- Manuals

- Brands

- Yamaha Manuals

- Motorcycle

- FAZER FZS1000

- Owner’s manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

OWNER’S MANUAL

FZS1000

FZS1000S

1C2-28199-E0

Related Manuals for Yamaha FAZER FZS1000

Summary of Contents for Yamaha FAZER FZS1000

-

Page 1

OWNER’S MANUAL FZS1000 FZS1000S 1C2-28199-E0… -

Page 3

In addition, the many tips given in this manual will help keep your motorcycle in the best possible con- dition. If you have any further questions, do not hesitate to contact your Yamaha dealer. The Yamaha team wishes you many safe and pleasant rides. So, remember to put safety first! -

Page 4: Important Manual Information

This manual should be considered a permanent part of this motorcycle and should remain with it even if the motorcycle is subsequently sold. Yamaha continually seeks advancements in product design and quality. Therefore, while this manual contains the most current product information available at the time of printing, there may be minor discrepancies between your motorcycle and this manual.

-

Page 5

IMPORTANT MANUAL INFORMATION EAU10200 FZS1000/FZS1000S OWNER’S MANUAL ©2003 by Yamaha Motor Co., Ltd. 1st edition, May 2003 All rights reserved. Any reprinting or unauthorized use without the written permission of Yamaha Motor Co., Ltd. is expressly prohibited. Printed in Japan. -

Page 6: Table Of Contents

TABLE OF CONTENTS SAFETY INFORMATION ….1-1 EXUP system ……. 3-16 Adjusting the throttle cable Sidestand ……..3-17 free play ……..6-17 DESCRIPTION ……..2-1 Ignition circuit cut-off system ..3-17 Adjusting the valve clearance ..6-17 Left view ……….2-1 Tires ……….6-17 Right view ……..2-2 PRE-OPERATION CHECKS …..

-

Page 7

TABLE OF CONTENTS Battery ……….6-30 Replacing the fuses ……6-31 Replacing a headlight bulb …6-32 Replacing a tail/brake light bulb …6-33 Replacing a turn signal light bulb ………..6-34 Front wheel ……..6-34 Rear wheel ……..6-35 Troubleshooting ……6-37 Troubleshooting charts ….6-38 MOTORCYCLE CARE AND STORAGE ……….7-1 Care ……….7-1 Storage ………..7-3… -

Page 8: Safety Information

SAFETY INFORMATION EAU10270 AND/OR WHEN MADE NECES- • Ride where other motorists can SARY BY MECHANICAL CONDI- see you. Avoid riding in another MOTORCYCLES SINGLE TIONS. motorist’s blind spot. TRACK VEHICLES. THEIR SAFE USE Many accidents involve inexperi- AND OPERATION ARE DEPENDENT Safe riding enced operators.

-

Page 9

Modifications made to this motorcycle other motorists can see you. the single most critical factor in the pre- not approved by Yamaha, or the re- The posture of the operator and vention or reduction of head injuries. moval of original equipment, may ren- passenger is important for proper Always wear an approved helmet. -

Page 10

Since Yamaha cannot should be kept to a minimum. 189 kg (417 lb). When loading within test all other accessories that may be •… -

Page 11

SAFETY INFORMATION Gasoline and exhaust gas • Do not park the motorcycle on a GASOLINE IS HIGHLY FLAMMA- slope or soft ground, otherwise it BLE: may fall over. • Always turn the engine off when • Do not park the motorcycle near refueling. -

Page 12: Description

DESCRIPTION EAU10410 Left view 1. Front fork compression damping force adjusting screw (page 3-13) 11.Shock absorber assembly rebound damping force adjusting knob (page 3-14) 2. Front fork rebound damping force adjusting screw (page 3-13) 12.Shift pedal (page 3-8) 3. Front fork spring preload adjusting bolt (page 3-13) 4.

-

Page 13: Right View

DESCRIPTION EAU10420 Right view 1. Owner’s tool kit (page 6-1) 2. Rear brake fluid reservoir (page 6-23) 3. Battery (page 6-30) 4. Front brake fluid reservoir (page 6-23) 5. Radiator cap (page 6-11) 6. Engine oil filter cartridge (page 6-8) 7.

-

Page 14: Controls And Instruments

DESCRIPTION EAU10430 Controls and instruments 1. Clutch lever (page 3-7) 2. Left handlebar switches (page 3-6) 3. Starter (choke) lever (page 3-11) 4. Speedometer unit (page 3-3) 5. Main switch/steering lock (page 3-1) 6. Tachometer unit (page 3-4) 7. Fuel gauge (page 3-5) 8.

-

Page 15: Instrument And Control Functions

INSTRUMENT AND CONTROL FUNCTIONS EAU10460 EAU10660 To unlock the steering Main switch/steering lock All electrical systems are off. The key can be removed. EAU10680 LOCK The steering is locked, and all electrical systems are off. The key can be re- moved.

-

Page 16: Indicator And Warning Lights

3. High beam indicator light “ ” for a few seconds, then go off, have a 4. Oil level warning light “ ” Yamaha dealer check the electrical cir- 5. Right turn signal indicator light “ ” cuit. 6. Coolant temperature warning light “…

-

Page 17: Speedometer Unit

“ON”. If the warning light does not come on for a few seconds, then go off, have a 1. Speedometer Yamaha dealer check the electrical cir- 2. Odometer/tripmeter cuit. 3. “SELECT” button 4. “RESET” button…

-

Page 18: Tachometer Unit

INSTRUMENT AND CONTROL FUNCTIONS be traveled on a full tank of fuel. This in- EAU11891 To set the clock Tachometer unit formation will enable you to plan future 1. Push both the “SELECT” and “RE- fuel stops. SET” buttons for at least two sec- onds.

-

Page 19: Self-Diagnosis Devices

EAU12110 Self-diagnosis devices Fuel gauge code, note the circuit-specific number This model is equipped with a self-diag- of r/min, and then have a Yamaha deal- nosis device for the following electrical er check the vehicle. circuits: ECA10040 throttle position sensor…

-

Page 20: Anti-Theft Alarm (Optional)

EAU12341 Right Anti-theft alarm (optional) Handlebar switches This model can be equipped with an Left optional anti-theft alarm by a Yamaha dealer. Contact a Yamaha dealer for more information. 1. Engine stop switch “ ” 2. Start switch “ ”…

-

Page 21: Clutch Lever

INSTRUMENT AND CONTROL FUNCTIONS position. To cancel the turn signal EAU12730 EAU12820 Hazard switch “ ” Clutch lever lights, push the switch in after it has re- With the key in the “ON” or “ ” posi- turned to the center position. tion, use this switch to turn on the haz- ard light (simultaneous flashing of all EAU12500…

-

Page 22: Shift Pedal

INSTRUMENT AND CONTROL FUNCTIONS EAU12870 EAU12930 EAU12941 Shift pedal Brake lever Brake pedal The brake lever is located at the right handlebar grip. To apply the front brake, pull the lever toward the handle- bar grip. 1. Shift pedal 1. Brake pedal The shift pedal is located on the left The brake pedal is on the right side of side of the engine and is used in com-…

-

Page 23: Fuel Tank Cap

INSTRUMENT AND CONTROL FUNCTIONS EAU13070 EAU13210 Fuel tank cap NOTE: Fuel The fuel tank cap cannot be closed un- less the key is in the lock. In addition, the key cannot be removed if the cap is not properly closed and locked. EWA11090 WARNING Make sure that the fuel tank cap is…

-

Page 24: Fuel Tank Breather Hose

Your Yamaha engine has been de- signed to use regular unleaded gaso- line with a research octane number of 91 or higher. If knocking (or pinging) oc-…

-

Page 25: Starter (Choke) Lever

INSTRUMENT AND CONTROL FUNCTIONS EAU13590 EAU13940 Starter (choke) lever “ ” Seat To remove the seat 1. Insert the key into the seat lock, and then turn it clockwise. 1. Projection 2. Seat holder 1. Starter (choke) lever “ ” 2.

-

Page 26: Helmet Holder

This storage compartment is designed When storing the owner’s manual or To open the helmet holder, insert the to hold an optional genuine Yamaha U- other documents in the storage com- key into the seat lock, and then turn the LOCK.

-

Page 27: Adjusting The Front Fork

INSTRUMENT AND CONTROL FUNCTIONS EAU14750 load thereby soften Rebound damping force Adjusting the front fork suspension, turn the adjusting bolt on This front fork is equipped with spring each fork leg in direction (b). preload adjusting bolts, rebound damp- NOTE: ing force adjusting screws and com- Align the appropriate groove on the ad- pression…

-

Page 28: Adjusting The Shock Absorber Assembly

INSTRUMENT AND CONTROL FUNCTIONS Compression damping force ECA10100 EAU15041 Adjusting the shock absorber CAUTION: assembly Never attempt to turn an adjusting This shock absorber assembly is mechanism beyond the maximum or equipped with a spring preload adjust- minimum settings. ing ring, a rebound damping force ad- justing knob and a compression NOTE: damping force adjusting screw.

-

Page 29

INSTRUMENT AND CONTROL FUNCTIONS To increase the spring preload and Rebound damping force Compression damping force thereby harden the suspension, turn the adjusting ring in direction (a). To de- crease the spring preload and thereby soften the suspension, turn the adjust- ing ring in direction (b). -

Page 30: Exup System

NOTE: EXUP system sorber to an open flame or other Although the total number of clicks of a This model is equipped with Yamaha’s high heat sources, otherwise it damping force adjusting mechanism EXUP (EXhaust Ultimate Power valve) may explode due to excessive may not exactly match the above spec- system.

-

Page 31: Sidestand

INSTRUMENT AND CONTROL FUNCTIONS EAU15300 below and have a Yamaha dealer re- EAU15321 Sidestand Ignition circuit cut-off system pair it if it does not function proper- The sidestand is located on the left side The ignition circuit cut-off system (com- of the frame.

-

Page 32

5. Push the start switch. Does the engine start? The neutral switch may be defective. The motorcycle should not be ridden until checked by a Yamaha dealer. With the engine still running: 6. Move the sidestand up. 7. Keep the clutch lever pulled. -

Page 33: Pre-Operation Checks

PRE-OPERATION CHECKS EAU15591 The condition of a vehicle is the owner’s responsibility. Vital components can start to deteriorate quickly and unexpectedly, even if the vehicle remains unused (for example, as a result of exposure to the elements). Any damage, fluid leakage or loss of tire air pressure could have serious consequences.

-

Page 34: Pre-Operation Check List

• If necessary, add recommended coolant to specified level. 6-11 • Check cooling system for leakage. • Check operation. • If soft or spongy, have Yamaha dealer bleed hydraulic system. • Check brake pads for wear. Front brake • Replace if necessary.

-

Page 35

• Make sure that operation is smooth. • Check cable free play. Throttle grip 6-17, 6-26 • If necessary, have Yamaha dealer adjust cable free play and lubricate cable and grip housing. • Make sure that operation is smooth. Control cables 6-26 •… -

Page 36: Operation And Important Riding Points

EWA10290 Yamaha dealer check the electrical cir- WARNING Never start the engine or oper- cuit. ate it in a closed area for any Before…

-

Page 37

Yamaha dealer check the with sufficient engine oil, have a electrical circuit. Yamaha dealer check the elec- trical circuit. -

Page 38: Starting A Warm Engine

OPERATION AND IMPORTANT RIDING POINTS EAU16640 EAU16671 ECA10260 Starting a warm engine Shifting CAUTION: Follow the same procedure as for start- Even with the transmission in ing a cold engine with the exception the neutral position, do not that the starter (choke) is not required coast for long periods of time when the engine is warm.

