В данном разделе размещено руководство по эксплуатации Рендж Ровер в кузове L322 от производителя

В данном разделе размещено два руководства по эксплуатации Рендж Ровер в кузове L322 от производителя

В данном разделе размещено руководство по эксплуатации Рендж Ровер в кузове L322 от производителя — LRL 38 02 55 102

В данном разделе размещено руководство по эксплуатации Рендж Ровер в кузове L322 от производителя — LRL 38 02 55 901

В данном разделе размещено руководство по эксплуатации Рендж Ровер в кузове L322 от производителя — LRL 38 02 55 801

В данном разделе размещено руководство по эксплуатации Рендж Ровер в кузове L322 от производителя — LRL 38 02 55 701

Хочу поделиться своей подборкой мануалов по ренжам. Выручали и не раз.

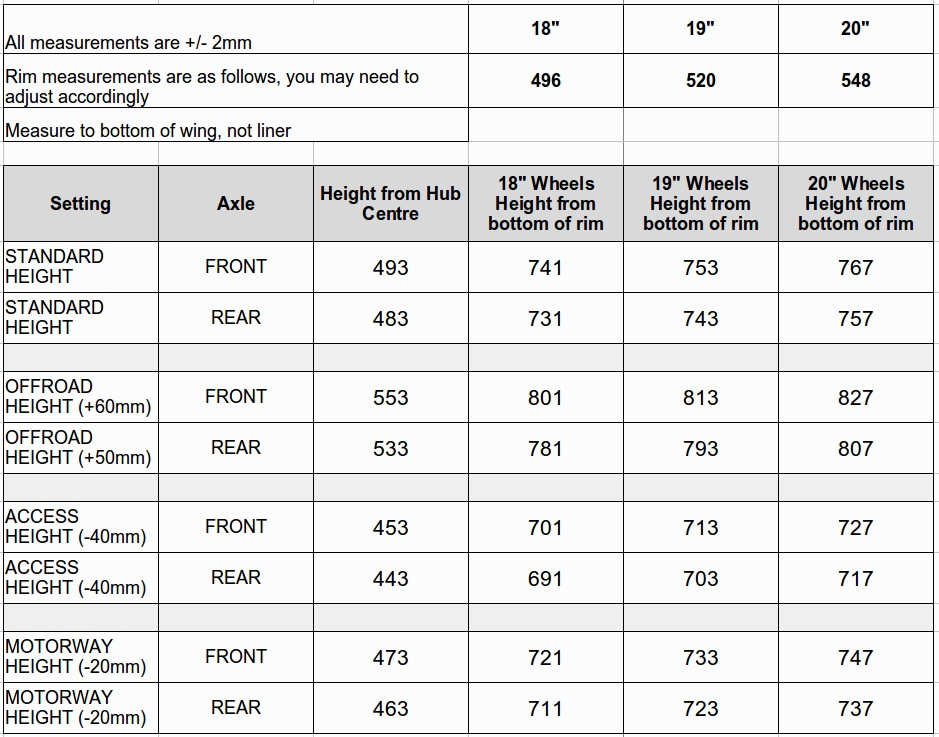

1. Таблица высоты калибровки пневмоподвески

2. Пособие по пневматической подвеске

yadi.sk/i/SlP44D9L3E4BLt

3. Электрическая библиотека (расшифровки разъемов, проводов и т.д.)

yadi.sk/i/l7WK4EdK3E4BVT

4. WORKSHOP MANUAL — SYSTEM DESCRIPTION AND OPERATION

— на русском

yadi.sk/i/fLlKPPD33E4Bs3

— на английском

yadi.sk/i/9cPTxEYp3E4C6X

5. Руководство по ремонту LRL0477RU

yadi.sk/i/vpPLjRsP3E4CAT

6. Руководство по ремонту с электросхемами (скан книги)

yadi.sk/i/wy00p5NV3E4CHp

7. AUX MFD E53

yadi.sk/i/y89ESnJA3E4CN9

Руководство по эксплуатации Range Rover содержит более 60 разделов, которые помогут содержать свой автомобиль в исправном состоянии, следить за функциональностью систем и знать, когда что необходимо менять

Чтобы машина работала исправно требуется соблюдать руководство по эксплуатации Рендж Ровер, потому что только завод-изготовитель знает до конца все особенности и нюансы авто. Технический Центр «Сервис Парк» предлагает скачать файл с инструкцией ко всем моделям этой марки. Если при прочтении руководства по Рендж Ровер Вог или другой модели возникнут вопросы, то всегда можно обратиться к специалисту центра за информационной и практической поддержкой.

Содержание

инструкции по эксплуатации автомобиля Range Rover

Руководство по эксплуатации Range Rover содержит более 60 разделов, которые помогут содержать свой автомобиль в исправном состоянии, следить за функциональностью систем и знать, когда что необходимо менять. Среди содержания документа есть очень простые советы: как безопасно совершать посадку в автомобиль, выходить из него, настроить работу подголовников по высоте и углу наклона, изменить их форму. Конечно, если водитель уже до этого использовал другую модель Рендж Ровера Спорт или Вог, то многие принципы и настройки будут похожи.

Есть в Рендж Ровер инструкции и полезные правила по следующим областям использования внедорожника:

- Настройка и регулировка положения передних и задних сидений.

- Слежение за исправностью подушек безопасности и своевременная диагностика.

- Управление световыми сигнализаторами.

- Навигация по сенсорному экрану.

- Настройка вентиляции и обогрева салона.

- Правильное распределение груза при перевозке и подсоединение прицепа.

- Рекомендации по использованию коробки передач в сочетании с различными режимами вождения и способы их установки.

- Практичные советы как снизить расход топлива при помощи системы Eco-Data.

- Правила ухода за датчиками парковки и их настройкой.

Инструкция

по эксплуатации: Предостережение перед первым запуском двигателя автомобиля Range Rover

Кроме вышеописанных рекомендаций по Range Rover инструкция по эксплуатации содержит и предостережения насчет первого самостоятельного запуска двигателя, с чем, возможно, будет труднее разобраться, если до этого водитель владел автомобилем классом ниже. В документе рекомендуется класть электронный ключ только в свободные карманы, которые не имеют экранированного слоя. Совмещение ключа с телефоном способно создать помехи и машина не распознает владельца. Аналогичное действие происходит и при хранении ключа в сумке с ноутбуком или игровой консолью.

Перед пуском двигателя советуются нажать на педаль тормоза и поставить селектор в положение P или N. Нажатием и отпусканием кнопки Start осуществляется запуск силовой установки. Если это происходит на дизельной версии в холодное время года, то руководство по эксплуатации Range Rover 3 сообщает, что последует задержка в несколько секунд для предпускового подогрева свечей. Аналогичное действие наблюдается и у других дизельных моделей. При этом всегда можно обратиться к специалистам «Сервис Парк» по телефону, чтобы узнать нормальна ли работа двигателя или наблюдается аномалия и нужна диагностика.

Знакомство

с панелью приборов Рендж Ровер

Всем новым владельцам Рендж Ровер инструкция по эксплуатации поможет разобраться в приборной панели, чтобы знать расположение сигналов и порядок отображения информации. Панель полностью цифровая, и на ней отображены:

- тахометр;

- спидометр;

- информация о положении селектора;

- уровень топлива;

- запас хода;

- данные о пробеге и времени до следующего технического обслуживания;

- наружная температура;

- информационная панель.

Бортовой компьютер может выводить сообщения о расходе топлива как среднем, так и за поезду или на данный момент времени (мгновенный). Руководство Range Rover сообщает, что если система самодиагностики выявила ошибку, то ее код отобразится на экране. В случае возникновения нескольких неисправностей одновременно коды будут отображаться сверху вниз в порядке серьезности поломки. При невозможности определить код лучше обратиться в «Сервис Парк», чтобы точно идентифицировать поломку и устранить ее.

Контроль

технических жидкостей в автомобиле

Немаловажно при эксплуатации внедорожника следить за уровнем рабочих жидкостей, что поможет избежать внезапного перегрева, заклинивания или выхода из строй основных систем. Руководство Рендж Ровер поможет узнать расположение всех горловин и определение уровня по ключевым меткам. Там наглядно изображены на картинке:

- крышка маслозаливной горловины, в зависимости от объема двигателя и вида топлива;

- горловина бачка тормозной жидкости;

- емкость от системы динамической стабилизации;

- крышка от бака с охлаждающей жидкостью;

- горловина от бачка омывателя для обычного и только холодного климата.

Владельцу Range Rover инструкция поможет произвести долив технических жидкостей самостоятельно, если он оказался далеко от автосервиса. В случае неуверенности в правильности определения нужной горловины, чтобы предупредить залив омывателя в тормозную систему или наоборот, всегда можно обратиться за консультацией по телефону в «Сервис Парк».

Нахождение

и замена предохранителей

Если вышла из строя одна из электронных систем (не работает омыватель фар, электропривод сидений, зеркал, обогрев, электроусилитель рулевого колеса), то руководство Range Rover Vogue или другой модели поможет узнать где находится блок с предохранителями от этой системы, и какой именно легкоплавкий элемент по цвету и расположению за нее отвечает. Так водитель сможет самостоятельно заменить сгоревший предохранитель без обращения в автосервис.

Полная Инструкция Рендж Ровер Вог и других автомобилей от этого же производителя доступна для скачивания на этом сайте файлом PDF, что позволит сохранить ее в телефоне или планшете и применять даже на дороге без наличия интернета. В случае непонятного поведения автомобиля или явных неисправностей лучше обратиться в технический центр «Сервис Парк», который специализируется на гарантийном и постгарантийном обслуживании марки Рендж Ровер всех поколений и годов выпуска. Здесь имеется одобренное заводом-изготовителем оборудование для диагностики и ремонта, а также квалифицированный персонал, который прошел обучение в специальных центрах Range Rover. Чтобы записаться на обслуживание или диагностику необходимо оформить заявку на сайте.

вам ответит мастер-приёмщик

Бегун Андрей

Page 1 — Electrical Library

Electrical LibraryNRRERL 28/11/01 10:02 am Page 1

Page 2 — ELECTRICAL LIBRARY

INTRODUCTIONRANGE ROVER 1.5Battery ChargingOnly recharge the battery with it removed from the vehicle. Always ensure any battery charging area is wel

Page 3

DESCRIPTION AND OPERATIONRANGE ROVER 4.75Light Check ModuleThe LCM (C2040) is located at the base of the RH ‘A’ post, and monitors the cond

Page 4 — CONTENTS

DESCRIPTION AND OPERATION4.76 RANGE ROVERBi-Xenon SystemPower DistributionFeed from the positive battery terminal (C0192) is supplied to fuse 53, fusi

Page 5

DESCRIPTION AND OPERATIONRANGE ROVER 4.77Headlamp Dipped BeamIn addition to the lamps outlined in the side lamps section, the LCM will provide feeds

Page 6

DESCRIPTION AND OPERATION4.78 RANGE ROVERAUTOMATIC HEADLAMP LEVELLINGDESCRIPTIONGeneralAutomatic headlamp levelling is only fitted to vehicles with bi

Page 7

DESCRIPTION AND OPERATIONRANGE ROVER 4.79ABS ECUThe ABS ECU (C0506) provides a vehicle speed signal to the headlamp levelling ECU (C1543) on a YW wir

Page 8

DESCRIPTION AND OPERATION4.80 RANGE ROVERFOG LAMPSDESCRIPTIONGeneralOperation of both the front and rear fog lamps is controlled by the Light Check Mo

Page 9

DESCRIPTION AND OPERATIONRANGE ROVER 4.81Rear Fog LampsPower DistributionFeed from the positive battery terminal (C0192) is supplied to fusible link

Page 10 — INTRODUCTION

DESCRIPTION AND OPERATION4.82 RANGE ROVERDIRECTION INDICATOR/HAZARD WARNING LAMPSDESCRIPTIONGeneralOperation of the direction indicator lamps is contr

Page 11

DESCRIPTION AND OPERATIONRANGE ROVER 4.83RH TurnThe LCM (C2040) monitors the condition of the column mounted direction indicator switch (C1832) by pr

