|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–1 |

AUTOMATIC TRANSAXLE

SYSTEM

PRECAUTION

|

NOTICE: |

AX |

||

|

• If the following parts have been replaced, initialize the |

|||

|

TCM and perform a road test to allow the TCM to learn |

|||

|

(See page AX-25). |

|||

|

– |

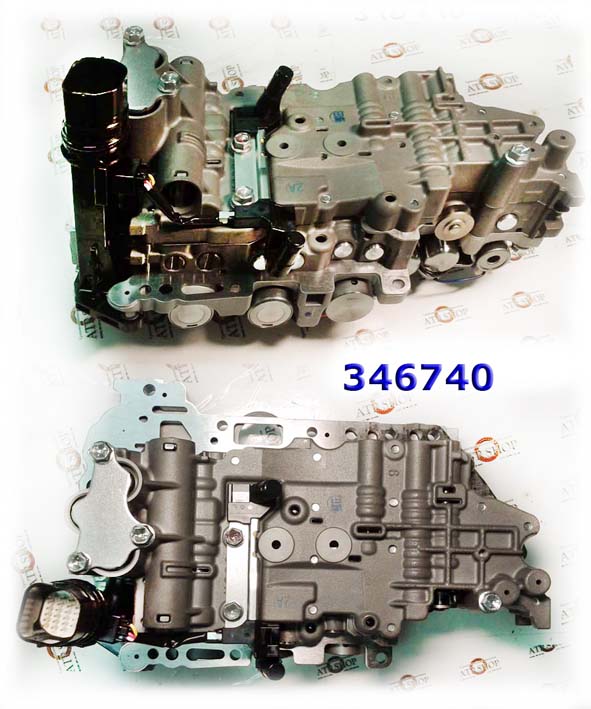

Valve body assembly |

||

|

– |

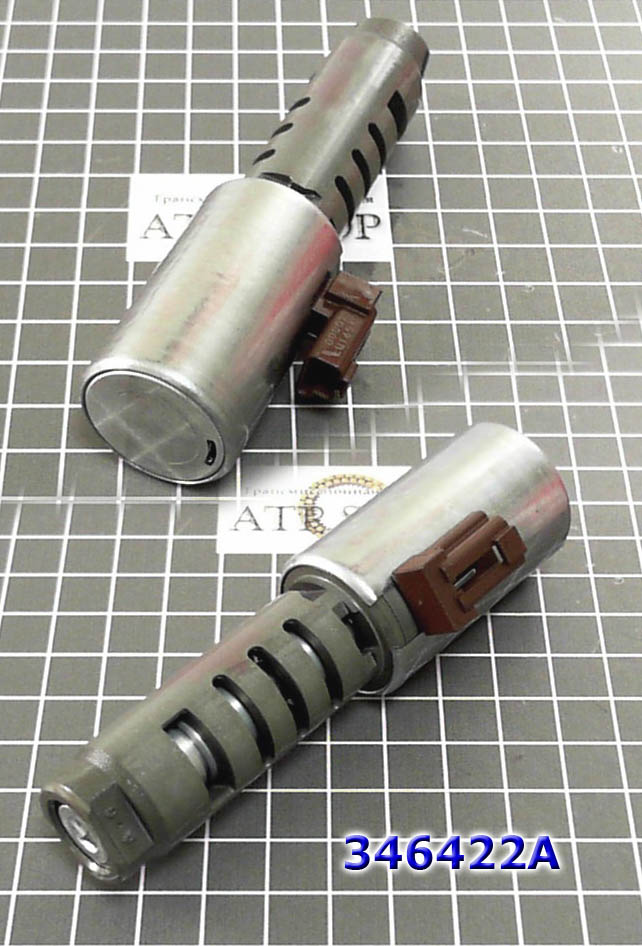

Shift solenoid SL3 |

||

|

– |

Shift solenoid SL4 |

||

|

• If the following parts have been replaced, perform a |

|||

|

road test to allow the TCM to learn (See page AX-25). |

|||

|

– |

Shift solenoid SL1 |

||

|

– |

Shift solenoid SL2 |

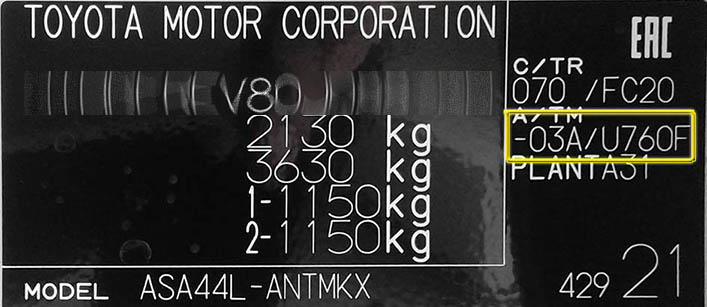

• If the TCM or transaxle has been replaced, register the transmission compensation code in the TCM (See page AX-19).

• Perform the RESET MEMORY (AT initialization) when replacing the automatic transmission assembly, engine assembly or ECM (See page AX-25).

1.The automatic transaxle is composed of highly precision-finished parts which need careful inspection before reassembly. Even a small nick could cause fluid leakage or affect transmission performance. The instructions here are organized so that you work on only one component group at a time. This will help avoid confusion caused by similar-looking parts of different sub-assemblies being on your workbench at the same time. The component groups are inspected and repaired from the converter housing side. Complete as much as possible of the inspection, repair and reassembly before proceeding to the next component group. If a defect is found in a certain component group during reassembly, inspect and repair this group immediately. If a component group cannot be assembled because some parts are being ordered, be sure to keep all parts of the group in a separate container while proceeding with disassembly, inspection, repair and reassembly of other component groups. Recommended: ATF WS

2.All disassembled parts should be washed clean and any fluid passages and holes should be blown through with compressed air.

3.Dry all parts with compressed air. Never use a shop rag or a piece of cloth to dry them.

4.When using compressed air, always aim away from yourself to prevent accidentally spraying ATF or kerosene in your face.

5.Only recommended automatic transmission fluid or kerosene should be used for cleaning.

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

6.After cleaning, the parts should be arranged in the correct order for efficient inspection, repair, and reassembly.

7.When disassembling a valve body, be sure to match each valve together with its corresponding spring.

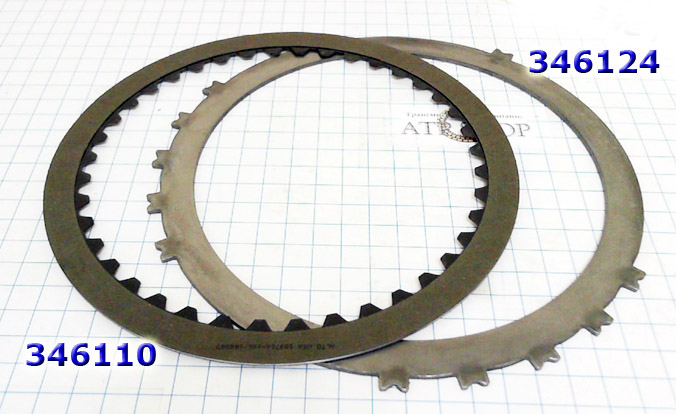

8.New discs for the brakes and clutches must be soaked in ATF for at least 15 minutes before reassembly.

9.All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with ATF prior to reassembly.

