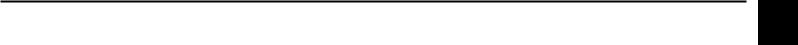

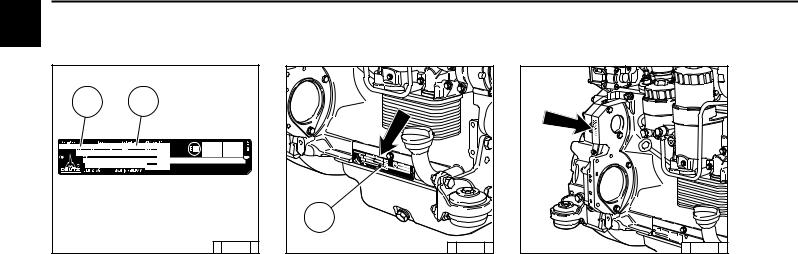

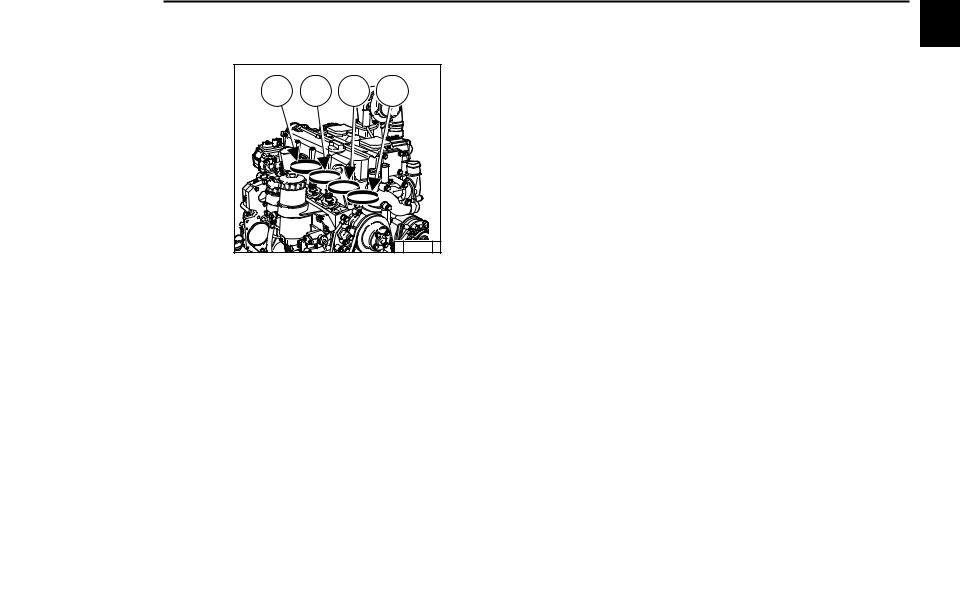

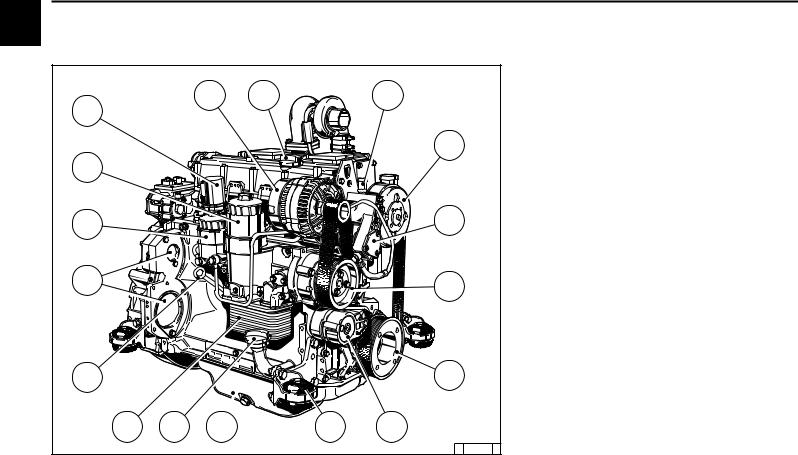

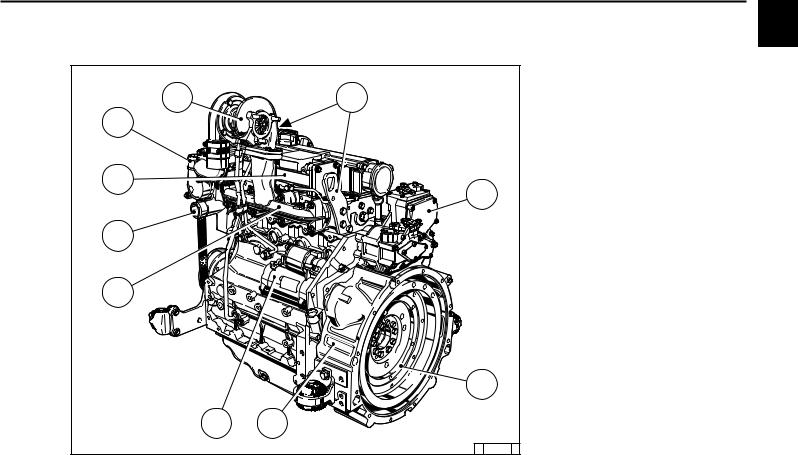

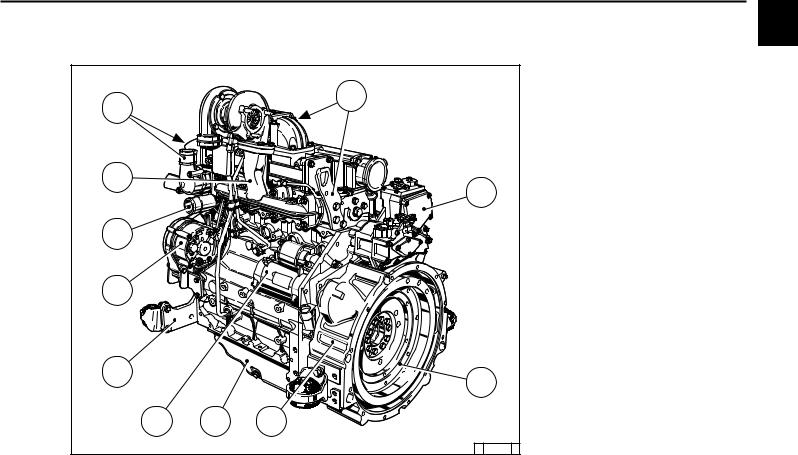

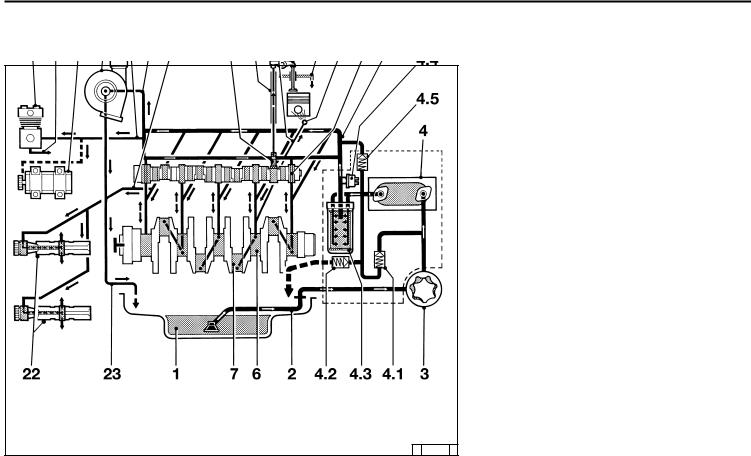

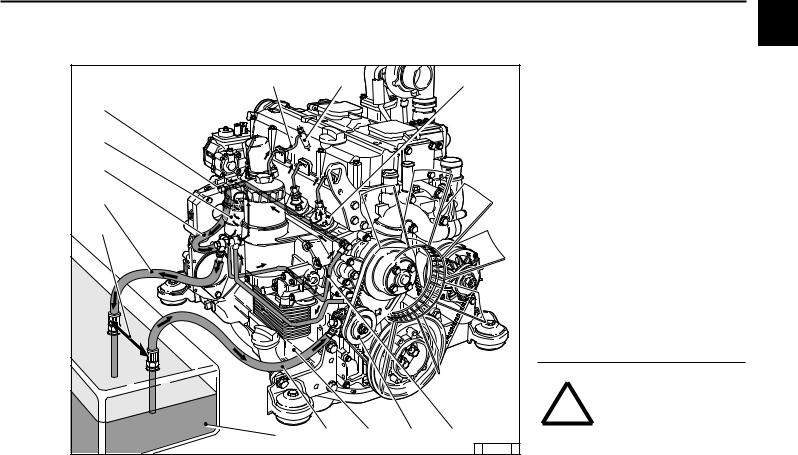

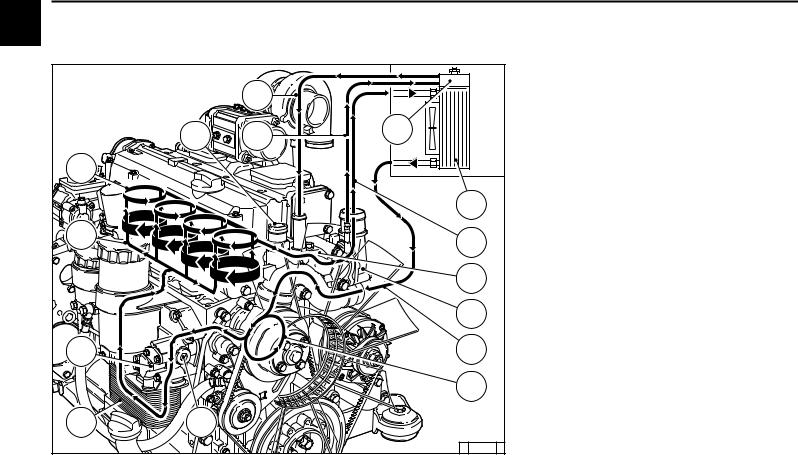

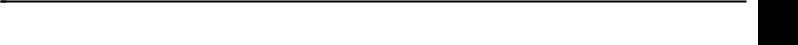

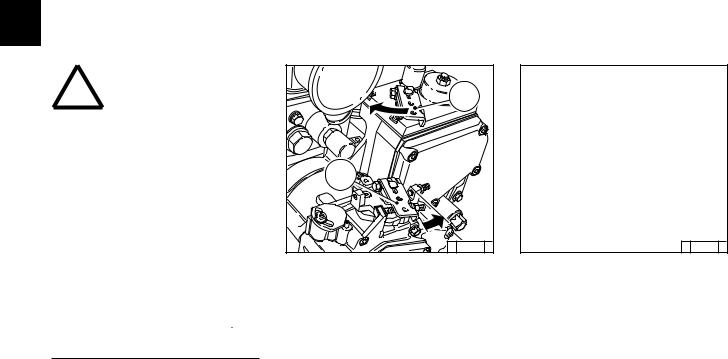

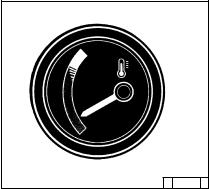

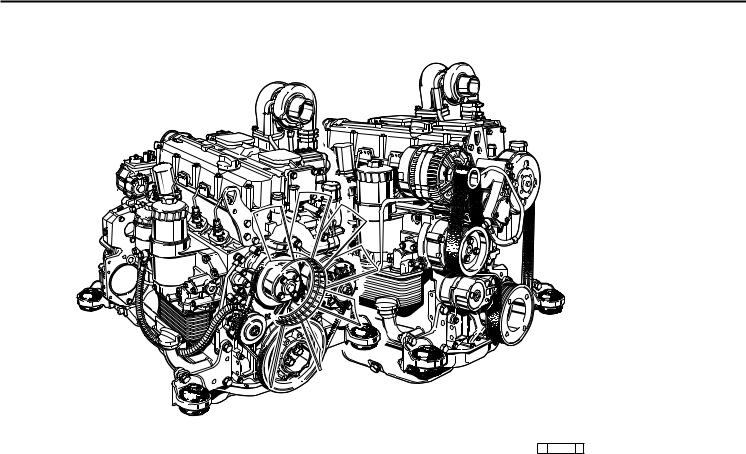

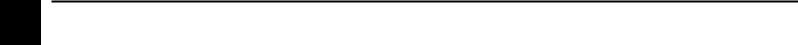

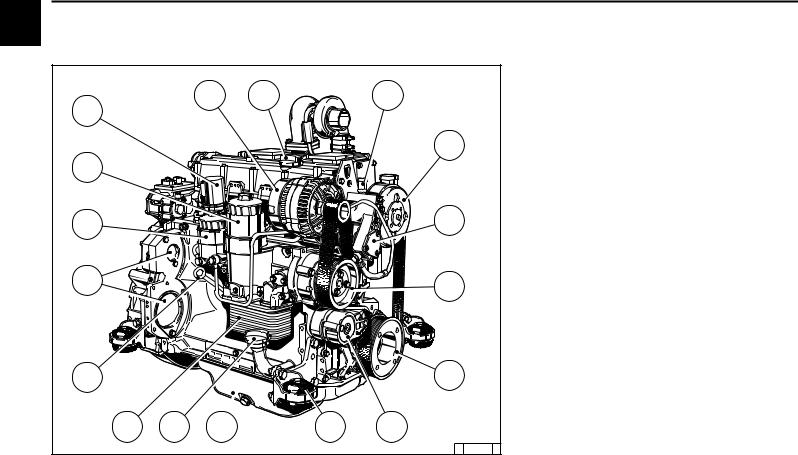

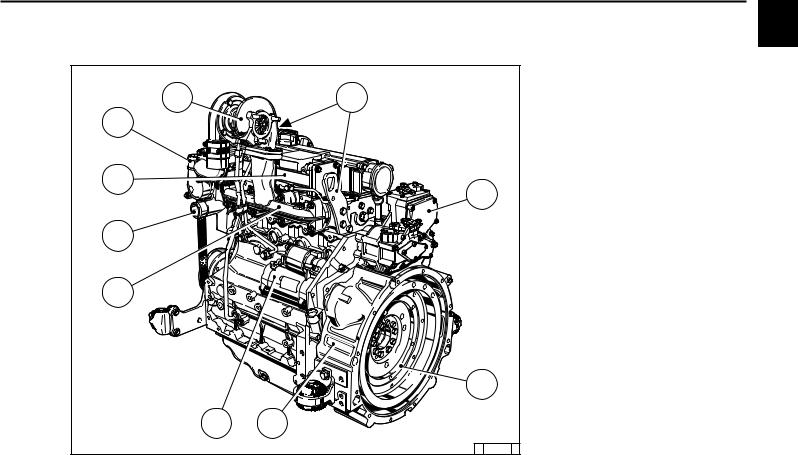

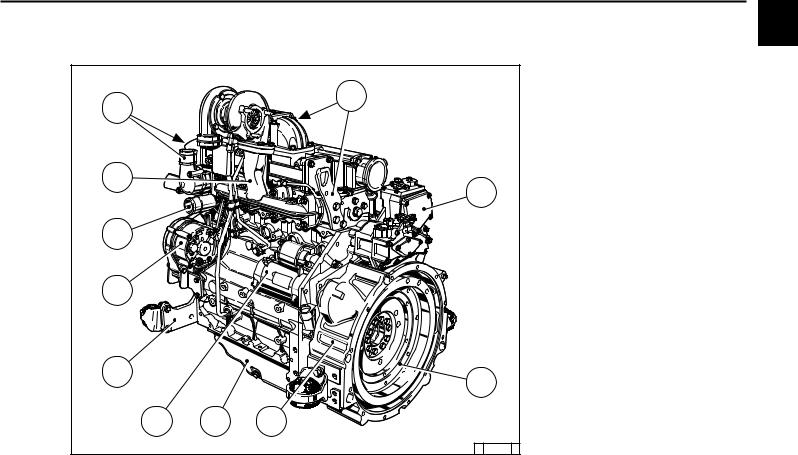

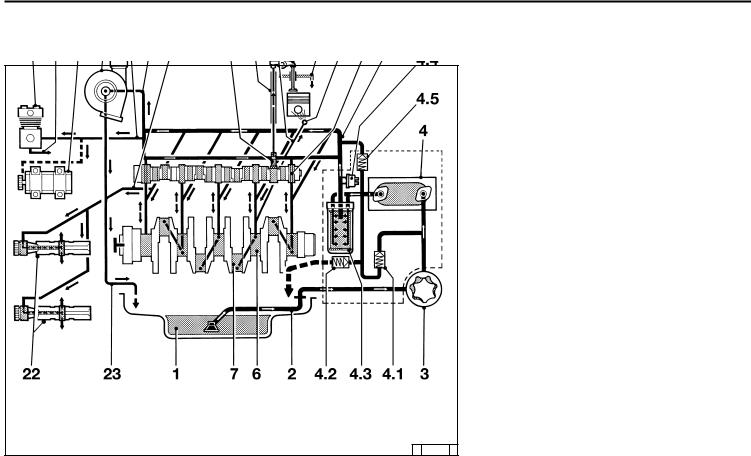

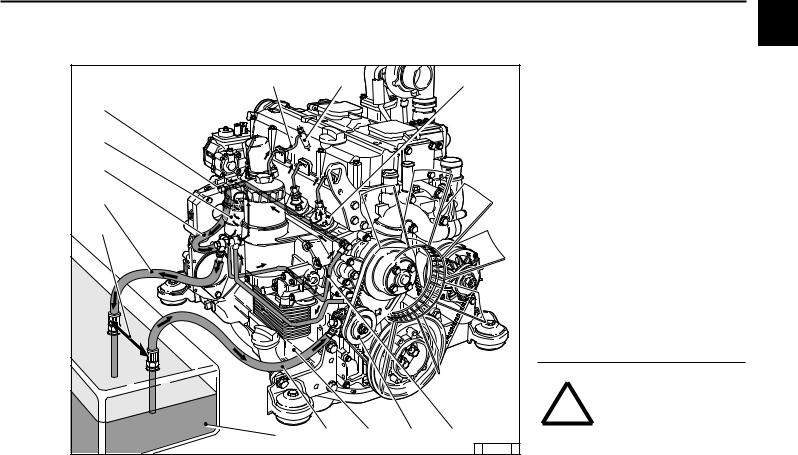

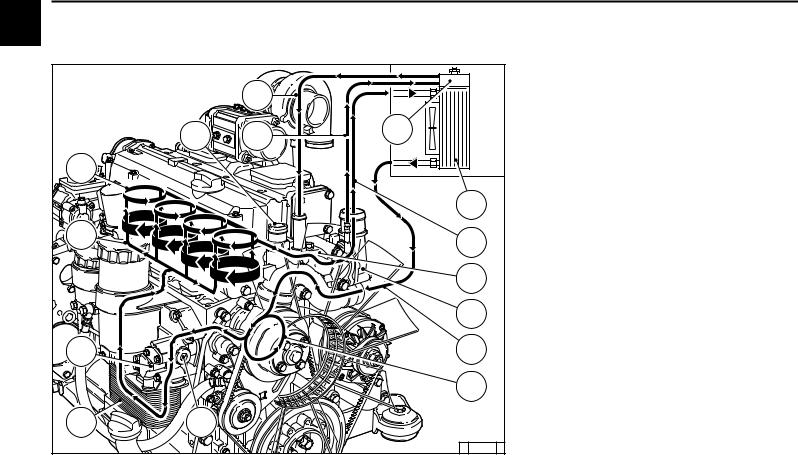

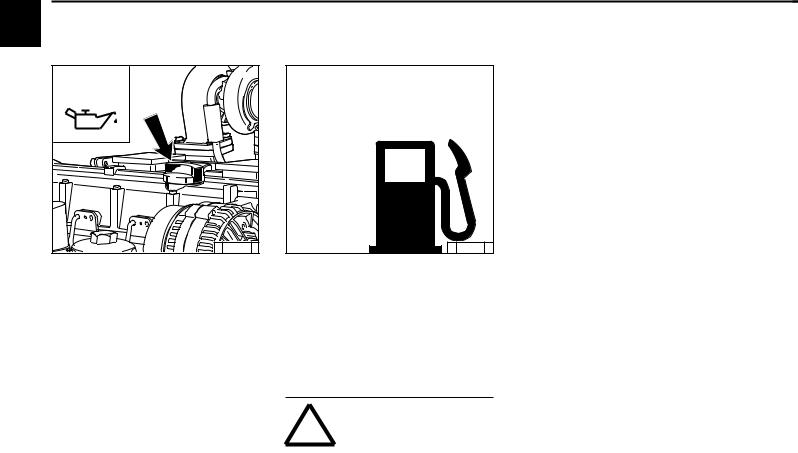

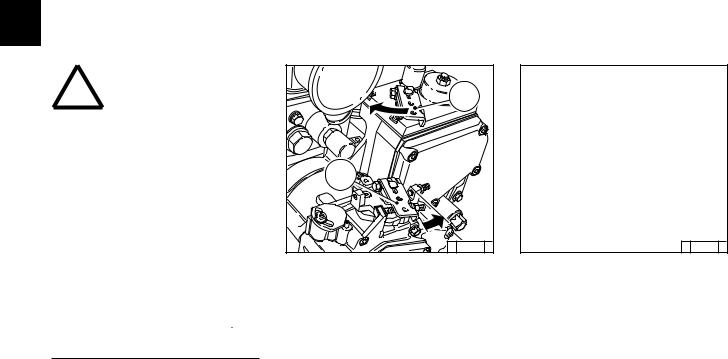

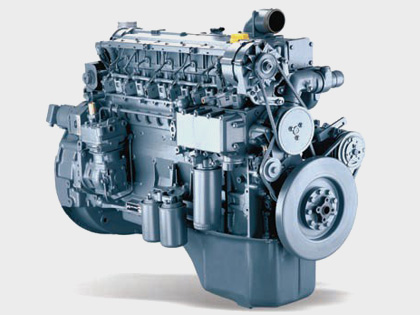

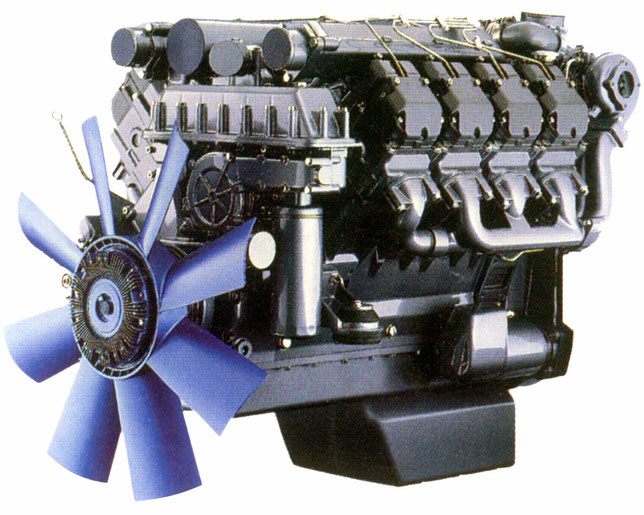

Operation Manual C 2000 2012 Revised (10-12) Doosan purchased Bobcat Company from Ingersoll-Rand Company in 2007. Any reference to Ingersoll-Rand Company or use of trademarks, service marks, logos, or other proprietary identifying marks belonging to Ingersoll-Rand Company in this manual is historical or nominative in nature, and is not meant to suggest a current affiliation between Ingersoll-Rand Company and Doosan Company or the products of either. 1 Gerade BA 2012 9912en Safety guidelines / Accident prevention ● Please read and observe the information given in this Operation Manual. This will enable you to avoid accidents, preserve the manufacturer’s warranty and maintain the engine in peak operating condition. ● This engine has been built exclusively for the application specified in the scope of supply, as described by the equipment manufacturer and is to be used only for the intended purpose. Any use exceeding that scope is considered to be contrary to the intended purpose. The manufacturer will not assume responsibility for any damage resulting therefrom. The risks involved are to be borne solely by the user. ● Use in accordance with the intended purpose also implies compliance with the conditions laid down by the manufacturer for operation, maintenance and servicing. The engine should only be operated by personnel trained in its use and the hazards involved. ● The relevant accident prevention guidelines and other generally accepted safety and industrial hygiene regulations must be observed. ● When the engine is running, there is a risk of injury through: - turning/hot components - engines with positive ignition - ignition systems (high electrical voltage) You must avoid contact at all times! 00_GB.p65 2 ● Unauthorized engine modifications will invalidate any liability claims against the manufacturer for resultant damage. Manipulations of the injection and regulating system may also influence the performance of the engine, and its emissions. Adherence to legislation on pollution cannot be guaranteed under such conditions. ● Do not change, convert or adjust the cooling air intake area to the blower. The manufacturer shall not be held responsible for any damage which results from such work. ● When carrying out maintenance/repair operations on the engine, the use of DEUTZ original parts is prescribed. These are specially designed for your engine and guarantee perfect operation. Non-compliance results in the expiry of the warranty! ● Maintenance and cleaning of the engine should only be carried out when the engine is switched off and has cooled down. You must ensure that the electrical systems have been switched off and the ignition key has been removed. Accident prevention guidelines concerning electrical systems (e.g. VDE-0100/-0101/0104/-0105 Electrical protective measures against dangerous touch voltage) are to be observed. When cleaning with fluids, all electrical components are to be covered impermeably. 04.02.2002, 14:23 Operation Manual 2012 0297 9912 en Engine Serial Number: Technical modifications required to improve our engines are reserved with regard to specification data and other technical information contained in this Operation Manual. No parts of this Manual may be reproduced in any form or by any means without our written approval. © 2003 Please enter the engine serial number here. This number should be quoted when inquiring about Customer Service, Repairs or Spare Parts (see Section 2.1). Foreword Dear Customer, Liquid-cooled DEUTZ engines are designed for a large number of applications. Consequently, a wide range of variants are offered to meet the requirements of specific cases. Your engine is appropriately equipped for the installation concerned, which means that not all of the components described in this Operation Manual are necessarily mounted to your engine. We have endeavored to highlight any differences so that you will be able to locate the operating and maintenance instructions relevant to your engine quickly and easily. Please read this Manual before starting your engine, and always observe the operating and maintenance instructions. We are available to help with any additional inquiries Sincerely, DEUTZ AG © 2003 © 31 493 0 Index General 2. Engine Description 2.1 Model 2.1.1 Rating Plate 2.1.2 Position of the Rating Plate 2.1.3 Engine Serial Number 2.1.4 Cylinder Enumeration 2.2 Engine Illustrations 2.2.1 Operating Side 2012 Ribbed V-belt Drive 2.2.2 Starter Side 2012 Ribbed V-belt Drive 2.2.3 Operating Side 2012 2.2.4 Starter Side 2012 2.3 Lube Oil Circuit Schematic 2.3.1 Lube Oil Plan 2.4 Fuel System 2.4.1 Fuel System Plan 2.5 Coolant System 2.5.1 Coolant Plan 2012 3. Engine Operation 3.1 Commissioning 3.1.1 Pour in Engine Oil 3.1.2 Filling Oil Bath Air Filter with Engine Oil 3.1.3 Pour in Fuel 3.1.4 Fill / Bleed Cooling System 3.1.5 Other Preparations 3.2 Starting 3.2.1 Electric Starting 3.3 Monitoring Operation 3.3.1 Engine Oil Pressure 3.3.2 Coolant Temperature 3.4 Shutting off 3.4.1 Mech. Stopping 3.4.2 Electr. Stopping 3.5 Operating Conditions 3.5.1 Winter Operation 3.5.2 High Ambient Temperature, High Altitude 4. Operating Media 4.1 Lube Oil 4.1.1 Quality 4.1.2 Viscosity 4.2 Fuel 4.2.1 Quality 4.2.2 Winter Fuel 4.3 Coolant 4.3.1 Water Quality for Coolant 4.3.2 Coolant Treatment 4.3.3 Cooling System Protectants 5. 5.1 5.2 5.3 6. 6.1 Routine Maintenance Maintenance Plan Maintenance Diagram Maintenance Work Completed 6.1.1 Oil Change Intervals 6.1.2 Check Oil Level, Change Engine Oil 6.1.3 Replace Oil Filter 6.1.4 Clean/Replace Oil Filter (Cup) 6.2 Fuel System 6.2.1 Replace Fuel Filter 6.2.2 Fuel Pre-filter, Clean Filter Element / Replace if Necessary 6.2.3 Bleed Fuel System with Fuel Pre-filter 6.2.4 Bleed Fuel System without Fuel Pre-filter 6.3 Cooling System 6.3.1 Cleaning Intervals 6.3.2 Clean Cooling System 6.3.3 Drain Cooling System 6.3.4 Fill / Bleed Cooling System 6.4 Combustion Air Filter 6.4.1 Cleaning Intervals 6.4.2 Emptying Cyclone Type Precleaner 6.4.3 Clean Oil Bath Air Filter 6.4.4 Dry Type Air Cleaner 6.5 Belt Drives 6.5.1 Check V-belts – 2012 Standard – 2012 with Ribbed V-belt Service and Maintenance Lubrication System © 2003 1. Index Tension V-belts Coolant / Fuel Pump 6.5.3 Replace V-belts Coolant / Fuel Pump 6.5.4 Replace V-belts Ribbed V-belts 6.5.5 Tension Alternator V-belts 6.5.6 Replace Alternator V-belts 6.5.7 Wedge rib V-belts wear limit examine 6.6 Adjustments 6.6.1 Check Valve Clearance (Adjust if Necessary) 6.6.1.1 Valve Clearance Adjustment Plan 6.7 Accessories 6.7.1 Battery 6.7.2 Rotary Current Alternator 6.7.3 Transportation Shackles © 2003 6.5.2 7. 7.1 8. 8.1 9. 9.1 9.2 9.3 Faults, Causes and Remedies Fault Table Engine Preservation Preservation Technical Specification Engine Specifications and Settings Screw Tightening Torques Tools 10. Service General DEUTZ Diesel Engines Care and Maintenance Service are the product of many years of research and development. The resulting know-how, coupled with stringent quality standards, guarantee their long service life, high reliability and low fuel consumption. It goes without saying that DEUTZ Diesel Engines meet the highest standards for environmental protection. Sound care and maintenance practices will ensure that the engine continues to meet the requirements placed on it. Recommended service intervals must be observed and service and maintenance work carried out conscientiously. Special care should be taken under abnormally demanding operating conditions. Please contact one of our authorized service representatives in the event of breakdowns or for spare parts inquiries. Our trained specialists will carry out repairs quickly and professionally, using only genuine spare parts. Original parts from DEUTZ AG are always produced in accordance with state-of-the-art technology. Please turn to the end of this manual for further service information. Beware of Running Engine Safety 1 California Proposition 65 Warning Shut the engine down before carrying out maintenance or repair work. Ensure that the engine cannot be accidentally started. Risk of accidents. When the work is complete, be sure to refit any panels and guards that may have been removed. Never fill the fuel tank while the engine is running. Observe industrial safety regulations when running the engine in an enclosed space or underground. This symbol is used for all safety warnings. Please follow them carefully. The attention of operating personnel should be drawn to these safety instructions. General safety and accident prevention regulations laid down by law must also be observed. ! Asbestos DEUTZ original parts are asbestosfree. Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. 