-

Bookmarks

Quick Links

Service

Service

Manual

Manual

3CX, 4CX,

3CX, 4CX,

& Variants

& Variants

From M/c No. 400001 To 460000

From M/c No. 400001 To 460000

Publicación No. 9803/3260 Issue 9

Publicación No. 9803/3260 Issue 9

General Information

General Information

Car r e e & & Sa

Ca

Safe fety ty

Routine Maintenance

Routine Maintenance

Attachments

Attachments

Body & Framework

Body & Framework

Electrics

Electrics

Controls

Controls

Hydraulics

Hydraulics

Transmision

Transmision

Brakes

Brakes

Engine

Engine

1 1

2 2

3 3

A

A

B B

C C

D D

E E

F F

G G

K

K

Summary of Contents for jcb 3CX

This manual is also suitable for:

4cx

JCB 3CX/4CX Eco Backhoe Loader PDF Specification

JCB 3CX,4CX Eco Backhoe Loader PDF Speci

Adobe Acrobat Document

8.5 MB

JCB 3CX/4CX/214/214e/215/217 PDF Service Manual

JCB 3CX_4CX_214_214e_215_217 PDF Service

Adobe Acrobat Document

37.4 MB

JCB Fastrac Service Manual PDF

Fastrac 3170, 3170 Plus, 3190, 3190 Plus, 3200, 3200 Plus, 3220, 3220 Plus, 3230, 3230 Plus

JCB Fastrac Service Manual PDF.pdf

Adobe Acrobat Document

544.8 KB

JCB 3CX/4CX Wiring Diagrams

JCB 3CX_4CX Wiring Diagrams.pdf

Adobe Acrobat Document

10.7 MB

JCB 354/360 PDF Service Manual

JCB 354_360 PDF Service Manual.pdf

Adobe Acrobat Document

1’016.5 KB

JCB 175 Electrical Wiring Diagram

JCB 175 Wiring Diagram.pdf

Adobe Acrobat Document

676.7 KB

JCB 220 Schematic Diagram

JCB 220 Schematic Diagram.pdf

Adobe Acrobat Document

247.0 KB

The lineup of JCB backhoe loaders is represented by 10 basic models of machines made in more than 30 variations. The line starts with small models of Mini CX and 1СХ and ends

with large powerful models of 4 CX, 4СХ Super and released in 2012 5CX. If we talk about machines introduced before 2012, then their power varies from 15 to 75 kW, the depth of digging is within

2.54-6.14 meters. Backhoe loaders can reach speeds of up to 40 km / h, while the mass of these machines is between 2.8 and 8.5 tons.

Backhoe loader JCB 5CX, the most powerful model in the company’s lineup, has wheels of the same size and four-wheel drive. The machine has a 120 hp engine. standard Tier 2.

JCB backhoe loaders can additionally be equipped with attachments, which significantly expands the scope of these machines. The list of replacement equipment for JCB backhoe

loaders is quite large. It includes more than 40 types of buckets intended for excavating attachments, hydraulic hammers, front buckets of different capacity and design (including with

side tipping), buckets for special work, road mills, equipment for digging trees, drills, road brushes with a width from 150 to 1100 mm, scrapers, seals, mowers, trenchers and grippers. There is

also a large assortment of hand-held equipment that connects to the hydraulic system of the backhoe loader: drills, jackhammers, perforators, water pumps and disk cutters. These tools can work in

parallel with the excavator. The standard JCB backhoe loader system allows the use of other manufacturers’ equipment.

Also, JCB backhoe loaders can be equipped with special tools developed by JCB specialists, such as a system for compensating for vibrations during travel, a mechanism for

hydraulically moving the excavator rig, a mechanism for telescopic extension of the handle, adjustable slip cushions for outriggers.