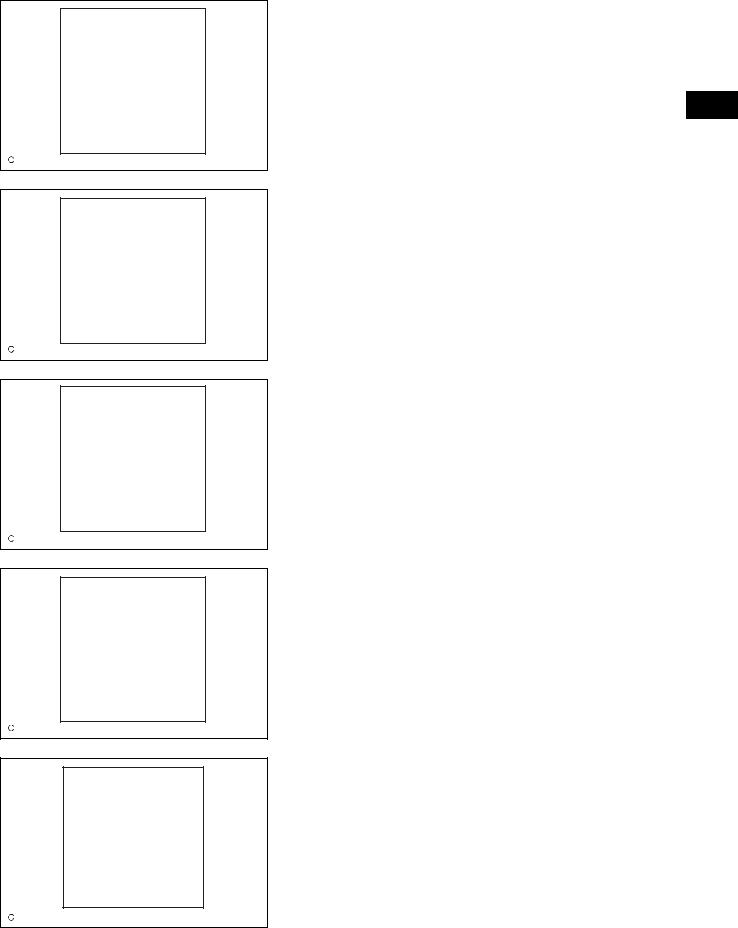

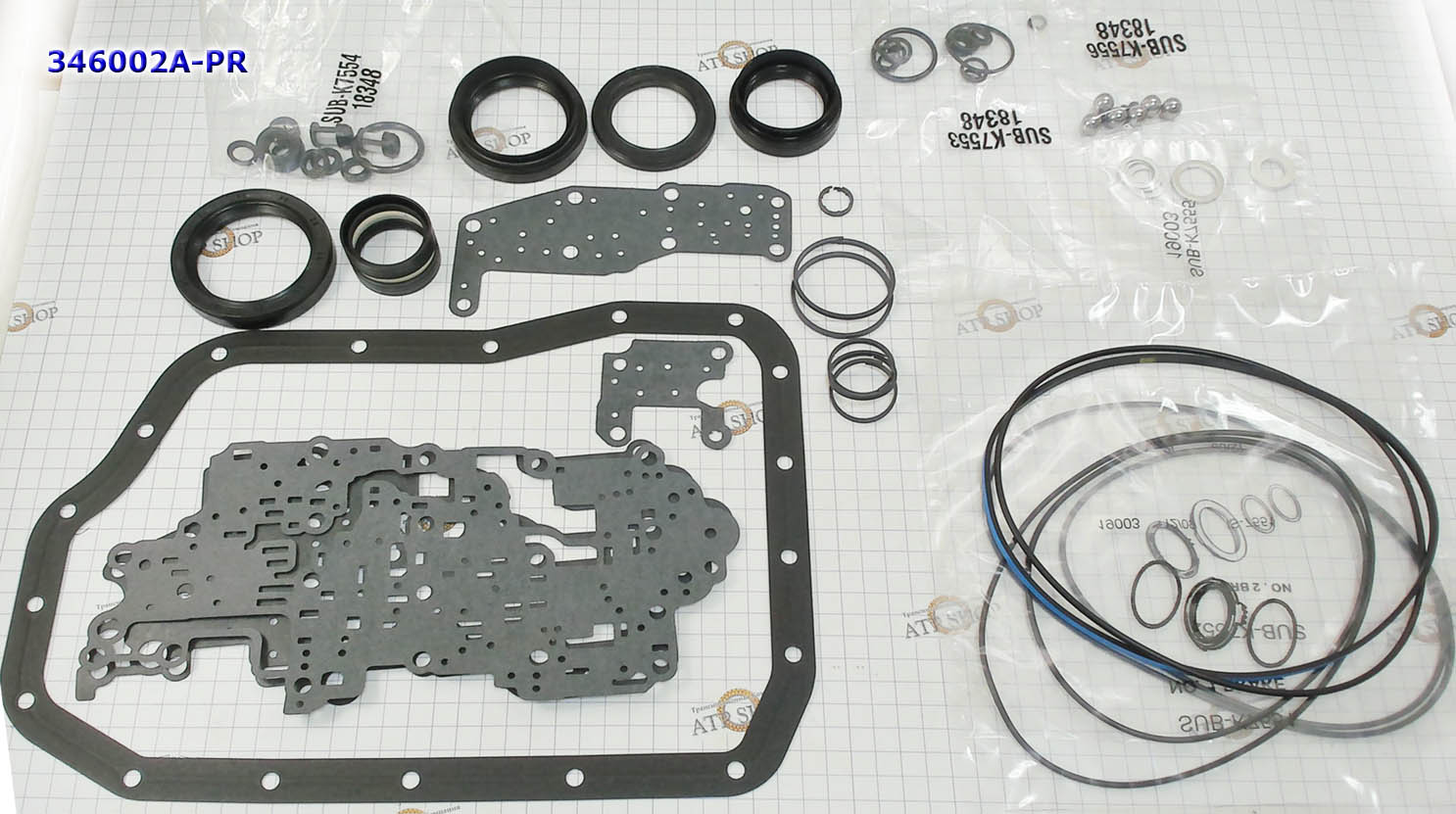

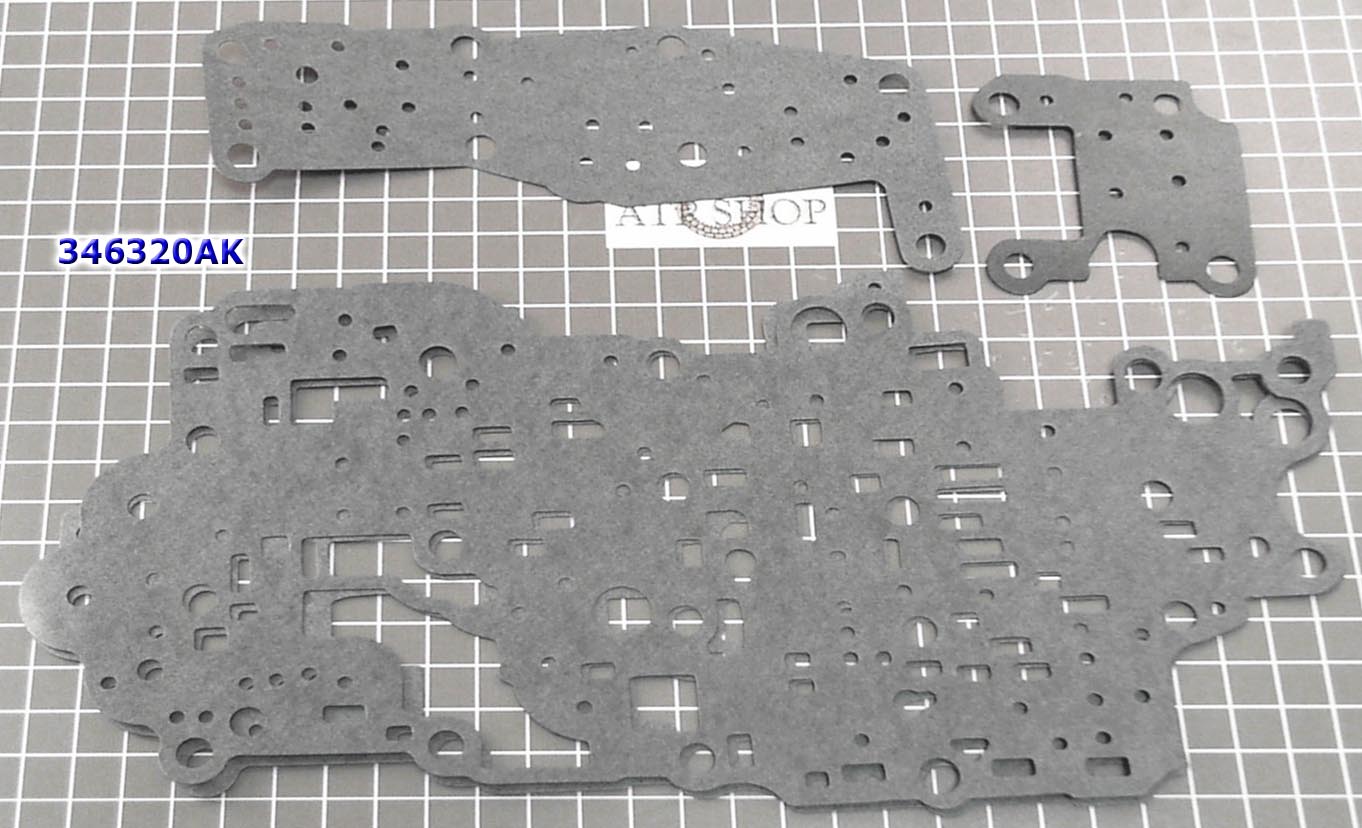

10.All gaskets, seals, and rubber O-rings should be replaced with new ones.

11.Do not apply adhesive cements to gaskets and similar parts.

12.Make sure that the ends of a snap ring are not aligned with one of the cutouts and that the snap ring is installed in the groove correctly.

13.When replacing a worn bushing, the sub-assembly containing the bushing must also be replaced.

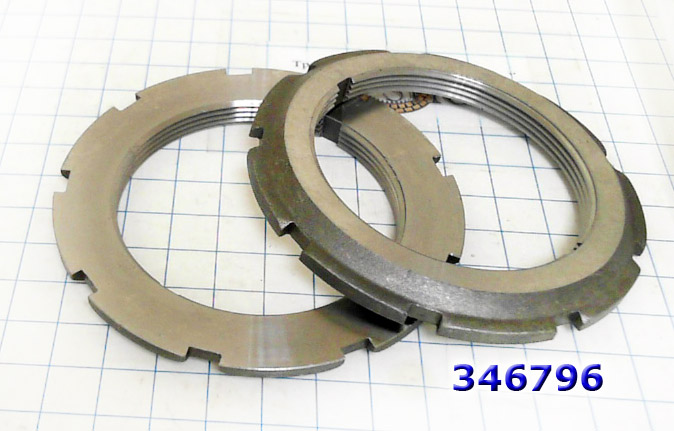

14.Check thrust bearings and races for wear or damage. If they are damaged, replace them.

15.When working with FIPG material, you must observe the following:

–Using a razor blade and a gasket scraper, remove all the old packing (FIPG) material from the gasket surface.

–Thoroughly clean all components to remove any loose material.

–Clean both sealing surfaces with a non-residue solvent.

–Parts must be reassembled within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

1.EXPRESSIONS OF IGNITION SWITCH

The type of ignition switch used on this model differs according to the specifications of the vehicle.

The expressions listed in the table below are used in this section.

|

Expression |

Switch Type |

||

|

Ignition Switch (Position) |

Engine Switch (Condition) |

||

|

Ignition switch off |

LOCK |

Off |

|

|

Ignition switch on (IG) |

ON |

On (IG) |

|

|

Ignition switch on (ACC) |

ACC |

ON (ACC) |

|

|

Engine start |

START |

Start |

|

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–3 |

||||

|

DEFINITION OF TERMS |

|||||

|

Term |

Definition |

||||

|

Monitor description |

Description of what the TCM monitors and how it detects malfunctions (monitoring purpose and its details). |

||||

|

Related DTCs |

Diagnostic code |

||||

|

Preconditions that allow the TCM to detect malfunctions. |

|||||

|

AX |

|||||

|

Typical enabling condition |

With all preconditions satisfied, the TCM sets the DTC when the monitored value(s) exceeds the |

||||

|

malfunction threshold(s). |

|||||

|

The priority order that is applied to monitoring, if multiple sensors and components are used to detect the |

|||||

|

Sequence of operation |

malfunction. |

||||

|

While another sensor is being monitored, the next sensor or component will not be monitored until the |

|||||

|

previous monitoring has concluded. |

|||||

|

Required sensor/components |

The sensors and components that are used by the TCM to detect malfunctions. |

||||

|

The number of times that the TCM checks for malfunctions per driving cycle. |

|||||

|

Frequency of operation |

«Once per driving cycle» means that the TCM detects malfunction only one time during a single driving |

||||

|

cycle. |

|||||

|

«Continuous» means that the TCM detects malfunction every time when the enabling conditions are met. |

|||||

|

Duration |

The minimum time that the TCM must sense a continuous deviation in the monitored value(s) before |

||||

|

setting a DTC. This timing begins after the «typical enabling conditions» are met. |

|||||

|

Malfunction thresholds |

Beyond this value, the TCM will conclude that there is a malfunction and set a DTC. |

||||

|

MIL illumination timing after a defect is detected. |

|||||

|

«Immediately» means that the TCM illuminates MIL the instant the TCM determines that there is a |

|||||

|

MIL operation |

malfunction. |

||||

|

«2 driving cycle» means that the TCM illuminates MIL if the same malfunction is detected again in the 2nd |

|||||

|

driving cycle. |

|||||

|

Normal operation range of sensors and solenoids under normal driving conditions. |

|||||

|

Component operating range |

Use these ranges as a reference. |

||||

|

They cannot be used to judge if a sensor or solenoid is defective. |

|||||

|

AX–4 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

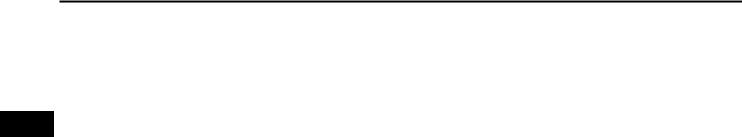

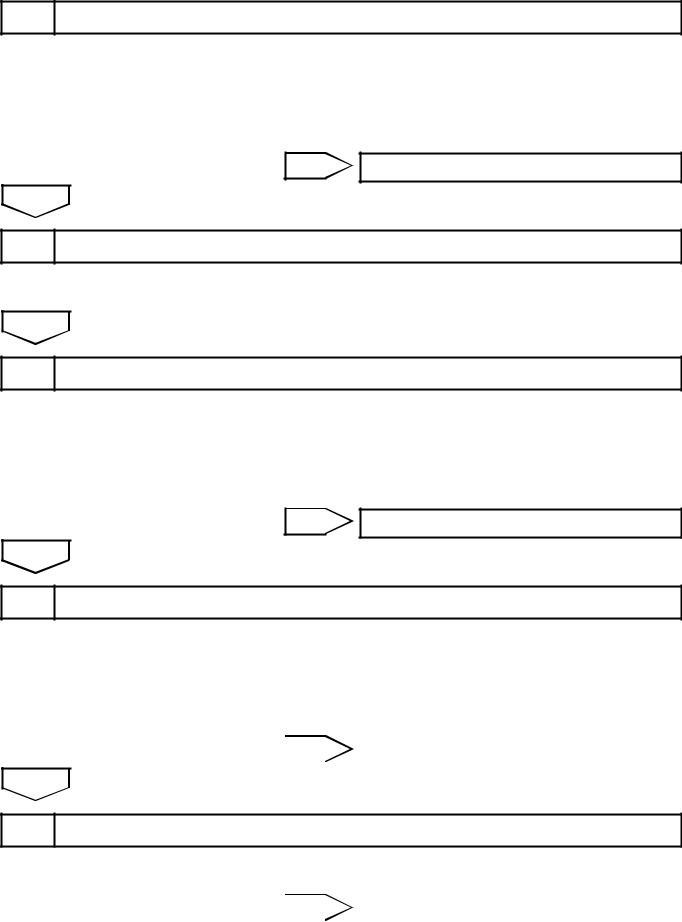

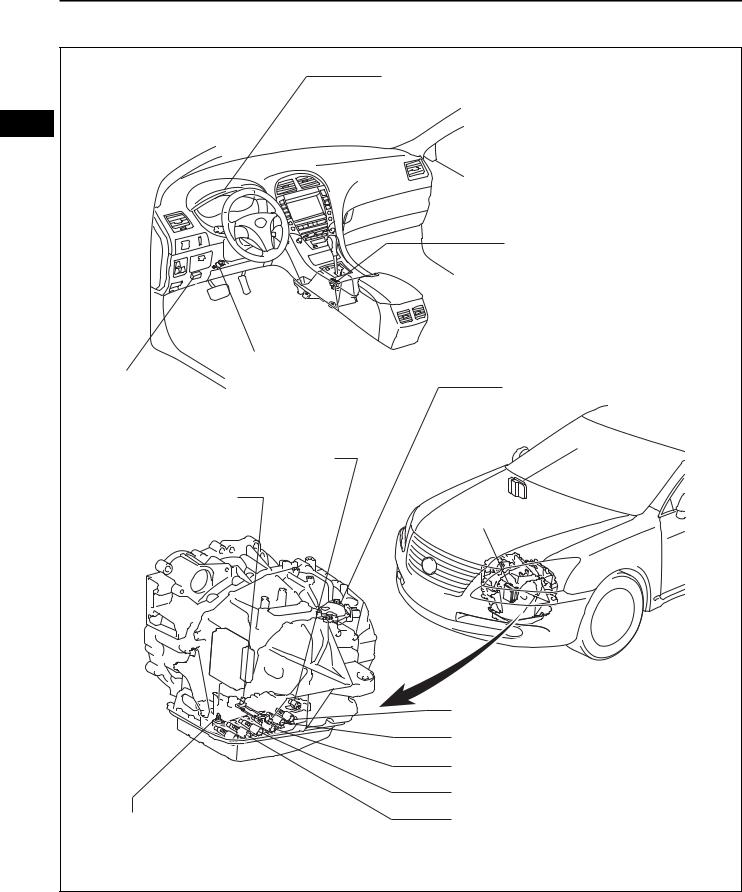

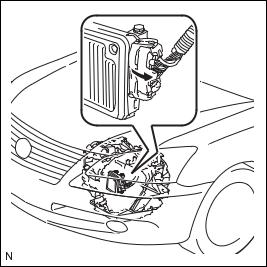

PARTS LOCATION

AX

STOP LIGHT SWITCH

DLC3

SHIFT SOLENOID VALVE (SL)

