-

nekesha

- Администратор

- Сообщения: 1668

- Зарегистрирован: 17 дек 2014, 03:43

- Благодарил (а): 2 раза

- Поблагодарили: 6 раз

Ford Maverick 2000-2007 / Форд Маверик 2000-2007

Руководство по эксплуатации, техобслуживанию и ремонту Ford Maverick / Форд Маверик

Operation, Maintenance and Repair Manual Ford Maverick

- Года выпуска: 2000-2007

Year of release: 2000-2007

Бензиновые двигатели: YF, L3, AJ

Gasoline engines: YF, L3, AJ

- Язык: Русский

Формат: PDF

Размер: 278 Мб

Russian language

Format: PDF

Size: 278 MB

Скачать документацию Ford Maverick / Форд Маверик

Download the documentation of Ford Maverick

для распаковки используйте пароль — avtoproblem-net.ru

use the password to unpack — avtoproblem-net.ru

Руководство на английском языке по техническому обслуживанию и ремонту автомобилей Nissan Patrol и Ford Maverick 1988-1997 годов выпуска.

- Автор: —

- Издательство: Haynes Publishing

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 89,3 Mb

Руководство по техническому обслуживанию и ремонту Ford Maverick и Nissan Patrol 1988-1997 годов выпуска.

- Автор: —

- Издательство: Алфамер Паблишинг

- Год издания: —

- Страниц: 304

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей Ford Escape и Ford Maverick 2000-2007 годов выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 582

- Формат: —

- Размер: —

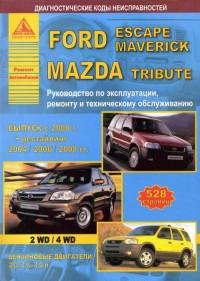

Руководство по эксплуатации и ремонту Ford Escape, Ford Maverick и Mazda Tribute с 2000 года выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 358

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту Ford Escape, Ford Maverick и Mazda Tribute с 2000 года выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 528

- Формат: —

- Размер: —

Мультимедийное руководство по техническому обслуживанию и ремонту Ford Maverick и Nissan Patrol 1988-1997 годов выпуска.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: —

- Размер: 39,5 Mb

Maverick 2001 (12.2000-07.2004) Workshop Manual

- Mechanical Repairs

- 1 General Information

- 100 Service Information

- 100-00 General Information

- Description and Operation

- Material Specification Glossary

- Special Tool Glossary

- Description and Operation

- 100-01 Identification Codes

- Description and Operation

- Identification Codes — Vehicles Built Up To: 07-2002

- Identification Codes — Vehicles Built From: 08-2002

- Description and Operation

- 100-02 Jacking and Lifting

- Description and Operation

- 100-02 Jacking and Lifting|Jacking

- 100-02 Jacking and Lifting|Lifting

- Description and Operation

- 100-04 Noise, Vibration and Harshness

- Description and Operation

- Noise, Vibration and Harshness (NVH)

- Diagnosis and Testing

- Noise, Vibration and Harshness (NVH)

- General Procedures

- Brake Disc Machining

- Exhaust System Neutralizing

- Powertrain-Drivetrain Mount Neutralizing

- Wheel Bearing Check

- Description and Operation

- 100-00 General Information

- 100 Service Information

- 2 Chassis

- 204 Suspension

- 204-00 Suspension System — General Information

- 204-00 Suspension System — General Information|Specifications

- Description and Operation

- Suspension System

- Wheel Alignment Angles

- Diagnosis and Testing

- Suspension System

- General Procedures

- Wheel Bearing Inspection

- Camber and Caster Adjustment

- Rear Toe Adjustment

- Front Toe Adjustment

- Lean Correction

- 204-01 Front Suspension

- 204-01 Front Suspension|Specifications

- Description and Operation

- Front Suspension

- Diagnosis and Testing

- Front Suspension

- Removal and Installation

- Wheel Bearing

- Lower Arm

- Wheel Studs

- Stabilizer Bar

- Strut and Spring Assembly

- Stabilizer Bar Link

- Disassembly and Assembly

- Strut and Spring Assembly

- 204-02 Rear Suspension

- Description and Operation

- Rear Suspension

- Diagnosis and Testing

- Rear Suspension

- Removal and Installation

- Wheel Bearing — 4×2

- Wheel Studs

- Wheel Bearing — 4×4

- Upper Arm

- Lower Arm

- Wheel Knuckle — 4×2

- Wheel Knuckle — 4×4

- Shock Absorber

- Diagnosis and Testing|Removal and Installation|Spring

- 204-02 Rear Suspension|Specifications

- Description and Operation

- 204-04 Wheels and Tires

- Description and Operation

- Wheels and Tires

- Diagnosis and Testing

- General Procedures

- Wheel Leaks

- Removal and Installation

- Wheel and Tire

- Wheels and Tires

- General Procedures

- 204-04 Wheels and Tires|Specifications

- Description and Operation

- 204-00 Suspension System — General Information

- 205 Driveline

- 205-00 Driveline System — General Information

- 205-00 Driveline System — General Information|Specifications

- Description and Operation

- Driveline System

- Diagnosis and Testing

- Driveline System

- 205-01 Driveshaft

- 205-01 Driveshaft|Specifications

- Description and Operation

- Driveshaft

- Diagnosis and Testing

- Driveshaft

- General Procedures

- Driveshaft Indexing

- Driveshaft Runout and Balancing

- Removal and Installation

- Driveshaft

- Universal Joints

- 205-02 Rear Drive Axle-Differential

- Description and Operation

- Rear Drive Axle and Differential

- Diagnosis and Testing

- Rear Drive Axle and Differential

- In-vehicle Repair

- Stub Shaft Pilot Bearing and Seal

- Differential Housing Cover

- Removal and Installation

- Axle Assembly

- Rotary Blade Coupling

- Differential Mass Damper

- Disassembly and Assembly

- Disassembly and Assembly|Axle

- 205-02 Rear Drive Axle-Differential|Specifications

- Description and Operation

- 205-04 Front Drive Halfshafts

- 205-04 Front Drive Halfshafts|Specifications

- Description and Operation

- Front Drive Halfshafts

- Diagnosis and Testing

- Front Drive Halfshafts

- Removal and Installation

- Halfshaft

- Intermediate Shaft

- Disassembly and Assembly

- Halfshaft

- Halfshaft Joint

- 205-05 Rear Drive Halfshafts

- 205-05 Rear Drive Halfshafts|Specifications

- Description and Operation

- Diagnosis and Testing

- Rear Drive Halfshafts

- Removal and Installation

- Halfshaft

- Disassembly and Assembly

- Halfshaft Joint

- Rear Drive Halfshafts

- Diagnosis and Testing

- 205-00 Driveline System — General Information

- 206 Brake System

- 206-00 Brake System — General Information

- Description and Operation

- Brake System

- Diagnosis and Testing

- Brake System

- General Procedures

- Brake System Bleeding

- Brake System Pressure Bleeding

- Component Bleeding

- Brake System Leak Check

- Brake Disc Runout Check

- 206-00 Brake System — General Information|Specifications

- Description and Operation

- 206-02 Drum Brake

- Description and Operation

- Drum Brake

- Diagnosis and Testing

- Drum Brake

- General Procedures

- Brake Shoe Adjustment

- Removal and Installation

- Brake Drum

- Brake Shoes

- Wheel Cylinder

- Brake Backing Plate

- Disassembly and Assembly

- Wheel Cylinder

- 206-02 Drum Brake|Specifications

- Description and Operation

- 206-03 Front Disc Brake

- 206-03 Front Disc Brake|Specifications

- Description and Operation

- Diagnosis and Testing

- Front Disc Brake

- Removal and Installation

- Brake Pads

- Brake Caliper Anchor Plate

- Brake Caliper

- Brake Disc

- Disassembly and Assembly

- Brake Caliper

- Front Disc Brake

- Diagnosis and Testing

- 206-05 Parking Brake and Actuation

- 206-05 Parking Brake and Actuation|Specifications

- Description and Operation

- Parking Brake

- Diagnosis and Testing

- Parking Brake

- General Procedures

- Parking Brake Cable Adjustment

- Removal and Installation

- Parking Brake Control

- Parking Brake Front Cable

- Parking Brake Rear Cables

- Parking Brake Warning Indicator Switch

- 206-06 Hydraulic Brake Actuation

- 206-06 Hydraulic Brake Actuation|Specifications

- Description and Operation

- Diagnosis and Testing

- Hydraulic Brake Actuation

- Removal and Installation

- Brake Pedal and Bracket

- Brake Fluid Reservoir

- Brake Master Cylinder

- Brake Pressure Control Valve

- Disassembly and Assembly

- Brake Master Cylinder

- Hydraulic Brake Actuation

- Diagnosis and Testing

- 206-07 Power Brake Actuation

- 206-07 Power Brake Actuation|Specifications

- Description and Operation

- Brake Booster

- Diagnosis and Testing

- Power Brake System

- Removal and Installation

- Brake Booster

- 206-09 Anti-Lock Control

- 206-09 Anti-Lock Control|Specifications

- Description and Operation

- Anti-Lock Control

- Diagnosis and Testing

- Anti-Lock Control

- Removal and Installation

- Hydraulic Control Unit (HCU)

- Anti-Lock Brake System (ABS) Module

- Front Wheel Speed Sensor

- Front Wheel Speed Sensor Ring

- Rear Wheel Speed Sensor

- Rear Wheel Speed Sensor Ring

- 206-00 Brake System — General Information

- 211 Steering System

- 211-00 Steering System — General Information

- 211-00 Steering System — General Information|Specifications

- Description and Operation

- Steering System

- Diagnosis and Testing

- Steering System

- General Procedures

- Power Steering System Flushing

- Power Steering System Purging

- Power Steering System Filling

- 211-02 Power Steering

- Description and Operation

- Power Steering

- Diagnosis and Testing

- Power Steering

- Removal and Installation

- Power Steering Fluid Reservoir

- Power Steering Pump — 2.0L Zetec-E (Zetec)

- Power Steering Pump — 3.0L Duratec-VE (VE6)

- Power Steering Pump Pulley

- Power Steering Pump to Steering Gear Pressure Line — 2.0L

- Power Steering Pump to Steering Gear Pressure Line — 3.0L

- Steering Gear to Fluid Cooler Return Hose

- Power Steering Fluid Cooler

- Steering Gear — LHD

- Steering Gear — RHD

- 211-02 Power Steering|Specifications

- Description and Operation

- 211-03 Steering Linkage

- 211-03 Steering Linkage|Specifications

- Description and Operation

- Diagnosis and Testing

- Steering Linkage

- Removal and Installation

- Steering Gear Boot

- Tie Rod End

- Steering Linkage

- Diagnosis and Testing

- 211-04 Steering Column

- 211-04 Steering Column|Specifications

- Description and Operation

- Diagnosis and Testing

- Steering Column

- Removal and Installation

- Ignition Switch Lock Cylinder

- Steering Wheel

- Steering Column

- Steering Column Coupling

- Steering Column Shaft

- Disassembly and Assembly

- Steering Column

- Steering Column

- Diagnosis and Testing

- 211-05 Steering Column Switches

- Description and Operation

- Steering Column Switches

- Diagnosis and Testing

- Steering Column Switches

- Removal and Installation

- Hazard Flasher Switch — LHD

- Steering Column Multifunction Switch

- Hazard Flasher Switch — RHD

- Ignition Switch — Vehicles Built Up To: 07-2002

- Description and Operation

- 211-00 Steering System — General Information

- 204 Suspension

- 3 Powertrain

- 303 Engine

- 303-00 Engine System — General Information

- 303-00 Engine System — General Information|Specifications

- Description and Operation

- 303-00 Engine System — General Information|Engine

- Diagnosis and Testing

- Diagnosis and Testing|Engine

- General Procedures

- Sprockets

- Camshaft Bearing Journal Diameter

- Camshaft Bearing Journal Clearance — Plastigage Method

- Camshaft End Play

- Camshaft Surface Inspection

- Camshaft Lobe Lift

- Camshaft Runout

- Crankshaft Main Bearing Journal Taper

- Crankshaft Main Bearing Journal Diameter

- Crankshaft Main Bearing Journal Clearance

- Crankshaft End Play

- Crankshaft Runout

- Crankshaft Connecting Rod Journal Diameter

- Cylinder Bore Taper

- Crankshaft Connecting Rod Journal Taper

- Piston Inspection

- Cylinder Bore Out-of-Round

- Piston Pin to Bore Diameter

- Piston Diameter

- Piston Selection

- Piston to Cylinder Bore Clearance

- Piston Ring End Gap

- Piston Pin Diameter

- Piston Ring-to-Groove Clearance

- Connecting Rod Cleaning

- Connecting Rod Large End Bore

- Connecting Rod Bushing Diameter

- Connecting Rod Twist

- Connecting Rod Bend

- Piston Wrist Pin Slide Clearance

- Connecting Rod Bearing Journal Clearance

- Camshaft Roller Follower Inspection

- Valve Tappet Hydraulic Leakdown Test

- Valve Tappet Inspection

- Valve Stem Diameter

- Valve Stem to Valve Guide Clearance

- Valve Inspection

- Valve Guide Reaming

- Valve Guide Inner Diameter

- Valve Spring Free Length

- Valve Spring Installed Length

- Valve Spring Strength

- Valve Spring Squareness

- Valve Seat Inspection

- Valve Seat Runout

- Valve Seat Width

- Cylinder Head Distortion

- Cylinder Bore Cleaning

- Cylinder Block Distortion

- Cylinder Block Core Plug Replacement

- Spark Plug Inspection

- Spark Plug Hole Thread Repair

- Exhaust Manifold Cleaning and Inspection

- Bearing Inspection

- 303-01A Engine — 2.0L Zetec-E (Zetec)

