- Manuals

- Brands

- Holip Manuals

- Inverter

- HLP-A Series

- Instruction manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Holip HLP-A Series

Summary of Contents for Holip HLP-A Series

-

Page 2

HLP-A Series… -

Page 4: Table Of Contents

HLP-A Series I. Introduction 1. Checks upon Delivery 2. Nameplate Description of HLP Series Inverter II. Safety Precautions 1. Before the Power-up 2. During the Power-up 3. During the Operation III. Standards and Specifications 1. Particular Specifications 2. General Specifications IV.

-

Page 5: Table Of Contents

HLP-A Series X. Care & Maintenance, Fault Information and Troubleshooting 82 1. Precautions about Inspection and Maintenance 2. Periodical Inspection and Maintenance items 3. Fault Indication and Troubleshooting 4. Faults and Analysis XI. Selection of Peripheral Devices and Disposition 1. Options 2.

-

Page 6: I. Introduction

HLP-A Series I. Introduction Thank you for purchasing and using the general-purpose inverter of HLP series of multi-functions and high performance. Please read carefully the operation manual before putting the inverter to use so as to correctly install and operate the inverter, give full play to its functions and ensure the safety.

-

Page 7: Checks Upon Delivery

HLP-A Series Caution ● Do not make any voltage-withstanding test with any component inside the inverter. These semi-conductor parts are subject to the damage of high voltage. ● Never connect the AC main circuit power supply to the output terminals U.V W of the inverter.

-

Page 8: Nameplate Description Of Hlp Series Inverter

HLP-A Series 2. Nameplate Description of HLP Series Inverter MODEL: Model: HLP A 01D5 43 C Hardware Version Voltage Rating,43 means 3-phase 380V Inverter Capacity,01D5 means 1.5KW Serial No., A means A series Trade Mark HLP-A Series…

-

Page 9: Ii. Safety Precautions

HLP-A Series II. Safety Precautions 1. Before the Power-up Caution ● Check to be sure that the voltage of the main circuit AC power supply matches the input voltage of the inverter. ● The symbol, , represents ground terminals. Be sure to make correct ground connection of the earth terminals of the motor and the inverter for safety.

-

Page 10

HLP-A Series ● Be su re to t u r n off the power supply before dissembling or assembling the operation keypanel and fixing the front cover to avoid bad contact causing faults or non-display of the operator. ● Do not install the inverter in a space with explosive gas to avoid the risk of explosion. -

Page 11: During The Power-Up

50Hz. The user must strictly follow the instruction to operate and make wire connection. Otherwise HOLIP will not responsible for the damages due to wrong operation. The user will responsible for the damages themselves.

-

Page 12: Particular Specifications

HLP-A Series III. Standards and Specifications 1. Particular Specifications Inverter Output Suitable Input Power Type Capacity Current Motor Voltage (KW) (KVA) (KW) One & Three phase HLPA00D423C 220V 50Hz One & Three phase HLPA0D7523C 0.75 0.75 220V 50Hz One & Three phase…

-

Page 13

HLP-A Series Inverter Output Suitable Input Power Type Capacity Current Motor Voltage (KW) (KVA) (KW) One & Three phase HLPA009023B 137.2 220V 50Hz HLPA0D7543C 3Φ380V 50Hz 0.75 0.75 HLPA01D543C 3Φ380V 50Hz HLPA02D243C 3Φ380V 50Hz HLPA03D743B 3Φ380V 50Hz HLPA05D543B 3Φ380V 50Hz 12.5… -

Page 14: General Specifications

HLP-A Series 2. General Specifications Inverter Series HLP-A Control Mode SPWM 380±15% for 380V power ; 220±15% Input Power for 220V power D i s p l a y i n g f r e q u e n c y, c u r r e n t , 5-Digits Display &…

-

Page 15

HLP-A Series 5 multi-function output terminals for displaying of r unning, zero speed, Multi-Outputs counter, external abnormity, program operation and other information and warnings. AV R (a u t o v o l t a g e r e g u l a t i o n) ,… -

Page 16: Iv. Storage And Installation

HLP-A Series IV. Storage and Installation 1. Storage The inverter must be kept in its original package box before installation. Pay attention to the followings when keeping it in storage if the inverter is not used for the time being: ●…

-

Page 17

HLP-A Series board under the inverter bottom base and install it again. If the inverter is installed on a loose surface, stress may cause damage of parts in the main circuit so as to damage the inverter. ● The inverter should be installed on non-combustible materials, such as iron plate. -

Page 18: V. Wiring

HLP-A Series V. Wiring 1. Main Circuit Wiring Schematic Diagram Power supply: ● Verify that the inverter’s rated voltage coincides with AC power supply voltage to avoid a damage of the inverter No fuse breaker: ● Refer to the related list Ground fault circuit interrupter: ●…

-

Page 19: Description Of Terminal Block

HLP-A Series 2. Description of Terminal Block 1 ) Arrangement of Main circuit Terminals HLPA00D423C-HLPA01D523C HLPA0D7543C-HLPA02D243C HLPA03D743B HLPA02D223B-HLPA03D723B HLPA05D543B-HLPA07D543B HLPA001143B-HLPA003043B HLPA05D523B-HLPA003023B HLPA003743B-HLPA016043B HLPA003723B-HLPA009023B Cabinet HLPA013243BG-HLPA041543B HLP-A Series…

-

Page 20

HLP-A Series 2) Arrangement of Control Circuit Terminals HLPA00D423C-HLPA01D523C HLPA0D7543C-HLPA02D243C HLPA03D743B-HLPA041543B HLPA001123B-HLPA009023B HLPA02D223B-HLPA03D723B HLPA05D523B-HLPA07D523B 3) Function Description of Main circuit Terminals Symbol Function Description Input terminal of AC line power. ( 220V class, for both R.S.T single/three phase, single phase connected to any two phases )… -

Page 21: Basic Connection Diagram

HLP-A Series Symbol Function Description Factory setting M a x . o u t p u t c u r r e n t +12V Power Supply 200mA M a x . o u t p u t c u r r e n t…

-

Page 22

HLP-A Series 12V/100mA HLPA00D423C-HLPA03D723B HLPA0D7543C-HLPA03D743B HLPA05D543B-HLPA07D543B HLP-A Series… -

Page 23

HLP-A Series EV(P24) HLPA001143B~HLPA003043B HLPA05D523B~HLPA003023B HLPA003743B~HLPA041543B HLPA003723B~HLPA009023B HLP-A Series… -

Page 24: Precautions On Wiring

HLP-A Series 4. Precautions on Wiring 1) For the main circuit wiring: ● While wiring the sizes and specifications of wires should be selected and the wiring should be executed according to the electrical engineering regulations to ensure the safety.

-

Page 25

HLP-A Series Control Input wire Output wire Model NFB(A) wire Screw HLPA07D523B HLPA001123B HLPA001523B HLPA18D523B HLPA002223B HLPA003023B HLPA004523B HLPA005523B HLPA007523B HLPA009023B HLPA0D7543C HLPA01D543C HLPA02D243C HLPA03D743B HLPA05D543B HLPA07D543B HLPA001143B HLPA001543B HLPA18D543B HLPA002243B HLPA003043B HLPA003743B HLPA004543B HLPA005543B HLPA007543B HLPA009043B HLPA011043B HLPA013243B HLPA016043B… -

Page 26

HLP-A Series Control NFB(A) Input wire Output wire Model wire Screw HLPA022043B 150×2 150×2 HLPA025043B 150×2 150×2 HLPA028043B 150×2 150×2 HLPA030043B 150×2 150×2 HLPA031543B 1000 185×2 150×2 HLPA034543B 1000 185×2 150×2 HLPA037543B 1200 240×2 185×2 HLPA040043B 1200 240×2 185×2 HLPA041543B 1200 240×2… -

Page 27

HLP-A Series (1) Good (2) Good (3) Not good HLP-A Series… -

Page 28: Vi.instruction Of The Digital Operator

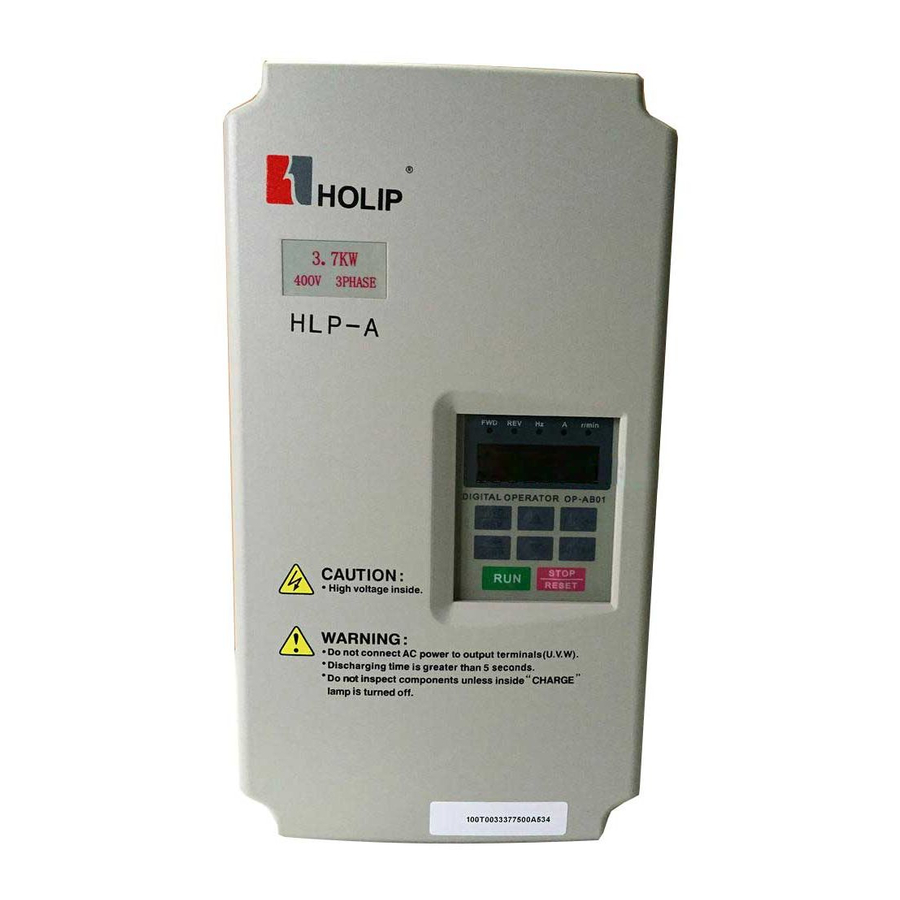

HLP-A Series VI. Instruction of the Digital Operator 1. Description of the Digital Operator Note: The inverter of the hardware version C can use the panel OP-AC01,the inverter of the hardware version B can use the panel OP-AB01 or OP- AB02.