SPEED SENSOR

ATF TEMPERATURE SENSOR (INCLUDED ATF PRESSURE SWITCHE)

COMBINATION METER

SHIFT LEVER

— TRANSMISSION CONTROL SWITCH

PARK / NEUTRAL POSITION SWITCH

ECM

TCM

SHIFT SOLENOID VALVE (SLT)

SHIFT SOLENOID VALVE (SLU)

SHIFT SOLENOID VALVE (SL2)

SHIFT SOLENOID VALVE (SL1)

SHIFT SOLENOID VALVE (SL3)

SHIFT SOLENOID VALVE (SL4)

C133208E01

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–5 |

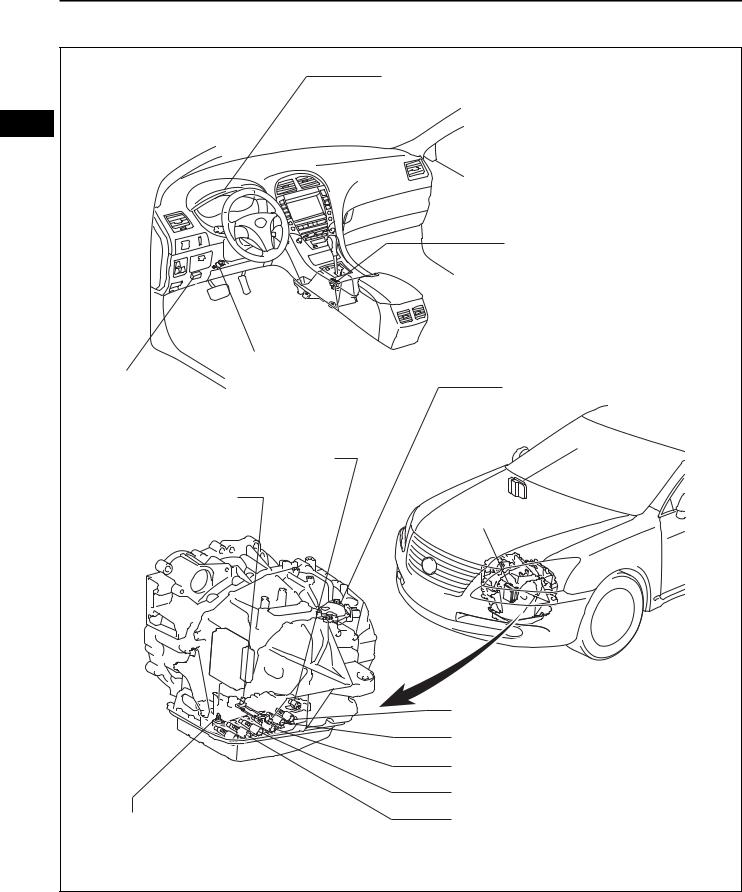

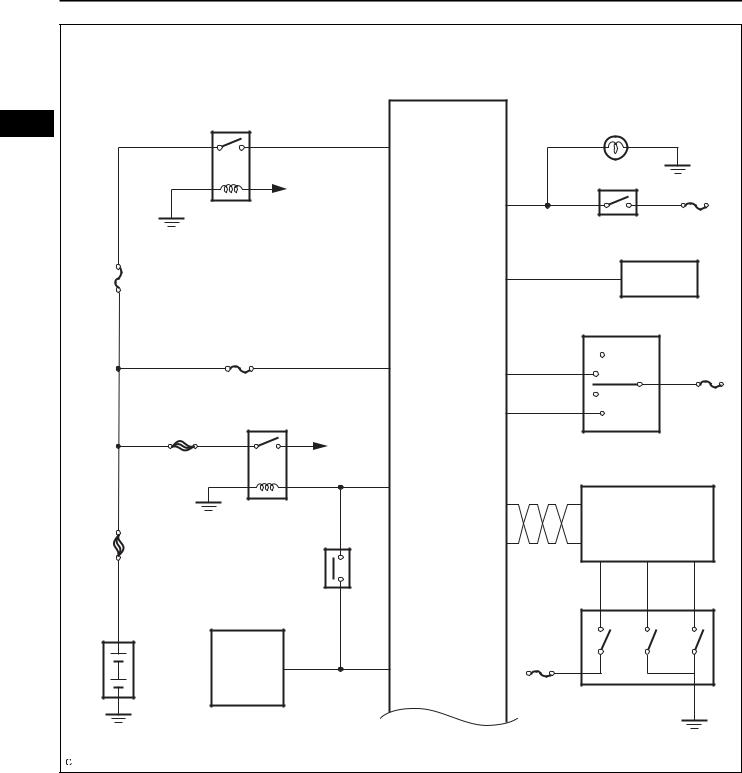

SYSTEM DIAGRAM

The configuration of the electronic control system in the

U660E automatic transaxle is as shown in the following chart.

|

INPUT TURBINE SPEED SENSOR |

SL1 |

SOLENOID VALVE SL1 |

AX |

|||

|

NTO |

||||||

|

COUNTER GEAR SPEED SENSOR |

SL2 |

SOLENOID VALVE SL2 |

||||

|

NCO |

||||||

|

ATF PRESSURE SWITCHES |

TPS1, 2, 3 |

SL3 |

SOLENOID VALVE SL3 |

|||

|

ATF TEMP. SENSOR |

THO1 |

|||||

|

TCM |

SL4 |

SOLENOID VALVE SL4 |

||||

|

STOP LIGHT SWITCH |

STP |

|||||

|

COMBINATION METER |

SPD |

SLU |

SOLENOID VALVE SLU |

|||

|

STARTER RELAY (Starter Signal) |

STA |

SLT |

SOLENOID VALVE SLT |

|||

|

PARK / NEUTRAL POSITION SWITCH |

NSW |

SL |

SOLENOID VALVE SL |

|||

|

R,D |

||||||

|

CAN+ |

CAN- |

DLC3 |

||||

|

NSW |

COMBINATION METER |

|||||

|

P,R,N,D |

CANH |

Shift Range Indicator Light |

||||

|

TRANSMISSION CONTROL SWITCH |

S,SFTU |

CANL |

Shift Position Indicator Light |

|||

|

SFTD |

||||||

|

VG |

S Mode Indicator Light |

|||||

|

MASS AIR FLOW METER |

Buzzer |

|||||

|

ENGINE COOLANT TEMP. SENSOR |

THW |

ECM |

W |

MIL |

||

|

CRANKSHAFT POSITION SENSOR |

NE |

#10 to #60 |

FUEL INJECTORS |

|||

|

THROTTLE POSITION SENSOR |

VPA1 |

IGT1 to 6 |

IGNITION COILS |

|||

|

VPA2 |

||||||

|

IGF |

||||||

|

ACCELERATOR PEDAL POSITION SENSOR |

VPA |

M |

THROTTLE CONTROL MOTOR |

|||

|

VPA2 |

||||||

|

C133209E01 |

|

AX–6 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|

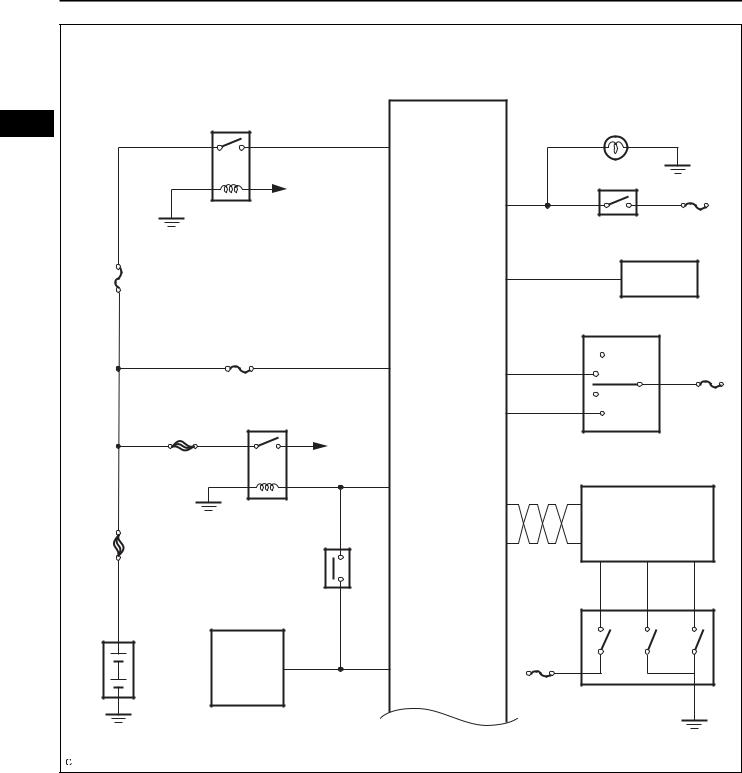

with Smart Key System: |

|||||||

|

TCM |

|||||||

|

AX |

+B |

||||||

|

Stop Light |

|||||||

|

To ECM |

|||||||

|

EFI MAIN |

STP |

||||||

|

Stop Light Switch |

STOP |

||||||

|

EFI MAIN |

SPD1 |

||||||

|

Combination Meter |

|||||||

|

EFI No. 1 |

|||||||

|

BATT |

R |

||||||

|

D |

GAUGE |

||||||

|

No. 1 |

|||||||

|

Park / Neutral Position Switch |

|||||||

|

ST/AM2 |

|||||||

|

STA |

CAN+ |

||||||

|

ST |

ECM |

||||||

|

FL MAIN |

CAN- |

S |

SFTLI SFTD |

||||

|

Park / Neutral |

|||||||

|

Position Switch |

|||||||

|

STR |

NSW |

ECU IG |

|||||

|

Transmission |

|||||||

|

No. 2 |

|||||||

|

Main Body ECU |

Control Switch |

||||||

|

C133214E05 |

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–7 |

|

without Smart Key System: |

TCM |

||||||

|

ALT |

AM1 |

NSW |

Stop Light |

AX |

|||

|

ST/AM2 |

STP |

Stop Light Switch |

STOP |

||||

|

Ignition Switch |

|||||||

|

STA |

SPD1 |

||||||

|

Combination Meter |

|||||||

|

Park / Neutral |

|||||||

|

Position Switch |

R |

||||||

|

GAUGE |

|||||||

|

ST |

D |

No. 1 |

|||||

|

Park / Neutral Position Switch |

|||||||

|

To Starter |

|||||||

|

BATT |

CAN+ |

ECM |

|||||

|

EFI No. 1 |

|||||||

|

CAN- |

S |

SFTLI |

SFTD |

||||

|

EFI |

|||||||

|

EFI MAIN |

+B |

||||||

|

FL MAIN |

To ECM |

||||||

|

ECU IG |

|||||||

|

No. 2 |

Transmission |

||||||

|

Control Switch |

|||||||

|

C133213E01 |

|

AX–8 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|

Automatic Transaxle |

||

|

AX |

SL1+ |

|

|

Shift Solenoid Valve SL1 |

||

|

SL1- |

||

|

SL2+ |

||

|

Shift Solenoid Valve SL2 |

||

|

SL2- |

||

|

SL3+ |

||

|

Shift Solenoid Valve SL3 |

||

|

SL3- |

||

|

SL4+ |

||

|

Shift Solenoid Valve SL4 |

SL4- |

|

|

SL |

||

|

Shift Solenoid Valve SL |

||

|

ATF Pressure Switch 1 |

TPS1 |

|

|

ATF Pressure Switch 2 |

TPS2 |

|

|

ATF Pressure Switch 3 |

TPS3 |

|

|

ATF Temperature Sensor |

THO1 |

|

|

E2 |

||

|

Input Turbine Speed Sensor |

NTB |

|

|

NTO |

||

|

Counter Gear Speed Sensor |

NCB |

|

|

NCO |

||

|

C133215E01 |

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–9 |

SYSTEM DESCRIPTION

1.SYSTEM DESCRIPTION

(a)The ECT (Electronic controlled automatic transaxle) is an automatic transaxle that has its shift timing

electronically controlled by the Transmission Control Module (TCM). The TCM detects electrical signals AX that indicate engine and driving conditions, and

controls the shift point, based on driver’s habits and road conditions. As a result, fuel efficiency and transaxle performance are improved.

