1669628761

FANUC

Инструкция по эксплуатации станка ЧПУ на русском языке на базе системы Fanuc 16, 18i, 21i. Инструкции в редактируемом формате DOC для программы microsoft word

Прикрепленные файлы

1

05.doc

1.1 МБ

2

06.doc

719 КБ

3

07.doc

411.5 КБ

4

08.doc

370.5 КБ

5

09.doc

228.5 КБ

6

10.doc

633.5 КБ

Добавить

комментарийЧтобы добавить комментарий, необходимо авторизоваться

Последние добавленные макеты

Резной наличник

Меч «Оскверненный испепелитель»

Клинок «Ледяная скорбь»

Набор из 100 вариантов топперов на все случаи жизни

Копилка — джойстик

Макет ключницы с дверью под 4 мм

Смотреть все

FANUC Series 16*

ODEL B

FANUC Series 18*-MODEL B

FANUC Series 160*-MODEL B

FANUC Series 180*-MODEL B

FANUC Series 160*s-MODEL B

FANUC Series 180*s-MODEL B

PARAMETER MANUAL

B-63530EN/03

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

B-63530EN/03 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

— Read this manual carefully, and store it in a safe place.

s-1

B-63530EN/03 PREFACE

PREFACE

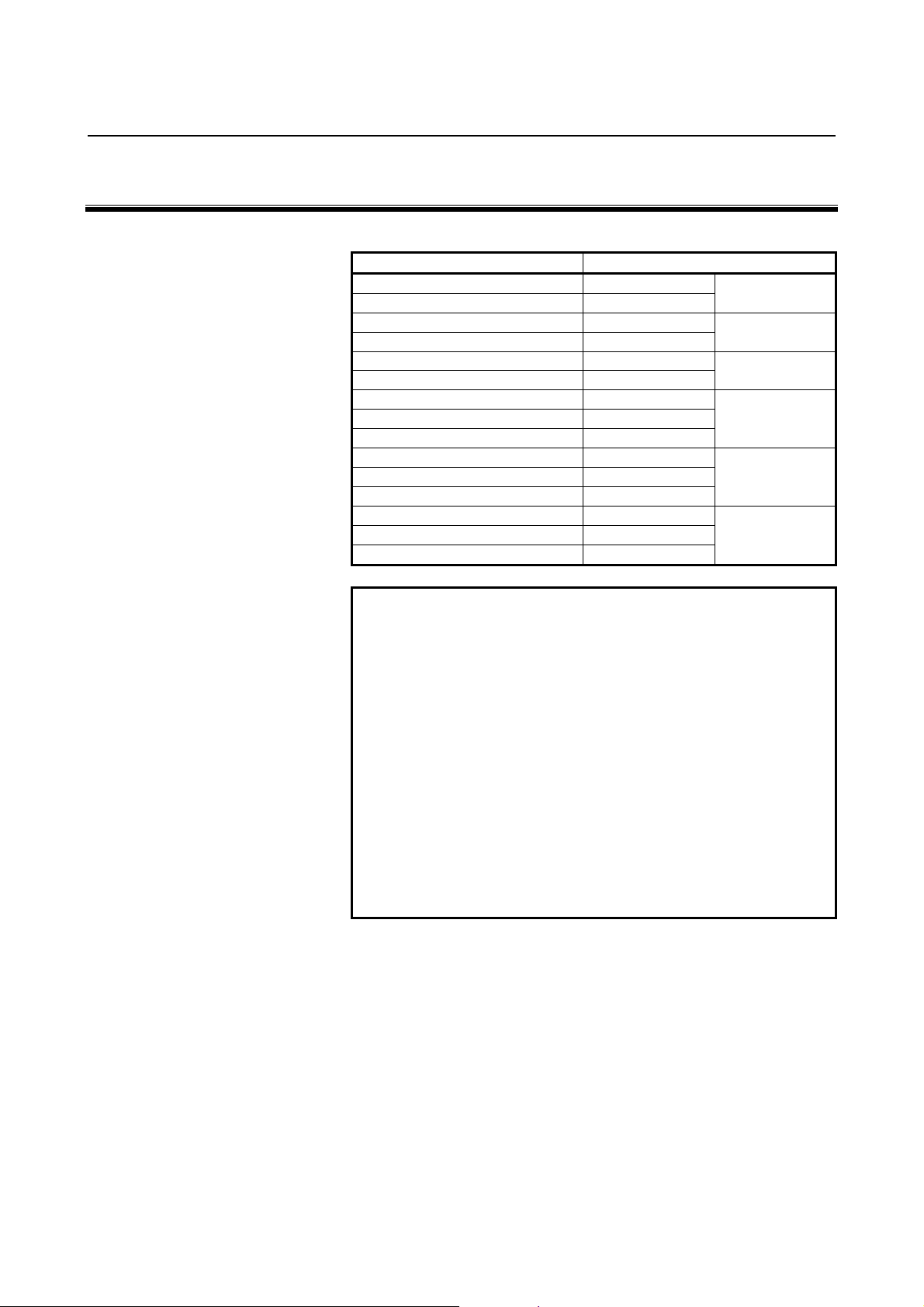

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 16i-TB 16i-TB

FANUC Series 16i-MB 16i-MB

FANUC Series 160i-TB 160i-TB

FANUC Series 160i-MB 160i-MB

FANUC Series 160is-TB 160is-TB

FANUC Series 160is-MB 160is-MB

FANUC Series 18i-TB 18i-TB

FANUC Series 18i-MB5 18i-MB5

FANUC Series 18i-MB 18i-MB

FANUC Series 180i-TB 180i-TB

FANUC Series 180i-MB5 180i-MB5

FANUC Series 180i-MB 180i-MB

FANUC Series 180is-TB 180is-TB

FANUC Series 180is-MB5 180is-MB5

FANUC Series 180is-MB 180is-MB

NOTE

1 For ease of explanation, the models may be

classified as follows:

T series:

16i-TB/160i-TB/160is-TB/18i-TB/180i-TB/180is-TB

M series:

16i-MB/160i-MB/160is-MB/18i-MB5/ 180i-MB5/

180is-MB5/18i-MB/180i-MB/180is-MB

2 In this manual, the 18i/180i/180is-MB indicates

both the 18i/180i/180is-MB5 and

18i/180i/180is-MB unless otherwise specified.

3 Some functions described in this manual may not

be applied to some products.

For details, refer to the DESCRIPTIONS

(B-63522EN).

Series 16i

Series 160i

Series 160is

Series 18i

Series 180i

Series 180is

p-1

PREFACE B-63530EN/03

Related manuals of Series 16i/18i/21i/160i/180i/210i/160is/180is/210is-MODEL

B

The following table lists the manuals related to Series 16i, Series 18i,

Series 21i, Series 160i, Series 180i, Series 210i, Series 160is, Series

180is, Series 210is-MODEL B. This manual is indicated by an

asterisk(*).

Related manuals of Series 16i/18i/21i/160i/180i/210i/160is/180is/ 210is-MODEL B

Manual name

DESCRIPTIONS B-63522EN

CONNECTION MANUAL (HARDWARE) B-63523EN

CONNECTION MANUAL (FUNCTION) B-63523EN-1

Series 16i/18i/160i/180i/160is/180is-TB

OPERATOR’S MANUAL

Series 16i/160i/160is-MB, Series 18i/180i/180i-MB5,

Series 18i/180i/180is-MB OPERATOR’S MANUAL

Series 21i/210i/210is-TB OPERATOR’S MANUAL

Series 21i/210i/210is-MB OPERATOR’S MANUAL

MAINTENANCE MANUAL B-63525EN

Series 16i/18i/160i/180i/160is/180is-MODEL B

PARAMETER MANUAL

Series 21i/210i/210is-MODEL B PARAMETER MANUAL

PROGRAMMING MANUAL

Macro Compiler/Macro Executor PROGRAMMING MANUAL B-61803E-1

C Language Executor PROGRAMMING MANUAL B-62443EN-3

FANUC MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

CAP (T series)

FANUC Super CAPi T OPERATOR’S MANUAL

FANUC Symbol CAPi T OPERATOR’S MANUAL

MANUAL GUIDE For Lathe PROGRAMMING MANUAL B-63343EN

MANUAL GUIDE For Lathe OPERATOR’S MANUAL B-63344EN

CAP (M series)

FANUC Super CAPi M OPERATOR’S MANUAL

MANUAL GUIDE For Milling PROGRAMMING MANUAL B-63423EN

MANUAL GUIDE For Milling OPERATOR’S MANUAL B-63424EN

PMC

PMC Ladder Language PROGRAMMING MANUAL B-61863E

PMC C Language PROGRAMMING MANUAL B-61863E-1

Network

I/O Link-II OPERATOR’S MANUAL B-62924EN

Profibus-DP Board OPERATOR’S MANUAL B-62924EN

Ethernet Board/DATA SERVER Board OPERATOR’S MANUAL B-63354EN

FAST Ethernet Board/FAST DATA SERVER

OPERATOR’S MANUAL

DeviceNet Board OPERATOR’S MANUAL B-63404EN

PC function

Screen Display Function OPERATOR’S MANUAL B-63164EN

Specification

number

B-63524EN

B-63534EN

B-63604EN

B-63614EN

B-63530EN *

B-63610EN

B-66102E

B-63284EN

B-63304EN

B-63294EN

B-63644EN

p-2

B-63530EN/03 PREFACE

Related manuals of SERVO MOTOR αi series

The following table lists the manuals related to SERVO MOTOR αi

series

Manual name Specification number

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi series

DESCRIPTIONS

FANUC LINEAR MOTOR series

DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series

DESCRIPTIONS

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

PARAMETER MANUAL

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βis series

PARAMETER MANUAL

B-65262EN

B-65272EN

B-65222EN

B-65282EN

B-65285EN

B-65270EN

B-65280EN

B-65270EN

Related manuals of SERVO MOTOR α series

The following table lists the manuals related to SERVO MOTOR α

series

Manual name Specification number

FANUC AC SERVO MOTOR α series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR α series

DESCRIPTIONS

FANUC SERVO AMPLIFIER α series

DESCRIPTIONS

FANUC SERVO MOTOR α series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR α series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR α series

PARAMETER MANUAL

Either of the following servo motors and the corresponding spindle

can be connected to the CNC covered in this manual.

• FANUC SERVO MOTOR αi series

• FANUC SERVO MOTOR α series

This manual mainly assumes that the FANUC SERVO MOTOR αi

series of servo motor is used. For servo motor and spindle information,

refer to the manuals for the servo motor and spindle that are actually

connected.

B-65142E

B-65152E

B-65162E

B-65165E

B-65150E

B-65160E

p-3

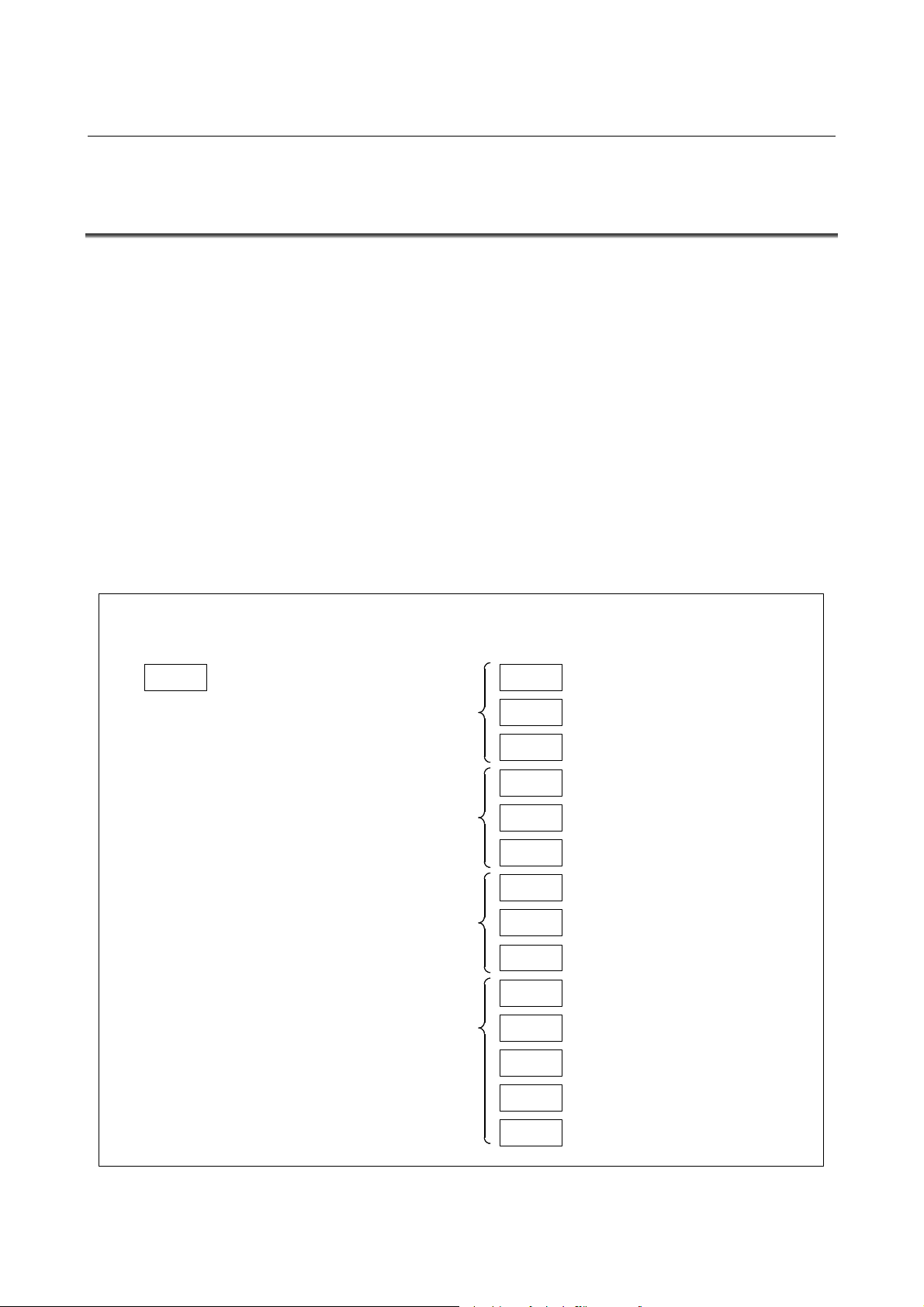

B-63530EN/03 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE ……………………………s-1

