Nissan Cabstar (Atlas) owner’s, operators, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

See also:

| Title | File Size | Download Links |

| Nissan Cabstar Ascendant A18 13TJ Operator Manual [PDF] | 1.9Mb | Download |

| Nissan CabStar bd30 Technical Data Sheet [PDF] | 2.3Mb | Download |

| Nissan Cabstar Euro 4 Parts Manual [PDF] | 5.8Mb | Download |

| Nissan Cabstar F24 Owner’s Maintenance Manual [PDF] | 2.8Mb | Download |

| Nissan Cabstar NT400 Technical Specifications [PDF] | 1.3Mb | Download |

| Nissan Cabstar RHD Electrical Unit [PDF] | 178.2kb | Download |

| Nissan Cabstar Schematic Diagrams [PDF] | 816kb | Download |

| Nissan Cabstar Service Manual – Engine Control System Manual [PDF] | 2.6Mb | Download |

| Nissan Atlas F24 (1.15-2t) Catalog [PDF] | 711.1kb | Download |

Nissan Cabstar is a reliable and high-tech vehicle for overcoming long distances and transporting goods. The presented repair manuals for Nissan Cabstar since 2006 (engine – diesel ZD30DDTi), maintenance, and operation of cars of this brand cover the full range of issues that a Nissan Cabstar owner, truck driver, or car service specialist may encounter. After all, it is on the level at which the truck’s maintenance is carried out, whether the features of its operation and repair are taken into account, the durability of the transport, and minimizing the cases of serious breakdowns, the risk of accidents depends.

Manuals are practical guides for everyday, which will certainly be useful to both an experienced motorist and a novice who has not yet had time to deal with the maintenance and repair of a powerful Nissan Cabstar.

The presentation of the material at a high professional level is successfully combined with clarity (the manual contains hundreds of illustrations), accessible and display of even very difficult repair procedures, and the logical structure of the manual and the alphabetical index will help you instantly find the information you need at the moment.

The first part of the manual provides a complete instruction manual for Nissan Cabstar, provides basic information about the external and internal structure of the car, the principles of operation of the main units, components, and systems of this vehicle, including detailed Nissan Cabstar wiring diagrams, with which it is easy to understand the electronic part of the truck. Also, this Nissan Cabstar repair manual contains important information about the frequency of maintenance and features of the use of this vehicle.

Special attention in the manuals is given to the repair of Nissan Cabstar. At the same time, all repair operations are described very clearly and logically, step by step, according to the principle from simple to complex. And even intermediate repair actions have links to those pages where they are described in more detail. This approach allows the motorist to cope with the main problems in the garage conditions and even with the help of a standard set of tools, without resorting to the assistance of car repair shop workers. Suppose the breakdown turns out to be too serious, and one cannot do without the services of a car service, then in any case, from this manual. In that case, the driver will learn about the nature and scope of the upcoming work and will be able to discuss these issues on an equal footing with the maintenance service or car repair shop personnel.

Nissan Cabstar

The Nissan Cabstar manual describes in detail how to correctly assemble, disassemble, lubricate, adjust, replace (if necessary) and diagnose and repair all the main units, assemblies, and systems of Nissan Cabstar – engine, automatic transmission, brake system (including anti-lock braking system). ABS brake system), transfer case, transmission, suspension, steering, and also describes the process of checking the machine’s electrical equipment.

The driver needs to be able to cope with unexpected malfunctions of the Nissan Cabstar during the journey when there may not be a qualified car service nearby. Still, it is necessary to continue the journey. Having a manual at hand, the motorist can identify the cause of the breakdown on his own and “revive” his four-wheeled comrade to calmly drive on without wasting time and money on a car service.

The application in the manual also contains a lot of interesting and important information for any motorist – summary tables (for example, the permissible level of wear of parts, lubricating oils, and fuel fluids), information about road safety, preparing Nissan Cabstar for the first trip, useful tips and much more.

Руководство по техническому обслуживанию и ремонту автомобилей Nissan Cabstar/Atlas/Condor 1984-1996 годов выпуска с бензиновыми и дизельными двигателями

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 304

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту грузовых автомобилей Nissan Atlas и Nissan Cabstar 2006-2014 годов выпуска с дизельным двигателем модели ZD30DDTi.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 288

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей Nissan Cabstar/Atlas/Condor 1984-1996 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Автонавигатор