- 303-01A Engine — 2.0L Zetec-E (Zetec)|Specifications

- Description and Operation

- Diagnosis and Testing

- Diagnosis and Testing|Engine

- In-vehicle Repair

- Intake Manifold

- Crankshaft Pulley

- Valve Cover

- Crankshaft Front Seal

- Timing Belt Cover

- Timing Belt

- Timing Drive Components

- In-vehicle Repair|Valve

- Valve Clearance Adjustment

- Valve Tappets

- Camshafts

- Camshaft Seal

- Exhaust Manifold

- Cylinder Head

- Oil Cooler

- Oil Pressure Sender

- In-vehicle Repair|Oil Pan

- Oil Level Indicator and Tube

- Flexplate

- Oil Pump Screen and Pickup Tube

- Flywheel

- Engine Mount

- Crankshaft Rear Seal

- Removal

- Engine — Vehicles With: Automatic Transaxle

- Engine — Vehicles With: Manual Transaxle

- Disassembly

- In-vehicle Repair|Disassembly|Engine

- Disassembly and Assembly of Subassemblies

- Cylinder Head

- Disassembly and Assembly of Subassemblies|Piston

- Assembly

- Assembly|Engine

- Installation

- Engine — Vehicles With: Automatic Transaxle

- Engine — Vehicles With: Manual Transaxle

- 303-01A Engine — 2.0L Zetec-E (Zetec)|Engine

- Diagnosis and Testing

- 303-01B Engine — 3.0L Duratec-VE (VE6)

- 303-01B Engine — 3.0L Duratec-VE (VE6)|Specifications

- Description and Operation

- 303-01B Engine — 3.0L Duratec-VE (VE6)|Engine

- Diagnosis and Testing

- Diagnosis and Testing|Engine

- In-vehicle Repair

- Lower Intake Manifold

- Upper Intake Manifold

- Engine Front Cover

- Valve Cover LH

- Valve Cover RH

- Camshafts LH

- Camshafts RH

- Timing Drive Components

- Roller Follower

- Hydraulic Lash Adjuster

- Crankshaft Pulley

- Crankshaft Front Seal

- Valve Spring

- Valve Seals

- Exhaust Manifold LH

- Exhaust Manifold RH

- Cylinder Head LH

- Cylinder Head RH

- Oil Cooler

- Oil Level Indicator and Tube

- Oil Pressure Sender

- In-vehicle Repair|Oil Pan

- Oil Pump Screen and Pickup Tube

- Oil Pan Baffle

- Oil Pump

- Crankshaft Rear Seal

- Flexplate

- Engine Support Insulators

- Removal

- In-vehicle Repair|Engine

- Disassembly

- In-vehicle Repair|Disassembly|Engine

- Disassembly and Assembly of Subassemblies

- Cylinder Head

- Disassembly and Assembly of Subassemblies|Piston

- Assembly

- Assembly|Engine

- Installation

- Assembly|Installation|Engine

- 303-03 Engine Cooling

- Description and Operation

- Engine Cooling

- Diagnosis and Testing

- Engine Cooling

- General Procedures

- Cooling System Inspection

- Cooling System Draining, Filling and Bleeding

- Cooling System Flushing

- Removal and Installation

- Block Heater

- Thermostat — 2.0L

- Thermostat — 3.0L

- Bypass Tube — 3.0L

- Thermostat Housing — 2.0L

- Water Pump — 2.0L

- Water Pump — 3.0L

- Cooling Fan

- Radiator

- Degas Bottle

- 303-03 Engine Cooling|Specifications

- Description and Operation

- 303-04A Fuel Charging and Controls — 2.0L Zetec-E (Zetec)

- 303-04A Fuel Charging and Controls — 2.0L Zetec-E (Zetec)|Specifications

- Description and Operation

- Diagnosis and Testing

- Fuel Charging and Controls

- Removal and Installation

- Throttle Body

- Fuel Charging Wiring Harness

- Fuel Injectors

- Fuel Injection Supply Manifold

- Fuel Pulse Damper

- Fuel Charging and Controls

- Diagnosis and Testing

- 303-04B Fuel Charging and Controls — 3.0L Duratec-VE (VE6)

- 303-04B Fuel Charging and Controls — 3.0L Duratec-VE (VE6)|Specifications

- Description and Operation

- Diagnosis and Testing

- Fuel Charging and Controls

- Removal and Installation

- Throttle Body

- Fuel Injectors

- Fuel Charging Wiring Harness

- Fuel Injection Supply Manifold

- Fuel Pulse Damper

- Fuel Pressure Relief Valve

- Fuel Charging and Controls

- Diagnosis and Testing

- 303-05 Accessory Drive

- 303-05 Accessory Drive|Specifications

- Description and Operation

- Diagnosis and Testing

- Accessory Drive

- Removal and Installation

- Accessory Drive Belt — 2.0L

- Accessory Drive Belt — 3.0L

- Water Pump Belt — 3.0L, Vehicles With: Coolant Pump Belt Tensioner

- Water Pump Belt — 3.0L, Vehicles Without: Coolant Pump Belt Tensioner

- Accessory Drive Belt Tensioner — 2.0L

- Accessory Drive Belt Tensioner — 3.0L

- Accessory Drive Belt Idler Pulley — 2.0L

- Water Pump Belt Tensioner — 3.0L

- Accessory Drive

- Diagnosis and Testing

- 303-06 Starting System

- Description and Operation

- Starting System

- Diagnosis and Testing

- Starting System

- General Procedures

- Starter Drive and Flywheel Ring Gear Inspection

- Removal and Installation

- Starter Motor — 2.0L

- Starter Motor — 3.0L

- 303-06 Starting System|Specifications

- Description and Operation

- 303-07A Engine Ignition — 2.0L Zetec-E (Zetec)

- 303-07A Engine Ignition — 2.0L Zetec-E (Zetec)|Specifications

- Description and Operation

- Diagnosis and Testing

- Engine Ignition

- Removal and Installation

- Ignition Coil

- Spark Plug Wires

- Ignition Coil Bracket

- Spark Plugs

- Engine Ignition

- Diagnosis and Testing

- 303-07B Engine Ignition — 3.0L Duratec-VE (VE6)

