РУКОВОДСТВО ПО ЛЕТНОЙ ЭКСПЛУАТАЦИИ

DA 40 NG

|

Категория летной годности |

: |

нормальная |

|

Требования |

: |

JAR-23 |

|

Серийный номер |

: |

________ |

|

Регистрация |

: |

________ |

|

Док. № |

: |

6.01.15-E |

|

Дата выпуска |

: |

01 апреля 2010 г. |

|

Подпись |

: |

|

|

Менеджер проекта со стороны |

||

|

EASA |

: |

|

|

Печать |

: |

|

|

Дата утверждения |

: |

|

|

(Дата утверждения EASA) |

Настоящее Руководство по летной эксплуатации утверждено Европейским агентством авиационной безопасности (EASA). № утверждения

|

DIAMOND AIRCRAFT INDUSTRIES GMBH |

|

|

N.A. OTTO-STR. 5 |

|

|

A-2700 WIENER NEUSTADT |

Стр. 0 — 0 |

|

AUSTRIA (АВСТРИЯ) |

Страница намеренно оставлена пустой.

|

Стр. 0 — 0a |

Ред. 0 |

01 апреля 2010 г. |

Док. № 6.01.15-E |

ПРЕДИСЛОВИЕ

Поздравляем вас с приобретением нового самолета DIAMOND DA 40 NG.

Умелая эксплуатация самолета позволяет повысить как безопасность полета, так и удовольствие от управления самолетом. Просим вас перед эксплуатацией самолета DIAMOND DA 40 NG ознакомиться с его конструкцией и особенностями.

Эксплуатация самолета разрешается только в соответствии с настоящим Руководством по летной эксплуатации и установленными в нем эксплуатационными ограничениями.

Перед началом эксплуатации самолета пилот обязан внимательно ознакомиться с настоящим Руководством по летной эксплуатации.

Если вы приобрели самолет DIAMOND DA 40 NG, ранее бывший в эксплуатации, просим вас сообщить нам свой адрес, чтобы мы могли высылать вам документацию, необходимую для безопасной эксплуатации самолета.

Настоящий документ защищен авторским правом. Все сопутствующие права, в частности, права на перевод, перепечатку, передачу по радиоканалу, копирование фотомеханическими или аналогичными средствами, а также хранение в системах обработки данных полного или частичного содержания настоящего документа сохраняются за правообладателем.

Авторское право © DIAMOND AIRCRAFT INDUSTRIES GMBH N.A. Otto-Strasse 5

A-2700 Wiener Neustadt, Austria (Австрия) Телефон: +43-2622-26700 Факс: +43-2622-26780

Эл. почта: office@diamond-air.at

|

Док. № 6.01.15-E |

Ред. 1 |

15 марта 2011 г. |

Стр. 0 — 1 |

0.1 УТВЕРЖДЕНИЕ

Информация, приведенная в утвержденных разделах, утверждена EASA. Вся прочая информация утверждена DAI на основании выданного EASA свидетельства DOA № EASA.21J.052 в соответствии с положениями Части 21.

0.2 РЕГИСТРАЦИЯ ИЗМЕНЕНИЙ

Все изменения, вносимые в настоящее руководство, за исключением следующих:

•Временные редакции,

•изменения уровня модификации (Раздел 1.1),

•изменения весовых и центровочных данных (Раздел 6.3),

•изменения в Перечне установленного оборудования (Раздел 6.5) и

•изменения в Перечне дополнительной документации (Раздел 9.2), подлежат регистрации в приведенной ниже таблице.

Новый или измененный текст помечается черной вертикальной чертой на левом поле страницы с изменениями. В нижнем колонтитуле указываются номер и дата редакции.

При внесении изменений в страницы, на которых приводится информация, относящаяся к самолету с вашим серийным номером (уровень модификации самолета, весовые и центровочные данные, Перечень установленного оборудования, Перечень дополнительной документации), эту информацию необходимо вписать в новые страницы от руки.

Временные редакции используются для включения в РЛЭ информации о системах и оборудовании до следующей «постоянной» Редакции настоящего Руководства по летной эксплуатации. Если действие «постоянной» Редакции распространяется на область применения Обязательной или Необязательной рекомендации по внесению изменений в конструкцию (MÄM/OÄM), действие соответствующей Временной редакции в применимой части отменяется. Например, действие Редакции 5 распространяется на область применения Необязательной рекомендации OÄM 40-039. В этом случае Временная редакция TR-OÄM-40-039 заменяется «постоянной» Редакцией 5.

Титульные страницы Временных редакций (для Временных редакций) вставляются в настоящее руководство после его титульной страницы; все другие страницы вставляются перед соответствующими страницами настоящего РЛЭ.

|

Стр. 0 — 2 |

Ред. 1 |

15 марта 2011 г. |

Док. № 6.01.15-E |

Страница намеренно оставлена пустой.

|

Стр. 0 — 4 |

Ред. 1 |

15 марта 2011 г. |

Док. № 6.01.15-E |

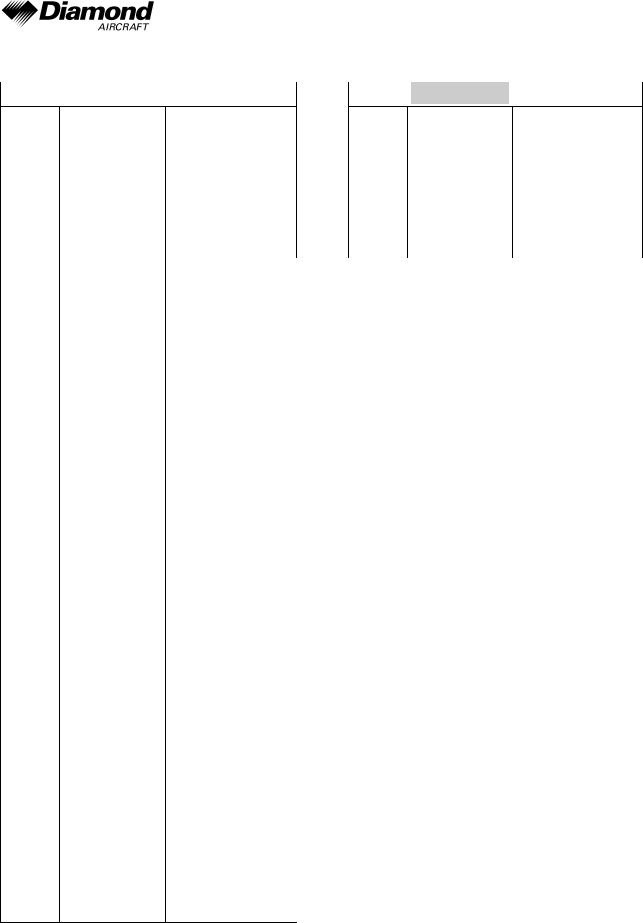

0.3 ПЕРЕЧЕНЬ ДЕЙСТВУЮЩИХ СТРАНИЦ

|

Раздел |

Стр. |

Дата |

Раздел |

Стр. |

Дата |

|||

|

0 |

0-0 |

01 апреля 2010 г. |

1 |

1-1 |

15 марта 2011 г. |

|||

|

0-0a |

01 апреля 2010 г. |

1-2 |

15 марта 2011 г. |

|||||

|

0-1 |

15 марта 2011 г. |

1-3 |

15 марта 2011 г. |

|||||

|

0-2 |

15 марта 2011 г. |

1-4 |

15 марта 2011 г. |

|||||

|

0-3 |

15 марта 2011 г. |

1-5 |

15 марта 2011 г. |

|||||

|

0-4 |

15 марта 2011 г. |

1-6 |

15 марта 2011 г. |

|||||

|

0-5 |

15 марта 2011 г. |

1-7 |

15 марта 2011 г. |

|||||

|

0-6 |

15 марта 2011 г. |

1-8 |

15 марта 2011 г. |

|||||

|

0-7 |

15 марта 2011 г. |

1-9 |

15 марта 2011 г. |

|||||

|

0-8 |

15 марта 2011 г. |

1-10 |

15 марта 2011 г. |

|||||

|

0-9 |

15 марта 2011 г. |

1-11 |

15 марта 2011 г. |

|||||

|

0-10 |

15 марта 2011 г. |

1-12 |

15 марта 2011 г. |

|||||

|

0-11 |

15 марта 2011 г. |

1-13 |

15 марта 2011 г. |

|||||

|

0-12 |

15 марта 2011 г. |

1-14 |

15 марта 2011 г. |

|||||

|

0-13 |

15 марта 2011 г. |

1-15 |

15 марта 2011 г. |

|||||

|

0-14 |

15 марта 2011 г. |

1-16 |

15 марта 2011 г. |

|||||

|

1-17 |

15 марта 2011 г. |

|||||||

|

1-18 |

15 марта 2011 г. |

|||||||

|

1-19 |

15 марта 2011 г. |

|||||||

|

1-20 |

15 марта 2011 г. |

|||||||

|

Док. № 6.01.15-E |

Ред. 1 |

15 марта 2011 г. |

Стр. 0 — 5 |

2утв. 2-1 15 марта 2011 г.

