- Manuals

- Brands

- Kubota Manuals

- Engine

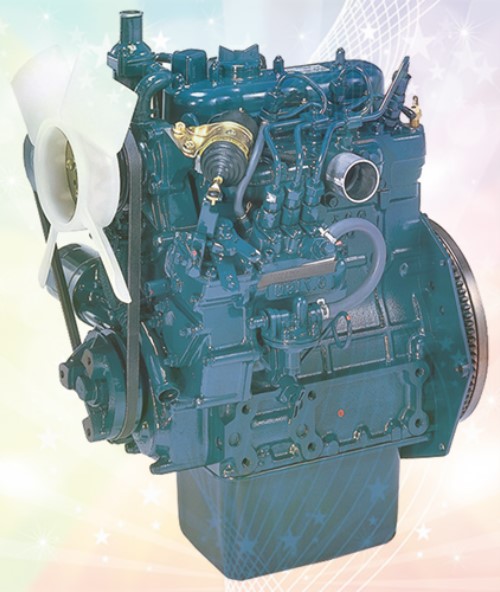

- D722-E2B

Manuals and User Guides for Kubota D722-E2B. We have 1 Kubota D722-E2B manual available for free PDF download: Workshop Manual

Kubota D722-E2B Workshop Manual (143 pages)

SM-E2B SERIES

Brand: Kubota

|

Category: Engine

|

Size: 7.26 MB

Table of Contents

-

Before Servicing and Repairing

3

-

Safety Information

3

-

Avoid Fires

4

-

Safety Starting

4

-

Safety Working

4

-

Prevent Acid Burns

5

-

Ventilate Work Area

5

-

Specifications

6

-

Performance Curves

9

-

Z482-E2B

9

-

D662-E2B

12

-

D722-E2B

13

-

D782-E2B

14

-

D902-E2B (3200 Min(Rpm) Spec.)

15

-

Dimensions

17

-

D662-E2B, D722-E2B

19

-

Table of Contents

22

-

General

22

-

1 Engine Identification

23

-

Model Name and Engine Serial Number

23

-

E2B Engine

24

-

Cylinder Number

24

-

-

2 General Precautions

25

-

3 Maintenance Check List

26

-

Lubricating Oil

27

-

-

4 Check and Maintenance

28

-

Daily Check Points

28

-

Checking Engine Oil Level

28

-

Checking and Replenish Coolant

29

-

-

Check Points of Initial 50 Hours

30

-

Changing Engine Oil

30

-

Replacing Oil Filter Cartridge

31

-

-

Check Point of Every 50 Hours

32

-

Checking Fuel Hose

32

-

Check Point of Every 75 Hours

33

-

Changing Engine Oil (for Optional Depth Oil Pans)

33

-

Check Points of Every 100 Hours

34

-

Changing Engine Oil (for Standard Depth Oil Pans)

34

-

Fan Belt Tension

35

-

Fan Belt Damage and Wear

35

-

Cleaning Air Cleaner Element

35

-

Cleaning Fuel Filter (Element Type Only)

36

-

Checking Battery Electrolyte Level

36

-

-

Check Point of Every 150 Hours

37

-

Replacing Oil Filter Cartridge (for Optional Depth Oil Pans)

37

-

Check Points of Every 200 Hours

37

-

Replacing Oil Filter Cartridge (for Standard Depth Oil Pans)

37

-

Check Points of Every 400 Hours

38

-

Checking Radiator Hoses and Clamp Bands

38

-

Checking Intake Air Line

38

-

Replacing Fuel Filter Cartridge (Cartridge Type)