-

Page 39: Tips For Reducing Fuel Consumption

OPERATION AND IMPORTANT RIDING POINTS EAU16800 EAU16841 Shift up points: Tips for reducing fuel Engine break-in 1st → 2nd: 20 km/h (12 mi/h) consumption There is never a more important period 2nd → 3rd: 30 km/h (19 mi/h) in the life of your engine than the period 3rd →…

-

Page 40: Parking

Do not park on a slope or on soft the tachometer red zone. ground, otherwise the vehicle If any engine trouble should oc- may overturn. cur during the engine break-in period, immediately have a Yamaha dealer check the vehi- cle.

-

Page 41: Periodic Maintenance And Minor Repair

Yamaha dealer certain maintenance work correctly. do it for you. NOTE: If you do not have the tools or experi- ence required for a particular job, have a Yamaha dealer perform it for you.

-

Page 42: Periodic Maintenance And Lubrication Chart

The annual checks must be performed every year, except if a kilometer-based maintenance is performed in- stead. From 50,000 km, repeat the maintenance intervals starting from 10,000 km. Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical skills. ODOMETER READING (× 1,000 km)

-

Page 43

PERIODIC MAINTENANCE AND MINOR REPAIR ODOMETER READING (× 1,000 km) ANNUAL ITEM CHECK OR MAINTENANCE JOB CHECK √ √ √ √ √ • Check for cracks or damage. 9 * Brake hoses • Replace. Every 4 years √ √ √ √… -

Page 44

PERIODIC MAINTENANCE AND MINOR REPAIR ODOMETER READING (× 1,000 km) ANNUAL ITEM CHECK OR MAINTENANCE JOB CHECK • Check starter (choke) operation. √ √ √ √ √ √ 22 * Carburetors • Adjust engine idling speed and synchronization. • Change. √… -

Page 45

PERIODIC MAINTENANCE AND MINOR REPAIR Hydraulic brake service • Regularly check and, if necessary, correct the brake fluid level. • Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid. • Replace the brake hoses every four years and if cracked or damaged. -

Page 46: Removing And Installing Panels

PERIODIC MAINTENANCE AND MINOR REPAIR EAU18770 The panels shown above need to be re- Removing and installing moved to perform some of the mainte- panels nance jobs described in this chapter. Refer to this section each time a panel needs to be removed and installed. EAU19292 Panels A and C To remove one of the panels…

-

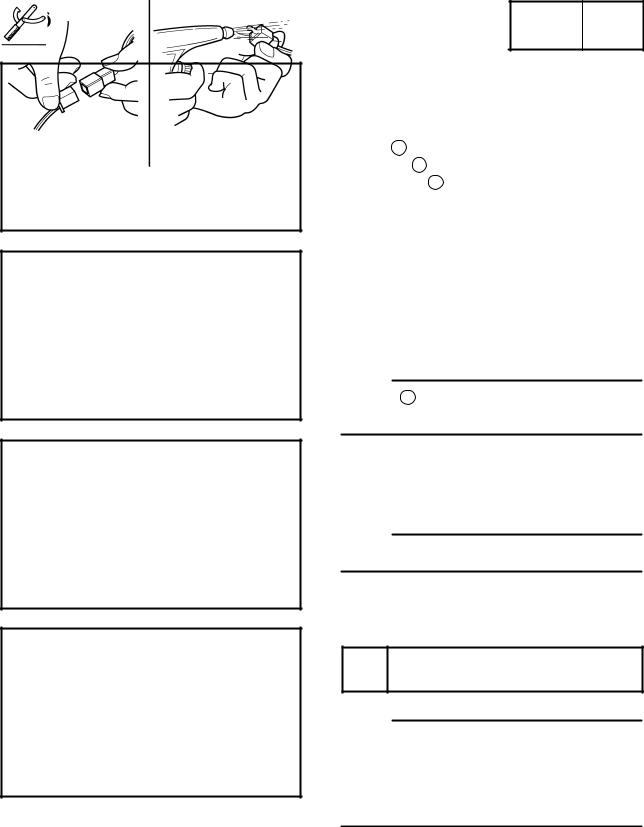

Page 47: Checking The Spark Plugs

Do not attempt to diagnose such 1. Spark plug cap problems yourself. Instead, have a 2. Remove the spark plug as shown, Yamaha dealer check the vehicle. with the spark plug wrench includ- ed in the owner’s tool kit.

-

Page 48: Engine Oil And Oil Filter Cartridge

PERIODIC MAINTENANCE AND MINOR REPAIR 3. Check each spark plug for elec- 2. Clean the surface of the spark plug EAU19890 Engine oil and oil filter trode erosion and excessive car- gasket and its mating surface, and cartridge bon or other deposits, and replace then wipe off any grime from the The engine oil level should be checked it if necessary.

-

Page 49: To Change Engine Oil

2. Oil filter cartridge NOTE: An oil filter wrench is available at a 1. Engine oil filler cap Yamaha dealer. 2. Engine oil level check window 1. Engine oil drain bolt 3. Maximum level mark 5. Apply a thin coat of engine oil to 4.

-

Page 50

PERIODIC MAINTENANCE AND MINOR REPAIR Recommended engine oil: See page 8-1. Oil quantity: Without oil filter cartridge replace- ment: 2.80 L (2.96 US qt) (2.46 Imp.qt) With oil filter cartridge replacement: 3.00 L (3.17 US qt) (2.64 Imp.qt) ECA11620 CAUTION: 1. -

Page 51: Coolant

If the oil level warning light flickers EAU20101 or remains on, immediately turn the To check the coolant level engine off and have a Yamaha dealer 1. Place the vehicle on the center- 1. Coolant reservoir check the vehicle. stand.

-

Page 52

2. Remove panels A and B. (See If water has been added to the page 6-6.) coolant, have a Yamaha dealer 3. Place a container under the engine check the antifreeze content of to collect the used coolant. -

Page 53

If ant as soon as possible, other- 7 Nm (0.7 m·kgf, 5 ft·lbf) coolant is leaking, have a Yamaha wise the engine may not be sufficiently cooled and the cool- dealer check the cooling system. -

Page 54: Cleaning The Air Filter Element

PERIODIC MAINTENANCE AND MINOR REPAIR EAU20681 Do not tilt or pull the fuel tank Cleaning the air filter element too much, otherwise the fuel The air filter element should be cleaned hoses may come loose, which at the intervals specified in the periodic could cause fuel leakage.

-

Page 55

Before installing the fuel tank, make sure that the fuel hoses are not damaged. If any fuel hose is damaged, do not start the engine but have a Yamaha dealer replace the hose, other- wise fuel may leak. Make sure that the fuel hoses are properly connected and 1. -

Page 56: Adjusting The Carburetors

Therefore, most carbu- checked and, if necessary, adjusted as retor adjustments should be left to a follows at the intervals specified in the Yamaha dealer, who has the neces- periodic maintenance and lubrication sary professional knowledge and expe- chart.

-

Page 57: Adjusting The Throttle Cable Free Play

Yamaha dealer at the intervals specified in the periodic Tire air pressure maintenance and lubrication chart. The tire air pressure should be checked and, if necessary, adjusted before each ride.

-

Page 58

189 kg (417 lb) glass fragments in it, or if the sidewall is weight evenly on both sides. * Total weight of rider, passenger, car- cracked, have a Yamaha dealer re- Adjust the suspension and tire go and accessories place the tire immediately. -

Page 59

PERIODIC MAINTENANCE AND MINOR REPAIR EWA10470 This motorcycle is equipped with cast Front tire: WARNING wheels and tubeless tires with valves. Size: Have a Yamaha dealer replace EWA10480 120/70 ZR17M/C (58W) WARNING Manufacturer/model: excessively worn tires. Besides METZELER/MEZ4Y FRONT being illegal, operating the vehi-… -

Page 60: Cast Wheels

If any damage is found, have a Yamaha dealer re- place the wheel. Do not attempt even the smallest repair to the wheel. A deformed or cracked 1.

-

Page 61: Adjusting The Brake Pedal Position

Yamaha dealer check the internal clutch mechanism. 1. Distance between brake pedal and footrest The top of the brake pedal should be positioned approximately 43.0 mm (1.69 in) below the top of the footrest as…

-

Page 62: Adjusting The Rear Brake Light Switch

If a brake pad has worn to the point that the wear indicator groove has almost disappeared, have a Yamaha dealer replace the brake pads as a set. 1. Rear brake light switch 2. Rear brake light switch adjusting nut 1.

-

Page 63: Checking The Brake Fluid Level

However, if the Use only the recommended quality brake fluid level goes down sud- 1. Minimum level mark brake fluid, otherwise the rubber denly, have a Yamaha dealer Rear brake seals may deteriorate, causing check the cause. leakage and poor braking perfor- mance.

-

Page 64: Changing The Brake Fluid

EAU22730 EAU22760 Changing the brake fluid Drive chain slack Have a Yamaha dealer change the The drive chain slack should be brake fluid at the intervals specified in checked before each ride and adjusted the NOTE after the periodic mainte- if necessary.

-

Page 65: Lubricating The Drive Chain

PERIODIC MAINTENANCE AND MINOR REPAIR 3. Tighten the locknuts, and then EAU23020 NOTE: Lubricating the drive chain tighten the axle nut to the specified Using the alignment marks on each The drive chain must be cleaned and torque. side of the swingarm, make sure that lubricated at the intervals specified in both chain pullers are in the same posi- the periodic maintenance and lubrica-…

-

Page 66: Checking And Lubricating The Cables

If a cable is damaged periodic maintenance chart. or does not move smoothly, have a Yamaha dealer check or replace it. Recommended lubricant: Engine oil EWA10720 WARNING…

-

Page 67: Checking And Lubricating The Brake And Shift Pedals

Lithium-soap-based grease (all-pur- Lithium-soap-based grease (all-pur- WARNING pose grease) pose grease) If the centerstand or sidestand does not move up and down smoothly, have a Yamaha dealer check or re- pair it. Recommended lubricant: Lithium-soap-based grease (all-pur- pose grease) 6-27…

-

Page 68: Lubricating The Rear Suspension

If any damage is found or the front Check the inner tubes for scratches, fork does not operate smoothly, damage and excessive oil leakage. have a Yamaha dealer check or re- pair it. To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi- tion.

-

Page 69: Checking The Steering

2. Hold the lower ends of the front fork legs and try to move them for- ward and backward. If any free play can be felt, have a Yamaha dealer check or repair the steering. 6-29…

-

Page 70: Battery

Electrolyte is poisonous and To charge the battery To charge a sealed-type (MF) dangerous since it contains sul- Have a Yamaha dealer charge the bat- battery, a special (constant-volt- furic acid, which causes severe tery as soon as possible if it seems to age) battery charger is required.

-

Page 71: Replacing The Fuses

EAU23622 2. Remove the blown fuse, and then 4. If the fuse immediately blows Replacing the fuses install a new fuse of the specified again, have a Yamaha dealer amperage. check the electrical system. Specified fuses: Main fuse: 30.0 A Headlight fuse: 20.0 A…

-

Page 72: Replacing A Headlight Bulb

PERIODIC MAINTENANCE AND MINOR REPAIR EAU23730 Headlight bulb Replacing a headlight bulb Do not touch the glass part of This model is equipped with two quartz the headlight bulb to keep it free bulb headlights. If a headlight bulb from oil, otherwise the transpar- burns out, replace it as follows.