Shift shock has been reduced by controlling the engine and transaxle simultaneously.

In addition, the ECT has features such as:

•Diagnostic function.

•Fail-safe function for use when a malfunction occurs.

|

AX–10 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX

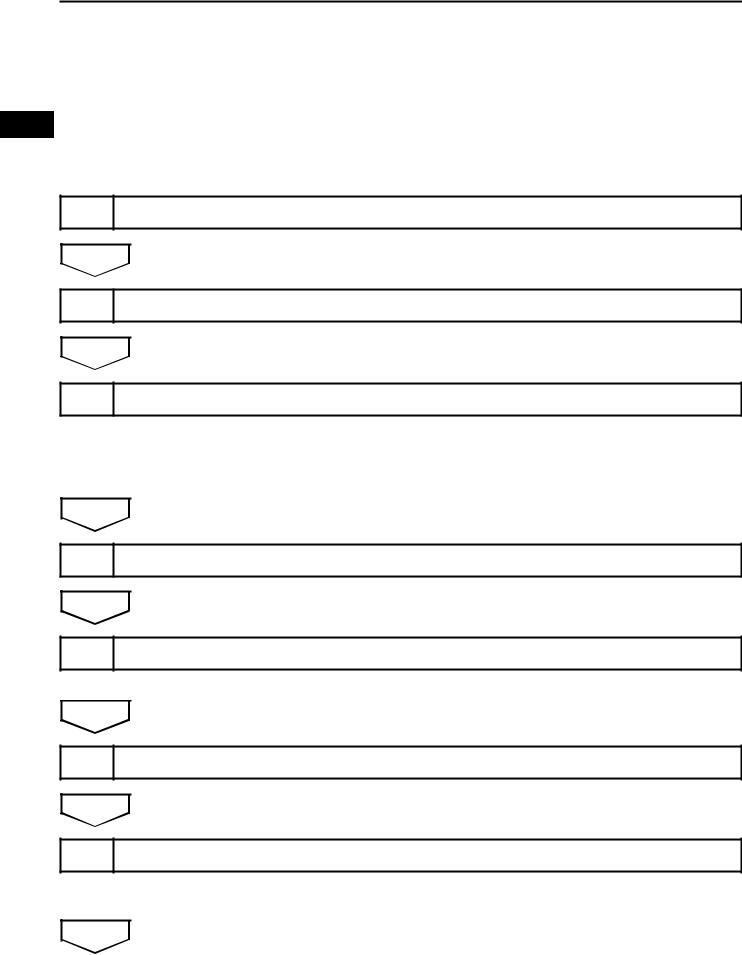

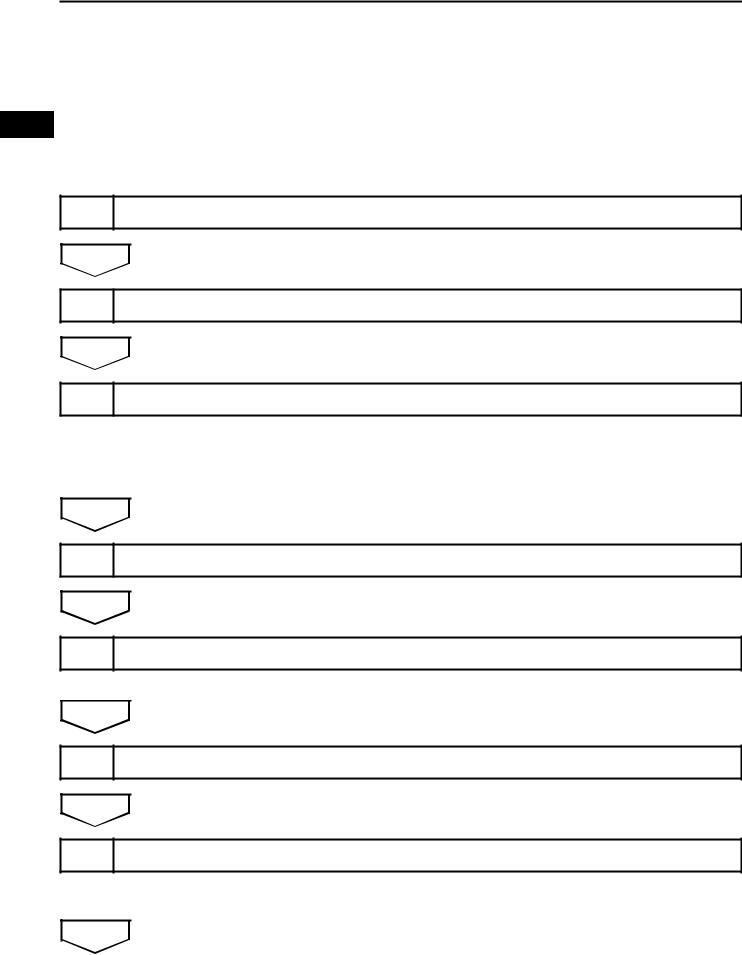

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

•The TCM of this system is connected to the CAN communication system. Therefore, before starting troubleshooting, make sure to check that there is no trouble in the CAN communication system.

•*: Use the intelligent tester.

1VEHICLE BROUGHT TO WORKSHOP

NEXT

2CUSTOMER PROBLEM ANALYSIS

NEXT

3INSPECT BATTERY VOLTAGE

Standard voltage: 11 to 14 V

If the voltage is below 11 V, recharge or replace the battery before proceeding.

NEXT

4CONNECT INTELLIGENT TESTER TO DLC3*

NEXT

5CHECK AND CLEAR DTCS AND FREEZE FRAME DATA*

(a) Refer to the DTC CHECK / CLEAR (See page AX-38).

NEXT

6VISUAL INSPECTION

NEXT

7SETTING CHECK MODE DIAGNOSIS*

(a)Refer to the CHECK MODE PROCEDURE (See page AX-39).

NEXT

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–11 |

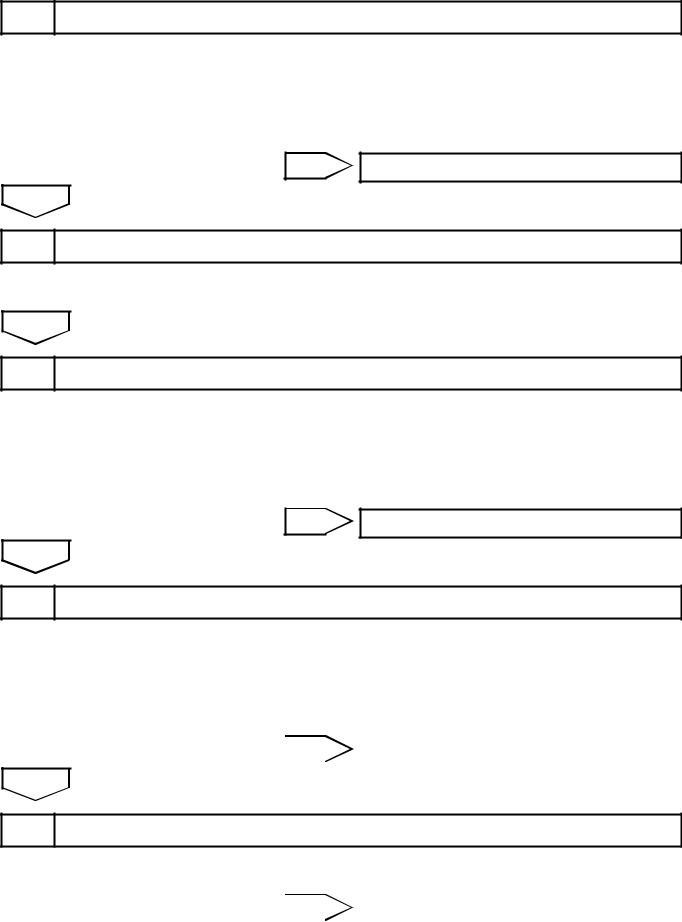

8PROBLEM SYMPTOM CONFIRMATION

(a)Refer to the ROAD TEST (See page AX-12).

Result

|

AX |

|||

|

Result |

Proceed to |

||

|

Symptom does not occur |

A |

||

|

Symptom occurs |

B |

||

B GO TO STEP 10

A

9 SYMPTOM SIMULATION

(a)Refer to the ELECTRONIC CIRCUIT INSPECTION PROCEDURE (See page IN-40).

NEXT

10 DTC CHECK*

(a)Refer to the DTC CHECK / CLEAR (See page AX-38).

Result

|

Result |

Proceed to |

|

DTC is not output |

A |

|

DTC is output |

B |

B GO TO STEP 18

A

11 BASIC INSPECTION

(a)Refer to the AUTOMATIC TRANSMISSION FLUID (See page AX-164).

(b)Refer to the PARK/NEUTRAL POSITION SWITCH (See page AX-174).

(c)Refer to the SHIFT LEVER ASSEMBLY (See page AX224).

OK

12 MECHANICAL SYSTEM TEST

(a)Refer to the MECHANICAL SYSTEM TEST (See page AX-15).

|

AX–12 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

||||||

|

OK |

|||||||

|

13 |

HYDRAULIC TEST |

||||||

|

(a) Refer to the HYDRAULIC TEST (See page AX-17). |

|||||||

|

AX |

|||||||

|

NG |

|||||||

|

GO TO STEP 17 |

|||||||

OK

14 MANUAL SHIFTING TEST

(a)Refer to the MANUAL SHIFTING TEST (See page AX18).

OK

15PROBLEM SYMPTOMS TABLE CHAPTER 1

(a)Refer to the PROBLEM SYMPTOMS TABLE (See page AX-29).

OK

16PROBLEM SYMPTOMS TABLE CHAPTER 2

(a)Refer to the PROBLEM SYMPTOMS TABLE (See page AX-29).

NEXT

17 PART INSPECTION

NEXT GO TO STEP 21

18 DTC CHART

(a)Refer to the DIAGNOSTIC TROUBLE CODE CHART (See page AX-46).

NEXT

19 CIRCUIT INSPECTION

NEXT

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–13 |

20 IDENTIFICATION OF PROBLEM

NEXT

21REPAIR OR REPLACE

NEXT

22CONFIRMATION TEST

AX

|

AX–14 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX

ROAD TEST

1.PROBLEM SYMPTOM CONFIRMATION

(a)Based on the result of the customer problem analysis, try to reproduce the symptoms. If the problem is that the transaxle does not shift up or down, or the shift point is too high or too low, conduct the following road test referring to the automatic shift schedule and attempt to duplicate the problem symptoms.

2.ROAD TEST NOTICE:

Perform the test at the ATF (Automatic Transmission Fluid) temperature 50 to 80°C (122 to 176°F) in the normal operation.

(a)D position test:

Shift into the D position and fully depress the accelerator pedal and check the following:

(1)Check up-shift operation.

Check that 1 to 2, 2 to 3, 3 to 4, 4 to 5 and 5 to 6 up-shifts take place, and that the shift points conform to the automatic shift schedule (See page SS-46).

HINT:

6th Gear Up-shift Prohibition Control

•Engine coolant temperature is 60°C (140°F) or less and vehicle speed is 50 mph (80 km/ h) or less.

