Комментарии

10

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

rzbor

Я езжу на Toyota Camry (XV40)

Как ни странно, не выходит найти распиновку 2azfe Camry 40. Поделитесь пожалуйста.

1 год

Hairat111

Я езжу на Lexus RX (2G)

Можно ссылку пожалуйста на руководство по ремонту 2AZFE?

2 года

trufan3500

Я езжу на Toyota Vitz (130)

Привет. Ссылка не работает, поделитесь?

4 года

sshturman

Я езжу на Toyota Camry (XV40)

Спасибо за ссылку!

1

7 лет

PACCOXA

Автор

Без машины

Рад что пригодилась.

7 лет

somebody

Несуществующий пользователь

Без машины

ого! весЧ!

1

7 лет

mit178

Я езжу на Mercedes-Benz E-class (W124)

Спасибо друг, надеюсь не пригодиться)))))

7 лет

PACCOXA

Автор

Без машины

))))

7 лет

Maxim0808

Я езжу на УАЗ 315195 Hunter

класс спасибо

1

7 лет

PACCOXA

Автор

Без машины

Рад что пригодилась.

7 лет

|

2AZ-FE ENGINE MECHANICAL – ENGINE |

EM–1 |

ENGINE

INSPECTION

1.INSPECT ENGINE COOLANT

(a)Inspect the engine coolant (See page CO-1).

2.INSPECT ENGINE OIL

(a)Inspect the engine oil (See page LU-1).

3.INSPECT BATTERY

(a)Inspect the battery (See page CH-4).

4.INSPECT SPARK PLUGS

(a)Inspect the spark plugs (See page IG-5).

5.INSPECT AIR CLEANER FILTER ELEMENT SUBASSEMBLY

(a)Remove the air cleaner filter element sub-assembly. EM

(b)Visually check that there is no dirt, blockage, and/or damage to the air cleaner filter element.

HINT:

•If there is any dirt or a blockage in the air cleaner filter element, clean it with compressed air.

•If any dirt or a blockage remains even after cleaning the air cleaner filter element with compressed air, replace it.

6.INSPECT IGNITION TIMING

(a)Warm up the engine.

|

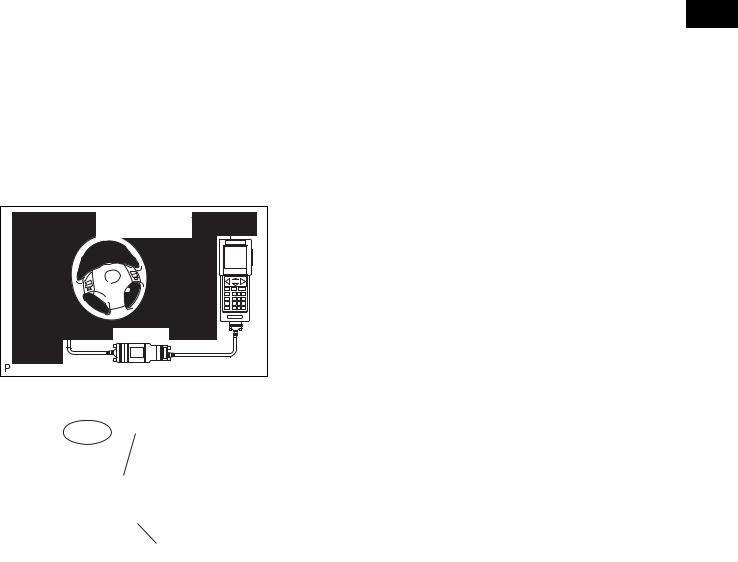

Intelligent Tester |

(b) When using the intelligent tester: |

|

|

Check the ignition timing. |

||

|

(1) Connect the intelligent tester to the DLC3. |

||

|

(2) Enter DATA LIST MODE on the intelligent |

||

|

tester. |

||

|

Ignition timing: |

||

|

8 to 12° BTDC at idle |

||

|

CAN VIM |

HINT: |

|

|

Refer to the intelligent tester operator’s manual |

||

|

DLC3 |

||

|

C110200E02 |

for help when selecting the DATA LIST. |

|

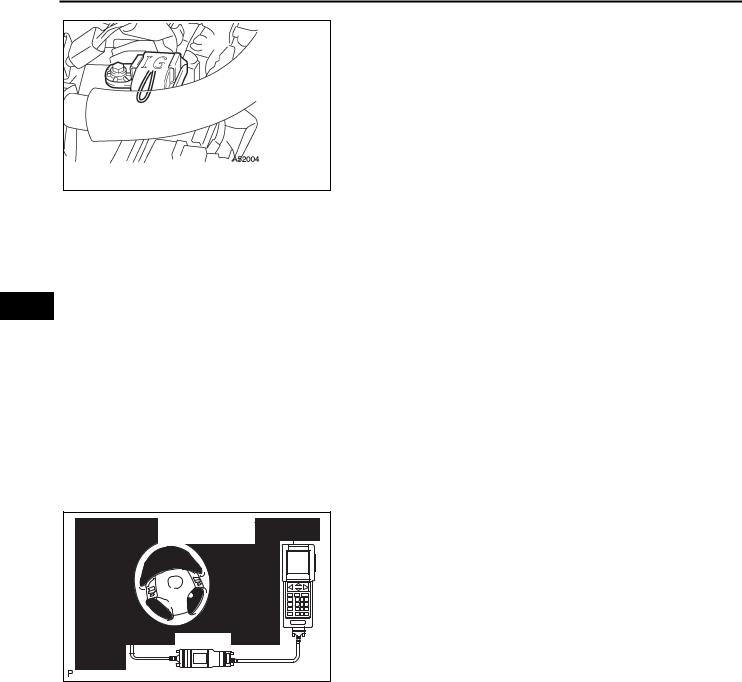

(c) When not using the intelligent tester: |

|||||||||

|

Check the ignition timing. |

|||||||||

|

DLC3 |

CG |

(1) Using SST, connect terminals 13 (TC) and 4 |

|||||||

|

(CG) of the DLC3. |

|||||||||

|

SST 09843-18040 |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 8 |

NOTICE: |

||

|

• Confirm the terminal numbers before |

|||||||||

|

9 10 111213141516 |

connecting them. Connection with a |

||||||||

|

wrong terminal can damage the engine. |

|||||||||

|

TC |

• Turn off all electrical systems before |

||||||||

|

A082779E69 |

|||||||||

|

connecting the terminals. |

|||||||||

|

• Perform this inspection after the cooling |

|||||||||

|

fan motor is turned off. |

2AZ-FE ENGINE MECHANICAL – ENGINE

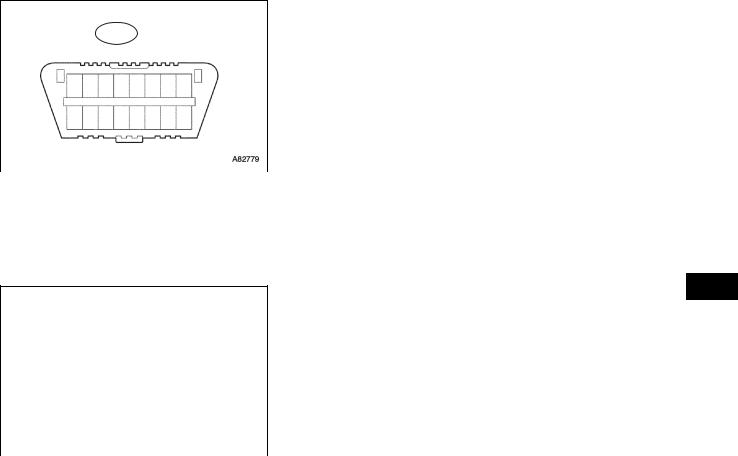

(2)Remove the No. 1 engine cover.

(3)Pull out the wire harness as shown in the illustration. Connect the clip of the timing light to the wire harness.

NOTICE:

•Use a timing light which can detect the first signal.

•After checking, be sure to tape the wire

harness.

A052004 (4) Check the ignition timing at idle.

Ignition timing:

8 to 12° BTDC at idle

NOTICE:

When checking the ignition timing, the transmission should be in neutral.

HINT:

After engine rpm is kept at 1,000 to 1,300 rpm for 5 seconds, check that it returns to idle speed.

(5)Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

(6)Check the ignition timing at idle.

Ignition timing:

5 to 15° BTDC at idle

(7)Confirm that the ignition timing moves to the advanced angle side when the engine rpm is increased.

(8)Remove the timing light.

|

Intelligent Tester |

|

CAN VIM |

|

DLC3 |

|

C110200E02 |

7. INSPECT ENGINE IDLE SPEED

(a) Warm up the engine.

(b) When using the intelligent tester: Check the idle speed.

(1) Connect the intelligent tester to the DLC3.

|

HINT: |

||

|

Refer to the intelligent tester operator’s manual |

||

|

for further details. |

||

|

(2) Enter DATA LIST MODE on the intelligent |

||

|

tester. |

||

|

Idle speed |

||

|

Item |

Specified Condition |

|

|

M/T |

650 to 750 rpm |

|

|

A/T |

610 to 710 rpm |

|

NOTICE:

• When checking the idle speed, the transmission should be in neutral.

• Check the idle speed with the cooling fan off.

• Switch off all accessories and air conditioning before connecting the intelligent tester.

|

2AZ-FE ENGINE MECHANICAL – ENGINE |

EM–3 |

(c)When not using the intelligent tester: Check the idle speed.

|

DLC3 |

(1) |

Using SST, connect the tachometer tester |

||||||||

|

probe to terminal 9 (TAC) of the DLC3. |

||||||||||

|

SST 09843-18030 |

||||||||||

|

1 2 3 4 5 6 |

7 8 |

(2) |

Check the idle speed. |

|||||||

|

9 10 11121314 |

15 16 |

Idle speed |

||||||||

|

Item |

Specified Condition |

|||||||||

|

TAC |

M/T |

650 to 750 rpm |

||||||||

|

A082779E70 |

||||||||||

|

A/T |

610 to 710 rpm |

|||||||||

|

8. INSPECT COMPRESSION |

|

|

(a) Warm up and stop the engine. |

|

|

(b) Disconnect the injector connectors. |

|

|

(c) Remove the ignition coils. |

|

|

(d) Remove the spark plugs. |

EM |

|

(e) Check the cylinder compression pressure. |

(1)Insert a compression gauge into the spark plug hole.

(2)Fully open the throttle.

(3)While cranking the engine, measure the compression pressure.

Compression pressure:

|

1.360 MPa (13.9 kgf/ cm2, 198 psi) |

|||

|

Minimum pressure: |

|||

|

0.98 MPa (10 kgf/ cm2, 142 psi) |

|||

|

A001037 |

|||

|

Difference between each cylinder: |

100 kPa (1.0 kgf/ cm2, 14 psi) NOTICE:

•Always use a fully charged battery to obtain an engine speed of 250 rpm or more.

•Check the other cylinders’ compression pressure in the same way.

•This measurement must be done as quickly as possible.

(4)If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the spark plug hole and inspect again.

HINT:

•If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

•If pressure stays low, a valve may be stuck or seated improperly, or there may be leakage in the gasket.

9.INSPECT CO/HC

(a)Start the engine.

(b)Run the engine at 2,500 rpm for approximately 180 seconds.

(c)Insert the CO/HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe during idling.

|

EM–4 |

2AZ-FE ENGINE MECHANICAL – ENGINE |

(d) Immediately check CO/HC concentration at idle and/or 2,500 rpm.

HINT:

• Complete the measuring within 3 minutes.

• Check regulations and restrictions in your area when performing 2 mode CO/HC concentration testing (engine check at both idle speed and at 2,500 rpm).

(e) If the CO/HC concentration does not comply with regulations, troubleshoot in the order given below.

(1) Check A/F sensor and heated oxygen sensor operation (See page EC-21).

(2) See the table below for possible causes, and then inspect and repair.

|

CO |

HC |

Problems |

Causes |

||||

|

1. |

Faulty ignitions: |

||||||

|

EM |

|||||||

|

– |

Incorrect timing |

||||||

|

Normal |

High |

Rough idle |

– Fouled, shorted or improperly gapped plugs |

||||

|

2. |

Incorrect valve clearance |

||||||

|

3. |

Leaky intake and exhaust valves |

||||||

|

4. |

Leaky cylinders |

||||||

|

1. |

Vacuum leaks: |

||||||

|

– |

PCV hoses |

||||||

|

Low |

High |

Rough idle |

– |

Intake manifold |

|||

|

(fluctuating HC reading) |

– |

Throttle body |

|||||

|

– |

Brake booster line |

||||||

|

2. |

Lean mixture causing misfire |

||||||

|

1. |

Restricted air filter |

||||||

|

2. |

Plugged PCV valve |

||||||

|

3. |

Faulty SFI system: |

||||||

|

Rough idle |

– |

Faulty pressure regulator |

|||||

|

High |

High |

– |

Defective ECT |

||||

|

(black smoke from exhaust) |

|||||||

|

– |

Defective MAF meter |

||||||

|

– |

Faulty ECM |

||||||

|

– |

Faulty injectors |

||||||

|

– Faulty throttle position sensor |

|||||||

|

2AZ-FE ENGINE MECHANICAL – DRIVE BELT |

EM–5 |

DRIVE BELT

|

COMPONENTS |

|

V-RIBBED BELT |

|

FRONT FENDER APRON SEAL RH |

|

EM |

|

ENGINE UNDER COVER RH |

|

A134946E01 |

|

EM–6 |

2AZ-FE ENGINE MECHANICAL – DRIVE BELT |

|

REMOVAL |

|||

|

1. |

REMOVE FRONT WHEEL RH |

||

|

2. |

REMOVE ENGINE UNDER COVER RH |

||

|

3. |

REMOVE FRONT FENDER APRON SEAL RH |

||

|

19 mm |

4. |

REMOVE V-RIBBED BELT |

|

|

(a) Using SST and 19 mm socket wrench, loosen the V- |

|||

|

Socket |

ribbed belt tensioner arm clockwise, then remove |

||

|

Wrench |

the V-ribbed belt. |

||

|

SST |

09216-42010 |

||

|

NOTICE: |

|||

|

• Be sure to connect SST and the tools so that |

|||

|

they are in line during use. |

|||

|

SST |

• When retracting the tensioner, turn it |

||

|

A114351E03 |

clockwise slowly for 3 seconds or more. Do |

||

|

EM |

not apply force rapidly. |

||

|

• After the tensioner is fully retracted, do not |

|||

|

apply force any more than necessary. |

INSPECTION

REPLACE

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear, frayed cords, etc. If any defect has been found, replace the V-ribbed belt.

HINT:

• Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should be replaced.

• A «new belt» is a belt which has been used for less than 5 minutes with the engine running.

• A «used belt» is a belt which has been used for 5 minutes or more with the engine running.

|

CORRECT |

INCORRECT |

|||

|

A131418E01 |

||||

|

19 mm |

INSTALLATION |

|||

|

1. |

INSTALL V-RIBBED BELT |

|||

|

Socket |

||||

|

Wrench |

(a) Using SST and 19 mm socket wrench, loosen the V- |

|||

|

ribbed belt tensioner arm clockwise, then install the |

||||

|

V-ribbed belt. |

||||

|

SST |

09216-42010 |

|||

|

NOTICE: |

||||

|

SST |

• Be sure to connect SST and the tools so that |

|||

|

A114351E03 |

they are in line during use. |

|||

|

• When retracting the tensioner, turn it |

||||

|

clockwise slowly for 3 seconds or more. Do |

||||

|

not apply force rapidly. |

|

2AZ-FE ENGINE MECHANICAL – DRIVE BELT |

EM–7 |

•After the tensioner is fully retracted, do not apply force any more than necessary.

(b)After installing the V-ribbed belt, check that it fits properly in the ribbed grooves. Check to confirm that the belt has not slipped out of the grooves on the bottom of the crank pulley by hand.

2.INSTALL FRONT FENDER APRON SEAL RH

3.INSTALL ENGINE UNDER COVER RH

4.INSTALL FRONT WHEEL RH

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

EM

|

EM–8 |

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

|

VALVE CLEARANCE |

EM

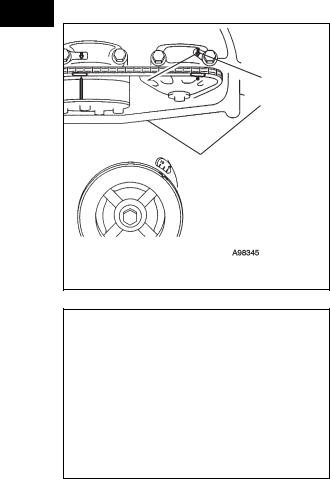

Timing Mark

Timing Mark

A098345E09

No. 1 Cylinder TDC/Compression

IN

EX

A098170E04

ADJUSTMENT

|

1. |

REMOVE FRONT WHEEL RH |

||

|

2. |

REMOVE ENGINE UNDER COVER LH |

||

|

3. |

REMOVE ENGINE UNDER COVER RH |

||

|

4. |

REMOVE FRONT FENDER APRON SUB-ASSEMBLY |

||

|

RH |

|||

|

5. |

REMOVE NO. 1 ENGINE COVER (See page EM-94) |

||

|

6. |

REMOVE IGNITION COIL ASSEMBLY (See page EM- |

||

|

106) |

|||

|

7. |

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

||

|

(See page EM-21) |

|||

|

8. |

SET NO. 1 CYLINDER TO TDC/COMPRESSION |

||

|

(a) Turn the crankshaft pulley until its groove and the |

|||

|

timing mark «0» of the timing chain cover are |

|||

|

aligned. |

|||

|

(b) Check that each timing mark of the camshaft timing |

|||

|

gear and sprocket is aligned with each timing mark |

|||

|

located on the No. 1 and No. 2 bearing caps as |

|||

|

shown in the illustration. If not, turn the crankshaft |

|||

|

by 1 revolution (360°) to align the timing marks as |

|||

|

above. |

|||

|

9. |

CHECK VALVE CLEARANCE |

||

|

(a) Check only the valves indicated. |

|||

|

(1) Using a feeler gauge, measure the clearance |

|||

|

between the valve lifter and camshaft. |

|||

|

Standard valve clearance (cold) |

|||

|

Item |

Standard Condition |

||

|

Intake |

0.19 to 0.29 mm (0.0075 to 0.0114 in.) |

||

|

Exhaust |

0.38 to 0.48 mm (0.0150 to 0.0189 in.) |

||

(2) Record any out-of-specification valve clearance measurements. They will be used later to determine the required replacement valve clearance lifters.

(b) Turn the crankshaft 1 revolution (360°) and set the No. 4 cylinder to the TDC/compression.

|

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

EM–9 |

No. 4 Cylinder TDC/Compression

IN

EX

A098171E04

A001082E01

(c) Check only the valves indicated.

|

(1) Using a feeler gauge, measure the clearance |

|||||

|

between the valve lifter and camshaft. |

|||||

|

Standard valve clearance (cold) |

|||||

|

Item |

Standard Condition |

||||

|

Intake |

0.19 to 0.29 mm (0.0075 to 0.0114 in.) |

||||

|

Exhaust |

0.38 to 0.48 mm (0.0150 to 0.0189 in.) |

||||

|

(2) Record any out-of-specification valve clearance |

|||||

|

measurements. They will be used later to |

|||||

|

determine the required replacement valve |

|||||

|

lifters. |

|||||

|

10. ADJUST VALVE CLEARANCE |

|||||

|

(a) Remove the No. 2 camshaft (see page EM-38). |

|||||

|

(b) Remove the camshaft (see page EM-38). |

|||||

|

(c) Remove the valve lifters. |

|||||

|

EM |

|||||

|

(d) |

Using a micrometer, measure the thickness of the |

||||

removed valve lifters.

(e)Calculate the thickness of a new lifter so that the valve clearance comes within the specified values.

New lifter thickness

|

Item |

Specification |

|

Intake |

A = B + (C — 0.24 mm (0.0095 in.)) |

|

Exhaust |

A = B + (C — 0.43 mm (0.0169 in.)) |

|

A |

New lifter thickness |

|

B |

Used lifter thickness |

|

C |

Measured valve clearance |

CALCULATION EXAMPLE (Intake):

1.Measured intake valve clearance = 0.40 mm (0.0158 in.)

(Measured — Specification = Excess clearance) (a)0.40 mm (0.0158 in.) — 0.24 mm (0.0095 in.) =

0.16 mm (0.0063 in.)

2.Measured used lifter measurement = 5.250 mm (0.2067 in.)

3.New lifter thickness = 5.410 mm (0.2130 in.) (Excess clearance + Used lifter thickness = Ideal new lifter)

(a)0.16 mm (0.0063 in.) + 5.250 mm (0.2067 in.) = 5.410 mm (0.2130 in.)

4.Closest new lifter = 5.420 mm (0.2134 in.)

– Select No. 42 lifter

|

EM–10 |

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

|

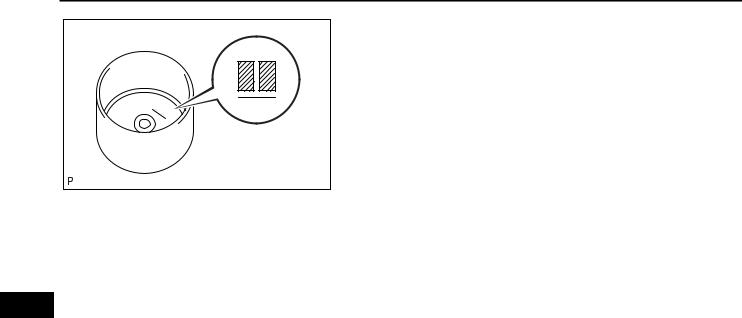

(f) Select a new lifter with a thickness as close as |

|

|

possible to the calculated values. |

|

|

HINT: |

|

|

• Lifters are available in 35 sizes in increments of |

|

|

42 |

0.020 mm (0.0008 in.), from 5.060 to 5.740 mm |

|

(0.1992 to 0.2260 in.). |

|

|

• The identification number inside the valve lifters |

|

|

shows the value to 2 decimal places. (The |

|

|

illustration shows 5.420 mm (0.2134 in.) |

|

|

A126901E01 |

EM

|

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

EM–11 |

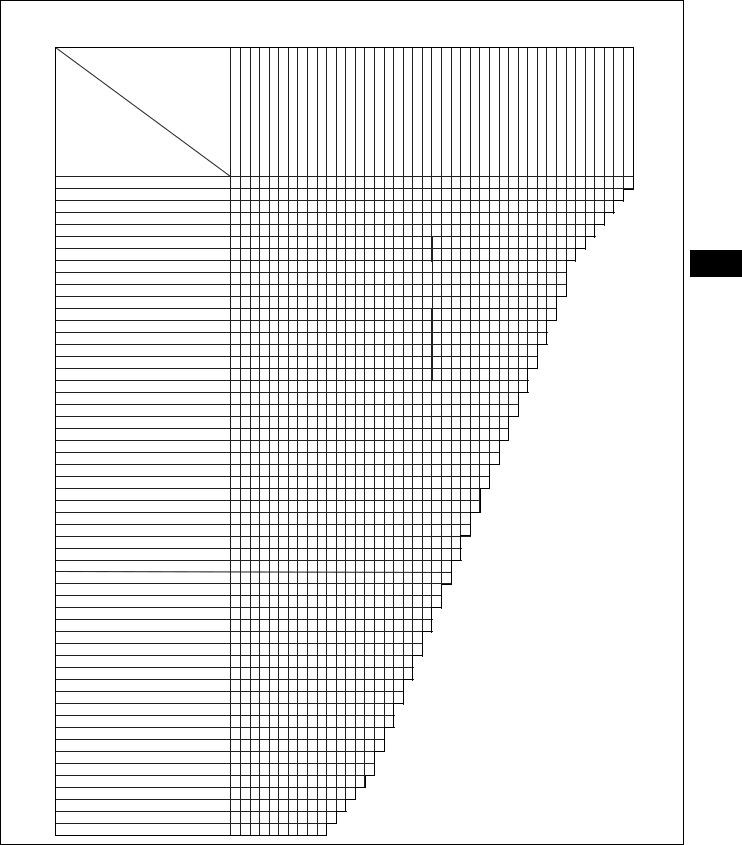

(g) Valve lifter selection chart (intake).

|

Measured clearance |

0.0012)-(0.0000 |

0.0020)-(0.0012 |

0.0028)-(0.0020 |

0.0035)-(0.0028 |

0.0043)-(0.0036 |

0.0051)-(0.0044 |

0.0059)-(0.0052 |

0.0067)-(0.0059 |

0.0074)-(0.0067 |

0.0114)-(0.0075 |

0.0122)-(0.0115 |

0.0130)-(0.0122 |

0.0138)-(0.0130 |

0.0146)-(0.0138 |

0.0154)-(0.0146 |

0.0161)-(0.0154 |

0.0169)-(0.0162 |

0.0177)-(0.0170 |

0.0185)-(0.0178 |

0.0193)-(0.0185 |

0.0201)-(0.0193 |

0.0209)-(0.0201 |

0.0217)-(0.0209 |

0.0224)-(0.0217 |

0.0232)-(0.0225 |

0.0240)-(0.0233 |

0.0248)-(0.0241 |

0.0256)-(0.0248 |

0.0264)-(0.0256 |

0.0272)-(0.0264 |

0.0280)-(0.0272 |

0.0287)-(0.0280 |

0.0295)-(0.0288 |

0.0303)-(0.0296 |

0.0311)-(0.0304 |

0.0319)-(0.0311 |

0.0327)-(0.0319 |

0.0335)-(0.0327 |

0.0343)-(0.0335 |

0.0350)-(0.0343 |

0.0358)-(0.0351 |

0.0366)-(0.0359 |

||

|

mm (in.) |

||||||||||||||||||||||||||||||||||||||||||||

|

Installed lifter |

mm (in.) |

0.030-0.000 |

0.050-0.031 |

0.070-0.051 |

0.090-0.071 |

0.110-0.091 |

0.130-0.111 |

0.150-0.131 |

0.170-0.151 |

0.189-0.171 |

0.290-0.190 |

0.310-0.291 |

0.330-0.311 |

0.350-0.331 |

0.370-0.351 |

0.390-0.371 |

0.410-0.391 |

0.430-0.411 |

0.450-0.431 |

0.470-0.451 |

0.490-0.471 |

0.510-0.491 |

0.530-0.511 |

0.550-0.531 |

0.570-0.551 |

0.590-0.571 |

0.610-0.591 |

0.630-0.611 |

0.650-0.631 |

0.670-0.651 |

0.690-0.671 |

0.710-0.691 |

0.730-0.711 |

0.750-0.731 |

0.770-0.751 |

0.790-0.771 |

0.810-0.791 |

0.830-0.811 |

0.850-0.831 |

0.870-0.851 |

0.890-0.871 |

0.910-0.891 |

0.930-0.911 |

|

|

thickness |

||||||||||||||||||||||||||||||||||||||||||||

|

5.060 |

(0.1992) |

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

||||||||||||||||||||||||||||||||||||||||||

|

5.080 |

(0.2000) |

06 |

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.100 |

(0.2008) |

06 08 |

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.120 |

(0.2016) |

06 08 10 |

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.140 |

(0.2024) |

06 08 10 12 |

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.160 |

(0.2031) |

06 08 10 12 14 |

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

EM |

||||||||||||||||||||||||||||||||||||||||

|

5.180 |

(0.2039) |

06 08 10 12 14 16 |

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 |

74 |

||||||||||||||||||||||||||||||||||||||||

|

5.200 |

(0.2047) |

06 08 10 12 14 16 18 |

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.210 |

(0.2051) |

06 08 10 12 14 16 18 20 |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.220 |

(0.2055) |

06 08 10 12 14 16 18 20 |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.230 |

(0.2059) |

06 08 10 12 14 16 18 20 |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.240 |

(0.2063) |

08 10 12 14 16 18 20 22 |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.250 |

(0.2067) |

06 08 10 12 14 16 18 20 22 |

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.260 |

(0.2071) |

06 10 12 14 16 18 20 22 24 |

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.270 |

(0.2075) |

08 10 12 14 16 18 20 22 24 |

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.280 |

(0.2079) |

08 12 14 16 18 20 22 24 26 |

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.290 |

(0.2083) |

10 12 14 16 18 20 22 24 26 |

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.300 |

(0.2087) |

10 14 16 18 20 22 24 26 28 |

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.310 |

(0.2091) |

12 14 16 18 20 22 24 26 28 |

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.320 |

(0.2094) |

12 16 18 20 22 24 26 28 30 |

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.330 |

(0.2098) |

14 16 18 20 22 24 26 28 30 |

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.340 |

(0.2102) |

14 18 20 22 24 26 28 30 32 |

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.350 |

(0.2106) |

16 18 20 22 24 26 28 30 32 |

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.360 |

(0.2110) |

16 20 22 24 26 28 30 32 34 |

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.370 |

(0.2114) |

18 20 22 24 26 28 30 32 34 |

44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.380 |

(0.2118) |

18 22 24 26 28 30 32 34 36 |

44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.390 |

(0.2122) |

20 22 24 26 28 30 32 34 36 |

46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.400 |

(0.2126) |

20 24 26 28 30 32 34 36 38 |

46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.410 |

(0.2130) |

22 24 26 28 30 32 34 36 38 |

48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.420 |

(0.2134) |

22 26 28 30 32 34 36 38 40 |

48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.430 |

(0.2138) |

24 26 28 30 32 34 36 38 40 |

50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.440 |

(0.2142) |

24 28 30 32 34 36 38 40 42 |

50 52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.450 |

(0.2146) |

26 28 30 32 34 36 38 40 42 |

52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.460 |

(0.2150) |

26 30 32 34 36 38 40 42 44 |

52 54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.470 |

(0.2154) |

28 30 32 34 36 38 40 42 44 |

54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.480 |

(0.2157) |

28 32 34 36 38 40 42 44 46 |

54 56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.490 |

(0.2161) |

30 32 34 36 38 40 42 44 46 |

56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.500 |

(0.2165) |

30 34 36 38 40 42 44 46 48 |

56 58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.510 |

(0.2169) |

32 34 36 38 40 42 44 46 48 |

58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.520 |

(0.2173) |

32 36 38 40 42 44 46 48 50 |

58 60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.530 |

(0.2177) |

34 36 38 40 42 44 46 48 50 |

60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.540 |

(0.2181) |

34 38 40 42 44 46 48 50 52 |

60 62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.550 |

(0.2185) |

36 38 40 42 44 46 48 50 52 |

62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.560 |

(0.2189) |

36 40 42 44 46 48 50 52 54 |

62 64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.570 |

(0.2193) |

38 40 42 44 46 48 50 52 54 |

64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.580 |

(0.2197) |

38 42 44 46 48 50 52 54 56 |

64 66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.590 |

(0.2201) |

40 42 44 46 48 50 52 54 56 |

66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.600 |

(0.2205) |

40 44 46 48 50 52 54 56 58 |

66 68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.620 |

(0.2213) |

42 46 48 50 52 54 56 58 60 |

68 70 72 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.640 |

(0.2220) |

44 48 50 52 54 56 58 60 62 |

70 72 74 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.660 |

(0.2228) |

46 50 52 54 56 58 60 62 64 |

72 74 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.680 |

(0.2236) |

48 52 54 56 58 60 62 64 66 |

74 74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.700 |

(0.2244) |

50 54 56 58 60 62 64 66 68 |

74 74 |

|||||||||||||||||||||||||||||||||||||||||

|

5.720 |

(0.2252) |

52 56 58 60 62 64 66 68 70 |

74 |

|||||||||||||||||||||||||||||||||||||||||

|

) |

5.740 |

(0.2260) |

54 58 60 62 64 66 68 70 72 |

A126931E02 |

||||||||||||||||||||||||||||||||||||||||

New lifter thickness

|

Lifter No. |

Thickness |

Lifter No. |

Thickness |

Lifter No. |

Thickness |

|

mm (in.) |

mm (in.) |

mm (in.) |

|||

|

06 |

5.060 (0.1992) |

30 |

5.300 (0.2087) |

54 |

5.540 (0.2181) |

|

EM–12 |

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

|||||

|

Lifter No. |

Thickness |

Lifter No. |

Thickness |

Lifter No. |

Thickness |

|

|

mm (in.) |

mm (in.) |

mm (in.) |

||||

|

08 |

5.080 (0.2000) |

32 |

5.320 |

(0.2094) |

56 |

5.560 (0.2189) |

|

10 |

5.100 (0.2008) |

34 |

5.340 |

(0.2102) |

58 |

5.580 (0.2197) |

|

12 |

5.120 (0.2016) |

36 |

5.360 |

(0.2110) |

60 |

5.600 (0.2205) |

|

14 |

5.140 (0.2024) |

38 |

5.380 |

(0.2118) |

62 |

5.620 (0.2213) |

|

16 |

5.160 (0.2031) |

40 |

5.400 |

(0.2126) |

64 |

5.640 (0.2220) |

|

18 |

5.180 (0.2039) |

42 |

5.420 |

(0.2134) |

66 |

5.660 (0.2228) |

|

20 |

5.200 (0.2047) |

44 |

5.440 |

(0.2142) |

68 |

5.680 (0.2236) |

|

22 |

5.220 (0.2055) |

46 |

5.460 |

(0.2150) |

70 |

5.700 (0.2244) |

|

24 |

5.240 (0.2063) |

48 |

5.480 |

(0.2157) |

72 |

5.720 (0.2252) |

|

26 |

5.260 (0.2071) |

50 |

5.500 |

(0.2165) |

74 |

5.740 (0.2260) |

|

28 |

5.280 (0.2079) |

52 |

5.520 |

(0.2173) |

— |

— |

EM

Standard intake valve clearance (cold): 0.19 to 0.29 mm (0.0075 to 0.0114 in.)

EXAMPLE:

The 5.250 mm (0.2067 in.) lifter is installed, and the measured clearance is 0.400 mm (0.0157 in.). Replace the 5.250 mm (0.2067 in.) lifter with a new No. 42 lifter.

|

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

EM–13 |

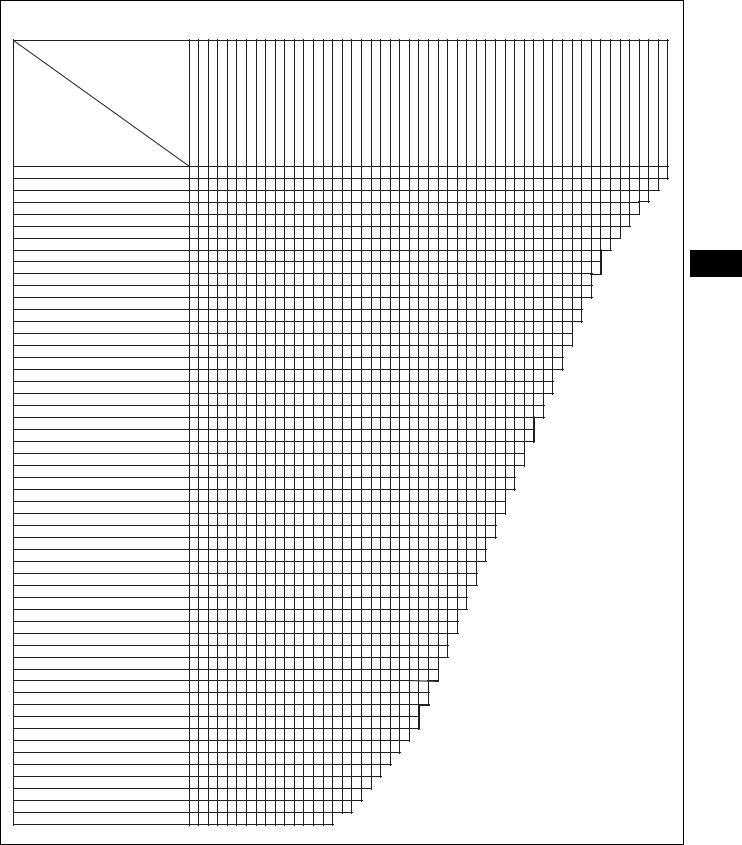

(h) Valve lifter selection chart (exhaust).

|

Installed lifter |

-(0.00000.0012) |

-(0.00120.0020) |

-(0.00200.0028) |

-(0.00280.0035) |

-(0.00360.0043) |

-(0.00440.0051) |

-(0.00520.0059) |

-(0.00590.0067) |

-(0.00670.0075) |

-(0.00750.0083) |

-(0.00830.0091) |

-(0.00910.0098) |

-(0.00990.0106) |

-(0.01070.0114) |

-(0.01150.0118) |

-(0.01180.0157) |

-(0.01580.0165) |

-(0.01660.0173) |

-(0.01740.0181) |

-(0.01810.0189) |

-(0.01890.0197) |

-(0.01970.0205) |

-(0.02050.0213) |

-(0.02130.0220) |

-(0.02210.0228) |

-(0.02290.0236) |

-(0.02370.0244) |

-(0.02440.0252) |

-(0.02520.0260) |

-(0.02600.0268) |

-(0.02680.0276) |

-(0.02760.0283) |

-(0.02840.0291) |

-(0.02920.0299) |

-(0.03000.0307) |

-(0.03070.0315) |

-(0.03150.0323) |

-(0.03230.0331) |

-(0.03310.0339) |

-(0.03390.0346) |

-(0.03470.0354) |

-(0.03550.0362) |

-(0.03630.0370) |

-(0.03700.0378) |

-(0.03780.0386) |

-(0.03860.0394) |

-(0.03940.0402) |

-(0.04020.0409) |

-(0.04100.0417) |

-(0.04180.0425) |

|

|

Measured clearance |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Measured clearance |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

mm (in.) |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

mm (in.) |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

thickness |

0.030- |

0.050- |

0.070- |

0.090- |

0.110- |

0.130- |

0.150- |

0.170- |

0.190- |

0.210- |

0.230- |

0.250- |

0.270- |

0.290- |

0.299- |

0.400- |

0.420- |

0.440- |

0.460- |

0.480- |

0.500- |

0.520- |

0.540- |

0.560- |

0.580- |

0.600- |

0.620- |

0.640- |

0.660- |

0.680- |

0.700- |

0.720- |

0.740- |

0.760- |

0.780- |

0.800- |

0.820- |

0.840- |

0.860- |

0.880- |

0.900- |

0.920- |

0.940- |

0.960- |

0.980- |

1.000- |

1.020- |

1.040- |

1.060- |

1.080- |

|

|

Installed lifter thickness |

0.000 |

0.031 |

0.051 |

0.071 |

0.091 |

0.111 |

0.131 |

0.151 |

0.171 |

0.191 |

0.211 |

0.231 |

0.251 |

0.271 |

0.291 |

0.300 |

0.401 |

0.421 |

0.441 |

0.461 |

0.481 |

0.501 |

0.521 |

0.541 |

0.561 |

0.581 |

0.601 |

0.621 |

0.641 |

0.661 |

0.681 |

0.701 |

0.721 |

0.741 |

0.761 |

0.781 |

0.801 |

0.821 |

0.841 |

0.861 |

0.881 |

0.901 |

0.921 |

0.941 |

0.961 |

0.981 |

1.001 |

1.021 |

1.041 |

1.061 |

|

|

mm (in.)mm (in.) |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

5.060 |

(0.1992) |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

5.080 |

(0.2000) |

06 |

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.100 |

(0.2008) |

06 08 |

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.120 |

(0.2016) |

06 08 10 |

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.140 |

(0.2024) |

06 08 10 12 |

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.160 |

(0.2031) |

06 08 10 12 14 |

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.180 |

(0.2039) |

06 08 10 12 14 16 |

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

EM |

|||||||||||||||||||||||||||||||||||||||||||||||

|

5.200 |

(0.2047) |

06 08 10 12 14 16 18 |

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.210 |

(0.2051) |

06 08 10 12 14 16 18 20 |

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.220 |

(0.2055) |

06 08 10 12 14 16 18 20 |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.230 |

(0.2059) |

06 08 10 12 14 16 18 20 22 |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.240 |

(0.2063) |

06 08 10 12 14 16 18 20 22 |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.250 |

(0.2067) |

06 08 10 12 14 16 18 20 22 24 |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.260 |

(0.2071) |

06 08 10 12 14 16 18 20 22 24 |

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.270 |

(0.2075) |

06 08 10 12 14 16 18 20 22 24 26 |

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.280 |

(0.2079) |

06 08 10 12 14 16 18 20 22 24 26 |

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.290 |

(0.2083) |

06 08 10 12 14 16 18 20 22 24 26 28 |

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.300 |

(0.2087) |

06 08 10 12 14 16 18 20 22 24 26 28 |

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.310 |

(0.2091) |

06 08 10 12 14 16 18 20 22 24 26 28 30 |

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.320 |

(0.2094) |

06 08 10 12 14 16 18 20 22 24 26 28 30 |

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.330 |

(0.2098) |

06 08 10 12 14 16 18 20 22 24 26 28 30 32 |

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.340 |

(0.2102) |

06 08 10 12 14 16 18 20 22 24 26 28 30 32 |

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.350 |

(0.2106) |

06 08 10 12 14 16 18 20 22 24 26 28 30 32 34 |

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.360 |

(0.2110) |

06 08 10 12 14 16 18 20 22 24 26 28 30 32 34 |

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.370 |

(0.2114) |

08 10 12 14 16 18 20 22 24 26 28 30 32 34 36 |

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.380 |

(0.2118) |

08 10 12 14 16 18 20 22 24 26 28 30 32 34 36 |

44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.390 |

(0.2122) |

10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 |

44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.400 |

(0.2126) |

10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 |

46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.410 |

(0.2130) |

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 |

46 48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.420 |

(0.2134) |

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 |

48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.430 |

(0.2138) |

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 |

48 50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.440 |

(0.2142) |

14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 |

50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.450 |

(0.2146) |

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 |

50 52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.460 |

(0.2150) |

16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 |

52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.470 |

(0.2154) |

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 |

52 54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.480 |

(0.2157) |

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 |

54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.490 |

(0.2161) |

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 |

54 56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.500 |

(0.2165) |

20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 |

56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.510 |

(0.2169) |

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 |

56 58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.520 |

(0.2173) |

22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 |

58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.530 |

(0.2177) |

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 |

58 60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.540 |

(0.2181) |

24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 |

60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.550 |

(0.2185) |

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 |

60 62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.560 |

(0.2189) |

26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 |

62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.570 |

(0.2193) |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 |

62 64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.580 |

(0.2197) |

28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 |

64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.590 |

(0.2201) |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 |

64 66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.600 |

(0.2205) |

30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 |

66 68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.620 |

(0.2213) |

32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 |

68 70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.640 |

(0.2220) |

34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 |

70 72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.660 |

(0.2228) |

36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 |

72 74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.680 |

(0.2236) |

38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 |

74 74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.700 |

(0.2244) |

40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 |

74 74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.720 |

(0.2252) |

42 44 46 48 50 52 54 56 58 60 62 64 66 68 70 |

74 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5.740 |

(0.2260) |

44 46 48 50 52 54 56 58 60 62 64 66 68 70 72 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

) |

A114356E01 |

New lifter thickness

|

Lifter No. |

Thickness |

Lifter No. |

Thickness |

Lifter No. |

Thickness |

|

mm (in.) |

mm (in.) |

mm (in.) |

|||

|

06 |

5.060 (0.1992) |

30 |

5.300 (0.2087) |

54 |

5.540 (0.2181) |

|

EM–14 |

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

|||||

|

Lifter No. |

Thickness |

Lifter No. |

Thickness |

Lifter No. |

Thickness |

|

|

mm (in.) |

mm (in.) |

mm (in.) |

||||

|

08 |

5.080 (0.2000) |

32 |

5.320 |

(0.2094) |

56 |

5.560 (0.2189) |

|

10 |

5.100 (0.2008) |

34 |

5.340 |

(0.2102) |

58 |

5.580 (0.2197) |

|

12 |

5.120 (0.2016) |

36 |

5.360 |

(0.2110) |

60 |

5.600 (0.2205) |

|

14 |

5.140 (0.2024) |

38 |

5.380 |

(0.2118) |

62 |

5.620 (0.2213) |

|

16 |

5.160 (0.2031) |

40 |

5.400 |

(0.2126) |

64 |

5.640 (0.2220) |

|

18 |

5.180 (0.2039) |

42 |

5.420 |

(0.2134) |

66 |

5.660 (0.2228) |

|

20 |

5.200 (0.2047) |

44 |

5.440 |

(0.2142) |

68 |

5.680 (0.2236) |

|

22 |

5.220 (0.2055) |

46 |

5.460 |

(0.2150) |

70 |

5.700 (0.2244) |

|

24 |

5.240 (0.2063) |

48 |

5.480 |

(0.2157) |

72 |

5.720 (0.2252) |

|

26 |

5.260 (0.2071) |

50 |

5.500 |

(0.2165) |

74 |

5.740 (0.2260) |

|

28 |

5.280 (0.2079) |

52 |

5.520 |

(0.2173) |

— |

— |

EM

Standard exhaust valve clearance (cold): 0.38 to 0.48 mm (0.0150 to 0.0189 in.)

EXAMPLE:

The 5.340 mm (0.2102 in.) lifter is installed, and the measured clearance is 0.430 mm (0.0169 in.). Replace the 5.340 mm (0.2102 in.) lifter with a new No. 42 lifter.

(i)Install the selected valve lifter.

11.INSTALL CAMSHAFT

(a)Apply a light coat of engine oil to the journal portion of the camshaft.

(b)Install the timing chain onto the camshaft timing

|

Paint Mark |

gear with the paint mark aligned with the timing |

|

mark on the camshaft timing gear as shown in the |

|

|

illustration. |

Timing Mark

A098176E04

(c)Examine the front marks and numbers, and check that the order is as shown in the illustration. Then install the bearing caps into the cylinder head.

(d)Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

A098177E03

|

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

EM–15 |

No. 1

7

8

4 2 6 10

A098177E06

Paint Mark

(e)Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

Torque: No. 1 bearing cap

30 N*m (301 kgf*cm, 22 ft.*lbf) No. 3 bearing cap

9.0N*m (92 kgf*cm, 80 in.*lbf)

12.INSTALL NO. 2 CAMSHAFT

(a)Apply a light coat of engine oil to the journal portion of the No. 2 camshaft.

(b)Put the No. 2 camshaft on the cylinder head with the paint mark of the chain aligned with the timing mark on the camshaft timing sprocket.

EM

Timing Mark

A098178E03

(c)While holding the No. 2 camshaft by hand, temporarily tighten the camshaft timing sprocket set bolt.

A086659

(d)Examine the front marks and numbers, and check that the order is as shown in the illustration. Then install the bearing caps onto the cylinder head.

(e)Apply a light coat of engine oil to the threads and under the heads of the bearing cap bolts.

A098174E05

|

7 |

||||

|

8 |

4 |

2 |

6 |

10 |

No. 2

A098174E07

(f)Using several steps, uniformly tighten the 10 bearing cap bolts in the sequence shown in the illustration.

Torque: No. 2 bearing cap

30 N*m (301 kgf*cm, 22 ft.*lbf) No. 3 bearing cap

9.0N*m (92 kgf*cm, 80 in.*lbf)

|

EM–16 |

2AZ-FE ENGINE MECHANICAL – VALVE CLEARANCE |

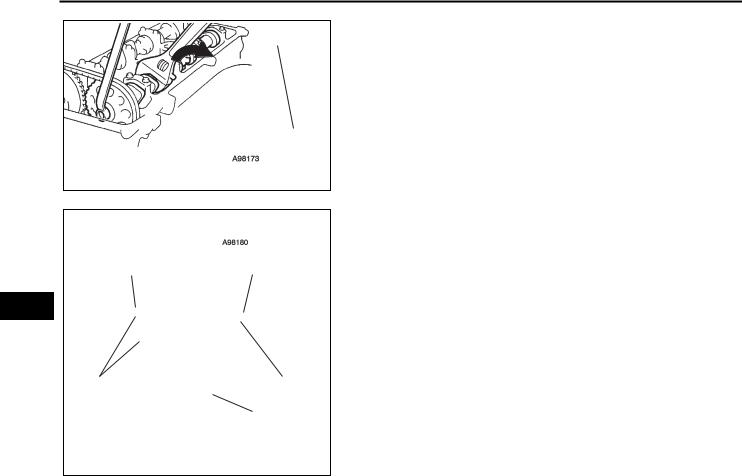

(g)While holding the camshaft with a wrench, tighten the camshaft timing sprocket set bolt.

|

Tighten |

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf) |

|

NOTICE: |

|

|

Be careful not to damage the valve lifter. |

Hold

A098173E04

|

7 Links |

|

|

Paint Mark |

Paint Mark |

EM

|

Timing Mark |

Timing Mark |

||||

|

Groove |

|||||

|

A098180E04 |

(h)Check that the paint marks on the chain are aligned with the timing marks on the camshaft timing gear and camshaft timing sprocket. Also, check that the crankshaft pulley groove is aligned with the timing mark «0» of the timing chain cover.

13.INSTALL NO. 1 CHAIN TENSIONER (See page EM-32)

14.INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (See page EM-33)

15.INSTALL IGNITION COIL ASSEMBLY (See page EM33)

16.CHECK FOR ENGINE OIL LEAKS

17.INSTALL NO. 1 ENGINE COVER (See page EM-121)

18.INSTALL FRONT FENDER APRON RH

19.INSTALL ENGINE UNDER COVER LH

20.INSTALL ENGINE UNDER COVER RH

21.INSTALL FRONT WHEEL RH

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–17 |

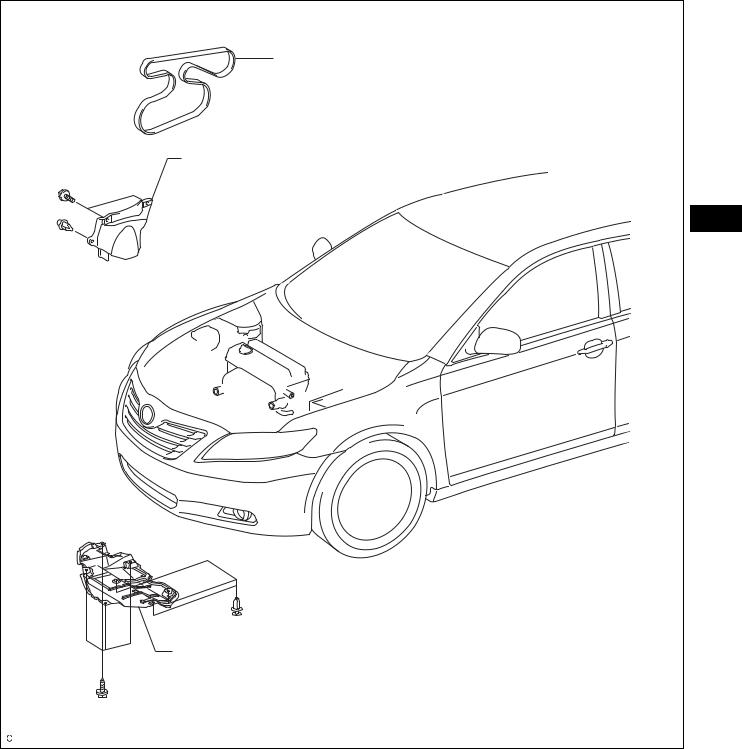

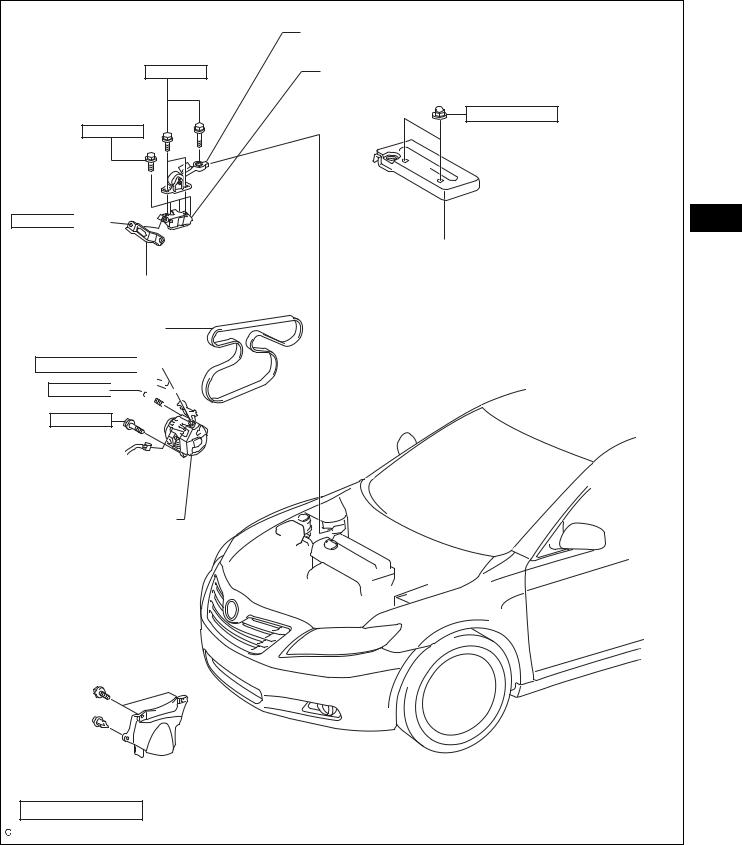

TIMING CHAIN

COMPONENTS

|

ENGINE MOVING CONTROL ROD SUB-ASSEMBLY |

|

|

64 (653, 47) |

NO. 2 ENGINE MOUNTING BRACKET RH |

|

9.0 (92, 80 in.*lbf) |

52 (531, 38)

64 (653, 47)

NO. 1 ENGINE COVER SUB-ASSEMBLY

NO. 2 ENGINE MOUNTING STAY RH

V-RIBBED BELT

9.8 (100, 87 in.*lbf)

21 (214, 15)

EM

GENERATOR ASSEMBLY

N*m (kgf*cm, ft.*lbf) : Specified torque

A134948E01

|

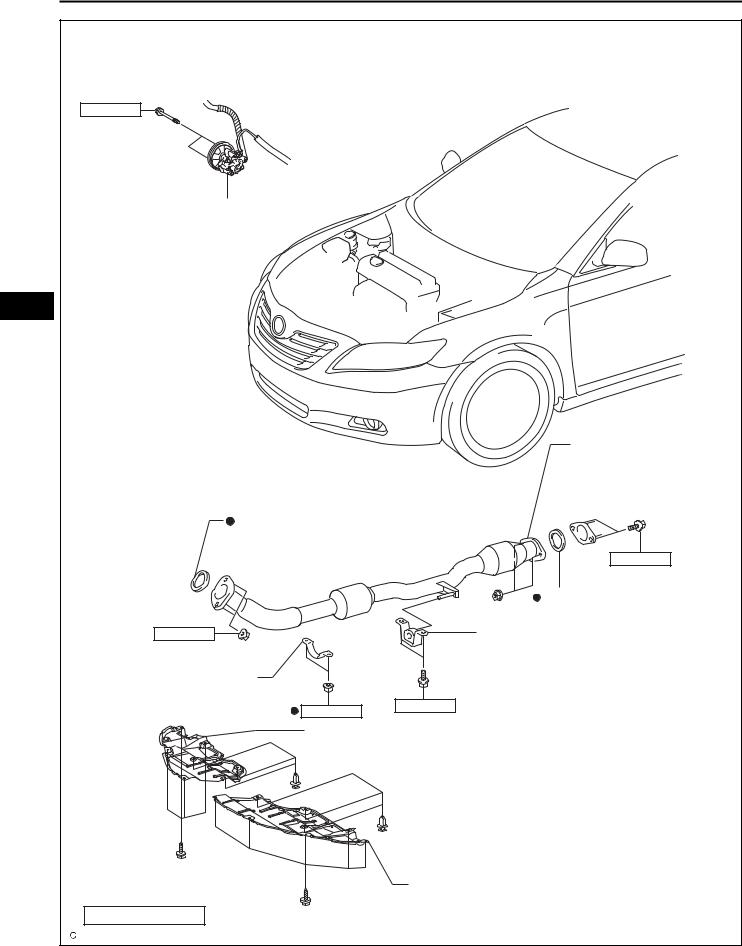

EM–18 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

43 (439, 32)

VANE PUMP ASSEMBLY

EM

|

FRONT EXHAUST |

|||

|

PIPE ASSEMBLY |

|||

|

EXHAUST PIPE GASKET |

|||

|

56 (571, 41) |

|||

|

EXHAUST PIPE GASKET |

|||

|

62 (633, 46) |

REAR EXHAUST PIPE NO. 1 |

||

|

SUPPORT BRACKET |

|||

|

FRONT EXHAUST PIPE NO. 1 |

|||

|

SUPPORT BRACKET |

33 (337, 24) |

33 (337, 24) |

|

|

ENGINE UNDER COVER RH |

ENGINE UNDER COVER LH

N*m (kgf*cm, ft.*lbf) : Specified torque

A134947E01

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–19 |

|

9.0 (92, 80 in.*lbf) |

||||

|

IGNITION COIL ASSEMBLY |

||||

|

14 (143, 10) |

||||

|

14 (143, 10) |

||||

|

11 (110, |

11 (110, |

|||

|

x6 |

x2 |

|||

|

CYLINDER HEAD COVER SUB-ASSEMBLY |

EM |

|||

|

CYLINDER HEAD COVER GASKET |

||||

|

CRANK POSITION |

||||

|

SENSOR |

||||

|

9.0 (92, 80 in.*lbf) |

||||

|

TMMK: 170 (1,733, 125) |

||||

|

TMC: 180 (1,835, 133) |

||||

|

CRANKSHAFT PULLEY |

OIL PAN SUB-ASSEMBLY |

|||

|

25 (255, 18) |

||||

|

OIL PAN DRAIN PLUG |

GASKET |

9.0 (92, 80 in.*lbf) |

||

|

x2 |

x12 |

|||

|

9.0 (92, 80 in.*lbf) |

||||

|

N*m (kgf*cm, ft.*lbf) : Specified torque |

Non-reusable part |

|||

|

A134922E01 |

|

EM–20 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

|

CHAIN SUB-ASSEMBLY |

NO. 1 CHAIN VIBRATION DAMPER |

|

CRANKSHAFT TIMING SPROCKET |

CHAIN TENSIONER

SLIPPER

NO. 2 CHAIN SUB-ASSEMBLY

OIL PUMP DRIVE SPROCKET

|

EM |

19 (194, 14) |

|

|

SPRING |

||

|

NO. 1 CRANKSHAFT |

CHAIN TENSIONER |

|

|

POSITION SENSOR |

12 (122, 9.0) |

|

|

PLATE |

30 (301, 22) |

|

|

9.0 (92, 80 in.*lbf) |

||

|

OIL PUMP DRIVEN SPROCKET |

||

|

TIMING CHAIN GUIDE |

NO. 1 CHAIN TENSIONER |

|

|

ASSEMBLY |

9.0 (92, 80 in.*lbf)

11 (112,

V-RIBBED BELT

TENSIONER

ASSEMBLY

55 (561, 41)

|

22 (220, 16) |

x4 |

|

STUD BOLT |

|

|

9.0 (92, 80 in.*lbf) |

|

|

60 (607, 44) |

|

|

TIMING CHAIN CASE OIL SEAL |

x8 |

|

25 (255, 18) |

|

|

N*m (kgf*cm, ft.*lbf) : Specified torque |

TIMING CHAIN COVER SUB-ASSEMBLY |

|

Non-reusable part |

A134923E01

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–21 |

REMOVAL

1.DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

2.REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY (See page EM-94)

3.REMOVE FRONT WHEEL RH

4.REMOVE ENGINE UNDER COVER LH

5.REMOVE ENGINE UNDER COVER RH

6.REMOVE FRONT FENDER APRON SEAL RH

7.DRAIN ENGINE OIL (See page LU-4)

8.REMOVE FRONT EXHAUST PIPE ASSEMBLY

HINT:

|

See page EX-2. |

|||

|

EM |

|||

|

9. |

REMOVE NO. 2 ENGINE MOUNTING STAY RH (See |

||

|

page EM-95) |

|||

|

10. |

REMOVE ENGINE MOVING CONTROL ROD SUB- |

||

|

ASSEMBLY (See page EM-95) |

|||

|

11. |

REMOVE NO. 2 ENGINE MOUNTING BRACKET RH |

||

|

(See page EM-96) |

|||

|

12. |

REMOVE V-RIBBED BELT (See page EM-6) |

||

|

13. |

REMOVE GENERATOR ASSEMBLY (See page CH-11) |

||

|

14. |

REMOVE VANE PUMP ASSEMBLY (See page EM- |

||

|

101) |

|||

|

15. |

REMOVE IGNITION COIL ASSEMBLY (See page EM- |

||

|

106) |

|||

|

16. |

DISCONNECT VENTILATION HOSE |

||

|

17. |

DISCONNECT NO. 2 VENTILATION HOSE |

||

|

18. |

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

||

|

(a) Remove the 2 bolts and disconnect the 2 engine |

|||

|

wires. |

|

EM–22 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

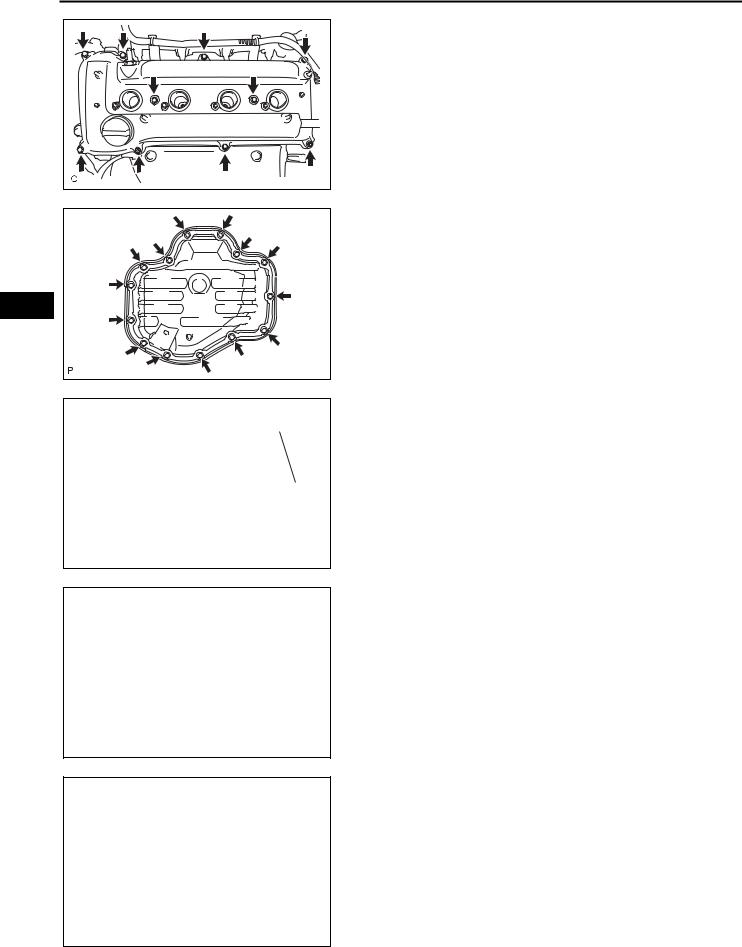

(b)Remove the 8 bolts, 2 nuts, and the cylinder head cover.

19.SET NO. 1 CYLINDER TO TDC/COMPRESSION (See page EM-8)

20.REMOVE CRANKSHAFT PULLEY (See page EM-75)

21.REMOVE CRANK POSITION SENSOR (See page ES411)

22. REMOVE OIL PAN SUB-ASSEMBLY

(a) Remove the 12 bolts and 2 nuts.

EM

A114333

SST

A000019E05

(b)Insert the blade of SST between the crankcase and oil pan. Cut through the sealer and remove the oil pan.

SST 09032-00100 NOTICE:

Be careful not to damage the contact surfaces of the crankcase, chain cover and oil pan.

23.REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a)Remove the 2 nuts, tensioner and gasket.

NOTICE:

Do not turn the crankshaft without the chain tensioner.

A098348E01

|

No. 1 Engine Hanger |

No. 2 Engine Hanger |

||||||||

A052507E05

24. INSTALL ENGINE HANGERS

(a) Install the No. 1 engine hanger and No. 2 engine hanger with the bolts as shown in the illustration. Parts No.:

|

No. 1 Engine hanger |

12281-28010 |

|

No. 2 Engine hanger |

12282-28010 |

|

Bolt |

91512-61020 |

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

(b) Attach the sling device to the engine hangers and chain block.

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–23 |

25.REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a)Lift the engine upward using the chain block.

NOTICE:

Do not lift the engine more than necessary.

(b) Remove the bolt, nut and V-ribbed belt tensioner.

26.REMOVE ENGINE MOUNTING INSULATOR

(a)Attach the engine chain hoist to the engine hangers. EM

CAUTION:

Do not attempt to hang the engine by hooking the chain to any other part.

(b)Remove the bolt and disconnect the engine mounting insulator FR.

A059880

(c)M/T:

Remove the bolt and disconnect the engine lateral control rod.

(d)Remove the 2 bolts and disconnect the steering gear return tube clamps from the frame.

|

EM–24 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

|||

|

(e) |

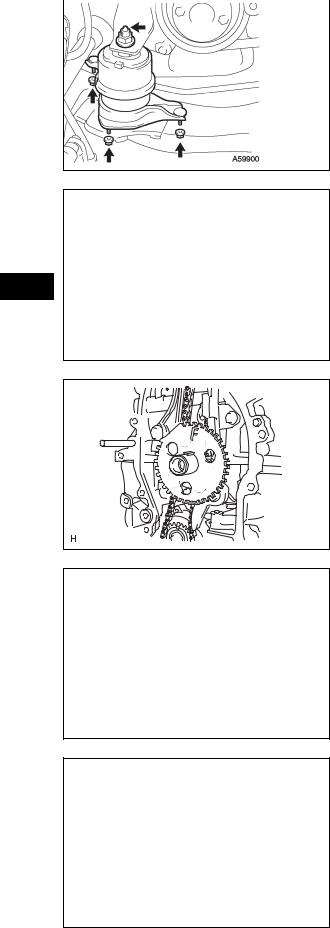

Remove the 4 nuts from the engine mounting |

|||

|

insulator RH. |

||||

|

(f) |

Raise the engine and remove the engine mounting |

|||

|

insulator RH. |

A059900

27.REMOVE ENGINE MOUNTING BRACKET RH

(a)Remove the 3 bolts and engine mounting bracket.

28.REMOVE TIMING CHAIN COVER SUB-ASSEMBLY (See page LU-11)

29.REMOVE TIMING CHAIN CASE OIL SEAL (See page LU-12)

30.REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

(a)Remove the crankshaft position sensor plate.

31.REMOVE CHAIN TENSIONER SLIPPER

(a)Remove the bolt and chain tensioner slipper.

A125372

32.REMOVE NO. 1 CHAIN VIBRATION DAMPER

(a)Remove the 2 bolts and chain vibration damper.

A125371

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–25 |

||

|

33. REMOVE TIMING CHAIN GUIDE |

|||

|

(a) Remove the bolt and timing chain guide. |

A125373

34. REMOVE CHAIN SUB-ASSEMBLY

(a) Remove the chain sub-assembly.

EM

A128185

35.REMOVE CRANKSHAFT TIMING SPROCKET

(a)Remove the crankshaft timing sprocket.

|

A125374 |

|||||||

|

36. REMOVE NO. 2 CHAIN SUB-ASSEMBLY |

|||||||

|

90° |

(a) Turn the crankshaft by 90° counterclockwise to align |

||||||

|

the adjusting hole of the oil pump drive shaft |

|||||||

|

sprocket with the groove of the oil pump. |

Groove

A098351E01

|

EM–26 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

||

|

(b) Insert a 4 mm diameter bar into the adjusting hole of |

|||

|

the oil pump drive shaft sprocket to lock the gear in |

|||

|

position, and then remove the nut. |

Groove

A098352E01

EM

(c) Remove the bolt, chain tensioner plate and spring.

Bolt

Spring

Chain Tensioner Plate

B011415E03

(d)Remove the chain tensioner, oil pump driven sprocket and chain.

A063847

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–27 |

INSPECTION

|

1. |

INSPECT CHAIN SUB-ASSEMBLY (See page EM-138) |

||

|

2. |

INSPECT NO. 2 CHAIN SUB-ASSEMBLY (See page |

||

|

EM-138) |

|||

|

3. |

INSPECT OIL PUMP DRIVE SPROCKET (See page |

||

|

EM-138) |

|||

|

4. |

INSPECT OIL PUMP DRIVE SHAFT SPROCKET (See |

||

|

page EM-139) |

|||

|

5. |

INSPECT CHAIN TENSIONER SLIPPER (See page |

||

|

EM-140) |

|||

|

6. |

INSPECT NO. 1 CHAIN VIBRATION DAMPER (See |

||

|

page EM-140) |

|||

|

7. |

INSPECT CHAIN TENSIONER PLATE (See page EM- |

||

|

EM |

|||

|

140) |

8.INSPECT NO. 1 CHAIN TENSIONER (See page EM140)

INSTALLATION

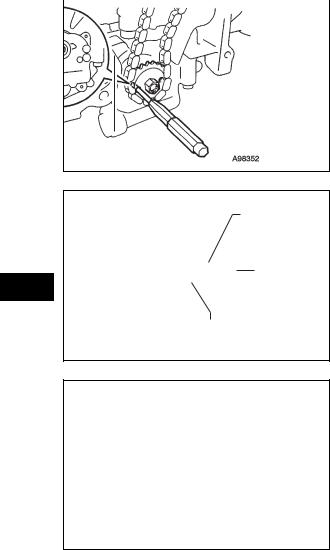

1.INSTALL NO. 2 CHAIN SUB-ASSEMBLY

(a)Set the crankshaft key into the left horizontal position.

(b)Turn the drive shaft so that the cutout faces upward.

B011424

Mark Link

Timing Mark

|

Oil Pump Drive |

Oil |

Pump |

|

Shaft Sprocket |

Drive Sprocket |

(c)Align the yellow mark links with the timing marks of each gear as shown in the illustration.

(d)Install the sprockets onto the crankshaft and oil pump shaft with the chain wrapped on the gears.

(e)Temporarily tighten the oil pump drive shaft sprocket with the nut.

Timing Mark

Mark Link

A094198E06

|

EM–28 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

||||

|

(f) Insert the damper spring into the adjusting hole, and |

|||||

|

then install the chain tensioner plate with the bolt. |

|||||

|

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf) |

|||||

|

Bolt |

|||||

Spring

Chain Tensioner Plate

A090851E03

(g)Align the adjusting hole of the oil pump drive shaft sprocket with the groove of the oil pump.

(h)Insert a 4 mm diameter bar into the adjusting hole of the oil pump drive shaft gear to lock the gear in position, and then tighten the nut.

Torque: 30 N*m (301 kgf*cm, 22 ft.*lbf)

(i)Rotate the crankshaft clockwise by 90°, and align the crankshaft key to the top.

A036525

2.INSTALL CRANKSHAFT TIMING SPROCKET

(a)Install the crankshaft timing sprocket.

A125374

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–29 |

3.INSTALL NO. 1 CHAIN VIBRATION DAMPER

(a)Install the chain vibration damper with the 2 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

|

4. INSTALL CHAIN SUB-ASSEMBLY |

||||

|

(a) Set the No. 1 cylinder to TDC/compression. |

||||

|

(1) Turn the camshafts with a wrench (using the |

||||

|

hexagonal lobe) to align the timing marks of the |

||||

|

camshaft timing gear with each timing mark |

||||

|

Timing Marks |

located on the No. 1 and No. 2 bearing caps as |

|||

|

EM |

||||

|

shown in the illustration. |

||||

Timing Marks

A053018E05

(2)Using the crankshaft pulley bolt, turn the crankshaft to position with the key on the crankshaft upward.

(b)Install the chain onto the crankshaft timing sprocket with the gold or pink mark link aligned with the timing mark on the crankshaft.

|

EM–30 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

||

|

(c) Using SST and a hammer, tap in the crankshaft |

|||

|

SST |

timing sprocket. |

||

|

SST 09309-37010 |

A098369E01

(d) Align the gold or yellow link with each timing mark Mark Link located on the camshaft timing gear and sprocket,

then install the chain.

EM

|

A098370E01 |

|

|

5. INSTALL CHAIN TENSIONER SLIPPER |

|

|

Hold |

(a) Install the chain tensioner slipper with the bolt. |

|

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf) |

|

|

A124787E01 |

6.INSTALL TIMING CHAIN GUIDE

(a)Install the timing chain guide with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

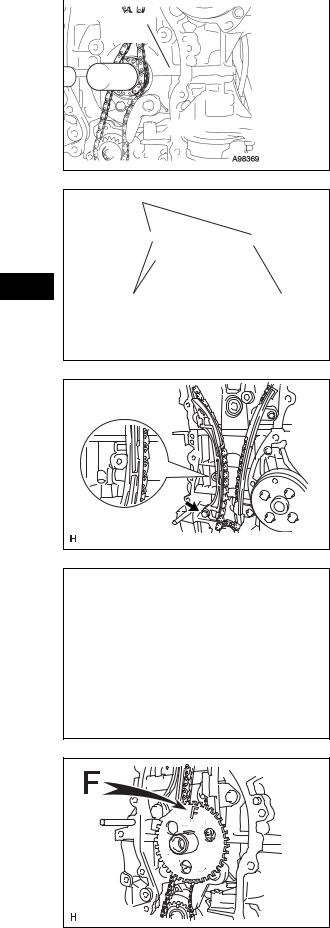

7.INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE

(a)Install the sensor plate with the «F» mark facing forward.

8.INSTALL TIMING CHAIN CASE OIL SEAL (See page LU-15)

9.INSTALL TIMING CHAIN COVER SUB-ASSEMBLY (See page LU-15)

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–31 |

10.INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a)Install the V-ribbed belt tensioner with the bolt and nut.

