#1

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 10 Март 2016 — 17:27

Инструкции по эксплуатации на русском языке:

Руководство по эксплуатации ER-6n, ER-6n ABS 2012-2016

Руководство по эксплуатации Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2012-2016

Вот руководства по ремонту (на английском языке):

Руководство по ремонту ER-6n (ABS) 2006-2008

Руководство по ремонту ER-6n (ABS) 2009-2011

Руководство по ремонту ER-6n (ABS) 2012-2016

Руководство по ремонту Ninja 650R, ER-6f (ABS) 2006-2008

Руководство по ремонту Ninja 650R, ER-6f (ABS) 2009-2011

Руководство по ремонту Ninja 650R, ER-6f (ABS) 2012-2016

Руководство по ремонту Ninja 650R ER-6f (ABS) 2012-2016 на русском языке!

Часть 1-2. Технические характеристики и периодическое обслуживание

Часть 3. Система впрыска топлива (DFI)

Часть 4-5. Система охлаждения. Двигатель

Часть 6-8. Сцепление. Система смазки двигателя. Снятие/установка двигателя

Часть 9. Трансмиссия

Часть 10-11. Колёса/шины. Цепная передача

Часть 12. Тормозная система

Часть 13-15. Подвеска. Рулевое управление. Рама

Часть 16. Электрооборудование

Часть 17-18. Прокладка шлангов, тросов и кабелей. Поиск и устранение неисправностей

Каталог запчастей на русском языке!

Каталог запчастей мотоцикла ER-6f 2012

Желающие приобрести руководство и каталог в бумажном виде могут сделать это в специальной теме.

Народ, я довершил наконец одно большое дело, нарисовал схему Ерша. Адаптировал для лучшего восприятия, перевёл все надписи на русский язык. Пользуйтесь на здоровье.

Схема электрооборудования ER-6F 2012 ABS:

Для вашего удобства, та же схема, в формате .PDF доступна для скачивания по ссылке.

У меня ещё много планов впереди: перевести на русский мануал по ремонту (сделано), сделать каталог запчастей на русском языке (сделано), создать что-то вроде интерактивной карты мотоцикла с указанием наиболее популярных расходников со ссылками на магазины и ещё многое.

Это не быстрый процесс, буду выкладывать по мере готовности. Другие модели пока охватить не готов, объём работы просто колоссальный.

Сообщение отредактировал Cher Tannov: 08 Ноябрь 2020 — 08:06

Дополняю, расширяю…

- SShMeL, alllex, Валентин_Н и 9 другим это нравится

- Наверх

#2

SShMeL

SShMeL

- Пол:Мужчина

- Страна:Россия

- Город:Москва

- Мото:Ninja 650r > Ninja ZX12R + ZRX1100

Отправлено 10 Март 2016 — 20:42

Спасибо огромное за схему, очень поможет мне разобраться почему перегорает ECU предохранитель при срабатывание сигнализации. Только в схеме ты забыл расписать блок предохранителей 1 и 2 добавь пожалуйста, я в принципе и без этого обойдусь, но все же. Еще можешь выложить исходники я бы для себя поправил, так как у меня нет ABS, добавил свое дополнительное оборудование и распечатал бы на А3.

- Наверх

#3

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 10 Март 2016 — 21:56

Опа!

Очень странно, описание блоков предохранителей было… Завтра поправлю. Влад, спасибо за то, что увидел упущение.

Сейчас на подходе схема мота без АВS, прошу тебя потерпеть.

Ребята, пишите, в чём ещё потребность, я буду прислушиваться.

Поправил схему, добавил описание блоков предохранителей. Обновил ссылки.

В работе ещё много проектов.

Сообщение отредактировал Cher Tannov: 15 Март 2016 — 15:50

- Наверх

#4

Wasilen

Wasilen

-

- Members

-

- 11 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Карасук, Новосибирской области

- Мото:Kawasaki Ninja EX650 2013

Отправлено 19 Март 2016 — 09:36

Спасибо за проделанную работу!

- Наверх

#5

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 19 Март 2016 — 15:56

Пожалуйста.

Всё для вас.

Добавил в каталог запчастей ещё несколько разделов. Серьёзно переработал дизайн. Кажется, теперь каталог стал зрительно более восприимчив.

Пользуйтесь.

Кстати, если у вас есть вопросы, пожелания, предложения или дополнения, высказывайте. Да и от помощи я бы не отказался…

Сообщение отредактировал Cher Tannov: 08 Июнь 2017 — 22:38

- Валентин_Н и endorfirma это нравится

- Наверх

#6

snorky_KoLXo3HuK

snorky_KoLXo3HuK

- Пол:Мужчина

- Страна:РФ

- Город:Митино, Юбутово

- Мото:ER-6f 13 > GL 1800

Отправлено 04 Апрель 2016 — 21:55

схема просто отличная, всё видно и понятно

- Наверх

#7

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 11 Май 2016 — 15:36

Братва, хорошая новость!

Я закончил перевод каталога запчастей на русский язык, выложил полную версию, пользуйтесь!

Не слабо, книжка получилась в палец толщиной:

Сообщение отредактировал Cher Tannov: 11 Май 2016 — 16:09

- SShMeL и Валентин_Н это нравится

- Наверх

#8

Dinis

Dinis

-

- Members

-

- 37 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Владимир

- Мото:ER-6F

Отправлено 28 Июнь 2016 — 11:34

Братва, хорошая новость!

Я закончил перевод каталога запчастей на русский язык, выложил полную версию, пользуйтесь!

Не слабо, книжка получилась в палец толщиной:

Хороший труд. Огромное спасибо!

- atomic это нравится

- Наверх

#9

Валентин_Н

Валентин_Н

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Ярославский

- Мото:ER-6F ’13

Отправлено 02 Июль 2016 — 22:21

Спасибо, попробую распечатать и сверстать в переплёт на работе пока никто не видит

- Наверх

#10

BazonXGK

BazonXGK

- Пол:Мужчина

- Страна:Россия

- Город:Севастополь

- Мото:Kawasaki Ninja EX650AF (2006г.)

Отправлено 20 Сентябрь 2016 — 16:22

Ну, что, народ, приступил я к переводу инструкции по ремонту. Быстро не ждите, объём титанический!

Идея нужная и полезная, будем ждать , удачи!

- Наверх

#11

PaulSankov

PaulSankov

-

- Members

-

- 16 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:г. Москва

- Мото:Zx-6r 636 06, Er-6n 13

Отправлено 12 Октябрь 2016 — 00:19

Ну, что, народ, приступил я к переводу инструкции по ремонту. Быстро не ждите, объём титанический!

Бесконечно ценный материал будет, колоссальная работа предстоит! Надеюсь, что все у тебя пойдет как по маслу в этом деле!

- Наверх

#12

Валентин_Н

Валентин_Н

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Ярославский

- Мото:ER-6F ’13

Отправлено 12 Октябрь 2016 — 12:47

Бесконечно ценный материал будет, колоссальная работа предстоит! Надеюсь, что все у тебя пойдет как по маслу в этом деле!

Очень круто!

Я когда каталог на запчасти распечатал и сброшюровал, на работе все автомобилисты обзавидовались…

- Наверх

#13

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 03 Декабрь 2016 — 11:11

Давно я новостей не писал по теме, всё руки не доходили.

Наконец дело по переводу мануала хоть немного продвинулось.

Оказалось, что всё гораздо сложнее, чем мне представлялось сначала. Дело в том, что буржуйская система нумерации страниц и каталогизации содержания представляется мне крайне неудобной. Посудите сами, если всего в книге 500 листов, то где находится лист 4-28 или 1-18 совершенно непонятно. А вот лист 250, понятно и ежу, находится в середине. Буду перерабатывать под привычную нам нумерацию, хоть это и дополнительный объём работы.

А пока на ваш суд выношу несколько страниц мануала. Понимаю, что хвастаться пока особо нечем, но, может вы замечания какие сделаете или идею подкинете…

- BazonXGK это нравится

- Наверх

#14

vyrcnk

vyrcnk

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Краснодар

- Мото:Honda CB1300SF Boldor 2007

Отправлено 05 Декабрь 2016 — 20:21

Хорошее дело! У меня с английским не очень. Вопрос по давлению в шинах. Неужели его раз в год проверять или через каждые 12 000 км? Может там что-то еще имелось ввиду? Встречал общие рекомендации для мотоцикла проверять перед каждым выездом. Лично мне каждый день это делать лень, хоть уже попадал. При экстренном торможении мотоцикл повел себя не так, как ожидалось. Хоть и закончилось все тогда нормально. Оказалось дело было в сниженном давлении. «На глаз» такое изменение давления не определить, а сцепные свойства, управляемость и износ могут измениться в больших пределах.

- Наверх

#15

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 05 Декабрь 2016 — 22:28

Там имелось ввиду именно давление в шинах. А проверять его надо гораздо чаще. Особенно, если катаешь каждый день.

Я раз в 2-3 недели обязательно на заправках проверяюсь. И, если надо, подкачиваю (обычно изношенные баллоны плохо держат давление).

- Наверх

#16

Руслан Казанский

Руслан Казанский

-

- Читатели

- 3 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Севастополь

- Мото:Kawasaki ER6-N

Отправлено 06 Декабрь 2016 — 03:29

МЕГА-Человечище! Респект!

Отправлено с моего iPhone используя Tapatalk

- olv956 это нравится

- Наверх

#17

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 01 Февраль 2017 — 18:13

Нерадостную весть я вам собираюсь сообщить. Обратил внимание, что осталось ещё 581 страница. Если я каждый день перевожу по 2 страницы, нескоро вы ещё дождётесь от меня результата.

Может имеет смысл разбить весь мануал на отдельные книги и выпускать по мере готовности? Или лучше целиком?

- Alpine это нравится

- Наверх

#18

untitled

untitled

- Пол:Мужчина

- Страна:Россия

- Город:Йошкар-Ола

- Мото:Kawasaki gpz400r, Kawasaki ER-6f

Отправлено 01 Февраль 2017 — 18:57

Может имеет смысл разбить весь мануал на отдельные книги и выпускать по мере готовности? Или лучше целиком?