-

Page 29: Description Of The Panel Type

HLP-A Series 2. Description of the panel type 3. List of the panel used in inverter Model Specification Panel type HLPA00D423C 0.4KW/220V OP-AC01 HLPA0D7523C 0.75KW/220V OP-AC01 HLPA01D523C 1.5KW/220V OP-AC01 HLPA02D223B 2.2KW/220V OP-AB01 HLPA03D723B 3.7KW/220V OP-AB01 HLPA05D523B 5.5KW/220V OP-AB02 HLPA009023B 90KW/220V HLPA0D7543C 0.75KW/380V…

-

Page 30: Description Of Operation Examples

HLP-A Series 2) Description of Display Items 5. Description of Operation Examples Indicator Procedures Display Explanation Lamp Power up Dsp2.0 FWD Hz Self detect when power-up, ↓ AXX.XX ¢ ¤ display version no. display ← running f requency PROG CD000…

-

Page 31

HLP-A Series Indicator Procedures Display Explanation Lamp ↓ FWD Hz Switch to main screen, display running DISP 50.00 ¤ ¤ f requency Switch of FWD.REV.rotation, display the ↓ 50.00→ 00.00 REV Hz status of REV.rotation → 50.00 ¤ ¤ ↓… -

Page 32: Vii. Commissioning

HLP-A Series VII. Commissioning 1. Important Checks before the Commissioning ● If there is any wrong connected wires? Pay special attention to the terminal of U.V.W; Make sure the power supply wires are connected to R.S.T, not U.V.W. ● If there is any metal powder or wires left on the base plate of the inverter or the terminal block, which may cause short circuit.

-

Page 33: Parameter And Function List

HLP-A Series VIII. Function List Parameter and Function List (Part 1) Set Range & Function Factory Category Code Function Explanation Setting CD000 Main Frequency 0.00~400.00 Hz 0.00 CD001 Max. Voltage 0.1V—* 220/380 CD002 Base Frequency 0.01~400.00 Hz 50.00 CD003 Intermediate Voltage 0.1V—*…

-

Page 34

HLP-A Series Parameter and Function List (Part 2) Set Range & Function Factory Category Code Function Explanation Setting 0: Rev Run forbidden; CD037 Rev. Rotation Select 1: Rev Run Enable 0: STOP Invalid CD038 STOP key select 1: STOP Valid CD039 S-Curve Time 0.0~6500.0S… -

Page 35

HLP-A Series Parameter and Function List (Part 3) Set Range & Function Factory Category Code Function Explanation Setting *CD056 Multi-output 1(DRV) 0: Invalid; 1: Run; 2: Fault indication; *CD057 Multi-output 2(UPF) 3: Zero Speed; Multi-output 4: Braking indication; *CD058 3(Terminals of 5: Set Frequency reach;… -

Page 36

HLP-A Series Parameter and Function List (Part 4) Set Range & Function Factory Category Code Function Explanation Setting Bias Direction at 0: Positive direction CD069 Higher Frequency 1: Negative direction Analog Negative Bias 0:Not allowable CD070 Reversed 1:Allowable AM Analog output… -

Page 37

HLP-A Series Parameter and Function List (Part 5) Set Range & Function Factory Category Code Function Explanation Setting CD095 AutoPLC Memory CD096 Reserved CD109 Number of Auxiliary CD110 Pump Continuous CD111 Operating Time of 1~9000min Aux.Pumps Interlocking Time of CD112 0.1~250S… -

Page 38

HLP-A Series Parameter and Function List (Part 6) Set Range & Function Factory Category Code Function Explanation Setting Set according to Motor CD130 Rated Motor Voltage nameplate Set according to Motor CD131 Rated Motor Current nameplate CD132 Motor pole number. -

Page 39

HLP-A Series Parameter and Function List (Part 7) Set Range & Function Factory Category Code Function Explanation Setting Communication Baud CD161 Rate Communication Data CD162 Method CD163 Reserved CD166 CD167 Display Items 0-31 CD168 Display Items Open Voltage Rating of… -

Page 40: Ix. Descriptions Of Functions

HLP-A Series IX. Descriptions of Functions CD000 Main Frequency Set Range: 0.00-400.00 Hz Unit: 0.01 Hz Factory Setting: 0.00 In the digital operator mode, the inverter will run at the set value of CD000. During running, the operating f requency can be changed by pressing ▲ or ▼ .

-

Page 41

HLP-A Series f requency the torque compensation will lose its f unction. When adjusting this parameter the output current of the inverter should be increased f rom low to high slowly according to the load of machines until it meets the starting requirement. -

Page 42

HLP-A Series Code Code CD003 CD005 CD012 CD013 CD035 CD003 CD005 CD012 CD013 CD035 Model Model A007523B A022043B A009023B A025043B A0D7543C A028043B A01D543C A030043B A02D243C 10.5 A03 1543B A03D743B 10.5 A034543B A05D543B A037543B A07D543B A040043B A041543B Note: ① Ramp Time 2 = Ramp Time 1 x 2 ②… -

Page 43

HLP-A Series This is set for preventing workers f rom false operation to avoid over-heat or some other mechanical faults, which might be caused due to too low operating f requency. The setting of Frequency Lower Limit must be less than the set value of CD007. -

Page 44

0Hz (See t2 in the diagram). HLP-A Series inverter have altogether 4 Ramp Times. For Ramp Time 2.3.4 the user can select the different ramp up or down time through the external terminals or switching of ramp time according to the actual needs. -

Page 45

HLP-A Series speed. When restarting, the current becomes higher, and over-current or stall may occur. So attention must be paid to the adjustment of current level of f requency track. Generally, CD144 is adjusted around 100. The concrete value can be set according to the characteristics of mechanical load. -

Page 46

HLP-A Series CD034 Source of Operating Frequency Set Range: 0—2 Unit: 1 Factory Setting: 0 0: Set by the operator. Operating f requency is given via the digital operator. 1 : Set by external terminals. Operating f requency is controlled by analog signals input via external terminals. -

Page 47

HLP-A Series is set by Ramp-up Time 4. When the jog button is released the inverter will stop output immediately. In case of jogging f unction please set the corresponding multi-input terminals to 07 or 08. This f unction is only valid at stop. It is invalid at running. For the related parameters refer to CD050-CD055. -

Page 48

HLP-A Series CD040 Up/Down Set Range: 0.01~2.50Hz Unit:0.01Hz Factory Setting:0.01 This parameter can be set in combination with CD073 for Up/Down of external control and the speed of increase and decrease. the step length of Up/Down=(the set value of CD040/0.01)× UP/DOWN speed CD041 Starting Frequency Set Range: 0.10—10.00 Hz… -

Page 49

HLP-A Series CD044 Skip Frequency 1 CD045 Skip Frequency 2 CD046 Skip Frequency 3 Set Range: 0.00—400.00 Hz Unit: 0.01Hz Factory Setting: 0.00 CD047 Skip Frequency Range Set Range: 0.10—10.00 Hz Unit: 0.01Hz Factory Setting: 0.50 These three f requency skipping points are set for avoiding a mechanical resonance point. -

Page 50

HLP-A Series CD050 Multi-input 1 (FOR function) Factory Setting: 02 CD051 Multi-input 2 (REV function) Factory Setting: 03 CD052 Multi-input 3 (RST function) Factory Setting: 10 CD053 Multi-input 4 (SPH function) Factory Setting: 17 CD054 Multi-input 5 (SPM function) Factory Setting: 18… -

Page 51

HLP-A Series of the inverter will be increased or decreased by one unit. When the switch of the terminal is hold the f requency will increase or decrease rapidly to a point and then increase or decrease 26: Down Function at even speed. When the power is up again af ter the power breakdown the changed f requency will not be memorized. -

Page 52

HLP-A Series 3. Description of Ramp Time 1 and 2: 1) This f unction is only valid when CD076 is set to 0, 1 and 2. Under the disturbance and internal control multi-speed it is invalid. 2) Any two multi-inputs can be combined for 4 kinds of ramp time for selection. -

Page 53

HLP-A Series Note: ( 1 ) This f unction is only valid when CD076 is set to 1, i.e. for 4-Speed of external control. ( 2 ) Low, middle and high speed f requency are determined by Frequency 2,3, 4. -

Page 54

HLP-A Series ( 8 ) When using the f unction of UP and DOWN, the keys of △ ▽ of the panel are valid. Af ter changing the values it needs to press SET (ENTER) key for confirmation and then the inverter can implement the action. Meanwhile the value will write to CD000, which will be memorized af ter a power breakdown. -

Page 55

HLP-A Series 02: Fault Indication: The contact will act when the inverter detects abnormal conditions. 03: Zero Speed: The contact will act when the output f requency of the inverter is less than its starting f requency. 04: DC Braking indication: The contact will act when the inverter is in DC braking. -

Page 56

HLP-A Series 28: PID Lower Limit Alarm: This contact will act when the PID feedback is smaller than the lower limit (the set value of CD156). 29: PID Upper Limit Alarm: This contact will act when the PID feedback is greater than the upper limit (the set value of CD155). -

Page 57

HLP-A Series CD061 Uniform Frequency 1 CD062 Uniform Frequency 2 Set Range: 0.00—400.00 Hz Unit: 0.01 Hz Factory Setting: 0.00 CD063 Uniform Frequency Range Set Range: 0. 1 0—10.00 Hz Unit: 0.01 Hz Factory Setting: 0.50 When the output f requency is more than the unif orm f requency the corresponding multi-outputs will act. -

Page 58

HLP-A Series Among which: U: Analog Voltage; U : Maximum Analog Voltage; I: Analog Current; I : Maximum Analog Current. For example, When +10V and 20mA are respectively entered for the analog input, the output f requency of the inverter is 50Hz. -

Page 59

HLP-A Series Setting: CD066=50 CD067=0 CD068=0 CD069=0 CD070=0 Not e: t h is c u r ve is a k i nd of s pecia l application of reverse ramp setting. When using transmitter for the control of pressure, temperature and others and while the control… -

Page 60

HLP-A Series CD072 UP/DOWN Function Set Range: 0-1 Unit: 1 Factory Setting: 0 0: Not memorized 1 : Memorized This parameter can be set for the selection of whether the values changed by the UP or DOWN shall be memorized or not af ter stop. The changed values… -

