Описание конструкции снегохода Yamaha.

- Год издания: —

- Страниц: 65

- Формат: PDF

- Размер: 6,9 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha BR250F.

- Год издания: 1981

- Страниц: 191

- Формат: PDF

- Размер: 8,7 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha BR250TG и Yamaha VK540EG.

- Год издания: 2001

- Страниц: 88

- Формат: PDF

- Размер: 8,7 Mb

Дополнение к руководству по техническому обслуживанию и ремонту снегохода Yamaha ET300E.

- Год издания: 1980

- Страниц: 8

- Формат: PDF

- Размер: 790 Kb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha FX Nytro моделей FX10/RFX10 различных модификаций.

- Год издания: 2007-2012

- Страниц: 94/118/122

- Формат: PDF

- Размер: 32,0 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha FX Nytro модели FX10 различных модификаций.

- Год издания: 2007-2011

- Страниц: 92/104

- Формат: PDF

- Размер: 18,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha FX Nytro модели FX10 различных модификаций.

- Год издания: 2007

- Страниц: 410

- Формат: PDF

- Размер: 13,5 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha MM700/VT700/VX700ER.

- Год издания: 2001

- Страниц: 100

- Формат: PDF

- Размер: 9,2 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha MM600/MM700/SX600/VT600/VT700/VX600/VX700 различных модификаций.

- Год издания: 1998-2002

- Страниц: —

- Формат: PDF

- Размер: 32,0 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ50/RPZ50 Venture различных модификаций.

- Год издания: 2006/2012

- Страниц: 110/120

- Формат: PDF

- Размер: 11,7 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ50 Phazer, Venture различных модификаций.

- Год издания: 2006-2009

- Страниц: 88/92/98/104

- Формат: PDF

- Размер: 21,6 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту снегохода Yamaha PZ50 Phazer, Venture различных модификаций.

- Год издания: 2006-2007

- Страниц: 424/114

- Формат: PDF

- Размер: 21,2 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегоходов Yamaha PZ500C и Yamaha VT500XLC.

- Год издания: 1998

- Страниц: 209

- Формат: PDF

- Размер: 6,0 Mb

Руководство на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ 500D/PZ500MLD/VT500XLD.

- Год издания: 1999

- Страниц: 83

- Формат: PDF

- Размер: 2,4 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha RS10/RS90/RSG90/RST90 RS Vecror, RS Venture различных модификаций.

- Год издания: 2004/2011/2012

- Страниц: 100/108/162

- Формат: PDF

- Размер: 31,0 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha RS90/RSG90/RST90 RS Vector, RS Venture различных модификаций.

- Год издания: 2004-2011

- Страниц: —

- Формат: PDF

- Размер: 63,5 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту снегоходов Yamaha RS90/RSG90/RST90 RS Venture различных модификаций.

- Год издания: 2004/2006/2008

- Страниц: 414/202/299

- Формат: PDF

- Размер: 37,1 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha RX10/RXW10 Apex различных модификаций.

- Год издания: 2001-2012

- Страниц: —

- Формат: PDF

- Размер: 28,6 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha RX90/RXW90 Apex различных модификаций.

- Год издания: 2002-2010

- Страниц: —

- Формат: PDF

- Размер: 48,2 Mb

Руководство на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha SRX700G.

- Год издания: 2001

- Страниц: 84

- Формат: PDF

- Размер: 6,6 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha SXV60/SXV70/VT60/VT70 различных модификаций.

- Год издания: 2003

- Страниц: 113/127

- Формат: PDF

- Размер: 10,5 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha SXV60/SXV70/VT60/VT70 различных модификаций.

- Год издания: 2001-2005

- Страниц: —

- Формат: PDF

- Размер: 48,3 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha VK10/VK10D RS Viking.

- Год издания: 2007/2012

- Страниц: 98/108

- Формат: PDF

- Размер: 15,6 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha VK10L и Yamaha VK10X.

- Год издания: 2005/2007

- Страниц: 98/88

- Формат: PDF

- Размер: 7,9 Mb

Дополнение к руководству по техническому обслуживанию и ремонту снегоходов Yamaha VK10L/VK10W.

- Год издания: 2005-2006

- Страниц: 360/103

- Формат: PDF

- Размер: 12,2 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha VK540E/VK540EC.

- Год издания: 2012

- Страниц: 82

- Формат: PDF

- Размер: 3,2 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha VK540EG/VK540EK.

- Год издания: 2001/2004

- Страниц: 76

- Формат: PDF

- Размер: 4,8 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha VK540EK.

- Год издания: 2000

- Страниц: 211

- Формат: PDF

- Размер: 4,9 Mb

Руководство по эксплуатации и техническому обслуживанию снегохода Yamaha VT500XL.

- Год издания: 2001

- Страниц: 84

- Формат: PDF

- Размер: 8,2 Mb

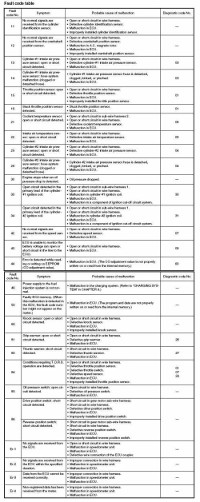

Коды неисправностей Yamaha.

- Год издания: —

- Страниц: 11

- Формат: JPG

- Размер: 1,7 Mb

4-я Красноармейская, 2А

Санкт-Петербург, 190005

Email: info@lenmoto.ru

Телефон: +7 (921) 930-81-18

Телефон: +7 (911) 928-08-06

Компания ЛенМото

Запчасти, аксессуары, экипировка, тюнинг для мотоциклов, скутеров, квадроциклов, снегоходов, багги, гидроциклов, катеров и лодочных моторов.

Подпишитесь на наши новости

Подписаться

|

Title |

File Size |

Download Links |

|

Yamaha BR250 Bravo Snowmobile Service Manual.pdf |

10.3Mb |

Download |

|

Yamaha BR250 Parts Catalog.rar |

8.3Mb |

Download |

|

Yamaha BR250F Service Manual.pdf |

10.8Mb |

Download |

|

Yamaha BR250TG/VK540EG Owner’s Manual.pdf |

8.7Mb |

Download |

|

Yamaha EC340E Supplementary Service Manual.pdf |

892.9kb |

Download |

|

Yamaha ET300E Supplementary Service Manual.pdf |

790.2kb |

Download |

|

Yamaha ET410 Parts Catalog.rar |

4.1Mb |

Download |

|

Yamaha FX Nytro Owner`s Manual.rar |

18.5Mb |

Download |

|

Yamaha FX Nytro Service Manual.pdf |

13.5Mb |

Download |

|

Yamaha FX/FX10/RFX10 Owner’s Manual.rar |

32Mb |

Download |

|

Yamaha FX10 Parts Catalog.rar |

13.2Mb |

Download |

|

Yamaha MM600/MM700 Parts Catalog.rar |

6.2Mb |

Download |

|

Yamaha MM600/MM700/MX600/VT600/VT700/VX600/VX700 Owner`s Manual.rar |

32Mb |

Download |

|

Yamaha MM700/VT700/VX700ER Owner`s Manual.pdf |

9.2Mb |

Download |

|

Yamaha Phazer Venture Lite PZ50MTA 2011 Supplementary Service Manual.pdf |

6.4Mb |

Download |

|

Yamaha PZ-series Parts Catalog.rar |

30Mb |

Download |

|

Yamaha PZ50 Owner`s Manual.rar |

11.7Mb |

Download |

|

Yamaha PZ50 Phazer, Venture Owner`s Manual.rar |

21.6Mb |

Download |

|

Yamaha PZ50 Service Manual.rar |

21.2Mb |

Download |

|

Yamaha PZ500/VT500 Owner`s Manual.pdf |

2.4Mb |

Download |

|

Yamaha PZ500C/VT500XLC Service Manual.rar |

6Mb |

Download |

|

Yamaha RS10/RS90/RSG90/RST90 Owner`s Manual.rar |

31Mb |

Download |

|

Yamaha RS90 Parts Catalog.rar |

7.6Mb |

Download |

|

Yamaha RS90/RSG90/RST90 RS Vector, RS Venture Owner`s Manual.rar |

63.5Mb |

Download |

|

Yamaha RS90/RSG90/RST90 RS Venture Service Manual.rar |

37.1Mb |

Download |

|

Yamaha RS90L Owner`s Manual.pdf |

5.8Mb |

Download |

|

Yamaha RSG90 Parts Catalog.rar |

3.5Mb |

Download |

|

Yamaha RST90 Parts Catalog.rar |

11.9Mb |

Download |

|

Yamaha RX-1 Service Manual.pdf |

18.8Mb |

Download |

|

Yamaha RX10 Parts Catalog.rar |

28Mb |

Download |

|

Yamaha RX10/RXW10 Owner`s Manual.rar |

28.6Mb |

Download |

|

Yamaha RX10LTGTYL Service Manual.pdf |

32.7Mb |

Download |

|

Yamaha RX90/RXW90 Apex Owner`s Manual.rar |

48.2Mb |

Download |

|

Yamaha RXW10 Parts Catalog.rar |

5.1Mb |

Download |

|

Yamaha SL292C 1971 Service Manual.pdf |

26Mb |

Download |

|

Yamaha Snowmobile Design Description.pdf |

6.9Mb |

Download |

|

Yamaha snowmobile fault codes list.rar |

1.7Mb |

Download |

|

Yamaha SRX700 Parts Catalog.rar |

5.9Mb |

Download |

|

Yamaha SRX700 Service Manual.pdf |

7.4Mb |

Download |

|

Yamaha SX500/600/700 Parts Catalog.rar |

10.7Mb |

Download |

|

Yamaha SXV-VT owner`s manual.rar |

48.3Mb |

Download |

|

Yamaha SXV60/SXV70/VT60/VT70 Owner`s Manual.rar |

48.3Mb |

Download |

|

Yamaha SXV70 Parts Catalog.rar |

14.6Mb |

Download |

|

Yamaha SXV70ERJ Owner’s Manual.pdf |

9.6Mb |

Download |

|

Yamaha VK10/VK10D RS Viking Owner`s Manual.rar |

15.6Mb |

Download |

|

Yamaha VK10/VK540 Parts Catalog.rar |

22.7Mb |

Download |

|

Yamaha VK10L/ Yamaha VK10X Owner`s Manual.rar |

7.9Mb |

Download |

|

Yamaha VK540EG/VK540EK Owner`s Manual.rar |

4.8Mb |

Download |

|

Yamaha VK540EK Service Manual.pdf |

4.9Mb |

Download |

|

Yamaha VT Parts Catalog.rar |

65.9Mb |

Download |

|

Yamaha VT500XL Owner`s Manual.pdf |

8.2Mb |

Download |

|

Yamaha VT700F Service Manual.pdf |

13.1Mb |

Download |

|

Yamaha VX500/600/700 Parts Catalog.rar |

21.2Mb |

Download |

|

Yamaha VX500SXBC Service Manual.pdf |

2.3Mb |

Download |

Yamaha is one of the oldest corporations in the world producing musical instruments, sound equipment, sports equipment, etc.

Yamaha began to produce snowmobiles from the beginning of the 60s of the last century, and already in 1968 the mass production of this equipment began. The company’s products were oriented to the

US and Canada markets.

A feature of Yamaha snowmobiles is that their motor was borrowed from motorcycles, due to this, snowmobiles received additional aggression. Every year, Yamaha increased

production, and by 1983, 500 thousand units of equipment had rolled off its conveyors, and by 1997, the line of one million snowmobiles had been overcome.

Production facilities are located in both Japan and the United States. Yamaha is considered the most successful manufacturer of snowmobiles, if we consider their financial performance. The

Japanese manufacturer worldwide employs more than 40 thousand employees. The domestic market of Japan in the total share of sales occupies only 12%, the remaining 88% is export.

The modern market divides snowmobiles into:

- Utilitarian;

- Tourist;

- Sports;

- Mountain.

Japanese utilitarian Yamaha snowmobiles are very popular in Russia. Especially Yamaha RS Viking Professional and Yamaha VK 540. This is a classic of the genre. If you need a

reliable utilitarian snowmobile, the first thing that comes to mind is, of course, Viking.

The latest VK540 IV has even greater cross-country ability in deep snow, carrying capacity, high-torque and endurance. At the same time, it is economical and highly reliable.

Everything in VK540 IV is aimed at giving you maximum pleasure from overcoming the virgin snow. The heart of the snowmobile is the time-tested 535cc 2-cylinder 2-stroke Yamaha engine, powerful

and tough. It is reliable and easy to maintain, and in combination with a 2-speed transmission expands the capabilities of the snowmobile. Innovatively designed wide skis with an optimized skate

profile provide excellent deep snow maneuverability and handling.

Lightweight and durable, the wide Camoplast Ripsaw Full Block ™ caterpillar is known for its exceptional cross-country ability. A new torsion rear suspension was used, leading drive wheels of the

track with external gearing. Electric heating of the handlebars of the steering wheel and the trigger of «gas», a high windshield were installed. Convenient seatpost and spacious trunk, 2-seater

seat, spacious footrests with non-slip surface. With VK540IV, work has never been so much fun!

Yamaha Japanese snowmobiles are always among the best in the world. In the 2011 lineup, 3 models were presented:

- Snowmobile Yamaha RS Venture TF

- Snowmobile Yamaha RS Venture GT

- Snowmobile Yamaha Venture Multi Purpose

Yamaha sports snowmobiles in 2011 were represented by only three models: FX Nytro R-TX, FX Nytro X-TX and APEX X-TX. All these models are suitable for fast driving along natural

trails and are of the rough trail type. It is important to recall that all of these models are 4-stroke. This is the general policy of Yamaha on environmentally friendly technology. Let us focus

on the new product of 2011 for the Russian market — the Yamaha APEX X-TX model. This is the first snowmobile to feature an EPS electric power steering system that sets new standards for handling

and stability. This model is equipped with a modified four-cylinder engine with an EXUP exhaust system and a fuel injection system. These improvements were made in order to significantly increase

peak power and torque at low and medium ranges of engine speed. A long 144 ”/ 3658mm track, new front suspension geometry, Dual Shock® suspensions and wide skis make it easy to cross any trails.

-

Page 1

SUPPLEMENTARY SERVICE MANUAL… -

Page 2

OE001 son inspecting or repairing the snowmobile. NOTICE CAUTION: This manual was written by the Yamaha Mo- tor Company primarily for use by Yamaha A CAUTION indicates special precautions dealers and their qualified mechanics. It is that must be taken to avoid damage to the not possible to put an entire mechanic’s… -

Page 3

OE031 ILLUSTRATED SYMBOLS (Refer to the illustration) Illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 General information 2 Periodic inspection and adjustment 3 Chassis 4 Power train 5 Engine overhaul 6 Cooling system 7 Carburetion 8 Electrical… -

Page 4: Table Of Contents

CONTENTS GENERAL INFORMATION ….ENGINE ……MACHINE IDENTIFICATION .

-

Page 5: General Information

MACHINE IDENTIFICATION/IMPORTANT INFORMATION INFO 1E001 GENERAL INFORMATION MACHINE IDENTIFICATION FRAME SERIAL NUMBER The frame serial number 1 is located on the right-hand side of the frame (just below the front of the seat). ENGINE SERIAL NUMBER The engine serial number 1 is located on the right-hand side of the crankcase.

-

Page 6: Power Train

Adjust the V-belt position by removing or adding a spacer 2 on each adjusting bolt. For this adjustment, consult a Yamaha deal- er or another qualified mechanic. CAUTION: As the V-belt wears, adjustment may be necessary.

-

Page 7

INSP DRIVE V-BELT 2. Adjust the position of the V-belt by re- moving or adding a spacer 1 on each adjusting bolt 2 . V-belt height adjustment To move V-belt up: Add spacer To move V-belt down: Reduce spacer 3. Tighten: S Adjusting bolt Adjusting bolt: 10 Nm (1.0 mSkg, 7.2 ftSlb) -

Page 8: Brake Pad Inspection

INSP BRAKE PAD INSPECTION/SLID RUNNER INSPECTION BRAKE PAD INSPECTION 1. Apply the brake lever. 2. Inspect: S Brake pad Wear indicator 1 nearly contacts the brake disc ! Replace the brake pads as a set. Wear limit a : 4.7 mm (0.185 in) SLIDE RUNNER INSPECTION 1.

-

Page 9: Tuning

INSP CLUTCH TUNING W White S Silver Blue CLUTCH P Pink R Red O Orange High altitude Y Yellow G Green Specifications Model: VX500SXB 4,500 X 7,000 ft X 3,500 ft 3,000 X 5,000 ft 6,500 X 10,000 ft Elevation Idle speed Approx.

-

Page 10

INSP CLUTCH W white S Silver Blue P Pink R Red O Orange Y Yellow G Green Specifications Model: VX700ER X 3,500 ft 3,000 X 5,000 ft 4,500 X 7,000 ft 6,500 X 10,000 ft Elevation Idle speed Approx. 1,600 r / min Clutch Approx. -

Page 11

INSP CLUTCH 2E331 The clutch may require tuning depending upon the area of operation and desired han- dling characteristics. The clutch can be tuned by changing engagement and shifting speed. Clutch engagement speed is defined as the engine speed where the machine first begins to move from a complete stop. -

Page 12: Gear Selection

INSP GEAR SELECTION GEAR SELECTION The reduction ratio of the driven gear to the drive gear must be set according to the snow conditions. If there are many rough surfaces unfavorable snow conditions, drive/driven gear ratio should be increased. If the surfaces are fairly smooth or better snow conditions exist, decrease the ratio.

-

Page 13

INSP GEAR SELECTION 3 Secondary spring Spring rate Wire Free No. of Parts No. NSmm/ rad Color gauge length Standard coils (kgmm/ rad) (mm) (mm) 90508-500B1 6003 (613) BROWN 90508-536A9 7147 (729) VX500 90508-556A2 8314 (848) GREEN VX700 90508-556A7 9460 (965) SILVER 4 Secondary spring twist angle Seat… -

Page 14

INSP GEAR SELECTION 6 Primary spring Spring rate Wire Outside Free Preload No. of Standard Parts No. N / mm Color gauge diameter length (kg) coils (kg / mm) (mm) (mm) (mm) 90501-481J1 9.8 (1.0) 196.1 (20) S-B-S 5.16 85.4 90501-487G8 14.7 (1.5) 147 (15) -

Page 15: Front Suspension

INSP FRONT SUSPENSION FRONT SUSPENSION Spring preload (700) 1. Adjust: S Turn the adjusting ring 1 to the proper position. Spring adjuster position Softer z ! Harder Preload Standard CAUTION: Be sure that the left and right spring preload is the same. Spring preload (500) 1.

-

Page 16: Rear Suspension

INSP REAR SUSPENSION REAR SUSPENSION Stopper band 1. Adjust: S Stopper band tension CAUTION: Be sure that the left and right length is the same. NOTE: This adjustment affects the handling charac- teristics of the machine. Adjustment steps: S Loosen the locknut 1 . S Turn the adjusting nut 2 in or out to adjust the stopper band tension.

-

Page 17

INSP REAR SUSPENSION Spring preload (500) 1. Adjust: S Turn the spring seat 1 in or out. Spring seat Standard Shorter z ! Longer distance Harder z ! Softer Preload Length Max. Min. (front) 172 mm 182 mm 192 mm (6.77 in) (7.17 in) (7.56 in) Length Max. -

Page 18: Chassis

CHAS CHASSIS SKI (500) 10 Nm (1.0 mSkg, 7.2 ftSlb) 21 Nm (2.1 mSkg, 15 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) : ESSO beacon 325 grease or Aeroshell grease #7A Order Job name/Part name Q’ty Remarks Ski removal Remove the parts in the order below. Cotter pin Ski column lower bracket Ski stopper…

-

Page 19: Inspection

CHAS SKI/FRONT SUSPENSION INSPECTION 1. Inspect: S Ski 1 S Ski runner 2 S Ski column lower bracket 3 S Ski handle 4 S Ski stopper 5 Wear/cracks/damage ! Replace. S Mounting bolt 6 S Collar 7 Wear/damage ! Replace. FRONT SUSPENSION This shock absorber contains highly com- pressed nitrogen gas.

-

Page 20: Installation

CHAS FRONT SUSPENSION INSTALLATION 1. Install: S Control rod 1 S Nut 2 S Joint 3 a Set length Left hand Model Set length (mm) angle (_) 460.2 ± 0.5 mm VX500 94 ± 1 (18.11 ± 0.0197 in) Upper 458.7 ±…

-

Page 21: Power Train

POWR SECONDARY SHEAVE ASSEMBLY 1. Install: S Secondary sheave spring 1 S Bolts 2 (along with the shims) Bolt: 10 Nm (1.0 mSkg, 7.2 ftSlb) 2. Install: S Stopper S Sliding sheave Screw (stopper): 6.5 Nm (0.65 mSkg, 4.6 ftSlb) 3.

-

Page 22: Drive Chain Housing

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING WITHOUT REVERSE MODEL (500) 10 Nm (1.0 mSkg, 7.2 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Drive chain housing removal Remove the parts in the order below.

-

Page 23: Installation

POWR DRIVE CHAIN HOUSING INSTALLATION During installation, pay attention to the fol- lowing point: A Make sure that the bearing seals face towards the drive chain, as shown. B Properly install the rubber seal onto the drive chain housing, making sure that these are no gaps.

-

Page 24: Drive Chain Housing And Jackshaft Installation

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING AND JACKSHAFT INSTALLATION 1. Install: S Drive chain housing S Jackshaft Installation steps: D Install the drive chain housing 1 . D Tighten the bolts 2 . Bolt (drive chain housing): 48 Nm (4.8 mSkg, 35 ftSlb) D Temporarily tighten the nuts 3 .

-

Page 25: With Reverse Model (700)

POWR DRIVE CHAIN HOUSING WITH REVERSE MODEL (700) 10 Nm (1.0 mSkg, 7.2 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Drive chain housing removal Remove the parts in the order below.

-

Page 26

POWR DRIVE CHAIN HOUSING Order Job name/Part name Q’ty Remarks Reverse drive gear Spring Chain tensioner Roller Collar Spring Journal Reverse driven gear Washer Forward driven sprocket Collar Counter gear Drive sprocket Drive chain Collar Washer Plate Shaft Drive chain housing For installation, reverse the removal procedure. -

Page 27: Installation

POWR DRIVE CHAIN HOUSING/JACKSHAFT INSTALLATION During installation, pay attention to the fol- lowing point: A Properly install the rubber seal onto the drive chain housing, making sure that these are no gaps. B Make sure that the bearing seals face towards the drive chain, as shown.

-

Page 28: Brake

POWR BRAKE BRAKE 1.5 Nm (0.15 mSkg, 1.1 ftSlb) 6 Nm (0.6 mSkg, 4.3 ftSlb) Order Job name/Part name Q’ty Remarks Brake caliper disassembly Disassembly the parts in the order below. Cap bolt Retaining pin Pad spring Brake pads Shim 1 Shim 2 Bleed screws Oil seals…

-

Page 29: Brake Pad Replacement

POWR BRAKE CAUTION: Disc brake components rarely require disas- sembly. DO NOT: D Disassemble components unless abso- lutely necessary. D Use solvents on internal brake compo- nents. D Use contaminated brake fluid for clean- ing. Use only clean brake fluid. D Allow brake fluid to come in contact with the eyes, otherwise eye injury may occur.

-

Page 30

POWR BRAKE 2. Install: S Brake pads S Pad spring Installation steps: S Connect a suitable hose 1 tightly to the caliper bleed screw 2 . Put the other end of this hose into an open container. S Loosen the caliper bleed screw and push the pistons into the caliper with the finger. -

Page 31: Slide Rail Suspension

POWR SLIDE RAIL SUSPENSION SLIDE RAIL SUSPENSION 71 Nm (7.1 mSkg, 51 ftSlb) Order Job name/Part name Q’ty Remarks Slide rail suspension removal Remove the parts in the order below. Tension adjuster Loosen. Blind caps Bolts Washer Slide rail suspension For installation, reverse the removal procedure.

-

Page 32

POWR SLIDE RAIL SUSPENSION 4 Nm (0.4 mSkg, 2.9 ftSlb) 15 Nm (1.5 mSkg, 11 ftSlb) 30 Nm (3.0 mSkg, 22 ftSlb) 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) Order Job name/Part name Q’ty… -

Page 33

POWR SLIDE RAIL SUSPENSION 24 Nm (2.4 mSkg, 17 ftSlb) 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) Order Job name/Part name Q’ty Remarks Suspension wheels Collar Wheel brackets Circlips Suspension wheels Bushings Shaft Rear suspension bracket Spacers Bushings Collar… -

Page 34

POWR SLIDE RAIL SUSPENSION 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) Order Job name/Part name Q’ty Remarks Rear shock absorber Bushings Collar Pull rod Collars Bushings Collars (700) Suspension wheels Control rods Bushings Screw Bushings –30–… -

Page 35

POWR SLIDE RAIL SUSPENSION 24 Nm (2.4 mSkg, 17 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) 75 Nm (7.5 mSkg, 54 ftSlb) Order Job name/Part name Q’ty Remarks Rear pivot arm Bushings Collar Collar Rear pivot arm bracket Collar Circlips Suspension wheels Wheel bracket Rear axle… -

Page 36: Front Axle And Track

POWR FRONT AXLE AND TRACK FRONT AXLE AND TRACK 27 mm INSTALLATION (1.06 in) Reverse the “REMOVAL” procedure. Note the following points. 1. Install: S Sprocket wheels S Guide wheels 60 mm 132.6 mm 201.4 mm (2.36 in) (5.22 in) (7.93 in) NOTE: 164.1 mm…

-

Page 37: Engine

ENGINE ASSEMBLY ENGINE ENGINE ASSEMBLY 90 Nm (9.0 mSkg, 65 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Engine removal Remove the parts in the order below. Exhaust pipe Carburetor Refer to “CARBURETOR”. Recoil starter Refer to “RECOIL STARTER”.

-

Page 38

ENGINE ASSEMBLY 23 Nm (2.3 mSkg, 17 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) 90 Nm (9.0 mSkg, 65 ftSlb) 23 Nm (2.3 mSkg, 17 ftSlb) Order Job name/Part name Q’ty Remarks Engine removal Remove the parts in the order below. Exhaust pipe Carburetor Refer to “CARBURETOR”. -

Page 39: Cylinder Head And Cylinder

CYLINDER HEAD AND CYLINDER CYLINDER HEAD AND CYLINDER INSPECTION 1. Measure: S Piston-to-cylinder clearance Measurement steps: 1st step: S Measure the cylinder bore “C” with a cylinder bore gauge 1 . NOTE: Measure the cylinder bore “C” parallel to, and at right angles to the crankshaft. Then find the average of the measurements.

-

Page 40

CYLINDER HEAD AND CYLINDER 2nd step: S Measure the piston skirt diameter “P” with a micrometer from distance a . a 500: 25 mm (0.98 in) 700: 15 mm (0.59 in) from the piston bottom edge. Piston size P 500: 67.930 X 67.935 mm (2.6745 X 2.6746 in) Standard 700: 70.425 X 70.430 mm… -

Page 41: Heat Exchanger

COOL HEAT EXCHANGER COOLING SYSTEM HEAT EXCHANGER 1. Measure: S Filler cap opening pressure Cap opens at pressure below the speci- fied pressure ! Replace. Cap opening pressure: 95 X 125 kPa (0.95 X 1.25 kg/cm 13.58 X 17.87 psi) Measurement steps: D Attach the cooling system tester (90890-01325, YU-24460-01) to the…

-

Page 42: Carburetion

CARB CARBURETORS CARBURETION CARBURETORS * Intake silencer D First, remove the throttle cable from the cable guide on the steering column. D Adjust the throttle cable free play while the cable is in the cable guide. D After adjusting the throttle cable free play, properly install the upper and lower intake silencer plates and seal.

-

Page 43

CARB CARBURETORS * Intake silencer D First, remove the throttle cable from the cable guide on the steering column. D Adjust the throttle cable free play while the cable is in the cable guide. D After adjusting the throttle cable free play, properly install the upper and lower intake silencer plates and seal. -

Page 44

CARB CARBURETORS Order Job name/Part name Q’ty Remarks Carburetor separation Separation the parts in the order below. Coolant hoses Starter cable holder Collar Spring Screw Loosen Starter rod Spring Starter levers Breather hoses Top covers Gaskets Throttle shaft connecting screws Connecting plate (upper) Connecting plate (lower) For assembly, reverse the separation… -

Page 45: Assembly

CARB CARBURETORS ASSEMBLY 1. Measure: S Float height a Out of specification ! Adjust. Float height: 22.3 ± 2.0 mm (0.878 ± 0.080 in) 13.3 ± 2.0 mm (0.524 ± 0.080 in) Measurement and adjustment steps: S Hold the carburetor in an upside down position.

-

Page 46: Specifications

Maximum torque r/min Starting system Recoil hand starter Electric and recoil hand starter Lubrication system: Separate lubrication (YAMAHA AUTOLUBE) Engine oil: Type YAMALUBE 2-cycle oil Tank capacity 3.0 L (2.6 Imp gt, 3.2 Us gt) Drive chain housing oil: Type Gear oil API “GL-3”…

-

Page 47

SPEC GENERAL SPECIFICATIONS Model VX500SXB VX700ER Carburetor: Type/quantity TM36 TM33 Manufacturer MIKUNI Spark plug: Type BR9ES Manufacturer 0.7 X 0.8 mm (0.028 X 0.031 in) Transmission: Primary reduction system V-Belt 3.8 X 1.0 : 1 Primary reduction ratio Clutch type Automatic centrifugal engagement Secondary reduction system… -

Page 48: Maintenance Specifications

SPEC MAINTENANCE SPECIFICATIONS MAINTENANCE SPECIFICATIONS ENGINE Model VX500SXB VX700ER Cylinder head: 23.3 X 23.9 cm 22.9 X 23.5 cm Volume (with spark plug) <Warp limit> <0.03 mm (0.0012 in)> * Lines indicate straight edge measurement. Cylinder: Material Aluminum alloy with dispersion coating 68.00 X 68.02 mm 70.50 X 70.52 mm…

-

Page 49

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Crankshaft: 61.95 X 62.00 mm 55.95 X 56.00 mm Crank width “A” (2.439 X 2.440 in) (2.203 X 2.205 in) 179.85 X 180.15 mm 291.75 X 292.30 mm Crank width “B” (7.080 X 7.093 in) (11.486 X 11.508 in) Crankshaft deflection “C”… -

Page 50

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Carburetor: Type/Quantity TM36/2 pcs. TM33/3 pcs. Manufacturer MIKUNI I.D. mark 8CJ10 8CH10 Main jet (M.J) #151.3 #1 : #145 #2, 3 : #143.8 Main air jet (M.A.J) ø2.5 – Pilot jet (P.J) Jet needle (J.N) 8CFY14-56-2 6DGM5-3 Needle jet (N.J) -

Page 51

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Thermostat: 50 X 55_C Opening temperature (122_F X 132_F) Valve lift 8 mm/70_C (159_F) –47–… -

Page 52: Power Train

SPEC MAINTENANCE SPECIFICATIONS POWER TRAIN Model VX500SXB VX700ER Transmission: Type V-belt automatic 3.8 X 1.0 : 1 Range of ratio 4,000 ± 200 r/min Engagement r/min 7,800 ± 250 r/min 8,300 ± 250 r/min Shift r/min 267 X 270 mm Sheave center distance “A”…

-

Page 53

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Rivet: Outer Part number 90261-06034 90261-06015 Material Steel Size 13.9 mm (0.55 in) 10.3 mm (0.40 in) Quantity 3 pcs Hole quantity 3 pcs Inner Part number 90261-06028 90261-06034 Material Aluminum Steel Size 10.3mm (0.40in) 13.9 mm (0.55 in) Quantity 3 pcs… -

Page 54

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Track: Part number 8AB-47110-10 8CH-47110-00 Width 381 mm (15.0 in) Length 3,072 mm (120.9 in) Pitch 64 mm (2.52 in) Number of links Height “B” 16 mm (0.63 in) 25 X 30 mm Deflection at 10 kg (22 lb) (0.98 X 1.18 in) Slide rail suspension: Front travel… -

Page 55

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Shock absorber: Damping force Front 3,320N ± 460N/0.3m/s 720 N ± 150N/0.3m/s Extension 1,110N ± 225N/0.3m/s 1,020 N ± 210N/0.3m/s Compression Rear 1,950N ± 264N/0.3m/s 2,206 N ± 657N/0.3m/s Extension 1,380N ± 235N/0.3m/s 726 N ± 216N/0.3m/s Compression Slide runner: Thickness… -

Page 56: Chassis

SPEC MAINTENANCE SPECIFICATIONS CHASSIS Model VX500SXB VX700ER Frame: Frame material Aluminum Seat height 685 mm (26.8 in) 730 mm (28.7 in) Luggage box location Rear side of seat Steering: Lock-to-lock angle (left) 29.6_ (R ski) 34.8_ (L ski) 29.4_ (R ski) 34.7_ (L ski) (right) 34.8_ (R ski) 29.6_ (L ski) 34.7_ (R ski) 29.4_ (L ski)

-

Page 57: Electrical

18_ at 4.500 r/min 24_ at 4.500 r/min Advanced type Electrical type Ignition coil: Model/Manufacturer 8AB-00/YAMAHA 8DG-00/YAMAHA Minimum spark gap 3 mm (0.118 in) or more 0.2 Ω ± 20% at 20_C (68_F) 0.06 Ω ± 20% at 20_C Primary coil resistance (68_F) 4.9 kΩ…

-

Page 58

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Rectifier/regulator: Model/manufacturer 8CR-00/MATSUSHITA 13.8 X 14.8 V No load regulated voltage 14.0 X 15.0 V Battery: (for electric model) Specific gravity – 1.280 Type – GM18Z-3A Electric starter system: (for electric model) Type – Bendix Starter motor: (for electric model) Model/manufacturer… -

Page 59

SPEC MAINTENANCE SPECIFICATIONS High altitude settings VX500SXB Tempera- – 40_C – 29_C – 18_C – 7_C 15_C ture (– 40_F) (– 20_F) (0_F) (20_F) (40_F) (60_F) Altitude 0 X 100 m MJ#155 MJ#153.8 MJ#152.5 MJ#151.3 MJ#150 (0 X 330 ft) JN-2.0 JN-2.0 JN-2.0… -

Page 60

SPEC MAINTENANCE SPECIFICATIONS High altitude settings VX700ER Tempera- – 40_C – 29_C – 18_C – 7_C 15_C ture (– 40_F) (– 20_F) (0_F) (20_F) (40_F) (60_F) Altitude MJ#1 #148.8 MJ#1 #147.5 MJ#1 #146.3 MJ#1 #145.0 MJ#1 #143.8 MJ#2#3 #147.5 MJ#2#3 #146.3 MJ#2#3 #145.0 MJ#2#3 #143.8 MJ#2#3 #142.5… -

Page 61

SPEC MAINTENANCE SPECIFICATIONS Tightening torque: Tightening torque Parts to be tightened Parts to be tightened Remarks Remarks mSkg ftSlb Crankcase (first) Tighten the bolts in two Crankcase (final) stages. Engine bracket (front) and frame 500 Engine bracket (front) and frame Engine bracket damper (front) Engine bracket and engine Engine bracket upper and lower (rear) -

Page 62

SPEC MAINTENANCE SPECIFICATIONS Tightening torque Parts to be tightened Parts to be tightened Remarks Remarks mSkg ftSlb Sliding frame and slide runner Slide rail suspension mounting bolt Rear pivot arm and bracket Apply LOCTITE Shock absorber and rear pivot arm Rear pivot arm and rod Rear suspension bracket and rod Control rod and sliding frame… -

Page 63

SPEC MAINTENANCE SPECIFICATIONS –59–… -

Page 64: Cable Routing <500

SPEC CABLE ROUTING CABLE ROUTING <500> –60–…

-

Page 65

SPEC CABLE ROUTING CABLE ROUTING <For 500> 1 Oil pump cable 2 Throttle cable 3 Fasten the wire harness. Do not fasten the throttle cable and oil pump cable. 4 Fasten the throttle cable and oil pump cable with a plastic clamp. Route the cable along the side of the handle holder. -

Page 66

SPEC CABLE ROUTING –62–… -

Page 67

SPEC CABLE ROUTING 35 To the conduction 36 Voltage regulator 37 Rectifire regulator 38 Fasten the wire harness with a plastic clamp. 39 Rectifire regulator (ECC model) 40 Brake hose holder 41 Fasten the wire harness with a plastic clamp. 42 To reverse gear 43 Fasten the wire harness, fuel breather hose and oil… -

Page 68

SPEC CABLE ROUTING –64–… -

Page 69

SPEC CABLE ROUTING 1 Wire lead (electrical starter model) 2 Carburetor switch coupler 3 Fasten the throttle cable and oil pump cable with a plastic clamp. 4 Air temperature sensor coupler (ECC model) 5 Coolant hose 6 Starter relay lead 7 Starter relay sub lead (electrical starter model) 8 Fasten the wire harness,… -

Page 70

SPEC CABLE ROUTING –66–… -

Page 71

SPEC CABLE ROUTING 32 Solenoid coupler (ECC model) 33 Ignition coil 34 Carburetor heating lever 35 Coolant hose 36 Speedometer cable 37 Fasten the throttle cable, water temperature sensor lead, carburetor switch lead and solenoid lead with a plastic clamp. 38 Water temperature sensor coupler 39 Under 50 mm (1.97 in) -

Page 72

SPEC CABLE ROUTING –68–… -

Page 73

SPEC CABLE ROUTING 1 Make sure that the oil tank cap and oil breather hose do not touch each other. 2 Route the fuel breather hose along the upper of the main harness. 3 Route the oil breather hose along the upper of the main harness. -

Page 74: Cable Routing <700

SPEC CABLE ROUTING CABLE ROUTING <700> –70–…

-

Page 75

SPEC CABLE ROUTING CABLE ROUTING <For 700> 1 Oil pump cable 2 Throttle cable 3 Do not fasten the throttle cable and oil pump wire with a plastic clamp. 4 Thumb warmer coupler 5 Engine stop switch coupler 6 Holder 7 Grip warmer coupler 8 Brake light switch coupler 9 Head light switch coupler… -

Page 76

SPEC CABLE ROUTING –72–… -

Page 77

SPEC CABLE ROUTING 37 DC back buzzer (reverse model) 38 Voltage regulator 39 Rectifier regulator 40 DC back buzzer coupler 41 Fasten the wire harness with a plastic clamp. 42 Brake hose holder 43 Fasten the wire harness with a plastic clamp. 44 To reverse gear 45 Fasten the wire harness, fuel breather hose and oil… -

Page 78

SPEC CABLE ROUTING –74–… -

Page 79

SPEC CABLE ROUTING 1 Fasten the carburetor switch, water temperature sensor lead, coolant hose, wire lead and battery negative lead with a plastic clamp. 2 Clamp 3 Fasten the ignition coil and starter cable with a plastic clamp. 4 Fasten the wire lead, battery negative lead and coolant hose with a plastic clamp. -

Page 80

SPEC CABLE ROUTING –76–… -

Page 81

SPEC CABLE ROUTING 1 Wire harness 2 50 mm (1.97 in) 3 Make sure that the oil tank cap and oil breather hose do not touch each other. 4 Route the fuel breather hose along the upper of the main harness. -

Page 82

WIRING DIAGRAM VX500SXB CDI magneto Brake light switch Rectifier / regulator Tail / brake light Starter relay / fuse Speedometer assembly Battery Oil level indicator light Starter motor Water temp. indicator light Main switch High beam indicator light Engine stop switch Speedometer light Throttle switch Tachometer assembly… -

Page 83

WIRING DIAGRAM VX700ER CDI magneto Brake light switch Rectifier / regulator Tail / brake light Starter relay / fuse Speedometer assembly Battery Oil level indicator light Starter motor Water temp indicator light Main switch High beam indicator light Engine stop switch Speedometer light Throttle switch Tachometer assembly… -

Page 84

PRINTED IN USA PRINTED ON RECYCLED PAPER…

Каталоги запчастей

Руководства и инструкции по ремонту и обслуживанию снегоходов

Arctic Cat

- ARCTIC CAT Спец. инструмент для ремонта снегоходов (скачать PDF, 2,7 МБ)

BRP Ski-Doo

- BRP Ski-Doo Elite 4-TEC электрическая схема (скачать PDF, 10,1 МБ)

- BRP Ski-Doo ZX Series сервисная информация (скачать PDF, 1,6 МБ)

- BRP Ski-Doo ZX Series электрические схемы (скачать PDF, 2,5 МБ)