1 Engine Description 2 © 2003 2.1 Model 2.2 Engine Illustrations 2.3 Lube Oil Circuit Schematic 2.4 Fuel System 2.5 Coolant System Engine Description 2.1.1 Rating Plate 2 A 2.1 Model 2.1.2 Position of the Rating Plate 2.1.3 Engine Serial Number B C © 26 332 3 © 2003 The model A , the engine serial number B and the performance data are stamped on the rating plate.The model and engine serial number must be given when ordering parts. © 31 488 0 The rating plate C is attached to the crankcase. © 31 823 0 The engine serial number is stamped on the arrow crankcase (arrow arrow) as well as the rating plate. Engine Description 2.1 Model 2.1.4 Cylinder Enumeration 1 2 3 2 4 © 31 813 0 © 2003 Cylinders are numbered consecutively, beginning at the flywheel. Engine Description 2.2 Engine Illustration 2.2.1 Operating Side 2012 Ribbed V-belt drive 2 1 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Alternator Oil filler Coolant connection compensation line Fan pulley Fuel pump Coolant pump Ribbed V-belt pulley on crankshaft Tension roller Feet Oil pan Oil filler neck Oil filter housing with engine oil cooler Oil dipstick Optional attachment of: Compressor or hydraulic pump 15 Fuel filter cartridge 16 Oil filter cartridge 17 Tractive electromagnet 3 17 4 © 2003 16 15 5 14 6 13 7 12 11 10 9 8 © 31 482 0 Engine Description 2.2 Engine Illustration 2.2.2 Starter Side 2012 Ribbed V-belt drive 2 18 18 19 20 21 22 23 24 25 26 27 19 27 26 Turbocharger Engine suspension Speed regulator Flywheel SAE housing Starter Exhaust manifold Coolant inlet Heater flange not shown Thermostat housing coolant outlet 20 25 24 23 22 © 31 483 0 © 2003 21 Engine Description 2.2 Engine Illustration 2.2.3 Operating Side 2012 2 14 1 13 2 12 3 11 4 10 © 2003 9 8 7 6 5 © 31 484 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Turbocharger Heater flange Fan Alternator V-belt pulley on crankshaft Coolant pump Fuel pump Oil filler Oil filter housing with engine oil cooler Oil filter housing with oil filter cartridge Oil dipstick Fuel filter Tractive electromagnet Oil filler neck Engine Description 2.2 Engine Illustration 2.2.4 Starter Side 2012 2 15 16 17 18 19 20 21 22 23 24 25 15 25 24 Engine suspension Speed regulator Flywheel SAE housing Oil pan Starter Feet Alternator Coolant inlet Exhaust manifold Coolant outlet 16 23 22 21 20 19 18 © 31 485 0 © 2003 17 Engine Description 2 2.3 Lube Oil Circuit Schematic 2.3.1 Lube Oil Plan 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 © 2003 21 22 23 © 31 808 0 Oil pan Intake line Lube oil pump Lube oil cooler 4.1 Heat exchanger bypass valve 4.2 Shut-off valve 4.3 Lube oil replacement filter 4.4 Oil pressure sensor Main oil pipe Crankshaft bearing Con-rod bearing Camshaft bearing Line to spray nozzle Spray nozzle for piston cooling Valve lifter with rocker arm impulse lubrication Stop rod, oil supply for rocker arm lubrication Rocker arm Return line to oil pan Oil line to turbocharger Turbocharger Oil line to compressor or hydraulic pump Compressor Hydraulic pump Return line from compressor or hydraulic pump Line to the differential (2x) Balancer shafts Turbocharger return to crankcase Engine Description 2.4 Fuel System 2 2.4.1 Fuel System Plan 9 1 2 3 4 5 6 7 8 9 10 11 Fuel tank Line to fuel pump Fuel pump Line to fuel filter Fuel filter Line to the injection pumps Injection pump Line to injection valve Injection valve Banjo bolt with pressure maintenance valve Return line to fuel filter housing from pressure maintenance valve (with cup filter installation only) 12 Return line to fuel tank 13 Maintain maximum possible distance 7 10 5 11 12 13 1 2 4 3 6 © 31 809 1 © 2003 8 Engine Description 2.5 Coolant System 2.5.1 Coolant block diagram 2012 Example: With cup filter 2 12 13 10 11 6 8 5 7 1 2 9 15 © 2003 3 4 14 © 31 810 1 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Thermostat housing Outlet neck cover Coolant pump Lube oil cooler Cylinder cooling Cylinder head cooling Line from engine to heat exchanger Heat exchanger Line from heat exchanger to thermostat Ventilation line to the compensation tank Compensation tank Coolant compensation line Coolant return from heater Coolant supply to heating at V-belts Coolant supply to heating at ribbed V-belts Engine Operation 3 Commissioning Starting Monitoring Operation Shutting off Operating Conditions © 2003 3.1 3.2 3.3 3.4 3.5 Engine Operation 3.1.1 Pour in Engine Oil 3 3.1 Commissioning 3.1.2 Oil Bath Air Filter with Engine Oil OIL FUEL © 26 398 0 © 31 491 0 © 2003 As a rule, engines are delivered without oil. Pour lube oil into the oil filler neck (arrow). Oil capacity, see 9.1. For oil grade and viscosity, see 4.1. Fill oil cup 1 of the oil bath air cleaner (if installed) with oil up to the arrow. For oil grade and viscosity, see 4.1. ! Never fill the fuel tank while the engine is running. Ensure cleanliness! Do not spill fuel! Engine Operation 3.1 Commissioning 3.1.3 Fill / Bleed Cooling System 3.1.4 Other Preparations ● 2012: In accordance with the radiator supplier’s specifications ● Unit engine: In accordance with the radiator supplier’s specifications ● Check battery and cable connections, see 6.7.1. 3 ● Trial run - After the engine has been prepared, carry out a brief trial run for approx. 10 minutes, without load if possible. During and after the trial run - Check the engine for leaks. After the engine has been turned off - Check oil level and top up if necessary, see 6.1.2. - Retension V-belts, see 6.5. ● Breaking in During the break-in phase - about 200 operating hours - check the oil level twice a day. After the engine is broken in, checking once a day will be sufficient. © 2003 ● In the event of commissioning engines which have been preserved Carry out removal of preservation in accordance with Chapter 8.1. Engine Operation 3.2 Starting 3.2.1 Electric Starting 3 without cold start assistance Before starting, make sure that nobody is standing in the immediate vicinity of the engine or driven machine. After repair work: Check that all guards have been replaced and that all tools have been removed from the engine. When starting with glow plugs, do not use any other starter substance (e.g. injection with start pilot). Risk of accident! Caution: If the speed regulator has been removed, the engine must not be started under any circumstances. Disconnect the battery! ! 2 1 © 2003 © 31 824 0 Do not actuate the starter for more than 20 seconds. If the engine does not catch, wait for one minute then try again. If the engine does not catch after two attempts, refer to the Fault Table (see 7.1). © 25 745 0 ● Disengage the clutch to separate the engine from any driven parts. ● Insert key - Position 0 = no operating voltage. ● Bring speed adjustment lever 1 into at least the middle speed position in the direction of the arrow. ● Turn key clockwise - Position 1 = operating voltage - Pilot lights 1 and 2 illuminate. ● Move cut-out handle 2 into operating position counter to the direction of the arrow. ● Push key in and turn further clockwise against spring pressure. - Position 2 = no function - Position 3 = start ● Release key as soon as engine fires - The pilot lights will go out. 3.2 Starting 3 with cold start assistance Heater flange © 25 746 2 ● Insert key - Position 0 = no operating voltage. ● Turn key clockwise - Position 1 = operating voltage. - Pilot lights illuminate, pre-glowing until glow indicator is extinguished. ● Release key as soon as engine fires. - The pilot lights will go out. © 2003 ● Push key in and turn further clockwise against spring pressure. - Position 2 = no function - Position 3 = start Engine Operation 3.3 Monitoring Operation 3.3.1 Engine Oil Pressure 3 Oil pressure lamp © 25 752 1 ● The oil pressure pilot light comes on with operating voltage on and engine off. ● The oil pressure pilot light must be extinguished when the engine is running. © 2003 Oil Pressure Gauge Oil Pressure Indicator © 25 753 0 ● The pointer must remain in the green sector over the entire operating range. © 25 754 0 ● The pointer of the oil pressure gauge must display the minimum oil pressure (see 9.1) 3.3 Monitoring Operation Engine Operation 3.3.2 Coolant temperature 3 © 26 246 0 © 2003 ● The engine temperature gauge pointer should always remain in the green sector. It should rarely enter the yellow-green sector. If the pointer enters the orange sector, the engine is overheating. Turn off and establish the cause from the Fault Table (see 7.1). Engine Operation 3.4.1 Mechanical Stopping 3 3.4 Shutting Off 3.4.2 Electrical Stopping 2 1 © 31 825 0 ● Move speed adjustment lever 1 to low idle. ● Move shut-off lever 2 until the engine comes to a stop. The charge pilot light and the oil pressure pilot light illuminate when the engine stops. © 2003 ● Turn key counterclockwise (to position 0) and remove. The pilot lights will go out. If possible, do not switch off the engine when under full load. Subsequently allow the engine to idle for approx. 2 mins. © 25 746 2 ● Turn key counterclockwise (to position 0) and remove. The pilot lights will go out. Engine Operation 3.5 Operating Conditions 3.5.1 Winter Operation ● Lube Oil Viscosity - Select the oil viscosity (SAE grade) according to the ambient temperature before starting the engine, see 4.1.2. - Increase oil change frequency when operating below -10 °C, see 6.1.1. ● Diesel Fuel - Use winter-grade diesel fuel for operation below 0 °C, see 4.2.2. 3 ● Battery - Efficient cold starting necessitates that the battery is well-charged, see 6.7.1. -The starting limit temperatures can be lowered by 4-5 °C by heating the battery up to about 20 °C. (To do so, remove the battery and store in a warm place). ● Coolant - Mixture ratio of anti-freeze / water for minimum temperature (max. -35 °C), see 4.3.1. ● Additional Maintenance Work - Drain the sludge from the fuel tank once a week (undo the sludge drain screw). - If necessary, adjust oilbath filter oil level, like the engine oil, to the ambient temperture. - Below -20 °C, after removing the starter if necessary, smear the ring gear on the flywheel via the pinion bore from time to time with cold-resistant grease. (e.g. Bosch grease FT 1 V 31). © 26 248 0 © 2003 ● Cold Start Assistance - The heater flange is automatically initialised at temperatures < -25 °C. Engine Operation 3.5 Operating Conditions 3.5.2 High Ambient Temperature High Altitude 3 ● Air density decreases as altitude or ambient temperature increase. As a result of this, the engine’s maximum output, the quality of the exhaust gas, the temperature level and, in extreme cases, starting behaviour, are impeded. In the event of non-stationary operation, use up to altitudes of 1000 m and temperatures of 30 °C is permissible. If the engine is to operate under unfavourable conditions (at higher altitudes or temperatures), it will be necessary to reduce the injected fuel quantity and thus, engine power. © 2003 ● If you have any doubts about engine operation under these or similar conditions, ask your engine or equipment supplier whether the engine has been derated in the interests of reliability, service life and exhaust gas quality (smoke!). Otherwise contact your service representative. C F 0 32 © 25 901 1 Operating Media 4 © 2003 4.1 Lube Oil 4.2 Fuel 4.3 Coolant Operating Media 4 4.1 Lube Oil 4.1.1 Quality Grade 4.1.2 Viscosity Lube oils are differentiated by Deutz according to their performance and quality class. Oils of other, comparable specifications can be used. Generally, multi-grade oils shall be used. In closed heated rooms at temperatures >5°C, also single-grade oils can be used. Approved oils: Deutz ACEA DQC I E2-96 DQC II DQC III E3/96/E5-02 E4-99 API CF/CF-4 CH-4/CG-4 - DHD - DHD-1 - © 2003 The precise assignment of the admissible oil qualities to the engines is indicated in chapter 6.1.1. If in doubt, contact your service representative. As the viscosity of lube oil is dependent on temperature, the choice of SAE grade should be governed by the ambient temperature prevailing at the engine operating site. Optimum operating behaviour will be attained if you take the accompanying oil viscosity diagram as