-

Page 1: Operating Instructions

MINI EXCAVATOR MODELS KX057-4 U48-4 U55-4 OPERATING INSTRUCTIONS RG948-8135-6 — Original — 07/2014…

-

Page 2

This documentation does neither extend nor restrict the contractual warranty. KUBOTA Baumaschinen GmbH reserves the right to change the information contained in this document with re- spect to future technical development without altering the basic characteristics of the excavators described herein and without amending this document. -

Page 3: Table Of Contents

Hoisting the excavator with a crane ………………….33 Transport on a flat bed trailer ……………………35 Description of the excavator ………………….37 Model overview ……………………….37 Model KX057-4, U48-4 and U55-4 ………………… 37 Dimensions………………………… 38 Dimensions KX057-4, U48-4 and U55-4……………….. 38 Specifications ……………………….40 Identification of the excavator……………………

-

Page 4

Wiper/washer system……………………51 Interior lighting ……………………..51 Fuse box ……………………….51 Tool compartment (KX057-4)………………….52 Tool compartment (U48-4 and U55-4) ………………… 52 Main battery……………………….52 Battery cut-off switch …………………….. 53 Cup holder ……………………….53 Tank filler neck and fill level monitor………………..53 Tank filler neck and fill level monitor with suction pump (optional only KX057-4)…… -

Page 5

Tables Safety instructions for starting the engine ………………..70 Starting the engine ……………………..71 Stopping the engine ……………………… 72 Observation of the displays after starting and during operation …………73 Driving the excavator ……………………. 75 Driving………………………… 76 Turning ……………………….77 During driving …………………….. -

Page 6

Tables Emergency stop functions ……………………106 Engine stop knob……………………..106 Manual lowering of the front attachments………………106 Filling up the washer system ……………………. 107 Refuelling the excavator ……………………107 Refuelling the excavator equipped with optional suction pump (only KX057-4)……. 108 Refuelling the excavator using the optional suction pump (optional only KX057-4)…… -

Page 7

Accessories ……………………..174 KUBOTA Rotary beacon ……………………174 KUBOTA Pipe safety valve ……………………174 Note on use……………………..175 KUBOTA Quick coupling systems and equipments …………….175 KUBOTA Bucket accessories…………………… 175 Replacing the bucket……………………175 Remove the bucket……………………176 Install the bucket……………………..177… -

Page 8: Abbreviations

Tables Abbreviations percent kilogramme ° degrees km/h kilometre per hour °C degree Celsius kilonewton 1/min revolutions per minute kilovolt Ampere kilowatt acc. according litre American Petroleum Institute L/min litres per minute approx. approximately sound pressure level operator’s place ASTM American Society for Testing and Materials measured sound power level metre CECE…

-

Page 9: General Symbols

Tables General symbols Warning light Swivel boom (left) Fuel indicator Swivel boom (right) Engine oil indicator Dozer up Charge indicator Dozer down Glow indicator Control lever direction Hydraulic oil Control lever direction Travel speed Rotary beacon Low speed Display selector switch Forward travel Auxiliary port enable switch Backward travel…

-

Page 10

Tables Overvoltage indicator Key indicator Anti-theft system fault indicator Wrong key indicator Insert key indicator Registration mode complete indicator Pull out key indicator Registration mode indicator Key registration indicator No overload warning indicator Voltage supply indicator 5 V Overload warning indicator Voltage supply indicator 12V Raise control lever lock indicator Lower control lever lock indicator… -

Page 11: General Information

General information Foreword These operating instructions apply only for the KUBOTA excavator models KX057-4, U48-4 and U55-4 complying with the following EC declaration of conformity (page 11). Safety instructions, the rules and regulations for the use of excavators given in these operating instructions apply to the excavators mentioned in this documentation.

-

Page 12: Date Of Issue Of The Operating Instructions

General information Date of issue of the operating instructions The date of issue of the operating instructions is printed on the bottom right of the front page of the book. Operating personnel The duties of personnel with respect to operation, servicing, repairs and safety inspections must be set forth clearly by the owner.

-

Page 13: Spare Parts

General information Spare parts Genuine spare parts can be ordered from KUBOTA dealers by stating the model and the serial # of the excavator. The item numbers for the spare parts are indicated in the spare parts catalogue.

-

Page 14: Safety Rules

Safety rules Safety rules Basic safety instructions The EC machine utilization directive (2009/104/EC) dated 16/09/2009 applies for the operation of the afore- mentioned excavator. The information in these operating instructions applies for maintenance and repairs. National rules and regulations apply where applicable. Duties, liability and warranty A basic requisite for the safe handling and problem-free operation of the excavator is the knowledge of the safety instructions and safety regulations.

-

Page 15: Safety Symbols

Safety rules The owner must ensure at his own responsibility that the safety rules are observed (page 14), unapproved use (page 16) and unauthorised operation are excluded and the approved use (page 16) is ensured and the excavator is operated in accordance with the contractual con- ditions of use.

-

Page 16: Approved Use

Safety rules Approved use The excavators specified in this operator’s manual may only be used for to loose the ground, excavating, picking up, transporting and dumping soils, rocks and other materials, for work with the dozer or with a breaker. The load may be transported largely without driving the excavator.

-

Page 17: Special Duties Of The Owner

Disposal must be undertaken in an appropriate way, according to legally prescribed pollution control and safety regulations. If you have questions about the correct disposal or storage of refuse and toxic waste, contact your KUBOTA dealer or a local waste management contractor.

-

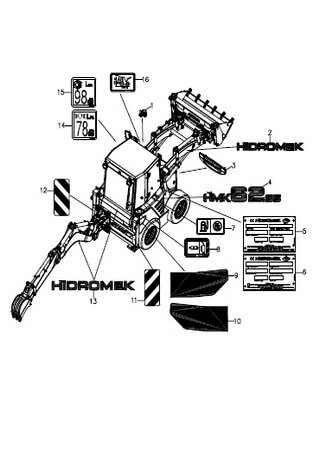

Page 18: Safety Labels On The Excavator

Safety rules Safety labels on the excavator Keep the safety and warning symbols (labels) on the excavator clean and legible, replacing them if necessary. The positioning of the safety symbols is illustrated in the following figures. Code #: 69198-5722-0 (both sides) Do not enter the swing area.

-

Page 19

Safety rules Code #: RG109-5796-0 Not an attachment point for lifting gear. Code #: RD809-5725-0 Do not enter the manoeuvring area. Code #: TA040-4958-0 Do not touch hot parts, such as exhaust muffler, etc. Code #: RC418-5737-0 Keep away from fan and V-belt. -

Page 20

Safety rules Code #: RD809-5733-0 (both sides) Use the attachment point only for clamping the excavator securely to a transport vehicle. Code #: RD809-5795-0 (both sides) For information about loosening the crawler, consult the operating instructions. Code #: RD809-5714-0 Emergency exit. -

Page 21

Safety rules Code #: RB419-5793-0 Risk of injury through windshield getting out of place. Always lock the windshield. Code #: RD809-5743-0 Caution: Always fasten the seat belt to avoid an increased risk of injury. Code #: 69198-5784-0 Attention: Read the operating instructions and make sure that the instructions have been under- stood before starting or operating the excavator. -

Page 22

Safety rules Code #: RA028-5724-0 Radiator: Risk of burns. Code #: RB238-5736-0 Diesel fuel only, no open fire. Code #: RD451-5748-0 Fill level monitor when refuelling. -

Page 23

Safety rules Code #: RD359-5726-0 Operation of the suction pump. (Optional KX057-4) Code #: RD809-5745-0 Do not touch hot parts, such as exhaust muffler, etc. -

Page 24

Safety rules 20) Code #: RD359-5747-0 KX057-4 20) Code #: RD459-5747-0 U48-4 20) Code #: RD559-5747-0 U55-4… -

Page 25

Safety rules 21) Code #: RH849-5749-0 Risk of accidents by exceeded load when lifting! When exceeding the nominal load, a beep sounds and a warning light illuminates. Turn on overload warning function before starting a lifting opera- tion! -

Page 26: Safety Devices

Safety rules Safety devices Before starting the excavator, all safety devices must be installed properly and operational. No manipulation of safety devices, e.g. the shorting of limit switches, is allowed. Protective devices may only be removed after the excavator is standing still and the engine is stopped and secured against restarting (starter switch in STOP position and key removed).

-

Page 27: Protective Structure Canopy And Cab

The seat belt must be fastened while the excavator is being operated. Do not make any structural changes to the protective structure. In the event of damage, please contact your KUBOTA dealer. (Do not repair!) Never operate the excavator without the protective structure.

-

Page 28: Pipe Safety Valve

Any manipulation can result in substantial personal injuries, even death, and is therefore strictly for- STOP bidden. The manipulation and repair of the pipe safety valves is forbidden. They may only be replaced by your KUBOTA dealer as a kit. Overload warning function An overload warning function informs the operator immediately if there is an overload.

-

Page 29: Hazards Coming From The Hydraulic System

Safety rules Hazards coming from the hydraulic system If hydraulic oil gets into the eyes, rinse them immediately with clear water and subsequently seek medical aid. Do not allow hydraulic oil to contact the skin or clothing. Skin parts which may have come in contact with hydraulic oil must be washed with water and soap immediately, if possible.

-

Page 30

Safety rules A fire extinguisher is not included in the basic equip- ment of the machine. -

Page 31: Recovery, Loading And Transport

Recovery, loading and transport Recovery, loading and transport Safety rules for recovery For recovery of the excavator, a towing vehicle of at least the same weight class as the excavator must be used. A tow bar must be used for the recovery. If a tow rope is used, an additional vehicle to brake the excavator must also be attached.

-

Page 32: Safety Rules For Transport

Recovery, loading and transport Safety rules for transport The ramps must have a sufficient load capacity for bearing the weight of the excavator. They must be placed securely on the transport vehicle and fastened. Support the loading area at the rear of the transport vehicle with sufficiently dimensioned supports. The ramps must be wider than the track of the excavator and have footboards on the side.

-

Page 33: Recovery

1 (mm) l 2 (mm) Bring the boom in line with the longitudinal axis of the swivel KX057-4 < 51 1680 4280 frame. U48-4 < 55 1250 3770 U55-4 < 57 1150 3805 Completely extend the boom cylinder, arm cylinder and bucket cylinder.

-

Page 34

Recovery, loading and transport Attach the lifting gear with shackles to the lifting eyes (1) on each side of the dozer. Attach the lifting gear with shackles to the lifting eyes (1) on each side of the boom. As soon as the lifting gear is attached to the excavator, press cloths between lifting gear and excavator to protect the excavator. -

Page 35: Transport On A Flat Bed Trailer

Recovery, loading and transport Transport on a flat bed trailer Adhere to the safety rules (page 14) and the safety STOP rules for transport (page 32). Place the loading ramps on the transport vehicle at an angle of 10° to 15°. Observe the track width. Safely attach the ramps to the transport vehicle to make sure they cannot slide while driv- ing upwards.

-

Page 36

Recovery, loading and transport For safe attachment, fully crowd the arm and bucket and lower the boom until the bucket linkage touches the loading area. Secure the chains and the dozer with beams (2). Secure the excavator against sliding on the transport vehicle with chocks or chains (1) (note the vehicle weight). -

Page 37: Description Of The Excavator

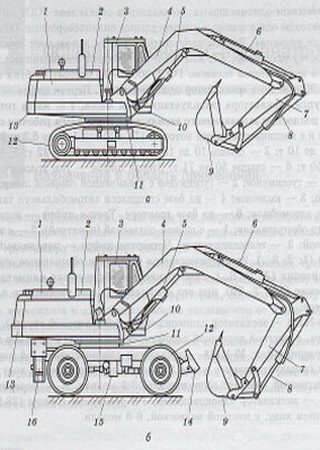

Description of the excavator Description of the excavator Model overview The excavator is available in three models KX057-4, U48-4 and U55-4. Model KX057-4, U48-4 and U55-4…

-

Page 38: Dimensions

Description of the excavator Dimensions The dimensions of the models KX057-4, U48-4 and U55-4 can be found in the following illustrations including ta- bles. Dimensions KX057-4, U48-4 and U55-4…

-

Page 39

Description of the excavator All dimensions in mm with original KUBOTA bucket and rubber crawlers KX057-4 1960 5820 4160 3890 3070 1270 4250 6260 1960 5665 4005 3630 2830 1270 4235 6025 2550 1960 6130 5520 1830 2420 2550 1960… -

Page 40: Specifications

Description of the excavator Specifications Following are the specifications for these series. KUBOTA Excavator Model name KX057-4 Type Rubber crawler Steel crawler Machine weight* 5470 5570 Operating weight** 5545 5645 Volume (SAE/CECE) m³ 0.17/0.15 Bucket (KUBOTA) Width with teeth Water-cooled four-cylinder…

-

Page 41

Description of the excavator KUBOTA Excavator Model name U48-4 Type Rubber crawler Steel crawler Machine weight* 4700 4800 Operating weight** 4775 4875 Volume (SAE/CECE) m³ 0.14/0.12 Bucket (KUBOTA) Width with teeth Water-cooled four-cylinder die- Type sel engine Model name KUBOTA V2607-DI-E3-BH… -

Page 42

Description of the excavator KUBOTA Excavator Model name U55-4 Type Rubber crawler Steel crawler Machine weight* 5325 5425 Operating weight** 5400 5500 Volume (SAE/CECE) m³ 0.16/0.13 Bucket (KUBOTA) Width with teeth Water-cooled four-cylinder Type diesel engine Model name KUBOTA V2607-DI-E3-BH… -

Page 43: Identification Of The Excavator

Description of the excavator Identification of the excavator The type plate of the excavator is located at the front of the swivel frame. The owner should enter the stamped data in the field on the back of the front cover. CE marking Serial # Max.

-

Page 44: Engine Number

Description of the excavator Engine number The engine number (1) is affixed to the engine block. Equipment The standard equipment of the excavator can be enhanced by optional equipment (accessories). Standard equipment This model has the following standard equipment: Operating instructions with protective cover Spare parts catalogue Filter wrench Grease gun…

-

Page 45: Assembly And Functions

Assembly and functions Assembly and functions Component overview Swivel frame Boom cylinder Track frame Bucket Rear view mirror Bucket linkage Operator’s place Auxiliary port connectors Cab door Bucket cylinder tank filler neck Drive sprocket Arm cylinder Crawler Boom Idler Working light (boom) Dozer Working lights (cab) Dozer cylinder…

-

Page 46: Operator’s Place

Assembly and functions Operator’s place The operator’s place is located in the middle of the cab. It includes the following control elements: Left control console Drive levers and control pedals Right control console Operator’s seat Left control console The left control console includes the following components: Control lever lock Rocker switch for the auxiliary port 2 Wrist rest…

-

Page 47: Drive Levers And Control Pedals

Assembly and functions Left control lever The left control lever is used to move the swivel frame and the arm. The figure, in conjunction with the following table, shows the functions of the left control lever. Position of control lever Movement Arm crowd Arm dump Swivel frame to the left…

-

Page 48: Right Control Console

Assembly and functions Right control console The right-hand control console contains the following components: Rocker switch for the auxiliary port 1 One way hold switch Travel speed button Dozer control lever Starter switch Potentiometer for the adjustment of the engine speed Heating and air-conditioner control (optional) Wiper/washer switch Engine stop knob…

-

Page 49

Assembly and functions Starter switch The starter switch serves as the master switch for the entire machine and as switch for pre-glowing and start- ing the engine. Potentiometer for the adjustment of the engine speed The operator can use this potentiometer to set the engine RPM to any desired speed. Heating and air-conditioner control (optional) Operate the heater and the air-conditioner using the heating and air-conditioner control (optional). -

Page 50: Display And Control Unit — Description

Assembly and functions Display and control unit — description The display and control unit’s switches are multifunctional and are also used to navigate the display menu. You will find detailed descriptions of the individual functions in the respective chapters. Menu button The menu button activates the navigation function for the display menu.

-

Page 51: Other Equipment To Be Found At The Machine

Assembly and functions Other equipment to be found at the machine Other equipment located at and around the machine is described below. Wiper/washer system The front window is provided with a wiper/washer system. The sys- tem is operated with the wiper/washer switch (1). Interior lighting An interior light (1) is located on the left side of the cab roof.

-

Page 52: Tool Compartment (Kx057-4)

The tool compartment (1) is located on the right-hand side of the ve- hicle before the side cover. Tool compartment (U48-4 and U55-4) The tool compartment (1) is located on the right-hand side of the ve- hicle under the side cover.

-

Page 53: Battery Cut-Off Switch

Assembly and functions Battery cut-off switch The battery cut-off switch (1) can be used to cut off the main power circuit. The battery cut-off switch is on the right vehicle side under the side cover. Cup holder There is a cup holder (1) in the right control console. Tank filler neck and fill level monitor The tank filler neck (1) is located at rear left-hand side (not if option- al suction pump is equipped, page 54) and it closed with a lockable…

-

Page 54: Tank Filler Neck And Fill Level Monitor With Suction Pump (Optional Only Kx057-4)

Assembly and functions Tank filler neck and fill level monitor with suction pump (optional only KX057-4) The excavator can be equipped with an optional suction pump (2). With this equipment, the suction pump, the tank filler neck (3) and the fill level monitor (1) are located below the left service cover (4) (only if equipped with optional suction pump).