Мое мнение — разбить на отдельные книги, кому нужно будет целиком, тот по завершению перевода объединит все книги в одну.

А если сделать отдельные книги по разделам, то будет проще работать с ними, т к по названию файла можно будет обратиться к тому или иному разделу.

- Наверх

#19

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 10 Март 2017 — 17:28

Как обещал, выложил в доступ полностью переведённые и оформленные 1 и 2 часть мануала.

Ссылка также доступна и в первом сообщении темы.

Подустал немного…

- Everybody, SShMeL, Валентин_Н и 3 другим это нравится

- Наверх

#20

vyrcnk

vyrcnk

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Краснодар

- Мото:Honda CB1300SF Boldor 2007

Отправлено 10 Март 2017 — 18:49

Великое и очень нужное дело! Благодарю!

- Наверх

Motorcycle

Service Manual

Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or procedure.

•Bend the pages back to match the black tab of the desired chapter number with the black tab on the edge at each table of contents page.

•Refer to the sectional table of contents for the exact pages to locate the specific topic required.

|

General Information |

1 |

j |

|

Periodic Maintenance |

2 |

j |

|

Fuel System (DFI) |

3 |

j |

|

Cooling System |

4 |

j |

|

Engine Top End |

5 |

j |

|

Clutch |

6 |

j |

|

Engine Lubrication System |

7 |

j |

|

Engine Removal/Installation |

8 |

j |

|

Crankshaft/Transmission |

9 |

j |

|

Wheels/Tires |

10 |

j |

|

Final Drive |

11 |

j |

|

Brakes |

12 |

j |

|

Suspension |

13 |

j |

|

Steering |

14 |

j |

|

Frame |

15 |

j |

|

Electrical System |

16 |

j |

|

Appendix |

17 |

j |

ER-6n

ER-6n ABS

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of Quality Assurance Division/Consumer Products & Machinery Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such changes to products manufactured previously. See your Motorcycle dealer for the latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication. Illustrations and photographs in this publication are intended for reference use only and may not depict actual model component parts.

|

© 2008 Kawasaki Heavy Industries, Ltd. |

First Edition (1) : Nov. 10, 2008 (M) |

LIST OF ABBREVIATIONS

|

A |

ampere(s) |

lb |

pound(s) |

|

ABDC |

after bottom dead center |

m |

meter(s) |

|

AC |

alternating current |

min |

minute(s) |

|

ATDC |

after top dead center |

N |

newton(s) |

|

BBDC |

before bottom dead center |

Pa |

pascal(s) |

|

BDC |

bottom dead center |

PS |

horsepower |

|

BTDC |

before top dead center |

psi |

pound(s) per square inch |

|

°C |

degree(s) Celsius |

r |

revolution |

|

DC |

direct current |

rpm |

revolution(s) per minute |

|

F |

farad(s) |

TDC |

top dead center |

|

°F |

degree(s) Fahrenheit |

TIR |

total indicator reading |

|

ft |

foot, feet |

V |

volt(s) |

|

g |

gram(s) |

W |

watt(s) |

|

h |

hour(s) |

Ω |

ohm(s) |

|

L |

liter(s) |

||

COUNTRY AND AREA CODES

|

AT |

Austria |

GB |

United Kingdom |

|

AU |

Australia |

MY |

Malaysia |

|

BR |

Brazil |

SEA |

South East Asia |

|

CA |

Canada |

TH |

Thailand |

|

CAL |

California |

US |

United States |

|

CH |

Switzerland |

WVTA (FULL H) |

WVTA Model with Honeycomb Catalytic |

|

Converter (Full Power) |

|||

|

DE |

Germany |

GB WVTA |

WVTA Model with Honeycomb Catalytic |

|

(FULL H) |

Converter (Left Side Traffic, Full Power) |

||

|

EUR |

Europe |

||

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of the United States Environmental Protection Agency and California Air Resources Board. Additionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance with applicable regulations of the California Air Resources Board on vehicles sold in California only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the vapors are routed through an oil separator to the inlet side of the engine. While the engine is operating, the vapors are drawn into combustion chamber, where they are burned along with the fuel and air supplied by the fuel injection system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust of this motorcycle. The fuel, ignition, and exhaust systems of this motorcycle have been carefully designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

The exhaust system of this model motorcycle manufactured primarily for sale in California includes a catalytic converter system.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. Instead, fuel vapors are routed into the running engine to be burned, or stored in a canister when the engine is stopped. Liquid fuel is caught by a vapor separator and returned to the fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is commonly referred to as the Act’s “tampering provisions”.

“Sec. 203(a) The following acts and the causing thereof are prohibited.

(3)(A) for any person to remove or render inoperative any device or element of design installed on or in a motor vehicle or motor vehicle engine in compliance with regulations under this title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer knowingly to remove or render inoperative any such device or element of design after such sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading motor vehicles or motor vehicle engines, or who operates a fleet of motor vehicles knowingly to remove or render inoperative any device or element of design installed on or in a motor vehicle or motor vehicle engine in compliance with regulations under this title following its sale and delivery to the ultimate purchaser…”

NOTE

○The phrase “remove or render inoperative any device or element of design” has been generally interpreted as follows.

1.Tampering does not include the temporary removal or rendering inoperative of devices or elements of design in order to perform maintenance.

2.Tampering could include.

a.Maladjustment of vehicle components such that the emission standards are exceeded.

b.Use of replacement parts or accessories which adversely affect the performance or durability of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the standards.

d.Permanently removing, disconnecting, or rendering inoperative any component or element of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW, THE VIOLATION OF WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING $10 000 PER VIOLATION.

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof. (1) The removal or rendering inoperative by any person other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below.

•Replacement of the original exhaust system or muffler with a component not in compliance with Federal regulations.

•Removal of the muffler(s) or any internal portion of the muffler(s).

•Removal of the air box or air box cover.

•Modifications to the muffler(s) or air inlet system by cutting, drilling, or other means if such modifications result in increased noise levels.

Foreword

This manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out maintenance and repair satisfactorily. Whenever the owner has insufficient experience or doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures before starting work, and then do the work carefully in a clean area. Whenever special tools or equipment are specified, do not use makeshift tools or equipment. Precision measurements can only be made if the proper instruments are used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period, we recommend that all repairs and scheduled maintenance be performed in accordance with this service manual. Any owner maintenance or repair procedure not performed in accordance with this manual may void the warranty.

To get the longest life out of your vehicle.

•Follow the Periodic Maintenance Chart in the Service Manual.

•Be alert for problems and non-scheduled maintenance.

•Use proper tools and genuine Kawasaki Motorcycle parts. Special tools, gauges, and testers that are necessary when servicing Kawasaki motorcycles are introduced by the Service Manual. Genuine parts provided as spare parts are listed in the Parts Catalog.

•Follow the procedures in this manual carefully. Don’t take shortcuts.

•Remember to keep complete records of maintenance and repair with dates and any new parts installed.

How to Use This Manual

In this manual, the product is divided into its major systems and these systems make up the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system and assists in locating their chapters. Each chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate the Electrical System chapter. Then, use the Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and CAUTION symbols, heed their instructions! Always follow safe operating and maintenance practices.

This warning symbol identifies special instructions or procedures which, if not correctly followed, could result in personal injury, or loss of life.

CAUTION

This caution symbol identifies special instructions or procedures which, if not strictly observed, could result in damage to or destruction of equipment.

This manual contains four more symbols (in addition to WARNING and CAUTION) which will help you distinguish different types of information.

NOTE

○This note symbol indicates points of particular interest for more efficient and convenient operation.

•Indicates a procedural step or work to be done.

○Indicates a procedural sub-step or how to do the work of the procedural step it follows. It also precedes the text of a NOTE.

In most chapters an exploded view illustration of the system components follows the Table of Contents. In these illustrations you will find the instructions indicating which parts require specified tightening torque, oil, grease or a locking agent during assembly.

GENERAL INFORMATION 1-1

General Information |

|

|

Table of Contents |

|

|

1 |

|

|

Before Servicing ……………………………………………………………………………………………………… |

1-2 |

|

Model Identification………………………………………………………………………………………………….. |

1-7 |

|

General Specifications……………………………………………………………………………………………… |

1-10 |

|

Unit Conversion Table ……………………………………………………………………………………………… |

1-13 |

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever necessary. This section explains the items that require particular attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following:

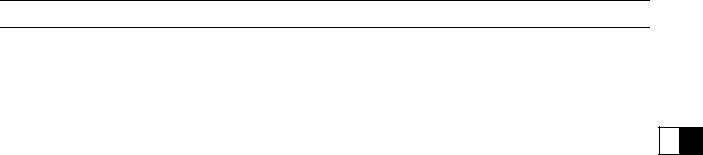

Battery Ground

Before completing any service on the motorcycle, disconnect the battery cables from the battery to prevent the engine from accidentally turning over. Disconnect the ground cable (–) first and then the positive (+). When completed with the service, first connect the positive (+) cable to the positive (+) terminal of the battery then the negative (–) cable to the negative terminal.

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury from possible sharp edges on the parts.

Solvent

Use a high-flash point solvent when cleaning parts. High -flash point solvent should be used according to directions of the solvent manufacturer.

