Caterpillar C7 ACERT. Electrical circuit.

MID code

10 Digital Diagnostic Tool

11 Communication adapter

12 Analyzer-programmer of the electronic control unit

13 «Electronic Technician» by Caterpillar

14 Electronic ignition system

15 Ignition control unit for spark-ignition engines

17 Engine control unit 34ХХ SI

18 Engine control unit 35ХХ SI

19 Engine control unit 36XX SI

20 Control unit for torsional loads

21 I / O Block G3600

22 Pressure control unit G3600

23 The detonation control unit

25 Control unit for injection air injection system at start-up

26 Computerized Monitoring System (CMS)

27 Electronic programmable gearbox control unit (EPTC II)

28 Traction control unit

29 Computerized profiler control system

30 Caterpillar Inspection System

31 Electronic Scraper Control System

33 Engine control unit? 2

34 Engine control unit? 3

35 Engine control unit? 4

36 Engine control unit? 1

37 Engine control unit? 5

38 Engine control unit? 6

39 Machine control unit

40 Engine control unit? 7

41 Engine control unit? 8

47 Redundant engine control unit

49 The main unit of the basic information processing system (VIMS)

50 Basic Information Processing System Analysis Unit (VIMS)

51 The main unit of the basic information display system (VIDS)

52 VIDS / VIMS graphic display unit

53 The main unit of the machine parameter display system (MIDS)

54 Control system? 2 from Caterpillar

57 Interface unit (interface unit)? 1

58 The matching unit? 2

59 The matching unit? 3

60 Interlocking unit? 4

65 Harmonization unit? 5

66 Harmonization unit? 6

67 Harmonization unit? 7

68 Harmonization unit? 8

73 Automatic travel control unit and two-speed fan

74 Payload monitoring system

75 Four-wheel drive control unit

76 Control unit for neutralization of nitrogen oxides in exhaust gases

77 Display of neutralization system for nitrogen oxides in exhaust gases

78 Farm Attachment System Control Unit

79 The hydrostatic gearbox control unit

81 Transmission control unit

82 Electronic control unit for working equipment

83 Automatic moderator control unit

84 Control unit for the asphalt paver burner

85 Engine fan control unit

86 Coordination unit with satellite navigation system

87 The chassis control unit

88 Control unit? 1 diesel generator set

89 Control unit? 2 diesel generator set

90 Control unit? 3 diesel generator set

91 Control unit? 4 diesel generator set

92 Control unit? 5 diesel generator set

93 Control unit? 6 diesel generator set

94 Control unit? 7 diesel generator set

95 Control unit? 8 diesel generator set

97 Customer Communication Unit

98 Customer communication unit (special)

99 Programmable relay control unit

100 Engine video display

101 Engine video display matching unit

102 Communication unit? 2 consumers

103 Remote display? 2

105 Hydraulic pump control unit

106 Electro-hydraulic control unit

108 Multifunctional control unit

109 Combined Combustion Combustion Control Module (ICSM)

110 Combined Combustion Combustion Control Module (ICSM)

111 Combined temperature control module

113 Tractor type transmission control unit

114 Slope gradient control unit

115 Tilt sensor unit

116 Combined brake control unit

117 Shift lever module

118 Asphalt paver material management system

119 Asphalt paver running control system

121 Computerized Earthquake Dispatching System (CAES)

122 Coupling unit

123 Data link translation module

129 The training block? 1

130 The training block? 2

131 Computer for testing modules

137 Display 1 slope gradient

138 Display №2 slope gradients

139 Display number 3 slope gradient

140 Display №4 slope steepness

141 Display №5 of slope steepness

142 Display №6 of slope steepness

255 Not programmed electronic control unit (ECM)

1300 Solenoid for changing the direction of movement of the elevator

1301 The gas supply valve solenoid (GAV) in the cylinder No.1

1302 The solenoid of the valve of giving of gas (GAV) in the cylinder №2

1303 The solenoid of the valve of giving of gas (GAV) in the cylinder №3

1304 The solenoid of the valve of giving of gas (GAV) in the cylinder №4

1305 The solenoid of the valve of giving of gas (GAV) in the cylinder №5

1306 The solenoid of the valve of giving of gas (GAV) in the cylinder №6

1307 The solenoid of the valve of giving of gas (GAV) in the cylinder №7

1308 The solenoid of the valve of giving of gas (GAV) in the cylinder №8

1309 The gas valve (GAV) solenoid in the cylinder No. 9

13010 The solenoid of the valve of giving of gas (GAV) in the cylinder №10

1311 The gas supply valve solenoid (GAV) in cylinder No. 11

1312 The gas supply valve solenoid (GAV) in the cylinder No. 12

1313 The solenoid of the valve of giving of gas (GAV) in the cylinder №13

1314 The gas valve (GAV) solenoid in the cylinder No.14

1315 The gas valve (GAV) solenoid in the cylinder No.15

1316 Gas supply valve solenoid (GAV) in cylinder No.16

1317 The solenoid valve of the gas supply (GAV) in the cylinder number 17

1318 The solenoid of the valve of giving of gas (GAV) in the cylinder №18

1319 The solenoid of the valve of giving of gas (GAV) in the cylinder №19

1320 The solenoid of the valve of giving of gas (GAV) in the cylinder №20

1321 Screw stop limit sensor

1322 Screw return switch

1323 Screw slip stopper solenoid

