Техническая документация по ремонту автомобилей Hyundai Santamo ( все годы выпуска) Бесплатно, без регистрации и СМС

Руководство по ремонту, эксплуатации и техническому обслуживанию Hyundai Santamo

— полные технические характеристик

-особенности эксплуатации

— устранение неисправностей Hyundai Santamo

— цветные электросхемы Hyundai Santamo

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по эксплуатации Hyundai Santamo

— полные технические характеристики Hyundai Santamo

— особенности эксплуатации

— устранение неисправностей

— цветные электросхемы

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту Hyundai Santamo в фотографиях

— полные технические характеристики

— особенности эксплуатации Hyundai Santamo

— устранение неисправностей

в фотографиях своими руками

— более 1980 фотографий процесса ремонта

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Каталог деталей и сборочных единиц Hyundai Santamo

— таблица взаимозаменяемости деталей автомобилей

— предназначен для работников СТО и владельцев автомобилей Hyundai Santamo

— каталог деталей Hyundai Santamo

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

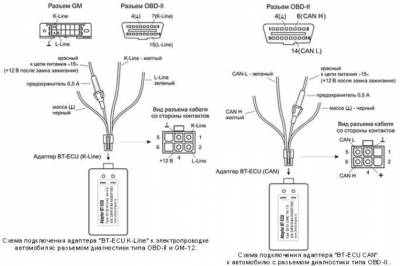

Подробная электросхема Hyundai Santamo

— полное описание электрооборудования Hyundai Santamo , подробная интерактивная электрическая схема Hyundai Santamo

— подробно описан алгоритм поиска неисправностей электрооборудования (стартер, генератор, система зажигания, впрыск, инжектор)

— подробная схема электрооборудования ( электро схема ) Hyundai Santamo

— распиновка разъемов электрических, распиновка электро проводки Hyundai Santamo

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту двигателя Hyundai Santamo

— полные технические характеристики двигателя Hyundai Santamo

— особенности конструкции и ремонта двигателя Hyundai Santamo

— подробное описание процессов разборки, дефектовки и сборки двигателя с фотографиями, ГРМ

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту коробок передач Hyundai Santamo

— полные технические характеристики КПП

— особенности конструкции и ремонта КПП Hyundai Santamo

— устранение неисправностей КПП трансмиссия, валы, шестерни, ШРУС

— подробное описание процессов разборки, дефектовки и сборки КПП с фотографиями

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

а вот здесь можно заработать на новую машину, и тогда старую не придется ремонтировать!!!

Hyundai Santamo

|

Hyundai SantamoЭлектронные книги Hyundai Santamo для автомобилистов бесплатно

Руководство по ремонту, эксплуатации и техническому обслуживанию Hyundai Santamo СКАЧАТЬ 291 Мб Руководство по ремонту Hyundai Santamo в фотографиях СКАЧАТЬ 128 Mб Секреты ремонта Hyundai Santamo СКАЧАТЬ 132 Мб Подробная схема электрооборудования Hyundai Santamo СКАЧАТЬ 88 Мб Каталог деталей Hyundai Santamo СКАЧАТЬ 36 Мб Руководство по ремонту двигателя Hyundai Santamo СКАЧАТЬ 53 Мб Руководство по ремонту трансмиссии Hyundai Santamo СКАЧАТЬ 154 Мб Коды неисправностей Hyundai Santamo СКАЧАТЬ 50 Мб Мультимедийное Руководство по тюнингу Hyundai Santamo СКАЧАТЬ 51 Мб Руководства по ремонту Hyundai Santamo

Уровень охлаждающей жидкости в расширительном бачке при холодном двигателе . . . . . . . . . . на 25—30 мм выше метки “MIN” |

Электронные книги Hyundai SANTAMO для автомобилистов бесплатно

Руководство по ремонту, эксплуатации и техническому обслуживанию Hyundai SANTAMO СКАЧАТЬ 194 Мб

(Руководство по ремонту Hyundai SANTAMO полная версия)

Руководство по ремонту Hyundai SANTAMO в фотографиях СКАЧАТЬ 116 Mб

(Ремонт Hyundai SANTAMO в фотографиях)

Секреты ремонта Hyundai SANTAMO СКАЧАТЬ 51 Мб

(подробное описание особенностей ремонта Hyundai SANTAMO )

Подробная схема электрооборудования Hyundai SANTAMO СКАЧАТЬ 72 Мб

( электросхема Hyundai SANTAMO )

Каталог деталей Hyundai SANTAMO СКАЧАТЬ 101 Мб

( Hyundai SANTAMO Каталог деталей и сборочных единиц )

Руководство по ремонту двигателя Hyundai SANTAMO СКАЧАТЬ 73 Мб

(ремонт двигателя Hyundai SANTAMO своими руками в фотографиях)

Руководство по ремонту трансмиссии Hyundai SANTAMO СКАЧАТЬ 104 Мб

(ремонт КПП и дифференциала Hyundai SANTAMO своими руками в фотографиях)

Коды неисправностей Hyundai SANTAMO СКАЧАТЬ 15 Мб

( Hyundai SANTAMO коды ошибок инжектора, распиновка, самодиагностика )

Мультимедийное Руководство по тюнингу Hyundai SANTAMO СКАЧАТЬ 115 Мб

(тюнинг Hyundai SANTAMO своими руками с фотографиями)

ТЕГИ: Руководства по ремонту Hyundai SANTAMO

бесплатно, без регистрации и СМС Hyundai SANTAMO

Бесплатно, без регистрации и СМС Hyundai SANTAMO

Hyundai SANTAMO

Книги для ремонта автомобилей Hyundai Santamo бесплатно, без регистрации и смс

|

Руководство по ремонту, эксплуатации и техническому обслуживанию Hyundai Santamo Мультимедийное руководство по ремонту Hyundai Santamo Руководство по ремонту Hyundai Santamo в фотографиях |

|

|||

|

скачать с depositfiles |

скачать с turbobit |

СКАЧАТЬ с vodafile |

||

|

Электросхема Hyundai Santamo Подробная схема электрооборудования Hyundai Santamo Интерактивная электросхема Hyundai Santamo |

|

|||

|

скачать с depositfiles |

скачать с turbobit |

|||

|

Каталог деталей Hyundai Santamo Каталог деталей и сборочных единиц Hyundai Santamo Таблица взаимозаменяемости деталей Hyundai Santamo |

|

|||

|

скачать с depositfiles |

скачать с turbobit |

|||

Другие файлы по теме:

Руководство по ремонту двигателя Hyundai Santamo (ремонт двигателя Hyundai Santamo своими руками) СКАЧАТЬ

Руководство по ремонту трансмиссии Hyundai Santamo ( ремонт КПП Hyundai Santamo своими руками ) СКАЧАТЬ

Руководство по тюнингу Hyundai Santamo (тюнинг Hyundai Santamo своими руками) скачать

Коды неисправностей Hyundai Santamo (инжектор Hyundai Santamo) СКАЧАТЬ

00

11

12

13

14

15

16

17

21

22

23

25

26

27

31

32

33

34

35

36

37

42

51

52

54

55

00109000812

General ……………………

Engine …………………….

Engine Lubrication ………….

Fuel ………………………

Engine Cooling ……………..

Intake and Exhaust …………

Engine Electrical ……………

Engine and Emission Control ….

Clutch …………………….

Manual Transmission ………..

Automatic Transmission ……..

Propeller Shaft ……………..

Front Axle ………………….

Rear Axle ………………….

Wheel and Tyre ……………..

Power Plant Mount …………..

Front Suspension ……………

Rear Suspension ……………

Service Brakes ……………..

Parking Brakes ……………..

Steering ……………………

Body ………………………

Exterior ……………………

Chassis Electrical …………..

WORKSHOP MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL

PYDE9802

WORKSHOP MANUAL

ENGINE GROUP PWEEjjjj

(Looseleaf edition)

ELECTRICAL WIRING PHDE9802

BODY REPAIR MANUAL PBDE9802

PARTS CATALOGUE

SPACE RUNNER B608V509Aj

SPACE WAGON B608W509Aj

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

“GDI” is the trade mark which Mitsubishi Motors

Corporation holds.

E

Mitsubishi Motors Corporation Aug. 1998

Interior and Supplemental

Restraint System (SRS) ……..

Heater, Air Conditioner and

Ventilation …………………

WARNING!

(1) Improper service or maintenance of any component of the SRS and seat belt with pre-tensioner,

or any SRS-related component, can lead to personal injury or death to service personnel (from

inadvertent firing of the air bag and seat belt with pre-tensioner) or to the driver and passenger

(from rendering the SRS inoperative).

(2) SRS components and seat belt with pre-tensioner should not be subjected to heat, so remove

the SRS-ECU, air bag module (driver’s side and front passenger’s side), clock spring, side

impact sensor, front seat assembly (side air bag module) and seat belt with pre-tensioner before

drying or baking the vehicle after painting.

SRS-ECU, air bag module, clock spring and side impact sensor: 93_C or more

Seat belt with pre-tensioner: 90_C or more

(3) Service or maintenance of any SRS component and seat belt with pre-tensioner or SRS-related

component must be performed only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

52B — Supplemental Restraint System (SRS), before beginning any service or maintenance

of any component of the SRS and seat belt with pre-tensioner or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

21-1

CLUTCH

CONTENTS

21109000190

GENERAL INFORMATION 2………………

SERVICE SPECIFICATIONS 2……………..

LUBRICANTS 2…………………………

ON-VEHICLE SERVICE 2…………………

Clutch Pedal Inspection and Adjustment 2…….

Bleeding 3……………………………….

CLUTCH PEDAL 4………………………

CLUTCH CONTROL 5……………………

Clutch Master Cylinder 7…………………..

CLUTCH —

General Information/Service Specifications/Lubricants/On-vehicle Service

21-2

GENERAL INFORMATION

21100010093

The clutch is a dry single-disc, diaphragm type;

hydraulic pressure is used for the clutch control.

SERVICE SPECIFICATIONS

21100030150

Items Standard value

Clutch pedal height mm 224 — 227 <L.H. drive vehicles>

211 — 214 <R.H. drive vehicles>

Clutch pedal clevis pin play mm 1-3

Clutch pedal free play mm 6-13

Distance between the clutch pedal and the toeboard

when the clutch is disengaged mm

125 or more

LUBRICANTS

21100040078

Items Specified lubricants Quantity

Clutch fluid Brake fluid DOT3 or DOT4 As required

Push rod assembly Rubber grease

Boot

Release cylinder push rod MITSUBISHI genuine grease

Part No. 0101011

ON-VEHICLE SERVICE

21100090158

CLUTCH PEDAL INSPECTION AND

ADJUSTMENT

1. Turn up the carpet, etc. under the clutch pedal.

2. Measure the clutch pedal height and the clutch pedal

clevis pin play.

Standard value (A):

224 — 227 <L.H. drive vehicles>

211 — 214 <R.H. drive vehicles>

Standard value (B): 1 — 3 mm

Clutch pedal height Clutch pedal clevis

pin play

A

B

CLUTCH —

On-vehicle Service

21-3

3. If the clutch pedal height and the clutch pedal clevis pin

play are outside the standard value, turn the setting nut

to adjust them to the standard value.

Caution

Do not push in the master cylinder push rod at this

time, otherwise the clutch will not operate properly.

4. After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of

the pedal pad) and the toeboard when the clutch is

disengaged are within the standard value ranges.

Standard value (C): 6 — 13 mm

Standard value (D): 125 mm or more

5. If the clutch pedal free play and the distance between

the clutch pedal and the toeboard when the clutch is

disengaged do not agree with the standard values, it

is probably the result of either air in the hydraulic system

or a faulty master cylinder or clutch. Bleed the air, or

disassemble and inspect the master cylinder or clutch.

6. Turn back the carpet, etc.

BLEEDING

21100140143

Specified fluid: Brake fluid DOT 3 or DOT 4

Caution

Use the specified brake fluid. Avoid using a mixture of

the specified fluid and other fluid.

Setting nut

Clutch pedal

12 Nm

Clutch pedal free play

Distance between the clutch pedal and the

toeboard when the clutch is disengaged

C

D

CLUTCH —

Clutch Pedal

21-4

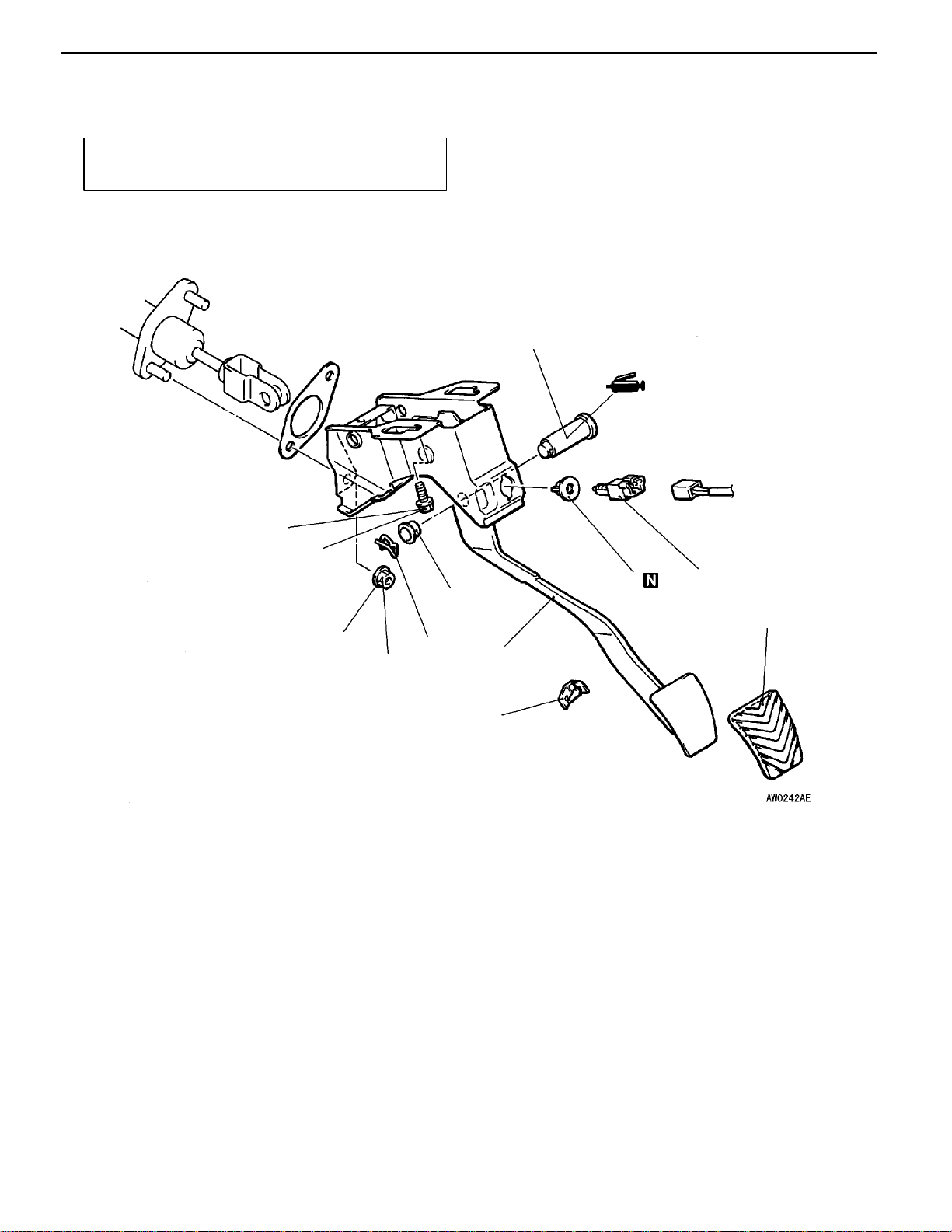

CLUTCH PEDAL

21100160224

REMOVAL AND INSTALLATION

Post-installation Operation

Clutch Pedal Adjustment (Refer to P.21-2)

10

2

8

4

5

6

7

9

3

12 Nm

1

12 Nm

Removal steps

1. Clutch switch

2. Clip

3. Snap pin

4. Bushing

5. Pin assembly

6. Clutch master cylinder mounting nut

7. Master cylinder member mounting bolt

8. Clutch pedal

9. Stopper <R.H. drive vehicles>

10. Pedal pad

CLUTCH —

Clutch Control

21-5

CLUTCH CONTROL

21100190216

REMOVAL AND INSTALLATION

Pre-removal Operation

Clutch Fluid Draining

Post-installation Operation

D Clutch Fluid Supplying

D Clutch Line Bleeding (Refer to P.21-3)

D Clutch Pedal Adjustment (Refer to P.21-2)

<L.H. drive vehicles>

Release

cylinder

push rod

Release

fork

7

6

8

4

8

5

2

1

3

9

19 Nm

Specified grease:

MITSUBISHI genuine

grease Part No. 0101011

15 Nm

7, 8

12 Nm

29 Nm

12 Nm

Clutch master cylinder removal

steps

1. Clevis pin assembly

2. Clutch pipe connection

3. Reservoir hose

4. Clutch master cylinder

Clutch release cylinder removal

steps

5. Clutch pipe connection

6. Clutch release cylinder

Clutch line removal steps

7. Clutch pipe

8. Clutch hose

9. Bracket

10. Clutch hose

CLUTCH —

Clutch Control

21-6

<R.H. drive vehicles>

Release

cylinder

push rod

Release fork

1

2

3

4

5

9

7

12 Nm

8

Specified grease:

MITSUBISHI genuine

grease Part No. 0101011

15 Nm

8

6

19 Nm

12 Nm

7

Clutch master cylinder removal

steps

1. Clevis pin assembly

2. Clutch pipe connection

3. Reservoir hose

4. Clutch master cylinder

Clutch release cylinder removal

steps

5. Clutch pipe connection

6. Clutch release cylinder

Clutch line removal steps

7. Clutch pipe

8. Bracket

9. Clutch hose

CLUTCH —

Clutch Control

21-7

DISASSEMBLY AND REASSEMBLY

21100210172

CLUTCH MASTER CYLINDER

Caution

Do not disassemble piston assembly.

1

2

3

4

5

6

2

8

2

2

3

4

4

1

Grease: Rubber grease

Clutch fluid:

Brake fluid DOT3 or DOT4

Piston repair kit

12 Nm

<L.H. drive vehicles>

<R.H. drive vehicles>

9

6

5

9

7

12 Nm

44 Nm

1

2

3

Disassembly steps

1. Piston stopper ring

2. Piston assembly

«

A

A 3. Push rod assembly

4. Boot

5. Spring pin

6. Nipple

7. Gasket

8. Damper assembly

9. Master cylinder body

CLUTCH —

Clutch Control

21-8

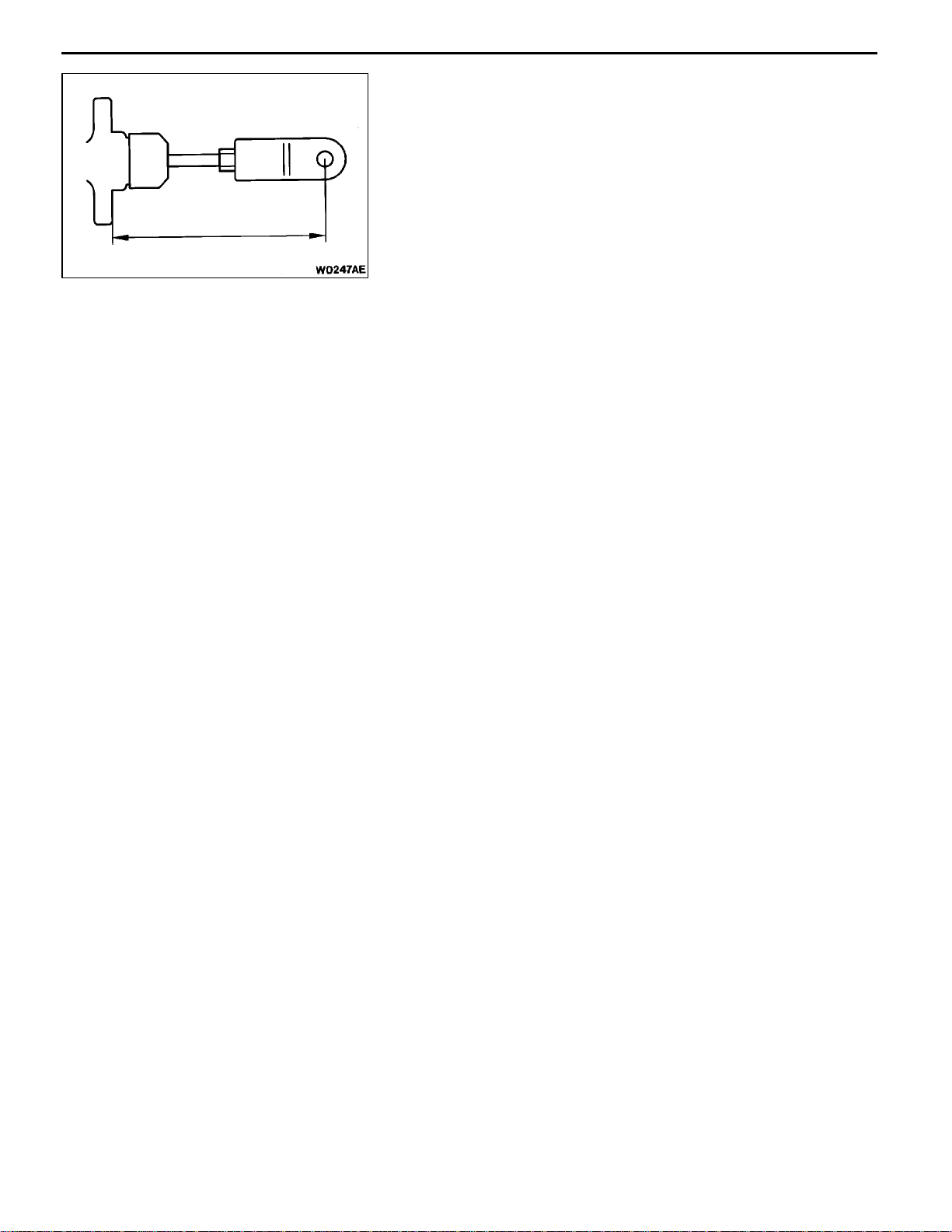

INSTALLATION SERVICE POINT

«

A

A

PUSH ROD ASSEMBLY INSTALLATION

Set the length of the push rod assembly to the shown

dimension to make the adjustment of clutch pedal easier.

<L.H. drive vehicles> 103 mm

<R.H. drive vehicles> 121 mm

22-1

MANUAL

TRANSMISSION

CONTENTS

22109000395

LUBRICANT 2………………………….

SPECIAL TOOLS 2……………………..

ON-VEHICLE SERVICE 3…………………

Transmission Oil Check 3…………………..

Transmission Oil Change 3…………………

Transfer Oil Check 3………………………

Transfer Oil Change

4

……………………..

Oil Temperature Sensor Check 4…………….

TRANSMISSION CONTROL* 5…………….

TRANSMISSION ASSEMBLY 8…………….

TRANSFER ASSEMBLY 15………………

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, ca n lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B — Supplemental

Restraint System(SRS)before beginning any service ormaintenanceof any componentoftheSRS or anySRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, side impact sensors and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

MANUAL TRANSMISSION — Lubricant/Special Tools

22-2

LUBRICANT

22100040310

Item Specified lubricant Quantity L

Transmission oil 2WD Hypoid gear oil SAE 75W — 90 or 75W — 85W 2.2

4WD

conforming to API GL-4

2.3

Transfer oil Hypoid gear oil SAE 75W — 90 or 75W — 85W

conforming to API GL-4

0.53

SPECIAL TOOLS

221000600224

Tool Number Name Use

MB990635 or

MB991113

Steering linkage

puller

Ball joint disconnection

GENERAL

SERVICE

TOOL

MZ203827

Engine lifter Supporting the engine assembly during

removal and installation of the transmission

MB991453 Engine hanger

MB991721 Sliding hammer Driving out of the output shaft

MB991 193 Plug To prevent excessive transfer oil loss or system

contamination

MANUAL TRANSMISSION — On-vehicle Service

22-3

ON-VEHICLE SERVICE

22100090308

TRANSMISSION OIL CHECK

1. Remove the oil filler plug.

2. Oil level should be at the lower portion of the filler plug

hole.

3. Check that the transmission oil is not noticeably dirty,

and that it has a suitable viscosity.

4. Tighten the filler plug to the specified torque.

Tightening torque: 32 Nm

TRANSMISSION OIL CHANGE 22100100315

1. Remove the drain plug to drain oil.

2. Tighten the drain plug to the specified torque.

3. Remove the filler plug and fill with specified oil till the

level comes to the lower portion of filler plug hole.

Transmission oil

Specified oil:

Hypoid gear oil SAE 75W — 90 or 75W — 85W

conforming to API GL-4

Quantity: <2WD> 2.2 L

<4WD> 2.3 L

4. Tighten the filler plug to the specified torque.

TRANSFER OIL CHECK 22100110134

1. Remove the oil filler plug.

2. Oil level should be at the lower portion of the filler plug

hole.

3. Check that the transfer oil is not noticeably dirty, and

it has a suitable viscosity.

4. Install the oil filler plug, and then tighten it to the specified

torque.

Tightening torque: 32 Nm

Transmission oil

Filler plug hole

Filler plug

Drain plug

32 Nm

Drain plug

Filler plug

MANUAL TRANSMISSION — On-vehicle Service

22-4

TRANSFER OIL CHANGE 22100120137

1. Remove the oil drain plug to drain oil.

2. Install the oil drain plug, and then tighten it to the specified

torque.

Tightening torque: 32 Nm

3. Remove the oil filler plug, and then fill with specified oil

till the level comes to the lower portion of filler plug hole.

Transfer oil

Specified oil:

Hypoid gear oil SAE 75W — 90 or 75W — 85W

conforming to API GL-4

Quantity: 0.53 L

4. Install the oil filler plug, and then tighten it to the specified

torque.

Specified torque: 32 Nm

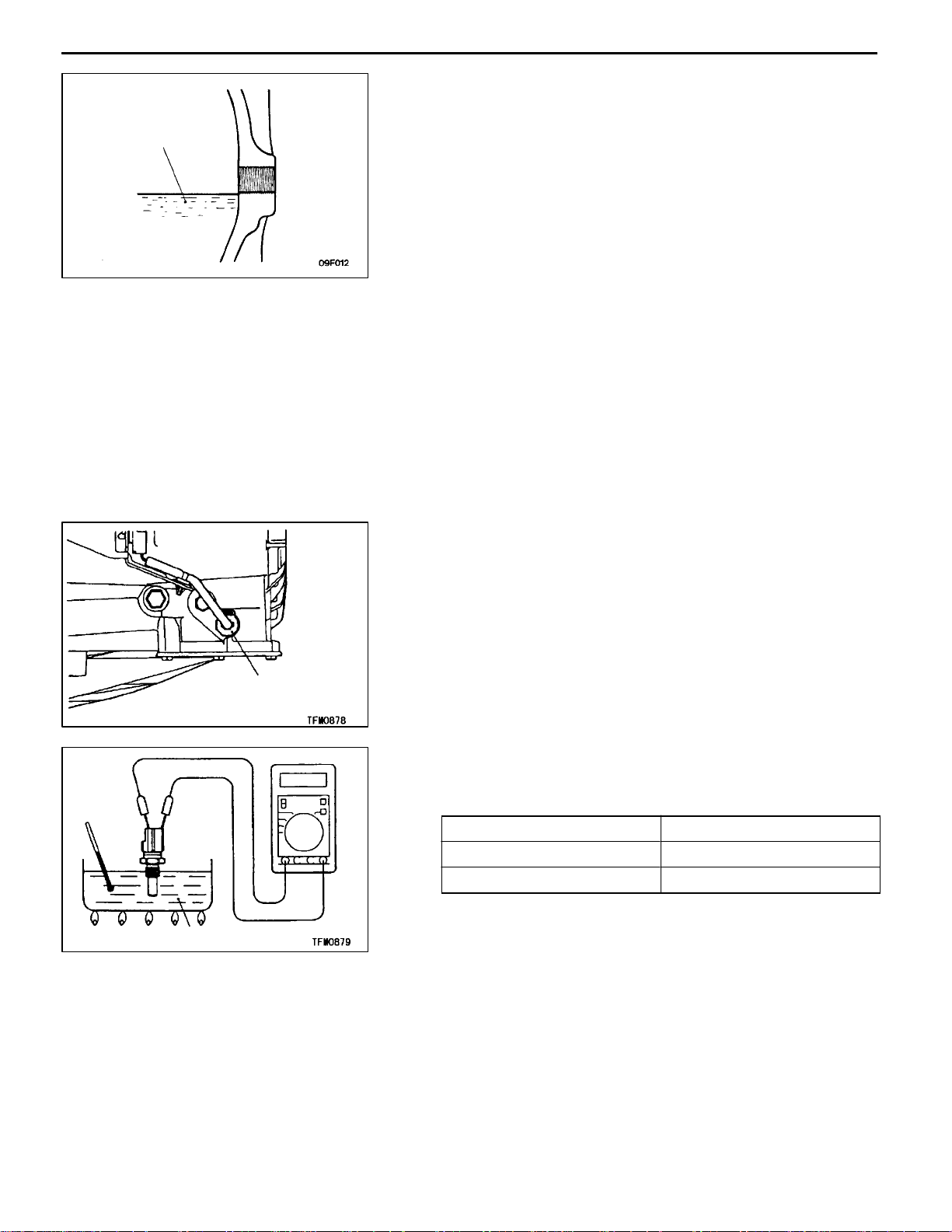

OIL TEMPERATURE SENSOR CHECK 22100670038

1. Remove the oil drain plug, and then drain the transmission

oil.

2. Remove the oil temperature sensor.

3. Measure the resistance between terminals 1 and 2 of

the oil temperature sensor connector.

Standard value:

Oil temperature

_

C Resistance k

W

20 2.31 — 2.59

110 0.145 — 0.149

4. If the resistance is not within the standard value, replace

the oil temperature sensor.

5. Install the oil temperature sensor, and then tighten it to

the specified torque.

Tightening torque: 20 — 25 Nm

6. Install the drain plug and tighten it to the specified torque.

Supply a transmission oil. (Refer to P.22-3.)

Transfer oil

Oil temperature

sensor

Transmission oil

MANUAL TRANSMISSION — Transmission Control

22-5

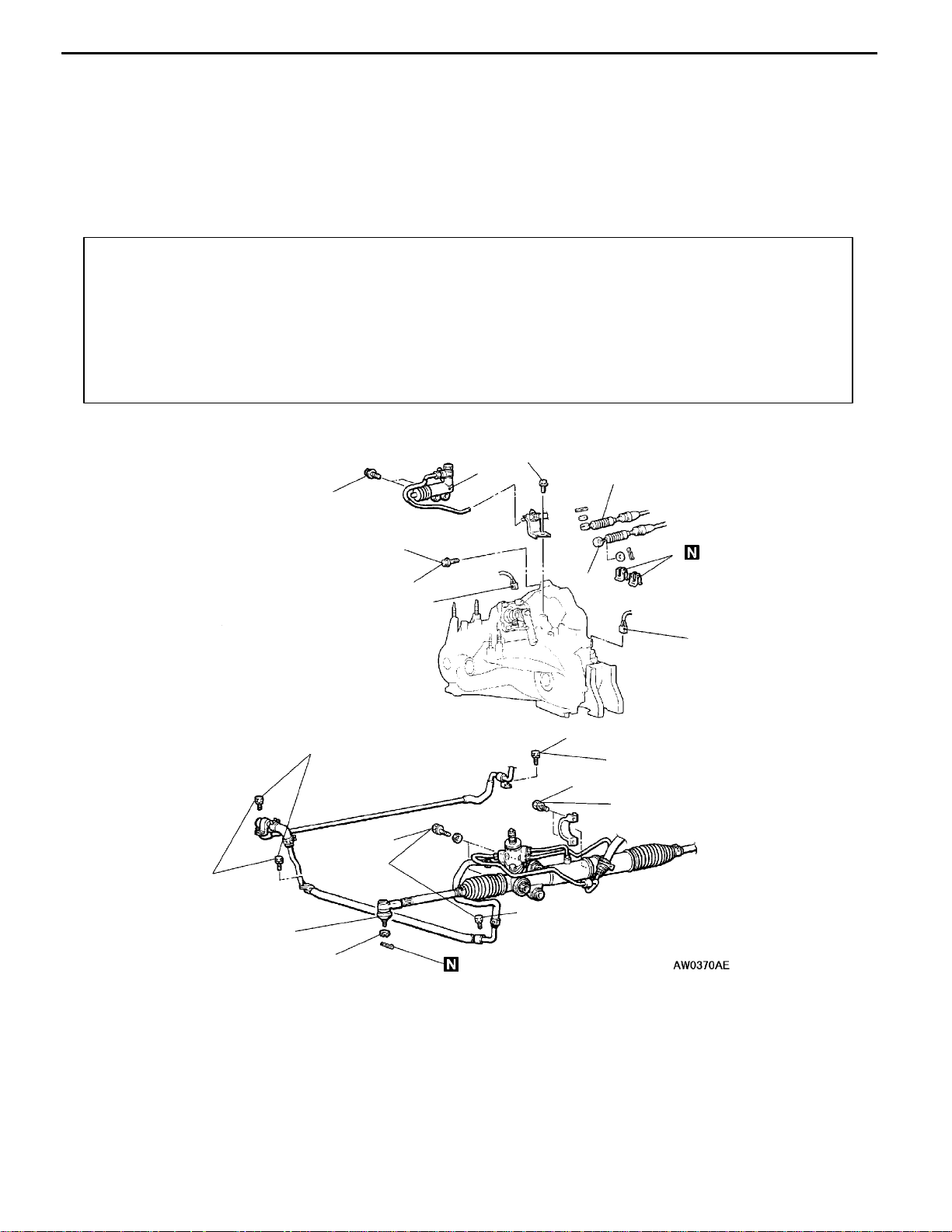

TRANSMISSION CONTROL

22100380238

REMOVAL AND INSTALLATION

Caution: SRS

Be careful not to subject the SRS-ECU to any shocks during removal and installation of the shift

cable and select cable assembly.

Pre-removal and Post-installation Operation

D Air Cleaner Assembly Removal and Installation

D Battery and Battery Tray Removal and Installation

1

2

3

4

5

6

7

9

10

13

8

11

12 Nm

10

12

14

5Nm

Shift cable and select cable

assembly removal steps

«

B

A

1. Shift knob

«

B

A

2. Spring washer

«

B

A

3. Nut

D

Center console box

(Refer to GROUP 52A.)

4. Insulator

5. Snap pin

6. Select cable connection

(Shift lever side)

7. Clip

8. Shift cable connection

(Shift lever side)

A

A

«»

A

A

9. Clip

10. Snap pin

«

A

A

11. Select cable connection

(Transmission side)

«

A

A

12. Shift cable connection

(Transmission side)

13. Shift lever assembly

«

A

A

14. Shift cable and select cable

assembly

Shift lever assembly removal steps

«

B

A

1. Shift knob

«

B

A

2. Spring washer

«

B

A

3. Nut

D

Center console box

(Refer to GROUP 52A.)

4. Insulator

5. Snap pin

6. Select cable connection

(Shift lever side)

7. Clip

8. Shift cable connection

(Shift lever side)

12. Shift lever assembly

MANUAL TRANSMISSION — Transmission Control

22-6

REMOVAL SERVICE POINTS

A

A

«

CLIP REMOVAL

Pry the tabs of the clip with a screwdriver or similar, and

then remove the clip.

INSTALLATION SERVICE POINTS

«

A

A

SHIFT CABLE AND SELECT CABLE ASSEMBLY/

SHIFT CABLE CONNECTION/SELECT CABLE

CONNECTION

1. Set the transmission side shift lever and the passenger

compartment side shift lever to the neutral position.

2. For the transmission side, t he paint marks on the shift

and select cable ends should face the snap pins.

3. Install new clips to the cable bracket at the transmission,

and then install shift cable and select cable to the cable

bracket.

4. Move the passenger compartment side shift lever to all

positions and check that the operation is smooth.

«

B

A

NUT/SPRING WASHER/SHIFT KNOB

INSTALLATION

1. Screw in the nut all the way by hand, turn back half

a turn, and then insert the spring washer.

2. Screw in the shift knob until it touches the spring washer,

and make one more turn. Then turn more to adjust the

shift pattern on the shift knob.

3. If the above steps are impossible, you can turn back

the shift knob by one turn at most after screwing in all

the way to adjust the shift pattern.

Tab s

Shift lever

Neutral position

MANUAL TRANSMISSION — Transmission Control

22-7

SHIFT LEVER ASSEMBLY 22100400101

DISASSEMBLY AND REASSEMBLY

12 Nm

14 Nm

9Nm

9Nm

2

3

4

7

8

10

13

14

15

16

4

12

1

5

6

11

10 Nm

9

Disassembly steps

1. Lever assembly

2. Bolt

3. Select lever

4. Bushing

5. Return spring

6. Collar

7. Bolt

8. Cap

9. Shift lever

10. Shift lever bushing

11. Base bracket

12. Lever mount bracket assembly

13. Insulator

14. Stay

15. Lever mount bracket

16. Base bracket

MANUAL TRANSMISSION — Transmission Assembly

22-8

TRANSMISSION ASSEMBLY

22100270290

<2WD>

REMOVAL AND INSTALLATION

Caution

The fasteners indicated by * should be tightened to the specified torque after the engine weight

is applied to the vehicle body.

Pre-removal and Post-installation Operation

D Transmission Oil Draining and Refilling (Refer to

P.22-3.)

D Air Cleaner Assembly Removal and Installation

D Battery and Battery Tray Removal and Installation

D Radiator and Coolant Reservoir Removal and

Installation (Refer to GROUP 14.)

D Starter Removal and Installation (Refer to GROUP

16.)

D Under Cover Removal and Installation

D Front Exhaust Pipe Removal and Installation (Refer

to GROUP 15.)

D Check the Dust Cover for Crack or Damage by

Pushing it with Finger <only after installation>

D Shift Lever Operation Check <only after installation>

D Instruments Operation Check <only after installation>

D Wheel Alignment Check <only after installation>

(Refer to GROUP 33A — On-vehicle Service.)

19 Nm

48 Nm

24 — 33 Nm

12 Nm

19 Nm

12 Nm

69 Nm

9

10

8

5

1

2

7

4

3

6

9

12 Nm

9

9

Removal steps

1. Clip (Refer to P.22-5.)

2. Select cable connection (Refer to

P.22-5.)

3. Shift cable connection (Refer to

P.22-5.)

4. Back-up lamp switch connector

5. Vehicle speed sensor connector

6. Clutch release cylinder connection

A

A

«

7. Tie rod end connection

A

B

«

8. Steering gear and linkage mounting

bolts

9. Oil line mounting bolts

10. Transmission assembly upper cou-

pling bolt

MANUAL TRANSMISSION — Transmission Assembly

22-9

14

44 Nm

13

12

15

19

20

22

9Nm

177 Nm

25

24

39 Nm

17

18

40 Nm

78 Nm

57 Nm*

48 Nm

14

81 Nm*

24

23

26

196 — 255 Nm

98 — 118 Nm

25

22 Nm

49 — 64 Nm*

49 — 64 Nm*

21

177 Nm

78 Nm

11

11. Stabilizer link connection

«

C

A 12. Lower arm connection

13. Wheel speed sensor connection

(Refer to GROUP 35B.)

A

C

«»

B

A 14. Drive shaft <Except SPACE

WAGON- R.H.>

A

C

«»

B

A 15. Drive shaft and inner shaft

<SPACE WAGON— R.H.>

17. Transmission stay

18. Bell housing cover

19. Front roll stopper connection

20. Rear roll stopper connection

21. Stay

22. Front member assembly

A

E

« 23. Transmission mount bracket

«

A

A 24. Transmission mount stopper

A

F

«DEngine and transmission assembly

supporting

A

G

« 25. Transmission assembly lower part

coupling bolts

A

G

« 26. Transmission assembly

MANUAL TRANSMISSION — Transmission Assembly

22-10

<4WD>

REMOVAL AND INSTALLATION

Caution

The fasteners indicated by * should be tightened to the specified torque after the engine weight

is applied to the vehicle body.

Pre-removal and Post-installation Operation

D Transmission Oil Draining and Refilling (Refer to

P.22-3.)

D Transfer Oil Draining and Refilling (Refer to P.22-3.)

D Air Cleaner Assembly Removal and Installation

D Battery and Battery Tray Removal and Installation

D Radiator and Coolant Reservoir Removal and

Installation (Refer to GROUP 14.)

D Starter Removal and Installation (Refer to GROUP

16.)

D Propeller Shaft Removal and Installation (Refer to

GROUP 25.)

D Under Cover Removal and Installation

D Front Exhaust Pipe Removal and Installation (Refer

to GROUP 15.)

D Check the Dust Cover for Crack or Damage by

Pushing it with Finger <only after installation>

D Shift Lever Operation Check <only after installation>

D Instruments Operation Check <only after installation>

D Wheel Alignment Check <only after installation>

(Refer to GROUP 33A — On-vehicle Service.)

12 Nm

48 Nm

24 — 33 Nm

69 Nm

19 Nm

9

10

8

5

1

2

4

3

6

7

19 Nm

9

9

12 Nm

12 Nm

9

Removal steps

1. Clip (Refer to P.22-5.)

2. Select cable connection (Refer to

P.22-5.)

3. Shift cable connection (Refer to

P.22-5.)

4. Back-up lamp switch connector

5. Vehicle speed sensor connector

6. Clutch release cylinder connection

A

A

«

7. Tie rod end connection

A

B

«

8. Steering gear and linkage mounting

bolts

9. Oil line mounting bolts

10. Transmission assembly upper cou-

pling bolt

MANUAL TRANSMISSION — Transmission Assembly

22-11

26

39 Nm

9Nm

18

16

17

14

21

19

177 Nm

48 Nm

25

13

78 Nm

98 — 118 Nm

20

22 Nm

23

44 Nm

57 Nm*

24

81 Nm*

24

25

14

196 — 255Nm

49 — 64 Nm*

49 — 64 Nm*

78 Nm

22

12

177 Nm

11

11. Stabilizer link connection

«

C

A 12. Lower arm connection

13. Wheel speed sensor connection

(Refer to GROUP 35B.)

A

C

«»

B

A 14. Drive shaft

A

D

«»

B

A 16. Output shaft

D Transfer assembly removal (Refer to

P.22-15.)

17. Transmission stay

18. Bell housing cover

19. Front roll stopper connection

20. Rear roll stopper connection

21. Stay

22. Front member assembly

A

E

« 23. Transmission mount bracket

«

A

A 24. Transmission mount stopper

A

F

«DEngine and transmission assembly

supporting

A

G

« 25. Transmission assembly lower part

coupling bolts

A

G

« 26. Transmission assembly

MANUAL TRANSMISSION — Transmission Assembly

22-12

REMOVAL SERVICE POINTS

A

A

«

TIE ROD END DISCONNECTION

Caution

1. Use thespecial tool to loosen the tie rod end mounting

nut. Only loosen the nut; do not remove it from the

ball joint.

2. Support the special tool with a cord, etc. not to let

it come off.

A

B

«

STEERING GEAR AND LINKAGE MOUNTING

BOLT REMOVAL

Remove the steering gear and linkage mounting bolts, and

then support the steering gear box to the vehicle body with

a wire.

A

C

«

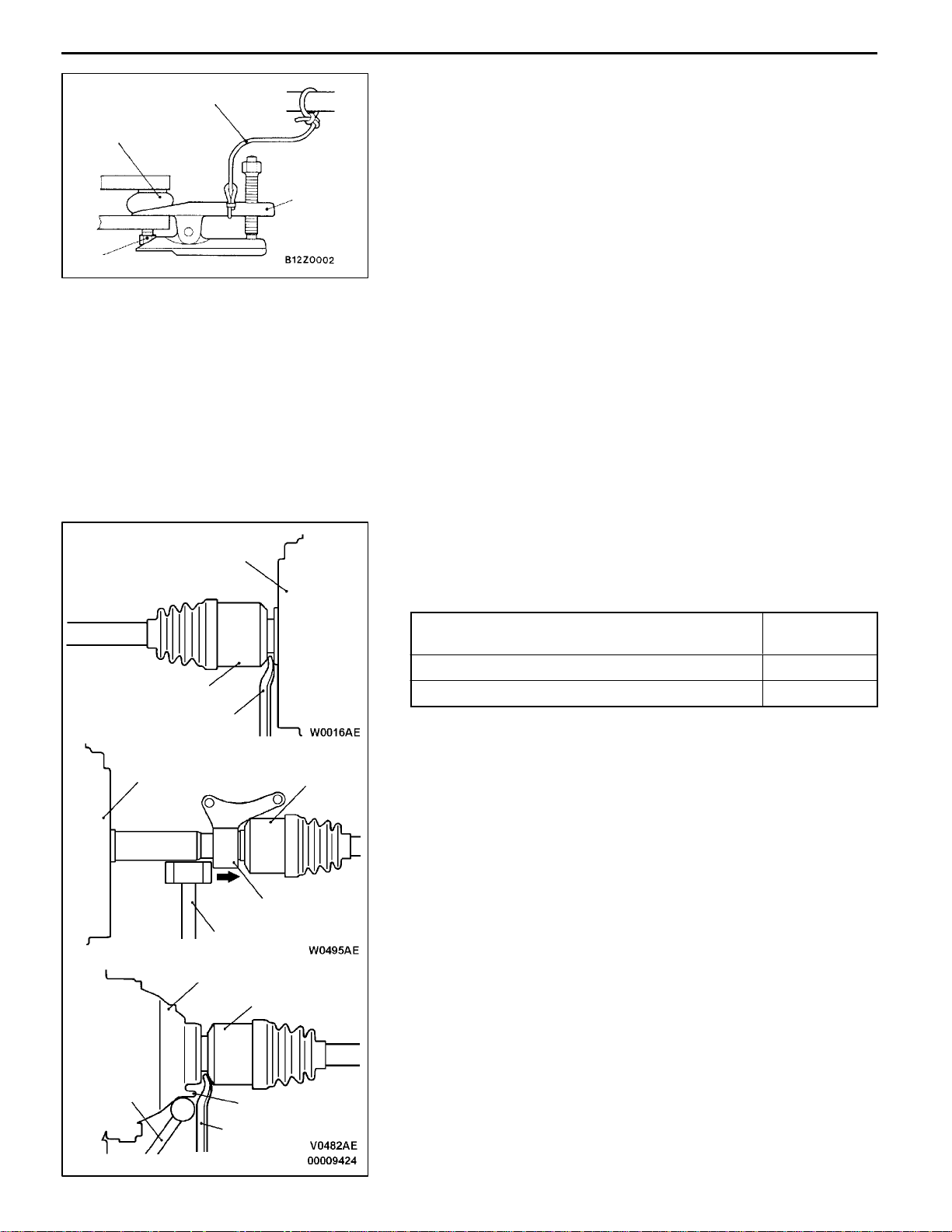

DRIVE SHAFT/DRIVE SHAFT AND INNER SHAFT

ASSEMBLY REMOVAL

Remove the drive shaft or the drive shaft and inner shaft

assembly from the transmission by the following procedure:

2WD (except SPACE WAGON — M/T— R.H.),

4WD (L.H.)

Fig. 1

2WD (SPACE WAGON- M/T— R.H.) Fig. 2

4WD (R.H.) Fig. 3

<Fig. 1>

Insert a pry bar between the drive shaft a n d the

transmission case, and then pry off the drive shaft.

<Fig. 2>

Tap the center bearing bracket with a hammer to remove

the drive shaft.

<Fig. 3>

Place a hammer on the projection at th e transfer and

insert a pry bar between the drive shaft and the transfer,

and then pry off the drive shaft.

Caution

1. Above-mentioned procedure must be observed.

Pulling the B.J. assembly to remove the drive shaft

or drive shaft and inner shaft assembly will damage

the T.J. assembly.

2. Take care that the transmission oil seal will not be

damaged by the drive shaft spline.

Cord

Ball joint

MB990635 or

MB991113

Nut

Transmission

Drive shaft

Transfer

Drive shaft

Center bearing bracket

Transmission

Drive shaft

Prybar

Hammer

Prybar

Hammer

Projection

Fig. 1

Fig. 2

Fig. 3

MANUAL TRANSMISSION — Transmission Assembly

22-13

A

D

«

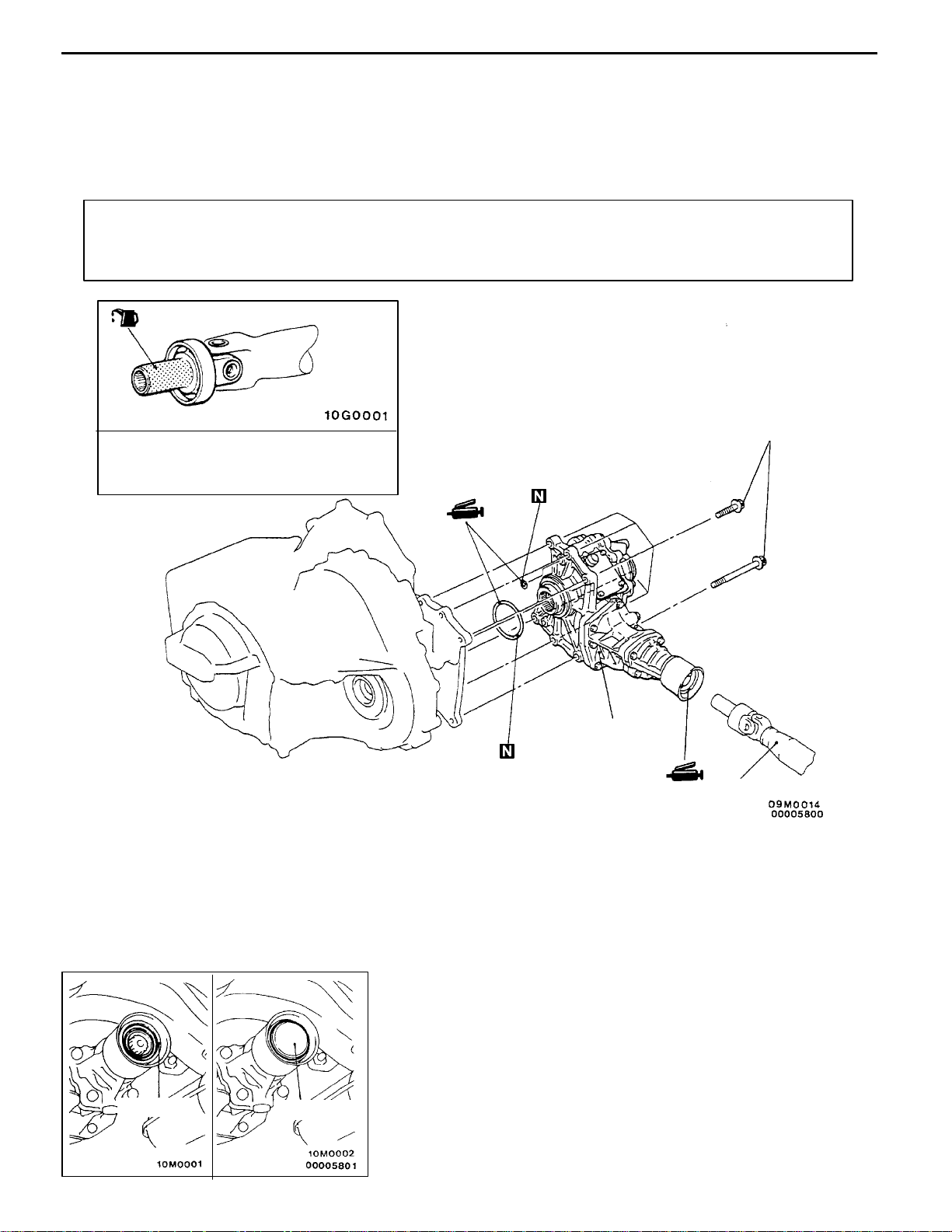

OUTPUT SHAFT REMOVAL

1. Use the special tool to withdraw the output shaft.

Caution

Be careful not to damage the oil seal of the

transmission by the spline of the output shaft.

2. Use a shop towel to cover the transmission case not

to let foreign material ge t into it.

A

E

«

TRANSMISSION MOUNT BRACKET REMOVAL

Carefully lower the transmission assembly with a garage jack,

and remove the transmission mount bracket.

A

F

«

ENGINE AND TRANSMISSION ASSEMBLY

SUPPORTING

Set the special tool to the vehicle to support the engine and

transmission assembly.

A

G

«

TRANSMISSION ASSEMBLY LOWER PART

COUPLING BOLTS/TRANSMISSION ASSEMBLY

REMOVAL

1. Support the transmission assembly with a transmission

jack.

2. Remove the transmission assembly lower part coupling

bolts, and lower the transmission assembly to remove.

INSTALLATION SERVICE POINTS

«

A

A

TRANSMISSION MOUNT STOPPER INSTALLATION

Install the transmission mount stopper so that the arrow points

as shown in the illustration.

NOTE

Disregard F and R stamped as a shared part.

MB991721

Output shaft

MZ203827

MB991453

Transmission

mount

stopper

Transmis-

sion

mount

bracket

Engine side

MANUAL TRANSMISSION — Transmission Assembly

22-14

«

B

A

OUTPUT SHAFT/DRIVE SHAFT INSTALLATION

Caution

Be careful not to damage the oil seal of the transmission

or transfer by the spline of the drive shaft or the output

shaft.

«

C

A

LOWER ARM INSTALLATION

1. Install the lower arm assembly to the knuckle.

Caution

The lower arm should not protrude 4 mm or more

from the knuckle end (A shown), otherwise grease

may pour out from the dust cover.

2. If grease has poured out due to the excessive arm

protrusion, the dust cover must be replaced (Refer to

GROUP 33A — Lower Arm).

3. There should be not clearance between the knuckle and

the dust cover.

Lower arm

assembly

Knuckle

A

MANUAL TRANSMISSION — Transfer Assembly

22-15

TRANSFER ASSEMBLY

REMOVAL AND INSTALLATION

Caution

The fasteners indicated by * should be tightened to the specified torque after the engine weight

is applied to the vehicle body.

Pre-removal and Post-installation Operation

D Transmission Oil Draining and Refilling (Refer to

P.22-3.)

D Transfer Oil Draining and Refilling (Refer to P.22-4.)

D Front Exhaust Pipe Removal and Installation (Refer

to GROUP 15.)

1

2

69 Nm

Gear oil:

Hypoid gear oil SAE 75W — 85W or

75W — 90 conforming to API GL-4

Removal steps

D

Drive shaft connection (Refer to

P.22-11.)

D

Output shaft (Refer to P.22-11.)

1. Front propeller shaft (Refer to

GROUP 25.)

A

A

«

2. Transfer assembly

REMOVAL SERVICE POINT

A

A

«

TRANSFER ASSEMBLY REMOVAL

Caution

1. Be careful not to damage the transfer oil seal lip.

2. Use the special tool to plug the transfer case opening

to to prevent excessive oil loss or system

contamination.

Oil seal lip

MB991113

NOTES

23-1

AUTOMATIC

TRANSMISSION

CONTENTS

23109000576

SERVICE SPECIFICATIONS 2……………..

LUBRICANT 2………………………….

SPECIAL TOOLS 2……………………..

TROUBLESHOOTING 4…………………..

ON-VEHICLE SERVICE 44……………….

Essential Service 44……………………….

A/T Control Component Location 50………….

A/T Control Component Check 51……………

Torque Converter Stall Test 53………………

Hydraulic Pressure Test 55…………………

Hydraulic Circuit 60……………………….

Line Pressure Adjustment 61………………..

Selector Lever Operation Check 61…………..

TRANSMISSION CONTROL* 63…………..

SHIFT LOCK AND KEY INTERLOCK

MECHANISMS 66………………………

TRANSMISSION ASSEMBLY 68…………..

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, ca n lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B — Supplemental

Restraint System(SRS)before beginning any service ormaintenanceof any componentoftheSRS or anySRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, side impact sensors and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

AUTOMATIC TRANSMISSION —

Service Specifications/Lubricant/Special Tools

23-2

SERVICE SPECIFICATIONS

23100030284

Items Standard value

Oil temperature sensor kW at 0_C 16.5 — 20.5

at 100_C 0.57 — 0.69

Resistance of damper clutch control solenoid valve coil (at 20_C) W 2.7 — 3.4

Resistance of Low-Reverse solenoid valve coil (at 20_C) W 2.7 — 3.4

Resistance of second solenoid valve coil (at 20_C) W 2.7 — 3.4

Resistance of underdrive solenoid valve coil (at 20_C) W 2.7 — 3.4

Resistance of overdrive solenoid valve coil (at 20_C) W 2.7 — 3.4

Stall speed r/min 4G93 2,200 — 2,700

4G64 2,300 — 2,800

LUBRICANT

23100040270

Items Specified lubricant Quantity L

Transmission fluid DIA QUEEN ATF SPII,ATF SPIIMor

equivalent

7.8

SPECIAL TOOLS

23100060351

Tool Number Name Use

MB991502 MUT-II sub

assembly

Checking of the diagnosis code

MD998330

(including

MD998331)

Oil pressure gauge

(2,942 kPa)

Measurement of oil pressure

MD998332 Adapter

MD998900 Adapter

AUTOMATIC TRANSMISSION —

Special Tools

23-3

Tool Number Name Use

MB990635 or

MB991113

Steering linkage

puller

Ball joint disconnection

MB991610 Oil filter wrench Removal and installation of automatic trans-

mission oil filter

GENERAL

SERVICE

TOOL

MZ203827

Engine lifter Supporting the engine assembly during

removal and installation of the transmission

MB991453 Engine hanger

assembly

Supporting the engine assembly during

removal and installation of the transmission

AUTOMATIC TRANSMISSION —

Troubleshooting

23-4

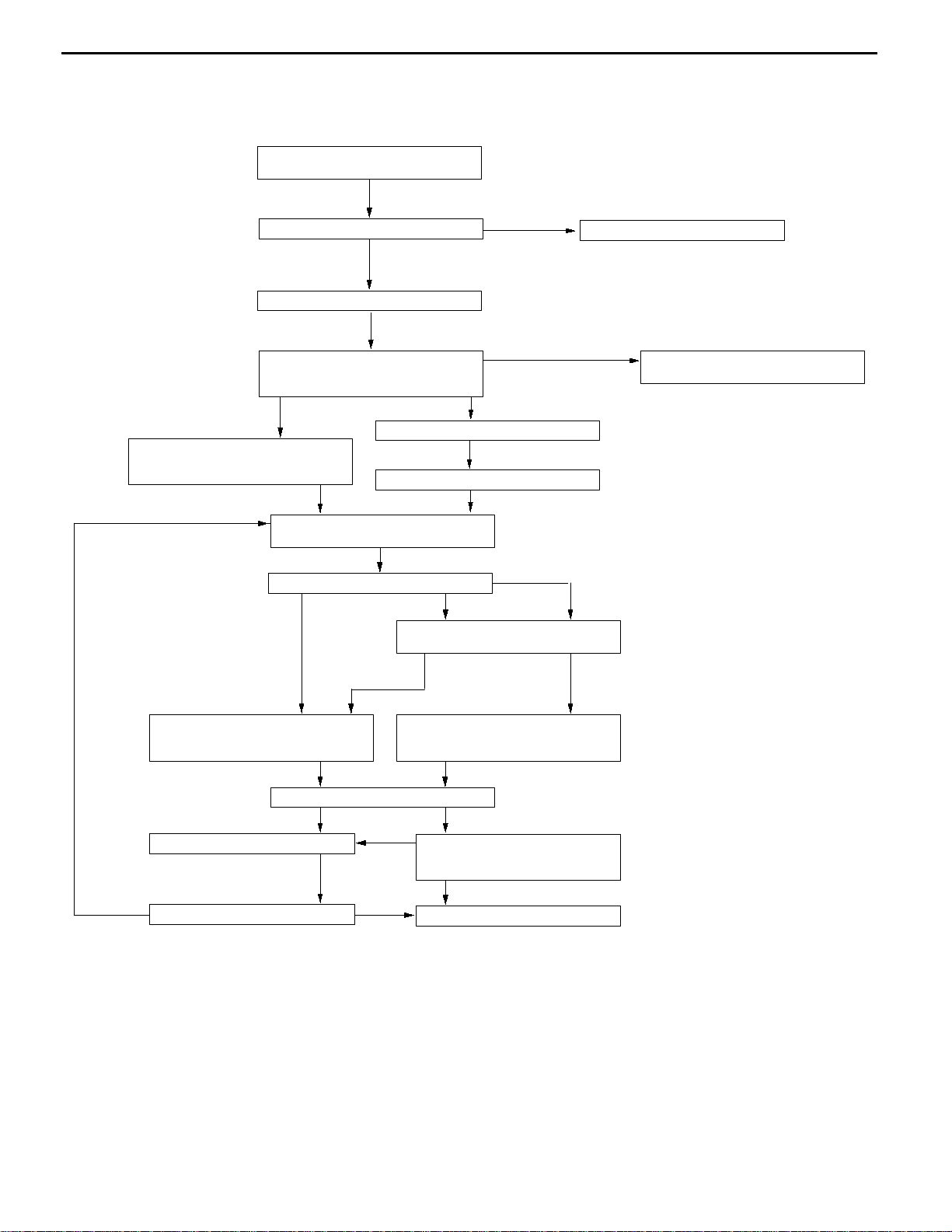

TROUBLESHOOTING

23100760657

STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Gathering information from custom-

er.

Check trouble symptoms.

Read the diagnosis code (GROUP 00

— How to Use Troubleshooting/In-

spection Service Points.)

Communication with

MUT-II not possible

Inspection Chart For Trouble

Symptoms (Refer to P.23-24.)

Diagnosis code

displayed

Erase the diagnosis code (GROUP

00 — How to Use Troubleshooting/In-

spection Service Points.)

No diagnosis code displayed

Carry out the essential service

(Refer to P.23-44.)

Road test (Refer to P.23-6.)

Abnormality exists (no diagnosis code)

No abnormality

Recheck diagnosis codes which

were read before the road test.

Abnormality exists

(diagnosis code

present)

Diagnosis

code displayed

No diagnosis

code displayed

To INSPECTION CHART FOR

DIAGNOSIS CODES

(Refer to P.23-12.)

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

(Refer to P.23-24.)

Search for cause.

Found Not found

Repair

Confirmation test (road test)

NG

NG

INTERMITTENT MALFUNCTION

(GROUP 00 — Points to Note for

Intermittent Malfunctions.)

OK

Completed

OK

Check ATF.

Replace ATF.

Check trouble symptoms.

Replace the A/T-ECU.

NG

OK

NG

AUTOMATIC TRANSMISSION —

Troubleshooting

23-5

DIAGNOSIS FUNCTION

23100770292

1. N range lamp

The N range lamp flashes at a frequency of approximately

1 Hz if there is an abnormality in any of the items in the

table below which are related to the A/T system. Check

the diagnosis code output if the N range lamp is flashing

at a frequency of approximately 1 Hz.

N range lamp flashing items

Crank angle sensor

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Out of phase at each shift point

Caution

If the N range lamp is flashing at a frequency of

approximately 2 Hz (faster than at 1 Hz), it means that

the automatic transmission fluid temperature is too high.

Stop the vehicle in a safe place and wait until the N range

lamp switches off.

2. Method of reading the diagnosis code

Use the MUT-II or the N range lamp to take a reading of

the diagnosis codes. (Refer to GROUP 00 — How to Use

Troubleshooting/Inspection Service Points.)

AUTOMATIC TRANSMISSION —

Troubleshooting

23-6

ROAD TEST

23100780622

Check by the following procedure.

No. State prior to test

and operation

Test and operation Judgement value Check item Diag-

nosis

code

No.

Inspection

procedure page

if there is an

abnormality

1 Ignition switch:

OFF

Ignition switch

(1) ON

Data list No. 54

Battery voltage [V]

Control relay 54 A/T Control

relay system

(23-23)

2 Ignition switch:

ON

Engine: Stopped

Selector lever

position: P

Selector lever

position

(1) P, (2) R,

(3) N, (4) D,

(5) 3, (6) 2, (7) L

Data list No. 61

(1) P, (2) R, (3)N,

(4) D, (5) 3, (6) 2,

(7) L

Inhibitor switch — Inhibitor switch

system (23-35)

position: P

Accelerator pedal

(1) Released

(2) Half depressed

(3) Depressed

Data list No. 11

(1) 300 — 1,000 mV

(2) Gradually rises

from (1)

(3) 4,500 — 5,500

mV

Throttle posi-

tion sensor

<4G93>

Accelerator

pedal position

sensor

<4G64>

11

12

14

Throttle

position sensor

system (23-13)

Accelerator

pedal position

sensor system

(23-13)

Data list No. 25

(1) OFF

(2) ON

Wide open

throttle switch

25 Wide open

throttle switch

system (23-15)

Brake pedal

(1) Depressed

(2) Released

Data list No. 26

(1) ON

(2) OFF

Stop lamp

switch

26 Stop lamp switch

system (23-16)

3 Ignition switch:

ST

Engine: Stopped

Starting test with

lever P or N range

Starting should be

possible

Starting

possible or

impossible

— Starting

impossible

(23-27)

4 Warming up Drive for 15

minutes or more so

that the automatic

fluid temperature

becomes 70 —

90_C.

Data list No. 15

Gradually rises to

70 — 90_C

Oil temperature

sensor

15 Oil temperature

sensor system

(23-13)

AUTOMATIC TRANSMISSION —

Troubleshooting

23-7

No. State prior to test

and operation

Test and operation Judgement value Check item Diag-

nosis

code

No.

Inspection

procedure page

if there is an

abnormality

5 Engine: Idling

Selector lever

position: N

Brake pedal

(Retest)

(1) Depressed

(2) Released

Data list No. 26

(1) ON

(2) OFF

Stop lamp

switch

26 Stop lamp switch

system (23-16)

A/C switch

(1) ON

(2) OFF

Data list No. 65

(1) ON

(2) OFF

Dual pressure

switch

— Dual pressure

switch system

(23-35)

Accelerator pedal

(1) Released

(2) Half depressed

Data list No. 21

(1) 550 — 850 r/min

Gradually rises

from (1)

Crank angle

sensor

21 Crank angle

sensor system

(23-14)

Data list No. 57

(2) Data changes

Communication

with engine-

ECU

51 Serial

communication

system (23-23)

Selector lever

position

(1) N ® D

Should be no

abnormal shifting

shocks

Malfunction

when starting

— Engine stalling

during shifting

(23-29)

(1) N ® D

(2) N ® R

Time lag should be

within 2 seconds

— Shocks when

changing from N

to D and large

time lag (23-29)

— Shocks when

changing from N

to R and large

time lag (23-30)

— Shocks when

changing from N

to D,N to R and

large time lag

(23-31)

Driving

impossible

— Does not move

forward (23-27)

— Does not

reverse (23-28)

— Does not move

(forward or

reverse) (23-28)

AUTOMATIC TRANSMISSION —

Troubleshooting

23-8

No. State prior to test

and operation

Test and operation Judgement value Check item Diag-

nosis

code

No.

Inspection

procedure page

if there is an

abnormality

6 Selector lever

position: N

(Carry out on a

Selector lever

position and

vehicle speed

Data list No. 63

(2) 1st, (4) 3rd, (3)

2nd, (5) 4th

Shift condition — —

flat and straight

road.)

(1) Idling in

L range

(Vehicle

stopped)

(2) Driving at

Data list No. 31

(2) 0 %, (4) 100 %,

(3) 100 %, (5) 100

%

Low and reverse

solenoid valve

31 Low and reverse

solenoid valve

system (23-16)

constant speed

of

10 km/h in

L position

Data list No. 32

(2) 0 %, (4) 0 %,

(3) 0 %, (5) 100 %

Underdrive

solenoid valve

32 Underdrive

solenoid valve

system (23-16)

(3) Driving at

constant speed

of

30 km/h in

Data list No. 33

(2)100 %, (4) 100

%, (3) 0 %, (5) 0 %

Second

solenoid valve

33 Second solenoid

valve system

(23-16)

2 position

(4) Driving at

50 km/h in

3 position with

accelerator fully

Data list No. 34

(2) 100 %, (4) 0 %,

(3) 100 %, (5) 0 %

Overdrive

solenoid valve

34 Overdrive

solenoid valve

system (23-16)

closed

(5) Driving at

constant speed

of

Data list No. 29

(1) 0 km/h

(4) 50 km/h

Vehicle speed

sensor

— Vehicle speed

sensor system

(23-36)

50 km/h in

D position

(Each

condition

Data list No. 22

(4) 1,800 — 2,100

r/min

Input shaft

speed sensor

22 Input shaft speed

sensor system

(23-14)

should be

maintained for

10 seconds or

more.)

Data list No. 23

(4) 1,800 — 2,100

r/min

Output shaft

speed sensor

23 Output shaft

speed sensor

system (23-15)

7 Selector lever

position: 3

(Carry out on a

flat and straight

road.)

Selector lever

position and

vehicle speed

(1) Release the ac-

celerator pedal

Data list No. 36

(1) 0 %

(2) Approx. 70 — 90

%

Damper clutch

control solenoid

valve

36

52

Damper clutch

control solenoid

valve system

(23-17)

fully while driv-

ing at 50 km/h

in 3rd gear.

(2) Driving at

constant speed

of 50 km/h in

3rd gear.

Data list No. 52

(1) Approx.

100 — 300 r/min

(2) Approx.

0 — 10 r/min

AUTOMATIC TRANSMISSION —

Troubleshooting

23-9

No. State prior to test

and operation

Test and operation Judgement value Check item Diag-

nosis

code

No.

Inspection

procedure page

if there is an

abnormality

8 Use the MUT-II to

stop the INVECS-

II function.

Monitor data list

No. 11, 23, and 63

with the MUT—II.

For (1), (2) and (3),

the reading should

be the same as the

Malfunction

when shifting

— Shocks and

running up

(23-31)

Selector lever (1) Accelerate to specified output

Displaced

— All points (23-32)

position: D

(Carry out on a flat

and straight road.)

4th gear at a

throttle

position

shaft speed and no

abnormal shocks

should occur.

shifting points

— Some points

(23-33)

and straight road.)

position

sensor output

of 1.5V

should occur.

For (4), (5) and (6),

downshifting

Does not shift

— No diagnosis

code (23-33)

(accelerator

opening angle

of 30 %).

(2) Gently

should occur

immediately

after the shifting

operation is made.

22 Input shaft

speed sensor

system (23-14)

(2) Gently

decelerate to a

standstill.

(3) Accelerate to

operation is made.

23 Output shaft

speed sensor

system (23-15)

4th gear at a

throttle

position

sensor output

Does not shift

from 1 to 2 or 2

to 1

31 Low and reverse

solenoid valve

system (23-16)

of 2.5 V

(accelerator

opening angle

33 Second

solenoid valve

system (23-16)

of 50%).

(4) While driving at

60 km/h in 4th

gear, shift

41 1st gear ratio is

not specified

(23-18)

down to

3 range.

(5) While driving at

42 2nd gear ratio is

not specified

(23-19)

40 km/h in 3rd

gear, shift

down to

2 range.

Does not shift

from 2 to 3 or 3

to 2

33 Second

solenoid valve

system (23-16)

(6) While driving at

20 km/h in 2nd

gear, shift

down to

34 Overdrive

solenoid valve

system (23-16)

down to

L range.

42 2nd gear ratio is

not specified

(23-19)

43 3rd gear ratio is

not specified

(23-20)

Does not shift

from 3 to 4 or 4

to 3

32 Underdrive

solenoid valve

system (23-16)

33 Second

solenoid valve

system (23-16)

43 3rd gear ratio is

not specified

(23-20)

44 4th gear ratio is

not specified

(23-21)

AUTOMATIC TRANSMISSION —

Troubleshooting

23-10

No. State prior to test

and operation

Test and operation Judgement value Check item Diag-

nosis

code

No.

Inspection

procedure page

if there is an

abnormality

9 Selector lever

position: N

(Carry out on a

Monitor data list

No. 22

and No. 23 with the

The ratio between

data list No. 22 and

No. 23 should be

Does not shift

22 Input shaft

speed sensor

system (23-14)

(Carry out on a

flat and straight

road.)

MUT-II.

(1) Move selector

lever to

the same as the

gear ratio when

reversing.

23 Output shaft

speed sensor

system (23-15)

R range, drive

at constant

speed of

10 km/h.

46 Reverse gear

ratio is not

specified (23-22)

SHIFT PATTERN

<4G93>

UPSHIFT PATTERN

Output shaft speed r/min

Thick line: Standard shift pattern

100

Throttle opening %

1,000

2,000

3,000

4,000

5,000

6,000

7,000

2

®

3

movement

range

3

®

4

movement

range

0

50

122

3

3

4

DOWNSHIFT PATTERN

3 (L,2)

4 (L,2,3)

Thick line: Standard shift pattern

Throttle opening %

2

¬

3

movement

range

3

¬

4

movement

range

100

1,000

2,000

3,000 4,000 5,000 6,000 7,000

Output shaft speed r/min

0

50

122

3

3

2 (L)

2

1

3

4

AUTOMATIC TRANSMISSION —

Troubleshooting

23-11

<4G64>

UPSHIFT PATTERN

Thick line: Standard shift pattern

Throttle opening %

100

Output shaft speed r/min

0

50

1

2

2

3

3

4

2 ® 3

movement

range

3 ® 4

movement

range

1,000 2,000

3,000 4,000

5,000 6,000

7,000

DOWNSHIFT PATTERN

4 (L,2,3)

Thick line: Standard shift pattern

Throttle opening %

2 ¬ 3

movement

range

3 ¬ 4

movement

range

100

1,000 2,000 3,000 4,000

5,000 6,000

7,000

Output shaft speed r/min

0

50

1

2

2

3

3

4

2 (L)

3 (L,2)

1

2

3

AUTOMATIC TRANSMISSION —

Troubleshooting

23-12

INSPECTION CHART FOR DIAGNOSIS CODE

23100790588

Code Diagnosis item Reference page

11 Throttle position sensor system Short circuit 23-13

12

<4G93>

Accelerator pedal position sensor system

Open circuit 23-13

14

Accelerator pedal position sensor system

<4G64>

Sensor maladjustment 23-13

15 Oil temperature sensor system Open circuit 23-13

21 Crank angle sensor system Open circuit 23-14

22 Input shaft speed sensor system Short circuit/open circuit 23-14

23 Output shaft speed sensor system Short circuit/open circuit 23-15

25 Wide open throttle switch system Short circuit 23-15

26 Stop lamp switch system Short circuit/open circuit 23-16

31 Low and reverse solenoid valve system Short circuit/open circuit 23-16

32 Underdrive solenoid valve system Short circuit/open circuit 23-16

33 Second solenoid valve system Short circuit/open circuit 23-16

34 Overdrive solenoid valve system Short circuit/open circuit 23-16

36 Damper control clutch solenoid valve system Short circuit/open circuit 23-17

41 1st gear ratio does not meet the specification 23-18

42 2st gear ratio does not meet the specification 23-19

43 3rd gear ratio does not meet the specification 23-20

44 4th gear ratio does not meet the specification 23-21

46 Reverse gear ratio does not meet the specification 23-22

51 Abnormal communication with engine-ECU 23-23

52 Damper control clutch solenoid valve system Defective system 23-17

54 A/T Control relay system Short circuit to earth/

open circuit

23-23

56 N range lamp system Short circuit to earth 23-24

AUTOMATIC TRANSMISSION —

Troubleshooting

23-13

INSPECTION PROCEDURES FOR DIAGNOSIS CODES

Code No. 11, 12, 14 Throttle position sensor system

<4G93>, accelerator pedal position sensor system

<4G64>

Probable cause

If the TPS or APS output voltage is 4.8 V or higher when the engine is idling, the

output is judged to be too high and diagnosis code No. 11 is output. If the TPS or

APS output voltage is 0.2 V or lower at times other than when the engine is idling,

the output is judged to be too low and diagnosis code No. 12 is output. If the TPS

or APS output voltage is 0.2 V or lower or if it is 1.2 V or higher when the engine

is idling, the TPS or APS adjustment is judged to be incorrect and diagnosis code

No. 14 is output.

D Malfunction of the throttle position sensor <4G93>

D Malfunction of the accelerator pedal position sensor

<4G64>

D Malfunction of connector

D Malfunction of the A/T-ECU

Throttle position sensor check <4G93>

(Refer to GROUP 13B — On-vehicle Service

link=13100320030.)

Accelerator pedal position sensor check<4G64>

(Refer to GROUP 13A — On-vehicle Service

link=13600430011.)

NG

Replace

OK

Check the following connectors:

D A-73, B-11 <4G93>

D A-63, A-27, B-11 <4G64>

NG

Repair

OK

Harness check

D Between throttle position sensor and A/T-ECU

<4G93>

D Between accelerator pedal position sensor and A/T-ECU

<4G64>

NG

Repair

OK

Check the trouble symptoms.

NG

Replace the A/T-ECU.

Code No. 15 Oil temperature sensor system Probable cause

If the oil temperature sensor output voltage is 2.6 V or more even after driving for

10 minutes or more (if the oil temperature does not increase), it is judged that there

is an open circuit in the oil temperature sensor and diagnosis code No. 15 is output.

D Malfunction of the oil temperature sensor

D Malfunction of connector

D Malfunction of the A/T-ECU

Oil temperature sensor check (Refer to P.23-51.)

NG

Replace

OK

Check the following connectors:

A-88, B-11

NG

Repair

OK

Harness check

D Between oil temperature sensor and A/T-ECU

NG

Repair

OK

Check the trouble symptoms.

NG

Replace the A/T-ECU.

AUTOMATIC TRANSMISSION —

Troubleshooting

23-14

Code No. 21 Crank angle sensor system Probable cause

If no output pulse is detected from the crank angle sensor for 5 seconds or more

while driving at 25 km/h or more, it is judged that there is an open circuit in the

crank angle sensor and diagnosis code No. 21 is output.

D Malfunction of the crank angle sensor

D Malfunction of connector

D Malfunction of the A/T-ECU

Check the following connectors:

A-71, B-51, B-11

NG

Repair

OK

Harness check

D Between crank angle sensor and A/T-ECU

NG

Repair

OK

Crank angle sensor system check

(Refer to GROUP 13 — Troubleshooting.)

OK

Check the trouble symptoms.

NG

Replace the A/T-ECU.

Code No. 22 Input shaft speed sensor system Probable cause

If no output pulse is detected from the input shaft speed sensor for 1 second or

more while driving in 3rd or 4th gear at a speed of 30 km/h or more, there is judged

to be an open circuit or short—circuit in the input shaft speed sensor and diagnosis

code No. 22 is output. If diagnosis code No. 22 is output four times, the transmission

is locked into 3rd gear (D range) or 2nd gear as a fail—safe measure, and the N

range lamp flashes at a frequency of 1 Hz.

D Malfunction of the input shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of connector

D Malfunction of A/T—ECU

L

: Refer to the Transmission Workshop Manual.

Replace the A/T—ECU.

A/T overhaul K

D Replace the underdrive clutch

retainer.

Replace the A/T—ECU.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

NG

OK

Check the trouble symptoms.

OK

Check the following harness:

D Between the input shaft speed

sensor and the ignition switch

D Between the input shaft speed

sensor and A/T—ECU

NG

Repair

NG

Check the trouble symptoms.

NG

OK

Check the trouble symptoms.

OK

Measure output waveform of the input

shaft speed sensor.

(using an oscilloscope)

D Engine: 2,000 r/min (approx. 50

km/h)

D Transmission: 3rd gear (Voltage)

OK:

Conforms to the waveform

shown at page 23-43 (Inspec-

tion procedure using an oscil-

loscope). There is no noise

in the output waveform.

NG

Replace the input shaft speed sensor.

Measure at the input shaft speed sensor

connector A-90.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

Battery voltage

(2) Voltage between 2 and earth

(Ignition switch: ON)

OK

approx. 5 V

(3) Continuity between 1 and earth

OK:

Continuity

NG

Check the following connectors:

A-90, B-14, B-93, B-89, B-11

NG

Repair

AUTOMATIC TRANSMISSION —

Troubleshooting

23-15

Code No. 23 Output shaft speed sensor system Probable cause

If the output from the output shaft speed sensor is continuously 50% lower than the

vehicle speed for 1 second or more while driving in 3rd or 4th gear at a speed of

30 km/h or more, there is judged to be an open circuit or short—circuit in the output

shaft speed sensor and diagnosis code No. 23 is output.

If diagnosis code No. 23 is output four times, the transmission is locked into 3rd

gear (D range) or 2nd gear as a fail—safe measure, and the N range lamp flashes

at a frequency of 1 Hz.

D Malfunction of the output shaft speed sensor

D Malfunction of the transfer drive gear or driven gear

D Malfunction of connector

D Malfunction of the A/T—ECU

L

: Refer to the Transmission Workshop Manual.

A/T overhaul L

D Replace the transfer drive gear and

driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Replace the A/T—ECU.

Replace the A/T—ECU.

NG

OK

Check the trouble symptoms.

OK

Check the following harness:

D Between the output shaft speed

sensor and the ignition switch

D Between the output shaft speed

sensor and A/T—ECU

NG

Repair

NG

Check the trouble symptoms.

NG

OK

Check the trouble symptoms.

OK

Measure output waveform of the output

shaft speed sensor.

(using an oscilloscope)

D Engine: 2,000 r/min

(approx. 50 km/h)

D Transmission: 3rd gear

(Voltage)

OK:

Conforms to the waveform

shown at page 23-43 (Inspec-

tion procedure using an oscil-

loscope). There is no noise

in the output waveform.

NG

Replace the output shaft speed sensor.

Measure at the output shaft speed sen-

sor connector A-82.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

Battery voltage

(2) Voltage between 2 and earth

(Ignition switch: ON)

OK:

approx. 5 V

(3) Continuity between 1 and earth

OK:

Continuity

NG

Check the following connectors:

A-82, B-14, B-93, B— 89, B-11

NG

Repair

Code No. 25 Wide open throttle switch system Probable cause

If the wide open throttle switch is on for 1 second or more with the throttle valve

opening angle at 70% or less, it is judged that there is a short circuit in the wide

open throttle switch and diagnosis code No. 25 is output.

D Malfunction of the wide open throttle switch

D Malfunction of connector

D Malfunction of A/T—ECU

Wide open throttle switch check (Refer to P.23-64.)

NG

Replace

OK

Check the following connectors:

B-61, B-10

NG

Repair

OK

Harness check

D Between the wide open throttle switch and the A/T—ECU.

NG

Repair

OK

Check the trouble symptoms.

NG

Replace the A/T—ECU.

AUTOMATIC TRANSMISSION —

Troubleshooting

23-16

Code No. 26 Stop lamp switch system Probable cause

If the stop lamp switch is on for 5 minutes or more while driving, it is judged that

there is a short circuit in the stop lamp switch and diagnosis code No. 26 is output.

D Malfunction of the stop lamp switch

D Malfunction of connector

D Malfunction of the A/T-ECU

Stop lamp switch check (Refer to GROUP 35 — Brake Pedal.)

NG

Replace

OK

Check the following connectors:

B-28, B-65, B-14, B-10

NG

Repair

OK

Harness check

D Between stop lamp switch and A/T-ECU

NG

Repair

OK

Check the trouble symptoms.

NG

Replace the A/T-ECU.

Code No. 31 Low and reverse solenoid valve system

Probable cause

Code No. 32 Underdrive solenoid valve system

Code No. 33 Second solenoid valve system

Code No. 34 Overdrive solenoid valve system

If the resistance value for a solenoid valve is too large or too small, it is judged

that there is a short-circuit or an open circuit in the solenoid valve and the respective

diagnosis codeis output. The transmission is locked into 3rd gearas a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

D Malfunction of solenoid valve

D Malfunction of connector

D Malfunction of the A/T-ECU

Solenoid valve check (Refer to P.23-52.)

NG

Replace

OK

Check the following connectors:

A-88, A — 12X, B-12, B-10

NG

Repair

OK

Harness check

D Between solenoid valve and A/T-ECU

NG

Repair

OK

Replace the solenoid valve.

Check the trouble symptoms.

NG

Replace the A/T-ECU.

AUTOMATIC TRANSMISSION —

Troubleshooting

23-17

Code No. 36, 52 Damper clutch control solenoid valve

system

Probable cause

If the resistance value for the damper clutch control solenoid valve is too large or

too small, it is judged that there is a short-circuit or an open circuit in the damper

clutch control solenoid valve and diagnosis code No. 36 is output. If the drive duty

rate for the damper clutch control solenoid valve is 100 % for a continuous period

of 4 seconds or more, it is judged that there is an abnormality in the damper clutch

control system and diagnosis code No. 52 is output. When diagnosis code No. 36

is output, the transmission is locked into 3rd gear as a fail-safe measure, and the

N range lamp flashes at a frequency of 1 Hz.

D Malfunction of thedamper clutch control solenoid valve

D Malfunction of connector

D Malfunction of the A/T-ECU

Damper clutch control solenoid valve check (Refer to P.23-52.)

NG

Replace

OK

Check the following connectors:

A-88, A-12X, B-12

NG

Repair

OK

Harness check

D Between damper clutch control solenoid valve and A/T-ECU

NG

Repair

OK

Replace the damper clutch control solenoid valve.

Check the trouble symptoms.

NG

Replace the A/T-ECU.

AUTOMATIC TRANSMISSION —

Troubleshooting

23-18

Code No. 41 1st gear ratio does not meet the specification Probable cause

If the output from the output shaft speed sensor multiplied by the 1st gear ratio is

not the same as the output from the input shaft speed sensor after shifting to 1st

gear has been completed, diagnosis code No. 41 is output. If diagnosis code No.

41 is output four times, the transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the low and reverse brake system

D Malfunction of the underdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

MUT-

II

Self-Diag code

Is the diagnosis code No. 22 output?

Yes

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

No

MUT-

II

Self-Diag code

Is the diagnosis code No. 23 output?

Yes

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shownon P.23-43 (Inspection

Procedure Using an Oscilloscope) is output (flashing be-

tween 0 ¨ 5V) and there is no noise appearing in

the waveform.

NG

Replace the input shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

OK

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shownon P.23-43 (Inspection

Procedure Using an Oscilloscope) is output (flashing be-

tween 0 ¨ 5V) and there is no noise appearing in

the waveform.

NG

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

OK

A/T overhaul L

D Underdrive clutch system check

(No. 42, No. 43, or no diagnosis code is output).

D Low and reverse brake system check

(No. 46 or no diagnosis code is output).

AUTOMATIC TRANSMISSION —

Troubleshooting

23-19

CodeNo.422ndgearratiodoesnotmeet the specification Probable cause

If the output from the output shaft speed sensor multiplied by the 2nd gear ratio

is not the same as the output from the input shaft speed sensor after shifting to

2nd gear has been completed, diagnosis code No. 42 is output. If diagnosis code

No. 42 is output four times, the transmission is locked into 3rd gear as a fail-safe

measure, and the N range lamp flashes at a frequency of 1 Hz.

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the second brake system

D Malfunction of the underdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

MUT-

II

Self-Diag code

Is the diagnosis code No. 22 output?

Yes

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

No

MUT-

II

Self-Diag code

Is the diagnosis code No. 23 output?

Yes

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shownon P.23-43 (Inspection

Procedure Using an Oscilloscope) is output (flashing be-

tween 0 ¨ 5V) and there is no noise appearing in

the waveform.

NG

Replace the input shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

OK

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shownon P.23-43 (Inspection

Procedure Using an Oscilloscope) is output (flashing be-

tween 0 ¨ 5V) and there is no noise appearing in

the waveform.

NG

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

OK

A/T overhaul L

D Underdrive clutch system check

(No. 41, No. 43, or no diagnosis code is output).

D Second brake system check

(No. 44 or no diagnosis code is output).

AUTOMATIC TRANSMISSION —

Troubleshooting

23-20

CodeNo.433rdgearratio does notmeet the specification Probable cause

If the output from the output shaft speed sensor multiplied by the 3rd gear ratio is

not the same as the output from the input shaft speed sensor after shifting to 3rd

gear has been completed, diagnosis code No. 43 is output. If diagnosis code No.

43 is output four times, the transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the underdrive clutch system

D Malfunction of the overdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

MUT-

II

Self-Diag code

Is the diagnosis code No. 22 output?

Yes

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

No

MUT-

II

Self-Diag code

Is the diagnosis code No. 23 output?

Yes

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shownon P.23-43 (Inspection

Procedure Using an Oscilloscope) is output (flashing be-

tween 0 ¨ 5V) and there is no noise appearing in

the waveform.

NG

Replace the input shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the underdrive clutch retainer.