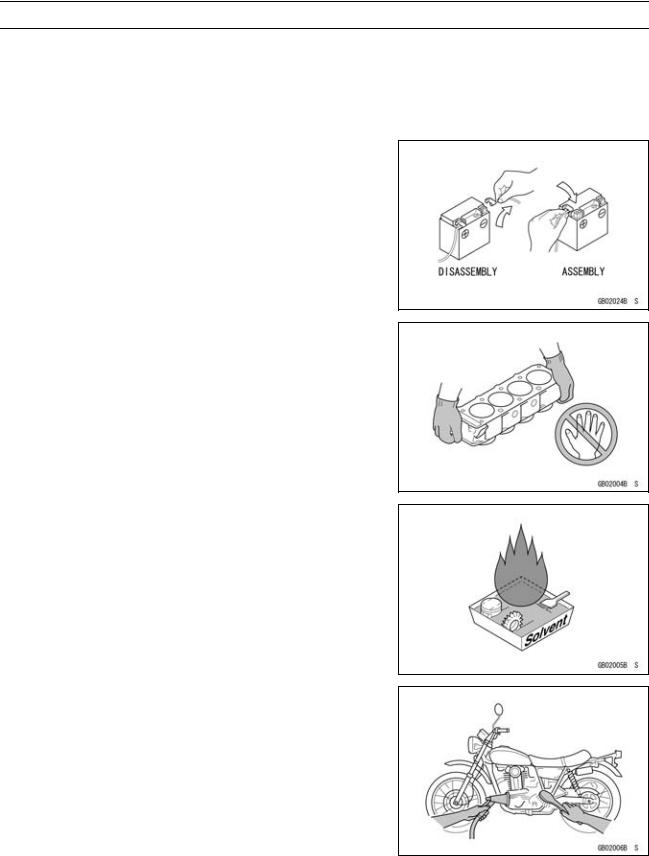

Cleaning Vehicle before Disassembly

Clean the vehicle thoroughly before disassembly. Dirt or other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease performance of the vehicle.

GENERAL INFORMATION 1-3

Before Servicing

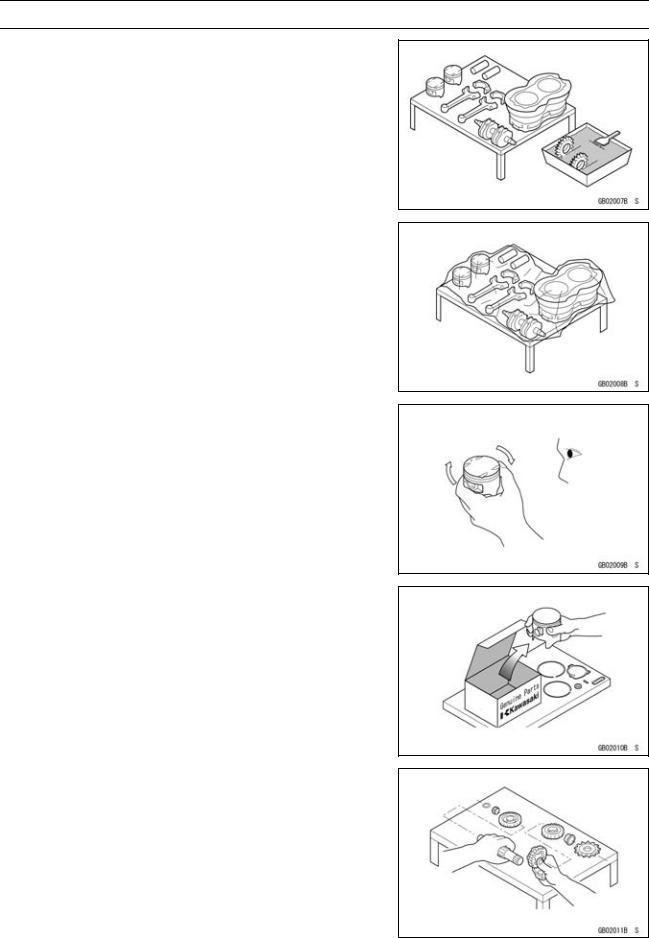

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been cleaned, store the parts in a clean area. Put a clean cloth or plastic sheet over the parts to protect from any foreign materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections of this manual for service limits on individual parts. Replace the parts if any damage has been found or if the part is beyond its service limit.

Replacement Parts

Replacement parts must be KAWASAKI genuine or recommended by KAWASAKI. Gaskets, O-rings, oil seals, grease seals, circlips or cotter pins must be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service Manual, follow the procedures given.

1-4 GENERAL INFORMATION

Before Servicing

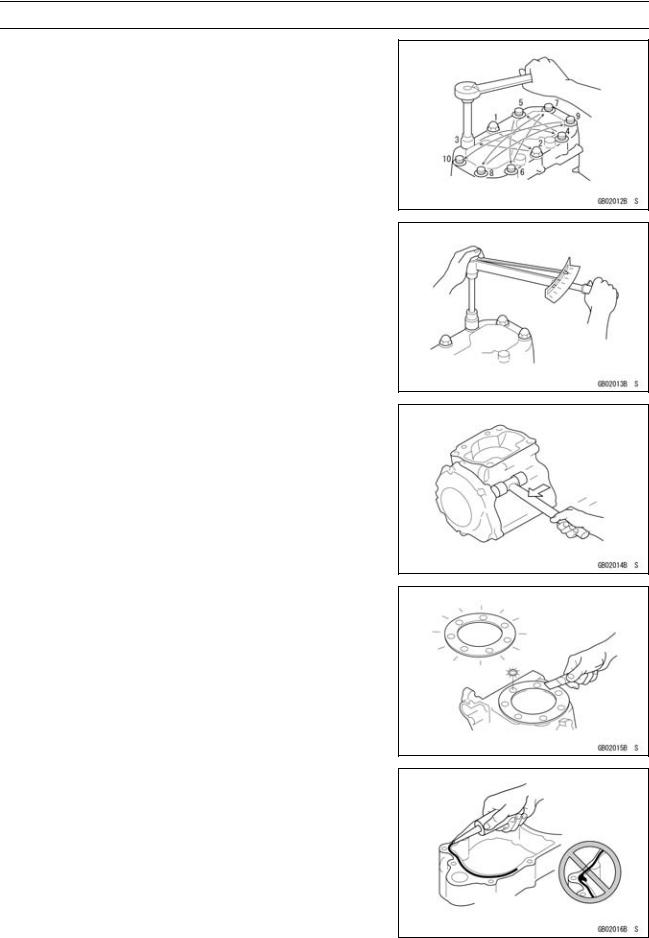

Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can lead to malfunction. Conversely when loosening the bolts, nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening sequence is not indicated, tighten the fasteners alternating diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may lead to serious damage. Tighten fasteners to the specified torque using a good quality torque wrench. Often, the tightening sequence is followed twice-initial tightening and final tightening with torque wrench.

Force

Use common sense during disassembly and assembly, excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non -permanent locking agent applied using an impact driver. Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing surfaces thoroughly so that no gasket material or other material remains. Install new gaskets and replace used O-rings when re-assembling

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a Non-permanent Locking Agent, clean the surfaces so that no oil residue remains before applying liquid gasket or non-permanent locking agent. Do not apply them excessively. Excessive application can clog oil passages and cause serious damage.

GENERAL INFORMATION 1-5

Before Servicing

Press

For items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use smooth movements when installing.

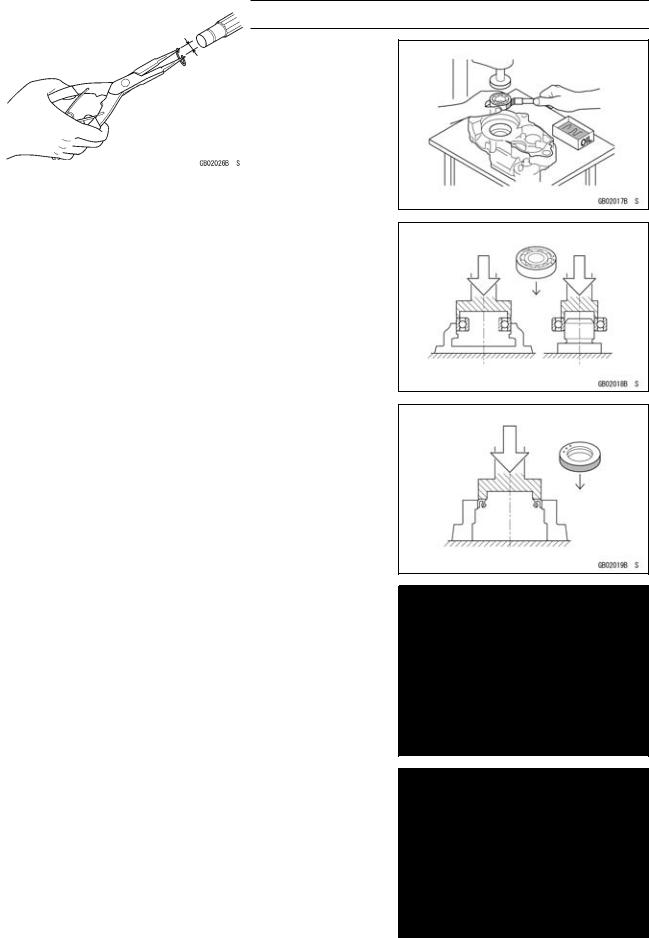

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is absolutely necessary. Replace with new ones whenever removed. Press bearings with the manufacturer and size marks facing out. Press the bearing into place by putting pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal is necessary. Replace with new ones whenever removed. Press new oil seals with manufacture and size marks facing out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing the seal.

Circlips, Cotter Pins

Replace circlips or cotter pins that were removed with new ones. Take care not to open the clip excessively when installing to prevent deformation.

1-6 GENERAL INFORMATION

Before Servicing

Lubrication

It is important to lubricate rotating or sliding parts during assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed from output side).