-

Page 73: Replacing A Tail/Brake Light Bulb

Replacing a tail/brake light and then connect the coupler. bulb 6. Install the panel. 1. Remove the seat. (See page 7. Have a Yamaha dealer adjust the 3-11.) headlight beam if necessary. 2. Remove the tail/brake light bulb cover. 1. Tail/brake light bulb socket 4.

-

Page 74: Replacing A Turn Signal Light Bulb

To remove the front wheel by removing the screw. EWA10820 WARNING It is advisable to have a Yamaha dealer service the wheel. Securely support the motor- cycle so that there is no danger of it falling over.

-

Page 75: Rear Wheel

2. Insert the wheel axle. EWA10820 3. Lower the front wheel so that it is WARNING on the ground. It is advisable to have a Yamaha 4. Install the brake calipers by install- dealer service the wheel. ing the bolts. Securely support the motor-…

-

Page 76

PERIODIC MAINTENANCE AND MINOR REPAIR 3. Disconnect the brake torque rod 6. Turn the drive chain slack adjust- EAU25841 To install the rear wheel from the brake caliper by removing ing bolts fully in direction (a). 1. Place the wheel and the brake cal- the nut and the bolt. -

Page 77: Troubleshooting

However, should your motorcycle require any repair, take it to a Yamaha Tightening torques: dealer, whose skilled technicians have Axle nut: 150 Nm (15.0 m·kgf, 108 ft·lbf)

-

Page 78: Troubleshooting Charts

Remove the spark plugs and check the electrodes. The engine does not start. Have a Yamaha dealer check the vehicle. Check the battery. 4. Battery The engine turns over The battery is good.

-

Page 79

Start the engine. If the engine overheats again, have a The coolant level Yamaha dealer check and repair the cooling system. is OK. NOTE: If coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended coolant as soon as possible. -

Page 80: Motorcycle Care And Storage

MOTORCYCLE CARE AND STORAGE EAU26010 ucts onto seals, gaskets, sprock- cleaning products, solvent or Care ets, the drive chain and wheel thinner, fuel (gasoline), rust re- While the open design of a motorcycle axles. Always rinse the dirt and de- movers or inhibitors, brake flu- reveals the attractiveness of the tech- greaser off with water.

-

Page 81

MOTORCYCLE CARE AND STORAGE After normal use ECA10790 5. Use spray oil as a universal clean- CAUTION: Remove dirt with warm water, a mild er to remove any remaining dirt. detergent, and a soft, clean sponge, 6. Touch up minor paint damage Do not use warm water since it in- and then rinse thoroughly with clean caused by stones, etc. -

Page 82: Storage

CAUTION: NOTE: fuel from deteriorating. Storing the motorcycle in a Consult a Yamaha dealer for advice on 5. Perform the following steps to pro- poorly ventilated room or cover- what products to use. tect the cylinders, piston rings, etc.

-

Page 83

MOTORCYCLE CARE AND STORAGE EWA10950 °C (90 °F)]. For more information WARNING on storing the battery, see page To prevent damage or injury from 6-30. sparking, make sure to ground the NOTE: spark plug electrodes while turning Make any necessary repairs before the engine over. -

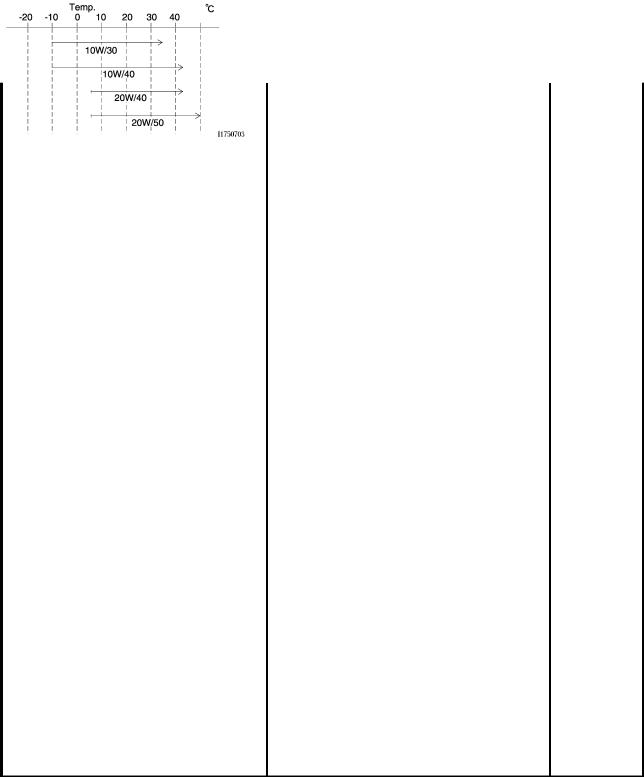

Page 84: Specifications

SPECIFICATIONS Dimensions: Engine oil: Fuel: Overall length: Type: Recommended fuel: 2125 mm (83.7 in) SAE10W30 or SAE10W40 or SAE15W40 Regular unleaded gasoline only Overall width: or SAE20W40 or SAE20W50 Fuel tank capacity: 765 mm (30.1 in) 21.0 L (5.55 US gal) (4.62 Imp.gal) Overall height: Fuel reserve amount: -20 -10…

-

Page 85

SPECIFICATIONS Operation: Manufacturer/model: Rim size: Left foot operation METZELER/MEZ4Y 17M/C x MT5.50 Gear ratio: Loading: Front brake: 1st: Maximum load: Type: 35/14 (2.500) 189 kg (417 lb) Dual disc brake 2nd: (Total weight of rider, passenger, cargo and Operation: 35/19 (1.842) accessories) Right hand operation 3rd:… -

Page 86

SPECIFICATIONS Charging system: Coolant temperature indicator light: A.C. magneto Battery: Fuses: Model: Main fuse: GT14B-4 30.0 A Voltage, capacity: Headlight fuse: 12 V, 12.0 Ah 20.0 A Headlight: Signaling system fuse: 20.0 A Bulb type: Ignition fuse: Halogen bulb 20.0 A Bulb voltage, wattage x quantity: Radiator fan fuse: Headlight:… -

Page 87: Consumer Information

Record the key identification number, vehicle identification number and mod- el label information in the spaces pro- vided below for assistance when ordering spare parts from a Yamaha dealer or for reference in case the vehi- cle is stolen. KEY IDENTIFICATION NUMBER: 1.

-

Page 88

1. Model label The model label is affixed to the frame under the seat. (See page 3-11.) Record the information on this label in the space provided. This information will be needed when ordering spare parts from a Yamaha dealer. -

Page 89

INDEX EXUP system ……..3-16 Parking………… 5-5 Part locations ………. 2-1 Air filter element, cleaning ….6-14 Pass switch……….3-6 Anti-theft alarm (optional) ……. 3-6 Front and rear brake pads, checking ..6-22 Periodic maintenance and Front fork, adjusting ……3-13 lubrication chart ……..6-2 Front fork, checking…….6-28 Battery ………. -

Page 90

INDEX Troubleshooting ……..6-37 Troubleshooting charts ……6-38 Turn signal indicator lights …… 3-2 Turn signal light bulb, replacing …. 6-34 Turn signal switch ……..3-6 Valve clearance, adjusting ….6-17 Vehicle identification number ….9-1 Wheel bearings, checking….. 6-29 Wheel (front) ……… -

Page 92

YAMAHA MOTOR CO., LTD. PRINTED ON RECYCLED PAPER PRINTED IN JAPAN 2003.06-0.4×1 CR…

EAS00000

FZS1000 (N)

SERVICE MANUAL2000 by Yamaha Motor Co.Ltd.

First edition, December 2000

All rights reserved. Any reproduction or unauthorized use without the written permission of Yamaha Motor Co., Ltd. is expressly prohibited.

EAS00003

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles should have a basic understanding of mechanics and the techniques to repair these types of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard to performance and emissions. Proper service with the correct tools in necessary to ensure that the vehicle will operate as designed. If there is any question about a service procedure, it is imperative that you contact a Yamaha dealer for any service information changes that apply to this model. This policy is intended to provide the customer with the most satisfaction from his vehicle and to conform with federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

This Service Manual contains information regarding periodic maintenance to the emission control system. Please read this material carefully.

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following.

|

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR |

||||

|

SAFETY IS INVOLVED! |

||||

|

Failure to follow WARNING instructions could result in severe injury or death to |

||||

|

the motorcycle operator, a bystander or |

||||

|

a person checking or repairing the mo- |

||||

|

torcycle. |

||||

|

A CAUTION indicates special precautions that must be taken to avoid damage |

||||

|

CAUTION: |

||||

|

to the motorcycle. |

||||

|

NOTE: |

||||

|

A NOTE provides key information to make procedures easier or clearer. |

EAS00007

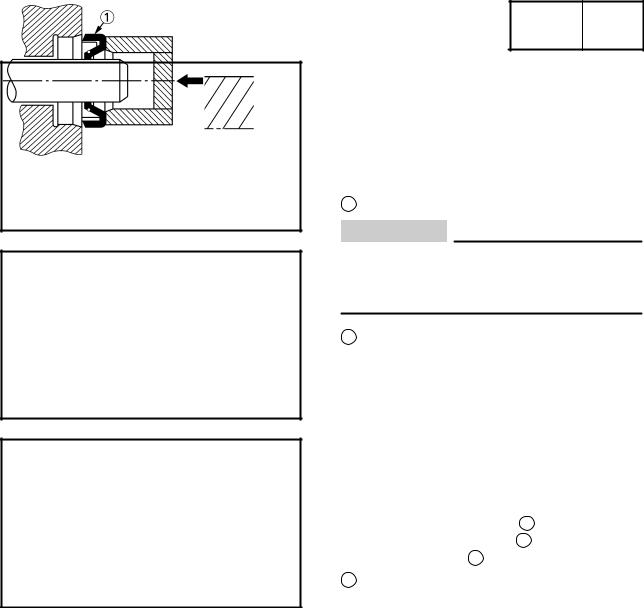

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order.

1The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each page indicate the current chapter. Refer to ªSYMBOLSº on the following page.

2Each chapter is divided into sections. The current section title is shown at the top of each page, except in Chapter 3 (ªPeriodic Checks and Adjustmentsº), where the sub-section title(-s) appears.

(In Chapter 3, ªPeriodic Checks and Adjustmentsº, the sub-section title appears at the top of each page, instead of the section title.)

3Sub-section titles appear in smaller print than the section title.

4To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

5Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a disassembly step.

6Symbols indicate parts to be lubricated or replaced (see ªSYMBOLSº).

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

8Jobs requiring more information (such as special tools and technical data) are described sequentially.

|

6 |

2 |

1 |

|

3 |

||

|

4 |

||

|

5 |

||

|

8 |

||

|

7 |

|

GEN |

SPEC |

|

|

INFO |

||

|

3 |

4 |

|

|

CHK |

CHAS |

|

|

ADJ |

||

|

5 |

6 |

|

|

ENG |

COOL |

|

|

7 |

8 |

|

|

CARB |

ELEC |

|

|

9 |

10 |

|

|

TRBL |

||

|

SHTG |

||

|

11 |

12 |

EAS00008

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 9 indicate the subject of each chapter.

1General information

2Specifications

3Periodic checks and adjustments

4Chassis

5Engine

6Cooling system

7Carburetor(-s)

8Electrical system

9Troubleshooting

Symbols 10 to 17 indicate the following.