Page 61

HLP-A Series Multi-f unction Terminals Results Multi-speed Multi-speed Multi-speed Main f requency and f requencies are determined by CD000 or potentiometer. Multi-speed 1 and f requency are determined by CD080. Multi-speed 2 and f requency are determined by CD081 . -

Page 62

HLP-A Series multi-f unction terminals. ⑥ This main f requency can be set in two ways. One method is to set it through CD000 and another is to set it through the potentiometer. When CD034 is set to 1 the f requency of Main Frequency is set by the potentiometer. -

Page 63

HLP-A Series be used the timer can be set to 0. ④ Running direction of each speed step is determined by CD078. ⑤ In the internal control multi-speed operation the running time and direction are determined by the setting of internal parameters. Any switching of external time and FOR/REV rotation is invalid. -

Page 64

HLP-A Series Explanation: 1. Stop after the program runs one cycle. When the command of auto program operation is given, the inverter will run with each set value of internal parameters. It will run for one cycle and then stop automatically. The inverter will not restart and run until it receives another command of operation. -

Page 65

HLP-A Series 0: For. 1 : Rev. Main Speed (CD000) For. Frequency 1 (CD080) Rev. Frequency 2 (CD081) For. Frequency 3 (CD082) Rev. Frequency 4 (CD083) For. Frequency 5 (CD084) For. Frequency 6 (CD085) Rev. Frequency 7 (CD086) For. The parameter value 01001010 is converted to a decimal value: 1 ×2… -

Page 66

HLP-A Series t5 Select Ramp Time 1 So CD079 is set to 99 t6 Select Ramp Time 1 Attach: 2 t7 Select Ramp Time 1 =16 2 =32 2 =64 2 =128 t8 Select Ramp Time 1 CD080 Frequency 2 Factory Setting 15.00**… -

Page 67

HLP-A Series CD096~CD109 Reserved *CD110 Number of Auxiliary Pump Set Range : 0—2 Unit: 1 Factory Setting: 0 This parameter is set for the number of auxiliary pump. The start or stop of the auxiliary pumps is controlled by using the multi-output contacts and Auxiliary Pump 1 or Auxiliary Pump 2 is controlled through the peripheral control circuit. -

Page 68

HLP-A Series CD1 13 and CD1 14 must be used in combination of CD061, CD062 and multi- outputs. Their main f unction is to increase or decrease the number of auxiliary pump. *CD115 Stopping Voltage Level Set Range:0~150% Unit:1% Factory Setting:95 This parameter is set for the voltage level of the master pump entering into sleep mode. -

Page 69

HLP-A Series The following is the block diagram of multi pumps operation: HLP-A Series… -

Page 70

HLP-A Series F ≥ CD061 P ≥ CD115 T ≥ CD116 F ≥ CD061 T ≥ CD113 CD120 Over-voltage Stall Prevention Set Range: 0—1 Unit: 1 Factory Setting: 1 0: Over-voltage stall prevention invalid 1 : Over-voltage stall prevention valid. -

Page 71

HLP-A Series inverter to increase. So when the f unction of over-voltage stall prevention is started, if the DC voltage of the inverter becomes too high, the inverter will stop decelerating till the voltage at DC decreases below the set value, then the inverter will go on to decelerate and the ramp-down time will be extended automatically. -

Page 72

HLP-A Series 100% current is the rated current of the motor. CD124 Over-torque Detect Mode Set Range: 0—3 Unit: 1 Factory Setting: 0 0: When reaching the f requency it starts to detect over-torque and when over- torque is detected it continues to run. -

Page 73

HLP-A Series CD127 Decel. Time for Stall Prevention at Constant Speed Factory Setting: 5.0 When the inverter is used for the loads of kinds of fan and pump CD122 can be set to 120. When the current of the inverter is greater than 120% the output f requency will decrease and the current will also decrease accordingly. -

Page 74

HLP-A Series CD133 Rated Motor Revolution Set Range: 0~9999r/min Unit: 1r/min Factory Setting: 1440 This is set according to the actual revolution of the motor. The displayed value is the same as this set value. It can be used as a monitoring parameter, which is convenient to the user. -

Page 75

HLP-A Series CD142 DC Braking Time at stop Set Range: 0.0~25.0S Unit: 0.1S Factory Setting: 0.0 Note: When this parameter is set to any non-zero value it starts DC brake at stop and sends the DC braking time to the motor. DC braking at stop is of ten used for a high-level stop or positioning control. -

Page 76

HLP-A Series CD147 Number of Abnormal Restart Set Range: 00—10 Unit: 1 Factory Setting: 00 Af ter the abnormal conditions (such as over-current and over-voltage) happens the inverter will automatically reset and restart. If the starting mode is set to normal mode it will start according to the normal procedures. -

Page 77

HLP-A Series *CD150 Proportional Constant (P) Set Range:0~1000.0% Unit:0.1% Factory Setting:100.0 This proportional constant is set for the error value gain. In case of I=0, D=0, it is only for proportional control. *CD151 Integral Time (T) Set Range:0.1~1000.0S Unit:0.1S Factory Setting:.5.0 The integral time (I) is set for the responding speed for PID. -

Page 78

HLP-A Series General operating methods of PID control: (1) Choose the correct transmitter (with the output specification of standard current signal 4-20mA). (2) Set the right target value. (3) If the output does not have oscillation, increase the proportional constant (P). -

Page 79

4: 8E1 For RTU 5: 8O1 For RTU CD163~CD166 Reserved HOLIP MODBUS Communication Protocol When using the RS485 communication interface, each of the inverters must be set for its own address so that the computer can use this individual address to carry out the control. -

Page 80

HLP-A Series example: 64H ASCII mode: Each of 8-bit data is composed of two ASC IIbyte, for example: One 1-bit data 64H (hexadecimal) is composed of ASC II byte“64”, included“6” (36H) and “4”(34H). Byte ASCII code Byte ASCII code 2: Communication Data Method (1) 8N1 For ASCII CD162=0 (… -

Page 81

HLP-A Series ( 5 ) 8E1 For RTU C D162=4 ( 6 ) 8O1 For RTU C D162=5 3 : Communication Document Formats 3. 1 ASCII Mode Communication Document Forms DATA (n-1) “ : ” ADDR FUNC CR(0DH) ..(3AH) -

Page 82

HLP-A Series If DATA is one word, the LEN=3, If DATA is one byte, the LEN=2 . When inverter has no this f unction code or reply no ef fect, the format as follows : ADDR 81H 01 FUNC b : Write f unction code data… -

Page 83

HLP-A Series word, LEN=3, when one byte or <1byte, LEN=2 . (5) DATA: <Data characters> data content. 2n ASCII compose n bytes, it have fif ty ASC II at most. (6) LRC : longitudinal redundancy check ASCII mode: Get LRC methods is that add ADDR to the last data, if the result is more than 256,then the result subtract 256 until the result is less then 256 (if the result is 128H, take 28H), then 100H subtract the result get LRC. -

Page 84

HLP-A Series all data. The last data of CRC register is CRC value. When send CRC value in command data, low bytes must change the sequence with high bytes, i.e. low bytes will be sent first. (7) Example 1 : Write 30.00Hz to inverter of 01… -

Page 85

HLP-A Series 5: Total running time of power up(Unit: Hour) 6-3 1 : Invalid CD168 Display Items Open Set Range: 0—7 Unit: 1 Factory Setting: 0 This parameter is set for selection of displaying of DC voltage, AC voltage and other items so that the customer can monitor and view them in sequence through the switch key. -

Page 86

CD181 Reserved CD182 Communication Protocol Select Set Range:0-1 Unit:1 Factory Setting:0 0: Holip MODBUS Communication Protocol 1 : Standard MODBUS Communication Protocol CD183~CD250 Reserved Note: * means the said parameter has a variety of set values or should be set specifically according to concrete conditions. -

Page 87: X. Care & Maintenance, Fault Information And Troubleshooting

HLP-A Series X. Care & Maintenance, Fault Information and Troubleshooting Periodical maintenances and inspections will keep your inverter in its normal state for long time. 1. Precautions about Inspection and Maintenance ● Be sure to turn off the power supply to the inverter (R.S.T) first before the inspection and maintenance.

-

Page 88: Fault Indication And Troubleshooting

HLP-A Series The inverter of HLP series is relatively perfective with the protection f unctions of overload, inter-phase short circuit, earth short circuit, under-voltage, overheating and over-current, etc. When a protection f unction happens with the inverter please check the reasons of faults according to the information listed in the table below.

-

Page 89

HLP-A Series Fault Fault Contents & Disposal methods Display Description E.ou.S Over-voltage at stop E.ou.a Over-voltage at 1 : Extend the Ramp-down Time or add a accel braking resistor. E.ou.n Over-voltage at 2: Improve the mains supply voltage and check… -

Page 90

HLP-A Series Fault Fault Contents & Disposal methods Display Description E.bT.A Braking transistor E.bT.n Please send it for repair. damage E.bT.d E.EC.S E.EC.n CPU fault Please contact the factory. E.EC.d E.EC.A E.EE.S E.EE.n Prom fault Please contact the factory. E.EE.d E.EE.A… -

Page 91: Faults And Analysis

HLP-A Series 4. Faults and Analysis (1) When RUN key is pressed, the motor does not run. 1) The setting of operation mode is wrong, i.e., under the operation mode of external control terminals, the inverter is started by the digital operator or under the operation mode of the digital operator it is started by the external control terminals.

-

Page 92

HLP-A Series phase to phase withstand voltage against shock than the maximum shock voltage. (7) The starting of the inverter interferes other control devices 1) Decrease the carrier f requency and reduce the number of actions of internal switches. 2) Install a noise filter at the power input of the inverter. -

Page 93: Options

HLP-A Series X I . S e l e c t i o n o f P e r i p h e r a l D e v i c e s a n d Disposition 1. Options Description…

-

Page 94: Disposition

HLP-A Series 3) DC reactors It is necessary to install a DC reactor when the capacity of power supply is more than 1000 KVA or the mains power capacity is higher than the rated capacity of the inverter. A DC reactor is also needed for the case with higher demand on the improvement of power f actor of power supply.

-

Page 95

HLP-A Series Connection ① Remove the jumpers of P and P1 terminals. ② Connect DC reactor to Terminals P and P1 as shown in the following diagram: DC Reactor Note: HLP inver ter of above 37 K W h a s c o n n e c t o r s. T h e inverter of below 37KW must not be connected with it. -

Page 96

HLP-A Series AC Reactor The incoming reactor is also named shif t-changing reactor and it is used for the incoming wire of the mains with AC f lowing inside. Its f unction is to suppress the harmonics of the inverter feedback to the mains. -

Page 97

HLP-A Series Braking resistor Braking torque Special Motor Specification Inverter Model 10%ED Ω HLPA016043B 36000 13.6/4 HLPA01 8543B 45000 13.6/5 1 85 HLPA020043B 45000 13.6/5 HLPA022043B 48000 13.6/5 HLPA025043B 48000 13.6/5 HLPA028043B 57600 13.6/6 HLPA030043B 57600 13.6/6 For the braking resistor used for the machines of above 3 15 KW please contact the factory. -

Page 98: Xii. Appendices

HLP-A Series XII. Appendices Appendix 1: Simple Examples of Application 1 . Disturbance Function (Generation of Triangle Wave) A curve as in lef t is generated. Parameter setting: CD076=3 CD000=30 CD080=27 CD086=0.5 CD087=10 CD088=10 2. Drawing Function Parameter setting: CD076=5…

-

Page 99

HLP-A Series Parameter setting: CD033=1 CD034=1 CD066=50 CD068=50 CD067= 1 CD069=0 CD070= 1 4. Internal Control 8 Speed Run A curve as shown in the following diagram is established. Internal control 8-speed run will stop af ter running for one cycle. -

Page 100

HLP-A Series 5. Linkage of Multi Pumps Attention: ① The f requency of the main inverter can be set by the potentiometer. ② The proportion relation of the inverters can be adjusted by CD068. For example: For F =1 : 2 : 3 the parameters of CD068 can… -

Page 101

HLP-A Series 6. Run by Switching of Power Frequency/Variable Frequency Note: ① K is a switch for power f requency/variable f requency. ② K is a start button and K is a stop button for power f requency. ③ The stopping mode is set for coasting stop. -

Page 102

HLP-A Series 7. Example application of simple water supply with constant pressure (1) Use a pressure transmitter with measuring range of 0-10kg, feedback of 4-20mA, requiring water supply at the pressure of 5kg with alarming at the upper limit of 6kg and the lower limit of 4kg. The start f rom the panel stops. -

Page 103

HLP-A Series ② The feedback signal is 4-20mA. Others are invalid. ③ In this example the target value is given by the potentiometer (0~10V) . ④ CD150, CD15 1 and CD152 should be set according the actual condition. (Refer to the parameter description.) ⑤… -

Page 104

HLP-A Series example the switching is made through the panel) 9. Example application of Auto PLC Suspend Requirement: Auto PLC can be suspended during the internal control multi- speed run. Af ter handling the related problems it can resume. (1) Connection… -

Page 105: Appendix 2: Appearance And Installation Dimensions

HLP-A Series Appendix 2: Appearance and Installation Dimensions Inverter Model Appearance and Installation Dimensions HLPA00D423C HLPA0D7523C HLPA01D523C HLPA0D7543C HLPA01D543C HLPA02D243C Unit: mm HLPA02D223B HLPA03D723B HLPA03D743B Unit: mm HLP-A Series…

-

Page 106

HLP-A Series HLPA05D523B HLPA07D523B Unit : mm HLPA05D543B~ HLPA07D543B Unit : mm HLP-A Series… -

Page 107

HLP-A Series HLPA001 123B HLPA005523B HLPA001 143B HLPA005543B Unit : mm HLPA007523B HLPA009023B HLPA007543B HLPA016043B Unit : mm HLP-A Series… -

Page 108

HLP-A Series Height of 4 hoisting eyes : 132~250KW 36mm 280~415KW 43mm HLPA013243BG HLPA016043BG HLPA01 8543B HLPA041543B 2. External Dimensions Table (Unit: mm) Inverter Model HLPA00D423C HLPA0D7523C HLPA01D523C 1 16 1 70 Φ5 HLPA0D7543C HLPA01D543C HLPA02D243C HLPA02D223B HLPA03D723B Φ5 HLPA03D743B HLPA05D523B Φ7… -

Page 109

HLP-A Series Inverter Model HLPA003043B 3 15 5 10 Φ8 HLPA003023B HLPA003743B Φ10 HLPA004543B HLPA005543B HLPA003723B Φ16 HLPA007543B HLPA004523B Φ16 HLPA009043B HLPA005523B HLPA007523B HLPA009023B Φ16 HLPA01 1043B HLPA013243B HLPA016043B Φ16 HLPA013243BG 1649 Φ16 HLPA016043BG HLPA01 8543B 1 805 Φ16 HLPA025043B… -

Page 110: Appendix 3: Appearance And Installation Dimensions

HLP-A Series Appendix 3: Appearance and Installation Dimensions Type Appearance and Installation Dimensions OP-AB01 OP-AC01 Unit : mm OP-AB02 Unit : mm HLP-A Series…

-

Page 111: Appendix 4: Description Of Parameter Setting For Hlp-A Inverter

HLP-A Series Appendix 4: Description of Parameter Setting for HLP-A Inverter 1 . Requirements: Use a potentiometer to control the speed and a button to control starting or stopping of the inverter. 2. Setting requirements: 1) Wiring ⑴ 220V power supply, connecting to any two terminals of R, S, T, 3φ220 connecting to R, S, T terminals;…

-

Page 112

HLP-A Series for confirmation. When 0 (i.e. content of CD033) is displayed, press Δ to change the value to “1” and press Key “SET” for confirmation. It will display END and later CD034. Other parameters can be set in the same way. Af ter finishing setting, find PROG Key and return to the main menu to show the value for f requency. -

Page 113: Appendix 5: User’s Records And Feedback

HLP-A Series Appendix 5: User’s Records and Feedback Factory User’s Factory User’s Code Function Code Function Setting Par. Setting Par. CD000 Main Frequency 0.00 CD087 Timer 1 10.0 220/380 CD001 Max. Voltage acc. to CD088 Timer 2 10.0 model CD002 Base Frequency 50.00…

-

Page 114

HLP-A Series Factory User’s Factory User’s Code Function Code Function Setting Par. Setting Par. Stall Prevention CD03 1 Starting Mode CD123 Level at Deceleration CD124 Over-torque Detect CD032 Stopping Mode Mode CD033 Source of Run CD125 Over-torque Detect Commands Level… -

Page 115

HLP-A Series Factory User’s Factory User’s Code Function Code Function Setting Par. Setting Par. CD148 Auto Voltage CD053 Multi-input 4 (SPH) Regulation CD149 Auto Energy CD054 Multi-input 5 (SPM) Saving CD150 Proportional CD055 Multi-input 6 (SPL) Constant (P) CD056 Multi-output 1… -

Page 116

HLP-A Series Factory User’s Factory User’s Code Function Code Function Setting Par. Setting Par. CD080 Frequency 2 15.00 CD180 Serial No. CD081 Frequency 3 20.00 CD181 Reserved CD182 Communication CD082 Frequency 4 25.00 Protocol Select CD183 CD083 Frequency 5 30.00…

(Ocr-Read Summary of Contents of some pages of the Holip HLP-A Series Document (Main Content), UPD: 11 May 2023)

-

39, HLP-A Series HLP-A Series — 34 — Parameter and Function List (Part 7) Categor y Code Function Set Range & Function Explanation Factory Setting Communication Functions CD161 Communication Baud Rate 0-3 1 CD162 Communication Data Method 0-5 0 CD163 ~ CD166 Reserved Monitoring Parameters CD167 Display Items 0-31 0 CD168 Display Items Open 0-7 0 CD169 Voltage Rating of Inverter Set according to the model * CD170 Rated Current of Inverter Set according to the model * …

-

92, HLP-A Series HLP-A Series — 87 — phase to phase withstand voltage against shock than the maximum shock voltage. (7) The starting of the inverter interferes other control devices 1) Decrease the carrier frequency and reduce the number of actions of internal switches. 2) Install a noise lter at the power input of the inverter. 3) Install a noise lter at the output of the inverter. 4) Make correct grounding for the inverter and the …

-

10, HLP-A Series HLP-A Series — 5 — ● Be sure to turn off the power supply before dissembling or assembling the operation keypanel and xing the front cover to avoid bad contact causing faults or non-display of the operator. ● Do not install the inverter in a space with explosive gas to avoid the risk of explosion. ● If the inverter is used at or above 1000m above seal level, the cooling efciency will be worse, so please run it by de-rating. ● Do not…

-

6, HLP-A Series HLP-A Series — 1 — I. Introduction Thank you for purchasing and using the general-purpose inverter of HLP series of multi-functions and high performance. Please read carefully the operation manual before putting the inverter to use so as to correctly install and operate the inverter, give full play to its functions and ensure the safety. Please keep the operation manual handy for future reference, maintenance, inspection and repair. Due to the inve…

-

8, Holip HLP-A Series HLP-A Series HLP-A Series — 3 — 2. Nameplate Description of HLP Series Inverter Hardware Version Model: HLP A 01D5 43 C Voltage Rating,43 means 3-phase 380V Inverter Capacity,01D5 means 1.5KW Serial No., A means A series Trade Mark MODEL:

… -

56, HLP-A Series HLP-A Series — 51 — 28: PID Lower Limit Alarm: This contact will act when the PID feedback is smaller than the lower limit (the set value of CD156). 29: PID Upper Limit Alarm: This contact will act when the PID feedback is greater than the upper limit (the set value of CD155). 30: Fan act: When the temperature of the inverter is increased or it is in running, this contact will act. 31: Electromagnetic Relay Act: Wh…

-

35, HLP-A Series HLP-A Series — 30 — Parameter and Function List (Part 3) Categor y Code Function Set Range & Function Explanation Factory Setting Input and Output Terminals *CD056 Multi-output 1(DRV) 0: Invalid; 1: Run; 2: Fault indication; 3: Zero Speed; 4: Braking indication; 5: Set Frequency reach; 6: Arbitrary Frequency 1 reach; 7: Arbitrary Frequency 2 reach; 8: In Accel.; 9: In D…

-

45, HLP-A Series HLP-A Series — 40 — CD032 Stopping Mode Set Range: 0—1 Unit: 1 Factory Setting: 0 Two stopping modes are available for the needs of different equipment. 0: Decelerating Stop When CD142 is set to 0, DC braking is invalid. When DC braking is invalid, the inverter will decelerate to the stopping f requency, and then stop outputs, and the motor will coast to stop. When CD142 is set to any non-zero value, DC braki…