38

-

-

Check Points of Every 500 Hours

39

-

Cleaning Water Jacket and Radiator Interior

39

-

Anti-Freeze

40

-

Replacing Fan Belt

40

-

-

Check Points of Every 1 or 2 Months

41

-

Recharging

41

-

Battery Specific Gravity

42

-

-

Check Point of Every Year

43

-

Replacing Air Cleaner Element

43

-

Check Point of Every 800 Hours

44

-

Checking Valve Clearance

44

-

Check Points of Every 1500 Hours

45

-

Nozzle Spraying Condition

45

-

Fuel Injection Pressure

45

-

Nozzle Valve Seat Tightness

45

-

Nozzle Holder

46

-

-

Check Points of Every 3000 Hours

47

-

Injection Timing

47

-

Checking Injection Pump

49

-

-

Check Points of Every 2 Years

50

-

Replacing Intake Air Line

50

-

Replacing Battery

50

-

Replacing Radiator Hoses and Clamp Bands

50

-

Replacing Fuel Hoses and Clamp Bands

51

-

-

-

5 Special Tools

54

-

Diesel Engine Compression Tester (for Glow Plug)

54

-

Diesel Engine Compression Tester (for Injection Nozzle)

54

-

Oil Pressure Tester

54

-

Injection Pump Pressure Tester

55

-

Valve Guide Replacing Tool

55

-

Bushing Replacing Tool

56

-

Flywheel Stopper

56

-

Crankshaft Bearing 1 Replacing Tool

57

-

Crank Sleeve Setter (for Z482/D662/D722/D782-E2B)

58

-

Mechanism

59

-

Closed Breather

60

-

Engine Body

60

-

Half-Floating Head Cover

60

-

Oil Pan (Z602-E2B, D902-E2B

61

-

Piston (Z602-E2B, D902-E2B

61

-

Cooling Fin (Z602-E2B, D902-E2B)

62

-

Cooling System

62

-

Servicing

63

-

Troubleshooting

64

-

Servicing Specifications

67

-

Tightening Torques for General Use Screws, Bolts and Nuts

74

-

Tightening Torques for Special Use Screws, Bolts and Nuts

75

-

Checking and Adjusting

76

-

Checking, Disassembling and Servicing

76

-

Compression Pressure

76

-

Cooling System

78

-

Engine Oil Pressure

78

-

Radiator Cap Air Leakage

79

-

Radiator Water Leakage

79

-

Thermostat Valve Opening Temperature

80

-

Fuel Tightness of Delivery Valve

82

-

Fuel Tightness of Pump Element

82

-

Battery Voltage

84

-

Electrical System

84

-

Magnetic Switch Test

86

-

Motor Test

86

-

Magnet Switch Continuity Test

87

-

No-Load Dynamo Output

87

-

Continuity Across Regulator’s Terminals

88

-

Regulating Voltage

88

-

Alternator on Unit Test

89

-

Engine Stop Solenoid Test (Energize to Stop Type)

89

-

Glow Plug Continuity

89

-

Glow Plug Lead Terminal Voltage

89

-

Engine Stop Solenoid Test (Energize to Run Type)

90

-

-

Disassembling and Assembling

91

-

Draining Engine Oil and Coolant

91

-

Alternator, Starter and Others

92

-

Cylinder Head Cover

92

-

-

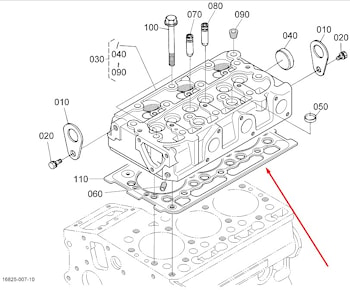

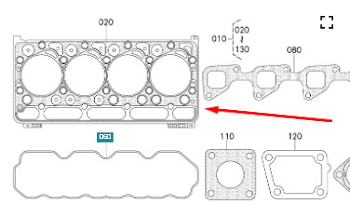

Cylinder Head, Valves and Oil Pan

92

-

External Components

92

-

Injection Pipes

92

-

Nozzle Heat Seal Service Removal Procedure

93

-

Nozzle Holder Assembly and Glow Plug

93

-

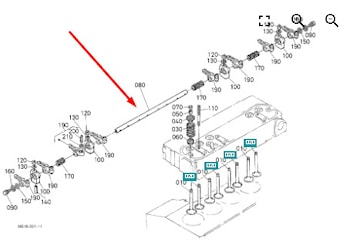

Rocker Arm and Push Rod

94

-

Cylinder Head

95

-

Thermostat Assembly

95

-

Water Pump Assembly

96

-

Tappets

98

-

Valves

98

-

Oil Pan and Oil Strainer

99

-

-

Gear Case and Timing Gears

100

-

Injection Pump, Fuel Feed Pump and Speed Control Plate (for Energize to Stop Type Engine Stop Solenoid)

100

-

Injection Pump, Fuel Feed Pump and Speed Control Plate (for Energize to Run Type Engine Stop Solenoid)

101

-

Fan Drive Pulley

103

-

Gear Case

104

-

Camshaft

105

-

Idle Gear

105

-

Fuel Camshaft

106

-

Oil Pump and Crankshaft Gear

106

-

Oil Pump and Crankshaft Gear (One-Side Maintenance Type)

106

-

Connecting Rod Cap

107

-

-

Piston and Connecting Rod

107

-

Piston Ring and Connecting Rod

109

-

Bearing Case Cover

110

-

-

Flywheel and Crankshaft

110

-

Crankshaft Assembly

111

-

Main Bearing Case Assembly

112

-

Main Bearing Case Assembly (Z602-E2B, D902-E2B)

113

-

Electromagnetic Drive Type

114

-

-

Starter

114

-

Planetary Gear Reduction Type

115

-

Dynamo

116

-

Alternator

117

-

Cylinder Head and Valves

118

-

Cylinder Head Surface Flatness

118

-

Servicing

118

-

Top Clearance

118

-

Clearance between Valve Stem and Valve Guide

119

-

Cylinder Head Flaw

119

-

Valve Recessing

119

-

Replacing Valve Guide

120

-

Valve Seating

120

-

Correcting Valve and Valve Seat

121

-

Valve Lapping

121

-

Free Length and Tilt of Valve Spring

122

-

Oil Clearance between Rocker Arm and Rocker Arm Shaft

122

-

Valve Spring Setting Load

122

-

Oil Clearance between Tappet and Tappet Guide Bore

123

-

Push Rod Alignment

123

-

Camshaft Side Clearance

124

-

Idle Gear Side Clearance

124

-

Timing Gear Backlash

124

-

Cam Height

125

-

Camshaft Alignment

125

-

Oil Clearance of Camshaft Journal

125

-

Oil Clearance between Idle Gear Shaft and Idle Gear Bushing

126

-

-

Piston and Connecting Rod

126

-

Piston Pin Bore I.D.

126

-

Replacing Idle Gear Bushing

126

-

Connecting Rod Alignment

127

-

Oil Clearance between Piton Pin and Small End Bushing

127

-

Replacing Small End Bushing

127

-

Clearance between Piston Ring and Piston Ring Groove

128

-

Piston Ring Gap

128

-

Crankshaft Alignment

129

-

Crankshaft Side Clearance

129

-

Oil Clearance between Crankpin and Crankpin Bearing

130

-

Oil Clearance between Crankshaft Journal and Crankshaft

131

-

Cylinder Wear

135

-

Replacing Crankshaft Sleeve (Z482-E2B, D662-E2B, D722-E2B, D782-E2B)

135

-

Clearance between Outer Rotor and Pump Body

136

-

Correcting Cylinder (Oversize)

136

-

-

Oil Pump

136

-

Rotor Lobe Clearance

136

-

Clearance between Rotor and Cover

137

-

Overrunning Clutch

137

-

-

Starter

137

-

Commutator and Mica

138

-

Armature Coil

139

-

Brush Holder

139

-

Brush Wear

139

-

-

Alternator

140

-

Bearing

140

-

Field Coil

140

-

Rotor

140

-

-

Stator

140

-

IC Regulator

141

-

Rectifier

141

-

Slip Ring

141

-

-

Advertisement

Advertisement

Related Products

-

Kubota D722-E4

-

Kubota D722-E3B

-

Kubota D722-E3

-

Kubota D782-E2B

-

Kubota D782-E

-

Kubota D782-E4

-

Kubota D782-E3

-

Kubota D782-E3B

-

Kubota D1005-E3BG

-

Kubota D1703-M-E

Kubota Categories

Tractor

Lawn Mower

Engine

Excavators

Farm Equipment

More Kubota Manuals

Насос подкачки топлива для двигателей Kubota D722, D662, D902, Z482 насос топливоподкачивающий для Bobcat 320, 321, 322, 323 Номер 6670498 номер детали: 16604-52032, 16604-52030, 15821-52030, 15841-52030, 19035-52030, 12581-52030, …

ось коромысел V1505 #16241-14266 применяемость: Kubota V1505 номер: #16241-14264, #16241-14266, #16241-14265, #16241-14264, #1624114264, #1624114266, #1624114265, #1624114264 rocker shaft …

Палец ковша #RG448-66760 оригинальный номер: RG448-66760 замена номера: RC418-66760, RC41866760, RG44866760 применяемость: Kubota KX71.3, KX91.3, KX121-3, U35m, U35 Kubota …

поршень +0,5 для ДВС Kubota 16423-21912 номер: D1703, V2203, V2403 применяемость: 16423-21910, 6657695, 6689744, H1640-21900, PN-60021, 1642321910, 6657695, 6689744, H164021900, PN60021, 1642321912, …

Поршень в сборе с кольцами V3300 — 1G563-21794 (+0.5) кросс номер — 1G563-21793, 1G563-21792, 07916-24812, 1G563-21790 Применяемость: Kubota V3300 (12v) M8200 (2wd / Rops) M8200-CAB (2wd / Cabin) M8200DT (4wd / Rops) M8200DT-CAB (4wd / Cabin) …

Прокладка выпускного коллектора #1A091-12350 применяемость: Kubota V2003, V2203, V2403 старый номер: …

Прокладка выпускного коллектора #1A091-12360 применяемость: Kubota V2003, V2203, V2403 старый номер: …

Прокладка головки блока цилиндров #1G790-03602 номер: 1G790-03602, 1G79003602, 1G790-03600, 6685078, XJBR-00891, 1G79003600, 6685078, XJBR00891 применяемость: Kubota V2203, V2403 Bobcat B300, BL370, X331, 334, 335, 337, 341, 430, 435, E42, E45, E50, …

Прокладка головки блока цилиндров #1G790-03620 номер: 1G790-03620, 1G790-03622, 6685080, XJBR-00894, 1G79003620, 1G79003622, 6685080, XJBR00894 применяемость: Kubota V2203, V2403 Bobcat B300, BL370, X331, 334, 335, 337, 341, 430, 435, E42, E45, E50, …

Прокладка головки блока цилиндров #1G790-03620 номер: 1G790-03630, 1G790-03632, 6685081, XJBR-00895, 1G79003630, 1G79003632, 6685081, XJBR00895 применяемость: Kubota V2203, V2403 Bobcat B300, BL370, X331, 334, 335, 337, 341, 430, 435, E42, E45, E50, …

Прокладка головки блока цилиндров для двигателя Kubota D782 MPN …

Прокладка головки блока цилиднров #1G770-03312 номер: 1G770-03312, 1G77003312, 1G770-03310, 1G77003310, 6684758 применяемость: Kubota V2003, V2003-T, V2003T Head gasket Kubota …

в наличии

495.00 бел.руб.