Page 12

DESCRIPTION AND OPERATION4.84 RANGE ROVERINTERIOR LAMPSDESCRIPTIONGeneralOperation of the interior lamps is controlled by the Body Control Unit (BCU)

Page 13

INTRODUCTION1.6 RANGE ROVERABBREVIATIONSGeneralAAmpereABS Anti-lock Braking System ac Alternating currentA/C Air ConditioningATC Automatic Temperatur

Page 14

DESCRIPTION AND OPERATIONRANGE ROVER 4.85Body Control Unit (BCU)The BCU (C0662) monitors the condition of all four doors and provides feeds to the fo

Page 15

DESCRIPTION AND OPERATION4.86 RANGE ROVERGlove Box LampThe BCU (C0662) monitors the condition of the glove box switch (C0227) by providing a feed on a

Page 16

DESCRIPTION AND OPERATIONRANGE ROVER 4.87INTERIOR ILLUMINATIONDESCRIPTIONGeneralOperation of the interior illumination LED’s and lamps is contro

Page 17

DESCRIPTION AND OPERATION4.88 RANGE ROVERLight Check Module (LCM)When the LCM (C2039) senses that the ignition switch is in either the auxiliary or ig

Page 18 — FUSE DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.89All the above are earthed on N wires. The LCM also provides a feed to the following LED’s on SR wires:l

Page 19

DESCRIPTION AND OPERATION4.90 RANGE ROVERINSTRUMENTSDESCRIPTIONGeneralThe instrument pack is a totally electronic device which receives analogue or di

Page 20

DESCRIPTION AND OPERATIONRANGE ROVER 4.91Analogue InstrumentsSpeedometerThe ABS ECU (C0506) provides the instrument pack (C0230) a pulsed signal on a

Page 21

DESCRIPTION AND OPERATION4.92 RANGE ROVERHORNSDESCRIPTIONGeneralTwo horns are located behind the RH side of the front bumper. Operation of the horns i

Page 22

DESCRIPTION AND OPERATIONRANGE ROVER 4.93CLOCKDESCRIPTIONGeneralThe analogue clock is mounted on the passenger side of the centre console, and is ill

Page 23

DESCRIPTION AND OPERATION4.94 RANGE ROVERCIGAR LIGHTERSDESCRIPTIONGeneralTwo cigar lighters are fitted to Range Rover. The front cigar lighter is loca

Page 24 — EARTH POINTS AND HEADERS

INTRODUCTIONRANGE ROVER 1.7HeVAC Heating, Ventilation and Air ConditioningHO2S Heated Oxygen SensorHDC Hill Descent Control HFS Heated Front Screen H

Page 25

DESCRIPTION AND OPERATIONRANGE ROVER 4.95ACCESSORY SOCKETSDESCRIPTIONGeneralTwo accessory sockets are fitted to Range Rover. The front accessory sock

Page 26

DESCRIPTION AND OPERATION4.96 RANGE ROVERTRAILER SOCKETDESCRIPTIONGeneralThe trailer socket is mounted at the rear of the vehicle, and receives inputs

Page 27

DESCRIPTION AND OPERATIONRANGE ROVER 4.97RH Tail LampWhen the LCM (C0937) detects that side or headlamps have been selected, it provides a feed to th

Page 28

DESCRIPTION AND OPERATION4.98 RANGE ROVERAUDIO SYSTEM – LOW LINEDESCRIPTIONGeneralFor a detailed description of the audio systems fitted to New Range

Page 29

DESCRIPTION AND OPERATIONRANGE ROVER 4.99AUDIO SYSTEM – MID-LINEDESCRIPTIONGeneralFor a detailed description of the audio systems fitted to New Range

Page 30

DESCRIPTION AND OPERATION4.100 RANGE ROVERAUDIO SYSTEM – HIGH LINEDESCRIPTIONGeneralFor a detailed description of the audio systems fitted to New Rang

Page 31

DESCRIPTION AND OPERATIONRANGE ROVER 4.101SATELLITE NAVIGATION SYSTEMDESCRIPTIONGeneralFor a detailed description of the satellite navigation system

Page 32

DESCRIPTION AND OPERATION4.102 RANGE ROVERSATELLITE NAVIGATION SYSTEM – NASDESCRIPTIONGeneralFor a detailed description of the satellite navigation sy

Page 33

DESCRIPTION AND OPERATIONRANGE ROVER 4.103TELEPHONEDESCRIPTIONGeneralFor a detailed description of the telephone systems fitted to New Range Rover, r

Page 34

DESCRIPTION AND OPERATION4.104 RANGE ROVERTELEPHONE – HANDS FREEDESCRIPTIONGeneralFor a detailed description of the telephone systems fitted to New Ra

Page 35

INTRODUCTION1.8 RANGE ROVERHOW TO USE THIS DOCUMENTFuse DetailsContains information on fuse functions and values and should be used together with the

Page 36

DESCRIPTION AND OPERATIONRANGE ROVER 4.105TELEPHONE – NASDESCRIPTIONGeneralFor a detailed description of the telephone systems fitted to New Range Ro

Page 37

DESCRIPTION AND OPERATION4.106 RANGE ROVERFUEL PUMPDESCRIPTIONTd6The fuel system on Td6 vehicles features three fuel pumps. A primary fuel pump is mou

Page 38

DESCRIPTION AND OPERATIONRANGE ROVER 4.107V8Power DistributionFeed from the positive battery terminal (C0192) is supplied to fusible link 2 and fusib

Page 39

DESCRIPTION AND OPERATION4.108 RANGE ROVERROTARY COUPLERDESCRIPTIONGeneralThe rotary coupler is a rotating link harness, acting as a bridge between th

Page 40

DESCRIPTION AND OPERATIONRANGE ROVER 4.109Driver AirbagFor detailed information on driver airbag operation, refer to the Supplementary Restraint Sys

Page 41

DESCRIPTION AND OPERATION4.110 RANGE ROVERPARK DISTANCE CONTROL (PDC)DESCRIPTIONGeneralPark Distance Control (PDC) provides an audible warning to the

Page 42

DESCRIPTION AND OPERATIONRANGE ROVER 4.111RH Inner SensorThe PDC ECU (C0958) provides a feed to the RH inner PDC sensor (C0965) on a GS wire. An eart

Page 43

DESCRIPTION AND OPERATION4.112 RANGE ROVERLH Outer SensorThe PDC ECU (C1457) provides a feed to the LH outer PDC sensor (C0402) on a GB wire. An earth

Page 44

DESCRIPTION AND OPERATIONRANGE ROVER 4.113TYRE PRESSURE MONITORING (TPM)DESCRIPTIONGeneralThe Tyre Pressure Monitoring (TPM) system continuously moni

Page 45

DESCRIPTION AND OPERATION4.114 RANGE ROVERSTEERING COLUMNDESCRIPTIONGeneralThe steering column fitted to New Range Rover features fully electrical adj

Page 46

INTRODUCTIONRANGE ROVER 1.91. Cav: The connector pin (cavity) number.2. Col: The colour of wire populating the connector pin.3. Cct: Identifies th

Page 47

DESCRIPTION AND OPERATIONRANGE ROVER 4.115Memory Steering ColumnPower DistributionFeed from the positive battery terminal (C0192) is supplied to the

Page 48

DESCRIPTION AND OPERATION4.116 RANGE ROVERSteering Wheel HeaterPower DistributionFeed from the positive battery terminal (C0192) is supplied to the st

Page 49

DESCRIPTION AND OPERATIONRANGE ROVER 4.117AIR SUSPENSIONDESCRIPTIONGeneralThe main function of the four wheel air suspension system is to maintain th

Page 50

DESCRIPTION AND OPERATION4.118 RANGE ROVERAir Suspension ECUThe air suspension ECU (C0867) is located behind the LH side of the fascia, and is connect

Page 51

DESCRIPTION AND OPERATIONRANGE ROVER 4.119RH Rear Height SensorThe air suspension ECU (C0867) provides a feed to the RH rear height sensor (C1698) on

Page 52 — + DOOR MIRRORS

DESCRIPTION AND OPERATION4.120 RANGE ROVERValve BlockThe valve block contains five solenoid valves which control the air supply as follows:RH FrontIf

Page 53

CONNECTORRANGE ROVER 5.1CONNECTORCIRCUIT REFERENCE NUMBERSCONNECTOR APPLICABILITYGeneralThe following table lists the circuit reference numbers again

Page 54

CONNECTOR5.2 RANGE ROVER30 Auxiliary Module (Europe)31 Auxiliary Module (NAS)

Page 55

CONNECTOR DETAILS C0001RANGE ROVERCONNECTOR DETAILSRANGE ROVERC0001Description: Lamp-Direction indicator/hazard warning-Front-LHLocation: Front of veh

Page 56

C0002 CONNECTOR DETAILSRANGE ROVERC0002Description: Lamp-Direction indicator/hazard warning-Front-RHLocation: Front of vehicle — RH sideColour: BLACKG

Page 57

INTRODUCTION1.10 RANGE ROVERFAULT DIAGNOSISGeneralWhen diagnosing an electrical fault, follow the steps below:1. Read the circuit description appropri

Page 58

CONNECTOR DETAILS C0003RANGE ROVERC0003Description: Horn (s)Location: Behind RH side of front bumperColour: GREYGender: FemaleP6868C0004C0003Cav Col C

Page 59

C0004 CONNECTOR DETAILSRANGE ROVERC0004Description: Horn (s)Location: Behind RH side of front bumperColour: GREYGender: FemaleP6868C0004C0003Cav Col C

Page 60

CONNECTOR DETAILS C0005RANGE ROVERC0005Description: Cooling fanLocation: Front of engine compartment — centreColour: BLACKGender: FemaleP6864C0005C154

Page 61

C0007 CONNECTOR DETAILSRANGE ROVERC0007Description: Switch-BonnetLocation: Rear RH side of engine compartmentColour: BLACKGender: FemaleP6884C0666C050

Page 62

CONNECTOR DETAILS C0008RANGE ROVERC0008Description: Pump-Washer-WindscreenLocation: Front LH side of engine compartmentColour: BLACKGender: FemaleP685

Page 63

C0009 CONNECTOR DETAILSRANGE ROVERC0009Description: Headlamp-LHLocation: Front of vehicle — LH sideColour: BLACKGender: FemaleP6860C0009C0071Cav Col C

Page 64

CONNECTOR DETAILS C0011RANGE ROVERC0011Description: Headlamp-RHLocation: Front of vehicle — RH sideColour: BLACKGender: FemaleP6866C0011C0070C1341Cav

Page 65

C0012 CONNECTOR DETAILSRANGE ROVERC0012Description: Lamp-Side repeater-Front-RHLocation: Front of vehicle — RH sideColour: BLACKGender: FemaleP6871C00

Page 66

CONNECTOR DETAILS C0013RANGE ROVERC0013Description: Lamp-Side repeater-Front-LHLocation: Front of vehicle — LH sideColour: BLACKGender: FemaleP6873C00

Page 67

C0017 CONNECTOR DETAILSRANGE ROVERC0017Description: Header -EarthLocation: LH side of engine compartmentColour: TIN-PLATEGender: MaleP6857C0362C0551C0

Page 68

INTRODUCTIONRANGE ROVER 1.11WIRE COLOUR CODESGeneralThe following list contains wire colour codes used on the vehicle harness’s.Code ColourBBlac

Page 69

CONNECTOR DETAILS C0018RANGE ROVERC0018Description: Header -EarthLocation: Front RH side of engine compartmentColour: TIN-PLATEGender: MaleP6867C0018C

Page 70

C0021 CONNECTOR DETAILSRANGE ROVERC0021Description: Pump-Washer-Rear screenLocation: Front LH side of engine compartmentColour: BLACKGender: FemaleP68

Page 71

CONNECTOR DETAILS C0026RANGE ROVERC0026Description: Switch-Brake fluid levelLocation: Rear of engine compartmentColour: BLACKGender: FemaleP6884C0666C

Page 72

C0028 CONNECTOR DETAILSRANGE ROVERC0028Description: Switch-Ignition — V8Location: Beneath centre consoleColour: WHITEGender: FemaleP6913C0049C0672C002

Page 73

CONNECTOR DETAILS C0030RANGE ROVERC0030Description: Motor-Wiper-WindscreenLocation: Rear of engine compartmentColour: BLACKGender: FemaleP6884C0666C05