- Description and Operation

- Engine Ignition

- Diagnosis and Testing

- Engine Ignition

- Removal and Installation

- Ignition Coil-On-Plug LH

- Ignition Coil-On-Plug RH

- Spark Plugs

- 303-07B Engine Ignition — 3.0L Duratec-VE (VE6)|Specifications

- Description and Operation

- 303-08 Engine Emission Control

- 303-08 Engine Emission Control|Specifications

- Description and Operation

- Diagnosis and Testing

- Engine Emission Control

- Removal and Installation

- Exhaust Gas Recirculation (EGR) Valve — 2.0L

- Exhaust Gas Recirculation (EGR) Valve — 3.0L

- Exhaust Manifold to Exhaust Gas Recirculation (EGR) Valve Tube — 2.0L

- Crankcase Ventilation Tube — 2.0L

- Exhaust Manifold to Exhaust Gas Recirculation (EGR) Valve Tube — 3.0L

- Differential Pressure Feedback Exhaust Gas Recirculation (EGR) Sensor

- Crankcase Vent Oil Separator — 2.0L

- Exhaust Gas Recirculation (EGR) Vacuum Regulator Valve — 2.0L

- Exhaust Gas Recirculation (EGR) Vacuum Regulator Valve — 3.0L

- Positive Crankcase Ventilation (PCV) Valve — 2.0L

- Engine Emission Control

- Diagnosis and Testing

- 303-12 Intake Air Distribution and Filtering

- 303-12 Intake Air Distribution and Filtering|Specifications

- Description and Operation

- Diagnosis and Testing

- Intake Air Distribution and Filtering

- Removal and Installation

- Air Cleaner Intake Pipe — 2.0L-3.0L

- Air Cleaner Outlet Pipe — 2.0L

- Intake Air Resonator — 2.0L-3.0L

- Air Cleaner — 2.0L-3.0L

- Air Cleaner Outlet Pipe — 3.0L

- Intake Air Distribution and Filtering

- Diagnosis and Testing

- 303-13 Evaporative Emissions

- 303-13 Evaporative Emissions|Specifications

- Description and Operation

- Evaporative Emissions

- Diagnosis and Testing

- General Procedures

- Evaporative Emission System Leak Test

- Removal and Installation

- Evaporative Emission Canister

- Evaporative Emission Canister Purge Valve

- Evaporative Emissions

- General Procedures

- 303-14 Electronic Engine Controls

- 303-14 Electronic Engine Controls|Specifications

- Description and Operation

- Electronic Engine Controls

- Diagnosis and Testing

- Electronic Engine Controls

- Removal and Installation

- Camshaft Position (CMP) Sensor — 2.0L

- Camshaft Position (CMP) Sensor — 3.0L

- Crankshaft Position (CKP) Sensor — 2.0L

- Power Steering Pressure (PSP) Switch — 3.0L

- Crankshaft Position (CKP) Sensor — 3.0L

- Powertrain Control Module (PCM)

- Throttle Position (TP) Sensor — 3.0L

- Throttle Position (TP) Sensor — 2.0L

- Idle Air Control (IAC) Valve — 3.0L

- Idle Air Control (IAC) Valve — 2.0L

- Engine Coolant Temperature (ECT) Sensor — 3.0L

- Mass Air Flow (MAF) Sensor

- Heated Oxygen Sensor (HO2S) — 2.0L

- Heated Oxygen Sensor (HO2S) RH — 3.0L

- Heated Oxygen Sensor (HO2S) LH — 3.0L

- Catalyst Monitor Sensor — 2.0L

- Catalyst Monitor Sensor LH — 3.0L

- Catalyst Monitor Sensor RH — 3.0L

- Knock Sensor (KS) — 2.0L

- Cylinder Head Temperature (CHT) Sensor — 2.0L

- Knock Sensor (KS) — 3.0L

- Clutch Pedal Position (CPP) Switch

- 303-00 Engine System — General Information

- 307 Automatic Transmission-Transaxle

- 307-01 Automatic Transmission-Transaxle

- 307-01 Automatic Transmission-Transaxle|Specifications

- Description and Operation

- Transaxle Description

- Range Selection

- Identification Tags

- Shift Patterns

- Disassembled Views

- Bushings, Bearing and Thrust Washer Locator

- Torque Converter

- Geartrain

- Hydraulic System

- Apply Components

- Transaxle Electronic Control System

- Diagnosis and Testing

- Diagnostic Strategy

- Diagnostic Flow Chart

- Road Testing Vehicle

- Preliminary Inspection

- Shift Point Road Test

- Torque Converter Diagnosis

- Visual Inspection

- Diagnostics

- Transaxle Drive Cycle Test

- Transmission-Transaxle Connector Layouts

- Diagnostic Trouble Code Charts

- Pinpoint Tests — Non OSC Equipped Vehicle

- Leakage Inspection

- Special Testing Procedures

- Transmission Fluid Cooler

- Diagnosis By Symptom

- General Procedures

- Transmission Fluid Cooler — Backflushing and Cleaning

- In-vehicle Repair

- Transmission Fluid Drain and Refill

- Turbine Shaft Speed (TSS) Sensor

- Main Control Valve Body

- Output Shaft Speed (OSS) Sensor

- Differential Seals RH

- Differential Seals LH

- Transmission Range (TR) Sensor

- Transaxle Front Support Insulator

- Transaxle Rear Support Insulator

- Transaxle Support Insulator LH

- Removal

- Transaxle

- Disassembly

- Transaxle

- Disassembly and Assembly of Subassemblies

- Chain Sprockets

- Torque Converter Housing

- Final Drive Carrier and Differential Assembly

- Forward-Coast-Direct Clutch Cylinder and Reverse Clutch Drum — Disassembly

- Forward One-Way Clutch

- Forward-Coast-Direct Clutches

- Forward-Coast-Direct Clutch Cylinder and Reverse Clutch Drum — Assembly

- Low One-Way Clutch Assembly

- Low-Reverse Piston

- Main Control Valve Body

- Transaxle Case

- Pump Assembly

- Reverse Clutch

- Planetary Gearsets and Chain Drive Parts

- Torque Converter Cleaning and Inspection

- Torque Converter

- Torque Converter Flushing

- Torque Converter End Play Check

- Torque Converter Leak Check

- Torque Converter Turbine Torque Check

- Torque Converter Insert Check

- Assembly

- Transmission

- Installation

- Transaxle

- 307-02 Transmission-Transaxle Cooling

- Description and Operation

- Transaxle Cooling

- Diagnosis and Testing

- Transaxle Cooling

- General Procedures

- Transmission Fluid Cooler — Backflushing and Cleaning

- Removal and Installation

- Auxiliary Transmission Fluid Cooler

- Transmission Fluid Cooler Tubes

- 307-02 Transmission-Transaxle Cooling|Specifications

- Description and Operation

- 307-05 Automatic Transmission-Transaxle External Controls

- 307-05 Automatic Transmission-Transaxle External Controls|Specifications

- Description and Operation

- External Controls

- Diagnosis and Testing

- External Controls

- General Procedures

- Selector Lever Cable Adjustment

- Removal and Installation

- Selector Lever

- Selector Lever Cable

- 307-01 Automatic Transmission-Transaxle

- 308 Manual Transmission-Transaxle, Clutch and Transfer Case

- 308-00 Manual Transmission-Transaxle and Clutch — General Information

- Description and Operation

- Manual Transaxle and Clutch

- Diagnosis and Testing

- Manual Transaxle and Clutch

- General Procedures

- Clutch Disc Check

- Clutch Master Cylinder Check

- Clutch Pressure Plate Check

- Flywheel Runout Check

- Clutch Release Fork Check

- Transmission Bearing Cone and Race Inspection

- Clutch System Bleeding

- Gearshift Cable Adjustment

- Removal and Installation

- Clutch Pressure Plate Locating Dowels

- Clutch Housing Locating Dowels

- 308-00 Manual Transmission-Transaxle and Clutch — General Information|Specifications