- Год издания: 2006

- Страниц: 303

- Формат: PDF

- Размер: 20,8 Mb

B ENGINE

SECTION

ENGINE MECHANICAL

CONTENTS

|

KA24DE |

|

|

PRECAUTIONS ………………………………………………… |

5 |

|

Precautions for Drain Coolant …………………………… |

5 |

|

Precautions for Disconnecting Fuel Piping …………. |

5 |

|

Precautions for Removal and Disassembly ………… |

5 |

|

Precautions for Inspection, Repair and Replace- |

|

|

ment ……………………………………………………………… |

5 |

|

Precautions for Assembly and Installation ………….. |

5 |

|

Parts Requiring Angular Tightening …………………… |

5 |

|

Precautions for Liquid Gasket …………………………… |

6 |

|

REMOVAL OF LIQUID GASKET SEALING ……… |

6 |

|

LIQUID GASKET APPLICATION PROCEDURE….. |

6 |

|

PREPARATION …………………………………………………. |

7 |

|

Special Service Tools ………………………………………. |

7 |

|

Commercial Service Tools ………………………………… |

8 |

|

NOISE, VIBRATION, AND HARSHNESS (NVH) |

|

|

TROUBLESHOOTING ……………………………………… |

10 |

|

NVH Troubleshooting —Engine Noise ……………. … |

10 |

|

Use the Chart Below to Help You Find the Cause |

|

|

of the Symptom. …………………………………………….. |

11 |

|

ENGINE ROOM COVER ………………………………….. |

12 |

|

Removal and Installation of Engine Room Right |

|

|

Side …………………………………………………………….. |

12 |

|

REMOVAL …………………………………………………. |

12 |

|

INSTALLTION ……………………………………………. |

12 |

|

Removal and Installation of Engine Room Rear |

|

|

Cover …………………………………………………………… |

12 |

|

REMOVAL …………………………………………………. |

12 |

|

INSTALLATION ………………………………………….. |

13 |

|

DRIVE BELTS …………………………………………………. |

14 |

|

Checking Drive Belts ……………………………………… |

14 |

|

Tension Adjustment ……………………………………….. |

14 |

|

POWER STEERING PUMP BELT ………………… |

14 |

|

AIR CONDITIONER COMPRESSOR BELT …… |

14 |

|

ALTERNATOR AND WATER PUMP BELT …….. |

15 |

|

Removal and Installation ………………………………… |

15 |

|

REMOVAL …………………………………………………. |

15 |

|

INSTALLATION ………………………………………….. |

15 |

|

AIR CLEANER AND AIR DUCT ………………………… |

16 |

|

Removal and Installation ………………………………… |

16 |

|

REMOVAL …………………………………………………. |

16 |

|

INSTALLATION ………………………………………….. |

17 |

|

Changing Air Cleaner Element ………………………… |

18 |

|

REMOVAL …………………………………………………. |

18 |

|

INSTALLATION ………………………………………….. |

18 |

|

THROTTLE BODY …………………………………………… |

19 |

|

Removal and Installation ………………………………… |

19 |

|

REMOVAL …………………………………………………. |

19 |

|

INSPECTION AFTER REMOVAL …………………. |

20 |

|

INSTALLATION ………………………………………….. |

20 |

|

Disassembly and Assembly …………………………….. |

20 |

|

DISASSEMBLY ………………………………………….. |

20 |

|

ASSEMBLY ……………………………………………….. |

20 |

|

INTAKE MANIFOLD ………………………………………… |

21 |

|

Removal and Installation ………………………………… |

21 |

|

REMOVAL …………………………………………………. |

21 |

|

INSPECTION AFTER REMOVAL …………………. |

22 |

|

INSTALLATION ………………………………………….. |

22 |

|

EXHAUST MANIFOLD …………………………………….. |

23 |

|

Removal and Installation ………………………………… |

23 |

|

REMOVAL …………………………………………………. |

23 |

|

INSPECTION AFTER REMOVAL …………………. |

24 |

|

INSTALLATION ………………………………………….. |

24 |

|

INSPECTION AFTER INSTALLATION …………… |

24 |

|

OIL PAN AND OIL STRAINER ………………………….. |

25 |

|

Removal and Installation ………………………………… |

25 |

|

REMOVAL …………………………………………………. |

25 |

|

INSPECTION AFTER REMOVAL …………………. |

25 |

|

INSTALLATION ………………………………………….. |

25 |

|

INSPECTION AFTER INSTALLATION …………… |

26 |

|

SPARK PLUG (CONVENTIONAL) …………………….. |

27 |

|

Removal and Installation ………………………………… |

27 |

|

REMOVAL …………………………………………………. |

27 |

|

INSPECTION AFTER REMOVAL …………………. |

27 |

|

INSTALLATION ………………………………………….. |

27 |

|

FUEL INJECTOR AND FUEL TUBE ………………….. |

28 |

|

Removal and Installation ………………………………… |

28 |

|

REMOVAL …………………………………………………. |

28 |

|

INSTALLATION ………………………………………….. |

29 |

|

INSPECTION AFTER INSTALLATION …………… |

29 |

EM-1

|

ROCKER COVER ……………………………………………. |

30 |

|

Removal and Installation ………………………………… |

30 |

|

REMOVAL …………………………………………………. |

30 |

|

INSTALLATION …………………………………………… |

30 |

|

CAMSHAFT …………………………………………………….. |

32 |

|

Removal and Installation ………………………………… |

32 |

|

REMOVAL …………………………………………………. |

32 |

|

INSTALLATION …………………………………………… |

34 |

|

INSPECTION AFTER REMOVAL ………………….. |

35 |

|

Valve Clearance …………………………………………….. |

38 |

|

INSPECTION ……………………………………………… |

38 |

|

ADJUSTMENT …………………………………………… |

38 |

|

SECONDARY TIMING CHAIN …………………………… |

41 |

|

Removal and Installation ………………………………… |

41 |

|

REMOVAL …………………………………………………. |

41 |

|

INSPECTION AFTER REMOVAL ………………….. |

44 |

|

INSTALLATION …………………………………………… |

45 |

|

PRIMARY TIMING CHAIN ………………………………… |

49 |

|

Removal and Installation ………………………………… |

49 |

|

REMOVAL …………………………………………………. |

50 |

|

INSPECTION AFTER REMOVAL ………………….. |

51 |

|

INSTALLATION …………………………………………… |

51 |

|

CYLINDER HEAD ……………………………………………. |

55 |

|

On-Vehicle Service ………………………………………… |

55 |

|

CHECKING COMPRESSION PRESSURE …….. |

55 |

|

Removal and Installation ………………………………… |

56 |

|

REMOVAL AND INSTALLATION …………………… |

56 |

|

Disassembly and Assembly …………………………….. |

57 |

|

DISASSEMBLY ………………………………………….. |

57 |

|

ASSEMBLY ……………………………………………….. |

58 |

|

INSPECTION AFTER DISASSEMBLY …………… |

58 |

|

ENGINE ASSEMBLY ……………………………………….. |

63 |

|

Removal and Installation ………………………………… |

63 |

|

REMOVAL …………………………………………………. |

64 |

|

INSTALLATION …………………………………………… |

65 |

|

INSPECTION AFTER INSTALLATION …………… |

66 |

|

CYLINDER BLOCK ………………………………………….. |

67 |

|

Disassembly and Assembly …………………………….. |

67 |

|

DISASSEMBLY ………………………………………….. |

68 |

|

ASSEMBLY ……………………………………………….. |

70 |

|

How to Select Piston and Bearing ……………………. |

74 |

|

DESCRIPTION …………………………………………… |

74 |

|

HOW TO SELECT PISTON ………………………….. |

75 |

|

HOW TO SELECT CONNECTING ROD BEAR- |

|

|

ING …………………………………………………………… |

75 |

|

HOW TO SELECT MAIN BEARING ………………. |

76 |

|

Inspection After Disassembly ………………………….. |

78 |

|

CRANKSHAFT SIDE CLEARANCE ………………. |

78 |

|

CONNECTING ROD SIDE CLEARANCE ………. |

78 |

|

PISTON AND PISTON PIN CLEARANCE ……… |

78 |

|

PISTON RING SIDE CLEARANCE ……………….. |

79 |

|

PISTON RING END GAP …………………………….. |

79 |

|

CONNECTING ROD BEND AND TORSION …… |

80 |

|

CONNECTING ROD BEARING (BIG END) ……. |

80 |

|

CONNECTING ROD BUSHING OIL CLEAR- |

|

|

ANCE (SMALL END) …………………………………… |

80 |

|

CYLINDER BLOCK DISTORTION ………………… |

81 |

|

INNER DIAMETER OF MAIN BEARING HOUS- |

|

ING ……………………………………………………………. |

81 |

|

PISTON TO CYLINDER BORE CLEARANCE ...82 |

|

|

OUTER DIAMETER OF CRANKSHAFT JOUR- |

|

|

NAL …………………………………………………………… |

83 |

|

OUTER DIAMETER OF CRANKSHAFT PIN …..83 |

|

|

OUT-OF-ROUND AND TAPER OF CRANK- |

|

|

SHAFT ………………………………………………………. |

83 |

|

CRANKSHAFT RUNOUT …………………………….. |

83 |

|

OIL CLEARANCE OF CONNECTING ROD |

|

|

BEARING …………………………………………………… |

84 |

|

OIL CLEARANCE OF MAIN BEARING ………….. |

84 |

|

CRUSH HEIGHT OF MAIN BEARING …………… |

85 |

|

OIL JET ……………………………………………………… |

85 |

|

OIL JET RELIEF VALVE ………………………………. |

85 |

|

FLY WHEEL RUNOUT ………………………………… |

86 |

|

SERVICE DATA AND SPECIFICATIONS (SDS) …..87 |

|

|

Standard and Limit …………………………………………. |

87 |

|

GENERAL SPECIFICATIONS ………………………. |

87 |

|

DRIVE BELTS …………………………………………….. |

87 |

|

INTAKE MANIFOLD AND EXHAUST MANI- |

|

|

FOLD ………………………………………………………… |

87 |

|

SPARK PLUG …………………………………………….. |

88 |

|

SECONDARY TIMING CHAIN ……………………… |

88 |

|

CYLINDER HEAD ……………………………………….. |

88 |

|

VALVE ……………………………………………………….. |

88 |

|

CAMSHAFT AND CAMSHAFT BEARING ………. |

92 |

|

CYLINDER BLOCK ……………………………………… |

92 |

|

PISTON, PISTON RING AND PISTON PIN ……. |

93 |

|

CONNECTING ROD ……………………………………. |

94 |

|

CRANKSHAFT ……………………………………………. |

94 |

|

MAIN BEARING ………………………………………….. |

95 |

|

CONNECTING ROD BEARING …………………….. |

95 |

|

FLYWHEEL ………………………………………………… |

96 |

|

Tightening Torque ………………………………………….. |

96 |

|

ZD30DD |

|

|

PRECAUTIONS ……………………………………………….. |

98 |

|

Precautions for Drain Coolant ………………………….. |

98 |

|

Precautions for Disconnecting Fuel Piping ………… |

98 |

|

Precautions for Removal and Disassembly ……….. |

98 |

|

Precautions for Inspection, Repair and Replace- |

|

|

ment …………………………………………………………….. |

98 |

|

Precautions for Assembly and Installation …………. |

98 |

|

Parts Requiring Angular Tightening ………………….. |

98 |

|

Precautions for Liquid Gasket ………………………….. |

99 |

|

REMOVAL OF LIQUID GASKET SEALING ……. |

99 |

|

LIQUID GASKET APPLICATION PROCEDURE… |

99 |

|

PREPARATION ……………………………………………… |

100 |

|

Special Service Tools ……………………………………. |

100 |

|

Commercial Service Tools …………………………….. |

102 |

|

NOISE, VIBRATION, AND HARSHNESS (NVH) |

|

|

TROUBLESHOOTING ……………………………………. |

103 |

|

NVH Troubleshooting —Engine Noise …………….. . |

103 |

|

Use the Chart Below to Help You Find the Cause |

|

|

of the Symptom. …………………………………………… |

104 |

|

ENGINE ROOM COVER …………………………………. |

105 |

|

Removal and Installation of Engine Room Right |

EM-2

|

Side …………………………………………………………… |

105 |

|

REMOVAL ……………………………………………….. |

105 |

|

INSTALLATION ………………………………………… |

105 |

|

Removal and Installation of Engine Room Rear |

|

|

Cover …………………………………………………………. |

105 |

|

REMOVAL ……………………………………………….. |

105 |

|

INSTALLATION ………………………………………… |

106 |

|

DRIVE BELTS ……………………………………………….. |

107 |

|

Checking Drive Belt ……………………………………… |

107 |

|

Tension Adjustment ……………………………………… |

107 |

|

Removal and Installation ………………………………. |

107 |

|

WATER PUMP, ALTERNATOR AND A/C COM- |

|

|

PRESSOR BELT ………………………………………. |

107 |

|

Drive Belt Auto Tensioner ……………………………… |

109 |

|

REMOVAL ……………………………………………….. |

109 |

|

INSPECTION AFTER REMOVAL ……………….. |

109 |

|

INSTALLATION ………………………………………… |

109 |

|

Dummy Pulley …………………………………………….. |

109 |

|

REMOVAL ……………………………………………….. |

109 |

|

INSPECTION AFTER REMOVAL ……………….. |

109 |

|

INSTALLATION ………………………………………… |

109 |

|

AIR CLEANER AND AIR DUCT ……………………….. |

110 |

|

Removal and Installation ……………………………….. |

110 |

|

REMOVAL ………………………………………………… |

110 |

|

INSTALLATION …………………………………………. |

111 |

|

Changing Air Cleaner Element ……………………….. |

112 |

|

REMOVAL ………………………………………………… |

112 |

|