Page 74

C0040 CONNECTOR DETAILSRANGE ROVERC0040Description: Diagnostic socketLocation: Behind driver side of fasciaColour: BLACKGender: FemaleP6916C0040Cav Co

Page 75

CONNECTOR DETAILS C0041RANGE ROVERC0041Description: Switch-LightingLocation: Behind driver side of fasciaColour: BLACKGender: FemaleP6920C0041Cav Col

Page 76

C0049 CONNECTOR DETAILSRANGE ROVERC0049Description: Coil-TransponderLocation: Beneath centre consoleColour: BLACKGender: FemaleP6913C0049C0672C0028C00

Page 77

CONNECTOR DETAILS C0050RANGE ROVERC0050Description: Sensor-Pad wearLocation: Behind LH front wheel arch linerColour: BLACKGender: FemaleP6877C0516C005

Page 78 — + FUEL BURNING HEATER – V8

C0053 CONNECTOR DETAILSRANGE ROVERC0053Description: Alternator/generator — Td6Location: LH side of engineColour:Gender:P7027C1216C0053Cav Col Cct1G31G

Page 79

INTRODUCTION1.12 RANGE ROVER

Page 80

CONNECTOR DETAILS C0056RANGE ROVERC0056Description: Motor-Blower-FrontLocation: Behind centre of fasciaColour:Gender:Cav Col Cct1BGALL2RGALL

Page 81

C0059 CONNECTOR DETAILSRANGE ROVERC0059Description: ECU-Engine ImmobilisationLocation: Beneath centre consoleColour: BLACKGender: FemaleP6914C1664C005

Page 82

CONNECTOR DETAILS C0070RANGE ROVERC0070Description: Motor-Headlamp levelling-RHLocation: Front of vehicle — RH sideColour: NATURALGender: FemaleP6866C

Page 83

C0071 CONNECTOR DETAILSRANGE ROVERC0071Description: Motor-Headlamp levelling-LHLocation: Front of vehicle — LH sideColour: NATURALGender: FemaleP6860C

Page 84

CONNECTOR DETAILS C0074RANGE ROVERC0074Description: Cigar lighter illuminationLocation: Beneath centre consoleColour: WHITEGender: FemaleP6911C0089C00

Page 85

C0075 CONNECTOR DETAILSRANGE ROVERC0075Description: Switch-Brake pedalLocation: Driver’s footwellColour: NATURALGender: FemaleP6976C0075Cav Col C

Page 86

CONNECTOR DETAILS C0076RANGE ROVERC0076Description: Lamp-Footwell-Front-RHLocation: Behind footwell trim panel — RH sideColour: BLACKGender: FemaleP69

Page 87

C0077 CONNECTOR DETAILSRANGE ROVERC0077Description: Lamp-Footwell-Front-LHLocation: Behind footwell trim panel — LH sideColour: BLACKGender: FemaleP69

Page 88

CONNECTOR DETAILS C0082RANGE ROVERC0082Description: Rotary couplerLocation: Underside of steering columnColour: GREENGender: FemaleP6955C1393C0082C204

Page 89

C0086 CONNECTOR DETAILSRANGE ROVERC0086Description: Cigar lighterLocation: Beneath centre consoleColour: BLACKGender: FemaleP6911C0089C0086C0074Cav Co

Page 90

FUSE DETAILSRANGE ROVER 2.1FUSE DETAILSIntroductionFuses are mounted in one of three fuse boxes. The engine compartment fuse box is located in the en

Page 91

CONNECTOR DETAILS C0089RANGE ROVERC0089Description: Cigar lighterLocation: Beneath centre consoleColour: BLACKGender: FemaleP6911C0089C0086C0074Cav Co

Page 92

C0091 CONNECTOR DETAILSRANGE ROVERC0091Description: Switch-HandbrakeLocation: Beneath centre consoleColour: BRASSGender: EyeletP6910C0350C0942C2322C00

Page 93

CONNECTOR DETAILS C0096RANGE ROVERC0096Description: Switch-Hazard Warning and CDL MasterLocation: Behind centre consoleColour: BLACKGender: FemaleP692

Page 94

C0099 CONNECTOR DETAILSRANGE ROVERC0099Description: Switch-Ignition — Td6Location: Beneath centre consoleColour: BLACKGender: FemaleP6913C0049C0672C00

Page 95

CONNECTOR DETAILS C0114RANGE ROVERC0114Description: Pump-FuelLocation: Above fuel tankColour: BLACKGender: FemaleP7012C0114Cav Col Cct1WUALL2 NBY ALL3

Page 96

C0117 CONNECTOR DETAILSRANGE ROVERC0117Description: Main harness to tail door harnessLocation: Rear of luggage compartmentColour: BLACKGender: MaleP69

Page 97

CONNECTOR DETAILS C0119RANGE ROVERC0119Description: Lamp-Load space-RHLocation: RH side of tail doorColour: BLACKGender: FemaleP6984C0119Cav Col Cct1N

Page 98

C0120 CONNECTOR DETAILSRANGE ROVERC0120Description: Lamp-Load space-LHLocation: LH side of taildoorColour: BLACKGender: FemaleP6983C0120Cav Col Cct1NY

Page 99

CONNECTOR DETAILS C0121RANGE ROVERC0121Description: Lamp-Tail-LHLocation: LH rear of vehicleColour: BLACKGender: FemaleC0121P6962Cav Col Cct1UGALL2BUA

Page 100 — DESCRIPTION AND OPERATION

C0125 CONNECTOR DETAILSRANGE ROVERC0125Description: Lamp-Tail-RHLocation: RH rear of vehicleColour: BLACKGender: FemaleP6963C0125Cav Col Cct1UNALL2BUA

Page 101

FUSE DETAILS2.2 RANGE ROVERENGINE COMPARTMENT FUSE BOXFuse Rating Vehicle FunctionF1 30 A V8 ECM, EAT ECU.F1 30 A Td6 ECM.F2 30 A V8 Variable camshaft

Page 102

CONNECTOR DETAILS C0132RANGE ROVERC0132Description: Sensor-Fuel rail pressure — Td6Location: Centre rear of engineColour:Gender:P7028C0132C0216Cav Col

Page 103 — + BRAKE AND REVERSE LAMPS

C0147 CONNECTOR DETAILSRANGE ROVERC0147Description: Sensor-Engine coolant levelLocation: Front LH side of engine compartmentColour: BLACKGender: Femal

Page 104

CONNECTOR DETAILS C0149RANGE ROVERC0149Description: Sensor-Mass air flow (MAF) — V8Location: Front RH side of engineColour:Gender:C0149P7038Cav Col Cc

Page 105

C0149 CONNECTOR DETAILSRANGE ROVERC0149Description: Sensor-Mass air flow (MAF) — Td6Location: Top of engineColour:Gender:P7026C0176C0149Cav Col Cct1YU

Page 106

CONNECTOR DETAILS C0162RANGE ROVERC0162Description: Engine harness to main harness — Td6Location: Inside E-boxColour:Gender:P7022C0162C0909C1526C0190C

Page 107

C0162 CONNECTOR DETAILSRANGE ROVERC0162Description: Engine harness to main harness — V8Location: Inside E-boxColour:Gender:P7020C0162C0606C0332C2089C1

Page 108

CONNECTOR DETAILS C0168RANGE ROVERC0168Description: Sensor-Crankshaft position (CKP) — Td6Location: LH side of engineColour:Gender:C0168P7035Cav Col C

Page 109

C0169 CONNECTOR DETAILSRANGE ROVERC0169Description: Sensor-Engine coolant temperature (ECT) — Td6Location: Rear LH side of engineColour:Gender:C0169C2

Page 110

CONNECTOR DETAILS C0176RANGE ROVERC0176Description: Sensor-Camshaft position (CMP) — Td6Location: Top of engineColour:Gender:P7026C0176C0149Cav Col Cc

Page 111

C0179 CONNECTOR DETAILSRANGE ROVERC0179Description: Solenoid-Starter motor — Td6Location: LH side of engineColour:Gender:P7034C0823C0179C0178Cav Col C

Page 112

ELECTRICAL LIBRARYLRL 0453ENG(2)Published by Land Rover© Land Rover 2002All rights reserved. No part of this publication may be reproduced, stored in

Page 113

FUSE DETAILSRANGE ROVER 2.3PASSENGER COMPARTMENT FUSE BOXLink Rating Vehicle FunctionFL1 80 A All Heated front screen relay.FL2 60 A Td6 Ignition sw

Page 114

CONNECTOR DETAILS C0182RANGE ROVERC0182Description: Clutch-Compressor-Air conditioning (A/C) — V8Location: Lower RH front of engine compartmentColour:

Page 115

C0184 CONNECTOR DETAILSRANGE ROVERC0184Description: Sensor-Temperature-Fuel rail — Td6Location: LH side of engine compartmentColour:Gender:P7033C2303C

Page 116

CONNECTOR DETAILS C0187RANGE ROVERC0187Description: Switch-Oil pressureLocation: Front LH side of engine compartmentColour: BLACKGender: FemaleP6855C0

Page 117

C0191 CONNECTOR DETAILSRANGE ROVERC0191Description: Solenoid-EGR — Td6Location: LH side of engineColour:Gender:C0169C2262P7029C0191Cav Col Cct1RW32NS3

Page 118

CONNECTOR DETAILS C0193RANGE ROVERC0193Description: ECU-Electronic automatic transmissionLocation: Inside E-boxColour: BLUEGender: FemaleP6882C0448C21

Page 119

C0195 CONNECTOR DETAILSRANGE ROVERC0195Description: AccelerometerLocation: Beneath centre consoleColour: BLACKGender: FemaleP6915C0256C0360C0195Cav Co

Page 120

CONNECTOR DETAILS C0216RANGE ROVERC0216Description: Sensor-Boost pressure — Td6Location: Centre rear of engineColour:Gender:P7028C0132C0216Cav Col Cct

Page 121

C0230 CONNECTOR DETAILSRANGE ROVERC0230Description: Instrument PackLocation: Behind instrument packColour: BLACKGender: FemaleP6925C0233C0230C0234Cav

Page 122

CONNECTOR DETAILS C0232RANGE ROVERC0232Description: Clock-AnalogueLocation: Behind centre consoleColour: BLACKGender: FemaleP6926C0232C0700C1629C1630C

Page 123

C0233 CONNECTOR DETAILSRANGE ROVERC0233Description: Instrument PackLocation: Behind instrument packColour: BLACKGender: FemaleP6925C0233C0230C0234Cav

Page 124

FUSE DETAILS2.4 RANGE ROVERFuse Rating Vehicle FunctionF1 5 A All Instrument packF2 5 A All Heated rear screen relay, rear blower motor relay, seat he

Page 125

CONNECTOR DETAILS C0234RANGE ROVERC0234Description: Instrument PackLocation: Behind instrument packColour: GREYGender: FemaleP6925C0233C0230C0234Cav C

Page 126

C0243 CONNECTOR DETAILSRANGE ROVERC0243Description: Selector-Automatic transmissionLocation: Beneath centre consoleColour: BLACKGender: FemaleP6909C06

Page 127

CONNECTOR DETAILS C0244RANGE ROVERC0244Description: Gearbox — Td6Location: RH side of gearboxColour:Gender:C0244P7030Cav Col Cct1W32O32R253N33B34YU34Y

Page 128

C0245 CONNECTOR DETAILSRANGE ROVERC0245Description: Lamp-Automatic gearbox selector indicatorLocation: Beneath centre consoleColour: WHITEGender: Fema

Page 129

CONNECTOR DETAILS C0246RANGE ROVERC0246Description: Heated screen-FrontLocation: Behind RH side of fasciaColour: BLACKGender: MaleP6919C0246C2081Cav C

Page 130

C0247 CONNECTOR DETAILSRANGE ROVERC0247Description: Heated screen-FrontLocation: Behind LH side of fasciaColour: BLACKGender: MaleP6921C2051C0247Cav C

Page 131

CONNECTOR DETAILS C0249RANGE ROVERC0249Description: Heater-SeatLocation: Behind centre consoleColour: NATURALGender: FemaleP6926C0232C0700C1629C1630C0

