- Manuals

- Brands

- YOKOGAWA Manuals

- Transmitter

- Dpharp EJX110A

Manuals and User Guides for YOKOGAWA Dpharp EJX110A. We have 4 YOKOGAWA Dpharp EJX110A manuals available for free PDF download: User Manual, Installation Manual

YOKOGAWA Dpharp EJX110A User Manual (66 pages)

Differential Pressure and Pressure Transmitters

Brand: YOKOGAWA

|

Category: Transmitter

|

Size: 3.11 MB

Table of Contents

-

Table of Contents

2

-

1 Introduction

4

-

Regarding this Manual

4

-

Safe Use of this Product

5

-

Warranty

6

-

ATEX Documentation

7

-

-

2 Handling Cautions

8

-

Model and Specifications Check

8

-

Unpacking

8

-

Storage

8

-

Selecting the Installation Location

9

-

Pressure Connection

9

-

Waterproofing of Cable Conduit Connections

9

-

Restrictions on Use of Radio Transceivers

9

-

Insulation Resistance and Dielectric Strength Test

9

-

Installation of an Explosion-Protected Instrument

10

-

FM Approval

10

-

CSA Certification

12

-

CENELEC ATEX (KEMA) Certification

14

-

Iecex Certification

17

-

-

EMC Conformity Standards

18

-

Pressure Equipment Directive (PED)

18

-

Low Voltage Directive

19

-

-

3 Component Names

20

-

4 Installation

21

-

Precautions

21

-

Mounting

21

-

Changing the Process Connection

22

-

Swapping the High/Low-Pressure Side Connection

23

-

Rotating Pressure-Detector Section 180

23

-

Using the Communicator

23

-

-

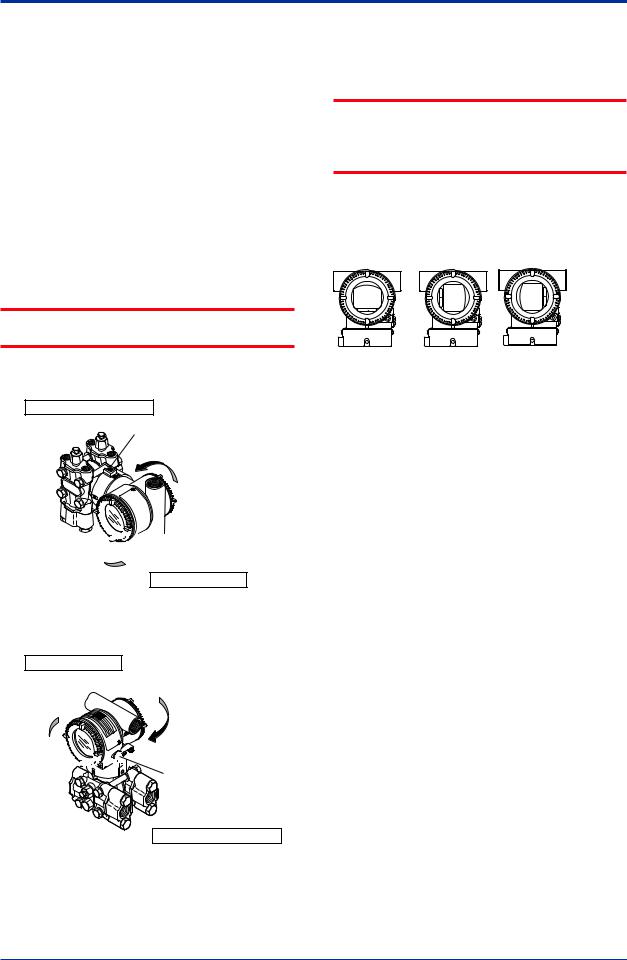

Rotating Transmitter Section

24

-

Changing the Direction of Integral Indicator

24

-

-

5 Installing Impulse Piping

25

-

Impulse Piping Installation Precautions

25

-

Connecting Impulse Piping to a Transmitter

25

-

Routing the Impulse Piping

26

-

-

Impulse Piping Connection Examples

28

-

-

6 Wiring

29

-

Wiring Precautions

29

-

Selecting the Wiring Materials

29

-

Connections of External Wiring to Terminal Box

29

-

Power Supply Wiring Connection

29

-

External Indicator Connection

29

-

Communicator Connection

29

-

Check Meter Connection

30

-

Status Output Connection

30

-

-

Wiring

30

-

Loop Configuration

30

-

General-Use Type and Flameproof Type

30

-

Intrinsically Safe Type

30

-

-

Wiring Installation

30

-

General-Use Type and Intrinsically Safe Type

30

-

Flameproof Type

31

-

-

-

Grounding

31

-

Power Supply Voltage and Load Resistance

31

-

-

7 Operation

32

-

Preparation for Starting Operation

32

-

Zero Point Adjustment

33

-

Adjusting Zero Point for Differential Pressure Transmitters

34

-

Adjusting Zero Point for Gauge/Absolute Pressure Transmitters

34

-

-

Starting Operation

34

-

Shutting down the Transmitter

35

-

Venting or Draining Transmitter Pressure-Detector Section

35

-

Draining Condensate

35

-

Venting Gas

35

-

-

Setting the Range Using the Range-Setting Switch

36

-

-

8 Maintenance

37

-

Overview

37

-

Calibration Instruments Selection

37

-

Calibration

37

-

Disassembly and Reassembly

39

-

Replacing the Integral Indicator

39

-

Replacing the CPU Board Assembly

40

-

Cleaning and Replacing the Capsule Assembly

40

-

Replacing the Process Connector Gaskets

41

-

-

Troubleshooting

42

-

Basic Troubleshooting

42

-

Troubleshooting Flowcharts

43

-

Alarms and Countermeasures

45

-

-

-

9 General Specifications

46

-

Standard Specifications

46

-

Performance Specifications

46

-

Functional Specifications

46

-

-

Model and Suffix Codes

50

-

Optional Specifications

50

-

Optional Specifications

55

-

Dimensions

58

-

Advertisement

YOKOGAWA Dpharp EJX110A Installation Manual (57 pages)

EJX Series and EJA-E Series Differential Pressure and Pressure Transmitters

Brand: YOKOGAWA

|

Category: Transmitter

|

Size: 16.44 MB

Table of Contents

-

Table of Contents

1

-

1 Introduction

2

-

For Safe Use of Product

3

-

Warranty

5

-

ATEX Documentation

6

-

-

2 Handling Cautions

7

-

Model and Specifications Check

8

-

Selecting the Installation Location

8

-

Pressure Connection

8

-

Installation of an Explosion-Protected Instrument

8

-

EMC Conformity Standards

28

-

Pressure Equipment Directive (PED)

29

-

Safety Requirement Standards

30

-

-

3 Installation

31

-

Mounting

31

-

Mounting the Diaphragm Seals

31

-

Diaphragm Seals Installation Consideration

32

-

Mounting the Flushing Connection Ring

33

-

3.5 Affixing The Teflon Film

34

-

Rotating Transmitter Section

35

-

Changing the Direction of Integral Indicator

35

-

-

4 Installing Impulse Piping

36

-

Impulse Piping Installation Precautions

36

-

Routing the Impulse Piping

37

-

Impulse Piping Connection Examples

38

-

Process Piping Installation Precautions (EJ115)

39

-

-

5 Wiring

41

-

Wiring Precautions

41

-

Connections of External Wiring to Terminal Box

41

-

Power Supply Wiring Connection

42

-

Status Output Connection

42

-

-

Wiring

44

-

Wiring Installation

45

-

RTD Cable Connection (EJX910A/EJX930A)

46

-

Grounding

48

-

Power Supply Voltage and Load Resistance

48

-

-

6 Operation

49

-

Preparation for Starting Operation

49

-

Zero Point Adjustment

49

-

Local Parameter Setting

50

-

-

7 Errors and Countermeasures

52

YOKOGAWA Dpharp EJX110A Installation Manual (60 pages)

Differential Pressure and Pressure Transmitters

Brand: YOKOGAWA

|

Category: Transmitter

|

Size: 11.44 MB

Table of Contents

-

Table of Contents

1

-

1 Introduction

2

-

For Safe Use of Product

4

-

Warranty

6

-

-

2 Handling Cautions

7

-

3 Installation

35

-

Mounting

35

-

-

4 Installing Impulse Piping

40

-

5 Wiring

45

-

Wiring Precautions

45

-

Wiring

48

-

Grounding

52

-

-

6 Operation

53

-

Preparation for Starting Operation

53

-

-

7 Errors and Countermeasures

56

Advertisement

YOKOGAWA Dpharp EJX110A User Manual (20 pages)

Differential Pressure and Pressure Transmitters

Brand: YOKOGAWA

|

Category: Transmitter

|

Size: 2.55 MB

Table of Contents

-

Table of Contents

2

-

Introduction

5

-

Regarding this Manual

5

-

Safe Use of this Product

6

-

Warranty

7

-

ATEX Documentation

8

-

Handling Cautions

9

-

Model and Specifications Check

9

-

Unpacking

9

-

Storage

9

-

Selecting the Installation Location

10

-

Pressure Connection

10

-

Waterproofing of Cable Conduit Connections

10

-

Restrictions on Use of Radio Transceivers

10

-

Insulation Resistance and Dielectric Strength Test

10

-

Installation of an Explosion-Protected Instrument

11

-

FM Approval

11

-

CSA Certification

13

-

Iecex Certification

18

-

EMC Conformity Standards

19

-

Pressure Equipment Directive (PED)

19

-

Low Voltage Directive

20

-

Installation

20

Advertisement

Related Products

-

YOKOGAWA DpharpEJX vigilantplant EJX130A

-

YOKOGAWA DpharpEJX vigilantplant EJX110

-

YOKOGAWA DP harp EJX120A

-

YOKOGAWA EJX118A

-

YOKOGAWA EJX115A

-

YOKOGAWA DP Harp EJX118B

-

YOKOGAWA EJX110B

-

YOKOGAWA EJX Series

-

YOKOGAWA DpharpEJX vigilantplant EJX910A

-

YOKOGAWA Dpharp vigilantplant EJA Series

YOKOGAWA Categories

Measuring Instruments

Test Equipment

Transmitter

Controller

Media Converter

More YOKOGAWA Manuals

Page 1 — IM 01C25B01-01E

User’sManualDifferential Pressure andPressure TransmittersEJ110, EJ120, EJ130, EJ310, EJ430, and EJ440IM 01C25B01-01EIM 01C25B01-01E13th E

Page 2 — Contents

<2. Handling Cautions>2-2IM 01C25B01-01E2.4 Selecting the Installation Location The transmitter is designed to withstand severe environmen

Page 3

<2. Handling Cautions>2-3IM 01C25B01-01E(b) Never apply a voltage exceeding 500 V DC (100 V DC with an internal lightning protector) for t

Page 4 — Revision Information

<2. Handling Cautions>2-4IM 01C25B01-01EIMPORTANTFor combined approval typesOnce a device of multiple approval type is installed, it should

Page 5 — 1. Introduction

<2. Handling Cautions>2-5IM 01C25B01-01ENote 4. Maintenance and Repair• The instrument modication or parts replacement by other than aut

Page 6 — <1. Introduction>

<2. Handling Cautions>2-6IM 01C25B01-01E2.9.2 CSA Certicationa. CSA Intrinsically Safe TypeCaution for CSA Intrinsically safe and noninc

Page 7 — 1.2 Warranty

<2. Handling Cautions>2-7IM 01C25B01-01E• Explosion-proof for Class I, Groups B, C and D.• Dustignition-proof for Class II/III, Groups E,

Page 8 — 1.3 ATEX Documentation

<2. Handling Cautions>2-8IM 01C25B01-01E2.9.3 ATEX Certication(1) Technical Dataa. ATEX Intrinsically Safe Ex ia Caution for ATEX Intri

Page 9 — 2. Handling Cautions

<2. Handling Cautions>2-9IM 01C25B01-01Eb. ATEX Flameproof TypeCaution for ATEX ameproof type.Note 1. Model EJX/EJA-E Series pressure tr

Page 10

<2. Handling Cautions>2-10IM 01C25B01-01E● ATEX Intrinsically Safe Ex icCaution for ATEX intrinsically safe Ex ic• Applicable Standard: E

Page 11

<2. Handling Cautions>2-11IM 01C25B01-01E(5) Maintenance and Repair WARNING The instrument modication or parts replacement by other than

Page 12 — IMPORTANT

iIM 01C25B01-01EDifferential Pressure and Pressure TransmittersEJ110, EJ120, EJ130,EJ310, EJ430, and EJ440IM 01C25B01-01E 13th Edition13t

Page 13

<2. Handling Cautions>2-12IM 01C25B01-01E• Installation RequirementsUo ≤ Ui, Io ≤ Ii, Po ≤ Pi, Co ≥ Ci + Ccable, Lo ≥ Li + Lcable Voc ≤

Page 14 — 2.9.2 CSA Certication

<2. Handling Cautions>2-13IM 01C25B01-01E2.11 Pressure Equipment Directive (PED)(1) General• EJX/EJA-E Series pressure transmitters are

Page 15

<3. Component Names>3-1IM 01C25B01-01E3. Component NamesHIGH LOWSlide switchBurnout direction switchWrite protection switchBurnout Directi

Page 16 — 2.9.3 ATEX Certication

<4. Installation>4-1IM 01C25B01-01E4. Installation4.1 Precautions Before installing the transmitter, read the cautionary notes in section

Page 17

<4. Installation>4-2IM 01C25B01-01EF0403.aiVertical pipe mounting(Process connector upside)Vertical pipe mounting(Process connector downsid

Page 18

<4. Installation>4-3IM 01C25B01-01E4.4 Swapping the High/Low-pressure Side ConnectionIMPORTANTThis section is applicable only for EJ110,

Page 19 — 2.9.4 IECEx Certication

<4. Installation>4-4IM 01C25B01-01E4.5 Rotating Transmitter SectionThe transmitter section can be rotated approximately 360° (180° to eith

Page 20

<5. Installing Impulse Piping>5-1IM 01C25B01-01E5. Installing Impulse Piping5.1 Impulse Piping Installation PrecautionsThe impulse piping

Page 22 — 3. Component Names

<5. Installing Impulse Piping>5-3IM 01C25B01-01E5.1.2 Routing the Impulse Piping(1) Process Pressure Tap AnglesIf condensate, gas, sedime

Page 24 — Connection

<5. Installing Impulse Piping>5-4IM 01C25B01-01E(7) Preventing FreezingIf there is any risk that the process uid in the impulse piping or

Page 26 — High Pressure Type)

<6. Wiring>6-2IM 01C25B01-01E6.3.4 Check Meter ConnectionAvailable only when /AL is not specied.Connect the check meter to the CHECK + an

Page 28 — (Figure 5.3)

<7. Operation>7-1IM 01C25B01-01E7. Operation7.1 Preparation for Starting OperationThis section describes the operation procedure for the

Page 29

<7. Operation>7-2IM 01C25B01-01EVent plug (Fill plug)Tap valveStop valveDrain valveF0702.aiFigure 7.1b Liquid Pressure Measurement Conrm

Page 30 — Examples

<7. Operation>7-3IM 01C25B01-01E7.2.1 Adjusting Zero Point for Differential Pressure TransmittersBefore adjusting zero point, make sure th

Page 31 — 6. Wiring

<7. Operation>7-4IM 01C25B01-01EIMPORTANT• Remove the communicator from the terminal box, and conrm that none of the terminal screws are

Page 32 — 6.4 Wiring

<7. Operation>7-5IM 01C25B01-01E7.5.2 Venting Gas1) Gradually open the vent screw to vent gas from the transmitter pressure-detector sec

Page 33 — Load Resistance

<7. Operation>7-6IM 01C25B01-01EIMPORTANT• Do not turn off the power to the transmitter immediately after completion of the change in the

Page 36 — 7.3 Starting Operation

<8. Maintenance>8-2IM 01C25B01-01ETable 8.1 Instruments Required for CalibrationName Yokogawa-recommended Instrument RemarksPower supply M

Page 38 — Range-setting Switch

<8. Maintenance>8-4IM 01C25B01-01E8.4.2 Replacing the CPU Board AssemblyThis subsection describes the procedure for replacing the CPU asse

Page 39

<8. Maintenance>8-5IM 01C25B01-01E Removing the Capsule AssemblyIMPORTANTExercise care as follows when cleaning the capsule assembly.• H

Page 40 — 8. Maintenance

<8. Maintenance>8-6IM 01C25B01-01E8.4.4 Replacing the Process Connector GasketsThis subsection describes process connector gasket replacem

Page 41

<8. Maintenance>8-7IM 01C25B01-01E8.5.2 Troubleshooting FlowchartsConnect communicator and check self-diagnostics.Does the self-diagnostic

Page 42 — Reassembly

<8. Maintenance>8-8IM 01C25B01-01EConnect a communicator and check self-diagnostics.Contact Yokogawa service personnel.F0809.aiAre valves o

Page 43 — Assembly

<8. Maintenance>8-9IM 01C25B01-01E8.5.3 Alarms and CountermeasuresTable 8.3 Alarm Message SummaryIndicator CauseOutput Operationduring Er

Page 44

<9. General Specications>9-1IM 01C25B01-01E9. General Specications9.1 Standard SpecicationsRefer to IM 01C25T02-01E for FOUNDATION Fie

Page 45 — 8.5 Troubleshooting

<1. Introduction>1-1IM 01C25B01-01E1. IntroductionThank you for purchasing the DPharp Differential Pressure and pressure transmitter.Your

Page 46 — <8. Maintenance>

<9. General Specications>9-2IM 01C25B01-01EEJA120E Measurement Span/RangekPa inH2O(/D1) mbar(/D3) mmH2O(/D4)ESpan 0.1 to 1 0.4 to 4 1 to 1

Page 47

<9. General Specications>9-3IM 01C25B01-01E Normal Operating Condition(Selected features may affect limits.)Ambient Temperature Limits –

Page 48

<9. General Specications>9-4IM 01C25B01-01EMaximum Over PressureEJ310Capsule PressureL, M 500 kPa abs (72 psia)A 16 MPa abs (2300 psia)B

Page 49 — 9. General Specications

<9. General Specications>9-5IM 01C25B01-01E Physical SpecicationsWetted Parts MaterialsDiaphragm, Cover Flange, Process Connector, Caps

Page 50

<9. General Specications>9-6IM 01C25B01-01E9.2 Model and Sufx CodesModel EJX110AModel Sufx Codes DescriptionEJX110A . . . . . . . . .

Page 52

<9. General Specications>9-8IM 01C25B01-01EModel EJX130AModel Sufx Codes DescriptionEJX130A . . . . . . . . . . . . . . . . . . . . . .

Page 53 — Physical Specications

<9. General Specications>9-9IM 01C25B01-01EModel EJX310AModel Sufx Codes DescriptionEJX310A . . . . . . . . . . . . . . . . . . . . . .

Page 55 — Model EJX120A

<9. General Specications>9-11IM 01C25B01-01EModel EJX440AModel Sufx Codes DescriptionEJX440A . . . . . . . . . . . . . . . . . . . . . .

Page 56 — Model EJX130A

<1. Introduction>1-2IM 01C25B01-01E• Yokogawa assumes no responsibilities for this product except as stated in the warranty.• If the cust

Page 57 — Model EJX310A

<9. General Specications>9-12IM 01C25B01-01EModel EJA110EModel Sufx Codes DescriptionEJA110E . . . . . . . . . . . . . . . . . . . . .

Page 58 — Model EJX430A

<9. General Specications>9-13IM 01C25B01-01EModel EJA120EModel Sufx Codes DescriptionEJA120E . . . . . . . . . . . . . . . . . . . . .

Page 59 — Model EJX440A

<9. General Specications>9-14IM 01C25B01-01EModel EJA130EModel Sufx Codes DescriptionEJA130E . . . . . . . . . . . . . . . . . . . . .

Page 60 — Model EJA110E

<9. General Specications>9-15IM 01C25B01-01EModel EJA310EModel Sufx Codes DescriptionEJA310E . . . . . . . . . . . . . . . . . . . . .

Page 61 — Model EJA120E

<9. General Specications>9-16IM 01C25B01-01EModel EJA430EModel Sufx Codes DescriptionEJA430E . . . . . . . . . . . . . . . . . . . . .

Page 62 — Model EJA130E

<9. General Specications>9-17IM 01C25B01-01EModel EJA440EModel Sufx Codes DescriptionEJA440E . . . . . . . . . . . . . . . . . . . . .

Page 63 — Model EJA310E

<9. General Specications>9-18IM 01C25B01-01ETable. 1 Wetted Parts Materials for EJ110, EJ120, EJ310, and EJ430Wetted partsmateria

Page 64 — Model EJA430E

<9. General Specications>9-19IM 01C25B01-01E9.3 Optional Specications Item Description CodeFactory Mutual (FM) FM Explosionproof *1Explo

Page 65 — Model EJA440E

<9. General Specications>9-20IM 01C25B01-01EItem Description CodeOil-prohibited use with dehydrating treatment *4Degrease cleansing treatm

Page 66

<9. General Specications>9-21IM 01C25B01-01E*9: Also see ‘Ordering Instructions’.*10: Applicable for M, H and V capsules of EJX110A with

Page 68

<9. General Specications>9-22IM 01C25B01-01E9.4 DimensionsModel EJ110Unit: mm (approx. inch)95(3.74)242(9.53)175(6.89)129(5.08)97(3.82)

Page 69

<9. General Specications>9-23IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)Electrical connectionfor code 5, 9, A, and D.Process con

Page 70 — Model EJ110

<9. General Specications>9-24IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.23)129(5.08)117(4.61)*154(2.13)ø78(3.07)ø70(2.76)39(1.54)12

Page 71 — Unit: mm (approx. inch)

<9. General Specications>9-25IM 01C25B01-01EModel EJ120Unit: mm (approx. inch)54(2.13)6(0.24)Electrical connectionfor code 5, 9, A, and

Page 72 — F0907.ai

<9. General Specications>9-26IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)ø78(3.07)ø70(2.76)Integral indicator (optional)Ground te

Page 73 — F0908.ai

<9. General Specications>9-27IM 01C25B01-01EModel EJ130Unit: mm (approx. inch)54(2.13)6(0.24)Process connection93(3.66)124(4.88)277(10.9

Page 74 — F0909.ai

<9. General Specications>9-28IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)ø78(3.07)ø70(2.76)Integral indicator (optional)Ground te

Page 75 — Model EJ130

<9. General Specications>9-29IM 01C25B01-01EModel EJ310Unit: mm (approx. inch)223(8.78)52(2.05)97(3.82)41(1.61)67(2.64)Process connectio

Page 76 — F0911.ai

<9. General Specications>9-30IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)129(5.08)59*1(2.32)27(1.06)ø78(3.07)ø70(2.76)39(1.54)12(

Page 77 — F0912.ai

<9. General Specications>9-31IM 01C25B01-01EModel EJ430Unit: mm (approx. inch)223(8.78)52(2.05)97(3.82)41(1.61)67(2.64)Process connectio

Page 78 — F0914.ai

<1. Introduction>1-4IM 01C25B01-01E1.3 ATEX DocumentationThis is only applicable to the countries in European Union.GBDKIENLSFPFDSLTLVPLES

Page 79 — Model EJ430

<9. General Specications>9-32IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)Electrical connectionfor code 5, 9, A, and D.Process con

Page 80 — F0916.ai

<9. General Specications>9-33IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)129(5.08)59*1(2.32)27(1.06)ø78(3.07)ø70(2.76)39(1.54)12(

Page 81 — F0918.ai

<9. General Specications>9-34IM 01C25B01-01EModel EJ440 Unit: mm (approx. inch)54(2.13)6(0.24)54(2.13)6(0.24)Process connection119(4.69)

Page 82 — Model EJ440

<9. General Specications>9-35IM 01C25B01-01EUnit: mm (approx. inch)54(2.13)6(0.24)ø78(3.07)ø70(2.76)Integral indicator (optional)Ground te

Page 83 — F0920.ai

iIM 01C25B01-01ERevision Information Title : Differential Pressure and Pressure Transmitters EJ110, EJ120, EJ130, EJ310, EJ430, and EJ

Page 84

iiIM 01C25B01-01EEdition Date Page Revised Item7th Feb. 2008 — Change of the style code, add EJX120A.General • Change the gure of amplier housing.1-

Page 85

<2. Handling Cautions>2-1IM 01C25B01-01E2. Handling CautionsThis chapter provides important information on how to handle the transmitter.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

User’s

Manual

Y okogawa Electric Corporation

EJX110A, EJX130A, EJX310A,

EJX430A and EJX440A

Differential Pressure and

Pressure Transmitters

IM 01C25B01-01E

IM 01C25B01-01E

5th Edition

Related Manuals for YOKOGAWA DpharpEJX vigilantplant EJX110

Summary of Contents for YOKOGAWA DpharpEJX vigilantplant EJX110

-

Page 1

User’s Manual EJX110A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure Transmitters IM 01C25B01-01E IM 01C25B01-01E 5th Edition Y okogawa Electric Corporation… -

Page 2: Table Of Contents

Selecting the Wiring Materials …………6-1 Connections of External Wiring to Terminal Box …….. 6-1 6.3.1 Power Supply Wiring Connection ……….6-1 FD No. IM 01C25B01-01E IM 01C25B01-01E 5th Edition: July 2006(YK) All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation…

-

Page 3

CONTENTS 6.3.2 External Indicator Connection …………6-1 6.3.3 Communicator Connection …………6-1 6.3.4 Check Meter Connection ………….. 6-2 6.3.5 Status Output Connection …………6-2 Wiring ………………..6-2 6.4.1 Loop Configuration …………… 6-2 General-use Type and Flameproof Type ……..6-2 Intrinsically Safe Type …………..6-2 6.4.2 Wiring Installation …………….. -

Page 4: Introduction

• All rights reserved. No part of this manual may be before you operate the instrument. reproduced in any form without Yokogawa’s written permission. • Yokogawa makes no warranty of any kind with NOTE regard to this manual, including, but not limited to, This manual describes the hardware configura- implied warranty of merchantability and fitness for a tions of EJX series transmitters.

-

Page 5: Safe Use Of This Product

Indicates a potentially hazardous situation which, protection provided by this instrument may be im- if not avoided, could result in death or serious paired. In this case, Yokogawa cannot guarantee that injury. the instrument can be safely operated. Please pay…

-

Page 6: Warranty

Yokogawa. (f) Modification • The purchaser shall bear the responsibility for repair • Yokogawa will not be liable for malfunctions or costs, even during the warranty period, if the damage resulting from any modification made to this malfunction is due to: instrument by the customer.

-

Page 7: Atex Documentation

Se si desidera ricevere i manuali operativi di prodotti Ex in lingua locale, mettersi in Alle Betriebsanleitungen für ATEX Ex bezogene contatto con l’ufficio Yokogawa più vicino o con un Produkte stehen in den Sprachen Englisch, Deutsch rappresentante.

-

Page 8: Handling Cautions

2. HANDLING CAUTIONS HANDLING CAUTIONS This chapter provides important information on how to 2.1 Model and Specifications handle the transmitter. Read this carefully before using Check the transmitter. EJX Series transmitters are thoroughly tested at the The model name and specifications are written on the factory before shipment.

-

Page 9: Selecting The Installation Location

2. HANDLING CAUTIONS (b) Make sure that there are no leaks in the impulse 2.4 Selecting the Installation piping. Location (c) Never apply a pressure higher than the specified maximum working pressure. The transmitter is designed to withstand severe environmental conditions. However, to ensure that it 2.6 Waterproofing of Cable will provide years of stable and accurate performance, take the following precautions when selecting the…

-

Page 10: Installation Of An Explosion-Protected Instrument

• Ambient temperature: –60 to 60 C intrinsically safe or explosionproof construction may be compromised and the instrument may be hazardous to operate. Please contact Yokogawa before making any repair or modification to an instrument. IM 01C25B01-01E…

-

Page 11

[Groups A, B, C, D, E, F and G] by other than authorized representative of Vmax = 30 V Ci = 6 nF Yokogawa Electric Corporation is prohibited and Imax = 200 mA Li = 0 H will void Factory Mutual Intrinsically safe and Pmax = 1 W Nonincendive Approval. -

Page 12: Csa Certification

• Ambient Temperature :–50 to 60 C by other than authorized representative of • Max. Process Temp.: 120 C Yokogawa Electric Corporation is prohibited and • Enclosure: IP66 and IP67 will void Factory Mutual Explosionproof Approval. Note 2. Entity Parameters •…

-

Page 13

2. HANDLING CAUTIONS Note 2. Wiring [Intrinsically Safe] Hazardous Location Nonhazardous Location [For CSA C22.2] Group IIC, Zone 0 • All wiring shall comply with Canadian Electrical Class I, II, III, Division 1, Code Part I and Local Electrical Codes. Groups A, B, C, D, E, F, G General •… -

Page 14: Cenelec Atex (Kema) Certification

Explosionproof) for use in hazardous locations. by other than authorized representative of Note 1. For the installation of this transmitter, Yokogawa Electric Corporation is prohibited and once a particular type of protection is will void KEMA Intrinsically safe Certification. selected, any other type of protection Note 5.

-

Page 15

• The instrument modification or parts replacement Note 4. Operation by other than authorized representative of • Keep the “WARNING” label attached to the Yokogawa Electric Corporation is prohibited and transmitter. will void Type of Protection “n”. WARNING: AFTER DE-ENERGIZING, DELAY 5 MINUTES BEFORE OPENING. -

Page 16

*2: “180-8750” is a zip code which represents the following address. WARNING 2-9-32 Nakacho, Musashino-shi, Tokyo Japan The instrument modification or parts replacement by other than an authorized Representative of Yokogawa Electric Corporation is prohibited and will void the certification. IM 01C25B01-01E… -

Page 17: Iecex Certification

/SU2 can be selected the type of by other than authorized representative of protection (IECEx Intrinsically Safe/type n or Yokogawa Electric Corporation and will void flameproof) for use in hazardous locations. IECEx Intrinsically safe and type n certification.

-

Page 18: Emc Conformity Standards

• The instrument modification or parts replacement EJX310A 0.01 Article 3, Paragraph 3 M, A, B by other than authorized representative of (SEP) Yokogawa Electric Corporation is prohibited and EJX430A 0.01 Article 3, Paragraph 3 H, A, B will void IECEx Certification. (SEP)

-

Page 19: Low Voltage Directive

2. HANDLING CAUTIONS 2.12 Low Voltage Directive Applicable standard : EN61010-1 (1) Pollution Degree 2 «Pollution degree» describes the degree to which a soild, liquid, or gas which deteriorates dielectric strength or surface resistivity is adhering. » 2 » applies to normal indoor atmosphere. Normally, only non-conductive pollution occurs.

-

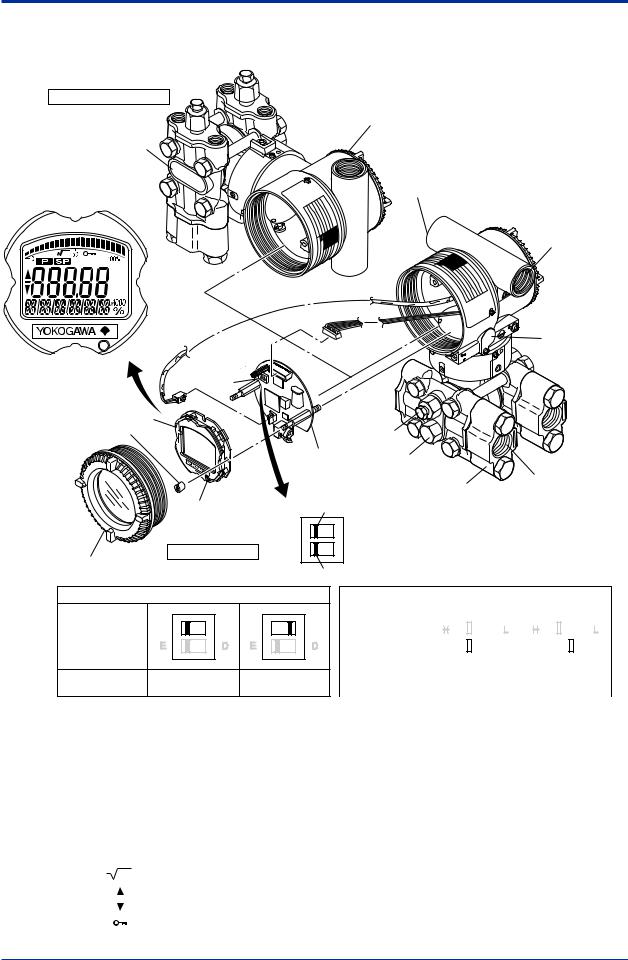

Page 20: Component Names

3. COMPONENT NAMES COMPONENT NAMES Vertical impulse piping type Pressure-detector section Terminal box cover Cover flange Horizontal impulse piping type External indicator (Note 1) conduit connection Conduit connection Zero- adjustment screw (Note 2) Slide switch Integral (Note 1) indicator Mounting screw Vent plug CPU assembly Drain plug…

-

Page 21: Installation

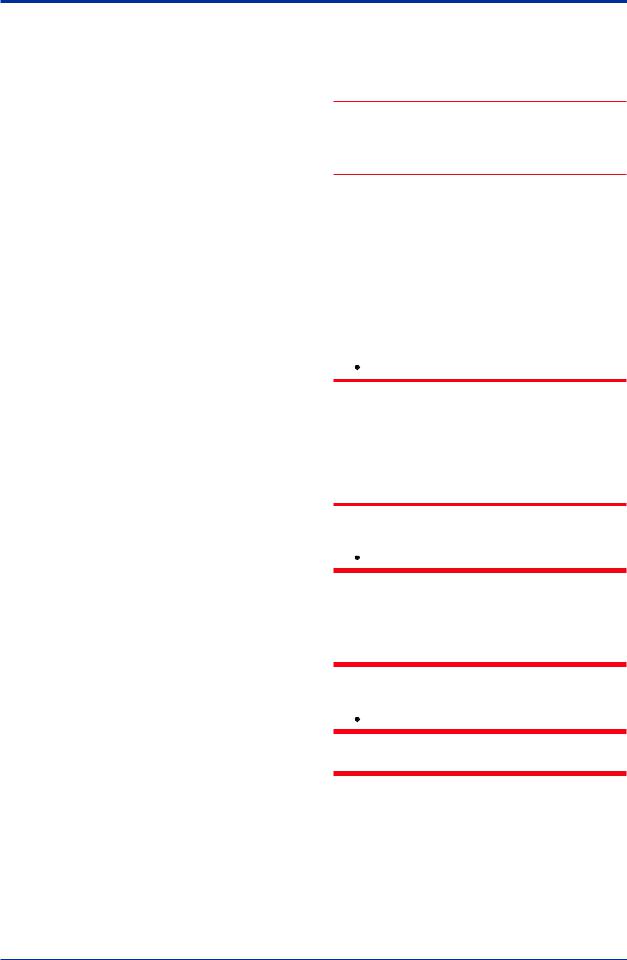

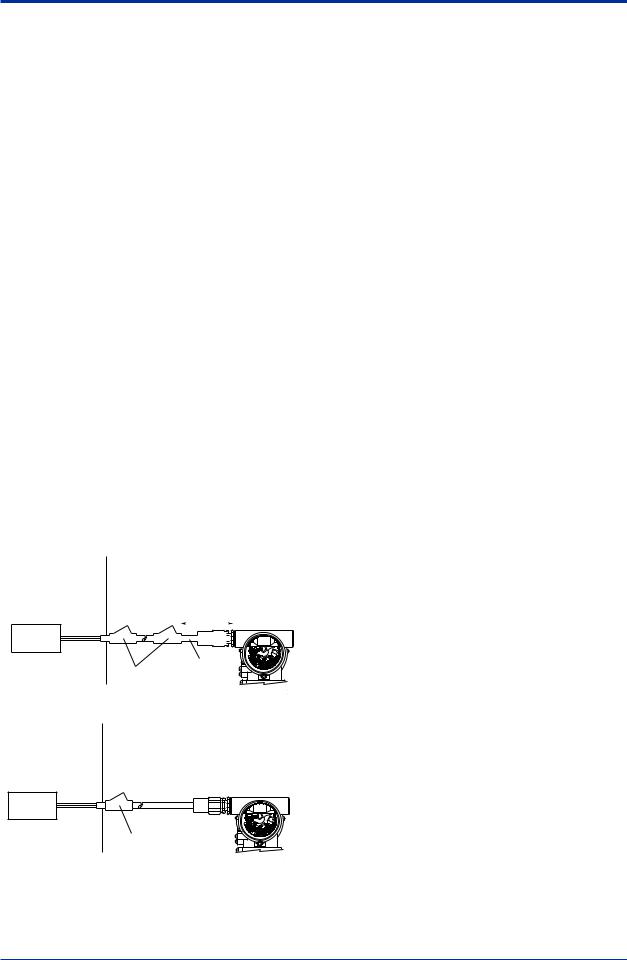

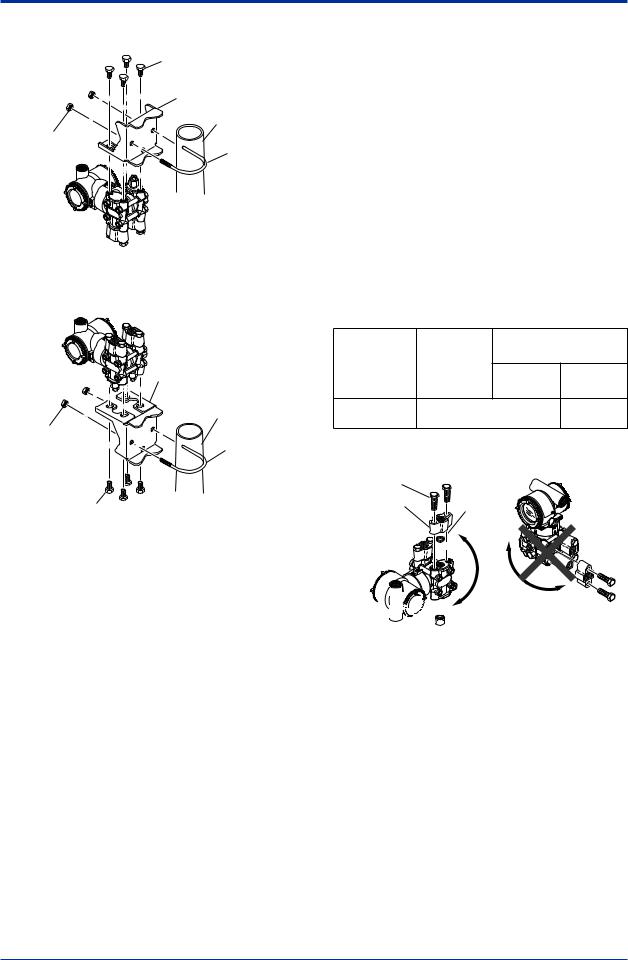

4 . INSTALLATION INSTALLATION 4.1 Precautions Vertical pipe mounting Before installing the transmitter, read the cautionary notes in section 2.4, “Selecting the Installation Loca- tion.” For additional information on the ambient conditions allowed at the installation location, refer to Transmitter subsection 9.1 “Standard Specifications.”…

-

Page 22: Changing The Process Connection

4 . INSTALLATION 4.3 Changing the Process Con- Vertical pipe mounting (Process connector downside) nection Transmitter The transmitter is shipped with the process connection mounting bolt specified at the time of ordering. To change the process connection,the drain (vent) plug must be repositioned. Mounting bracket To reposition a drain (vent) plug, use a wrench to slowly and gently unscrew it.

-

Page 23: Swapping The High/Low-Pressure Side Connection

4 . INSTALLATION 4.4 Swapping the High/Low- 4.4.2 Using the Communicator pressure Side Connection This method is applicable only to the Model EJX110A and EJX130A. With a communicator, you can change which process IMPORTANT connection is used as the high-pressure side without This section is applicable only for EJX110A and mechanically rotating the pressure-detector section 180 EJX130A differential transmitters, and not…

-

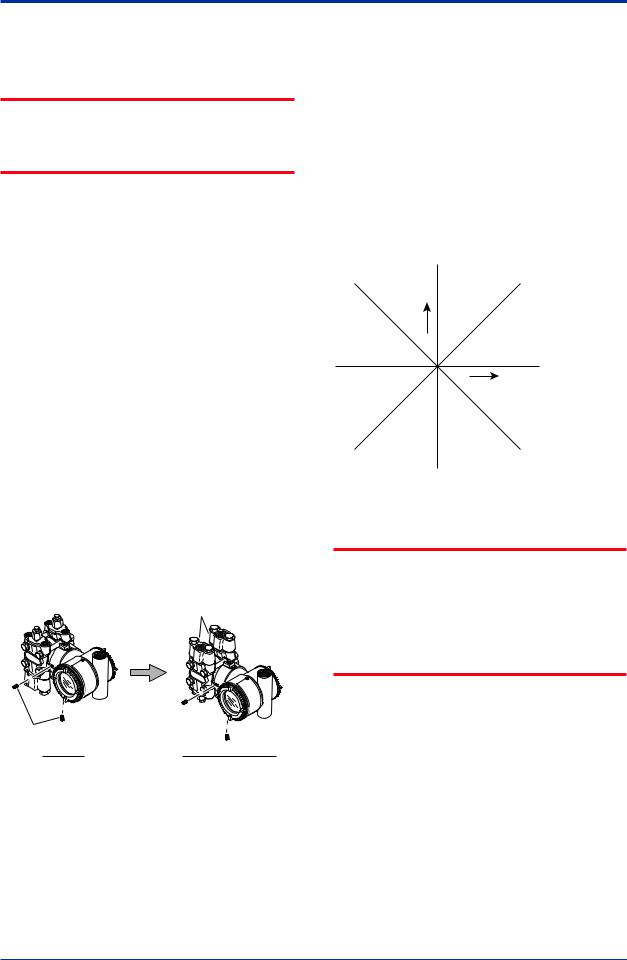

Page 24: Rotating Transmitter Section

4 . INSTALLATION 4.5 Rotating Transmitter Section 4.6 Changing the Direction of Integral Indicator The transmitter section can be rotated approximately 360 (180 to either direction or 360 to one direction from the original position at shipment, depending on IMPORTANT the configuration of the instrument.) It can be fixed at any angle within above range.

-

Page 25: Installing Impulse Piping

5. INSTALLING IMPULSE PIPING INSTALLING IMPULSE PIPING 5.1 Impulse Piping Installation (2) Changing the Process Connector Piping Connections (Figure 4.1) (for differential Precautions pressure transmitters) The impulse piping that connects the process outputs to The impulse piping connection distances can be the transmitter must convey the process pressure changed between 51 mm, 54 mm and 57 mm by accurately.

-

Page 26: Routing The Impulse Piping

5. INSTALLING IMPULSE PIPING 3) Install the pipe assemblies between the 3-valve NOTE manifold and the process connectors and lightly tighten the ball head lock nuts. (The ball-shaped ends of the pipes must be handled carefully, since After completing the connection of the transmit- they will not seal properly if the ball surface is ter and 3-valve manifold, be sure to CLOSE the scratched or otherwise damaged.)

-

Page 27

5. INSTALLING IMPULSE PIPING (2) Position of Process Pressure Taps and (6) Preventing Wind Speed Effects in Very Transmitter Low Differential Pressure Measurement (for differential pressure transmitters) If condensate (or gas) accumulates in the impulse piping, it should be removed periodically by opening the drain (or vent) plugs. -

Page 28: Impulse Piping Connection Examples

5. INSTALLING IMPULSE PIPING 5.2 Impulse Piping Connection Liguid Steam Examples Orifice Condensate pot Figure 5.5 and 5.6 show examples of typical impulse valve piping connections. Before connecting the transmitter to the process, study the transmitter installation Union location, the process piping layout, and the characteris- or flange tics of the process fluid (corrosiveness, toxicity, flammability, etc.), in order to make appropriate…

-

Page 29: Wiring

6. WIRING WIRING 6.1 Wiring Precautions 6.3 Connections of External Wiring to Terminal Box 6.3.1 Power Supply Wiring Connection IMPORTANT Connect the power supply wiring to the SUPPLY + • Lay wiring as far as possible from electrical and – terminals. When /AL is specified, also refer to noise sources such as large capacity transform- subsection 6.3.5.

-

Page 30: Check Meter Connection

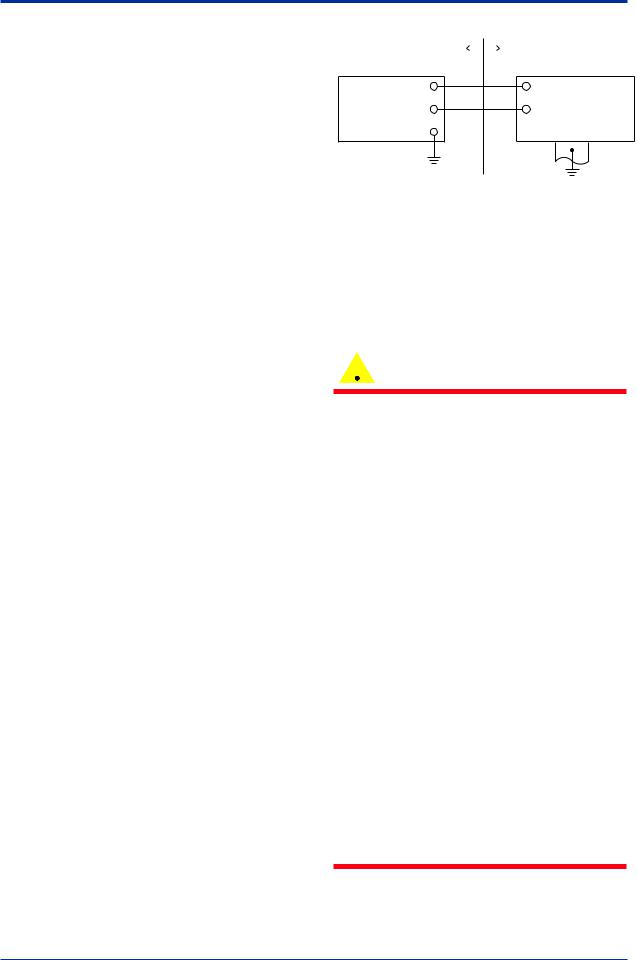

6. WIRING (1) General-use Type and Flameproof Type 6.3.4 Check Meter Connection Available only when /AL is not specified. Hazardous Location Nonhazardous Location Connect the check meter to the CHECK + and – Transmitter terminal box terminals. (Use hooks.) Distributor (Power supply unit) •…

-

Page 31: Flameproof Type

6. WIRING 6.5 Grounding (2) Flameproof Type Wire cables through a flameproof packing adapter, or Grounding is always required for the proper operation use a flameproof metal conduit. of transmitters. Follow the domestic electrical require- Wiring cable through flameproof packing adapter. ments as regulated in each country.

-

Page 32: Operation

7. OPERATION OPERATION 7.1 Preparation for Starting Venting Gas from the Transmitter Pressure- detector Section Operation • Since the piping in the example of figure 7.1 is constructed to be self-venting, no venting operation is This section describes the operation procedure for the required.

-

Page 33: Zero Point Adjustment

7. OPERATION NOTE Vent plug (Fill plug) If any of the above errors are indicated on the display of the integral indicator or the communi- Tap valve cator, refer to subsection 8.5.3 for the corrective action. Stop valve Verify and Change Transmitter Parameter Setting and Values The parameters related to the following items are set at factory as specified in order.

-

Page 34: Adjusting Zero Point For Differential Pressure Transmitters

7. OPERATION (2) When you cannot obtain the Low Range 7.2.1 Adjusting Zero Point for Differential Value from the actual measured value of 0%; Pressure Transmitters Adjust the transmitter output to the actual measured Before adjusting zero point, make sure that the equaliz- value obtained by a digital manometer or a glass ing valve is open.

-

Page 35: Shutting Down The Transmitter

7. OPERATION 7.5.1 Draining Condensate • Tighten the zero-adjustment cover mounting screw to secure the cover. 1) Gradually open the drain screw or drain plug and drain the transmitter pressure-detector section. (See figure 7.5.) 7.4 Shutting Down the Transmitter 2) When all accumulated liquid is completely re- moved, close the drain screw or drain plug.

-

Page 36: Setting The Range Using The Range-Setting Switch

7. OPERATION Note 1: Wait until the pressure inside the pressure-detector section 7.6 Setting the Range Using the has stabilized before proceeding to the next step. Range-setting Switch Note 2: If the pressure applied to the transmitter exceeds the previous LRV (or URV), the integral indicator may display error number “AL.30”…

-

Page 37: Maintenance

8. MAINTENANCE MAINTENANCE 8.1 Overview 8.2 Calibration Instruments Se- lection WARNING Table 8.1 lists the instruments that can be used to calibrate a transmitter. When selecting an instrument, Since the accumulated process fluid may be consider the required accuracy level. Exercise care toxic or otherwise harmful, take appropriate care when handling these instruments to ensure they to avoid contact with the body or inhalation of…

-

Page 38

0.1% or higher level, there may be difficulties in calibration to this level in the field. For calibration to the 0.1% level, contact Yokogawa representatives from which the instrument was purchased or the nearest Yokogawa office. -

Page 39: Disassembly And Reassembly

Phillips screwdriver JIS B4633, No. 2 indicator to a transmitter. If such modification is Slotted screwdriver absolutely required, contact Yokogawa. Allen wrenches JIS B4648 One each, nominal 3, 4 and 2.5 mm Allen wrenches…

-

Page 40: Replacing The Cpu Board Assembly

If the capsule. you wish to replace the capsule assembly with one of a different measurement range, contact Yokogawa. NOTE The user is permitted, however, to replace a Be careful not to apply excessive force to the capsule assembly with another of the same CPU assembly when removing it.

-

Page 41: Replacing The Process Connector Gaskets

8. MAINTENANCE Removing the Capsule Assembly 7) After completing reassembly, adjust the zero point and recheck the parameters. IMPORTANT Transmitter section Exercise care as follows when cleaning the capsule assembly. • Handle the capsule assembly with care, and be especially careful not to damage or distort the diaphragms that contact the process fluid.

-

Page 42: Troubleshooting

Process connector gasket complex causes, these flow charts may not identify all. If you have difficulty isolating or correcting a problem, contact Yokogawa service personnel. 8.5.1 Basic Troubleshooting First determine whether the process variable is actually abnormal or a problem exists in the measurement system.

-

Page 43: Troubleshooting Flowcharts

Fix pressure leaks, paying particular attention to connections for impulse Adjust the zero point. piping,pressure-detector section, etc. Is there Contact Yokogawa service personnel. continuity through the transmitter loop wiring? F0808.EPS Do the loop numbers match? Find/correct broken conductor or wiring error.

-

Page 44

Provide lagging and/or cooling, or allow adequate ventilation. Were appropriate instruments used for calibration? Refer to Section 8.2 when selecting instruments for calibration. Is output adjusted correctly? Adjust the output. Contact Yokogawa service personnel. F0809.EPS IM 01C25B01-01E… -

Page 45: Alarms And Countermeasures

8. MAINTENANCE 8.5.3 Alarms and Countermeasures Table 8.1 Alarm Message Summary Output Operation Indicator Cause Countermeasure during Error None Sensor problem. Outputs the signal (Hold, Replace capsule when error AL. 01 High, or Low) set with keeps appearing even CAP. ERR parameter.

-

Page 46: General Specifications

9. GENERAL SPECIFICATIONS GENERAL SPECIFICATIONS Failure Alarm “ ” 9.1 Standard Specifications Output status at CPU failure and hardware error; Up-scale: 110%, 21.6 mA DC or more (standard) Refer to IM 01C25T02-01E for FOUNDATION Fieldbus Down-scale: –5%, 3.2 mA DC or less communication type marked with “…

-

Page 47

9. GENERAL SPECIFICATIONS EJX130A EJX310A Capsule Pressure 100(750) M, H 32 MPa (4500 psi) M,A and B capsule EJX310A L capsule Capsule Pressure 10(75) 130 kPa abs (38 inHg abs) 3.5 MPa abs (500 psia) 16 MPa abs (2300 psia) 2.7(20) Working Applicable range… -

Page 48

9. GENERAL SPECIFICATIONS Supply & Load Requirements “ ” (Optional features Use the following formula to determine cable length for or approval codes may affect electrical require- specific applications: ments.) With 24 V DC supply, up to a 550 load can be used. See + 10,000) –… -

Page 49

9. GENERAL SPECIFICATIONS Connections Refer to “MODEL AND SUFFIX CODE.” Process Connection of Cover Flange(models except for EJX440A- D) : IEC61518 IM 01C25B01-01E… -

Page 50: Model And Suffix Codes

9. GENERAL SPECIFICATIONS 9.2 MODEL AND SUFFIX CODES MODEL EJX110A Model Suffix Codes Description EJX110A Differential pressure transmitter · · · · · · · · · · · · · · · · · · · · · · · · · Output signal 4 to 20 mA DC with digital communication (BRAIN protocol) -D ·…

-

Page 51

9. GENERAL SPECIFICATIONS MODEL EJX310A Model Suffix Codes Description · · · · · · · · · · · · · · · · · · · · · · · · · Absolute pressure transmitter EJX310A Output Signal -D ·… -

Page 52

9. GENERAL SPECIFICATIONS MODEL EJX430A Model Suffix Codes Description EJX430A Gauge pressure transmitter · · · · · · · · · · · · · · · · · · · · · · · · · Output Signal 4 to 20 mA DC with digital communication (BRAIN protocol) -D ·… -

Page 53

9. GENERAL SPECIFICATIONS MODEL EJX130A Model Suffix Codes Description EJX130A Differential pressure transmitter · · · · · · · · · · · · · · · · · · · · · · · · · Output signal 4 to 20 mA DC with digital communication (BRAIN protocol) -D ·… -

Page 54

9. GENERAL SPECIFICATIONS MODEL EJX440A Model Suffix Codes Description · · · · · · · · · · · · · · · · · · · · · · · · · Absolute pressure transmitter EJX440A Output Signal -D ·… -

Page 55: Optional Specifications

Flameproof [No. IECEx CSA 05.0002] Flameproof for Zone1, Ex d IIC T6…T4 T0912.EPS Contact Yokogawa representative for the codes indicated as ‘-’. *1: Applicable for Electrical connection code 2, 4, 7, and 9. *2: Applicable for Electrical connection code 2 and 7.

-

Page 56

9. GENERAL SPECIFICATIONS Item Description Code Terminal cover only Color change Painting Both sides of amplifier covers, Munsell 7.5 R4/14 Coating change Anti-corrosion coating Transmitter power supply voltage: 10.5 to 32 V DC ( 10.5 to 30 V DC for intrinsically safe type.) Lightning protector Allowable current: Max. -

Page 57

9. GENERAL SPECIFICATIONS Item Description Code Cover flange Material certificate Cover flange, Process connector Test Pressure: 16 MPa(2300 psi) Test Pressure: 25 MPa(3600 psi) Nitrogen(N ) Gas Pressure test/ Test Pressure: 3.5 MPa(500 psi) Leak test certificate Retention time: one minute Test Pressure: 500 kPa(2000 inH Test Pressure: 50 kPa(200 inH Test Pressure: 32 MPa(4500 psi) -

Page 58: Dimensions

9. GENERAL SPECIFICATIONS 9.4 DIMENSIONS Model EJX110A Unit: mm (approx. inch) Vertical Impulse Piping Type (Installation code 7) 245(9.65) 110(4.33) 178(7.01) (0.47) (3.82) (5.08) (1.54) 2-inch pipe (O.D. 60.5 mm) Mounting bracket Vent/drain Electrical connection plugs (L-type, optional) for code 5 and 9. Vent/drain plugs External indicator Conduit connection…

-

Page 59

9. GENERAL SPECIFICATIONS Unit : mm (approx.inch) Bottom Process Connection Type (Installation code B) 95 (3.74) 188 (7.40) External indicator Zero conduit connection (3.11) 110 (4.33) adjustment (optional) (2.13) Conduit (0.23) connection (0.47) (1.54) Electrical connection for code 5 and 9. Mounting Integral bracket… -

Page 60

9. GENERAL SPECIFICATIONS Model EJX130A Vertical Impulse Piping Type (Installation code 7) 120(4.72) 245(9.65) 110(4.33) 178(7.01) (0.47) (3.82) (5.08) 2-inch pipe (1.54) (O.D. 60.5 mm) Mounting bracket Vent/drain Electrical connection (L-type, optional) plugs for code 5 and 9. Vent/drain plugs External indicator Conduit connection (optional) -

Page 61

9. GENERAL SPECIFICATIONS Model EJX430A, EJX310A Unit: mm (approx. inch) Vertical Impulse Piping Type (Installation code 7) 110(4.33) 245(9.65) 178(7.01) (0.47) (1.54) 2-inch pipe (3.82) (5.08) (O.D. 60.5 mm) Mounting bracket Vent/drain plug Electrical connection (L-type, optional) for code 5 and 9. Open to atmosphere Vent/drain plugs External indicator… -

Page 62

9. GENERAL SPECIFICATIONS Bottom Process Connection Type (Installation code B) Unit : mm (approx.inch) 95 (3.74) 188 (7.40) External indicator Zero conduit connection (3.11) 110 (4.33) adjustment (optional) (2.13) Conduit (0.23) connection (0.47) (1.54) Electrical connection for code 5 and 9. Mounting Integral bracket… -

Page 63

9. GENERAL SPECIFICATIONS Model EJX440A Vertical Impulse Piping Type (Installation code 7) 120(4.72) 245(9.65) 110(4.33) 178(7.01) (0.47) (3.82) (5.08) 2-inch pipe (1.54) (O.D. 60.5 mm) Mounting bracket Vent/drain Electrical connection (L-type, optional) plugs for code 5 and 9. Vent/drain plugs External indicator Conduit connection (optional) -

Page 64

9. GENERAL SPECIFICATIONS ● Terminal Wiring ● Terminal Configuration Communication Power supply and output terminal SUPPLY – Check meter terminals (BT200 etc.) connection hook *1*2 External indicator (ammeter) terminal *1*2 connection hook CHECK – Status contact output terminal ALARM – (when /AL is specified) Ground terminal CHECK + or… -

Page 65

REVISION RECORD Title: EJX110A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure Transmitters Manual No.: IM 01C25B01-01E Edition Date Page Revised Item Mar. 2004 — New publication Apr. 2004 — Revise words and phrases. 2.9.3 • Correct Ambient temperature –60 –50 •… -

Page 66

8.4.3 Add table for torque. Add notes for reassembling EJX130A and EJX440A. 8.4.4 Add table for torque. 9-1 through 9-18 Add specifications, codes, and dimensions for EJX130A, EJX310Aand EJX440A. July 2006 2.9.3 Change applicable standards for ATEX type n. IM 01C25B01-01E…

Differential Pressure and

Pressure Transmitters

EJ110, EJ120,

EJ130, EJ310,

EJ430, and EJ440

IM 01C25B01-01E

IM 01C25B01-01E

13th Edition

i

Differential Pressure and Pressure Transmitters

EJ110, EJ120, EJ130,

EJ310, EJ430, and EJ440

|

IM 01C25B01-01E 13th Edition |

||||

|

Contents |

||||

|

1. |

Introduction………………………………………………………………………………….. |

1-1 |

||

|

Regarding This Manual…………………………………………………………………………………… |

1-1 |

|||

|

1.1 |

Safe Use of This Product ……………………………………………………………………… |

1-2 |

||

|

1.2 |

Warranty………………………………………………………………………………………………. |

1-3 |

||

|

1.3 |

ATEX Documentation……………………………………………………………………………. |

1-4 |

||

|

2. |

Handling Cautions………………………………………………………………………… |

2-1 |

||

|

2.1 |

Model and Specifications Check…………………………………………………………… |

2-1 |

||

|

2.2 |

Unpacking……………………………………………………………………………………………. |

2-1 |

||

|

2.3 |

Storage…………………………………………………………………………………………………. |

2-1 |

||

|

2.4 |

Selecting the Installation Location ……………………………………………………….. |

2-2 |

||

|

2.5 |

Pressure Connection……………………………………………………………………………. |

2-2 |

||

|

2.6 |

Waterproofing of Cable Conduit Connections……………………………………….. |

2-2 |

||

|

2.7 |

Restrictions on Use of Radio Transceivers……………………………………………. |

2-2 |

||

|

2.8 |

Insulation Resistance and Dielectric Strength Test……………………………….. |

2-2 |

||

|

2.9 |

Installation of an Explosion-Protected Instrument…………………………………. |

2-3 |

||

|

2.9.1 |

FMApproval…………………………………………………………………………… |

2-4 |

||

|

2.9.2 |

CSACertification.……………………………………………………………………. |

2-6 |

||

|

2.9.3 |

ATEX Certification.………………………………………………………………….. |

2-8 |

||

|

2.9.4 |

IECEx Certification.……………………………………………………………….. |

2-11 |

||

|

2.10 |

EMC Conformity Standards………………………………………………………………… |

2-12 |

||

|

2.11 |

Pressure Equipment Directive (PED)…………………………………………………… |

2-13 |

||

|

2.12 |

Low Voltage Directive…………………………………………………………………………. |

2-13 |

||

|

3. |

Component Names……………………………………………………………………….. |

3-1 |

||

|

4. |

Installation……………………………………………………………………………………. |

4-1 |

||

|

4.1 |

Precautions …………………………………………………………………………………………. |

4-1 |

||

|

4.2 |

Mounting |

……………………………………………………………………………………………… |

4-1 |

|

|

4.3 |

Changing the Process Connection……………………………………………………….. |

4-2 |

||

|

4.4 |

Swapping the High/Low-pressure Side Connection………………………………. |

4-3 |

||

|

4.4.1 |

Rotating Pressure-detector Section 180° …………………………………… |

4-3 |

||

|

4.4.2 |

Using the Communicator………………………………………………………….. |

4-3 |

||

|

4.5 |

Rotating Transmitter Section………………………………………………………………… |

4-4 |

||

|

4.6 |

Changing the Direction of Integral Indicator …………………………………………. |

4-4 |

|

13th Edition: June 2013 (YK) |

IM 01C25B01-01E |

|

All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation |

ii

|

5. |

Installing Impulse Piping……………………………………………………………….. |

5-1 |

||

|

5.1 |

Impulse Piping Installation Precautions………………………………………………… |

5-1 |

||

|

5.1.1 |

Connecting Impulse Piping to a Transmitter.………………………………. |

5-1 |

||

|

5.1.2 |

Routing the Impulse Piping………………………………………………………. |

5-3 |

||

|

5.2 |

Impulse Piping Connection Examples…………………………………………………… |

5-4 |

||

|

6. |

Wiring…………………………………………………………………………………………… |

6-1 |

||

|

6.1 |

Wiring Precautions……………………………………………………………………………….. |

6-1 |

||

|

6.2 |

Selecting the Wiring Materials………………………………………………………………. |

6-1 |

||

|

6.3 |

Connections of External Wiring to Terminal Box……………………………………. |

6-1 |

||

|

6.3.1 |

Power Supply Wiring Connection………………………………………………. |

6-1 |

||

|

6.3.2 |

External Indicator Connection…………………………………………………… |

6-1 |

||

|

6.3.3 |

Communicator Connection……………………………………………………….. |

6-1 |

||

|

6.3.4 |

Check Meter Connection………………………………………………………….. |

6-2 |

||

|

6.3.5 |

Status Output Connection.……………………………………………………….. |

6-2 |

||

|

6.4 |

Wiring…………………………………………………………………………………………………… |

6-2 |

||

|

6.4.1 |

Loop Configuration………………………………………………………………….. |

6-2 |

||

|

6.4.2 |

Wiring Installation.…………………………………………………………………… |

6-2 |

||

|

6.5 |

Grounding……………………………………………………………………………………………. |

6-3 |

||

|

6.6 |

Power Supply Voltage and Load Resistance…………………………………………. |

6-3 |

||

|

7. |

Operation……………………………………………………………………………………… |

7-1 |

||

|

7.1 |

Preparation for Starting Operation………………………………………………………… |

7-1 |

||

|

7.2 |

Zero PointAdjustment………………………………………………………………………….. |

7-2 |

||

|

7.2.1 |

Adjusting Zero Point for Differential Pressure Transmitters…………… |

7-3 |

||

|

7.2.2 |

Adjusting Zero Point for Gauge/Absolute Pressure Transmitters .… |

7-3 |

||

|

7.3 |

Starting Operation………………………………………………………………………………… |

7-3 |

||

|

7.4 |

Shutting Down the Transmitter……………………………………………………………… |

7-4 |

||

|

7.5 |

Venting or Draining Transmitter Pressure-detector Section…………………… |

7-4 |

||

|

7.5.1 |

Draining Condensate……………………………………………………………….. |

7-4 |

||

|

7.5.2 |

Venting Gas……………………………………………………………………………. |

7-5 |

||

|

7.6 |

Setting the Range Using the Range-setting Switch……………………………….. |

7-5 |

||

|

8. |

Maintenance…………………………………………………………………………………. |

8-1 |

||

|

8.1 |

Overview………………………………………………………………………………………………. |

8-1 |

||

|

8.2 |

Calibration Instruments Selection…………………………………………………………. |

8-1 |

||

|

8.3 |

Calibration……………………………………………………………………………………………. |

8-1 |

||

|

8.4 |

Disassembly and Reassembly………………………………………………………………. |

8-3 |

||

|

8.4.1 |

Replacing the Integral Indicator…………………………………………………. |

8-3 |

||

|

8.4.2 |

Replacing the CPU BoardAssembly………………………………………….. |

8-4 |

||

|

8.4.3 |

Cleaning and Replacing the CapsuleAssembly………………………….. |

8-4 |

||

|

8.4.4 |

Replacing the Process Connector Gaskets.……………………………….. |

8-6 |

IM 01C25B01-01E

iii

|

8.5 |

Troubleshooting…………………………………………………………………………………… |

8-6 |

||

|

8.5.1 |

Basic Troubleshooting……………………………………………………………… |

8-6 |

||

|

8.5.2 |

Troubleshooting Flowcharts.…………………………………………………….. |

8-7 |

||

|

8.5.3 |

Alarms and Countermeasures.…………………………………………………. |

8-9 |

||

|

9. |

General Specifications………………………………………………………………….. |

9-1 |

||

|

9.1 |

Standard Specifications……………………………………………………………………….. |

9-1 |

||

|

9.2 |

Model and Suffix Codes………………………………………………………………………… |

9-6 |

||

|

9.3 |

Optional Specifications ………………………………………………………………………. |

9-19 |

||

|

9.4 |

Dimensions………………………………………………………………………………………… |

9-22 |

Revision Information

When using the Transmitters in a Safety Instrumented Systems(SIS) application, refer toAppendixAin either IM 01C25T01-06EN for the HART protocol or IM 01C25T03-01E for the BRAIN protocol.

IM 01C25B01-01E

1.Introduction

Thank you for purchasing the DPharp Differential Pressure and pressure transmitter.

Your transmitter was precisely calibrated at the factory before shipment. To ensure both safety and efficiency, please read this manual carefully before you operate the instrument.

This manual describes the hardware configurations of the transmitters listed in below. For information on the software configuration and operation, please refer to either

IM 01C25T03-01E for the BRAIN communication type, or IM 01C25T01-06EN for the HART communication type.

For FOUNDATION Fieldbus protocol type, please refer to IM 01C25T02-01E.

For PROFIBUS PAprotocol type, please refer to IM 01C25T04-01EN.

|

Model |

Style code |

|

EJX110A |

S3 |

|

EJX120A |

S1 |

|

EJX130A |

S2 |

|

EJX310A |

S2 |

|

EJX430A |

S2 |

|

EJX440A |

S2 |

|

EJA110E |

S1 |

|

EJA120E |

S1 |

|

EJA130E |

S1 |

|

EJA310E |

S1 |

|

EJA430E |

S1 |

|

EJA440E |

S1 |

To ensure correct use of this instrument, read both the hardware and software manuals thoroughly before use.

When using the transmitters in a Safety Instrumented Systems (SIS) application, refer toAppendix 1 in either IM 01C25T01-06EN for the HART protocol or IM 01C25T03-01E for the BRAIN protocol.The instructions and procedures in this section must be strictly followed in order to maintain the transmitter for this safety level.

When describing the model name like EJ110, it shows the applicability for both EJX110Aand EJA110E. The same representations are used for the other models, too.

Unless otherwise stated, the illustrations in this manual are of the EJ110differential pressure transmitter. Users of the other models should bear in mind that certain features of their instrument will differ from those shown in the illustrations of the EJ110.

Regarding This Manual

•This manual should be provided to the end user.

•The contents of this manual are subject to change without prior notice.

•All rights reserved. No part of this manual may be reproduced in any form without Yokogawa’s written permission.

•Yokogawa makes no warranty of any kind with regard to this manual, including, but not limited to, implied warranty of merchantability and fitness for a particular purpose.

•If any question arises or errors are found, or if any information is missing from this manual, please inform the nearest Yokogawa sales office.

•The specifications covered by this manual are limited to those for the standard type under the specified model number break-down and do not cover custom-made instruments.

•Please note that changes in the specifications, construction, or component parts of the instrument may not immediately be reflected in this manual at the time of change, provided that postponement of revisions will not cause difficulty to the user from a functional or performance standpoint.

IM 01C25B01-01E

•Yokogawa assumes no responsibilities for this product except as stated in the warranty.

•If the customer or any third party is harmed by the use of this product, Yokogawa assumes no responsibility for any such harm owing to any defects in the product which were not predictable, or for any indirect damages.

•The following safety symbols are used in this manual:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices.

Indicates that operating the hardware or software in this manner may damage it or lead to system failure.

Draws attention to information essential for understanding the operation and features.

1.1Safe Use of This Product

For the safety of the operator and to protect the instrument and the system, please be sure to follow this manual’s safety instructions when handling this instrument. If these instructions are not heeded, the protection provided by this instrument may be impaired. In this case, Yokogawa cannot guarantee that the instrument can be safely operated. Please pay special attention to the following points:

(a) Installation

•This instrument may only be installed by an engineer or technician who has an expert knowledge of this device. Operators are not allowed to carry out installation unless they meet this condition.

•With high process temperatures, care must be taken not to burn yourself by touching the instrument or its casing.

•Never loosen the process connector nuts when the instrument is installed in a process. This can lead to a sudden, explosive release of process fluids.

•When draining condensate from the pressure detector section, take appropriate precautions to prevent the inhalation of harmful vapors and the contact of toxic process fluids with the skin or eyes.

•When removing the instrument from a hazardous process, avoid contact with the fluid and the interior of the meter.

•All installation shall comply with local installation requirements and the local electrical code.

(b) Wiring

•The instrument must be installed by an engineer or technician who has an expert knowledge of this instrument. Operators are not permitted to carry out wiring unless they meet this condition.

•Before connecting the power cables, please confirm that there is no current flowing through the cables and that the power supply to the instrument is switched off.

IM 01C25B01-01E

(c) Operation

•Wait 5 min. after the power is turned off, before opening the covers.

(d) Maintenance

•Please carry out only the maintenance procedures described in this manual. If you require further assistance, please contact the nearest Yokogawa office.

•Care should be taken to prevent the build up of dust or other materials on the display glass and the name plate. To clean these surfaces, use a soft, dry cloth.

(e) Explosion Protected Type Instrument

•Users of explosion proof instruments should refer first to section 2.9 (Installation of an Explosion Protected Instrument) of this manual.

•The use of this instrument is restricted to those who have received appropriate training in the device.

•Take care not to create sparks when accessing the instrument or peripheral devices in a hazardous location.

(f)Modification

•Yokogawa will not be liable for malfunctions or damage resulting from any modification made to this instrument by the customer.

1.2Warranty

•The warranty shall cover the period noted on the quotation presented to the purchaser at the time of purchase. Problems occurring during the warranty period shall basically be repaired free of charge.

•If any problems are experienced with this instrument, the customer should contact the Yokogawa representative from which this instrument was purchased or the nearest Yokogawa office.

•If a problem arises with this instrument, please inform us of the nature of the problem and the circumstances under which it developed, including the model specification and serial number.Any diagrams, data and other information you can include in your communication will also be helpful.

•The party responsible for the cost of fixing the problem shall be determined by Yokogawa following an investigation conducted by Yokogawa.

•The purchaser shall bear the responsibility for repair costs, even during the warranty period, if the malfunction is due to:

—Improper and/or inadequate maintenance by the purchaser.

—Malfunction or damage due to a failure to handle, use, or store the instrument in accordance with the design specifications.

—Use of the product in question in a location not conforming to the standards specified by Yokogawa, or due to improper maintenance of the installation location.

—Failure or damage due to modification or repair by any party except Yokogawa or an approved representative of Yokogawa.

—Malfunction or damage from improper relocation of the product in question after delivery.

—Reason of force majeure such as fires, earthquakes, storms/floods, thunder/ lightening, or other natural disasters, or disturbances, riots, warfare, or radioactive contamination.

IM 01C25B01-01E

1.3ATEX Documentation

This is only applicable to the countries in European Union.

CZ

DK

EST

NL

PL

SF

SLO

P

H

F

BG

D

RO

S

M

GR

IM 01C25B01-01E

|

<2. Handling Cautions> |

2-1 |

2.Handling Cautions

This chapter provides important information on how to handle the transmitter. Read this carefully before using the transmitter.

The transmitters are thoroughly tested at the factory before shipment. When taking delivery of an instrument, visually check them to make sure that no damage occurred during shipment.

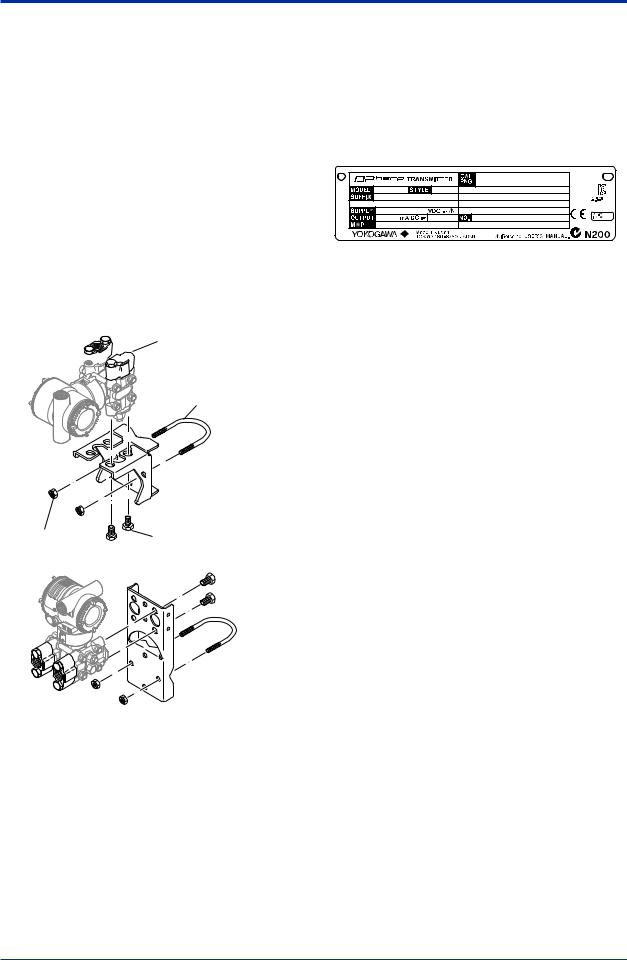

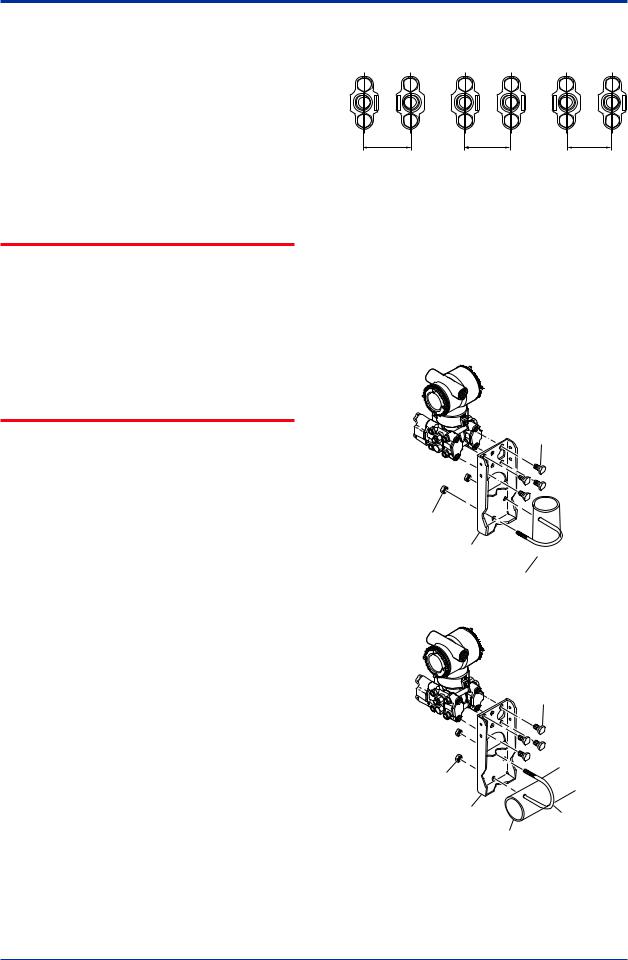

Also check that all transmitter mounting hardware shown in figure 2.1 is included. If the transmitter is ordered without the mounting bracket and the process connector, the transmitter mounting hardware will not be included.After checking the transmitter, carefully repack it in its box and keep it there until you are ready to install it.

Bolt

Gasket

U-bolt

|

U-bolt nut |

Transmitter mounting bolt |

F0201.ai

Figure 2.1 Transmitter Mounting Hardware

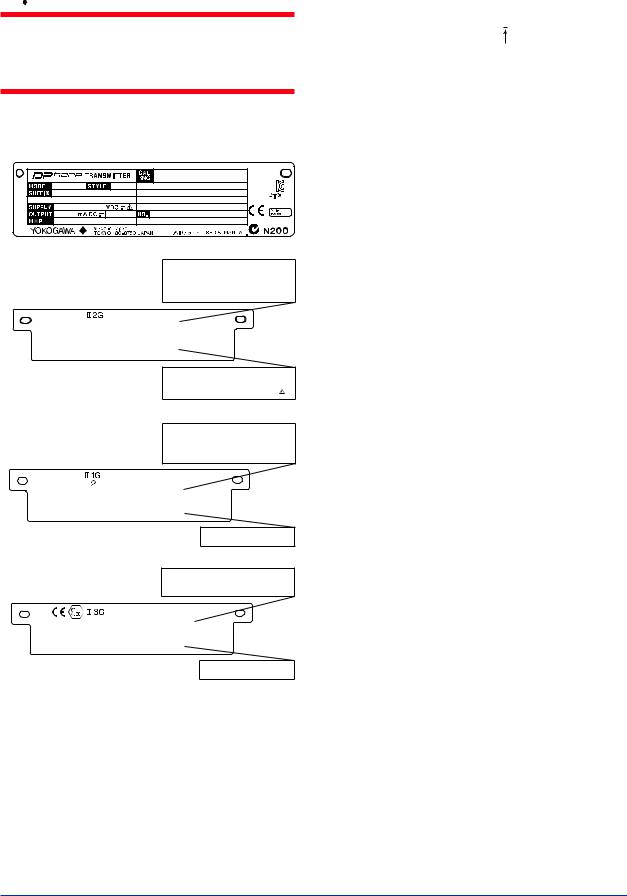

2.1Model and Specifications Check

The model name and specifications are written on the name plate attached to the case.

F0202.ai

Figure 2.2 Name Plate (EJX110A)

2.2Unpacking

Keep the transmitter in its original packaging to prevent it from being damaged during shipment. Do not unpack the transmitter until it reaches the installation site.

2.3Storage

The following precautions must be observed when storing the instrument, especially for a long period.

(a)Select a storage area which meets the following conditions:

•It is not exposed to rain or subject to water seepage/leaks.

•Vibration and shock are kept to a minimum.

•It has an ambient temperature and relative humidity within the following ranges.

Ambient temperature:

–40* to 85°C without integral indicator

–30* to 80°C with integral indicator

* –15°C when /HE is specified.

Relative humidity: 0% to 100% R.H.

Preferred temperature and humidity: approx. 25°C and 65% R.H.

(b)When storing the transmitter, repack it carefully in the packaging that it was originally shipped with.

(c)If the transmitter has been used, thoroughly clean the chambers inside the cover flanges, so that there is no process fluid remaining inside. Before placing it in storage, also make sure that the pressure-detector is securely connected to the transmitter section.

IM 01C25B01-01E

|

<2. Handling Cautions> |

2-2 |

2.4Selecting the Installation Location

The transmitter is designed to withstand severe environmental conditions. However, to ensure that it will provide years of stable and accurate performance, take the following precautions when selecting the installation location.

(a)Ambient Temperature

Avoid locations subject to wide temperature variations or a significant temperature gradient. If the location is exposed to radiant heat from plant equipment, provide adequate thermal insulation and/or ventilation.

(b)AmbientAtmosphere

Do not install the transmitter in a corrosive atmosphere. If this cannot be avoided, there must be adequate ventilation as well as measures to prevent the leaking of rain water and the presence of standing water in the conduits.

(c)Shock and Vibration

Although the transmitter is designed to be relatively resistant to shock and vibration, an installation site should be selected where this is kept to a minimum.

(d)Installation of Explosion-protected Transmitters An explosion-protected transmitters is certified for installation in a hazardous area containing specific gas types. See subsection 2.9 “Installation of an Explosion-Protected Transmitters.”

2.5Pressure Connection

•Never loosen the process connector bolts when an instrument is installed in a process. The device is under pressure, and a loss of seal can result in a sudden and uncontrolled release of process fluid.

•When draining toxic process fluids that have condensed inside the pressure detector, take appropriate steps to prevent the contact of such fluids with the skin or eyes and the inhalation of vapors from these fluids.

The following precautions must be observed in order to safely operate the transmitter under pressure.

(a)Make sure that all the process connector bolts are tightened firmly.

(b)Make sure that there are no leaks in the impulse piping.

(c)Never apply a pressure higher than the specified maximum working pressure.

2.6Waterproofing of Cable Conduit Connections

Apply a non-hardening sealant to the threads to waterproof the transmitter cable conduit connections. (See figure 6.8, 6.9 and 6.10.)

2.7Restrictions on Use of Radio Transceivers

Although the transmitter has been designed to resist high frequency electrical noise, if a radio transceiver is used near the transmitter or its external wiring, the transmitter may be affected by high frequency noise pickup. To test this, start out from a distance of several meters and slowly approach the transmitter with the transceiver while observing the measurement loop for noise effects. Thereafter use the transceiver outside the range where the noise effects were first observed.

2.8Insulation Resistance and Dielectric Strength Test

Since the transmitter has undergone insulation resistance and dielectric strength tests at the factory before shipment, normally these tests are not required. If the need arises to conduct these tests, heed the following:

(a)Do not perform such tests more frequently than is absolutely necessary. Even test voltages that do not cause visible damage to the insulation may degrade the insulation and reduce safety margins.

IM 01C25B01-01E

|

<2. Handling Cautions> |

2-3 |

(b)Never apply a voltage exceeding 500 V DC (100 V DC with an internal lightning protector) for the insulation resistance test, nor a voltage exceeding 500 VAC (100 VAC with an internal lightning protector) for the dielectric strength test.

(c)Before conducting these tests, disconnect all signal lines from the transmitter terminals. The procedure for conducting these tests is as follows:

•Insulation Resistance Test

1)Short-circuit the + and – SUPPLY terminals in the terminal box.

2)Turn OFF the insulation tester. Then connect the insulation tester plus (+) lead wire to the shorted SUPPLY terminals and the minus (–) leadwire to the grounding terminal.

3)Turn ON the insulation tester power and measure the insulation resistance. The voltage should be applied as briefly as possible to verify that the insulation resistance is at least 20 MΩ.

4)After completing the test and being very careful not to touch exposed conductors disconnect the insulation tester and connect a 100 kΩ resistor between the grounding terminal and the shortcircuiting SUPPLY terminals. Leave this resistor connected at least one second to discharge any static potential. Do not touch the terminals while it is discharging.

•Dielectric Strength Test

1)Short-circuit the + and – SUPPLY terminals in the terminal box.

2)Turn OFF the dielectric strength tester. Then connect the tester between the shorted SUPPLY terminals and the grounding terminal. Be sure to connect the grounding lead of the dielectric strength tester to the ground terminal.

3)Set the current limit on the dielectric strength tester to 10 mA, then turn ON the power and gradually increase the test voltage from ‘0’to the specified voltage.

4)When the specified voltage is reached, hold it for one minute.

5)After completing this test, slowly decrease the voltage to avoid any voltage surges.

2.9Installation of an ExplosionProtected Instrument

For FOUNDATION Fieldbus explosion protected type, please refer to IM 01C22T02-01E.

For PROFIBUS PAexplosion protected type, please refer to IM 01C25T04-01EN.

If a customer makes a repair or modification to an intrinsically safe or explosionproof instrument and the instrument is not restored to its original condition, its intrinsically safe or explosionproof construction may be compromised and the instrument may be hazardous to operate. Please contact Yokogawa before making any repair or modification to an instrument.

This instrument has been tested and certified as being intrinsically safe or explosionproof. Please note that severe restrictions apply to this instrument’s construction, installation, external wiring, maintenance and repair.Afailure to abide by these restrictions could make the instrument a hazard to operate.

Maintaining the safety of explosionproof equipment requires great care during mounting, wiring, and piping. Safety requirements also place restrictions on maintenance and repair. Please read the following sections very carefully.

The range setting switch must not be used in a hazardous area.

IM 01C25B01-01E

|

<2. Handling Cautions> |

2-4 |

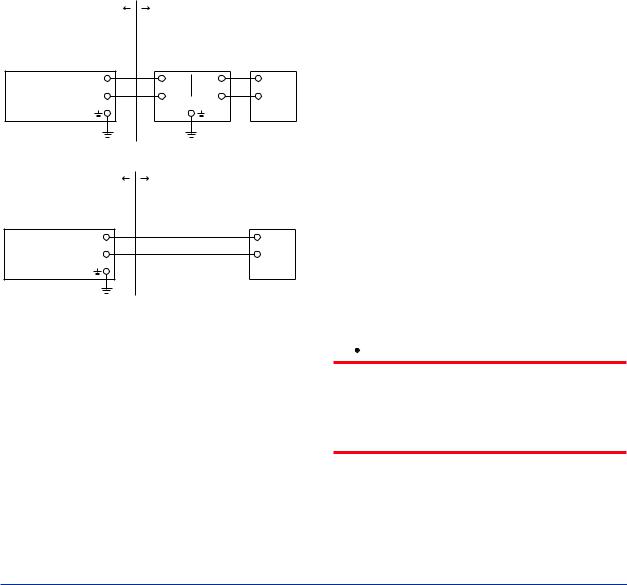

For combined approval types

Once a device of multiple approval type is installed, it should not be re-installed using any other approval types.Apply a permanent mark in the check box of the selected approval type on the certification label on the transmitter to distinguish it from unused approval types.

All the blind plugs which accompany the EJX/ EJA-E transmitters upon shipment from the factory are certified by the applicable agency in combination with those transmitters. The plugs which are marked with the symbols “◊ Ex” on their surfaces are certified only in combination with the EJX/EJA-E series transmitters.

2.9.1 FMApproval

a.FM Intrinsically Safe Type

Caution for FM intrinsically safe type. (Following contents refer “DOC. No. IFM022-A12”)

Note 1. Model EJX/EJA-E Series Differential, gauge and absolute pressure transmitters with optional code /FS1 are applicable for use in hazardous locations.

•Applicable Standard: FM3600, FM3610, FM3611, FM3810

•Intrinsically Safe for Class I, Division 1, GroupsA, B, C & D. Class II, Division 1, Groups E, F & G and Class III, Division 1, Class I, Zone 0 in Hazardous Locations,AEx ia IIC

•Nonincendive for Class I, Division 2, Groups A, B, C & D. Class II, Division 2, Groups F & G, Class I, Zone 2, Groups IIC, in Hazardous Locations.

•Outdoor hazardous locations, NEMATYPE 4X.

•Temperature Class: T4

•Ambient temperature: –60 to 60°C

Note 2. Entity Parameters

•Intrinsically SafeApparatus Parameters [GroupsA, B, C, D, E, F and G]

|

Vmax = 30 V |

Ci = 6 nF |

|

Imax = 200 mA |

Li = 0 µH |

|

Pmax = 1 W |

*AssociatedApparatus Parameters (FM approved barriers)

|

Voc ≤ 30 V |

Ca > 6 nF |

|

Isc ≤ 200 mA |

La > 0 µH |

|

Pmax ≤ 1W |

•Intrinsically SafeApparatus Parameters [Groups C, D, E, F and G]

|

Vmax = 30 V |

Ci = 6 nF |

|

Imax = 225 mA |

Li = 0 µH |

|

Pmax = 1 W |

*AssociatedApparatus Parameters (FM approved barriers)

|

Voc ≤ 30 V |

Ca > 6 nF |

|

Isc ≤ 225 mA |

La > 0 µH |

|

Pmax ≤ 1 W |

•Entity Installation Requirements

Vmax ≥ Voc or Uo or Vt, Imax ≥ Isc or Io or It, Pmax (or Po) ≤ Pi, Ca or Co ≥ Ci + Ccable, La or Lo ≥ Li + Lcable

Note 3. Installation

•Barrier must be installed in an enclosure that meets the requirements ofANSI/ISAS82.01.

•Control equipment connected to barrier must not use or generate more than 250 V rms or V dc.

•Installation should be in accordance with ANSI/ISARP12.6 “Installation of Intrinsically Safe Systems for Hazardous (Classified) Locations” and the National Electric Code (ANSI/NFPA70).

•The configuration of associated apparatus must be FMRCApproved.

•Dust-tight conduit seal must be used when installed in a Class II, III, Group E, F and G environments.

•Associated apparatus manufacturer’s installation drawing must be followed when installing this apparatus.

•The maximum power delivered from the barrier must not exceed 1 W.

•Note a warning label worded “SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY,” and “INSTALL INACCORDANCE WITH DOC. No. IFM022A12”

IM 01C25B01-01E

|

<2. Handling Cautions> |

2-5 |

Note 4. Maintenance and Repair

•The instrument modification or parts replacement by other than authorized representative of Yokogawa Electric Corporation is prohibited and will void Factory Mutual Intrinsically safe and NonincendiveApproval.

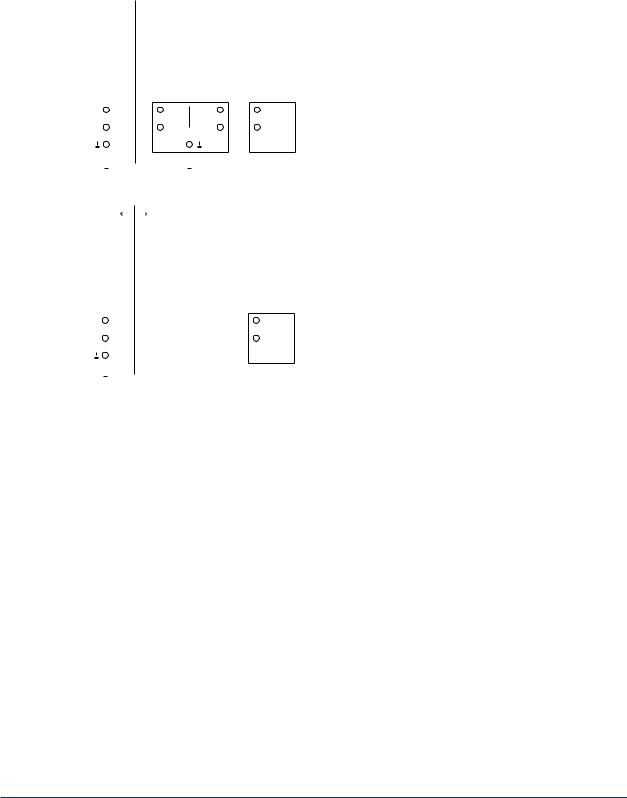

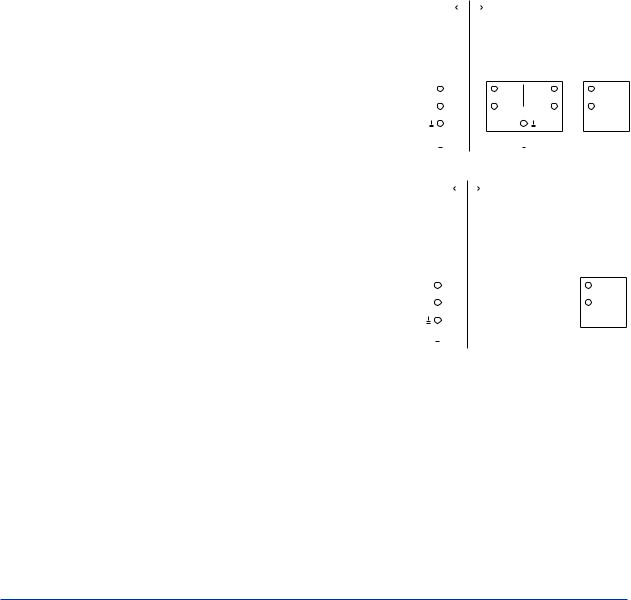

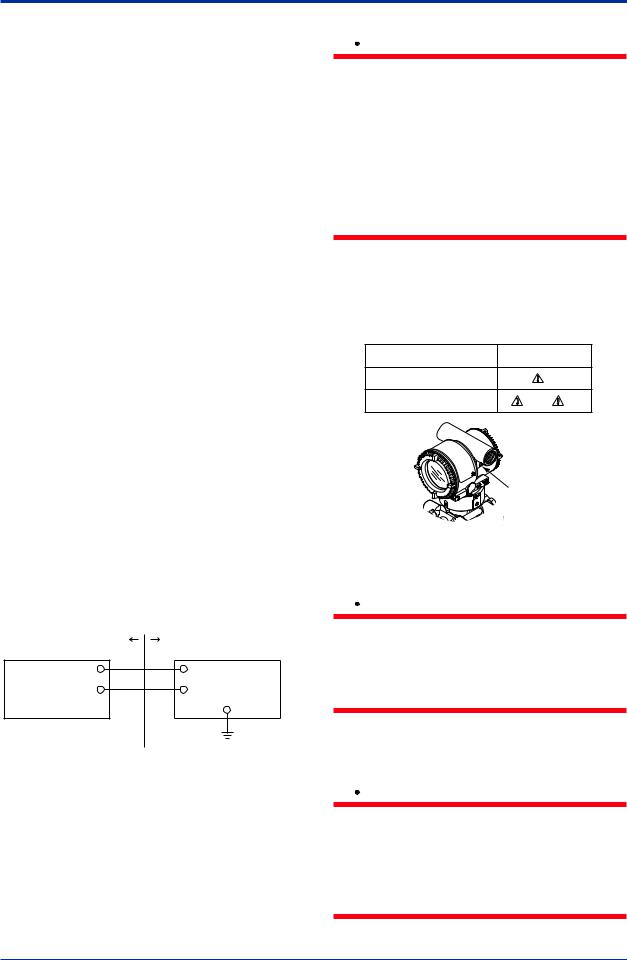

[Intrinsically Safe]

Hazardous Location

|

Class I, II, III, Division 1, |

||||||||||||||||||||

|

Groups A, B, C, D, E, F, G |

||||||||||||||||||||

|

Class 1, Zone 0 in |

||||||||||||||||||||

|

Hazardous (Classified) |

General |

|||||||||||||||||||

|

Locations AEx ia IIC |

||||||||||||||||||||

|

Purpose |

||||||||||||||||||||

|

Pressure Transmitters |

Safety Barrier |

Equipment |

||||||||||||||||||

|

+ |

+ |

+ |

+ |

|||||||||||||||||

|

Supply |

– |

– |

– |

– |

||||||||||||||||

|

F0203-1.ai |

||||||||||||||||||||

|

[Nonincendive] |

||||||||||||||||||||

|

Hazardous Location |

Nonhazardous Location |

|||||||||||||||||||

|

Class I, II, Division 2, |

||||||||||||||||||||

|

Groups A, B, C, D, F, G |

||||||||||||||||||||

|

Class 1, Zone 2, Group IIC, |

||||||||||||||||||||

|

in Hazardous (Classified) |

General |

|||||||||||||||||||

|

Locations |

||||||||||||||||||||

|

Purpose |

||||||||||||||||||||

|

Pressure Transmitters |

Equipment |

|||||||||||||||||||

|

Supply |

+ |

+ |

||||||||||||||||||

|

– |

– |

|||||||||||||||||||

|

Not Use |

||||||||||||||||||||

|

Safety Barrier |

F0203-2.ai |

|||||||||||||||||||

b. FM Explosionproof Type

Caution for FM explosionproof type.

Note 1. Model EJX/EJA-E Series pressure transmitters with optional code /FF1 are applicable for use in hazardous locations.

•Applicable Standard: FM3600, FM3615, FM3810,ANSI/NEMA250

•Explosionproof for Class I, Division 1, Groups B, C and D.

•Dust-ignitionproof for Class II/III, Division 1, Groups E, F and G.

•Enclosure rating: NEMATYPE 4X.

•Temperature Class: T6

•Ambient Temperature: –40 to 60°C

•Supply Voltage: 42 V dc max.