10Serviceable with engine mounted

11Filling fluid

12Lubricant

13Special tool

14Tightening torque

15Wear limit, clearance

16Engine speed

17Electrical data

Symbols 18 to 23 in the exploded diagrams indicate the types of lubricants and lubrication points.

18Engine oil

19Gear oil

20Molybdenum disulfide oil

21Wheel bearing grease

22Lithium soap base grease

23Molybdenum disulfide grease

Symbols 24 to 25 in the exploded diagrams indicate the following:

24Apply locking agent (LOCTITER)

25Replace the part

EAS00012

TABLE OF CONTENTS

|

GENERAL INFORMATION |

|||||

|

GEN |

1 |

||||

|

INFO |

|||||

|

SPECIFICATIONS |

|||||

|

SPEC |

2 |

||||

|

PERIODIC CHECKS AND |

|||||

|

CHK |

3 |

||||

|

ADJUSTMENTS |

|||||

|

ADJ |

|||||

|

CHASSIS |

|||||

|

CHAS |

4 |

||||

|

ENGINE |

|||||

|

ENG |

5 |

||||

|

COOLING SYSTEM |

|||||

|

COOL |

6 |

||||

|

CARBURETORS |

|||||

|

CARB |

7 |

||||

|

ELECTRICAL SYSTEM |

|||||

|

ELEC |

8 |

||||

|

TROUBLESHOOTING |

|||||

|

TRBL |

9 |

||||

|

SHTG |

GEN

INFO

CHAPTER 1

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 VEHICLE IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 MODEL CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 PREPARATION FOR REMOVAL AND DISASSEMBLY . . . . . . . . . . 1-2 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 GASKETS, OIL SEALS AND O-RINGS . . . . . . . . . . . . . . . . . . . . . . . . 1-2 LOCK WASHERS/PLATES AND COTTER PINS . . . . . . . . . . . . . . . . 1-2 BEARINGS AND OIL SEALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 CIRCLIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

CHECKING THE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

GEN INFO

GEN

MOTORCYCLE IDENTIFICATION INFO

EAS00014

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

EAS00017

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is stamped into the right side of the steering head.

EAS00018

MODEL CODE

The model code label 1 is affixed to the frame. This information will be needed to order spare parts.

1-1

GEN

IMPORTANT INFORMATION INFO

EAS00020

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

1.Before removal and disassembly, remove all dirt, mud, dust and foreign material.

2.Use only the proper tools and cleaning equipment.

Refer to the ªSPECIAL TOOLSº section.

3.When disassembling, always keep mated parts together. This includes gears, cylinders, pistons and other parts that have been ºmatedº through normal wear. Mated parts must always be reused or replaced as an assembly.

4.During disassembly, clean all of the parts and place them in trays in the order of disassembly. This will speed up assembly and allow for the correct installation of all parts.

5.Keep all parts away from any source of fire.

EAS00021

REPLACEMENT PARTS

1.Use only genuine Yamaha parts for all replacements. Use oil and grease recommended by Yamaha for all lubrication jobs. Other brands may be similar in function and appearance, but inferior in quality.

EAS00022

GASKETS, OIL SEALS AND O-RINGS

1.When overhauling the engine, replace all gaskets, seals and O-rings. All gasket surfaces, oil seal lips and O-rings must be cleaned.

2.During reassembly, properly oil all mating

|

grease |

parts and bearings and apply grease onto |

|

the oil seal lips with greace. |

EAS00023

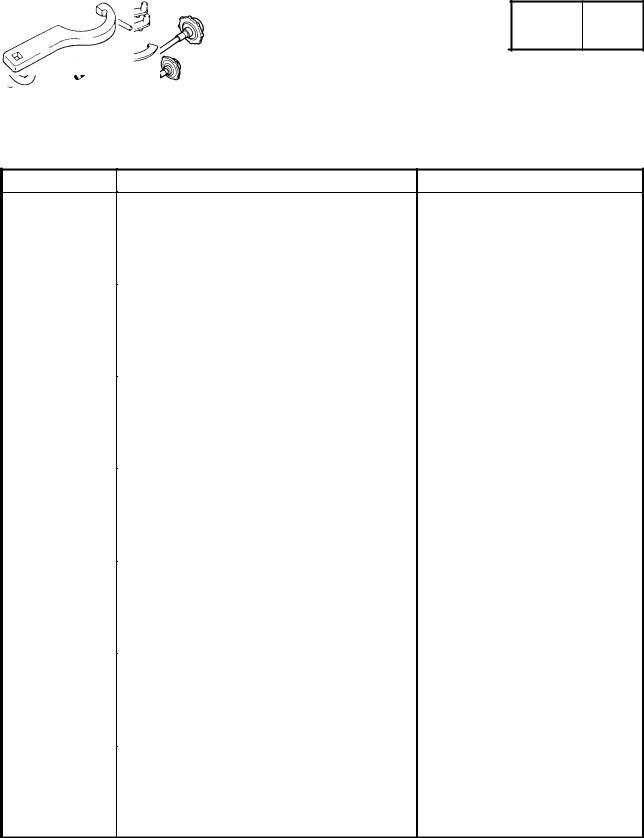

LOCK WASHERS/PLATES AND COTTER PINS

1.After removal, replace all lock washers/plates 1 and cotter pins. After the bolt or nut has been tightened to specification, bend the lock tabs along a flat of the bolt or nut.

1-2

IMPORTANT INFORMATION

EAS00024

GEN INFO

BEARINGS AND OIL SEALS

1.Install bearings and oil seals so that the manufacturer’s marks or numbers are visible. When installing oil seals, apply a light coat of lithium soap base grease onto the oil seal lips. Oil bearings liberally when installing, if appropriate.

1 Oil seal

CAUTION:

Do not spin the bearing with compressed air because this will damage the bearing surfaces.

1 Bearing

EAS00025

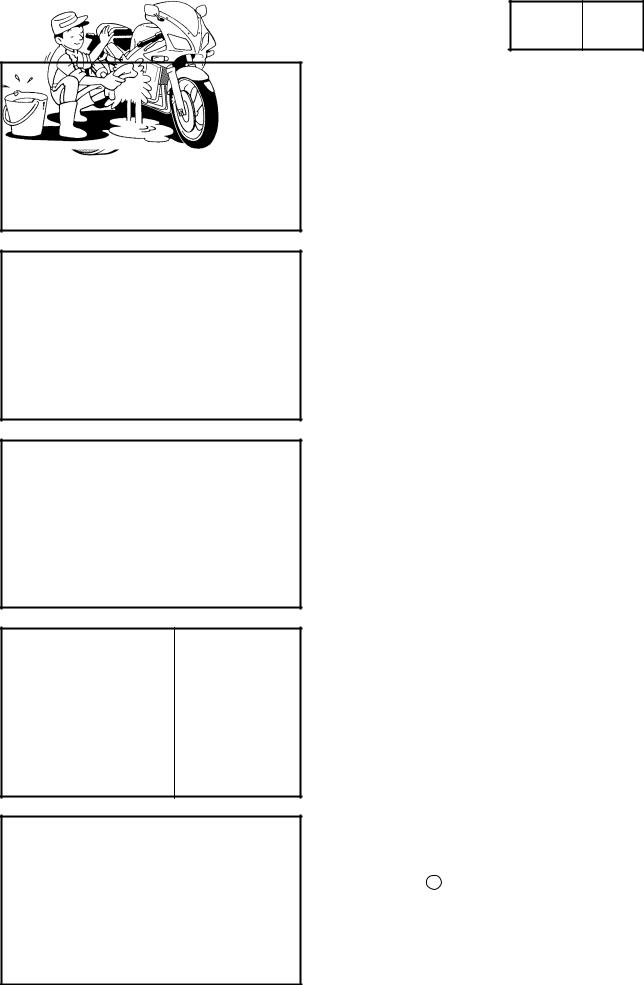

CIRCLIPS

1.Before reassembly, check all circlips carefully and replace damaged or distorted circlips. Always replace piston pin clips after one use. When installing a circlip 1 , make sure that the sharp-edged corner 2 is positioned opposite the thrust 3 that the circlip receives.

4 Shaft

1-3

GEN

CHECKING THE CONNECTIONS INFO

EAS00026

CHECKING THE CONNECTIONS

Check the leads, couplers, and connectors for stains, rust, moisture, etc.

1.Disconnect:

lead 1

coupler 2

connector 3

2.Check:

lead

coupler

connector

Moisture Dry with an air blower. Rust/stains Connect and disconnect several times.

3.Check:

all connections

Loose connection Connect properly.

NOTE:

If the pin 1 on the terminal is flattened, bend it up.

4.Connect:

lead

coupler

connector

NOTE:

Make sure that all connections are tight.

5.Check:

continuity

(with a pocket tester)

Pocket tester 90890-03112

NOTE:

If there is no continuity, clean the terminals.

When checking the wire harness, perform steps 1 to 3.

As a quick remedy, use a contact revitalizer available at most part stores.

1-4

GEN

SPECIAL TOOLS INFO

EAS00027

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers or both may differ depending on the country. When placing an order, refer to the list provided below to avoid any mistakes.

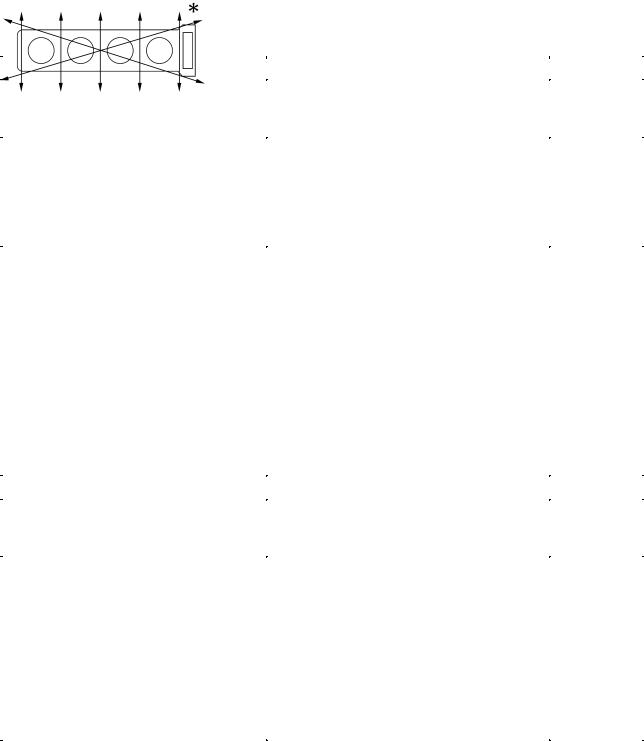

|

Tool No. |

Tool name/Function |

Illustration |

Rotor puller

|

90890-01080 |

|

|

This tool is used to remove the generator |

|

|

rotor. |

|

|

Rotor holding tool |

|

|

90890-01235 |

This tool is used to hold the generator rotor |

|

when removing or installing the generator |

|

|

rotor bolt or pickup coil rotor bolt. |

|

|

Piston pin puller set |

|

|

90890-01304 |

|

|

This tool is used to remove the piston pins. |

|

|

Fuel level gauge |

|

|

90890-01312 |

|

|

This tool is used to measure the fuel level in |

|

|

the float chamber. |

|

|

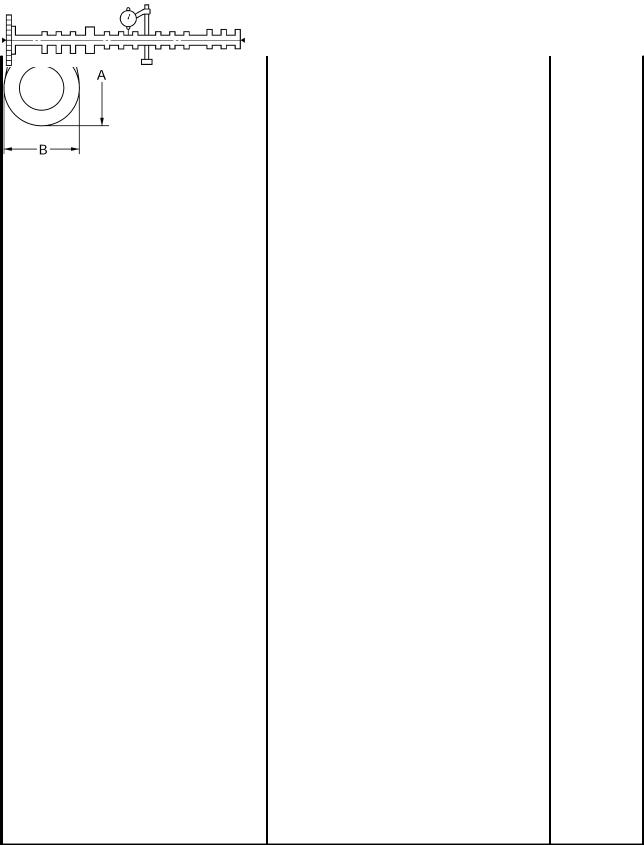

Radiator cap |

Radiator cap tester |

|

tester |

Adapter |

|

90890-01325 |

|

|

Adapter |

These tools are used to check the cooling |

|

90890-01352 |

system. |

|

Steering nut wrench |

|

|

90890-01403 |

|

|

This tool is used to loosen or tighten the |

|

|

steering stem ring nuts. |

|

|

Damper rod holder |

|

|

90890-01447 |

This tool is used to hold the damper rod as- |

|

sembly when loosening or tightening the |

|

|

damper rod assembly bolt. |

1-5

|

SPECIAL TOOLS |

GEN |

|||||

|

INFO |

||||||

|

Tool No. |

Tool name/Function |

Illustration |

||||

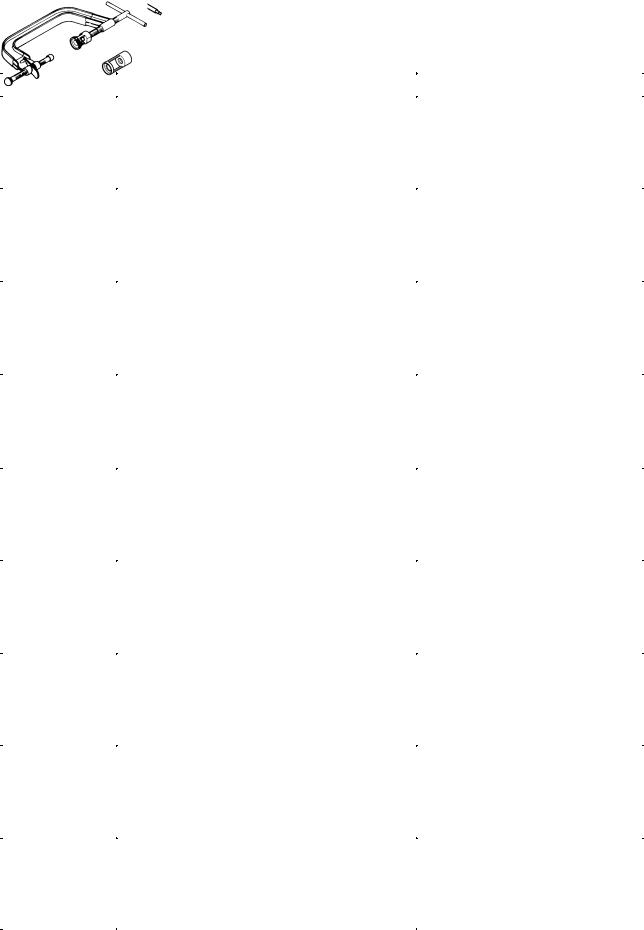

|

Oil filter wrench |

||||||

|

90890-01426 |

||||||

|

This tool is needed to loosen or tighten the |

||||||

|

oil filter cartridge. |

||||||

|

Rod holder |

||||||

|

90890-01434 |

||||||

|

This tool is used to support the damper ad- |

||||||

|

justing rod. |

||||||

|

Rod puller |

Rod puller |

|||||

|

90890-01437 |

Rod puller attachment |

|||||

|

Rod puller |

||||||

|

attachment |

These tools are used to pull up the front |

|||||

|

90890-01436 |

fork damper rod. |

|||||

|

Fork seal driver |

Fork seal driver weight |

|||||

|

weight |

Fork seal driver attachment (ù43) |

|||||

|

90890-01367 |

||||||

|

Fork seal driver |

This tool is used to install the front fork’s oil |

|||||

|

attachment (ù43) |

||||||

|

seal and dust seal. |

||||||

|

90890-01374 |

||||||

|

Micrometer (50 75 mm) |

||||||

|

90890-03008 |

||||||

|

This tool is used to measure the piston skirt |

||||||

|

diameter. |

||||||

|

Vacuum gauge |

||||||

|

Vacuum gauge |

||||||

|

90890-03094 |

This guide is used to synchronize the car- |

|||||

|

buretors. |

||||||

|

Compression |

Compression gauge |

|||||

|

gauge |

Compression gauge adapter |

|||||

|

90890-03081 |

||||||

|

Compression |

These tools are used to measure engine |

|||||

|

gauge adapter |

||||||

|

compression. |

||||||

|

90890-04136 |

||||||

|

Pocket tester |

||||||

|

90890-03112 |

||||||

|

This tool is used to check the electrical sys- |

||||||

|

tem. |

||||||

|

Engine tachometer |

||||||

|

90890-03113 |

||||||

|

This tool is used to check engine speed. |

||||||

1-6

|

SPECIAL TOOLS |

GEN |

|||||

|

INFO |

||||||

|

Tool No. |

Tool name/Function |

Illustration |

||||

|

Timing light |

||||||

|

90890-03141 |

||||||

|

This tool is used to check the ignition tim- |

||||||

|

ing. |

||||||

|

Carburetor angle driver 2 |

||||||

|

90890-03173 |

||||||

|

This tool is used to turn the pilot screw |

||||||

|

when adjusting the engine idling speed. |

||||||

|

Valve spring com- |

Valve spring compressor |

|||||

|

pressor |

Valve spring compressor attachment |

|||||

|

90890-04019 |

||||||

|

Attachmenht |

These tools are used to remove or install |

|||||

|

90890-04108 |

||||||

|

the valve assemblies. |

||||||

|

90890-04114 |

||||||

|

Middle driven shaft |

Middle driven shaft bearing driver |

|||||

|

bearing driver |

Mechanical seal installer |

|||||

|

90890-04058 |

||||||

|

Mechanical seal |

These tools are used to install the water |

|||||

|

installer |

||||||

|

pump seal. |

||||||

|

90890-04078 |

||||||

|

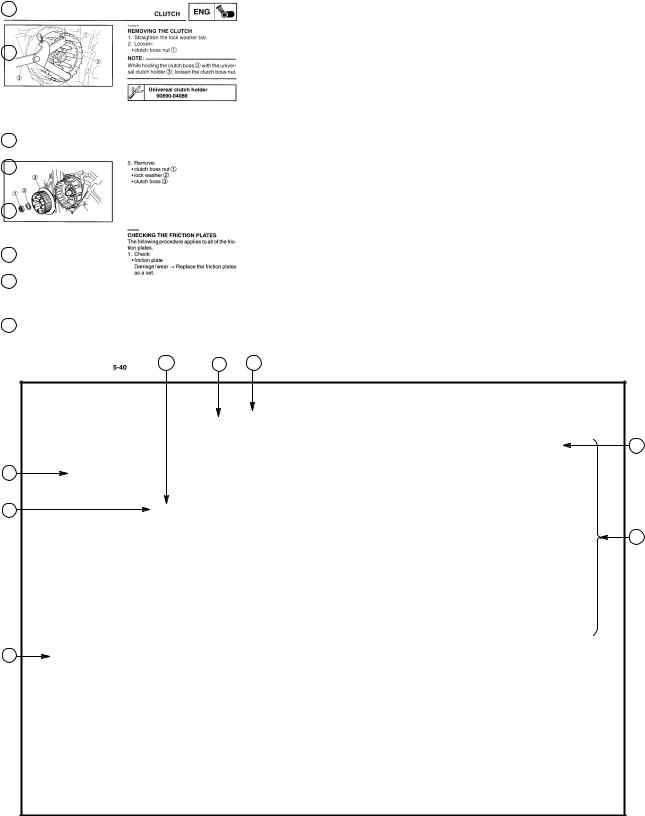

Universal clutch holder |

||||||

|

90890-04086 |

This tool is used to hold the clutch boss |

|||||

|

when removing or installing the clutch boss |

||||||

|

nut. |

||||||

|

Valve guide remover (ù4) |

||||||

|

90890-04111 |

Valve guide remover (ù4.5) |

|||||

|

90890-04116 |

This tool is used to remove or install the |

|||||

|

valve guides. |

||||||

|

Valve guide installer (ù4) |

||||||

|

90890-04112 |

Valve guide installer (ù4.5) |

|||||

|

90890-04117 |

||||||

|

This tool is used to install the valve guides. |

||||||

|

Valve guide reamer (ù4) |

||||||

|

90890-04113 |

Valve guide reamer (ù4.5) |

|||||

|

90890-04118 |

This tool is used to rebore the new valve |

|||||

|

guides. |

||||||

|

Ignition checker |

||||||

|

90890-06754 |

||||||

|

This tool is used to check the ignition sys- |

||||||

|

tem components. |

||||||

1-7

|

SPECIAL TOOLS |

GEN |

|||||

|

INFO |

||||||

|

Tool No. |

Tool name/Function |

Illustration |

||||

|

Yamaha bond No. 1215 |

||||||

|

90890-85505 |

||||||

|

This bond is used to seal two mating sur- |

||||||

|

faces (e.g., crankcase mating surfaces). |

||||||

1-8

SPEC

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CHASSIS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18 GENERAL TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18 ENGINE TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19 CHASSIS TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

LUBRICATION POINTS AND LUBRICANT TYPES . . . . . . . . . . . . . . . . 2-23 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

COOLING SYSTEM DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

ENGINE OIL LUBRICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

LUBRICATION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

|

GENERAL SPECIFICATIONS |

SPEC |

|||||

|

SPECIFICATIONS |

||||||

|

GENERAL SPECIFICATIONS |

||||||

|

Item |

Standard |

Limit |

||||

|

Model code |

5VL1 (A) (B) (D) (DK) (E) (GB) (GR) (I) |

|||||

|

(N) (NL) (S) (SF) (CH) (P) |

||||||

|

5LV2 (F) |

||||||

|

5LV3 (D) |

||||||

|

5LV4 (AUS) |

||||||

|

Dimensions |

||||||

|

Overall length |

2,125 mm |

|||||

|

Overall width |

765 mm |

|||||

|

Overall height |

1,190 mm |

|||||

|

Seat height |

820 mm |

|||||

|

Wheelbase |

1,450 mm |

|||||

|

Minimum ground clearance |

140 mm |

|||||

|

Minimum turning radius |

2,900 mm |

|||||

|

Weight |

||||||

|

Wet (with oil and a full fuel tank) |

231 kg |

|||||

|

Dry (without oil and fuel) |

208 kg |

|||||

|

Maximum load (total of cargo, rider, |

189 kg |

|||||

|

passenger, and accessories) |

||||||

2-1

|

ENGINE SPECIFICATIONS |

SPEC |

||||

|

ENGINE SPECIFICATIONS |

|||||

|

Item |

Standard |

Limit |

|||

|

Engine |

|||||

|

Engine type |

Liquid-cooled, 4-stroke, DOHC |

||||

|

Displacement |

998 cm3 |

||||

|

Cylinder arrangement |

Forward-inclined parallel 4-cylinder |

||||

|

Bore stroke |

74 58 mm |

||||

|

Compression ratio |

11.4 : 1 |

||||

|

Engine idling speed |

1,050 1,150 r/min |

||||

|

Vacuum pressure at engine idling |

30 kPa (225 mm Hg) |

||||

|

speed |

1,450 kPa (14.5 kg/cm2) at 400 r/min |

||||

|

Standard compression pressure |

|||||

|

(at sea level) |

|||||

|

Fuel |

|||||

|

Recommended fuel |

Regular unleaded gasoline |

||||

|

Fuel tank capacity |

|||||

|

Total (including reserve) |

21 L |

||||

|

Reserve only |

4.0 L |

||||

|

Engine oil |

|||||

|

Lubrication system |

Wet sump |

||||

|

Recommended oil |

|||||

|

SAE20W40SE or SAE10W30SE |

|

Quantity |

||

|

Total amount |

3.7 L |

|

|

Without oil filter cartridge |

2.8 L |

|

|

replacement |

||

|

With oil filter cartridge replacement |

3.0 L |

|

|

Oil pressure (hot) |

45 kPa at 1,100 r/min |

|

|

(0.45 kg/cm2 at 1,100 r/min) |

||

|

Relief valve opening pressure |

490 570 kPa (4.9 5.7 kg/cm2) |

2-2

|

ENGINE SPECIFICATIONS |

SPEC |

|||||

|

Item |

Standard |

Limit |

||||

|

Oil filter |

||||||

|

Oil filter type |

Cartridge (paper) |

|||||

|

Bypass valve opening pressure |

180 220 kPa (1.8 2.2 kg/cm2) |

|||||

|

Oil pump |

||||||

|

Oil pump type |

Trochoid |

|||||

|

Inner-rotor-to-outer-rotor-tip |

0.09 0.15 mm |

|||||

|

clearance |

||||||

|

Outer-rotor-to-oil-pump-housing |

0.03 0.08 mm |

|||||

|

clearance |

||||||

|

Cooling system |

||||||

|

Radiator capacity |

2.4 L |

|||||

|

Radiator cap opening pressure |

95 125 kPa (0.95 1.25 kg/cm2) |

|||||

|

Radiator core |

||||||

|

Width |

340 mm |

|||||

|

Height |

238 mm |

|||||

|

Depth |

24 mm |

|||||

|

Coolant reservoir |

||||||

|

Capacity |

0.3 L |

|||||

|

Water pump |

||||||

|

Water pump type |

Single-suction centrifugal pump |

|||||

|

Reduction ratio |

68/43 28/28 (1.581) |

|||||

|

Max. impeller shaft tilt |

0.15 mm |

|||||

|

Starting system type |

Electric starter |

|||||

|

Spark plugs |

||||||

|

Model (manufacturer) quantity |

CR9E/U27ESR-N (NGK/DENSO) 4 |

|||||

|

Spark plug gap |

0.7 0.8 mm |

|||||

|

Cylinder head |

||||||

|

Max. warpage |

0.1 mm |

|||||

2-3

|

ENGINE SPECIFICATIONS |

SPEC |

|||

|

Item |

Standard |

Limit |

||

|

Camshafts |

||||

|

Drive system |

Chain drive (right) |

|||

|

Camshaft cap inside diameter |

24.500 X 24.521 mm |

|||

|

Camshaft journal diameter |

24.459 X 24.472 mm |

|||

|

Camshaft-journal-to-camshaft- |

0.028 X 0.062 mm |

|||

|

cap clearance |

||||

|

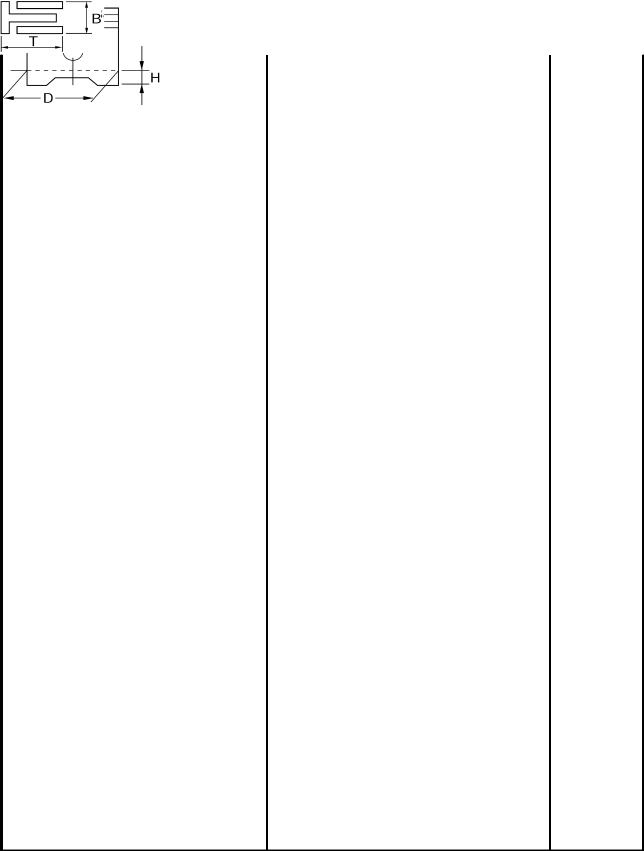

Intake camshaft lobe dimensions |

|

Measurement A |

32.5 X 32.6 mm |

32.4 mm |

|

Measurement B |

24.95 X 25.05 mm |

24.85 mm |

|

Measurement C |

7.45 X 7.65 mm |

Exhaust camshaft lobe dimensions

|

Measurement A |

32.95 X 33.05 mm |

32.85 mm |

|

Measurement B |

24.95 X 25.05 mm |

24.85 mm |

|

Measurement C |

7.75 X 7.95 mm |

|

|

Max. camshaft runout |

0.03 mm |

2-4

|

ENGINE SPECIFICATIONS |

SPEC |

||||

|

Item |

Standard |

Limit |

|||

|

Timing chain |

|||||

|

Model/number of links |

RH2015/130 |

||||

|

Tensioning system |

Automatic |

||||

|

Valves, valve seats, valve guides |

|||||

|

Valve clearance (cold) |

|||||

|

Intake |

0.11 X 0.20 mm |

||||

|

Exhaust |

0.21 X 0.25 mm |

||||

|

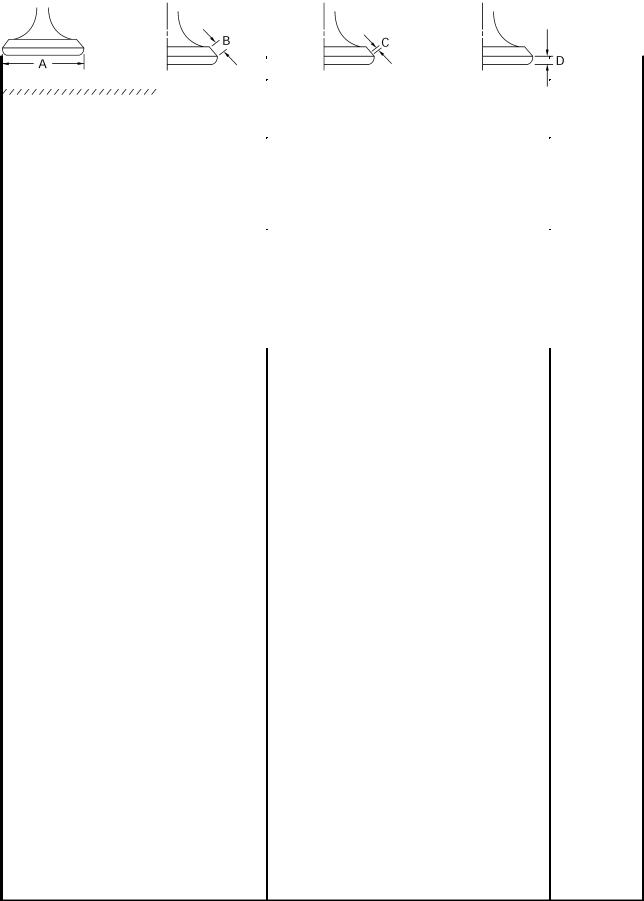

Valve dimensions |

|||||

|

Head Diameter |

Face Width |

Seat Width |

Margin Thickness |

|

Valve head diameter A |

|||

|

Intake |

22.9 X 23.1 mm |

||

|

Exhaust |

24.4 X 24.6 mm |

||

|

Valve face width B |

|||

|

Intake |

1.76 X 2.90 mm |

||

|

Exhaust |

1.76 X 2.90 mm |

||

|

Valve seat width C |

|||

|

Intake |

0.9 X 1.1 mm |

||

|

Exhaust |

0.9 X 1.1 mm |

||

|

Valve margin thickness D |

|||

|

Intake |

0.5 X 0.9 mm |

||

|

Exhaust |

0.5 X 0.9 mm |

||

|

Valve stem diameter |

|||

|

Intake |

3.975 X 3.990 mm |

3.945 mm |

|

|

Exhaust |

4.465 X 4.480 mm |

4.43 mm |

|

|

Valve guide inside diameter |

|||

|

Intake |

4.000 X 4.012 mm |

4.05 mm |

|

|

Exhaust |

4.500 X 4.512 mm |

4.55 mm |

|

|

Valve-stem-to-valve-guide clearance |

|||

|

Intake |

0.010 X 0.037 mm |

0.08 mm |

|

|

Exhaust |

0.020 X 0.047 mm |

0.10 mm |

|

|

Valve stem runout |

0.01 mm |

|

Valve seat width |

||

|

Intake |

0.9 X 1.1 mm |

|

|

Exhaust |

0.9 X 1.1 mm |

2-5

|

ENGINE SPECIFICATIONS |

SPEC |

|||

|

Item |

Standard |

Limit |

||

|

Valve springs |

||||

|

Free length |

||||

|

Intake |

38.9 mm |

|||

|

Exhaust |

40.67 mm |

|||

|

Installed length (valve closed) |

||||

|

Intake |

34.5 mm |

|||

|

Exhaust |

35 mm |

|||

|

Compressed spring force |

||||

|

(installed) |

||||

|

Intake |

82 96 N (8.36 9.79 kg) |

|||

|

Exhaust |

110 126 N (11.22 12.85 kg) |

|||

|

Spring tilt |

|

Intake |

2.5_/ |

|

|

1.7 mm |

||

|

Exhaust |

2.5_/ |

|

|

1.8 mm |

||

|

Winding direction (top view) |

||

|

Intake |

Clockwise |

|

|

Exhaust |

Clockwise |

|

Cylinders |

||

|

Cylinder arrangement |

Forward-inclined, parallel 4-cylinder |

|

|

Bore stroke |

74 58 mm |

|

|

Compression ratio |

11.4 : 1 |

|

|

Bore |

74.00 74.01 mm |

|

|

Max. taper |

0.05 mm |

|

|

Max. out-of-round |

0.05 mm |

2-6

|

ENGINE SPECIFICATIONS |

SPEC |

|||

|

Item |

Standard |

Limit |

||

|

Piston |

||||

|