-

Page 55

Assembly and functions The air is drawn in through the cabin filter (1) as fresh air via the air intake to the right of the cabin (3) or as recirculated air in the cabin. With the lever (21) the air intake can be switched between recircu- lated air (A) and fresh air (B). -

Page 56: Engine Compartment

Assembly and functions Engine compartment The engine compartment (figure below) is positioned at the rear of the swivel frame; it is covered by a lockable hinged cover. Air filter Oil dipstick Fuel injection pump Oil filler opening Filter indicator Starter Engine Fuel filter Coolant expansion reservoir…

-

Page 57: Hydraulic System

Assembly and functions Hydraulic system All controls enable the functions via a hydraulic oil pilot control circuit. The accumulator allows the boom and the arm to be lowered in case of an engine failure. The hydraulic oil tank contains the suction filter and the return filter. Using the return change valve for the auxiliary port you can activate a direct return flow to the hydraulic oil tank while auxiliary port 1 is in operation.

-

Page 58: Operation

Operation Operation Safety rules for operation The safety instructions (page 14) must be followed. The excavator may only be operated according to its approved use (page 16). The excavator may only be operated by trained personnel (page 12). Do not operate the excavator when under the influence of drugs, medication or alcohol. Stop operation when getting tired.

-

Page 59: Safety For Children

Operation Safety for children Children are normally attracted to machines and their normal operation. If children are in the vicinity of the machine and are not at a suitable distance and in the field of vision of the operator, this can STOP lead to serious accidents or even death of the children.

-

Page 60: Working In The Vicinity Of Overhead Power Lines

Operation Working in the vicinity of overhead power lines When working with the excavator in the vicinity of overhead power lines and tram lines, a minimum distance as specified in the following table must be maintained between the excavator and its attachments and the power line. Rated voltage [V] Safe distance [m] up to 1 kV…

-

Page 61: Initial Operation

Operation Initial operation Before initial operation, the excavator must first be checked visually for external transit damages and checked if the shipped equipment is complete as ordered. Check fluid levels as described in the «Maintenance» section (page 126). For a description of all operation features refer to the «Operating the excavator» section (page 64) as well as the following sections.

-

Page 62: Setting The Time

Operation Setting the time Turn the starter switch to the RUN position. Press button 1. The user menu appears in the display. Press button 2 or 3 until «Clock Set» is selected in the display. Press button 5 to confirm. Date and time appear in the display.

-

Page 63: Date And Time Display Format

Operation Date and time display format Time can be displayed in the 12- or 24-hour format, while the date format can be changed to day, month, year. Turn the starter switch to the RUN position. Press button 1. The user menu appears in the display. Press button 2 or 3 until «Various Settings»…

-

Page 64: Running-In Of The Excavator

Operation Running-in of the excavator During the first 50 hours of operation, the following points should be adhered to in all cases: Warm up the excavator at an average engine speed and with a low load; do not let it warm up at idling position. Do not overload the excavator.

-

Page 65: Checking The Coolant Level

Operation Checking the coolant level Check the coolant level in the expansion reservoir (1). The fluid level must be between FULL and LOW. Do not open the radiator cap. STOP If the coolant level is below the LOW mark, refill cool- ant (page 131).

-

Page 66: Checking The V-Belts

Operation Checking the V-belts The engine must be switched off and the key removed! STOP Do not attempt to grasp rotating or moving parts. Press in the V-belt (1) at position «A»; the belt must give way for 7 to 9 mm (at a pressure of 6 to 7 kg). Adjust the V-belts if nec- essary (page 133).

-

Page 67: Checking The Oil Level Of The Hydraulic System

Operation Checking the oil level of the hydraulic system Operate the boom, arm, bucket and boom swing mechanism so that all hydraulic cylinders are extended half way. Lower the dozer onto the ground. See the «Placing out of operation» section (page 97). Check the oil level in the sight glass (1).

-

Page 68: Checking The Electric Cables And Connections

Operation Checking the electric cables and connections Check all accessible electric cables, connectors and connections for condition and security. Repair or replace damaged parts. Check the fuse box and fuse holders for oxidation and dirt, clean if necessary. Checking fuel level, coolant temperature and time The following function can be carried out when the key is not in the starter switch.

-

Page 69: Adjusting The Operator’s Seat

Operation Adjusting the operator’s seat Adjust the operator’s seat so that fatigue-free and comfortable working is possible. It should be pos- sible to operate all controls safely. Horizontal seat adjustment (seat stand-off) Pull the horizontal seat adjustment lever (4) up and move the seat to the desired position by moving it forward or back, then release the lever.

-

Page 70: Seat Belt

Operation Seat belt Buckle up (figure above/1). Check that the seat belt is fastened tightly. Do not operate the excavator without the seat belt fastened. STOP Rear view mirrors adjustment Check the adjustment of the rear view mirrors. If necessary, adjust the mirrors until the optimum sight is en- sured.

-

Page 71: Starting The Engine

Operation Starting the engine Place the potentiometer (1) to the centre position between . The AUTO IDLE switch (2) is switched off. The indicator does not light up. Insert the key into the starter switch (3) and turn it to the RUN position.

-

Page 72: Stopping The Engine

Operation Turn the starter switch to the START position and hold it there until the engine has started. Release the starter switch. Lower the left control console and make sure that the control lever lock engages. Let the engine run at middle speed until the operating temperature has been reached. After the engine has reached its operating temperature, set the engine speed required for operation: Move the potentiometer towards until the engine reaches the required speed.

-

Page 73: Observation Of The Displays After Starting And During Operation

Operation Observation of the displays after starting and during operation The operator must observe the display indicators and displays after starting and during operation. The warning light (1) flashes red when a system fault or technical malfunction occurs. Stop the engine im- mediately! The warning light flashes yellow when the system issues a warning.

-

Page 74

Operation If the coolant temperature is too high, cool down the engine by changing into idle. The display message as in the figure on the right appears. Allow the machine to idle for five minutes before switching off the engine! Check the level of the coolant in the expansion tank. -

Page 75: Driving The Excavator

Operation Also stop the engine immediately if the engine speed rises or drops suddenly, abnormal noises are heard, the excavating devices do not respond to the control lever as expected or the exhaust fumes are black or white. When the engine is still cold, white smoke for a short time is normal. Driving the excavator Adhere to the general safety rules (page 14) and the safety rules for operation (page 58).

-

Page 76: Driving

Operation Approach overhangs and edges of ditches carefully as they could cave in. Drive slowly downhill, do not allow the vehicle speed to in- crease uncontrollably. Close the cab door. When driving, the bucket should be approx. 200 to 400 mm (A) over the ground (see figure).

-

Page 77: Turning

Operation Two audible signals will sound and the indicator (1) will come up. Pressing the travel speed button again switches back to normal speed and only one signal will sound. Do not drive fast on muddy or uneven terrain, also if another control is operated (e.g. turning the swiv- STOP el frame).

-

Page 78: From A Standing Position

Operation From a standing position Leave the right drive lever in neutral, push the left drive lever forward. In this case, the turning radius is determined by the right track. (A) The excavator makes a right turn. Turning on the spot Do not make a turn on the spot with the travel speed STOP button actuated.

-

Page 79: Driving Uphill And Downhill

Operation Driving uphill and downhill Exercise extreme caution when driving up and down a STOP slope. Do not use the travel speed button. When driving on gradients, raise the bucket approx. 200 to 400 mm (A) above the ground (see figure). When driving on gradients, let the bucket slide over the ground if the terrain allows it.

-

Page 80: Making Sharp Turns

Operation Making sharp turns On streets with a high-friction tarmac, e.g. concrete, do not make sharp turns. Protecting the crawler against salt Do not work with the machine on the seashore. (The salt will cause the steel insert to corrode.) Operating the controls during excavation work Always observe the following safety instructions when working with the excavator.

-

Page 81: Note On Using Wider And Deeper Buckets

Operation Note on using wider and deeper buckets When using a wider or deeper bucket, take good care when swinging or retracting the front attachments to make sure that the bucket does not hit the cab. Operating the dozer When working with the dozer, operate both drive le- vers with the left hand and the dozer control lever with the right hand.

-

Page 82: Overview Of Control Lever Functions (Standard Setting)

Operation Overview of control lever functions (standard setting) The figure shows, in connection with the following table, the func- tions of the left and right control levers. Control lever Movement Right control lever Lower boom Raise boom Bucket crowd Bucket dump Left control lever Arm crowd Arm dump…

-

Page 83: Operating The Arm

Operation Operating the arm To dump the arm, push the left control lever forward (figure/ ). To crowd the arm, pull the left control lever back (figure/ ). The arm moves as shown in the figure.

-

Page 84: Operating The Bucket

Operation Operating the bucket To crowd (digging) the bucket, move the right control lever to the left (figure/ ). To dump (empty) the bucket, move the right control lever to the right (figure/ ). When crowding the bucket, take care that the teeth do not hit the dozer.

-

Page 85: Swivelling The Swivel Frame

Operation Swivelling the swivel frame No person is allowed to stand in the swivel area during STOP the movement. Swivel carefully to avoid any contact of the front at- tachments with adjacent objects. To turn anticlockwise, move the left control lever to the left (fig- ure/ ).