Page 132

C0251 CONNECTOR DETAILSRANGE ROVERC0251Description: Air bag-PassengerLocation: Behind passenger side of fasciaColour: BLACKGender: MaleP6957C0251Cav C

Page 133 — + STEERING COLUMN

CONNECTOR DETAILS C0253RANGE ROVERC0253Description: Main harness to seat harnessLocation: Beneath RH seatColour: YELLOWGender: FemaleP6993C0253Cav Col

Page 134

C0255 CONNECTOR DETAILSRANGE ROVERC0255Description: Main harness to seat harnessLocation: Beneath LH seatColour: YELLOWGender: FemaleP6998C0662C0661C0

Page 135

FUSE DETAILSRANGE ROVER 2.5F34 7.5 A All HeVAC control module.F35 5 A All Centre console switch pack, Hill Descent Control switch.F36 5 A All Not use

Page 136

CONNECTOR DETAILS C0256RANGE ROVERC0256Description: DCU-AirbagLocation: Beneath centre consoleColour: NATURALGender: FemaleP6915C0256C0360C0195Cav Col

Page 137

C0274 CONNECTOR DETAILSRANGE ROVERC0274Description: Valve block-Air SuspensionLocation: Beneath vehicle — RH sideColour: BLACKGender: FemaleP7004C0770

Page 138

CONNECTOR DETAILS C0278RANGE ROVERC0278Description: Switch-Wash/wipe-WindscreenLocation: Top of steering columnColour: BLACKGender: FemaleP6952C0278C2

Page 139

C0286 CONNECTOR DETAILSRANGE ROVERC0286Description: HeaderLocation: Beneath front passenger’s seatColour:Gender:P6998C0662C0661C0660C0286C0255Cav

Page 140

CONNECTOR DETAILS C0304RANGE ROVERC0304Description: Motor-Window-RearLocation: Behind rear door trim panelColour: BLACKGender: FemaleC0304P6905Cav Col

Page 141

C0310 CONNECTOR DETAILSRANGE ROVERC0310Description: Speaker-Low range-Rear-RHLocation: Behind rear door trim panelColour: BLACKGender: FemaleP6904C031

Page 142

CONNECTOR DETAILS C0311RANGE ROVERC0311Description: Speaker-Mid range-Rear-RHLocation: Behind rear door trim panelColour: WHITEGender: FemaleP6903C073

Page 143

C0322 CONNECTOR DETAILSRANGE ROVERC0322Description: Passenger door harness to main harnessLocation: Base of passenger side ‘A’ postColour: B

Page 144

CONNECTOR DETAILS C0331RANGE ROVERC0331Description: Engine control module (ECM)Location: Inside E-boxColour: BLACKGender: FemaleP6882C0448C2138C0193C0

Page 145

C0332 CONNECTOR DETAILSRANGE ROVERC0332Description: Engine control module (ECM) — V8Location: Inside E-boxColour:Gender:P7020C0162C0606C0332C2089C1895

Page 146 — CONNECTOR

FUSE DETAILS2.6 RANGE ROVERREAR FUSE BOXFuse Rating Vehicle FunctionF1 20 A All Front cigar lighter, Rear cigar lighter, Front accessory socket.F2 25

Page 147

CONNECTOR DETAILS C0332RANGE ROVERC0332Description: Engine control module (ECM) — Td6Location: Inside E-boxColour: BLUEGender: MaleP7020C0162C0606C033

Page 148 — CONNECTOR DETAILS C0001

C0333 CONNECTOR DETAILSRANGE ROVERC0333Description: Main harness to air suspension harnessLocation: Behind RH front wheel arch linerColour: BLACKGende

Page 149 — C0002 CONNECTOR DETAILS

CONNECTOR DETAILS C0336RANGE ROVERC0336Description: Door harness to main harnessLocation: Base of driver side ‘A’ postColour: BLACKGender: F

Page 150 — CONNECTOR DETAILS C0003

C0350 CONNECTOR DETAILSRANGE ROVERC0350Description: Socket-Accessory-RearLocation: Luggage compartment — RH sideColour:Gender:P6959C2047C0350Cav Col C

Page 151 — C0004 CONNECTOR DETAILS

CONNECTOR DETAILS C0350RANGE ROVERC0350Description: Socket-Accessory-FrontLocation: Beneath centre consoleColour: WHITEGender: FemaleP6910C0350C0942C2

Page 152 — CONNECTOR DETAILS C0005

C0353 CONNECTOR DETAILSRANGE ROVERC0353Description: Mirror-Door-Passenger sideLocation: Behind passenger’s door trim panelColour:Gender:P6892C053

Page 153 — C0007 CONNECTOR DETAILS

CONNECTOR DETAILS C0355RANGE ROVERC0355Description: Lamp-Interior-FrontLocation: Front of headlining in the centreColour: BLACKGender: FemaleP6932C035

Page 154 — CONNECTOR DETAILS C0008

C0357 CONNECTOR DETAILSRANGE ROVERC0357Description: Lamp-Interior-RearLocation: Behind centre headliningColour: NATURALGender: FemaleP6935C0357C0359Ca

Page 155 — C0009 CONNECTOR DETAILS

CONNECTOR DETAILS C0359RANGE ROVERC0359Description: Sensor-VolumetricLocation: Behind centre headliningColour: BLACKGender: FemaleP6935C0357C0359Cav C

Page 156 — CONNECTOR DETAILS C0011

C0360 CONNECTOR DETAILSRANGE ROVERC0360Description: Earth-SRSLocation: Beneath centre consoleColour: TIN-PLATEGender: EyeletP6915C0256C0360C0195Cav Co

Page 157 — C0012 CONNECTOR DETAILS

EARTH POINTS AND HEADERSRANGE ROVER 3.1EARTH POINTS AND HEADERSGeneralThe following illustration indicates the general position of each earth point a

Page 158 — CONNECTOR DETAILS C0013

CONNECTOR DETAILS C0362RANGE ROVERC0362Description: Earth-ABSLocation: Rear LH side of engine compartmentColour: TIN-PLATEGender: EyeletP6857C0362C055

Page 159 — C0017 CONNECTOR DETAILS

C0363 CONNECTOR DETAILSRANGE ROVERC0363Description: Switch-Sunroof-FrontLocation: Front of headlining in the centreColour: BLACKGender: FemaleP6931C13

Page 160 — CONNECTOR DETAILS C0018

CONNECTOR DETAILS C0369RANGE ROVERC0369Description: Speaker-PDCLocation: Driver’s footwellColour: NATURALGender: FemaleP6950C1352C1577C0076C0405C

Page 161 — C0021 CONNECTOR DETAILS

C0381 CONNECTOR DETAILSRANGE ROVERC0381Description: Heated rear window (HRW)Location: LH side of taildoorColour: BLACKGender: FemaleP6987C0381Cav Col

Page 162 — CONNECTOR DETAILS C0026

CONNECTOR DETAILS C0382RANGE ROVERC0382Description: Heated rear window (HRW)Location: RH side of tail doorColour: BLACKGender: FemaleP6988C0382Cav Col

Page 163 — C0028 CONNECTOR DETAILS

C0383 CONNECTOR DETAILSRANGE ROVERC0383Description: Motor-Lock-Tail doorLocation: Centre of taildoor, behind trim panelColour: BLACKGender: FemaleP698

Page 164 — CONNECTOR DETAILS C0030

CONNECTOR DETAILS C0384RANGE ROVERC0384Description: Tail door harness to main harnessLocation: Rear of luggage compartmentColour: BLACKGender: FemaleP

Page 165 — C0040 CONNECTOR DETAILS

C0388 CONNECTOR DETAILSRANGE ROVERC0388Description: Motor-Wiper-Rear screenLocation: Centre of taildoor, behind trim panelColour: BLACKGender: FemaleP

Page 166 — CONNECTOR DETAILS C0041

CONNECTOR DETAILS C0400RANGE ROVERC0400Description: Sensor-PDC-Inner-Front-LHLocation: Behind LH side of front bumperColour: GREYGender: FemaleP6861C0

Page 167 — C0049 CONNECTOR DETAILS

C0401 CONNECTOR DETAILSRANGE ROVERC0401Description: Sensor-PDC-Inner-Front-RHLocation: Behind RH side of front bumperColour: GREYGender: FemaleP6862C0

Page 169 — C0053 CONNECTOR DETAILS

CONNECTOR DETAILS C0402RANGE ROVERC0402Description: Sensor-PDC-Outer-Front-LHLocation: Behind LH side of front bumperColour: GREYGender: FemaleP6861C0

Page 170 — CONNECTOR DETAILS C0056

C0403 CONNECTOR DETAILSRANGE ROVERC0403Description: Sensor-PDC-Outer-Front-RHLocation: Behind RH side of front bumperColour: GREYGender: FemaleP6862C0

Page 171 — C0059 CONNECTOR DETAILS

CONNECTOR DETAILS C0405RANGE ROVERC0405Description: Speaker-PDCLocation: Driver’s footwellColour: BLACKGender: FemaleP6950C1352C1577C0076C0405C03

Page 172 — CONNECTOR DETAILS C0070

C0416 CONNECTOR DETAILSRANGE ROVERC0416Description: Sensor-Temperature-Heater coolantLocation: Lower RH front of engine compartmentColour:Gender:P6865

Page 173 — C0071 CONNECTOR DETAILS

CONNECTOR DETAILS C0420RANGE ROVERC0420Description: Air suspension harness to main harnessLocation: Behind RH front wheel arch linerColour: BLACKGende

Page 174 — CONNECTOR DETAILS C0074

C0435 CONNECTOR DETAILSRANGE ROVERC0435Description: Main harness to door harnessLocation: LH ‘C’ postColour: BLACKGender: MaleP6908C0435C080

Page 175 — C0075 CONNECTOR DETAILS

CONNECTOR DETAILS C0436RANGE ROVERC0436Description: Main harness to door harnessLocation: RH ‘C’ postColour: BLACKGender: MaleP6907C0803C043

Page 176 — CONNECTOR DETAILS C0076

C0442 CONNECTOR DETAILSRANGE ROVERC0442Description: Motor-Door lock-RearLocation: Behind rear door trim panelColour: BLUEGender: FemaleP6906C0442Cav C

Page 177 — C0077 CONNECTOR DETAILS

CONNECTOR DETAILS C0448RANGE ROVERC0448Description: Main harness to engine harness — V8Location: Inside E-boxColour: NATURALGender: MaleP6882C0448C213

Page 178 — CONNECTOR DETAILS C0082

C0455 CONNECTOR DETAILSRANGE ROVERC0455Description: Lamp-Reverse-RHLocation: RH rear of vehicleColour:Gender:P6966C0455Cav Col Cct1N32WY3

Page 179 — C0086 CONNECTOR DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.1DESCRIPTION AND OPERATIONANTI-THEFT ALARM AND CENTRAL DOOR LOCKING (CDL)DESCRIPTIONAnti-Theft AlarmThe anti-t

Page 180 — CONNECTOR DETAILS C0089

CONNECTOR DETAILS C0459RANGE ROVERC0459Description: Main harness to door harnessLocation: Base of driver side ‘A’ postColour: BLACKGender: M

Page 181 — C0091 CONNECTOR DETAILS

C0463 CONNECTOR DETAILSRANGE ROVERC0463Description: Main harness to door harnessLocation: Base of passenger side ‘A’ postColour: BLACKGender

Page 182 — CONNECTOR DETAILS C0096

CONNECTOR DETAILS C0472RANGE ROVERC0472Description: Lamp-Reverse-LHLocation: LH rear of vehicleColour:Gender:P6967C0472Cav Col Cct1N32WY3

Page 183 — C0099 CONNECTOR DETAILS

C0473 CONNECTOR DETAILSRANGE ROVERC0473Description: Main harness to trailer harnessLocation: Rear of luggage compartment — RH sideColour: NATURALGende

Page 184 — CONNECTOR DETAILS C0114

CONNECTOR DETAILS C0476RANGE ROVERC0476Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 185 — C0117 CONNECTOR DETAILS

C0477 CONNECTOR DETAILSRANGE ROVERC0477Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 186 — CONNECTOR DETAILS C0119