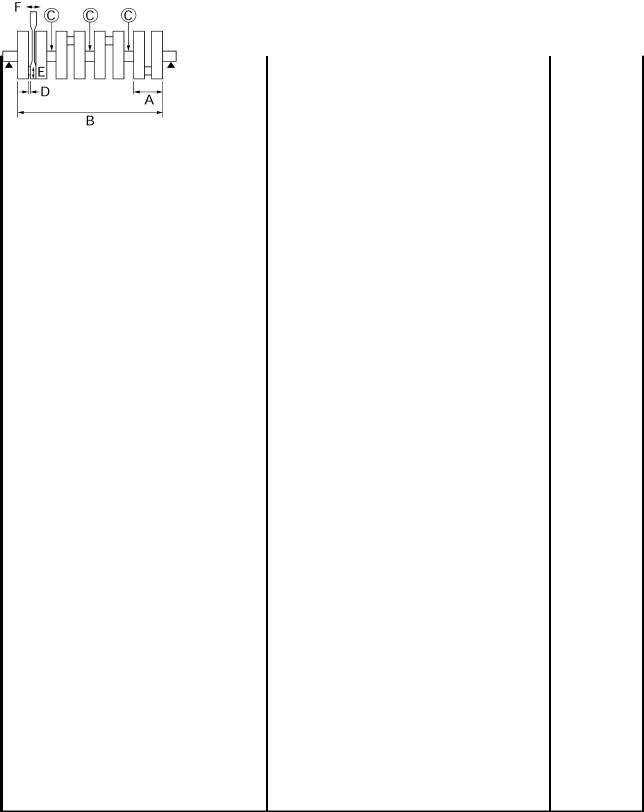

Piston-to-cylinder clearance |

0.030 0.055 mm |

0.12 mm |

||

|

Diameter D |

73.955 73.970 mm |

|

Height H |

5 mm |

|

|

Piston pin bore (in the piston) |

||

|

Diameter |

17.002 17.013 mm |

17.043 |

|

Offset |

||

|

Offset direction |

Intake side |

|

|

Piston pins |

||

|

Outside diameter |

16.991 17.000 mm |

16.971 |

|

Piston-pin-to-piston-pin-bore |

0.002 0.022 mm |

0.072 mm |

|

clearance |

||

|

Piston rings |

||

|

Top ring |

|

Ring type |

Barrel |

|

|

Dimensions (B T) |

0.90 2.75 mm |

|

|

End gap (installed) |

0.32 0.44 mm |

|

|

Ring side clearance |

0.030 0.065 mm |

2nd ring

|

Ring type |

Taper |

|

|

Dimensions (B T) |

0.8 2.8 |

|

|

End gap (installed) |

0.43 0.58 mm |

|

|

Ring side clearance |

0.020 0.055 mm |

Oil ring

|

Dimensions (B T) |

1.5 2.6 mm |

|

|

End gap (installed) |

0.10 0.35 |

2-7

|

ENGINE SPECIFICATIONS |

SPEC |

|||

|

Item |

Standard |

Limit |

||

|

Connecting rods |

||||

|

Crankshaft-pin-to-big-end-bearing |

0.031 X 0.055 mm |

|||

|

clearance |

||||

|

Bearing color code |

±1 = Violet 0 = White 1 = Blue 2 = Black |

|||

|

Crankshaft |

|

Width A |

52.40 X 57.25 mm |

||

|

Width B |

300.75 X 302.65 mm |

||

|

Max. runout C |

0.03 mm |

||

|

Big end side clearance D |

0.160 X 0.262 mm |

||

|

Crankshaft-journal-to-crankshaft- |

0.029 X 0.053 mm |

||

|

journal-bearing clearance |

|||

|

Bearing color code |

±1 = Pink/violet 0 = Pink/white |

||

|

1 |

= Pink/blue 2 = Pink/black |

||

|

3 |

= Pink/brown |

||

|

Clutch |

|||

|

Clutch type |

Wet, multiple disc |

||

|

Clutch release method |

Cam (pull rod type) |

||

|

Clutch release method operation |

Cable operation |

||

|

Operation |

Left-hand operation |

||

|

Clutch cable free play (at the end |

10 X 15 mm |

||

|

of the clutch lever) |

|||

|

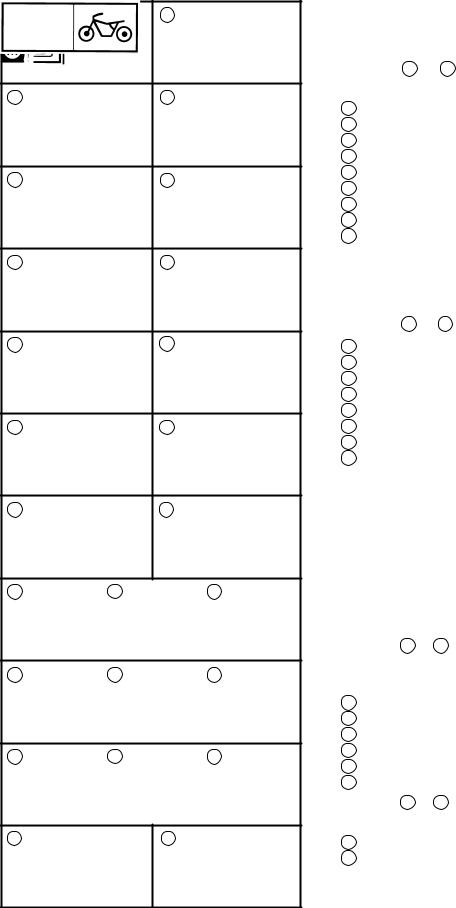

Friction plates |

|||

|

Thickness |

2.92 X 3.08 mm |

2.82 mm |

|

|

Plate quantity |

8 |

||

|

Thickness |

3.42 X 3.58 mm |

3.32 mm |

|

|

Plate quantity |

1 |

||

|

Clutch plates |

|||

|

Thickness |

1.9 X 2.1 mm |

||

|

Plate quantity |

8 |

||

|

Max. warpage |

0.1 mm |

||

|

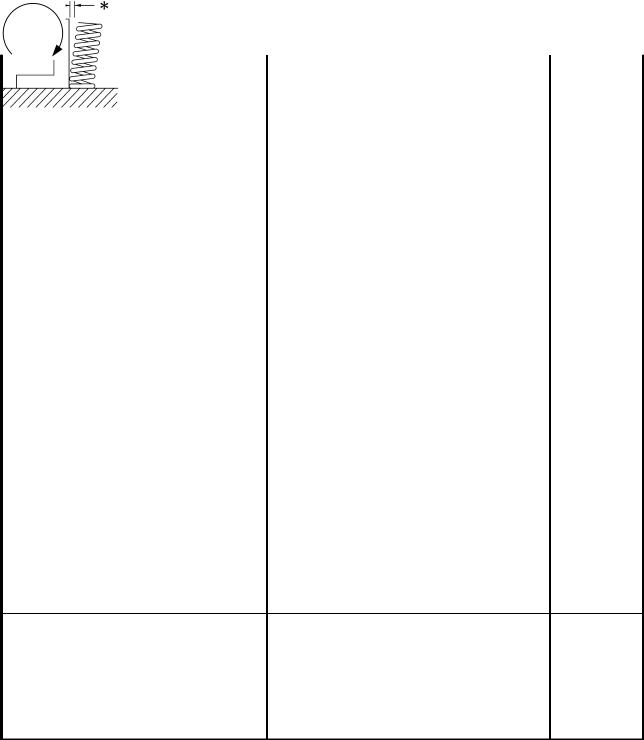

Clutch springs |

|||

|

Free length |

50 mm |

||

|

Spring quantity |

6 |

2-8

|

ENGINE SPECIFICATIONS |

SPEC |

||||

|

Item |

Standard |

Limit |

|||

|

Transmission |

|||||

|

Transmission type |

Constant mesh, 6-speed |

||||

|

Primary reduction system |

Spur gear |

||||

|

Primary reduction ratio |

68/43 (1.581) |

||||

|

Secondary reduction system |

Chain drive |

||||

|

Secondary reduction ratio |

44/16 (2.750) |

||||

|

Operation |

Left-foot operation |

||||

|

Gear ratios |

|||||

|

1st gear |

35/14 (2.500) |

||||

|

2nd gear |

35/19 (1.842) |

||||

|

3rd gear |

30/20 (1.500) |

||||

|

4nd gear |

28/21 (1.333) |

||||

|

5th gear |

30/25 (1.200) |

||||

|

6th gear |

29/26 (1.115) |

||||

|

Max. main axle runout |

0.08 mm |

||||

|

Max. drive axle runout |

0.08 mm |

||||

|

Shifting mechanism |

|||||

|

Shift mechanism type |

Guide bar |

||||

|

Max. shift fork guide bar bending |

0.1 mm |

||||

|

Installed shift rod length |

260 mm |

||||

|

Air filter type |

Dry element |

||||

|

Fuel pump |

|||||

|

Pump type |

Electrical |

||||

|

Model (manufacturer) |

4SV (MITSUBISHI) |

||||

|

Output pressure |

20 kPa (0.2 kg/cm2) |

2-9

|

ENGINE SPECIFICATIONS |

SPEC |

||||

|

Item |

Standard |

Limit |

|||

|

Carburetors |

|||||

|

Model (manufacturer) quantity |

BSR37 (MIKUNI) 4 |

||||

|

Throttle cable free play (at the |

3 5 mm |

||||

|

flange of the throttle grip) |

|||||

|

ID mark |

5LV1 00 |

||||

|

Main jet |

Carburetors 1 and 4: #132.5 |

||||

|

Carburetors 2 and 3: #130 |

|||||

|

Main air jet |

#80 |

||||

|

Jet needle |

Carburetor 1 and 4: 5D129-3/5 |

||||

|

Carburetor 2 and 3: 5D130-3/5 |

|||||

|

Needle jet |

P-OM |

||||

|

Pilot air jet |

#85 |

||||

|

Pilot outlet |

1.0 |

||||

|

Pilot jet |

#15 |

||||

|

Bypass 1 |

0.9 |

||||

|

Bypass 2 |

0.9 |

||||

|

Bypass 3 |

0.9 |

||||

|

Pilot screw turns out |

2.0 |

||||

|

Valve seat size |

1.5 |

||||

|

Starter jet 1 |

#42.5 |

||||

|

Starter jet 2 |

0.8 |

||||

|

Throttle valve size |

#115 |

||||

|

Fuel level (above the line on the |

3.0 4.0 mm |

||||

|

float chamber) |

|||||

|

Max. EXUP cable free play (at the |

1.5 mm |

||||

|

EXUP valve pulley) |

2-10

|

CHASSIS SPECIFICATIONS |

SPEC |

|||||

|

CHASSIS SPECIFICATIONS |

||||||

|

Item |

Standard |

Limit |

||||

|

Frame |

||||||

|

Frame type |

Double cradle |

|||||

|

Caster angle |

26_ |

|||||

|

Trail |

104 mm |

|||||

|

Front wheel |

||||||

|

Wheel type |

Cast wheel |

|||||

|

Rim |

||||||

|

Size |

17 MT3.50 |

|||||

|

Material |

Aluminum |

|||||

|

Wheel travel |

140 mm |

|||||

|

Wheel runout |

||||||

|

Max. radial wheel runout |

1 mm |

|||||

|

Max. lateral wheel runout |

0.5 mm |

|||||

|

Rear wheel |

||||||

|

Wheel type |

Cast wheel |

|||||

|

Rim |

||||||

|

Size |

17 MT5.50 |

|||||

|

Material |

Aluminum |

|||||

|

Wheel travel |

135 mm |

|||||

|

Wheel runout |

||||||

|

Max. radial wheel runout |

1 mm |

|||||

|

Max. lateral wheel runout |

0.5 mm |

|||||

|

Front tire |

||||||

|

Tire type |

Tubeless |

|||||

|

Size |

120/70 ZR17 (58W) |

|||||

|

Model (manufacturer) |

MEZ4Y FRONT (METZELER) |

|||||

|

BT020F U (BRIDGESTONE) |

||||||

|

Tire pressure (cold) |

250 kPa (2.5 kgf/cm2, 2.5 bar) |

|||||

|

0 90 kg |

||||||

|

90 201 kg |

250 kPa (2.5 kgf/cm2, 2.5 bar) |

|||||

|

High-speed riding |

250 kPa (2.5 kgf/cm2, 2.5 bar) |

|||||

|

Min. tire tread depth |

1.6 mm |

2-11

|

CHASSIS SPECIFICATIONS |

SPEC |

|||

|

Item |

Standard |

Limit |

||

|

Rear tire |

||||

|

Tire type |

Tubeless |

|||

|

Size |

180/55 ZR17 (73W) |

|||

|

Model (manufacturer) |

MEZ4Y (METZELER) |

|||

|

BT020R U (BRIDGESTONE) |

||||

|

Tire pressure (cold) |

270 kPa (2.7 kgf/cm2, 2.7 bar) |

|||

|

0 90 kg |

||||

|

90 201 kg |

290 kPa (2.9 kgf/cm2, 2.9 bar) |

|||

|

High-speed riding |

290 kPa (2.9 kgf/cm2, 2.9 bar) |

|||

|

Min. tire tread depth |

1.6 mm |

|||

|

Front brakes |

||||

|

Brake type |

Dual-disc brake |

|||

|

Operation |

Right-hand-operation |

|||

|

Recommended fluid |

DOT 4 |

|||

|

Brake discs |

||||

|

Diameter thickness |

298 5 mm |

|||

|

Min. thickness |

4.5 mm |

|||

|

Max. deflection |

0.1 mm |

|||

|

Brake pad lining thickness |

5.5 mm |

0.5 mm |

|

Master cylinder inside diameter |

14 mm |

|

|