5th Gear Up-shift Prohibition Control

•Engine coolant temperature is 55°C (131°F) or less and vehicle speed is 32 mph (51 km/

h) or less.

4th Gear Up-shift Prohibition Control

• Engine coolant temperature is 47°C (117°F) or less and vehicle speed is 31 mph (49 km/ h) or less.

Lock-up Prohibition Control

•Brake pedal is depressed.

•Accelerator pedal is released.

•Engine coolant temperature is 60°C (140°F) or less.

(2)Check for shift shock and slip.

Check for shock and slip at the 1 to 2, 2 to 3, 3 to 4, 4 to 5 and 5 to 6th up-shifts.

(3)Check for abnormal noise and vibration. Check for abnormal noise and vibration when

up-shifting from 1 to 2, 2 to 3, 3 to 4, 4 to 5 and 5 to 6 while driving with the shift lever in the D position, and also while driving in the lock-up condition.

HINT:

The check for the cause of abnormal noise and vibration must be done thoroughly as it could also be due to loss of balance in the differential, torque converter clutch, etc.

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–15 |

(4)Check kick-down operation.

Check vehicle speeds when the 2nd to 1st, 3rd to 2nd, 4th to 3rd, 5th to 4th, and 6th to 5th kickdowns take place while driving with the shift lever in the D position. Confirm that each speed

is within the applicable vehicle speed range

indicated in the automatic shift schedule (See AX page SS-46).

(5)Check for abnormal shock and slip at kick-down.

(6)Check the lock-up mechanism.

•Drive the vehicle with the shift lever in the D position (2nd, 3rd, 4th, 5th or 6th gear) at a steady speed (lock-up ON).

•Lightly depress the accelerator pedal and check that the engine speed does not change

abruptly.

HINT:

•There is no lock-up function in the 1st gears.

•If there is a jump in engine speed, this indicates that lock-up is not operating.

(b)S position test

Shift to the S position, depress the accelerator pedal and check the following:

(1)Check shift operation.

•With the shift lever in the S position (while the vehicle is stopped), shift into the «+» position to check that the shift position on the combination meter changes as follows: 1 to 2, 2 to 3, 3 to 4, 4 to 5 and 5 to 6.

•While driving in the 5 (S) position and 5th gear (at a vehicle speed of approximately 34 to 40 mph (55 to 65 km/h), shift into the «-» position and check if the 4th gear down-shift occurs and proper engine braking occurs.

•While driving in the 4 (S) position and 4th gear (at a vehicle speed of approximately 19 to 25 mph (30 to 40 km/h), shift into the «-» position and check if the 3rd gear down-shift occurs and proper engine braking occurs.

•While driving in the 3 (S) position and 3rd gear (at a vehicle speed of approximately 12 to 19 mph (20 to 30 km/h), shift into the «-» position and check if the 2nd gear down-shift occurs and proper engine braking occurs.

•While driving in the 2 (S) position and 2nd gear (at a vehicle speed of approximately 6 to 12 mph (10 to 20 km/h), shift into the «-» position and check if the 1st gear down-shift

occurs and proper engine braking occurs. HINT:

Manual shift (S position) is prohibited under either of the following conditions:

• Down-shifting may cause engine overrun.

|

AX–16 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||

|

• The driver continuously down-shifts. (Down- |

||||

|

shifting to 1st gear may not be performed.) |

||||

|

(c) |

R position test: |

|||

|

Shift into the R position, lightly depress the |

||||

|

accelerator pedal, and check that the vehicle moves |

||||

|

backward without any abnormal noise or vibration. |

||||

|

AX |

||||

|

CAUTION: |

||||

|

Before conducting this test ensure that the test |

||||

|

area is free from people and obstruction. |

||||

|

(d) |

P position test: |

|||

|

Stop the vehicle on a grade (more than 5°) and after |

shifting into the P position, release the parking brake. Then, check that the parking lock pawl holds the vehicle in place.

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–17 |

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

|

The object of this test is to check the overall |

|||

|

performance of the transaxle and engine by |

|||

|

measuring the stall speeds in the D position. |

AX |

||

|

NOTICE: |

|||

|

• Driving test should be done on a paved road |

|||

|

(a nonskid road). |

|||

|

• Perform the test at the normal operating ATF |

|||

|

(Automatic Transmission Fluid) temperature |

|||

|

50 to 80°C (122 to 176°F). |

|||

|

• Do not continuously run this test for longer |

|||

|

than 5 seconds. |

|||

|

• To ensure safety, perform this test in a wide, |

|||

|

clear level area which provides good traction. |

|||

|

• The stall test should always be carried out in |

|||

|

pairs. One technician should observe the |

|||

|

conditions of wheels or wheel stoppers from |

|||

|

a safe location outside the vehicle while the |

|||

|

other is doing the test. |

|||

|

(1) Chock the 4 wheels. |

|||

|

(2) Connect the intelligent tester to the DLC3. |

|||

|

(3) Fully apply the parking brake. |

|||

|

(4) Keep your left foot pressed firmly on the brake |

|||

|

pedal. |

|||

|

(5) Start the engine. |

|||

|

(6) Using the intelligent tester, shift into the D |

|||

|

position and hold 3rd gear using active test. |

|||

|

Press all the way down on the accelerator pedal |

|||

|

with your right foot. |

|||

|

(7) Quickly read the stall speed at this time. |

|||

|

Stall speed: |

|||

|

Evaluation: |

2,520 +- 150 rpm |

||

|

Problem |

Possible cause |

||

|

• Engine power output may be insufficient |

|||

|

• Stator one-way clutch is not operating properly |

|||

|

(a) Stall engine speed is low in D position |

HINT: |

||

|

If the value is less than the specified value by 600 rpm or more, the |

|||

|

torque converter could be faulty. |

|||

|

• Line pressure is too low |

|||

|

(b) Stall engine speed is high in D position |

• Clutch No. 1 (C1) slipping |

||

|

• One-way clutch (F1) is not operating properly |

|||

|

• Improper fluid level |

|||

|

AX–18 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

||||

|

(b) Measure the time lag. |

|||||

|

(1) When the shift lever is shifted while the engine is |

|||||

|

idling, there will be a certain time lapse or lag |

|||||

|

before the shock can be felt. This is used for |

|||||

|

checking the condition of the clutches and |

|||||

|

brakes. |

|||||

|

AX |

|||||

|

NOTICE: |

|||||

|

• Perform the test at the normal operating |

|||||

|

ATF (Automatic Transmission Fluid) |

|||||

|

temperature: 50 to 80°C (122 to 176°F). |

|||||

|

• Be sure to allow 1 minute interval between |

|||||

|

tests. |

|||||

|

• Perform the test three times and measure |

|||||

|

the time lags. Calculate the average value |

|||||

|

of the three time lags. |

|||||

|

(2) Connect the intelligent tester to the DLC3. |

|||||

|

(3) Fully apply the parking brake. |

|||||

|

(4) Start and warm up the engine and check idle |

|||||

|

speed. |

|||||

|

Idle speed: |

|||||

|

approx. 650 rpm (In N position and A/C |

|||||

|

OFF) |

|||||

|

(5) Shift the lever from N to D position. Using a stop |

|||||

|

watch, measure the time from when the lever is |

|||||

|

shifted until the shock is felt. |

|||||

|

Time lag: |

|||||

|

N to D less than 1.2 seconds |

|||||

|

(6) In the same way, measure the time lag for N to |

|||||

|

R. |

|||||

|

Time lag: |

|||||

|

N to R less than 1.5 seconds |

|||||

|

Evaluation (If N to D or N to R time lag is longer than the specified time): |

|||||

|

Problem |

Possible cause |

||||

|

• Line pressure is too low |

|||||

|

N to D time lag is longer |

• Clutch No.1 (C1) is worn |

||||

|

• One-way clutch (F1) is not operating properly |

|||||

|

• Line pressure is too low |

|||||

|

N to R time lag is longer |

• Brake No. 2 (B2) is worn |

||||

|

• Brake No. 3 (B3) is worn |

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–19 |

|

HYDRAULIC TEST |

||

|

1. |

PERFORM HYDRAULIC TEST |

|

|

(a) Measure the line pressure. |

||

|

NOTICE: |

||

|

• Perform the test at the normal operating ATF |

AX |

|

|

(Automatic Transmission Fluid) temperature: |

||

|

50 to 80°C (122 to 176°F). |

||

|

• The line pressure test should always be |

||

|

carried out in pairs. One technician should |

||

|

observe the conditions of wheels or wheel |

||

|

stoppers outside the vehicle while the other |

||

|

is performing the test. |

||

|

• Be sure to prevent SST hose from interfering |

||

|

with the exhaust pipe. |

||

|

• This check must be conducted after checking |

||

|

and adjusting engine. |

||

|

• Perform the test with the A/C is OFF. |

||

|

SST |

• When conducting stall test, do not continue |

|

|

more than 5 seconds. |

||

|

SST |

||

|

(1) Warm up the ATF (Automatic Transmission |

||

|

C133223E01 |

||

|

Fluid). |

||

(2)Lift the vehicle up.

(3)Remove the engine under cover.

(4)Connect the intelligent tester to the DLC3.

(5)Remove the test plug on the transaxle case front left side and install the SST.

SST 09992-00095 (09992-00231, 0999200271)

(6)Start the engine.

(7)Shift to the D position, and then use the intelligent tester to hold 3rd gear using active test. Measure the line pressure while the engine is idling.

Specified line pressure:

|

Condition |

D position kPa (kgf/cm2, psi) |

|

|

Idling |

362 to 412 kPa |

|

|

(3.7 to 4.2 kgf/cm2, 52 to 60 psi) |

||

(8) Turn the ignition switch OFF.

|

AX–20 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|

(9) Disconnect the connector of the TCM. |

|||

|

HINT: |

|||

|

Disconnect the connector only when performing |

|||

|

the D position stall test. |

|||

|

(10)Start the engine. |

|||

|

AX |

(11)Firmly depress the brake pedal, shift to the D |

||

|

position, depress the accelerator pedal all the |

|||

|

way down, and check the line pressure while the |

|||

|

stall test is performed. |

|||

|

Specified line pressure: |

|||

|

Condition |

D position kPa (kgf/cm2, psi) |

||

|

Stall test |

1,160 to 1,350 kPa |

||

|

(11.8 to 13.8 kgf/cm2, 168 to 196 psi) |

|||

|

(12)Turn the ignition switch OFF. |

|||

|

C133211 |

(13)Connect the TCM connector, depress the brake |

||

|

pedal firmly, shift to the R position, and check |

|||

|

that the line pressure while the engine is idling |

|||

|

and during the stall test. |

|||

|

Specified line pressure: |

|||

|

Condition |

R position kPa (kgf/cm2, psi) |

||

|

Idling |

806 to 916 kPa |

||

|

(8.2 to 9.3 kgf/cm2, 117 to 133 psi) |

|||

|

Stall test |

1,890 to 2,000 kPa |

||

|

(19.3 to 20.4 kgf/cm2, 274 to 290 psi) |

|||

|

(14)Remove the SST, install the test plug. |

|||

|

Evaluation: |

(15)Clear the DTC. |

||

|

Problem |

Possible cause |

||

|

Measured values are higher than the specified value in all positions |

• Shift solenoid valve (SLT) defective |

||

|

• |

Regulator valve defective |

||

|

• Shift solenoid valve (SLT) defective |

|||

|

Measured values are lower than the specified value in all positions |

• |

Regulator valve defective |

|

|

• |

Oil pump defective |

||

|

Pressure is low in the D position only |

• D position circuit fluid leak |

||

|

• Clutch No. 1 (C1) defective |

|||

|

• R position circuit fluid leak |

|||

|

Pressure is low in the R position only |

• |

Brake No. 2 (B2) defective |

|

|

• Brake No. 3 (B3) defective |

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–21 |

MANUAL SHIFTING TEST

1.PERFORM MANUAL SHIFTING TEST

HINT:

• With this test, it can be determined whether trouble

|

occurs in the electrical circuit. Also, trouble can be a |

||||||

|

mechanical problem in the transaxle. |

AX |

|||||

|

• |

If any abnormalities are found in the following test, the |

|||||

|

problem is in the transaxle itself. |

||||||

|

(a) |

Disconnect the TCM connector. |

|||||

|

(b) |

Drive the vehicle with the TCM disconnected. |

|||||

|

Shifting the shift lever to the D position to check |

||||||

|

whether the shifting condition changes as shown in |

||||||

|

the table below. |

||||||

|

Shift Position |

Shifting Condition |

|||||

|

D |

No Shift (No Change) |

|||||

|

HINT: |

||||||

|

When driving the vehicle with the TCM |

||||||

|

disconnected, the gear position will be as follows: |

||||||

|

• When the shift lever is in the D position, the |

||||||

|

transmission will stay in 3rd gear. |

||||||

|

• When the shift lever is in the R or the P position, |

||||||

|

the transmission will also be in the R or P |

||||||

|

position respectively. |

||||||

|

(c) |

Connect the connector of the TCM. |

|||||

|

(d) |

Clear the DTC (See page AX-38). |

|

AX–22 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX

QR Code Label

#-

Transmission

Compensa-

tion Code

QR Code Label

REGISTRATION

NOTICE:

•When the automatic transaxle is replaced, the transaxle’s compensation code must be input into the TCM (Proceed to step 1).