-

60, HLP-A Series HLP-A Series — 55 — CD072 UP/DOWN Function Set Range: 0-1 Unit: 1 Factory Setting: 0 0: Not memorized 1: Memorized This parameter can be set for the selection of whether the values changed by the UP or DOWN shall be memorized or not af ter stop. The changed values whether to be memorized or not means when they are changed by UP or DOWN during operation and the inverter is restarted af ter stop these changed values shall be memorized…

-

15, Holip HLP-A Series HLP-A Series HLP-A Series — 10 — Multi-Outputs 5 multi-function output terminals for displaying of running, zero speed, counter, external abnormity, program operation and other information and warnings. Other Functions AVR (auto voltage regulation), Deceleration stop or free-stop, DC brake, auto reset and restart, frequency track, PLC control, traverse function, drawing control, auto energy-savings, carrier adjustable by max. …

-

12, HLP-A Series HLP-A Series — 7 — III. Standards and Specications 1. Particular Specications Type Input Voltage Power (KW) Inverter Capacity ( K VA) Output Current (A) Suitable Motor (KW) HLPA00D423C One & Three phase 220V 50Hz 0.4 1.0 2.5 0.4 HLPA0D7523C One & Three phase 220V 50Hz 0.75 2.0 5.0 0.75 HLPA01D523C One & Three phase 220V 50Hz 1.5 2.8 7.0 1.5 HLPA02D223B One & Three phase 220V 50H…

-

85, HLP-A Series HLP-A Series — 80 — 5: Total running time of power up(Unit: Hour) 6 -31: I n v a l i d This parameter is set f or selection of displaying of DC voltage, AC voltage and other items so that the customer can monitor and view them in sequence through the switch key. It can be is set rst in the binary 3 bits mode, and then converted to a decimal value. CD168 Display Items Open Set Range: 0—7 Unit: 1 Factory Setting: 0 0: Invalid …

-

40, Holip HLP-A Series HLP-A Series HLP-A Series — 35 — IX. Descriptions of Functions CD000 Main Frequency ** Set Range: 0.00-400.00 Hz Unit: 0.01 Hz Factory Setting: 0.00 In the digital operator mode, the inverter will run at the set value of CD000. During running, the operating f requency can be changed by pressing ▲ or ▼. During multi-speed running, the main f requency is taken …

-

51, HLP-A Series HLP-A Series — 46 — of the inverter will be increased or decreased by one unit. When the switch of the terminal is hold the f requency will increase or decrease rapidly to a point and then increase or decrease 26: Down Function at even speed. When the power is up again af ter the power breakdown the changed frequency will not be memorized. 27: Counter Pulse When this terminal is set for the counter it can r…

-

53, HLP-A Series HLP-A Series — 48 — Not e: ( 1 ) This f unction is only valid when CD076 is set to 1, i.e. for 4-Speed of exter nal cont rol. ( 2 ) Low, middle and high speed f requency are determined by Frequency 2,3, 4. ( 3 ) Ramp time is determined by Ramp Select terminal. ( 4 ) When all high, middle and low speeds have signal inputs it will give priority in the sequence of high, middle and low speed. 5. Description of UP and DOWN…

-

27, HLP-A Series HLP-A Series — 22 — (1) Good (2) Good (3) Not good

…

Table of Contents for Holip HLP-A Series:

-

HLP-A Series HLP-A Series — 81 — 01 is for f ault clear. Others have no f unction. CD176 Fault Clear ** Set Range: 00—10 Unit: 1 Factory Setting: 00 0: Constant torque 1: For kinds of fan. It can be observed, but not changed. CD177 Inverter Model Set Range: 0—1 Unit: 1 Factory Setting: 0 0: 50Hz 1: 60Hz It is f actory setting. It can be observed, but not set. 0: Holip MODBUS Commu nication Protocol 1: Standard

-

HLP-A Series HLP-A Series — 22 — (1) Good (2) Good (3) Not good

-

HLP-A Series HLP-A Series — 110 — Code Function Factor y Setting U s e r’s Pa r. Code Function Factor y Setting U s e r’s Pa r. CD053 Multi-input 4 (SPH) 17 C D14 8 Auto Voltage Regulation 1 CD054 Multi-input 5 (SPM) 18 CD149 Auto Energy Saving 0 CD055 Multi-input 6 (SPL) 19 C D150 Proportional Constant (P) 10 0 CD056 Multi-output 1 01 C D151 Integral Time(I) 5.0 CD057 Multi-output 2 05 C D152 Dif ferential T

-

HLP-A Series HLP-A Series — 73 — General operating methods of PID control: (1) Choose the correct transmitter (with the output specication of standard current signal 4-20mA). (2) Set the right target value. (3) If the output does not have oscillation, increase the proportional constant (P). (4) If the output does not have oscillation, decrease the integral time (Ti). (5) If the output do not have oscillation, increase the dif ferential time (Td). (6) Concrete applications can be referred

-

HLP-A Series HLP-A Series — 62 — CD096~CD109 Reserved This parameter is set for the number of auxiliary pump. The start or stop of the auxiliary pumps is controlled by using the multi-output contacts and Auxiliary Pump 1 or Auxiliary Pump 2 is controlled through the peripheral cont rol circuit. *CD110 Number of Auxiliary Pump Set Range : 0—2 Unit: 1 Factory Setting: 0 In case of two pumps with only one pump in duty, in order

-

HLP-A Series HLP-A Series — 101 — HLPA05D523B HLPA07D523B Unit : mm HLPA05D543B~ HLPA07D543B Unit : mm

-

HLP-A Series HLP-A Series — 97 — 7. Example application of simple water supply with constant pressure (1) Use a pressure transmitter with measuring range of 0-10kg, feedback of 4-20mA, requiring water supply at the pressure of 5kg with alarming at the upper limit of 6kg and the lower limit of 4kg. The start f rom the panel stops. Parameters: CD032=1 CD035=5 CD052 (RST f unction) =32 CD058=28 CD059=29 C D150 = * C D151= * C D15

-

HLP-A Series HLP-A Series — 1 — I. Introduction Thank you for purchasing and using the general-purpose inverter of HLP series of multi-functions and high performance. Please read carefully the operation manual before putting the inverter to use so as to correctly install and operate the inverter, give full play to its functions and ensure the safety. Please keep the operation manual handy for future reference, maintenance, inspection and repair. Due to the inverter of a kind of electrical and electronic product it must be installed, tested

-

HLP-A Series HLP-A Series — 15 — 2) Arrangement of Control Circuit Terminals HLPA00D423C-HLPA01D523C HLPA0D7543C-HLPA02D243C HLPA03D743B-HLPA041543B HLPA001123B-HLPA009023B HLPA02D223B-HLPA03D723B HLPA05D523B-HLPA07D523B 3) Function Description of Main circuit Terminals Symbol Function Description R.S.T Input terminal of AC line power. ( 220V class, for both single/three phase, single phase connected to any two phases ) U.V.W Output terminal of the inverter P.Pr Connector for braking resistor. P1P Connector for DC reactor (When using a DC reacto

-

HLP-A Series HLP-A Series — 26 — Note: ● ¢ means ashing. ¤ means bright. ● For monitoring AC, DC, T and other items they can be only switched and displayed after the parameter setting. ● When it is powered up again after a power breakdown the inverter will display the screen previous to the power breakdown after its self detection. Procedures Display Indicator Lamp Explanation ↓ DISP 50.00 FWD Hz ¤ ¤ Switch to main screen, displ

-

HLP-A Series HLP-A Series — 66 — inverter to increase. So when the f unction of over-voltage stall prevention is started, if the DC voltage of the inverter becomes too high, the inverter will stop decelerating till the voltage at DC decreases below the set value, then the inverter will go on to decelerate and the ramp-down time will be extended automatically. When the inverter is in ramp-up, due to overload or too short ramp-up time, the output current of the inverter will go up quickly and exceed the set standard level. When this happe

-

HLP-A Series HLP-A Series — 4 — II. Safety Precautions 1. Before the Power-up Caution ● Check to be sure that the voltage of the main circuit AC power supply matches the input voltage of the inverter. ● The symbol, E , represents ground terminals. Be sure to make correct ground connection of the earth terminals of the motor and the inverter for safety. ● No contactor should be installed between the power supply and the inverter to b

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Holip HLP-A Series device using right now.

| Document’s Content and Additional Information | Share Manual |

|---|---|

|

Holip HLP-A Series Instruction manual

Pages Preview: Document Transcription:

See Details |

-

Page 2

HLP-A Series… -

Page 4: Table Of Contents

HLP-A Series I. Introduction 1. Checks upon Delivery 2. Nameplate Description of HLP Series Inverter II. Safety Precautions 1. Before the Power-up 2. During the Power-up 3. During the Operation III. Standards and Specifications 1. Particular Specifications 2. General Specifications IV.

-

Page 5: Table Of Contents

HLP-A Series X. Care & Maintenance, Fault Information and Troubleshooting 82 1. Precautions about Inspection and Maintenance 2. Periodical Inspection and Maintenance items 3. Fault Indication and Troubleshooting 4. Faults and Analysis XI. Selection of Peripheral Devices and Disposition 1. Options 2.

-

Page 6: I. Introduction

HLP-A Series I. Introduction Thank you for purchasing and using the general-purpose inverter of HLP series of multi-functions and high performance. Please read carefully the operation manual before putting the inverter to use so as to correctly install and operate the inverter, give full play to its functions and ensure the safety.

-

Page 7: Checks Upon Delivery

HLP-A Series Caution ● Do not make any voltage-withstanding test with any component inside the inverter. These semi-conductor parts are subject to the damage of high voltage. ● Never connect the AC main circuit power supply to the output terminals U.V W of the inverter.

-

Page 8: Nameplate Description Of Hlp Series Inverter

HLP-A Series 2. Nameplate Description of HLP Series Inverter MODEL: Model: HLP A 01D5 43 C Hardware Version Voltage Rating,43 means 3-phase 380V Inverter Capacity,01D5 means 1.5KW Serial No., A means A series Trade Mark HLP-A Series…

-

Page 9: Ii. Safety Precautions

HLP-A Series II. Safety Precautions 1. Before the Power-up Caution ● Check to be sure that the voltage of the main circuit AC power supply matches the input voltage of the inverter. ● The symbol, , represents ground terminals. Be sure to make correct ground connection of the earth terminals of the motor and the inverter for safety.

-

Page 10

HLP-A Series ● Be su re to t u r n off the power supply before dissembling or assembling the operation keypanel and fixing the front cover to avoid bad contact causing faults or non-display of the operator. ● Do not install the inverter in a space with explosive gas to avoid the risk of explosion. -

Page 11: During The Power-Up

50Hz. The user must strictly follow the instruction to operate and make wire connection. Otherwise HOLIP will not responsible for the damages due to wrong operation. The user will responsible for the damages themselves.

-

Page 12: Particular Specifications

HLP-A Series III. Standards and Specifications 1. Particular Specifications Inverter Output Suitable Input Power Type Capacity Current Motor Voltage (KW) (KVA) (KW) One & Three phase HLPA00D423C 220V 50Hz One & Three phase HLPA0D7523C 0.75 0.75 220V 50Hz One & Three phase…

-

Page 13

HLP-A Series Inverter Output Suitable Input Power Type Capacity Current Motor Voltage (KW) (KVA) (KW) One & Three phase HLPA009023B 137.2 220V 50Hz HLPA0D7543C 3Φ380V 50Hz 0.75 0.75 HLPA01D543C 3Φ380V 50Hz HLPA02D243C 3Φ380V 50Hz HLPA03D743B 3Φ380V 50Hz HLPA05D543B 3Φ380V 50Hz 12.5… -

Page 14: General Specifications

HLP-A Series 2. General Specifications Inverter Series HLP-A Control Mode SPWM 380±15% for 380V power ; 220±15% Input Power for 220V power D i s p l a y i n g f r e q u e n c y, c u r r e n t , 5-Digits Display &…

-

Page 15

HLP-A Series 5 multi-function output terminals for displaying of r unning, zero speed, Multi-Outputs counter, external abnormity, program operation and other information and warnings. AV R (a u t o v o l t a g e r e g u l a t i o n) ,… -

Page 16: Iv. Storage And Installation

HLP-A Series IV. Storage and Installation 1. Storage The inverter must be kept in its original package box before installation. Pay attention to the followings when keeping it in storage if the inverter is not used for the time being: ●…

-

Page 17

HLP-A Series board under the inverter bottom base and install it again. If the inverter is installed on a loose surface, stress may cause damage of parts in the main circuit so as to damage the inverter. ● The inverter should be installed on non-combustible materials, such as iron plate. -

Page 18: V. Wiring

HLP-A Series V. Wiring 1. Main Circuit Wiring Schematic Diagram Power supply: ● Verify that the inverter’s rated voltage coincides with AC power supply voltage to avoid a damage of the inverter No fuse breaker: ● Refer to the related list Ground fault circuit interrupter: ●…

-

Page 19: Description Of Terminal Block

HLP-A Series 2. Description of Terminal Block 1 ) Arrangement of Main circuit Terminals HLPA00D423C-HLPA01D523C HLPA0D7543C-HLPA02D243C HLPA03D743B HLPA02D223B-HLPA03D723B HLPA05D543B-HLPA07D543B HLPA001143B-HLPA003043B HLPA05D523B-HLPA003023B HLPA003743B-HLPA016043B HLPA003723B-HLPA009023B Cabinet HLPA013243BG-HLPA041543B HLP-A Series…

-

Page 20

HLP-A Series 2) Arrangement of Control Circuit Terminals HLPA00D423C-HLPA01D523C HLPA0D7543C-HLPA02D243C HLPA03D743B-HLPA041543B HLPA001123B-HLPA009023B HLPA02D223B-HLPA03D723B HLPA05D523B-HLPA07D523B 3) Function Description of Main circuit Terminals Symbol Function Description Input terminal of AC line power. ( 220V class, for both R.S.T single/three phase, single phase connected to any two phases )… -

Page 21: Basic Connection Diagram

HLP-A Series Symbol Function Description Factory setting M a x . o u t p u t c u r r e n t +12V Power Supply 200mA M a x . o u t p u t c u r r e n t…

-

Page 22

HLP-A Series 12V/100mA HLPA00D423C-HLPA03D723B HLPA0D7543C-HLPA03D743B HLPA05D543B-HLPA07D543B HLP-A Series… -

Page 23

HLP-A Series EV(P24) HLPA001143B~HLPA003043B HLPA05D523B~HLPA003023B HLPA003743B~HLPA041543B HLPA003723B~HLPA009023B HLP-A Series… -

Page 24: Precautions On Wiring

HLP-A Series 4. Precautions on Wiring 1) For the main circuit wiring: ● While wiring the sizes and specifications of wires should be selected and the wiring should be executed according to the electrical engineering regulations to ensure the safety.

-

Page 25

HLP-A Series Control Input wire Output wire Model NFB(A) wire Screw HLPA07D523B HLPA001123B HLPA001523B HLPA18D523B HLPA002223B HLPA003023B HLPA004523B HLPA005523B HLPA007523B HLPA009023B HLPA0D7543C HLPA01D543C HLPA02D243C HLPA03D743B HLPA05D543B HLPA07D543B HLPA001143B HLPA001543B HLPA18D543B HLPA002243B HLPA003043B HLPA003743B HLPA004543B HLPA005543B HLPA007543B HLPA009043B HLPA011043B HLPA013243B HLPA016043B… -

Page 26

HLP-A Series Control NFB(A) Input wire Output wire Model wire Screw HLPA022043B 150×2 150×2 HLPA025043B 150×2 150×2 HLPA028043B 150×2 150×2 HLPA030043B 150×2 150×2 HLPA031543B 1000 185×2 150×2 HLPA034543B 1000 185×2 150×2 HLPA037543B 1200 240×2 185×2 HLPA040043B 1200 240×2 185×2 HLPA041543B 1200 240×2… -

Page 27

HLP-A Series (1) Good (2) Good (3) Not good HLP-A Series… -

Page 28: Vi.instruction Of The Digital Operator

HLP-A Series VI. Instruction of the Digital Operator 1. Description of the Digital Operator Note: The inverter of the hardware version C can use the panel OP-AC01,the inverter of the hardware version B can use the panel OP-AB01 or OP- AB02.

-

Page 29: Description Of The Panel Type

HLP-A Series 2. Description of the panel type 3. List of the panel used in inverter Model Specification Panel type HLPA00D423C 0.4KW/220V OP-AC01 HLPA0D7523C 0.75KW/220V OP-AC01 HLPA01D523C 1.5KW/220V OP-AC01 HLPA02D223B 2.2KW/220V OP-AB01 HLPA03D723B 3.7KW/220V OP-AB01 HLPA05D523B 5.5KW/220V OP-AB02 HLPA009023B 90KW/220V HLPA0D7543C 0.75KW/380V…

-

Page 30: Description Of Operation Examples

HLP-A Series 2) Description of Display Items 5. Description of Operation Examples Indicator Procedures Display Explanation Lamp Power up Dsp2.0 FWD Hz Self detect when power-up, ↓ AXX.XX ¢ ¤ display version no. display ← running f requency PROG CD000…

-

Page 31

HLP-A Series Indicator Procedures Display Explanation Lamp ↓ FWD Hz Switch to main screen, display running DISP 50.00 ¤ ¤ f requency Switch of FWD.REV.rotation, display the ↓ 50.00→ 00.00 REV Hz status of REV.rotation → 50.00 ¤ ¤ ↓… -

Page 32: Vii. Commissioning

HLP-A Series VII. Commissioning 1. Important Checks before the Commissioning ● If there is any wrong connected wires? Pay special attention to the terminal of U.V.W; Make sure the power supply wires are connected to R.S.T, not U.V.W. ● If there is any metal powder or wires left on the base plate of the inverter or the terminal block, which may cause short circuit.

-

Page 33: Parameter And Function List

HLP-A Series VIII. Function List Parameter and Function List (Part 1) Set Range & Function Factory Category Code Function Explanation Setting CD000 Main Frequency 0.00~400.00 Hz 0.00 CD001 Max. Voltage 0.1V—* 220/380 CD002 Base Frequency 0.01~400.00 Hz 50.00 CD003 Intermediate Voltage 0.1V—*…

-

Page 34

HLP-A Series Parameter and Function List (Part 2) Set Range & Function Factory Category Code Function Explanation Setting 0: Rev Run forbidden; CD037 Rev. Rotation Select 1: Rev Run Enable 0: STOP Invalid CD038 STOP key select 1: STOP Valid CD039 S-Curve Time 0.0~6500.0S… -

Page 35

HLP-A Series Parameter and Function List (Part 3) Set Range & Function Factory Category Code Function Explanation Setting *CD056 Multi-output 1(DRV) 0: Invalid; 1: Run; 2: Fault indication; *CD057 Multi-output 2(UPF) 3: Zero Speed; Multi-output 4: Braking indication; *CD058 3(Terminals of 5: Set Frequency reach;… -

Page 36

HLP-A Series Parameter and Function List (Part 4) Set Range & Function Factory Category Code Function Explanation Setting Bias Direction at 0: Positive direction CD069 Higher Frequency 1: Negative direction Analog Negative Bias 0:Not allowable CD070 Reversed 1:Allowable AM Analog output… -

Page 37

HLP-A Series Parameter and Function List (Part 5) Set Range & Function Factory Category Code Function Explanation Setting CD095 AutoPLC Memory CD096 Reserved CD109 Number of Auxiliary CD110 Pump Continuous CD111 Operating Time of 1~9000min Aux.Pumps Interlocking Time of CD112 0.1~250S… -

Page 38

HLP-A Series Parameter and Function List (Part 6) Set Range & Function Factory Category Code Function Explanation Setting Set according to Motor CD130 Rated Motor Voltage nameplate Set according to Motor CD131 Rated Motor Current nameplate CD132 Motor pole number. -

Page 39

HLP-A Series Parameter and Function List (Part 7) Set Range & Function Factory Category Code Function Explanation Setting Communication Baud CD161 Rate Communication Data CD162 Method CD163 Reserved CD166 CD167 Display Items 0-31 CD168 Display Items Open Voltage Rating of… -

Page 40: Ix. Descriptions Of Functions

HLP-A Series IX. Descriptions of Functions CD000 Main Frequency Set Range: 0.00-400.00 Hz Unit: 0.01 Hz Factory Setting: 0.00 In the digital operator mode, the inverter will run at the set value of CD000. During running, the operating f requency can be changed by pressing ▲ or ▼ .

-

Page 41

HLP-A Series f requency the torque compensation will lose its f unction. When adjusting this parameter the output current of the inverter should be increased f rom low to high slowly according to the load of machines until it meets the starting requirement. -

Page 42

HLP-A Series Code Code CD003 CD005 CD012 CD013 CD035 CD003 CD005 CD012 CD013 CD035 Model Model A007523B A022043B A009023B A025043B A0D7543C A028043B A01D543C A030043B A02D243C 10.5 A03 1543B A03D743B 10.5 A034543B A05D543B A037543B A07D543B A040043B A041543B Note: ① Ramp Time 2 = Ramp Time 1 x 2 ②… -

Page 43

HLP-A Series This is set for preventing workers f rom false operation to avoid over-heat or some other mechanical faults, which might be caused due to too low operating f requency. The setting of Frequency Lower Limit must be less than the set value of CD007. -

Page 44

0Hz (See t2 in the diagram). HLP-A Series inverter have altogether 4 Ramp Times. For Ramp Time 2.3.4 the user can select the different ramp up or down time through the external terminals or switching of ramp time according to the actual needs. -

Page 45

HLP-A Series speed. When restarting, the current becomes higher, and over-current or stall may occur. So attention must be paid to the adjustment of current level of f requency track. Generally, CD144 is adjusted around 100. The concrete value can be set according to the characteristics of mechanical load. -

Page 46

HLP-A Series CD034 Source of Operating Frequency Set Range: 0—2 Unit: 1 Factory Setting: 0 0: Set by the operator. Operating f requency is given via the digital operator. 1 : Set by external terminals. Operating f requency is controlled by analog signals input via external terminals. -

Page 47

HLP-A Series is set by Ramp-up Time 4. When the jog button is released the inverter will stop output immediately. In case of jogging f unction please set the corresponding multi-input terminals to 07 or 08. This f unction is only valid at stop. It is invalid at running. For the related parameters refer to CD050-CD055. -

Page 48

HLP-A Series CD040 Up/Down Set Range: 0.01~2.50Hz Unit:0.01Hz Factory Setting:0.01 This parameter can be set in combination with CD073 for Up/Down of external control and the speed of increase and decrease. the step length of Up/Down=(the set value of CD040/0.01)× UP/DOWN speed CD041 Starting Frequency Set Range: 0.10—10.00 Hz… -

Page 49

HLP-A Series CD044 Skip Frequency 1 CD045 Skip Frequency 2 CD046 Skip Frequency 3 Set Range: 0.00—400.00 Hz Unit: 0.01Hz Factory Setting: 0.00 CD047 Skip Frequency Range Set Range: 0.10—10.00 Hz Unit: 0.01Hz Factory Setting: 0.50 These three f requency skipping points are set for avoiding a mechanical resonance point. -

Page 50

HLP-A Series CD050 Multi-input 1 (FOR function) Factory Setting: 02 CD051 Multi-input 2 (REV function) Factory Setting: 03 CD052 Multi-input 3 (RST function) Factory Setting: 10 CD053 Multi-input 4 (SPH function) Factory Setting: 17 CD054 Multi-input 5 (SPM function) Factory Setting: 18… -

Page 51

HLP-A Series of the inverter will be increased or decreased by one unit. When the switch of the terminal is hold the f requency will increase or decrease rapidly to a point and then increase or decrease 26: Down Function at even speed. When the power is up again af ter the power breakdown the changed f requency will not be memorized. -

Page 52

HLP-A Series 3. Description of Ramp Time 1 and 2: 1) This f unction is only valid when CD076 is set to 0, 1 and 2. Under the disturbance and internal control multi-speed it is invalid. 2) Any two multi-inputs can be combined for 4 kinds of ramp time for selection. -

Page 53

HLP-A Series Note: ( 1 ) This f unction is only valid when CD076 is set to 1, i.e. for 4-Speed of external control. ( 2 ) Low, middle and high speed f requency are determined by Frequency 2,3, 4. -

Page 54

HLP-A Series ( 8 ) When using the f unction of UP and DOWN, the keys of △ ▽ of the panel are valid. Af ter changing the values it needs to press SET (ENTER) key for confirmation and then the inverter can implement the action. Meanwhile the value will write to CD000, which will be memorized af ter a power breakdown. -

Page 55

HLP-A Series 02: Fault Indication: The contact will act when the inverter detects abnormal conditions. 03: Zero Speed: The contact will act when the output f requency of the inverter is less than its starting f requency. 04: DC Braking indication: The contact will act when the inverter is in DC braking. -

Page 56

HLP-A Series 28: PID Lower Limit Alarm: This contact will act when the PID feedback is smaller than the lower limit (the set value of CD156). 29: PID Upper Limit Alarm: This contact will act when the PID feedback is greater than the upper limit (the set value of CD155). -

Page 57

HLP-A Series CD061 Uniform Frequency 1 CD062 Uniform Frequency 2 Set Range: 0.00—400.00 Hz Unit: 0.01 Hz Factory Setting: 0.00 CD063 Uniform Frequency Range Set Range: 0. 1 0—10.00 Hz Unit: 0.01 Hz Factory Setting: 0.50 When the output f requency is more than the unif orm f requency the corresponding multi-outputs will act. -

Page 58

HLP-A Series Among which: U: Analog Voltage; U : Maximum Analog Voltage; I: Analog Current; I : Maximum Analog Current. For example, When +10V and 20mA are respectively entered for the analog input, the output f requency of the inverter is 50Hz. -

Page 59

HLP-A Series Setting: CD066=50 CD067=0 CD068=0 CD069=0 CD070=0 Not e: t h is c u r ve is a k i nd of s pecia l application of reverse ramp setting. When using transmitter for the control of pressure, temperature and others and while the control… -

Page 60

HLP-A Series CD072 UP/DOWN Function Set Range: 0-1 Unit: 1 Factory Setting: 0 0: Not memorized 1 : Memorized This parameter can be set for the selection of whether the values changed by the UP or DOWN shall be memorized or not af ter stop. The changed values… -

Page 61

HLP-A Series Multi-f unction Terminals Results Multi-speed Multi-speed Multi-speed Main f requency and f requencies are determined by CD000 or potentiometer. Multi-speed 1 and f requency are determined by CD080. Multi-speed 2 and f requency are determined by CD081 . -

Page 62

HLP-A Series multi-f unction terminals. ⑥ This main f requency can be set in two ways. One method is to set it through CD000 and another is to set it through the potentiometer. When CD034 is set to 1 the f requency of Main Frequency is set by the potentiometer. -

Page 63

HLP-A Series be used the timer can be set to 0. ④ Running direction of each speed step is determined by CD078. ⑤ In the internal control multi-speed operation the running time and direction are determined by the setting of internal parameters. Any switching of external time and FOR/REV rotation is invalid. -

Page 64

HLP-A Series Explanation: 1. Stop after the program runs one cycle. When the command of auto program operation is given, the inverter will run with each set value of internal parameters. It will run for one cycle and then stop automatically. The inverter will not restart and run until it receives another command of operation. -

Page 65

HLP-A Series 0: For. 1 : Rev. Main Speed (CD000) For. Frequency 1 (CD080) Rev. Frequency 2 (CD081) For. Frequency 3 (CD082) Rev. Frequency 4 (CD083) For. Frequency 5 (CD084) For. Frequency 6 (CD085) Rev. Frequency 7 (CD086) For. The parameter value 01001010 is converted to a decimal value: 1 ×2… -

Page 66

HLP-A Series t5 Select Ramp Time 1 So CD079 is set to 99 t6 Select Ramp Time 1 Attach: 2 t7 Select Ramp Time 1 =16 2 =32 2 =64 2 =128 t8 Select Ramp Time 1 CD080 Frequency 2 Factory Setting 15.00**… -

Page 67

HLP-A Series CD096~CD109 Reserved *CD110 Number of Auxiliary Pump Set Range : 0—2 Unit: 1 Factory Setting: 0 This parameter is set for the number of auxiliary pump. The start or stop of the auxiliary pumps is controlled by using the multi-output contacts and Auxiliary Pump 1 or Auxiliary Pump 2 is controlled through the peripheral control circuit. -

Page 68

HLP-A Series CD1 13 and CD1 14 must be used in combination of CD061, CD062 and multi- outputs. Their main f unction is to increase or decrease the number of auxiliary pump. *CD115 Stopping Voltage Level Set Range:0~150% Unit:1% Factory Setting:95 This parameter is set for the voltage level of the master pump entering into sleep mode. -

Page 69

HLP-A Series The following is the block diagram of multi pumps operation: HLP-A Series… -

Page 70

HLP-A Series F ≥ CD061 P ≥ CD115 T ≥ CD116 F ≥ CD061 T ≥ CD113 CD120 Over-voltage Stall Prevention Set Range: 0—1 Unit: 1 Factory Setting: 1 0: Over-voltage stall prevention invalid 1 : Over-voltage stall prevention valid. -

Page 71

HLP-A Series inverter to increase. So when the f unction of over-voltage stall prevention is started, if the DC voltage of the inverter becomes too high, the inverter will stop decelerating till the voltage at DC decreases below the set value, then the inverter will go on to decelerate and the ramp-down time will be extended automatically. -

Page 72

HLP-A Series 100% current is the rated current of the motor. CD124 Over-torque Detect Mode Set Range: 0—3 Unit: 1 Factory Setting: 0 0: When reaching the f requency it starts to detect over-torque and when over- torque is detected it continues to run. -

Page 73

HLP-A Series CD127 Decel. Time for Stall Prevention at Constant Speed Factory Setting: 5.0 When the inverter is used for the loads of kinds of fan and pump CD122 can be set to 120. When the current of the inverter is greater than 120% the output f requency will decrease and the current will also decrease accordingly. -

Page 74

HLP-A Series CD133 Rated Motor Revolution Set Range: 0~9999r/min Unit: 1r/min Factory Setting: 1440 This is set according to the actual revolution of the motor. The displayed value is the same as this set value. It can be used as a monitoring parameter, which is convenient to the user. -

Page 75

HLP-A Series CD142 DC Braking Time at stop Set Range: 0.0~25.0S Unit: 0.1S Factory Setting: 0.0 Note: When this parameter is set to any non-zero value it starts DC brake at stop and sends the DC braking time to the motor. DC braking at stop is of ten used for a high-level stop or positioning control. -

Page 76

HLP-A Series CD147 Number of Abnormal Restart Set Range: 00—10 Unit: 1 Factory Setting: 00 Af ter the abnormal conditions (such as over-current and over-voltage) happens the inverter will automatically reset and restart. If the starting mode is set to normal mode it will start according to the normal procedures. -

Page 77

HLP-A Series *CD150 Proportional Constant (P) Set Range:0~1000.0% Unit:0.1% Factory Setting:100.0 This proportional constant is set for the error value gain. In case of I=0, D=0, it is only for proportional control. *CD151 Integral Time (T) Set Range:0.1~1000.0S Unit:0.1S Factory Setting:.5.0 The integral time (I) is set for the responding speed for PID. -

Page 78

HLP-A Series General operating methods of PID control: (1) Choose the correct transmitter (with the output specification of standard current signal 4-20mA). (2) Set the right target value. (3) If the output does not have oscillation, increase the proportional constant (P). -

Page 79

4: 8E1 For RTU 5: 8O1 For RTU CD163~CD166 Reserved HOLIP MODBUS Communication Protocol When using the RS485 communication interface, each of the inverters must be set for its own address so that the computer can use this individual address to carry out the control. -

Page 80

HLP-A Series example: 64H ASCII mode: Each of 8-bit data is composed of two ASC IIbyte, for example: One 1-bit data 64H (hexadecimal) is composed of ASC II byte“64”, included“6” (36H) and “4”(34H). Byte ASCII code Byte ASCII code 2: Communication Data Method (1) 8N1 For ASCII CD162=0 (… -

Page 81

HLP-A Series ( 5 ) 8E1 For RTU C D162=4 ( 6 ) 8O1 For RTU C D162=5 3 : Communication Document Formats 3. 1 ASCII Mode Communication Document Forms DATA (n-1) “ : ” ADDR FUNC CR(0DH) ..(3AH) -

Page 82

HLP-A Series If DATA is one word, the LEN=3, If DATA is one byte, the LEN=2 . When inverter has no this f unction code or reply no ef fect, the format as follows : ADDR 81H 01 FUNC b : Write f unction code data… -

Page 83

HLP-A Series word, LEN=3, when one byte or <1byte, LEN=2 . (5) DATA: <Data characters> data content. 2n ASCII compose n bytes, it have fif ty ASC II at most. (6) LRC : longitudinal redundancy check ASCII mode: Get LRC methods is that add ADDR to the last data, if the result is more than 256,then the result subtract 256 until the result is less then 256 (if the result is 128H, take 28H), then 100H subtract the result get LRC. -

Page 84

HLP-A Series all data. The last data of CRC register is CRC value. When send CRC value in command data, low bytes must change the sequence with high bytes, i.e. low bytes will be sent first. (7) Example 1 : Write 30.00Hz to inverter of 01… -

Page 85

HLP-A Series 5: Total running time of power up(Unit: Hour) 6-3 1 : Invalid CD168 Display Items Open Set Range: 0—7 Unit: 1 Factory Setting: 0 This parameter is set for selection of displaying of DC voltage, AC voltage and other items so that the customer can monitor and view them in sequence through the switch key. -

Page 86

CD181 Reserved CD182 Communication Protocol Select Set Range:0-1 Unit:1 Factory Setting:0 0: Holip MODBUS Communication Protocol 1 : Standard MODBUS Communication Protocol CD183~CD250 Reserved Note: * means the said parameter has a variety of set values or should be set specifically according to concrete conditions. -

Page 87: X. Care & Maintenance, Fault Information And Troubleshooting

HLP-A Series X. Care & Maintenance, Fault Information and Troubleshooting Periodical maintenances and inspections will keep your inverter in its normal state for long time. 1. Precautions about Inspection and Maintenance ● Be sure to turn off the power supply to the inverter (R.S.T) first before the inspection and maintenance.

-

Page 88: Fault Indication And Troubleshooting

HLP-A Series The inverter of HLP series is relatively perfective with the protection f unctions of overload, inter-phase short circuit, earth short circuit, under-voltage, overheating and over-current, etc. When a protection f unction happens with the inverter please check the reasons of faults according to the information listed in the table below.

-

Page 89

HLP-A Series Fault Fault Contents & Disposal methods Display Description E.ou.S Over-voltage at stop E.ou.a Over-voltage at 1 : Extend the Ramp-down Time or add a accel braking resistor. E.ou.n Over-voltage at 2: Improve the mains supply voltage and check… -

Page 90

HLP-A Series Fault Fault Contents & Disposal methods Display Description E.bT.A Braking transistor E.bT.n Please send it for repair. damage E.bT.d E.EC.S E.EC.n CPU fault Please contact the factory. E.EC.d E.EC.A E.EE.S E.EE.n Prom fault Please contact the factory. E.EE.d E.EE.A… -

Page 91: Faults And Analysis

HLP-A Series 4. Faults and Analysis (1) When RUN key is pressed, the motor does not run. 1) The setting of operation mode is wrong, i.e., under the operation mode of external control terminals, the inverter is started by the digital operator or under the operation mode of the digital operator it is started by the external control terminals.

-

Page 92

HLP-A Series phase to phase withstand voltage against shock than the maximum shock voltage. (7) The starting of the inverter interferes other control devices 1) Decrease the carrier f requency and reduce the number of actions of internal switches. 2) Install a noise filter at the power input of the inverter. -

Page 93: Options

HLP-A Series X I . S e l e c t i o n o f P e r i p h e r a l D e v i c e s a n d Disposition 1. Options Description…

-

Page 94: Disposition

HLP-A Series 3) DC reactors It is necessary to install a DC reactor when the capacity of power supply is more than 1000 KVA or the mains power capacity is higher than the rated capacity of the inverter. A DC reactor is also needed for the case with higher demand on the improvement of power f actor of power supply.

-

Page 95

HLP-A Series Connection ① Remove the jumpers of P and P1 terminals. ② Connect DC reactor to Terminals P and P1 as shown in the following diagram: DC Reactor Note: HLP inver ter of above 37 K W h a s c o n n e c t o r s. T h e inverter of below 37KW must not be connected with it. -

Page 96

HLP-A Series AC Reactor The incoming reactor is also named shif t-changing reactor and it is used for the incoming wire of the mains with AC f lowing inside. Its f unction is to suppress the harmonics of the inverter feedback to the mains. -

Page 97

HLP-A Series Braking resistor Braking torque Special Motor Specification Inverter Model 10%ED Ω HLPA016043B 36000 13.6/4 HLPA01 8543B 45000 13.6/5 1 85 HLPA020043B 45000 13.6/5 HLPA022043B 48000 13.6/5 HLPA025043B 48000 13.6/5 HLPA028043B 57600 13.6/6 HLPA030043B 57600 13.6/6 For the braking resistor used for the machines of above 3 15 KW please contact the factory. -

Page 98: Xii. Appendices

HLP-A Series XII. Appendices Appendix 1: Simple Examples of Application 1 . Disturbance Function (Generation of Triangle Wave) A curve as in lef t is generated. Parameter setting: CD076=3 CD000=30 CD080=27 CD086=0.5 CD087=10 CD088=10 2. Drawing Function Parameter setting: CD076=5…

-

Page 99

HLP-A Series Parameter setting: CD033=1 CD034=1 CD066=50 CD068=50 CD067= 1 CD069=0 CD070= 1 4. Internal Control 8 Speed Run A curve as shown in the following diagram is established. Internal control 8-speed run will stop af ter running for one cycle. -

Page 100

HLP-A Series 5. Linkage of Multi Pumps Attention: ① The f requency of the main inverter can be set by the potentiometer. ② The proportion relation of the inverters can be adjusted by CD068. For example: For F =1 : 2 : 3 the parameters of CD068 can… -

Page 101

HLP-A Series 6. Run by Switching of Power Frequency/Variable Frequency Note: ① K is a switch for power f requency/variable f requency. ② K is a start button and K is a stop button for power f requency. ③ The stopping mode is set for coasting stop. -

Page 102

HLP-A Series 7. Example application of simple water supply with constant pressure (1) Use a pressure transmitter with measuring range of 0-10kg, feedback of 4-20mA, requiring water supply at the pressure of 5kg with alarming at the upper limit of 6kg and the lower limit of 4kg. The start f rom the panel stops. -

Page 103

HLP-A Series ② The feedback signal is 4-20mA. Others are invalid. ③ In this example the target value is given by the potentiometer (0~10V) . ④ CD150, CD15 1 and CD152 should be set according the actual condition. (Refer to the parameter description.) ⑤… -

Page 104

HLP-A Series example the switching is made through the panel) 9. Example application of Auto PLC Suspend Requirement: Auto PLC can be suspended during the internal control multi- speed run. Af ter handling the related problems it can resume. (1) Connection… -

Page 105: Appendix 2: Appearance And Installation Dimensions

HLP-A Series Appendix 2: Appearance and Installation Dimensions Inverter Model Appearance and Installation Dimensions HLPA00D423C HLPA0D7523C HLPA01D523C HLPA0D7543C HLPA01D543C HLPA02D243C Unit: mm HLPA02D223B HLPA03D723B HLPA03D743B Unit: mm HLP-A Series…

-

Page 106

HLP-A Series HLPA05D523B HLPA07D523B Unit : mm HLPA05D543B~ HLPA07D543B Unit : mm HLP-A Series… -

Page 107

HLP-A Series HLPA001 123B HLPA005523B HLPA001 143B HLPA005543B Unit : mm HLPA007523B HLPA009023B HLPA007543B HLPA016043B Unit : mm HLP-A Series… -

Page 108

HLP-A Series Height of 4 hoisting eyes : 132~250KW 36mm 280~415KW 43mm HLPA013243BG HLPA016043BG HLPA01 8543B HLPA041543B 2. External Dimensions Table (Unit: mm) Inverter Model HLPA00D423C HLPA0D7523C HLPA01D523C 1 16 1 70 Φ5 HLPA0D7543C HLPA01D543C HLPA02D243C HLPA02D223B HLPA03D723B Φ5 HLPA03D743B HLPA05D523B Φ7… -

Page 109

HLP-A Series Inverter Model HLPA003043B 3 15 5 10 Φ8 HLPA003023B HLPA003743B Φ10 HLPA004543B HLPA005543B HLPA003723B Φ16 HLPA007543B HLPA004523B Φ16 HLPA009043B HLPA005523B HLPA007523B HLPA009023B Φ16 HLPA01 1043B HLPA013243B HLPA016043B Φ16 HLPA013243BG 1649 Φ16 HLPA016043BG HLPA01 8543B 1 805 Φ16 HLPA025043B… -

Page 110: Appendix 3: Appearance And Installation Dimensions

HLP-A Series Appendix 3: Appearance and Installation Dimensions Type Appearance and Installation Dimensions OP-AB01 OP-AC01 Unit : mm OP-AB02 Unit : mm HLP-A Series…

-