- JCB 3CX 4CX PDF Service Manuals

- JCB 3CX 4CX ECO 2010 Operator’s manual for the backhoe loader

- JCB 3CX PDF Service Manual

- JCB 3CX,4CX Eco Backhoe Loader PDF Specification

- JCB 4CX PDF Service Manual

- JCB 214 PDF Service Manual

- JCB 214e PDF Service Manual

- JCB 215 PDF Service Manual

- JCB 217 PDF Service Manual

- JCB 354 PDF Service Manual

- JCB 360 PDF Service Manual

- JCB 444 Mechanical Engine PDF Service Manual

- JCB 444 Mechanical PDF Manual

- JCB Fastrac 3170 PDF Service Manual

- JCB Fastrac 3170 Plus PDF Service Manual

- JCB Fastrac 3190 PDF Service Manual

- JCB Fastrac 3190 Plus PDF Service Manual

- JCB Fastrac 3200 PDF Service Manual

- JCB Fastrac 3200 Plus PDF Service Manual

- JCB Fastrac 3220 PDF Service Manual

- JCB Fastrac 3220 Plus PDF Service Manual

- JCB Fastrac 3230 PDF Service Manual

- JCB Fastrac 3230 Plus PDF Service Manual

Operation, maintenance and repair manual + expendable parts catalog for backhoe loaders, electrical diagrams, error codes, troubleshooting,

The publication contains an operating manual, detailed information on the maintenance of the machine (including machine lubrication maps), repair and adjustment of engine system elements

(including the diesel engine fuel system, lubrication, cooling, starting and charging systems), manual gearbox (Synchro Shuttle), automatic transmissions (Powersoft 4 and 6-speed), steering

(models 2WS and 4WS), front and rear axles of various modifications (SD55, SD70, PD70, SD70, SD80), brake mechanisms , hydraulic mechanisms and elements of hydraulic control of various systems of

a loader, excavator, hydraulic cylinders, etc.

Service Repair Manuals

JCB Fastrac 3170 PDF

Service Manual

3170, 3170 Plus

3190, 3190 Plus

3200, 3200 Plus

3220, 3220 Plus

3230, 3230 Plus

JCB JS200 Service Repair

Manual

JS200

from machine no. 705001

JS210

from machine no. 705648

JS220

from machine no. 705001

JS240

from machine no. 708001

JS260

from machine no. 708501

JCB 3CX, 4CX, 214e, 214, 215, 217 & Variants Service Manual

JCB-Introduction Download

JCB-General Information Download

JCB-Care & Safety Download

JCB-Routine Maintenance Download

JCB-Attachments Download

JCB-Body & Framework Download

JCB-Electrics Download

JCB-Controls Download

JCB-Hydraulics Download

JCB-Transmission Download

JCB-Brakes Download

JCB-Steering Download

JCB-Engine Download

JCB-Crawler Excavator JS330NLC JS330LC JS330XD Owner Parts Book Download

JCB-Excavator Js200 260 Electrical System Manual Download

JS-Auto Range — Tracked Excavators -JCB Engine JS115 JS130 JS145 JS160 JS180 JS200 JS210 JS220 Service Manual Download

JCB-Telescopic 530, 532, 533, 535, 537,540 Operator Handbook Download

JCB-220 Schematic Diagram Download

JCB-3CX/4CX Wiring Diagrams Download

JCB-ROUGH TERRAIN FORKLIFTS 930/940 Spec Sheet Download

JCB-LOADALL 508C Download

JCB-ROBOT SKID STEERS 160/170 Download

JCB-3CX/4CX Eco Backhoe Loader PDF Specification Download

JCB-3CX/4CX/214/214e/215/217 PDF Service Manual Download

JCB-354/360 PDF Service Manual Download

JCB-Fastrac Service Manual Download

JCB-175 Electrical Wiring Diagram Download

JCB-Engine Tier II Parts 9802/2910 -JCB444 4 Cylinder Download

JCB-3CXSM Sideshift 460001on Owner Parts Book Download

JCB-Generator Brochure Download

JCB 1CX 751600 to 752999 Operators Manual Download

Troubleshooting/fault code,error kode JCB Excavator JS 200 JS 210 JS 220 JS 240 JS 260 Download