•When the TCM is replaced, the existing transaxle compensation codes must be input into the new TCM (Proceed to step 2).

1.INPUT COMPENSATION CODE NOTICE:

Transaxle compensation codes are unique, 60-digit alphanumeric values printed on the QR label. If an incorrect transaxle compensation code is input into the TCM, shift shock may occur.

(a)Record the transmission compensation code specified on the QR label.

HINT:

The transaxle compensation code is imprinted on the QR label.

(b)Shift the shift lever to N or P position.

(c)Connect the intelligent tester to the DLC3.

(d)Turn the ignition switch on (IG).

(e)Turn the tester on.

NOTICE:

Do not start the engine.

C133268E01

M-OBD / OBD MENU [Name of system]

1 : DATA LIST

1 : DTC INFO

3 : ACTIVE TEST

4 : SNAPSHOT

6 : RESET MEMORY

8 : CHECK MODE

9 : AT CODE UTILITY

(f)Enter the menu items in this order: DIAGNOSIS / OBD/MOBD / ECT / AT CODE UTILITY.

(g)Press «ENTER».

C133193

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–23 |

(h) Select «AT CODE REGIST».

AT CODE UTILITY (i) Press «ENTER».

[Name of system]

1 : AT CODE REGIST

2 : AT CODE RESET

AX

C133194

(j) Press «ENTER» again to proceed.

NOTICE

This function is used to input a compensation code and initialize the ECU after an A/T

assembly or ECU has been replaced.

PRESS [ENTER]

C133195

CHECK

Gear Selector is in P. Vehicle is stopped. Engine is OFF. Engine switch is ON(IG).

PRESS [ENTER]

(k) Press «ENTER» again to proceed.

C133196

(l) Press «ENTER» again to proceed.

NOTICE

This function must not be performed without referring the service manual.

PRESS [ENTER]

C133197

A/T CODE REGIST

Select a function.

1.SET A/T CODE

2.READ A/T CODE

(m)Select «SET A/T CODE».

(n)Press «ENTER».

|

AX–24 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||

|

(o) Select «INPUT A/T CODE». |

||||||

|

A/T CODE REGIST |

(p) Press «ENTER». |

|||||

|

SET A/T CODE |

||||||

|

Select a way of |

||||||

|

setting the code. |

||||||

|

1. INPUT A/T CODE |

||||||

|

2. SAVED A/T CODE |

||||||

|

AX |

|

PRESS [ENTER] |

|||

|

C133199 |

|||

|

code input method |

(q) Register the compensation code. |

||

|

(1) |

Press «ENTER». |

||

|

INPUT A/T CODE |

|||

|

Press [ ] / [ |

] to |

||

|

shift the cursor |

|||

|

right/left. |

|||

|

Press [ ] / [ |

] to |

||

|

shift the cursor |

|||

|

up/down. |

|||

|

Input alphanumeric |

|||

|

with 10 key and |

|||

|

* key. |

|||

|

PRESS [ENTER] |

|||

|

C133200 |

|

A/T CODE REGIST |

|

Input the code |

|

printed on the A/T. |

|

PRESS [ENTER] |

|

C133201 |

A/T CODE REGIST

SET CODE

A/T CODE REGIST is complete.

PRESS [EXIT]

C133203

(2)Manually input the transaxle compensation code. The code is a 60-digit alphanumeric value imprinted on the QR label.

(r)Check that the compensation code displayed on the screen is correct by comparing it with the 60-digit alphanumeric value on the QR label.

NOTICE:

If an incorrect transaxle compensation code is input into the TCM, shift shock will occur.

HINT:

Input letters by operating the keys from 0 to 5 while pressing the * key.

(s)Press «ENTER» to set the compensation code to the TCM.

HINT:

• If the registration process fails, the compensation code may be incorrect. Check the compensation code again.

• If the attempted compensation code is correct, a problem with the wire harness or a bad connection with the DLC3 may cause a registration failure. Check the wire harness and the DLC3 connection. If no problem is found, the TCM may be malfunctioning. Check the TCM and repeat this operation.

2.TRANSFER COMPENSATION CODE NOTICE:

Transaxle compensation codes are 60-digit alphanumeric values imprinted on the QR label. If an incorrect transaxle compensation code is input into the TCM, shift shock may occur.

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–25 |

M-OBD / OBD MENU [Name of system]

1 : DATA LIST

1 : DTC INFO

3 : ACTIVE TEST

4 : SNAPSHOT

6 : RESET MEMORY

8 : CHECK MODE

9 : AT CODE UTILITY

|

HINT: |

||

|

The following operation is available for use with TCMs |

||

|

that can transmit the registered transaxle compensation |

||

|

code to the intelligent tester. |

||

|

(a) |

Shift the shift lever to N or P position. |

|

|

(b) |

Connect the intelligent tester to the DLC3. |

AX |

|

(c) |

Turn the ignition switch on (IG). |

(d)Turn the tester on.

NOTICE:

Do not start the engine.

HINT:

The transaxle compensation code is imprinted on the QR label.

(e)Read the transaxle compensation code.

(1)Enter the menu items in this order: DIAGNOSIS / OBD/MOBD / ECT / AT CODE UTILITY.

(2)Press «ENTER».

C133193

AT CODE UTILITY [Name of system]

1 : AT CODE REGIST

2 : AT CODE RESET

(3)Select «AT CODE REGIST».

(4)Press «ENTER».

C133194

(5) Press «ENTER» again to proceed.

NOTICE

This function is used to input a compensation code and initialize the ECU after an A/T

assembly or ECU has been replaced.

PRESS [ENTER]

C133195

|

AX–26 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||||

|

(6) Press «ENTER» again to proceed. |

||||||||

|

CHECK |

||||||||

|

Gear Selector is in P. |

||||||||

|

Vehicle is stopped. |

||||||||

|

Engine is OFF. |

||||||||

|

Engine switch is |

||||||||

|

ON(IG). |

||||||||

|

AX |

||||||||

|

PRESS [ENTER] |

||||||||

|

C133196 |

||||||||

NOTICE

This function must not be performed without referring the service manual.

PRESS [ENTER]

C133197

A/T CODE REGIST

Select a function.

1.SET A/T CODE

2.READ A/T CODE

PRESS [ENTER]

C133198

A/T CODE REGIST

READ A/T CODE is completed.

PRESS [EXIT]

C133206

(7) Press «ENTER» again to proceed.

(8)Select «READ A/T CODE».

(9)Press «ENTER».

(10)Press «EXIT».

NOTICE:

Do not use the code specified on the transaxle QR label even if the transmission compensation code cannot be read using the intelligent tester. The code printed on an in-service transaxle may not match its current characteristics. Replace the TCM with a new one and perform a road test to allow the TCM to learn.

(11)Turn the ignition switch off.

(f)Replace the TCM.

(g)Set the transaxle compensation code.

(1)Turn the ignition switch on (IG).

(2)Turn the tester on.

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–27 |

M-OBD / OBD MENU [Name of system]

1 : DATA LIST

1 : DTC INFO

3 : ACTIVE TEST

4 : SNAPSHOT

6 : RESET MEMORY

8 : CHECK MODE

9 : AT CODE UTILITY

(3)Enter the menu items in this order: DIAGNOSIS / OBD/MOBD / ECT / AT CODE UTILITY.

(4)Press «ENTER».

AX

C133193

(5) Press «ENTER» again to proceed.

NOTICE

This function is used to input a compensation code and initialize the ECU after an A/T

assembly or ECU has been replaced.

PRESS [ENTER]

C133195

CHECK

Gear Selector is in P. Vehicle is stopped. Engine is OFF. Engine switch is ON(IG).

PRESS [ENTER]

(6) Press «ENTER» again to proceed.

C133196

(7) Press «ENTER» again to proceed.

NOTICE

This function must not be performed without referring the service manual.

PRESS [ENTER]

C133197

A/T CODE REGIST

Select a function.

1.SET A/T CODE

2.READ A/T CODE

(8)Select «SET A/T CODE».

(9)Press «ENTER».

|

AX–28 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||||

|

(10) Select «SAVED A/T CODE». |

||||||||

|

A/T CODE REGIST |

(11) Press «ENTER». |

|||||||

|

SET CODE |

||||||||

|

A/T CODE REGIST |

||||||||

|

is complete. |

||||||||

|

AX |

||||||||

|

PRESS [EXIT] |

||||||||

|

C133203 |

||||||||

|

(12) Press «EXIT». |

||||||||

|

A/T CODE REGIST |

||||||||

|

SET CODE |

||||||||

|

A/T CODE REGIST |

||||||||

|

is complete. |

||||||||

|

PRESS [EXIT] |

||||||||

|

C133203 |

||||||||

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–29 |

M-OBD / OBD MENU [Name of system]

1 : DATA LIST

1 : DTC INFO

3 : ACTIVE TEST

4 : SNAPSHOT

6 : RESET MEMORY

8 : CHECK MODE

9 : AT CODE UTILITY

INITIALIZATION

1.RESET TRANSAXLE COMPENSATION CODE NOTICE:

The transaxle compensation code can be reset only

|

with the intelligent tester. |

||

|

HINT: |

AX |

|

|

The TCM memorizes the condition that the ECT controls |

||

|

the automatic transaxle assembly and engine assembly |

||

|

according to those characteristics. Therefore, when the |

||

|

automatic transaxle assembly, engine assembly, or TCM |

||

|

has been replaced, it is necessary to reset the memory |

||

|

so that the TCM can memorize the new information. |

||

|

Reset procedure is as follows. |

(a)Shift the shift lever to N or P position.

(b)Turn the ignition switch off.

(c)Connect the intelligent tester to the DLC3.

(d)Turn the ignition switch on (IG) and push the intelligent tester main switch on.

(e)Enter the menu items in this order: DIAGNOSIS / OBD/MOBD / ECT / AT CODE UTILITY.

C133193

AT CODE UTILITY [Name of system]

1 : AT CODE REGIST

2 : AT CODE RESET

(f)Select «AT CODE RESET».

(g)Press the «ENTER»

CAUTION:

After the transaxle compensation code, be sure to perform a road test to allow TCM to learn.

2.PERFORM ROAD TEST TO ALLOW TCM TO LEARN NOTICE:

Perform the following procedures while strictly observing all traffic laws and speed limits.

C133194 (a) From a standstill, achieve highest possible speed with the accelerator pedal opened 15% or less. Keep the accelerator pedal angle steady while driving the vehicle.

(b)Repeat the previous step until shift shock no longer occurs.

(c)From a standstill, achieve highest possible speed with the accelerator pedal opened 25% or more. Keep the accelerator pedal angle steady while driving the vehicle.