INSTALLATION …………………………………………. |

112 |

|

INTAKE MANIFOLD COLLECTOR AND INTAKE |

|

|

MANIFOLD ……………………………………………………. |

113 |

|

Removal and Installation ……………………………….. |

113 |

|

REMOVAL ………………………………………………… |

113 |

|

INSPECTION AFTER REMOVAL ………………… |

115 |

|

INSTALLATION …………………………………………. |

115 |

|

EXHAUST MANIFOLD ……………………………………. |

117 |

|

Removal and Installation ……………………………….. |

117 |

|

REMOVAL ………………………………………………… |

117 |

|

INSPECTION AFTER REMOVAL ………………… |

118 |

|

INSTALLATION …………………………………………. |

118 |

|

INSPECTION AFTER INSTALLATION …………. |

118 |

|

OIL PAN AND OIL STRAINER …………………………. |

119 |

|

Removal and Installation ……………………………….. |

119 |

|

REMOVAL ………………………………………………… |

119 |

|

INSTALLATION ………………………………………… |

120 |

|

INSPECTION AFTER INSTALLATION ………… |

120 |

|

GLOW PLUG ………………………………………………… |

121 |

|

Removal and Installation ………………………………. |

121 |

|

REMOVAL ……………………………………………….. |

121 |

|

INSTALLATION ………………………………………… |

122 |

|

VACUUM PUMP ……………………………………………. |

123 |

|

Removal and Installation ………………………………. |

123 |

|

REMOVAL ……………………………………………….. |

123 |

|

INSTALLATION ………………………………………… |

123 |

|

INSPECTION AFTER INSTALLATION ………… |

123 |

|

INJECTION TUBE AND INJECTION NOZZLE ….. |

125 |

|

Removal and Installation ………………………………. |

125 |

|

REMOVAL ……………………………………………….. |

125 |

|

INSPECTION AFTER REMOVAL ……………….. |

127 |

|

INSTALLATION ………………………………………… |

127 |

|

INSPECTION AFTER INSTALLATION …………. |

128 |

|

ELECTRONICCONTROLFUELINJECTIONPUMP. 129 |

|

|

Removal and Installation ………………………………. |

129 |

|

REMOVAL ……………………………………………….. |

129 |

|

INSTALLATION ………………………………………… |

132 |

|

INSPECTION AFTER INSTALLATION …………. |

134 |

|

ROCKER COVER ………………………………………….. |

135 |

|

Removal and Installation ………………………………. |

135 |

|

REMOVAL ……………………………………………….. |

135 |

|

INSTALLATION ………………………………………… |

136 |

|

CAMSHAFT ………………………………………………….. |

138 |

|

Removal and Installation ………………………………. |

138 |

|

REMOVAL ……………………………………………….. |

139 |

|

INSPECTION AFTER REMOVAL ……………….. |

139 |

|

INSTALLATION ………………………………………… |

141 |

|

Valve Clearance ………………………………………….. |

142 |

|

INSPECTION …………………………………………… |

142 |

|

ADJUSTMENTS ……………………………………….. |

144 |

|

TIMING CHAIN ………………………………………………. |

147 |

|

Removal and Installation ………………………………. |

147 |

|

REMOVAL ……………………………………………….. |

147 |

|

INSPECTION AFTER REMOVAL ……………….. |

149 |

|

INSTALLATION ………………………………………… |

149 |

|

TIMING GEAR ……………………………………………….. |

151 |

|

Removal and Installation ………………………………. |

151 |

|

REMOVAL ……………………………………………….. |

152 |

|

INSPECTION AFTER REMOVAL ……………….. |

155 |

|

INSTALLATION ………………………………………… |

157 |

|

CYLINDER HEAD ………………………………………….. |

160 |

|

On-Vehicle Service ………………………………………. |

160 |

|

CHECKING COMPRESSION PRESSURE …… |

160 |

|

Removal and Installation ………………………………. |

161 |

|

REMOVAL ……………………………………………….. |

161 |

|

INSPECTION AFTER REMOVAL ……………….. |

162 |

|

INSTALLATION ………………………………………… |

163 |

|

Disassembly and Assembly …………………………… |

166 |

|

DISASSEMBLY ………………………………………… |

166 |

|

ASSEMBLY ……………………………………………… |

167 |

|

INSPECTION AFTER DISASSEMBLY …………. |

167 |

|

ENGINE ASSEMBLY ……………………………………… |

172 |

|

Removal and Installation ………………………………. |

172 |

|

REMOVAL ……………………………………………….. |

172 |

|

INSTALLATION ………………………………………… |

174 |

|

INSPECTION AFTER INSTALLATION …………. |

175 |

|

CYLINDER BLOCK ……………………………………….. |

176 |

|

Disassembly and Assembly …………………………… |

176 |

|

DISASSEMBLY ………………………………………… |

177 |

|

ASSEMBLY ……………………………………………… |

181 |

|

How to Select Piston ……………………………………. |

184 |

|

DESCRIPTION …………………………………………. |

184 |

|

SELECTIVE PISTON COMBINATION …………. |

184 |

|

INSPECTION AFTER DISASSEMBLY …………. |

185 |

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-3

SERVICE DATA AND SPECIFICATIONS (SDS) … 194

|

Standard and Limit ……………………………………….. |

194 |

|

GENERAL SPECIFICATIONS …………………….. |

194 |

|

INTAKE MANIFOLD AND EXHAUST MANI- |

|

|

FOLD ………………………………………………………. |

194 |

|

DRIVE BELTS ………………………………………….. |

194 |

|

CYLINDER HEAD …………………………………….. |

195 |

|

VALVE ……………………………………………………… |

195 |

|

CAMSHAFT AND CAMSHAFT BEARING ……. |

199 |

|

CYLINDER BLOCK ……………………………………. |

199 |

|

PISTON, PISTON RING AND PISTON PIN …..200 |

|

|

CONNECTING ROD ………………………………….. |

201 |

|

CRANKSHAFT ………………………………………….. |

201 |

|

AVAILABLE MAIN BEARING ………………………. |

202 |

|

AVAILABLE CONNECTING ROD BEARING …. |

202 |

|

MISCELLANEOUS COMPONENTS …………….. |

202 |

|

Tightening torque …………………………………………. |

203 |

EM-4

PRECAUTIONS

PRECAUTIONS

Precautions for Drain Coolant

●Drain coolant when engine is cooled.

Precautions for Disconnecting Fuel Piping

[KA24DE]

PFP:00001

A

EBS007JS

EM

EBS007JT

●Before starting work, make sure no fire or spark producing items are in the work area.

●Release fuel pressure before disassembly.

●After disconnecting pipes, plug openings to stop fuel leakage.

|

Precautions for Removal and Disassembly |

EBS007JU |

●When instructed to use special service tools, use the specified tools. Always be careful to work safely, avoid forceful or uninstructed operations.

● Exercise maximum care to avoid damage to mating or sliding surfaces.

● Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials. ● Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

● When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactly as specified.

|

Precautions for Inspection, Repair and Replacement |

EBS007JV |

●Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and replace if necessary.

|

Precautions for Assembly and Installation |

EBS007JW |

●Use torque wrench to tighten bolts or nuts.

●When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified, do exactly as specified.

● Replace with new gasket, packing, oil seal or O-ring.

● Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction and blockage.

● Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

●Release air within route after draining coolant.

●After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems

for leakage.

|

Parts Requiring Angular Tightening |

EBS007JX |

●Use an angle wrench for the final tightening of the following engine parts:

– Cylinder head bolts

– Connecting rod cap nuts

●Do not use a torque value for final tightening.

●The torque value for these parts are for a preliminary step.

●Ensure thread and seat surfaces are clean and coated with engine oil.

EM-5

PRECAUTIONS

[KA24DE]

|

Precautions for Liquid Gasket |

EBS007JY |

REMOVAL OF LIQUID GASKET SEALING

●After removing the mounting bolts and nuts, disconnect and remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

●In areas where the cutter is difficult to use, use a plastic hammer to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed screwdriver is used, be careful not to damage the mating sur-

faces.

PBIC0275E

LIQUID GASKET APPLICATION PROCEDURE

1.Using a scraper, remove the old liquid gasket adhering to the gasket application surface and the mating surface.

●Remove the liquid gasket completely from the groove of the gasket application surface, mounting bolts, and bolt holes.

2.Wipe the gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

3.Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

PBIC0003E

4.Apply the gasket without breaks to the specified location with the specified dimensions.

●If there is a groove for the liquid gasket application, apply the gasket to the groove.

●As for the bolt holes, normally apply the gasket inside the holes. Occasionally, it should be applied outside the holes. Make sure to read the text of service manual.

●Within five minutes of gasket application, install the mating component.

|

● If the liquid gasket protrudes, wipe it off immediately. |

EMA0622D |

●Do not retighten after the installation.

●After 30 minutes or more have passed from the installation, fill the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe them.

EM-6

|

PREPARATION |

||

|

[KA24DE] |

||

|

PREPARATION |

PFP:00002 |

|

|

Special Service Tools |

EBS007JZ |

|

|

Tool number |

Description |

|

|

Tool name |

||

|

KV10111100 |

Removing steel oil pan and rear timing chain |

|

|

Seal cutter |

case |

|

ZZA0013D |

|

|

KV10117100 |

Loosening or tightening heated oxygen |

|

Heated oxygen sensor wrench |

sensors with 22 mm (0.87 in) hexagon nut |

|

ZZA1007D |

|

|

KV10105800 |

Removing and installing idler sproket |

|

Timing chain stopper |

|

ZZA1006D |

|

|

KV101151S0 |

Changing valve lifter shims |

|

Lifter stopper set |

1KV10115120 Lifter stopper

2KV10115110 Camshaft pliers

|

ZZA0103D |

|

|

KV10112100 |

Tightening bolts for bearing cap, cylinder |

|

Angle wrench |

head, etc. |

|

ZZA0120D |

||

|

KV10116200 |

Disassembling and assembling valve |

|

|

Valve spring compressor |

components |

|

|

KV10111200 |

||

|

Adapter |

||

|

ZZA0993D |

||

|

KV10116100 |

Removing valve oil seal |

|

|

Valve oil seal puller |

ZZA0015D

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-7

|

PREPARATION |

||

|

[KA24DE] |

||

|

Tool number |

Description |

|

|

Tool name |

||

|

KV10116300 |

Installing valve oil seal |

|

|

Valve oil seal drift |

a: 25 mm (0.98 in) dia. |

|

|

b: 14.4 mm (0.567 in) dia. |

||

|

c: 11.8 mm (0.465 in) dia. |

||

|

d: 10 mm (0.39 in) dia. |

||

|

e: 11 mm (0.43 in) |

||

|

f: 9 mm (0.35 in) |

||

|

NT602 |

||

|

ST0501S000 |

Engine overhaul |

|

|

Engine stand assembly |

ZZA0022D

KV10105001

Engine attachment

|

ZZA1061D |

|

|

ST16610001 |

Removing crankshaft pilot bushing |

|

Pilot bushing puller |

(M/T model only) |

ZZA0046D

KV10114700

Main bearing cap remover

|

ZZA0023D |

|

|

EM03470000 |

Installing piston assembly into cylinder bore |

|

Piston ring compressor |

|

S-NT044 |

|

|

WS39930000 |

Pressing the tube of liquid gasket |

|

Tube presser |

|

S-NT052 |

|

|

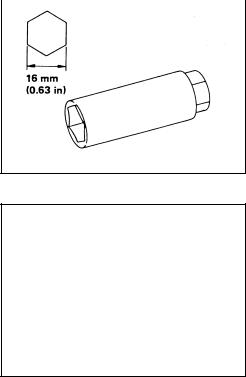

Commercial Service Tools |

EBS007K0 |

EM-8

PREPARATION

[KA24DE]

Tool number

Tool name Description

Quick connector release Removing fuel tube quick connectors in engine room

(Available in SEC. 164 of PARTS

CATALOG: Part No. 16441 6N210)

PBIC0198E

|

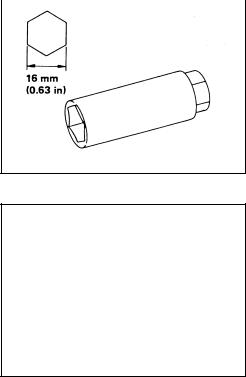

Spark plug wrench |

Removing and installing spark plug |

S-NT047

|

Valve seat cutter set |

Finishing valve seat dimensions |

S-NT048

|

Piston ring expander |

Removing and installing piston ring |

|

S-NT030 |

||

|

Valve guide drift |

Removing and installing valve guide |

|

|

Intake & Exhaust: |

||

|

a: 109.5 mm (0.413 in) dia. |

||

|

b: 6.6 mm (0.260 in) dia. |

||

|

S-NT015 |

||

|

Valve guide reamer |

1: Reaming valve guide inner hole |

|

|

2: Reaming hole for oversize valve guide |

||

|

Intake & Exhaust: |

||

|

d1 : 7.0 mm (0.276 in) dia. |

||

|

d2 : 11.175 mm (0.440 in) dia. |

||

|

S-NT016 |

||

|

Rear oil seal drift |

Installing rear oil seal |

ZZA0025D

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-9

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

|

[KA24DE] |

|

|

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING |

PFP:00003 |

|

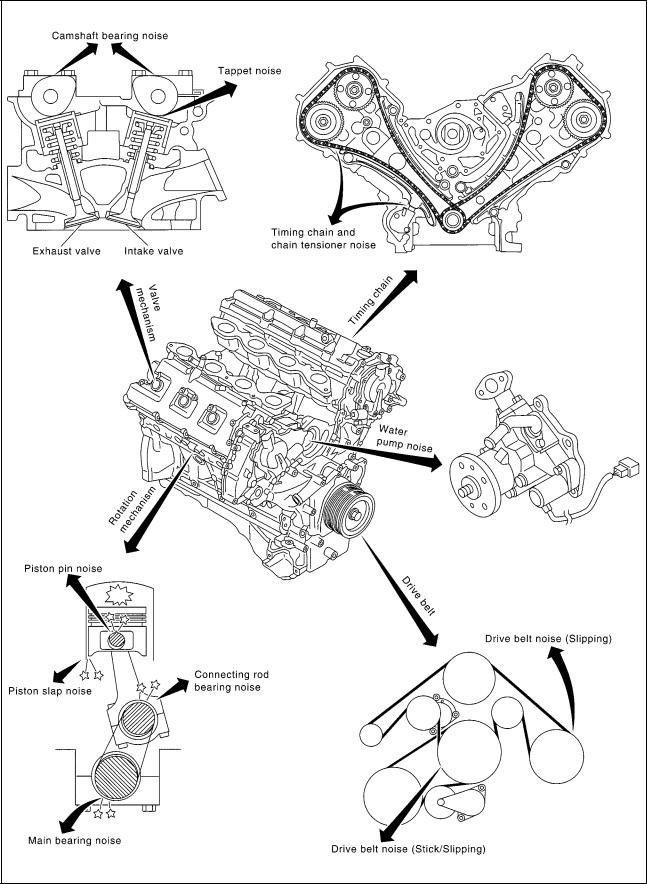

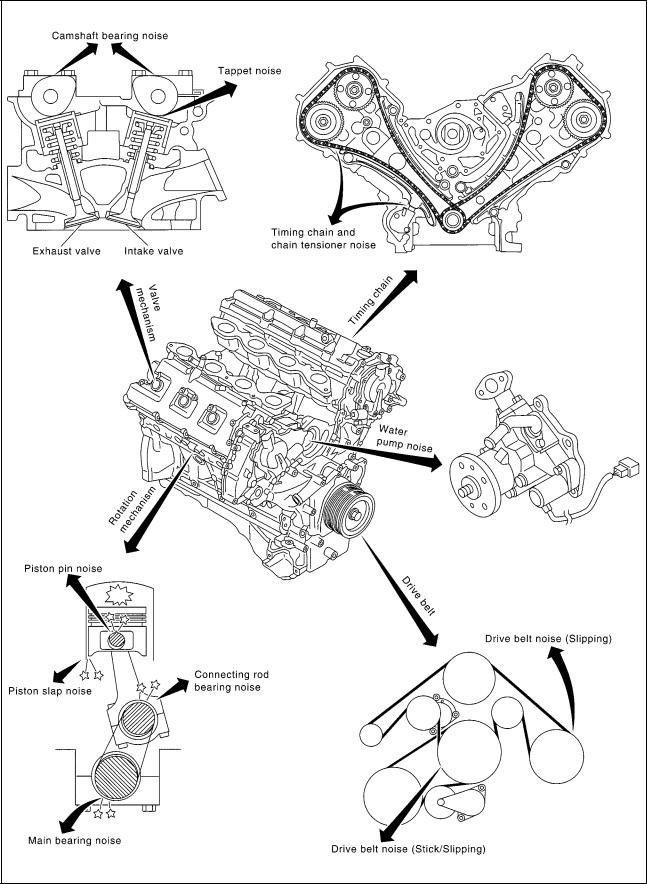

NVH Troubleshooting —Engine Noise |

EBS007K1 |

PBIC0192E

EM-10

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[KA24DE]

|

Use the Chart Below to Help You Find the Cause of the Symptom. |

EBS007K2 |

1.Locate the area where noise occurs.

2.Confirm the type of noise.

3.Specify the operating condition of engine.

4.Check specified noise source.

If necessary, repair or replace these parts.

|

Operating condition of engine |

||||||||||||||

|

Location |

Type of |

Source of |

Refer- |

|||||||||||

|

Before |

After |

When |

When |

When |

While |

Check item |

||||||||

|

of noise |

noise |

noise |

ence page |

|||||||||||

|

warm- |

warm- |

start- |

||||||||||||

|

idling |

racing |

driving |

||||||||||||

|

up |

up |

ing |

||||||||||||

|

Top of |

Ticking or |

C |

A |

— |

A |

B |

— |

Tappet |

Valve clearance |

EM-38 |

||||

|

engine |

clicking |

noise |

||||||||||||

|

Rocker |

||||||||||||||

|

Camshaft |

Camshaft journal clear- |

|||||||||||||

|

cover |

EM-36 |

|||||||||||||

|

Rattle |

C |

A |

— |

A |

B |

C |

bearing |

ance |

||||||

|

Cylinder |

||||||||||||||

|

EM-35 |

||||||||||||||

|

noise |

Camshaft runout |

|||||||||||||

|

head |

||||||||||||||

|

Piston and piston pin |

||||||||||||||

|

Slap or |

— |

A |

— |

B |

B |

— |

Piston pin |

clearance |

EM-80 |

|||||

|

knock |

noise |

Connecting rod bush- |

EM-80 |

|||||||||||

|

ing clearance |

||||||||||||||

|

Piston-to-bore clear- |

||||||||||||||

|

Crank- |

ance |

EM-80 |

||||||||||||

|

Piston ring side clear- |

||||||||||||||

|

Slap or |

Piston |

EM-79 |

||||||||||||

|

shaft pul- |

||||||||||||||

|

A |

— |

— |

B |

B |

A |

ance |

||||||||

|

rap |

slap noise |

EM-79 |

||||||||||||

|

ley |

||||||||||||||

|

Piston ring end gap |

||||||||||||||

|

EM-80 |

||||||||||||||

|

Cylinder |

||||||||||||||

|

Connecting rod bend |

||||||||||||||

|

block |

||||||||||||||

|

and torsion |

||||||||||||||

|

(Side of |

||||||||||||||

|

Connecting rod bush- |

||||||||||||||

|

engine) |

Connect- |

|||||||||||||

|

ing clearance (Small |

||||||||||||||

|

Oil pan |

||||||||||||||

|

ing rod |

EM-80 |

|||||||||||||

|

Knock |

A |

B |

C |

B |

B |

B |

end) |

|||||||

|

bearing |

EM-80 |

|||||||||||||

|

Connecting rod bear- |

||||||||||||||

|

noise |

||||||||||||||

|

ing clearance (Big end) |

||||||||||||||

|

Main |

Main bearing oil clear- |

EM-84 |

||||||||||||

|

Knock |

A |

B |

— |

A |

B |

C |

bearing |

ance |

||||||

|

EM-83 |

||||||||||||||

|

noise |

Crankshaft runout |

|||||||||||||

|

Front of |

Timing |

Timing chain cracks |

||||||||||||

|

engine |

chain and |

|||||||||||||

|

Tapping or |

and wear |

EM-44 |

||||||||||||

|

Timing |

A |

A |

— |

B |

B |

B |

chain ten- |

|||||||

|

ticking |

Timing chain tensioner |

EM-51 |

||||||||||||

|

chain |

sioner |

|||||||||||||

|

operation |

||||||||||||||

|

cover |

noise |

|||||||||||||

|

Other |

||||||||||||||

|

Squeak- |

drive belts |

|||||||||||||

|

ing or fizz- |

A |

B |

— |

B |

— |

C |

(Sticking |

Drive belts deflection |

||||||

|

ing |

or slip- |

EM-14 |

||||||||||||

|

ping) |

||||||||||||||

|

Front of |

||||||||||||||

|

Other |

Idler pulley bearing |

|||||||||||||

|

engine |

||||||||||||||

|

Creaking |

A |

B |

A |

B |

A |

B |

drive belts |

|||||||

|

operation |

||||||||||||||

|

(Slipping) |

||||||||||||||

|

Squall |

Water |

|||||||||||||

|

A |

B |

— |

B |

A |

B |

pump |

Water pump operation |

CO-21 |

||||||

|

Creak |

||||||||||||||

|

noise |

||||||||||||||

|

A: Closely related B: Related |

C: Sometimes related |

—: Not related |

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-11

ENGINE ROOM COVER

|

[KA24DE] |

|

|

ENGINE ROOM COVER |

PFP:14049 |

|

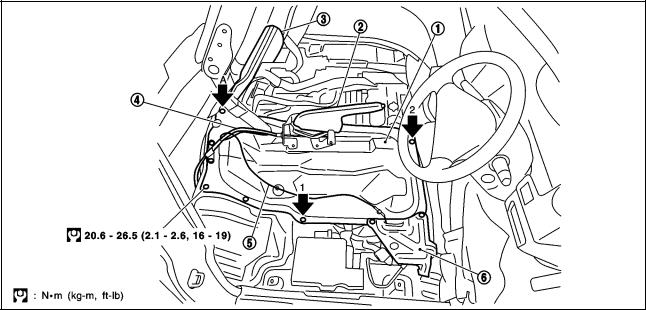

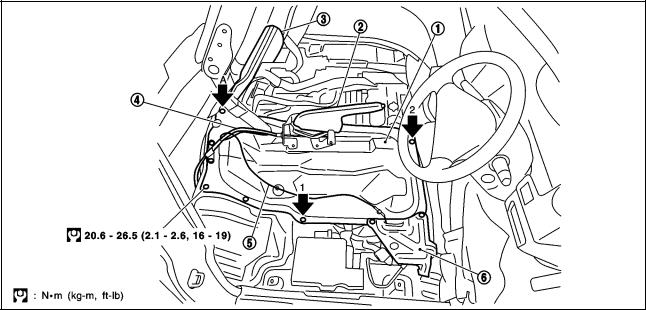

Removal and Installation of Engine Room Right Side |

EBS00ALX |

KBIA0741E

|

1. |

Engine room right side cover |

2. |

Parking brake lever |

3. |

Engine room left side cover |

|

4. |

Parking brake cable |

5. |

Harness |

6. |

Harness protector |

REMOVAL

1.Open engine compartment LH cover and secure it.

2.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

3.Partially remove floor carpet.

4.Disconnect harness protector secured together at front right. Disconnect harness connector to move harness routed on top of engine compartment RH cover aside.

5.Move parking brake lever and cable from engine compartment RH cover. Refer to PB-3, «PARKING BRAKE SYSTEM» .

6.Remove mounting bolts, and remove engine compartment RH cover.

CAUTION:

When taking it out of vehicle, do not allow it to interfere with vehicle.

INSTALLTION

●Install in reverse order of removal following instructions below.

1.Temporarily tighten bolt No. 1 shown in the figure.

2.Tighten bolt No. 2 shown in figure to specified torque.

3.Tighten other bolts except bolt “A” shown in the figure (bolt No. 1 is included) to specified torque in any given order.

4.Close engine compartment LH cover.

5.Tighten bolt “A” shown in the figure to specified torque.

|

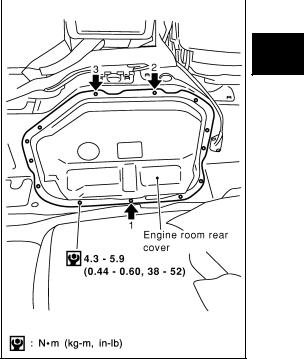

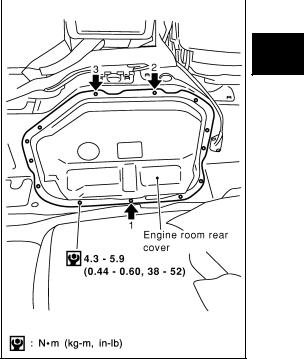

Removal and Installation of Engine Room Rear Cover |

EBS00ALY |

REMOVAL

1.Move folded seat on engine compartment rear cover side rearward, if applicable.

2.Partially remove floor carpet.

3.Remove mounting bolts, and remove engine compartment rear cover.

EM-12

ENGINE ROOM COVER

|

[KA24DE] |

||

|

INSTALLATION |

||

|

Following instructions below, install in reverse order of removal. |

A |

|

1.Tighten bolts No. 1 to No. 3 shown in the figure to specified torque in this order.

|

2. Tighten other bolts to specified torque in any given order. |

EM |

C

D

E

F

G

KBIA0742E

H

I

J

K

L

M

EM-13

|

DRIVE BELTS |

|

|

[KA24DE] |

|

|

DRIVE BELTS |

PFP:02117 |

|

Checking Drive Belts |

EBS007K4 |

WARNING:

Be sure to perform when the engine is stopped.

●Inspection should be done only when engine is cold, or over 30 minutes after engine is stopped.

●Measure belt tension with tension meter (special service tool) at points marked

●Measure belt deflection by applying load of 98.1 N {10 kg} to

PBIC0422E

|

Unit: mm (in) |

|||||

|

Deflection adjustment |

|||||

|

Used belt |

New belt |

||||

|

Limit |

After adjustment |

||||

|

Alternator |

11 (0.43) |

7 — 8 (0.28 — 0.31) |

6 — 7 (0.24 — 0.28) |

||

|

Air conditioner compressor |

13 (0.51) |

8 — 10 (0.31 — 0.39) |

7 — 8 (0.28 — 0.31) |

||

|

Power steering oil pump |

13 (0.51) |

8 — 10 (0.31 — 0.39) |

7 — 8 (0.28 — 0.31) |

||

|

Applied pushing force |

98 N (10 kg, 72 lb) |

||||

|

Tension Adjustment |

EBS00AM2 |

CAUTION:

●When belt is replaced with a new one, tighten it a little stronger than current one to accommodate for insufficient adaptability with pulley grooves.

●When tension of belt being used exceeds ″Retightening limit″, adjust it to value for ″Used belt″.

●When installing belt, make sure that it is correctly engaged with pulley groove.

●Keep oil and water away from belt.

●Do not twist or bend belt excessively.

POWER STEERING PUMP BELT

1.Open and fix engine compartment LH cover.

2.Loosen idler pulley lock nut (A) and adjust tension by turning adjusting bolt (B).

●For specified belt tension, refer to EM-14, «Checking Drive Belts» .

3.Tighten nut (A).

EMK0571D

AIR CONDITIONER COMPRESSOR BELT

1.Open and fix engine compartment LH cover (passenger side for RHD models or driver-side for LHD models).

2.Loosen idler pulley lock nut (C) and adjust tension by turning adjusting bolt (D). ● For specified belt tension, refer to EM-14, «Checking Drive Belts» .

3.Tighten nut (C).

EM-14

ALTERNATOR AND WATER PUMP BELT

1.Remove front-side under cover.

2.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

3.Remove engine compartment RH cover. Refer to EM-12, «ENGINE ROOM COVER» .

4.Loosen alternator mounting bolt (E) and adjuster lock bolt (F), and adjust tension by turning adjusting nut

(G).

● For specified belt tension, refer to EM-14, «Checking Drive Belts» .

5.Tighten bolts (E), (F) and (G).

|

: 45.1 — 59.8 N·m (4.6 — 6.1 kg-m, 34 |

— 44 ft-lb) for E bolt |

|

: 15.7 — 20.6 N·m (1.6 — 2.1 kg-m, 12 |

— 15 ft-lb) for F bolt |

|

: 6.5 — 7.6 N·m (0.67 — 0.77 kg-m, 58 — 67 in-lb) for G bolt |

|

|

Removal and Installation |

EBS007K6 |

REMOVAL

●Loosen each belt while referring to «Adjustment», and remove them one by one starting from the one in front.

INSTALLATION

1.Install belts to pulley in reverse order of removal.

2.Adjust belt tension.

CAUTION:

●When checking belt tension immediately after installation, first, adjust to specified value. Then, after turning crankshaft more than two turns, re-adjust to specified value to avoid variation in deflection between pulleys.

●Tighten idler pulley lock nut by hand and measure tension without looseness.

3.Tighten each adjusting bolt and nut to the specified torque.

4.Make sure that tension of each belt is within the standard.

EM-15

AIR CLEANER AND AIR DUCT

|

[KA24DE] |

|

|

AIR CLEANER AND AIR DUCT |

PFP:16500 |

|

Removal and Installation |

EBS007K8 |

KBIA0821E

|

1 |

PCV hose |

2 |

Air duct |

3 |

Collar |

|

4 |

Grommet |

5 |

Clamp |

6 |

Collar |

|

7 |

Grommet |

8 |

Resonator |

9 |

Clamp |

|

10 |

Resonator |

11 |

Clamp |

12 |

Air hose |

|

13 |

Resonator |

14 |

Clamp |

15 |

Mass air flow meter |

|

16 |

Air cleaner case |

17 |

Grommet |

18 |

Air cleaner element |

|

19 |

Washer |

20 |

Wing nut |

21 |

Seal ring |

|

22 |

Dust pan |

23 |

Washer |

24 |

Wing nut |

|

25 |

Dust exhaust valve |

26 |

Grille |

27 |

Screw |

|

28 |

Air duct |

29 |

Grommet |

30 |

Air duct |

|

31 |

Resonator |

32 |

Grommet |

33 |

Collar |

|

34 |

Resonator |

35 |

Clamp |

REMOVAL

1.Remove rear-side under cover.

2.Open and fix engine room LH cover.

3.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

4.Remove engine room RH cover. Refer to EM-12, «ENGINE ROOM COVER» .

5.Remove floor cover behind RH seat.

6.Disconnect harness connector from airflow sensor.

EM-16

AIR CLEANER AND AIR DUCT

[KA24DE]

7.For correct installation, make matching marks on each connection.

8.Remove from engine side after separating the system with the following procedure.

a.Remove PCV hose (A).

b.Remove air duct (B).

c.Separate air hose (C) and resonator (D).

d.Remove resonator (E).

e.Remove air hose (C).

f.Remove resonator (D).

g.Remove mass air flow sensor (F).

CAUTION:

●Handle with care, avoiding any shocks.

●Do not disassemble it.

●Do not touch sensor part.

h.After removing mud flap of front RH wheel, remove resonator

(G).

i.When removing following parts, remove EVAP canister, and set it aside.

j.Remove resonator (H).

k.Remove air cleaner case (I).

9.When removing components inside vehicle on right-hand, remove them with the following procedure.

a.Remove components up to air cleaner case (I), referring to step 8.

b.Remove intake grille from outside of vehicle.

c.Remove kicking plate on RH side, and lift up panel under RH side seat belt anchor.

d.Lift up air duct (J) from vehicle opening, and separate it from air duct (K).

e.Pull and remove air duct (K).

f.Remove air duct (J) from mounting hole of air duct (K).

INSTALLATION

Install in reverse order of removal, paying attention to points below.

●After aligning matching marks marked when removing, install each connection, and firmly tighten clamps.

●Install dust drain valve so that its opening is along circumference.

KBIA0819E

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-17

AIR CLEANER AND AIR DUCT

[KA24DE]

|

Changing Air Cleaner Element |

EBS0096T |

REMOVAL

NOTE:

●Mark ″*″ in the figure shows part of lift arm.

●For replacement of air cleaner element, it is not necessary to lift up vehicle.

1.Remove brake pipe protector under vehicle, behind front RH wheel.

2.Remove 3 clips, and the cover at the bottom of air cleaner case.

3.Remove wing nut, dust pan under air cleaner case, and then air cleaner element.

KBIA0749E

INSTALLATION

Install in the reverse order of removal.

EM-18

|

THROTTLE BODY |

|||||

|

[KA24DE] |

|||||

|

THROTTLE BODY |

PFP:16298 |

||||

|

Removal and Installation |

A |

||||

|

EBS008X7 |

|||||

|

EM |

|||||

|

C |

|||||

|

D |

|||||

|

E |

|||||

|

F |

|||||

|

G |

|||||

|

H |

|||||

|

I |

|||||

|

KBIA0823E |

|||||

|

1 |

Bracket |

2 |

Throttle position sensor harness |

3 |

Water hose |

|

4 |

Throttle body |

5 |

Bracket |

6 |

Water hose |

|

7 |

Gasket |

8 |

Intake manifold |

REMOVAL

1.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

2.Remove engine compartment RH cover. Refer to EM-12, «ENGINE ROOM COVER» .

3.Remove air duct on throttle body. Refer to EM-16, «AIR CLEANER AND AIR DUCT» .

4.Disconnect accelerator cable, and set it aside.

5.Disconnect harness connector.

6.Disconnect water hose.

● After disconnection, plug the hose to prevent coolant leaks.

7.Loosen mounting bolts in reverse order shown in the figure, and remove throttle body.

PBIC0424E

EM-19

THROTTLE BODY

[KA24DE]

INSPECTION AFTER REMOVAL

●If idle is rough when engine is cold or warmed up, check and adjust the fast idle cam (FIC). Refer to EC28, «Fast Idle Cam (FIC) Inspection and Adjustment» .

INSTALLATION

Install in reverse order of removal, paying attention to points below.

●For throttle body, tighten mounting bolts in two steps in the numerical order shown in the figure.

●For adjustment of accelerator cable, refer to ACC-3, «ACCELERATOR CONTROL SYSTEM (KA24DE)» .

|

PBIC0424E |

|

|

Disassembly and Assembly |

EBS008X8 |

PBIC0425E

|

1 |

Throttle body |

2 |

Throttle position sensor |

3 |

IACV-FICD solenoid valve |

|

4 |

Washer |

5 |

Spring |

6 |

plunger |

|

7 |

Gasket |

8 |

IACV-AAC valve |

DISASSEMBLY

Disassemble referring to the component illustration.

ASSEMBLY

Assemble in reverse order of disassembly, paying attention to points below.

●Insert throttle position sensor into throttle body, with connectors positioned as shown in the figure. Then rotate it in the direction shown by arrow and temporarily tighten mounting screws.

●While they are turned in direction shown by arrow, circumference of sensor hits projection. Avoid hitting projection by giving slight space, and insert projection into inside of mounting screw long hole. (It is temporarily held in place by counter-action of spring.)

●After adjustment on vehicle, tighten mounting screws.

For adjusting procedure, refer to EC-45, «Basic Inspection» .

PBIC0426E

EM-20

|

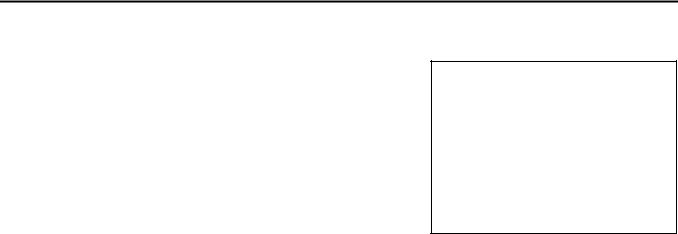

INTAKE MANIFOLD |

|||||

|

[KA24DE] |

|||||

|

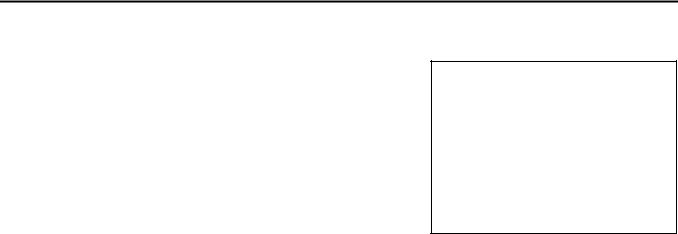

INTAKE MANIFOLD |

PFP:14003 |

||||

|

Removal and Installation |

A |

||||

|

EBS007K9 |

|||||

|

EM |

|||||

|

C |

|||||

|

D |

|||||

|

E |

|||||

|

F |

|||||

|

G |

|||||

|

H |

|||||

|

I |

|||||

|

J |

|||||

|

K |

|||||

|

L |

PBIC0427E

M

|

1 |

Bracket |

2 |

Grounding wire |

3 |

Bracket |

|

4 |

Vacuum hose |

5 |

Intake manifold |

6 |

Heater pipe |

|

7 |

Water hose |

8 |

Water hose |

9 |

Intake manifold support |

|

10 |

Vacuum hose |

11 |

Thermal transmitter |

12 |

Water outlet |

|

13 |

Gasket |

14 |

Water hose |

15 |

PCV hose |

|

16 |

Gasket |

17 |

Air relief plug |

18 |

Gasket |

|

19 |

Engine coolant temperature sensor |

20 |

Gasket |

REMOVAL

1.Release fuel pressure. Refer to EC-27, «Fuel Pressure Release» .

2.Drain coolant. Refer to CO-9, «ENGINE COOLANT» .

3.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

4.Remove engine compartment RH cover and rear cover. Refer to EM-12, «ENGINE ROOM COVER» .

5.Remove floor cover behind RH seat.

EM-21

INTAKE MANIFOLD

[KA24DE]

6.Move aside main harness above intake manifold.

7.Disconnect PCV hose between rocker cover and air duct.

8.Remove air duct between throttle body and mass air flow sensor. Refer to EM-16, «AIR CLEANER AND AIR DUCT» .

9.Remove throttle body. Refer to EM-19, «THROTTLE BODY» .

10.Remove fuel tube and injector assembly. Refer to EM-28, «FUEL INJECTOR AND FUEL TUBE» .

11.Disconnect radiator hose (upper).

12.Disconnect hoses connected to intake manifold.

NOTE:

Separate water hose and PCV hose behind intake manifold when removing intake manifold.

13.Remove intake manifold with the following procedure.

a.Loosen mounting bolts and nuts in reverse order shown in the figure.

b.Pull out stud bolts on rear.

c.Disconnect water hose and PCV hose on back side, and remove intake manifold.

PBIC0428E

INSPECTION AFTER REMOVAL

Surface Distortion

●Using straightedge and feeler gauge, inspect surface distortion of intake manifold.

|

Limit |

: 0.1 mm (0.004 in) |

PBIC0429E

INSTALLATION

Assemble in reverse order of removal, paying attention to the following.

Intake Manifold Bolts

●Tighten in numerical order as shown in the figure.

PBIC0428E

Water Outlet

●Install gasket so that identification mark face as shown in component parts drawing.

EM-22

|

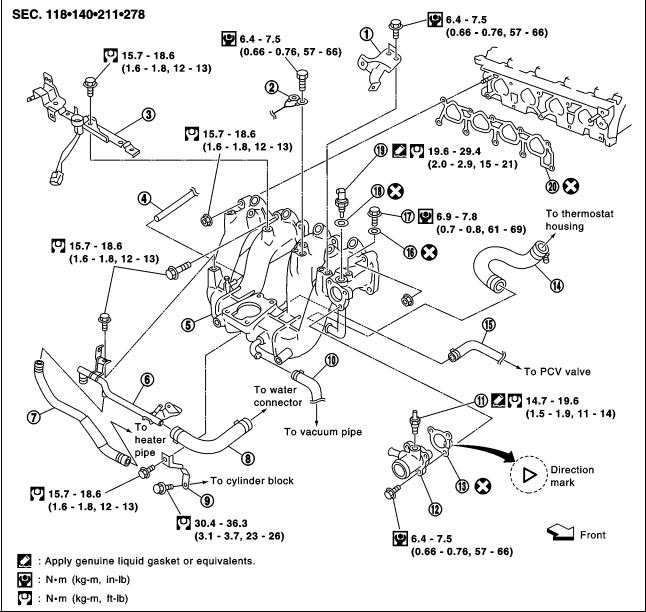

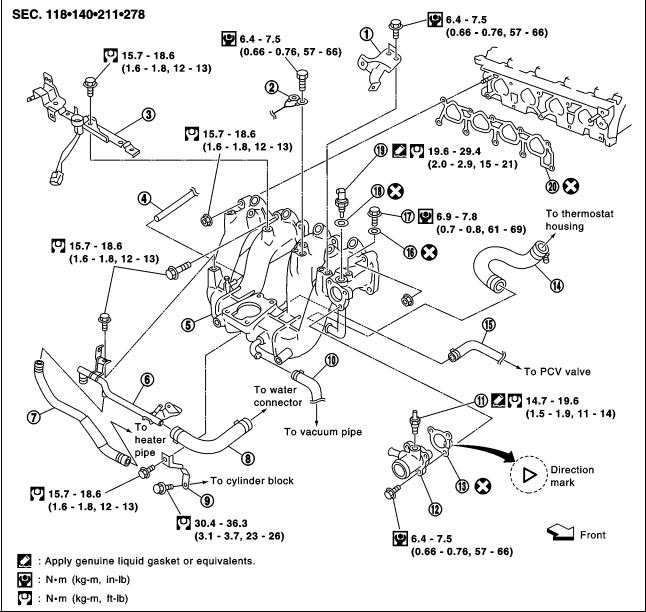

EXHAUST MANIFOLD |

|||||

|

[KA24DE] |

|||||

|

EXHAUST MANIFOLD |

PFP:14004 |

||||

|

Removal and Installation |

A |

||||

|

EBS008RQ |

|||||

|

EM |

|||||

|

C |

|||||

|

D |

|||||

|

E |

|||||

|

F |

|||||

|

G |

|||||

|

H |

|||||

|

I |

|||||

|

KBIA0825E |

|||||

|

1 |

Exhaust manifold |

2 |

Gasket |

3 |

Heated oxygen sensor |

|

4 |

Oil level gauge guide |

5 |

Exhaust manifold cover |

6 |

Bracket |

REMOVAL

|

1. |

Remove under cover on rear side. |

||

|

2. |

Remove exhaust front tube. Refer to EX-2, «EXHAUST SYSTEM» . |

||

|

3. |

Open and fix engine compartment LH cover. |

||

|

4. |

Remove heated oxygen sensor with the following procedure. |

||

|

a. |

Remove engine compartment rear cover. Refer to EM-12, «ENGINE ROOM COVER» . |

||

|

b. |

Disconnect heated oxygen sensor harness connector from bracket on intake manifold No. 4 port, and |

||

|

remove all harness clamps. |

|||

|

c. |

Using socket for heated oxygen sensor removal and installation |

||

|

(special service tool), remove heated oxygen sensor. |

|||

|

5. |

Remove exhaust manifold cover. |

KBIA0826E

EM-23

EXHAUST MANIFOLD

[KA24DE]

6.Loosen mounting nuts in reverse order shown in the figure, and remove exhaust manifold.

PBIC0430E

INSPECTION AFTER REMOVAL

●Using straightedge and feeler gauge, inspect surface distortion of intake manifold.

|

Limit |

: 0.3 mm (0.012 in) |

PBIC0431E

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

●Tighten in numerical order as shown in the figure.

PBIC0430E

INSPECTION AFTER INSTALLATION

Start engine, and check for exhaust gas leakage and unusual noise by increasing engine speed.