.

|

| [English] | [Français] | [Español] | [Deutsch] | [Italiano] | [Português] |

Download

Kubota Diesel Engines: owner’s, service and maintenance manuals, error codes list, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

| Title | File Size | Download Links |

| Kubota 03-M-E3B SERIES / 03-M-DI-E3B SERIES / 03-M-E3BG SERIES Diesel Engine Workshop Manual [PDF] | 2.9Mb | Download |

| Kubota 05-E2B / G Series Diesel Engine Workshop Manual [PDF] | 3.6Mb | Download |

| Kubota 05-Series Diesel Engine Workshop Manual [PDF] | 6.9Mb | Download |

| Kubota D1005-E3BG / D1305-E3BG / D1105-E3BG / V1505-E3BG Diesel Engine Operator’s Manual [PDF] | 946.5kb | Download |

| Kubota D1703-M-BG [PDF] | 146.1kb | Download |

| Kubota Dl-105-BG2-SAE-1 / 2 Diesel Engine Workshop Manual [PDF] | 2.5Mb | Download |

| Kubota Engine Model Identification [PDF] | 66.3kb | Download |

| Kubota Engine Parts Manual [PDF] | 2.8Mb | Download |

| Kubota KND2800 / 3200 Diesel Engine Workshop Manual [PDF] | 13.9Mb | Download |

| Kubota V2607-DI-T-E3-B / V3307-DI-T-E3-B Diesel Engine Operator Manual [PDF] | 1.8Mb | Download |

| Kubota V3300-E2B,V3300-T-E2B Diesel Engine Workshop Manual [PDF] | 4Mb | Download |

| Kubota V3600-E3, V3600-T-E3, V3800-DI-T-E3, V3300-E3BG, V3600-T-E3BG Diesel Engine Operator Manual [PDF] | 6.8Mb | Download |

| Kubota Z402-B Aixam-1 Diesel Engine Parts Manual [PDF] | 1.7Mb | Download |

| Kubota Z482 Diesel Engine Workshop Manual [PDF] | 9.6Mb | Download |

| Kubota Z482E, Z602E, D662E, D722E, D782E, D902E Diesel Engine Workshop Manual [PDF] | 6.2Mb | Download |

In 1923, Kubota introduced engines to its extensive product line when it investigated and created its first 3-horsepower Type A industrial engine.

The original Kubota high-performance, small, and lightweight engines have gained a high degree of confidence in the worldwide market, despite the company’s continued expansion of its line of engines. Currently, demand is highest for compact Kubota diesel engines with a maximum output of 86.4 kW. In addition, they are small, able to function in challenging environments, and highly maintainable. Due to these qualities, Kubota sells its engines to various factories that manufacture various types of machinery and diesel power plants.

Three plants in Japan, the Sakai Rinkai Plant, Sakai Plant, and Tsukuba Plant, have had ISO 9002 quality management system certification since 1994 and are where Kubota engines are made. KUBOTA Corporation employs the most cutting-edge technology solutions and automated systems to create its goods, including robotic product assembly and quality control, which fully removes the impact of the human component.

KUBOTA SUPER MINI

For small enterprises, Kubota Super MINI diesel engines are the best option.

Kubota. The features of Kubota Super MINI diesel engines are wonderful craftsmanship and build quality, remarkable power, and amazing longevity. For many years, experts in Japan have been creating and enhancing diesel engines, and they have had incredible commercial success. As a result, products from Kubota are well-liked and in high demand worldwide.

Compact liquid-cooled engines are available in the trim line. So the maker could keep the device’s tiny dimensions and incredibly lightweight while combining unmatched quality and power in these variants, adequate for light industrial use.

Diesel Kubota Super MINI engines come with 2 or 3 cylinders depending on the model. They are competent to do the responsibilities and completely satisfy the demands of a bit of power. Moreover, diesel engines are quite simple to maintain and fix.

Kubota D902 diesel engine

The dependable Kubota D902 diesel engine is appealing due to its small size, low fuel consumption, and low emissions. In addition, high-quality components guarantee the motors’ reliability, and the straightforward design reduces the cost of maintenance.

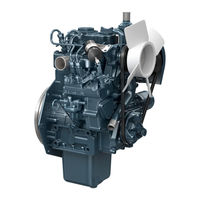

Kubota D722 diesel engine

The Kubota D722 small diesel engine meets the Tier 4 environmental criteria with a vortex combustion chamber. The engine stands out for its high level of dependability, lightweight, and alluring large resource. The engine requires less maintenance and uses little gasoline.

Kubota D722

Kubota Z602 diesel engine

Among the Japanese manufacturer’s 2-cylinder small engines, the practical diesel engine Kubota Z602 is the most potent. By expanding the piston diameter, it was feasible to enhance the practical qualities. It provides excellent thermal load protection and less hazardous emissions.

Kubota Z482 diesel engine

Trustworthy diesel engine The Kubota Z482’s combustion chamber is tuned. The motors differ between profitability, compact construction, and extended operational life. The engine is utilized in the creation of small equipment and functions well in mototops and electric generators.

KUBOTA SUPER 03-M

Diesel engines of Kubota Super 03-M are essential for the machinery to operate well.

The diversity of these engines is astounding. These units’ primary function is to outfit renowned brands’ generators, power plants, and specialized industrial equipment.

The top producer of small, medium and high-power diesel engines is Kubota. The manufacturer’s goods outperform analogs and competing models because of their unmatched quality, astounding compactness, and extended lifespan.

What constitutes the cause of success? It all comes down to having a deep affection for the enterprise you work so hard to build over many years into the ideal engine. Diesel engines like the Kubota Super 03-M are extremely near to this ideal.

Depending on the level of completion, the engines in this series have 3 or 4 cylinders. A 44 kW power output from the displacement engine is enough for big technological facilities, including industrial generators.

These powerful diesel engines are surprisingly light—less than 200 kg. They are quite straightforward and simple to maintain, and independent repairs are possible in the case of failure.

Kubota D1503-M diesel engine

The Kubota D-1503 M is a small diesel engine with good performance, efficiency, and few hazardous emissions. Modern wear-resistant materials were used to make all the key parts, which increased the unit’s resources. Throughout the duration of its service life, the engine operates steadily.

Kubota D1703-M diesel engine

The Kubota D-1703 M diesel engine is very effective, has a small footprint, and is ecologically friendly. The level of hazardous emissions has decreased because of the redesigned vortex chamber. The engine successfully resists large heat loads while operating with minimal noise and vibration levels.

Kubota D1803-M diesel engine

The Kubota D-1803 M diesel engine is a dependable and useful engine with a small size and lightweight. It is distinguished by an operational stability and the capacity to sustain heavy loads for an extended period of time. The engine works with minimal noise and vibration uses little fuel, and is ecologically beneficial.

Kubota V2203-M diesel engine

The contemporary Kubota V-2203 M diesel engine is small in size and operates quietly. A high-performance motor that complies with all environmental regulations. An efficient cooling system ensures work stability, and direct infusion ensures efficiency.

Kubota V2403-M diesel engine

The Kubota V-2403 M is a strong diesel engine with a small size. Installed on expert power generators and used as a drive for industrial machinery. The motor has minimal amounts of hazardous pollutants, operates quietly, and is inexpensive.

Kubota V2403-M-T diesel engine (Turbo)

The most productive engine in the model range is the strong Kubota V-2403 M-T turbocharged diesel engine. The motor is very dependable and uses little gasoline. The engine conforms fully with the strictest environmental criteria for power units and operates quietly with little vibration.

KUBOTA SUPER 05

Diesel Kubota Super 05 engines are a crucial component of industrial machinery.

The Kubota Super 05 diesel engines are well-designed and have a long service life in addition to high power, good quality, small size, and lightweight.

Low noise and vibration levels, as well as the most effective fuel combustion, set apart this model line. Depending on the level of completion, the four-stroke engine has 3 or 4 cylinders. It has a low fuel consumption rate, and the engine’s three-vortex combustion chamber assures practically full diesel combustion.

Industrial machinery can be powered by Kubota Super 05 diesel engines, as well as generators and stations from different suppliers. Considering their tiny size, they operate with incredible efficiency. The devices that are being shown can produce power up to 33 kW while weighing up to 140 kg. Moreover, the motors’ straightforward and sensible design makes it easy to do self-maintenance and, if required, repairs.

Kubota D1005 diesel engine

Electric generators and motor pumps are intended for the small Kubota D1005 diesel engine. The motor has the lowest emissions for its class, low noise and vibration levels, and efficiency. In addition, the engine is lightweight, has a straightforward design, and is appealing due to its dependability.

Kubota D1105 diesel engine

The practical Kubota D1105 diesel engine features a small, light construction that makes installation much easier. The three-vortex chamber ensures complete fuel combustion, which is a warranty for efficiency and low emissions. The engine produces low amounts of vibration and noise.

Kubota D1105-T diesel engine (Turbo)

Due to its small size, the Kubota D1105-T’s strong turbocharged diesel engine is the ideal option for industrial pumps and generators. The motor satisfies the strictest international environmental requirements while using minimal gasoline.

Kubota D1305 diesel engine

The dependable Kubota D1305 diesel engine’s longer piston stroke improved power substantially without enlarging or adding weight to the engine. Under heavy loads, the cooling circuit guarantees reliable functioning. The low level of noise and vibration and profitability of the motor is different.

Kubota V1505-T (Turbo) Engine

The Kubota V1505-T turbocharged diesel engine is notable for its great power, efficiency, and usefulness. It is small, quiet, and vibration-free. Tier 4 environmental criteria, among others, are complied with thanks to the sophisticated swirl chamber.

KUBOTA SUPER 07

The Kubota 07 series engine is a completely new approach to engine design that has been created to satisfy the various demands of engines used in a range of industrial applications.

Utilizing Kubota’s innovative foundry technology, the distinctive cylinder block design produced a greater displacement while preserving the 2.4L engine’s overall proportions.

The engine is protected from thermal stress by a sophisticated liquid cooling system with a main channel and inter-cylinder ducts, assuring great power density, longevity, and dependability of Kubota 07 series engines.

Kubota V3307 DI-T diesel engine

One of the Japanese manufacturer’s most powerful engines in the model lineup is the practical diesel engine Kubota V3307 DI-T. Its small size, low cost, and environmental friendliness make it the most widely applicable. In addition, low maintenance expenses are guaranteed by the engine’s straightforward design.

Kubota V2607 DI-T diesel engine

The powerful and portable Kubota V2607 DI-T diesel engine includes an injection system with higher pressure. As a result, the motor is more efficient and powerful, and the improved swirl chamber guarantees minimal levels of hazardous pollutants. In addition, low amounts of vibration and noise are produced by the engine.

KUBOTA V3 3300

Diesel engines from the Kubota Series V3 3300 are a helpful helper in industrial settings.

Equipment that is robust is needed for industrial applications. The pinnacle of dependability, high performance, and steady operation for the course of their service lives are Kubota Series V3 3300 diesel engines.

Diesel engines with a combined volume of around 3300 cubic meters are combined in the series that is being shown. They stand out for having tremendous power ranging from 35 to 60 horsepower while still being reasonably light at 260 kg. Kubota’s corporate brand excellently combines performance and compactness.

Kubota Series V3 3300 diesel engines are made to power specialized and small-profile production machinery as well as expansive industrial operations. Moreover, Kubota engines are really simple to maintain and simple to fix because of the validated and exact equipment.

Kubota V3300T (Turbo) Diesel engine

The Kubota V3 3300T (turbo) tiny diesel engine includes an improved swirl chamber and a direct injection system. Efficiency, low levels of toxic pollutants, and a long lifespan make the motor appealing. In addition, the thermal load protection mechanism on the engine is efficient.

