Service Manual KX125J

Item # 99924-1153-02

MSRP

$46.40

Kawasaki service manuals contain enough detail and basic information to make them useful to the owner who desires to do his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out the work satisfactorily.

Most items ship to dealer within 5-7 business days for free. Special dealer only items may be excluded.

Additional shipping charges apply to qualified ship to home orders.

Price and specifications are subject to change without notice or liability. Availability is subject to production, stocking and demand. Manufacturers suggested retail prices shown.

- WARRANTY INFORMATION

File Specifications:795/795339-kx125.pdf file (26 Jun 2023) |

Accompanying Data:

Kawasaki KX125 Motorcycle PDF Service Manual (Updated: Monday 26th of June 2023 05:25:11 AM)

Rating: 4.5 (rated by 63 users)

Compatible devices: Z1000SX 2012, KLR650 -, NINJA ZX-12R, Contours 1000GTR, KLR650 2014, Ninja Super Sport Ninja, Ninja ZX-10R 2013, VN800-A.

Recommended Documentation:

Service Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the Kawasaki KX125 Document (Main Content), UPD: 26 June 2023)

-

Kawasaki KX125 User Manual

-

Kawasaki KX125 User Guide

-

Kawasaki KX125 PDF Manual

-

Kawasaki KX125 Owner’s Manuals

Recommended: 710 Gardener, M61WH74S, SCAK240 — HES SYSTEM, HII 63500 T, HD7002

Links & Tools

-

90cc Dirt RunnerRead this manual carefully. It contains important safety information.No one under the age of 16 should operate this dirt bike. Always wear a helmet; It could save your Life!Do not remove this operator’s manual from this vehicle.Please obtain, review, and follow provincial / municipal government …

Dirt Runner 90cc 66

-

Top1st cover4th coverTop1st cover4th cover8 mm8 mmNo.346 VZ1500 99011-40H50-03A 2/1No.346 VZ1500 99011-40H50-03A 2/1 DIC184(TDP006) DIC15799011-40H50-03AVZ1500VZ1500Part No. 99011-40H50-03AJuly, 2008 ENTKK9Printed in Japan300 TAKATSUKA, MINAMI, HAMAMATSU, JAPAN99011-40H50-03AVZ1500VZ15 …

VZ1500 195

-

Comparison chartSUZUKIBOULEVARD C90THONDAINTERSTATEYAMAHAV-Star TourerOverall length 2,560 mm (100.8 in.) 2,650 mm 2,490 mmSeat height 720 mm (28.3 in.) 681 mm 690 mmCurb mass 363 kg (800 lbs) 323 kg 323 kgDisplacement 1462 cm3 (89.2 cu. in) 1312 cm31304 cm3Max output 59.6 kw / 4,800 40 kw / 4,250 …

2013 C90T Boulevard 2

-

9 9 5 0 1 — 3 1 1 5 0 — 0 1 E背厚 4 mmPrinted in JapanK7USE THIS MANUAL WITH:RV125 SERVICE MANUAL (99500-31233-01E)RV125 DIC120No.3900 RV125K7_01E SUPPLY 99500-31150-01E 2006.8.28 Cover_14 PS Printing (4 mm) 2/1 K7 …

shogun sports 125 107

Operating Impressions, Questions and Answers:

Motorcycle

Service Manual

Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or procedure.

•Bend the pages back to match the black tab of the desired chapter number with the black tab on the edge at each table of contents page.

•Refer to the sectional table of contents for the exact pages to locate the specific topic required.

|

General Information |

1 |

j |

|

Periodic Maintenance |

2 |

j |

|

Fuel System |

3 |

j |

|

Cooling System |

4 |

j |

|

Engine Top End |

5 |

j |

|

Engine Right Side |

6 |

j |

|

Engine Removal/Installation |

7 |

j |

|

Engine Bottom End/Transmission |

8 |

j |

|

Wheels/Tires |

9 |

j |

|

Final Drive |

10 |

j |

|

Brakes |

11 |

j |

|

Suspension |

12 |

j |

|

Steering |

13 |

j |

|

Electrical System |

14 |

j |

|

Appendix |

15 |

j |

KX125

KX250

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of Quality Assurance Division/Consumer Products & Machinery Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such changes to products manufactured previously. See your Motorcycle dealer for the latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication. Illustrations and photographs in this publication are intended for reference use only and may not depict actual model component parts.

|

© 2002 Kawasaki Heavy Industries, Ltd., |

7th Edition (1) : Mar. 22, 2007 (K) |

LIST OF ABBREVIATIONS

|

A |

ampere(s) |

lb |

pound(s) |

|

ABDC |

after bottom dead center |

m |

meter(s) |

|

AC |

alternating current |

min |

minute(s) |

|

ATDC |

after top dead center |

N |

newton(s) |

|

BBDC |

before bottom dead center |

Pa |

pascal(s) |

|

BDC |

bottom dead center |

PS |

horsepower |

|

BTDC |

before top dead center |

psi |

pound(s) per square inch |

|

°C |

degree(s) Celsius |

r |

revolution |

|

DC |

direct current |

rpm |

revolution(s) perminute |

|

F |

farad(s) |

TDC |

top dead center |

|

°F |

degree(s) Fahrenheit |

TIR |

total indicator reading |

|

ft |

foot, feet |

V |

volt(s) |

|

g |

gram(s) |

W |

watt(s) |

|

h |

hour(s) |

Ω |

ohm(s) |

|

L |

liter(s) |

Read OWNER’S MANUAL before operating

Foreword

This manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out maintenance and repair satisfactorily. Whenever the owner has insufficient experience or doubts as to his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures before starting work, and then do the work carefully in a clean area. Whenever special tools or equipment are specified, do not use makeshift tools or equipment. Precision measurements can only be made if the proper instruments are used, and the use of substitute tools may adversely affect safe operation.

To get the longest life out of your motorcycle:

•Follow the Periodic Maintenance Chart in the Service Manual.

•Be alert for problems and non-scheduled maintenance.

•Use proper tools and genuine Kawasaki motorcycle parts. Special tools, gauges, and testers that are necessary when servicing Kawasaki Motorcycles are introduced by the Service Manual. Genuine parts provided as spare parts are listed in the Parts Catalog.

•Follow the procedures in this manual carefully. Don’t take shortcuts.

•Remember to keep complete records of maintenance and repair with dates and any new parts installed.

How to Use this Manual

In this manual, the product is divided into its major systems and these systems make up the manual’s chapters. The Quick Reference Guide shows you all of the product’s system and assists in locating their chapters. Each chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate the Electrical System chapter. Then, use the Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and CAUTION symbols, heed their instructions! Always follow safe operating and maintenance practices.

This warning symbol identifies special instructions or procedures which, if not correctly followed, could result in personal injury, or loss of life.

CAUTION

This caution symbol identifies special instructions or procedures which, if not strictly observed, could result in damage to or destruction of equipment.

This manual contains four more symbols (in addition to WARNING and CAUTION) which will help you distinguish different types of information.

NOTE

○This note symbol indicates points of particular interest for more efficient and convenient operation.

•Indicatesdone. a procedural step or work to be ○Indicates a procedural sub-step or how to do the work of the procedural step it follows. It

also precedes the text of a NOTE.

In most chapters an exploded view illustration of the system components follows the Table of Contents. In these illustrations you will find the instructions indicating which parts require specified tightening torque, oil, grease or a locking agent during assembly.

GENERAL INFORMATION 1-1

General Information |

|||

|

1 |

|||

|

Table of Contents |

|||

|

Before Servicing ……………………………………………………………………………………………………… |

1-2 |

||

|

Model Identification………………………………………………………………………………………………….. |

1-5 |

||

|

General Specifications……………………………………………………………………………………………… |

1-7 |

||

|

Technical Information……………………………………………………………………………………………….. |

1-13 |

||

|

Unit Conversion Table ……………………………………………………………………………………………… |

1-21 |

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever necessary. This section explains the items that require particular attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following:

(1) Dirt

Before removal and disassembly, clean the motorcycle. Any dirt entering the engine will shorten the life of the motorcycle. For the same reason, before installing a new part, clean off any dust or metal filings.

(2) Battery Ground

Disconnect the ground (–) cable from the battery before performing any disassembly operations on the motorcycle. This prevents the engine from accidentally turning over while work is being carried out, sparks from being generated while disconnecting the leads from electrical parts, as well as damage to the electrical parts themselves. For reinstallation, first connect the positive cable to the positive (+) terminal of the battery

(3) Installation, Assembly

Generally, installation or assembly is the reverse of removal or disassembly. However, if installation or assembly sequence is given in this Service Manual, follow it. Note parts locations and cable, wire, and hose routing during removal or disassembly so they can be installed or assembled in the same way. It is preferable to mark and record the locations and routing whenever possible.

(4) Tightening Sequence

When installing bolts, nuts, or screws for which a tightening sequence is given in this Service Manual, make sure to follow the sequence. When installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit, thus ensuring that the part has been installed in its proper location. Then, tighten them to the specified torque in the tightening sequence and method indicated. If tightening sequence instructions are not given, tighten them evenly in a cross pattern. Conversely, to remove a part, first loosen all the bolts, nuts, or screws that are retaining the part a 1/4-turn before removing them.

(5) Torque

When torque values are given in this Service Manual, use them. Either too little or too much torque may lead to serious damage. Use a good quality, reliable torque wrench.

(6) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If a part seems especially difficult to remove or install, stop and examine what may be causing the problem. Whenever tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use an impact driver for screws (particularly for the removing screws held by non-permanent locking agent) in order to avoid damaging the screw heads.

(7) Edges

Watch for sharp edges, as they could cause injury through careless handling, especially during major engine disassembly and assembly. Use a clean piece of thick cloth when lifting the engine or turning it over.

(8) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North America is standard solvent (generic name). Always follow manufacturer and container directions regarding the use of any solvent.

(9) Gasket, O-ring

Replace a gasket or an O-ring with a new part when disassembling. Remove any foreign matter from the mating surface of the gasket or O-ring to ensure a perfectly smooth surface to prevent oil or compression leaks.

(10)Liquid Gasket, Locking Agent

Clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used. Apply them sparingly. Excessive amount may block engine oil passages and cause serious damage.

GENERAL INFORMATION 1-3

Before Servicing

(11)Press

When using a press or driver to install a part such as a wheel bearing, apply a small amount of oil to the area where the two parts come in contact to ensure a smooth fit.

(12)Ball Bearing and Needle Bearing

Do not remove a ball bearing or a needle bearing unless it is absolutely necessary. Replace any ball or needle bearings that were removed with new ones. Install bearings with the manufacturer and size marks facing out, applying pressure evenly with a suitable driver. Apply force only to the end of the race that contacts the press fit portion, and press it evenly over the base component.

(13)Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. Oil or grease seals should be pressed into place using a suitable driver, applying a force uniformly to the end of seal until the face of the seal is even with the end of the hole, unless instructed otherwise. When pressing in an oil or grease seal which has manufacturer’s marks, press it in with the marks facing out.

(14)Circlip, Retaining Ring, and Cotter Pin

When installing circlips and retaining rings, take care to compress or expand them only enough to install them and no more. Install the circlip with its chamfered side facing load side as well.

Replace any circlips, retaining rings, and cotter pins that were removed with new ones, as removal weakens and deforms them. If old ones are reused, they could become detached while the motorcycle is driven, leading to a major problem.

(15)Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the sliding surfaces have an adequate lubricative film. During assembly, make sure to apply oil to any sliding surface or bearing that has been cleaned. Old grease or dirty oil could have lost its lubricative quality and may contain foreign particles that act as abrasives; therefore, make sure to wipe it off and apply fresh grease or oil. Some oils and greases in particular should be used only in certain applications and may be harmful if used in an application for which they are not intended.

(16)Direction of Engine Rotation

To rotate the crankshaft manually, make sure to do so in the direction of positive rotation. Positive rotation is counterclockwise as viewed from the left side of the engine. To carry out proper adjustment, it is furthermore necessary to rotate the engine in the direction of positive rotation as well.

(17)Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are removed.