1326 Code of the location of the electronic control unit (ECM)

1327. The left brake pedal position sensor

1328 Right-hand brake pedal position sensor

1329 The contact sensor of the left brake pedal

1330 Right brake pedal sensor connector

1401 Transmission gear solenoid # 1

1402 Transmission Gear Solenoid # 2

1403 Gearbox solenoid # 3

1404 Transmission Gear Solenoid # 4

1405 Transmission Gear Solenoid # 5

1406 Gearbox solenoid # 6

1407 Transmission Gear Solenoid # 7

1408 Transmission Gear Solenoid # 8

1409 Transmission gear solenoid # 9

1410 Gearbox solenoid №10

1411 Transmission Gear Solenoid # 11

1412 Gearbox solenoid №12

1413 Gearbox solenoid # 13

1414 Transmission Gear Solenoid # 14

1415 Gearbox solenoid # 15

1416 Gearbox solenoid # 16

1417 Transmit Solenoid # 17

1418 Gearbox solenoid # 18

1419 Gearbox solenoid № 19

1420 Transaxle Solenoid

(Ocr-Read Summary of Contents of some pages of the Caterpillar C13 Document (Main Content), UPD: 06 February 2023)

-

93, Caterpillar C13 SEBU7901-01 93 Reference Information Section Customer Service i01028392 Ordering Replacement Parts SMCS Code: 7567 When replacement parts are required for this product Caterpillar recommends using Caterpillar replacement p arts or parts with equivalent spec- ifications including, but not limited to, physical dimensions, type, strength and material. Failure to heed this warning can lead to prema- ture failures, product…

-

90, 90 SEBU7901-01 Warranty Section Warranty Information Customer Assistance (Emission Control Systems Warranty) Caterpillar Inc. intends to ensure that the Emission Control Systems warranty is properly administered. If you do not receive adequate warranty service under the Emission Control Systems Warranty, call or write to the following address: Caterpillar Inc. Manager, Engine Business P.O. Box 0600 Mossville, IL 61552…

-

24, 24 SEBU7901-01 Operation Section Gauges and Indicators Gauges and Indicators i01465281 Gauges and Indicators SMCS Code: 1900; 7450 Your engine m ay not have the same gauges or all of the gauges that are described. For more information about the gauge package, see the literature that is provided by t he OEM. Gauges provide indications of engine performance. Ensure that t he gauges are in good working order. Determine the normal operating range by observing th…

-

35, SEBU7901-01 35 Operation Section Engine Starting Engine Starting i02109067 Before Starting Engine SMCS Code: 1000; 1400; 1450 Perform the r equired daily maintenance and other periodic maintenance before the engine is started. Inspect the engine compartment. This inspection can help prevent major repairs at a later date. Refer to the Operation and Maintenance Manual, “Maintenance Interval Schedule” for more information. • For the maximum service life of …

-

64, Caterpillar C13 64 SEBU7901-01 Maintenance Section Crankshaft Vibration Damper — Inspect A water tempera ture regulator that fails in the open position will cause the engine operating temperature to be too low during partial load operation. Low engine operat ing temperatures during partial loads could cause an excessive carbon buildup inside the cylinders. This excessive carbon buildup could result in an acceler ated wear of th…

-

70, 70 SEBU7901-01 Maintenance Section Engine Crankcase Breather — Clean Observe the ser vice indicator. The air cleaner element should be cleaned or the air cleaner element should be replaced when one of the following conditions oc cur: • The yellow diaphragm enters the red zone. • The red piston locks in the visible position. Test the Service Indicator Service indic ators are important instruments. • …

-

30, 30 SEBU7901-01 Operation Section Engine Diagnostics Engine Diagnostics i01563934 Self-Diagnostics SMCS Code: 1000; 1900; 1901; 1902 Caterpillar Electronic Engines have the capability to perform a self-diagnostics test. When the system detects an active problem, the “DIAGNOSTIC” lamp is activated. Diagnostic codes will be stored in permanent memory in the Electronic Control Module (ECM). The diagnostic codes can be retrieved by using the following components: • Caterpillar electronic…

-

36, 36 SEBU7901-01 Operation Section Engine Starting 2. Turn the keyswi tch to the RUN position. Leave the keyswitch in the RUN position for 15 seconds. 3. Turn the keysw itch to the START position in order to engage the electric starting motor and crank the engine. NOTICE Do not engage the starting motor when flywheel is turning. Do not start the engine under load. If the engine fails to start within 30 seconds, release the sta…

-

15, SEBU7901-01 15 Safety Section Engine Electronics g00771487 Illustration 13 Typical ex ample Alternate Grounding Stud To Battery Ground Proper grounding for the engine electrical system is necessary for optimum engine performance and relia bility. Improper grounding will result in uncontrolled electrical circuit paths and in unreliable electrical circuit paths. Uncontrolled electrical circuit paths can result in damage to main bearings, to crankshaft bearing journal sur…

-

100, 100 SEBU7901-01 Index Section R Radiator — Clean ……………………………………………. 85 Radiator Restr ictions ……………………………………… 42 Reference Information Section ………………………… 91 Reference Material ………………………………………… 94 Additional Ref erence Material………………………. 95 Coolants……………………………………………………. 94 Fuels …………

-

63, SEBU7901-01 63 Maintenance Section Cooling System Water Temperature Regulator — Replace 3. Add tap water to the mixing bottle in order to bring the level up to the “10 ml” mark. Place the cap on the bottle and shake the bottle. 4. Add 2 to 3 drops of the “NITRITE INDICATOR SOLUTION B” to the mixing bottle. Move the bottle in a circular motion in order to mix the solution. 5. Add 1 drop of “NITRITE TEST SOLUTION A” to the mix…

-

52, Caterpillar C13 52 SEBU7901-01 Maintenance Section Maintenance Interval Schedule Every 114 000 L ( 30 000 US gal) of Fuel or 3000 Service H ours Aftercooler Core — Clean/Test …………………………. 53 Every 170 400 L ( 45 000 US gal) of Fuel or 3000 Service H ours Crankshaft Vibration Damper — Inspect …………….. 64 Electronic Un it Injector — Inspect/Adjust ……………. 65 Engine — Clean ……………………………………………… 66 Engine Mounts — Inspect …….…

-

19, SEBU7901-01 19 Product Information Section Model Views An electronic g overnor controls the output of the unit injectors in order to maintain the engine rpm that is desired. The functions of the governor include a programmable low idle and a 20 rpm to 200 rpm governor overrun. Very high inj ection pressures are produced by electronically controlled, mechanically actuated unit injectors. The injectors combine the pumpi…

-

58, 58 SEBU7901-01 Maintenance Section Cooling System Coolant (ELC) — Change 5. Loosen the cap f or the coolant recovery tank slowly in order to relieve any pressure. Remove the cap for the coolant recovery tank. 6. Pour coolant into the coolant recovery tank until the coolant reaches the “COLD FULL” mark. DO NOT fill th e coolant recovery tank above the “COLD FULL” mark. 7. Clean the cap for the coolant recovery tank. Install the cap for the coolant re…

-

10, Caterpillar C13 10 SEBU7901-01 Safety Section Burn Prevention • Comply with app licable rules and regulations for the work place. In the United States, use Occupational Safety and Health Administration (OSHA) requir ements. These OSHA requirements can be found in “29 CFR 1910.1001”. • Obey environ mental regulations for the disposal of asbestos. • Stay away fro m areas that might have asbestos particles in the air. Dispose of Waste Properly g00706404 Illustration 8 Improperly dis…

-

18, 18 SEBU7901-01 Product Information Section Model Views g01244139 Illustration 15 Right side view of C11 and C13 industrial engine (1) Oil pressure connection and location for oil sampling (2) Lifting eye (3) Jacket water heater (4) Air inlet (5) Air outlet to aftercooler (6) Water inlet (7) Heater inlet for lubrication (8) Oil drain (9) Mounting block for an oil filter bypass (10) Oil filter i0209417 4 Engine Description SMCS Code: 1000 Table 1…

-

65, SEBU7901-01 65 Maintenance Section Electronic Unit Injector — Inspect/Adjust Inspect the Drive Coupling Inspect the drive coupling according to the instructions that are provided by the OEM of the coupling. For the following service information, see the literature that is provided by the OEM of the coupling: • Lubrication requirements • Specifications for the end play • “Reusability Guidelines” • Replacement ins…

-

11, SEBU7901-01 11 Safety Section Fire Prevention and Explosion Prevention Flammable flui ds that are leaking or spilled onto hot surfaces or onto electrical components can cause a fire. Fire may cause personal injury and property damage. A flash fire may result if the covers for the engine crankcase ar e removed within fifteen minutes after an emergency shutdown. Determine wh ether the engine will be operated in an environ…

-

83, SEBU7901-01 83 Maintenance Section Overhaul Considerations • Caterpillar de aler exchange components • Caterpillar Inc. remanufactured exchange components Overhaul Reco mmendation To minimize downtime, a scheduled engine overhaul by your Caterp illar dealer is recommended. This will provide you with the best cost/value relationship. Note: Overhau l programs vary according to the engine application and according to the dealer that performs the overhaul. Consult your Caterpillar dealer …

-

8, 8 SEBU7901-01 Safety Section General Hazard Information i02327617 General Hazard Information SMCS Code: 1000; 7405 g00104545 Illustration 4 Attach a “Do Not Operate” warning tag or a similar warning tag to the start switch or to the controls before the e ngine is serviced or before the engine is repaired. These warning tags (Special Instruction, SEHS7332) are available from your Caterpillar dealer. Att ach the warnin…

- Артикул: 4914 — назовите при заказе по телефону

- Издательство: СпецИнфо

- ISBN: 978-5-86234-030-3

- Число страниц: 92

- Формат: А5

- Переплет: Мягкий

- V диз дв: 11.1; 12.5

Цена в интернет-магазине: 2 426 руб.

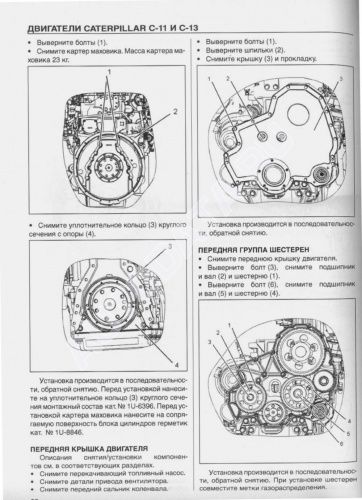

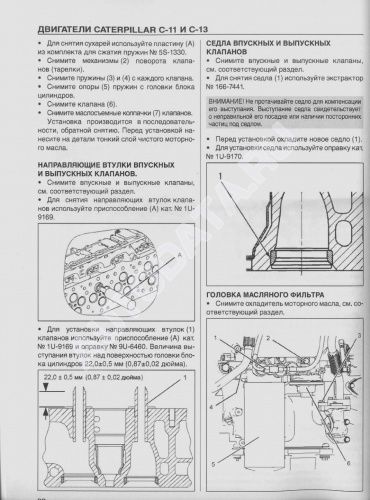

Книга Двигатели Катерпиллер C11 и С13 дизельные 11.1, 12.5. Технические характеристики, коды неисправностей. Руководство по ремонту и техническому обслуживания двигателя.

Двигатели Катерпиллар C11 и С13 устанавливались на американские грузовые автомобили International, Freightliner, Kenworth, Peterbilt и др.

Помимо руководства по ремонту представлены техническое обслуживание и диагностические коды неиправностей.

Книга предназначена для широкого круга читателей – водителей, специалистов и техников, работающих в области авторемонта, а также может использоваться в качестве учебного пособия для персонала автосервисов, автомастерских и станций технического обслуживания.

Купить книгу по ремонту и эксплуатации двигателей Caterpillar C11 и С13 дизельные 11.1, 12.5 Вы можете в нашем интернет-магазине с доставкой Почтой России или курьером по Москве.

Похожие товары

Интернет-портал Легион-Автодата создан для удобных покупок: автолитературы, программ для диагностики автомобиля, диагностических приборов, адаптеров elm327, автоаксессуаров и инструментов для авторемонта. Купить книги и приборы для диагностики и ремонта автомобиля Вы можете в нашем интернет магазине.

Удобно оплатить руководства по ремонту и эксплуатации выбранных Вами марок авто любой из платежных систем.

Заказать доставку автокниги почтой без предоплаты, курьером по Москве, регионам и в более 200 пунктов самовывоза по всей России.

Download Complete Service Repair Manual for Caterpillar C11 and C13 On-highway Engine

This Factory Service Repair Manual offers all the service and repair Caterpillar C11 and C13 On-highway Engine. The information on this manual covered everything you need to know when you want to repair or service Caterpillar C11 and C13 On-highway Engine.

Models Covered:

Caterpillar C11 and C13 On-highway Engine

KCA1-UP, KCB1-UP, JAM1-UP

Manual Contents:

Safety

Torque Specifications

Specifications

System Operation Texting and Adjusting

Disassembly abd Assembly

Troubleshooting

Special Instruction

Electronic PTO Installation and Application Guide

Electrical System

Schematic

C11, C13, C15 On-highway Engine Operation and Maintenance Manual

Added files:

one safe source

dealer service tool catalog

shop supplies and tools

battery cross reference guide

battery specification sheet

This manual can be used by anyone from a first time owner/amateur to a professional technician.Even the most novice mechanic can also easily follow the step-by-step guides which are made simple by the illustrations and drawings.Keep this manual handy and use it often. Performing routine, preventive maintenance will save you time & money by helping to prevent premature failure and unnecessary repairs.

Your will receive a download link immediately after your payment is completed.So please make sure your email address is correct.

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English

Complete service repair manual with Electrical Wiring Diagrams for Caterpillar Engines C11, C13, C15, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Caterpillar Diesel Engines C-11, C-13, C-15 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 5,143 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

Caterpillar C-11, C-13, & C-15 (BXS) (EPA04) Troubleshooting.pdf

Caterpillar C-11 & C-13 Cooling System (2005 Peterbilt 387).pdf

Caterpillar C-11 & C-13 Fuel System (2005 Peterbilt 387).pdf

Caterpillar C-11 & C-13 Intake, Exhaust & Turbocharger.pdf

Caterpillar C-11 & C-13 Mechanical (2005 Peterbilt 387).pdf

Caterpillar C-13 & C-15 EPA07 Troubleshooting (2008 Peterbilt 389).pdf

LEBT3886 — Electrical & Electronic Installation & Application Guide (C11, C13 & C15 Truck Engines EPA 2004).pdf

M0073474 — Troubleshooting (C11, C13, C15, and C18 Industrial Engines)