утв. 2-2 15 марта 2011 г.

утв. 2-3 15 марта 2011 г.

утв. 2-4 15 марта 2011 г.

утв. 2-5 15 марта 2011 г.

утв. 2-6 15 марта 2011 г.

утв. 2-7 15 марта 2011 г.

утв. 2-8 15 марта 2011 г.

утв. 2-9 15 марта 2011 г.

утв. 2-10 15 марта 2011 г.

утв. 2-11 15 марта 2011 г.

утв. 2-12 15 марта 2011 г.

утв. 2-13 15 марта 2011 г.

утв. 2-14 15 марта 2011 г.

утв. 2-15 15 марта 2011 г.

утв. 2-16 15 марта 2011 г.

утв. 2-17 15 марта 2011 г.

утв. 2-18 15 марта 2011 г.

утв. 2-19 15 марта 2011 г.

утв. 2-20 15 марта 2011 г.

утв. 2-21 15 марта 2011 г.

утв. 2-22 15 марта 2011 г.

утв. 2-23 15 марта 2011 г.

утв. 2-24 15 марта 2011 г.

утв. 2-25 15 марта 2011 г.

утв. 2-26 15 марта 2011 г.

утв. 2-27 15 марта 2011 г.

2утв. 2-28 15 марта 2011 г.

утв. 2-29 15 марта 2011 г.

утв. 2-30 15 марта 2011 г.

утв. 2-31 15 марта 2011 г.

утв. 2-32 15 марта 2011 г.

|

Стр. 0 — 6 |

Ред. 1 |

15 марта 2011 г. |

Док. № 6.01.15-E |

- Manuals

- Brands

- Diamond Aircraft Manuals

- Tools

- DA 40 NG

- Airplane maintenance manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for Diamond Aircraft DA 40 NG

Summary of Contents for Diamond Aircraft DA 40 NG

-

Page 1

AIRCRAFT DA 40 NG AIRPLANE MAINTENANCE MANUAL Copyright © by DIAMOND AIRCRAFT INDUSTRIES, Wiener Neustadt, Austria… -

Page 2

Introduction DA 40 NG AMM AIRCRAFT This document is protected by copyright. All associated rights, in particular those of translation, reprinting, radio transmission, reproduction by photo-mechanical or similar means and storing in data processing facilities, in whole or part, are reserved. -

Page 3

Time Limits and Maintenance Checks 05-10 Time Limits 05-20 Scheduled Maintenance Checks 05-21 Flight-Line Checks 05-25 Drain Holes Inspection Checklist and Report 05-28 Maintenance Checklist DA 40 NG 05-50 Unscheduled Maintenance Checks 06-00 Dimensions and Areas 07-00 Lifting and Shoring 07-10 Jacking 08-00… -

Page 4

Table of Contents DA 40 NG AMM AIRCRAFT 21-00 Air Conditioning, Heating and Ventilation 21-50 Cooling 21-51 Cooling (OÄM 40-316/i or later installed) 22-00 Auto Flight 22-10 Autopilot, GFC 700 22-11 Autopilot, KAP 140 23-00 Communications 23-10 Speech Communication with G1000 System Installed… -

Page 5

Table of Contents DA 40 NG AMM AIRCRAFT 32-00 Landing Gear 32-10 Main Landing Gear 32-20 Nose Landing Gear 32-40 Wheels and Brakes 33-00 Lights 33-10 Lights — Flight Compartment 33-40 Exterior Lights 34-00 Navigation 34-10 Flight Environment Data 34-20… -

Page 6

Table of Contents DA 40 NG AMM AIRCRAFT 56-00 Windows 56-10 Flight Compartment Windows 57-00 Wings 57-10 Wing Structure 57-50 Flaps 57-60 Aileron 61-00 Propeller 61-10 Propeller Assembly 61-20 Propeller Control 71-00 Power Plant 71-10 Engine Cowling 71-20 Engine Mounting… -

Page 7

Record of Revision DA 40 NG AMM AIRCRAFT Record of Revision 1. Record of Revision Use this check list to record and control all of the revisions which you put in this Airplane Maintenance Manual (AMM). Put the affected pages of the revision into the AMM as soon as you get them. Remove and destroy the pages which are superseded. -

Page 8

Record of Revision DA 40 NG AMM AIRCRAFT 2. Record of Incorporated Temporary Revisions The following Temporary Revisions are incorporated into the DA 40 NG AMM by Revision 1: Temporary Revision Number Description of Temporary Revision AMM-TR-MÄM 40-434 Cowling Redesign AMM-TR-MÄM 40-434/a… -

Page 9

Record of Revision DA 40 NG AMM AIRCRAFT The following Temporary Revisions are incorporated into the DA 40 NG AMM by Revision 2: Temporary Revision Number Description of Temporary Revision AMM-TR-MÄM 40-502/a & Replacement of Charged Air Hoses with Tube AMM-TR-MÄM 40-506/a… -

Page 10

Record of Revision DA 40 NG AMM AIRCRAFT The following Temporary Revisions are incorporated into the DA 40 NG AMM by Revision 3: Temporary Revision Number Description of Temporary Revision AMM-TR-MÄM 40-561 New GFC 700 Autopilot Hardware AMM-TR-MÄM 40-619 Passenger Door Improvement AMM-TR-MÄM 40-635… -

Page 11

Record of Revision DA 40 NG AMM AIRCRAFT Temporary Revision Number Description of Temporary Revision AMM-TR-MÄM 40-865 Conservation of Exterior Parts AMM-TR-MÄM 40-868 Garmin Hard- und Software Upgrade I AMM-TR-MÄM 40-874 Engine Oils AMM-TR-MÄM 40-899 Improved Air Charge Hose AMM-TR-OÄM 40-251 Electrical Pedal Adjustment AMM-TR-OÄM 40-258… -

Page 12

Record of Revision DA 40 NG AMM AIRCRAFT Intentionally left blank Page x Doc # 6.02.15 01 Sep 2017 Rev. 3… -

Page 13

List of Effective Pages DA 40 NG AMM AIRCRAFT LIST OF EFFECTIVE PAGES 1. General The list of effective pages uses this abbreviation: Table of Contents. Record of Revisions. LOEP List of Effective Pages. All Sections have a Title Page and a Table of Contents. The TOC can have one page or it can have many pages. -

Page 14

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 03-00 01 Sep 2017 05-10 01 Sep 2017 05-28-00 01 Sep 2017 03-00 01 Sep 2017… -

Page 15

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 05-28-50 01 Sep 2017 05-50 01 Sep 2017 08-00 Title 1 01 Sep 2017 05-50 01 Sep 2017… -

Page 16

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 09-00 01 Sep 2017 11-20 01 Sep 2017 12-10 01 Sep 2017 09-10 01 Sep 2017… -

Page 17

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 20-00 TOC 1 01 Sep 2017 21-00 01 Sep 2017 21-51 01 Sep 2017 21-00 01 Sep 2017… -

Page 18

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 22-10 01 Sep 2017 22-11 01 Sep 2017 23-10 01 Sep 2017 22-10 01 Sep 2017… -

Page 19

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 23-51 01 Sep 2017 24-30 01 Sep 2017 24-33 01 Sep 2017 24-30 01 Sep 2017… -

Page 20

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 24-60 01 Sep 2017 25-10 01 Sep 2017 25-60 01 Sep 2017 24-60 01 Sep 2017… -

Page 21

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 27-10 01 Sep 2017 27-20 01 Sep 2017 27-38 01 Sep 2017 27-20 01 Sep 2017… -

Page 22

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 27-50 01 Sep 2017 28-10 01 Sep 2017 28-20 01 Sep 2017 27-50 01 Sep 2017… -

Page 23

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 28-40 01 Sep 2017 31-20 01 Sep 2017 31-40 01 Sep 2017 31-40 01 Sep 2017… -

Page 24

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 32-10 01 Sep 2017 32-20 01 Sep 2017 32-40 01 Sep 2017 32-10 01 Sep 2017… -

Page 25

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 33-40 01 Sep 2017 34-00 01 Sep 2017 34-22 01 Sep 2017 34-10 01 Sep 2017… -

Page 26

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 34-42 01 Sep 2017 34-56 01 Sep 2017 51-20 01 Sep 2017 34-42 01 Sep 2017… -

Page 27

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 51-30 01 Sep 2017 52-00 TOC 2 01 Sep 2017 52-10 01 Sep 2017 52-00 01 Sep 2017… -

Page 28

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 53-10 01 Sep 2017 55-20 01 Sep 2017 56-10 01 Sep 2017 53-10 01 Sep 2017… -

Page 29

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 57-10 01 Sep 2017 61-10 01 Sep 2017 61-20 01 Sep 2017 61-10 01 Sep 2017… -

Page 30

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 71-00 01 Sep 2017 71-60 01 Sep 2017 72-00 01 Sep 2017 71-00 01 Sep 2017… -

Page 31

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 75-00 01 Sep 2017 76-00 TOC 2 01 Sep 2017 77-40 01 Sep 2017 76-00 01 Sep 2017… -

Page 32

List of Effective Pages DA 40 NG AMM AIRCRAFT Chapter Page Revision Chapter Page Revision Chapter Page Revision Section Date Section Date Section Date 78-00 01 Sep 2017 81-00 TOC 1 01 Sep 2017 92-00 01 Sep 2017 79-00 Title 1 01 Sep 2017… -

Page 33

Introduction DA 40 NG AMM AIRCRAFT CHAPTER 01 INTRODUCTION Doc # 6.02.15 Page 1 01-TITLE Rev. 3 01 Sep 2017… -

Page 34

Introduction DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 01-TITLE Rev. 3 01 Sep 2017… -

Page 35: Table Of Contents

Introduction DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 01 INTRODUCTION General …………1 Revision Service .