Kubota V3300 diesel engine

The Kubota V3 3300 tiny diesel engine has an improved swirl chamber and direct injection. Efficiency, low levels of toxic pollutants, and a long lifespan make the motor appealing. In addition, the thermal load protection mechanism on the engine is efficient.

KUBOTA V3 3600

Diesel engines from the Kubota Series V3 3600 are a useful addition to industrial enterprises.

Equipment that is robust and strong is needed for industrial applications. The pinnacle of dependability, high performance, and stable operation for the course of their service lives are Kubota Series V3 3600 diesel engines.

Diesel engines with a combined volume of around 3600 cubic meters are combined in the series that is being shown. They stand out for having considerable power ranging from 66 to 85 hp and a comparatively light weight of up to 250 kg. Kubota’s corporate brand combines performance and compactness in an excellent way.

Diesel engines from the Kubota Series V3 3600 are intended for use in specialized and narrow-profile manufacturing machinery as well as in big industrial facilities. Kubota engines are really simple to maintain and simple to fix because of the validated and exact equipment.

Kubota V3600-T diesel engine (Turbo)

A turbocharger is included with the potent Kubota V3 3600-T diesel engine’s V-shaped design. A direct injection system lowers fuel consumption, and a tailored combustion chamber lowers the number of hazardous pollutants. The engine is lightweight, highly efficient, and has a compact construction.

Kubota V3600 diesel engine

The Kubota V3 3600 tiny diesel engine has an improved swirl chamber and direct injection. Efficiency, low levels of toxic pollutants, and a long lifespan make the motor appealing. In addition, the thermal load protection mechanism on the engine is efficient.

KUBOTA V3 3800

The diesel engines in the series on display have a capacity of around 3800 cubic meters. They stand out for having high power ranging from 81.5 to 97.6 hp and a reasonably lightweight of no more than 267 kg. Kubota’s corporate brand excellently combines performance and compactness.

Through the end of 2011, Kubota V3800 turbocharged direct injection engines in North America and Europe will meet EPA Interim Tier 3 and EU Stage 3A exhaust pollution regulations.

Nitrogen oxide (NOx) emissions are only reduced mechanically, such as the compact cooled exhaust gas recirculation (EGR) system, and compliance with environmental regulations is achieved with the least amount of extra devices necessary.

Kubota V3800 DI-T diesel engine (Turbo)

The turbocharger is part of the Kubota V3800 DI-strong T’s and small diesel engine. High performance and widespread usage of the motor as a drive for industrial machinery. The engine is affordable, quiet and vibration-free, ecologically beneficial, and modest.

Kubota D722-E2B Diesel Engine Service Manual

INCLUDES: Kubota D722-E2B Diesel Engine Service Manual

140 pages in .pdf format

5.8 MB in .zip format for super fast downloads!

This factory Kubota Tractor Service Manual Download will give you complete step-by-step information on repair, servicing, and preventative maintenance for your Kubota. The Kubota Workshop Manual is highly detailed with photos and illustrations to help guide you through every repair and troubleshooting procedure. This repair manual contains all you need to know to keep your Kubota tractor, mower, or excavator working right and is the only service repair manual you will need. It will help you understand, care for, and lower the repair and maintenance cost for your Kubota.

This KUBOTA D722-E2B Diesel Engine service manual is the same service manual used by professional Kubota technicians.

This factory Kubota manual is a fully indexed and searchable pdf file. All pages are printable, so you can easily print what you need and take it with you into the garage or workshop. Save money $$ by doing your own service and repairs! These Kubota Manuals make it easy for any skill level with these very easy to follow, step-by-step instructions! Instant Download means no shipping cost or waiting for a CD to arrive in the mail… you will receive this Kubota Manual immediately via instant download on completion of payment via our secure payment processor. We accept all major credit/debit cards/paypal.

Take advantage of our online sale and download your Kubota manual for 50% off the printed dealer price!

manuals.ltd

manuals.ltd