EM-24

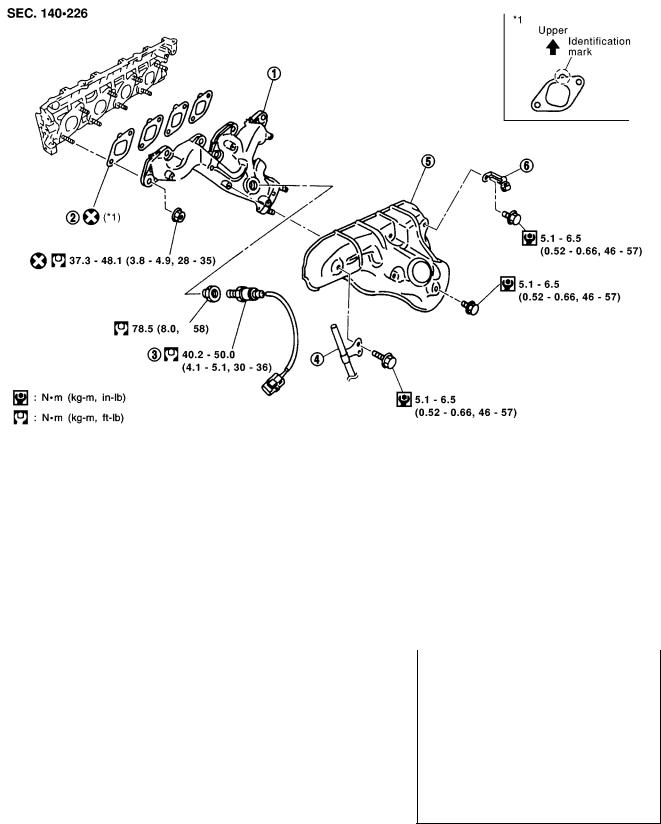

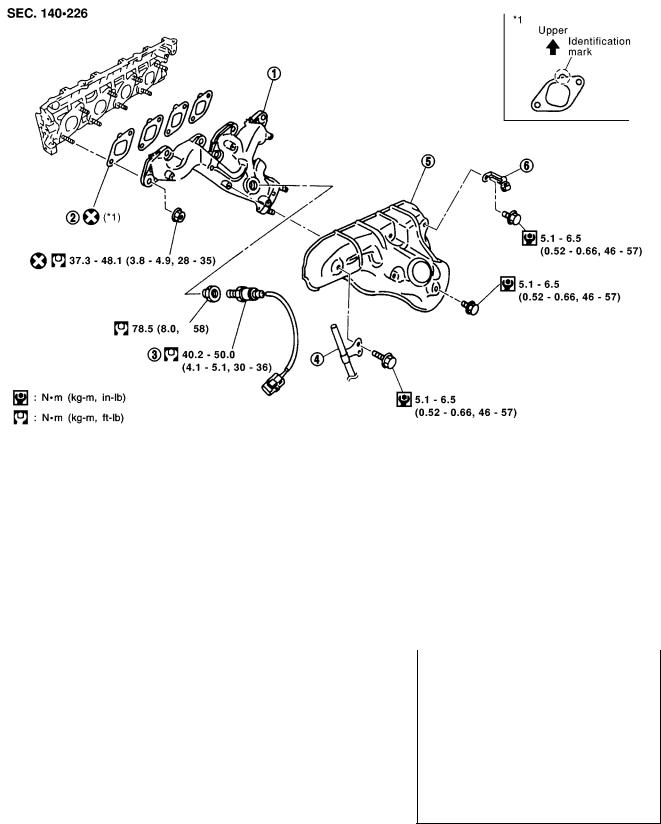

OIL PAN AND OIL STRAINER

|

[KA24DE] |

|||||||

|

OIL PAN AND OIL STRAINER |

PFP:11110 |

||||||

|

Removal and Installation |

A |

||||||

|

EBS007KB |

|||||||

|

EM |

|||||||

|

C |

|||||||

|

D |

|||||||

|

E |

|||||||

|

F |

|||||||

|

PBIC0432E |

G |

||||||

|

1 |

Gasket |

2 |

Oil strainer |

3 Oil pan drain plug washer |

|||

|

4 |

Oil pan drain plug |

5 |

Oil pan |

H |

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1.Remove under covers on front-side, and rear-side.

2.Drain engine oil. Refer to LU-5, «ENGINE OIL» .

3.Loosen mounting bolts in reverse order shown in the figure, and remove them.

NOTE:

There are no screw holes in the area marked with

4.Using a seal cutter (special service tool), separate liquid gasket, and remove oil pan.

5.Remove oil strainer.

SEM980F

INSPECTION AFTER REMOVAL

Check oil strainer and clean it if any object attached.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

EM-25

OIL PAN AND OIL STRAINER

[KA24DE]

Installing Oil Pan

1.Apply liquid gasket thoroughly as shown in illustration. ● Use Genuine Liquid Gasket or equivalent.

PBIC0433E

2.Tighten mounting bolts in numerical order as shown in the figure.

NOTE:

There are no screw holes in the area marked with

SEM985F

Installing Drain Plug Washer

Refer to illustration of component parts for installation direction.

INSPECTION AFTER INSTALLATION

Check for leakage of engine oil when engine is warmed.

EM-26

SPARK PLUG (CONVENTIONAL)

|

[KA24DE] |

||||

|

SPARK PLUG (CONVENTIONAL) |

PFP:22401 |

|||

|

Removal and Installation |

A |

|||

|

EBS008YM |

||||

|

REMOVAL |

||||

|

1. |

Open and fix engine compartment LH cover. |

EM |

||

|

2. |

Disconnect high-tension cables from rocker cover. |

|||

|

3. |

Remove spark plugs with a spark plug wrench (commercial ser- |

|||

●Remove and install No. 4 cylinder by connecting extension bar of 75 mm and universal socket to spark plug wrench.

D

E

SMA581C

INSPECTION AFTER REMOVAL

Check spark plug gap. Adjust or replace if necessary.

|

Standard |

: 1.0 — 1.1 mm (0.039 — 0.043 in) |

|

|

Spark plug: |

||

|

Make |

NGK |

|

|

Standard type |

BKR5E-11 |

|

|

Cold type |

BKR6E-11 |

|

|

BKR7E-11 |

||

●Use a wire brush for cleaning, if necessary.

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

Spark plug:

●Refer to EM-30, «ROCKER COVER» for installation of spark plug cap and high-tension cables.

L

M

EM-27

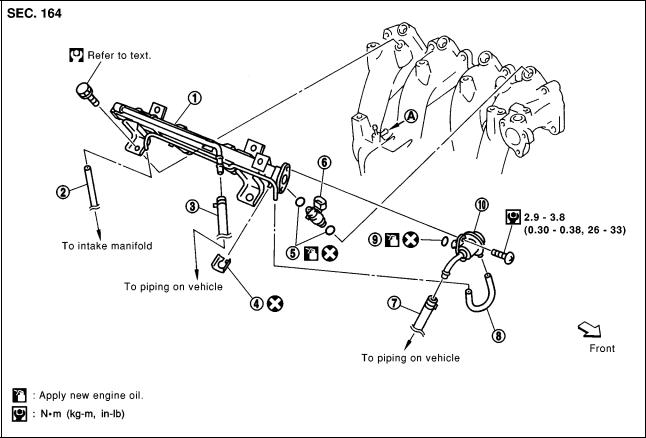

FUEL INJECTOR AND FUEL TUBE

|

[KA24DE] |

|

|

FUEL INJECTOR AND FUEL TUBE |

PFP:16600 |

|

Removal and Installation |

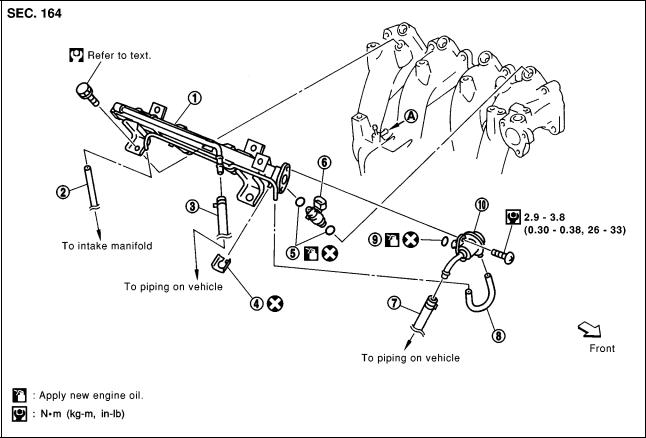

EBS007KE |

KBIA0827E

|

1 |

Fuel tube |

2 |

Vacuum hose |

3 |

Fuel feed hose |

|

4 |

Clip |

5 |

O-ring |

6 |

Fuel injector |

|

7 |

Fuel return hose |

8 |

Vacuum hose |

9 |

O-ring |

|

10 |

Fuel pressure regulator |

CAUTION:

●Apply new engine oil when installing the parts that specified to do so in the figure.

REMOVAL

1.Release fuel pressure. Refer to EC-27, «Fuel Pressure Release» .

2.Remove RH seat. Refer to SE-4, «FRONT SEAT» .

3.Remove engine compartment RH cover. Refer to EM-12, «ENGINE ROOM COVER» .

4.Disconnect PCV hose between rocker cover and air duct.

5.Remove air duct on throttle body. Refer to EM-16, «AIR CLEANER AND AIR DUCT» .

6.Disconnect fuel injector harness connector.

7.Move aside main harness above intake manifold.

8.Disconnect vacuum hose from fuel tube.

9.Disconnect fuel feed hose and fuel return hose.

CAUTION:

Plug hoses to prevent fuel from draining.

10.Remove fuel tube and injector assembly.

CAUTION:

Do not incline it, or remaining fuel in pipes may drain from pipes.

EM-28

FUEL INJECTOR AND FUEL TUBE

[KA24DE]

11.Expand and remove clips securing fuel injectors.

12.Extract fuel injectors straight from fuel tubes.

●Be careful not to damage injector nozzles during removal.

●Do not bump or drop fuel injectors.

●Do not disassemble.

PBIC0227E

INSTALLATION

|

1. |

Carefully install O-rings, including the one used with the pressure regulator. |

|

● |

Lubricate O-rings by smearing new engine oil. |

|

● |

Be careful not to damage O-rings and surfaces for O-ring sealing with service tools, finger nails or |

|

clips. Do not expand or twist O-rings. |

|

|

● |

Discard old clips; replace with new ones. |

2.Position clips in grooves on fuel injectors.

●Make sure that protrusions of fuel injectors are aligned with cutouts of clips after installation.

3.Align protrusions of fuel tubes with those of fuel injectors.

4.Do not incline it, or remaining fuel in pipes may drain from pipes.

●Insert hose until its end touches bulge on fuel tube. Install clamp, avoiding bulge, and securely tighten it.

5.Tighten fuel tube assembly mounting bolts alternatively in two steps.

PBIC0227E

6.Connect fuel feed nose and fuel return hose.

●Insert hose until its end touches bulge on fuel tube. Install clamp, avoiding bulge, and securely tighten it.

7.Install all removed parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Check on Fuel Leakage

1.Start the engine, and run it for a few minutes with engine at idle.

2.Stop the engine, and check for fuel leakage both visually and by odor of gasoline.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped, as engine becomes extremely hot.

EM-29

|

ROCKER COVER |

|

|

[KA24DE] |

|

|

ROCKER COVER |

PFP:13264 |

|

Removal and Installation |

EBS007KF |

KBIA0828E

|

1 |

PCV hose |

2 |

Oil filler cap |

3 Rocker cover |

|

4 |

Gasket |

5 |

Gasket |

REMOVAL

1.Open and fix engine compartment LH cover.

2.Remove engine compartment rear cover. Refer to EM-12, «ENGINE ROOM COVER» .