-

Page 36

Introduction DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 01-CONTENTS Rev. 3 01 Sep 2017… -

Page 37: Introduction

This Airplane Maintenance Manual contains the data necessary to do the maintenance of the DA 40 NG. It contains a full description of the systems, trouble shooting procedures, removal and installation procedures and maintenance instructions. It does not contain maintenance data for components removed from the airplane (maintenance shop data).

-

Page 38: Manual Configuration

Introduction DA 40 NG AMM AIRCRAFT 4. Manual Configuration This manual is written using the regulations of the Air Transport Association of America Specification 100 (ATA 100). Each system is given a chapter number from the ATA 100. Where applicable, a chapter contains sections for each sub-system.

-

Page 39

Introduction DA 40 NG AMM AIRCRAFT A. The ATA100 Numbering System The ATA100 numbering system uses 3 pairs of numbers, for example: 57-50-xx Chapter / System Section / Subsystem Unit / Subject Number (Wings) (Flaps) (Not normally used) The first pair of numbers show the system. System 57 is the Wings. Chapter 57 contains the data for the wings. -

Page 40

Introduction DA 40 NG AMM AIRCRAFT The main contents of each group of chapters is given below: (1) Group A — Introduction Chapter 1 tells you about the Airplane Maintenance Manual, and Chapter 2 tells you how to use the Airplane Maintenance Manual. -

Page 41

Introduction DA 40 NG AMM AIRCRAFT (5) Group E — Propeller Chapter 61 contains the maintenance procedures for the propeller. Refer to the propeller manufacturer’s manual for other data. (6) Group F — Power Plant This group of chapters describes the engine and its systems which make the Power Plant. It contains the maintenance procedures for maintenance on the airplane. -

Page 42: Page Numbering System

Introduction DA 40 NG AMM AIRCRAFT 5. Page Numbering System This manual uses the ATA 100 page block-numbering system. The page number is at the bottom on the outer edge. It is adjacent to the chapter/section number. Each topic in a section has numbers from these page blocks: Description and Operation — Pages 1 to 99.

-

Page 43

Manual Organization DA 40 NG AMM AIRCRAFT CHAPTER 02 ORGANIZATION AND HANDLING OF THE MANUAL Doc # 6.02.15 Page 1 02-TITLE Rev. 3 01 Sep 2017… -

Page 44

Manual Organization DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 02-TITLE Rev. 3 01 Sep 2017… -

Page 45

Manual Organization DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 02 ORGANIZATION AND HANDLING OF THE MANUAL General …………1 Applicability . -

Page 46

Manual Organization DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 02-CONTENTS Rev. 3 01 Sep 2017… -

Page 47: Organization And Handling Of The Manual

Manual Organization DA 40 NG AMM AIRCRAFT CHAPTER 02 ORGANIZATION AND HANDLING OF THE MANUAL 1. General For data about a system, look in the list of chapters and find the chapter number. The first page of each chapter after the title page shows the contents.

-

Page 48: Service Bulletins

Manual Organization DA 40 NG AMM AIRCRAFT 5. Service Bulletins Service Bulletins get issued when necessary. They give the operator more information on inspections, maintenance, repairs or modifications. Service Bulletins have 4 categories: A. Alert Service Bulletins Alert Service Bulletins are issued if there is an immediate danger (risk of damage or total loss).

-

Page 49: Service Information

Manual Organization DA 40 NG AMM AIRCRAFT 6. Service Information A Service Information tells the operator about permitted installations or provided information to installed or additional equipment. It also gives the applicable technical data. 7. Concession-Reports and Non-Conformance-Reports Concession- and Non-Conformance-Reports are tools to approve and document deviations from the standard manufacturing processes during construction and assembly of an individual airplane (for example, handling of a mis-drilled hole in the fuselage).

-

Page 50: Abbreviations

Manual Organization DA 40 NG AMM AIRCRAFT 8. Abbreviations Where possible, the abbreviations used correspond with the related regulations. Ampere Anti-Collision Light Automatic Direction Finder A.M.E. Aircraft Maintenance Engineer Ampere-Hour A&P Aircraft and Power Plant Mechanic Airspeed Indicator Controller Area Network…

-

Page 51

Manual Organization DA 40 NG AMM AIRCRAFT Secondary Engine Display Serial Number Time Between Overhaul TSMOH Time Since Major Overhaul Ultra High Frequency TTSN Total Time Since New TTSO Total Time Since Overhaul Volt Visual Flight Rules Very High Frequency… -

Page 52: Conversion Factors And Abbreviations

Manual Organization DA 40 NG AMM AIRCRAFT 9. Conversion Factors and Abbreviations Dimension Conversion Factor Conversion Factor Unit [Abbreviation] SI to US/Imperial US/Imperial to SI Length [m] / 0.3048 = [ft] Meter [m] [mm] / 25.4 = [in] Millimeter [mm] [km] / 1.852 = [nm]…

-

Page 53

Manual Organization DA 40 NG AMM AIRCRAFT Dimension Conversion Factor Conversion Factor Unit [Abbreviation] SI to US/Imperial US/Imperial to SI Force or Weight Newton [N] [N] / 4.448 = [lb] Decanewton [daN] [daN] / 0.4448 = [lb] Pound [lb] [lb] x 4.448 = [N] [lb] x 0.4448 = [daN]… -

Page 54: Torque Conversion Graphs

Manual Organization DA 40 NG AMM AIRCRAFT 10. Torque Conversion Graphs Use Figure 1 for conversion of torque values Nm — lbf.ft. Use Figure 2 for conversion of Nm — lbf.in. 10 15 20 25 30 45 50 55 60 65 70 75 80 85 90 95 100 Newton.Metre (Nm)

-

Page 55

Manual Organization DA 40 NG AMM AIRCRAFT 0.5 1.0 1.5 2.0 2.5 3.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 Newton.Metre (Nm) Figure 2: Nm — lbf.in. Find the Nm value on the horizontal axis. Move vertically to the solid black diagonal line. Then move horizontally to the vertical axis. -

Page 56

Manual Organization DA 40 NG AMM AIRCRAFT Intentionally left blank Page 10 Doc # 6.02.15 02-00-00 01 Sep 2017 Rev. 3… -

Page 57

General Description DA 40 NG AMM AIRCRAFT CHAPTER 03 GENERAL DESCRIPTION OF THE AIRPLANE Doc # 6.02.15 Page 1 03-TITLE Rev. 3 01 Sep 2017… -

Page 58

General Description DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 03-TITLE Rev. 3 01 Sep 2017… -

Page 59

General Description DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 03 GENERAL DESCRIPTION OF THE AIRPLANE General …………1 Description . -

Page 60

General Description DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 03-CONTENTS Rev. 3 01 Sep 2017… -

Page 61: General

DA 40 NG airplane. 2. Description The DA 40 NG is a single-engine, four seat, low-wing monoplane. It has a cantilever wing and a ‘T’ tail. The airplane structure is fiber-reinforced plastic composite. This gives a very strong but light structure.