(d)Repeat the previous step until shift shock no longer occurs.

|

AX–30 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||||||

|

3. |

RESET MEMORY |

|||||||||

|

NOTICE: |

||||||||||

|

• Perform the RESET MEMORY (AT initialization) |

||||||||||

|

when replacing the engine assembly. |

||||||||||

|

• The RESET MEMORY can be performed only with |

||||||||||

|

the intelligent tester. |

||||||||||

|

AX |

||||||||||

|

HINT: |

||||||||||

|

The ECM memorizes the condition that the ECT controls |

||||||||||

|

the automatic transmission assembly and engine |

||||||||||

|

assembly according to those characteristics. Therefore, |

||||||||||

|

when the automatic transmission assembly, engine |

||||||||||

|

assembly, or ECM has been replaced, it is necessary to |

||||||||||

|

reset the memory so that the ECM can memorize the |

||||||||||

|

new information. |

||||||||||

|

(a) Reset procedure is as follows. |

||||||||||

|

(1) Turn the engine switch off. |

||||||||||

|

(2) Connect the intelligent tester to the DLC3. |

||||||||||

|

(3) Turn the ignition switch on (IG) position. |

||||||||||

|

(4) Turn the intelligent tester main switch on. |

||||||||||

|

(5) Select the item «DIAGNOSIS / OBD/MOBD / |

||||||||||

|

M-OBD / OBD MENU |

ECT / RESET MEMORY». |

|||||||||

|

[Name of system] |

NOTICE: |

|||||||||

|

1 |

: DATA LIST |

|||||||||

|

After performing the RESET MEMORY, be |

||||||||||

|

1 |

: DTC INFO |

|||||||||

|

3 |

: ACTIVE TEST |

sure to perform the ROAD TEST (See page |

||||||||

|

4 |

: SNAPSHOT |

|||||||||

|

6 |

: RESET MEMORY |

AX-12) described previously. |

||||||||

|

8 |

: CHECK MODE |

|||||||||

|

9 |

: AT CODE UTILITY |

|||||||||

|

C133193 |

||||||||||

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–31 |

MONITOR DRIVE PATTERN

1.MONITOR DRIVE PATTERN FOR ECT TEST

(a)Perform this drive pattern as one method to simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due

to differences from the actual driving conditions. AX Some codes may not be detected using this drive pattern.)

HINT:

Preparation for driving

•Warm up the engine sufficiently. (Engine coolant temperature should be 60°C (140°F) or higher)

•Drive the vehicle when the atmospheric temperature is -10°C (14°F) or higher.

(Malfunction may not be detected when the atmospheric temperature is less than -10°C (14°F))

Notice on driving

•Drive the vehicle through all gears.

Stop to 1st to 2nd to 3rd to 4th to 5th to 6th (lockup ON).

•Confirm engine braking using the S position. While driving in the 6 (S) position and 6th gear lock-up, shift to the «-» position to down-shift from 6th to 5th, 5th to 4th, 4th to 3rd, 3rd to 2nd, 2nd to 1st.

Check that proper engine braking occurs whenever down-shift takes place.

•Repeat the above driving pattern three times or

more.

NOTICE:

•The monitor status can be checked using the intelligent tester. When using the intelligent tester, monitor status can be found in «OBD/ MOBD / ECT / DATA LIST».

•In the event that the drive pattern must be interrupted (possibly due to traffic conditions or other factors), the drive pattern can be resumed and, in most cases, the monitor can be completed.

•Perform this drive pattern on a road with the fewest hills possible and strictly observe the posted speed limits and traffic laws while driving.

|

AX–32 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

Vehicle Speed

|

Maintain a constant speed or gradual acceleration (with the throttle open) for 3 minutes or more.*1 |

|||

|

AX |

Approx. |

Lock-up ON |

|

|

62 mph |

|||

|

Vehicle Speed |

|||

|

(100 km/h) |

|||

Approx. 50 mph (80 km/h)

|

0 |

||

|

Warmed up |

Stop (Idling) |

|

|

sufficiently |

||

Normal acceleration through all the gears from 1st to 6th

G031593E30

HINT:

*1: Drive the vehicle at a sufficient speed in the uppermost gear, to allow lock-up to engage. The vehicle can be driven at a speed lower than that in the above diagram under the lock-up condition.

NOTICE:

It is necessary to drive the vehicle for approximately 30 minutes to detect DTC P0711 (ATF temperature sensor malfunction).

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–33 |

PROBLEM SYMPTOMS TABLE

HINT:

If a normal code is displayed during the diagnostic trouble code check although the problem or symptom still occurs, check the electrical circuits for each symptom in the order

given in the charts on the following pages. Proceed to the AX page given in the chart and perform troubleshooting.

The Matrix Chart is divided into 2 chapters. Chapter 1:

Refer to the table below when the trouble cause is considered to be electrical.

If the instruction «Proceed to next circuit inspection shown on matrix chart» is given in the flow chart of each circuit, proceed to the circuit with the next highest number in the table to continue the check.

If the trouble still occurs even though there are no abnormalities in any of the other circuits, check and replace the TCM.

Chapter 2:

Chapter 2 covers on and off vehicle repair of the transaxle. Contents specified in the table below may not match while fail-safe control is operating.

1. Chapter 1: Electronic Circuit Matrix Chart

|

Symptom |

Suspected area |

See page |

||

|

No up-shift (1st to 2nd) |

1. |

Shift solenoid valve (SL3) circuit *1 |

AX-105 |

|

|

2. |

TCM |

IN-40 |

||

|

No up-shift (2nd to 3rd) |

1. |

Shift solenoid valve (SL4) circuit *1 |

AX-148 |

|

|

2. |

TCM |

IN-40 |

||

|

1. |

Shift solenoid valve (SL2) circuit *1 |

AX-92 |

||

|

No up-shift (3rd to 4th) |

2. Engine coolant temp. sensor circuit *1 |

ES-145 |

||

|

3. |

TCM |

IN-40 |

||

|

1. |

Shift solenoid valve (SL1) circuit *1 |

AX-84 |

||

|

No up-shift (4th to 5th) |

2. |

Shift solenoid valve (SL4) circuit *1 |

AX-148 |

|

|

3. |

Engine coolant temp. sensor circuit |

ES-145 |

||

|

4. |

TCM |

IN-40 |

||

|

1. |

Engine coolant temp. sensor circuit *1 |

ES-145 |

||

|

No up-shift (5th to 6th) |

2. |

Shift solenoid valve (SL3) circuit *1 |

AX-105 |

|

|

3. |

Shift solenoid valve (SL4) circuit *1 |

AX-148 |

||

|

4. |

TCM |

IN-40 |

||

|

No down-shift (6th to 5th) |

1. |

Shift solenoid valve (SL4) circuit *1 |

AX-148 |

|

|

2. |

TCM |

IN-40 |

||

|

No down-shift (5th to 4th) |

1. |

Shift solenoid valve (SL1) circuit *1 |

AX-84 |

|

|

2. |

TCM |

IN-40 |

||

|

1. |

Shift solenoid valve (SL2) circuit *1 |

AX-92 |

||

|

No down-shift (4th to 3rd) |

2. Shift solenoid valve (SL4) circuit *1 |

AX-148 |

||

|

3. |

TCM |

IN-40 |

||

|

1. |

Shift solenoid valve (SL4) circuit *1 |

AX-148 |

||

|

No down-shift (3rd to 2nd) |

2. Shift solenoid valve (SL3) circuit *1 |

AX-105 |

||

|

3. |

TCM |

IN-40 |

||

|

No down-shift (2nd to 1st) |

1. |

Shift solenoid valve (SL3) circuit *1 |

AX-100 |

|

|

2. |

TCM |

IN-40 |

||

|

AX–34 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||

|

Symptom |

Suspected area |

See page |

||||

|

1. |

Shift solenoid valve (SLU) circuit *1 |

AX-136 |

||||

|

2. |

Shift solenoid valve (SL) circuit |

AX-139 |

||||

|

No lock-up |

3. |

Engine coolant temp. sensor circuit *1 |

ES-145 |

|||

|

4. |

Stop light switch circuit *1 |

AX-71 |

||||

|

AX |

5. |

Speed sensor NT circuit *1 |

AX-66 |

|||

|

6. TCM |

IN-40 |

|||||

|

No lock-up off |

1. TCM |

IN-40 |

||||

|

1. |

Shift solenoid valve (SLT) circuit *1 |

AX-128 |

||||

|

2. |

Speed sensor NT circuit *1 |

AX-66 |

||||

|

Shift point too high or too low |

3. |

Speed sensor NC circuit *1 |

AX-95 |

|||

|

4. |

Accelerator pedal position sensor circuit *1 |

ES-334 |

||||

|

5. |

ATF temperature sensor circuit *1 |

AX-55 |

||||

|

6. |

TCM |

IN-40 |

||||

|

Up-shift from 3rd to 4th while engine is cold |

1. |

Engine coolant temp. sensor circuit *1 |

ES-145 |

|||

|

2. |

TCM |

IN-40 |

||||

|

Up-shift from 4th to 5th while engine is cold |

1. |

Engine coolant temp. sensor circuit *1 |

ES-145 |

|||

|

2. |

TCM |

IN-40 |

||||

|

No gear change by shifting into «+» or «-» while shifting |

1. Transmission control switch circuit |

AX-154 |

||||

|

the lever |

2. TCM |

IN-40 |

||||

|

Harsh engagement (N to D) |

1. |

Shift solenoid valve (SL1) circuit *1 |

AX-84 |

|||

|

2. |

TCM |

IN-40 |

||||

|

1. |

Speed sensor NT circuit *1 |

AX-66 |

||||

|

Harsh engagement (Lock-up) |

2. |

Speed sensor NC circuit *1 |

AX-95 |

|||

|

3. |

Shift solenoid valve (SLU) circuit *1 |

AX-136 |

||||

|

4. |

TCM |

IN-40 |

||||

|

1. |

Accelerator pedal position sensor circuit *1 |

ES-334 |

||||

|

2. |

Shift solenoid valve (SLT) circuit *1 |

AX-128 |

||||

|

Harsh engagement (Any driving position) |

3. Speed sensor NC circuit |

AX-95 |

||||

|

4. |

Speed sensor NT circuit *1 |

AX-66 |

||||

|

5. |

TCM |

IN-40 |

||||

|

Poor acceleration |

1. |

Shift solenoid valve (SLT) circuit *1 |

AX-128 |

|||

|

2. |

TCM |

IN-40 |

||||

|

No engine brake |

1. TCM |

IN-40 |

||||

|

No kick-down |

1. TCM |

IN-40 |

||||

|

Engine stalls when starting off or stopping |

1. TCM |

IN-40 |

||||

|

1. |

Park/neutral position switch circuit *1 |

AX-158 |

||||

|

Malfunction in shifting |

2. Transmission control switch circuit |

AX-154 |

||||

|

3. |

TCM |

IN-40 |

||||

|

Slip or shudder (5th to 6th and 6th to 5th) |

1. Shift solenoid valve (SLT) circuit *1 |

AX-128 |

||||

|

Initial acceleration or subsequent acceleration is |

1. |

Shift solenoid valve (SL1) circuit |

AX-84 |

|||

|

2. |

Shift solenoid valve (SLT) circuit |

AX-128 |

||||

|

improper. Vehicle is stuck in a gear (1st to 6th). |

||||||

|

3. |

TCM |

IN-40 |

||||

|

Acceleration is improper when the gear is 4th or |

1. |

Shift solenoid valve (SL2) circuit |

AX-92 |

|||

|

2. |

Shift solenoid valve (SLT) circuit |

AX-128 |

||||

|

higher. |

||||||

|

3. |

TCM |

IN-40 |

||||

|

Initial acceleration or subsequent acceleration is |

1. Shift solenoid valve (SL2) circuit |

AX-92 |

||||

|

improper. Vehicle does not shift down (from 4th to 3rd). |

||||||

|

2. |

TCM |

IN-40 |

||||

|

Vehicle is stuck in a gear (1st to 4th). |

||||||

|

Acceleration is improper when the gear is 6th. |

1. |

Shift solenoid valve (SL3) circuit |

AX-105 |

|||

|

2. |

TCM |

IN-40 |

||||

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–35 |

|||||

|

Symptom |

Suspected area |

See page |

||||

|

1. |

Shift solenoid valve (SL4) circuit |

AX-148 |

||||

|

Acceleration is improper when the gear is 3rd or 5th. |

2. Shift solenoid valve (SLT) circuit |

AX-128 |

||||

|

3. |

TCM |

IN-40 |

||||

|

Initial acceleration or subsequent acceleration is |

1. Shift solenoid valve (SL4) circuit |

AX-148 |

||||

|

improper. Vehicle does not shift down (from 3rd to |

||||||

|

2. |

TCM |

IN-40 |

AX |

|||

|

2nd). No up-shift (5th to 6th). |

||||||

HINT:

*1: When the circuit is defective, a DTC may be output.