- Description and Operation

- 308-01 Clutch

- Description and Operation

- 308-01 Clutch|Clutch

- Diagnosis and Testing

- Diagnosis and Testing|Clutch

- Removal and Installation

- Clutch Release Fork

- Pilot Bearing

- Clutch Disc and Pressure Plate

- Flywheel Ring Gear

- 308-01 Clutch|Specifications

- Description and Operation

- 308-02 Clutch Controls

- Description and Operation

- Clutch Controls

- Diagnosis and Testing

- Clutch Controls

- Removal and Installation

- Clutch Pedal

- Clutch Master Cylinder

- Slave Cylinder

- 308-02 Clutch Controls|Specifications

- Description and Operation

- 308-03 Manual Transmission-Transaxle

- Description and Operation

- Manual Transaxle

- Diagnosis and Testing

- Manual Transaxle

- General Procedures

- Transaxle Draining and Filling

- Bearings

- In-vehicle Repair

- Halfshaft Seal

- Vehicle Speed Sensor (VSS)

- Transaxle LH Support Insulator

- Transaxle Front Support Insulator

- Transaxle Rear Support Insulator

- Removal

- Transaxle

- Disassembly

- Transaxle

- Disassembly and Assembly of Subassemblies

- Input Shaft

- Output Shaft

- Synchronizers

- Differential

- Assembly

- Transaxle

- Installation

- Transaxle

- 308-03 Manual Transmission-Transaxle|Specifications

- Description and Operation

- 308-06 Manual Transmission-Transaxle External Controls

- 308-06 Manual Transmission-Transaxle External Controls|Specifications

- Description and Operation

- External Controls

- Removal and Installation

- Gearshift Lever

- Gearshift Cables

- Gearshift Stabilizer Bar Bushing

- Gearshift Stabilizer Bar

- Gearshift Lever Boot

- 308-07A Four-Wheel Drive Systems

- Description and Operation

- Four-Wheel Drive Systems

- Diagnosis and Testing

- Four-Wheel Drive Systems

- Removal and Installation

- Mode Select Switch (MSS)

- 308-07A Four-Wheel Drive Systems|Specifications

- Description and Operation

- 308-07B Transfer Case

- 308-07B Transfer Case|Specifications

- Description and Operation

- Diagnosis and Testing

- Transfer Case

- General Procedures

- Transfer Case Draining and Filling

- In-vehicle Repair

- Transfer Case Rear Output Shaft Seal

- Halfshaft Seal RH

- Transfer Case Inner Halfshaft Seal

- Transfer Case Rear Output Shaft Flange

- Transfer Case Rear Output Shaft Flange Dust Shield

- Transfer Case Driven Gear Seal

- Removal

- Transfer Case — 3.0L

- Transfer Case — 2.0L

- Installation

- Transfer Case — 3.0L

- Transfer Case — 2.0L

- Transfer Case

- Diagnosis and Testing

- 308-00 Manual Transmission-Transaxle and Clutch — General Information

- 309 Exhaust System

- 309-00 Exhaust System

- Description and Operation

- Exhaust System

- Diagnosis and Testing

- Exhaust System

- Removal and Installation

- Muffler and Tailpipe

- Catalytic Converter — 2.0L

- Resonator — 3.0L

- Catalytic Converter — 3.0L

- Exhaust Flexible Pipe — 3.0L

- 309-00 Exhaust System|Specifications

- Description and Operation

- 309-00 Exhaust System

- 310 Fuel System

- 310-00 Fuel System — General Information

- 310-00 Fuel System — General Information|Specifications

- Description and Operation

- Fuel System

- Diagnosis and Testing

- Fuel System

- General Procedures

- Fuel System Pressure Release — 2.0L

- Fuel System Pressure Release — 3.0L

- Fuel Tank Draining

- Spring Lock Couplings

- Vapor Tube Fittings

- Quick Release Coupling — Push Connect

- Quick Release Coupling — R Clip

- 310-01 Fuel Tank and Lines

- Description and Operation

- Fuel Tank and Lines

- Diagnosis and Testing

- Fuel Tank and Lines

- Removal and Installation

- Fuel Tank

- Fuel Tank Support Straps

- Fuel Pump Module

- Fuel Tank Filler Pipe

- Inertia Fuel Shutoff (IFS) Switch

- Fuel Filter

- 310-01 Fuel Tank and Lines|Specifications

- Description and Operation

- 310-02 Acceleration Control

- Description and Operation

- Acceleration Control

- Diagnosis and Testing

- Acceleration Control

- Removal and Installation

- Accelerator Cable — 2.0L

- Accelerator Pedal and Shaft

- Accelerator Cable — 3.0L

- Accelerator Cable Bracket

- 310-02 Acceleration Control|Specifications

- Description and Operation

- 310-03 Speed Control

- 310-03 Speed Control|Specifications

- Description and Operation

- Speed Control

- Diagnosis and Testing

- Speed Control

- Removal and Installation

- Speed Control Cable

- Speed Control Actuator

- Speed Control Switch

- Speed Control Deactivator Switch

- 310-00 Fuel System — General Information

- 303 Engine

- 4 Electrical

- 412 Climate Control System

- 412-00 Climate Control System — General Information

- Description and Operation

- Climate Control System

- Diagnosis and Testing

- Climate Control System

- General Procedures

- Refrigerant System Tests

- Spring Lock Coupling

- Air Conditioning (A-C) Clutch Air Gap Adjustment

- Air Conditioning Line (Peanut) Fitting

- Manifold Gauge Set Connection

- Electronic Leak Detection

- Discharging and Recovery

- Fluorescent Dye Leak Detection

- Air Conditioning (A-C) System Recovery, Evacuation and Charging

- Refrigerant System Filtering Following Air Conditioning (A-C) Compressor Installation

