high-strength aluminum. It is equipped with two camshafts and four valves per cylinder. The cylinder head… |

|

[Page 15] Mercedes-Benz OM 651 Oil pan 14 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Special design features • Two-piece design • Lower section of oil pan made of plastic •Noise-optimized • Service-optimized and cost-optimized … |

|

[Page 16] Mercedes-Benz OM 651 Mechanical system 15 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Crankshaft assembly Crankshaft The forged crankshaft with eight counterweights is supported by five bearings for effective vibration damping. The radiuses of… |

|

[Page 17] Mercedes-Benz OM 651 Crankshaft assembly 16 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Camshafts The gear drive drives the camshaft sprockets and the connected camshafts via a timing chain. The mainte- nance free timing chai… |

|

[Page 18] Mercedes-Benz OM 651 Mechanical system 17 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Valve assembly Valve assembly with hydraulic valve clearance compensation The valve assembly was modified with the aim of opti- mizing friction and reducing t… |

|

[Page 19] Mercedes-Benz OM 651 Gear drive 18 Mechanical system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Gear drive One of the most important innovations is the gear drive in combination with a chain drive on the output side. The reduction in the vib… |

|

[Page 20] Mercedes-Benz OM 651 Mechanical system 19 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Belt drive Belt routing The ancillary assemblies are driven by a single-piece, low-maintenance poly-V belt. The poly-V belt is tensioned by an automatic bel… |

|

[Page 21] Mercedes-Benz OM 651 Common rail injection 20 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Injection technology Engine 651 uses the new Common Rail technology of the second generation from Delphi. The maximum injection pressure has… |

|

[Page 22] Mercedes-Benz OM 651 Common rail injection Combustion 21 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Piezo injectors An important component of the new Common Rail technology are the piezo injectors, which are an entirely new development. The … |

|

[Page 23] Mercedes-Benz OM 651 Common rail injection 22 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Advantages of the new injection technology The advantages gained with the new technology include a larger available injection volume as well a… |

|

[Page 24] Mercedes-Benz OM 651 Common rail injection Combustion 23 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Injection quantity correction Injection quantity correction consists of two proce- dures: • Main injection quantity correction • Zero quant… |

|

[Page 25] Mercedes-Benz OM 651 Charging 24 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q General With engine 651, Mercedes-Benz has continued the development of dual stage turbocharging in its 4-cylinder inline diesel engines in a passenger … |

|

[Page 26] Mercedes-Benz OM 651 Charging Combustion 25 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Dual stage turbocharging 108 Exhaust manifold 110 High-pressure turbocharger (HD-Lader) 110 / 1 HD-Lader compressor impeller 110 / 2 HD-Lader turbine … |

|

[Page 27] Mercedes-Benz OM 651 Charging 26 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Boost pressure control during wide open throttle operation up to 1,200 rpm The boost pressure control flap (LRK) is almost closed up to an engine speed of … |

|

[Page 28] Mercedes-Benz OM 651 Charging Combustion 27 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Boost pressure control during wide open throttle operation between 1,200 and 2,800 rpm As of an engine speed of 1,200 rpm during wide open throttle operati… |

|

[Page 29] Mercedes-Benz OM 651 Charging 28 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Boost pressure control during wide open throttle operation as of 2,800 rpm The LRK is fully open as of an engine speed of 2,800 rpm. This causes almost th… |

|

[Page 30] Mercedes-Benz OM 651 Air supply Combustion 29 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Air ducting The hot film mass air flow sensor (HFM) is located in the clean air line downstream of the air filter housing. It determines the mass and te… |

|

[Page 31] Mercedes-Benz OM 651 Air supply 30 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Intake port shutoff The intake port shutoff (EKAS) function ensures the best possible ratio between air mixing and air mass in all engine load condition… |

|

[Page 32] Mercedes-Benz OM 651 Air supply Combustion 31 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Throttle valve The throttle valve actuator uses the throttle valve to influence the air volume fed to the engine and the mixing ratio of charge air and … |

|

[Page 33] Mercedes-Benz OM 651 Exhaust system 32 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Exhaust gas recirculation The exhaust system of engine 651 combines two tech- nologies for emission reduction. Exhaust gas recircu- lation (EGR) reduc… |

|

[Page 34] Mercedes-Benz OM 651 Exhaust system Combustion 33 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Exhaust gas recirculation path Part of the exhaust gas enters the exhaust gas recircu- lation system via the exhaust manifold. The EGR path is made up… |

|

[Page 35] Mercedes-Benz OM 651 Exhaust system 34 Combustion Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Oxidation catalytic converter The oxidation catalytic converter is part of the exhaust system and is located in the exhaust tract down- stream of the… |

|

[Page 36] Mercedes-Benz OM 651 Exhaust system Combustion 35 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q DPF regeneration The exhaust back pressure increases as the soot load of the DPF increases. A sensor measures the pressure differential upstream of a… |

|

[Page 37] Mercedes-Benz OM 651 Engine cooling 36 Cooling and lubrication Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine lubrication and cooling circuit The coolant pump pumps coolant through two sepa- rate ducts. The lower duct supplies the crankcase… |