-

Page 62

The nose leg attaches to the forward fuselage. Each main wheel has a disc brake on the inside. Hydraulic pressure operates each disc brake. The flight control system uses conventional ailerons, elevator and rudder. The DA 40 NG has two control sticks and two rudder pedal assemblies to operate the primary flight-controls. Push-pull rods operate the ailerons and elevator. -

Page 63

A starter key controls the engine starter motor. It also serves as ELECTRIC MASTER key switch. The DA 40 NG has a full range of flight instruments. These include Pitot/static instruments to show airspeed and altitude, as well as electrically driven instruments to show direction. If the G1000 system is installed most indications are shown on the G1000 and only the backup instruments are installed on the instrument panel. -

Page 64: Equipment Data

AIRCRAFT 3. Equipment Data The table below gives you the name and address of the manufacturers who supply systems and/or equipment for the DA 40 NG. This will help you get more data on a system and/or equipment. Equipment/System Address…

-

Page 65

General Description DA 40 NG AMM AIRCRAFT Equipment/System Address Chapter Autopilot System Bendix/King (if KAP 140 A/P is installed): 400 North Rogers Road Olathe, Kansas 66062-1212 Tel: (913) 782-0400 (USA and Canada) (913) 782-0700 (other countries) Website: www.bendixking.com Battery: Concorde Battery Corp. -

Page 66

General Description DA 40 NG AMM AIRCRAFT Equipment/System Address Chapter Backup Attitude Gyro: Mid-Continent Instrument Co., Inc. 7706 E, Osie, Wichita, Kansas 67207 Tel: (316) 683-5619 Fax: (316) 683-1861 Website: www.mcico.com Wheels and Brakes: Parker Hannifin Corporation Aircraft Wheel and Brake Division… -

Page 67: Handling Of Identification Data

General Description DA 40 NG AMM AIRCRAFT Equipment/System Address Chapter Austro Engines E4-A Engine: Austro Engine GmbH Rudolf Diesel-Str. 11 A-2700 Wiener Neustadt Austria Tel: +43 (2622) 23 000 Fax: +43 (2622) 23 000 — 2711 Homepage: www.austroengine.at 4. Handling of Identification Data…

-

Page 68

General Description DA 40 NG AMM AIRCRAFT Intentionally left blank Page 8 Doc # 6.02.15 03-00-00 01 Sep 2017 Rev. 3… -

Page 69

Airworthiness DA 40 NG AMM Limitations CHAPTER 04 AIRWORTHINESS LIMITATIONS Doc # 6.02.15 Page 1 04-TITLE Rev. 3 01 Sep 2017… -

Page 70

Airworthiness DA 40 NG AMM Limitations AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 04-TITLE Rev. 3 01 Sep 2017… -

Page 71

Airworthiness DA 40 NG AMM Limitations TABLE OF CONTENTS CHAPTER 04 AIRWORTHINESS LIMITATIONS Airworthiness Limitations ……….3 Continued Airworthiness . -

Page 72

Airworthiness DA 40 NG AMM Limitations AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 04-CONTENTS Rev. 3 01 Sep 2017… -

Page 73

Airworthiness DA 40 NG AMM Limitations CHAPTER 04 AIRWORTHINESS LIMITATIONS THIS AIRWORTHINESS LIMITATIONS SECTION IS APPROVED BY EUROPEAN AVIATION SAFETY AGENCY (EASA) IN ACCORDANCE WITH THE APPLICABLE CERTIFICATION PROCEDURES AND THE TYPE CERTIFICATION BASIS. IT SPECIFIES THE AIRWORTHINESS LIMITATIONS REQUIRED BY JAR 23. -

Page 74

Airworthiness DA 40 NG AMM Limitations AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 04-00-00 01 Sep 2017 Rev. 3… -

Page 75

Note: Regular inspections of the airplane including replacement and overhaul of certain components are required to ensure Continued Airworthiness of the DA 40 NG. For possible airworthiness limitations of engine, propeller, components and vendor equipment refer to the applicable Maintenance data as listed in Section 05-00. -

Page 76

(2) Life Time Limit / Structure Checks There is no structural life limit. Note: The DA 40 NG has been designed and tested under a ‘damage tolerant structure’ philosophy. Therefore the structural inspections given in Chapter 05 cover all required structure checks. -

Page 77

Limitations C. Color of Airframe It is mandatory to paint the DA 40 NG white as described in Chapter 51 of this manual. This will prevent the temperature of the structure from becoming too high. Examples of approves shades are:… -

Page 78

Airworthiness DA 40 NG AMM Limitations AIRCRAFT Intentionally left blank Page 6 Doc # 6.02.15 04-00-00 01 Sep 2017 Rev. 3… -

Page 79

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT CHAPTER 05 TIME LIMITS AND MAINTENANCE CHECKS Doc # 6.02.15 Page 1 05-TITLE Rev. 3 01 Sep 2017… -

Page 80

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 05-TITLE Rev. 3 01 Sep 2017… -

Page 81

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT TABLE OF CONTENTS CHAPTER 05 TIME LIMITS AND MAINTENANCE CHECKS General …………1 Chapter Configuration . -

Page 82

Drain Holes Inspection Checklist ……..1 Section 05-28 Maintenance Checklist DA 40 NG Section 05-28-00 Maintenance Checklist Engine General . -

Page 83

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-91 Engine Ground Test Report Engine Ground Test Report ……… . 1… -

Page 84

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 05-CONTENTS 01 Sep 2017 Rev. 3… -

Page 85: Time Limits And Maintenance Checks

TIME LIMITS AND MAINTENANCE CHECKS 1. General This Chapter will help to do the maintenance of the DA 40 NG correctly. Refer to Sections 04-00 and 05-00 for maintenance and inspections. The times given in this Chapter are times recommended by the airplane manufacturer. Do the scheduled maintenance at the given times, because they are the minimum required to keep the airplane in a good technical condition.

-

Page 86

Maintenance Checks AIRCRAFT E. Section 05-28 Section 05-28 contains the Maintenance Checklist for the DA 40 NG airplane. The Section is subdivided into engine and airframe sections and provides checklists for the engines and the airframe and the corresponding reports. -

Page 87

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT G. Referenced Maintenance Data Use latest revision of referenced maintenance data. Supplier Document Name Document No. Artex Installation and Maintenance Manual for the 570-1600 ME406 ELT Austro Engine Austro Engine Operation Manual AE300 E4.01.01… -

Page 88: Definitions

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 3. Definitions In this Airplane Maintenance Manual, the words that follow have special meanings: Adjust. To put to a specified position or condition. For example, adjust the clearance to 1 mm.

-

Page 89

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Task. An assigned work or a procedure. For example, each step of the task has an identification letter. Test. That which you do when you operate or examine an item to make sure that it agrees with the applicable specifications. -

Page 90

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 6 Doc # 6.02.15 05-00-00 01 Sep 2017 Rev. 3… -

Page 91: Time Limits

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-10 Time Limits 1. General This Section lists time limits for scheduled Maintenance on airframe and components, and replacement or overhaul of components directly or by reference. Obey the time limits in this Section to keep the airplane in a technical good condition.

-

Page 92

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT If an inspection is carried out earlier than allowed by the specified tolerance, all subsequent inspection intervals are counted from that inspection. For example: If the 100 hour inspection was done at 83 hours, the next inspection must be done at 183 hours. -

Page 93: Component Time Limits

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 3. Component Time Limits A. Maintenance Requirements The following table lists airplane components and systems which require overhaul or specific checks. Where an interval is given in both flight time and calendar years, the limit which is reached first must be used.

-

Page 94

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Kind Interval Component Maintenance Requirement hrs. yrs. Ope. Fire extinguisher. Overhaul. ± 60 days Check valve in front of fuel Clean check valve mesh. 1000 transfer pump. ± 50 Pitot-static system. -

Page 95

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT B. Airplane Life-Limited Components The following table lists life limited airplane components which must be replaced at a specific time. Where an interval is given in both flight time and calendar years, the limit which is reached first must be applied. -

Page 96

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Replacement Time Kind of Component Operation hrs. yrs. Co-incident Fuel bypass valve. with engine TBO. Fuel tank vent hoses. 8 ± 60 days Fuel filter element. 100 ± 10 1 ± 30 days… -

Page 97: Component Time Tracking

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 4. Component Time Tracking To make sure that components overhaul/replacement is done at the correct time you must record the data that follows in the Airplane Maintenance Log for each component requiring overhaul/replacement: Serial Number.

-

Page 98

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 8 Doc # 6.02.15 05-10-00 01 Sep 2017 Rev. 3… -

Page 99: Scheduled Maintenance Checks

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-20 Scheduled Maintenance Checks 1. General Do the scheduled maintenance checks in this Section at the intervals (flight hours and calendar time) stated in Section 05-10, Paragraph 3. Note: Only persons or maintenance organizations authorized by national Regulatory Authorities of the country where the airplane is registered may do these checks.

-

Page 100: Maintenance Checklist Organization

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 2. Maintenance Checklist Organization Do the scheduled maintenance checks with reference to the Maintenance Checklist in this Section. Before starting a check, complete the requirements of Paragraphs 2 and 3 of the checklist. In parallel do the scheduled drain hole checks with reference to the Drain Holes Inspection Checklist and Report.

-

Page 101: Major Structural Inspection

The Major Structural Inspection (MSI) is an important part of the infinite lifetime concept of the DA 40 NG. It is required to prove the structural integrity of the airframe. It must be carried out at the intervals shown in Section 05-20.

-

Page 102

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 05-20-00 01 Sep 2017 Rev. 3… -

Page 103: Flight-Line Checks

DO ALL THE STEPS OF THE DAILY CHECK CAREFULLY. ACCIDENTS CAN OCCUR IF THE DAILY CHECK IS NOT DONE CORRECTLY. The schedule for the pilot’s daily check is in the Airplane Flight Manual for the DA 40 NG. 3. Post-Flight Check Do the post-flight check after the last flight of the day.

-

Page 104

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 05-21-00 01 Sep 2017 Rev. 3… -

Page 105: Drain Holes Inspection Checklist And Report

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-25 Drain Holes Inspection Checklist and Report 1. General Do a check of the drain holes. The drain holes must not be blocked by dirt or other residues. Make sure to remove all foreign objects and clean the drain holes to their full diameter.