JCB Product Support Laptop Based Diagnostic Tool Manual Download

JCB Electrical Wiring Diagrams

JCB 175 Wiring Diagram Download

JCB 220 Schematic Diagram Download

JCB 175 Schematic Diagram Download

Interesting facts about the company and technology JCB

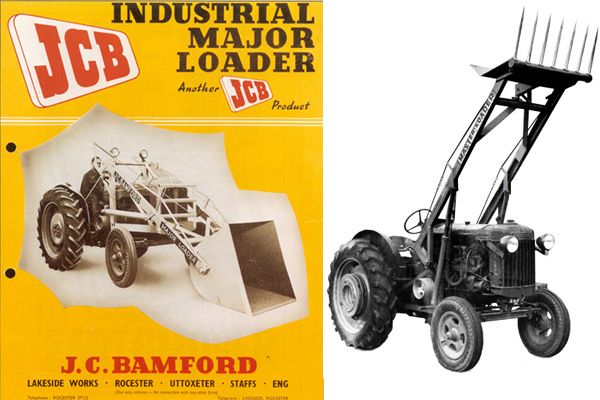

- The very first machine created by Joseph Bamford was an agricultural trailer. He built his own in the garage, in fact, from a pile of scrap metal, and subsequently sold it for only 45 pounds

sterling. Curiously, that day when he completed his work on the trailer, his first child was born — the son Anthony.

- Do you know the origin of the name of the brand JCB? Perhaps you think that this is some kind of abbreviation hiding behind its letters a resounding slogan? No, everything is much simpler.

Initially, these letters are the initials of the company’s founder, Joseph (J) Cyril (C) Bamford. Such letters first appeared on the world’s first backhoe loader, which Bamford invented in 1953.

- In 1950, the company JCB moved to the premises of the old cheese factory in Rochester, where, in fact, began the real history of the company. Here Bamford decides to paint his cars in bright

yellow with the initial letters of his own name.

- The yellow color of special equipment was first used by Caterpillar — a brand with a long history of special equipment production.

JCB cars were originally painted blue and red. But the decision to change the color was made, first of all, because the yellow color on the construction site draws attention to itself, which

means it calls for attention. Currently, many construction vehicles are painted yellow.

- In 1953, it was Joseph Bamford who invented the world’s first excavator loader model MK1.

- The production of all JCB backhoe loaders for the year «takes» more than 14 million bolts, 60,000 tons of iron and 26,000 tons of sheet steel.

- Creating a single backhoe loader at the JCB factory takes approximately 2 days. The company’s main production line is located in a rural area, near Uttoxeter in Staffordshire (England),

however, the company’s factories also operate in the United States, India, Brazil and China.

- The world’s fastest wheel loader produced by JCB. The JCB GT model can reach speeds of up to 193 km / h thanks to its powerful 7.4-liter 1000-strong engine.

- In 1975, Joseph Bamford resigned, passing the case to his sons. Anthony Bamford became the managing director and continues to lead the business today. Joseph Bamford died in

2001 at the age of 84. At the time of his death, JCB already employed more than 4,500 people, producing about 30,000 vehicles per year in 12 factories located on four continents.

Руководство по эксплуатации и техническому обслуживанию погрузчиков JCB 3CX/4CX ECO.

- Автор: —

- Издательство: JCB Service

- Год издания: 2004

- Страниц: 343

- Формат: PDF

- Размер: 243,8 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей экскаваторов-погрузчиков JCB 3CX/4CX и их модификаций 1991-2010 годов выпуска с двигателями объемом 4,0/4,4 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 568

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей экскаваторов-погрузчиков JCB 3CX/4CX и их модификаций c 2010 года выпуска.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 860

- Формат: —

- Размер: —

Руководство на английском языке по ремонту экскаваторов-погрузчиков JCB 3CX и JCB 4CX.

- Автор: —

- Издательство: Motorist

- Год издания: —

- Страниц: 890

- Формат: —

- Размер: —

Руководство на английском языке по ремонту двигателей JCB 444.

- Автор: —

- Издательство: JCB

- Год издания: 2004

- Страниц: 432

- Формат: PDF

- Размер: 185,8 Mb

Руководство на английском языке по эксплуатации и техническому обслуживанию экскаваторов-погрузчиков JCB 4CX.

- Автор: —

- Издательство: Automechanic

- Год издания: —

- Страниц: 214

- Формат: —

- Размер: —

BACKHOE LOADER | 3CX/4CX ECO

Gross Power: 55kW (74hp) – 81kW (109hp) Maximum Dig Depth: 4m – 6.14m Maximum Shovel Capacity: 1.0m3 – 1.3m3

COST OF OWNERSHIP AND EFFICIENCY.