a guide. Should the temperature fall temporarily below the limits of the SAE grade selected, cold starting may be affected but the engine will not be damaged. In order to keep wear to a minimum, do not exceed application limits for extended periods of time. Synthetic lube oils feature an improved temperature and oxidation stability. Only with preheating 30 298 1 Operating Media 4.1 Lube Oil Turbocharged engines with uprated power and engines with high loading The oils listed in enclosure 1 are to be used for the following engines and applications: COM/EPA II version and increased output BF4M 2012/C > 95 kW BF6M 2012/C > 143 kW (bore 101 + 98-MVS) BF6M 2012/C > 135 kW (bore 98 mech. FIE) all engines in CHP plants all engines in gensets operating in parallel with the mains/with each other engines in combines with: These are high-grade oils according to ACEA or API. In addition most of these oils are partly synthetic, some even fully synthetic (5W-40) and thus achieve the thermal stability required for the relevant application and are distinguished by a low tendency to cause deposits in the turbocharger and in the charge air pipes with closed-circuit crankcase breather 4 Lube oils for engines with uprated power and engines with high loading SAE class Availability Producer Type of lube oil DEUTZ TXL-10W40 FE 10W-40 AGIP AGIP ARAL GmbH ARAL GmbH BAYWA BAYWA Castrol GmbH Agip Sigma Ultra TFE Autol Valve Ultra FE Aral MegaTurboral Aral SuperTurboral BayWa Super Truck 1040 MC BayWa Turbo 4000 Castrol SYNTRUCK 10W-40 10W-40 10W-40 5W-30 10W-40 10W-40 5W-40 Castrol GmbH Castrol DYNAMAX 7,5W-40 CHEVRON Chevron Delo 400 Synthtic ESSO Essolube XTS 501 FINA FINA KAPPA FIRST FINA FINA KAPPA ULTRA FUCHS DEA DEA Cronos Synth FUCHS DEA DEA Cronos Premium LD FUCHS DEA Fuchs Titan Cargo MC FUCHS DEA Deutz Oel TLL 10W-40 MB FUCHS DEA DEA Cronos Premium FX FUCHS DEA Fuchs Titan Unic Plus MC MOBIL OIL Mobil Delvac 1 SHC MOBIL OIL Mobil Delvac 1 MOBIL OIL Mobil Delvac XHP Extra BP OIL International BP Vanellus HT Extra Shell International Shell Myrina TX / Shell Rimula Ultra Shell International Shell Myrina TX / Shell Rimula Ultra TOTAL TOTAL RUBIA TIR 86000 Schmierölraffinerie Wintershall TFG Salzbergen GmbH The table will be extended as and when required. 5W-40 10W-40 5W-30 10W-40 5W-40 10W-40 10W-40 10W-40 10W-40 10W-40 5W-40 5W-40 10W-40 10W-40 5W-30 10W-40 10W-40 10W-40 worldwide Germany worldwide worldwide South Gemany South Gemany Europe, North America, Brazil Argentina, Australia, South Africa Europe, North America, Brazil Argentina, Australia, South Africa North America Europe Europe Europe Germany, Europe Germany, Europe worldwide Germany Europe worldwide Europe, SE Asia, Africa worldwide Europe, SE Asia Europe Europe, different description in some countries Europe, different description in some countries worldwide Europe © 2003 4.1.2.1 Specific lube oil definitions Operating Media 4 4.2.1 Quality 4.2.2 Winter Fuel Use commercially available diesel fuel with less than 0.5 % sulphur content. If the sulphur content is higher, oil change intervals should be reduced (see 6.1.1). Waxing may occur at low temperatures, clogging the fuel system and reducing engine efficiency. Use winter-grade diesel fuel (up to -20 °C) for operation below 0 °C. This is made available within good time by filling stations prior to the start of the winter season. The following fuel specifications / standards are approved: DIN EN 590 BS 2869: A1 and A2 (with A2, take note of the sulphur content!) ASTM D 975-88; 1-D and 2-D NATO Code F-54 and F-75 Exhaust emission values which may be determined in the case of type approval tests always refer to the reference fuel prescribed by the authorities for the type approval test. © 2003 4.2 Fuel Kerosene must be added at temperatures below -20 °C. The relevant percentages are given in the adjacent diagram. Special diesel fuels may be used in arctic climatic zones up to -44 °C. If summer-grade diesel fuel must be used at temperatures below 0 °C, up to 60% kerosene can be added (see diagram). +32 0 +23 -5 +14 - 10 + 5 - 15 I - 4 - 20 - 13 - 25 II - 22 - 30 °F ! 0 10 20 30 40 50 60 % B A In most cases, adequate resistance to cold can be obtained by adding a flow improver (additive). Please ask your DEUTZ partner. Diesel fuels must never be mixed with gasoline (Normal and Super grades)! °C © 26 441 1 Legend: I Summer-grade diesel fuel II Winter-grade diesel fuel A Ambient temperature B Percentage of kerosen added ! Mix in tank only! Fill with the appropriate amount of kerosene first, then add the diesel fuel. 4.3 Coolant Operating Media 4 4.3.1 Quality of Water for Coolant 4.3.2 Coolant Treatment 4.3.3 Cooling System Protectants The values listed below must not be exceeded. In order to examine the quality of your water, a test case can be ordered from DEUTZ under Order No. 12130382. In the case of liquid-cooled engines, special attention must be paid to the treatment and control of the coolant, as the engine may otherwise become damaged as a result of corrosion, cavitation and freezing. The treatment of the coolant is carried out by adding a cooling system protectant to the cooling water. The cooling system must be continuously monitored, see 5.1. In addition to checking the coolant level, this also involves checking the concentration of the cooling system protectant. The cooling system protectant concentration can be checked with commercially available testers (example: gefo glycomat ®). DEUTZ cooling system protectant must be purchased in drums under Order No. 01011490 (5 litres) or 1221 1500 (210 litres). These are nitrite, amine and phosphate-free, and provide effective protection against corrosion, cavitation and freezing. If the above mentioned cooling system protectant is unavailable, the following products may be used in exceptional cases. Manufacturer Product designation min. max. 6.5 8.5 3 Chloride ion content [mg / dm ] - 100 Sulphate ion content [mg / dm3] - 100 Total hardness [°dGH] 3 20 AVIA ARAL BASF DEA SHELL AVIA Antifreeze Extra Antifreeze Extra Glysantin G 48 DEA Radiator Antifreeze SHELLGlycoShell The cooling system protectant in the coolant should not fall below or exceed the following concentration: Cooling system protectant Water max. 45 Vol.% 55% min. 35 Vol.% 65% Filling volume, see chart over page in combination with specifications in Chapter 9.1. The use of other cooling system protectants, e.g. chemical anti-corrosion agents, is possible in exceptional cases. Consult DEUTZ Service. ! If nitrite-based cooling system protectants are mixed with amine-based agents, dangerous nitrosamines are formed. ! Cooling system protectants must be disposed of in an environmentally-friendly manner. © 2003 Water quality pH value at 20 °C Operating Media 4 4.3 Coolant Cooling system protection Cooling system protection content of coolant system *) [Litres] Frost protection in [ °C] 18 35 –22 6,3 7,0 7,7 8,75 9,5 40 –28 7,2 8,0 8,8 10 45 –35 8,1 9,0 9,9 50 –45 9,0 10 11 in 20 22 27 30 32 35 10,5 11,2 12,3 10,8 12 12,8 14 11,3 12,2 13,5 14,4 15,8 12,5 13,5 15 16 17,5 Cooling system protectant *) For coolant content of your engine, see Operation Manual Chapter 9.1. Note: Grey sector only after consulting head office © 2003 25 Routine Maintenance 5 © 2003 5.1 Maintenance Schedule 5.2 Maintenance Chart 5.3 Maintenance Work Completed Routine Maintenance 5.1 Maintenance Schedule check= ● adjust= ❍ clean= ▲ replace= ■ ⇓ prior to or during 1st trial run, check 2x daily during the breaking in phase or when commissioning new and overhauled engines 5 ⇓ every 10 hours of operation or daily Operating hours (OP) every Years 250 ● 500 1000 1 5 0 0 12000 1 2 ● ■ ■ ■ ● ■ ■ ● ● ▲ ■ ● ■ ■ ● ● ● ● ● ● ■ ● ● ● ● ● ▲ ❍ ■ Operation Industrial engines The specified engine maintenance values are permissible recommended maximums. Depending on usage, reduced maintenance intervals may be necessary, comply with the unit manufacturer’s operating instructions. # Maintenance must only be carried out by authorised service personnel Top lube oil up if necessary Lube oil (oil change intervals depending on engine use), see TR 0199-99-3002 Oil filter cartridge (at each lube oil change) Fuel filter cartridge Flexible fuel leak oil lines (replace completely) Injection valve Fuel pre-cleaner/ filter element (cleaning or replace if necessary) Coolant (additive concentration) Coolant pump Coolant level Intake air cleaner (If available, maintain according to maintenance indicator) Intercooler (drain lube oil/condensation) Battery and cable connectors Engine monitoring system, warning system Valve clearance V-belts (retension or replace if necessary) © 2003 * When the warning system responds (lamp/horn), the fuel pre-filter must be emptied immediately Section 6.1.2/3.3.4 6.1.1/ 6.1.2 6.1.3 6.2.1 # 4.2/ 5.2 4.3.1/ 2/ 3 # – 6.4.3 /6.4.4 6.7.1 3.3 # 6.6.1# 6.5.1 Routine Maintenance 5.1 Maintenance Schedule check= ● adjust= ❍ clean= ▲ replace= ■ prior to or during 1st trial run, check 2x daily during the breaking in phase or when commissioning new and overhauled engines every 10 hours of operation or daily In hours of operation (HO) every Years 250 ● ● ● 500 1000 1500 12000 1 2 ● ● ● ■ 5 Industrial engines The specified engine maintenance values are permissible recommended maximums. Depending on usage, reduced maintenance intervals may be necessary, comply with the unit manufacturer’s operating instructions. # Maintenance must only be carried out by authorised service personnel Operation Check engine for leaks (visual inspection) Engine suspension (replace if damaged) Fastenings, hose connections / clamps Basic overhaul Section – 9.2 – # Page 2 of 2 prior to or during 1st trial run, check 2x daily during the breaking in phase or when commissioning new and overhauled engines every 10 hours of operation or daily In hours of operation (HO) every 250 Years 500 1000 3000 6000 12000 1 ■ 2 Operation Injection valve Additions and modifications for engines with EPA approval The specified engine maintenance values arepermissible recommended maximums. Depending on usage, reduced maintenance intervals may be necessary, comply with the unit manufacturer’s operating instructions. # Maintenance must only be carried out by authorised service personnel Section # © 2003 check= ● adjust= ❍ clean= ▲ replace= ■ Max. permissible reference times in operating hours (HO) every Routine Maintenance 5.2 Maintenance Chart Check that this is the case. If necessary, ask your engine or equipment supplier for a fresh supply of labels. h Std. AIR 1252000 10 500 OIL The maintenance chart shown on this page is supplied as a self-adhesive label with each engine. It should be affixed where it can be seen clearly on the engine or driven equipment. 