-

Page 86: Operating The Auxiliary Ports

Operation Operating the auxiliary ports Implements are operated using the auxiliary ports. Only implements approved by KUBOTA may be used. The implements must be operated in accord- STOP ance with the operating instructions supplied with them. With the use of a breaker or another attachment for demolition work, where material (e.g. asphalt) is…

-

Page 87: Auxiliary Port 1

Operation Auxiliary port 1 The following figure illustrates the auxiliary port 1 and auxiliary port 1 rocker switch (3) connectors. The proportional control enables you to smoothly con- trol the implement speed. Example: If you move the rocker switch half a turn to the left, the implement moves at half speed.

-

Page 88: One Way Hold Operation

Operation One way hold operation For one way hold operation, the return change valve has to be set to the direct return flow position (page 94). Activate the operation setting for the «one way flow». Switching on Briefly push the one way hold switch (1). The oil flows on one side to auxiliary port 1 (2) on the left side of the arm.

-

Page 89

Operation Select the mode of operation Mode 0 Mode 1 Mode 2 Mode 3 Auxiliary port not active Flow rate index Icon Flashing Flashing Flashing Auxiliary port enable switch Flow in one direction Auxiliary port 1 Not active Max. flow rate Limited flow volume (oil to connector 2 only) Auxiliary port 2… -

Page 90: Flow Rate Setting

Operation Flow rate setting Suppose the same implement has to be attached to a different excavator. Even when using identical flow rate set- tings for the other excavator, the working speed may differ. For each excavator, you need to individually adjust the flow rate settings.

-

Page 91

Operation You can select the following symbols: Auxiliary port (default) Brush cutter Rotary grapple Grapple Auger Dipper bucket Breaker Tilt bucket Deactivated There is no relationship between the icons and the flow control settings. Select icons to suit the images of at- tachments to be connected. -

Page 92

Operation Press button 1 to complete the settings and return to the normal display. It is possible that some implements will not be activated even when the bar graph is not at its lowest level. Even when the bar graphs are at the same height, it is possible that the implements will not operate identically. -

Page 93

Operation Setting the maximum flow rate Lower the control lever lock Is the control le- (UNLOCKED po- ver lock locked? sition) Is the Start the engine engine running? Selecting the operating mode Selection of symbols Moving the arrow marking Setting the maximum flow rate… -

Page 94: Return Change Valve For Direct Return Flow

Operation Return change valve for direct return flow The change valve has two settings. When «direct return flow» is enabled, the return flow is directed from the implement to the hydraulic oil tank via the return filter. The return flow is directed via the right auxiliary port 1 connector at the arm on- When «indirect return flow»…

-

Page 95: Pressure Relief Of The Hydraulic System

Operation Pressure relief of the hydraulic system Lower front attachments and dozer completely. Turn the starter switch to the STOP position. Wait until the engine has come to a standstill. Turn the starter switch to the RUN position. Do not start the engine! Lower the left control console (1) and make sure that the con- trol lever lock (2) engages.

-

Page 96

Operation You will see the setting of the flow rates in the display. The bar height «A» shows the flow rate at the respective auxiliary port con- nectors (1, 2, 3 and 4). If the bar graph is set to the lowest level (as shown in connector 3, no bar obvious), flow is blocked and there is no oil flow. -

Page 97: Placing Out Of Operation

Operation Placing out of operation Park the excavator in such a way that it can not move and is secured against unauthorised use. STOP Drive the excavator onto level ground. Extend the hydraulic cylinders as follows: Boom: Half-extended Arm: Half-extended Bucket: Half-extended Dozer:…

-

Page 98: Operating The Heating And Air-Conditioner System (Optional)

Operation Operating the heating and air-conditioner system (optional) All the heating and air-conditioner system operations described below must be carried out while the engine is running. Heating the cab Set the temperature control (1) to the desired position. Blue ! Cold Red ! Warm Set the blower switch (2) to position 1, 2 or 3.

-

Page 99: De-Icing Or Demisting The Windows

Operation De-icing or demisting the windows Proceed as follows to de-ice the windows or clean them of conden- sation: Set the temperature control (1) to the «Warm» position. Blue ! Cold Red ! Warm Set the blower switch (2) to the 3 position. Use the air-conditioner switch (3, optional) to switch the system on.

-

Page 100: To Turn On The Washer System

Operation To turn on the washer system The washer system can be operated irrespective of whether the wiper is on or off. If the wiper is on: Press the switch (1) to the WIPER/WASHER position again and hold it down. If the wiper is off: Press the switch (1) to the OFF position and hold it down.

-

Page 101: Operating The 12 V Plug

Operation Operating the 12 V plug Open the cover cap (1) and put the load into the 12 V plug. The rated current of the connected load must not ex- ceed 10 A. Opening and closing the cab door Opening the cab door from outside Unlock the cab door at the door lock (3).

-

Page 102: Opening The Cab Door From The Inside

Operation Opening the cab door from the inside Pull the release lever (1) and open the door. If the cab door is not closed again right away, lock the door at the cab wall. Opening and closing the windows Front window Always lock the front window.

-

Page 103: Side Window

Operation Side window Pull the grip (1) to release the lock and pull side window open to the rear or to the front. To close the side window, slide it forward or backward until the lock snaps in at the window frame. Operating the working light (boom) The starter switch is in the RUN position.

-

Page 104: Cold Weather Operation

Operation Cold weather operation Operating the excavator at an ambient temperature below 5 °C is regarded as cold weather operation. Necessary preparations prior to the winter season If necessary, replace the engine oil and hydraulic oil with those of the viscosities specified for winter. Only use regular diesel fuel with winter additives.

-

Page 105: Jump-Starting The Excavator

Operation Jump-starting the excavator Only a vehicle or starting device with a 12 V power supply may be used. STOP The operator must remain seated on the operator’s place, the battery jumper cables must be con- nected by a second person. Make the battery accessible, and remove the positive terminal cover.

-

Page 106: Emergency Stop Functions

Operation Emergency stop functions In case of emergency, you can switch off the engine and lower the boom manually. Engine stop knob If the engine cannot be stopped with the key, it can be stopped man- ually. To stop the engine, pull the knob (1) until the engine stops. After the engine has stopped, push in the knob.

-

Page 107: Filling Up The Washer System

Operation Filling up the washer system Open the cap (1) of the washer system reservoir (2) and add water or a cleaning agent. In winter, use a cleaning agent with antifreeze. Refuelling the excavator When refuelling the excavator, smoking, an open flame, or other sources of ignition are not allowed. The danger zone has to be clearly marked with signs.

-

Page 108: Refuelling The Excavator Equipped With Optional Suction Pump (Only Kx057-4)

Operation Refuelling the excavator equipped with optional suction pump (only KX057-4) Stop the engine. Open the left service cover (page 114). Remove the filler cap (1) by turning it anticlockwise. Fill diesel fuel up to the base of the filler neck. Screw on the filler cap and close the service cover.

-

Page 109: Fill Level Monitor When Refuelling

Operation Switch on the suction pump. To do this, press the black button (1). Upon reaching the maximum fill level, the suction pump will automatically switch off. To switch it off manually, press the red button (2). Screw on the filler cap and close the service cover. Fill level monitor when refuelling The momentary fill level during refuelling can be determined by means of an acoustic signal.

-

Page 110: Bleeding The Fuel System

Operation Bleeding the fuel system If the excavator fuel tank was run empty or the water separator was cleaned, the fuel system must be bled. To bleed the fuel system, move the starter switch to the RUN position. The electrical fuel pump will bleed the fuel system automatically within approx.

-

Page 111: Fuse Layout Of The Fuse Box

Operation Remove the defective fuse from the fuse box (1) and replace it. The fuse layout is shown in the figure below. Fuse layout of the fuse box Cab working lights AUTO IDLE engine Boom working light Horn switch Horn Control unit Interior lighting Rotary beacon…

-

Page 112: Main Fuses

Operation Main fuses Remove the defective main fuse from the main fuse box (1) and replace it. Fuse layout: Not assigned Alternator (80 A) Main fuse (50 A) Engine cut-off switch/cab relay (fan motor) (50 A) Operating the battery cut-off switch In order for the excavator to be operated, the battery cut-off switch (1) must be in the ON position.

-

Page 113: Opening/Closing The Side Cover

Operation Secure the engine compartment cover with the catch (1). Make sure that the catch has snapped into place prop- erly. If the engine cover is unexpectedly slammed shut, STOP for example by another person or by the wind, serious injury could result.

-

Page 114: Opening/Closing The Tool Compartment (Kx057-4 Only)

Operation Opening/closing the tool compartment (KX057-4 only) Open the side cover (page 113). Tilt the lid (1). To close, lower the lid again and close the side cover. Opening/closing the service covers Opening/closing the front service covers Insert the key in the lock (1) of the cover (2) and turn it clock- wise.