CONNECTOR DETAILS C0478RANGE ROVERC0478Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 187 — C0120 CONNECTOR DETAILS

C0479 CONNECTOR DETAILSRANGE ROVERC0479Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 188 — CONNECTOR DETAILS C0121

CONNECTOR DETAILS C0502RANGE ROVERC0502Description: Sensor-ABS-Rear-LHLocation: Below LH rear wheelarchColour: BLUEGender: FemaleP7009C2028 C0502Cav C

Page 189 — C0125 CONNECTOR DETAILS

C0503 CONNECTOR DETAILSRANGE ROVERC0503Description: Sensor-ABS-Rear-RHLocation: Below RH rear wheelarchColour: BLUEGender: FemaleP7006C0968C0503Cav Co

Page 190 — CONNECTOR DETAILS C0132

DESCRIPTION AND OPERATION4.2 RANGE ROVERCentral Door Locking (CDL) and SuperlockingTwo levels of locking are available; Central Door Locking (CDL) and

Page 191 — C0147 CONNECTOR DETAILS

CONNECTOR DETAILS C0506RANGE ROVERC0506Description: ECU-ABSLocation: Rear LH side of engine compartmentColour:Gender:P6879C0506C2036Cav Col Cct1NALL2R

Page 192 — CONNECTOR DETAILS C0149

C0507 CONNECTOR DETAILSRANGE ROVERC0507Description: Pump-Return-ABSLocation: Rear of engine compartmentColour: BLACKGender: FemaleP6884C0666C0507C0026

Page 193 — C0149 CONNECTOR DETAILS

CONNECTOR DETAILS C0513RANGE ROVERC0513Description: Lamp-Fog-Front-RHLocation: Front of vehicle — RH sideColour: GREYGender: FemaleP6851C0513Cav Col C

Page 194 — CONNECTOR DETAILS C0162

C0514 CONNECTOR DETAILSRANGE ROVERC0514Description: Lamp-Fog-Front-LHLocation: Front of vehicle — LH sideColour: GREYGender: FemaleP6852C0514Cav Col C

Page 195 — C0162 CONNECTOR DETAILS

CONNECTOR DETAILS C0516RANGE ROVERC0516Description: Sensor-ABS-Front-LHLocation: Behind LH front wheel arch linerColour: BLUEGender: FemaleP6877C0516C

Page 196 — CONNECTOR DETAILS C0168

C0517 CONNECTOR DETAILSRANGE ROVERC0517Description: Sensor-ABS-Front-RHLocation: Behind RH front wheel arch linerColour: BLUEGender: FemaleP6874C0517C

Page 197 — C0169 CONNECTOR DETAILS

CONNECTOR DETAILS C0522RANGE ROVERC0522Description: Fuel injector-No.1 — Td6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P702

Page 198 — CONNECTOR DETAILS C0176

C0523 CONNECTOR DETAILSRANGE ROVERC0523Description: Fuel injector-No.2 — Td6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P702

Page 199 — C0179 CONNECTOR DETAILS

CONNECTOR DETAILS C0524RANGE ROVERC0524Description: Fuel injector-No.3 — Td6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P702

Page 200 — CONNECTOR DETAILS C0182

C0525 CONNECTOR DETAILSRANGE ROVERC0525Description: Fuel injector-No.4 — Td6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P702

Page 201 — C0184 CONNECTOR DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.3OPERATIONAnti-Theft AlarmPower DistributionFeed from the positive battery terminal (C0192) is supplied to fus

Page 202 — CONNECTOR DETAILS C0187

CONNECTOR DETAILS C0526RANGE ROVERC0526Description: Fuel injector-No.5 — Td6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P702

Page 203 — C0191 CONNECTOR DETAILS

C0527 CONNECTOR DETAILSRANGE ROVERC0527Description: Fuel injector-No.6Location: Top of engineColour: BLACKGender: FemaleC0526C0524C0523C0525P7025C0527

Page 204 — CONNECTOR DETAILS C0193

CONNECTOR DETAILS C0530RANGE ROVERC0530Description: Speakers-High RangeLocation: Behind driver’s door trim panelColour:Gender:P6887C0530C0599Cav

Page 205 — C0195 CONNECTOR DETAILS

C0531 CONNECTOR DETAILSRANGE ROVERC0531Description: Speakers-High RangeLocation: Behind passenger’s door trim panelColour:Gender:P6892C0531C0353C

Page 206 — CONNECTOR DETAILS C0216

CONNECTOR DETAILS C0537RANGE ROVERC0537Description: Lamp-Side-Front-RHLocation: Behind RH side of front bumperColour:Gender:P6863C0002C0537Cav Col Cct

Page 207 — C0230 CONNECTOR DETAILS

C0538 CONNECTOR DETAILSRANGE ROVERC0538Description: Lamp-Side-Front-LHLocation: Behind LH side of front bumperColour:Gender:P6853C0001C0538Cav Col Cct

Page 208 — CONNECTOR DETAILS C0232

CONNECTOR DETAILS C0546RANGE ROVERC0546Description: ECU-Delay-Windscreen wiperLocation: Rear LH side of engine compartmentColour: BLACKGender: FemaleP

Page 209 — C0233 CONNECTOR DETAILS

C0550 CONNECTOR DETAILSRANGE ROVERC0550Description: EarthLocation: Front RH side of engine compartmentColour: TIN-PLATEGender: MaleP6867C0018C0550Cav

Page 210 — CONNECTOR DETAILS C0234

CONNECTOR DETAILS C0551RANGE ROVERC0551Description: Header -EarthLocation: Front LH side of engine compartmentColour: TIN-PLATEGender: MaleP6857C0362C

Page 211 — C0243 CONNECTOR DETAILS

C0552 CONNECTOR DETAILSRANGE ROVERC0552Description: Header -EarthLocation: Base of RH ‘A’ postColour: TIN-PLATEGender: MaleP6974C0552Cav Col

Page 212 — CONNECTOR DETAILS C0244

DESCRIPTION AND OPERATION4.4 RANGE ROVERVolumetric SensorThe volumetric sensor monitors the inside of the vehicle by emitting a series of ultrasound p

Page 213 — C0245 CONNECTOR DETAILS

CONNECTOR DETAILS C0553RANGE ROVERC0553Description: Header -EarthLocation: Beneath LH seatColour: TIN-PLATEGender: MaleP7000C0553Cav Col Cct0NALL

Page 214 — CONNECTOR DETAILS C0246

C0554 CONNECTOR DETAILSRANGE ROVERC0554Description: Header -EarthLocation: Beneath footwell carpet — LH sideColour: TIN-PLATEGender: MaleP6977C0554C15

Page 215 — C0247 CONNECTOR DETAILS

CONNECTOR DETAILS C0555RANGE ROVERC0555Description: Header -EarthLocation: Luggage compartment — RH sideColour: TIN-PLATEGender: MaleP6990C0555C0706Ca

Page 216 — CONNECTOR DETAILS C0249

C0556 CONNECTOR DETAILSRANGE ROVERC0556Description: EarthLocation: Front LH side of engine compartmentColour: TIN-PLATEGender: EyeletP6855C0556C0187Ca

Page 217 — C0251 CONNECTOR DETAILS

CONNECTOR DETAILS C0559RANGE ROVERC0559Description: EarthLocation: RH side of engine compartmentColour: TIN-PLATEGender: EyeletP7024C0559C0629Cav Col

Page 218 — CONNECTOR DETAILS C0253

C0570 CONNECTOR DETAILSRANGE ROVERC0570Description: Holder-Fuse — Td6Location: Inside E-boxColour:Gender:P7022C0162C0909C1526C0190C0189C0570C1895Cav C

Page 219 — C0255 CONNECTOR DETAILS

CONNECTOR DETAILS C0570RANGE ROVERC0570Description: Holder-Fuse — V8Location: Inside E-boxColour:Gender:P7022C0162C0909C1526C0190C0189C0570C1895Cav Co

Page 220 — CONNECTOR DETAILS C0256

C0580 CONNECTOR DETAILSRANGE ROVERC0580Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour:Gender:P6956C0583C0580C0632C0585C058

Page 221 — C0274 CONNECTOR DETAILS

CONNECTOR DETAILS C0581RANGE ROVERC0581Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: BLACKGender: FemaleP6956C0583C0580C

Page 222 — CONNECTOR DETAILS C0278

C0582 CONNECTOR DETAILSRANGE ROVERC0582Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour:Gender:P6956C0583C0580C0632C0585C058

Page 224 — CONNECTOR DETAILS C0304

DESCRIPTION AND OPERATIONRANGE ROVER 4.5Battery Backed-Up Sounder (BBUS)The BBUS (C0666) is mounted adjacent the brake servo, and is provided a const

Page 225 — C0310 CONNECTOR DETAILS

CONNECTOR DETAILS C0583RANGE ROVERC0583Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: BLUEGender: FemaleP6956C0583C0580C0

Page 226 — CONNECTOR DETAILS C0311

C0584 CONNECTOR DETAILSRANGE ROVERC0584Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: NATURALGender: FemaleP6956C0583C058

Page 227 — C0322 CONNECTOR DETAILS

CONNECTOR DETAILS C0585RANGE ROVERC0585Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: BLACKGender: FemaleP6956C0583C0580C

Page 228 — CONNECTOR DETAILS C0331

C0586 CONNECTOR DETAILSRANGE ROVERC0586Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: BLACKGender: FemaleP6956C0583C0580C

Page 229 — C0332 CONNECTOR DETAILS

CONNECTOR DETAILS C0587RANGE ROVERC0587Description: Fuse box-Passenger compartmentLocation: Behind gloveboxColour: NATURALGender: FemaleP6956C0583C058

Page 230 — CONNECTOR DETAILS C0332

C0588 CONNECTOR DETAILSRANGE ROVERC0588Description: Fuse box-Passenger compartmentLocation: Behind passenger compartment fuseboxColour:Gender:C0592C05

Page 231 — C0333 CONNECTOR DETAILS

CONNECTOR DETAILS C0589RANGE ROVERC0589Description: Fuse box-Passenger compartmentLocation: Behind passenger compartment fuseboxColour:Gender:C0592C05

Page 232 — CONNECTOR DETAILS C0336

C0590 CONNECTOR DETAILSRANGE ROVERC0590Description: Fuse box-Passenger compartmentLocation: Behind passenger compartment fuseboxColour:Gender:C0592C05

Page 233 — C0350 CONNECTOR DETAILS

CONNECTOR DETAILS C0591RANGE ROVERC0591Description: Fuse box-Passenger compartmentLocation: Behind passenger compartment fuseboxColour: TIN-PLATEGende

Page 234 — CONNECTOR DETAILS C0350

C0592 CONNECTOR DETAILSRANGE ROVERC0592Description: Fuse box-Passenger compartmentLocation: Behind passenger compartment fuseboxColour:Gender:C0592C05

Page 235 — C0353 CONNECTOR DETAILS

DESCRIPTION AND OPERATION4.6 RANGE ROVERCentral Door Locking (CDL)Power DistributionFeed from the positive battery terminal (C0192) is supplied to the

Page 236 — CONNECTOR DETAILS C0355

CONNECTOR DETAILS C0599RANGE ROVERC0599Description: Sensor-Anti-trap-DriverLocation: Behind driver’s door trim panelColour:Gender:P6887C0530C0599

Page 237 — C0357 CONNECTOR DETAILS

C0600 CONNECTOR DETAILSRANGE ROVERC0600Description: Sensor-Anti-trap-PassengerLocation: Behind passenger’s door trim panelColour:Gender:P6892C053

Page 238 — CONNECTOR DETAILS C0359

CONNECTOR DETAILS C0603RANGE ROVERC0603Description: Engine control module (ECM) — Td6Location: Inside E-boxColour:Gender:P7023C0604C0603C2138C1835C019

Page 239 — C0360 CONNECTOR DETAILS

C0603 CONNECTOR DETAILSRANGE ROVERC0603Description: Engine control module (ECM) — V8Location: Inside E-boxColour:Gender:P7039C0604C0603C0606C0332C0331

Page 240 — CONNECTOR DETAILS C0362

CONNECTOR DETAILS C0604RANGE ROVERC0604Description: Engine control module (ECM) — Td6Location: Inside E-boxColour:Gender:P7023C0604C0603C2138C1835C019