Acceleration Is Poor or Throttle Response Is Poor.pdf

Alternator Problem — Charging Problem and_or Noisy Operation.pdf

Battery Problem.pdf

Cat ET Service Features.pdf

Component Location.pdf

Configuration Parameters.pdf

Coolant Contains Fuel.pdf

Coolant Contains Oil.pdf

Coolant Level Is Low.pdf

Coolant Level — Test.pdf

Coolant Temperature Is High.pdf

Cooling Fan — Calibrate.pdf

Cooling Fan Control — Test.pdf

Cooling Fan Is Always ON.pdf

Crankcase Fumes Disposal Tube Has Oil Draining.pdf

Crankcase Pressure Is High.pdf

Crankcase Pressure Is Low.pdf

Customer Passwords.pdf

Cylinder Is Noisy.pdf

Data Link — Test.pdf

Diagnostic Capabilities.pdf

Diagnostic Trouble Codes.pdf

ECM — Replace.pdf

ECM Software — Install.pdf

ECM Will Not Accept Factory Passwords.pdf

Electrical Connectors — Inspect.pdf

Electrical Connectors.pdf

Electrical Power Supply — Test.pdf

Electronic Display Module — If Equipped.pdf

Electronic Service Tools.pdf

Engine Cranks but Does Not Start.pdf

Engine Does Not Crank.pdf

Engine Has Early Wear.pdf

Engine Has Mechanical Noise (Knock).pdf

Engine Misfires, Runs Rough or Is Unstable.pdf

Engine Monitoring System.pdf

Engine Overcrank Occurrence.pdf

Engine Overspeeds.pdf

Engine Shutdown Occurrence.pdf

Engine Shutdown Occurs Intermittently.pdf

Engine Stalls at Low RPM.pdf

Engine Top Speed Is Not Obtained.pdf

Engine Vibration Is Excessive.pdf

Ether Starting Aid — Test.pdf

Event Codes.pdf

Exhaust Balance Valve — Test.pdf

Exhaust Has Excessive White Smoke.pdf

Exhaust System Contains Coolant.pdf

Exhaust System Contains Fuel.pdf

Exhaust System Contains Oil.pdf

Exhaust Temperature Is High.pdf

Factory Passwords.pdf

Fuel Consumption Is Excessive.pdf

Fuel Pressure Is High.pdf

Fuel Temperature Is High.pdf

General Information.pdf

Idle Speed Is High.pdf

Indicator Lamp Problem.pdf

Injector Solenoid — Test.pdf

Injector Trim File — Install.pdf

Inlet Air Is Restricted.pdf

Intake Manifold Air Temperature Is High.pdf

Oil Consumption Is Excessive.pdf

Oil Contains Coolant.pdf

Oil Contains Fuel.pdf

Oil Pressure Is Low.pdf

Power Is Intermittently Low or Power Cutout Is Intermittent.pdf

Retarder — Test.pdf

Sensor Calibration Required — Test.pdf

Sensor Signal (Analog, Active) — Test.pdf

Sensor Signal (Analog, Passive) — Test.pdf

Sensor Supply — Test.pdf

Service Information Report.pdf

Shutdown (Ground Level) — Test.pdf

Solenoid Valve — Test.pdf

Speed Control — Test.pdf

Speed_Timing — Test.pdf

Symptom Troubleshooting.pdf

System Overview.pdf

Test ECM Mode.pdf

Timing — Calibrate.pdf

Timing — Calibrate.pdf.merge_part.pdf

Timing — Calibrate.pdf.original_part.pdf

Valve Lash Is Excessive.pdf

Valve Rotator or Spring Lock Is Free.pdf

Variable Valve Actuator Response — Test.pdf

Welding Precaution.pdf

RENR8045 — Schematic (C11 & C13 Industrial Engine Electrical System)

Collage Schematic.pdf

Main Schematic.pdf

RENR8045 — Schematic (C11 & C13 Industrial Engine Electrical System).pdf

RENR8632 — Disassembly & Assembly (C11 & C13 Industrial Engines)

Accessory Drive — Install.pdf

Accessory Drive — Remove.pdf

Atmospheric Pressure Sensor — Remove and Install 1.pdf

Atmospheric Pressure Sensor — Remove and Install 2.pdf

Bearing Clearance — Check 1.pdf

Bearing Clearance — Check 2.pdf

Camshaft Bearings — Install 1.pdf

Camshaft Bearings — Install 2.pdf

Camshaft Bearings — Remove 1.pdf

Camshaft Bearings — Remove 2.pdf

Camshaft Gear — Remove and Install 1.pdf

Camshaft Gear — Remove and Install 2.pdf

Camshaft — Install 1.pdf

Camshaft — Install 2.pdf

Camshaft Position Sensor — Remove and Install 1.pdf

Camshaft Position Sensor — Remove and Install 2.pdf

Camshaft — Remove 1.pdf

Camshaft — Remove 2.pdf

Coolant Temperature Sensor — Remove and Install 1.pdf

Coolant Temperature Sensor — Remove and Install 2.pdf

Crankshaft Front Seal — Install.pdf

Crankshaft Front Seal — Remove.pdf

Crankshaft Gear — Remove and Install.pdf

Crankshaft — Install 1.pdf

Crankshaft — Install 2.pdf

Crankshaft Main Bearings — Install 1.pdf

Crankshaft Main Bearings — Install 2.pdf

Crankshaft Main Bearings — Remove 1.pdf

Crankshaft Main Bearings — Remove 2.pdf

Crankshaft Position Sensor — Remove and Install 1.pdf

Crankshaft Position Sensor — Remove and Install 2.pdf

Crankshaft Rear Seal — Install.pdf

Crankshaft Rear Seal — Remove.pdf

Crankshaft — Remove 1.pdf

Crankshaft — Remove 2.pdf

Cylinder Head — Install.pdf

Cylinder Head — Remove.pdf

Cylinder Liner — Install 1.pdf

Cylinder Liner — Install 2.pdf

Cylinder Liner — Remove 1.pdf

Cylinder Liner — Remove 2.pdf

Electric Starting Motor — Remove and Install 1.pdf

Electric Starting Motor — Remove and Install 2.pdf

Electronic Unit Injector — Install.pdf

Electronic Unit Injector — Remove.pdf

Electronic Unit Injector Sleeve — Install.pdf

Electronic Unit Injector Sleeve — Remove.pdf

Engine Control Module — Remove and Install 1.pdf

Engine Control Module — Remove and Install 2.pdf

Engine Oil Cooler — Install.pdf

Engine Oil Cooler — Remove.pdf

Engine Oil Filter Base — Assemble 1.pdf

Engine Oil Filter Base — Assemble 2.pdf

Engine Oil Filter Base — Disassemble 1.pdf

Engine Oil Filter Base — Disassemble 2.pdf

Engine Oil Filter Base — Install.pdf

Engine Oil Filter Base — Remove.pdf

Engine Oil Pan — Remove and Install 1.pdf

Engine Oil Pan — Remove and Install 2.pdf

Engine Oil Pressure Sensor — Remove and Install 1.pdf

Engine Oil Pressure Sensor — Remove and Install 2.pdf

Engine Oil Pump — Assemble 1.pdf

Engine Oil Pump — Assemble 2.pdf

Engine Oil Pump — Disassemble 1.pdf

Engine Oil Pump — Disassemble 2.pdf

Engine Oil Pump — Install.pdf

Engine Oil Pump — Remove.pdf

Exhaust Manifold — Remove and Install 1.pdf

Exhaust Manifold — Remove and Install 2.pdf

Flywheel Housing — Remove and Install 1.pdf

Flywheel Housing — Remove and Install 2.pdf

Flywheel — Install.pdf

Flywheel — Remove.pdf

Front Cover — Install.pdf

Front Cover — Remove.pdf

Fuel Filter Base — Remove and Install 1.pdf

Fuel Filter Base — Remove and Install 2.pdf

Fuel Temperature Sensor — Remove and Install 1.pdf

Fuel Temperature Sensor — Remove and Install 2.pdf

Fuel Transfer Pump — Install.pdf

Fuel Transfer Pump — Remove.pdf

Gear Group (Front) — Install.pdf

Gear Group (Front) — Remove.pdf

Housing (Front) — Install.pdf

Housing (Front) — Remove.pdf

Inlet Air Temperature Sensor — Remove and Install.pdf

Inlet and Exhaust Valve Guides — Remove and Install 1.pdf

Inlet and Exhaust Valve Guides — Remove and Install 2.pdf

Inlet and Exhaust Valve Seat Inserts — Remove and Install 1.pdf

Inlet and Exhaust Valve Seat Inserts — Remove and Install 2.pdf

Inlet and Exhaust Valve Springs — Remove and Install 1.pdf

Inlet and Exhaust Valve Springs — Remove and Install 2.pdf

Inlet and Exhaust Valves — Remove and Install 1.pdf

Inlet and Exhaust Valves — Remove and Install 2.pdf

Lifter Group — Remove and Install 1.pdf

Lifter Group — Remove and Install 2.pdf

Piston Cooling Jets — Remove and Install 1.pdf

Piston Cooling Jets — Remove and Install 2.pdf

Pistons and Connecting Rods — Assemble 1.pdf

Pistons and Connecting Rods — Assemble 2.pdf

Pistons and Connecting Rods — Disassemble 1.pdf

Pistons and Connecting Rods — Disassemble 2.pdf

Pistons and Connecting Rods — Install 1.pdf

Pistons and Connecting Rods — Install 2.pdf

Pistons and Connecting Rods — Remove 1.pdf

Pistons and Connecting Rods — Remove 2.pdf

Rocker Shaft and Pushrod — Install.pdf

Rocker Shaft and Pushrod — Remove.pdf

Rocker Shaft — Assemble .pdf

Rocker Shaft — Disassemble.pdf

Turbocharger — Install.pdf

Turbocharger Outlet Pressure Sensor — Remove and Install.pdf

Turbocharger — Remove.pdf

Valve Mechanism Cover Base — Remove and Install 1.pdf

Valve Mechanism Cover Base — Remove and Install 2.pdf

Vibration Damper and Pulley — Remove and Install 1.pdf

Vibration Damper and Pulley — Remove and Install 2.pdf

Water Pump — Assemble 1.pdf

Water Pump — Assemble 2.pdf

Water Pump — Disassemble 1.pdf

Water Pump — Disassemble 2.pdf

Water Pump — Install.pdf

Water Pump — Remove.pdf

Water Temperature Regulator Housing — Remove and Install.pdf

RENR8632 — Disassembly & Assembly (C11 & C13 Industrial Engines).pdf

RENR9214 — Disassembly and Assembly (C11 and C13 Engines for Caterpillar Built Machines)