|

[Page 38] Mercedes-Benz OM 651 Cooling and lubrication 37 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine cooling Cooling circuit 1 Coolant pump 2 Oil / water heat exchanger 3Crankcase 4 Cylinder head 5 Coolant collector 6Chain case housing 7 Bypass… |

|

[Page 39] Mercedes-Benz OM 651 Engine lubrication and oil circuit 38 Cooling and lubrication Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Lubricating system The engine lubrication system minimizes the mechan- ical friction and thus the wear on moving par… |

|

[Page 40] Mercedes-Benz OM 651 Cooling and lubrication 39 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine lubrication and oil circuit Oil circuit 1 Oil pan 2 Prefilter 3 Oil pump (volume-controlled) 4 Pressure limiting valve 5 Pressure differential v… |

|

[Page 41] Mercedes-Benz OM 651 Oil pump 40 Cooling and lubrication Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Oil pump The oil pump is volume-controlled at the clean oil side and has a rotary vane design. The control pressure is 4.7 bar. The oil pump … |

|

[Page 42] Mercedes-Benz OM 651 Cooling and lubrication 41 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Coolant pump Coolant pump The coolant pump ensures that the coolant circulates in the coolant circuit. It is made of plastic, which makes a contributi… |

|

[Page 43] Mercedes-Benz OM 651 Engine control unit 42 Electrical and electronic systems Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q CDI control unit The CDI control unit is located on the air filter housing. The CDI control unit is equipped with cooling… |

|

[Page 44] Mercedes-Benz OM 651 Electrical and electronic systems 43 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Glow system Instant Start System The electronically controlled Instant Start System consists of a glow output stage and four ceramic glow p… |

|

[Page 45] Mercedes-Benz OM 651 Vacuum control 44 Pneumatic system Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Vacuum control The vacuum pump is driven indirectly via the oil pump drive. It generates vacuum pressure and is connected to the vacuum system… |

|

[Page 46] Mercedes-Benz OM 651 Pneumatic system 45 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Vacuum control Vacuum system shown on engine 651.911 ➡ Travel direction arrow aAmbient pressure 7 Cylinder head 8 Vacuum pump 9 Coolant pump 10 EGR cooler … |

|

[Page 47] Mercedes-Benz OM 651 Emission reduction 46 Environmental protection Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Emission reduction measures The wide range of new technical features used in the development of engine 651 have made it possible to… |

|

[Page 48] Mercedes-Benz OM 651 Environmental protection 47 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Emission reduction Thermal management Along with optimization of the warm-up and cooling processes, the newly designed thermal management system inco… |

|

[Page 49] Mercedes-Benz OM 651 New features 48 Service information Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Dual stage turbocharging The vacuum units of the turbocharger can be replaced individually with the turbocharger installed. Attention must be … |

|

[Page 50] Mercedes-Benz OM 651 Service information 49 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q New features Piezo injector The piezo injectors are marked with a 24-digit I2C code. The I2C coding permits even more accurate tuning (injection quantity… |

|

[Page 51] Mercedes-Benz OM 651 Engine 50 Special tools Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q l Socket wrench Use For removing shift valve for controlling piston cooling. Part number W 651 589 00 09 00 FG 18 Set B Hold-down device Use Fixing camsha… |

|

[Page 52] Mercedes-Benz OM 651 Special tools 51 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine Leak test adapter Use For leak testing charge air system. Part number W 651 589 02 91 00 FG 09 Set B Counterholder Use For holding pinion of high-pressure … |

|

[Page 53] Mercedes-Benz OM 651 Engine 52 Special tools Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q 3-pin adapter cable Use For testing Hall sensor on camshaft. Part number W 651 589 01 63 00 FG 15 Set B 5-pin adapter cable Use For testing resistances and… |

|

[Page 54] Mercedes-Benz OM 651 Special tools 53 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Engine Rear radial shaft sealing ring insertion tool Use For inserting rear radial shaft sealing ring of crankshaft. Part number W 651 589 01 61 00 FG 03 Set B A… |

|

[Page 55] Mercedes-Benz OM 651 Engine 54 Special tools Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Counterholder Use For fixing crankshaft belt pulley in place when loosening mounting screws. Part number W 651 589 00 40 00 FG 03 Set B P58.20-2241-00 i… |

|

[Page 56] Mercedes-Benz OM 651 55 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Abbreviations AGR Exhaust gas recirculation (EGR) CAN Controller Area Network CDI Common rail Direct Injection CO Carbon monoxide CO 2 Carbon dioxide DAS Diagnosis Assistance S… |

|

[Page 57] Mercedes-Benz OM 651 Index 56 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q A Air ducting . . . . . . . . . . . . . . . . . 29 Air supply . . . . . . . . . . . . . . . . . 29 B … |

|

[Page 58] Mercedes-Benz OM 651 57 Introduction of New Generation of 4-Cylinder Inline Engines, OM 651 q Index L Lubricating system . . . . . . . . . . . . . 38 M Main injection quantity correction . . . . . . 23 N Number of cylinders … |