Page 241 — C0363 CONNECTOR DETAILS

C0604 CONNECTOR DETAILSRANGE ROVERC0604Description: Engine control module (ECM) — V8Location: Inside E-boxColour:Gender:P7039C0604C0603C0606C0332C0331

Page 242 — CONNECTOR DETAILS C0369

CONNECTOR DETAILS C0606RANGE ROVERC0606Description: Engine control module (ECM) — Td6Location: Inside E-boxColour:Gender:P7023C0604C0603C2138C1835C019

Page 243 — C0381 CONNECTOR DETAILS

C0606 CONNECTOR DETAILSRANGE ROVERC0606Description: Engine control module (ECM) — V8Location: Inside E-boxColour:Gender:P7020C0162C0606C0332C2089C1895

Page 245 — C0383 CONNECTOR DETAILS

C0615 CONNECTOR DETAILSRANGE ROVERC0615Description: Switch-Tail door openLocation: Centre of taildoor, behind trim panelColour:Gender:P6968C2052C0615C

Page 246 — CONNECTOR DETAILS C0384

DESCRIPTION AND OPERATIONRANGE ROVER 4.7Drivers DoorThe BCU controls operation of the drivers door lock via the drivers door module. The drivers door

Page 247 — C0388 CONNECTOR DETAILS

CONNECTOR DETAILS C0617RANGE ROVERC0617Description: Motor-Lock-Tail doorLocation: LH side of taildoorColour:Gender:P6969C0617Cav Col Cct1N32UW3

Page 248 — CONNECTOR DETAILS C0400

C0620 CONNECTOR DETAILSRANGE ROVERC0620Description: Sensor-Low washer fluid levelLocation: Front LH side of engine compartmentColour: BLACKGender: Fem

Page 249 — C0401 CONNECTOR DETAILS

CONNECTOR DETAILS C0629RANGE ROVERC0629Description: Solenoid valve-Boost Control — Td6Location: RH side of engine compartmentColour:Gender:P7024C0559C

Page 250 — CONNECTOR DETAILS C0402

C0642 CONNECTOR DETAILSRANGE ROVERC0642Description: Sensor-Heated oxygen (HO2S)Location: Beneath centre of vehicleColour:Gender:P6940C0642Cav Col Cct1

Page 251 — C0403 CONNECTOR DETAILS

CONNECTOR DETAILS C0643RANGE ROVERC0643Description: Sensor-Heated oxygen (HO2S)Location: Beneath centre of vehicleColour:Gender:P6941C0643C1858Cav Col

Page 252 — CONNECTOR DETAILS C0405

C0644 CONNECTOR DETAILSRANGE ROVERC0644Description: Sensor-Heated oxygen (HO2S)Location: Beneath centre of vehicleColour:Gender:C0644P6943Cav Col Cct1

Page 253 — C0416 CONNECTOR DETAILS

CONNECTOR DETAILS C0645RANGE ROVERC0645Description: Sensor-Heated oxygen (HO2S)Location: Beneath centre of vehicleColour:Gender:P6942C0645C1544Cav Col

Page 254 — CONNECTOR DETAILS C0420

C0646 CONNECTOR DETAILSRANGE ROVERC0646Description: Fan-E-boxLocation: Inside E-boxColour: NATURALGender: FemaleP6882C0448C2138C0193C0331C1886C0646C21

Page 255 — C0435 CONNECTOR DETAILS

CONNECTOR DETAILS C0660RANGE ROVERC0660Description: Body control unit (BCU)Location: Beneath front passenger’s seatColour: GREYGender: FemaleP699

Page 256 — CONNECTOR DETAILS C0436

C0661 CONNECTOR DETAILSRANGE ROVERC0661Description: Body control unit (BCU)Location: Beneath front passenger’s seatColour: GREYGender: FemaleP699

Page 257 — C0442 CONNECTOR DETAILS

DESCRIPTION AND OPERATION4.8 RANGE ROVERRear Passenger DoorsWhen the BCU (C0662) receives an unlock signal from the RF receiver, it provides a feed to

Page 258 — CONNECTOR DETAILS C0448

CONNECTOR DETAILS C0662RANGE ROVERC0662Description: Body control unit (BCU)Location: Beneath front passenger’s seatColour: BLACKGender: FemaleP69

Page 259 — C0455 CONNECTOR DETAILS

C0666 CONNECTOR DETAILSRANGE ROVERC0666Description: Sounder-Alarm-Battery backed upLocation: Rear of engine compartmentColour: NATURALGender: FemaleP6

Page 260 — CONNECTOR DETAILS C0459

CONNECTOR DETAILS C0672RANGE ROVERC0672Description: Sensor-Key inLocation: Beneath centre consoleColour: BLACKGender: FemaleP6913C0049C0672C0028C0099C

Page 261 — C0463 CONNECTOR DETAILS

C0673 CONNECTOR DETAILSRANGE ROVERC0673Description: Solenoid-InterlockLocation: Beneath centre consoleColour:Gender:P6913C0049C0672C0028C0099C0673Cav

Page 262 — CONNECTOR DETAILS C0472

CONNECTOR DETAILS C0674RANGE ROVERC0674Description: Receiver-Radio frequency (RF)Location: Centre of taildoor, behind trim panelColour: BLACKGender: F

Page 263 — C0473 CONNECTOR DETAILS

C0675 CONNECTOR DETAILSRANGE ROVERC0675Description: Switch-Transmision-High-LowLocation: Beneath centre consoleColour:Gender:P6909C0675C0245C0243Cav C

Page 264 — CONNECTOR DETAILS C0476

CONNECTOR DETAILS C0690RANGE ROVERC0690Description: Solenoid-Fuel flap releaseLocation: Rear of luggage compartment — RH sideColour: BLACKGender: Fema

Page 265 — C0477 CONNECTOR DETAILS

C0698 CONNECTOR DETAILSRANGE ROVERC0698Description: Mirror-interiorLocation: Top of windscreenColour:Gender:P6934C0961C0698Cav Col Cct1UY262WY103GW264

Page 266 — CONNECTOR DETAILS C0478

CONNECTOR DETAILS C0700RANGE ROVERC0700Description: Switch pack-Centre consoleLocation: Behind centre consoleColour: GREYGender: FemaleP6926C0232C0700

Page 267 — C0479 CONNECTOR DETAILS

C0706 CONNECTOR DETAILSRANGE ROVERC0706Description: Header -EarthLocation: Luggage compartment — RH sideColour: TIN-PLATEGender: MaleP6990C0555C0706Ca

Page 268 — CONNECTOR DETAILS C0502

DESCRIPTION AND OPERATIONRANGE ROVER 4.9ENGINE IMMOBILISATIONDESCRIPTIONGeneralThe function of the engine immobilisation system is to prevent unautho

Page 269 — C0503 CONNECTOR DETAILS

CONNECTOR DETAILS C0707RANGE ROVERC0707Description: Header -EarthLocation: Rear of luggage compartmentColour: TIN-PLATEGender: MaleP6965C0707Cav Col C

Page 270 — CONNECTOR DETAILS C0506

C0726 CONNECTOR DETAILSRANGE ROVERC0726Description: Speakers-Low rangeLocation: Behind passenger’s door trim panelColour:Gender:P6894C0726Cav Col

Page 271 — C0507 CONNECTOR DETAILS

CONNECTOR DETAILS C0732RANGE ROVERC0732Description: Switch-Window-RearLocation: Behind rear door trim panelColour: BLACKGender: FemaleP6903C0732C2015C

Page 272 — CONNECTOR DETAILS C0513

C0736 CONNECTOR DETAILSRANGE ROVERC0736Description: Mirror-Vanity-RHLocation: Headlining — front RH sideColour: BLACKGender: FemaleP6937C0736Cav Col C

Page 273 — C0514 CONNECTOR DETAILS

CONNECTOR DETAILS C0737RANGE ROVERC0737Description: Mirror-Vanity-LHLocation: Headlining — front LH sideColour: BLACKGender: FemaleP6936C0737Cav Col C

Page 274 — CONNECTOR DETAILS C0516

C0740 CONNECTOR DETAILSRANGE ROVERC0740Description: Motor-Window-DriverLocation: Behind driver’s door trim panelColour: BLACKGender: FemaleP6898C

Page 275 — C0517 CONNECTOR DETAILS

CONNECTOR DETAILS C0741RANGE ROVERC0741Description: Motor-Window-PassengerLocation: Behind passenger’s door trim panelColour: BLACKGender: Female

Page 276 — CONNECTOR DETAILS C0522

C0751 CONNECTOR DETAILSRANGE ROVERC0751Description: Seat link harness to main harnessLocation: Beneath front seatColour:Gender:P6992C0751Cav Col Cct13

Page 277 — C0523 CONNECTOR DETAILS

CONNECTOR DETAILS C0752RANGE ROVERC0752Description: Seat link harness to main harnessLocation: Beneath front seatColour:Gender:C0752P7001Cav Col Cct13

Page 278 — CONNECTOR DETAILS C0524

C0770 CONNECTOR DETAILSRANGE ROVERC0770Description: Valve block-Air SuspensionLocation: Beneath vehicle — RH sideColour: BLACKGender: FemaleP7004C0770

Page 279 — C0525 CONNECTOR DETAILS

DESCRIPTION AND OPERATION4.10 RANGE ROVERSteering Column Interlock ECUThe steering column interlock ECU (C2055) receives the following power supplies:

Page 280 — CONNECTOR DETAILS C0526

CONNECTOR DETAILS C0771RANGE ROVERC0771Description: Valve block-Air SuspensionLocation: Beneath vehicle — RH sideColour: BLACKGender: FemaleP7004C0770

Page 281 — C0527 CONNECTOR DETAILS

C0784 CONNECTOR DETAILSRANGE ROVERC0784Description: ECU-Sunroof-1Location: Front of headlining in the centreColour: BLACKGender: FemaleP6933C0784Cav C

Page 282 — CONNECTOR DETAILS C0530

CONNECTOR DETAILS C0786RANGE ROVERC0786Description: Main harness to air conditioning (A/C) harnessLocation: Behind centre consoleColour: BLACKGender:

Page 283 — C0531 CONNECTOR DETAILS

C0787 CONNECTOR DETAILSRANGE ROVERC0787Description: Sensor-Throttle position (TP)Location: Driver’s footwellColour: BLACKGender: FemaleP6975C0787

Page 284 — CONNECTOR DETAILS C0537

CONNECTOR DETAILS C0790RANGE ROVERC0790Description: Sensor-SunlightLocation: Fascia — top centreColour: PURPLEGender: FemaleP6930C0790Cav Col Cct1YN52

Page 285 — C0538 CONNECTOR DETAILS

C0803 CONNECTOR DETAILSRANGE ROVERC0803Description: Door harness to main harnessLocation: Base of ‘C’ post RH sideColour: BLACKGender: Femal

Page 286 — CONNECTOR DETAILS C0546

CONNECTOR DETAILS C0821RANGE ROVERC0821Description: Header -EarthLocation: Beneath RH seatColour: TIN-PLATEGender: MaleP6995C0821Cav Col Cct0NALL

Page 287 — C0550 CONNECTOR DETAILS

C0823 CONNECTOR DETAILSRANGE ROVERC0823Description: Starter motor — Td6Location: LH side of engineColour:Gender:P7034C0823C0179C0178Cav Col Cct1BG3

Page 288 — CONNECTOR DETAILS C0551

CONNECTOR DETAILS C0832RANGE ROVERC0832Description: Lamp-brake-high mountedLocation: Centre of taildoor, behind trim panelColour:Gender:P6986C0832C083

Page 289 — C0552 CONNECTOR DETAILS

C0835 CONNECTOR DETAILSRANGE ROVERC0835Description: Motor-Wiper-Rear screenLocation: Centre of taildoor, behind trim panelColour: BLACKGender: FemaleP

Page 290 — CONNECTOR DETAILS C0553

DESCRIPTION AND OPERATIONRANGE ROVER 4.11V8Power DistributionFeed from the positive battery terminal (C0192) is supplied to the following on an R wir