Torque: 60 N*m (607 kgf*cm, 44 ft.*lbf) NOTICE:

Do not lift the engine more than necessary.

11.INSTALL ENGINE MOUNTING BRACKET RH

(a)Install the engine mounting bracket with the 3 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

EM

A052481

12. INSTALL ENGINE MOUNTING INSULATOR

A (a) Raise the engine and install the engine mounting insulator RH.

|

(b) Install the engine mounting insulator RH with the 4 |

||

|

nuts. |

||

|

Torque: Nut A |

||

|

B |

95 N*m (969 kgf*cm, 70 ft.*lbf) |

|

|

Nut B |

||

|

B |

B |

87 N*m (888 kgf*cm, 64 ft.*lbf) |

|

A059900E02 |

||

|

(c) Install the steering gear return tube clamps to the |

||

|

frame with the 2 bolts. |

||

|

Torque: 8.0 N*m (80 kgf*cm, 69 in.*lbf) |

||

|

A138332 |

(d)Install the engine mounting insulator FR with the bolt.

Torque: 87 N*m (888 kgf*cm, 64 ft.*lbf)

A059880

|

EM–32 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

||||

|

M/T |

(e) M/T: |

||||

|

Install the engine lateral control rod with the bolt. |

|||||

|

Torque: 89 N*m (910 kgf*cm, 66 ft.*lbf) |

|||||

|

A060825E01 |

|||||

|

13. INSTALL OIL PAN SUB-ASSEMBLY |

|||||

|

(a) Remove any old packing material and be careful not |

|||||

|

to drop any oil on the contact surfaces of the |

|||||

|

cylinder block and oil pan. |

|||||

|

(b) Apply a continuous bead of seal packing (Diameter |

|||||

|

EM |

3.0 to 4.0 mm (0.118 to 0.157 in.)) as shown in the |

||||

|

illustration. |

|||||

|

Seal packing: |

|||||

|

Toyota Genuine Seal Packing Block, Three |

|||||

|

Bond 1207B or Equivalent |

|||||

|

NOTICE: |

|||||

|

• Remove any oil from the contact surfaces. |

|||||

|

• Install the oil pan within 3 minutes after |

|||||

|

Seal Packing |

applying seal packing. |

||||

|

• Do not start the engine for at least 2 hours |

|||||

|

6.0 mm (0.236 in.) |

after installing. |

||||

|

(c) Install the oil pan to the cylinder block. |

|||||

|

Seal Diameter: 3.0 to 4.0 mm |

|||||

|

A114332E01 |

|||||

|

9 |

10 |

(d) Uniformly tighten the 12 bolts and 2 nuts in the |

|||

|

11 |

sequence shown in the illustration. |

||||

|

1, 15 |

|||||

|

8 |

12 |

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf) |

|||

|

7 |

14. INSTALL CRANK POSITION SENSOR (See page ES- |

||||

|

13 |

411) |

||||

|

15. INSTALL CRANKSHAFT PULLEY (See page EM-76) |

|||||

|

6 |

|||||

|

5 |

4 |

3 |

2 |

14 |

|

|

A114333E01 |

16.INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

(a)Release the ratchet pawl, then fully push in the plunger and hook the hook to the pin so that the plunger is in the position shown in the illustration.

A098376E03

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–33 |

(b)Install a new gasket and the chain tensioner with the 2 nuts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf) NOTICE:

If the hook releases the plunger while the chain tensioner is being installed, set the hook again.

|

Engine Front |

||

|

A098377E03 |

||

|

(c) Turn the crankshaft counterclockwise, then |

EM |

|

|

disconnect the plunger knock pin from the hook. |

||

|

Disconnect |

||

|

Hook |

Turn |

|

|

Pin |

||

|

A112204E02 |

|

Plunger |

|

|

Push |

Turn |

|

A112205E02 |

(d)Turn the crankshaft clockwise, then check that the plunger is extended.

17.INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(a)Remove any old packing material from the contact surface.

|

EM–34 |

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

|

(b) Apply seal packing to the 2 locations shown in the |

|||||

|

illustration. |

|||||

|

Seal packing: |

|||||

|

Toyota Genuine Seal Packing Block, Three |

|||||

|

Bond 1207B or Equivalent |

|||||

|

NOTICE: |

|||||

|

• Remove any oil from the contact surface. |

|||||

|

• Install the cylinder head cover within 3 |

|||||

|

minutes of applying seal packing. |

|||||

|

A094205E01 |

• Do not add engine oil for at least 2 hours after |

||||

|

installing the cylinder head cover. |

|||||

|

A |

A |

A |

A |

(c) Install the cylinder head cover with the 8 bolts and 2 |

|

|

nuts. |

|||||

|

B |

Torque: Bolt A |

||||

|

B |

11 N*m (112 kgf*cm, 8 ft.*lbf) |

||||

|

EM |

Bolt B |

||||

|

14 N*m (143 kgf*cm, 10 ft.*lbf) |

|||||

|

Nut |

|||||

|

11 N*m (112 kgf*cm, 8 ft.*lbf) |

|||||

|

A |

Nut |

||||

|

A |

Nut |

A127550E01 |

(d)Install the 2 engine wires with the 2 bolts.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

18.INSTALL NO. 2 VENTILATION HOSE

19.INSTALL VENTILATION HOSE

20.INSTALL IGNITION COIL ASSEMBLY

(a)Install the 4 ignition coils with the 4 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

21.INSTALL VANE PUMP ASSEMBLY (See page EM-113)

22.INSTALL GENERATOR ASSEMBLY (See page CH-19)

23.INSTALL V-RIBBED BELT (See page EM-6)

24.INSTALL NO. 2 ENGINE MOUNTING BRACKET RH (See page EM-118)

25.INSTALL ENGINE MOVING CONTROL ROD SUBASSEMBLY (See page EM-119)

26.INSTALL NO. 2 ENGINE MOUNTING STAY RH (See page EM-119)

27.INSTALL FRONT EXHAUST PIPE ASSEMBLY

HINT:

See page EX-3.

28.ADD ENGINE OIL

29.CONNECT CABLE TO NEGATIVE BATTERY TERMINAL (See page EM-120)

30.CHECK FOR ENGINE OIL LEAKS

31.CHECK FOR EXHAUST GAS LEAKS

32.CHECK IGNITION TIMING (See page EM-1)

|

2AZ-FE ENGINE MECHANICAL – TIMING CHAIN |

EM–35 |

33.INSTALL FRONT FENDER APRON SEAL RH

34.INSTALL ENGINE UNDER COVER LH

35.INSTALL ENGINE UNDER COVER RH

36.INSTALL FRONT WHEEL RH

37.INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY (See page EM-121)

EM

|

2AZ-FE ENGINE MECHANICAL – CAMSHAFT |

EM–35 |

|

CAMSHAFT |

|

|

COMPONENTS |

|

|

V-RIBBED BELT |

|

|

9.0 (92, 80 in.*lbf) |

|

|

NO. 1 ENGINE COVER SUB-ASSEMBLY |

EM |

|

FRONT FENDER APRON SEAL RH |

|

|

ENGINE UNDER COVER RH |

|

|

ENGINE UNDER COVER LH |

|

|

N*m (kgf*cm, ft.*lbf) : Specified torque |

|

|

A134949E01 |

|

EM–36 |

2AZ-FE ENGINE MECHANICAL – CAMSHAFT |

EM

9.0 (92, 80 in.*lbf)

IGNITION COIL ASSEMBLY

11 (112,

VENTILATION HOSE

CYLINDER HEAD COVER

SUB-ASSEMBLY

GASKET

N*m (kgf*cm, ft.*lbf) : Specified torque

A134919E01

|

2AZ-FE ENGINE MECHANICAL – CAMSHAFT |

EM–37 |

|

9.0 (92, 80 in.*lbf) |

||

|

NO. 3 CAMSHAFT BEARING CAP |

||

|

30 (301, 22) |

x16 |

|

|

x4 |

||

|

NO. 1 CAMSHAFT BEARING CAP |

NO. 3 CAMSHAFT BEARING CAP |

|

|

NO. 2 CAMSHAFT BEARING CAP |

CAMSHAFT |

|

|

EM |

||

|

NO. 2 CAMSHAFT |

||

|

54 (551, 40) |

||

|

CAMSHAFT TIMING GEAR ASSEMBLY |

NO. 2 CAMSHAFT TIMING SPROCKET |

|

|

54 (551, 40) |

||

|

9.0 (92, 80 in.*lbf) |

||

|

NO. 1 CHAIN TENSIONER ASSEMBLY |

||

|

GASKET |

||

|

N*m (kgf*cm, ft.*lbf) : Specified torque |

||

|

Non-reusable part |

||

|

A134921E01 |

|

EM–38 |

2AZ-FE ENGINE MECHANICAL – CAMSHAFT |

|

REMOVAL |

EM

1.REMOVE FRONT WHEEL RH

2.REMOVE ENGINE UNDER COVER LH

3.REMOVE ENGINE UNDER COVER RH

4.REMOVE FRONT FENDER APRON SEAL RH

5.REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY (See page EM-94)

6.REMOVE IGNITION COIL ASSEMBLY (See page EM106)

7.REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY (See page EM-21)

8.SET NO. 1 CYLINDER TO TDC/COMPRESSION (See page EM-8)

9.REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY (See page EM-22)

10.REMOVE NO. 2 CAMSHAFT

|

Loosen |

(a) While holding the camshaft with a wrench, loosen |

|

the camshaft timing set bolt. |

Hold

A098173E03

(b)Using several steps, uniformly loosen and remove the 10 bearing cap bolts in the sequence shown in the illustration.

(c)Remove the 5 bearing caps.

(d)While holding the No. 2 camshaft by hand, remove the camshaft timing sprocket set bolt.

(e)Remove the camshaft timing sprocket from the No. 2 camshaft with the timing chain wrapped on the sprocket.

(f)Remove the camshaft timing sprocket from the timing chain.

A086659

|

2AZ-FE ENGINE MECHANICAL – CAMSHAFT |

EM–39 |

|

11. REMOVE CAMSHAFT |

||||||||||||||||

|

(a) Using several steps, uniformly loosen and remove |

||||||||||||||||

|

the 10 bearing cap bolts in the sequence shown in |

||||||||||||||||

|

the illustration. |

||||||||||||||||

|

9 |

||||||||||||||||

|

1 |

5 |

7 |

3 |

|||||||||||||

|

2 |

(b) Remove the 5 bearing caps. |

|||||||||||||||

|

(c) Remove the camshaft and camshaft timing gear |

||||||||||||||||

|

while holding the timing chain by hand. |

||||||||||||||||

|

4 |