2. Chapter 2: On-Vehicle Repair and Off-Vehicle Repair

|

Symptom |

Suspected area |

See page |

||

|

Vehicle does not move in any forward and reverse |

1. Valve body assembly |

AX-181 |

||

|

positions. |

2. Torque converter clutch |

AX-239 |

||

|

1. |

Valve body assembly |

AX-181 |

||

|

Vehicle does not move in R position. |

2. |

Brake No. 2 (B2) |

AX-274 |

|

|

3. |

Brake No. 3 (B3) |

AX-274 |

||

|

4. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||

|

1. |

Valve body assembly |

AX-181 |

||

|

No up-shift (1st to 2nd) |

2. Brake No. 1 (B1) |

AX-274 |

||

|

3. |

Shift solenoid valve (SL3)*1 |

AX-100 |

||

|

1. |

Valve body assembly |

AX-181 |

||

|

No up-shift (2nd to 3rd) |

2. Brake No. 3 (B3) |

AX-274 |

||

|

3. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||

|

1. |

Valve body assembly |

AX-181 |

||

|

No up-shift (3rd to 4th) |

2. Clutch No. 2 (C2) |

AX-274 |

||

|

3. |

Shift solenoid valve (SL2)*1 |

AX-87 |

||

|

1. |

Valve body assembly |

AX-181 |

||

|

No up-shift (4th to 5th) |

2. Brake No. 3 (B3) |

AX-274 |

||

|

3. |

Shift solenoid valve (SL3)*1 |

AX-100 |

||

|

1.Valve body assembly |

AX-181 |

|||

|

No up-shift (5th to 6th) |

2. Brake No. 1 (B1) |

AX-274 |

||

|

3. |

Shift solenoid valve (SL3)*1 |

AX-100 |

||

|

1. |

Brake No. 3 (B3) |

AX-274 |

||

|

No down-shift (6th to 5th) |

2. Shift solenid valve (SL4)*1 |

AX-142 |

||

|

3. |

Valve body assembly |

AX-181 |

||

|

1. |

Shift solenoid valve (SL1)*1 |

AX-79 |

||

|

No down-shift (5th to 4th) |

2. Clutch No. 1 (C1) |

AX-274 |

||

|

3. |

Valve body assembly |

AX-181 |

||

|

1. |

Brake No. 3 (B3) |

AX-274 |

||

|

No down-shift (4th to 3rd) |

2. Shift solenid valve (SL4)*1 |

AX-142 |

||

|

3. |

Valve body assembly |

AX-181 |

||

|

1. |

Brake No. 1 (B1) |

AX-274 |

||

|

No down-shift (3rd to 2nd) |

2. Shift solenid valve (SL3)*1 |

AX-100 |

||

|

3. |

Valve body assembly |

AX-181 |

||

|

No down-shift (2nd to 1st) |

1. Valve body assembly |

AX-181 |

||

|

No lock-up or No lock-up off |

1. |

Valve body assembly |

AX-181 |

|

|

2. |

Torque converter clutch |

AX-239 |

||

|

AX–36 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

|||||

|

Symptom |

Suspected area |

See page |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

2. |

C1 accumulator |

AX-274 |

||||

|

Harsh engagement (N to D) |

3. One-way clutch No. 1 (F1) |

AX-274 |

||||

|

4. |

Clutch No. 1 (C1) |

AX-274 |

||||

|

AX |

5. |

Shift solenoid valve (SL1)*1 |

AX-79 |

|||

|

1. Valve body assembly |

AX-181 |

|||||

|

Harsh engagement (Lock-up) |

2. Torque converter clutch |

AX-239 |

||||

|

3. |

Shift solenoid valve (SLU)*1 |

AX-131 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (N to R) |

2. |

Brake No. 2 (B2) |

AX-274 |

|||

|

3. |

Brake No. 3 (B3) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||||

|

Harsh engagement (1 to 2 to 3 to 4 to 5 to 6) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Shift solenoid valve (SLT)*1 |

AX-121 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (1st to 2nd) |

2. |

B1 accumulator |

AX-274 |

|||

|

3. |

Brake No. 1 (B1) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL3)*1 |

AX-100 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (2nd to 3rd) |

2. |

B3 accumulator |

AX-274 |

|||

|

3. |

Brake No. 3 (B3) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (3rd to 4th) |

2. |

C2 accumulator |

AX-274 |

|||

|

3. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL2)*1 |

AX-87 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (4th to 5th) |

2. |

B3 accumulator |

AX-274 |

|||

|

3. |

Brake No. 3 (B3) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (5th to 6th) |

2. |

B1 accumulator |

AX-274 |

|||

|

3. |

Brake No. 1 (B1) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL3)*1 |

AX-100 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

Harsh engagement (6th to 5th) |

2. |

B3 accumulator |

AX-274 |

|||

|

3. |

Brake No. 3 (B3) |

AX-274 |

||||

|

4. |

Shift solenoid valve (SL4)*1 |

AX-142 |

||||

|

1. |

Valve body assembly |

AX-181 |

||||

|

2. |

Oil strainer |

— |

||||

|

3. |

Brake No. 1 (B1) |

AX-274 |

||||

|

Slip or shudder (Forward and reverse: After warm-up) |

4. |

Brake No. 2 (B2) |

AX-274 |

|||

|

5. |

Brake No. 3 (B3) |

AX-274 |

||||

|

6. |

One-way clutch No. 1 (F1) |

AX-274 |

||||

|

7. |

Clutch No. 1 (C1) |

AX-274 |

||||

|

8. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

Slip or shudder (Particular position: just after engine |

1. Torque converter clutch |

AX-239 |

||||

|

starts) |

||||||

|

Slip or shudder (R position) |

1. |

Brake No. 2 (B2) |

AX-274 |

|||

|

2. |

Brake No. 3 (B3) |

AX-274 |

||||

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–37 |

|||||

|

Symptom |

Suspected area |

See page |

||||

|

Slip or shudder (1 position) |

1. |

One-way clutch No. 1 (F1) |

AX-274 |

|||

|

2. |

Clutch No. 1 (C1) |

AX-274 |

||||

|

Slip or shudder (2 position) |

1. |

Brake No. 1 (B1) |

AX-274 |

|||

|

2. |

Clutch No. 1 (C1) |

AX-274 |

||||

|

Slip or shudder (3 position) |

1. |

Brake No. 3 (B3) |

AX-274 |

AX |

||

|

2. |

Clutch No. 1 (C1) |

AX-274 |

||||

|

Slip or shudder (4 position) |

1. |

Clutch No. 1 (C1) |

AX-274 |

|||

|

2. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

Slip or shudder (5 position) |

1. |

Brake No. 3 (B3) |

AX-274 |

|||

|

2. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

Slip or shudder (6 position) |

1. |

Brake No. 3 (B3) |

AX-274 |

|||

|

2. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

No engine braking (1st position) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Brake No. 2 (B2) |

AX-274 |

||||

|

No engine braking (2nd position) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Brake No. 1 (B1) |

AX-274 |

||||

|

No engine braking (3rd position) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Brake No. 3 (B3) |

AX-274 |

||||

|

No engine braking (4th position) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

No kick-down |

1. Valve body assembly |

AX-181 |

||||

|

Shift point too hight or too low |

1. Valve body assembly |

AX-181 |

||||

|

Poor acceleration (All positions) |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Torque converter clutch |

AX-239 |

||||

|

Poor acceleration (6th) |

1. |

Brake No. 1 (B1) |

AX-274 |

|||

|

2. |

Clutch No. 2 (C2) |

AX-274 |

||||

|

Engine stalls when starting off or stopping |

1. |

Valve body assembly |

AX-181 |

|||

|

2. |

Torque converter clutch |

AX-239 |

||||

HINT:

*1: When the circuit is defective, a DTC may be output.

|

AX–38 |

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

TERMINALS OF ECU

1. TCM

C56

|

AX |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

||||||||

|

9 |

8 |

||||||||||||||

|

17 16 15 14 13 12 11 10 |

|||||||||||||||

|

26 25 24 23 22 21 20 19 |

18 |

||||||||||||||

|

C133222E01 |

|||||||||||||||

|

HINT: |

|||||||||||||||

|

Each TCM terminal’s standard voltage is shown in the |

|||||||||||||||

|

table below. |

|||||||||||||||

|

In the table, first follow the information under «Condition». |

|||||||||||||||

|

Look under «Symbols (Terminals No.)» for the terminals |

|||||||||||||||

|

to be inspected. The standard voltage between the |

|||||||||||||||

|

terminals is shown under «Specified Condition». |

|||||||||||||||

|

Use the illustration above as a reference for the TCM |

|||||||||||||||

|

terminals. |

|||||||||||||||

|

Symbols (Terminals No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|||||||||||

|

IG switch ON (IG) and |

10 to 14 V |

||||||||||||||

|

shift lever in R position |

|||||||||||||||

|

R shift position switch |

|||||||||||||||

|

R (C56-15) — E1 (C56-8) |

W — B-W |

||||||||||||||

|

IG switch ON (IG) and |

|||||||||||||||

|

signal |

|||||||||||||||

|

shift lever in any position |

Below 1 V |

||||||||||||||

|

except R position |

|||||||||||||||

|

IG switch ON (IG) and |

|||||||||||||||

|

shift lever in D or 3 |

10 to 14 V |

||||||||||||||

|

D (C56-16) — E1 (C56-8) |

R — B-W |

D shift position switch |

position |

||||||||||||

|

signal |

IG switch ON (IG) and |

||||||||||||||

|

shift lever in any position |

Below 1 V |

||||||||||||||

|

except D and 3 position |

|||||||||||||||

|

STP (C56-12) — E1 (C56-8) |

B — B-W |

Stop light switch signal |

Brake pedal is depressed |

7.5 to 14 V |

|||||||||||

|

Brake pedal is released |

Below 1.5 V |

||||||||||||||

|

IG switch ON (IG) and |

|||||||||||||||

|

shift lever in P or N |

Below 2 V |

||||||||||||||

|

NSW (C56-11) — E1 (C56-8) |

L — B-W |

Park/neutral switch signal |

position |

||||||||||||

|

IG switch ON (IG) and |

|||||||||||||||

|

shift lever in any position |

10 to 14 V |

||||||||||||||

|

except P or N position |

|||||||||||||||

|

Cranking (shift lever |

|||||||||||||||

|

position in P or N position, |

10 to 14 V |

||||||||||||||

|

STA (C56-10) — E1 (C56-8) |

Y — B-W |

Starter signal |

ignition switch START) |

||||||||||||

|

IG switch ON (IG) and |

|||||||||||||||

|

shift lever in any position |

Below 2 V |

||||||||||||||

|

except P or N position |

|||||||||||||||

|

SPD1 (C56-3) — E1 (C56-8) |

BR — B-W |

Speed signal from |

Vehicle speed 12 mph (20 |

Pulse generation |

|||||||||||

|

combination meter |

km/h) |

(See waveform 1) |

|||||||||||||

|

Battery (for measuring |

|||||||||||||||

|

BATT (C56-1) — E1 (C56-8) |

W-L — B-W |

battery voltage and for |

Always |

9 to 14 V |

|||||||||||

|

TCM memory) |

|||||||||||||||

|

IG2 (C56-13) — E1 (C56-8) |

L-B — B-W |

Ignition switch |

Ignition switch ON (IG) |

9 to 14 V |

|||||||||||

|

+B (C56-18) — E1 (C56-8) |

W-L — B-W |

Power source of TCM |

Ignition switch ON (IG) |

9 to 14 V |

|||||||||||

|

CAN+ (C56-6) — E1 (C56-8) |

B — B-W |

CAN communication line |

Ignition switch ON (IG) |

Pulse generation |

|||||||||||

|

(See waveform 2) |

|||||||||||||||

|

U660E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM |

AX–39 |

|||||||||||

|

Symbols (Terminals No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

||||||||

|

CAN- (C56-7) — E1 (C56-8) |

Y — B-W |

CAN communication line |

Ignition switch ON (IG) |

Pulse generation |

||||||||

|

(See waveform 3) |

||||||||||||

|

(a) Waveform 1 |

||||||||||||

|

5 V/DIV. |

Reference: |

|||||||||||

|

Terminal |

SPD1 — E1 |

AX |

||||||||||

|

Tool setting |

2 V/DIV., 20 ms./DIV. |

|||||||||||

|

Vehicle condition |

Vehicle speed 12 mph (20 km/h) |

|||||||||||

|

GND |

||||||||||||

20 ms./DIV.

G034872E02

(b)Waveform 2

Reference:

|

1 V/DIV |

Terminal |

CAN+ — E1 |

|

Tool setting |