Page 291 — C0554 CONNECTOR DETAILS

CONNECTOR DETAILS C0839RANGE ROVERC0839Description: Main harness to air conditioning (A/C) harnessLocation: Behind centre consoleColour: BLACKGender:

Page 292 — CONNECTOR DETAILS C0555

C0862 CONNECTOR DETAILSRANGE ROVERC0862Description: Sensor-Steering angleLocation: Underside of steering columnColour: BLACKGender: MaleP6971C1392C086

Page 293 — C0556 CONNECTOR DETAILS

CONNECTOR DETAILS C0867RANGE ROVERC0867Description: ECU-Air suspensionLocation: Behind LH side of fasciaColour:Gender:C2031C2030C0867P6944Cav Col Cct1

Page 295 — C0570 CONNECTOR DETAILS

CONNECTOR DETAILS C0873RANGE ROVERC0873Description: Pump-Air suspensionLocation: Rear of luggage compartmentColour: NATURALGender: FemaleC0873P6964Cav

Page 296 — CONNECTOR DETAILS C0570

C0876 CONNECTOR DETAILSRANGE ROVERC0876Description: Main harness to PDC harnessLocation: Rear of luggage compartment — RH sideColour: BLACKGender: Mal

Page 297 — C0580 CONNECTOR DETAILS

CONNECTOR DETAILS C0879RANGE ROVERC0879Description: Pump-Air injectionLocation: Behind RH front wheel arch linerColour: BLACKGender: FemaleP6869C0879C

Page 298 — CONNECTOR DETAILS C0581

C0884 CONNECTOR DETAILSRANGE ROVERC0884Description: Sensor-Ambient air temperatureLocation: Behind the front grilleColour: BLACKGender: FemaleP6859C08

Page 299 — C0582 CONNECTOR DETAILS

CONNECTOR DETAILS C0909RANGE ROVERC0909Description: Engine harness to main harness — Td6Location: Inside E-boxColour:Gender:P7022C0162C0909C1526C0190C

Page 300 — CONNECTOR DETAILS C0583

C0916 CONNECTOR DETAILSRANGE ROVERC0916Description: Lamp-Side marker-Front-RHLocation: Front of vehicle — RH sideColour: BLACKGender: FemaleP7014C0916

Page 301 — C0584 CONNECTOR DETAILS

DESCRIPTION AND OPERATION4.12 RANGE ROVERTransponder CoilThe transponder coil (C0049) is connected to the immobilisation ECU (C0059) by YU and YN wire

Page 302 — CONNECTOR DETAILS C0585

CONNECTOR DETAILS C0917RANGE ROVERC0917Description: Lamp-Side marker-Front-LHLocation: Front of vehicle — LH sideColour: BLACKGender: FemaleC0917P7015

Page 303 — C0586 CONNECTOR DETAILS

C0918 CONNECTOR DETAILSRANGE ROVERC0918Description: Lamp-Side marker-Rear-RHLocation: RH rear of vehicleColour: BLACKGender: FemaleP7016C0918Cav Col C

Page 304 — CONNECTOR DETAILS C0587

CONNECTOR DETAILS C0919RANGE ROVERC0919Description: Lamp-Side marker-Rear-LHLocation: LH rear of vehicleColour: BLACKGender: FemaleC0919P7017Cav Col C

Page 305 — C0588 CONNECTOR DETAILS

C0925 CONNECTOR DETAILSRANGE ROVERC0925Description: Heater-Fuel burningLocation: Rear of engine compartmentColour: BLACKGender: FemaleC0925C0926P7036C

Page 306 — CONNECTOR DETAILS C0589

CONNECTOR DETAILS C0926RANGE ROVERC0926Description: Heater-Fuel burningLocation: Rear of engine compartmentColour: BLACKGender: FemaleC0925C0926P7036C

Page 307 — C0590 CONNECTOR DETAILS

C0932 CONNECTOR DETAILSRANGE ROVERC0932Description: ECU-Electronic automatic transmission — Td6Location: Inside E-boxColour:Gender:P7023C0604C0603C213

Page 308 — CONNECTOR DETAILS C0591

CONNECTOR DETAILS C0934RANGE ROVERC0934Description: Washer jet-HeatedLocation: Under bonnet, RH sideColour: BLACKGender: FemaleP6881C0934C0946Cav Col

Page 309 — C0592 CONNECTOR DETAILS

C0937 CONNECTOR DETAILSRANGE ROVERC0937Description: Module-Lighting switchLocation: Base of RH ‘A’ postColour: BLACKGender: FemaleP6973C0937

Page 310 — CONNECTOR DETAILS C0599

CONNECTOR DETAILS C0942RANGE ROVERC0942Description: Socket-AccessoryLocation: Beneath centre consoleColour:Gender:P6910C0350C0942C2322C0091Cav Col Cct

Page 311 — C0600 CONNECTOR DETAILS

C0946 CONNECTOR DETAILSRANGE ROVERC0946Description: Heater-Washer jet-LHLocation: Under bonnet, LH sideColour: BLACKGender: FemaleP6881C0934C0946Cav C

Page 312 — CONNECTOR DETAILS C0603

DESCRIPTION AND OPERATIONRANGE ROVER 4.13WINDOWSDESCRIPTIONGeneralOperation of all four windows is controlled by the Body Control Unit (BCU) via the

Page 313 — C0603 CONNECTOR DETAILS

CONNECTOR DETAILS C0950RANGE ROVERC0950Description: Sensor-Airbag-Side-LHLocation: Base of ‘B’ post LH sideColour:Gender:P6997C0950Cav Col C

Page 314 — CONNECTOR DETAILS C0604

C0951 CONNECTOR DETAILSRANGE ROVERC0951Description: Sensor-Airbag-Side-RHLocation: Base of ‘B’ post RH sideColour:Gender:P6996C0951Cav Col C

Page 315 — C0604 CONNECTOR DETAILS

CONNECTOR DETAILS C0957RANGE ROVERC0957Description: ECU-PDCLocation: Luggage compartment — RH sideColour: BLACKGender: FemaleP6948C0958C0957C1457Cav C

Page 316 — CONNECTOR DETAILS C0606

C0958 CONNECTOR DETAILSRANGE ROVERC0958Description: ECU-PDCLocation: Luggage compartment — RH sideColour: BLACKGender: FemaleP6948C0958C0957C1457Cav C

Page 317 — C0606 CONNECTOR DETAILS

CONNECTOR DETAILS C0960RANGE ROVERC0960Description: Sensor-TiltLocation: Beneath front passenger’s seatColour: BLACKGender: MaleP6999C1537C0960Ca

Page 318

C0961 CONNECTOR DETAILSRANGE ROVERC0961Description: Sensor-RainLocation: Top of windscreenColour: BLACKGender: FemaleP6934C0961C0698Cav Col Cct1PR142N

Page 319 — C0615 CONNECTOR DETAILS

CONNECTOR DETAILS C0963RANGE ROVERC0963Description: Sensor-PDC-Outer-Rear-LHLocation: Behind LH side of rear bumperColour: GREYGender: FemaleP6945C096

Page 320 — CONNECTOR DETAILS C0617

C0964 CONNECTOR DETAILSRANGE ROVERC0964Description: Sensor-PDC-Inner-Rear-LHLocation: Behind LH side of rear bumperColour: GREYGender: FemaleP6945C096

Page 321 — C0620 CONNECTOR DETAILS

CONNECTOR DETAILS C0965RANGE ROVERC0965Description: Sensor-PDC-Inner-Rear-RHLocation: Behind RH side of rear bumperColour: GREYGender: FemaleP6946C096

Page 322 — CONNECTOR DETAILS C0629

C0966 CONNECTOR DETAILSRANGE ROVERC0966Description: Sensor-PDC-Outer-Rear-RHLocation: Behind RH side of rear bumperColour: GREYGender: FemaleP6946C096

Page 323 — C0642 CONNECTOR DETAILS

DESCRIPTION AND OPERATION4.14 RANGE ROVERWhen the drivers door switch is moved to the ‘Down’ position, the feed from fuse 11 of the front pa

Page 324 — CONNECTOR DETAILS C0643

CONNECTOR DETAILS C0968RANGE ROVERC0968Description: Sensor-Pad wearLocation: Below RH rear wheelarchColour: BLACKGender: FemaleP7006C0968C0503Cav Col

Page 325 — C0644 CONNECTOR DETAILS

C0987 CONNECTOR DETAILSRANGE ROVERC0987Description: Speaker-PDCLocation: Luggage compartment — RH sideColour: BLACKGender: FemaleP6947C0987C0380C0473C

Page 326 — CONNECTOR DETAILS C0645

CONNECTOR DETAILS C0994RANGE ROVERC0994Description: Relay-Heated front screenLocation: Behind driver side of fasciaColour: BLACKGender: FemaleP6923C09

Page 327 — C0646 CONNECTOR DETAILS

C1216 CONNECTOR DETAILSRANGE ROVERC1216Description: Switch-Oil pressure — Td6Location: LH side of engineColour:Gender:P7027C1216C0053Cav Col Cct1NG3

Page 328 — CONNECTOR DETAILS C0660

CONNECTOR DETAILS C1294RANGE ROVERC1294Description: Illumination-Heater Control-LHLocation: Behind centre of fasciaColour: BLACKGender: FemaleP6928C12

Page 329 — C0661 CONNECTOR DETAILS

C1295 CONNECTOR DETAILSRANGE ROVERC1295Description: Illumination-Heater Control-RHLocation: Behind centre of fasciaColour: BLACKGender: FemaleP6928C12

Page 330 — CONNECTOR DETAILS C0662

CONNECTOR DETAILS C1303RANGE ROVERC1303Description: Microphone-TelephoneLocation: Front of headlining in the centreColour: BLACKGender: FemaleP6931C13

Page 331 — C0666 CONNECTOR DETAILS

C1319 CONNECTOR DETAILSRANGE ROVERC1319Description: ECU-Transfer boxLocation: Rear LH side of engine compartmentColour: GREYGender: FemaleP6886C1319C0

Page 332 — CONNECTOR DETAILS C0672

CONNECTOR DETAILS C1340RANGE ROVERC1340Description: Motor-Wiper-Headlamp-LHLocation: Front of vehicle — LH sideColour: BLACKGender: FemaleC1340P6854Ca

Page 333 — C0673 CONNECTOR DETAILS

C1341 CONNECTOR DETAILSRANGE ROVERC1341Description: Motor-Wiper-Headlamp-RHLocation: Front of vehicle — RH sideColour: BLACKGender: FemaleP6866C0011C0

Page 335 — C0675 CONNECTOR DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.15RearPower DistributionFeed from the positive battery terminal (C0192) is supplied to fuse 53 and fuse 60 of

Page 336 — CONNECTOR DETAILS C0690

CONNECTOR DETAILS C1342RANGE ROVERC1342Description: Pump-Power washLocation: Front LH side of engine compartmentColour: BLACKGender: FemaleP6858C0021C

Page 337 — C0698 CONNECTOR DETAILS

C1352 CONNECTOR DETAILSRANGE ROVERC1352Description: Speaker-PDCLocation: Driver’s footwellColour: BLACKGender: FemaleP6950C1352C1577C0076C0405C03

Page 338 — CONNECTOR DETAILS C0700

CONNECTOR DETAILS C1392RANGE ROVERC1392Description: Relay-Steering columnLocation: Underside of steering columnColour: BLACKGender: FemaleP6971C1392C0

Page 339 — C0706 CONNECTOR DETAILS

C1393 CONNECTOR DETAILSRANGE ROVERC1393Description: Switch-Steering columnLocation: Underside of steering columnColour:Gender:P6955C1393C0082C2041Cav

Page 340 — CONNECTOR DETAILS C0707

CONNECTOR DETAILS C1394RANGE ROVERC1394Description: Motor-Column-TelescopeLocation: Underside of steering columnColour: BLACKGender: FemaleP6972C1397C

Page 341 — C0726 CONNECTOR DETAILS

C1395 CONNECTOR DETAILSRANGE ROVERC1395Description: Motor-Column-HeightLocation: Top of steering columnColour: BLACKGender: FemaleP6953C1396C1832C1395

Page 342 — CONNECTOR DETAILS C0732

CONNECTOR DETAILS C1396RANGE ROVERC1396Description: Motor-Column-TelescopeLocation: Top of steering columnColour: BLACKGender: FemaleP6953C1396C1832C1

Page 343 — C0736 CONNECTOR DETAILS

C1397 CONNECTOR DETAILSRANGE ROVERC1397Description: Motor-Column-HeightLocation: Underside of steering columnColour: BLACKGender: FemaleP6972C1397C139

Page 344 — CONNECTOR DETAILS C0737

CONNECTOR DETAILS C1449RANGE ROVERC1449Description: Motor-Central door locking-DriverLocation: Behind driver’s door trim panelColour: BLUEGender:

Page 345 — C0740 CONNECTOR DETAILS

C1451 CONNECTOR DETAILSRANGE ROVERC1451Description: Motor-Central door locking-PassengerLocation: Behind passenger’s door trim panelColour: BLUEG

Page 346 — CONNECTOR DETAILS C0741

DESCRIPTION AND OPERATION4.16 RANGE ROVERAnti-TrapThe anti-trap system consists of an anti-trap seal, which runs along the door glass frame. The seal

Page 347 — C0751 CONNECTOR DETAILS

CONNECTOR DETAILS C1455RANGE ROVERC1455Description: Relay-InterlockLocation: Rear LH side of engine compartmentColour: BLACKGender: FemaleP6886C1319C0

Page 348 — CONNECTOR DETAILS C0752

C1457 CONNECTOR DETAILSRANGE ROVERC1457Description: ECU-PDCLocation: Luggage compartment — RH sideColour: BLACKGender: FemaleP6948C0958C0957C1457Cav C

Page 349 — C0770 CONNECTOR DETAILS

CONNECTOR DETAILS C1474RANGE ROVERC1474Description: Airbag-ITS-Rear-LHLocation: Rear of headliningColour: BLACKGender: FemaleP7002C1474Cav Col Cct1Y20

Page 350 — CONNECTOR DETAILS C0771

C1475 CONNECTOR DETAILSRANGE ROVERC1475Description: Airbag-Side-Rear-RHLocation: Rear of headliningColour: BLACKGender: FemaleP7003C1475Cav Col Cct1G2

Page 351 — C0784 CONNECTOR DETAILS

CONNECTOR DETAILS C1477RANGE ROVERC1477Description: Airbag-ITS-Front-LHLocation: Behind LH side of fasciaColour: BLACKGender: FemaleP6978C1477Cav Col

Page 352 — CONNECTOR DETAILS C0786

C1478 CONNECTOR DETAILSRANGE ROVERC1478Description: Airbag-ITS-Front-RHLocation: Behind RH side of fasciaColour: BLACKGender: FemaleP6979C1478Cav Col

Page 353 — C0787 CONNECTOR DETAILS

CONNECTOR DETAILS C1495RANGE ROVERC1495Description: Lamp-Number plate and tail door switchLocation: Centre of taildoor, behind trim panelColour: NATUR

Page 354 — CONNECTOR DETAILS C0790

C1498 CONNECTOR DETAILSRANGE ROVERC1498Description: Airbag-Side-PassengerLocation: Behind passenger’s door trim panelColour:Gender:P6896C1498Cav

Page 355 — C0803 CONNECTOR DETAILS

CONNECTOR DETAILS C1499RANGE ROVERC1499Description: Airbag-Side-DriverLocation: Behind driver’s door trim panelColour:Gender:P6891C1499Cav Col Cc

Page 356 — CONNECTOR DETAILS C0821

C1500 CONNECTOR DETAILSRANGE ROVERC1500Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 357 — C0823 CONNECTOR DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.17SUNROOFDESCRIPTIONGeneralOperation of the sunroof is controlled via the three position switch located on the

Page 358 — CONNECTOR DETAILS C0832

CONNECTOR DETAILS C1501RANGE ROVERC1501Description: Glow plug — Td6Location: LH side of engineColour:Gender:C1501C1500C0479C0478C0477C0476P7032Cav Col

Page 359 — C0835 CONNECTOR DETAILS

C1537 CONNECTOR DETAILSRANGE ROVERC1537Description: ECU-Tyre deflationLocation: Beneath front passenger’s seatColour: BLACKGender: FemaleP6999C15

Page 360 — CONNECTOR DETAILS C0839

CONNECTOR DETAILS C1543RANGE ROVERC1543Description: ECU-Headlamp levellingLocation: Passenger’s footwellColour: GREYGender: FemaleP6977C0554C1543

Page 361 — C0862 CONNECTOR DETAILS

C1544 CONNECTOR DETAILSRANGE ROVERC1544Description: Sensor-Crankshaft position (CKP)Location: Rear RH side of engineColour:Gender:P6942C0645C1544Cav C

Page 362 — CONNECTOR DETAILS C0867

CONNECTOR DETAILS C1548RANGE ROVERC1548Description: Sensor-Air Temperature Control (ATC)Location: Front of engine compartment — centreColour: BLACKGen

Page 363 — C0867 CONNECTOR DETAILS

C1577 CONNECTOR DETAILSRANGE ROVERC1577Description: Speaker-PDCLocation: Driver’s footwellColour: NATURALGender: FemaleP6924C1577Cav Col Cct1N62Y

Page 364 — CONNECTOR DETAILS C0873

CONNECTOR DETAILS C1604RANGE ROVERC1604Description: Main harness to navigation harnessLocation: Luggage compartment — LH sideColour: BLACKGender: Male

Page 365 — C0876 CONNECTOR DETAILS

C1610 CONNECTOR DETAILSRANGE ROVERC1610Description: Sensor-Pressure-AirLocation: RH side of engine compartmentColour: BLACKGender: FemaleP7013C1610Cav

Page 366 — CONNECTOR DETAILS C0879

CONNECTOR DETAILS C1611RANGE ROVERC1611Description: Sensor-Pressure-AirLocation: Beneath vehicle — RH sideColour: BLACKGender: FemaleP7008C1611Cav Col

Page 367 — C0884 CONNECTOR DETAILS

C1629 CONNECTOR DETAILSRANGE ROVERC1629Description: Module-HEVAC controlLocation: Behind centre consoleColour: GREYGender: FemaleP6926C0232C0700C1629C

Page 368 — CONNECTOR DETAILS C0909

DESCRIPTION AND OPERATION4.18 RANGE ROVERSunroof ECUThe sunroof ECU (C0784) provides a feed to the sunroof switch (C0363) on a YS wire. If the switch

Page 369 — C0916 CONNECTOR DETAILS

CONNECTOR DETAILS C1630RANGE ROVERC1630Description: Module-HEVAC controlLocation: Behind centre consoleColour: BLACKGender: FemaleP6926C0232C0700C1629

Page 370 — CONNECTOR DETAILS C0917

C1664 CONNECTOR DETAILSRANGE ROVERC1664Description: Switch-SteptronicLocation: Beneath centre consoleColour: PURPLEGender: FemaleP6914C1664C0059Cav Co

Page 371 — C0918 CONNECTOR DETAILS

CONNECTOR DETAILS C1667RANGE ROVERC1667Description: Regulator-Fuel pressure — Td6Location: LH side of engineColour:Gender:C1667P7031Cav Col Cct1RW32NU

Page 372 — CONNECTOR DETAILS C0919

C1696 CONNECTOR DETAILSRANGE ROVERC1696Description: Sensor-Height-Front-LHLocation: Behind LH front wheel arch linerColour: BLACKGender: FemaleP6878C1

Page 373 — C0925 CONNECTOR DETAILS

CONNECTOR DETAILS C1697RANGE ROVERC1697Description: Sensor-Height-Front-RHLocation: Behind RH front wheel arch linerColour: BLACKGender: FemaleP6875C1

Page 374 — CONNECTOR DETAILS C0926

C1698 CONNECTOR DETAILSRANGE ROVERC1698Description: Sensor-Height-Rear-RHLocation: Below RH rear wheelarchColour: BLACKGender: FemaleP6938C1698Cav Col

Page 375 — C0932 CONNECTOR DETAILS

CONNECTOR DETAILS C1699RANGE ROVERC1699Description: Sensor-Height-Rear-LHLocation: Below LH rear wheelarchColour: BLACKGender: FemaleP6939C1699Cav Col

Page 376 — CONNECTOR DETAILS C0934

C1794 CONNECTOR DETAILSRANGE ROVERC1794Description: Lamp-Door sill-Front-RHLocation: Behind RH side of fasciaColour:Gender:P6922C1794Cav Col Cct1N122R

Page 377 — C0937 CONNECTOR DETAILS

CONNECTOR DETAILS C1795RANGE ROVERC1795Description: Lamp-Door sill-Front-LHLocation: Behind LH side of fasciaColour:Gender:P6923C0994C1795Cav Col Cct1

Page 378 — CONNECTOR DETAILS C0942

C1832 CONNECTOR DETAILSRANGE ROVERC1832Description: Switch-Steering column-LightingLocation: Top of steering columnColour:Gender:P6953C1396C1832C1395C

Page 379 — C0946 CONNECTOR DETAILS

DESCRIPTION AND OPERATIONRANGE ROVER 4.19DOOR MIRRORSDESCRIPTIONGeneralThe door mirrors operate when the ignition switch is turned to the ‘auxil

Page 380 — CONNECTOR DETAILS C0950

CONNECTOR DETAILS C1835RANGE ROVERC1835Description: ECU-Electronic automatic transmission — Td6Location: Inside E-boxColour:Gender:P7023C0604C0603C213

Page 382 — CONNECTOR DETAILS C0957

CONNECTOR DETAILS C1858RANGE ROVERC1858Description: Transfer gearbox — V8Location: LH side of transfer boxColour:Gender:P6941C0643C1858Cav Col Cct1N32

Page 383 — C0958 CONNECTOR DETAILS

C1886 CONNECTOR DETAILSRANGE ROVERC1886Description: Relay-Air injection pumpLocation: Inside E-boxColour:Gender:P6882C0448C2138C0193C0331C1886C0646C21

Page 384 — CONNECTOR DETAILS C0960

CONNECTOR DETAILS C1889RANGE ROVERC1889Description: BatteryLocation: Rear of engine compartmentColour: YELLOWGender: FemaleP6885C1889Cav Col Cct1NALL2

Page 385 — C0961 CONNECTOR DETAILS

C1895 CONNECTOR DETAILSRANGE ROVERC1895Description: Relay-Engine control module (ECM) — Td6Location: Inside E-boxColour:Gender:P7022C0162C0909C1526C01

Page 386 — CONNECTOR DETAILS C0963

CONNECTOR DETAILS C1895RANGE ROVERC1895Description: Relay-Engine control module (ECM) — V8Location: Inside E-boxColour:Gender:P7020C0162C0606C0332C208

Page 387 — C0964 CONNECTOR DETAILS

C2003 CONNECTOR DETAILSRANGE ROVERC2003Description: PDC harness to main harnessLocation: Rear of luggage compartmentColour:Gender:P6951C0876C2003Cav C

Page 388 — CONNECTOR DETAILS C0965

CONNECTOR DETAILS C2015RANGE ROVERC2015Description: Sensor-Anti-trap-Rear-RHLocation: Behind rear door trim panelColour:Gender:P6903C0732C2015C0311Cav

Page 389 — C0966 CONNECTOR DETAILS

C2016 CONNECTOR DETAILSRANGE ROVERC2016Description: Module-Passenger doorLocation: Behind passenger’s door trim panelColour:Gender:P6895C2057C201

Page 390 — CONNECTOR DETAILS C0968

DESCRIPTION AND OPERATION4.20 RANGE ROVERDrivers Door MirrorHorizontal AdjustmentWhen RH adjustment of the drivers door mirror is required, the driver

Page 391 — C0987 CONNECTOR DETAILS

CONNECTOR DETAILS C2017RANGE ROVERC2017Description: Module-Drivers doorLocation: Behind driver’s door trim panelColour:Gender:P6890C2271C2017C218

Page 392 — CONNECTOR DETAILS C0994

C2020 CONNECTOR DETAILSRANGE ROVERC2020Description: Fuse box-RearLocation: Luggage compartment — RH sideColour:Gender:P6949C2021 C2022C2023C2020C2024C

Page 393 — C1216 CONNECTOR DETAILS