-

Page 106: Drain Holes Inspection Checklist

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Drain Holes Inspection Checklist Drain Hole Location Ref. Hours Initials 1.14 On lowest point of the fin 1.15 On lowest point of the EPC connector 1.16 In rudder bolt mounting shell (on top of the rudder) 1.17…

-

Page 107

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Drain Holes Inspection Checklist Ref. Drain Hole Location Hours Initials ELEVATOR TRIM TAB 5.01 Lower shell, leading edge section, LH & RH 5.02 Lower shell, in front of trailing edge bonding, LH & RH RUDDER 6.01… -

Page 108

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 1.22 1.16 To be checked only in production or repair 1.18 1.15 1.17 1.20 1.21 1.19 1.26 1.23 1.25 1.11 1.14 1.12 To be checked only Maintenance Access in production or repair… -

Page 109

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 1.02 1.10 1.06 1.09 1.01 1.04 1.07 1.13 1.24 1.03 1.05 1.08 1.13 1.01 1.04 1.06 1.10 1.09 1.02 100 Hours Check Horizontal Drainage Hole 200 Hours Check Vertical Drainage Hole… -

Page 110

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 2.02 2.01 2.01 2.02 100 Hours Check Horizontal Drainage Hole 200 Hours Check Vertical Drainage Hole 2000 Hours Check Exterior Drainage Hole Drainage Hole Inside the Structure Figure 3: Drain Holes Canopy Page 6 Doc # 6.02.15… -

Page 111

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 2.03 100 Hours Check Horizontal Drainage Hole 200 Hours Check Vertical Drainage Hole 2000 Hours Check Exterior Drainage Hole Drainage Hole Inside the Structure Figure 4: Drain Holes Passenger Door Doc # 6.02.15… -

Page 112

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 3.07 3.02 3.07 3.06 3.06 3.09 3.09 3.05 3.01 3.05 3.08 3.08 3.04 3.04 4.01 4.01 4.02 4.02 3.03 3.07 5.01 5.01 5.02 5.02 100 Hours Check Horizontal Drainage Hole… -

Page 113

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT View on Arrow A 6.01 6.01 100 Hours Check Horizontal Drainage Hole 200 Hours Check Vertical Drainage Hole 2000 Hours Check Exterior Drainage Hole Drainage Hole Inside the Structure Figure 6: Drain Holes Rudder Doc # 6.02.15… -

Page 114

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Maintenance Access Maintenance Access 7.11 7.09 7.08 7.07 7.12 7.10 7.03 7.01 9.02 7.12 7.04 7.09 7.09 7.08 7.07 9.04 7.05 7.06 9.03 7.02 9.01 8.01 View A 7.06 7.09… -

Page 115: Maintenance Checklist Da 40 Ng

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28 Maintenance Checklist DA 40 NG Section 05-28-00 Maintenance Checklist Engine 1. General Enter the applicable data in the blocks below: Registration _________________ Date _________________ Airplane S/N _________________ Engine S/N…

-

Page 116: Preparation

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 2. Preparation CAUTION: OBSERVE THE COMPONENT TIME LIMITS STATED IN SECTIONS 04-00 AND 05-10 OF THIS AIRPLANE MAINTENANCE MANUAL. Do the following items before you start the applicable check: Interval (Flight Hours)

-

Page 117: Engine Ground Test

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 3. Engine Ground Test Do an engine ground test as follows (complete a copy of the Engine Ground Test Record as part of the engine ground test. (Refer to Section 05-28-91):…

-

Page 118: Engine Maintenance Checklist

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 4. Engine Maintenance Checklist 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials WARNING: MAKE SURE THE EXHAUST SYSTEM IS COOL BEFORE YOU DO MAINTENANCE ON THE ENGINE.

-

Page 119

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials Verify proper mixture ratio of the coolant. Refer to the AE Maintenance Manual, latest revision. -

Page 120

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials Examine the bonding cables and their connectors in the engine area: S Look specially for rub marks and damage. -

Page 121

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials Examine the air intake and turbo-charging system: Look specially for signs of chafing or damage on these items: S Air filter. -

Page 122

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials % % % % % % Inspect the V-clamp on the pressure side of the turbo… -

Page 123

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials % % % % Perform a coolant tank pressure relief valve test. -

Page 124

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Engine 100 200 1000 2000 Time Initials Examine the engine mounts. Look specially for: S Cracks or corrosion. No cracks or corrosion allowed. -

Page 125: Propeller

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 5. Propeller 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items, Propeller 100 200 1000 2000 Time Initials WARNING: DO NOT LET PERSONS GO INTO THE DANGER AREA OF THE PROPELLER.

-

Page 126

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 12 Doc # 6.02.15 05-28-00 01 Sep 2017 Rev. 3… -

Page 127: Maintenance Checklist Airframe

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-50 Maintenance Checklist Airframe Note: The items of the Major Structural Inspection (MSI) are included in the maintenance checklist of the airframe and identified by the term ‘MSI’ in the ‘Time’ column.

-

Page 128

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Do a function test of the door unlocked warning light system. -

Page 129

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Remove the main and nose wheels. S Clean and lubricate the bearings (Refer to Section 12-20). -

Page 130

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the mounting for the landing gear. Look specially for: S Incorrect attachment. -

Page 131

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Remove the access panel for the nose landing gear leg. -

Page 132

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the elastomer pack center tube (if OÄM 40-379 is NOT installed): S Remove elastomer pack. -

Page 133

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials % % % If OÄM 40-379 is installed: Remove and examine the damper assembly and lower attachment brackets: S Check for damage. -

Page 134: Cockpit

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 2. Cockpit 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials WARNING: DO NOT LOOSEN THE LEVER FOR THE ADJUSTABLE BACKREST OF THE FRONT SEATS UNINTENTIONALLY.

-

Page 135

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the aileron and elevator control system. Look specially for incorrect attachment and loose or missing lock devices. -

Page 136

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the brake fluid reservoirs on the co-pilot’s side. Make sure the fluid level is correct: S The fluid level must be 12 mm to 25 mm (½… -

Page 137

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the alternate static valve. Make sure that: S The valve is correctly attached. -

Page 138

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the trim control in the center console. Make sure that: S There is full and free movement. -

Page 139: Center Fuselage, Internal

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials If the emergency axe (OÄM 40-326) is installed: S Check attachments for looseness.

-

Page 140

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the cabin baggage compartment. Look specially for damage and insecure attachment. Inspect the following components: S Baggage compartment structure. -

Page 141

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the flap-actuator indicator and position switches. Look specially for incorrect attachment and operation. -

Page 142

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Check the following components for wear and/or corrosion, if installed: S Servo. -

Page 143: Rear Fuselage

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 4. Rear Fuselage 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the complete surface of the rear fuselage.

-

Page 144

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the ECU backup battery: S Check for leakage, damage, insecure mounting, and loose connectors. -

Page 145: Tail

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 5. Tail 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the complete surface of the aft part of the fuselage, vertical stabilizer, and horizontal stabilizer.

-

Page 146

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the bottom edge of the rudder. Look specially for cracks and deformation. -

Page 147

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Inspect the interior structure of the horizontal stabilizer through all access holes with mirror and flashlight. -

Page 148

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Inspect the inner skin of the rear fuselage through all access holes with mirror and flashlight. -

Page 149: Wings

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 6. Wings 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the complete surface of the wings. Look specially for damage (dents, cracks, holes and delamination).

-

Page 150

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Remove the flap and aileron bellcrank access panels in the wing (Refer to Section 52-40). -

Page 151

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Inspect the interior structure of the wing through all access holes with mirror and flashlight. Check for damage, cracks, delamination and disbonding from the wing skin. -

Page 152

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials WARNING: DO NOT GET FUEL ON YOU. FUEL CAN CAUSE SKIN DISEASE. DO NOT ALLOW FIRE NEAR FUEL. -

Page 153

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Examine the fuel tanks: S Remove the fuel tanks. S Look specially for corrosion, leaks and other damage. -

Page 154: General

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 7. General 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials If necessary, inspect optional equipment. Refer to Chapter 9 of the Airplane Flight Manual (Supplements).

