File Specifications:1434/1434570-versys_1000.pdf file (26 Feb 2023) |

Accompanying Data:

Kawasaki VERSYS 1000 Motorcycle PDF Service Manual (Updated: Sunday 26th of February 2023 11:00:22 AM)

Rating: 4.1 (rated by 49 users)

Compatible devices: NINJA 6502014, Vulcan 1500 Classic Fi, Voyager XII, KLX450R -, KX450F 2013, klx450, Z800 ABS, VN900.

Recommended Documentation:

Service Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the Kawasaki VERSYS 1000 Document (Main Content), UPD: 26 February 2023)

-

647, ELECTRICAL SYSTEM 16-87 Immobilizer System (Equipped Models) If there is any problem in the registration, the red warning indicator light (LED) and immobilizer warning indicator [A] blink to display the collation error. Immobilizer Amplifier Failure When Registered Ignition Key is Inserted. Ignition Key Collation Error • The ignition key 1 is successfully registered in the ECU. The red warning indicator light (L…

-

194, Kawasaki VERSYS 1000 3-104 FUEL SYSTEM (DFI) Purge Valve (Service Code 3A) (DTC P0443) (Other than US, CA, ID and SEA-B2 Models) Purge Valve Removal/Installation • Remove: Upper Fairing (see Upper Fairing Removal in the Frame chapter) Nut [A] • Remove the purge valve from the bracket. • Disconnect the purge valve lead connector [B]. • Slide the clamps [C]. • Disconnect the hoses [D]. • Installation is the reverse of removal. • Run the hoses correctly (…

-

173, FUEL SYSTEM (DFI) 3-83 Oxygen Sensor (Service Code 33) (DTC P0130, P0132) Oxygen Sensor Inspection (Service Code 33/DTC P0132) (Checking wire for short circuit to power supply wire) • Remove: Oxygen Sensor Lead Connector (see Oxygen Sensor Removal in the Electrical System chapter) • Connect the measuring adapter [A] between the harness connector and oxygen sensor. Main Harness [B] Oxygen Sensor [C] Special Tool — Measuring Adapter: 57001-1700 • Connect a digital meter [D] …

-

592, 16-32 ELECTRICAL SYSTEM Charging System If using the rotor holder (57001-1757). • Hold the alternator rotor steady with the rotor holder [A]. • Remove the rotor bolt [B] and washer. Special Tool — Rotor Holder: 57001-1757 • Using the flywheel puller [A], remove the alternator rotor [B] from the crankshaft. Special Tool — Flywheel Puller Assembly, M38 × 1.5/M35 × 1.5: 57001-1615 NOTICE Do not attempt to strike the alternator rotor itself. Striking the rotor can cause …

-

475, BRAKES 12-53 Anti-Lock Brake System • Visually inspect the connector terminals [A]. Replace the ABS hydraulic unit or main harness if either of the terminals are cracked, bent, or otherwise damaged. If the ABS hydraulic unit connector is clogged with mud or dust, blow it off with compressed air. Front Wheel Rotation Sensor Removal NOTICE The wheel rotation sensor should be handled care- fully, never struck sharply, as with a hammer, or al- lowed to fall on a hard surface since the wheel rota-…

-

47, PERIODIC MAINTENANCE 2-25 Periodic Maintenance Procedures Cooling System Coolant Level Inspection NOTE ○ Check the level when the engine is cold (room or ambi- ent temperature). • Check the coolant level in the reserve tank [A] with the motorcycle held perpendicular (Do not use the side stand). If the coolant level is lower than the “L” level line [B], re- move the right fuel tank cover (see Fuel Tank Cover Re-…

-

354, Kawasaki VERSYS 1000 9-8 CRANKSHAFT/TRANSMISSION Special Tools and Sealants Bearing Puller: 57001-135 Outside Circlip Pliers: 57001-144 Bearing Puller Adapter: 57001-317 Bearing Driver, 32: 57001-382 Bearing Driver Set: 57001-1129 Flywheel Holder: 57001-1313 Liquid Gasket, TB1216B: 92104-1064 Liquid Gasket, TB1207B: 92104-2068