THE LATEST 3CX AND 4CX BACKHOES DON’T

JUST PROVIDE YOU WITH THE POWER TO

GET THINGS DONE; THEY ALSO OFFER YOU

COUNTLESS FEATURES TO ENSURE THAT

PERFORMANCE IS EFFICIENT, AND

OWNERSHIP COSTS ARE REDUCED.

An efficient drivetrain.

1 JCB’s EcoMAX engine doesn’t require exhaust

after treatment, heat-resistant oils or AdBlue, all of which saves money on servicing.

2 By producing high levels of power and torque

even at engine speeds as low as 1200rpm, EcoMAX can provide fuel-efficient matching of transmission and hydraulics.

JCB’s unique TorqueLock system is now standard on 81kW (109hp) Powershift model 3CX and 4CX backhoes. Combined with our optional 6-speed Autoshift transmission, it can help save up to 25% on fuel and 10% on road travel time.

|

3 For ultimate efficiency, our unique new |

|||

|

entry-level 55kW high torque (400Nm) engine |

|||

|

provides excellent excavator performance with the |

|||

|

fuel usage of a low power unit. |

1 |

2 |

3 |

23CX/4CX ECO BACKHOE LOADER

COST OF OWNERSHIP AND EFFICIENCY

Residual benefits.

4 Our EcoMAX engine can be adapted to run on lower-grade fuels, which makes the 3CX and 4CX easily resalable across different territories. This, of course, boosts residuals.

A JCB 3CX or 4CX is a great asset in many respects, not least financially – huge global demand, plus legendary productivity, plus superb build quality equals maximum resale value.

Added efficiency.

As products of the JCB Efficient Design programme, our T4i backhoe loaders use up to 9% less fuel than our Tier 3 models.

To reduce noise and save fuel, we’ve fitted the 3CX and 4CX with a viscous fan as standard; this only cuts in when it’s needed, and doesn’t draw engine power.

|

5 High back-off brakes reduce viscous drag during |

|||

|

roading and rehandling, which in turn improves |

|||

|

economy by up to 2%. |

|||

|

6 Because the 3CX and 4CX are fitted with a |

|||

|

Thatcham-approved security system (depending |

|||

|

on territory), you could benefit from lower |

|||

|

insurance premiums. |

|||

|

A new high output variable flow pump reduces cycle |

|||

|

times and saves fuel. On manual machines, it also |

|||

|

provides lighter lever effort for easier control. |

4 |

5 |

6 |

|

3CX/4CX ECO BACKHOE LOADER |

3 |

QUALITY, RELIABILITY AND DURABILITY.

THE LATEST JCB 3CX AND 4CX ECO MACHINES ARE DESIGNED FOR HARD WORK. THEY’RE MADE USING ONLY THE VERY FINEST MATERIALS AND PROCESSES, WHICH ARE TESTED, TRIED AND PROVEN TO EXCEL. THEY’RE ALSO PROTECTED FROM THE INEVITABLE RIGOURS OF SITE LIFE.

|

Damage limitation. |

|||

|

To stop the 3CX or 4CX’s kingpost hoses from |

|||

|

snagging and sustaining damage, we enclose them |

|||

|

in a flexible, robust guide. |

|||

|

The steering ram on these backhoes is protected |

|||

|

1 |

from impact damage whilst loading, because it’s |

||

|

mounted behind the front axle. |

|||

|

To protect boom and dipper hoses from the |

|||

|

perils of trenchwork, we’ve enclosed them inside the |

|||

|

rear structures of the machine. |

|||

|

The rams on our 3CX and 4CX machines are |

|||

|

ultra-reliable because they’re protected from |

|||

|

debris when loading by optional JCB clam shovel |

|||

|

ram guards. |

|||

|

3 |

To safeguard from impact damage on site, the |

||

|

3CX and 4CX are now fitted with rear light guards. |

43CX/4CX ECO BACKHOE LOADER

QUALITY, RELIABILITY, DURABILITY

Built to last.

6For added rigidity – and to protect hoses from damage – a 3CX or 4CX has flat plate-depressed loader arms, while cat tail welds reduce stress concentrations.

7The plastic fuel tank on the 3CX and 4CX is completely rustproof for ultimate fuel injection

8The single-piece composite cab floor on these backhoes is also rustproof, and has moulded water channels.

9JCB’s robot welded single-piece chassis maximises strength and minimises weight.

Tested to the limits.

|

10 All the materials with which we construct our |

|||||||

|

backhoe loaders are tested to the very max. By |

|||||||

|

exposing those materials to extreme temperatures, |

|||||||

|

7 |

10 |

||||||

|

chemicals, salt, oil and light, we know they’ll survive |

|||||||

|

the most hostile conditions. |

|||||||

|

11 To prove the durability of our new EcoMAX |

|||||||

|

engines, we’ve tested them for 110,000 hours in 70 |

|||||||

|

different machines across the toughest applications |

|||||||

|

and environments. |

|||||||

|

The axles and transmissions of JCB 3CXs and 4CXs |

|||||||

|

are built for a 12,000-hour life, with the heavyweight |

|||||||

|

axles designed to withstand massive shock loads. The |

|||||||

|

rear axle alone has a static load rating of 25,000kg, |

|||||||

|

and a dynamic load rating of 12,500kg. |

8 |

9 |

11 |

||||

|

3CX/4CX ECO BACKHOE LOADER |

5 |

PRODUCTIVITY AND PERFORMANCE.

JCB BACKHOES HAVE ALWAYS LED THE WAY IN POWER AND PERFORMANCE, AND OUR LATEST 3CX AND 4CX MODELS ARE NO EXCEPTION. IN EVERY RESPECT

– FROM DIGGING TO LIFTING AND MANOEUVRING – THESE MACHINES WILL MAXIMISE YOUR PRODUCTIVITY.

For enhanced loading performance and smoother gear changes, we offer a 6-speed gearbox with low ratio first and second gears.

A productive drivetrain.

1Choose from three engines to suit your requirements – with 55kW, 68kW and 81kW options, you can balance ultra efficiency against ultimate performance.

2To give your 3CX or 4CX even greater traction and performance, as well as reduced tyre wear, opt for our automatic limited slip differentials.

|

Innovative hydraulics. |

|

|

There’s more tractive effort at the pile than ever, |

|

|

thanks to new variable flow pump power management |

|

|

combined with our new EcoMAX engine. |

|

|

3 The 3CX Contractor and 4CX’s heavy-duty lift |

|

|

rams provide 3.87 tonnes of force for improved |

|

|

lifting performance. |

1 |

With a 160-litre fuel tank, the 3CX and 4CX ECO machines are designed to do a huge amount of work between refills.

Fast and responsive cycles are guaranteed, courtesy of an increased 165 l/min peak hydraulic flow.

63CX/4CX ECO BACKHOE LOADER

PRODUCTIVITY AND PERFORMANCE

Digging further.

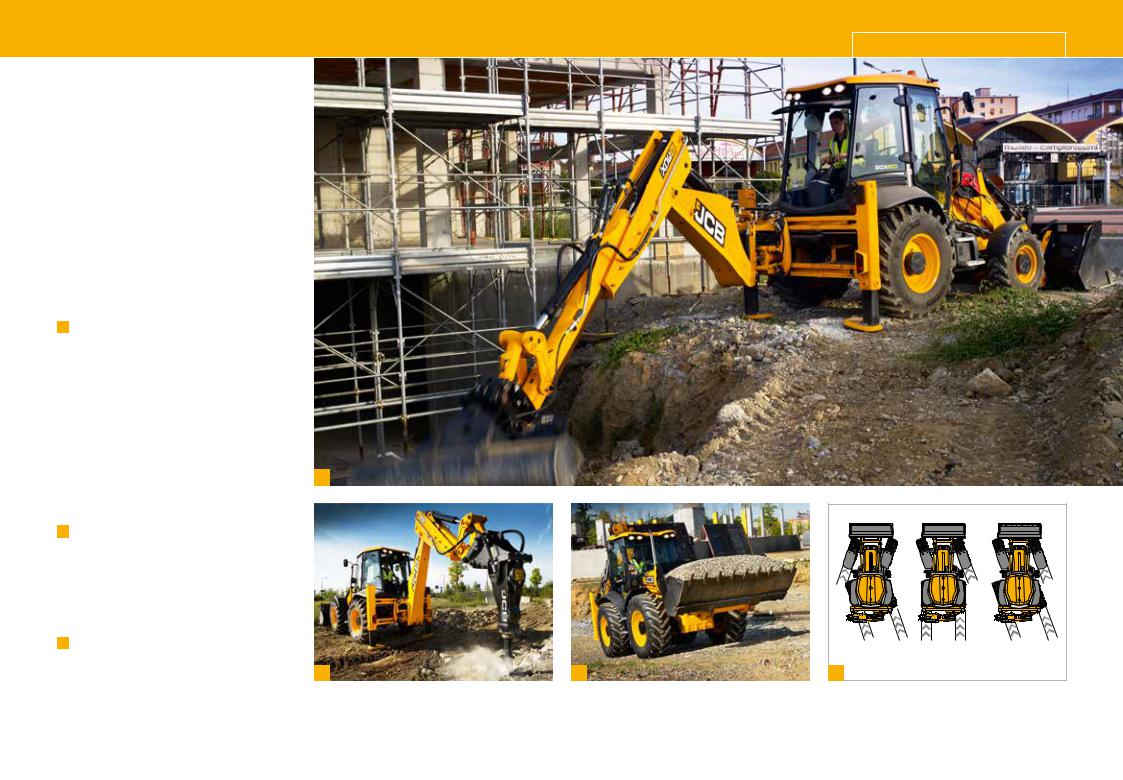

A 3CX or 4CX ECO’s 4-ram self-levelling loader automatically adjusts the shovel on both raise and lower cycles without any need for manual adjustment. It also provides unhindered front shovel visibility, especially when loading at height.

The JCB return-to-dig feature means operators can quickly reset the shovel to dig.

4To ensure an extra 1.2m dig depth and reach

–and to minimise repositioning – the 3CX and 4CX are fitted with our inner box design Extradig feature.

Both the 3CX and 4CX ECO boast high ground clearances of up to 370mm, together with 20° departure angles. This means operators can work easily on steep slopes and uneven ground at maximum productivity.

|

JCB 4CX: |

4 |

||||

|

the ultimate backhoe loader. |

|||||

|

5 As the largest, most productive backhoe |

|||||

|

model we produce, boasting unparalleled power, |

|||||

|

peformance and versatility, the JCB 4CX ECO is |

|||||

|

the ideal machine for just about any application, |

|||||

|

from road-building to house-building, waste |

|||||

|

recycling and landscaping. |

|||||

|

6 The 4CX ECO’s large optional 1.3m³ shovel |

Four-wheel steer |

Two-wheel steer |

Crab-steer mode |

||

|

capacity along with 3 steering modes provide |

|||||

|

exceptional on-site productivity. |

5 |

6 |

6 |

|

3CX/4CX ECO BACKHOE LOADER |

7 |

COMFORT AND EASE OF USE.

IN ORDER TO HELP YOU REAP THE MAXIMUM BENEFIT OF THE 3CX AND 4CX’S SUPERIOR PERFORMANCE, WE’VE DESIGNED THESE MACHINES TO BE ALL-DAY COMFY, ERGONOMIC AND EXTREMELY INTUITIVE FOR OPERATORS TO USE.

A great place to work.

All our ECO backhoes have low noise levels, with our 55kW (74hp) engine models offering the quietest operation.

1 To help operators get to work quickly and safely,

our optional heated front screen removes any built-up frost and ice without the need to climb across the machine on cold mornings. A cab pre-heating option can be set to warm the cab automatically without starting the engine.

|

2 There’s storage aplenty in our 3CX and 4CX |

2 |

1 |

|

cabs; work tools are easy to carry, the cab |

||

|

environment is well-organised and, on A/C models, |

||

|

there’s an in-cab cool box for food and drinks. |

||

|

3 For added comfort and reduced material spillage, |

||

|

JCB’s SmoothRide System minimises bounce |

||

|

during travel. |

||

|

4 Exclusive to JCB backhoe loader, we have |

||

|

integrated a hot drinks machine option into the cab to |

||

|

provide you with a delicious cup of hot tea or coffee |

||

|

throughout the day. |

2 |

3 |

JCB’s single piece glass provides optimum visibility across the work area of a 3CX or 4CX ECO, while our narrow front bonnet allows extra visibility to the front shovel and wheels.

4

83CX/4CX ECO BACKHOE LOADER