- Refrigerant Oil Adding

- Refrigerant Identification Testing

- Inspection and Assembly Requirements

- Vacuum Hose Repair

- Contaminated Refrigerant Handling

- 412-00 Climate Control System — General Information|Specifications

- Description and Operation

- 412-01 Air Distribution and Filtering

- Description and Operation

- Diagnosis and Testing

- Air Distribution

- Removal and Installation

- Rear Footwell Duct

- Defroster Duct

- Center Register Duct

- Air Distribution

- Diagnosis and Testing

- Description and Operation

- 412-02 Heating and Ventilation

- Description and Operation

- Heating and Ventilation

- Diagnosis and Testing

- Heating and Ventilation

- Removal and Installation

- Heater Hose — 2.0L

- Heater Hose — 3.0L

- Blower Motor Wheel

- Blower Motor

- Heater Core

- Heater Core Housing

- Evaporator Core Housing

- 412-02 Heating and Ventilation|Specifications

- Description and Operation

- 412-03 Air Conditioning

- 412-03 Air Conditioning|Specifications

- Description and Operation

- Diagnosis and Testing

- Air Conditioning

- Removal and Installation

- Air Conditioning (A-C) Compressor — 3.0L

- Air Conditioning (A-C) Compressor — 2.0L

- Air Conditioning (A-C) Compressor Bracket

- Clutch and Clutch Field Coil

- Air Conditioning (A-C) Compressor Shaft Seal

- Evaporator Core — RHD

- Evaporator Core — LHD

- Evaporator Core Orifice

- Suction Accumulator — LHD

- Suction Accumulator — RHD

- Air Conditioning (A-C) Cycling Switch

- Air Conditioning (A-C) Pressure Relief Valve

- Pressure Cutoff Switch

- Condenser Core

- Manifold and Tube Assembly — LHD

- Manifold and Tube Assembly — RHD

- Condenser to Evaporator Line — LHD

- Condenser to Evaporator Line — RHD

- Air Conditioning

- Diagnosis and Testing

- 412-04 Control Components

- Description and Operation

- Control Components

- Diagnosis and Testing

- Control Components

- Removal and Installation

- Climate Control Assembly

- Temperature Control Switch — LHD

- Function Selector Switch — LHD

- Blower Motor Switch — LHD

- Temperature Blend Door Control Cable — LHD

- Defrost Vent Blend Door Vacuum Control Motor — LHD

- Instrument Panel Blend Door Vacuum Control Motor — LHD

- Recircluation Blend Door Vacuum Control Motor — LHD

- Footwell Vent Blend Door Vacuum Control Motor — LHD

- Climate Control Assembly Illumination Bulbs

- Defrost Vent-Register Blend Door Actuator — RHD

- Air Inlet Blend Door Actuator — RHD

- Temperature Blend Door Actuator — RHD

- Description and Operation

- 412-00 Climate Control System — General Information

- 413 Instrumentation and Warning Systems

- 413-00 Instrument Cluster and Panel Illumination

- Description and Operation

- Instrument Cluster and Panel Illumination — Vehicles Built Up To: 07-2002

- Instrument Cluster and Panel Illumination — Vehicles Built From: 08-2002

- Diagnosis and Testing

- Instrument Cluster and Panel Illumination

- Removal and Installation

- Instrument Cluster Bulb

- Selector Lever Indicator Bulb

- Instrument Panel Dimmer Switch

- Description and Operation

- 413-01 Instrument Cluster

- Description and Operation

- Instrument Cluster

- Diagnosis and Testing

- Instrument Cluster

- Removal and Installation

- Instrument Cluster

- Warning Indicator Bulb

- Cluster Lens

- Description and Operation

- 413-06 Horn

- 413-06 Horn|Specifications

- Description and Operation

- 413-06 Horn|Horn

- Diagnosis and Testing

- Removal and Installation

- Diagnosis and Testing|Removal and Installation|Horn

- Diagnosis and Testing|Horn

- Removal and Installation

- 413-09 Warning Devices

- Description and Operation

- Gauges and Warning Devices

- Diagnosis and Testing

- Gauges and Warning Devices

- Description and Operation

- 413-00 Instrument Cluster and Panel Illumination

- 414 Battery and Charging System

- 414-00 Charging System — General Information

- 414-00 Charging System — General Information|Specifications

- Description and Operation

- Charging System

- Diagnosis and Testing

- Charging System

- General Procedures

- Battery Charging

- 414-01 Battery, Mounting and Cables

- Description and Operation

- Battery and Cables

- Diagnosis and Testing

- Diagnosis and Testing|Battery

- General Procedures

- Battery Disconnect

- Removal and Installation

- General Procedures|Removal and Installation|Battery

- Battery Cables — 2.0L

- Battery Tray

- Battery Cables — 3.0L

- 414-01 Battery, Mounting and Cables|Specifications

- Description and Operation

- 414-02 Generator and Regulator

- Description and Operation

- Generator

- Diagnosis and Testing

- Generator

- Removal and Installation

- Generator — 3.0L

- Generator — 2.0L

- 414-02 Generator and Regulator|Specifications

- Description and Operation

- 414-00 Charging System — General Information

- 415 Information and Entertainment Systems

- 415-00 Information and Entertainment System — General Information

- Diagnosis and Testing

- Audio System

- Diagnosis and Testing

- 415-01 Audio Unit

- 415-01 Audio Unit|Specifications

- Description and Operation

- Diagnosis and Testing

- Audio System

- Removal and Installation

- Compact Disc (CD) Changer

- Ground Strap

- Audio Unit

- Audio System

- Diagnosis and Testing

- 415-02 Antenna

- Description and Operation

- 415-02 Antenna|Antenna

- Diagnosis and Testing

- Diagnosis and Testing|Antenna

- Removal and Installation

- Antenna Base

- Antenna Upper Cable — LHD

- Antenna Upper Cable — RHD

- 415-02 Antenna|Specifications

- Description and Operation

- 415-03 Speakers

- Description and Operation

- Speakers

- Diagnosis and Testing

- Speakers

- Description and Operation

- 415-00 Information and Entertainment System — General Information

- 417 Lighting

- 417-01 Exterior Lighting

- Description and Operation

- Exterior Lighting

- Diagnosis and Testing

- Headlamps

- Stoplamps

- Turn Signal and Hazard Lamps

- Parking, Rear and License Lamps

- Front Fog Lamps

- Rear Fog Lamps

- Reversing Lamps

- Trailer Lamps

- Headlamp Leveling

- General Procedures

- Headlamp Adjustment — Photometric Aiming Method

- Headlamp Adjustment — Screen Aiming Method

- Removal and Installation

- Side Lamp-Front Turn Signal Lamp Bulb

- Headlamp Bulb

- High Mounted Stoplamp Bulb

- Fog Lamp Bulb

- Headlamp Assembly

- Rear Lamp Assembly

- Fog Lamp

- License Plate Lamp

- Fog Lamp Switch

- Brake Pedal Position (BPP) Switch

- Description and Operation

- 417-02 Interior Lighting

- Description and Operation

- Interior Lighting

- Diagnosis and Testing

- Interior Lighting

- Removal and Installation

- Cargo Lamp

- Interior-Map Reading Lamp

- Description and Operation

- 417-01 Exterior Lighting

- 418 Electrical Distribution

- 418-00 Module Communications Network

- 418-00 Module Communications Network|Specifications

- Description and Operation

- Communications Network

- Diagnosis and Testing

- Communications Network

- General Procedures

- Communication Circuit Wiring Repair

- 418-01 Module Configuration

- Diagnosis and Testing

- Module Configuration

- General Procedures

- Programmable Module Installation

- Programmable Module Installation Using Backup Data

- Customer Preference Items

- Diagnosis and Testing

- 418-00 Module Communications Network

- 419 Electronic Feature Group

- 419-01A Anti-Theft — Active

- 419-01A Anti-Theft — Active|Specifications

- Description and Operation

- Anti-Theft — Active

- Diagnosis and Testing

- Anti-Theft — Active

- Removal and Installation

- Anti-Theft Alarm Horn

- 419-01B Anti-Theft — Passive

- Description and Operation

- Anti-Theft — Passive

- Diagnosis and Testing

- Anti-Theft — Passive

- General Procedures

- Key Programming Using Two Programmed Keys — Vehicles Built From: 08-2002

- Key Programming Using Two Programmed Keys — Vehicles Built Up To: 07-2002

- Key Programming Switch State Control — Vehicles Built Up To: 07-2002

- Key Programming Switch State Control — Vehicles Built From: 08-2002

- Key Programming Using Diagnostic Equipment

- Spare Key Programming — Vehicles Built Up To: 07-2002

- Spare Key Programming — Vehicles Built From: 08-2002

- Anti-Theft Security Access — Vehicles Built Up To: 07-2002

- Anti-Theft Security Access — Vehicles Built From: 08-2002

- Removal and Installation

- Passive Anti-Theft System (PATS) Transceiver

- 419-01B Anti-Theft — Passive|Specifications

- Description and Operation

- 419-10 Multifunction Electronic Modules

- 419-10 Multifunction Electronic Modules|Specifications

- Description and Operation

- Module Controlled Functions

- Diagnosis and Testing

- Multifunction Electronic Module

- Removal and Installation

- Generic Electronic Module (GEM)