Replacement parts will be damaged or lose their original function once they are removed. Therefore, always replace these parts with new ones every time they are removed. Although the previously mentioned gasket, O-ring, ball bearing, needle bearing, grease seal, oil seal, circlip, and cotter pin have not been so designated in their respective text, they are replacement parts.

(18)Electrical Leads

All the electrical leads are either one-color or two-color. A two-color lead is identified first by the primary color and then the stripe color. For example, a yellow lead with thin red stripes is referred to as a “yellow/red” lead; it would be a “red/yellow” lead if the colors were reversed. Unless instructed otherwise, electrical leads must be connected to leads of the same color.

Two-Color Electrical

1-4 GENERAL INFORMATION

Before Servicing

(19)Inspection

When parts have been disassembled, visually inspect these parts for the following conditions or other damage. If there is any doubt as to the condition of them, replace them with new ones.

|

Abrasion |

Crack |

Hardening |

Warp |

|

Bent |

Dent |

Scratch |

Wear |

|

Color change |

Deterioration |

Seizure |

(20)Specifications

Specification terms are defined as follows:

“Standards” show dimensions or performances which brand-new parts or systems have. “Service Limits” indicate the usable limits. If the measurement shows excessive wear or deteri-

orated performance, replace the damaged parts.

GENERAL INFORMATION 1-5

Model Identification

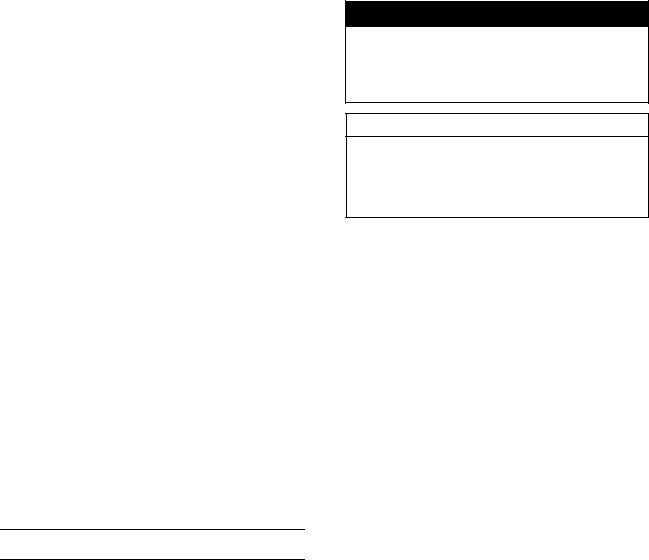

KX125-M1 Left Side View

KX125-M1 Right Side View

1-6 GENERAL INFORMATION

Model Identification

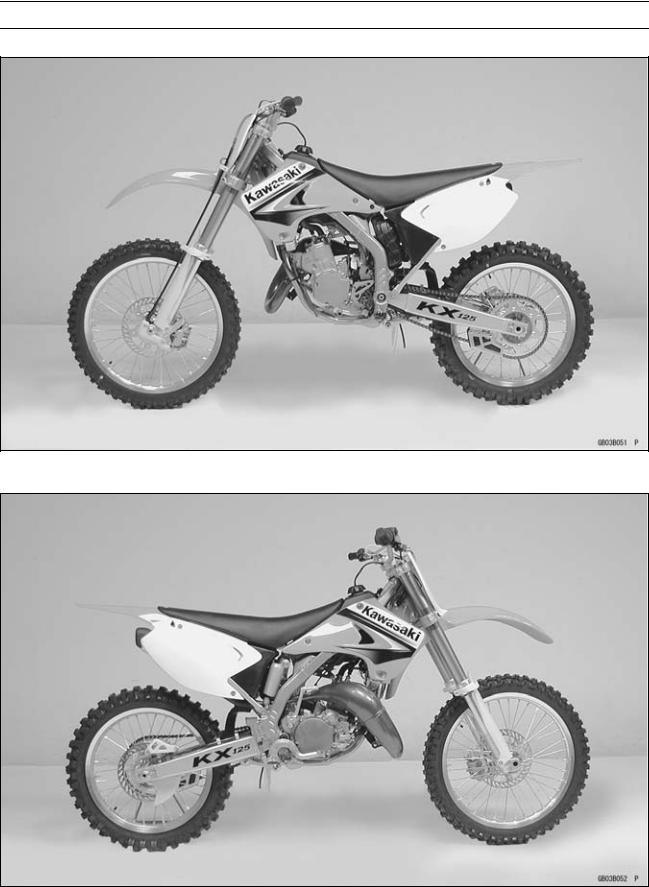

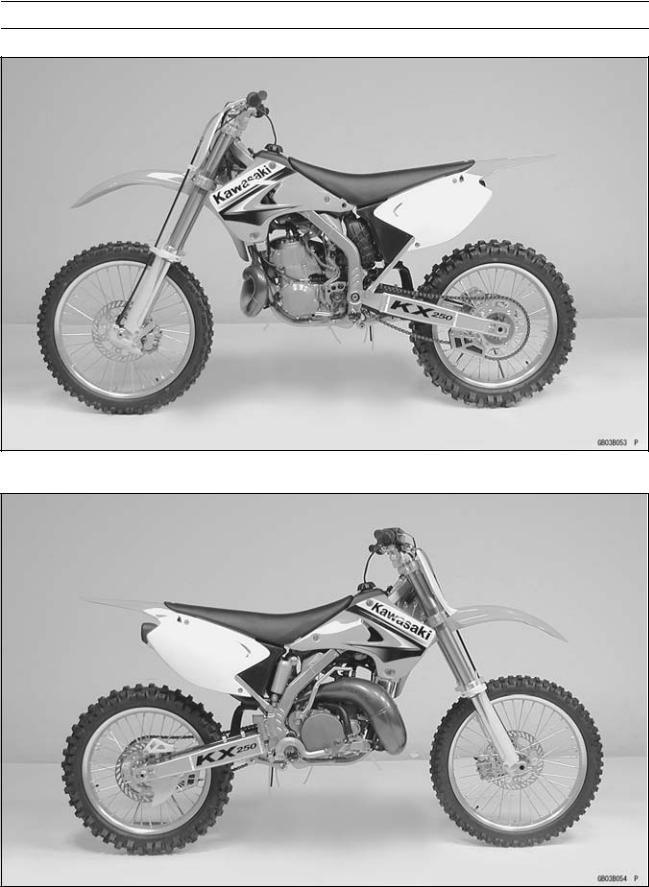

KX250-M1 Left Side View

KX250-M1 Right Side View

GENERAL INFORMATION 1-7

General Specifications

|

Items |

KX125-M1 |

KX125-M2 M3 |

KX125M6F |

|

|

Dimensions |

||||

|

Overall Length |

2 155 mm (84.8 in.) |

2 165 mm (85.2 in.) |

||

|

Overall Width |

825 mm (32.5 in.) |

840 mm (33.1 in.) |

815 mm (32.1 in.) |

|

|

Overall Height |

1 200 mm (47.2 in.) |

1 265 mm (49.8 in.) |

||

|

Wheelbase |

1 455 mm (57.3 in.) |

1 470 mm (57.9 in.) |

||

|

Road Clearance |

340 mm (13.4 in.) |

← |

||

|

Seat Height |

930 mm (36.6 in.) |

940 mm (37.0 in.) |

||

|

Dry Mass |

87 kg (192 lb) |

← |

||

|

Curb Mass: |

||||

|

Front |

45 kg (99 lb) |

← |

||

|

Rear |

47 kg (104 lb) |

← |

||

|

Fuel Tank Capacity |

8.2 L (2.2 US gal) |

← |

||

|

Engine |

||||

|

Type |

2-stroke, single cylinder, |

← |

||

|

crankcase reed valve |

||||

|

Cooling System |

Liquid-cooled |

← |

||

|

Bore and Stroke |

54.0 × 54.5 mm (2.13 × 2.15 in.) |

← |

||

|

Displacement |

124 cm³(7.6 cu in.) |

← |

||

|

Compression Ratio: |

||||

|

Low Speed |

10.6 : 1 |

11.1 : 1 (EUR) 10.9 : 1 |

||

|

High Speed |

8.1 : 1 |

8.5 : 1 (EUR) 8.3 : 1 |

||

|

Carburetion System |

Carburetor, MIKUNI TMX38χ |

← |

||

|

Starting System |

Primary kick |

← |

||

|

Ignition System |

CDI |

← |

||

|

Ignition Timing |

13° BTDC @9 710 r/min (rpm) |

13° BTDC @9 710 r/min (rpm) |

||

|

Spark Plug |

NGK BR9EIX |

NGK R6918B-9 |

NGK BR9ECMVX |

|

|

Port Timing |

||||

|

Inlet: |

||||

|

Open |

Full open |

← |

||

|

Close |

– |

– |

||

|

Scavenging: |

||||

|

Open |

64.9° BBDC |

← |

||

|

Close |

64.9° ABDC |

← |

||

|

Exhaust: |

||||

|

Open |

73.8° BBDC (low speed), |

← |

||

|

95.4° BBDC (high speed) |

← |

|||

|

Close |

73.8° ABDC (low speed), |

← |

||

|

95.4° ABDC (high speed) |

← |

|||

|

Lubrication System |

Petrol mix (32 : 1) |

← |

||

|

(Gasoline : Oil) |

||||

|

Drive Train |

||||

|

Primary Reduction |

||||

|

System: |

||||

|

Type |

Gear |

← |

||

|

Reduction Ratio |

3.200 (64/20) |

← |

1-8 GENERAL INFORMATION

General Specifications

|

Items |

KX125-M1 |

KX125-M2 |

M3 |

KX125M6F |

|

Clutch Type |

Wet, multi disc |

← |

||

|

Transmission: |

||||

|

Type |

6-speed, constant mesh, return |

← |

||

|

shift |

||||

|

Gear Ratios: |

||||

|

1st |

2.384 (31/13) |

← |

||

|

2nd |

1.857 (26/14) |

← |

||

|

3rd |

1.529 (26/17) |

← |

||

|

4th |

1.294 (22/17) |

← |

||

|

5th |

1.125 (27/24) |

← |

||

|

6th |

1.000 (25/25) |

← |

||

|

Final Drive System: |

||||

|

Type |

Chain drive |

← |

||

|

Reduction Ratio |

3.923 (51/13) |

← |

||

|

Overall Drive Ratio |

12.553 @Top gear |

← |

||

|

Transmission Oil: |

||||

|

Grade |

API SE, SF or SG |

← |

API SH, SJ or |

|

|

API SH or SJ with JASO MA |

SL with JASOMA |

|||

|

(KX125M7F ) |

||||

|

Viscosity |

SAE 10W-40 |

← |

||

|

Capacity |

0.7 L (0.74 US qt) |

← |

||

|

Frame |

||||

|

Type |

Tubular, semi-double cradle |

← |

||

|

Steering Angle |

45° to either side |

42° to either side |

||

|

Caster (rake angle) |

27.5° |

27° |

||

|

Trail |

100 mm (3.9 in.) |

113 mm (4.4 in.) |

||

|

Front Tire: |

||||

|

Size |

80/100-21 51M |

← |

||

|

Make/Type |

DUNLOP, Tube type |

← |

||

|

Rear Tire: |

||||

|

Size |

100/90-19 57M |

← |

||

|

Make/Type |

DUNLOP, Tube type |

← |

||

|

Rim Size: |

||||

|

Front |

21 × 1.60 |

← |

||

|

Rear |

19 × 1.85 |

← |

||

|

Front Suspension: |

||||

|

Type |

Telescopic fork (up side down) |

← |

||

|

Wheel Travel |

300 mm (11.8 in.) |

← |

||

|

Rear Suspension: |

||||

|

Type |

Swingarm (Uni-trak) |

Swingarm (New Uni-trak) |

||

|

Wheel Travel |

310 mm (12.2 in.) |

← |

||

|

Brake Type: |

||||

|

Front and Rear |

Single disc |

← |

||

GENERAL INFORMATION 1-9

General Specifications

|

Items |

KX125-M1 |

KX125-M2 |

M3 |

KX125M6F |

|

|

Effective Disc Diameter: |

|||||

|

Front |

220 mm (8.7 in.) |

225 |

mm (8.9 |

in.) |

|

|

Rear |

200 mm (7.9 in.) |

215 |

mm (8.5 |

in.) |

Specifications are subject to change without notice, and may not apply to every country. (EUR): Europe Model

1-10 GENERAL INFORMATION

General Specifications

|

Items |

KX250-M1 |

KX250-M2 |

|

|

Dimensions |

|||

|

Overall Length |

2 175 mm (85.6 in.) |

← |

|

|

Overall Width |

825 mm (32.5 in.) |

840 mm (33.1 in.) |

|

|

Overall Height |

1 205 mm (47.4 in.) |

1 265 mm (49.8 in.) |

|

|

Wheelbase |

1 480 mm (58.3 in.) |

← |

|

|

Road Clearance |

355 mm (14.0 in.) |

340 mm (13.4 in.) |

|

|

Seat Height |

945 mm (37.2 in.) |

← |

|

|

Dry Mass |

97 kg (214 lb) |

← |

|

|

Curb Mass: |

|||

|

Front |

50 kg (110 lb) |

← |

|

|

Rear |

51 kg (112 lb) |

← |

|

|

Fuel tank Capacity |

8.2 L (2.2 US gal) |

← |

|

|

Engine |

|||

|

Type |

2-stroke, single cylinder, piston |

← |

|

|

reed valve |

|||

|

Cooling System |

Liquid-cooled |

← |

|

|

Bore and Stroke |

66.4 × 72.0 mm (2.61 × 2.85 in.) |

← |

|

|

Displacement |

249 cm³ (15.25 cu in.) |

← |

|

|

Compression Ratio |

|||

|

Low Speed |

10.1 : 1 |

10.5 : |

1 |

|

High Speed |

8.6 : 1 |

8.8 : |

1 |

|

Carburetion System |

Carburetor, KEIHIN PWK38S |

← |

|

|

Starting System |

Primary kick |

← |

|

|

Ignition System |

CDI |

← |

|

|

Ignition Timing |

14° BTDC @7 740 r/min (rpm) |

← |

|

|

Spark Plug |

NGK BR8EIX |

← |

|

|

Port Timing: |

|||

|

Inlet: |

|||

|

Open |

Full open |

← |

|

|

Close |

– |

– |

|

|

Scavenging: |

|||

|

Open |

57.6° BBDC |

59.3° BBDC |

|

|

Close |

57.6° ABDC |

59.3° ABDC |

|

|

Exhaust: |

|||

|

Open |

78.1° BBDC (low speed), |

78.4° BBDC (low speed), |

|

|

91.4° BBDC (high speed) |

92.2° BBDC (high speed) |

||

|

Close |

78.1° ABDC (low speed), |

78.4° ABDC (low speed), |

|

|

91.4° ABDC (high speed) |

92.2° ABDC (high speed) |

||

|

Lubrication System (Gasoline: Oil) |

Petrol mix (32 : 1) |

← |

|

|

Drive Train |

|||

|

Primary Reduction System: |

|||

|

Type |

Gear |

← |

|

|

Reduction ratio |

3.000 (63/21) |

← |

|

|

Clutch Type |

Wet, multi disc |

← |

GENERAL INFORMATION 1-11

General Specifications

|

Items |

KX250-M1 |

KX250-M2 |

|

|

Transmission: |

|||

|

Type |

5 speed, constant mesh, return |

← |

|

|

shift |

|||

|

Gear Ratios: |

|||

|

1st |

1.800 (27/15) |

← |

|

|

2nd |

1.437 (23/16) |

← |

|

|

3rd |

1.176 (20/17) |

← |

|

|

4th |

1.000 (21/21) |

← |

|

|

5th |

0.869 (20/23) |

← |

|

|

Final Drive System |

|||

|

Type |

Chain drive |

← |

|

|

Reduction Ratio |

3.769 (49/13) |

← |

|

|

Overall Drive Ratio |

9.832 @Top gear |

← |

|

|

Transmission Oil: |

|||

|

Grade |

API SE, SF or SG |

← |

|

|

API SH or SJ with JASO MA |

← |

||

|

Viscosity |

SAE 10W-40 |

← |

|

|

Capacity |

0.85 L (0.90 US qt) |

← |

|

|

Frame |

|||

|

Type |

Tubular, semi-double cradle |

← |

|

|

Steering Angle |

45° to either side |

42° to either side |

|

|

Caster (rake angle) |

27° |

← |

|

|

Trail |

97 mm (3.8 in.) |

112 mm (4.4 in.) |

|

|

Front Tire: |

|||

|

Size |

80/100-21 51M |

← |

|

|

Make/Type |

BRIDGESTONE, Tube type |

← |

|

|

(EUR) DUNLOP, Tube type |

← |

||

|

Rear Tire: |

|||

|

Size |

110/90-19 62M |

← |

|

|

Make/Type |

BRIDGESTONE, Tube type |

← |

|

|

(EUR) DUNLOP, Tube type |

← |

||

|

Rim Size: |

|||

|

Front |

21 × 1.60 |

← |

|

|

Rear |

19 × 2.15 |

← |

|

|

Front Suspension: |

|||

|

Type |

Telescopic fork (up side down) |

← |

|

|

Wheel Travel |

300 mm (11.8 in.) |

← |

|

|

Rear Suspension: |

|||

|

Type |

Swingarm (Uni-trak) |

Swingarm (New Uni-trak) |

|

|

Wheel Travel |

310 mm (12.2 in.) |

← |

|

|

Brake Type: |

|||

|

Front and Rear |

Single disc |

← |

|

1-12 GENERAL INFORMATION

General Specifications

|

Items |

KX250-M1 |

KX250-M2 |

|

Effective Disc Diameter: |

||

|

Front |

220 mm (8.7 in.) |

225 mm (8.9 in.) |

|

Rear |

200 mm (7.9 in.) |

215 mm (8.5 in.) |

Specifications are subject to change without notice, and may not apply to every country. (EUR): Europe Model

GENERAL INFORMATION 1-13

Technical Information

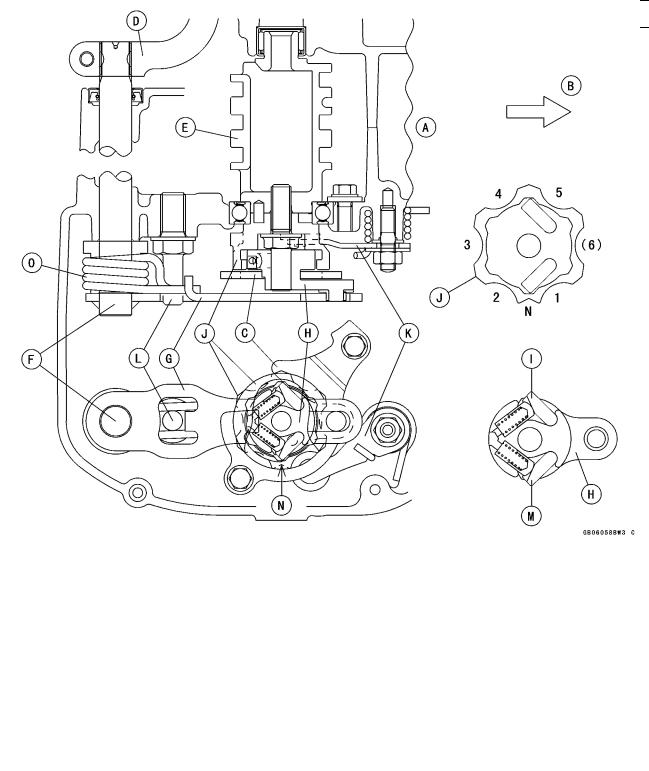

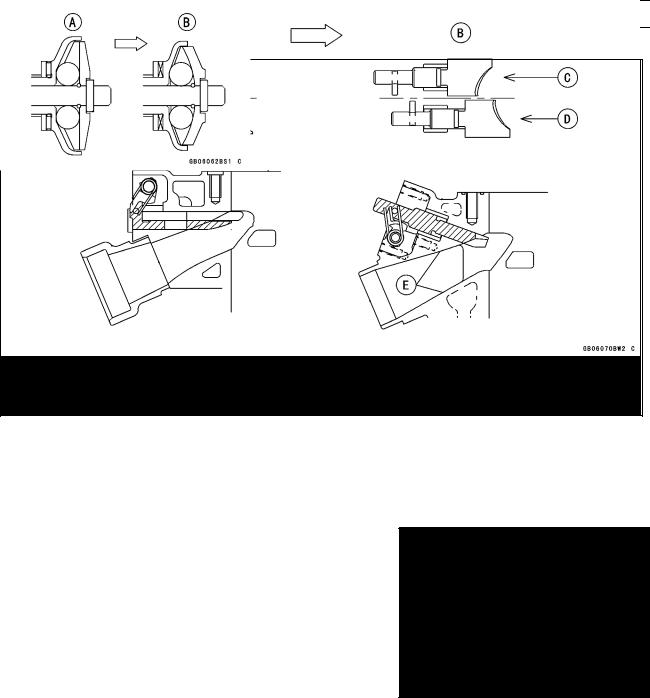

Ratchet-Type Shift Mechanism (KX250M, KX125M)

○The shift mechanism of the KX250M (5-speed) is shown in the following figure.

○This mechanism is stronger and simpler than the usual slide type and enables light and positive shifting. When the shift pedal [D] is applied, its turning force is transmitted almost directly to the shift drum [E].

○The mechanism has shorter length between the shift drum and the drive shaft, compared with the previous model (for example, from 67 mm to 43.2 mm for KX125).

○The shift force is transmitted as follows:

Shift Pedal → Shift Shaft [F] → Shift Mechanism Arm [G] → Ratchet [H] → Pawls [I], [M] in Ratchet → Shift Drum Cam [J] → Shift Forks → Gears

|

A. Top View |

F. Top View |

K. Gear Set Lever |

|

B. Front |

G. Shift Mechanism Arm |

L. Return Spring Pin |

|

C. Ratchet Plate |

H. Ratchet |

M. Lower Pawl |

|

D. Shift Pedal |

I. Upper Pawls |

N. Neutral Detent |

|

E. Shift Drum |

J. Shift Drum Cam |

O. Return Spring |

1-14 GENERAL INFORMATION

Technical Information

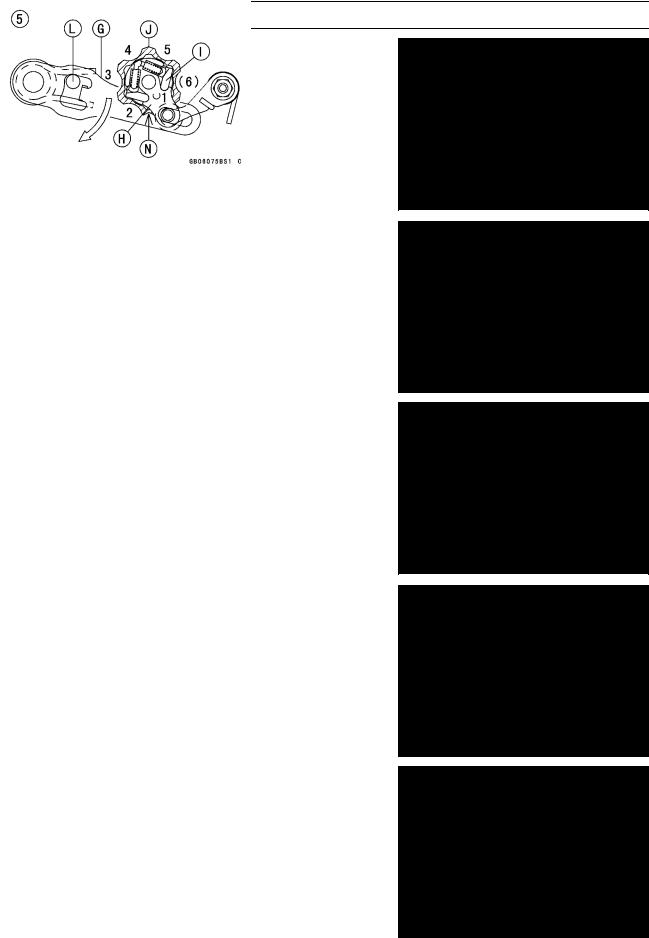

○This mechanism operates as follows:

1.Suppose the 1st gear position is set as shown. Neutral Detent [N]

2.Shift Up (for example: shift from 1st to 2nd) (→) : transmitting of shift force

The shift pedal is lifted. → The arm [G] turns counterclockwise until it stops at pin [L]. → ratchet [H] → lower pawl [M] → shift drum cam [J] → shift drum → The gear is shifted in 2nd position.

3.Ratchet Returns.

The arm [G] returns by force of spring [O]. →The ratchet

[H]disengages to be free by itself. → The set lever [K] holds the shift drum cam [J]. → The ratchet [H] returns (turns clockwise).

4.The 2nd Gear Position settles.

The upper and lower pawls [I], [M] catch the next teeth inside the shift drum cam [J] → The ratchet [H] settles in position. → The 2nd gear position settles.

5.Shift Down (for example: shift from 2nd to 1st)

The shift pedal is depressed. →The arm [G] turns clockwise until it stops at the pin [L]. → ratchet [H] → upper pawl [I] → shift drum cam [J] → shift drum → The gear is shifted into 1st position. → (continues to operate in the same way as Shift Up)

GENERAL INFORMATION 1-15

Technical Information

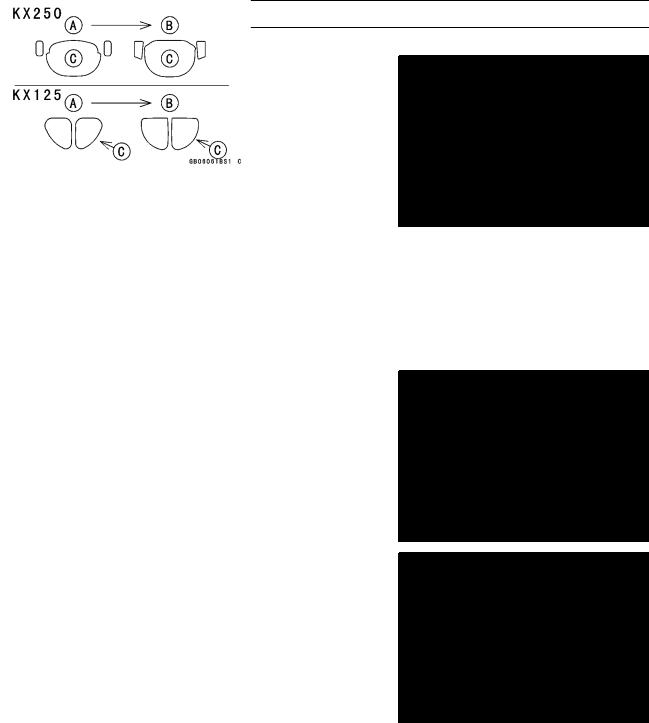

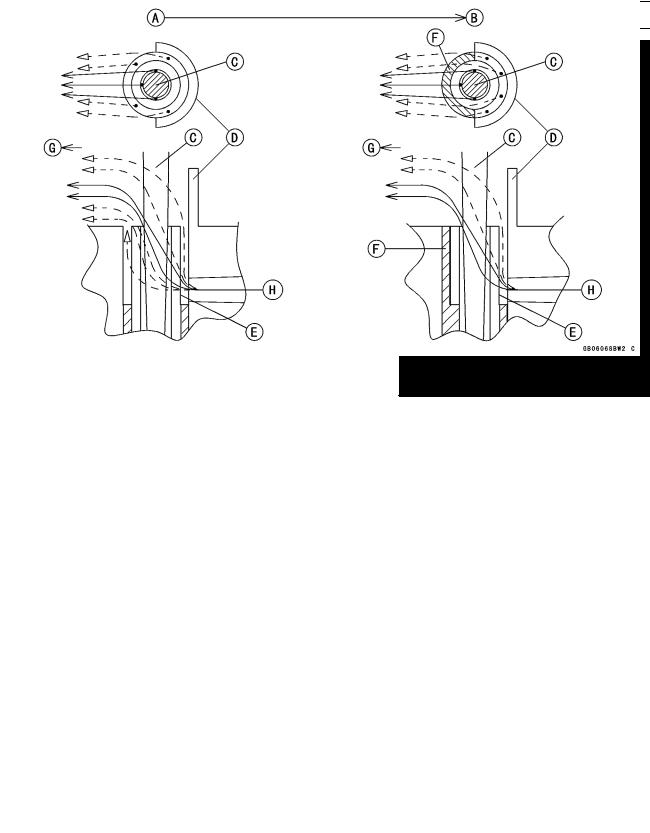

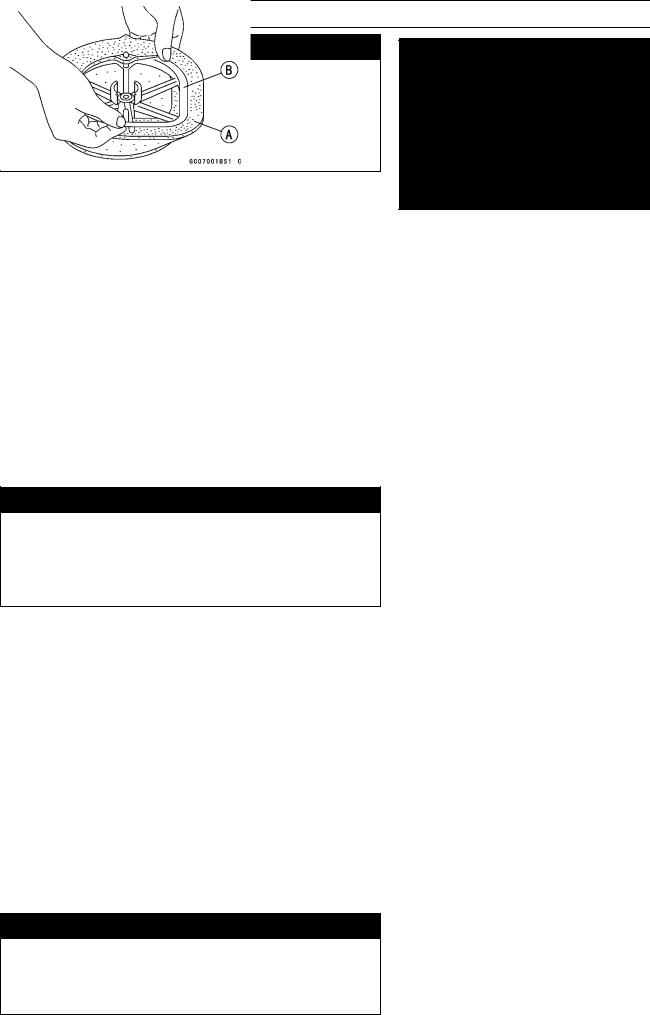

Chrome Composite Plating Cylinder (KX250M, KX125M)

○This new cylinder bore [A] has Kawasaki’s composite cylinder plating, which is used for the first time on two stroke engines. The composite plating includes a nickel-phosphorous alloy, inorganic materials like ceramic, silicone carbide and some organic materials.

○The treatment improves heat transfer of the cylinder for consistent power output, allows closer piston-to-cylinder clearances for more horsepower.

○The treatment is porous, so it holds lubrication well, and hard, so it resists abrasion and seizure.

○This plating gets on well even the chamfered edge of the cylinder top or port.

○This improves the surface of the chamber at the top of the cylinder, preventing hot spots, resultant pre-ignition and other abnormal combustion in the chamber.

Previous Cylinder [A] New Cylinder [B] Exhaust Port [C] Cylinder Top [D]

○This enables the top end of the exhaust port from round to straight in order to make gas flow smooth and improve mid-high performance and extending piston ring life.

Previous Cylinder [A] New Cylinder [B] Exhaust Port [C]

1-16 GENERAL INFORMATION

Technical Information

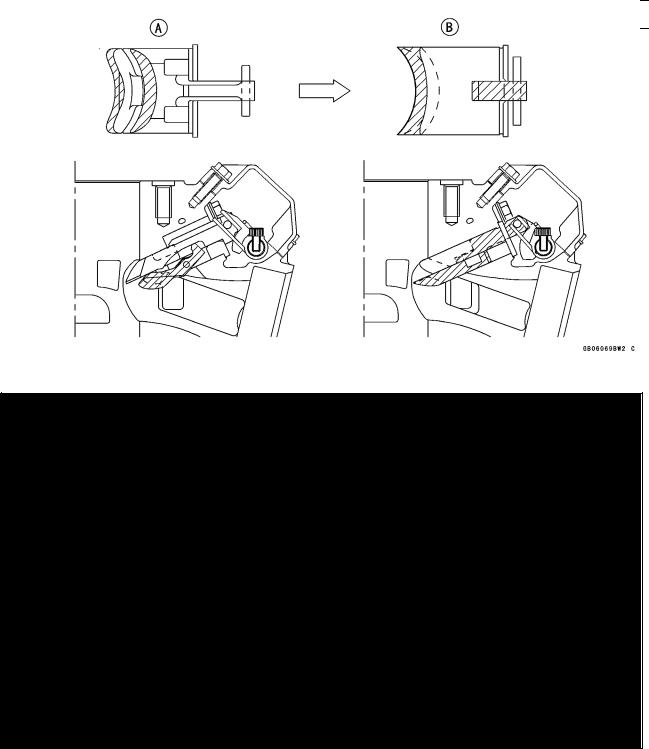

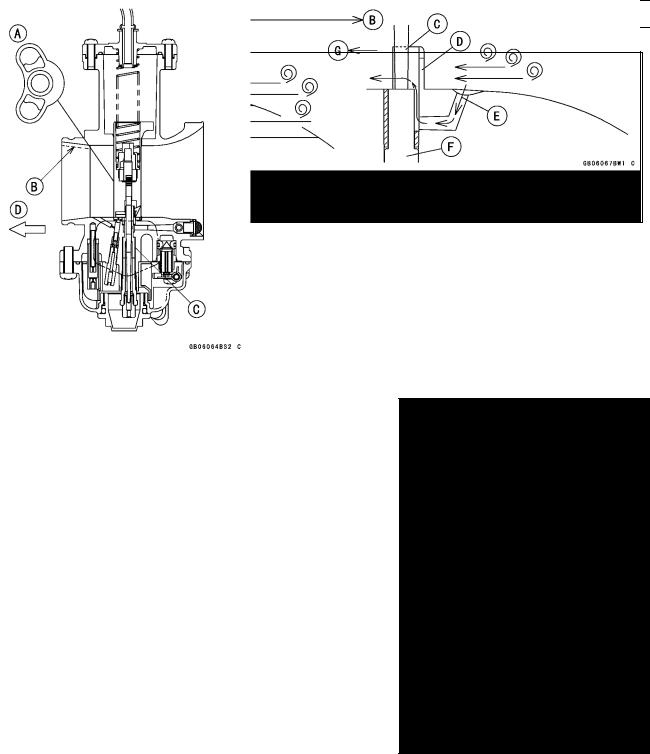

KIPS (Kawasaki Integrated Power Valve System, KX250M, KX125M)

○KIPS varies the exhaust port height to broaden the useful rpm range for low end and mid-range without sacrificing the top end power (see ’95 KDX200H Service Manual (Part No. 99924-1181-01) for basic information about KIPS).

○KIPS is 2-stage-3-way type: the main exhaust port is opened earlier than the sub-exhaust ports (2-stage) and they are opened differently in low, middle and high rpm (3-way).

(In low rpm)

resonator: open to fully, sub-exhaust ports and main exhaust port: close (In middle rpm)

resonator: close, main exhaust port: open to fully, sub-exhaust ports open to halfway (In high rpm)

resonator: close, main exhaust port and sub-exhaust ports open fully. ○The KIPS valve is now made of aluminum instead of steel to save weight.

○The KIPS main valve holder shape is modified to match the straightened exhaust port, and timing for the main and sub-valves is changed to deliver more power in the low to mid-range.

○The main valve end is changed from thick end to thin end, reducing exhaust pressure on the valve and making valve operation smooth.