-

Page 115: Replacing The Bucket

Operation Replacing the bucket When replacing the bucket, make sure to wear an eye protection, a helmet and protective gloves. STOP During attaching and detaching, chippings and burrs may occur at the bolts or bushings. These may STOP cause severe injuries. Never use your fingers for the alignment of the components (linkage, bucket, arm).

-

Page 116: Red Key (For Registering)

Use only the special KUBOTA key ring. Other key rings can lead to signal failures between the key and starter switch, and the engine can possibly not start or a key registration cannot be performed.

-

Page 117: Registering A Black Key For The Machine

Operation If you attempt to register a fifth black key, the display will show the «Stop Register» message and registration cannot be carried out. Stop register Registering a black key for the machine Register a black key only under the following conditions: Make sure that there are no persons within the excavator’s working area.

-

Page 118

Operation Pull out the red key. The display shows the «Insert key» message. Insert black key into the starter switch. Do not turn the key at this point. If the key is in the RUN position, turn it back to the STOP position. Insert key After a brief moment, the display shows the «Pull out black key»… -

Page 119: Troubleshooting

Troubleshooting Troubleshooting The troubleshooting section includes only malfunctions and incorrect operations which must be remedied by the operator. Any other malfunctions may only be eliminated by trained personnel. The troubleshooting must be per- formed with the aid of the troubleshooting table. In order to locate a malfunction, first look in the MALFUNCTION column for the corresponding excavator malfunction.

-

Page 120: Troubleshooting: Operation

Troubleshooting Troubleshooting: Operation MALFUNCTION POSSIBLE CAUSE REPAIR Operation Exhaust gas colour very black Air filter restricted Check, clean and replace the air fil- ter (page 137). Insufficient engine power Air filter restricted Check, clean and replace the air fil- ter (page 137). Fuel filter restricted or water in fuel Check the water separator for water system…

-

Page 121: Troubleshooting: Display Indications

If the machine develops a fault, one of the following messages will appear on the display. In the event of problems please inform your KUBOTA dealer immediately. If the information symbol (i) appears in the display, you can view detailed information by pressing the information button. Inform your KUBOTA dealer which messages appeared in the display. Display Problem/Error…

-

Page 122

Fuel sensor error The fuel sensor has de- Press the display selector Inform your KUBOTA veloped a fault; the fuel switch (button 5) to return to dealer immediately. gauge does not appear the default display. -

Page 123

When the V-belt is OK, let the not go out, inform engine run until indicator goes your KUBOTA dealer out. immediately. Oil pressure too low The engine oil pressure Stop the engine immediately. Inform your KUBOTA is too low. -

Page 124

2 will not dealer immediately. function. Periodic This message means Operate the machine as usual. Ask your KUBOTA check soon (notice) that the regular service dealer about the rel- is due shortly. evant parts. Run the maintenance proce- dure. -

Page 125

Display Problem/Error Preliminary Measure Solution Period check This message means The machine can be operated Ask your KUBOTA passed (warning) that the regular service but service must be carried out dealer about the rel- is due. urgently. evant parts. Run the maintenance proce- dure. -

Page 126: Maintenance

A careful maintenance of the excavator will guarantee functional safety and longer service life. Neglect of the servicing will void the warranty and any liability by KUBOTA. Only use spare parts that are recommended by the manufacturer. Non-approved spare parts of inferior quality or wrong classification result in an increased risk of accidents.

-

Page 127: General Maintenance Chart: 50 To 500 Hours Of Operation

Maintenance General maintenance chart: 50 to 500 hours of operation Operator servicing Elapsed hours of operation General maintenance Interval Page Check the fuel level daily Check the coolant level daily Checking the engine oil level daily Check the hydraulic oil level daily Grease the bucket bolt and daily…

-

Page 128: General Maintenance Chart: 550 To 1000 Hours Of Operation

Maintenance General maintenance chart: 550 to 1000 hours of operation Operator servicing Elapsed hours of operation General maintenance 1000 Interval Page Check the fuel level daily Check the coolant level daily Checking the engine oil level daily Check the hydraulic oil level daily Grease the bucket bolt and daily…

-

Page 129: Servicing Maintenance Chart: 50 To 500 Hours Of Operation

Maintenance Servicing maintenance chart: 50 to 500 hours of operation Servicing by skilled personnel or KUBOTA dealer Elapsed hours of operation * Servicing Interval Page Check the coolant hoses and » » 250 h hose clamps » » Check and adjust the V-belt…

-

Page 130: Servicing Maintenance Chart: 550 To 1000 Hours Of Operation

Maintenance Servicing maintenance chart: 550 to 1000 hours of operation Servicing by skilled personnel or KUBOTA dealer Elapsed hours of operation Servicing 1000 Interval Page Check the coolant hoses and » » 250 h hose clamps » » Check and adjust the V-belt…

-

Page 131: Cleaning The Excavator

Maintenance Cleaning the excavator Before cleaning, shut down the engine and secure it against starting. STOP If a steam cleaner is used for cleaning the excavator, do not direct the steam jet at electric compo- nents. Do not direct a water jet into the intake opening of the air filter. Do not clean the excavator with inflammable liquids.

-

Page 132: Cleaning The Radiators And The Condenser

Maintenance Do not open the radiator cap while the engine is still STOP hot, risk of scalding. Open the side cover (page 113). Remove the radiator cap (1) by turning it anticlockwise. The coolant level should be at the lower mark of the filler plug; if not, add coolant.

-

Page 133: Checking, Adjusting And Replacing The V-Belts

Maintenance Checking, adjusting and replacing the V-belts Adjusting the V-belts Open the engine compartment cover (page 112). Check the V-belt (page 66). Remove the mounting screws (2). Tighten the V-belts by adjusting the tension roller (1). Press in the V-belt (3) at position «A». The V-belt must give way for approx.

-

Page 134: Replacing The Coolant

Maintenance Replacing the coolant Drain the coolant only when the engine is cold. STOP Total cooling system capacity: 8.1 L Open the engine compartment and side cover (page 112). Remove the radiator cap (1) by turning it anticlockwise. Open the central coolant drain plug (1) and drain the coolant completely.

-

Page 135: Replacing The Engine Oil And Oil Filter

Maintenance Replacing the engine oil and oil filter Open the engine compartment cover (page 112). The engine oil change must be carried out while the engine is warm. Caution: The engine oil and the oil filter are very hot ! risk of scalding. STOP Place an oil pan with a capacity of about 15 L under the engine oil drain.

-

Page 136: Filling The Engine Oil

Maintenance Filling the engine oil Filling capacity: 9.0 L Remove the oil filler cap (2) and fill engine oil. See the «Recom- mended lubricants» section (page 159). Screw in the oil filler cap. Start the engine (page 71). The engine oil pressure indicator must go out as soon as the engine has started.

-

Page 137: Checking, Cleaning And Replacing The Air Filter

Maintenance Checking, cleaning and replacing the air filter If the excavator is operated in a particularly dusty envi- ronment, the air filter must be checked more often. Open the engine compartment cover (page 112). Open the clips (2) and remove the cover (1). Pull the outer filter element (1) out of the air filter case (3) and check it for dirt.

-

Page 138: Replacing The Fuel Filter

Maintenance Replacing the fuel filter Open the engine compartment cover (page 112). Turn the cock (1) at the water separator to the OFF position. Remove the fuel filter (2). Wet the rubber seal of the new filter with fuel. Install a new filter and tighten it by hand. Set the cock to the ON position.

-

Page 139: Cleaning The Water Separator

Maintenance Cleaning the water separator Open the engine compartment cover (page 112). Place a cleaning cloth under the water separator to prevent fuel from running onto the ground. Turn the cock (1) to the OFF position. Remove the filter cup (2). Empty the filter cup and clean it with clean diesel fuel.

-

Page 140: Checking The Fuel Lines And The Air Intake Hoses

Maintenance Checking the fuel lines and the air intake hoses Check all accessible fuel lines (1), air intake hoses (2) and clamps (3) to ensure that they are not damaged and are firmly seated. Repair or replace damaged parts. Replacing the return filter in the hydraulic oil tank Pay attention to utmost cleanliness when servicing the hydraulic system.

-

Page 141: Replacing The Tank Breather Filter

Maintenance Remove the return filter (3) with rod (5) . Loosen the screw (4). Remove the return filter and replace it with a new one. Discard the return filter in accordance with the prevail- ing environmental protection regulations. Tighten the screw (4). Check the condition of the sealing ring of the hydraulic oil tank cover.

-

Page 142: Replacing The Pilot Circuit Filter

Maintenance Replacing the pilot circuit filter Open the side cover (page 113). Remove the filler plug (1) from the hydraulic oil tank. Remove the filter cup (2) from the filter head (1). Remove the filter element (1) from the filter head. Install a new filter along with the included new sealing ring.

-

Page 143: Replacing The Suction Filter In The Hydraulic Oil Tank

Maintenance Replacing the suction filter in the hydraulic oil tank Pay attention to utmost cleanliness when servicing the hydraulic system. This service may only be carried out after the hydraulic oil has cooled down. STOP The suction filter must be replaced along with the hydraulic oil. Open the side cover (page 113).

-

Page 144: Topping Up/Changing The Hydraulic Oil

Maintenance Topping up/changing the hydraulic oil Pay attention to utmost cleanliness when servicing the hydraulic system. This service may only be carried out after the hydraulic oil has cooled down. STOP The suction filter must be changed along with the hydraulic oil. Operate the boom, arm, bucket and boom swing mechanism so that all hydraulic cylinders are extended half way.

-

Page 145: Filling The Hydraulic Oil

Maintenance Filling the hydraulic oil Filling quantity with oil change: approx. 45 L Total hydraulic system capacity: 79 L Remove the filler plug (1) from the hydraulic oil tank. Insert a clean funnel with a strainer into the filler plug opening. Fill hydraulic oil to half way up the sight glass (1).

-

Page 146: Battery Service

Maintenance Battery service Regular maintenance can extend the life cycle of the battery considerably. When servicing a battery, always wear suitable protective gloves and eye protection. Checking the battery Open the side cover (page 113). The battery liquid level must be between the LOWER LEVEL (6) and UPPER LEVEL (5) markings.

-

Page 147: Installing/Uninstalling And Replacing The Battery

Maintenance The battery can only be charged if the starter switch is in the STOP position and the key removed. STOP Make the battery accessible. Check the electrolyte level in the battery, adding distilled water if required. When disconnecting and connecting the battery, always observe the specified order ! risk of short STOP circuit.

-

Page 148: Lubrication

Maintenance Lubrication The following describes all lubricating tasks which should be performed with the superstructure. Greasing the swivel gear Fill grease through the grease nipple (1) with a grease gun. Grease at each 90° position of the swivel gear. Fill a to- tal of approx.

-

Page 149: Greasing The Swing Bracket

Maintenance Greasing the swing bracket Lubricate both greasing points (see figure to the right) – see the «Recommended lubricants» section (page 159) – by injecting grease until fresh grease emerges. Wipe emerged grease off immediately and store dirty cleaning cloths in the containers provided for disposal. Other greasing points Start the engine (page 71).

-

Page 150: Checking And Tensioning The Crawler Tension

Maintenance Checking and tensioning the crawler tension If the crawlers are too tight, wear is increased. If the crawlers are too loose, wear is increased and the crawlers may come off. When parking an excavator with rubber crawlers, ensure that the ∞…

-

Page 151: Checking The Crawler Tension (Steel)

Maintenance Checking the crawler tension (steel) Check the crawler sag as shown in the figure. Crawler sag «A» 75-80 mm If the crawler sag is more than 80 mm, adjust the crawler. If necessary, tighten or loosen the crawler. Start the excavator and rotate the lifted crawler briefly. Caution: The area around the rotating crawler must be free of persons.

-

Page 152: Replace The Drive Unit Oil

Maintenance Replace the drive unit oil Only change the oil when the drive unit is warm to the hand; if not, drive the excavator warm. Park the excavator on level ground so that the drain plug (figure below, position 3) is positioned at the bottom. Place a catch tray with a minimum capacity of 2 L under the drain plug.

-

Page 153: Checking The Pipes And Hoses Of The Heating And Air-Conditioner Systems

Check that all the pipes and hoses of the heating and air-conditioner systems are in serviceable condition (no cracks, bulges or hard spots) and are firmly seated. If there are any defects found, consult your KUBOTA deal- er. Only trained personnel may work on the heating and air-conditioner systems.

-

Page 154: Checking The Coolant Content (Air-Conditioner Only)

A low refrigerant level affects the performance of the equipment and the air-conditioner will eventually automati- cally switch off. If you find out that the refrigerant level is too low, please contact your KUBOTA dealer. Open the side cover (page 113).

-

Page 155: Viewing The Operations Log

Maintenance Viewing the operations log The operations log enables the operation of the excavator over the previous three months to be checked. Turn the starter switch to the RUN position. Press button 1. The user menu appears in the display. Press button 2 or 3 until «Log Record»…

-

Page 156: Checking The Bolted Joints

Maintenance Checking the bolted joints The table below contains the torques for nuts and bolts. These may only be tightened with a torque wrench. Miss- ing torques can be requested from KUBOTA. Tightening torque for screws Nm ( kgf#m 4 T (4.6) 7 T (8.8)

-

Page 157: Tightening Torque For Hydraulic Hoses

Maintenance Tightening torque for hydraulic hoses Nm ( kgf#m Nut type Nut type Dimension (ORS) (Metal seal) (ORS) 7.8~11.8 1/8 ( — ) (0.8~1.2) 24.5~29.4 35.2~43.1 1/4 (9/16-18) (2.5~3.0) (3.6~4.4) 37.2~42.1 60.0~73.5 3/8 (11/16-16) (3.8~4.3) (6.1~7.5) 58.8~63.7 70.6~86.2 1/2 (13/16-16) (6.0~6.5) (7.2~8.8) 117.6~127.4…

-

Page 158: Tightening Torque For Hydraulic Adapters

Maintenance Tightening torque for hydraulic adapters Tightening torque Comments Thread size Wrench size Steel pipe kgf#m (Pipe union) (guide number) (OD) R (conical thread) G (round thread) 19.6~29.4 17 mm 8 mm 1/8″ 2.0~3.0 0.67 in. 0.31 in. With O-ring Tightening torque for 36.3~44.1 19 mm…

-

Page 159: Recommended Lubricants

HLP SYNTH ISO 15380 Panolin 2 % mineral oil in the Hydraulic system. Please contact your KUBOTA dealer. In winter or at SAE 75 low tempera- SAE 80 tures In summer or at Gear oil SAE 90…

-

Page 160: Excavator Repairs

Maintenance Recommendation Product designation Note Quality Manufac- Range of use Viscosity Product requirement turer The machine is deliv- ered with summer die- sel*. In winter, fill up with diesel fuel for winter operation. ASTM D975 To prepare for winter, Fuel EN 590 allow the engine to run for a few minutes…

-

Page 161: Safety Inspection

Safety inspection Safety inspection All safety inspections are based on the national worker’s protection regulations, safety regulations and technical specifications applicable to the country where the machine is deployed. The owner (operator) (page 18) should arrange for the safety inspections to be performed at specified intervals according to national rules and regulations.

-

Page 162: Taking Out Of Service And Storage

Taking out of service and storage Taking out of service and storage If the excavator is taken out of service for up to six months, the measures before, during and after taking out of service must be carried out as described below. If the vehicle is to be taken out of service for a period of over six months, contact the manufacturer for additional measures.

-

Page 163: Start-Up After Taking Out Of Service

Taking out of service and storage Start-up after taking out of service If necessary, clean the excavator thoroughly (page 131). Check the hydraulic oil for condensate water. Replace the oil if necessary (page 144). Remove the grease from the piston rods of the hydraulic cylinders. Install the battery (page 147).

-

Page 164: Lifting Capacity Of The Excavator

Load suspensions (e.g. hooks) may only be welded on by suitably qualified personnel. For this type of work, please contact your KUBOTA dealer. At every point of the implement or the boom, the lifting attachment must withstand a load of two-and-a-half-…

-

Page 165: Load Suspension Device

Lifting capacity of the excavator Load suspension device Assumed is a load suspension device with all the characteristics listed below. The system must withstand a load two-and-a-half-times its rated lifting load, irrespective of the point at which that load is applied. The system must be designed in such a way as to practically exclude any objects which have been lifted falling from the lifting attachment, for example by means of a protective attachment designed for this purpose.

-

Page 166: Max. Lifting Load During Swivel Operation Is 360

Lifting capacity of the excavator Max. lifting load during swivel operation is 360° KX057-4 / arm 1570 mm and arm 1820 mm U48-4 / arm 1450 mm…

-

Page 167

Lifting capacity of the excavator U55-4 / arm 1570 mm… -

Page 168

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL KX057-4 SPECIFICATION CAB VERSION WITH RUBBER CRAWLER ARM 1820 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1000 1500 2000 2500 3000 3500 4000 4500 5000… -

Page 169

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL KX057-4 SPECIFICATION CAB VERSION WITH WIDE STEEL CRAWLER ARM 1820 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1000 1500 2000 2500 3000 3500 4000 4500… -

Page 170

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL KX057-4 SPECIFICATION CAB VERSION WITH STEEL CRAWLER ARM 1570 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1000 1500 2000 2500 3000 3500 4000 4500 5000… -

Page 171

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL U48-4 SPECIFICATION CAB VERSION WITH RUBBER CRAWLER ARM 1450 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1500 2000 2500 3000 3500 4000… -

Page 172

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL U55-4 SPECIFICATION CAB VERSION WITH RUBBER CRAWLER ARM 1570 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1000 1500 2000 2500 3000 3500 4000 4500 5000… -

Page 173

Lifting capacity of the excavator Lifting capacity over front end, dozer down MODEL U55-4 SPECIFICATION CAB VERSION WITH WIDE STEEL CRAWLER ARM 1570 mm kN (t) LIFT POINT RADIUS (mm) LIFT POINT HEIGHT Mini- Maxi- 1000 1500 2000 2500 3000 3500 4000 4500… -

Page 174: Accessories

Any manipulation can result in substantial personal injuries, even death, and is therefore strictly for- STOP bidden. The manipulation and repair of the pipe safety valves is forbidden. They may only be replaced by your KUBOTA dealer as a kit.