-

Page 155

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 100 hr items marked X* apply to US registered airplanes only Interval Inspection Items 100 200 1000 2000 Time Initials Lower the airplane off jacks. (Refer to Section 07-10). Do an operational test of the external lights. -

Page 156

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Note: If a Maintenance Check was done, complete the Maintenance Report. Refer to Section 05-28-90. Note: If a Major Structural Inspection (MSI) was done, complete the Findings Report for the Major Structural Inspection (MSI). Refer to Section 05-28-93. -

Page 157: Maintenance Report

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-90 Maintenance Report 1. Maintenance Report Complete a copy of the Maintenance Report after all of the applicable maintenance tasks in the Maintenance Checklist have been initialed. DA 40 NG…

-

Page 158

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 05-28-90 01 Sep 2017 Rev. 3… -

Page 159

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-91 Engine Ground Test Report 1. Engine Ground Test Report Do the engine test in accordance with Section 71-00 and record results and comments. WARNING: DO NOT STAND WITHIN THE DANGER AREA OF THE PROPELLER. -

Page 160

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 05-28-91 01 Sep 2017 Rev. 3… -

Page 161

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-92 Check Flight Report 1. Check Flight Report CHECK FLIGHT DA 40 NG AIRCRAFT (See Maintenance Checklist for Applicability) Page 1 of 4 Registration: Pilot: Airdrome: Date: Take-Off: Landing:… -

Page 162

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT CHECK FLIGHT DA 40 NG AIRCRAFT (See Maintenance Checklist for Applicability) Page 2 of 4 Registration: Pilot: Airdrome: Date: Take-Off: Landing: Findings Functional Check, Flight Behavior Engine oil temperature indicator… -

Page 163

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT CHECK FLIGHT DA 40 NG AIRCRAFT (See Maintenance Checklist for Applicability) Page 3 of 4 Registration: Pilot: Airdrome: Date: Take-Off: Landing: Findings Functional Check, Flight Behavior Autopilot (if GFC 700 is installed): S HDG mode. -

Page 164

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT CHECK FLIGHT DA 40 NG AIRCRAFT (See Maintenance Checklist for Applicability) Page 4 of 4 Registration: Pilot: Airdrome: Date: Take-Off: Landing: Findings Functional Check, Flight Behavior Pitot heat Stall warning… -

Page 165: Major Structural Inspection Check Findings Report

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-28-93 Major Structural Inspection Check Findings Report 1. General Complete the Findings Report and report the following: Defects found during the Major Structural Inspection (MSI). Structural defects found during the associated 2000 hour inspection.

-

Page 166

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Enter the applicable data in the blocks below: FINDINGS REPORT DA 40 NG AT MAJOR STRUCTURAL INSPECTION (MSI) Registration __________________ Date _______________ Airplane Airplane S/N _________________ Operating Hours _______________ AMM Rev. -

Page 167

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT defect/finding repair method, remarks at TSN All defects have been repaired. The airplane is airworthy with respect to its maintenance condition. Place: _____________________________________ Date: _____________________________________ Authorized: _____________________________________ Doc # 6.02.15… -

Page 168

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 05-28-93 01 Sep 2017 Rev. 3… -

Page 169: Unscheduled Maintenance Checks

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Section 05-50 Unscheduled Maintenance Checks 1. General Unscheduled maintenance checks are necessary after any incident that could cause damage to the airplane. 2. Hard Landing Check Figure 1 shows the hard landing check areas. You must do a hard landing check when the pilot makes a report of a hard landing or when ground handling applies unusual loads.

-

Page 170

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items Examine the tires. Look specially for cuts in the Refer to Section 32-40. side walls. Examine the wheel rims. Look specially for cracks and deformation of the flanges. -

Page 171

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items (11) If OÄM 40-379 is installed: Remove and examine the damper assembly: S Check for damage. S Check for looseness of spring. S Check damper for leakage. -

Page 172

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items If the adjustable front seats (OÄM 40-252 or OÄM 40-375) are installed: WARNING: DO NOT ENGAGE THE LEVER OR BUTTON FOR THE ADJUSTABLE BACKREST OF THE FRONT SEATS UNINTENTIONALLY. THE SPRING LOADED BACKREST MAY SNAP FORWARD AND CAN CAUSE INJURY. -

Page 173

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Firewall Top Hat Profile Closing Rib Bearings for Nose Gear Assembly Nose Gear Assembly Rear Main Bulkhead Front Closing Rib Main Landing Gear Rib Reinforcement Rib (if installed) Inner Mounting… -

Page 174

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Firewall Top Hat Profile NLG Damper Closing Rib Bearings for Nose Gear Assembly Nose Gear Assembly Rear Main Bulkhead Front Closing Rib Main Landing Gear Ribs Inner Mounting Outer Mounting… -

Page 175: Propeller Strike

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 3. Propeller Strike A propeller strike can be a moving propeller (engine running) which has hit a solid object. Or it can be a moving object that hits a propeller that is not moving.

-

Page 176: Engine Fire

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 4. Engine Fire WARNING: BEFORE YOU DO WORK ON THE AIRPLANE MAKE SURE THE FIRE HAS BEEN EXTINGUISHED. LET THE ENGINE COOL AND DISCONNECT THE BATTERY. WARNING: FIRE CAN SERIOUSLY WEAKEN CFRP. IF YOU FIND ANY DAMAGE TO CFRP, DO NOT OPERATE THE AIRPLANE.

-

Page 177

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items Examine the fuselage compartment. Look specially for: S Blisters on the paint or burn marks. S Disbonding of the nacelle skin from the firewall. If you find any damage, ask the airplane manufacturer for advice. -

Page 178: Lightning Strike

Refer to the Wiring Diagrams for data about the electrical wiring. Note: If you find any lightning damage you must make a record of the damage and ask Diamond Aircraft for advice before you repair or operate the airplane. Page 10 Doc # 6.02.15…

-

Page 179

S Propeller and spinner. Make a record of the damage you find S Exhaust pipes. and ask Diamond Aircraft for advice before you repair or operate the S Engine breather. airplane. S Canopy handles. -

Page 180

S Pitot head. Make a record of the damage you find S Static discharge wicks. and ask Diamond Aircraft for advice before you repair or operate the S Wing tip. airplane. S Strobe lights. -

Page 181

Make a record of the damage you find S Horizontal stabilizer tip. and ask Diamond Aircraft for advice S Static discharge wicks. before you repair or operate the airplane. S Trailing edge. -

Page 182

Key Items Examine the metal conduction tubes and Make a record of any damage you find bonding strips in the fuselage and in the wings. and ask Diamond Aircraft for advice Look specially for: before you repair or operate the airplane. -

Page 183

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items (13) Do a test of these attitude and direction systems: S Magnetic compass. S Directional gyro. S Artificial horizon. S Turn & bank indicator. (14) Operate the engine power controls through their Refer to Section 76-10. -

Page 184: Over Temperature

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Detail Steps/Work Items Key Items (19) Do an ECU test. Refer to Section 71-00. (20) Do an ECU VOTER test. Refer to Section 71-00. (21) Contact the engine manufacturer. (22) Do a compass check swing.

-

Page 185: Oil Pressure Loss

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT 8. Oil Pressure Loss Detail Steps/Work Items Key Items Check the oil quantity. Check the indication. Check the wiring. Check if negative g-load flights have been conducted. (Visual inspection of the breather outlet for oil contamination).

-

Page 186

Time Limits and DA 40 NG AMM Maintenance Checks AIRCRAFT Intentionally left blank Page 18 Doc # 6.02.15 05-50-00 01 Sep 2017 Rev. 3… -

Page 187

Dimensions and Areas DA 40 NG AMM AIRCRAFT CHAPTER 06 DIMENSIONS AND AREAS Doc # 6.02.15 Page 1 06-TITLE Rev. 3 01 Sep 2017… -

Page 188

Dimensions and Areas DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 06-TITLE Rev. 3 01 Sep 2017… -

Page 189

Dimensions and Areas DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 06 DIMENSIONS AND AREAS General …………1 Dimensions . -

Page 190

Dimensions and Areas DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 06-CONTENTS Rev. 3 01 Sep 2017… -

Page 191

DIMENSIONS AND AREAS 1. General The DA 40 NG uses the System Internationale (SI) for dimensions and areas. Imperial dimensions are also given in brackets. For example: Wing span 11.63 m (38.16 ft). Conversions between SI units and imperial units are given in Chapter 02. -

Page 192

Ø 1.90 m (74.8 in) 2.97 m (9.7 ft) 11.63 m (38.15 ft) Ground Line, Static 3.29 m (10.8 ft) Figure 1: DA 40 NG, Overall Dimensions (Approximate Values) Page 2 Doc # 6.02.15 06-00-00 01 Sep 2017 Rev. 3… -

Page 193

Goodyear 8.50-6; 6 PR, TT 3. Adjustment Values The measurements of the DA 40 NG are recorded on an Adjustment Report at the factory when the airplane is built. See Figure 2 and 3. These Reports become part of the airplane records. -

Page 194

Dimensions and Areas DA 40 NG AMM AIRCRAFT Figure 2: Control Surface Adjustment Report Page 4 Doc # 6.02.15 06-00-00 01 Sep 2017 Rev. 3… -

Page 195

Dimensions and Areas DA 40 NG AMM AIRCRAFT Adjustment Report Registration Date Horizontal Main Landing Gear (at Empty Rudder Wings Stabilizer Weight, on Glide Sheets) Controls Cable Angle of Camber Leading Edge Dihedral Tension Incidence (Wing Supported) Sweep Back Differ-… -

Page 196

Dimensions and Areas DA 40 NG AMM AIRCRAFT Main Landing Gear Wheel Track and Camber Report (for test/adjustment procedure refer to Section 32-10 Paragraph 3 Check procedure Measured data Perform check at empty weight (fuel tank empty) Set airplane MLG wheels on relocatable plates (2 steel plates 250 x 300 x 2 mm;… -