- 419-01A Anti-Theft — Active

- 412 Climate Control System

- 5 Body and Paint

- 501 Body and Paint

- 501-00 Body System — General Information

- 501-00 Body System — General Information|Specifications

- Description and Operation

- 501-00 Body System — General Information|Body

- Insulation

- Diagnosis and Testing

- Body System

- Body Sealer Types and Applications

- 501-02 Front End Body Panels

- 501-02 Front End Body Panels|Specifications

- Description and Operation

- Front End Body Panels

- Removal and Installation

- Fender Splash Shield

- Cowl Panel Grille

- 501-02 Front End Body Panels|Removal and Installation|Fender

- 501-03 Body Closures

- 501-03 Body Closures|Specifications

- Description and Operation

- Body Closures

- General Procedures

- Front Door Hinge Adjustment

- Rear Door Hinge Adjustment

- Rear Door Alignment

- Front Door Alignment

- Striker Adjustment

- 501-05 Interior Trim and Ornamentation

- 501-05 Interior Trim and Ornamentation|Specifications

- Description and Operation

- Interior Trim

- Removal and Installation

- B-Pillar Trim Panel

- C-Pillar Trim Panel

- Front Door Trim Panel

- Rear Door Trim Panel

- Headliner

- 501-08 Exterior Trim and Ornamentation

- 501-08 Exterior Trim and Ornamentation|Specifications

- Description and Operation

- Exterior Trim

- Removal and Installation

- Radiator Grille — Vehicles Built Up To: 07-2002

- Radiator Grille — Vehicles Built From: 08-2002

- Front Door Moulding — Vehicles Built Up To: 07-2002

- Rear Door Moulding — Vehicles Built Up To: 07-2002

- Front Door Moulding — Vehicles Built From: 08-2002

- Rocker Panel Moulding — Vehicles Built Up To: 07-2002

- Rear Door Moulding — Vehicles Built From: 08-2002

- Rocker Panel Moulding — Vehicles Built From: 08-2002

- Fender Moulding — Vehicles Built Up To: 07-2002

- Fender Moulding — Vehicles Built From: 08-2002

- 501-09 Rear View Mirrors

- Description and Operation

- Rear View Mirrors

- Diagnosis and Testing

- Rear View Mirrors

- Removal and Installation

- Exterior Mirror

- 501-09 Rear View Mirrors|Specifications

- Description and Operation

- 501-10 Seating

- 501-10 Seating|Specifications

- Description and Operation

- 501-10 Seating|Seats

- Diagnosis and Testing

- Diagnosis and Testing|Seats

- Removal and Installation

- Seat Control Switch

- Driver Seat Backrest

- Passenger Seat Backrest

- Rear Seat Backrest — Vehicles With: 60-40 Split Seat

- Rear Seat Backrest

- Driver Seat Track

- Passenger Seat Track

- Driver Seat

- Passenger Seat

- Rear Seat Backrest Latch

- Disassembly and Assembly

- Driver Seat Cushion

- Passenger Seat Cushion

- Rear Seat Cushion

- Driver Seat Backrest

- Passenger Seat Backrest

- Rear Seat Backrest

- 501-11 Glass, Frames and Mechanisms

- Description and Operation

- Glass, Frames and Mechanisms

- Diagnosis and Testing

- Glass, Frames and Mechanisms

- General Procedures

- Heated Window Grid Wire Repair

- Lead Terminal Repair

- Removal and Installation

- Window Control Switch

- Rear Window Defrost Switch — Vehicles Built Up To: 07-2002

- Rear Window Defrost Switch — Vehicles Built From: 08-2002

- Liftgate Window Glass

- Front Door Window Glass — Vehicles Built Up To: 07-2002

- Front Door Window Glass — Vehicles Built From: 08-2002

- Rear Quarter Window Glass

- Rear Door Window Glass

- Front Door Window Regulator — Vehicles Built Up To: 07-2002

- Front Door Window Regulator — Vehicles Built From: 08-2002

- Rear Door Window Regulator — Vehicles Built From: 08-2002

- Rear Door Window Regulator — Vehicles Built Up To: 07-2002

- Windshield Glass

- Front Door Glass Top Run

- Rear Door Glass Top Run

- 501-11 Glass, Frames and Mechanisms|Specifications

- Description and Operation

- 501-12 Instrument Panel and Console

- 501-12 Instrument Panel and Console|Specifications

- Description and Operation

- Instrument Panel

- Overhead Console

- Floor Console

- Removal and Installation

- Instrument Panel

- Instrument Cluster Center Finish Panel — LHD

- Instrument Cluster Finish Panel — RHD

- 501-14 Handles, Locks, Latches and Entry Systems

- 501-14 Handles, Locks, Latches and Entry Systems|Specifications

- Description and Operation

- Handles, Locks, Latches and Entry Systems — Vehicles Built Up To: 07-2002

- Handles, Locks, Latches and Entry Systems — Vehicles Built From: 08-2002

- Diagnosis and Testing

- Locks, Latches and Entry Systems

- General Procedures

- Remote Transmitter Programming

- Removal and Installation

- Hood Latch

- Front Door Latch — Vehicles Built Up To: 07-2002

- Front Door Latch — Vehicles Built From: 08-2002

- Rear Door Latch

- Fuel Filler Door Latch — RHD

- Liftgate Window Latch

- Liftgate Latch

- Hood Latch Release Handle

- Exterior Front Door Handle

- Exterior Rear Door Handle

- Interior Door Handle

- Door Lock Cylinder

- Liftgate Lock Cylinder

- Ignition Lock Cylinder — Vehicles Built From: 08-2002

- Liftgate Latch Remote Control

- Fuel Filler Door Release Handle and Cable — RHD

- Liftgate Latch Actuator

- 501-16 Wipers and Washers

- 501-16 Wipers and Washers|Specifications

- Description and Operation

- Front Wipers and Washers

- Rear Wipers and Washers

- Diagnosis and Testing

- Wipers and Washers

- General Procedures

- Windshield Wiper Blade and Pivot Arm Adjustment

- Washer Hose Repair

- Rear Window Wiper Blade and Pivot Arm Adjustment

- Removal and Installation

- Front Wiper Pivot Arm

- Rear Wiper Pivot Arm

- Wiper Mounting Arm and Pivot Shaft

- Rear Window Wiper Motor

- Windshield Wiper Motor

- Windshield Washer Pump

- Rear Window Washer Pump

- Washer Pump and Reservoir

- Windshield Wiper-Washer Switch

- 501-17 Roof Opening Panel

- Description and Operation

- Roof Opening Panel

- Diagnosis and Testing

- Roof Opening Panel

- General Procedures

- Roof Opening Panel Alignment

- Removal and Installation

- Roof Opening Panel Shield

- Roof Opening Panel

- Roof Opening Panel Frame

- Roof Opening Panel Motor

- Roof Opening Panel Front Drain Hose

- Air Deflector

- Roof Opening Panel Rear Drain Hose

- Roof Opening Panel Module

- 501-17 Roof Opening Panel|Specifications

- Description and Operation

- 501-19 Bumpers

- Description and Operation

- 501-19 Bumpers|Bumpers

- Removal and Installation

- Front Bumper Cover