… -

669, ELECTRICAL SYSTEM 16-109 Relay Box The relay box [A] has relays and diodes. The relays and diodes can not be removed. Relay B ox Removal/Installation NOTICE Never drop the relay box especially on a hard sur- face. Such a shock to the relay box can damage it. • Remove the fuel tank (see Fuel Tank Removal in the Fuel System (DFI) chapter). • Disconnect: Connectors [A] • Remove the ECU bracket screws [B]. • Lift up the relay box [C] with rubber protector [D]. • Remove the relay box [A…

-

368, 9-22 CRANKSHAFT/TRANSMISSION Crankshaft and Connecting Rods Connecting Rod Big End Bearing Insert/Crankpin Wear Inspection • Remove the connecting rod big end (see Connecting Rod Removal). • Cut strips of plastigage (press gauge) to crankpin width. Place a strip on the crankpin parallel to the crankshaft installed in the correct position. • Tighten the connecting rod big end nuts to the specified torque (see Connecting Rod Installation). NOTE ○ Do not mo…

-

249, COOLING SYSTEM 4-23 Hose and Pipes Hose Installation • Install the hoses and pipes, being careful to follow bend- ing direction. Avoid sharp bending, kinking, flattening or twisting. • Run the hoses (see Cable, Wire, and Hose Routing sec- tion in the Appendix chapter). • Install the clamp [A] as near as possible to the hose end to clear the raised rib of the fitting. This will prevent the hoses from working loose. …

-

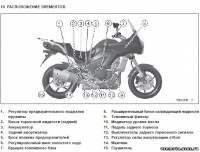

320, 7-4 ENGINE LUBRICATION SYSTEM Engine Oil Flow Chart 1. Balancer Oil Passage 2. Camshaft Oil Passage 3. Crankshaft Oil Passage 4. Drive Shaft Oil Passage 5. Output Shaft Oil Passage 6. Oil Pump 7. Oil Pipe 8. Oil Screen 9. Oil Pressure Relief Valve 10. Oil Filter 11. Oil Pressure Switch 12. Main Oil Passage 13. Engine Oil 14. Blowby Gas

… -

469, BRAKES 12-47 Anti-Lock Brake System • Recheck the service code indication; erase the service code, perform the pre-diagnosis inspection 1 and 2, and retrieve the s ervice code. If the yellow ABS indicator light (LED) [A] lights, the ABS hydraulic unit has trouble. Replace the ABS hydraulic unit. If the yellow ABS indicator light (LED) does not light, ABS system is normal (service code is not stored; tempo…

-

Kawasaki VERSYS 1000 User Manual

-

Kawasaki VERSYS 1000 User Guide

-

Kawasaki VERSYS 1000 PDF Manual

-

Kawasaki VERSYS 1000 Owner’s Manuals

Recommended: KH 1024, NETWARE 6-DOCUMENTATION, uMusic System, 790.7887 Series

Links & Tools

Operating Impressions, Questions and Answers:

Service Manual, KLZ100B

Item # 99924-1487-04

MSRP

$89.95

Kawasaki service manuals contain enough detail and basic information to make them useful to the owner who desires to do his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out the work satisfactorily.

Most items ship to dealer within 5-7 business days for free. Special dealer only items may be excluded.

Additional shipping charges apply to qualified ship to home orders.

Price and specifications are subject to change without notice or liability. Availability is subject to production, stocking and demand. Manufacturers suggested retail prices shown.

- WARRANTY INFORMATION

Table of Contents for Kawasaki VERSYS 1000:

-

FUEL SYSTEM (DFI) 3-45 Self-Diagnosis Service Code DTC (Diagnostic Trouble Code) System Problems P0115 Water temperature sensor malfunction, wiring open or short to power supply wire 14 P0117 FI Water temperature sensor malfunction, wiring short to ground P2226 Intake air pressure sensor #2 malfunction, wiring open or short to power supply wire P2227 Intake air pressure sensor #2 malfunction 16 P2228 FI/KTRC Intake air pressure sensor #2 malfunction, wiring short to ground 21 P0335 FI/KTRC Crankshaft sensor malfunction, wiring open or short 24 P2158 FI/KTRC Rear wh

-

STEERING 14-11 Handlebar Handlebar Removal • Remove: Clamp [A] Clutch Lever Holder Clamp Bolts [B] Clutch Lever Holder [C] Left Switch Housing [D] Handlebar Weight [E] Handlebar Grip [F] • Remove: Front Master Cylinder [A] (see Front Master Cylinder Re- moval in the Brakes chapter) Clamp [B] Right Switch Housing [C] Handlebar Weight [D] Throttle Grip [E] • Remove: Handlebar Holder Bolts [A] Handlebar Holders [B] Handlebars [ C] • Remove: Guide Bolts [A] Guides [B]

-

FUEL SYSTEM (DFI) 3-9 Exploded View Torque No. Fastener N·m kgf·m ft·lb Remarks 1 Fuel Tank Cap Bolts 4.5 0.46 40 in·lb 2 Fuel Tank Bolts 8.0 0.82 71 in·lb 3 Fuel Tank Bracket Bolts 8.0 0.82 71 in·lb 4 Fuel Pump Bolts 10 1.0 89 in·lb L, S 5 Canister Bracket Bolts 6.9 0.70 61 in·lb 6. US, CA, ID and SEA-B2 Models 7. Other than US, CA, ID and SEA-B2 Models 8. Canister 9. Purge Valve L: Apply a non-permanent locking agent. R: Replacement Parts

-

Part No.99924-1487-01 MODEL APPLICATION Year Model Beginning Frame No. 2015 KLZ1000BF JKALZCB1FA000001 JKALZT00BBA000001 :This digit in the frame number changes from one machine to another.

-

FUEL SYSTEM (DFI) 3-103 Oxygen Sensor Heater (Service Code 67) (DTC P0030) Oxygen Sensor Circuit 1. ECU 2. Frame Ground 2 3. Engine Ground 4. Battery 12 V 8 Ah 5. Main Fuse 30 A 6. ECU Fuse 15 A 7. Starter Relay 8. Relay Box 9. ECU Main Relay 10. Fuse Box 1 11. Ignition Fuse 15 A 12. Ignition Switch 13. Oxygen Sensor

-

COOLING SYSTEM 4-11 Water Pump Water Pump Removal • Drain: Coolant (see Coolant Change in the Periodic Mainte- nance chapter) Engine Oil (see Engine Oil Change in the Periodic Main- tenance c hapter) • Remove: Engine Sprocket Cover (see Engine Sprocket Removal in the Final Drive chapter) • Remove the water pipe bolts [A], and disconnect the water pipes [B]. • Remove: Water P ump Cover Bolts [A] Clamp [B] Water Pump Cover [C] • Remove: Water Pump Impeller Bolt [A] and Washer Water Pump Impeller [B] Dowel Pins [C] • Remove the water

-

ELECTRICAL SYSTEM 16-111 Relay Box Relay Box Internal Circuit A: Headlight Circuit Relay B: ECU Main Relay C: Fuel Pump Relay D: Starter Circuit Relay E: Fan Relay

-

PERIODIC MAINTENANCE 2-5 Torque and Locking Agent The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc. All of the values are for use with dry solvent — cleaned threads unless otherwise indicated. Letters used in the “Remarks” column mean: AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque. G: Apply grease. L: Apply a non-permanent locking agent. LG: Apply liquid

-

16-58 ELECTRICAL SYSTEM Lighting System • Install the hook [A] and connect the connector [B] to the headlight bulb. • Fit the dust cover [A] onto the headlight housing with its lead toward downward. • After installation, adjust the headlight aim (see Headlight Aiming Inspection in the Periodic Maintenance chapter). Headlight Removal/Installation • Remove: Upper Fairing (see Upper Fairing Removal in the Frame chapter) • Open the clamps [A] on both sides. • Remove: Headlight Bolts [A] and Wa

-

FUEL SYSTEM (DFI) 3-97 Subthrottle Valve Actuator (Service Code 62) (DTC P2100) Subthrottle Valve Actuator Removal NOTICE Do not remove the subthrottle valve actuator [A] since it has been adjusted and set with precision at the factory. Never drop the throttle body assy especially on a hard surface. Such a shock to the subthrottle valve actuator can damage it. Subthrottle Valve Ac tuator Inspection (Checking wire for open circuit) • Remove: Air Cleaner Housing (see Air Cl

-

FUEL SYSTEM (DFI) 3-47 Self-Diagnosis Service Codes Parts or Function Output Signal Usable Range or Criteria Backups by ECU 21 Crankshaft Sensor Crankshaft sensor must send 22 signals to the ECU at the 1 cranking. If the crankshaft sensor fails, the engine stops by itself. 24 Rear Wheel Rotation Sensor Rear wheel rotation sensor must send 45 signals to theECUatthe1rotationof the wheel. If the rear wheel rotation sensor system fails (the signal is missing, wiring open

-

2-16 PERIODIC MAINTENANCE Periodic Maintenance Procedures Fuel System (DFI) Air Cleaner Element Replacement NOTE ○ In dusty areas, the element should be replaced more frequently than the recommended interval. WARNING If dirt or dust is allowed to pass through into the throttle body assy, the throttle may become stuck, possibly causing accident. Replace the air cleaner element according to the maintenance chart. NOTICE If dirt gets through i

-

SUSPENSION 13-25 Rear Shock Absorber • Remove: Rear Shock Absorber Nut and Bolt (Lower) [A] Rear Shock Absorber Bolt (Upper) [B] • Remove the rear shock absorber [C] from rearside. • Turn up the heat insulation rubber plate. • Remove the rear shock absorber nut (upper) [A]. Rear Shock Absorber Installation • Replace the rear shock absorber nuts with new ones. • Install the rear shock absorber nut (

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Kawasaki VERSYS 1000 device using right now.

Материал из Enduro.team

Перейти к: навигация, поиск

Kawasaki Versys 1000

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Kawasaki Versys 1000 (KLE1000)

- Сервисный мануал (Service Manual) на Kawasaki Versys 1000 (2011)

- Мануал по крепежам для Kawasaki Versys 1000

- Руководство пользователя (Owners Manual) для Kawasaki Versys 1000 (на русском)

Обзор модели

- Kawasaki Versys 1000

Категории:

- Сервисная документация

- Kawasaki документация

Меню сайта

-

Мотообъявления

-

Мануалы скачать

-

Мануалы читать

-

Обратная связь

-

Гостевая книга

-

Мотоновости

-

Фотоальбом

-

Микрофиши

-

Мотостатьи

| Поиск по сайту |

| Категории раздела | ||||||||||||||||||

|

| Статистика |

|

Онлайн всего: 1 Онлайн гостей: 1 Онлайн пользователей: 0 |

| Наш опрос |

|

В поездке документы на Ваш мотоцикл находятся Дома В кармане В мотоцикле Нет документов [ Результаты · Архив опросов ] Всего ответов: 253 мануалы для:[ИЖ П] |

|

|

|

Суббота, 23.09.2023, 15:08 Приветствую Вас Гость | RSS | Вход |

| Все мото здесь!!! | |||

|

| Главная » Файлы » KAWASAKI |

VERSYS1000

[  СКАЧАТЬ БЕСПЛАТНО МАНУАЛ ДЛЯ KAWASAKI VERSYS1000 (5.73 Mb) СКАЧАТЬ БЕСПЛАТНО МАНУАЛ ДЛЯ KAWASAKI VERSYS1000 (5.73 Mb)

] |

10.04.2016, 13:50 |

Название: Руководство по эксплуатации Kawasaki VERSYS1000  Автор: Производитель Формат: pdf Размер: 5,7 МБ Качество: Хорошее Язык: Русский Жанр: Мото-мануал Издательство: Напечатано в Таиланде Страниц: 197 Год издания: 2011 Описание: Руководство по обслуживанию и эксплуатации мотоцикла Кавасаки VERSYS1000 на русском языке. |

|

Категория: KAWASAKI | Добавил: Talabas07 |

|

| Просмотров: 1483 | Загрузок: 81

| Рейтинг: 0.0/0 |

Похожие файлы:

- ZZR 600 (400)

- ER-6f

- ER-6n

- KLX250

- Ninja 250R

- Ninja 300

- Ninja ZX-10R

- Z750R

- Z800

- Z1000SX

- ZZ-R1100

- Kawasaki

| Всего комментариев: 0 | |

Войдите: