Примечание: большая часть софта скачивается напрямую с сервера производителя, поэтому система не может определить размер файла и в колонке «размер» может стоять ‘0’

| Тип | Документ | Язык | Категория | Размер | Дата |

|---|---|---|---|---|---|

Программируемые контроллеры серий DVP / AX-3 / AS, панели оператора серий DOP, TP |

RU | Рекламные материалы | 38.99Mb | 08.09.2023 | |

ISPSoft v3.17 (ПО для контроллеров AS/AH/DVP. Совместимо с Windows® XP/Vista/7 (32-bit/64-bit)/8/10(64-bit) |

EN | Программное обеспечение | 0Mb | 16.05.2023 | |

COMMGR v.1.14 — integrated communication management software (Windows® XP/7(32-bit/64-bit)/8/10 (64-bit) |

EN | Программное обеспечение | 0Mb | 18.02.2022 | |

WPLSoft v2.51 (ПО для контроллеров DVP. Совместимо с Windows® XP/Vista/7(32-bit/64-bit)/8/10(64-bit) |

EN | Программное обеспечение | 0Mb | 30.11.2021 | |

Примеры программ для контроллеров DVP |

EN | Программное обеспечение | 52.77Mb | 16.06.2021 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP» |

RU | Рекламные материалы | 27.08Mb | 09.06.2021 | |

Инструкция по совместному использованию симуляторов панелей оператора Delta DOP-100 и контроллеров Delta AS/DVP/AH |

RU | Руководства пользователя | 2.97Mb | 16.11.2020 | |

Сертификат соответствия EAC на ПЛК серий AS/AH/DVP 24В (2020-2025) |

RU | Сертификаты | 1.56Mb | 20.10.2020 | |

Примеры программ для ПЛК DVP и панелей оператора DOP-100 |

EN | Программное обеспечение | 56.81Mb | 05.10.2020 | |

Руководство по программированию DVP-ES2/EX2/SS2/SA2/SX2/SE & TP04P |

EN | Руководства пользователя | 11.5Mb | 15.09.2020 | |

Каталог по ПЛК Delta |

EN | Рекламные материалы | 6Mb | 13.08.2020 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP |

RU | Рекламные материалы | 38.79Mb | 12.08.2020 | |

Свидетельство об утверждении типа средств измерения DVP |

RU | Сертификаты | 0.94Mb | 30.07.2020 | |

Сертификат соответствия EAC на ПЛК серий AS/AH/DVP (2019-2024) |

RU | Сертификаты | 2.14Mb | 21.01.2020 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP» |

RU | Рекламные материалы | 24Mb | 19.03.2019 |

Перейти к контенту

Примечание: большая часть софта скачивается напрямую с сервера производителя, поэтому система не может определить размер файла и в колонке «размер» может стоять ‘0’

Категория файлов:

| Тип | Документ | Язык | Категория | Размер | Дата |

|---|---|---|---|---|---|

ISPSoft v3.16 (ПО для контроллеров AS/AH/DVP. Совместимо с Windows® XP/Vista/7 (32-bit/64-bit)/8/10(64-bit) |

EN | Программное обеспечение | 0Mb | 30.06.2022 | |

COMMGR v.1.14 — integrated communication management software (Windows® XP/7(32-bit/64-bit)/8/10 (64-bit) |

EN | Программное обеспечение | 0Mb | 18.02.2022 | |

WPLSoft v2.51 (ПО для контроллеров DVP. Совместимо с Windows® XP/Vista/7(32-bit/64-bit)/8/10(64-bit) |

EN | Программное обеспечение | 0Mb | 30.11.2021 | |

Примеры программ для контроллеров DVP |

EN | Программное обеспечение | 52,77Mb | 16.06.2021 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP» |

RU | Рекламные материалы | 27,08Mb | 09.06.2021 | |

Инструкция по совместному использованию симуляторов панелей оператора Delta DOP-100 и контроллеров Delta AS/DVP/AH |

RU | Руководства пользователя | 2,97Mb | 16.11.2020 | |

Сертификат соответствия EAC на ПЛК серий AS/AH/DVP 24В (2020-2025) |

RU | Сертификаты | 1,56Mb | 20.10.2020 | |

Примеры программ для ПЛК DVP и панелей оператора DOP-100 |

EN | Программное обеспечение | 56,81Mb | 05.10.2020 | |

Руководство по программированию DVP-ES2/EX2/SS2/SA2/SX2/SE & TP04P |

EN | Руководства пользователя | 11,5Mb | 15.09.2020 | |

Каталог по ПЛК Delta |

EN | Рекламные материалы | 6Mb | 13.08.2020 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP |

RU | Рекламные материалы | 38,79Mb | 12.08.2020 | |

Свидетельство об утверждении типа средств измерения DVP |

RU | Сертификаты | 0,94Mb | 30.07.2020 | |

Сертификат соответствия EAC на ПЛК серий AS/AH/DVP (2019-2024) |

RU | Сертификаты | 2,14Mb | 21.01.2020 | |

Каталог «Программируемые контроллеры серий DVP/AH/AS и панели оператора DOP/TP» |

RU | Рекламные материалы | 24Mb | 19.03.2019 | |

Инструкция по программированию контроллеров DVP [Внимание! Версия 2013 г., сверяйтесь с последней версией на англ. языке] |

RU | Руководства пользователя | 11,78Mb | 04.12.2018 |

14 точек дискретного ввода/вывода (8DI + 6DO)

Шина расширения до 480 вх/вых

Выгодная цена

ModBUS COMx2, RS-232 / RS-485

Высокоскоростные входы, < 20 кГц

- ЦПУ: 14 точек дискретного ввода/вывода (8DI + 6DO).

- Расширение до 480 вх/вых.

- Память: программа – 8 К шагов, регистры данных – 5 К слов.

- Время обработки инструкций: базовая – 0,35…1 мкс, прикладная (MOV) – 3,4 мкс.

- Два COM-порта: RS-232, RS-485 (Modbus, ASCII / RTU).

- 4 высокоскоростных импульсных выхода: 10 кГц.

- 8 каналов высокоскоростного счета и внешних прерываний: 4 входа по 20 кГц и 4 выхода по 10 кГц.

- Бесплатное ПО.

| Артикул | DVP14SS211R | DVP14SS211T |

|---|---|---|

| Напряжение питания | =24 В (-15%, +20%), с защитой от переполюсовки | |

| Потребляемая мощность | 1,8 Вт | |

| Входы | ||

| Тип входа | PNP или NPN | |

| Потребляемый ток | 5 мА при =24 В | |

| Время фильтрации | 10 мс (регулируется в диапазоне 0-20 мс, регистр D1020) | |

| Выходы | Реле | Транзистор |

| Максимальный ток | 1,5 А / 1 точка (5 А общий) | 0,5 А / 1 точка (3 А общий) |

| Рабочее напряжение | ~250 В, < =30 В | =5…30 В |

| Максимальная нагрузка (индуктивная) | см. руководство по эксплуатации | 15 Вт (=30 В) |

| Время реакции | около 10 мс | выкл. – вкл. (Y0-Y3) 20 мкс, (Y4, Y5) 100 мкс вкл. – выкл. (Y0-Y3) 30 мкс, (Y4, Y5) 100 мкс |

Hello everyone!

In some previous posts plc247.com wrote an article to guide you to use PLC Delta DVP14SS2 to control Servo Motor Yaskawa Sigma 7 & Mitsubishi MR-J4-A.

- Mitsubishi FX3U ” Stepping Motor” Control Tutorial

Today plc247.com will continue to guide you to use the Delta PLC to control the stepper motor using Driver DM542, this is a very popular driver used all over the world because of its extremely cheap price but good quality.

Delta DVP-14SS2 & DM542 Driver “Wiring Diagram”

Note: Most Step Controllers can only control = 5V signal. With DM542 Driver we can control from 5 > 24 V

+ R= 2K2Ω: Reduce voltage from 24VDC to 5VDC

+ DM542 Setting 1000PLS = 1 Rev.

PLC Delta Programming

+ Simple program to control Stepping Motor

Project Video Example

======

Required Software

- Download PLC Delta Programming Software

Please share the article to the community if you find it useful. Subscribe to Youtube channel and Website to read new articles from plc247.com

Thanks and Best Regards!

You may also like

About the author

plc247.com

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ООО НПК «Промпривод » 150008, г. Ярославль, пр. Машиностроителей, д. 83. ПОКАЗАТЬ СХЕМУ ПРОЕЗДА Червячный редуктор, цилиндрический редуктор, мотор редуктор от ведущего поставщика редукторов. Создание и продвижение сайтов в Ярославле. «Perspektiva» |

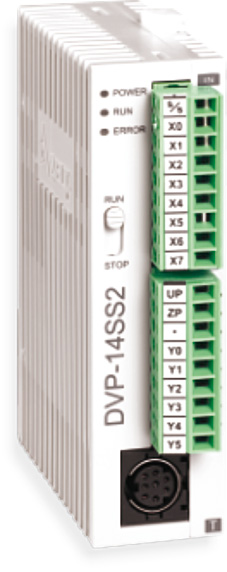

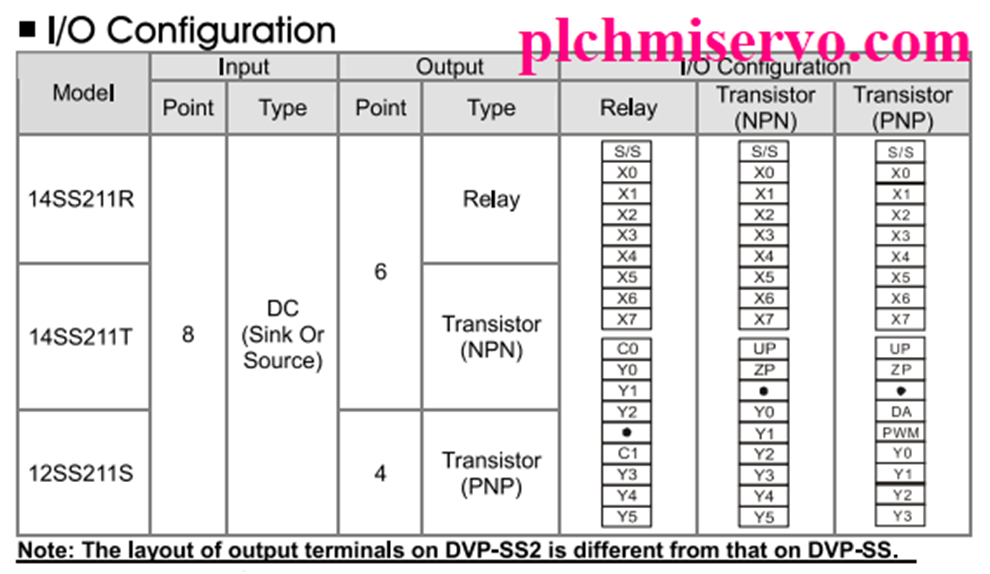

The Delta DVP SS2-S is the slim type Second Generation Programmable Logic Controller (PLC) of Delta Electronics. The DVP SS2 Programmable Logic Controller (PLC) Includes 0ne 12-point Programmable Logic Controller (PLC) and two 14-point Programmable Logic Controller (PLC). A DVP SS2 Series Programmable Logic Controller (PLC) provides various types of instructions, Small Sizes, and Program Capacity is 8k Steps. However, Today plchmiservo.com would like to share the [Download] 14SS2 Manual Delta PLC Programming Manual also how to download the manual.

DVP SS2 Series Programmable Logic Controller (PLC) is able to connect all DVP-S Series Extension Modules, Including Digital Input Output Module (Maximum 480 I/O Points), Analog Input Module AD, Analog Output Module DA, Temperature Module PT, and TC. DVP SS2 Series Programmable Logic Controller (PLC) Supports 08 Extension Modules. DVP SS2 Series Programmable Logic Controller has 04 groups of High Speed (10KHZ) Pulse Output.

User Can Easily Install the PLC, Also User Does not has to install any batteries in the delta DVP SS2 Series Programmable Logic Controller (PLC). DVP SS2 Series (PLC) Program and Latched data stored in the Flash Memory. DVP SS2 Series Programmable Logic Controller used for Small projects and medium projects, also used in various types of Factories. Today plchmiservo.com would like to share the Manual Delta DVP SS2 Series User Manual and Delta PLC Programming Example Manual with you.

Specification of the Delta DVP14-SS2-S PLC

+Power Supply Voltage: 24V DC (-15% ~ 20 %) With counter connection Protection on the DC Input Power.

+Digital Input Number: 8 Points X0, X1…..X7

+Digital Output Number: 6 points Y0, Y1…Y6

+Input Type: DC (Sink or Source)

+Communication Port: Two Communication Port COM1 RS232 and COM2 RS485 MODBUS ASCII/RTU Mode.

Note That: The Power is connected to Two terminals 24C DC and 0V, the range of power (20.4 V DC to 28.8 V DC). If the Power input Voltage is Less than 20.4 V DC, the Programmable Logic Controller (PLC) will stop running; all outputs will be off, also Error Indicator Blinking Continuously.

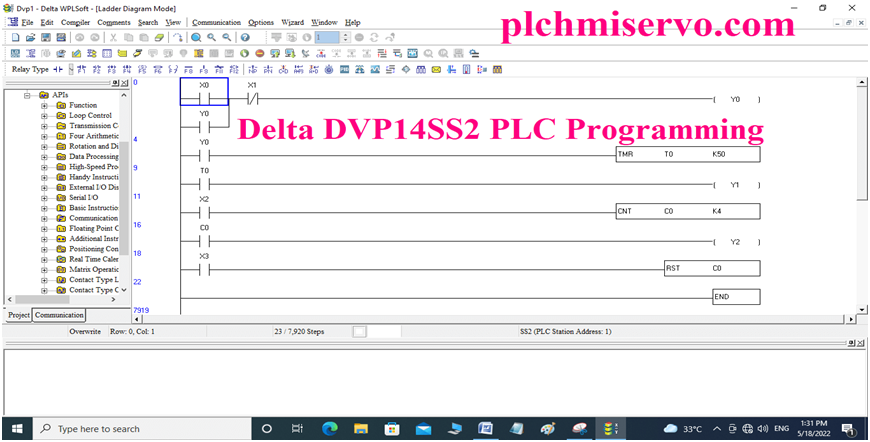

Program of the Delta DVP14SS2-S PLC

+Step 01: At First Download the Software from our Website then Extract it and Install then Open the Software WPLSoft V2.51, or Others Version then click on File then click on New and Select the Model then click OK and Edit the Program

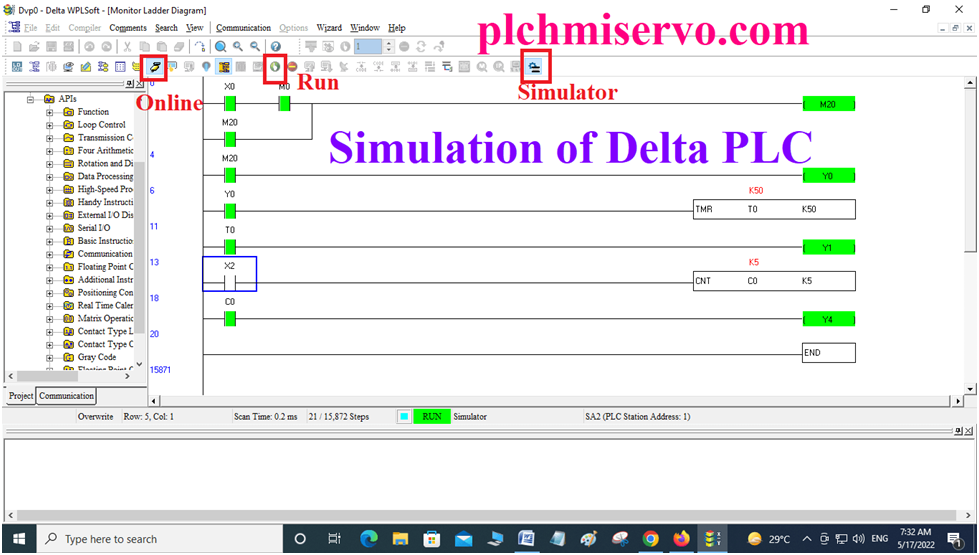

+ Step 2: After Programming the PLC DVP14SS2-S then Simulation the program, So Click on Simulator Click on Online, and click on Run.

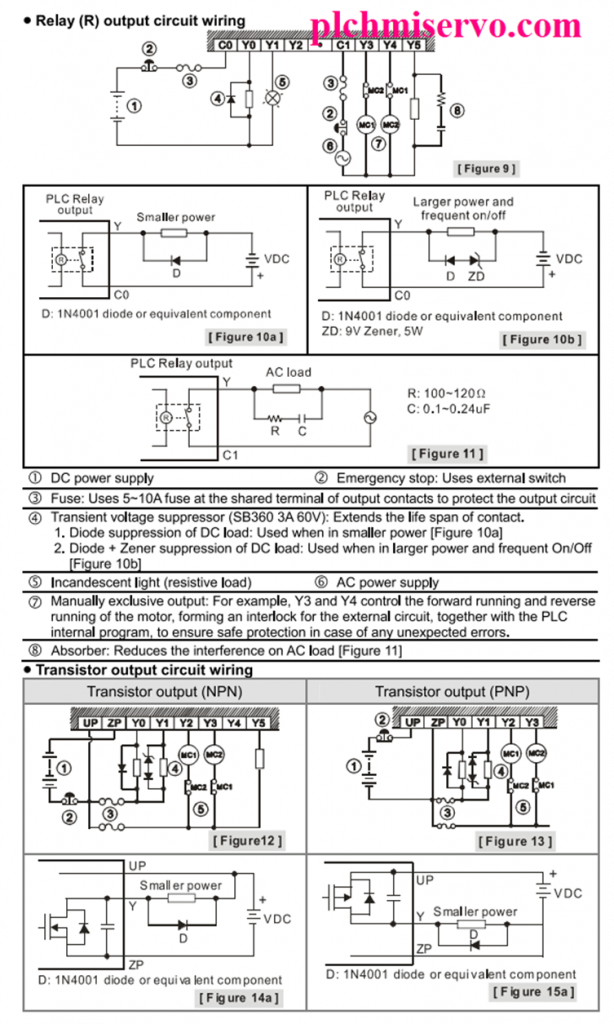

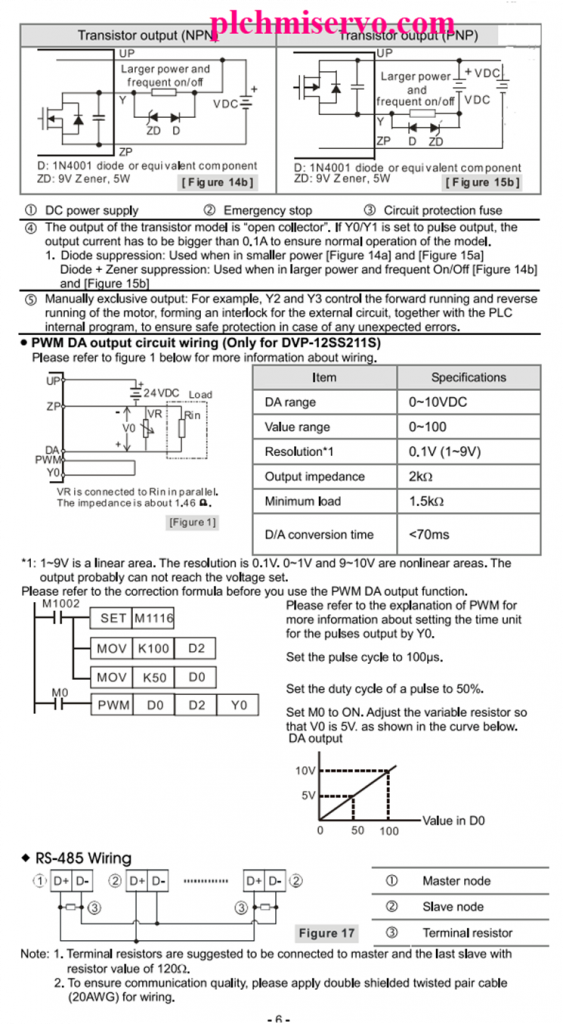

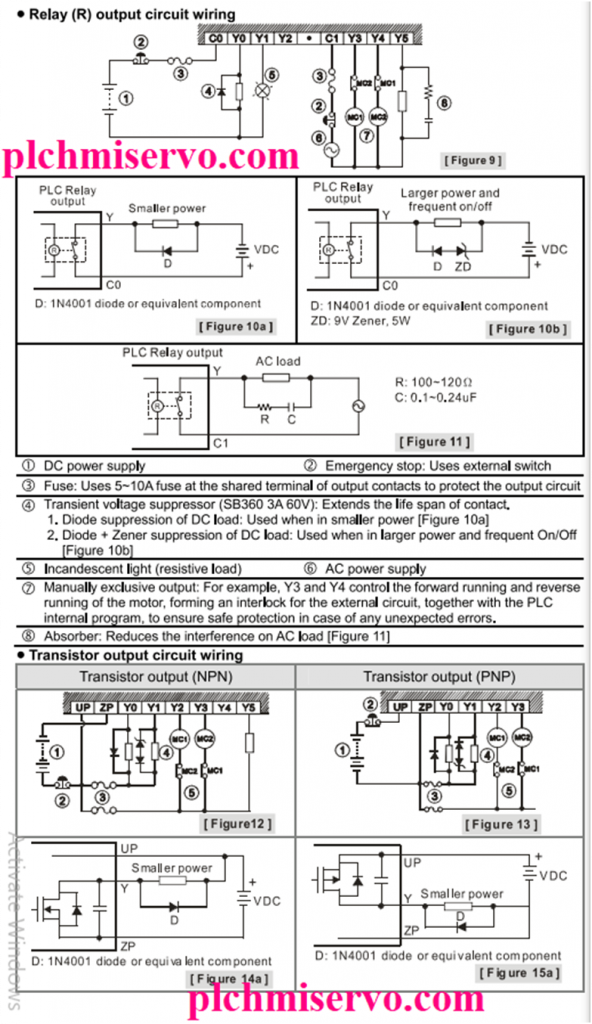

Wiring Diagram of the Delta DVPSS2-S

+Step 01: Digital Input and Output Wiring Connection of DVP-SS2-S Programmable Logic Controller (PLC), Also COM2 RS485 Wiring Connection.

>>>> Download 14SS2 Manual Delta PLC Programming Manual Google Drive Link>>>>

We have given the link [Download] 14SS2 Manual Delta PLC Programming Manual on google drive so click on the link to download your required manual.

+ [Download] Delta DVP14SS2-S Manual Delta PLC Programming Manual

Download Link:

https://drive.google.com/file/d/1PE4ZQlk4yar7OAfZEZSNDBZ4r2bFboZc/view?usp=sharing

Link: + [Download] DVP Series Delta PLC Programming Examples Manual

Thanks for Reading our Article In you need a DVP14SS2 Programmable Logic Controller or any help with Software, Programming examples, and Manual Link, Please contact our admin via mail or WhatsApp.

+Delta HMI

+Delta servo

Contents

6

Table of Contents

7

PLC Concepts

11

PLC Scan Method

12

Scanning Process

12

Input Signal

12

Scan Time

12

Current Flow

13

NO Contact, NC Contact

13

PLC Registers and Relays

13

Reverse Current

13

Ladder Logic Symbols

14

Creating a PLC Ladder Program

15

Execution Order of the Sample Program

15

LD / LDI (Load no Contact / Load NC Contact)

16

Or / Ori

16

LDP / LDF (Load Rising Edge Trigger/ Load Falling Edge Trigger)

16

AND / ANI (Connect no Contact in Series / Connect NC Contact in Series)

16

ANDP / ANDF (Connect Rising Edge in Series/ Connect Falling Edge in Series)

16

ORP / ORF (Connect Rising Edge in Parallel/ Connect Falling Edge in Parallel)

16

ANB (Connect Block in Series)

16

ORB (Connect Block in Parallel)

17

MPS / MRD / MPP (Branch Instructions)

17

STL (Step Ladder Programming)

17

RET (Return)

18

Conversion between Ladder Diagram and Instruction List Mode

19

Fuzzy Syntax

20

Correcting Ladder Diagram

21

Basic Program Design Examples

23

Example 1 — Stop First Latched Circuit

23

Example 2 — Start First Latched Circuit

23

Example 3 — Latched Circuit of SET and RST

23

Example 4 — Power down Latched Circuit

24

Example 5 — Conditional Control

24

Example 6- Interlock Control

24

Example 7 — Sequential Control

24

Example 8 — Oscillating Circuit

25

Example 9 – Oscillating Circuit with Timer

25

Example 10 — Flashing Circuit

25

Example 11 — Trigger Circuit

25

Example 13 — Output Delay Circuit

26

Example 14 — Timing Extension Circuit

26

Example 15 – Counting Range Extension Circuit

26

Example 16 — Traffic Light Control (Step Ladder Logic)

26

Wplsoft Programming (SFC Mode)

29

Programming Concepts

31

ES2/EX2 Memory Map

32

SS2 Memory Map

34

SA2/SX2 Memory Map

36

SE Memory Map

39

Status and Allocation of Latched Memory

41

PLC Bits, Nibbles, Bytes, Words, Etc

42

Binary, Octal, Decimal, BCD, Hex

42

M Relay

43

S Relay

52

T (Timer)

53

Accumulative Timer

53

Timers for Subroutines and Interrupts

53

C (Counter)

54

High-Speed Counters

55

Applicable Software High Speed Counters

56

AB-Phase Input High-Speed Counter

59

Special Data Register

60

E, F Index Registers

69

Nest Level Pointer[N], Pointer[P], Interrupt Pointer [I]

70

CJ Condition Jump

70

CALL Subroutine, SRET Subroutine END

70

External Interrupt

71

Timer Interrupt

71

Counter Interrupt

71

Communication Interrupt

71

Applications of Special M Relays and D Registers

72

Special M and Special D Relevant to RTC

74

Adjustment on Input Terminal Response Time

75

X6 Pulse Width Detecting Function

75

Communication Error Code

75

Pulse Output Mark and Mask Function

76

Execution Completed Flag

76

Clear Instruction

76

Function Group COM Port Function

77

Output State Latched in STOP Mode

77

Disabling All y Outputs

77

RUN/STOP Switch

77

Modifying COM1 Communication Format

78

Modiying COM2 Communication Format

78

Modifying COM3 Communication Format

79

RTU Mode Setting of COM1、COM2、COM3

79

Enable SPD Function

80

Communication Response Delay

80

Fixed Scan Time

81

Analog Function Built in the PLC

81

The Description of D1113 for 30EX2

82

The Status of the Analog Input Channel of 30EX2

82

The Upper/Lower Limit Values for the Analog Input Mode of 30EX2

82

The Description of D1115 for 30EX2

83

The Analog Input Modes for 30EX2

83

Enable 2-Speed Output Function of DDRVI/DDRVA Instruction

83

Program Execution Error

85

I/O Modules Detection

85

Reverse Interrupt Trigger Pulse Direction

85

Stores Value of High-Speed Counter When Interrupt Occurs

85

Enabling Force-ON/OFF of Input Point X

86

ID of Right Side Modules on ES2/EX2/SS2/SA2/SX2/SE

86

ID of Left Side Modules on SA2/SX2/SE

87

Mapping Function for Right-Side High-Speed Special Modules

87

Output Clear Signals When ZRN Is Completed

87

Plc Link

87

Frequency Detection Function

99

Fetching the Value in a Hardware Counter

99

Instruction Set

101

Basic Instructions (Without API Numbers)

102

Explanations to Basic Instructions

102

Pointers

113

Application Programming Instructions

115

Instruction Composition

115

Length of Operand (16-Bit or 32-Bit Instruction)

116

16-Bit MOV Instruction

116

32-Bit DMOV Instruction

116

Explanation of the Format of Application Instruction

116

Continuous Execution Vs. Pulse Execution

117

Pulse Execution Instruction

117

Continuous Execution Instruction

117

Operands

117

Kn Values

118

Flags

118

General Flags

118

Error Operation Flags

119

Flags to Extend Functions

119

Limitations for Times of Using Instructions

119

Limitation of Synchronized Execution

120

Numeric Values

120

Assign Continuous Bit Numbers

121

Floating Point Operation

121

Application Instructions Revelant to Floating Point

121

Binary Floating Point

122

Decimal Floating Point

122

Numerical List of Instructions (Classified According to the Function)

124

Loop Control

124

Transmission Comparison

124

Four Arithmetic Operations

124

Rotation and Displacement

125

Data Processing

125

High Speed Processing

125

Handy Instructions

126

External I/O Display

126

Serial I/O

126

Basic Instructions

127

Communication Instructions

127

Additional Instruction

129

Positioning Control

129

Real Time Calendar

130

Gray Code

130

Matrix Operation

130

Contact Type Logic Operation

131

Contact Type Comparison

131

Specific Bit Control

132

Floating-Point Contact Type Comparison

132

Numerical List of Instructions (in Alphabetic Order)

134

Detailed Instruction Explanation

141

Interrupt Return

148

Enable Interrupt

148

Disable Interrupt

148

CJ Instruction Program Flow

152

CALL Instruction Program Flow

153

Watchdog Timer Refresh

154

Start of a FOR-NEXT Loop

156

End of a FOR-NEXT Loop

156

Compare

159

Zone Compare

160

Move

161

Shift Move

162

Compliment

165

Block Move

166

Fill Move

168

Exchange

169

Convert bin to BCD

171

Convert BCD to bin

172

4-Digit DIP Switch in BCD Format

173

4-Digit 7-Segment Display in BCD Format

173

Addition

175

Subtraction

177

Multiplication

178

Division

180

Increment

182

Decrement

183

Logical Word and

184

Logical Dword and

185

Logical Word or

186

Logical Dword or

187

Logical Word XOR

188

Logical Dword XOR

189

2’S Complement

190

Ss2Sx230Drorprotation

192

Rotate Left

193

Rotation Right with Carry

194

Rotation Left with Carry

195

Bit Shift Right

196

Bit Shift Left

197

Word Shift Right

198

Word Shift Left

200

Shift Register Write

201

Shift Register Read

202

Zone Reset

203

Decode

205

Encode

207

Sum of Active Bits

209

Check Specified Bit Status

210

Mean

211

Timed Annunciator Set

212

Annunciator Reset

213

Square Root

215

Floating Point

216

Refresh

219

Refresh and Filter Adjust

221

Input Matrix

223

High Speed Counter Set

226

Block Diagram of Software Counters and Comparators:

227

High Speed Counter Reset

233

High Speed Zone Compare

234

Speed Detection

238

Pulse Output

240

Description of Associated Special D Registers

243

More Explanations for M1347,M1348, M1524, M1525

243

Pulse Width Modulation

245

Pulse Ramp

247

Explanations on Associated Flags and Registers

249

Description on Associated Flags

249

Description on Associated Special Registers

250

Operation of Mark Function on Y0

250

Operation of Mask Function on Y0

252

Adding Mask and Alignment Mark Function for CH0 and CH1

253

Execution of the Mask Function (Use Y0 as an Example)

254

Adding Fixed Slope Function for CH0 and CH1

254

Y1 and Y3 Relative Parameters for Alignment Mark Function

255

Y1 and Y3 Relative Parameters for Fixed Slope Function

255

Robot Arm Control (by ist Instruction)

257

Control Purpose

257

Motion of the Robot Arm

257

I/O Devices

257

START Circuit

258

Manual Mode

258

Zero Return Mode

258

Ladder Diagram

259

Auto Operation

259

Flag Explanation

261

Disable “All Output Reset” Function

261

Incremental Drum Sequencer

266

Teaching Timer

268

Special Timer

270

Alternate State

272

Ramp Variable Value

273

Data Transform and Move

275

Data Sort

293

Ten Key Input

296

Hexadecimal Key Input

298

DIP Switch

301

7-Segment Decoder

303

7-Segment with Latch

304

Arrow Switch

308

ASCII Code Conversion

310

Print (ASCII Code Output)

311

Read CR Data from Special Modules

313

Write CR Data into Special Modules

315

Serial Communication

317

Example Program of RS-485 Communication

339

Rising-Edge Output

371

Rising–Edge Detection Operation

372

Falling–Edge Detection Operation

373

Rising-Edge Series Connection

374

Falling-Edge Series Connection

375

Rising-Edge Parallel Connection

376

Falling-Edge Parallel Connection

377

Timer

378

16-Bit Counter

379

32-Bit Counter

380

Inverse Operation

381

Falling-Edge Output

382

Read Modbus Data

383

Registers for Received Data (Responding Messages)

385

Communication between PLC and VFD-B Series AC Motor Drive

386

Registers for Data to be Sent (Sending Messages)

386

Write Modbus Data

388

Communication between PLC and VFD-B Series AC Motor Drives

389

Reverse Operation of VFD

393

Stop VFD

393

Read VFD Status

398

Reset Abnormal VFD

402

LRC Checksum

405

CRC Checksum

408

Floating Point Compare

410

Floating Point Zone Compare

411

Move Floating Point Data

412

Ethernet Communication

413

16-Bit Multiplication

416

32-Bit Multiplication

416

Degree/Radian

420

Float to Scientific Conversion

422

Scientific to Float Conversion

423

Floating Point Addition

425

Floating Point Subtraction

426

Floating Point Multiplication

427

Floating Point Division

428

Float Exponent Operation

429

Float Natural Logarithm Operation

430

Float Logarithm Operation

431

Floating Point Square Root

432

Floating Point Power Operation

433

Float to Integer

435

Sine

436

Cosine

438

Tangent

440

Arc Sine

442

Arc Cosine

444

Arc Tangent

446

Delay

447

General PWM Output

450

Fuzzy Temperature Control

451

Byte Swap

457

Reading the Data from the File Register

458

Writing the Data into the File Register

459

MODBUS Read/ Write

460

Mov H87

479

Set M1120

479

Mov K100

479

Rst M1143

479

Receiving Completed

479

M1143 = off ASCII Mode

479

ASCII Mode (M1143 = OFF)

480

When X0 = ON, MODRW Instruction Executes the Function Specified by Function Code

480

Set Communication Protocol as 9600, 8, E

483

Retain Communication Protocol

483

Set Communication Timeout as 100Ms

486

Data Address: H2000

486

Connection Device

487

Address: K1

487

Absolute Position Read

491

Zero Return

496

Adjustable Speed Pulse Output

502

Relative Position Control

503

Absolute Position Control

507

Time Compare

510

Time Zone Compare

511

Time Addition

512

Time Subtraction

513

Time Read

515

Time Write

517

Transfer Designated Bits

519

Hour Meter

520

BIN — Gray Code

522

Gray Code — bin

523

GPS Data Receiving

529

Sum of Multiple Devices

535

Matrix and

537

Matrix or

539

Matrix XOR

540

Matrix XNR

541

Matrix Inverse

542

Matrix Compare

543

Matrix Bit Read

545

Matrix Bit Write

547

Matrix Bit Shift

549

Matrix Bit Rotate

551

Matrix Bit Status Count

553

2-Axis Relative Point to Point Motion

554

2-Axis Absolute Point to Point Motion

557

Single-Axis Pulse Output by Table

567

Close Loop Position Control

569

Variable Speed Pulse Output

576

Immediately Change Frequency

580

Proportional Calculation

583

Parameter Proportional Calculation

585

Compare Table

589

ASDA Servo Drive R/W

591

Catch Speed and Proportional Output

594

Serial Type Logic Operation

597

Parallel Type Logic Operation

598

Serial Type Comparison

600

Parallel Type Comparison

601

Contact Type Timer

602

Output Specified Bit of a Word

603

Set on Specified Bit of a Word

604

Reset Specified Bit of a Word

605

Load no Contact by Specified Bit

606

Load NC Contact by Specified Bit

607

Connect no Contact in Series by Specified Bit

608

Connect NC Contact in Series by Specified Bit

609

Connect no Contact in Parallel by Specified Bit

610

Connect NC Contact in Parallel by Specified Bit

611

Floating Point Contact Type Comparison LD

612

Floating Point Contact Type Comparison and

613

Floating Point Contact Type Comparison or

614

DMV Communication Command

615

Communication Combination Function Code

616

Comparing Contact Type Absolute Values LDZ

620

Comparing Contact Type Absolute Values ANDZ

622

Comparing Contact Type Absolute Values ORZ

624

Self-Defined Ethernet Communication Port

626

TCP Socket Connection

630

Communications

633

Communication Ports

634

Communication Format

634

Communication Protocol ASCII Mode

635

Communication Data Structure

635

ADR (Communication Address)

635

CMD (Command Code) and DATA

636

LRC CHK (Checksum)

637

Exception Response

637

Communication Protocol RTU Mode

639

Address (Communication Address)

639

CRC CHK (Check Sum)

640

PLC Device Address

642

Command Code

644

Command Code: 02, Read Status of Contact (Input Point X Is Included)

645

Command Code: 03, Read Content of Register (T, C, D)

646

Command Code: 05, Force ON/OFF Single Contact

647

Command Code: 06, Set Content of Single Register

648

Command Code: 15, Force ON/OFF Multiple Contacts

648

Command Code: 16, Set Content of Multiple Registers

649

Sequential Function Chart

651

Step Ladder Instruction [STL], [RET]

652

Sequential Function Chart (SFC)

652

The Operation of STL Program

654

Actions of Step Points

654

STL Transition

655

Repeated Usage of Output Coil

655

Repeated Usage of Timer

656

Transfer of Step Points

656

SET Sn

656

OUT Sn

657

Restrictions on Using Certain Instructions

658

Basic Instructions Applicable in a Step

658

Points to Note for Designing a Step Ladder Program

660

Sequence Jump

661

Restrictions on Diverging Sequence

661

Reset Step Points and Disable Output

661

Latched Step

661

Types of Sequences

662

Single Sequence: the Basic Type of Sequence

662

Single Sequence Without Divergence and Convergence

662

Step Jump

663

Reset Sequence

663

Structure of Simultaneous Divergence

664

Structure of Alternative Divergence

664

Ladder Diagram of Simultaneous Divergence

664

SFC Diagram of Simultaneous Divergence

664

Structure of Simultaneous Convergence

665

Structure of Alternative Convergence

665

Example of Alternative Divergence & Alternative Convergence

666

Example of Simultaneous Divergence & Simultaneous Convergence

667

Example of the Simultaneous Divergence & Alternative Convergence

668

Restrictions on Divergence Sequence

671

IST Instruction

673

Control Panel

675

Troubleshooting

679

Common Problems and Solutions

680

Error Code Table (Hex)

682

Error Detection Devices

684

Canopen Function and Operation

685

The Introduction of Canopen

686

The Description of the Canopen Functions

686

The Input/Output Mapping Areas

687

The Installation and the Network Topology

687

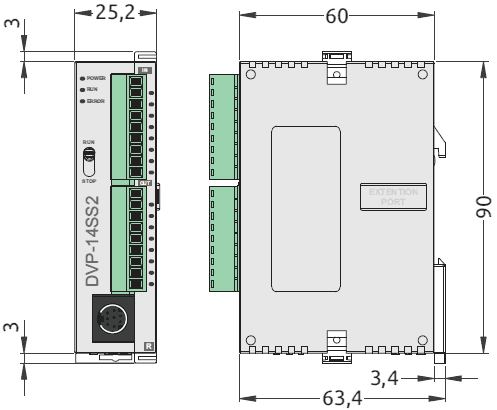

The Dimensions

687

The Profile

688

The CAN Interface and the Network Topology

688

The Pins of COM3 (CAN Interface)

688

The CAN Signal and the Data Frame Format

688

The CAN Network Endpoint and the Topology Structure

689

The Topology Structure of the Canopen Network

690

The Canopen Protocol

693

The Introduction of the Canopen Protocol

693

The Object Dictionary

693

The Canopen Communication Object

694

SDO (Service Data Object)

695

The Format of the Reply Message

696

NMT (Network Management Object)

696

Module Control Services

696

Error Control Services

697

Boot-Up Services

698

Other Predefined Canopen Communication Objects (SYNC and EMCY)

698

Emergency Object

699

The Predefined Connection Set

699

Data Structure of SDO Request Message

700

Sending SDO, NMT and Reading Emergency Message through the Ladder Diagram

700

Data Structure of NMT Message

702

The Data Format of the NMT Response Message

703

Data Structure of EMERGENCY Request Message

703

The Data Format of the Emergency Response Message

704

Emergency Response Data

705

Example on Sending SDO through the Ladder Diagram

705

Explanation of Request Message Devices

706

Editing the Ladder Diagram through Wplsoft

706

Indicators and Troubleshooting

707

Explanation of Response Message Devices

707

POWER Indicator

707

RUN Indicator

707

Canopen Network Node State Display

708

Application Example

710

Hardware Connection

710

Setting Servo Parameters

710

Setting Canopen Baud Rate and Node ID of DVP-ES2-C

711

Network Scanning

714

Node Configuration

714

“Error Control Protocol”

714

“Auto SDO Configuration”

714

PDO Mapping

715

PDO Transmission Type

715

Program Explanation

717

The Mapping Relation between Master and Slave

717

Object Dictionary

718

Installing a USB Driver in the PLC

727

A.1 Installing the USB Driver in Windows 7

728

A.2 Installing the USB in Windows 8

730

A.3 Installing the USB Driver in Windows 10

733

Setting and Using an Ethernet Plc/Module

735

Specifications for an Ethernet Plc/Module

736

Ethernet Control Registers

736

Station Addresses of Ethernet Modules

736

DVPEN01-SL (Left-Side Ethernet Communication Module)

738

DVP-FEN01 (DVP-EH3 Series Ethernet Communication Card

740

Searching for an Ethernet PLC

740

B.3.1 Communication Setting

741

B.3.2 Broadcast Search

742

Searching for a Model Specified

743

B.3.4 Searching by an IP Address

745

Ethernet/Ip List

746

Data Exchange

746

B.4 Data Exchange

746

Ethernet/Ip Information Supported by DVP-SE Series Plcs

747

Ethernet/Ip Objects Supported by DVP-SE Series Plcs

748

TCP/IP Interface Object

750

Ethernet Link Object

750

Setting the RTU Mapping

751

B.6 RTU Mapping

751

Application of the RTU Mapping

752

Inforamation about TP Series Text Panels

755

C.1 TP Memory Map

756

Special Data Register

757

Special Auxiliary Relay

766

Instructions Applicable to TP

775

Basic Instructions

775

C.4 Instructions Applicable to TP

775

Numerical List of Instructions

776

Additional Remarks on High-Speed Instructions

780

D.1 Current Consumption of a Slim Plc/An Extension Module

781

Current Supply and Current Consumption of a PLC (+24VDC)

782

Current Consumption of a Slim Plc/An Extension Module

782

Calculating the Maximum Current Consumed by a System

783

Current Consumption of a Special Input/Output Module (+24VDC)

783

Current Consumption of a Left-Side High-Speed Special Module (+24VDC

783