(KX250M)

A.Previous KIPS

B.New KIPS

GENERAL INFORMATION 1-17

Technical Information

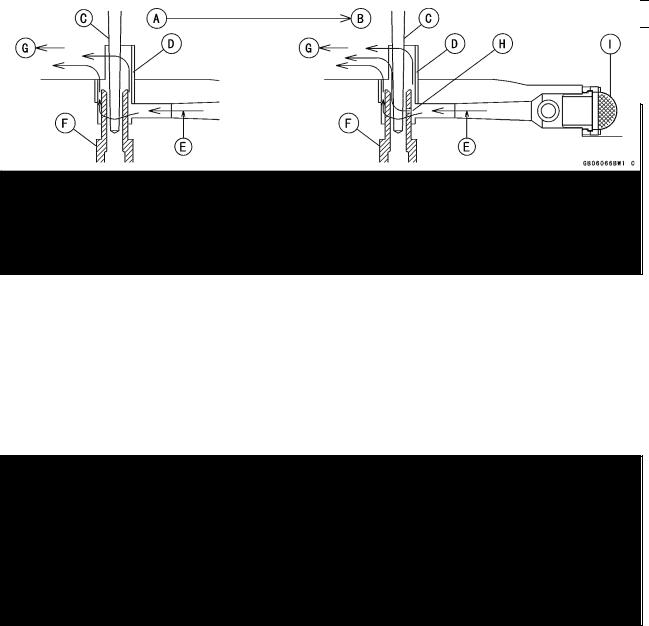

(KX125M)

A.Previous KIPS

B.New Model

C.Full Opened Position

D.Low Speed Position

E.Straightened Exhaust Passage

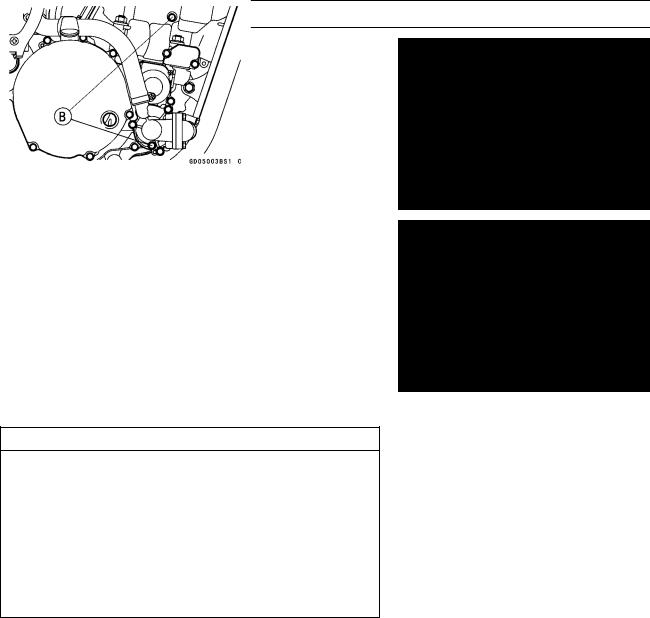

○The KIPS governor is modified so that the exhaust valves operate over a wider rpm range to improve low and mid -range power and smooth the power delivery.

○The KX250’s governor inside is changed from straight to concave in order to move the balls smoothly.

Previous Governor [A] New Governor [B]

Carburetor (KX250M)

○The 38.7 mm (1.524 in.) Keihin PWK 38S carburetor helps boost mid-range and top-end power.

1-18 GENERAL INFORMATION

Technical Information

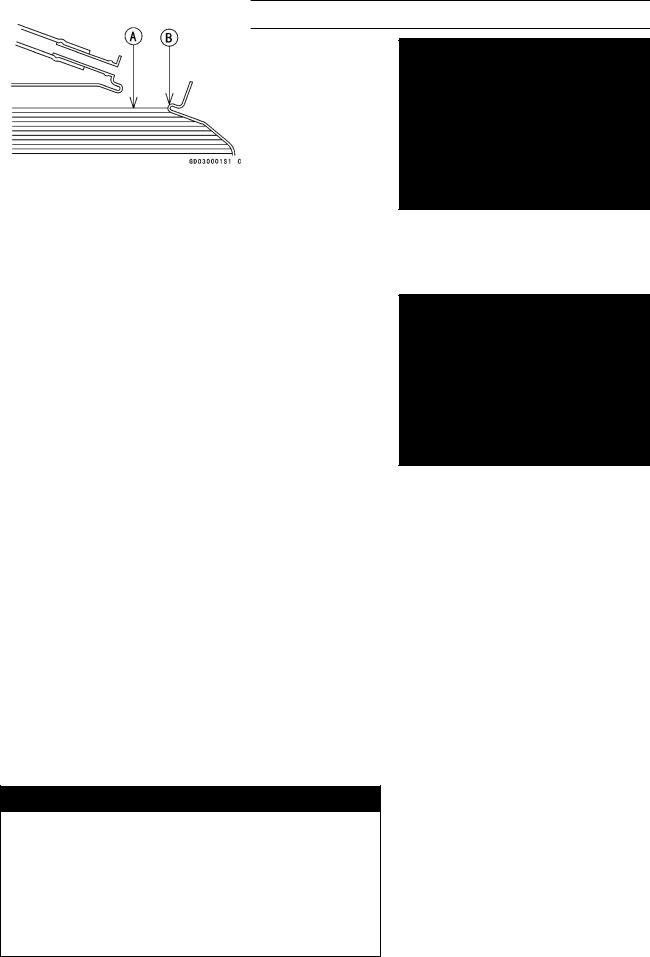

○The crescent shaped slide [A] enables the needle to sit closer to the intake ports for quicker throttle response.

○Large bores in the front and back of the carburetor and a smoother shape (38 to 40 mm-tapered bore [B]) boost mixture flow for more mid-range and top-end power.

○The semi air bleed needle jet [C] improves throttle response in the very low and low range.

Front [D]

○The air baffle forms vacuum, the stop narrows the outlet and speeds up outflow from the needle jet, improving atomization.

|

←—: |

Fuel Droplets |

||

|

← — -: |

Fuel Mist |

||

|

A. Previous Carburetor |

E. Needle Jet |

||

|

B. New Carburetor |

F. Stop |

||

|

C. Jet Needle |

G. Engine Inlet |

||

|

D. Air Baffle |

H. Main Air |

○The new main air inlet tends to take in static pressure and to exclude dynamic pressure and vortexes, making the main air flow stable.

GENERAL INFORMATION 1-19

Technical Information

A.Previous Carburetor

B.New Carburetor

C.Jet Needle

D.Air Baffle

E.Main Air

F.Needle Jet

G.Engine Inlet

Carburetor (KX125M)

○The 38 mm (1.496 in.) Mikuni TMX 38-27 carburetor helps boost mid-range and top-end power.

○The arched slide [A] improves throttle response in the very low and low ranges.

○Large bores in the front and back of the carburetor and a smoother shape (38 to 40 mm-tapered bore [B]) boost mixture flow for more mid-range and top-end power.

○The semi air bleed needle jet [C] improves throttle response in the low range and provides proper mixture from the low to top range.

Front [D]

1-20 GENERAL INFORMATION

Technical Information

○In low range, fuel drops in the fuel/air mixture is larger and tends to stick to the carburetor wall. The arched slide deflects fuel/air mixture flow from the wall to the middle of the carburetor for better atomization and better throttle response.

A.Previous Carburetor

B.New Carburetor

C.Flat Slide (piston valve)

D.Arched Shape Slide (piston valve)

E.Engine Intake

○The semi air bleed hole is positioned at the side of the needle jet, where fuel mixes with air well (due to enough fuel and faster air flow than in main bore), resulting in better atomizing. The air screen suppresses dynamic pressure around the main air inlet.

A.Previous Carburetor

B.New Carburetor

C.Jet Needle

D.Air Baffle

E.Main Air

F.Needle Jet

G.Engine Intake

H.Semi Air Bleed Hole

I.Air Screen

GENERAL INFORMATION 1-21

Unit Conversion Table

Prefixes for Units: |

Units of Length: |

|

Prefix |

Symbol |

Power |

||

|

mega |

M |

× 1 000 |

000 |

|

|

kilo |

k |

× |

1 000 |

|

|

centi |

c |

× |

0.01 |

|

|

milli |

m |

× |

0.001 |

|

|

micro |

µ |

× 0.000001 |

Units of Mass:

|

kg |

× |

2.205 |

= |

lb |

|

g |

× |

0.03527 |

= |

oz |

Units of Volume:

|

L |

× |

0.2642 |

= |

gal (US) |

|

L |

× |

0.2200 |

= |

gal (imp) |

|

L |

× |

1.057 |

= |

qt (US) |

|

L |

× |

0.8799 |

= |

qt (imp) |

|

L |

× |

2.113 |

= |

pint (US) |

|

L |

× |

1.816 |

= |

pint (imp) |

|

mL |

× |

0.03381 |

= |

oz (US) |

|

mL |

× |

0.02816 |

= |

oz (imp) |

|

mL |

× |

0.06102 |

= |

cu in |

Units of Force:

|

N |

× |

0.1020 |

= |

kgf |

|

N |

× |

0.2248 |

= |

lb |

|

kgf |

× |

9.807 |

= |

N |

|

kgf |

× |

2.205 |

= |

lb |

|

km |

× |

0.6214 |

= |

mile |

|

m |

× |

3.281 |

= |

ft |

|

mm |

× |

0.03937 |

= |

in |

Units of Torque:

|

N·m |

× |

0.1020 |

= |

kgf·m |

|

N·m |

× |

0.7376 |

= |

ft·lb |

|

N·m |

× |

8.851 |

= |

in·lb |

|

kgf·m |

× |

9.807 |

= |

N·m |

|

kgf·m |

× |

7.233 |

= |

ft·lb |

|

kgf·m |

× |

86.80 |

= |

in·lb |

Units of Pressure:

|

kPa |

× |

0.01020 |

= |

kgf/cm² |

|

kPa |

× |

0.1450 |

= |

psi |

|

kPa |

× |

0.7501 |

= |

cm Hg |

|

kgf/cm² |

× |

98.07 |

= |

kPa |

|

kgf/cm² |

× |

14.22 |

= |

psi |

|

cm Hg |

× |

1.333 |

= |

kPa |

Units of Speed:

km/h × 0.6214 = mph

Units of Power:

|

kW |

× |

1.360 |

= |

PS |

|

kW |

× |

1.341 |

= |

HP |

|

PS |

× |

0.7355 |

= |

kW |

|

PS |

× |

0.9863 |

= |

HP |

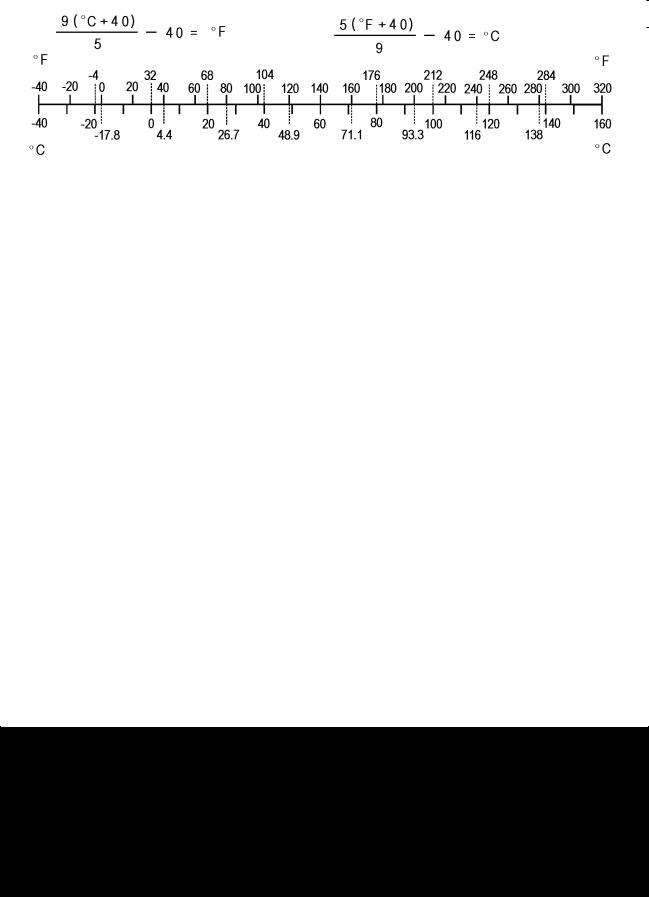

Units of Temperature:

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

|

Table of Contents |

2 |

||

|

Periodic Maintenance Chart ……………………………………………………………………………………… |

2-3 |

||

|

Torque and Locking Agent………………………………………………………………………………………… |

2-5 |

||

|

Specifications …………………………………………………………………………………………………………. |

2-10 |

||

|

Special Tools ………………………………………………………………………………………………………….. |

2-13 |

||

|

Periodic Maintenance Procedures……………………………………………………………………………… |

2-14 |

||

|

Fuel System…………………………………………………………………………………………………………. |

2-14 |

||

|

Fuel Hose and Connections Inspection …………………………………………………………………. |

2-14 |

||

|

Throttle Cable Inspection …………………………………………………………………………………….. |

2-14 |

||

|

Carburetor Inspection …………………………………………………………………………………………. |

2-15 |

||

|

Air Cleaner Element Cleaning and Inspection ………………………………………………………… |

2-15 |

||

|

Fuel Tank and Tap Cleaning ………………………………………………………………………………… |

2-16 |

||

|

Cooling System…………………………………………………………………………………………………….. |

2-16 |

||

|

Coolant Inspection ……………………………………………………………………………………………… |

2-17 |

||

|

Water Hoses and Connections Inspection……………………………………………………………… |

2-19 |

||

|

Engine Top End ……………………………………………………………………………………………………. |

2-19 |

||

|

Cylinder Head Warp Inspection ……………………………………………………………………………. |

2-19 |

||

|

Cylinder Wear Inspection…………………………………………………………………………………….. |

2-20 |

||

|

Piston Diameter Measurement …………………………………………………………………………….. |

2-20 |

||

|

Piston/Cylinder Clearance Inspection ……………………………………………………………………. |

2-21 |

||

|

Piston Ring, Piston Ring Groove Inspection …………………………………………………………… |

2-22 |

||

|

Piston Ring End Gap Inspection …………………………………………………………………………… |

2-23 |

||

|

Piston, Piston Pin, Connecting Rod Wear Inspection ………………………………………………. |

2-23 |

||

|

Exhaust Valve Cleaning and Inspection…………………………………………………………………. |

2-24 |

||

|

Exhaust System Inspection………………………………………………………………………………….. |

2-24 |

||

|

Muffler Cleaning and Inspection …………………………………………………………………………… |

2-24 |

||

|

Muffler Baffle Change …………………………………………………………………………………………. |

2-25 |

||

|

Engine Right Side…………………………………………………………………………………………………. |

2-25 |

||

|

Clutch Inspection ……………………………………………………………………………………………….. |

2-25 |

||

|

Clutch Plates Inspection ……………………………………………………………………………………… |

2-26 |

||

|

Engine Bottom End/Transmission …………………………………………………………………………… |

2-27 |

||

|

Transmission Oil Change…………………………………………………………………………………….. |

2-27 |

||

|

Wheels/Tires………………………………………………………………………………………………………… |

2-28 |

||

|

Tire Air Pressure Inspection/Adjustment………………………………………………………………… |

2-28 |

||

|

Tires Inspection………………………………………………………………………………………………….. |

2-29 |

||

|

Spoke Tightness Inspection…………………………………………………………………………………. |

2-30 |

||

|

Rim Runout Inspection………………………………………………………………………………………… |

2-30 |

||

|

Wheel Bearing Inspection ……………………………………………………………………………………. |

2-30 |

||

|

Final Drive……………………………………………………………………………………………………………. |

2-31 |

||

|

Drive Chain Inspection………………………………………………………………………………………… |

2-31 |

||

|

Drive Chain Wear Inspection ……………………………………………………………………………….. |

2-32 |

||

|

Drive Chain Lubrication……………………………………………………………………………………….. |

2-33 |

||

|

Sprockets Inspection…………………………………………………………………………………………… |

2-33 |

||

|

Rear Sprocket Warp (Runout) Inspection ………………………………………………………………. |

2-34 |

||

|

Brakes…………………………………………………………………………………………………………………. |

2-34 |

||

|

Brake Lever Play Adjustment……………………………………………………………………………….. |

2-34 |

||

|

Brake Fluid Level Inspection………………………………………………………………………………… |

2-35 |

2-2 PERIODIC MAINTENANCE

|

Brake Fluid Change ……………………………………………………………………………………………. |

2-36 |

|

Brake Pad Wear Inspection …………………………………………………………………………………. |

2-37 |

|

Brake Master Cylinder Cup and Dust Seal Replacement …………………………………………. |

2-37 |

|

Brake Caliper Fluid Seal and Dust Seal Replacement …………………………………………….. |

2-37 |

|

Brake Hoses and Connections Inspection ……………………………………………………………… |

2-38 |

|

Brake Hose Replacement ……………………………………………………………………………………. |

2-38 |

|

Suspension………………………………………………………………………………………………………….. |

2-39 |

|

Front Fork Inspection ………………………………………………………………………………………….. |

2-39 |

|

Front Fork Oil Change/Oil Level Adjustment (each fork leg) …………………………………….. |

2-40 |

|

Rear Shock Absorber Oil Change…………………………………………………………………………. |

2-42 |

|

Swingarm and Uni-Trak Linkage Inspection …………………………………………………………… |

2-42 |

|

Swingarm and Uni-Trak Linkage Pivot Lubrication ………………………………………………….. |

2-42 |

|

Chain Guide Wear Inspection ………………………………………………………………………………. |

2-43 |

|

Chain Slipper Wear Inspection …………………………………………………………………………….. |

2-43 |

|

Steering ………………………………………………………………………………………………………………. |

2-43 |

|

Steering Inspection …………………………………………………………………………………………….. |

2-43 |

|

Steering Stem Bearing Lubrication ……………………………………………………………………….. |

2-46 |

|

Frame …………………………………………………………………………………………………………………. |

2-46 |

|

Frame Inspection ……………………………………………………………………………………………….. |

2-46 |

|

Electrical System ………………………………………………………………………………………………….. |

2-47 |

|

Spark Plug Cleaning and Inspection……………………………………………………………………… |

2-47 |

|

Spark Plug Gap Inspection ………………………………………………………………………………….. |

2-47 |

|

General Lubrication ………………………………………………………………………………………………. |

2-48 |

|

Lubrication ………………………………………………………………………………………………………… |

2-48 |

|

Nut, Bolt, and Fastener Tightness …………………………………………………………………………… |

2-49 |

|

Tightness Inspection …………………………………………………………………………………………… |

2-49 |

PERIODIC MAINTENANCE 2-3

Periodic Maintenance Chart

The maintenance must be done in accordance with this chart to keep the motorcycle in good running condition.

|

FREQUENCY |

After |

Every |

Every |

Every |

||||

|

each |

3 races |

5 races |

10 |

As re- |

See |

|||

|

race or |

or 7.5 |

or 12.5 |

races |

quired |

Page |

|||

|

OPERATION |

2.5 hr |

hr |

hr |

or 25 hr |

||||

|

Spark plug — clean and inspect † |

• |

R |

2-47 |

|||||

|

Clutch — inspect |

• |

2-25 |

||||||

|

E |

Clutch plates — inspect † |

• |

R |

2-26 |

||||

|

Throttle cable — inspect |

• |

2-14 |

||||||

|

Air cleaner element — clean and inspect |

• |

2-15 |

||||||

|

N |

Air cleaner element — replace |

If damaged |

2-15 |

|||||

|

Carburetor — inspect |

• |

2-15 |

||||||

|

Transmission oil — change |

• |

2-27 |

||||||

|

G |

Piston and piston ring — clean and inspect† |

• |

R |

2-20 |

||||

|

Cylinder head, cylinder — inspect |

• |

2-19 |

||||||

|

Connecting rodinspect † |

• |

R |

2-23 |

|||||

|

Exhaust valve — clean and inspect |

• |

2-24 |

||||||

|

Exhaust system — inspect |

• |

2-24 |

||||||

|

N |

Muffler — clean and inspect † |

• |

2-24 |

|||||

|

Muffler baffle — change |

• |

2-25 |

||||||

|

Kick pedal and shift pedal — clean |

• |

– |

||||||

|

E |

Sprockets — inspect † |

• |

2-34 |

|||||

|

Coolant — inspect † |

• |

R |

2-17 |

|||||

|

Water hoses and connections — inspect † |

• |

2-19 |

||||||

|

Brake adjustment — inspect † |

• |

2-34 |

||||||

|

C |

Brake pad wear — inspect † |

• |

2-37 |

|||||

|

Brake fluid level — inspect † |

• |

2-35 |

||||||

|

H |

Brake fluid — change |

Every 2 years |

2-36 |

|||||

|

Brake master cylinder cup and dust cover — |

Every 2 years |

2-37 |

||||||

|

A |

replace |

|||||||

|

Brake caliper fluid seal and dust seal — |

Every 2 years |

2-37 |

||||||

|

replace |

||||||||

|

S |

Brake hoses and pipe — replace |

Every 4 years |

2-38 |

|||||

|

Brake hoses, connections — inspect † |

• |

2-38 |

||||||

|

S |

Spoke tightness and rim runout — inspect † |

• |

2-30 |

|||||

|

Wheel bearing — inspect † |

• |

2-30 |

||||||

|

I |

Drive chain — inspect |

• |

2-31 |

|||||

|

Drive chain — lubricate |

• |

2-33 |

||||||

|

S |

Drive chain wear — inspect † |

• |

2-32 |

|||||

|

Chain slipper and guide — replace |

If damaged |

2-43 |

||||||

|

Rear sprocket warp (runout) — inspect † |

• |

2-34 |

||||||

|

Front fork — inspect and clean |

• |

2-39 |

||||||

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

|

FREQUENCY |

After |

Every |

Every |

Every |

As re- |

See |

|

|

each |

3 races |

5 races |

10 |

||||

|

race or |

or 7.5 |

or 12.5 |

races |

quired |

Page |

||

|

OPERATION |

2.5 hr |

hr |

hr |

or 25 hr |

|||

|

Front fork oil — change |

1st time after 2 races, then every 5 races |

2-40 |

|||||

|

Rear shock absorber oil — change |

1st time after 2 races, then every 5 races |

2-42 |

|||||

|

C |

Fuel Tank and Tap — clean |

• |

2-16 |

||||

|

H |

Fuel hose — replace |

Every 4 years |

2-14 |

||||

|

A |

Fuel hose, connections — inspect † |

• |

2-14 |

||||

|

S |

Steering — inspect † |

• |

2-43 |

||||

|

S |

Steering stem bearing — lubricate |

• |

2-46 |

||||

|

I |

Swingarm and Uni-Trak linkage pivots — |

• |

2-42 |

||||

|

lubricate |

|||||||

|

S |

Swingarm and Uni-Trak linkage — inspect † |

• |

2-42 |

||||

|

Wheel/tire (air pressure, excessive wear or |

• |

2-28 |

|||||

|

damage) — inspect |

|||||||

|

Frame — clean and inspect |

• |

2-46 |

|||||

|

Nuts, bolts, and fasteners tightnessinspect † |

• |

2-49 |

|||||

|

General lubrication — perform |

• |

2-48 |

†: Replace, add, adjust, clean or torque if necessary. R: Replace

PERIODIC MAINTENANCE 2-5

Torque and Locking Agent

Tighten all bolts and nuts to the proper torque using an accurate torque wrench. If insufficiently tightened, a bolt or nut may become damaged, strip an internal thread, or break and then fall out. The following table lists the tightening toque for the major bolts and nuts, and the parts requiring use of a non-permanent locking agent or liquid gasket.

When checking the tightening toque of the bolts and nuts, first loosen the bolt or nut by half a turn and then tighten to specified torque.

Letters used in the “Remarks” column mean:

L : Apply a non-permanent locking agent to the threads. LG : Apply liquid gasket to the threads.