Accessory Drive — Install.pdf

Accessory Drive — Remove.pdf

Alternator — Remove and Install.pdf

Atmospheric Pressure Sensor — Remove and Install.pdf

Bearing Clearance — Check.pdf

Boost Pressure Sensor — Remove and Install.pdf

Camshaft Bearings — Install.pdf

Camshaft Bearings — Remove.pdf

Camshaft Gear — Remove and Install.pdf

Camshaft — Install.pdf

Camshaft Position Sensor — Remove and Install.pdf

Camshaft — Remove.pdf

Crankshaft Front Seal — Install.pdf

Crankshaft Front Seal — Remove.pdf

Crankshaft Gear — Remove and Install.pdf

Crankshaft — Install.pdf

Crankshaft Main Bearings — Install.pdf

Crankshaft Main Bearings — Remove.pdf

Crankshaft Position Sensor — Remove and Install.pdf

Crankshaft Rear Seal — Install.pdf

Crankshaft Rear Seal — Remove.pdf

Crankshaft — Remove.pdf

Cylinder Head — Install.pdf

Cylinder Head — Remove.pdf

Cylinder Liner — Install.pdf

Cylinder Liner — Remove.pdf

Electric Starting Motor — Remove and Install.pdf

Electric Starting Motor — Remove and Install.pdf.merge_part.pdf

Electric Starting Motor — Remove and Install.pdf.original_part.pdf

�� Electronic Unit Injector — Install.pdf

Electronic Unit Injector — Remove.pdf

Electronic Unit Injector Sleeve — Install.pdf

Electronic Unit Injector Sleeve — Remove.pdf

Engine Control Module — Remove and Install.pdf

Engine Oil Cooler — Install.pdf

Engine Oil Cooler — Remove.pdf

Engine Oil Filter Base — Assemble.pdf

Engine Oil Filter Base — Disassemble.pdf

Engine Oil Filter Base — Install.pdf

Engine Oil Filter Base — Remove.pdf

Engine Oil Pan — Remove and Install.pdf

Engine Oil Pressure Sensor — Remove and Install.pdf

Engine Oil Pump — Assemble.pdf

Engine Oil Pump — Disassemble.pdf

Engine Oil Pump — Install.pdf

Engine Oil Pump — Remove.pdf

Exhaust Manifold — Remove and Install.pdf

Fan Drive Mounting Group — Remove and Install.pdf

Flywheel Housing — Remove and Install.pdf

Flywheel — Install.pdf

Flywheel — Remove.pdf

Front Cover — Install.pdf

Front Cover — Remove.pdf

Fuel Filter Base — Remove and Install.pdf

Fuel Temperature Sensor — Remove and Install.pdf

Fuel Transfer Pump — Install.pdf

Fuel Transfer Pump — Remove.pdf

Gear Group (Front) — Install.pdf

Gear Group (Front) — Remove.pdf

Gear Group (Rear) — Remove and Install.pdf

Housing (Front) — Install.pdf

Housing (Front) — Remove.pdf

Inlet Air Temperature Sensor — Remove and Install.pdf

Inlet and Exhaust Valve Guides — Remove and Install.pdf

Inlet and Exhaust Valve Seat Inserts — Remove and Install.pdf

Inlet and Exhaust Valve Springs — Remove and Install.pdf

Inlet and Exhaust Valves — Remove and Install.pdf

Inlet Manifold — Install.pdf

Inlet Manifold — Remove.pdf

Lifter Group — Remove and Install.pdf

Piston Cooling Jets — Remove and Install.pdf

Pistons and Connecting Rods — Assemble.pdf

Pistons and Connecting Rods — Disassemble.pdf

Pistons and Connecting Rods — Install.pdf

Pistons and Connecting Rods — Remove.pdf

Rocker Shaft and Pushrod — Install.pdf

Rocker Shaft and Pushrod — Remove.pdf

Rocker Shaft — Assemble.pdf

Rocker Shaft — Disassemble.pdf

Turbocharger — Install.pdf

Turbocharger — Remove.pdf

Valve Actuator (Variable) — Remove and Install.pdf

Valve Mechanism Cover Base — Remove and Install.pdf

Valve Mechanism Cover — Remove and Install.pdf

Vibration Damper and Pulley — Remove and Install.pdf

Water Pump — Assemble.pdf

Water Pump — Disassemble.pdf

Water Pump — Install.pdf

Water Pump — Remove.pdf

Water Temperature Regulator — Remove and Install.pdf

SEBP4130 — Parts Manual (C-13 Industrial Engine).pdf

SEBU8087 — Operation & Maintenance Manual (C13 & C15 On-highway Engines).pdf

SENR9698-01 — Troubleshooting (C11, C13, C-15 On-highway Engines).pdf

SENR9698-09 — Troubleshooting (C11, C13, C-15 On-highway Engines).pdf

SENR9702 — Specifications (C11 & C13 On-highway Engines).pdf

SENR9703 — Systems Operations — Testing & Adjusting (C11 & C13 On-highway Engines).pdf

SENR9704-05 — Disassembly & Assembly (C11 & C13 On-highway Engines).pdf

SENR9704 — Disassembly & Assembly (C11 & C13 On-highway Engines).pdf

SENR9705 — Schematic (C11, C13 On-highway Truck Engines Electrical System).pdf

SENR9852 — Specifications (C11 & C13 Industrial Engines)

Air Lines 1.pdf

Air Lines 2.pdf

Alternator and Regulator 10.pdf

Alternator and Regulator 11.pdf

Alternator and Regulator 12.pdf

Alternator and Regulator 1.pdf

Alternator and Regulator 2.pdf

Alternator and Regulator 3.pdf

Alternator and Regulator 4.pdf

Alternator and Regulator 5.pdf

Alternator and Regulator 6.pdf

Alternator and Regulator 7.pdf

Alternator and Regulator 8.pdf

Alternator and Regulator 9.pdf

Atmospheric Pressure Sensor.pdf

Belt Tension Chart.pdf

Camshaft 1.pdf

Camshaft 2.pdf

Connecting Rod 1.pdf

Connecting Rod 2.pdf

Connecting Rod Bearing Journal.pdf

Coolant Conditioner Base.pdf

Coolant Temperature Sensor.pdf

Crankshaft.pdf

Crankshaft Seals .pdf

Cylinder Block.pdf

Cylinder Head.pdf

Cylinder Head Valves 1.pdf

Cylinder Head Valves 2.pdf

Cylinder Liner 1.pdf

Cylinder Liner 2.pdf

Electric Starting Motor 1.pdf

Electric Starting Motor 2.pdf

Electric Starting Motor 3.pdf

Electric Starting Motor 4.pdf

Electric Starting Motor 5.pdf

Electric Starting Motor 6.pdf

Electric Starting Motor 7.pdf

Electric Starting Motor 8.pdf

Electric Starting Motor 9.pdf

Electronic Unit Injector 1.pdf

Electronic Unit Injector 2.pdf

Electronic Unit Injector 3.pdf

Electronic Unit Injector 4.pdf

Engine Design 1.pdf

Engine Design 2.pdf

Engine Oil Filter Base 1.pdf

Engine Oil Filter Base 2.pdf

Engine Oil Pan 1.pdf

Engine Oil Pan 2.pdf

Engine Oil Pan 3.pdf

Engine Oil Pan 4.pdf

Engine Oil Pan 5.pdf

Engine Oil Pressure Sensor.pdf

Engine Oil Pump .pdf

Engine Support (Front) 1.pdf

Engine Support (Front) 2.pdf

Engine Support (Front) 3.pdf

Engine to Transmission Adapter 1.pdf

Engine to Transmission Adapter 2.pdf

Engine to Transmission Adapter 3.pdf

Exhaust Manifold.pdf

Fan Drive.pdf

Flywheel Housing 1.pdf

Flywheel Housing 2.pdf

Flywheel Housing Cover 1.pdf

Flywheel Housing Cover 2.pdf

Flywheel.pdf

Fuel Filter and Water Separator.pdf

Fuel Filter Base.pdf

Fuel Priming Pump.pdf

Fuel Temperature Sensor.pdf

Fuel Transfer Pump 1.pdf

Fuel Transfer Pump 2.pdf

Gear Group (Front).pdf

Housing (Front).pdf

Inlet Manifold Temperature Sensor.pdf

Main Bearing Journal.pdf

Piston and Rings.pdf

Piston Cooling Jet.pdf

SpeedTiming Sensor 1.pdf

SpeedTiming Sensor 2.pdf

SpeedTiming Sensor 3.pdf

Turbocharger.pdf

Valve Mechanism.pdf

Water Pump.pdf

Water Temperature Regulator 1.pdf

Water Temperature Regulator 2.pdf

Water Temperature Regulator Housing.pdf

SENR9852 — Specifications (C11 & C13 Industrial Engines).pdf

SENR9853 — Systems Operation (C11 & C13 Industrial Engines)

Air Inlet and Exhaust System.pdf

Basic Engine.pdf

Cooling System.pdf

Electrical System.pdf

Electronic Control System Components.pdf

Fuel System.pdf

General Information.pdf

Lubrication System.pdf

SENR9853 — Systems Operation (C11 & C13 Industrial Engines).pdf

SENR9853 — Testing & Adjusting (C11 & C13 Industrial Engines)

Air in Fuel — Test.pdf

Air Inlet and Exhaust System — Inspect.pdf

Battery — Test.pdf

Charging System — Test.pdf

Compression — Test.pdf

Connecting Rod Bearings — Inspect.pdf

Cooling System — Check — Overheating.pdf

Cooling System — Inspect.pdf

Cooling System — Test.pdf

Cylinder Block — Inspect.pdf

Cylinder Liner Projection — Inspect 1.pdf

Electric Starting System — Test.pdf

Electronic Unit Injector — Adjust.pdf

Electronic Unit Injector — Test.pdf

Engine Crankcase Pressure (Blowby) — Test.pdf

Engine Oil Pressure — Test.pdf

Engine Valve Lash — InspectAdjust.pdf

Excessive Bearing Wear — Inspect.pdf

Excessive Engine Oil Consumption — Inspect.pdf

Exhaust Temperature — Test.pdf

Finding Top Center Position for No. 1 Piston.pdf

Flywheel Housing — Inspect.pdf

Flywheel — Inspect.pdf

Fuel Quality — Test.pdf

Fuel System — Inspect.pdf

Fuel System Pressure — Test.pdf

Fuel System — Prime.pdf

Gear Group (Front) — Time.pdf

Increased Engine Oil Temperature — Inspect.pdf

Inlet Manifold Pressure — Test.pdf

Main Bearings — Inspect.pdf

Pinion Clearance — Adjust.pdf

Piston Ring Groove — Inspect.pdf

Turbocharger — Inspect.pdf

Variable Valve Actuators — InspectAdjust.pdf

Vibration Damper — Check.pdf

Water Pump — Test.pdf

Water Temperature Regulator — Test.pdf

SENR9853 — Testing & Adjusting (C11 & C13 Industrial Engines).pdf

Caterpillar Engines C11, C13, C15 Repair Service Manual