Caliper cylinder inside diameter |

30.2 mm and 27 mm |

|

|

Rear brake |

||

|

Brake type |

Single-disc brake |

|

|

Operation |

Right-foot operation |

|

|

Brake pedal position (from the top |

35 40 mm |

|

|

of the brake pedal to the top of the |

||

|

rider footrest) |

||

|

Recommended fluid |

DOT 4 |

|

|

Brake discs |

||

|

Diameter thickness |

267 5 mm |

|

|

Min. thickness |

4.5 mm |

|

|

Max. deflection |

0.1 mm |

|

|

Brake pad lining thickness |

5.5 mm |

0.5 mm |

|

Master cylinder inside diameter |

12.7 mm |

|

|

Caliper cylinder inside diameter |

42.9 mm |

2-12

|

CHASSIS SPECIFICATIONS |

SPEC |

|||||

|

Item |

Standard |

Limit |

||||

|

Front suspension |

||||||

|

Suspension type |

Telescopic fork |

|||||

|

Front fork type |

Coil spring/oil damper |

|||||

|

Front fork travel |

140 mm |

|||||

|

Spring |

||||||

|

Free length |

344.0 mm |

|||||

|

Spacer length |

78.5 mm |

|||||

|

Installed length |

320.0 mm |

|||||

|

Spring rate (K1) |

8.1 N/mm (0.83 kg/mm) |

|||||

|

Spring rate (K2) |

11.8 N/mm (1.2 kg/mm) |

|||||

|

Spring stroke (K1) |

0 55 mm |

|||||

|

Spring stroke (K2) |

55 140 mm |

|||||

|

Optional spring available |

No |

|||||

|

Fork oil |

||||||

|

Recommended oil |

Suspension oil ª01º or equivalent |

|||||

|

Quantity (each front fork leg) |

440 cm3 |

|||||

|

Level (from the top of the inner |

140 mm |

|||||

|

tube, with the inner tube fully |

||||||

|

compressed, and without the |

||||||

|

fork spring) |

||||||

|

Spring preload adjusting positions |

||||||

|

Minimum |

5 (fully turned out position) |

|||||

|

Standard |

2 |

|||||

|

Maximum |

1 |

|||||

|

Rebound damping adjusting |

||||||

|

positions |

||||||

|

Minimum* |

17 |

|||||

|

Standard* |

7 |

|||||

|

Maximum* |

1 |

|||||

|

Compression damping adjusting |

||||||

|

positions |

||||||

|

Minimum* |

21 |

|||||

|

Standard* |

6 |

|||||

|

Maximum* |

1 |

|||||

|

*from the fully turned-in position |

2-13

|

CHASSIS SPECIFICATIONS |

SPEC |

|||||

|

Item |

Standard |

Limit |

||||

|

Steering |

||||||

|

Steering bearing type |

Angular ball bearings |

|||||

|

Rear suspension |

||||||

|

Suspension type |

Swingarm (link suspension) |

|||||

|

Rear shock absorber assembly |

Coil spring/gas-oil damper |

|||||

|

type |

||||||

|

Rear shock absorber assembly |

65 mm |

|||||

|

travel |

||||||

|

Spring |

||||||

|

Free length |

182.5 mm |

|||||

|

Installed length |

163 mm |

|||||

|

Spring rate (K1) |

73.6 N/mm (7.5 kgf/mm) |

|||||

|

Spring stroke (K1) |

0 X 65 mm |

|||||

|

Optional spring available |

No |

|||||

|

Standard spring preload gas/air |

1,200 kPa (12 kgf/cm2) |

|||||

|

pressure |

||||||

|

Spring preload adjusting positions |

||||||

|

Minimum |

1 |

|||||

|

Standard |

6 |

|||||

|

Maximum |

11 |

|||||

|

Rebound damping adjusting |

||||||

|

positions |

||||||

|

Minimum* |

20 |

|||||

|

Standard* |

10 |

|||||

|

Maximum* |

3 |

|||||

|

Compression damping adjusting |

||||||

|

positions |

||||||

|

Minimum* |

1 |

|||||

|

Standard* |

7 |

|||||

|

Maximum* |

12 |

|||||

|

*from the fully turned-in position |

||||||

|

Swingarm |

||||||

|

Free play (at the end of the |

||||||

|

swingarm) |

||||||

|

Radial |

1 mm |

|||||

|

Axial |

1 mm |

|||||

|

Drive chain |

||||||

|

Model (manufacturer) |

50ZVM (DAIDO) |

|||||

|

Link quantity |

116 |

|||||

|

Drive chain slack |

40 X 50 mm |

|||||

|

Maximum ten-link section |

150.1 mm |

152.5 mm |

||||

2-14

|

ELECTRICAL SPECIFICATIONS |

SPEC |

|||||

|

ELECTRICAL SPECIFICATIONS |

||||||

|

Item |

Standard |

Limit |

||||

|

System voltage |

12 V |

|||||

|

Ignition system |

||||||

|

Ignition system type |

Transistorized coil ignition |

|||||

|

Ignition timing |

5_ BTDC at 1,100 r/min |

|||||

|

Advanced timing |

55_ BTDC at 5,000 r/min |

|||||

|

Advancer type |

Throttle position sensor and electrical |

|||||

|

Pickup coil resistance/color |

248 372 Ω/Gy-B |

|||||

|

Transistorized coil ignition unit |

TNDF66 (DENSO) |

|||||

|

model (manufacturer) |

||||||

|

Ignition coils |

||||||

|

Model (manufacturer) |

J0313 (DENSO) |

|||||

|

Minimum ignition spark gap |

6 mm |

|||||

|

Primary coil resistance |

1.87 2.53 Ω |

|||||

|

Secondary coil resistance |

12 18 kΩ |

|||||

|

Spark plug caps |

||||||

|

Material |

Rubber |

|||||

|

Resistance |

10 kΩ |

|||||

|

Throttle position sensor standard |

4 6 kΩ |

|||||

|

resistance |

||||||

|

Charging system |

||||||

|

System type |

AC magneto |

|||||

|

Model (manufacturer) |

F4T361 (MITSUBISHI) |

|||||

|

Normal output |

14 V/365 W at 5,000 r/min |

|||||

|

Stator coil resistance/color |

0.27 0.33 Ω at 20_C/W-W |

|||||

|

Rectifier/regulator |

||||||

|

Regulator type |

Semiconductor short circuit |

|||||

|

Model (manufacture) |

SH650C-11 (SHINDENGEN) |

|||||

|

No-load regulated voltage |

14.1 14.9 V |

|||||

|

Rectifier capacity |

18 A |

|||||

|

Withstand voltage |

200 V |

|||||

|

Battery |

||||||

|

Battery type |

GT14B-4 |

|||||

|

Battery voltage/capacity |

12 V/12AH |

|||||

|

Headlight type |

Halogen bulb |

|||||

|

Bulbs (voltage/wattage quantity) |

||||||

|

Headlight |

12 V 60 W/55 W 2 |

|||||

|

Auxiliary light |

12 V 5 W 2 |

|||||

|

Tail/brake light |

12 V 5 W/21 W 2 |

|||||

|

Turn signal light |

12 V 21 W 4 |

|||||

|

Meter light |

12 V 2 W 3 |

|||||

2-15

|

ELECTRICAL SPECIFICATIONS |

SPEC |

||||

|

Item |

Standard |

Limit |

|||

|

Indicator light |

|||||

|

(voltage/wattage quantity) |

|||||

|

Neutral indicator light |

14 V 1.4 W 1 |

||||

|

High beam indicator light |

14 V 1.4 W 1 |

||||

|

Oil level indicator light |

14 V 1.4 W 1 |

||||

|

Turn signal indicator light |

14 V 1.4 W 2 |

||||

|

Fuel indicator light |

12 V 2 W 1 |

||||

|

Water temperature indicator light |

LED |

||||

|

Electric starting system |

|||||

|

System type |

Constant mesh |

||||

|

Starter motor |

|||||

|

Model (manufacturer) |

SM-13 (MITSUBA) |

||||

|

Power output |

0.8 kW |

||||

|

Brushes |

|||||

|

Overall length |

12.5 mm |

4 mm |

|||

|

Spring force |

7.65 10.01 N (780 1,021 gf) |

||||

|

Commutator resistance |

0.025 0.035 Ω |

||||

|

Commutator diameter |

28 mm |

27 mm |

|||

|

Mica undercut |

0.7 mm |

||||

|

Starter relay |

|||||

|

Model (manufacturer) |

MS5F-631 (JIDECO) |

||||

|

Amperage |

180 A |

||||

|

Coil resistance |

4.18 4.62 Ω |

||||

|

Horn |

|||||

|

Horn type |

Plain |

||||

|

Model (manufacturer) quantity |

YF-12 (NIKKO) 1 |

||||

|

Max. amperage |