-

Page 175: Note On Use

Various attachments are nev- ertheless of limited use only. KUBOTA Bucket accessories For further bucket accessories, please contact your KUBOTA dealer or authorized retailer. Replacing the bucket When replacing the bucket, make sure to wear an eye protection, a safety helmet and protective STOP gloves.

-

Page 176: Remove The Bucket

Accessories Remove the bucket Set the bucket down on flat, level ground. Stop the engine. Ensure that the components listed below remain free of dirt and dust. Unscrew the bolt locks on the bolts (2) and (3).. The bucket is mounted with the bolts (2) and (3) in a total of four bearing eyes.

-

Page 177: Install The Bucket

Accessories Install the bucket Ensure that the components listed below are free of dirt and dust. Ensure that there is an O-ring (6) attached to each bearing eye (5). Check O-rings and dust protection seals (7) for damage, re- place if necessary. Align the bearing bore of the arm (4) to the bearing bore (3) on the bucket.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

XN08 MINI CRAWLER EXCAVATOR

OPERATION & MAINTENANCE MANUAL

SHANDONG RHINOCEROS ENGINEERING MACHINERY CO., LTD

ADD: Dingyuanzhai Industrial Park, Liaocheng City, Shandong China

Tel: +86-635-8362550

Fax: +86-635-5846000

1

Related Manuals for RHINOCEROS XN08

Summary of Contents for RHINOCEROS XN08

-

Page 1

XN08 MINI CRAWLER EXCAVATOR OPERATION & MAINTENANCE MANUAL SHANDONG RHINOCEROS ENGINEERING MACHINERY CO., LTD ADD: Dingyuanzhai Industrial Park, Liaocheng City, Shandong China Tel: +86-635-8362550 Fax: +86-635-5846000… -

Page 2

Preface Chapter I Usage Features and Performance Parameters of Rhinoceros 0.8T Excavators Section I Usage and features Section II Main performance parameters Chapter II Basic Structures and Work principle of Rhinoceros 0.8T Excavators Section I Overview Section II Work principle… -

Page 3

Excavators Section I Usage and features Rhinoceros 0.8T Excavators are provided with excavating, crushing, ditch cleaning, drilling and bulldozing, with their attachments quick hitched and thus its utilization up greatly. In addition, they are easy to operate and transport and flexible to work at narrow site. -

Page 4

Quick hitch Narrow bucket Log grab Mechanical thumb Auger Ripper Rake… -

Page 5

Section II Main performance parameters… -

Page 6

Overall dimensions Unit: mm A Wheel track B Overall length of track 1090 C Ground clearance of platform D Ground clearance of platform tail E Chassis width F Crawler width H Crawler height I Transportation length 2770 J Overall height 1330 Work range Unit: mm… -

Page 7

1-1. Mounted on the rotary table are the regular full-swing type hydraulic excavators, main components of drive system, swing mechanism and auxiliary devices, which are referred to as upper rotary. Therefore, a Rhinoceros 0.8T excavator is divided into work equipment, upper rotary and traveling mechanism. -

Page 8

Section II Work principle of excavators Diesel engine changes the chemical energy of diesel into mechanical energy that is then altered with hydraulic gear pump to hydraulic energy that is distributed to each actuating element (such as hydraulic cylinder, swing motor and traveling motor). -

Page 9

The hydraulic excavator could have multiple work equipment, up to dozens of varieties, with backhoe and ripper most popular. Rhinoceros 0.8T excavator has the boom, arm and bucket articulated with each other, as shown in figure and swing around their articulated points respectively with aid of the hydraulic cylinder, finishing the excavating, lifting and unloading. -

Page 10

5.2 Bucket 5.2.1 Basic requirements The longitudinal profile of bucket meets the law of motion of various materials inside of bucket, facilitating the material flow and minimizing the loading resistance and thus fulfilling the bucket. Bucket teeth are mounted to increase the linear specific pressure of bucket onto material, with unit cutting resistance relatively low and easing to cut in and break soil. -

Page 11

Hydraulic system structure of Rhinoceros 0.8T excavators I. Rotary motor… -

Page 13

II. Main pump Driven gear Lug-shaped baffle Nylon Lug-shaped gasket Rubber L-4 Side plate Pump body Rectangular seal ring Rubber L-4 Bearing Combine parts Front cover Combine parts Oil seal NY19×32×7 Retainer 32 Driving gear shaft Washer 10 Screw M10×65-10.9 Traveling motor Disc Valve Motors—6000 series -005 and -006 Drive, Main… -

Page 14

Seal package Code Name (reference dimensions mm) Quantity Dust cover (OD 50.9) Copper sheet (OD 60.45) Seal ring of output shaft (OD 63.56) O-ring (ID92.87,Shore hardness70) End seal ring (ID 45.72) O-ring (ID 6.07) O-ring (ID 94.97) O-ring (ID 11.2) Front-type seal ring (ID 62.23) Front-type seal ring (ID 35.82) O-ring (ID 92.33,Shore hardness 90) -

Page 16

Section IV Schematics of main valve Reserved Steering Traveling Front shovel Traveling Boom Bucket… -

Page 17

Section V. Electrical system diagram… -

Page 18

Chapter III Service Technologies of Rhinoceros 0.8T Excavators Being of high temperature and pressure, the Rhinoceros 0.8T excavator could have the hydraulic oil temperature as high as 85℃, the engine silencer temperature as high as 700℃ and pressure as high as 16-18MPa. Therefore, the operators should be specially trained to obtain the proper certificates and to be familiar with the contents in this manual before the operations. -

Page 19

When hydraulic oil is less than 25℃, it is needed to preheat the machine before any work; otherwise machine may not respond or react very quickly, leading to severe accident. Therefore it is needed to preheat machine if it is cold: ①. -

Page 20

Boom down Arm stretch Left turn Right turn Bucket Load Bucket Unload Boom Up Arm Back 2.2 Basic excavation Before excavation, the arm cylinder should have angle with the arm as 90°, bucket with ground to be excavated as 30°. Only in such case, can each cylinder have the max. excavating force. It is suitable for relatively hard soil, so as to decrease the excavating resistance. -

Page 21

Section IV Operational Precautions Prohibitions and precautions for hydraulic excavators Avoid the landsliding and the stone falling. Avoid any striking of work equipment. Avoid the bucket from colliding with other vehicle body, the loaded bucket crossing over other vehicle cab or persons. -

Page 22

Chapter VI Maintenance of Rhinoceros 0.8T Excavators Section I Daily inspection and maintenance Interval (h) Item Quantity Remark Check the engine oil level in sump ★ Check the hydraulic oil level in hydraulic oil tank ★ Check the fuel level in tank ★… -

Page 23

Section II Periods of overhaul, medium and minor repair Interval (h) Item Quantity Remark 1000 1500 2000 2500 4000 Greasing of slewing ★ bearing Greasing of slewing ★ bearing gears Change the engine oil ● ▲ ★ Change the hydraulic △… -

Page 24

Technical maintenance A Grease Interval (h) Parts Quantity 1000 2000 Pivot at base of boom Pivot at base of boom 1. Lubrication cylinder ★ of work equipment Pivots of bucket and pins connecting rod Others: ★ 2. Lubrication of slewing bearing ★… -

Page 25

● Others Pivot between boom and arm; pivot of arm cylinder plunger; pivot at base of bucket cylinder. Slewing bearing — every 250h Park machine on the flat ground. Lower the bucket onto ground. Idle engine at low speed for 5min. Turn the ignition switch to OFF and then take off the key. -

Page 26

B. Engine oil Interval (h) Parts Quantity 1000 2000 Engine oil ● ▲ ★ Engine oil filter ● ▲ ★ According to the temperature range during the interval, select the viscosity of oil listed in the table below: Recommended engine oil brand: 15W—40 engine oil… -

Page 27

Inspection of engine oil level ―――-each day Change of engine oil ―――every 500 h Change the engine oil filter ―――every 500 h Start up engine to preheat up engine oil properly. Park the vehicle on the flat ground. Lower the bucket onto the ground. Idle engine at low speed for 5min. -

Page 28

Inspection and maintenance of hydraulic system Caution: in work, the hydraulic system may become very hot. Please cool the machine down before inspection or maintenance! Before maintenance of hydraulic system, make sure the machine stands on flat and solid ground. Lower the bucket onto ground and shut down engine. -

Page 29

I. Inspection of hydraulic oil level — each day Important: With no hydraulic oil, never start up engine! Park machine on the flat ground. Completely retract the arm cylinder and extend out the bucket cylinder, so as to locate the machine. Lower the bucket onto the ground. -

Page 30

III. Change the hydraulic oil —2000 h Replace the hydraulic oil suction filter element —-every 1000 h Caution: do not do so until the hydraulic oil cools down as it may be very hot. Park machine on the flat ground. Completely retract the arm cylinder and extend out the bucket cylinder, so as to locate the machine. -

Page 31

23. Check the hydraulic oil level in hydraulic oil tank and add it if needed. . V. Inspection of hose and pipeline — Each day —every 250 h Caution: any sprayed fluid could penetrate your skin, leading to personal casualty! Therefore, use a paperboard to check for leakage. -

Page 32

Please use the genuine Rhinoceros excavator parts Interval (h) Check points Abnormal Measures Replace it Hose surface Leakage 1 Replace it Every day Hose end Leakage 2 Tighten or replace the Connector body Leakage 3 hose or O-ring Crack 4… -

Page 33

Fuel system capacity of fuel tank: 7L Interval (h) Parts Quantity 1000 2000 Drain dirt out of collector of fuel ★ tank Check the oil-water separator ★ Change the oil-water separator ★ Leakage ★ ★ Check the fuel hose. Crack / twist / others ★… -

Page 34

Manually loosen the drain plug at bottom of oil-water separator. After the draining, manually tighten the drain to ensure no leakage of oil or air. Caution: after the draining, make sure air is drained out of fuel system to make sure the engine could start up normally. -

Page 35

Note: ★ Maintenance interval under normal conditions Maintenance needed at the first inspection Contact dealers or Rhinoceros. Check the bucket teeth — each day Check if the bucket teeth is worn or loosened. Worn beyond the service limit, the bucket teeth may be replaced. -

Page 36

Caution: care must be taken to avoid the metal scrap from flying out, leading to personal injury. Wear the goggles or the safe glasses or safe devices suitable for operations! Change the bucket Caution: while hitting out or into the connecting pin, care must be taken to prevent against any personal injury due to out-flied metal scrap. -

Page 37

Check the bolts and nuts for tightening torque ……every 250 h (initially at 50 h) Check the tightness at initial 50h and then every 250 h. Tighten it to the set torque if needed. Replace it with bolts and nuts with same or higher grade. Important: please use the torque wrench to check the torques of bolts and nuts! Metric bolts and nuts Thread dimensions… -

Page 38

Maintenance under the special cases Operational conditions Precautions for maintenance Before operation, check all the drain plugs are tightened up. Moor land, rainy or snowy After operation, clean machine and check bolts and nuts for break, damage, looseness or loss. Lubricate all parts to be lubricated on time. Before operation, check all the drain plugs are tightened up. -

Page 39

Chapter XII Troubleshooting Section I General To ensure excellent performance of Rhinoceros excavator, all components and parts are of high quality. Machine’s performance and service life are determined not only by manufacturing quality and assembling quality, but also maintenance quality. -

Page 40

Symptom Possible causes How to solve The main pump supplying fuel to unilateral Change crawler is damaged. The main valve rod is stuck and the spring is Repair or change broken The unilateral crawler fails to move Traveling motor is damaged Change The upper and lower chambers of swivel Change the oil seal or clean the… -

Page 41

Symptom Possible causes How to solve The sealing component of central rotation Change the sealing component connector is aged and damaged. The left and right crawlers are of different Adjust tightening. Boom (bucket rod and Main valve core is stuck or valve rod spring bucket) move to one Repair or change breaks. -

Page 42

Symptom Possible causes How to solve other abnormalities) Rotary valve rod on main valve is stuck. Repair Rotary motor is damaged Repair or change The rotation support is damaged. Change The right and left rotation of multiway valve Adjust Indifferent left and right is of different overloaded pressure rotation speed (no other Rotation valve rod of multiway valve is… -

Page 43

Section IV Troubleshooting of electrical control system Fault codes of electrical control system of excavator The engine fails to start The engine flames out during operation The engine fails to flame out Automatic slow-down does not work Slewing and traveling of all working devices. Principle diagram 1. -

Page 44

Possible causes Standard value in regular condition and reference value of fault diagnosis Unlocked 1MΩ Between 105 and Locked Below 1Ω ★Turn the start switch of engine to OFF as preparation and keep it at OFF during diagnosis. If all PS, GND, signals and engine start input are correct while engine start output is abnormal, the engine starter relay fails. -

Page 45

Section V Troubleshooting of diesel engine Symptoms of failed startup of engine: When starting the engine, the starter drives the engine but the engine fails to be started. Possible causes: (1) Low battery; (2) Battery terminal is rusted or loose; (3) Battery earth wire is rusted or loose or poor GND of engine;… -

Page 46

(5) Inspect and repair the engine. Only when the engine works well can the start-up fail never or seldom happen. Check if it is hard to start the engine Symptom: (1) Starter runs at correct rpm and drives the engine; however, it is hard to start the engine. (2) It is hard to start the engine when it is cold. -

Page 47

(4) Start circuit is disabled. (5) Electromagnetic relay armature is adherent; (6) Starter fault (7) Driving gear of starter is stuck by engine flywheel gear ring; (8) Driving gear of starter adheres to the bearing. (9) The starter fails to drive the engine; (10) Engine fault;… -

Page 48

Attachment: BOM of vehicle parts Exploded drawing of 0.8T excavator assembly Name Quantity Remark Upper frame assembly Lower frame assembly Front work equipment assembly Slewing bearing assembly Connecting shaft between boom and upper frame Connecting shaft between boom and upper frame Pivot sleeve… -

Page 49

1 Lower frame Part No. Part Name Quantity Remark Welded dozer shovel Welded lower frame Slewing joint Rubber crawler Lock nut Sprocket nuts Drive wheel Connecting disc Sprocket bolts 1.10 Bolts fixing the track roller 1.11 Traveling motor 1.12 Track roller 1.13 Idler assembly 1.14… -

Page 50

2 Upper frame assembly Part No. Part Name Quantity Remark Welded upper frame Covers of rear housing Covers of left housing Covers of right housing Welded inside support frame Rear counterweight plate 1 set Arm rest Seat and supports… -

Page 51

2 Upper frame assembly Part No. Part Name Quantity Remark Left- upper cover 2.10 Right — upper cover 2.11 L- shaped covers 2.12 Console 2.13 Pedal 2.14 Hydraulic oil tank 2.15 Hydraulic oil tank 2.16 Hydraulic oil tank support 2.17 Diesel tank 2.18 Multiway valve… -

Page 52

3. Front work equipment Part No. Part Name Quantity Remark Boom Bucket Connecting rod Push rod Boom cylinder Arm cylinder Bucket cylinder Medium shaft of boom 3.10 Rear shaft of arm cylinder 3.11 Front shaft of arm cylinder 3.12 Front shaft of boom 3.13 Rear shaft of bucket cylinder 3.14…

IHI 25VX-3 Excavator Operation Manual

IHI 25VX-3 Excavator Operation Manual

IHI 25VX-3 Excavator Operation Manual PD

Adobe Acrobat Document

5.2 MB

IHI 9VX3 Mini-Excavator Service Manual

IHI 9VX3 Mini-Excavator Service Manual

IHI 9VX3 Mini-Excavator Service Manual P

Adobe Acrobat Document

893.0 KB

IHI 45V4 Mini Excavator Parts Catalog

IHI 45V4 Mini Excavator Parts Catalog

IHI 45V4 Mini Excavator Parts Catalog PD

Adobe Acrobat Document

7.8 MB

IHI 35V4 Mini Excavator Parts Catalog

IHI 35V4 Mini Excavator Parts Catalog

IHI 35V4 Mini Excavator Parts Catalog PD

Adobe Acrobat Document

6.9 MB

IHI 30V4 Mini Excavator Parts Catalog

IHI 30V4 Mini Excavator Parts Catalog

IHI 30V4 Mini Excavator Parts Catalog PD

Adobe Acrobat Document

6.8 MB

IHI 85V4 Mini Excavator Parts Catalog

IHI 85V4 Mini Excavator Parts Catalog

IHI 85V4 Mini Excavator Parts Catalog PD

Adobe Acrobat Document

8.9 MB

History of IHI Mini Excavators

A group of companies from Japan — Ishikawajima (IHI) has significant success in various industries. IHI is

involved in shipbuilding, engine manufacturing, turbine manufacturing, etc.

In addition, this group of companies successfully operates a division that specializes in the production of various equipment for construction work