PREFACE……………………………………………………………………………………….p-1

1 DISPLAYING PARAMETERS……………………………………………………….. 1

2 SETTING PARAMETERS FROM MDI ……………………………………………. 2

3 INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE …………………………………………. 4

3.1 OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER

INTERFACE ……………………………………………………………………………………..5

3.2 INPUTTING PARAMETERS THROUGH THE READER/PUNCHER

INTERFACE ……………………………………………………………………………………..6

4 DESCRIPTION OF PARAMETERS ………………………………………………..7

4.1 PARAMETERS OF SETTING……………………………………………………………… 9

4.2 PARAMETERS OF READER/PUNCHER INTERFACE OR REMOTE

BUFFER ………………………………………………………………………………………… 14

4.2.1 Parameters Common to all Channels…………………………………………………………….15

4.2.2 Parameters of Channel 1 (I/O CHANNEL=0) ……………………………………………….16

4.2.3 Parameters of Channel 1 (I/O CHANNEL=1) ……………………………………………….18

4.2.4 Parameters of Channel 2 (I/O CHANNEL=2) ……………………………………………….18

4.2.5 Parameters of Channel 3 (I/O CHANNEL=3) ……………………………………………….19

4.3 PARAMETERS OF DNC1/DNC2 INTERFACE …………………………………….23

4.4 PARAMETERS OF M-NET INTERFACE…………………………………………….. 27

4.5 PARAMETERS OF REMOTE DIAGNOSIS…………………………………………. 30

4.6 PARAMETERS OF DNC1 INTERFACE #2 ………………………………………….34

4.7 PARAMETERS OF MEMORY CARD INTERFACE………………………………. 36

4.8 PARAMETERS OF FACTOLINK ……………………………………………………….. 37

4.9 PARAMETERS OF DATA SERVER…………………………………………………… 39

4.10 PARAMETERS OF ETHERNET………………………………………………………… 40

4.11 PARAMETERS OF POWER MATE CNC MANAGER…………………………… 41

4.12 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM………………… 42

4.13 PARAMETERS OF COORDINATES………………………………………………….. 58

4.14 PARAMETERS OF STORED STROKE CHECK ………………………………….. 68

4.15 PARAMETERS OF CHUCK AND TAILSTOCK BARRIER (T SERIES)……. 74

4.16 PARAMETERS OF FEEDRATE ………………………………………………………… 78

c-1

TABLE OF CONTENTS B-63530EN/03

4.17 PARAMETERS OF ACCELERATION/DECELERATION CONTROL …….. 100

4.18 PARAMETERS OF SERVO (1 OF 2) ………………………………………………..133

4.19 PARAMETERS OF DI/DO ………………………………………………………………. 188

4.20 PARAMETERS OF DISPLAY AND EDIT (1 OF 2) ……………………………… 194

4.21 PARAMETERS OF PROGRAMS ……………………………………………………..236

4.22 PARAMETERS OF PITCH ERROR COMPENSATION ………………………. 249

4.23 PARAMETERS OF SPINDLE CONTROL ………………………………………….262

4.24 PARAMETERS OF TOOL COMPENSATION ……………………………………. 315

4.25 PARAMETERS OF WHEEL WEAR COMPENSATION……………………….. 337

4.26 PARAMETERS OF CANNED CYCLES…………………………………………….. 338

4.26.1 Parameters of Canned Cycle for Drilling …………………………………………………….338

4.26.2 Parameters of Threading Cycle ………………………………………………………………….346

4.26.3 Parameters of Multiple Repetitive Canned Cycle …………………………………………346

4.26.4 Parameters of Small-hole Peck Drilling Cycle……………………………………………..350

4.27 PARAMETERS OF RIGID TAPPING ………………………………………………..355

4.28 PARAMETERS OF SCALING AND COORDINATE SYSTEM

ROTATION …………………………………………………………………………………… 384

4.29 PARAMETERS OF SINGLE DIRECTION POSITIONING……………………. 388

4.30 PARAMETERS OF POLAR COORDINATE INTERPOLATION …………….389

4.31 PARAMETERS OF NORMAL DIRECTION CONTROL……………………….. 392

4.32 PARAMETERS OF INDEX TABLE INDEXING…………………………………… 396

4.33 PARAMETERS OF INVOLUTE INTERPOLATION ……………………………..398

4.34 PARAMETERS OF EXPONENTIAL INTERPOLATION ………………………. 401

4.35 PARAMETERS OF FLEXIBLE SYNCHRONOUS CONTROL………………. 402

4.36 PARAMETERS OF STRAIGHTNESS COMPENSATION (1 OF 2) ……….. 406

4.37 PARAMETERS OF INCLINATION COMPENSATION ………………………… 410

4.38 PARAMETERS OF CUSTOM MACROS…………………………………………… 411

4.39 PARAMETERS OF ONE TOUCH MACRO ……………………………………….. 420

4.40 PARAMETERS OF PATTERN DATA INPUT ……………………………………..421

4.41 PARAMETERS OF POSITIONING BY OPTIMAL ACCELERATION ……..422

4.42 PARAMETERS OF SKIP FUNCTION ………………………………………………. 428

4.43 PARAMETERS OF AUTOMATIC TOOL OFFSET (T SERIES) AND

AUTOMATIC TOOL LENGTH MEASUREMENT (M SERIES) ……………… 436

4.44 PARAMETERS OF EXTERNAL DATA INPUT …………………………………… 439

4.45 PARAMETERS OF FINE TORQUE SENSING…………………………………… 440

4.46 PARAMETERS OF MANUAL HANDLE RETRACE…………………………….. 442

4.47 PARAMETERS OF GRAPHIC DISPLAY…………………………………………… 450

c-2

B-63530EN/03 TABLE OF CONTENTS

4.47.1 Parameters of Graphic Display / Dynamic Graphic Display…………………………..450

4.47.2 Parameters of Graphic Color……………………………………………………………………..455

4.48 PARAMETERS OF RUN HOUR AND PARTS COUNT DISPLAY…………. 457

4.49 PARAMETERS OF TOOL LIFE MANAGEMENT ……………………………….. 461

4.50 PARAMETERS OF POSITION SWITCH FUNCTIONS ……………………….. 468

4.51 PARAMETERS OF MANUAL OPERATION AND AUTOMATIC

OPERATION…………………………………………………………………………………. 472

4.52 PARAMETERS OF MANUAL HANDLE FEED, MANUAL HANDLE

INTERRUPTION AND TOOL DIRECTION HANDLE FEED …………………. 480

4.53 PARAMETERS OF MANUAL LINEAR/CIRCULAR FUNCTION……………. 487

4.54 PARAMETERS OF REFERENCE POSITION SETTING WITH

MECHANICAL STOPPER ………………………………………………………………. 488

4.55 PARAMETERS OF SOFTWARE OPERATOR’S PANEL …………………….. 490

4.56 PARAMETERS OF PROGRAM RESTART……………………………………….. 495

4.57 PARAMETERS OF HIGH-SPEED MACHINING (HIGH-SPEED CYCLE

MACHINING / HIGH-SPEED REMOTE BUFFER) ………………………………496

4.58 PARAMETERS OF ROTARY TABLE DYNAMIC FIXTURE OFFSET ……. 504

4.59 PARAMETERS OF POLYGON TURNING ………………………………………… 506

4.60 PARAMETERS OF EXTERNAL PULSE INPUT…………………………………. 513

4.61 PARAMETERS OF HOBBING MACHINE AND SIMPLE ELECTRIC

GEAR BOX (EGB) …………………………………………………………………………. 514

4.62 PARAMETERS OF AXIS CONTROL BY PMC…………………………………… 527

4.63 PARAMETERS OF TWO-PATH CONTROL………………………………………. 536

4.64 PARAMETERS OF INTERFERENCE CHECK BETWEEN TWO TOOL

POSTS (TWO-PATH) (FOR TWO-PATH CONTROL)…………………………. 538

4.65 PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

SUPERIMPOSED CONTROL ………………………………………………………….541

4.66 PARAMETERS OF ANGULAR AXIS CONTROL ………………………………..561

4.67 PARAMETERS OF B-AXIS CONTROL…………………………………………….. 564

4.68 PARAMETERS OF SIMPLE SYNCHRONOUS CONTROL ………………….571

4.69 PARAMETERS OF SEQUENCE NUMBER COMPARISON AND STOP .. 581

4.70 PARAMETERS OF CHOPPING ………………………………………………………. 582

4.71 PARAMETERS OF HIGH-SPEED AND HIGH-PRECISION CONTOUR

CONTROL BY RISC (M SERIES) …………………………………………………….585

4.71.1 Parameters of Acceleration/Deceleration before Interpolation ……………………….585

4.71.2 Parameters of Automatic Speed Control ……………………………………………………..589

4.72 PARAMETERS OF HIGH-SPEED POSITION SWITCH (1 OF 2) ………….602

c-3

TABLE OF CONTENTS B-63530EN/03

4.73 OTHER PARAMETERS …………………………………………………………………. 608

4.74 PARAMETERS OF TROUBLE DIAGNOSIS ……………………………………… 618

4.75 PARAMETERS OF MAINTENANCE ………………………………………………… 619

4.76 PARAMETERS OF EMBEDDED MACRO…………………………………………. 621

4.77 PARAMETERS OF HIGH-SPEED POSITION SWITCH (2 OF 2) ………….628

4.78 PARAMETERS OF SUPERIMPOSED COMMAND FUNCTION IN

BINARY OPERATION ……………………………………………………………………. 631

4.79 PARAMETERS OF SERVO SPEED CHECK …………………………………….. 632

4.80 PARAMETERS OF MANUAL HANDLE FUNCTIONS…………………………. 633

4.81 PARAMETERS OF MANUAL HANDLE FOR 5-AXIS MACHINING ………. 634

4.82 PARAMETERS OF MANUAL HANDLE FEED ……………………………………637

4.83 PARAMETERS OF MULTI-PATH CONTROL …………………………………….639

4.84 PARAMETERS OF ACCELERATIOON CONTROL ……………………………. 648

4.85 PARAMETERS OF EXTERNAL DECELERATION POSITIONS

EXPANSION…………………………………………………………………………………. 650

4.86 PARAMETERS OF OPERATION HISTORY ……………………………………… 652

4.87 PARAMETERS OF DISPLAY AND EDIT (2 OF 2) ……………………………… 656

4.88 PARAMETERS OF TOOL MANAGEMENT FUNCTIONS……………………. 660

4.89 PARAMETERS OF STRAIGHTNESS COMPENSATION (2 OF 2) ……….. 665

4.90 PARAMETERS OF INTERPOLATION TYPE STRAIGHTNESS

COMPENSATION………………………………………………………………………….. 667

4.91 PARAMETERS OF MACHINING CONDITION SELECTING SCREEN …. 669

4.92 PARAMETERS OF DUAL CHECK SAFETY ………………………………………681

4.93 PARAMETERS OF SERVO (2 OF 2) ………………………………………………..689

4.94 PARAMETERS OF SERVO GUIDE Mate …………………………………………. 690

4.95 PARAMETERS OF INTERFERENCE CHECK FOR ROTARY AREA……. 691

4.96 PARAMETERS OF SLIDE AXIS CONTROL FOR LINK-TYPE

PRESSES…………………………………………………………………………………….. 708

4.97 PARAMETERS OF AI/AI-NANO HIGH-PRECISION CONTOUR

CONTROL AND FUNCTIONS RELATED FOR RISC PROCESSOR

OPERATION…………………………………………………………………………………. 710

4.98 PARAMETERS OF 5-AXIS MACHINING ………………………………………….. 726

APPENDIX

A. CHARACTER CODE LIST …………………………………………………………763

c-4

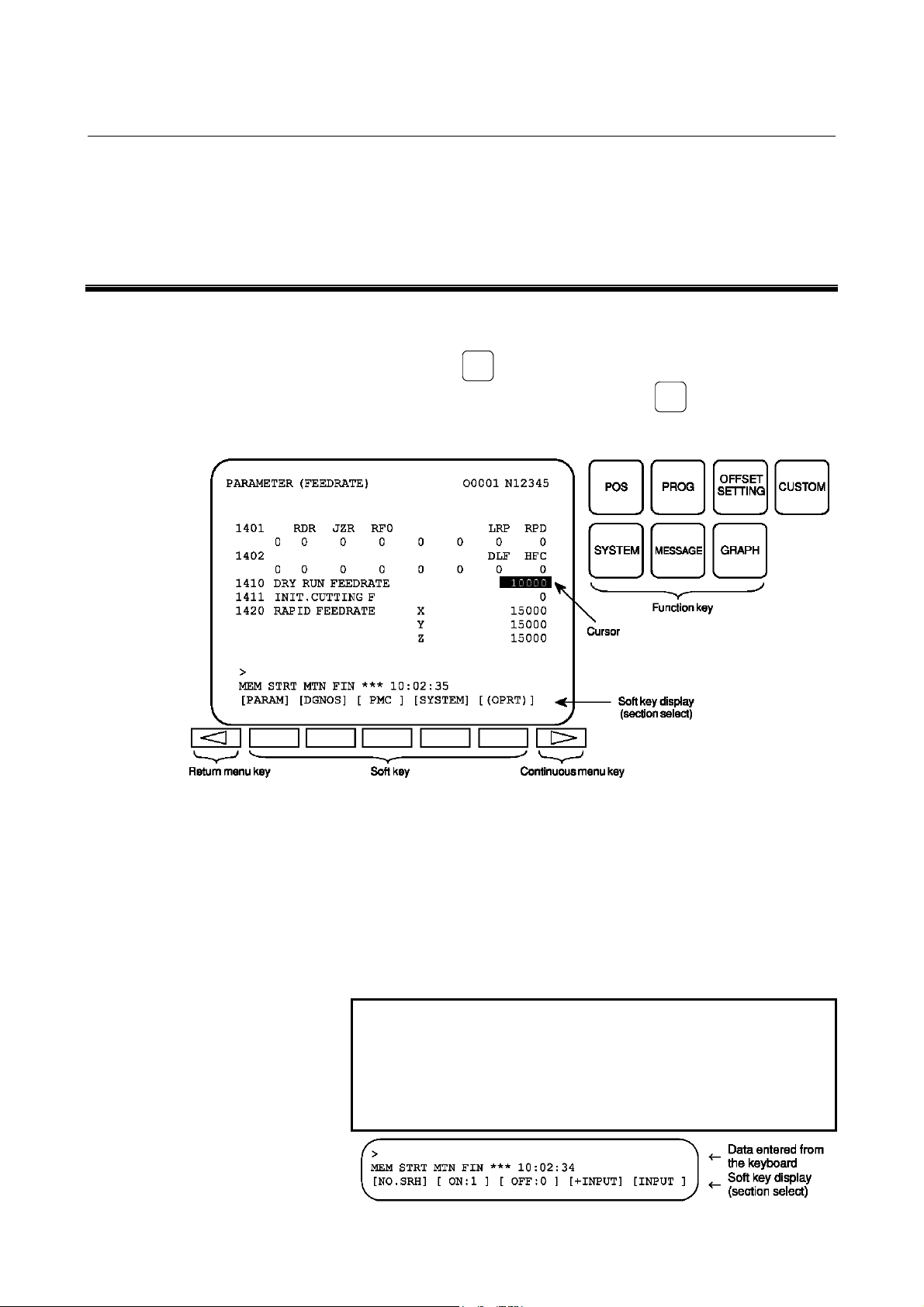

B-63530EN/03 1.DISPLAYING PARAMETERS

1 DISPLAYING PARAMETERS

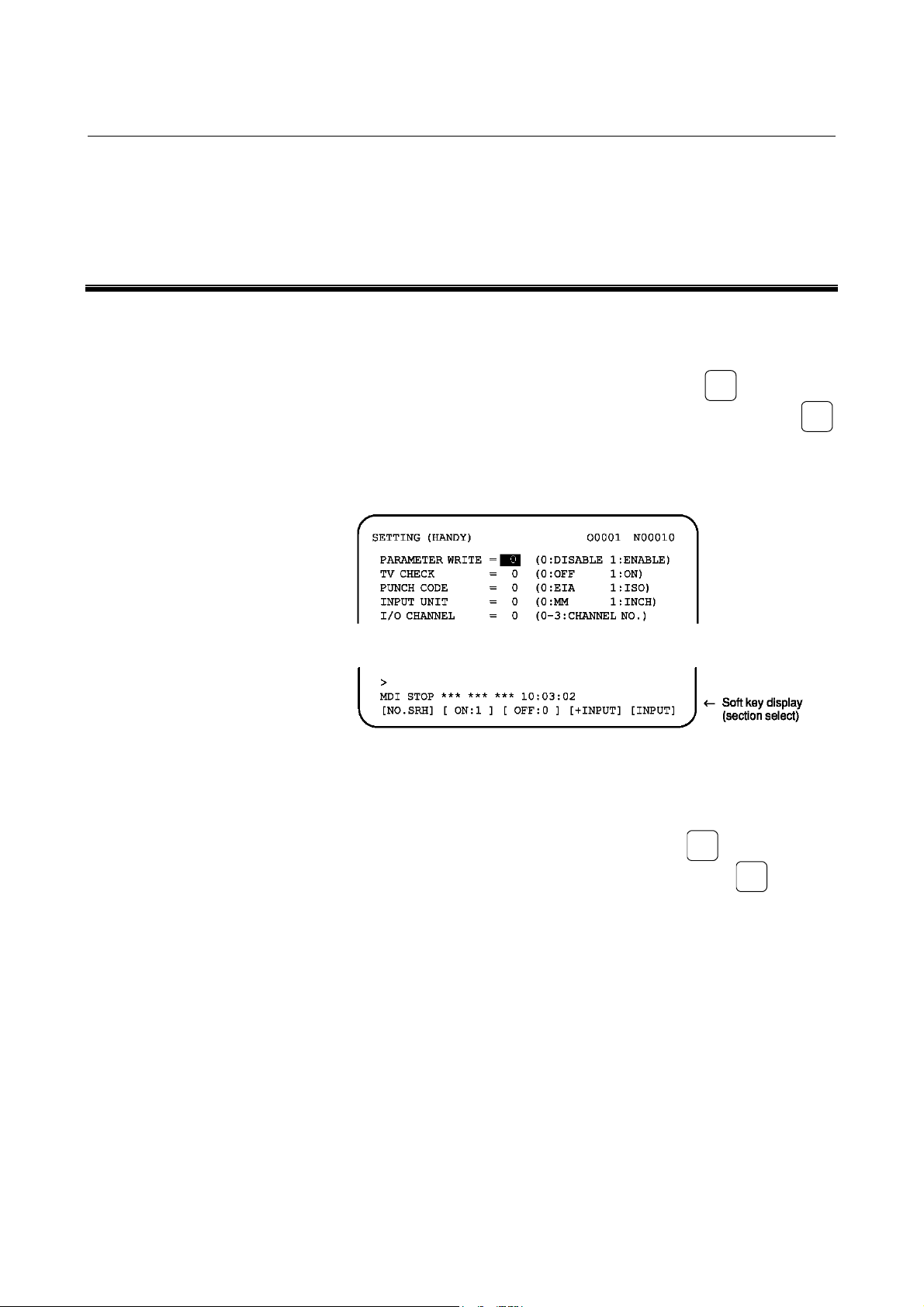

Follow the procedure below to display parameters.

SYSTEM

(1) Press the

required, or alternatively, press the

then the [PARAM] section display soft key. The parameter

screen is then selected.

function key on the MDI as many times as

SYSTEM

function key once,

(2) The parameter screen consists of multiple pages. Use step (a) or

(b) to display the page that contains the parameter you want to

display.

(a) Use the page select key or the cursor move keys to display

the desired page.

(b) Enter the data number of the parameter you want to display

from the keyboard, then press the [NO.SRH] soft key. The

parameter page containing the specified data number

appears with the cursor positioned at the data number. (The

NOTE

If key entry is started with the section select soft

data is displayed in reverse video.)

keys displayed, they are replaced automatically by

operation select soft keys including [NO.SRH].

Pressing the [(OPRT)] soft key can also cause the

operation select keys to be displayed.

— 1 —

2.SETTING PARAMETERS FROM MDI B-63530EN/03

2 SETTING PARAMETERS FROM MDI

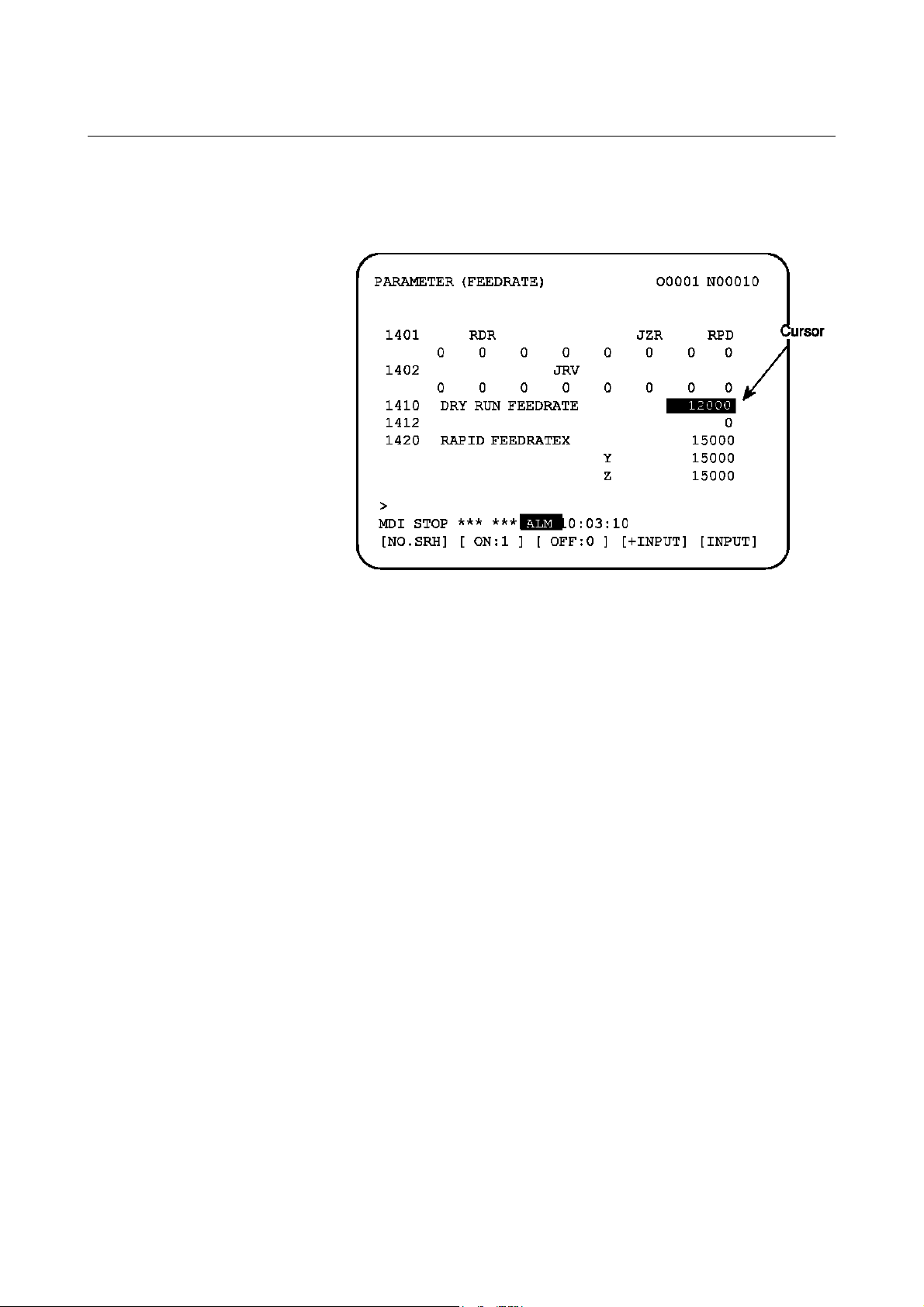

Follow the procedure below to set parameters.

(1) Place the NC in the MDI mode or the emergency stop state.

(2) Follow the substeps below to enable writing of parameters.

OFFSET

SETTING

1. To display the setting screen, press the

as many times as required, or alternatively press the

function key once, then the [SETTING] section select soft

key. The first page of the setting screen appears.

2. Position the cursor on «PARAMETER WRITE» using the

cursor move keys.

function key

OFFSET

SETTING

3. Press the [(OPRT)] soft key to display operation select soft

keys.

4. To set «PARAMETER WRITE=» to 1, press the [ON:1]

soft key, or alternatively enter 1 and press the [INPUT] soft

key. From now on, the parameters can be set. At the same

time an alarm condition (P/S100 PARAMETER WRITE

ENABLE) occurs in the CNC.

SYSTEM

(3) To display the parameter screen, press the

many times as required, or alternatively press the

key once, then the [PARAM] section select soft key.

(See Chapter 1 «DISPLAYING PARAMETERS.»)

(4) Display the page containing the parameter you want to set, and

position the cursor on the parameter. (See Chapter 1

«DISPLAYING PARAMETERS.»)

function key as

SYSTEM

function

— 2 —

B-63530EN/03 2.SETTING PARAMETERS FROM MDI

(5) Enter data, then press the [INPUT] soft key. The parameter

indicated by the cursor is set to the entered data.

[Example] 12000 [INPUT]

Data can be entered continuously for parameters, starting at

the selected parameter, by separating each data item with a

semicolon (;).

[Example]

Entering 10;20;30;40 and pressing the [INPUT] key assigns

values 10, 20, 30, and 40 to parameters in order starting at

the parameter indicatedby the cursor.

(6) Repeat steps (4) and (5) as required.

(7) If parameter setting is complete, set «PARAMETER WRITE=»

to 0 on the setting screen to disable further parameter setting.

(8) Reset the NC to release the alarm condition (P/S100).

If an alarm condition (P/S000 PLEASE TURN OFF POWER)

occurs in the NC, turn it off before continuing operation.

— 3 —

3.INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE B-63530EN/03

3 INPUTTING AND OUTPUTTING

PARAMETERS THROUGH THE

READER/PUNCHER INTERFACE

This section explains the parameter input/output procedures for

input/output devices connected to the reader/puncher interface.

The following description assumes the input/output devices are ready

for input/output. It also assumes parameters peculiar to the

input/output devices, such as the baud rate and the number of stop bits,

have been set in advance. (See Section 4.2.)

— 4 —

B-63530EN/03 3.INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE

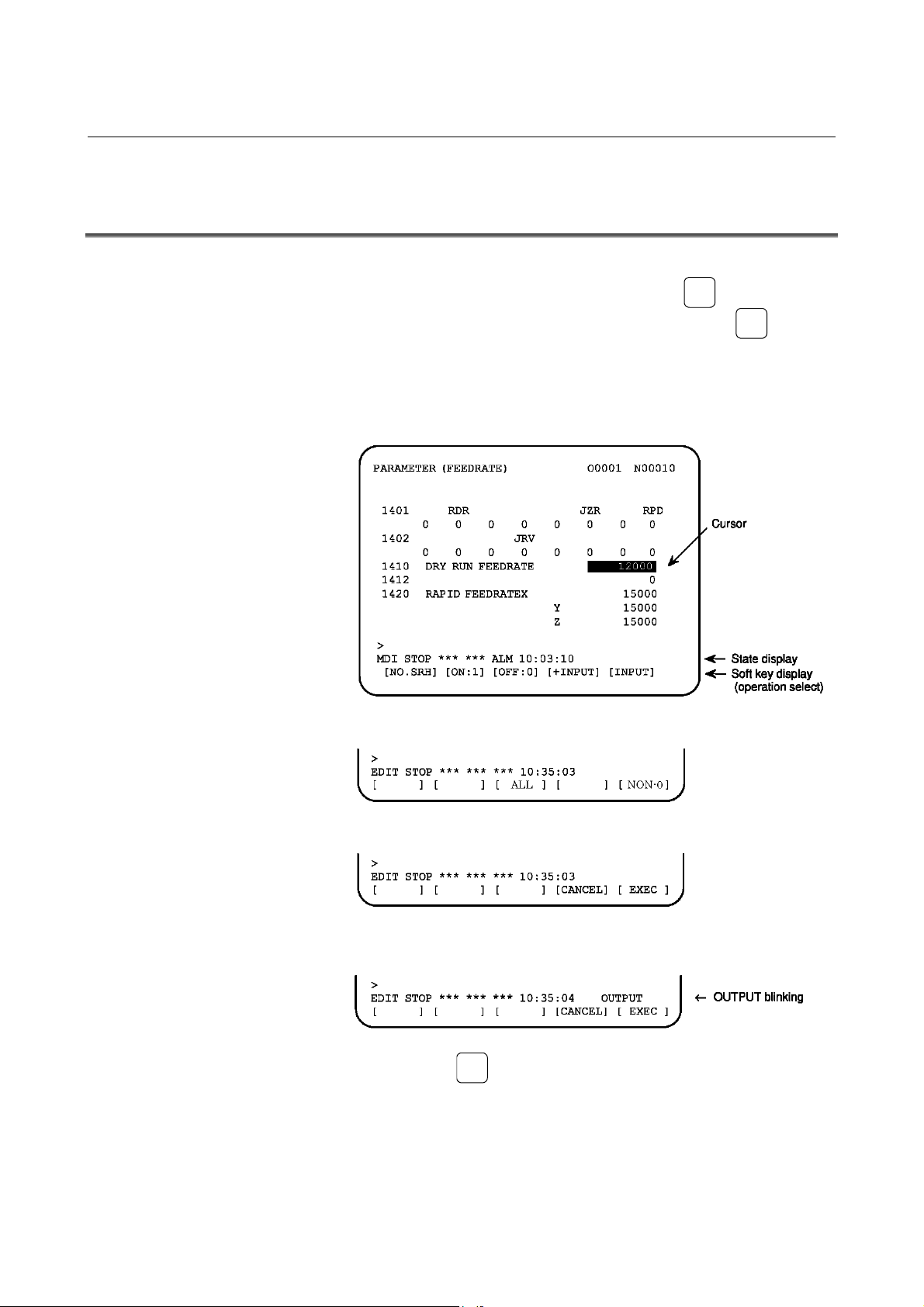

3.1 OUTPUTTING PARAMETERS THROUGH THE

READER/PUNCHER INTERFACE

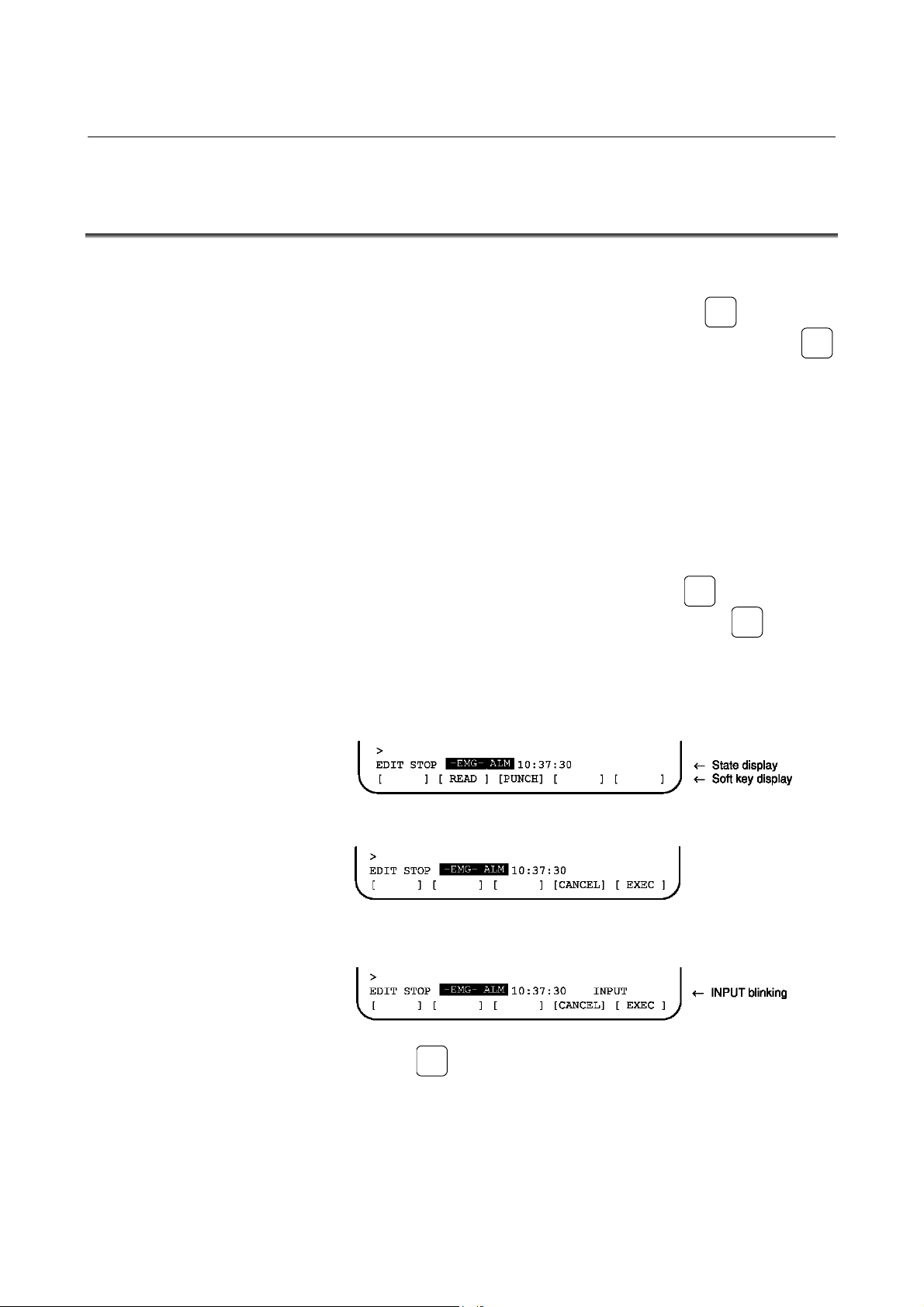

(1) Select the EDIT mode or set to Emergency stop.

SYSTEM

(2) To select the parameter screen, press the

many times as required, or alternatively press the

key once, then the [PARAM] section select soft key.

(3) Press the [(OPRT)] soft key to display operation select soft keys,

then press the forward menu key located at the right-hand side of

the soft keys to display another set of operation select keys

including [PUNCH].

function key as

SYSTEM

function

(4) Pressing the [ALL] or [NON-0]soft key changes the soft key

display as shown below:

(5) Pressing the [PUNCH] soft key changes the soft key display as

shown below:

(6) Press the [EXEC] soft key to start parameter output. When

parameters are being output, «OUTPUT» blinks in the state

display field on the lower part of the screen.

(7) When parameter output terminates, «OUTPUT» stops blinking.

Press the

RESET

key to interrupt parameter output.

— 5 —

3.INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE B-63530EN/03

3.2 INPUTTING PARAMETERS THROUGH THE

READER/PUNCHER INTERFACE

(1) Place the NC in the emergency stop state.

(2) Enable parameter writing.

OFFSET

SETTING

1. To display the setting screen, press the

as many times as required, or alternatively press the

function key once, then the [SETTING] section select soft

key. The first page of the setting screen appears.

2. Position the cursor on «PARAMETER WRITE» using the

cursor move keys.

3. Press the [(OPRT)] soft key to display operation select soft

keys.

4. To set «PARAMETER WRITE=» to 1, press the ON:1 soft

key, or alternatively enter 1, then press the [INPUT] soft

key. From now on, parameters can be set. At the same time

an alarm condition (P/S100 PARAMETER WRITE

ENABLE) occurs in the NC.

(3) To select the parameter screen, press the

SYSTEM

function key

OFFSET

SETTING

function key as

SYSTEM

many times as required, or alternatively press the

key once,

then [PARAM] soft key.

(4) Press the [(OPRT)] soft key to display operation select keys, then

press the forward menu key located at the right-hand side of the

soft keys to display another set of operation select soft keys

including [READ].

(5) Pressing the [READ] soft key changes the soft key display as

shown below:

(6) Press the [EXEC] soft key to start inputting parameters from the

input/output device. When parameters are being input, «INPUT»

blinks in the state display field on the lower part of the screen.

(7) When parameter input terminates, «INPUT» stops blinking. Press

RESET

the

key to interrupt parameter input.

(8) When parameter read terminates, «INPUT» stops blinking, and

an alarm condition (P/S000) occurs in the NC. Turn it off before

continuing operation.

— 6 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4 DESCRIPTION OF PARAMETERS

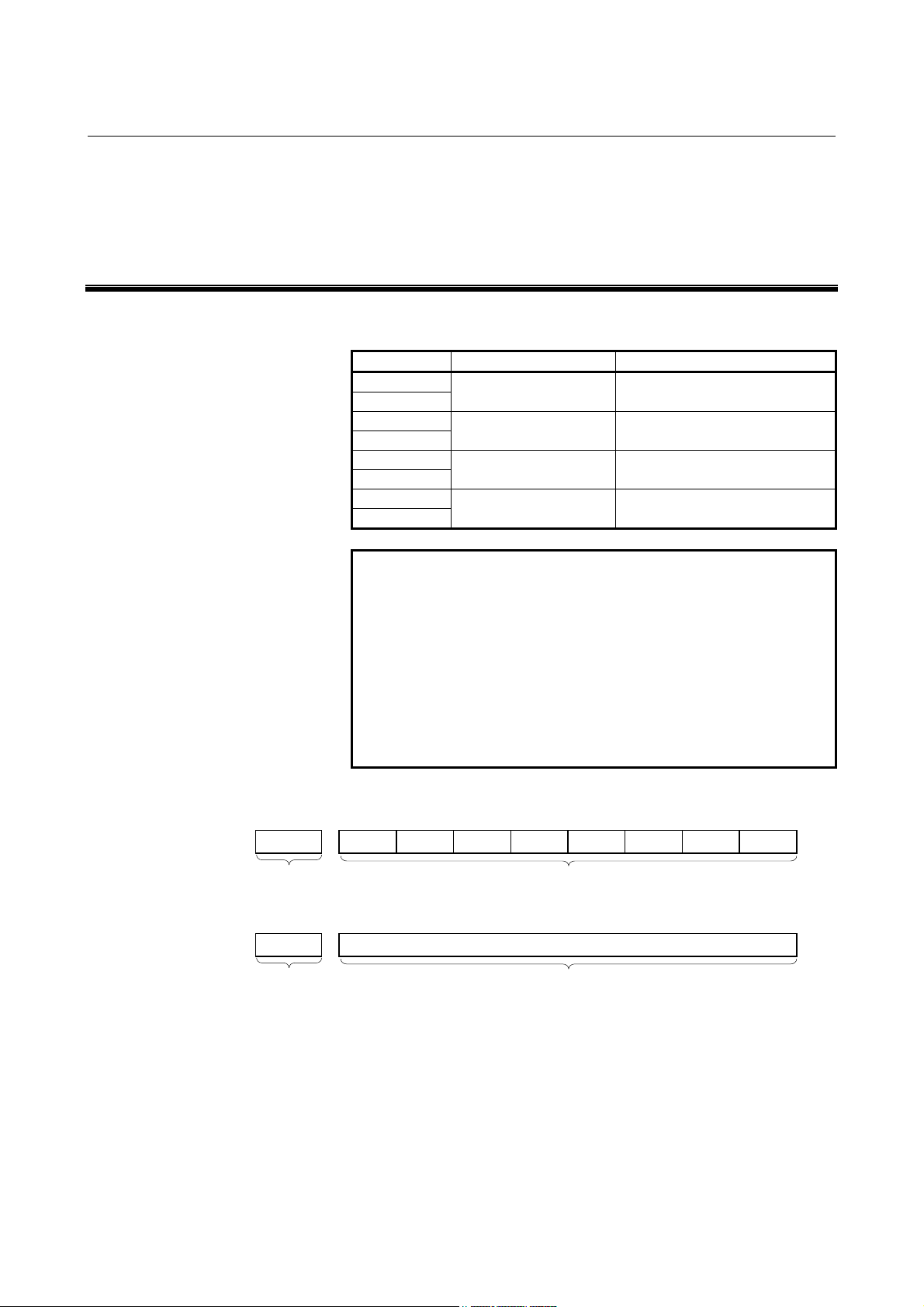

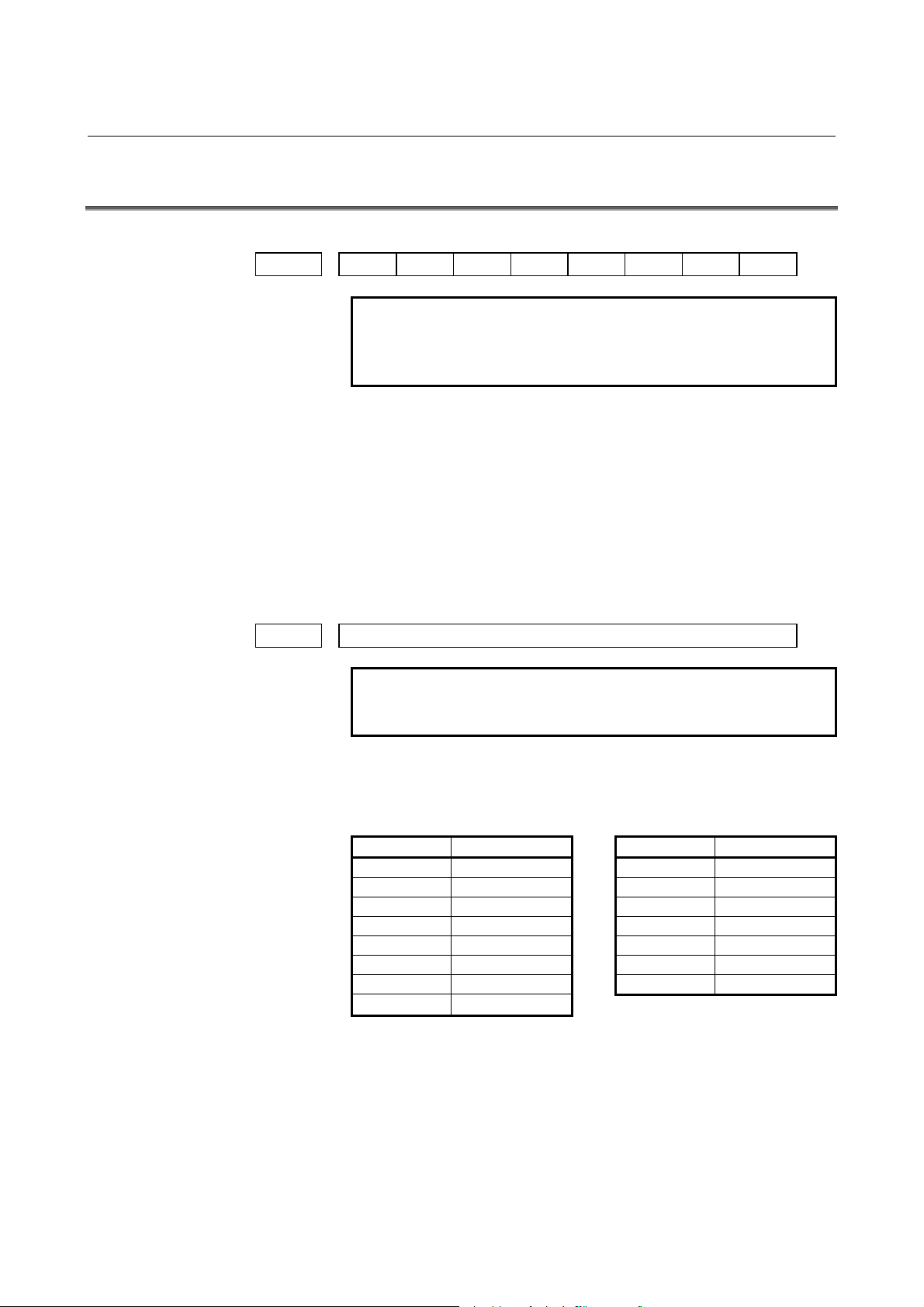

Parameters are classified by data type as follows:

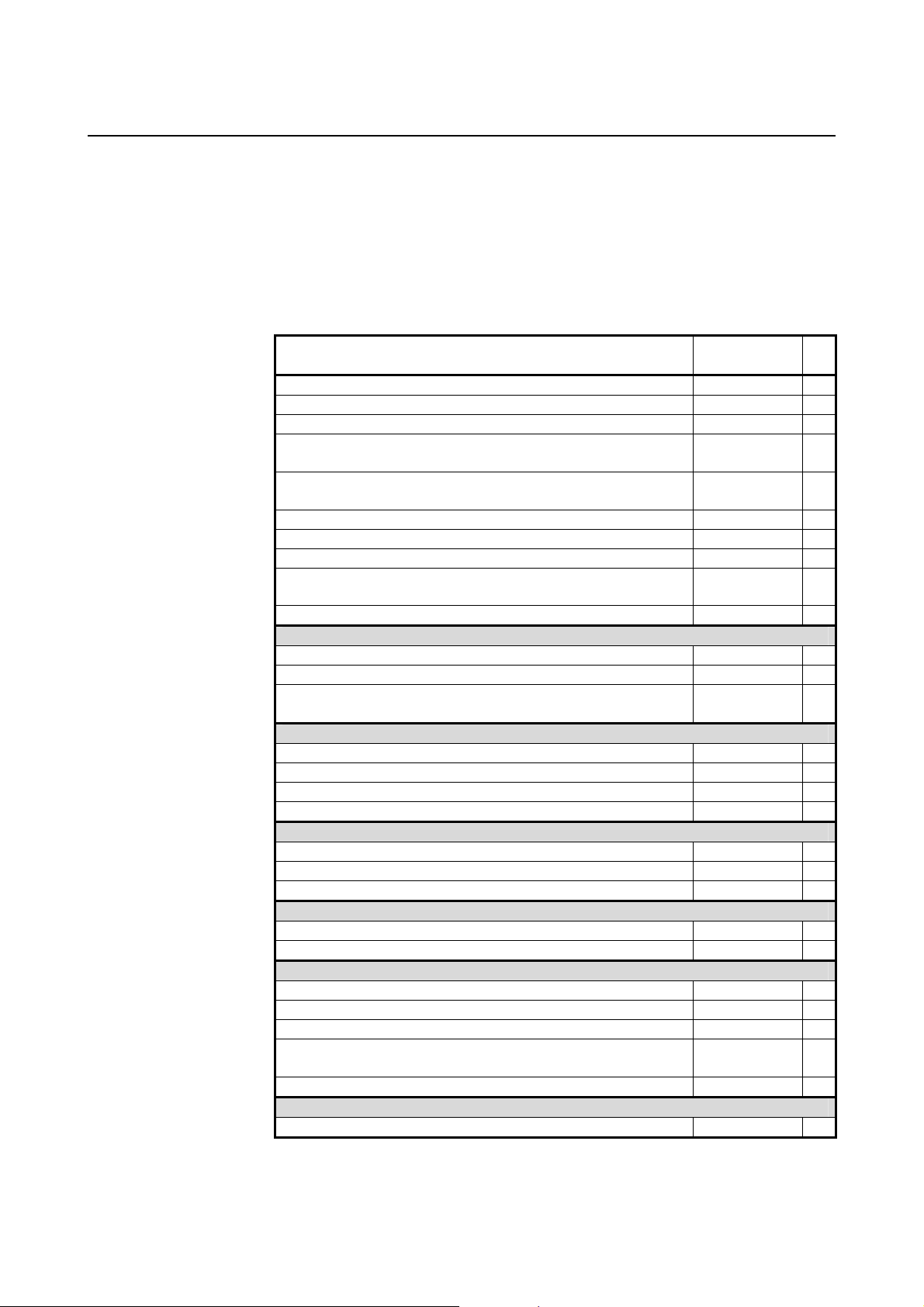

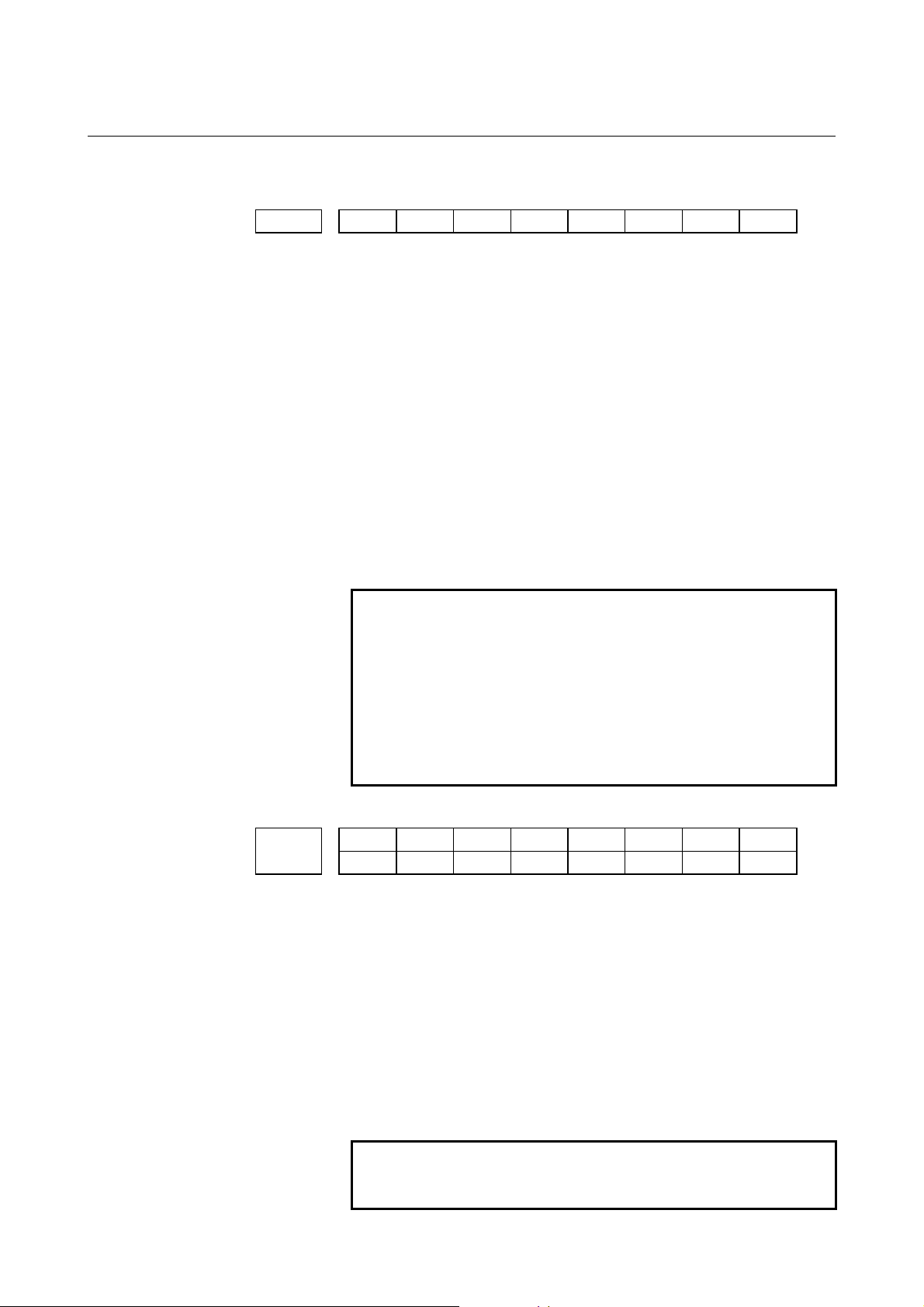

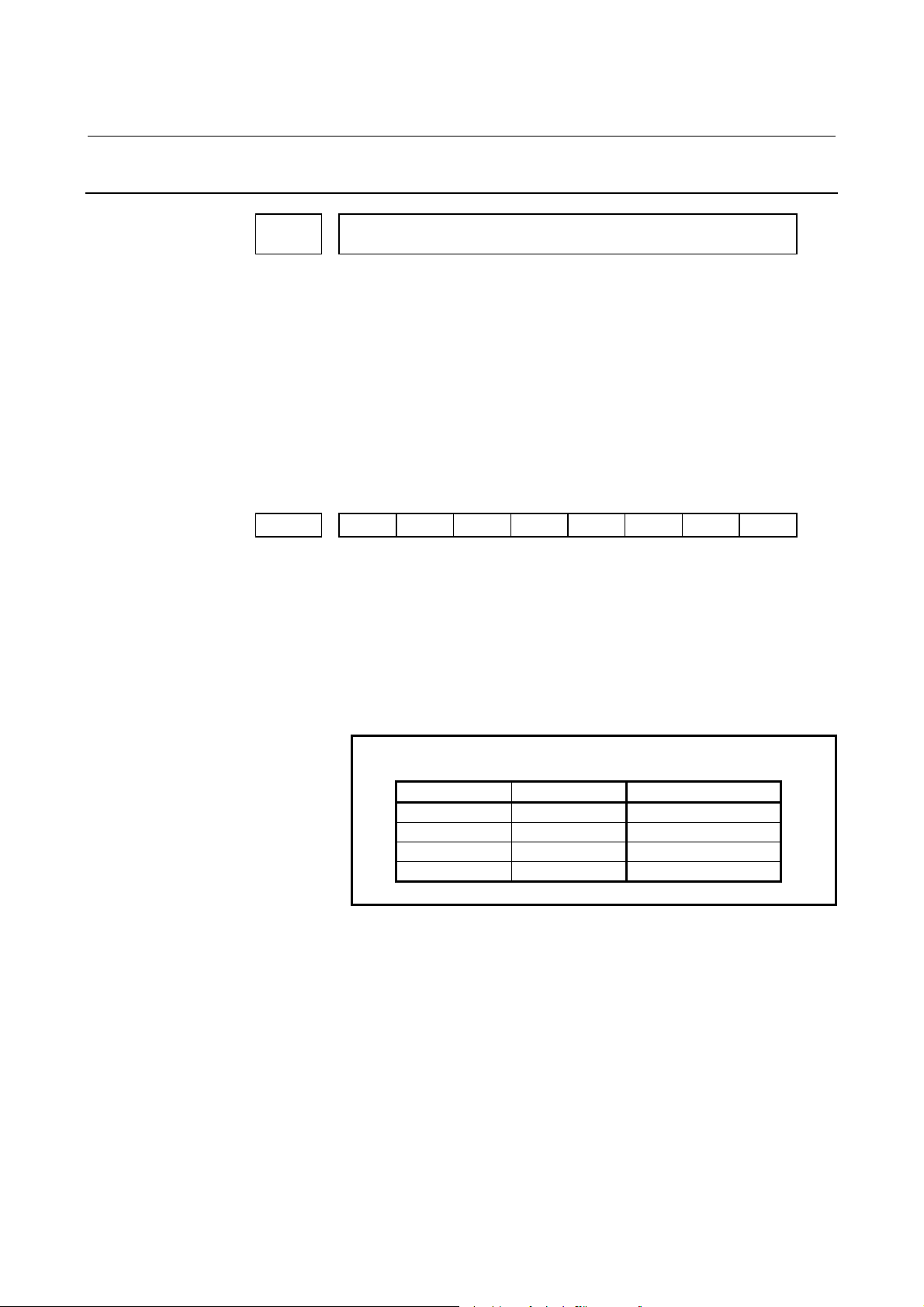

Table 4 Data Types and Valid Data Ranges of Parameters

Data type Valid data range Remarks

Bit

Bit axis

Byte

Byte axis

Word

Word axis

2-word

2-word axis

NOTE

1 For the bit type and bit axis type parameters, a

single data number is assigned to 8 bits. Each bit

has a different meaning.

2 The axis type allows data to be set separately for

each control axis.

3 The valid data range for each data type indicates a

general range. The range varies according to the

parameters. For the valid data range of a specific

parameter, see the explanation of the parameter.

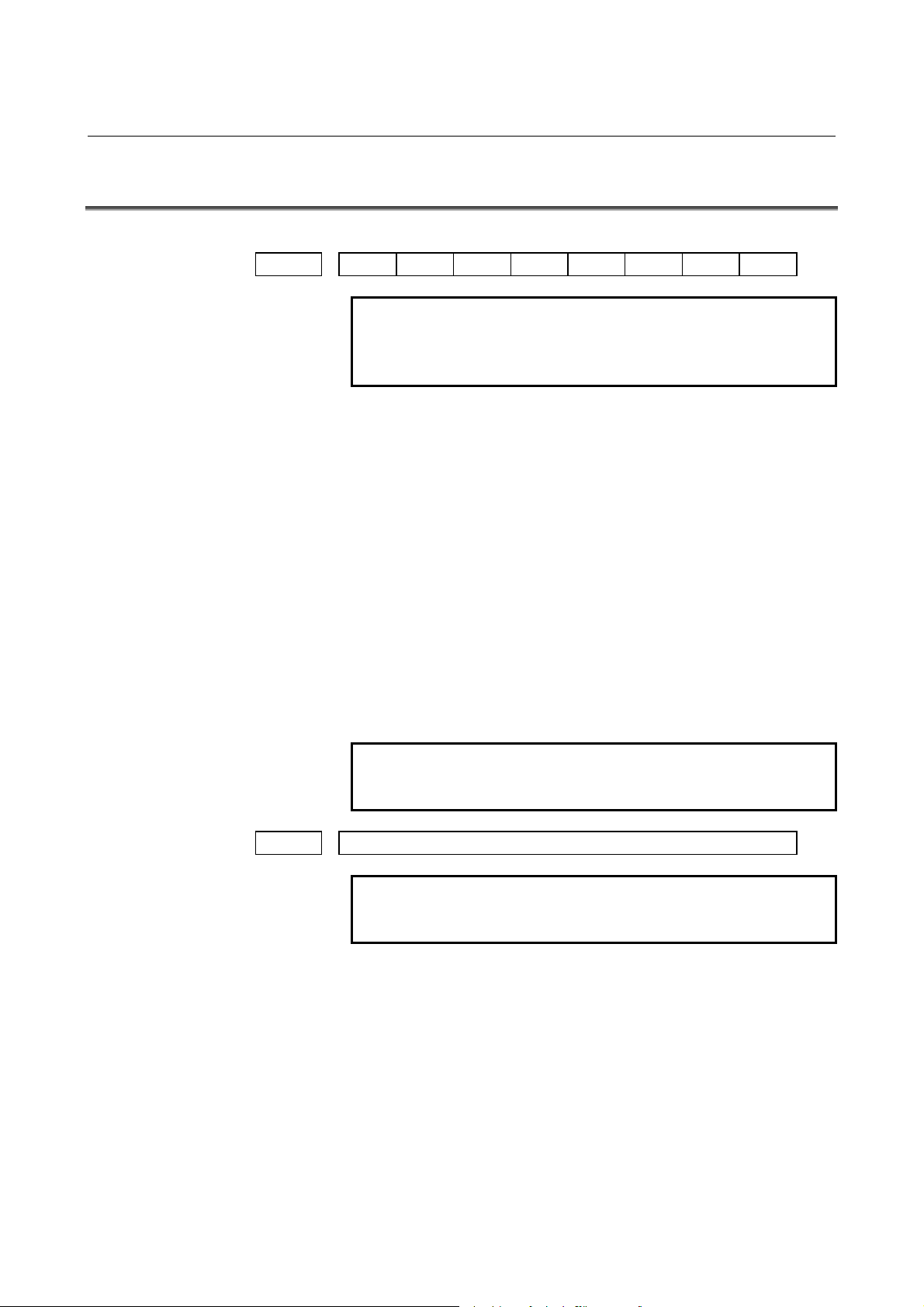

(1) Notation of bit type and bit axis type parameters

#7 #6 #5 #4 #3 #2 #1 #0

0000 SEQ INI ISO TVC

Data No. Data #0 to #7 are bit positions.

1023 Number of the servo axis for each axis

Data No. Data.

(2) Notation of parameters other than bit type and bit axis type

0 or 1

-128 to 127

0 to 255

-32768 to 32767

0 to 65535

-99999999 to 99999999

In some parameters, signs are

ignored.

In some parameters, signs are

ignored.

— 7 —

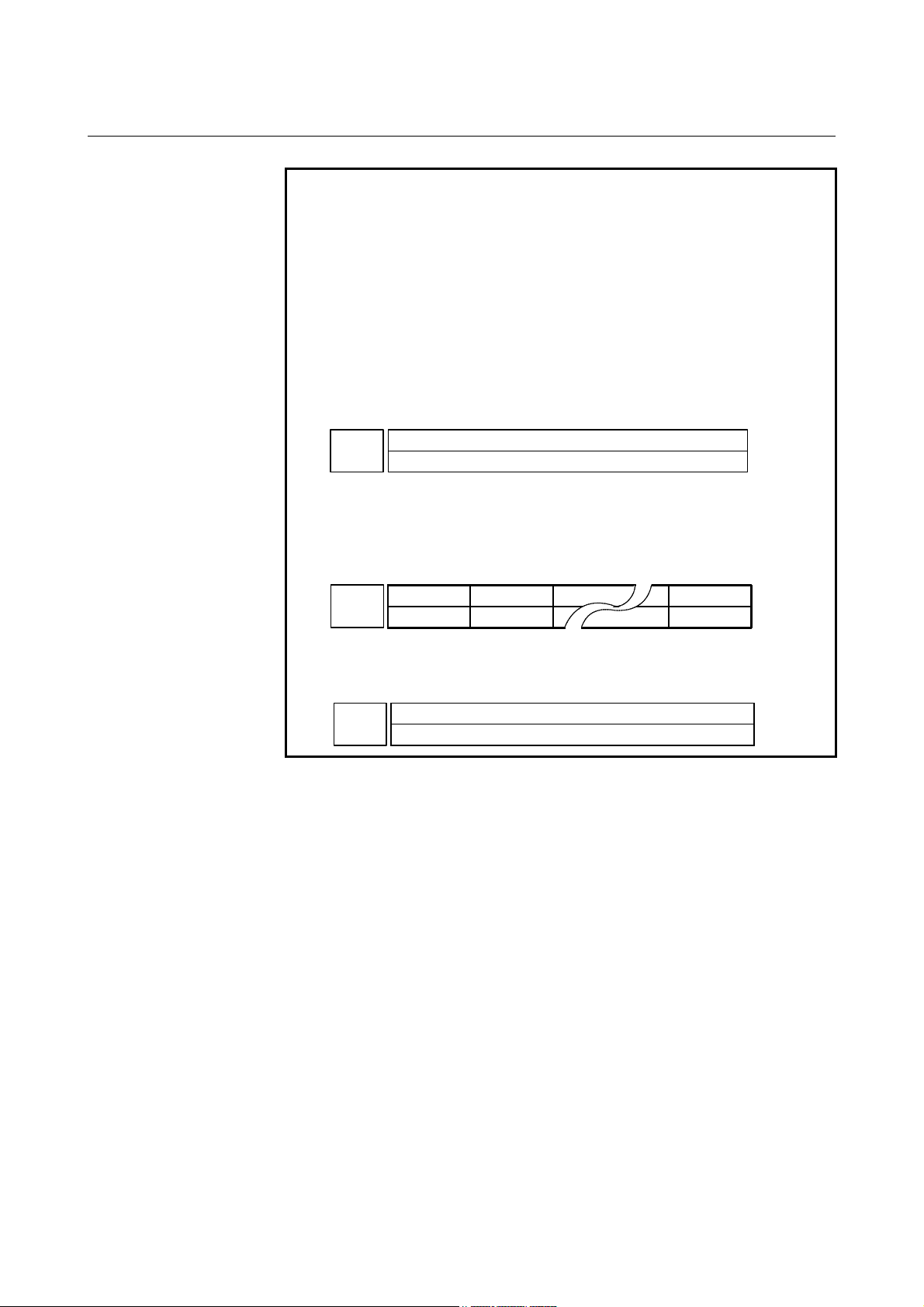

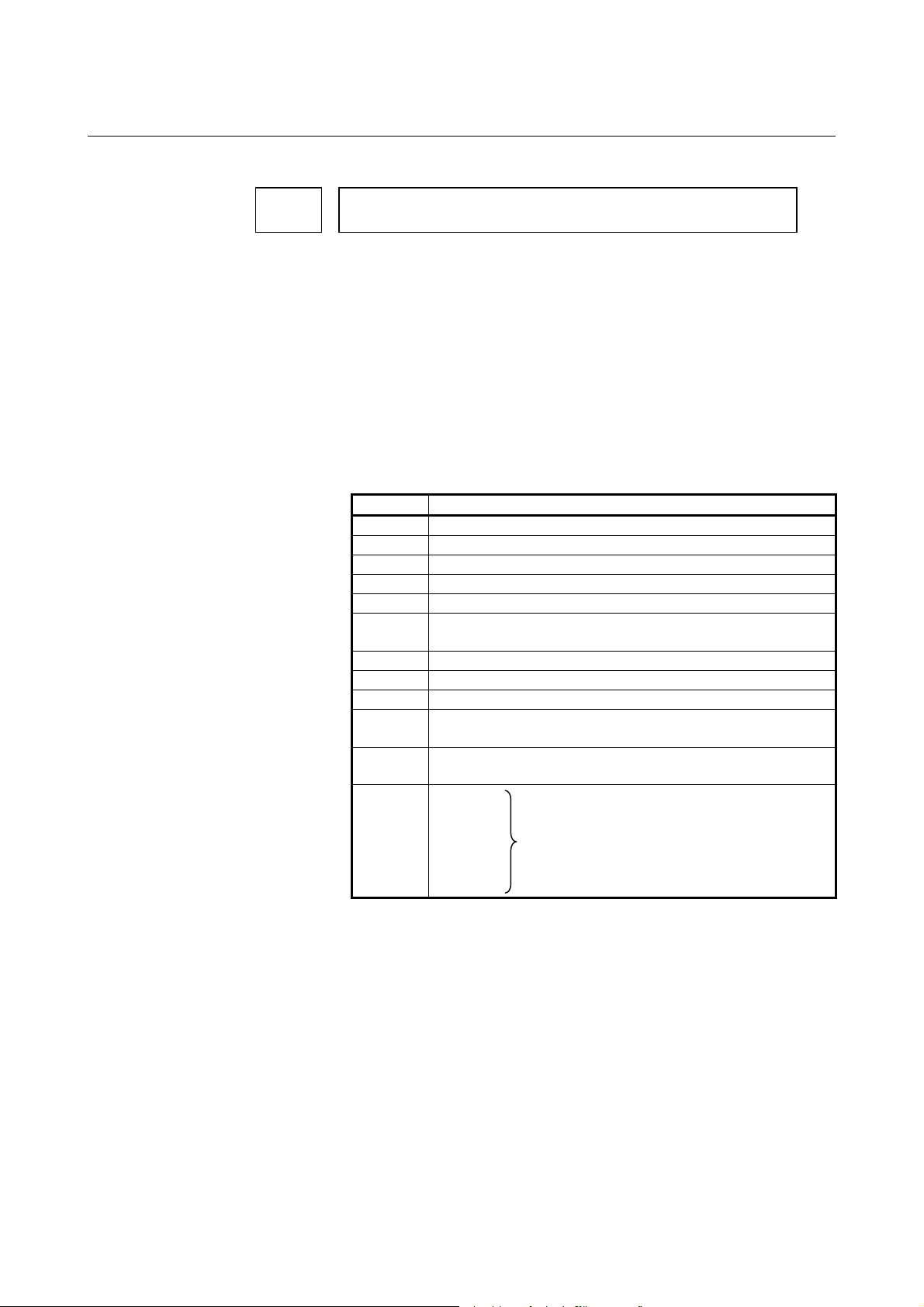

4.DESCRIPTION OF PARAMETERS B-63530EN/03

NOTE

1 The bits left blank in Chapter 4 “DESCRIPTION OF

PARAMETERS” and parameter numbers that appear on

the display but are not found in the parameter list are

reserved for future expansion. They must always be 0.

2 Parameters having different meanings between the T

series and M series and parameters that are valid only for

the T or M series are indicated in two levels as shown

below. Parameters left blank are unavailable.

[Example1]

Parameter No. 5010 has different meanings for the T

series and M series.

5010

Tool nose radius compensation …

Tool compensation C …

T series

M series

[Example2]

DPI is a parameter common to the M and T series, but

GSB and GSC are parameters valid only for the T

series.

#7 #6 #0

3401

GSC GSB DPI

DPI

T series

M series

[Example3]

The following parameter is provided only for the M

series.

1450

F1 digit feed …

T series

M series

— 8 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4.1 PARAMETERS OF SETTING

#7 #6 #5 #4 #3 #2 #1 #0

0000 SEQ INI ISO TVC

At least one of these parameters can also be set on the “Setting

screen”.

[Data type] Bit

TVC TV check

0 : Not performed

1 : Performed

ISO Code used for data output

0 : EIA code

1 : ISO code

INI Unit of input

0 : In mm

1 : In inches

SEQ Automatic insertion of sequence numbers

0 : Not performed

1 : Performed

When a program is prepared by using MDI keys in the part program

storage and edit mode, a sequence number can automatically be

assigned to each block in set increments. Set the increment to

parameter No. 3216.

#7 #6 #5 #4 #3 #2 #1 #0

0001 FCV

At least one of these parameters can also be set on the “Setting

screen”.

[Data type] Bit

FCV Tape format

0 : Series 16 standard format

1 : Series 15 format

NOTE

1 Programs created in the Series 15 tape format can

be used for operation on the following functions:

(1) Subprogram call M98

(2) Threading with equal leads G32 (T series)

(3) Canned cycle G90, G92, G94 (T series)

(4) Multiple repetitive canned cycle G71 to G76 (T

series)

(5) Drilling canned cycle G73, G74, G76, G80 to

G89 (M series)

(6) Cutter compensation C (M series)

2 When the tape format used in the Series 15 is used

for this CNC, some limits may add. Refer to the

Series 16i/18i/160i/180i/160is/180is-MODEL B

OPERATOR’S MANUAL.

— 9 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

#7 #6 #5 #4 #3 #2 #1 #0

0002 SJZ RDG

At least one of these parameters can also be set on the “Setting

screen”.

[Data type] Bit

RDG Remote diagnosis is

0 : Not performed.

1 : Performed.

To use an RS-232C serial port for performing remote diagnosis,

connect and setup the modem, cable, and the like, then set 1 in this

parameter. When using a modem card, the setting is not necessary.

SJZ Manual reference position is performed as follows:

0 : When no reference position has been set, reference position

return is performed using deceleration dogs. When a reference

position is already set, reference position return is performed

using rapid traverse and deceleration dogs are ignored.

1 : Reference position return is performed using deceleration dogs at

all times.

NOTE

SJZ is enabled when bit 3 (HJZ) of parameter

No.1005 is set to 1. When a reference position is

set without a dog, (i.e. when bit 1 (DLZ) of

parameter No.1002 is set to 1 or bit 1 (DLZx) of

parameter No.1005 is set to 1) reference position

return after reference position setting is performed

using rapid traverse at all times, regardless of the

setting of SJZ.

#7 #6 #5 #4 #3 #2 #1 #0

0012

RMVx AICx MIRx

RMVx MIRx

At least one of these parameters can also be set on the “Setting

screen”.

[Data type] Bit axis

MIRx Mirror image for each axis

0 : Mirror image is off.

1 : Mirror image is on.

AICx The travel distance of an axis command is:

0 : Determined by the value specified with the address.

1 : Always handled as an incremental value.

RMVx Releasing the assignment of the control axis for each axis

0 : Not released

1 : Released

NOTE

RMVx is valid when bit 7 (RMBx) of parameter No.

1005 is 1.

— 10 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0020

I/O CHANNEL: Selection of an input/output device or selection of input

device in the foreground

This parameter can also be set on the “Setting screen”.

[Data type] Byte

[Valid data range] 0 to 35

The CNC provides the following interfaces for data transfer to and

from the host computer and external input/output devices:

• Input/output device interface (RS-232C serial port 1 or 2)

• Remote buffer interface (RS-232C/RS-422)

• DNC1/DNC2 interface

In addition, data can be transferred to and from the power mate CNC

via the FANUC I/O Link.

This parameter selects the interface used to transfer data to and from

an input/output device.

Setting Description

0 or 1 RS-232C serial port 1

2 RS-232C serial port 2

3 Remote buffer interface

4 Memory card interface (NC side)

5 Data server interface

6

7 Memory card interface (touch panel side)

10 DNC1/DNC2 interface, OSI-Ethernet

12 DNC1 interface #2

15

16

20

21

22

to

34

35

The DNC operation is performed or M198 is specified by

FOCAS1/Ethernet or DNC1/Ethernet.

M198 is specified by FOCAS1/HSSB. (Bit 1 (NWD) of

parameter No. 8706) must also be specified.)

The DNC operation is performed or M198 is specified by

FOCAS1/ HSSB (port 2).

Group 0

Group 1

Group 2

to

Group 14

Group 15

Data is transferred between the CNC and a

power mate CNC in group n (n: 0 to 15) via the

FANUC I/O Link.

Supplemental remark 1

If the DNC operation is performed with FOCAS1/HSSB, the

setting of parameter No. 20 does not matter. The DMMC signal

<G042.7> is used.

Supplemental remark 2

If bit 0 (IO4) of parameter No. 110 is set to control the I/O

channels separately, the I/O channels can be divided into four

types: input and output in the foreground and input and output in

the background. If so, parameter No. 20 becomes a parameter for

selecting the input device in the foreground.

— 11 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

NOTE

1 An input/output device can also be selected using the setting screen. Usually, the

setting screen is used.

2 The specifications (such as the baud rate and the number of stop bits) of the

input/output devices to be connected must be set in the corresponding parameters

for each interface beforehand. (See Section 4.2.) I/O CHANNEL = 0 and I/O

CHANNEL = 1 represent input/output devices connected to RS-232C serial port 1.

Separate parameters for the baud rate, stop bits, and other specifications are

provided for each channel.

Motherboard

RS-232C serial port 1

R232-1(JD36A)

RS-232C serial port 2

Serial communication board

Remote buffer board

DNC1 board

DNC2 board

JD36B

R232-2

R232-3(JD28A)

R422-1(JD6A)

I/O CHANNEL=0, 1

(Channel 1)

I/O CHANNEL=2

(Channel 2)

I/O CHANNEL=3

(Channel 3)

I/O CHANNEL=3

(Channel 3)

RS-232-C I/O device

RS-232-C I/O device

RS-232-C I/O device

(when a remote buffer or DNC2 board is used)

RS-422 I/O device

(when a remote buffer or DNC1 board is used)

3 The input/output device interface may be referred to as the reader/puncher

interface.

RS-232C serial port 1 and RS-232C serial port 2 are also referred to as channel 1

and channel 2, respectively. The remote buffer interface is also referred to as

channel 3.

— 12 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0021 Setting of the output device in the foreground

0022 Setting of the input device in the background

0023 Setting of the output device in the background

These parameters can also be set on the “Setting screen”.

[Data type] Byte

[Valid data range] 0 to 3, 5, 10

These parameters are valid only when bit 0 (IO4) of parameter No.

110 is set to control the I/O channels separately.

The parameters set individual input/output devices if the I/O channels

are divided into these four types: input and output in the foreground

and input and output in the background. The input device in the

foreground is set in parameter No. 20. For the details of the settings,

see the table provided with the description of parameter No. 20.

NOTE

If different input/output devices are simultaneously

used in the foreground and background, just a

value from 0 to 3 can be specified for the

background device.

If an attempt is made to use a busy input/output

device, an alarm (P/S233 or BP/S233) will be

raised. Note that the settings 0 and 1 indicate the

same input/output device.

— 13 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

4.2 PARAMETERS OF READER/PUNCHER INTERFACE OR

REMOTE BUFFER

To exchange data (such as programs and parameters) with an external

input/output device by using the input/output device interface

(RS-232C serial port) or remote buffer interface, the parameters

described below need to be set.

In the setting parameter I/O CHANNEL, specify which of the

input/output devices connected to the three channels (RS-232C serial

port 1, RS-232C serial port 2, and remote buffer interface) is to be

used.

Furthermore, set the specifications (specification number, baud rate,

the number of stop bits, and so forth) of the input/output device

connected to each channel in the parameters corresponding to each

channel beforehand.

For setting of the specifications of channel 1, two sets of parameters

are available.

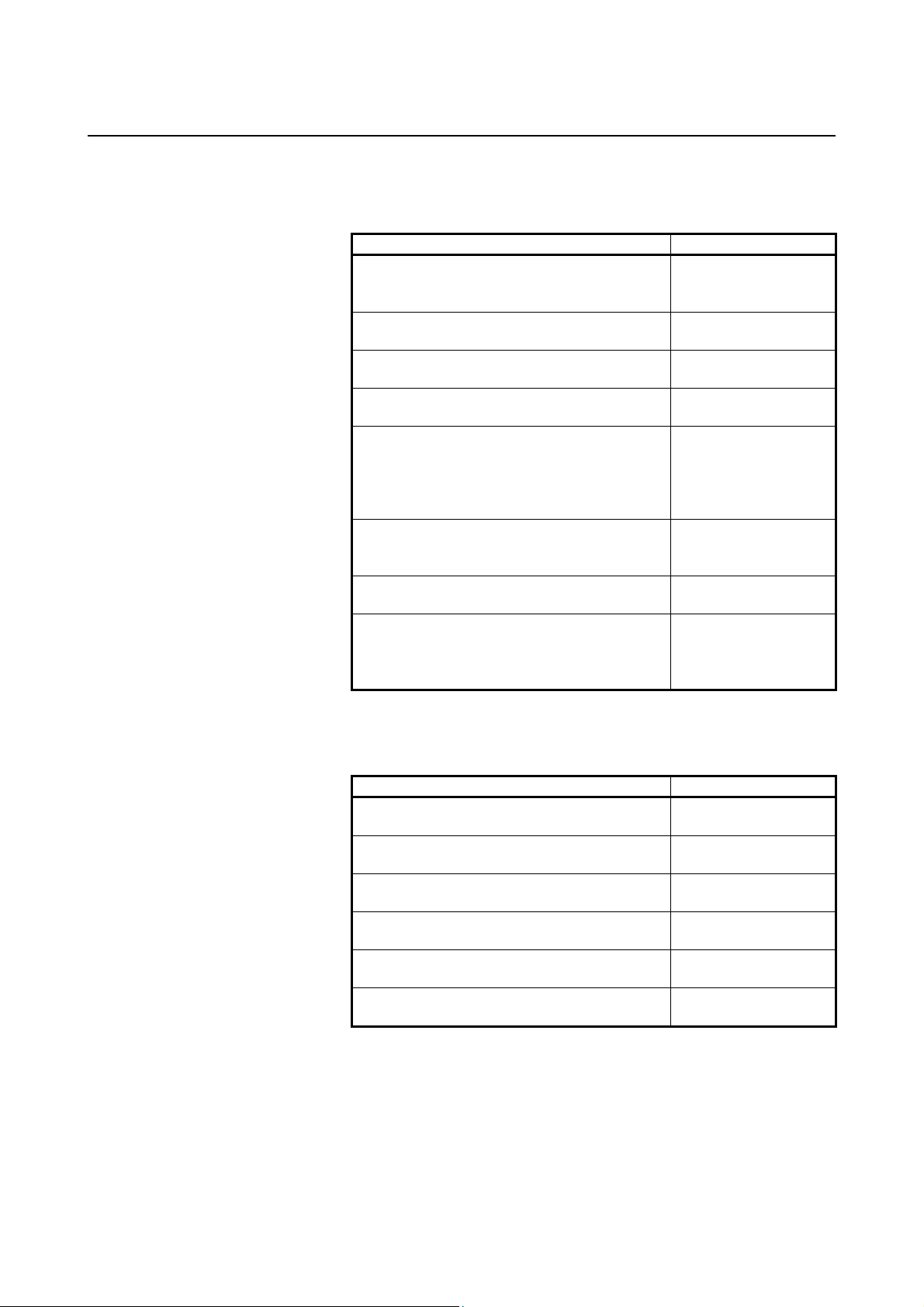

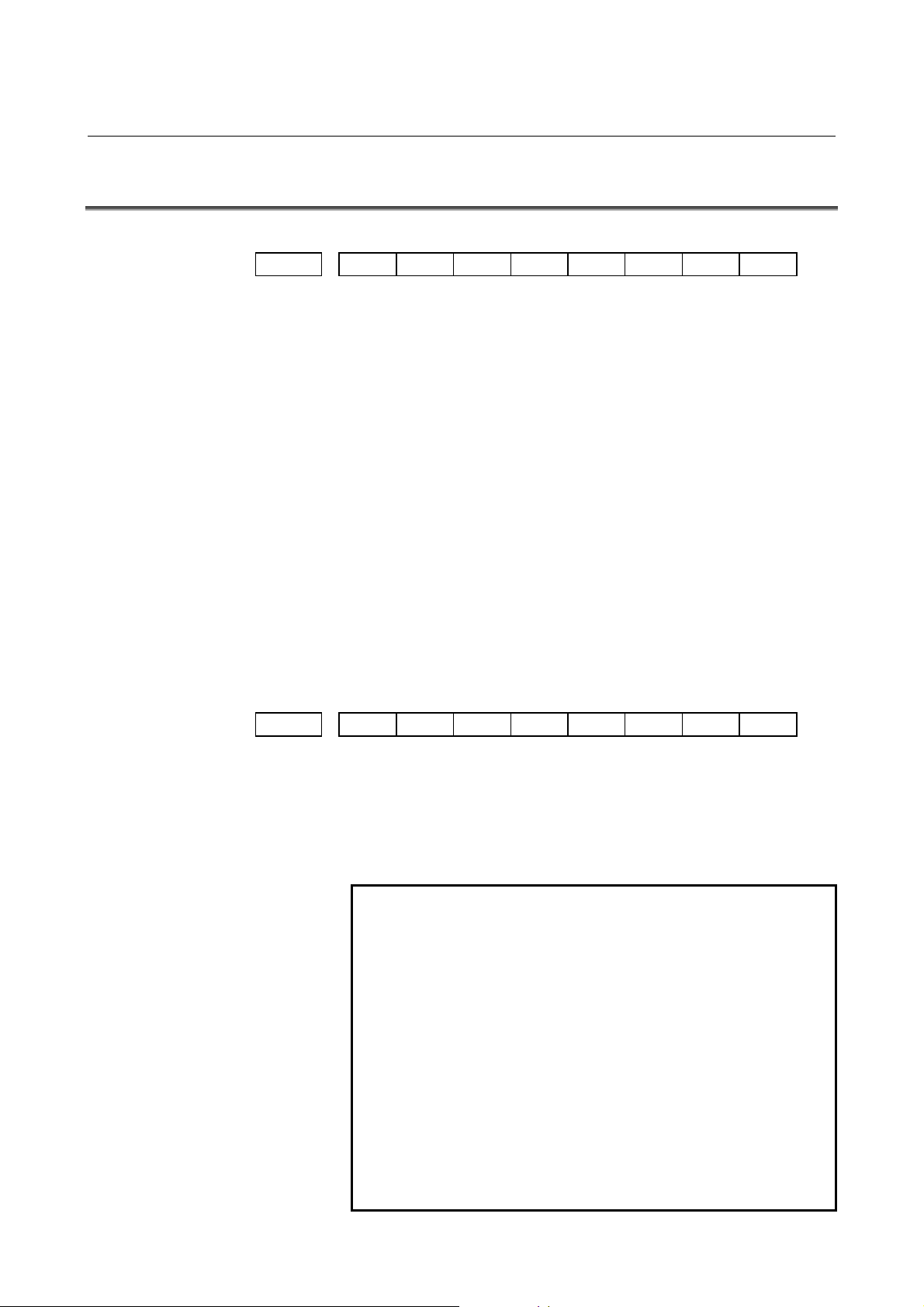

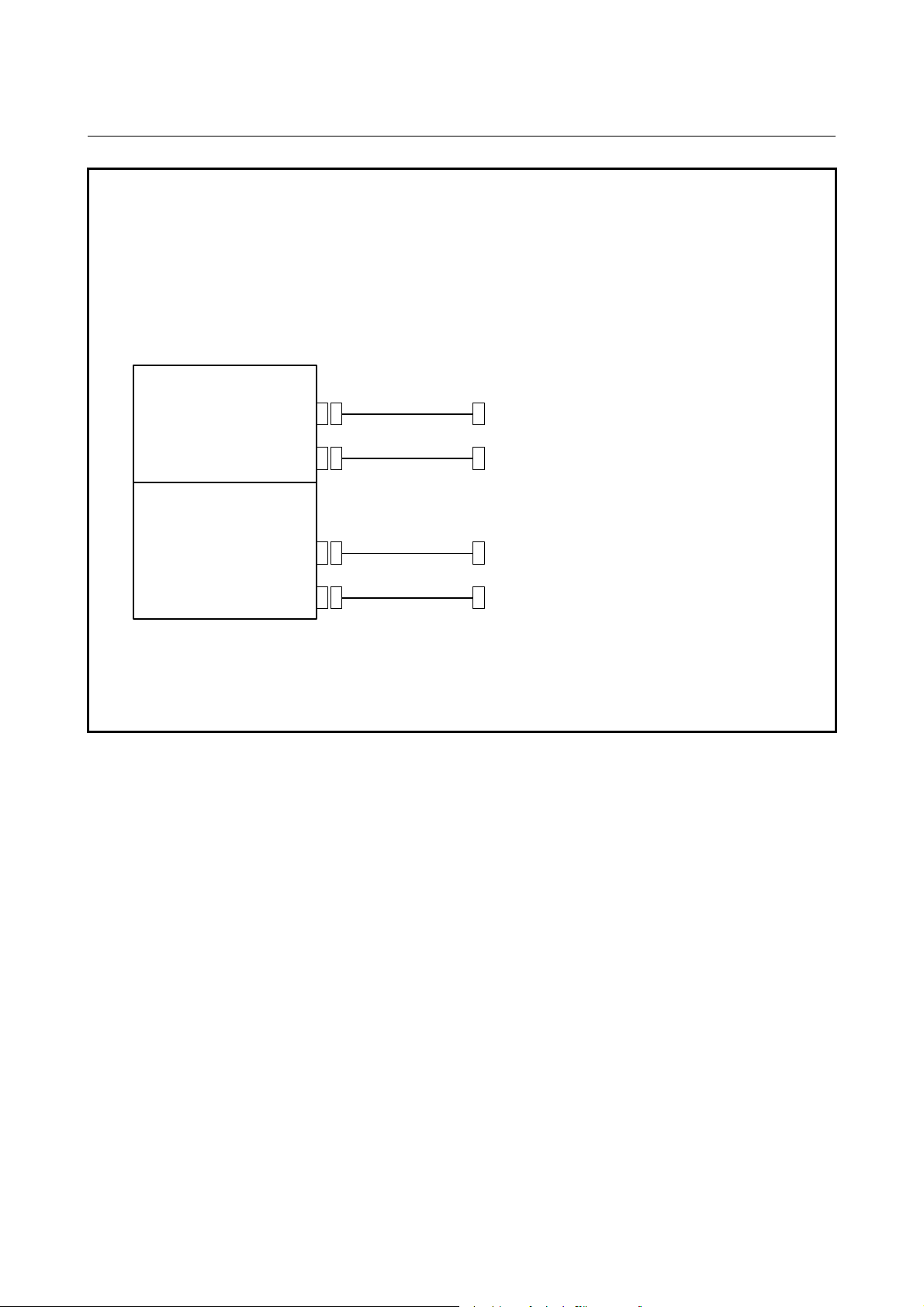

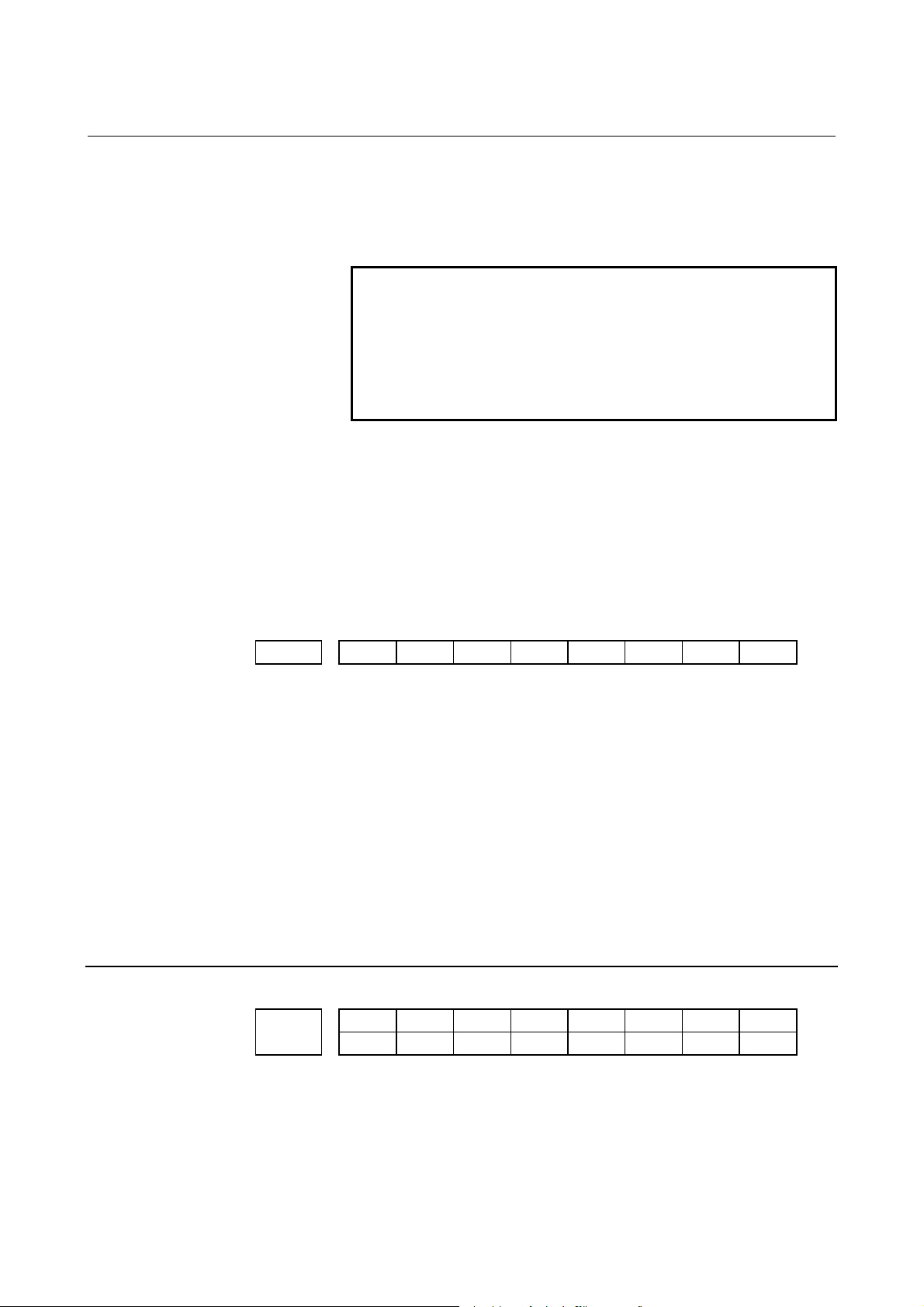

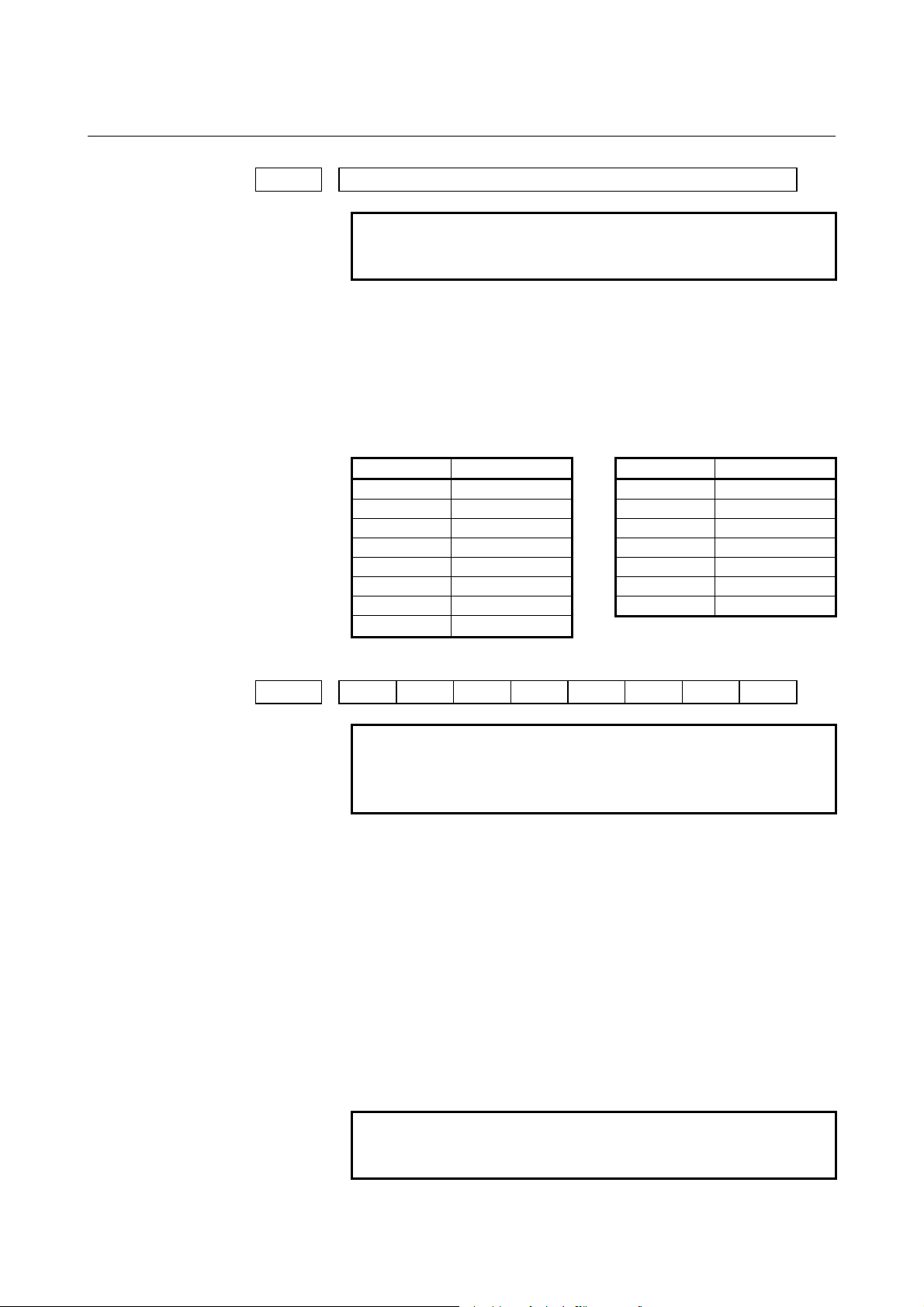

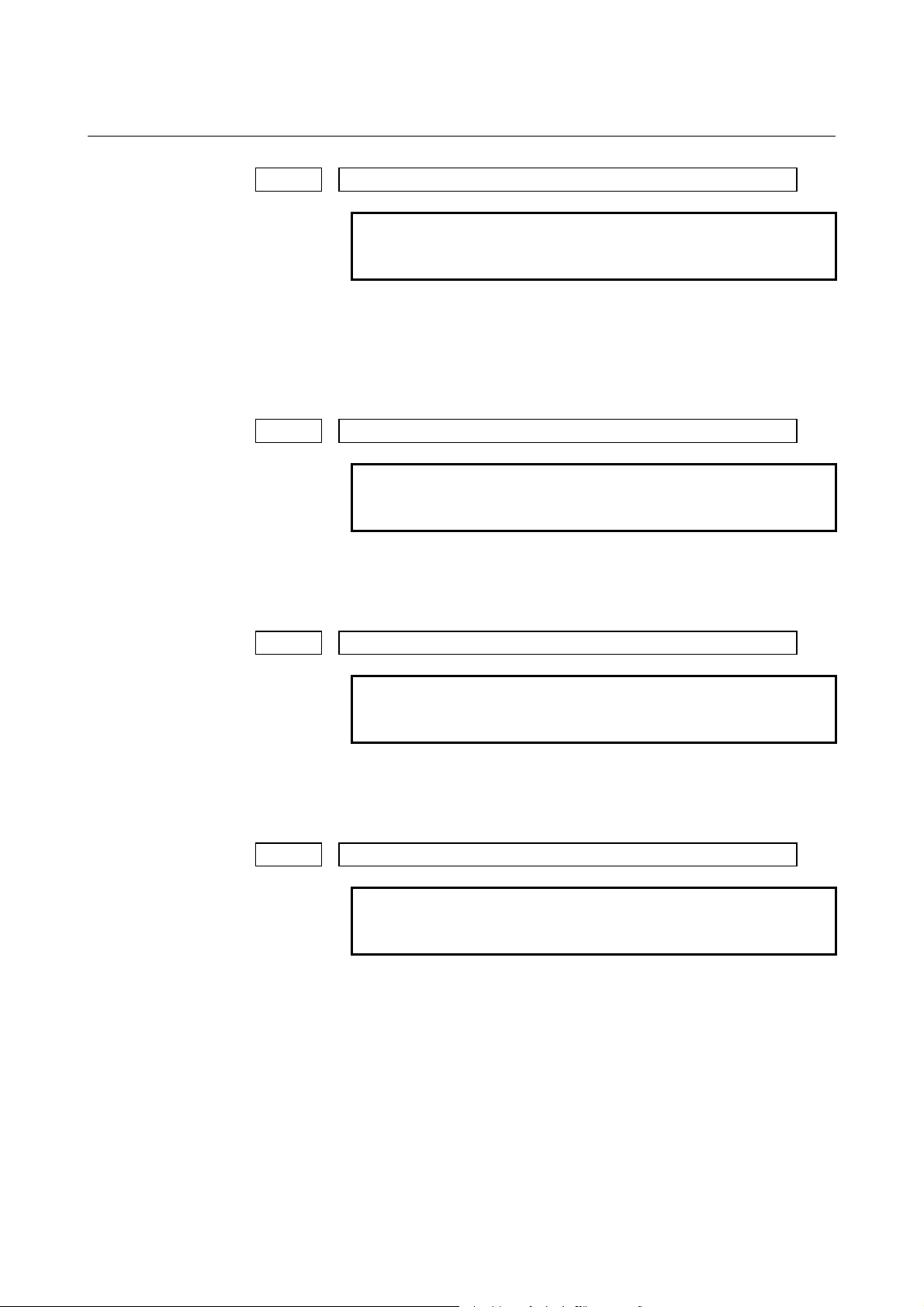

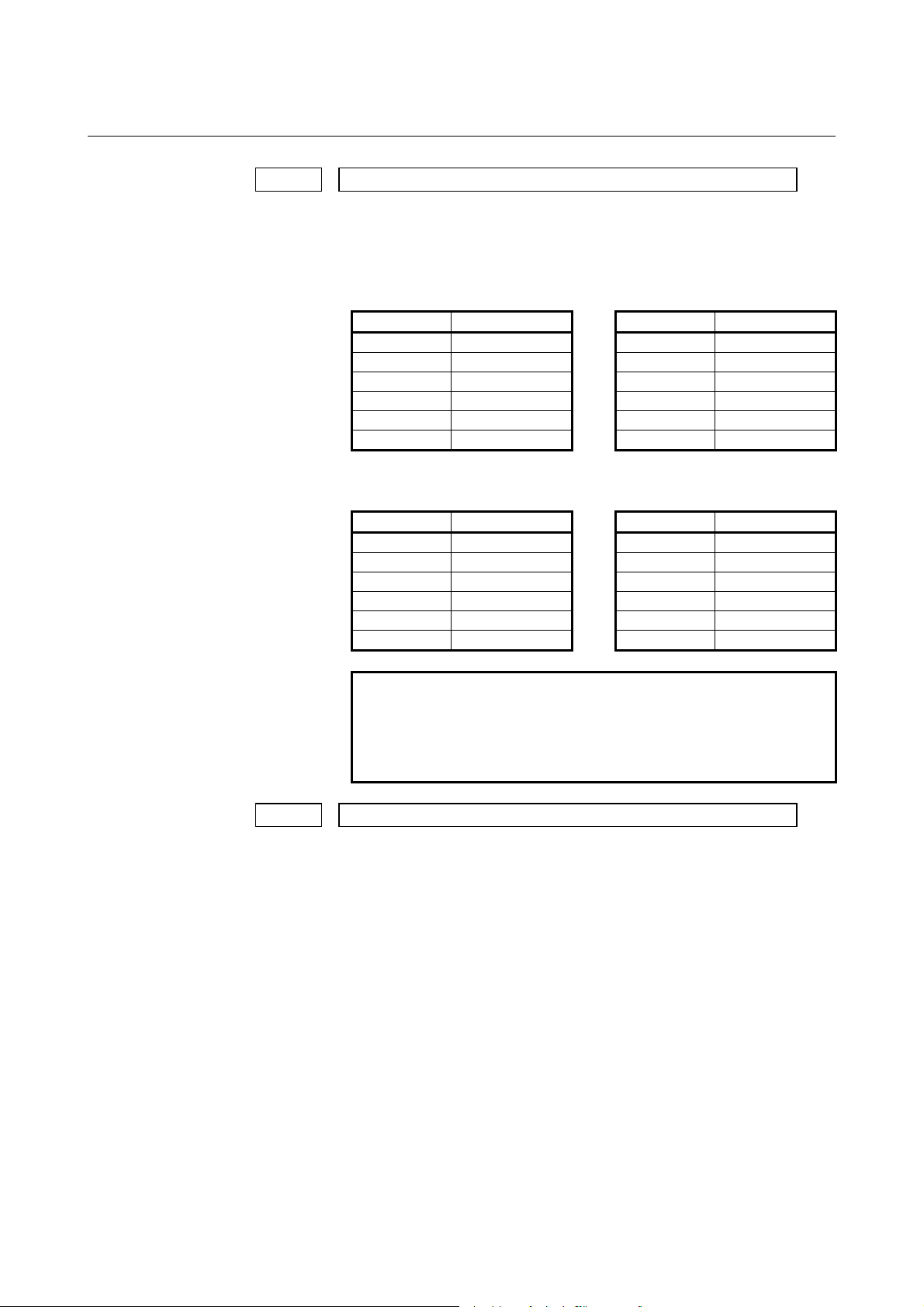

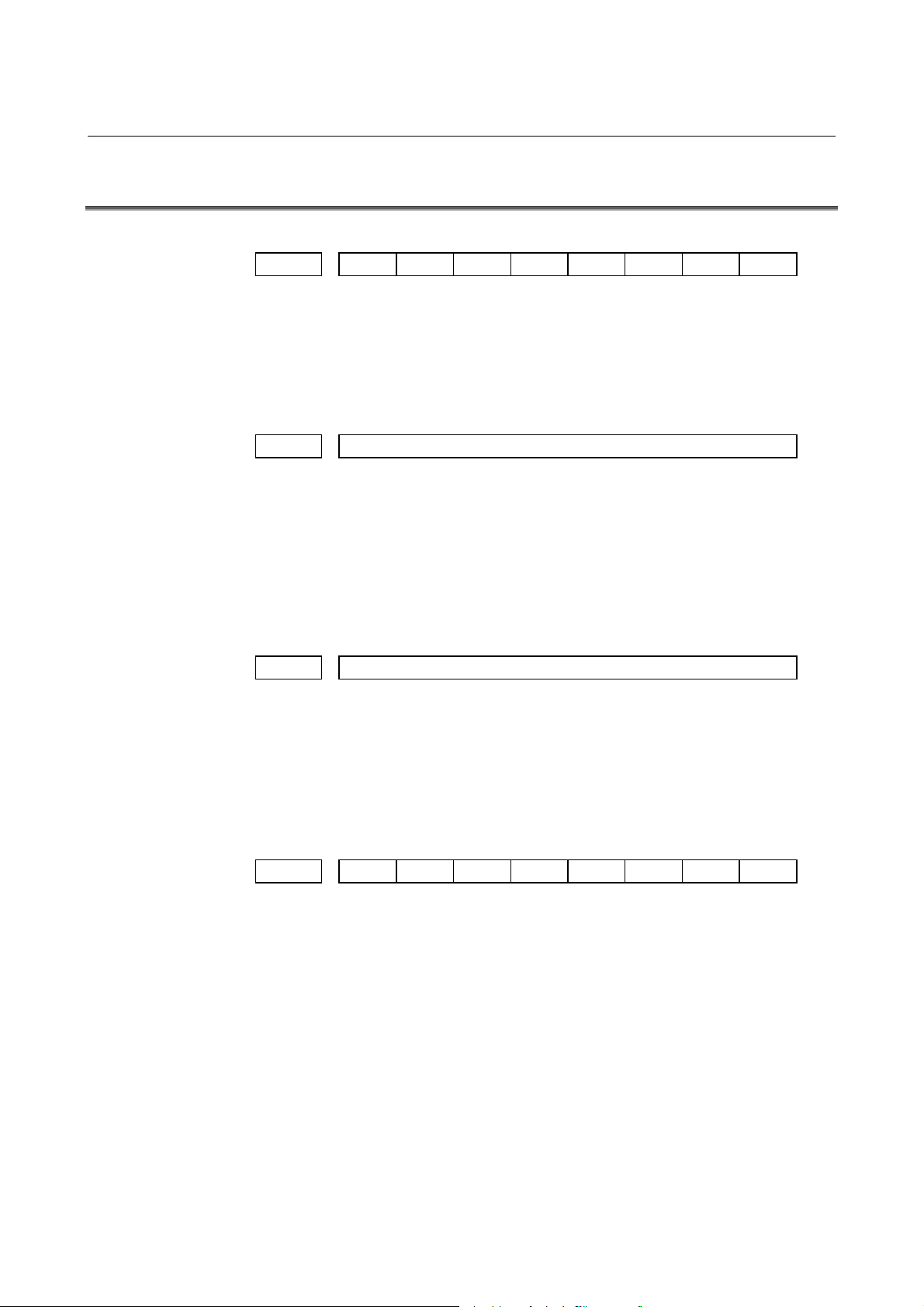

Fig. 4.2 shows the input/output device interface parameters

corresponding to each channel.

Input/output channel number (parameter No.0020)

↓

No. 0020

Specify a channel for an

input/output device.

I/O CHANNEL

=0 : Channel 1

=1 : Channel 1

=2 : Channel 2

=3 : Channel 3

I/O CHANNEL

I/O CHANNEL=0

(channel 1)

I/O CHANNEL=1

(channel 1)

I/O CHANNEL=2

(channel 2)

I/O CHANNEL=3

(channel 3)

No. 0101

No. 0102

No. 0103

No. 0111

No. 0112

No. 0113

No. 0121

No. 0122

No. 0123

No. 0131

No. 0132

No. 0133

No. 0134

No. 0135

Stop bit and other data

Number specified for the input/output

Baud rate

Stop bit and other data

Number specified for the input/output

Baud rate

Stop bit and other data

Number specified for the input/output

Baud rate

Stop bit and other data

Number specified for the input/output

Baud rate

Selection of protocol

Selection of RS-422 or RS-232C, and

other data

— 14 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4.2.1 Parameters Common to all Channels

0024

[Data type] Byte

#7 #6 #5 #4 #3 #2 #1 #0

0100 ENS IOP ND3 NCR CRF CTV

[Data type] Bit

CTV: Character counting for TV check in the comment section of a

CRF EOB (end of block) to be output in the ISO code:

NCR Output of the end of block (EOB) in ISO code

Port for communication with the PMC ladder development tool (FANUC

LADDER-III)

This parameter can also be set on the “Setting screen”.

This parameter sets the port to be used for communication with the

PMC ladder development tool (FANUC LADDER-III).

0 : According to the setting on the PMC online screen

1 : RS-232C serial port 1 (JD36A)

2 : RS-232C serial port 2 (JD36B)

10 : High-speed interface (HSSB (COP7) or Ethernet)

11 : High-speed interface or RS-232C serial port 1

12 : High-speed interface or RS-232C serial port 2

program.

0 : Performed

1 : Not performed

0 : Depends on the setting of bit 3 (NCR) of parameter No. 100.

1 : is «CR»»LF».

NOTE

The EOB output patterns are as shown below:

NCR CRF EOB output format

0 0 «LF» «CR» «CR»

0 1 «CR» «LF»

1 0 «LF»

1 1 «CR» «LF»

0 : LF, CR, CR are output.

1 : Only LF is output.

— 15 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

ND3 In DNC operation, a program is:

0 : Read block by block. (A DC3 code is output for each block.)

1 : Read continuously until the buffer becomes full. (A DC3 code is

output when the buffer becomes full.)

NOTE

In general, reading is performed more efficiently

when ND3 set to 1. This specification reduces the

number of buffering interruptions caused by

reading of a series of blocks specifying short

movements. This in turn reduces the effective cycle

time.

IOP Specifies how to stop program input/output operations.

0 : An NC reset can stop program input/output operations.

1 : Only the [STOP] soft key can stop program input/output

operations. (A reset cannot stop program input/output

operations.)

ENS Action taken when a NULL code is found during read of EIA code

0 : An alarm is generated.

1 : The NULL code is ignored.

#7 #6 #5 #4 #3 #2 #1 #0

0110 IO4

[Data type] Bit

IO4 Separate control of I/O channel numbers is:

0 : Not performed.

1 : Performed.

If the I/O channels are not separately controlled, set the input/output

device in parameter No. 20.

If the I/O channels are separately controlled, set the input device and

output device in the foreground and the input device and output device

in the background in parameters No. 20 to No. 23 respectively.

Separate control of I/O channels makes it possible to perform

background editing, program input/output, and the like during the

DNC operation.

4.2.2 Parameters of Channel 1 (I/O CHANNEL=0)

#7 #6 #5 #4 #3 #2 #1 #0

0101

[Data type] Bit

SB2 The number of stop bits

NFD ASI SB2

NFD ASI HAD SB2

0 : 1

1 : 2

— 16 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

HAD An alarm raised for the internal handy file is:

0 : Not displayed in detail on the NC screen. (PS alarm 86 is

displayed.)

1 : Displayed in detail on the NC screen.

ASI Code used at data input/output

0 : EIA or ISO code (Input: Automatic determination/Output:

Setting of bit 1 (ISO) of parameter No. 0000)

1 : ASCII code for both input and output

NOTE

When using ASCII code for data input/output (when

setting ASI to 1), set also bit 1 (ISO) of parameter

No. 0000 to 1.

NFD Feed before and after the data at data output

0 : Output

1 : Not output

NOTE

When input/output devices other than the FANUC

PPR are used, set NFD to 1.

0102

[Data type] Byte

Number specified for the input/output device (when the I/O CHANNEL is set

to 0)

Set the number specified for the input/output device used when the

I/O CHANNEL is set to 0, with one of the set values listed in Table

4.2.2 (a).

Table 4.2.2 (a)

Set value Input/output device

0 RS-232C (Used control codes DC1 to DC4)

1

2 FANUC CASSETTE ADAPTOR 3 (FANUC CASSETTE F1)

3

4 RS-232C (Not used control codes DC1 to DC4)

5 Portable tape reader

6

FANUC CASSETTE ADAPTOR 1 (FANUC CASSETTE B1/

B2)

FANUC PROGRAM FILE Mate, FANUC FA Card Adaptor

FANUC FLOPPY CASSETTE ADAPTOR, FANUC Handy File

FANUC SYSTEM P-MODEL H

FANUC PPR

FANUC SYSTEM P-MODEL G, FANUC SYSTEM P-MODEL H

— 17 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0103 Baud rate (when the I/O CHANNEL is set to 0)

[Data type] Byte

Set baud rate of the input/output device used when the I/O

CHANNEL is set to 0, with a set value in Table 4.2.2 (b).

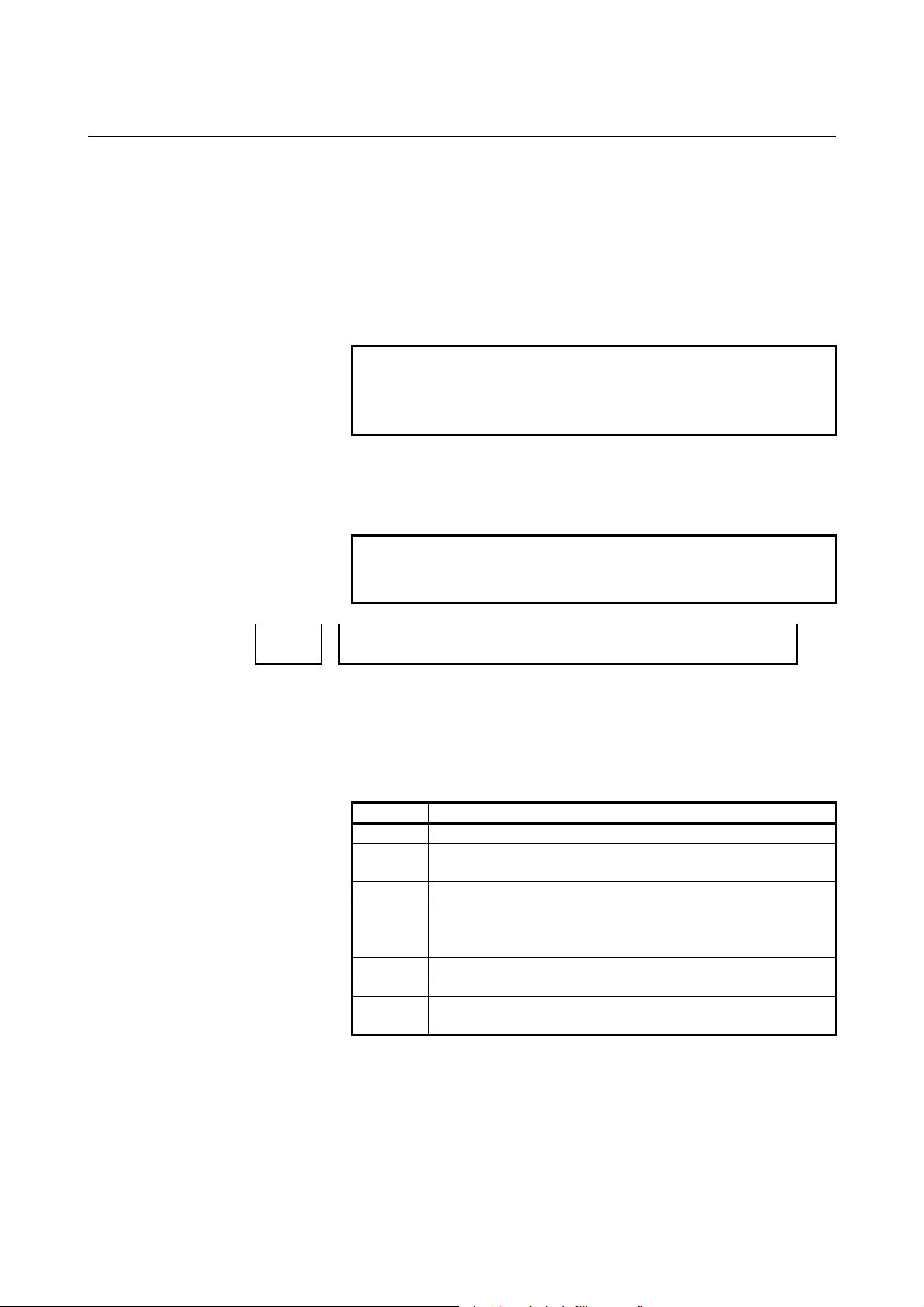

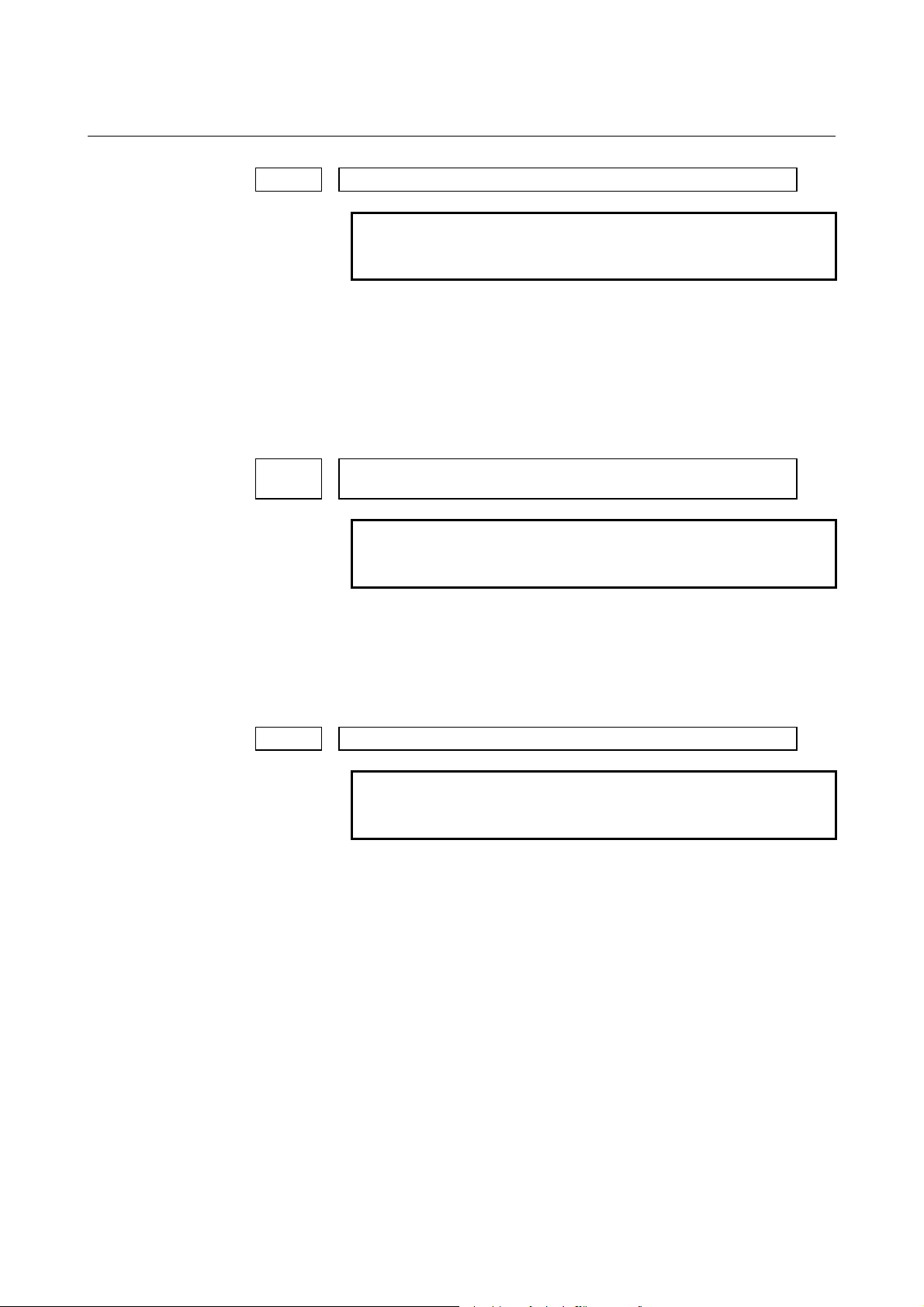

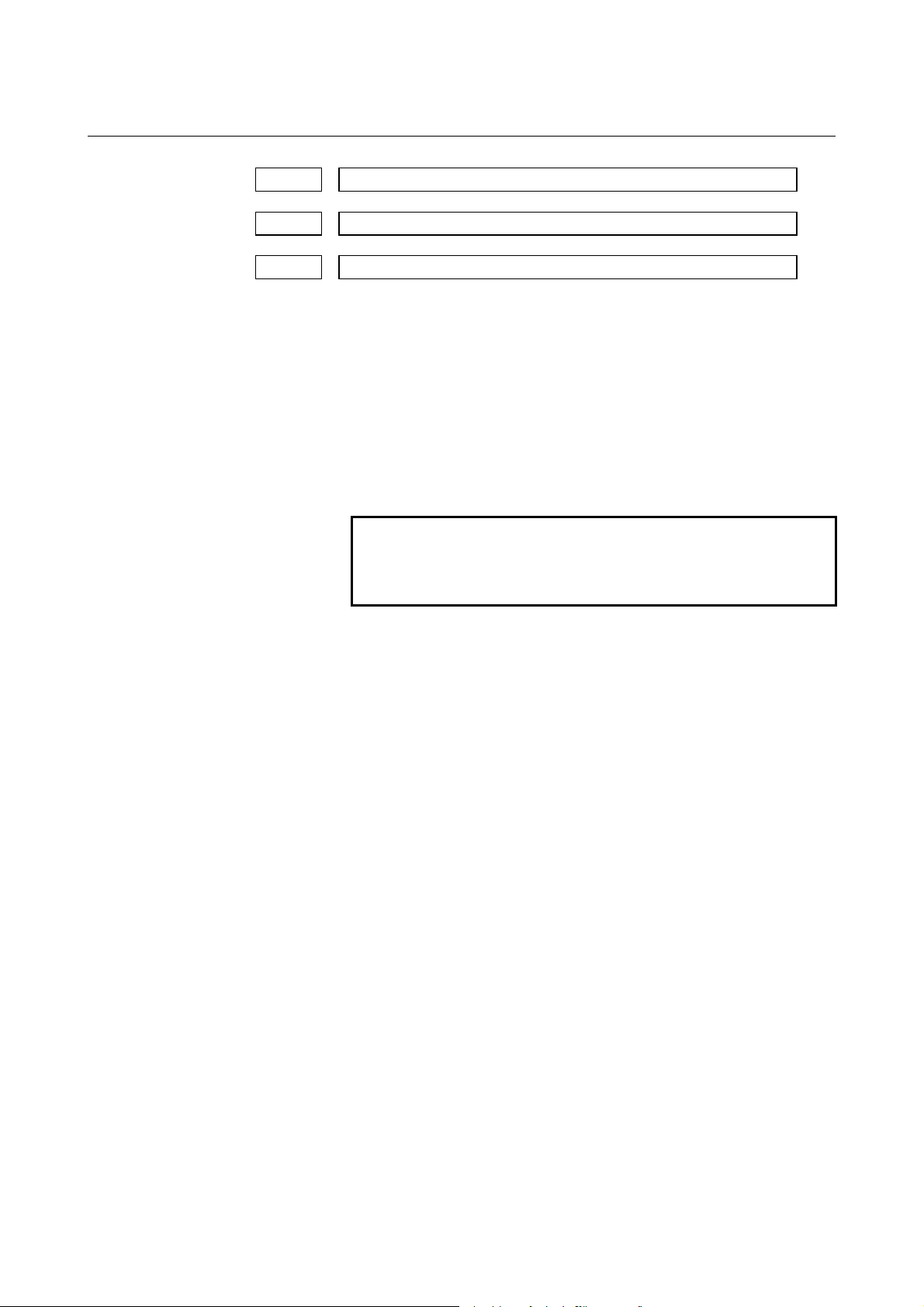

Table 4.2.2 (b)

Set value Baud rate (bps) Set value Baud rate (bps)

1 50 9 2400

2 100 10 4800

3 110 11 9600

4 150 12 19200

5 200 13 38400

6 300 14 57600

7 600 15 76800

8 1200

16 115200

4.2.3 Parameters of Channel 1 (I/O CHANNEL=1)

#7 #6 #5 #4 #3 #2 #1 #0

0111 NFD ASI SB2

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 1. The

meanings of the bits are the same as for parameter No. 0101.

0112 Number specified for the input/output device (when I/O CHANNEL is set to 1)

[Data type] Byte

Set the number specified for the input/output device used when

the I/O CHANNEL is set to 1, with one of the set values listed in

Table 4.2.2 (a).

0113 Baud rate (when I/O CHNNEL is set to 1)

[Data type] Byte

Set the baud rate of the input/output device used when I/O

CHANNEL is set to 1, with a value in Table 4.2.2 (b).

4.2.4 Parameters of Channel 2 (I/O CHANNEL=2)

#7 #6 #5 #4 #3 #2 #1 #0

0121 NFD ASI SB2

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 2. The

meanings of the bits are the same as for parameter No. 0101.

— 18 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0122 Number specified for the input/output device (when I/O CHANNEL is set to 2)

[Data type] Byte

Set the number specified for the input/output device used when I/O

CHANNEL is set to 2, with a value in Table 4.2.2 (a).

0123 Baud rate (when the I/O CHANNEL is set to 2)

[Data type] Byte

Set the baud rate of the input/output device used when I/O

CHANNEL is set to 2, with a value in Table 4.2.2 (b).

4.2.5 Parameters of Channel 3 (I/O CHANNEL=3)

#7 #6 #5 #4 #3 #2 #1 #0

0131 NFD ASI SB2

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 3. The

meanings of the bits are the same as for parameter No. 0101.

0132 Number specified for the input/output device (when I/O CHANNEL is set to 3)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

Set the number specified for the input/output device used when I/O

CHANNEL is set to 3, with a number in Table 4.2.2 (a).

— 19 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0133 Baud rate (when the I/O CHANNEL is set to 3)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

Set the baud rate of the input/output device used when the I/O

CHANNEL is set to 3 according to the table 4.2.5.

Valid data range: 1 to 15 (up to a baud rate of 86400 bps) for the

RS-422 interface or 1 to 12 (up to a baud rate of 19200 bps) for the

RS-232C interface.

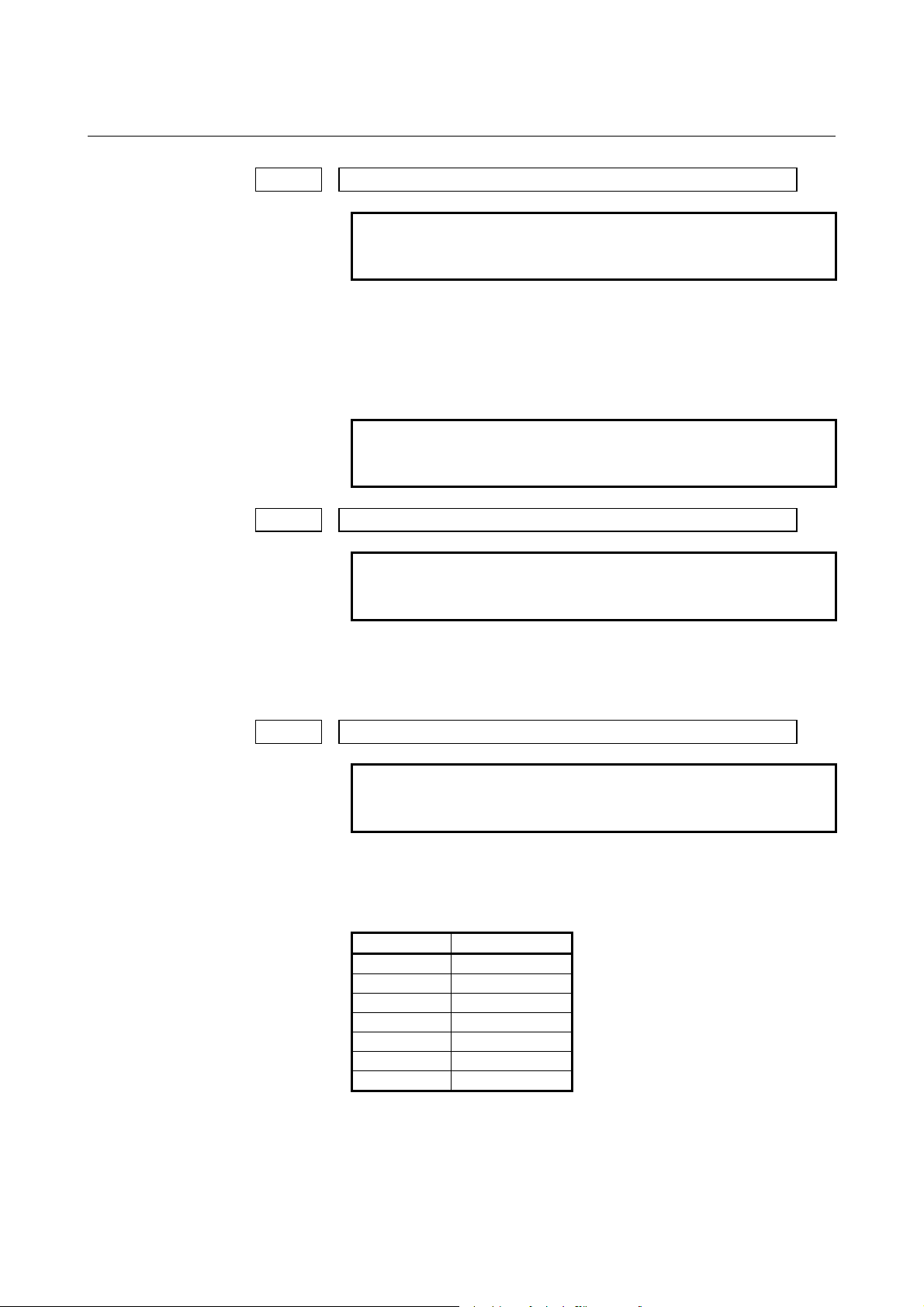

Table 4.2.5

Set value Baud rate (bps) Set value Baud rate (bps)

1 50 9 2400

2 100 10 4800

3 110 11 9600

4 150 12 19200

5 200 13 38400

6 300 14 76800

7 600 15 86400

8 1200

#7 #6 #5 #4 #3 #2 #1 #0

0134 CLK NCD SYN PRY

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

PRY Parity bit

0 : Not used

1 : Used

SYN Reset/alarm in protocol B

0 : Not reported to the host

1 : Reported to the host with SYN and NAK codes

NCD CD (signal quality detection) of the RS-232C interface

0 : Checked

1 : Not checked

CLK Baud rate clock when the RS-422 interface is used

0 : Internal clock

1 : External clock

NOTE

When the RS-232C interface is used, set this bit to

0.

— 20 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0135 RMS R42 PRA ETX ASC

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

ASC Communication code except NC data

0 : ISO code

1 : ASCII code

ETX End code for protocol A or extended protocol A

0 : CR code in ASCII/ISO

1 : ETX code in ASCII/ISO

NOTE

Use of ASCII/ISO is specified by bit 0 (ASC) of

parameter No. 135.

PRA Communication protocol

0 : Protocol B

1 : Protocol A

R42 Interface

0 : RS-232C interface

1 : RS-422 interface

RMS State of remote/tape operation when protocol A is used

0 : Always 0 is returned.

1 : Contents of the change request of the remote/tape operation in

the SET command from the host is returned.

#7 #6 #5 #4 #3 #2 #1 #0

0138

[Data type] Bit

MDP In data output by a memory card, the series information is:

FNL In data output by RS-232C of the loader control function, the series

BIO In multi-path control, NC data input/output via the memory card

OWM When NC data or NC programs are punched to the memory card, a

MDN OWN BIO FNL MDP

MDN OWN FNL MDP

0 : Not added to the output file name.

1 : Added to the output file name.

information is:

0 : Not added to the output file name.

1 : Added to the output file name.

interface is:

0 : Controlled on a path-by-path basis.

1 : Controlled in a batch for all paths.

file overwrite confirmation message is:

0 : Displayed.

1 : Not displayed.

— 21 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

MDN The DNC operation function by a memory card is:

0 : Disabled.

1 : Enabled. (A PCMCIA card attachment is required.)

NOTE

Use a PCMCIA card attachment suited to the CNC

to secure the memory card in the CNC.

— 22 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4.3 PARAMETERS OF DNC1/DNC2 INTERFACE

#7 #6 #5 #4 #3 #2 #1 #0

0140 ECD NCE BCC

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

BCC The BCC value (block check characters) is:

0 : Checked.

1 : Not checked.

This parameter is dedicated to the DNC2 interface.

Even if the BCC value is not checked, the BCC value itself must be

specified.

NCE The ER (RS-232C) and TR (RS422) signals are:

0 : Checked.

1 : Not checked.

This parameter is dedicated to the DNC2 interface.

ECD Error code of negative acknowledgment

0 : A four-digit hexadecimal error code is added to a negative

acknowledgment.

1 : No error code is added to a negative acknowledgment.

This parameter is dedicated to the DNC2 interface.

NOTE

To use FANUC DNC2 communications library for

the host computer, set this parameter to 1.

0141 System for connection between the CNC and host (DNC1 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 1 or 2

This parameter specifies the system for connection (DNC1 interface)

between the CNC and host.

Set value

1 : Point-to-point connection

2 : Multipoint connection

— 23 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0142 Station address of the CNC (DNC1 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 2 to 52

This parameter specifies the station address of the CNC when the

CNC is connected via the DNC1 interface using multipoint

connection.

0143 Time limit specified for the timer monitoring a response (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Unit of data] sec

[Valid data range] 1 to 60 (The standard setting is 3.)

0144 Time limit specified for the timer monitoring the EOT signal (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Unit of data] sec

[Valid data range] 1 to 60 (The standard setting is 5.)

0145 Time required for switching RECV and SEND (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Unit of data] sec

[Valid data range] 1 to 60 (The standard setting is 1.)

— 24 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0146 Number of times the system retries holding communication (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Unit of data] Number of times

[Valid data range] 1 to 10 (The standard setting is 3.)

Set the maximum number of times the system retries holding

communication with the remote device if the remote device uses an

invalid protocol in the data-link layer or the remote device does not

respond to the request.

0147

Number of times the system sends the message in response to the NAK

signal (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Unit of data] Number of times

[Valid data range] 1 to 10 (The standard setting is 2.)

Set the maximum number of times the system retries sending the

message in response to the NAK signal.

0148 Number of characters in overrun (DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 10 to 225 (The standard setting is 10.)

Set the number of characters the system can receive after transmission

is stopped (CS off).

— 25 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0149

Number of characters in the data section of the communication packet

(DNC2 interface)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Word

[Valid range] 80 to 256 (The standard setting is 256.)

If the specified value is out of range, a value of 80 or 256 is used.

The standard setting is 256.

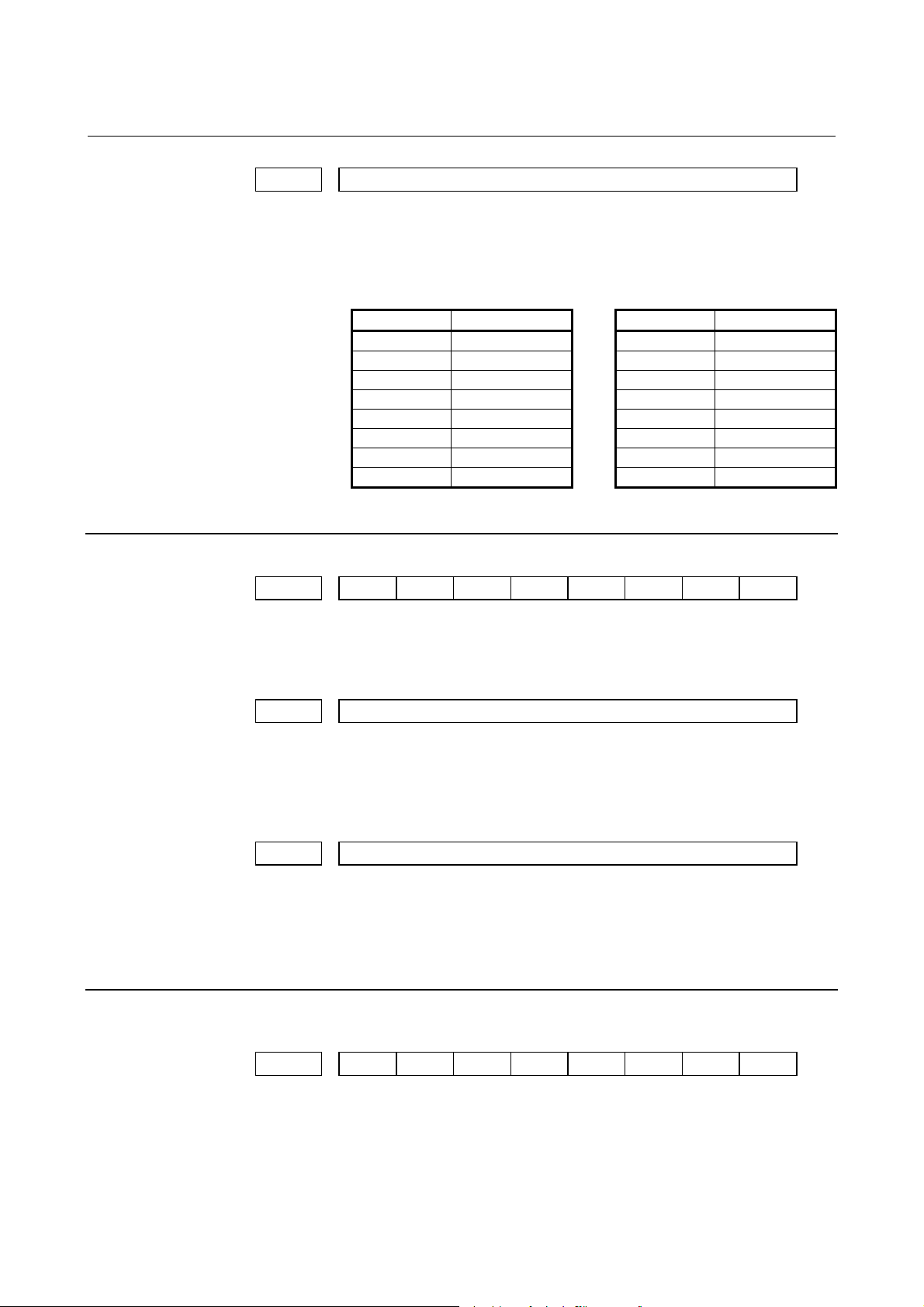

This parameter determines the maximum length of the packet used in

transmission over the DNC2 interface. Including the two characters at

the start of the packet, the four characters used for a command, and the

three characters at the end, the maximum number of characters in the

packet is nine plus the number specified in parameter No.0149.

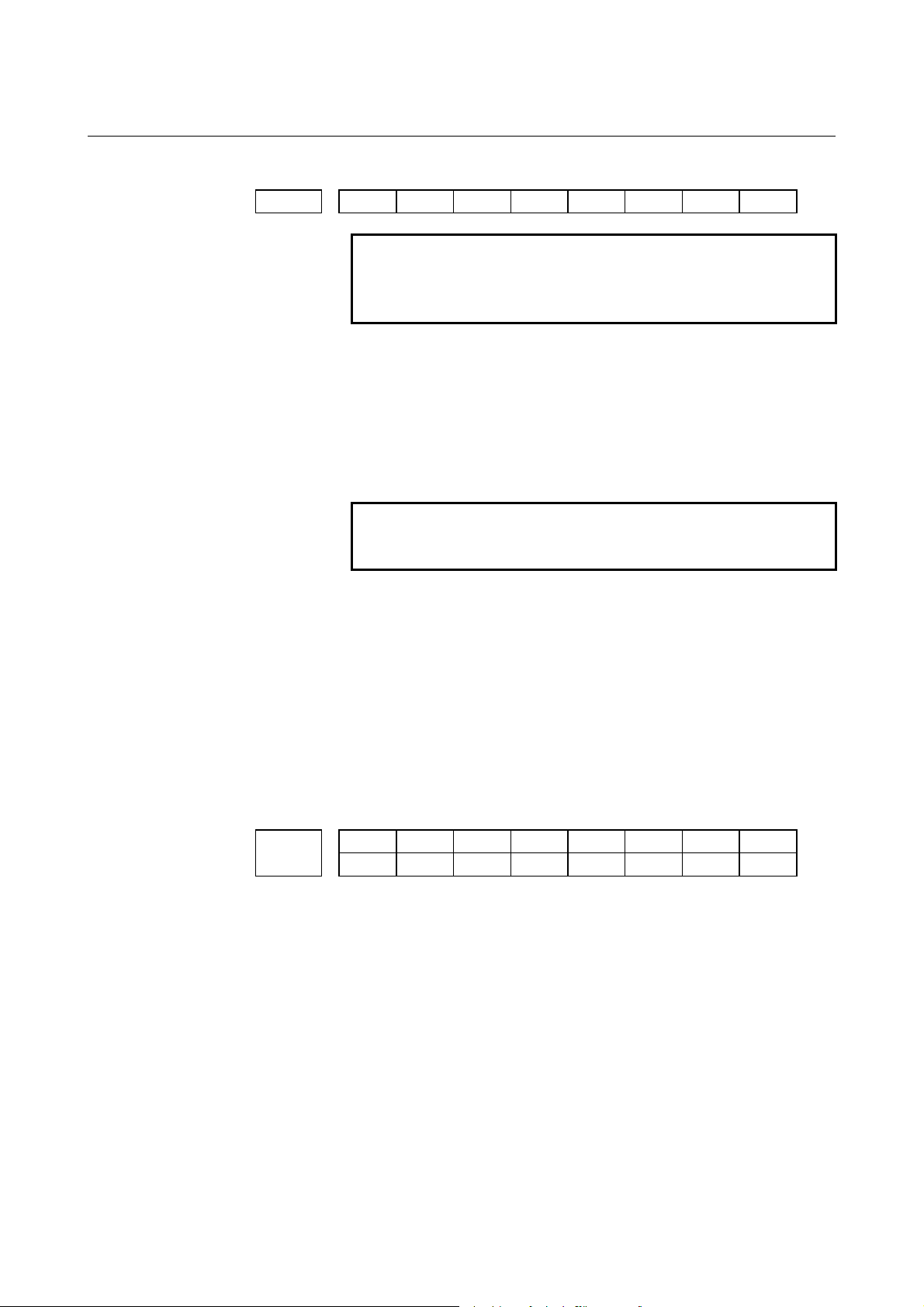

Length of the packet

DLE

STX

2 bytes 4 bytes 80 to 256 bytes 3 bytes

Command Data section DEL ETX BCC

— 26 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4.4 PARAMETERS OF M-NET INTERFACE

#7 #6 #5 #4 #3 #2 #1 #0

0161 SRS PEO SRP SRL

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

SRL Number of characters used in the serial interface

0 : Seven bits

1 : Eight bits

SRP Vertical parity in the serial interface

0 : Vertical parity is not checked.

1 : Vertical parity is checked.

PEO Either odd or even parity is used for vertical parity in the serial

interface

0 : Odd parity is used.

1 : Even parity is used.

NOTE

This bit is effective when bit SRP is set to 1.

SRS Stop bit in the serial interface

0 : One stop bit is used.

1 : Two stop bits are used.

0171 Length of DI data in bytes in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid range] 1 to 32

Specify the length of DI data in bytes (number of byte of data actually

transferred from the PLC unit to the CNC unit) in the serial interface.

— 27 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0172 Length of DO data in bytes in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid range] 1 to 32

Specify the length of DO data in bytes (number of bytes of data

actually transferred from the CNC unit to the PLC unit) in the serial

interface.

NOTE

When a self-loop test is performed, specify the

same value in parameters No.0171 and No.0172.

0173 Station address in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid range] 1 to 15

Specify a station address in the serial interface.

0174 Baud rate in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid range] 0 to 6 (The standard setting is 3.)

Specify a baud rate for the serial interface.

Set value Baud rate (bps)

1 2400

2 4800

3 9600

4 19200

5 38400

6 57600

7 76800

— 28 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0175 Time required for connecting two stations in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Word

[Unit of data] msec

[Valid range] 1 to 32767 (The standard setting is 10000.)

Specify a time limit from when the connection sequence is completed

for the self-station to when the normal transfer sequence starts in the

serial interface.

0176 Time required for polling in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Word

[Unit of data] msec

[Valid data range] 1 to 32767 (The standard setting is 500.)

Specify a time limit for polling in the normal sequence at the

self-station in the serial interface.

0177 Time required from SAI to BCC in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Word

[Unit of data] msec

[Valid data range] 1 to 32767 (The standard setting is 50.)

Specify a time limit from when the SAI signal starts to be transferred

to when the BCC signal has been sent.

0178 Time between a reception and the next transmission in M-NET

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Word

[Unit of data] msec

[Valid data range] 1 to 32767 (The standard setting is 1.)

Specify the time from when data has been received to when the next

data starts to be transmitted.

— 29 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

4.5 PARAMETERS OF REMOTE DIAGNOSIS

#7 #6 #5 #4 #3 #2 #1 #0

0002 RDG

[Data type] Bit

RDG Remote diagnosis is:

0 : Not performed.

1 : Performed.

If an RS-232C serial port is used to carry out remote diagnosis,

connect and set up the modem, cable, and the like, then set 1 in this

parameter. When using a modem card, the setting is not necessary.

#7 #6 #5 #4 #3 #2 #1 #0

0201 MCB NCR ASC SB2

[Data type] Bit

SB2 The number of stop bits is

0 : 1.

1 : 2.

To carry out remote diagnosis, set 0.

ASC The code to be used for data output is:

0 : ISO code.

1 : ASCII code.

To carry out remote diagnosis, set 1.

NCR EOB (end of block) is output as:

0 : «LF»»CR»»CR».

1 : Just as «LF».

To carry out remote diagnosis, set 1.

MCB The baud rate setting for data input/output between the modem card

and CNC is:

0 : 9600 bps (fixed).

1 : Determined by the setting of parameter No. 203.

For the detailed setting while MCB is set to 1, see parameter No. 203.

— 30 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0203 Baud rate (for remote diagnosis)

[Data type] Byte

Set the baud rate of data input/output by remote diagnosis, with

reference to the tables given below.

When using an RS-232C serial port

Set value Baud rate (bps) Set value Baud rate (bps)

1 50 7 600

2 100 8 1200

3 110 9 2400

4 150 10 4800

5 200 11 9600

6 300

12 19200

When using a modem card (when bit 6 (MCB) of parameter No. 201

is set to 1)

Set value Baud rate (bps) Set value Baud rate (bps)

1 28800 7 600

2 38400 8 1200

3 57600 9 2400

4 — 10 4800

5 — 11 9600

6 300

12 19200

NOTE

The tables above indicate the baud rates of

communication between the CNC and modem. The

actual communication baud rate may be lowered,

depending on the modem and communication line.

0204 Remote diagnosis channel

[Data type] Byte

[Valid data range] 0, 1, 2

The interface to be used for remote diagnosis is:

0,1 : RS-232C serial port 1 (channel 1).

2 : RS-232C serial port 2 (channel 2).

To carry out remote diagnosis using RS-232C, the reader/puncher

interface is required.

— 31 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

0211 Password 1 for remote diagnosis

0212 Password 2 for remote diagnosis

0213 Password 3 for remote diagnosis

[Data type] 2-word

[Valid data range] 1 to 99999999

Specify a password for using the remote diagnosis function.

The remote diagnosis function has the following password settings.

Data can be protected by preventing a third party from accessing any

system parameter or machining program without permission.

Password 1:

Set a password for the whole service of the remote diagnosis

function. (The whole remote diagnosis service is available only

when this password is input on the host side (PC, for instance).)

Password 2:

Set a password of a part program. (The input/output, verification,

and the like of a program are possible only when this password is

input on the host side (PC, for instance).)

Password 3:

Set a password of a parameter. (The input/output or the like of a

parameter is possible only when this password is input on the

host side (PC, for instance).)

NOTE

Once any value other than 0 is specified as a

password, the password can be changed only

when the same value is specified in the

corresponding keyword (parameters No. 221 to No.

223). If any value other than 0 is specified as a

password, the password setting is not displayed on

the parameter screen (blank display is provided).

Take great care when setting the password.

— 32 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0221 Keyword 1 for remote diagnosis

0222 Keyword 2 for remote diagnosis

0223 Keyword 3 for remote diagnosis

[Data type] 2-word

[Valid range] 1 to 99999999

Set a keyword corresponding to a password of the remote diagnosis

function.

Keyword 1: Keyword for password 1 (parameter No. 211)

Keyword 2: Keyword for password 2 (parameter No. 212)

Keyword 3: Keyword for password 3 (parameter No. 213)

If any value other than 0 is specified as a password (parameters No.

211 to No. 213), the password can be changed only when the same

value is specified as the corresponding keyword.

NOTE

The keyword value is reset to 0 at power-up. On

the parameter screen, the keyword setting is not

displayed (blank display is provided).

— 33 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

4.6 PARAMETERS OF DNC1 INTERFACE #2

#7 #6 #5 #4 #3 #2 #1 #0

0231 NFD ASI SB2

NOTE

When at least one of these parameters is set, the

power must be turned off before operation is

continued.

[Data type] Bit

SB2 Number of stop bits

0 : 1 bit

1 : 2 bits

ASI Data input code

0 : IEA or ISO (automatic recognition)

1 : ASCII Code

NFD When data is out, feed holes are

0 : Output before and after data section

1 : Not output

0233 Baud rate (DNC1 interface #2)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 1 to 15

Specify a baud rate.

Set value Baud rate (bps) Set value Baud rate (bps)

1 50 9 2400

2 100 10 4800

3 110 11 9600

4 150 12 19200

5 200 13 38400

6 300 14 76800

7 600 15 86400

8 1200

— 34 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

0241 Mode of connection between the host and CNC (DNC1 interface #2)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 1 or 2

This parameter sets the mode of connection between the host and

CNC.

Setting Mode

1 Point-to-point mode

2 Multipoint mode

0242 CNC station address (DNC 1 interface #2)

NOTE

When this parameter is set, the power must be

turned off before operation is continued.

[Data type] Byte

[Valid data range] 2 to 52

This parameter sets a CNC station address when the CNC is to be

connected in the multipoint mode.

— 35 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

4.7 PARAMETERS OF MEMORY CARD INTERFACE

#7 #6 #5 #4 #3 #2 #1 #0

0300 PCM

[Data type] Bit

PCM If the CNC screen display function is enabled, when a memory card

interface is provided on the NC side,

0 : The memory card interface on the NC side is used.

1 : The memory card interface on the PC side is used.

This parameter is valid when 4 (memory card interface) is set in

parameter No. 20. This parameter is valid only while the CNC screen

display function is active.

— 36 —

B-63530EN/03 4.DESCRIPTION OF PARAMETERS

4.8 PARAMETERS OF FACTOLINK

#7 #6 #5 #4 #3 #2 #1 #0

0801 SB2

[Data type] Bit

SB2 The number of stop bits is:

0 : 1 bit.

1 : 2 bits.

(Set the number of stop bits when an RS-232C port is specified as the

FACTOLINK communication port.)

0802 Communication channel for the FACTOLINK

[Data type] Byte

Set the communication port for use with the FACTOLINK.

1 : RS-232C serial port 1

2 : RS-232C serial port 2

11 : Ethernet board port 1

12 : Ethernet board port 2

13 : Ethernet board port 3

21 : Embedded Ethernet

0803 Communication baud rate for the FACTOLINK

[Data type] Byte

Set the communication baud rate when an RS-232C port is specified

as the FACTOLINK communication port.

10 : 4800 bps

11 : 9600 bps

12 : 19200 bps (Recommendation value)

#7 #6 #5 #4 #3 #2 #1 #0

0810 FMN FTM FYR FCL FAS BGS

[Data type] Bit

BGS When the FACTOLINK screen is not displayed, FACTOLINK alarm

task communication is:

0 : Not activated.

1 : Activated.

FAS If FACTOLINK uses the Answer or AnswerEx command, the answer

number A01. is:

0 : Displayed in the answer field.

1 : Not displayed in the answer field.

FCL The FACTOLINK clock is:

0 : Not displayed in reverse video.

1 : Displayed in reverse video.

— 37 —

4.DESCRIPTION OF PARAMETERS B-63530EN/03

FYR In the FACTOLINK clock display, years in the 99/01/23 00:00 format

(bit 4 (FTM) of parameter No. 0810 set to 1) are represented:

0 : By a two-digit number.

1 : By a four-digit number.

FTM The FACTOLINK clock is displayed in this format:

0 : Wed Nov 12 00:00:00

1 : 97/11/12 00:00:00

FMN The FACTOLINK screen is displayed:

0 : In color.

1 : With two levels of gray.

0811 Logging type for the FACTOLINK

[Data type] Byte

0812 PMC address of logging data for the FACTOLINK

[Data type] Word

0813 Logging data length for the FACTOLINK

[Data type] Word

0814 Logging wait address for the FACTOLINK

[Data type] Word

0815 FACTOLINK logging data transmission interval

[Data type] 2-word

0820 FACTOLINK device address (1)

0821 FACTOLINK device address (2)

0822 FACTOLINK device address (3)

0823 FACTOLINK device address (4)

0824 FACTOLINK device address (5)

0825 FACTOLINK device address (6)

0826 FACTOLINK device address (7)

0827 FACTOLINK device address (8)

0828 FACTOLINK device address (9)

[Data type] Byte

See following manuals for the parameters related to the FACTOLINK.

• FANUC Ethernet Board/DATA SERVER Board OPARATOR’S

MANUAL (B-63354EN)

• FANUC FACTOLINK SCRIPT FUNCTION OPERATOR’S

MANUAL (B-75054EN)

— 38 —

FANUC Series 16*/160*/160*s-MODEL B

FANUC Series 18*/180*/180*s-MODEL B

FANUC Series 21*/210*/210*s-MODEL B

CONNECTION MANUAL (HARDWARE)

B-63523EN/03

• No part of this manual may be reproduced in any form. • All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the countryfrom where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.However, we cannot describe all the matters which must not be done, or which cannot bedone, because there are so many possibilities.Therefore, matters which are not especially described as possible in this manual should beregarded as ”impossible”.

This manual contains the program names or device names of other companies, some ofwhich are registered trademarks of respective owners. However, these names are notfollowed by or in the main body.

B–63523EN/03 DEFINITION OF WARNING, CAUTION, AND NOTE

s–1

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to themachine. Precautions are classified into Warning and Caution according to their bearing on safety.Also, supplementary information is described as a Note. Read the Warning, Caution, and Notethoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the userbeing injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is notobserved.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

B–63523EN/03 PREFACE

p–1

PREFACE

This manual describes the electrical and structural specifications requiredfor connecting the CNC control unit to a machine tool. The manualoutlines the components commonly used for FANUC CNC control units,as shown in the configuration diagram in Chapter 2, and suppliesadditional information on using these components. The manual outlinesthe I/O unit, servo, spindle, and other components common to FANUCCNC control units, and supplies additional information on using thesecomponents in this CNC control unit. For detailed specifications, referto the manuals of these components.

For options not covered in this manual, also refer to the manuals of thesecomponents.

The models covered by this manual, and their abbreviations, are :

Product Name Abbreviations

FANUC Series 16i–TB 16i–TB

FANUC Series 16i–MB 16i–MBSeries 16i

FANUC Series 18i–TB 18i–TB

FANUC Series 18i–MB5 18i–MB5 Series 18i

FANUC Series 18i–MB 18i–MB

FANUC Series 21i–TB 21i–TB

FANUC Series 21i–MB 21i–MBSeries 21i

FANUC Series 160i–TB 160i–TB

FANUC Series 160i–MB 160i–MBSeries 160i

FANUC Series 180i–TB 180i–TB

FANUC Series 180i–MB5 180i–MB5 Series 180i

FANUC Series 180i–MB 180i–MB

FANUC Series 210i–TB 210i–TB

FANUC Series 210i–MB 210i–MBSeries 210i

FANUC Series 160is–TB 160is–TB

FANUC Series 160is–MB 160is–MBSeries 160is

FANUC Series 180is–TB 180is–TB

FANUC Series 180is–MB5 180is–MB5 Series 180is

FANUC Series 180is–MB 180is–MB

FANUC Series 210is–TB 210is–TB

FANUC Series 210is–MB 210is–MBSeries 210is

Applicable models

PREFACE B–63523EN/03

p–2

This manual consists of chapters 1 to 15 and appendixes at the end of thebook.

Chapter and title Contents

Chapter 1CONFIGURATION

Provides general information related to the connection of the i Series CNC, as well as anintroduction to detailed information.

Chapter 2TOTAL CONNECTION DAIGRAMS

Describes how to connect peripheral units to the i Series CNC.

Chapter 3INSTALLATION

Describes the installation requirements for using the i Series CNC.1) Required power supply capacity2) Heat output3) Locations of connectors on the control unit4) Action against noise

Chapter 4POWER SUPPLAY CONNECTION

Describes how to make connections related to the power supply of the i Series CNC.

Chapter 5CONNECTION TO CNC PERIOHERALS

Describes how to connect the following peripheral devices to the i Series CNC:1) MDI unit2) I/O device (RS–232–C)3) High–speed skip (HDI)4) Built–in ethernet

Chapter 6SPINDLE CONNECTION

Describes how to connect spindle–related units to the i Series CNC.

Chapter 7SERVO INTERFACE

Describes how to connect servo–related units to the i Series CNC.

Chapter 8CNC DISPLAY UNIT WITH PCFUNCTIONS

Describes how to connect a CNC display unit with PC functions to the i Series CNC.

Chapter 9CONNECTION TO FANUC I/O Link

Describes how to connect machine interface I/O with the FANUC I/O Link.

Chapter 10EMERGENCY STOP SIGNAL

Describes how to handle the emergency stop signal.Be sure to read this chapter.

Chapter 11REMOTE BUFFER INTERFACE(INCLUDING FANUC DNC1 AND DNC2)

Describes the remote buffer, DNC1, and DNC2 interfaces that can be used with the i Series CNC.

Chapter 12HIGH–SPEED SERIAL BUS (HSSB)

Describes the high–speed serial bus (HSSB) that can be used with the i Series CNC.

Chapter 13CONNECTION TO OTHERNET–WORKS

Describes how to connect the i Series CNC to networks.

Chapter 14CONNECTION FOR Series160is/180is/210is

Describes connection for Series 160is/180is/210is

APPENDIX A) EXTERNAL DIMENSIONS OF EACH UNITB) 20–PIN INTERFACE CONNECTORS AND CABLESC) CONNECTION CABLE (SUPPLIED FROM US)D) OPTICAL FIBER CABLEE) LIQUID CRYSTAL DISPLAY (LCD)F) MEMORY CARD INTERFACE

Organization of thismanuals

B–63523EN/03 PREFACE

p–3

The following table lists the manuals related to Series 16i, Series 18i,Series 21i, Series 160i, Series 180i, Series 210i, Series 160is, Series180is, Series 210is–MODEL B. This manual is indicated by anasterisk(*).

Manual name Specificationnumber

DESCRIPTIONS B–63522EN

CONNECTION MANUAL (HARDWARE) B–63523EN *

CONNECTION MANUAL (FUNCTION) B–63523EN–1

Series 16i/18i/160i/180i/160is/180is–TBOPERATOR’S MANUAL

B–63524EN

Series 16i/160i/160is–MB, Series 18i/180i/180is–MB5,Series 18i/180i/180is–MB OPERATOR’S MANUAL

B–63534EN

Series 21i/210i/210is–TB OPERATOR’S MANUAL B–63604EN

Series 21i/210i/210is–MB OPERATOR’S MANUAL B–63614EN

MAINTENANCE MANUAL B–63525EN

Series 16i/18i/160i/180i/160is/180is–MODEL BPARAMETER MANUAL

B–63530EN

Series 21i/210i/210is–MODEL B PARAMETER MANUAL B–63610EN

PROGRAMMING MANUAL

Macro Compiler/Macro Executor PROGRAMMING MANUAL

B–61803E–1

FANUC MACRO COMPILER (For Personal Computer)PROGRAMMING MANUAL

B–66102E

C Language Executor PROGRAMMING MANUAL B–62443EN–3

CAP (T series)

FANUC Super CAPi T OPERATORS MANUAL B–63284EN

FANUC Symbol CAPi T OPERATOR’S MANUAL B–63304EN

MANUAL GUIDE For Lathe PROGRAMMING MANUAL B–63343EN

MANUAL GUIDE For Lathe OPERATOR’S MANUAL B–63344EN

CAP (M series)

FANUC Super CAPi M OPERATOR’S MANUAL B–63294EN

MANUAL GUIDE For Milling PROGRAMMING MANUAL B–63423EN

MANUAL GUIDE For Milling OPERATOR’S MANUAL B–63424EN

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUAL B–61863E–1

Related manuals ofSeries 16i/18i/21i/160i/180i/210i/160is/ 180is/210is–MODEL B

PREFACE B–63523EN/03

p–4

Manual nameSpecification

number

Network

FANUC I/O Link–II CONNECTION MANUAL B–62714EN

Profibus–DP Board OPERATOR’S MANUAL B–62924EN

Ethernet Board/DATA SERVER Board OPERATOR’S MANUAL

B–63354EN

FAST Ethernet Board/FAST DATA SERVER OPERATOR’S MANUAL

B–63644EN

DeviceNet Board OPERATOR’S MANUAL B–63404EN

PC function

Screen Display Function OPERATOR’S MANUAL B–63164EN

The following table lists the manuals related to SERVO MOTOR i series

Manual name Specificationnumber

AC SERVO MOTOR αi series DESCRIPTIONS B–65262EN

AC SERVO MOTOR αi series PARAMETER MANUAL B–65270EN

AC SPINDLE MOTOR αi series DESCRIPTIONS B–65272EN

AC SPINDLE MOTOR αi series PARAMETER MANUAL B–65280EN

SERVO AMPLIFIER αi series DESCRIPTIONS B–65282EN

SERVO MOTOR αi series MAINTENANCE MANUAL B–65285EN

The following table lists the manuals related to SERVO MOTOR series

Manual name Specificationnumber

FANUC AC SERVO MOTOR α series DESCRIPTIONS B–65142

FANUC AC SERVO MOTOR α series PARAMETER MANUAL

B–65150

FANUC AC SPINDLE MOTOR α series DESCRIPTIONS B–65152

FANUC AC SPINDLE MOTOR α series PARAMETER MANUAL

B–65160

FANUC SERVO AMPLIFIER α series DESCRIPTIONS B–65162

FANUC SERVO MOTOR α series MAINTENANCE MANUAL

B–65165

Either of the following servo motors and the corresponding spindle canbe connected to the CNC covered in this manual.

FANUC SERVO MOTOR i series FANUC SERVO MOTOR series

This manual mainly assumes that the FANUC SERVO MOTOR i seriesof servo motor is used. For servo motor and spindle information, refer tothe manuals for the servo motor and spindle that are actually connected.

Related manuals ofSERVO MOTOR αi series

Related manuals ofSERVO MOTOR α series

B–63523EN/03 Table of Contents

c–1