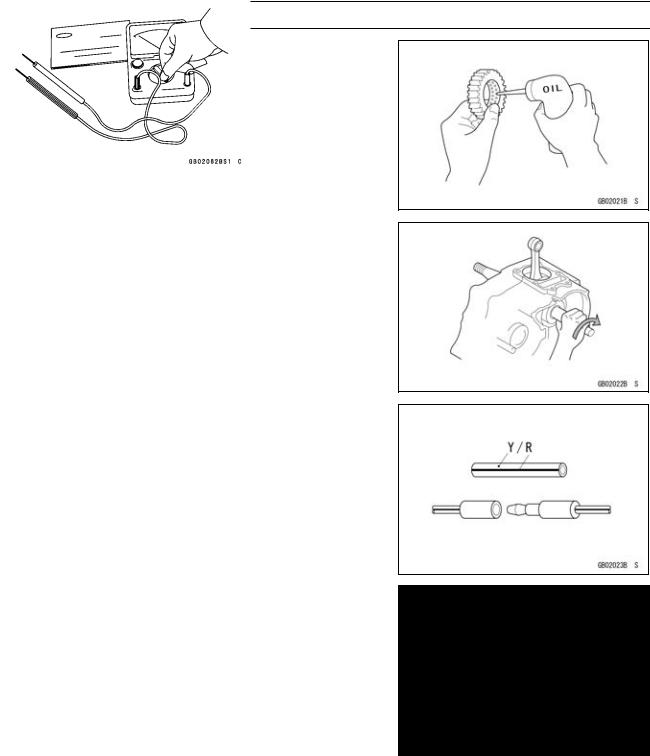

Electrical Leads

A two-color lead is identified first by the primary color and then the stripe color. Unless instructed otherwise, electrical leads must be connected to those of the same color.

Instrument

Use a meter that has enough accuracy for an accurate measurement. Read the manufacture’s instructions thoroughly before using the meter. Incorrect values may lead to improper adjustments.