- Rear Bumper Cover

- Front Bumper

- Rear Bumper

- 501-19 Bumpers|Specifications

- Description and Operation

- 501-20A Safety Belt System

- 501-20A Safety Belt System|Specifications

- Description and Operation

- Safety Belt System

- Diagnosis and Testing

- Safety Belt System

- General Procedures

- Safety Belt Cleaning

- Safety Belt With Anchor Plate Thread Damage

- Safety Belt Shoulder Height Adjuster With Stripped Weld Nuts

- Safety Belt Procedure After a Collision

- Safety Belt Tongue Rotated On Belt

- Removal and Installation

- Front Safety Belt Retractor

- Rear Safety Belt Retractor

- Safety Belt Buckle and Pretensioner

- Rear Center Safety Belt — LHD

- Rear Center Safety Belt — RHD

- Safety Belt Shoulder Height Adjuster

- Child Safety Seat Tether Anchor

- Rear Safety Belt Buckle RH and Centre — LHD

- Rear Safety Belt Buckle LH — LHD

- Rear Safety Belt Buckle RH and Centre — RHD

- Rear Safety Belt Buckle LH — RHD

- 501-20B Supplemental Restraint System

- 501-20B Supplemental Restraint System|Specifications

- Description and Operation

- Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS)

- Diagnosis and Testing

- Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS)

- Diagnostic Instructions — Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS)

- Pinpoint Tests — Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS)

- General Procedures

- Deployed Air Bag Disposal

- Unserviceable Air Bag Disposal

- Scrapped Vehicle Undeployed Driver Air Bag Disposal

- Scrapped Vehicle Undeployed Side Air Bag Disposal

- Scrapped Vehicle Undeployed Passenger Air Bag Disposal

- Deployed Safety Belt Pretensioner Disposal

- Unserviceable Safety Belt Pretensioner Disposal

- Wiring Repair

- Scrapped Vehicle Undeployed Safety Belt Pretensioner Disposal

- J Nut Repair

- Stripped Weld Nut Repair

- Missing Weld Nut Repair

- Removal and Installation

- Side Impact Sensor LH — LHD

- Side Impact Sensor RH — LHD

- Side Impact Sensor RH — RHD

- Side Impact Sensor LH — RHD

- Restraints Control Module (RCM) — LHD

- Restraints Control Module (RCM) — RHD

- Passenger Air Bag Module — LHD

- Passenger Air Bag Module — RHD

- Driver Air Bag Module

- Side Air Bag Module

- Clockspring

- 501-25 Body Repairs — General Information

- 501-25 Body Repairs — General Information|Specifications

- Description and Operation

- Description and Usage of Body Repair Literature

- Health and Safety Precautions

- 501-25 Body Repairs — General Information|Symbols

- Environmental Regulations

- Body Construction

- Diagnosis and Damage Evaluation

- Body Sheet Metal

- Establish Repair Method

- Tools and Equipment for Body Repairs

- Straightening

- Alignment Check

- Complete Panel Replacement-Partial Replacement

- Corrosion Damage-Corrosion Repair

- Corrosion Prevention

- Cutting Technique

- Sealer, Underbody Protection Material and Adhesives

- Panel Beating Technique and Smart Repairs

- Paintless Dent Removal

- Plastic Repairs

- Joining Techniques

- Special Repair Techniques

- Impact of Insufficient Repair Quality

- Water Leaks

- Wind Noise

- Noise, Vibration and Harshness

- 501-26 Body Repairs — Vehicle Specific Information and Tolerance Checks

- Description and Operation

- Body and Frame

- General Procedures

- Underbody Tolerance Check

- Frame Tolerance Check

- Body Tolerance Check

- Description and Operation

- 501-36 Paint — General Information

- 501-36 Paint — General Information|Specifications

- Description and Operation

- Description and Usage of Paint Literature

- 501-36 Paint — General Information|Symbols

- Health and Safety Precautions

- Environmental Regulations

- Factory Paint Application

- Paintwork Defects and Damage

- Tools and Equipment for Paint Repairs

- Refinishing Materials

- Additional Materials

- Paint Repairs

- Painting Plastic Parts

- Spot Repairs

- Color Identification and Chromatics

- Corrosion Prevention

- Tips and Tricks

- 501-00 Body System — General Information

- 502 Frame and Mounting

- 502-00 Uni-Body, Subframe and Mounting System

- Description and Operation

- Frame Assembly

- General Procedures

- Underbody Misalignment Check

- Body Misalignment Check

- Removal and Installation

- Rear Subframe

- Front Subframe

- 502-00 Uni-Body, Subframe and Mounting System|Specifications

- Description and Operation

- 502-00 Uni-Body, Subframe and Mounting System

- 501 Body and Paint

- 1 General Information

- Body and Paint

- 5 Body and Paint

- 501 Body and Paint

- 501-25 Body Repairs — General Information

- 501-25 Body Repairs — General Information|Specifications

- Description and Operation

- Description and Usage of Body Repair Literature

- Health and Safety Precautions

- 501-25 Body Repairs — General Information|Symbols

- Environmental Regulations

- Body Construction

- Body Sheet Metal

- Diagnosis and Damage Evaluation

- Tools and Equipment for Body Repairs

- Establish Repair Method

- Alignment Check

- Straightening

- Complete Panel Replacement-Partial Replacement

- Corrosion Prevention

- Corrosion Damage-Corrosion Repair

- Sealer, Underbody Protection Material and Adhesives

- Cutting Technique

- Panel Beating Technique and Smart Repairs

- Paintless Dent Removal

- Joining Techniques

- Plastic Repairs

- Special Repair Techniques

- Water Leaks

- Impact of Insufficient Repair Quality

- Wind Noise

- Noise, Vibration and Harshness

- 501-26 Body Repairs — Vehicle Specific Information and Tolerance Checks

- Description and Operation

- Body and Frame

- General Procedures

- Underbody Tolerance Check

- Frame Tolerance Check

- Body Tolerance Check

- Description and Operation

- 501-36 Paint — General Information

- 501-36 Paint — General Information|Specifications

- Description and Operation

- Description and Usage of Paint Literature

- Health and Safety Precautions

- 501-36 Paint — General Information|Symbols

- Environmental Regulations

- Factory Paint Application

- Paintwork Defects and Damage

- Tools and Equipment for Paint Repairs

- Refinishing Materials

- Additional Materials

- Paint Repairs

- Painting Plastic Parts

- Spot Repairs

- Color Identification and Chromatics

- Corrosion Prevention

- Tips and Tricks

- 501-25 Body Repairs — General Information

- 501 Body and Paint

- 5 Body and Paint