5 a in. 1500 ex. Routine work should be carried out according to the schedule in 5.1. OIL 500 FU EL 1000 10 10 ER WAT OIL max. © 2003 0297 9901 1 ! Stop the engine before carrying out any maintenance work. 2012 Routine Maintenance 5.2 Maintenance Chart The maintenance chart shown on this page is supplied as a self-adhesive label with each engine. It should be affixed where it can be seen clearly on the engine or driven equipment. Check that this is the case. If necessary, ask your engine or equipment supplier for a fresh supply of labels. Routine work should be carried out according to the schedule in 5.1. 5 max . min. © 2003 2012 0297 9902 0 min. 9912EN_K05-1.P65 37 17.02.2003, 12:05 Uhr Routine Maintenance 5 Op. hours 50-150 Date * Signature/stamp 5.3 Maintenance Work Completed Op. hours - 125 250 375 500 625 750 875 1000 1125 1250 1375 1500 1625 1750 1875 2000 2115 2250 2375 2500 2625 2750 © 2003 * following commissioning of new and overhauled engines. Duly completed maintenance jobs can be recorded and signed off in the above chart. Date Signature/stamp Routine Maintenance 5.3 Maintenance Work Completed Op. hours Date Signature/stamp Op. hours 2875 3000 3125 3250 3375 3500 3625 3750 3875 4000 4125 4250 4375 4500 4625 4750 4875 5000 5125 5250 5375 5500 5625 5750 Date 5 Signature/stamp © 2003 Duly completed maintenance jobs can be recorded and signed off in the above chart. Routine Maintenance 5 Op. hours Date Signature/stamp 5.3 Maintenance Work Completed Op. hours 5875 6000 6125 6250 6375 6500 6625 6750 6875 7000 7125 7250 7375 7500 7625 7750 7825 8000 8125 8250 8375 8500 8625 8750 © 2003 Duly completed maintenance jobs can be recorded and signed off in the above chart. Date Signature/stamp Routine Maintenance 5.3 Maintenance Work Completed Op. hours Date Signature/stamp Op. hours 8875 9000 9125 9250 9375 9500 9625 9750 9875 10000 10125 10250 10375 10500 10625 10750 10825 11000 11125 11250 11375 11500 11625 11750 Date 5 Signature/stamp © 2003 Duly completed maintenance jobs can be recorded and signed off in the above chart. Routine Maintenance 5 © 2003 Op. hours Date Signature/stamp 5.3 Maintenance Work Completed Op. hours Date Signature/stamp Service and Maintenance 6 © 2003 6.1 Lubrication System 6.2 Fuel System 6.3 Cooling System 6.4 Combustion Air Filter 6.5 Belt Drives 6.6 Adjustments 6.7 Accessories Service and Maintenance 6 6.1 Lubrication System 6.1.1 Oil Change Intervals ● The oil change intervals are dependent on the engine application and the quality of the lube oil. ● If the engine runs fewer hours during the year than stated in the table, the oil should be changed at least once a year. ● If, for vehicle engines, lube oil change intervals are determined by operating hours, the lube oil change intervals indicated in table 6.1.1.1. equipment engines. ● The table refers to the following conditions: – For diesel fuel: sulfur content max. 0.5 % by weight. – Continuous ambient temperatures down to -10 °C / +14°F ● For fuels – with sulfur content is > 0.5 to 1 % or – continuous ambient temperature below -10 °C/+14°F or – with bio-diesel fuels in accordance with DIN 51606-FAME the intervals between oil changes should be halved. © 2002 ● In the case of fuels containing more than 1 % sulfur, contact your service representative. Change the oil with the engine off but still warm (lube oil temperature approx. 80 °C). ENGLISCH • Kapitel 6 • Seite 52 9682en_K06.p65 52 30.07.2003, 10:13 Service and Maintenance 6.1 Lubrication System 6 6.1.1.2 Lube oil change intervals for industrial and marine engines Lube oil grade ACEA-specfication API-specification Worldwide specification special DEUTZ release list Standard lube oil code for building equipment and nonraod vehicles Engine Engine version series 2012 DQC I DQC II DQC III E2-96 CF/CF-4 E3-96/E5-02 CG-4/CH-4 E4-99 - EO... EO...A, EO...B DHD-1 EO...C Enclosure 1 - Lube oil change intervals in op. hours Oil use normal high All engines except for: BF4M2012C P > 95 kW BF6M2012C P > 143 kW, from nonroad stage II at cylinder bore 101 mm or 98 mm with MV system BF6M2012C P > 135 kW, from nonroad stage II at cylinder bore 98 mm with mech. injection system Other engines from nonroad stage II eng. in harv. machines, block-typethermal power stat., gensets** Oil use normal high 250 - 500 - 500 500 500 - - 500 - 500 - 500 500 *Gensets as referred to here are units operating in parallel with the mains / with each other. Emergency power units are dealt with in TR 0199-99-1126. Oil use normal high © 2003 Deutz lube oil quality class Service and Maintenance 6.1 Lubrication System 6.1.1.2 Oil change intervals for vehicle engines 6 Schmieröl-Qualität Deutz lube oil quality class ACEA specification API specification worldwide specification special DEUTZ release © 2003 E2-96 CF/CF-4 - DQC II DQC III E3-96/E5-02 E4-99 CG-4/CH-4 DHD-1 Enclosure 1 Engine version Lube oil change intervals in km 25 2012 Euro I 10 000 15 000 20 000 Euro II and Euro III, except for: 15 000 20 000 BF4M2012C > 95 kW from Euro II 20 000 20 000 BF6M2012C > 143 kW from Euro II at cylinder bore 101 mm with or 98 mm with MV system > 135 kW from Euro II at cylinder bore 98 mm 20 000 with mechanical injection system 40 2012 Local Euro I 15 000 20 000 30 000 traffic Euro II and Euro III,except for: 20 000 30 000 BF4M2012C > 95 kW from Euro II 30 000 BF6M2012C > 143 kW from Euro II at cylinder 30 000 bore 101 mm with or 98 mm with MV system > 135 kW from Euro II at cylinder 30 000 bore 98 mm with mechanical injection system 60 2012 Long Euro I 20 000 30 000 40 000 distance Euro II and Euro III, except for: 30 000 40 000 traffic BF6M2012C > 143 kW from Euro II at cylinder 40 000 bore 101 mm with or 98 mm with MV system > 135 kW from Euro II at cylinder 40 000 bore 98 mm with mechanical injection system If, for vehicle engines, lube oil change intervals are determined by operating hours, the lube oil change intervals indicated in table 4.1. for “Oil use under normal duty” will apply. Average speed in km/h approx. ] Application Site vehicles/ busses DQC I Service and Maintenance 6.1 Lubrication System © 25 729 0 Ensure that the engine or vehicle is in a level position. Engine warm: Shut engine off, wait for 5 minutes and check oil level. Engine cold: Check oil level. Remove the oil dipstick. Wipe the dipstick with a non-fibrous, clean cloth. Insert it to the stop and remove again. Check the oil level, and if necessary, top up to the “MAX” mark. - If the oil level is only just above the “MIN” mark, more oil must be added. The level must not fall below the “MIN” mark. 6 6.1.2.2 Engine Oil Change © 26 022 0 Run engine until warm. Ensure that the engine or vehicle is in a level position. - Lube oil temperature approx. 80 °C. Switch off the engine. © 26 023 0 Place oil tray under the engine. Unscrew oil drain screw. Drain oil. Screw oil drain screw in with new seal ring and tighten. (Tightening torque see 9.2). Pour in lube oil. - For grade / viscosity, see 4.1 - For quantity, see 9.1. Check oil level, see 6.1.2.1. Caution when draining hot oil: Risk of scalding! Do not let used oil run into the soil but collect it in a container! Dispose of this in accordance with environmental regulations! © 2003 6.1.2 Check Oil Level / Change Engine Oil 6.1.2.1 Check Oil Level 6.1.2.1Check Service and Maintenance 6.1 Lubrication System 6.1.3 Replace Oil Filter 6 © 25 880 0 ● With attached locking piston: Undo tensioning screws and remove tensioning clamps downwards. ● Undo the lube oil filter cartridge using a commercial tool and spin off. ● Catch any escaping oil. © 25 881 0 © 25 882 0 ● Clean any dirt from the filter carrier sealing surface. ● Tighten the lube oil filter cartridge with another half-turn. ● Lightly oil the rubber gasket of the new lube oil filter cartridge. ● If locking piston is available: Position tensioning clamps and tighten with tensioning screws. ● Manually screw in the new cartridge until the gasket is flush. ● Check oil level, see 6.1.2. ● Check oil pressure, see 3.3.1. © 2003 ● Check lube oil filter cartridge seal for leaks. Caution is required in the case of hot oil: Risk of scalding! 6.1 Lubrication System Service and Maintenance 6.1.4 Clean / Replace Oil Filter (Cup) 6 1 2 3 4 © 30 074 0 Caution is required in the case of hot oil: Risk of scalding! ● Replace and lightly oil the rubber gasket 2. ● Carefully insert new paper filter cartridge 3 into guide 4. ● Tighten lube oil filter cover 1 in a clockwise direction (25 Nm). ● Start engine. ● Check oil level, see 6.1.2. ● Check oil pressure, see 3.3.1. ● Check lube oil filter attachment for leaks. © 2003 ● Switch off the engine. ● Loosen lube oil filter cover 1 and unscrew in an anticlockwise direction, emties itself the system automatically (drain valve). ● Carefully loosen paper filter cartridge 3 upwards from the guide 4. ● Catch any escaping oil. ● Replace paper filter cartridge 3. ● Clean any dirt from the sealing surface of the filter carrier and lube oil filter cover 1 and fromb the guide 4. Service and Maintenance 6.2 Fuel System 6.2.1 Replace Fuel Filter 6 © 25 880 0 Close the fuel shut-off valve. © 2003 Undo fuel filter cartridge with commercial tool and spin off. © 25 881 0 Apply light film of oil or diesel fuel to the rubber gasket of the new fuel filter cartridge. Catch any escaping fuel. Manually screw in the new cartridge until the gasket is flush. Clean any dirt from the filter carrier sealing surface. Tighten the fuel filter cartridge with a final half-turn. © 25 882 0 Open fuel shutoff valve. Check for leaks. The fuel system does not need to be bled. Keep naked flames away when working on the fuel system. Do not smoke! Service and Maintenance 6.2 Fuel System 6.1.4 Clean / Replace Fuel Oil Filter (Cup) 6 1 2 3 4 © 30 074 0 Keep naked flames away when working on the fuel system. Do not smoke! ● Replace and lightly oil the rubber gasket 2. ● Carefully insert new paper filter cartridge 3 into guide 4. ● Tighten fuel oil filter cover 1 in a clockwise direction (25 Nm). ● Start engine. ● Check fuel oil filter attachment for leaks. © 2003 ● Switch off the engine. ● Loosen fuel oil filter cover 1 and unscrew in an anticlockwise direction, emties itself the system automatically (drain valve). ● Carefully loosen paper filter cartridge 3 upwards from the guide 4. ● Catch any escaping oil. ● Replace paper filter cartridge 3. ● Clean any dirt from the sealing surface of the filter carrier and fuel oil filter cover 1 and fromb the guide 4. Service and Maintenance 6.2 Fuel System 6.2.3 Clean / purge or change fuel pre-filter 6 © 2003 © 31 811 2 Clean (purge) - remove water: ● Turn off engine or, in the case of a changeover filter, switch over to the other filter. ● Close the fuel stopcock or supply. (if available) ● Open the bleed screw 1 on the cover 2 ● Place the fuel collector underneath the fuel pre-filter. ● Empty water and dirt from the bowl 6 by opening (press in and turn slightly without using force) the drain cock 8 and close the drain cock 8 again ● Close the bleed screw 1 on the cover 2 again ● Bleed the fuel pipe according to instructions, see 6.2.5 opposite Changing the filter element 5: Change at least once a year or as required (drop in performance also after purging) ● Turn off the engine or switch to other filter in case of changeover filter ● Close the fuel stopcock or supply (if available) ● Loosen the cover screws 3 diagonally ● Remove the cover 2 ● Remove the spring cassette 4 ● Remove the filter element 5 from the bracket ● Insert new filter element 5 ● Place spring cassette 4 on the element ● Check that the cover seal is fit properly in the cover 2 and check for damage (change if necessary) ● Tighten the cover 2 with the screws 3 diagonally (torque 6 Nm) ● Check the cover 2 for proper fit and leaks ● Bleed the fuel system, see 6.2.4. The connection of a warning system (lamp/horn) via contacts 7 is specified. Immediate maintenance is necessary when the warning system is triggered. Naked flames are prohibited when working on the fuel system! Do not smoke! Dispose of old fuel in an environmentally friendly way! Service and Maintenance 6.2 Fuel System 6.2.5 Bleed Fuel System without Fuel Pre-filter 6.2.4 Bleed Fuel System with Fuel Pre-filter 6 Place fuel collection container beneath the fuel pre-filter. Bleed: Keep naked flames away when working on the fuel system. Do not smoke! Dispose of used fuel in an environmentally-friendly manner! 9 9 © 31 812 0 © 31 812 0 ● Bring engine regulator into stop position. ● Open fuel shut-off valve. ● Loosen pressure maintenance valve 9. Collect any escaping fuel and dispose of this in an environmentally-friendly manner. ● Turn engine over with starter (max. 20 sec.) until bubble-free fuel escapes from pressure maintenance valve 9. ● Tighten pressure maintenance valve 9. ● Bring engine regulator into start position and start. ● Check for leaks after starting the engine. Keep naked flames away when working on the fuel system. Do not smoke! Dispose of used fuel in an environmentally-friendly manner! © 2003 In the event of re-commissioning, following maintenance work or if the tank has been run empty, the fuel system must be bled. Bring engine regulator into stop position. Position fuel collection container beneath filter housing 8 / pressure maintenance valve 9. Open fuel shut-off valve, pressure maintenance valve 9, bleeder screw 1. Turn engine over with starter (max. 20 sec.) until bubble-free fuel escapes from bleeder screw 1 and pressure maintenance valve 9. Firmly tighten bleeder screw 1 and pressure maintenance valve 9. Bring engine regulator into start position and start. Check for leaks after starting the engine. Service and Maintenance 6.3 Cooling System 6.3.1 Cleaning Intervals 6 ● The amount of contamination in the cooling system depends on the engine application. ● Oil and fuel residues on the engine increase the risk of contamination. Therefore pay special attention to leaks if the engine is used in dusty environments. ● Serious contamination occurs, for example: - on construction sites where there is a high level of air-borne dust. - in harvesting applications where there are high concentrations of chaff and chopped straw in the vicinity of the machine. ● Because applications vary, cleaning intervals have to be determined from case to case. The cleaning intervals given in the table below can be used as a guide. 6.3.2 Clean Cooling System Checking or cleaning intervals Engine application Guideline values OH 2000 1000 500 250 © 2003 125 Ships, electrical modules in enclosed areas, pumps. Vehicles on paved roads Tractors, fork-lift trucks, drivable electric units. Vehicles on construction sites and unpaved roads, construction machines, compressors, underground mining units. Agricultural machines, tractors in harvesting applications. ● External cooling system: Clean according to cooling system manufacturer’s specifications. Service and Maintenance 6.3 Cooling System 6.3.3 Drain Cooling System 1 6.3.4 Fill / Bleed Cooling System 2012 6 max . min. ● Position a collecting pan beneath screw plug 1. ● Remove screw plug 1 at crankcase. ● Drain coolant. ● Tighten screw plug 1 again. ● If screw plug 1 is not accessible, drainage can be carried out at the engine radiator (coolant channel). Fill / bleed cooling system see Chapter 6.3.4 Caution when draining hot coolant: Risk of scalding! Collect coolant on draining. Dispose of this in accordance with environmental regulations! 2012 ● Open radiator cap item 1. ● Loosen vent hose item 2. ● Fill coolant item 1b in up to the “MAX” mark or filling limit (if fitted, system heater valve must be open). ● Connect vent hose, item 6, + tighten screw plug item 4. ● Close radiator cap item 7. ● Start engine and warm up until thermostat opens. ● Switch off the engine. ● Check coolant level when engine is cold, and top up if necessary. ● Close radiator cap item 1. Bleed ● External cooling system: According to cooling system manufacturer’s specifications. © 2003 © 31 816 0 0297 9902 0 min. Service and Maintenance 6.4 Combustion Air Filter 6.4.1 Cleaning Intervals 6 The amount of dirt in the combustion air filter depends on the amount of dust in the air and the size of the air filter used. If a high level of dust is anticipated, a cyclone-type pre-cleaner can be fitted in front of the combustion air filter. ● Cleaning intervals must therefore be determined from case to case. ● If dry type air filters are used, cleaning should only be carried out according to the service indicator or service switch. ● Filter servicing is needed when: - Service indicator the red signal 1 is fully visible when the engine is off. - Service switch the yellow pilot light comes on when the engine is running. © 2003 ● After carrying out service work, press the reset button on the service indicator. The service indicator is now ready for operation again. © 25 885 1 6.4.2 Emtying Cyclone Type Precleaner © 25 886 0 ● Undo wing nut 1 and remove cover 2. ● Remove collector bowl 3 from lower section 4 and empty. Clean leaves, straw and other foreign matter from lower section of precleaner. ● Reposition collector bowl 3 onto lower section 4, fasten cover 2 in place by tightening wing nut 1. Never fill collector bowl with oil. Replace collector bowl if damaged. Service and Maintenance 6.4.3 Clean Oil Bath Air Filter 6 © 25 885 1 ● Turn engine off and wait about 10 minutes for the oil to drain from filter housing 1. ● Loosen snap clips 2 and remove oil cup 3 with filter element 4; if necessary, loosen filter element with the aid of a screwdriver at the separating point. Do not damage rubber gasket 5! ● Remove dirty oil and sludge. Clean oil cup. ● Clean filter element 4 in diesel fuel and allow to drip-dry thoroughly. ● Clean filter housing 1 if very dirty. ● Inspect and replace rubber gasket 5 and 6 if necessary. ● Fill oil cup with engine oil up to the mark (arrow) (for viscosity, see 4.1.2). ● Refit oil cup and element to filter housing and secure with snap clips. Never clean filter with gasoline. Dispose of old oil in accordance with environmental regulations! © 2003 6.4 Combustion Air Filter Service and Maintenance 6.4.4 Dry Type Air Filter Dust Discharge Valve 6 Filter Cartridge © 25 888 1 ● Empty dust discharge valve 1 by pressing apart lips of discharge slot as indicated by arrows. ● Clean discharge slot from time to time. ● Remove any caked dirt by pressing together the upper section of the valve. © 2003 6.4 Combustion Air Filter © 25 889 0 ● Undo clip fasteners 1. ● Take off hood 2 and remove cartridge 3. ● Clean cartridge (replace at least once a year) ● Clean cartridge 3. - Using dry compressed air (max. 5 bar), blow out from inside outwards, or - Tap out (in emergencies only). Do not damage the cartridge, or - Wash out according to manufacturer’s specifications. ● Check paper filter (light showing through) and gaskets for damage. Replace if necessary. ● After five filter services or after two years at the latest, replace safety cartridge 4 (never clean!). To do so: - Undo hex nut 5 and remove cartridge 4. - Insert new cartridge, re-install hex nut and tighten. ● Install cartridge 3, replace hood 2 and do up clip fasteners 1. Never clean filter cartridge with gasoline or hot fluids! Service and Maintenance 6.5 Belt Drives 6.5.1 Check V-belts 2012 Standard 6 2012 with Ribbed V-belt ● Visually inspect entire V-belt for damage. ● Replace damaged V-belts. ● After installing new belts, run engine for 15 minutes, then check belt tension. ● To check the tension of the V-belt, use a tension gauge (see 9.3). - Place indicator arm 1 into gauge. - Position guide 3 on V-belt 2, midway between the pulleys, with flange 3 on bottom of gauge against the edge of belt. - Push slowly on the black pad 4 at right angles to V-belt 2 until the spring is heard or felt to trigger. © 31 818 0 © 26 261 1 - Carefully raise the gauge without changing the position of indicator arm 1. - Read off the value where the indicator arm 1 intersects scale 5 (arrow) and read indicator arm 1 off. For settings, see 9.1. - If necessary, retension belt and measure again. Check, tension and change Vbelts only with the engine off. If necessary, reinstall V-belt © 2003 © 31 817 0 Service and Maintenance 6.5.2 Tension V-belts Coolant / Fuel Pump 6 6.5.3 Replace V-belts Coolant / Fuel Pump 6.5.4 Replace V-belts Ribbed V-belts 1 1 3 6.5 Belt Drives 2 3 2 2 1 © 31 819 0 © 2003 ● Loosen screws 1 and 2. ● Press fuel pump 3 in direction of arrow until the correct V-belt tension has been achieved. ● Tighten screws 1 and 2 again. Check, tension and change Vbelts only with the engine off. If necessary, reinstall V-belt guard. © 31 821 0 ● Loosen screws 1 and 2. ● Press fuel pump 3 in direction of arrow. ● Remove V-belt and position new belt. ● Press fuel pump counter to direction of arrow until the correct V-belt tension has been achieved. ● Tighten screws 1 and 2 again. © 31 814 0 ● Press tension roller in direction of arrow until the ribbed V-belt is free. ● First remove ribbed V-belt from the smallest roller. ● Position new ribbed V-belt. ● Press tension roller counter to direction of arrow until the ribbed V-belt is tensioned. Check whether ribbed V-belt is positioned correctly in its guide. Service and Maintenance 6.5 Belt Drives 6.5.5 Tension V-belts Alternator 6.5.6 Replace V-belts Alternator 5 5 3 1 4 © 31 822 0 © 31 820 0 Check, tension and change Vbelts only with the engine off. If necessary, reinstall V-belt guard. 1 2 2 Loosen screws 1, 2 and 4. l Adjust alternator 5 in direction of arrow by turning screw 3 until correct V-belt tension is achieved. Retighten screws 1, 2 and 4. 3 Loosen fuel pump V-belt, see 6.5.3 Loosen screws 1, 2 and 4. Adjust screw 3 until V-belt can be removed. Position new belt. Adjust screw 3 until the correct V-belt tension has been achieved. Retighten screws 1, 2 and 4. Tension fuel pump V-belt, see 6.5.4. © 2003 4 6 Service and Maintenance 6.5 Belt Drives 6.5.7 Wedge rib V-belts wear limit examine. 