GENERAL INFORMATION 1-7

Model Identification

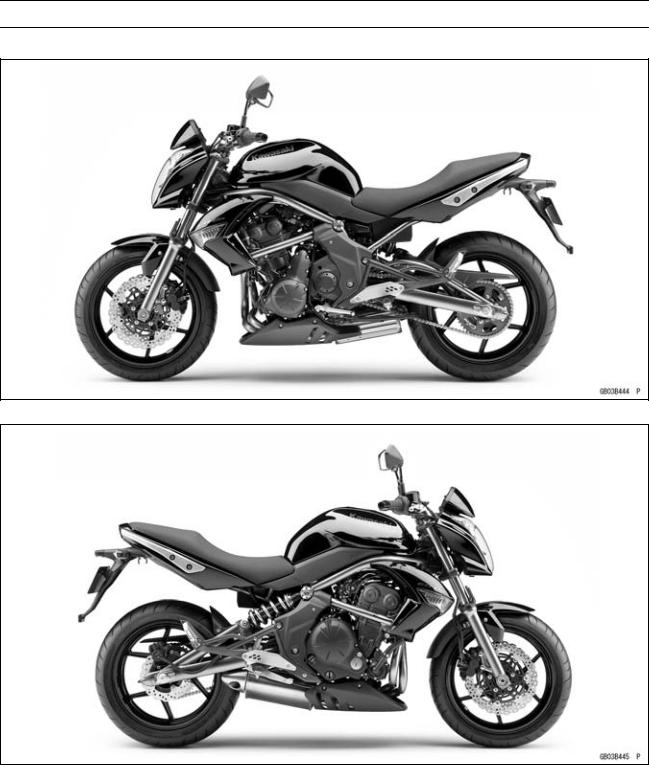

ER650C9F (EUR Models) Left Side View

ER650C9F (EUR Models) Right Side View

1-8 GENERAL INFORMATION

Model Identification

ER650C9F (US, CA Models) Left Side View

ER650C9F (US, CA Models) Right Side View

GENERAL INFORMATION 1-9

Model Identification

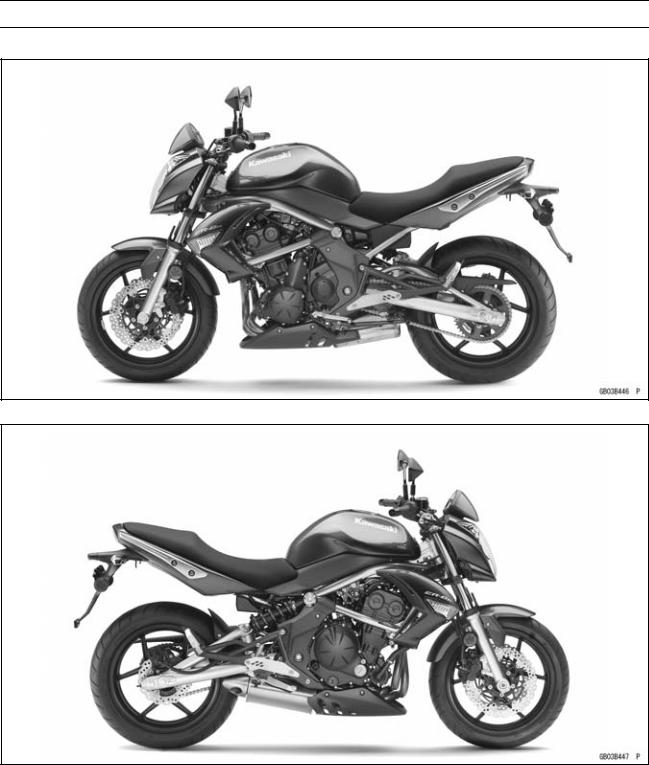

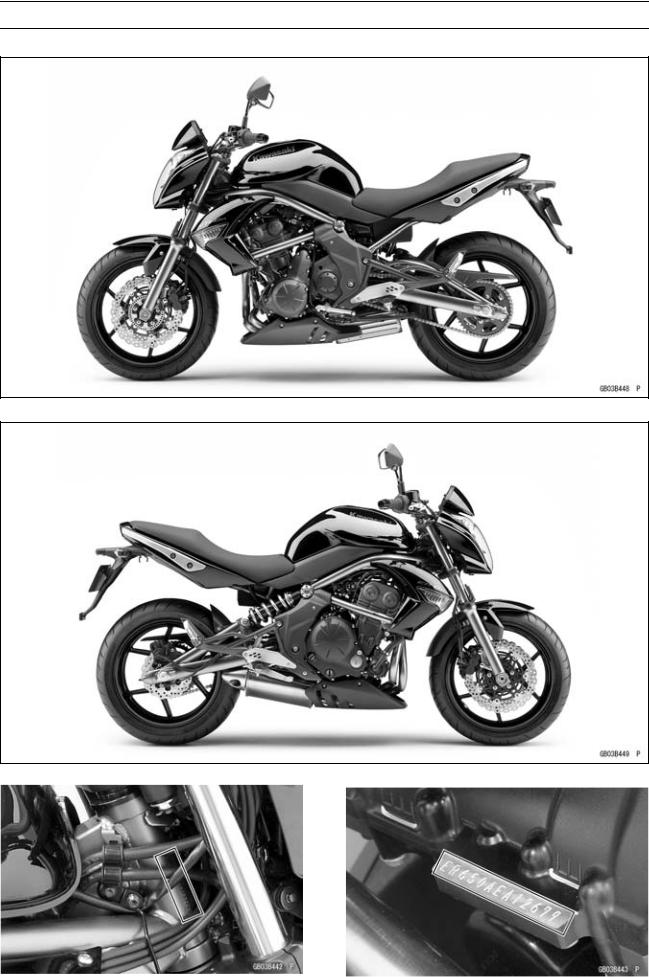

ER650D9F Left Side View

ER650D9F Right Side View

|

Frame Number |

Engine Number |

|

1-10 GENERAL INFORMATION

General Specifications

|

Items |

ER650C9F, ER650D9F |

|

|

Dimensions |

||

|

Overall Length |

2 100 mm (82.68 in.) |

|

|

Overall Width |

760 mm (29.9 in.) |

|

|

Overall Height |

1 100 mm (43.31 in.) |

|

|

Wheelbase |

1 405 mm (55.31 in.) |

|

|

Road Clearance |

140 mm (5.51 in.) |

|

|

Seat Height |

785 mm (30.9 in.) |

|

|

Curb Mass: |

||

|

ER650C Models: |

200 kg (441 lb) |

|

|

Front |

100 kg (221 lb) |

|

|

Rear |

100 kg (221 lb) |

|

|

ER650D Models: |

204 kg (450 lb) |

|

|

Front |

101 kg (223 lb) |

|

|

Rear |

103 kg (227 lb) |

|

|

Fuel Tank Capacity |

15.5 L (4.10 US gal.) |

|

|

Performance |

||

|

Minimum Turning Radius |

2.7 m (8.9 ft) |

|

|

Engine |

||

|

Type |

4-stroke, DOHC, 2-cylinder |

|

|

Cooling System |

Liquid-cooled |

|

|

Bore and Stroke |

83.0 × 60.0 mm (3.27 × 2.36 in.) |

|

|

Displacement |

649 cm³ (39.6 cu in.) |

|

|

Compression Ratio |

11.3 : 1 |

|

|

Maximum Horsepower |

53 kW (72 PS) @8 500 r/min (rpm) |

|

|

(MY) 52 kW (71 PS) @8 000 r/min (rpm) |

||

|

(US, CA, CAL) – – – |

||

|

Maximum Torque |

66 N·m (6.7 kgf·m, 49 ft·lb) @7 000 r/min (rpm) |

|

|

(US, CA, CAL) – – – |

||

|

Carburetion System |

FI (Fuel Injection), KEIHIN TTK38 × 2 |

|

|

Starting System |

Electric starter |

|

|

Ignition System |

Battery and coil (transistorized) |

|

|

Timing Advance |

Electronically advanced (IC igniter in ECU) |

|

|

Ignition Timing |

From 10° BTDC @1 300 r/min (rpm) |

|

|

To 34° BTDC @5 000 r/min (rpm) |

||

|

Spark Plug |

NGK CR9EIA-9 |

|

|

Cylinder Numbering Method |

Left to right, 1-2 |

|

|

Firing Order |

1-2 |

|

|

Valve Timing: |

||

|

Inlet: |

||

|

Open |

31° BTDC |

|

|

Close |

61° ABDC |

|

|

Duration |

272° |

|

|

GENERAL INFORMATION 1-11 |

|

|

General Specifications |

|

|

Items |

ER650C9F, ER650D9F |

|

Exhaust: |

|

|

Open |

50° BBDC |

|

Close |

30° ATDC |

|

Duration |

260° |

|

Lubrication System |

Forced lubrication (semi-dry sump) |

|

Engine Oil: |

|

|

Grade |

API SE, SF or SG |

|

API SH, SJ, SL or SM with JASO MA, MA1 or MA2 |

|

|

Viscosity |

SAE 10W-40 |

|

Capacity |

2.4 L (2.5 US qt) |

|

Drive Train |

|

|

Primary Reduction System: |

|

|

Type |

Gear |

|

Reduction Ratio |

2.095 (88/42) |

|

Clutch Type |

Wet multi disc |

|

Transmission: |

|

|

Type |

6-speed, constant mesh, return shift |

|

Gear Ratios: |

|

|

1st |

2.438 (39/16) |

|

2nd |

1.714 (36/21) |

|

3rd |

1.333 (32/24) |

|

4th |

1.111 (30/27) |

|

5th |

0.966 (28/29) |

|

6th |

0.852 (23/27) |

|

Final Drive System: |

|

|

Type |

Chain drive |

|

Reduction Ratio |

3.067 (46/15) |

|

Overall Drive Ratio |

5.473 @Top gear |

|

Frame |

|

|

Type |

Tubular, diamond |

|

Caster (Rake Angle) |

24.5° |

|

Trail |

102 mm (4.02 in.) |

|

Front Tire: |

|

|

Type |

Tubeless |

|

Size |

120/70 ZR17 M/C (58W) |

|

Rim Size |

17 × 3.50 |

|

Rear Tire: |

|

|

Type |

Tubeless |

|

Size |

160/60 ZR17 M/C (69W) |

|

Rim Size |

17 × 4.50 |

|

Front Suspension: |

|

|

Type |

Telescopic fork |

|

Wheel Travel |

120 mm (4.72 in.) |

1-12 GENERAL INFORMATION

General Specifications

|

Items |

ER650C9F, ER650D9F |

|

Rear Suspension: |

|

|

Type |

Swingarm |

|

Wheel Travel |

125 mm (4.92 in.) |

|

Brake Type: |

|

|

Front |

Dual discs |

|

Rear |

Single disc |

|

Electrical Equipment |

|

|

Battery |

12 V 10 Ah |

|

Headlight: |

|

|

Type |

Semi-sealed beam |

|

Bulb: |

|

|

High |

12 V 55 W + 55 W (quartz-halogen) |

|

Low |

12 V 55 W (quartz-halogen) |

|

Tail/Brake Light |

LED |

|

Alternator: |

|

|

Type |

Three-phase AC |

|

Rated Output |

24 A/14 V @5 000 r/min (rpm) |

Specifications are subject to change without notice, and may not apply to every country.

GENERAL INFORMATION 1-13

Unit Conversion Table

|

Prefixes for Units: |

Units of Length: |

|

Prefix |

Symbol |

Power |

||

|

mega |

M |

× 1 000 |

000 |

|

|

kilo |

k |

× |

1 000 |

|

|

centi |

c |

× |

0.01 |

|

|

milli |

m |

× |

0.001 |

|

|

micro |

µ |

× |

0.000001 |

Units of Mass:

|

kg |

× |

2.205 |

= |

lb |

|

g |

× |

0.03527 |

= |

oz |

Units of Volume:

|

L |

× |

0.2642 |

= |

gal (US) |

|

L |

× |

0.2200 |

= |

gal (imp) |

|

L |

× |

1.057 |

= |

qt (US) |

|

L |

× |

0.8799 |

= |

qt (imp) |

|

L |

× |

2.113 |

= |

pint (US) |

|

L |

× |

1.816 |

= |

pint (imp) |

|

mL |

× |

0.03381 |

= |

oz (US) |

|

mL |

× |

0.02816 |

= |

oz (imp) |

|

mL |

× |

0.06102 |

= |

cu in |

Units of Force:

|

km |

× |

0.6214 |

= |

mile |

|

m |

× |

3.281 |

= |

ft |

|

mm |

× |

0.03937 |

= |

in |

Units of Torque:

|

N·m |

× |

0.1020 |

= |

kgf·m |

|

N·m |

× |

0.7376 |

= |

ft·lb |

|

N·m |

× |

8.851 |

= |

in·lb |

|

kgf·m |

× |

9.807 |

= |

N·m |

|

kgf·m |

× |

7.233 |

= |

ft·lb |

|

kgf·m |

× |

86.80 |

= |

in·lb |

Units of Pressure:

|

kPa |

× |

0.01020 |

= |

kgf/cm² |

|

kPa |

× |

0.1450 |

= |

psi |

|

kPa |

× |

0.7501 |

= |

cmHg |

|

kgf/cm² |

× |

98.07 |

= |

kPa |

|

kgf/cm² |

× |

14.22 |

= |

psi |

|

cmHg |

× |

1.333 |

= |

kPa |

Units of Speed:

km/h × 0.6214 = mph

Units of Power:

|

N |

× |

0.1020 |

= |

kg |

kW |

× |

1.360 |

= |

PS |

||

|

N |

× |

0.2248 |

= |

lb |

|||||||

|

kW |

× |

1.341 |

= |

HP |

|||||||

|

kg |

× |

9.807 |

= |

N |

|||||||

|

PS |

× |

0.7355 |

= |

kW |

|||||||

|

kg |

× |

2.205 |

= |

lb |

|||||||

|

PS |

× |

0.9863 |

= |

HP |

|||||||

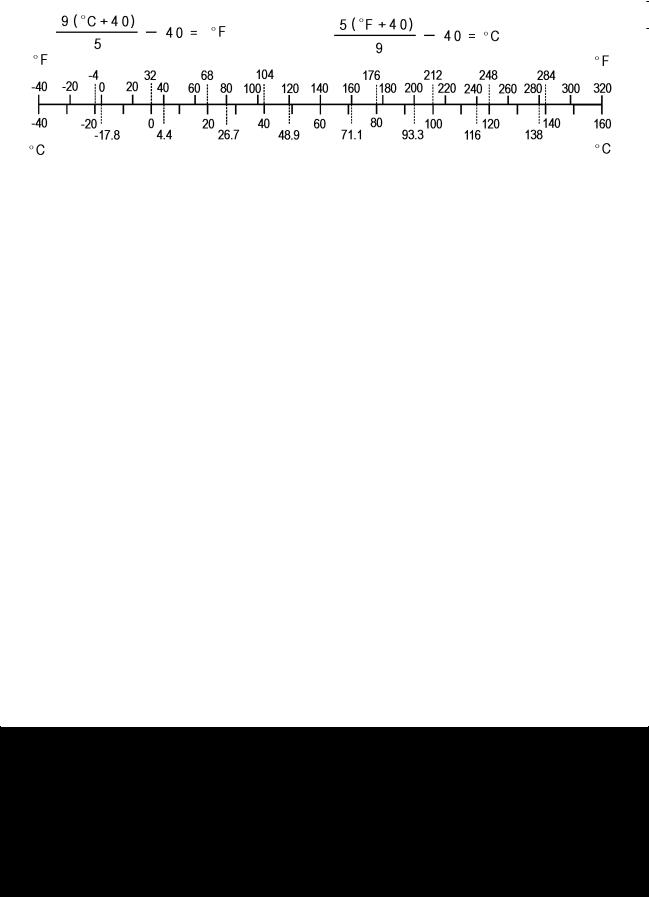

Units of Temperature:

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

|

Periodic Maintenance Chart ……………………………………………………………………………………… |

2-3 |

||

|

2 |

|||

|

Torque and Locking Agent………………………………………………………………………………………… |

2-6 |

||

|

Specifications |

2-12 |

||

|

Special Tools ………………………………………………………………………………………………………….. |

2-14 |

||

|

Periodic Maintenance Procedures……………………………………………………………………………… |

2-15 |

||

|

Fuel System (DFI)…………………………………………………………………………………………………. |

2-15 |

||

|

Air Cleaner Element Cleaning………………………………………………………………………………. |

2-15 |

||

|

Throttle Control System Inspection……………………………………………………………………….. |

2-16 |

||

|

Engine Vacuum Synchronization Inspection…………………………………………………………… |

2-16 |

||

|

Idle Speed Inspection …………………………………………………………………………………………. |

2-18 |

||

|

Idle Speed Adjustment………………………………………………………………………………………… |

2-19 |

||

|

Fuel Hose Inspection (fuel leak, damage, installation condition) ……………………………….. |

2-19 |

||

|

Evaporative Emission Control System Inspection (CAL, SEA and TH Models) …………… |

2-19 |

||

|

Cooling System…………………………………………………………………………………………………….. |

2-20 |

||

|

Coolant Level Inspection……………………………………………………………………………………… |

2-20 |

||

|

Water Hose Damage and Installation Condition Inspection………………………………………. |

2-21 |

||

|

Engine Top End ……………………………………………………………………………………………………. |

2-21 |

||

|

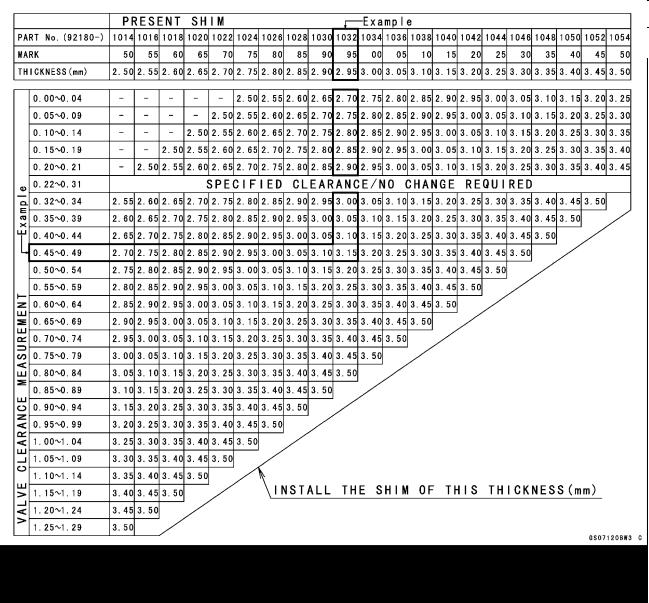

Valve Clearance Inspection …………………………………………………………………………………. |

2-21 |

||

|

Valve Clearance Adjustment………………………………………………………………………………… |

2-22 |

||

|

Air Suction System Damage Inspection…………………………………………………………………. |

2-25 |

||

|

Clutch………………………………………………………………………………………………………………….. |

2-25 |

||

|

Clutch Operation Inspection…………………………………………………………………………………. |

2-25 |

||

|

Wheels/Tires………………………………………………………………………………………………………… |

2-26 |

||

|

Air Pressure Inspection……………………………………………………………………………………….. |

2-26 |

||

|

Wheel/Tire Damage Inspection…………………………………………………………………………….. |

2-26 |

||

|

Tire Tread Wear, Abnormal Wear Inspection ………………………………………………………….. |

2-26 |

||

|

Wheel Bearing Damage Inspection ………………………………………………………………………. |

2-27 |

||

|

Final Drive……………………………………………………………………………………………………………. |

2-28 |

||

|

Drive Chain Lubrication Condition Inspection …………………………………………………………. |

2-28 |

||

|

Drive Chain Slack Inspection ……………………………………………………………………………….. |

2-28 |

||

|

Drive Chain Slack Adjustment ……………………………………………………………………………… |

2-29 |

||

|

Wheel Alignment Inspection ………………………………………………………………………………… |

2-30 |

||

|

Drive Chain Wear Inspection ……………………………………………………………………………….. |

2-30 |

||

|

Chain Guide Inspection……………………………………………………………………………………….. |

2-31 |

||

|

Brake System ………………………………………………………………………………………………………. |

2-31 |

||

|

Brake Fluid Leak (Brake Hose and Pipe) Inspection ……………………………………………….. |

2-31 |

||

|

Brake Hose and Pipe Damage and Installation Condition Inspection…………………………. |

2-32 |

||

|

Brake Fluid Level Inspection………………………………………………………………………………… |

2-32 |

||

|

Brake Pad Wear Inspection …………………………………………………………………………………. |

2-33 |

||

|

Brake Operation Inspection …………………………………………………………………………………. |

2-34 |

||

|

Brake Light Switch Operation Inspection ……………………………………………………………….. |

2-34 |

||

|

Suspensions ………………………………………………………………………………………………………… |

2-35 |

||

|

Front Forks/Rear Shock Absorber Operation Inspection ………………………………………….. |

2-35 |

||

|

Front Fork Oil Leak Inspection……………………………………………………………………………… |

2-35 |

||

|

Rear Shock Absorber Oil Leak Inspection ……………………………………………………………… |

2-35 |

||

|

Steering System …………………………………………………………………………………………………… |

2-36 |

||

|

Steering Play Inspection ……………………………………………………………………………………… |

2-36 |

||

|

Steering Play Adjustment…………………………………………………………………………………….. |

2-36 |

||

|

Steering Stem Bearing Lubrication ……………………………………………………………………….. |

2-37 |

||

|

Electrical System ………………………………………………………………………………………………….. |

2-38 |

2-2 PERIODIC MAINTENANCE

|

Lights and Switches Operation Inspection……………………………………………………………… |

2-38 |

|

Headlight Aiming Inspection ………………………………………………………………………………… |

2-40 |

|

Sidestand Switch Operation Inspection …………………………………………………………………. |

2-41 |

|

Engine Stop Switch Operation Inspection………………………………………………………………. |

2-42 |

|

Others …………………………………………………………………………………………………………………. |

2-43 |

|

Chassis Parts Lubrication ……………………………………………………………………………………. |

2-43 |

|

Bolts, Nuts and Fasteners Tightness Inspection……………………………………………………… |

2-44 |

|

Replacement Parts ……………………………………………………………………………………………….. |

2-45 |

|

Air Cleaner Element Replacement………………………………………………………………………… |

2-45 |

|

Fuel Hose Replacement ……………………………………………………………………………………… |

2-45 |

|

Coolant Change …………………………………………………………………………………………………. |

2-46 |

|

Radiator Hose and O-ring Replacement………………………………………………………………… |

2-48 |

|

Engine Oil Change……………………………………………………………………………………………… |

2-48 |

|

Oil Filter Replacement ………………………………………………………………………………………… |

2-49 |

|

Brake Hose and Pipe Replacement………………………………………………………………………. |

2-50 |

|

Brake Fluid Change ……………………………………………………………………………………………. |

2-51 |

|

Master Cylinder Rubber Parts Replacement ………………………………………………………….. |

2-52 |

|

Caliper Rubber Parts Replacement ………………………………………………………………………. |

2-53 |

|

Spark Plug Replacement …………………………………………………………………………………….. |

2-56 |

PERIODIC MAINTENANCE 2-3

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition.The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