S : Tighten the fasteners following the specified sequence.

|

Fastener |

Torque |

Remarks |

||||

|

N·m |

kgf·m |

ft·lb |

||||

|

Fuel System |

||||||

|

Carburetor Holder Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Carburetor Holding Clamp Screw |

1.5 |

0.15 |

13 in·lb |

|||

|

Reed Valve Screws |

1.0 |

0.1 |

9 in·lb |

|||

|

Carburetor Top Cover Screws (KX125) |

3.0 |

0.3 |

26 in·lb |

|||

|

Carburetor Top Cover Allen Bolts (KX250) |

35 in·lb |

|||||

|

3.9 |

0.4 |

|||||

|

Throttle Sensor Bolt (KX250) |

2.0 |

0.2 |

17 in·lb |

|||

|

Rear Frame Mounting Bolts |

34 |

3.5 |

25 |

|||

|

Air Cleaner Duct Clamp Screw |

1.5 |

0.15 |

13 in·lb |

|||

|

Fuel Tap Plate Mounting Screws |

0.8 |

0.08 |

7 in·lb |

|||

|

Air Cleaner Duct Nuts |

3.0 |

0.3 |

26 in·lb |

|||

|

Air Cleaner Housing Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Cooling System |

||||||

|

Water Pump Cover Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Water Pump Impeller Bolt |

6.9 |

0.7 |

61 in·lb |

|||

|

Water Hose Clamp Screws |

1.5 |

0.15 |

13 in·lb |

|||

|

Coolant Drain Bolt (Water Pump Cover) |

8.8 |

0.9 |

78 in·lb |

|||

|

Coolant Drain Bolt (Cylinder) (KX250) |

8.8 |

0.9 |

78 in·lb |

|||

|

Water Hose Elbow Fitting Bolts (Cylinder) (KX250) |

8.8 |

0.9 |

78 in·lb |

|||

|

Water Pump Cover Fitting Bolts (KX250) |

5.9 |

0.6 |

52 in·lb |

|||

|

Radiator Shroud Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Radiator Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Radiator Screen Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Radiator Bracket Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Engine Top End |

||||||

|

Main Valve Cover Bolts |

5.9 |

0.6 |

52 in·lb |

|||

|

Cylinder Head Nuts |

25 |

2.5 |

18 |

S |

||

|

Spark Plug |

27 |

2.8 |

20 |

|||

|

Engine Mounting Bracket Nuts: |

||||||

|

Engine Side 10 mm (KX125/250-M1) |

44 |

4.5 |

33 |

|||

|

Engine Side 10 mm (KX125/250-M2 ) |

49 |

5.0 |

36 |

|||

|

Frame Side 8 m |

29 |

3.0 |

22 |

|||

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

||||

|

N·m |

kgf·m |

ft·lb |

||||

|

KIPS Cover Bolts: |

||||||

|

KX125-M1 |

4.9 |

0.5 |

43 in·lb |

|||

|

KX125-M2 |

8.8 |

0.9 |

78 in·lb |

|||

|

KX250 |

2.9 |

0.3 |

26 in·lb |

|||

|

Cylinder Nuts: |

||||||

|

KX125 |

25 |

2.5 |

18 |

|||

|

KX250 |

34 |

3.5 |

25 |

|||

|

Cylinder Left Cover Bolts (KX250) |

52 in·lb |

|||||

|

5.9 |

0.6 |

|||||

|

Main Lever Mounting Allen Bolt |

3.9 |

0.4 |

35 in·lb |

L |

||

|

Governor Shaft Lever Mounting Bolt (KX125) |

6.9 |

0.7 |

61 in·lb |

|||

|

Exhaust Valve Retaining Bolts (KX125) |

5.9 |

0.6 |

52 in·lb |

|||

|

Main Shaft Stopper Pin Plug (KX125) |

0.8 |

0.08 |

7 in·lb |

|||

|

Main Valve Retaining Bolts (KX250) |

5.9 |

0.6 |

52 in·lb |

|||

|

Operating Rod Retaining Screw (KX250) |

5.4 |

0.55 |

48 in·lb |

|||

|

Operating Rod Left Side Plug (KX250) |

22 |

2.2 |

16 |

|||

|

Main Valve Rod Cover Screw (KX250) |

5.9 |

0.6 |

52 in·lb |

|||

|

Coolant Drain Plug (Cylinder) (KX250) |

8.8 |

0.9 |

78 in·lb |

|||

|

Inner Pipe Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

L |

||

|

Muffler Pipe Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

L |

||

|

Muffler Damper Mounting Bolts (KX125/250-M2 ) |

8.8 |

0.9 |

78 in·lb |

|||

|

Expansion Chamber Mounting Bolt (KX125/250-M2 ) |

12 |

1.2 |

104in·lb |

|||

|

Muffler Mounting Bolt |

8.8 |

0.9 |

78 in·lb |

|||

|

Engine Right Side |

||||||

|

Clutch Hub Nut |

98 |

10.0 |

72 |

|||

|

Clutch Spring Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Clutch Cover Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Governor Shaft Lever Positioning Plug |

0.6 |

0.06 |

5 in·lb |

|||

|

Oil Filler Cap |

1.5 |

0.15 |

13 in·lb |

|||

|

Right Engine Cover Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Governer Shaft Lever Mounting Bolt (KX125) |

6.9 |

0.7 |

61 in·lb |

|||

|

Exhaust Valve Advancer Lever Mounting Allen Bolts |

3.9 |

0.4 |

35 in·lb |

L |

||

|

Primary Gear Nut (KX125) |

59 |

6.0 |

43 |

|||

|

Gear Set Lever Nut |

8.8 |

0.9 |

78 in·lb |

|||

|

Ratchet Plate Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Kick Ratchet Guide Bolt |

8.8 |

0.9 |

78 in·lb |

|||

|

Kick Pedal Bolt: |

||||||

|

KX125 |

12 |

1.2 |

104 in·lb |

|||

|

KX250 |

25 |

2.5 |

18 |

|||

|

Shift Pedal Bolt |

9.8 |

1.0 |

87 in·lb |

|||

|

External Shift Mechanism Return Spring Pin (KX250) |

42 |

4.3 |

31 |

L |

||

|

Gear Set Lever Pivot Stud |

– |

– |

– |

L (Planted |

||

|

Side) |

||||||

PERIODIC MAINTENANCE 2-7

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Engine Removal/Installation |

|||||

|

Engine Mounting Nuts: |

|||||

|

KX125/250-M1 |

44 |

4.5 |

33 |

||

|

KX125/250-M2 |

49 |

5.0 |

36 |

||

|

Engine Mounting Bracket Nuts: |

|||||

|

Engine Side 10 mm (KX125/250-M1) |

44 |

4.5 |

33 |

||

|

Engine Side 10 mm (KX125/250-M2 ) |

49 |

5.0 |

36 |

||

|

Frame Side 8 mm |

29 |

3.0 |

22 |

||

|

Swingarm Pivot Shaft Nut |

98 |

10.0 |

72 |

||

|

Engine Bottom End/Transmission |

|||||

|

Output Shaft Bearing Retaining Screws |

5.4 |

0.55 |

48 in·lb |

L |

|

|

Shift Drum Bearing Retaining Screws (KX125-M1) |

6.4 |

0.65 |

56 in·lb |

L |

|

|

Shift Drum Bearing Retaining Bolts (KX125-M2 ) |

8.8 |

0.9 |

78 in·lb |

L |

|

|

Shift Drum Bearing Retaining Bolts (KX250) |

8.8 |

0.9 |

78 in·lb |

L |

|

|

Drive Shaft Bearing Retaining Bolts (KX250) |

8.8 |

0.9 |

78 in·lb |

||

|

Engine Oil Drain Bolt |

20 |

2.0 |

14.5 |

||

|

Crankcase Bolts |

8.8 |

0.9 |

78 in·lb |

||

|

Flywheel Bolt (KX125) |

22 |

2.2 |

16 |

||

|

Flywheel Nut (KX250) |

78 |

8.0 |

58 |

||

|

Shift Drum Operating Cam Bolt |

24 |

2.4 |

17 |

L |

|

|

Cylinder Stud |

– |

– |

– |

L (Planted |

|

|

Side) |

|||||

|

Wheels/Tires |

|||||

|

Front Axle Nut |

78 |

8.0 |

58 |

||

|

Front Axle Clamp Bolts |

20 |

2.0 |

14.5 |

||

|

Rear Axle Nut |

108 |

11.0 |

80 |

||

|

Spoke Nipple |

2.2 or |

0.22 or |

19 in·lb or |

||

|

more |

more |

more |

|||

|

Final Drive |

|||||

|

Rear Axle Nut |

108 |

11.0 |

80 |

||

|

Rear Sprocket Nuts |

34 |

3.5 |

25 |

||

|

Engine Sprocket Cover Bolts |

4.9 |

0.5 |

43 in·lb |

||

|

Brakes |

|||||

|

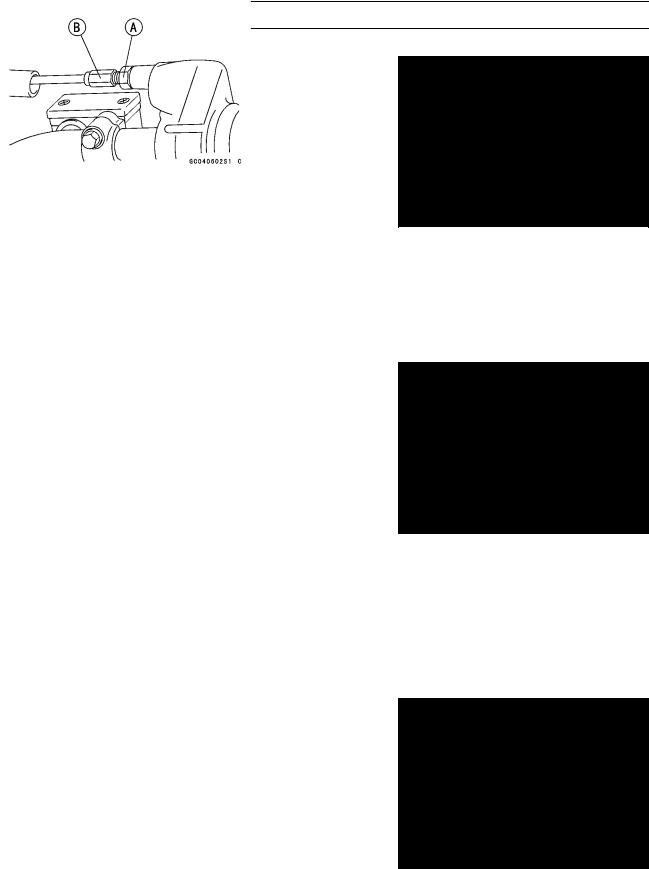

Front Master Cylinder Clamp Bolts |

8.8 |

0.9 |

78 in·lb |

||

|

Brake Lever Pivot Bolt |

5.9 |

0.60 |

52 in·lb |

||

|

Brake Lever Pivot Bolt Locknut |

5.9 |

0.60 |

52 in·lb |

||

|

Brake Hose Banjo Bolts |

25 |

2.5 |

18 |

||

|

Brake Pad Bolt |

18 |

1.8 |

13 |

||

|

Caliper Bleed Valves (Front, Rear) |

7.8 |

0.8 |

69 in·lb |

||

|

Caliper Mounting Bolts (Front) |

25 |

2.5 |

18 |

||

|

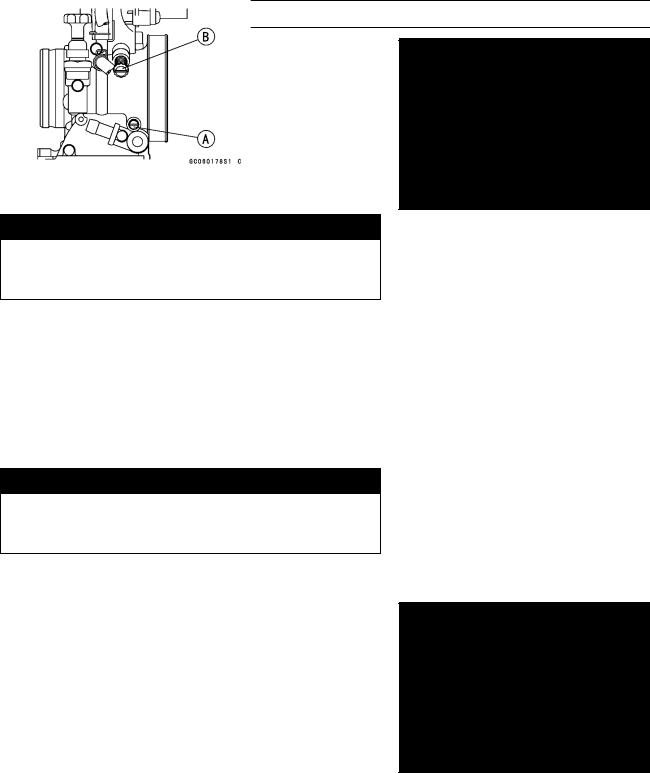

Rear Master Cylinder Mounting Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Rear Master Cylinder Push Rod Locknut |

18 |

1.8 |

13 |

||

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

||||

|

N·m |

kgf·m |

ft·lb |

||||

|

Brake Disc Mounting Bolts: |

||||||

|

Front |

9.8 |

1.0 |

87 in·lb |

L |

||

|

Rear |

23 |

2.3 |

17 |

L |

||

|

Caliper Holder Shaft |

27 |

2.8 |

20 |

|||

|

Rear Brake Pad Bolt Plug |

2.5 |

0.25 |

22 in·lb |

|||

|

Brake Pedal Mounting Bolt |

25 |

2.5 |

18 |

|||

|

Suspension |

||||||

|

Front Fork Top Plug |

29 |

3.0 |

22 |

|||

|

Front Fork Clamp Bolts (Upper, Lower) |

20 |

2.0 |

14.5 |

|||

|

Piston Rod Nut |

28 |

2.9 |

21 |

|||

|

Front Axle Clamp Bolts |

20 |

2.0 |

14.5 |

|||

|

Front Fork Cylinder Valve Assembly |

54 |

5.5 |

40 |

L |

||

|

Swingarm Pivot Shaft Nut |

98 |

10.0 |

72 |

|||

|

Tie-Rod Mounting Nut (Front, Rear) |

83 |

8.5 |

61 |

|||

|

Rocker Arm Pivot Nut |

83 |

8.5 |

61 |

|||

|

Rear Shock Absorber Mounting Nuts: |

||||||

|

Upper |

39 |

4.0 |

29 |

|||

|

Lower |

34 |

3.5 |

25 |

|||

|

Steering |

||||||

|

Steering Stem Head Nut |

98 |

10.0 |

72 |

|||

|

Steering Stem Locknut |

4.9 |

0.5 |

43 in·lb |

|||

|

Handlebar Holder Bolts |

25 |

2.5 |

18 |

|||

|

Front Fork Clamp Bolts (Upper, Lower) |

20 |

2.0 |

14.5 |

|||

|

Electrical System |

||||||

|

Flywheel Bolt |

22 |

2.2 |

16 |

|||

|

Flywheel Nut |

78 |

8.0 |

58 |

|||

|

Stator Plate Mounting Screws |

4.4 |

0.45 |

39 in·lb |

|||

|

Spark Plug |

27 |

2.8 |

20 |

|||

|

Magneto Cover Bolts: (KX125/250-M1) |

4.9 |

0.5 |

43 in·lb |

|||

|

Magneto Cover Bolts: KX125/250-M2 ) |

3.9 |

0.4 |

35 in·lb |

|||

|

C.D.I Unit Mounting Bolts |

8.8 |

0.9 |

78 in·lb |

|||

|

Ignition Coil Mounting Bolts |

78 in·lb |

|||||

|

8.8 |

0.9 |

PERIODIC MAINTENANCE 2-9

Torque and Locking Agent

Basic Torque for General Fasteners

|

Threads dia. (mm) |

Torque |

|||||||||

|

N·m |

kgf·m |

ft·lb |

||||||||

|

5 |

3.4 |

4.9 |

0.35 |

0.50 |

30 |

43 in·lb |

||||

|

6 |

5.9 |

7.8 |

0.60 |

0.80 |

52 |

69 in·lb |

||||

|

8 |

14 |

19 |

1.4 |

1.9 |

10.0 |

13.5 |

||||

|

10 |

25 |

34 |

2.6 |

3.5 |

19.0 |

25 |

||||

|

12 |

44 |

61 |

4.5 |

6.2 |

33 |

45 |

||||

|

14 |

73 |

98 |

7.4 |

10.0 |

54 |

72 |

||||

|

16 |

115 |

155 |

11.5 |

16.0 |

83 |

115 |

||||

|

18 |

165 |

225 |

17.0 |

23.0 |

125 |

165 |

||||

|

20 |

225 |

325 |

23 |

33 |

165 |

240 |

2-10 PERIODIC MAINTENANCE

Specifications

|

Item |

Standard |

Service Limit |

||||

|

Fuel System |

||||||

|

Throttle Grip Free Play |

2 3 mm (0.08 0.12 in.) |

– – – |

||||

|

Air Cleaner Element Oil |

High quality foam air filter oil |

– – – |

||||

|

Read Valve Warp |

0.5 mm (0.020 in.) |

|||||

|

Cooling System |

– – – |

|||||

|

Coolant: |

||||||

|

Type (recommended) |

Permanent type antifreeze |

|||||

|

Color |

Green |

|||||

|

Mixed Ratio |

Soft water 50% and coolant 50% |

|||||

|

Freezing Point |

–35°C (–31°F) |

|||||

|

Total Amount: |

||||||

|

KX125 |

0.97 L (1.02 US qt) |

|||||

|

KX250 |

1.20 L (1.27 US qt) |

|||||

|

Engine Top End |

||||||

|

Cylinder Head Warp |

– – – |

0.03 mm (0.0012 in.) |

||||

|

Cylinder, Piston (KX125): |

||||||

|

Cylinder Inside Diameter (15 mm |

54.010 |

54.025 mm |

54.10 mm (2.130 in.) |

|||

|

(0.59 in.) below of the cylinder |

(2.1264 |

2.1270 in.) |

||||

|

head) |

||||||

|

Piston Diameter |

53.955 |

53.970 mm |

53.81 mm (2.118 in.) |

|||

|

(2.1242 |

2.1480 in.) |

|||||

|

Piston/Cylinder Clearance |

0.040 |

0.070 mm (0.0016 |

0.0028 in.) |

– – – |

||

|

Piston Ring/Groove clearance |

0.015 |

0.050 mm (0.0006 |

0.0020 in.) |

0.15 mm (0.006 in.) |

||

|

Piston Ring Groove Width |

1.01 |

1.03 mm (0.0398 |

0.0406 in.) |

1.11 mm (0.044 in.) |

||

|

Piston Ring Thickness |

0.980 |

0.995 mm (0.0386 |

0.0392 in.) |

0.91 mm (0.036 in.) |

||

|

Piston Ring End Gap |

0.35 |

0.55 mm (0.0138 |

0.0217 in.) |

0.85 mm (0.033 in.) |

||

|

Piston Pin Diameter |

14.995 |

15.000 mm |

14.96 mm (0.589 in.) |

|||

|

(0.5904 |

0.5906 in.) |

|||||

|

Piston Pin Hole Diameter |

15.001 |

15.011 mm |

15.08 mm (0.594 in.) |

|||

|

(0.5906 |

0.5910 in.) |

|||||

|

Connection Rod Small End Inside |

19.003 |

19.014 mm |

19.05 mm (0.750 in.) |

|||

|

Diameter |

(0.7481 |

0.7486 in.) |

||||

|

Cylinder, Piston (KX250): |

||||||

|

Cylinder Inside Diameter (30 mm |

66.400 |

66.415 mm |

66.46 mm (2.617 in.) |

|||

|

(1.18 in.) below of the cylinder |

(2.6142 |

2.6148 in.) |

||||

|

Head) |

||||||

|

Piston Diameter |

66.336 |

66.351 mm |

66.19 mm |

|||

|

(2.6116 |

2.6122 in.) |

(2.6059 in.) |

||||

|

Piston/Cylinder Clearance |

0.049 |

0.079 mm (0.0019 |

0.0031 in.) |

– – – |

||

|

Piston Ring/Groove Clearance |

0.025 |

0.06 mm |

0.16 mm (0.006 in.) |

|||

|

(0.00098 0.00236 in.) |

||||||

|

Piston Ring Groove Width |

1.01 |

1.03 mm (0.0398 |

0.0406 in.) |

1.11 mm (0.044 in.) |

||

|

Piston Ring Thickness |

0.970 |

0.985 mm (0.0382 |

0.0388 in.) |

0.90 mm (0.035 in.) |

||

|

Piston Ring End Gap |

0.25 |

0.45 mm (0.0098 |

0.0177 in.) |

0.75 mm (0.030 in.) |

||

|

Piston Pin Diameter |

17.995 |

18.000 mm |

17.96 mm (0.707 in.) |

|||

|

(0.7085 |

0.7087 in.) |

PERIODIC MAINTENANCE 2-11

Specifications

|

Item |

Standard |

Service Limit |

||||

|

Piston Pin Hole Diameter |

18.001 |

18.011 mm |

18.08 mm (0.712 in.) |

|||

|

(0.7087 |

0.7091 in.) |

|||||

|

Connection Rod Small End Inside |

22.003 |

22.012 mm |

22.05 mm (0.868 in.) |

|||

|

Diameter |

(0.8663 |

0.8666 in.) |

||||

|

Engine Right Side |

||||||

|

Clutch Lever Free Play |

2 3 mm (0.08 0.12 in.) |

– – – |

||||

|

Friction Plate Thickness |

||||||

|

KX125 |

2.72 |

2.88 mm (0.107 |

0.113 in.) |

2.6 mm (0.102 in.) |

||

|

KX250 |

2.92 |

3.08 mm (0.115 |

0.121 in.) |

2.8 mm (0.110 in.) |

||

|

Steel Plate Thickness: |

||||||

|

KX125 |

1.5 1.7 mm (0.059 0.067 in.) |

1.4 mm (0.055 in.) |

||||

|

KX250 |

1.46 |

1.74 mm (0.057 |

0.069 in.) |

1.36 mm (0.054 in.) |

||

|

Friction Plate Warp |

0.15 mm (0.006 in.) or Less |

0.3 mm (0.012 in.) |

||||

|

Steel Plate Warp |

0.2 mm (0.008 in.) or Less |

0.3 mm (0.012 in.) |

||||

|

Engine Bottom End/Transmission |

||||||

|

Transmission Oil: |

||||||

|

Grade |

API SE, SF or SG |

|||||

|

API SH or SJ with JASO MA |

||||||

|

API SH, SJ or SL with JASO MA |

||||||

|

(KX125M7F ) |

||||||

|

Viscosity |

SAE 10W-40 |

|||||

|

Capacity: |

||||||

|

KX125 |

0.7 L (0.74 US qt) |

|||||

|

KX250 |

0.85 L (0.90 US qt) |

– – – |

||||

|

Wheels/Tires |

||||||

|

Rim Runout (with tire installed): |

||||||

|

Axial |

TIR 1.0 mm (0.04 in.) or less |

TIR 2 mm (0.08 in.) |

||||

|

Radial |

TIR 1.0 mm (0.04 in.) or less |

TIR 2 mm (0.08 in.) |

||||

|

Final Drive |

||||||

|

Drive Chain Slack |

52 62 mm (2.05 2.44 in.) |

– – – |

||||

|

Drive Chain 20 Link Length |

317.5 |

318.2 mm (12.50 12.53 in.) |

323 mm (12.72 in.) |

|||

|

Rear Sprocket Warp (Runout) |

TIR 0.4 mm (0.016 in.) or less |

TIR 0.5 mm (0.020 |

||||

|

in.) |

||||||

|

Brakes |

||||||

|

Brake Lever Play |

Adjustable (to suit rider) |

– – – |

||||

|

Brake Fluid: |

||||||

|

Type: |