Page 197

Dimensions and Areas DA 40 NG AMM AIRCRAFT dvs = 0° +1°/-0° (Track Sum) ±1° ±1° FS 2194 Main Landing Gear Loaded with Empty Weight ° ° 1° 1° ° ° S (Track) S+200 (Total Track Distance) Figure 4: Main Landing Gear Track and Camber Doc # 6.02.15… -

Page 198

Dimensions and Areas DA 40 NG AMM AIRCRAFT 4. Weight and Static Moments of Control Surfaces WARNING: IF YOU REPAINT (OR DO REPAIRS TO) THE CONTROL SURFACES, YOU MUST MAKE SURE THAT THE WEIGHTS AND STATIC MOMENTS OF THE CONTROL SURFACES ARE IN THE LIMITS IN THE CONTROL SURFACE BALANCING REPORT. -

Page 199

Lifting and Shoring DA 40 NG AMM AIRCRAFT CHAPTER 07 LIFTING AND SHORING Doc # 6.02.15 Page 1 07-TITLE Rev. 3 01 Sep 2017… -

Page 200

Lifting and Shoring DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 07-TITLE Rev. 3 01 Sep 2017… -

Page 201

Lifting and Shoring DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 07 LIFTING AND SHORING General …………1… -

Page 202

Lifting and Shoring DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 07-CONTENTS Rev. 3 01 Sep 2017… -

Page 203

LIFTING AND SHORING 1. General The DA 40 NG has no hoisting points. Use straps to lift the airplane. You can use your hands to lift the wings and the horizontal stabilizer. Section 07-10 tells you how to lift the airplane with jacks. -

Page 204

Lifting and Shoring DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 07-00-00 01 Sep 2017 Rev. 3… -

Page 205

Jacking 1. General The DA 40 NG has three jacking points. There are main jacking points under each stub-wing. The tie-down hole in the lower fin makes the tail jacking point. For maintenance lift the fuselage with the three hydraulic jacks. Use a trestle with a special former to hold the front of the fuselage. Use standard trestles under the wings at the position where the tips connect to the wing. -

Page 206

Lifting and Shoring DA 40 NG AMM AIRCRAFT Nose Wing Trestle Wing Trestle Main Jack Main Jack Trestle Tail Jacking Main Jacking Point Point LH & RH Nose Tail Jack Trestle Figure 1: Lifting the Airplane on Jacks Page 2 Doc # 6.02.15… -

Page 207

Lifting and Shoring DA 40 NG AMM AIRCRAFT B. Lifting the Airplane Detail Steps/Work Items Key Items/References CAUTION: IF THE AIRPLANE IS IN THE OPEN THEN ALIGN IT INTO THE WIND. MAXIMUM WIND SPEED: 10 KM/H (6 KTS). Apply the parking brake. Put chocks under the main wheels. -

Page 208

Lifting and Shoring DA 40 NG AMM AIRCRAFT C. Lowering the Airplane Detail Steps/Work Items Key Items/References WARNING: MAKE SURE THAT THE AREA UNDER THE AIRPLANE IS CLEAR BEFORE YOU LOWER THE AIRPLANE. Remove the nose trestle from under the fuselage. -

Page 209

Weighing and Levelling DA 40 NG AMM AIRCRAFT CHAPTER 08 WEIGHING AND LEVELLING Doc # 6.02.15 Page 1 08-TITLE Rev. 3 01 Sep 2017… -

Page 210

Weighing and Levelling DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 08-TITLE Rev. 3 01 Sep 2017… -

Page 211

Weighing and Levelling DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 08 WEIGHING AND LEVELLING General …………1… -

Page 212

Weighing and Levelling DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 08-CONTENTS Rev. 3 01 Sep 2017… -

Page 213

Weighing and Levelling DA 40 NG AMM AIRCRAFT CHAPTER 08 WEIGHING AND LEVELLING 1. General This Chapter tells you how to weigh the airplane. It also tells you how to level the airplane. Use the procedures in Section 08-10 to weigh the airplane and to calculate the airplane moment. Use the procedures in Section 08-20 to level the airplane. -

Page 214

Weighing and Levelling DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 08-00-00 Rev. 3 01 Sep 2017… -

Page 215

Figure 6). The reference plane for the DA 40 NG is a transverse, vertical plane in front of the airplane. It is at right angles to the horizontal reference line. The reference plane lies 2,194 mm (86.38 in) in front of the stub-wing leading edge at the wing joint on each side. -

Page 216

Weighing and Levelling DA 40 NG AMM AIRCRAFT Spirit Level Horizontal Part of Baggage Compartment Frame Figure 1: Level the Airplane Laterally for Weighing 600 mm (23.62 in.) Sprit Level 31 mm (1.22 in.) Wedge Figure 2: Level the Airplane Longitudinally for Weighing Page 2 Doc # 6.02.15… -

Page 217

Weighing and Levelling DA 40 NG AMM AIRCRAFT 2. Weighing with Electronic Weighing Units at the Jacking Points If you can use electronic weighing units to weigh the airplane, you can use the jacks to make the airplane level. You must obey the manufacturers’ instructions on the weighing units. -

Page 218

Weighing and Levelling DA 40 NG AMM AIRCRAFT Reference Plane Arm — Empty Weight X 2194 mm (86.38 in.) 2394 mm (94.25 in.) X 7312 mm (287.87 in.) Legend: = Arm, Reference Plane to Center Line of Main Jacking Points. -

Page 219

Weighing and Levelling DA 40 NG AMM AIRCRAFT B. Weighing Procedure with Electronic Weighing Units at the Jacking Points Detail Steps/Work Items Key Items/References Note: Weigh the airplane in a closed room. This will avoid any wind causing weighing errors. -

Page 220

Weighing and Levelling DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References (11) Read the value from the right main jack weighing unit. Enter the value on the Weighing Report under MAIN G Gross. (12) Read the value from the tail jack weighing unit. -

Page 221

DA 40 NG AMM AIRCRAFT WEIGHING REPORT Model: DA 40 NG Serial Number:___________ Registration:_____________ Data with reference to the Type Certificate Data Sheet and the Airplane Flight Manual. Reference Plane: Vertical plane 2194 mm (86.38 in) in front of the leading edge of wing at the root rib. -

Page 222

Weighing and Levelling DA 40 NG AMM AIRCRAFT Reference Plane Arm — Empty Weight X 2194 mm (86.38 in.) If necessary, use blocks under wheels to ensure horizontal alignment Ramp same Height as Nose Scale Legend: = Arm, Reference Plane to center line of main wheels. -

Page 223

Weighing and Levelling DA 40 NG AMM AIRCRAFT 3. Weighing with Mechanical Scales Under the Wheels If you use mechanical scales to weigh the airplane, you must also use wooden blocks under the wheels to level the airplane. You must obey the manufacturers’ instructions on the scales. -

Page 224

Weighing and Levelling DA 40 NG AMM AIRCRAFT B. Weighing Procedure with Mechanical Scales Under the Wheels Detail Steps/Work Items Key Items/References Note: Weigh the airplane in a closed room. This will avoid any wind causing weighing errors. Make a copy of the Weighing Report form. -

Page 225

Weighing and Levelling DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References (13) Make the airplane level longitudinally: Refer to Figure 2. S Place a wedge on the rear fuselage with the thin end forward. S Place a spirit level on the wedge. -

Page 226

Weighing and Levelling DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References (20) Use the plumb line to mark the position of the reference plane on the floor: S Hold the plumb line against the leading edge Do this on each side. -

Page 227

Weighing and Levelling DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References (32) Calculate the Empty Weight, G, from the Net values. Net G + Net G + Net G (33) Calculate the Empty Weight Moment, M. )+( G… -

Page 228

DA 40 NG AMM AIRCRAFT WEIGHING REPORT Model: DA 40 NG Serial Number:___________ Registration:_____________ Data with reference to the Type Certificate Data Sheet and the Airplane Flight Manual. Reference Plane: Vertical plane 2194 mm (86.38 in) in front of the leading edge of wing at the root rib. -

Page 229

Weighing and Levelling DA 40 NG AMM AIRCRAFT Section 08-20 Levelling 1. General These procedures tell you how to make the airplane level. See Section 07-10 for lifting the airplane with jacks. Make the airplane level with jacks unless you are weighing the airplane. If you weigh the airplane, change the airplane tire pressures or use blocks to make the airplane level (see Section 08-10). -

Page 230

Weighing and Levelling DA 40 NG AMM AIRCRAFT Spirit Level Horizontal Part of Baggage Compartment Frame Figure 1: Level the Airplane Laterally 600 mm (23.62 in.) Sprit Level 31 mm (1.22 in.) Wedge Figure 2: Level the Airplane Longitudinally Page 2 Doc # 6.02.15… -

Page 231

Weighing and Levelling DA 40 NG AMM AIRCRAFT B. Level the Airplane with Jacks Procedure Detail Steps/Work Items Key Items/References Note: Level the airplane in a closed room. This will avoid any wind causing levelling errors. Lift the airplane on jacks. -