- BRP Ski-Doo ZX Series рулевое управление, передняя ходовая часть (скачать PDF, 2,4 МБ)

- BRP Ski-Doo ZX Series задняя ходовая часть (скачать PDF, 3,6 МБ)

- BRP Ski-Doo ZX Series электрическая система (скачать PDF, 3 МБ)

- BRP Ski-Doo ZX Series трансмиссия (скачать PDF, 3 МБ)

- BRP Ski-Doo ZX Series ремонт двигателя 377F, 503F, 552F, 493, 593, 593HO, 693, 793, 793HO (скачать PDF, 8,6 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X электрическая схема (скачать PDF, 2 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X сервисная информация (скачать PDF, 364 КБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X рама, пластик (скачать PDF, 584 КБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X рулевое управление, передняя ходовая часть (скачать PDF, 2,5 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X задняя ходовая часть (скачать PDF, 1,9 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X электрическая система (скачать PDF, 2,2 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X трансмиссия (скачать PDF, 2,7 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X ремонт двигателя 593HO, 793 (скачать PDF, 5,7 МБ)

- BRP Ski-Doo MX Z 600HO, HO X, HO 007 SE, 800 Sport, 800X справочник неисправностей (скачать PDF, 650 КБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec сервисная информация (скачать PDF, 357 КБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec рулевое управление, передняя ходовая часть (скачать PDF, 1,1 МБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec электрическая схема (скачать PDF, 1,6 МБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec электрическая система (скачать PDF, 490 КБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec трансмиссия (скачать PDF, 2 МБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec диагностика двигателя (скачать PDF, 2,7 МБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec ремонт двигателя (скачать PDF, 5,2 МБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec регламент технического обслуживания (скачать PDF, 330 КБ)

- BRP Ski-Doo Legend, Grand Touring V-1000 4-tec спец.инструмент для ремонта снегохода (скачать PDF, 1,7 МБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI сервисная информация (скачать PDF, 312 КБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI электрическая схема (скачать PDF, 1,6 МБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI электрическая система (скачать PDF, 584 КБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI ремонт системы SDI (скачать PDF, 2 МБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI ремонт двигателя 793 SDI (скачать PDF, 4,2 МБ)

- BRP Ski-Doo Legend, Grand Touring 800 SE SDI регламент технического обслуживания (скачать PDF, 280 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC электрическая схема (скачать PDF, 995 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC сервисная информация (скачать PDF, 288 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC рама, пластик (скачать PDF, 304 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC рулевое управление, передняя ходовая часть (скачать PDF, 1,4 МБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC задняя ходовая часть (скачать PDF, 2,2 МБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC электрическая система (скачать PDF, 4,8 МБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC трансмиссия (скачать PDF, 8,7 МБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC ремонт двигателя 277, 443, 503, 593 (скачать PDF, 13,3 МБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC справочник неисправностей (скачать PDF, 484 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC регламент технического обслуживания (скачать PDF, 355 КБ)

- BRP Ski-Doo Tundra R, Skandic LT, WT, SWT, WT LC спец.инструмент для ремонта снегоходов (скачать PDF, 2,1 МБ)

- BRP Ski-Doo MX Z 440, 600, 800, Summit 600HO, 800HO сервис, ремонт (скачать PDF, 11,3 МБ)

- BRP Ski-Doo Сервисная информация 2000-2004г. (скачать PDF, 4,9 МБ)

YAMAHA

- YAMAHA СНЕГОХОДЫ «КОДЫ ОШИБОК» (скачать PDF, 69 КБ)

- YAMAHA Спец.инструмент для ремонта снегоходов (скачать PDF, 1,3 МБ)

- YAMAHA VK 540 III Viking Общая информация (скачать PDF, 2 МБ)

- YAMAHA VK 540 III Viking Техническая информация (скачать PDF, 5,7 МБ)

- YAMAHA VK 540 III Viking Рулевое управление, передняя подвеска, лыжи (скачать PDF, 1,9 МБ)

- YAMAHA VK 540 III Viking Трансмиссия, тормозная система, задняя подвеска, трек (скачать PDF, 5,8 МБ)

- YAMAHA VK 540 III Viking Ремонт двигателя (скачать PDF, 4,9 МБ)

- YAMAHA VK 540 III Viking Карбюратор (скачать PDF, 1,2 МБ)

- YAMAHA VK 540 III Viking Электросистема (скачать PDF, 2,9 МБ)

- YAMAHA VK 540 III Viking Электрическая схема (скачать PDF, 312 КБ)

- YAMAHA VK 540 III Viking Сервисная информация (скачать PDF, 2 МБ)

- YAMAHA VK10 Viking сервис, ремонт 1 (скачать PDF, 5,5 МБ)

- YAMAHA VK10 Viking сервис, ремонт 2 (скачать PDF, 6 МБ)

- YAMAHA RX10, RXW10 сервис, ремонт 1 (скачать PDF, 6,8 МБ)

- YAMAHA RX10, RXW10 сервис, ремонт 2 (скачать PDF, 3,5 МБ)

- YAMAHA RS 90, сервис, ремонт дополнение 1 (скачать PDF, 9,8 МБ)

- YAMAHA RS 90, сервис, ремонт дополнение 2 (скачать PDF, 5,7 МБ)

- YAMAHA Venture, Phazer PZ50 сервис, ремонт (скачать PDF, 9,5 МБ)

- YAMAHA FX 10 NYTRO сервис, ремонт (скачать PDF, 18,6 МБ)

- YAMAHA RPZ50 проблема впускной системы (скачать PDF, 3,4 МБ)

- YAMAHA RPZ50 проблема рулевого управления (скачать PDF, 853 КБ)

- YAMAHA PZ50 проблема запуска ниже -20° (скачать PDF, 887 КБ)

- YAMAHA RS 90, RSG 90, RST 90 сервис, ремонт (скачать PDF, 18,9 МБ)