|

FREQUENCY |

Whichever |

* ODOMETER READING |

|||||||||||||

|

comes first |

× 1 000 km |

See |

|||||||||||||

|

(× 1 000 mile) |

|||||||||||||||

|

Page |

|||||||||||||||

|

1 |

6 |

12 |

18 |

24 |

30 |

36 |

|||||||||

|

ITEM |

Every |

(0.6) |

(3.75) |

(7.5) |

(11.25) |

(15) |

(18.75) |

(22.5) |

|||||||

|

Fuel System |

|||||||||||||||

|

Air cleaner element — clean |

• |

• |

• |

2–15 |

|||||||||||

|

Throttle control system (play, |

year |

• |

• |

• |

• |

2–16 |

|||||||||

|

smooth return, no drag) — inspect |

|||||||||||||||

|

Engine vacuum synchronization |

• |

• |

• |

2–16 |

|||||||||||

|

— inspect |

|||||||||||||||

|

Idle speed — inspect |

• |

• |

• |

• |

2–18 |

||||||||||

|

Fuel leak (fuel hose and pipe) — |

year |

• |

• |

• |

• |

2–19 |

|||||||||

|

inspect |

|||||||||||||||

|

Fuel hose and pipe damage — |

year |

• |

• |

• |

• |

2–19 |

|||||||||

|

inspect |

|||||||||||||||

|

Fuel hose and pipe installation |

year |

• |

• |

• |

• |

2–19 |

|||||||||

|

condition — inspect |

|||||||||||||||

|

Evaporative emission control |

• |

• |

• |

• |

• |

• |

• |

||||||||

|

system function (CAL, TH, SEA |

2–19 |

||||||||||||||

|

Models) — inspection |

|||||||||||||||

|

Cooling System |

|||||||||||||||

|

Coolant level — inspect |

• |

• |

• |

• |

2–20 |

||||||||||

|

Coolant leak (water hose and |

year |

• |

• |

• |

• |

2–21 |

|||||||||

|

pipe) — inspect |

|||||||||||||||

|

Water hose damage — inspect |

year |

• |

• |

• |

• |

2–21 |

|||||||||

|

Water hose installation condition |

year |

• |

• |

• |

• |

2–21 |

|||||||||

|

— inspect |

|||||||||||||||

|

Engine Top End |

|||||||||||||||

|

Valve |

US, CA, CAL |

• |

|||||||||||||

|

clearance — |

Models |

2–21 |

|||||||||||||

|

inspect |

Other than US, |

Every 42 000 km (26 250 mile) |

|||||||||||||

|

CA, CAL Models |

|||||||||||||||

|

Air suction system damage — |

• |

• |

• |

2–25 |

|||||||||||

|

inspect |

|||||||||||||||

|

Clutch |

|||||||||||||||

|

Clutch operation (play, |

• |

• |

• |

• |

|||||||||||

|

disengagement, engagement) — |

2–25 |

||||||||||||||

|

inspect |

|||||||||||||||

|

Wheels and Tires |

|||||||||||||||

|

Tire air pressure — inspect |

year |

• |

• |

• |

2–26 |

||||||||||

|

Wheel/tire damage — inspect |

• |

• |

• |

2–26 |

|||||||||||

|

Tire tread wear, abnormal wear |

• |

• |

• |

2–26 |

|||||||||||

|

— inspect |

|||||||||||||||

|

Wheel bearing damage — inspect |

year |

• |

• |

• |

2–27 |

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

|

FREQUENCY |

Whichever |

* ODOMETER READING |

|||||||||||||

|

comes first |

× 1 000 km |

See |

|||||||||||||

|

(× 1 000 mile) |

|||||||||||||||

|

Page |

|||||||||||||||

|

1 |

6 |

12 |

18 |

24 |

30 |

36 |

|||||||||

|

ITEM |

Every |

(0.6) |

(3.75) |

(7.5) |

(11.25) |

(15) |

(18.75) |

(22.5) |

|||||||

|

Final Drive |

|||||||||||||||

|

Drive chain lubrication condition |

Every 600 km (400 mile) |

2–28 |

|||||||||||||

|

— inspect # |

|||||||||||||||

|

Drive chain slack — inspect # |

Every 1 000 km (600 mile) |

2–28 |

|||||||||||||

|

Drive chain wear — inspect # |

• |

• |

• |

2–30 |

|||||||||||

|

Chain guide wear — inspect |

• |

• |

• |

2–31 |

|||||||||||

|

Brakes |

|||||||||||||||

|

Brake fluid leak (brake hose and |

year |

• |

• |

• |

• |

• |

• |

• |

2–31 |

||||||

|

pipe) — inspect |

|||||||||||||||

|

Brake hose and pipe damage — |

year |

• |

• |

• |

• |

• |

• |

• |

2–32 |

||||||

|

inspect |

|||||||||||||||

|

Brake hose and pipe installation |

year |

• |

• |

• |

• |

• |

• |

• |

2–32 |

||||||

|

condition — inspect |

|||||||||||||||

|

Brake fluid level — inspect |

6 months |

• |

• |

• |

• |

• |

• |

• |

2–32 |

||||||

|

Brake pad wear — inspect # |

• |

• |

• |

• |

• |

• |

2–33 |

||||||||

|

Brake operation (effectiveness, |

year |

• |

• |

• |

• |

• |

• |

• |

2–34 |

||||||

|

play, no drag) — inspect |

|||||||||||||||

|

Brake light switch operation — |

• |

• |

• |

• |

• |

• |

• |

2–34 |

|||||||

|

inspect |

|||||||||||||||

|

Suspension |

|||||||||||||||

|

Front forks/rear shock absorber |

• |

• |

• |

||||||||||||

|

operation (damping and smooth |

2–35 |

||||||||||||||

|

stroke) — inspect |

|||||||||||||||

|

Front forks/rear shock absorber |

year |

• |

• |

• |

2–35 |

||||||||||

|

oil leak — inspect |

|||||||||||||||

|

Steering |

|||||||||||||||

|

Steering play — inspect |

year |

• |

• |

• |

• |

2–36 |

|||||||||

|

Steering stem bearings — |

2 years |

• |

2–37 |

||||||||||||

|

lubricate |

|||||||||||||||

|

Electrical System |

|||||||||||||||

|

Lights and switches operation — |

year |

• |

• |

• |

2–38 |

||||||||||

|

inspect |

|||||||||||||||

|

Headlight aiming — inspect |

year |

• |

• |

• |

2–40 |

||||||||||

|

Sidestand switch operation — |

year |

• |

• |

• |

2–41 |

||||||||||

|

inspect |

|||||||||||||||

|

Engine stop switch operation — |

year |

• |

• |

• |

2–42 |

||||||||||

|

inspect |

|||||||||||||||

|

Others |

|||||||||||||||

|

Chassis parts — lubricate |

year |

• |

• |

• |

2–43 |

||||||||||

|

Bolts and nuts tightness — inspect |

• |

• |

• |

• |

2–44 |

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

PERIODIC MAINTENANCE 2-5

Periodic Maintenance Chart

Periodic Replacement Parts

|

FREQUENCY |

Whichever |

* ODOMETER |

|||||||||

|

comes |

READING |

||||||||||

|

× 1 000 km |

See |

||||||||||

|

first |

|||||||||||

|

(× 1 000 mile) |

|||||||||||

|

Page |

|||||||||||

|

1 |

12 |

24 |

36 |

48 |

|||||||

|

ITEM |

Every |

(0.6) |

(7.5) |

(15) |

(22.5) |

(30) |

|||||

|

Air cleaner element # — replace |

2 years |

2–45 |

|||||||||

|

Fuel hose — replace |

4 years |

• |

2–45 |

||||||||

|

Coolant — change |

3 years |

• |

2–46 |

||||||||

|

Radiator hose and O-ring — replace |

3 years |

• |

2–48 |

||||||||

|

Engine oil # — change |

year |

• |

• |

• |

• |

• |

2–48 |

||||

|

Oil filter — replace |

year |

• |

• |

• |

• |

• |

2–49 |

||||

|

Brake hose and pipe — replace |

4 years |

• |

2–50 |

||||||||

|

Brake fluid — change |

2 years |

• |

• |

2–51 |

|||||||

|

Rubber parts of master cylinder and caliper — replace |

4 years |

• |

2–52 |

||||||||

|

Spark plug — replace |

• |

• |

• |

• |

2–56 |

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque. EO: Apply engine oil.

L: Apply a non-permanent locking agent to the threads. Lh: Left-hand Threads

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10 : 1)

R:Replacement Parts

S:Follow the specified tightening sequence. Si: Apply silicone grease (ex. PBC grease).

SS:Apply silicone sealant.

|

Fastener |

Torque |

Remarks |

|||||

|

N·m |

kgf·m |

ft·lb |

|||||

|

Fuel System (DFI) |

|||||||

|

Crankshaft Sensor Bolts |

6.0 |

0.61 |

53 in·lb |

||||

|

Fuel Level Sensor Bolts |

6.9 |

0.70 |

61 in·lb |

L |

|||

|

Fuel Pump Bolts |

9.8 |

1.0 |

87 in·lb |

L, S |

|||

|

Oxygen Sensor (Equipped Models) |

44 |

4.5 |

32 |

||||

|

Speed Sensor Bolt |

7.8 |

0.80 |

69 in·lb |

L |

|||

|

Speed Sensor Bracket Bolts |

1.0 |

87 in·lb |

|||||

|

9.8 |

|||||||

|

Switch Housing Screws |

3.5 |

0.36 |

31 in·lb |

||||

|

Timing Rotor Bolt |

40 |

4.1 |

30 |

||||

|

Water Temperature Sensor |

12 |

1.2 |

106 in·lb |

||||

|

Cooling System |

|||||||

|

Baffle Plate Bolts |

5.9 |

0.60 |

52 in·lb |

||||

|

Radiator Bolt |

15 |

1.5 |

11 |

||||

|

Water Hose Clamp Screws |

2.0 |

0.20 |

18 in·lb |

||||

|

Thermostat Housing Bolts |

9.8 |

1.0 |

87 in·lb |

||||

|

Water Pump Cover Bolts |

87 in·lb |

||||||

|

9.8 |

1.0 |

||||||

|

Water Pump Drain Bolt |

9.8 |

1.0 |

87 in·lb |

||||

|

Water Pump Impeller Bolt |

9.8 |

1.0 |

87 in·lb |

||||

|

Water Temperature Sensor |

12 |

1.2 |

106 in·lb |

||||

|

Engine Top End |

|||||||

|

Air Suction Valve Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||||

|

Baffle Plate Bolts |

5.9 |

0.60 |

52 in·lb |

||||

|

Camshaft Cap Bolts |

12 |

1.2 |

106 in·lb |

S |

|||

|

Camshaft Chain Tensioner Cap Bolt |

20 |

2.0 |

15 |

||||

|

Camshaft Chain Tensioner Mounting Bolts |

9.8 |

1.0 |

87 in·lb |

||||

|

Camshaft Sprocket Bolts |

15 |

1.5 |

11 |

L |

|||

|

Cylinder Head Bolts (M10) |

56 |

5.7 |

41 |

MO, S |

|||

|

Cylinder Head Bolts (M6) |

12 |

1.2 |

106 in·lb |

S |

|||

|

Cylinder Head Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||||

|

Rear Camshaft Chain Guide Bolts |

20 |

2.0 |

15 |

L |

|||

|

Spark Plugs |

15 |

1.5 |

11 |

||||

PERIODIC MAINTENANCE 2-7

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Throttle Body Assy Holder Bolts |

12 |

1.2 |

106 in·lb |

||

|

Cylinder Bolt (M8) |

27.5 |

2.8 |

20 |

MO, S |

|

|

Cylinder Nut |

49 |

5.0 |

36 |

MO, S |

|

|

Cylinder Bolts (M6) |

106 in·lb |

S |

|||

|

12 |

1.2 |

||||

|

Exhaust Pipe Manifold Holder Nuts |

17 |

1.7 |

13 |

||

|

Muffler Body Mounting Bolt (Front) |

20 |

2.0 |

15 |

||

|

Muffler Body Mounting Bolt (Rear) |

20 |

2.0 |

15 |

||

|

Clutch |

|||||

|

Clutch Cable Clamp Bracket Bolt |

9.8 |

1.0 |

87 in·lb |

||

|

Clutch Cable Holder Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Clutch Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Clutch Hub Nut |

130 |

13.3 |

96 |

R |

|

|

Clutch Lever Clamp Bolts |

7.8 |

0.80 |

69 in·lb |

S |

|

|

Clutch Spring Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Timing Rotor Bolt Cap |

4.9 |

0.50 |

43 in·lb |

||

|

Oil Filler Plug |

– |

– |

– |

Hand-tighten |

|

|

Oil Pump Chain Guide Bolts |

12 |

1.2 |

106 in·lb |

L (1) |

|

|

Oil Pump Sprocket Bolt |

12 |

1.2 |

106 in·lb |

L, Lh |

|

|

Timing Inspection Cap |

3.9 |

0.40 |

35 in·lb |

||

|

Engine Lubrication System |

|||||

|

Engine Oil Drain Plug |

30 |

3.1 |

22 |

||

|

Filter Plate Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Holder Mounting Bolt |

25 |

2.5 |

18 |

L |

|

|

Lower Fairing Bracket Bolts |

12 |

1.2 |

106 in·lb |

L |

|

|

Oil Filter |

17.5 |

1.8 |

13 |

EO, R |

|

|

Oil Pan Bolts |

12 |

1.2 |

106 in·lb |

S |

|

|

Oil Passage Plug |

20 |

2.0 |

15 |

L |

|

|

Oil Passage Plug (M6) |

3.9 |

0.40 |

35 in·lb |

||

|

Oil Pipe Plate Bolt |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Oil Plate Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Oil Pressure Relief Valve |

15 |

1.5 |

11 |

L |

|

|

Oil Pressure Switch |

15 |

1.5 |

11 |

SS |

|

|

Oil Pump Chain Guide Bolts |

12 |

1.2 |

106 in·lb |

L (1) |

|

|

Oil Pump Cover Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Oil Pump Sprocket Bolt |

12 |

1.2 |

106 in·lb |

L, Lh |

|

|

Engine Removal/Installation |

|||||

|

Engine Bracket Bolts (Left) |

25 |

2.5 |

18 |

S |

|

|

Engine Bracket Bolts (Right) |

25 |

2.5 |

18 |

S |

|

|

Engine Mounting Nut (Lower) |

44 |

4.5 |

32 |

S |

|

|

Engine Mounting Nut (Rear) |

44 |

4.5 |

32 |

S |

|

|

Engine Mounting Bolt (Left) |

44 |

4.5 |

32 |

S |

|

|

Engine Mounting Bolt (Right) |

44 |

4.5 |

32 |

S |

|

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||||

|

N·m |

kgf·m |

ft·lb |

|||||

|

Crankshaft/Transmission |

|||||||

|

Breather Plate Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Race Holder Screw |

4.9 |

0.50 |

43 in·lb |

L |

|||

|

Connecting Rod Big End Nuts |

see Text |

← |

← |

MO |

|||

|

Crankcase Bolt (M8, L = 110 mm) |

27.5 |

2.8 |

20 |

S |

|||

|

Crankcase Bolt (M6, L = 32 mm) |

19.6 |

2.0 |

14 |

S |

|||

|

Crankcase Bolts (M6, L = 38 mm) |

19.6 |

2.0 |

14 |

S |

|||

|

Crankcase Bolts (M6, L = 45 mm) |

19.6 |

2.0 |

14 |

S |

|||

|

Crankcase Bolt (M8, L = 50 mm) |

27.5 |

2.8 |

20 |

S |

|||

|

Crankcase Bolts (M8, L = 60 mm) |

35 |

3.6 |

26 |

MO, S |

|||

|

Crankcase Bolt (M8, L = 60 mm) |

27.5 |

2.8 |

20 |

S |

|||

|

Crankcase Bolts (M8, L = 73 mm) |

35 |

3.6 |

26 |

MO, S |

|||

|

Crankcase Bolts (M9, L = 113 mm) |

44 |

4.5 |

32 |

MO, S |

|||

|

Crankcase Bolts (M9, L = 83 mm) |

44 |

4.5 |

32 |

MO, S |

|||

|

Upper Crankcase Bolt (M8, L = 120 mm) |

27.5 |

2.8 |

20 |

S |

|||

|

Upper Crankcase Bolts (M8, L = 110 mm) |

27.5 |

2.8 |

20 |

S |

|||

|

Oil Pipe Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Oil Plate Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Shift Shaft Return Spring Pin |

29 |

3.0 |

21 |

L |

|||

|

Timing Rotor Bolt |

40 |

4.1 |

30 |

||||

|

Drive Shaft Bearing Holder Screw |

4.9 |

0.50 |

43 in·lb |

L |

|||

|

Gear Positioning Lever Bolt |

12 |

1.2 |

106 in·lb |

L |

|||

|

Neutral Switch |

15 |

1.5 |

11 |

||||

|

Neutral Switch Holder Screw |

4.9 |

0.50 |

43 in·lb |

L |

|||

|

Transmission Case Oil Nozzle |

2.9 |

0.30 |

26 in·lb |

L |

|||

|

Shift Drum Bearing Holder Screws |

4.9 |

0.50 |

43 in·lb |

L |

|||

|

Shift Drum Cam Bolt |

12 |

1.2 |

106 in·lb |

L |

|||

|

Shift Lever Bolt |

12 |

1.2 |

106 in·lb |

||||

|

Shift Rod Plate Bolt |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Shift Shaft Cover Bolts |

9.8 |

1.0 |

87 in·lb |

L (3) |

|||

|

Shift Shaft Cover Screw |

4.9 |

0.50 |

43 in·lb |

L, S |

|||

|

Transmission Case Bolts |

20 |

2.0 |

15 |

||||

|

Wheels/Tires |

|||||||

|

Front Axle |

108 |

11.0 |

80 |

||||

|

Front Axle Clamp Bolt |

34 |

3.5 |

25 |

||||

|

Rear Axle Nut |

108 |

11.0 |

80 |

||||

|

Final Drive |

|||||||

|

Engine Sprocket Nut |

125 |

12.7 |

92 |

MO |

|||

|

Rear Axle Nut |

108 |

11.0 |

80 |

||||

|

Rear Sprocket Nuts |

59 |

6.0 |

44 |

||||

|

Speed Sensor Bolt |

7.8 |

0.80 |

69 in·lb |

L |

|||

|

Speed Sensor Bracket Bolts |

9.8 |

1.0 |

87 in·lb |

||||

PERIODIC MAINTENANCE 2-9

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Brakes |

|||||

|

Caliper Bleed Valve |

7.8 |

0.80 |

69 in·lb |

||

|

Brake Hose Banjo Bolts |

25 |

2.5 |

18 |

||

|

Brake Lever Pivot Bolt |

1.0 |

0.10 |

9 in·lb |

Si |

|

|

Brake Lever Pivot Bolt Locknut |

5.9 |

0.60 |

52 in·lb |

||

|

Brake Disc Mounting Bolts |

27 |

2.8 |

20 |

L |

|

|

Front Brake Light Switch Screw |

1.2 |

0.12 |

11 in·lb |

||

|

Front Brake Reservoir Cap Screws |

1.5 |

0.15 |

13 in·lb |

||

|

Front Caliper Mounting Bolts |

34 |

3.5 |

25 |

||

|

Front Master Cylinder Clamp Bolts |

11 |

1.1 |

97 in·lb |

S |

|

|

Brake Pedal Bolt |

8.8 |

0.90 |

78 in·lb |

||

|

Rear Caliper Mounting Bolts |

25 |

2.5 |

18 |

||

|

Rear Master Cylinder Mounting Bolts |

25 |

2.5 |

18 |

||

|

Rear Master Cylinder Push Rod Locknut |

17 |

1.7 |

13 |

||

|

Brake Pipe Joint Nuts (ER650D Models) |

18 |

1.8 |

13 |

||

|

Wheel Rotation Sensor Bolts (ER650D Models) |

|||||

|

20 |

2.0 |

15 |

|||

|

Suspension |

|||||

|

Front Axle Clamp Bolt |

34 |

3.5 |

25 |

||

|

Front Fork Bottom Allen Bolts |

30 |

3.1 |

22 |

L |

|

|

Front Fork Clamp Bolts (Lower) |

20 |

2.0 |

15 |

AL |

|

|

Front Fork Clamp Bolts (Upper) |

20 |

2.0 |

15 |

||

|

Front Fork Top Plugs |

25 |

2.5 |

18 |

||

|

Rear Shock Absorber Bolts |

59 |

6.0 |

44 |

||

|

Swingarm Pivot Shaft Nut |

108 |

11.0 |

80 |

||

|

Steering |

|||||

|

Front Fork Clamp Bolts (Lower) |

20 |

2.0 |

15 |

AL |

|

|

Front Fork Clamp Bolts (Upper) |

20 |

2.0 |

15 |

||

|

Handlebar Holder Bolts |

25 |

2.5 |

18 |

S |

|

|

Handlebar Holder Mounting Nuts |

34 |

3.5 |

25 |

||

|

Switch Housing Screws |

3.5 |

0.36 |

31 in·lb |

||

|

Steering Stem Head Bolt |

108 |

11.0 |

80 |

||

|

Steering Stem Nut |

20 |

2.0 |

15 |

||

|

Frame |

|||||

|

Footpeg Stay Bolts |

25 |

2.5 |

18 |

S |

|

|

Front Fender Mounting Bolts |

8.8 |

0.90 |

78 in·lb |

||

|

Front Turn Signal Light Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||

|

Grab Rail Mounting Bolts |

25 |

2.5 |

18 |

||

|

Lower Fairing Bracket Bolts |

12 |

1.2 |

106 in·lb |

L |

|

|

Lower Fairing Mounting Bolts |

8.8 |

0.90 |

78 in·lb |

||

|

Seat Lock Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||

|

Sidestand Bolt |

44 |

4.5 |

32 |

||

|

Sidestand Switch Bolt |

8.8 |

0.90 |

78 in·lb |

L |

|

2-10 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||||

|

N·m |

kgf·m |

ft·lb |

|||||

|

Electrical System |

|||||||

|

Tail/Brake Light Mounting Bolts |

8.8 |

0.90 |

78 in·lb |

||||

|

License Plate Light Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||||

|

Alternator Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||||

|

Alternator Lead Holding Plate Bolt |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Alternator Rotor Bolt |

155 |

15.8 |

114 |

MO |

|||

|

Engine Ground Lead Terminal Bolt |

9.8 |

1.0 |

87 in·lb |

||||

|

Front Brake Light Switch Screw |

1.2 |

0.12 |

11 in·lb |

||||

|

Front Turn Signal Light Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||||

|

Fuel Pump Bolts |

9.8 |

1.0 |

87 in·lb |

L, S |

|||

|

Meter Cover Screws |

1.2 |

0.12 |

11 in·lb |

||||

|

Regulator/Rectifier Bolts |

8.8 |

0.90 |

78 in·lb |

||||

|

Switch Housing Screws |

3.5 |

0.36 |

31 in·lb |

||||

|

Sidestand Switch Bolt |

8.8 |

0.90 |

78 in·lb |

L |

|||

|

Starter Motor Terminal Nut |

6.0 |

0.61 |

53 in·lb |

||||

|

Starter Motor Clutch Bolts |

3.5 |

L |

|||||

|

34 |

25 |

||||||

|

Starter Motor Mounting Bolts |

9.8 |

1.0 |

87 in·lb |

L |

|||

|

Starter Motor Terminal Locknut |

11 |

1.1 |

97 in·lb |

||||

|

Starter Motor Through Bolts |

5.0 |

0.51 |

44 in·lb |

||||

|

Stator Coil Bolts |

12 |

1.2 |

106 in·lb |

L |

|||

|

Crankshaft Sensor Bolts |

6.0 |

0.61 |

53 in·lb |

||||

|

Neutral Switch |

15 |

1.5 |

11 |

||||

|

Oil Pressure Switch |

15 |

1.5 |

11 |

SS |

|||

|

Oxygen Sensor (Equipped Models) |

44 |

4.5 |

32 |

||||

|

Spark Plugs |

15 |

1.5 |

11 |

||||

|

Speed Sensor Bolt |

7.8 |

0.80 |

69 in·lb |

L |

|||

|

Timing Rotor Bolt |

40 |

4.1 |

30 |

||||

|

Water Temperature Sensor |

12 |

1.2 |

106 in·lb |

||||

|

Fuel Level Sensor Bolts |

6.9 |

0.70 |

61 in·lb |

L |

|||

PERIODIC MAINTENANCE 2-11

Torque and Locking Agent

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

|

Threads Diameter |