Page 232

Weighing and Levelling DA 40 NG AMM AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 08-20-00 01 Sep 2017 Rev. 3… -

Page 233

Towing and Taxiing DA 40 NG AMM AIRCRAFT CHAPTER 09 TOWING AND TAXIING Doc # 6.02.15 Page 1 09-TITLE Rev. 3 01 Sep 2017… -

Page 234

Towing and Taxiing DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 09-TITLE Rev. 3 01 Sep 2017… -

Page 235

Towing and Taxiing DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 09 TOWING AND TAXIING General …………1… -

Page 236

Towing and Taxiing DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 09-CONTENTS Rev. 3 01 Sep 2017… -

Page 237

Towing and Taxiing DA 40 NG AMM AIRCRAFT CHAPTER 09 TOWING AND TAXIING 1. General You can move the airplane on the ground by hand or by taxiing it. Use the procedures in Section 09-10 and Section 09-20 to move the airplane safely. Section 09-10 tells you how to tow the airplane. Section 09-20 tells you how to taxi the airplane. -

Page 238

Towing and Taxiing DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 09-00-00 01 Sep 2017 Rev. 3… -

Page 239

Towing 1. General You can move the airplane without using a tow bar. You can push or pull the DA 40 NG at the wing tip, at the wing nose, and at the propeller blades near the spinner. 2. Towing Procedure WARNING: DO NOT PUSH ON THE SPINNER. -

Page 240

Towing and Taxiing DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 09-10-00 01 Sep 2017 Rev. 3… -

Page 241

Section 09-20 Taxiing 1. General When you taxi the DA 40 NG you use the toe operated brakes to steer the airplane. To make the airplane turn operate the left or the right toe brake. WARNING: YOU MUST NOT TAXI THE AIRPLANE UNLESS YOU HAVE BEEN TRAINED TO TAXI AND HAVE BEEN AUTHORIZED BY YOUR AIRWORTHINESS AUTHORITY. -

Page 242

Towing and Taxiing DA 40 NG AMM AIRCRAFT Key Items/References Detail Steps/Work Items WARNING: MAKE SURE THE BRAKES OPERATE CORRECTLY WHEN YOU TAXI THE AIRPLANE. IF THE BRAKES SHOULD FAIL, YOU MUST BE ABLE TO STOP THE AIRPLANE BEFORE YOU HIT PERSONS OR EQUIPMENT. -

Page 243

Towing and Taxiing DA 40 NG AMM AIRCRAFT Figure 1: The Safety Range for Taxiing the DA 40 NG Airplane Doc # 6.02.15 Page 3 09-20-00 Rev. 3 01 Sep 2017… -

Page 244

Towing and Taxiing DA 40 NG AMM AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 09-20-00 01 Sep 2017 Rev. 3… -

Page 245

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT CHAPTER 10 PARKING, MOORING, STORAGE AND RETURN TO SERVICE Doc # 6.02.15 Page 1 10-TITLE Rev. 3 01 Sep 2017… -

Page 246

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 10-TITLE Rev. 3 01 Sep 2017… -

Page 247

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 10 PARKING, MOORING, STORAGE AND RETURN TO SERVICE General …………1… -

Page 248

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 10-CONTENTS Rev. 3 01 Sep 2017… -

Page 249: General

1. General Always park or moor the DA 40 NG when it is not in use. Use the procedures in Section 10-10 for parking the airplane. Use the procedure in Section 10-20 to moor the airplane. If the airplane is parked over-night, we recommend that you moor the airplane.

-

Page 250

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 10-00-00 01 Sep 2017 Rev. 3… -

Page 251: Parking And Storage

5 to 30 days. Use the storage procedure if the airplane will be parked for more than 30 days. All pilots and all maintenance staff for the DA 40 NG must know the procedures in this Section. CAUTION: MAKE SURE THAT THE AIRPLANE IS CORRECTLY MOORED AND PROTECTED IF STRONG WINDS ARE FORECAST.

-

Page 252

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References CAUTION: DO NOT SET THE PARKING BRAKE WHEN THE BRAKES ARE OVER-HEATED. THE BRAKES CAN SEIZE ON. Set the parking brake ON. Pull the lever fully aft, and push both brake pedals at least two times. -

Page 253

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT C. Long-Term Parking CAUTION: MAKE SURE TO PERFORM THE LONG TERM PARKING PROCEDURE WHEN THE AIRPLANE IS PARKED FOR A LONG TIME. IF THE PROCEDURE IS NOT FOLLOWED CORRECTLY, DAMAGE TO THE AIRPLANE CAN OCCUR. -

Page 254: Storage

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT 2. Storage If the airplane is parked (or not operated) for more than 30 days, you have to do this storage procedure. A. Equipment and Material Item Quantity Part Number Wheel chocks.

-

Page 255: Mooring

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Section 10-20 Mooring 1. General CAUTION: IF THE AIRPLANE MUST BE STORED OUTSIDE FOR A LONG TIME, THEN YOU MUST MOOR IT. STRONG WINDS OR GUSTS CAN CAUSE DAMAGE TO AN AIRPLANE WHICH IS NOT MOORED.

-

Page 256

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Wing Tie-Down Point Wing Tie-Down Point Mooring Ring Mooring Ring Rear Tie-Down Point Figure 1: Location of Mooring Points on the Airplane Page 2 Doc # 6.02.15 10-20-00 01 Sep 2017 Rev. 3… -

Page 257: Return To Service

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT Section 10-30 Return to Service 1. General Do this procedure when the airplane has been parked (or stored) for more than 5 days. 2. Return to Service Procedure A. Storage Time Less Than One Year…

-

Page 258

Parking, Mooring, etc. DA 40 NG AMM AIRCRAFT B. Storage Time One Year and More Detail Steps/Work Items Key Items/References Contact the engine manufacturer Austro Engine GmbH. If necessary, install loose equipment which was removed for storage. If the battery has been removed: Refer to Section 24-31. -

Page 259

Placards and Markings DA 40 NG AMM AIRCRAFT CHAPTER 11 PLACARDS AND MARKINGS Doc # 6.02.15 Page 1 11-TITLE Rev. 3 01 Sep 2017… -

Page 260

Placards and Markings DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 11-TITLE Rev. 3 01 Sep 2017… -

Page 261

Placards and Markings DA 40 NG AMM AIRCRAFT TABLE OF CONTENTS CHAPTER 11 PLACARDS AND MARKINGS General …………1… -

Page 262

Placards and Markings DA 40 NG AMM AIRCRAFT Intentionally left blank Page 2 Doc # 6.02.15 11-CONTENTS Rev. 3 01 Sep 2017… -

Page 263

Placards and Markings DA 40 NG AMM AIRCRAFT CHAPTER 11 PLACARDS AND MARKINGS 1. General Placards are used for identification and indication. They show the function, operation and operating limitations of systems and equipment. Note: Placards must not be removed, exchanged or altered unless approved by the national Airworthiness Authority. -

Page 264

Placards and Markings DA 40 NG AMM AIRCRAFT B. Replace a Placard Use this procedure for both internal and external foil placards. Detail Steps/Work Items Key Items/References Remove the old placard: S Heat the placard with a hot air blower. -

Page 265

Exterior Placards and Markings 1. General Figure 1 and 2 show the exterior markings and placards for the DA 40 NG. For the safety walk adhesive strips are installed. Refer to the Maintenance Practices for more details about the positioning of the safety walk adhesive strips. -

Page 266

Placards and Markings DA 40 NG AMM AIRCRAFT WARNING If neither OÄM 40-339 OÄM 40-400 APPROVED FUEL: installed JET-A1 If OÄM 40-348 and or see Airplane Flight Manual OÄM 40-130 is If OÄM 40-339 or installed OÄM 40-400 is installed Usable Fuel Qty.:… -

Page 267

Placards and Markings DA 40 NG AMM AIRCRAFT Basic 3.3 bar / 48 psi If OÄM 40-334 is installed 1.2 bar / 17 psi Basic 3.1 bar / 45 psi If OÄM 40-334 is installed 1.2 bar / 17 psi If MÄM 40-574 &… -

Page 268

Placards and Markings DA 40 NG AMM AIRCRAFT Intentionally left blank Page 4 Doc # 6.02.15 11-20-00 Rev. 3 01 Sep 2017… -

Page 269

Placards and Markings DA 40 NG AMM AIRCRAFT Maintenance Practices 1. General This Section tells you how to replace safety walk adhesive strips. 2. Replace the Safety Walk Adhesive Strips A. Equipment Item Quantity Part Number Safety walk template. D44-1127-10-52. -

Page 270

Placards and Markings DA 40 NG AMM AIRCRAFT Detail Steps/Work Items Key Items/References Remove the adhesives layer of the safety walk adhesive strips from surface: S Use fresh acetone or Socomore® cleaning cloth (P/N: 29003-C86-C10) to remove the adhesive layer. Do not use cleaning or polishing agents which contain silicon. -

Page 271