6 a © 31 879 0 © 2003 ● Wear limit of the wedge ribV- belt as follows examine: ● Distance between the nose of the flexibiliti clamping arm and the notice of the firm tension adjuster housing examine. ● If „ a “ is smaller than 3 mm, then the wedge rib V- belt is to be exchanged Service and Maintenance 6 © 2003 6.6 Adjustments Service and Maintenance 6.6 Adjustments 6.6.1 Check Valve Clearance, Adjust if Necessary 6 © 19 691 2 © 2003 Loosen ventilation valve and swing to the side. Remove the cylinder head cover. Position crankshaft as per schematic, see 6.6.1.1. Before adjusting valve clearance, allow engine to cool down for at least 30 minutes. The oil temperature should be below 80 °C. Check valve clearance 1 between rocker arm / tappet contact face 2 and valve 3 with feeler gauge 6 (there should be only slight resistance when feeler blade is inserted). For permissible valve clearance, see 9.1. © 26 262 1 Adjust valve clearance if necessary: - Release locknut 4. - Use screwdriver 7 to turn setscrew 5 so that the correct valve clearance 1 is attained after locknut 4 has been tightened. Check and adjust valve clearance on all cylinders. Reinstall cylinder head cover (with new gasket if necessary). Swing ventilation valve into position and fasten. 6.6 Adjustments Service and Maintenance 6.6.1.1 Valve Clearance Adjustment Schematic 6 Crankshaft Position 1: Turn crankshaft until both valves in cylinder 1 overlap (exhaust valve about to close, inlet valve about to open). Adjust valve clearance according to schematic (marked in black) black). Mark respective rocker arm with chalk to show that adjustment has been carried out. © 26 263 2 © 2003 Crankshaft Position 2: Turn crankshaft one full revolution (360°). Adjust valve clearance according to schematic (marked in black). Service and Maintenance 6.7.1 Battery 6.7.1.1 Check Battery and Cable Connections 6 6.7.1.2 Check Electrolyte Level © 25 895 0 24232 3 Keep battery clean and dry. Remove sealing caps 1. Undo dirty clamps. If testers 2 are present: Electrolyte level should reach the base of these. Clean terminal posts (+ and -) and clamps of the battery, and grease with acid-free and acid-resistant grease. When reassembling, ensure that clamps make good contact. Tighten clamp bolts hand-tight. © 2003 6.7 Accessories Without testers: The electrolyte level should be 10-15 mm above the top of the plates. If necessary, top up with distilled water. Screw sealing caps back in. 6.7.1.3 Check Electrolyte Density 6.7.1.3Check © 25 896 0 Measure the electrolyte density of individual cells with a commercial hydrometer. The hydrometer reading (see table on following page) indicates the battery’s state of charge. During measurement, the temperature of the electrolyte should preferably be 20 °C. Service and Maintenance 6.7 Accessories 6 Electrolyte density in [kg/ l] in [°Bé (Baumé scale)*] Charge status Normal Tropical Normal Tropical 1.28 1.23 32 27 well charged 1.20 1.12 24 16 semi-charged, re-charge 1.12 1.08 16 11 discharged, immediately charge The gases emitted by the battery are explosive! Keep sparks and naked flames away from the battery! Do not allow battery acid to come into contact with skin or clothing! Wear protective goggles! Do not rest tools on the battery! © 2003 * Measurement of electrolyte density in ° Bé (Baumé scale) is out of date and rarely used today. Service and Maintenance 6.7.2 Rotary Current Alternator 6 6.7 Accessories 6.7.3 Transportation Shackles Notes on the three-phase system: Never disconnect the cables between battery, alternator and regulator while the engine is running. If, however, it is necessary to start and operate the engine without the battery, disconnect the regulator from the alternator before starting. Be sure not to confuse the battery terminals. Replace defective charge pilot lamp bulb immediately. When cleaning the engine: Do not spray the alternator with a direct jet of water/ steam! Allow the engine to run warm so that the remaining water evaporates. © 31 826 0 ● Only use proper lifting gear when transporting the engine. The habit of touching a lead against the frame to check whether it is live must under no circumstances be used with three-phase electrical systems. © 2003 In case of electric welding, connect the ground terminal on the welder directly to the piece being welded. Use only the correct lifting gear ! © 31 827 0 Faults, Causes and Remedies 7 © 2003 7.1 Fault Table Faults, Causes and Remedies 7 ● Faults can frequently be attributed to the fact that the engine has been incorrectly operated or not serviced. ● Each time a fault occurs, check whether all operating and servicing regulations have been complied with. ● A corresponding fault table can be found on the opposite page. © 2003 ● If the cause of a fault cannot be determined, or you are unable to remedy a fault yourself, then please contact your DEUTZ Service representative. Before starting, make sure that nobody is standing in the immediate vicinity of the engine or driven machine. In the event of repair work: Caution: If the speed regulator has been removed, the engine must not be started under any circumstances. Disconnect the battery! ! Faults, Causes and Remedies Faults Engine does not start or is difficult to start (Starting speed is not achieved on starting) Engine starts, but runs irregularly or fails Engine becomes excessively hot. Temperature warning system responds Engine output is deficient Engine does not run on all cylinders Engine oil pressure is non-existant or excessively low Engine oil consumption excessive Engine smokes - blue - white - black Cause ● Not declutched (where possible) ● ● Below starting limit temperature ● ● Engine shut-off lever still in stop position (shutoff magnet defective) ● ● Oil level too low ● ● ● ● Oil level too high ● ● ● Excessive inclination of engine ● Adjust throttle to half actuation travel ● ● ● Air cleaner clogged / turbocharger defective ● ● ● Air cleaner service switch / indicator defective ● ● CPD* defective (connection line leaks) ● ● ● Charge air line leaking ● Coolant pump defective ● ● Intercooler soiled ● Coolant heat exchanger soiled Cooling fan defective, torn or loose V-belt ● ● ● ● ● (fuel pump in belt drive) ● ● Cooling air temperature rise / heating short circuits ● Battery defective or discharged *CPD = Charge pressure-dependent full-load stop Measures Check Adjust Replace Clean Top up Bleed 7 P E W R A L Section Engine Operation P P P A S P/E P/E Combustion air P / W P P P/W Cooling system P / R P/R P/R P/W P P Table 1 of 2 Electrics © 2003 7.1 Fault Table Faults, Causes and Remedies 7 Faults Engine does not start or is difficult to start (Starting speed is not achieved on starting) Engine starts, but runs irregularly or fails Engine becomes excessively hot. Temperature warning system responds Engine output is deficient Engine does not run on all cylinders Engine oil pressure is non-existant or excessively low Engine oil consumption excessive Engine smokes - blue - white - black Cause ● Cable connections, starter, electrical circuit loose or oxidised ● Starter defective or pinion does not engage ● ● ● ● ● Incorrect valve clearance ● ● ● ● Injection line leaks ● Ventilation line blocked (coolant heat exchanger) ● ● Sheathed glow plugs defective ● ● ● ● ● ● ● Injection valve defective ● ● ● ● Air in the fuel system ● ● ● ● Fuel filter / fuel pre-cleaner soiled ● Oil filter defective ● ● ● Incorrect engine lube oil SAE class or quality ● ● ● ● Fuel quality not as per operation manual ● Coolant deficiency 7.1 Fault Table Measures Check Adjust Replace Clean Top up Reduce P E W R A S Section Electrics P P Engine E P P/R P P/W P/W P/R/W W Operating media W P/W P/A © 2003 Table 2 of 2 Engine Preservation 8 © 2003 8.1 Preservation Engine Preservation 8.1 8 8.1 Preservation Preservation If the engine is to remain idle for an extended period of time, it is necessary to take protective measures to prevent the formation of corrosion. The preservative measures described here will protect the engine for up to approx. 6 months. The procedure will have to be reversed before the engine is recommissioned. Anti-corrosion oils to specification: - MIL-L 21260B - TL 9150-037/2 - Nato Code C 640 / 642 Recommended cleaning agent to remove pre servatives: - Petroleum benzine (hazardous materials class A3) Preserve engine: Clean engine (poss. with cold cleaner). Radiator cleaning, see 6.3.2. Run engine until warm, then turn off. Drain engine oil, see 6.1.2, and fill with anticorrosion oil. Drain coolant, see 6.3.3. Top up anti-corrosion agent, see specifications. Clean oil bath air filter if necessary, see 6.4.3, and top up anti-corrosion oil. Drain fuel tank. Make up a mixture of 90 % diesel fuel and 10 % anti-corrosion oil, and refill fuel tank. Allow the engine to run for approx. 10 mins. Switch off the engine. Manually turn the engine over several times. When turning over with starter, set shutoff lever to stop position. Remove V-belts and store in wrapped condition. Spray grooves on V-belt pulleys 2 with anticorrosion spray. Drain anti-corrosion agent, see 6.3.3. © 2003 Lightly preserve coolant filler neck and seal with cap. Seal intake ports and exhaust ports. Remove engine preservation: Remove anti-corrosion agent from grooves in V-belt pulleys 2. Install V-belts. Retension after brief operation if necessary, see 6.5. Remove covers from intake port 3 and exhaust port 4. Disconnect coolant inlet and outlet neck covers, remove protection and connect to cooling system. Top up coolant, see 6.3.4. System must be bled. Commission engine Technical Specification 9 © 2003 9.1 Engine Specifications and Settings 9.2 Torque Wrench Settings 9.3 Tools Technical Specification Model Number of cylinders Cylinder arrangement Bore Stroke 9 9.1 Engine Specifications and Settings ----------- BF4M 2012 ------------------------ BF4M 2012 C ---------------------- BF6M 2012 C ------------------------ 4 --------------------------------------- 4 ---------------------------------------- 6 ------------------------------------------------------------------- vertical in line ------------------------------------------------[mm] ---------------------------------------------------------- ø 101 ------------------------------------------------------[mm] ----------------------------------------------------------- 126 -------------------------------------------------------- Total displacement [cm3] ---------------- 4.04 ----------------------------------- 4.04 ----------------------------------- 6.06 ------------Compression ratio [ε]. ------------------------------------------------------------ 19 --------------------------------------------------------Working cycle -------------------------------------------------- Four-stroke diesel ---------------------------------------------Combustion system ---------------------------------- with turbocharging and direct fuel injection -----------------------------Charge air cooling --------------- without --------------------------------- with ------------------------------------ with ------------Direction of rotation -------------------------------------------------- counter-clockwise ----------------------------------------------Weight 2012/ C including cooling system to DIN 70020-A [approx.kg] ------------------------------------------------- Refer to head-office --------------------------------------------Engine output [kW] Max. speed [1/rpm] Valve clearance with cold engine (PTs) [mm] Valve clearance with cold engine standard [mm] Injector opening pressure [bar] Start of feed [°CS BTOC] Firing order of the engine V-belt tension: Alternator / fan [N] Fuel pump - coolant pump [N] Compressor [N] Ribbed V-belt tension spring-loaded tension roller [N] © 2003 1) 2) ------------------ 75 ------------------------------------ 103 ------------------------------------ 155 ---------------------------------------------------------------------- 2500 ----------------------------------------------------------------------------------------------- Inlet 0.3 + 0.1 / exhaust 0.5 + 0.1. ------------------------------------------------------------------------- Adjustment with special tool, see 6.6.1 ------------------------------------------------------------------------------------------- 250 -------------------------------------------------------------------------------------------------------------------- 1). ---------------------------------------------------------------------- 1-3-4-2 ------------------------------- 1-3-4-2 ----------------------------- 1-5-3-6-2-4 --------------------------------------------------- Pre-tension / re-tension 2) -------------------------------------------------------------------------------------------------------------------------- 450 / 300 ± 50. ------------------------------------------------------------------------------------------------------ 450 / 300 ± 50. ------------------------------------------------------------------------------------------------------ 550 / 450 ± 50. ------------------------------------------------------------------------------------------------------ 900 / 600 ± 50. -------------------------------------------------- Engine output, speed, start of delivery are stamped on engine rating plate, etc., see also 2.1. Re-tension 15 minutes after the engine has been operated under load. 9.1 Engine Specifications and Settings Model ling Coolant volume 2012/ C [ca.ltr.] Perm. constant coolant temperature Engine exhaust, output group I [°C] Engine exhaust, output group II-IV [°C] Thermostat opening commencement at [°C] Thermostat fully open from [°C] Coolant pre-heating Coolant pump Feed pressure in [bar] Feed quantity in [m3 /h] Power consumption in [kW] Lubrication Oil temperature in oil pan Min. oil pressure when warm (120 °C and SAE oil 15 W 40 ) and low idle Technical Specification ----------- BF4M 2012 ------------------------ BF4M 2012 C ---------------------- BF6M 2012 C ----------------------------------------- Liquid-cooled / cooling system protection ------------------------------- 9 ----------------- 5,6 ------------------------------------- 5,6 ------------------------------------ 7,3 ------------------------------------------------------------------- max.110 6) . -------------------------------------------------------------------------------------------------------- max. 105 6) . ------------------------------------------------------------------------------------------------------------- 7) . ------------------------------------------------------------------------------------------------------------------ 83 8) . ------------------------------------------------------------------------------------------------------------------ (4 . ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------ 9) . --------------------------------------------------------. --------------------------------------------------------9) . --------------------------------------------------------9) ------------------------------------------------- Pressure lubrication --------------------------------------------[°C] ----------------------------------------------------------- 125 -------------------------------------------------------[bar] ------------------------------------------------------------ 0,8 -------------------------------------------------------- Oil plate filling quantity without filter [approx.ltr.] --------------- 8.5 3) . -------------------------------- 8.5 3) . ------------------------------- 12.5 3) . ----------Oil plate filling quantity with filter [approx.ltr.] ---------------- 10 3) . ---------------------------------- 10 3). --------------------------------- 14.0 3). ----------3) Approx. values may vary depending on version. The upper oil dipstick mark is always authoritative. Only necessary in winter operation, see 3.5.1. 5) Engine content without radiator only. Content of external cooling system depending on cooling system version. 6) Other output groups have different values, consultation with head office is required. 7) In the case of external cooling systems with outlet regulation, the thermostat begins to open at 87 °C 8) In the case of external cooling systems with outlet regulation, the thermostat is fully open at 102 °C 9) Consultation with head office is required (differ depending on engine version) © 2003 4) Technical Specification 9.2 Screw Tightening Torques 9 Installation location Pre-tension [Nm] Re-tension [Nm] 1. Stage 2. Stage 3. Stage 1. Stage 2. Stage 3. Stage 4. Stage Total [Nm] Cylinder head screw 8.5 Rocker arm adjustment screw 21 Foot on flywheel side 187 M16x40 8. 8.8 A 4 C 187 M16x40 8. 8.8 A 4 C Foot on fan side 30 45 Intake manifold 8.5 Exhaust manifold 21 Oil drain screw 50 Injection valve attachment 16 Torx Injection line attachment 30 M14x1.5 Oil pan (cast) Oil pan (sheet metal) © 2003 Comments 29 21 Technical Specification 9.3 Tools TORX V-belt tension gauge 26002 0 25899 0 A TORX wrench set is used with engines in the 2012 series. This system was chosen because of the many advantages it offers: ● Outstanding accessibility to bolts. ● High load transfer when loosening and tightening. ● Almost impossible for socket to slide off or break, thereby practically ruling out the risk of injury. 9 The V-belt tension gauge can be obtained under order number 8115 + 8120 from: WILBÄR Postfach 14 05 80 D-42826 Remscheid WILBÄR Postfach 14 05 80 D-42826 Remscheid © 2003 TORX tools can be ordered from: © 2003 9 Notes en Warnings to Place on Equipment Warning in the Manual CALIFORNIA CALIFORNIA Proposition 65 Warning Proposition 65 Warning Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. or CALIFORNIA Proposition 65 Warning Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. Notes CALIFORNIA PROPOSITION 65 INFORMATION TO CALIFORNIA CUSTOMERS AND TO CUSTOMERS SELLING DIESEL ENGINE EQUIPMENT INTO OR FOR USE IN CALIFORNIA. Proposition 65, a California law, requires warnings on products which expose individuals in California to chemicals listed under that law, including certain chemicals in diesel engine exhaust. Obligations of Manufactures of Diesel-Powered Off-Road Equipment. The California Superior Court has approved either of the following two methods of compliance with Proposition 65 requirements by manufactures of off-road equipment containing diesel engines. (The court order containing these provisions is attached.) 1. On-Equipment Warning. Place the warning pictured in attachment 1 on all equipment shipped by you into or for sale in California after January 1, 1996. The warning must be in a location where it is easily visible to the operator of the equipment when (s)he is operating the equipment. The warning must be secured to the equipment. If warnings or operating instructions are provided through a digital display, you may usee that method of providing warning. 2. Operator Manual Warning. When the operator manual is next revised or by December 31, 1995 whichever is earlier, place the warning in attachment 2 in the operator manual. The warning may be either printed in the manual or on a sticker. The warning must appear in one of the following locations: ● ● ● ● ● Inside The front cover Inside the back cover Outside the front cover Outside the back cover As the first page of text Under either alternative, the warning must appear in the same size, print and format as the attachment selected or be of an equally conspicuous size and format. If the warning is provided in an on-screen display, the warning must contain the language in the attachment and must be provided at the time of or in connection with ignition in the same manner as other safety warnings electronically communicated on screen. Obligation of Resellers of Diesel Engines. This letter must accompany any loose diesel engine sold in California. Should you have any questions, please call Deutz Corporation Product Support Department. en Service en Order-No.: 0312 0806 Knowing it’s DEUTZ DEUTZ has always stood for excellence in motor construction, pioneering many developments in the industry. As an independent motor manufacturer, we offer — worldwide — a comprehensive range of diesel and gas motors spanning from 4kW to 7,400kW. Our products are perfectly tailored to meet our customers’ individual requirements. Over 1.4 million DEUTZ motors do their job reliably all over the world. We are determined to preserve the high standard of performance and dependability of our motors, thus keeping our customers satisfied at all times. Therefore we are represented worldwide through a network of highly competent service partners who will meet the needs of our customers, wherever they are. This is why DEUTZ is not only the name for motors which pack a lot of inventive genius. DEUTZ also means reliable service and comprehensive support to enhance your motor’s performance. This index Sales & Service offers you an overview of the DEUTZ partners in your vicinity, including the products for which they are responsible and the range of services provided. But even when no direct product responsibility is mentioned, your DEUTZ partner will be happy to help you with expert advice. The Index is constantly updated. Please ask your DEUTZ service partner for the latest edition. DEUTZ AG — at your service. Order-No.: 0312 0807 (CD-ROM) DEUTZ AG Deutz-Mülheimer Str. 147-149 D-51057 Köln Obtainable from the local service Partner reponsible for you or from: Phone: 0049-221-822-0 Telefax: 0049-221-822-5304 Telex: 8812-0 khd d http://www.deutz.de 10 DEUTZ AG Service-Technik Instandhaltungstechnik Motoren Deutz-Mülheimer Str. 147-149 D-51063 Köln Tel.: ++49 (0) 2 21- 8 22 - 0 Fax: ++49 (0) 2 21- 8 22 - 53 58 Internet: www.deutz.de E-mail: [email protected] Printed in Germany All rights reserved 3. Edition, © 03/03 We move your world Order No.: 0297 9912 en

Руководство по эксплуатации

2012

© 2003

© 2003

●Внимательно прочитайте это руководствопоэксплуатацииистрогособлюдайте

содержащиеся в нем указания. Таким

образомВыизбежитенесчастныхслучаев, сохраните гарантию изготовителя и

получите в свое распоряжение полно-

функциональный двигатель, постоянно готовый к работе.

●Двигатель предназначен для работы исключительнопоназначению,определен-

ному в документации на комплект постав-

ки, и имеет соответствующую конструкцию, разработанную изготовителем

оборудования (использование по

назначению). Любое другое применение рассматривается как использование не

по назначению. Изготовитель не несет

ответственности за возникший по этой причине ущерб. Весь риск при этом

полностью возлагается на пользователя.

●Киспользованиюпоназначениюотносится

также соблюдение правил эксплуатации,

обслуживания и ремонта, установленных изготовителем. К эксплуатации, обслужи-

ванию и ремонту двигателя допускается

только изучивший настоящее руководство и проинструктированный по технике безопасности персонал.

●Следует также соблюдать соответствующие правила предотвращения не-

счастныхслучаевипрочиеобщепринятые

правила техники безопасности и производственной гигиены.

●На работающем двигателе могут представлять опасность травмирования:

— вращающиеся и горячие детали;

На двигателях с принудительным зажиганием:

— системазажигания(высокоеэлектрическое

напряжение). Избегайте прикосновения!

●Самовольное внесение изменений в конструкцию двигателя исключает

ответственность изготовителя за

понесенный в результате этого ущерб. Кроме того, вмешательство в системы

подачи топлива и регулирования может

понизитьмощностьдвигателяиухудшить состав выхлопных газов. При этом не

будет обеспечиваться соблюдение

законодательных норм по охране окружающей среды.

●Не допускается изменять, загораживать или закрывать приток охлажда-

ющего воздуха к вентилятору.

Изготовитель не несет ответственности за возникшие в результате

этого повреждения.

●При выполнении работ по обслужи-

ванию и ремонту двигателя следует

применять только фирменные запасные части DEUTZ. Они изготовлены

специально для Вашего двигателя и

обеспечивают его безотказную работу. При несоблюдении этого условия

гарантия аннулируется.

●Работы по обслуживанию и очистке можно выполнять только на выклю-

ченном и охлажденном двигателе. При

этом следует следить за тем, чтобы было отключено электрооборудование

и вынут ключ зажигания.

Следует соблюдать правила предупреждения несчастных случаев при

работе на электроустановках (напри-

мер, стандарт -VDE-0100/-0101/-0104/- 0105, „Меры предосторожности при

работе с токоведущими частями,

находящимися под опасным напряжением“).

На время очистки с применением

жидкостей необходимо плотно закрыть

все части электрооборудования.

Номер двигателя:

Впишитездесьномердвигателя. Этооблегчит

решениевопросовприобращениивсервисную службу по поводу обслуживания, ремонта и

заказа запасных частей (см. раздел 2.1).

Приведенные в этом руководстве по

эксплуатации иллюстрации и данные могут отличаться от реального оборудования из-за

технических усовершенствований двигателя.

Полная или частичная перепечатка и размножениевлюбойформевозможнытолько

с письменного разрешения изготовителя.

Руководство по

эксплуатации

2012

0312 1370 ru

© 2003

Предисловие

Уважаемыйзаказчик!

Двигатели с жидкостным охлаждением

маркиDEUTZ предназначеныдляширокого

кругаприменения. Приэтомбогатыйвыбор предлагаемых вариантов обеспечивает

выполнение самых разнообразных

требований заказчика.