3.Disconnect PCV hose.

4.Disconnect spark plug cap and high-tension cables, and set them aside.

5.Loosen mounting bolts in reverse order shown in the figure, and remove rocker cover.

PBIC0434E

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

EM-30

ROCKER COVER

Installing Rocker Cover

1.Apply liquid gasket to positions shown in the figure (semicircular plug seal on engine side: total 4).

● Use genuine liquid gasket or equivalents.

2.Install rocker cover so that semicircular plug part on rocker cover gasket is securely inserted into mounting part on engine.

3.Tighten mounting bolts in numerical order shown in the figure.

NOTE:

No.1 and No.2 means dual step tightening.

Spark Plug Cap and High Tension Cable

●Install them to clips, and perform wiring of cables, referring to the figure for correct placement.

[KA24DE]

A

EM

C

PBIC0435E D

E

F

G

PBIC0434E

H

I

J

K

L

M

EMK0592D

EM-31

|

CAMSHAFT |

|

|

[KA24DE] |

|

|

CAMSHAFT |

PFP:13001 |

|

Removal and Installation |

EBS007KG |

|

PBIC0436E |

||||

|

1 |

Camshaft bracket |

2 |

Camshaft (Intake) |

3 Camshaft sprocket (Intake) |

|

4 |

Camshaft sprocket (Exhaust) |

5 |

Camshaft (Exhaust) |

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1.Remove following parts.

●Power steering pump belt (Refer to EM-14, «DRIVE BELTS» .)

●Power steering pump support bracket

●Idler pulley bracket for power steering pump belt

●Rocker cover (Refer to EM-30, «ROCKER COVER» .)

2.Set No.1 cylinder to TDC in compression stroke.

a.Rotate crankshaft pulley clockwise and align notch of matching marks (yellow paint) to timing indicator on front cover.

PBIC0437E

EM-32

CAMSHAFT

b.At same time, make sure that matching marks on camshaft sprockets are located as shown in the figure. Make matching marks on secondary timing chain links with paint.

●If dislocated, rotate crankshaft pulley one more turn to line up matching marks to positions in the figure.

3.Push secondary timing chain tensioner with metal bar, then fix it with stopper pin.

CAUTION:

Do not remove cylinder head front cover.

NOTE:

When cylinder head front cover is removed, cylinder head gasket needs to be replaced.

● Using hard wire, make a stopper pin as shown in the figure.

4.Hold camshaft hexagonal head with 26 mm (1.02 in) spanner, and loosen camshaft sprocket bolt.

NOTE:

Each camshaft has two camshaft hexagonal heads: one in front, and the other in rear.

[KA24DE]

A

EM

C

PBIC0438E

D

E

F

G

PBIC0439E

H

I

J

PBIC0440E K

L

M

EMK0468D

EM-33

CAMSHAFT

[KA24DE]

5.Remove camshaft sprockets.

●Hold secondary timing chain in place, using chain stopper (special service tool) to prevent it from slipping from idler sprocket.

PBIC0441E

6.Loosen mounting bolts of camshaft brackets in several steps in the numerical order shown in the figure, and remove them.

7.Remove camshaft.

8.Remove adjusting shim and valve lifter.

●Check mounting positions, and store them without mixing them up.

PBIC0442E

INSTALLATION

1.Install valve lifters and adjusting shims.

●Install them in their original positions.

●Install adjusting shims with their stamp marks facing downward (valve lifter side).

2.Install camshaft.

●Intake and exhaust are identified by direction of No. 1 cylinder cam nose when knock pin at front end faces straight upward.

For intake:

Cam nose faces toward intake manifold side For exhaust:

Cam nose faces toward exhaust manifold side

PBIC0443E

●Install camshafts so that knock pins at front end face straight upward (position of No.1 cylinder at compression TDC).

PBIC0444E

EM-34

CAMSHAFT

|

[KA24DE] |

||||

|

3. Install camshaft bracket. |

A |

|||

|

● Install them in their original positions and directions, referring |

||||

|

to mark on top surface of camshaft bracket. |

||||

|

EM |

||||

|

C |

||||

|

PBIC0445E |

||||

|

D |

||||

4.Tighten camshaft bracket mounting bolts in two steps in numerical order shown in the figure.

CAUTION:

Tighten them from outside toward inside.

PBIC0442E

|

5. Install camshaft sprockets. |

||

|

● Camshaft sprockets are common for intake and exhaust |

||

|

sides. Sprockets have two matching marks. When aligning |

||

|

matching marks, refer to the figure. |

||

|

● Align matching mark of camshaft sprocket and that of second- |

||

|

ary timing chain made on it when removed. Then install cam- |

||

|

shaft. |

||

|

● If they are not aligned, align them by turning hexagonal part of |

||

|

camshaft with a spanner. |

||

|

● Make sure that timing chain does not slip on idler pulley, and |

PBIC0438E |

|

|

remove chain stopper (special service tool). |

||

●Hold hexagonal part of camshaft with spanner, and tighten camshaft sprocket mounting bolt.

NOTE:

Each camshaft has one hexagonal part at both front and rear, respectively.

6.Pull out stopper pins from secondary timing chain tensioner.

7.Check and adjust valve clearance. Refer to EM-38, «Valve Clearance» .

8.Install other parts in reverse order of removal.

INSPECTION AFTER REMOVAL

Camshaft Runout

●Put V block on, and support No.1 and No.5 journal of camshaft.

●Set dial gauge vertically to No.3 journal.

●Turn camshaft to one direction with hands, and measure camshaft runout (Total indicator reading) on dial gauge.

|

Standard |

: Less than 0.04 mm (0.0016 in) |

|

Limit |

: 0.08 mm (0.0031 in) |

SEM926C

EM-35

CAMSHAFT

[KA24DE]

Camshaft Cam Height

1.Measure camshaft cam height.

Standard:

Intake: 41.755 — 41.945 mm (1.644 — 1.651 in)

Exhaust: 41.815 — 42.005 mm (1.646 — 1.654 in)

Limit:

Intake and exhaust: 0.2 mm (0.008 in)

2.If wear is beyond the limit, replace camshaft.

PBIC0039E

Camshaft Journal Clearance

Outer Diameter of Camshaft Journal

●Measure outer diameter of camshaft journal.

|

Standard |

: 27.935 — 27.955 mm (1.0998 — 1.1006 in) |

Inner Diameter of Camshaft Bracket

●Tighten camshaft bracket bolt with specified torque.

●Using inside micrometer, measure inner diameter of camshaft bracket.

|

Standard |

: 28.000 — 28.025 mm (1.1024 — 1.1033 in) |

Calculation of Camshaft Journal Clearance

(Journal clearance) = (inner diameter of camshaft bracket) – (outer diameter of camshaft journal)

|

Standard |

: 0.045 — 0.090 mm (0.0018 — 0.0035 in) |

|

Limit |

: 0.15 mm (0.0059 in) |

●When out of the specified range above, replace either or both camshaft and cylinder head.

NOTICE:

Inner diameter of camshaft bracket is manufactured together with cylinder head. Replace the whole cylinder head assembly.

Camshaft End Play

●Install dial gauge in thrust direction on front end of camshaft. Measure end play of dial gauge when camshaft is moved forward/backward (in direction to axis).

|

Standard |

: 0.070 — 0.148 mm (0.0028 — 0.0058 in) |

|

Limit |

: 0.2 mm (0.008 in) |

●When out of the specified range, replace with new camshaft and measure again.

●When out of the specified range again, replace with new cylinder head.

PBIC0446E

EM-36

CAMSHAFT

Camshaft Sprocket Runout

1.Install camshaft in cylinder head.

2.Install camshaft sprocket to camshaft.

3.Measure camshaft sprocket runout.

|

Limit |

: Less than 0.15 mm (0.0059 in) |

4.If it exceeds the limit, replace camshaft sprocket.

Valve Lifter and Adjusting Shim

●Check if surface of valve lifter and adjusting shim has any wear or cracks.

Valve Lifter Clearance

Outer Diameter of Valve Lifter

●Measure outer diameter of valve lifter.

|

Standard |

: 33.960 — 33.975 mm (1.3370 — 1.3376 in) |

Valve Lifter Hole Diameter

●Using inside micrometer, measure diameter of valve lifter hole of cylinder head.

|

Standard |

: 34.000 — 34.021 mm (1.3386 — 1.3394 in |

Calculation of Valve Lifter Clearance

(Valve lifter clearance) = (hole diameter of valve lifter) – (outer diameter of valve lifter)

|

Standard |

: 0.025 — 0.061 mm (0.0010 — 0.0024 in |

●When out of specified range, referring to each specification of outer and inner diameter, replace either or both valve lifter and cylinder head.

[KA24DE]

A

EM

C

KBIA0181J D

E

F

G

SEM160D H

I

J

K

SEM961E

L

M

PBIC0447E

EM-37

CAMSHAFT

Valve Clearance

INSPECTION

Check valve clearance while engine is warm but not running.

1.Remove rocker cover and all spark plugs.

2.Set No. 1 cylinder at TDC on its compression stroke. ● Align pointer with TDC mark on crankshaft pulley.

●Check that valve lifters on No. 1 cylinder are loose and valve lift-

ers on No. 4 are tight.

If not, turn crankshaft one revolution (360°) and align as above.

3.Check only those valves shown in the figure.

4.Using a feeler gauge, measure clearance between valve lifter and camshaft.

●Record any valve clearance measurements which are out of specification. They will be used later to determine the required replacement adjusting shim.

Valve clearance (HOT) :

|

Intake |

0.31 — 0.39 mm (0.012 — 0.015 in) |

|

Exhaust |

0.39 — 0.47 mm (0.015 — 0.019 in) |

5.Turn crankshaft one revolution (360°) and align mark on crankshaft pulley with pointer.

6.Check those valves shown in the figure.

●Use the same procedure as mentioned in step 4.

7.If all valve clearances are within specification, install the following parts.

●Rocker cover

●All spark plugs

ADJUSTMENT

Adjust valve clearance while engine is cold.

[KA24DE]

EBS007KH

PBIC0437E

AEM382

SEM304D

AEM383

EM-38

CAMSHAFT

1.Turn crankshaft to position cam lobe on camshaft of valve that must be adjusted upward.

2.Place Tool (A) around camshaft as shown in figure.

3.Rotate Tool (A) so that lifter is pushed down.

Before placing Tool (A), rotate notch toward center of cylinder head (See figure.), to simplify shim removal later.

CAUTION:

Be careful not to damage cam surface with Tool (A).

4.Place Tool (B) between camshaft and the edge of the valve lifter to retain valve lifter.

CAUTION: