-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

PanelView

Standard Operator

Terminals

PV300 Micro, PV300, PV550,

PV600, PV900, PV1000, PV1400

User Manual

Related Manuals for Allen-Bradley PV300 Micro

Summary of Contents for Allen-Bradley PV300 Micro

-

Page 1

PanelView Standard Operator Terminals PV300 Micro, PV300, PV550, PV600, PV900, PV1000, PV1400 User Manual… -

Page 2

Identifies information that is critical for successful IMPORTANT application and understanding of the product. Allen-Bradley, MicroLogix, ControlLogix, FlexLogix, CompactLogix, SLC, PLC, RSLogix, RSLinx, PanelView, PanelBuilder32 are trademarks of Rockwell Automation DeviceNet is a trademark of The Open DeviceNet Vendors Association Modbus is a trademark of Modicon, Inc. -

Page 3: Table Of Contents

Table of Contents Preface Objectives……..P-1 Contents of Manual .

-

Page 4

Alarms ……..5-18 Installing the PV300 Micro… -

Page 5

Table of Contents Installing the PV300 Terminal Chapter 7 Chapter Objectives ……7-1 Hazardous Locations . -

Page 6

Table of Contents Installing the PV1400 Terminal Chapter 11 Chapter Objectives ……11-1 Enclosures . -

Page 7: Objectives

Tells how to copy applications to and from a memory card. Running Applications Describes objects common to most applications. Installing the PV300 Micro Describes enclosure or panel mounting of the Terminal PanelView 300 Micro terminal. Installing the PV300 Terminal Describes enclosure or panel mounting of the PanelView 300 terminal.

-

Page 8: Intended Audience

Preface Intended Audience No special knowledge is required to understand this manual or operate the PanelView terminals. Before running an application, you must know the functions of all screens and screen objects. This information is available from the application designer. Equipment installers must be familiar with standard panel installation techniques.

-

Page 9: Technical Support

Preface Technical Support If you have questions about the PanelView terminals or the PanelBuilder32 software, please refer to the online manuals or online help provided with the PanelBuilder32 installation CD. These publications are also available from the Automation Bookstore or Manuals Online at the www.ab.com website.

-

Page 10: What’s New

Preface What’s New Ethernet communications is now supported on the following PanelView terminals. • PanelView 550 • PanelView 600 • PanelView 900 (not supported on the monochrome versions) • PanelView 1000 • PanelView 1400 All of these terminals are available with an EtherNet/IP connector and RS-232 port for file transfers and/or printing.

-

Page 11: Chapter 1 Chapter Objectives

• AC or DC power (L1 at the end of a catalog number indicates a DC terminal, for example, 2711-B5A1L1, or -T9C1L1). • Stainless steel bezel available on PanelView 550 keypad or keypad & touch terminals. Contact your Allen-Bradley representative for availability. Publication 2711-UM014B-EN-P…

-

Page 12

PanelView 300 Micro Monochrome Terminals The PanelView 300 Micro is available only with 24V dc input power and does not have a printer port. The PV300 Micro contains a single RS-232 communication port which supports either DF1 or DH485 communication protocols as specified in the table below. -

Page 13

Terminal Overview PanelView 550 Monochrome Terminals The Touch Screen version of the PanelView 550 terminal is available only with 24V dc power. The L1 in the catalog number indicates DC power. Communication Port Catalog Operator Printer Port DH-485 RS-232 DeviceNet ControlNet RS-232 Ethernet… -

Page 14

Terminal Overview PanelView 600 Color Terminals Communication Port Catalog Operator Printer Port DH-485 RS-232 DeviceNet ControlNet RS-232 Ethernet Input RS-232 Number (DH-485) (DF1) 2711-B6C1 2711-B6C2 2711-B6C3 2711-B6C5 2711-B6C8 Touch Screen and Keypad 2711-B6C9 2711-B6C10 2711-B6C15 2711-B6C16 2711-B6C20 2711-K6C1 2711-K6C2 2711-K6C3 2711-K6C5 2711-K6C8 Keypad… -

Page 15

Terminal Overview PanelView 900 Monochrome Terminals These terminals are no longer available for purchase. Communication Port Catalog Operator Printer Port DH-485 RS-232 DeviceNet ControlNet RS-232 Input RS-232 Number (DH-485) (DF1) 2711-T9A1 2711-T9A2 2711-T9A3 2711-T9A5 Touch 2711-T9A8 Screen 2711-T9A9 2711-T9A10 2711-T9A15 2711-T9A16 2711-K9A1 2711-K9A2… -

Page 16

Terminal Overview PanelView 1000 Color Terminals Communication Port Catalog Operator Printer Port DH-485 RS-232 DeviceNet ControlNet RS-232 Ethernet Input RS-232 Number (DH-485) (DF1) 2711-T10C1 2711-T10C3 2711-T10C8 2711-T10C9 Touch Screen 2711-T10C10 2711-T10C15 2711-T10C16 2711-T10C20 2711-K10C1 2711-K10C3 2711-K10C8 2711-K10C9 Keypad 2711-K10C10 2711-K10C15 2711-K10C16 2711-K10C20 Add L1 to the end of the catalog number for 24V dc power. -

Page 17

Terminal Overview PanelView 1400 Color Terminals Communication Port Catalog Operator Printer Port DH-485 RS-232 DeviceNet ControlNet RS-232 Ethernet Input RS-232 Number (DH-485) (DF1) 2711-T14C1 2711-T14C3 2711-T14C8 2711-T14C9 Touch Screen 2711-T14C10 2711-T14C15 2711-T14C16 2711-T14C20 2711-K14C1 2711-K14C3 2711-K14C8 2711-K14C9 Keypad 2711-K14C10 2711-K14C15 2711-K14C16 2711-K14C20 Publication 2711-UM014B-EN-P… -

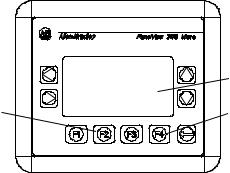

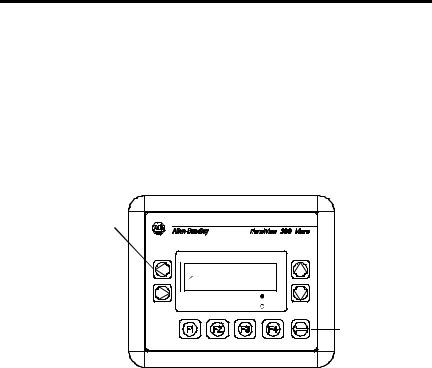

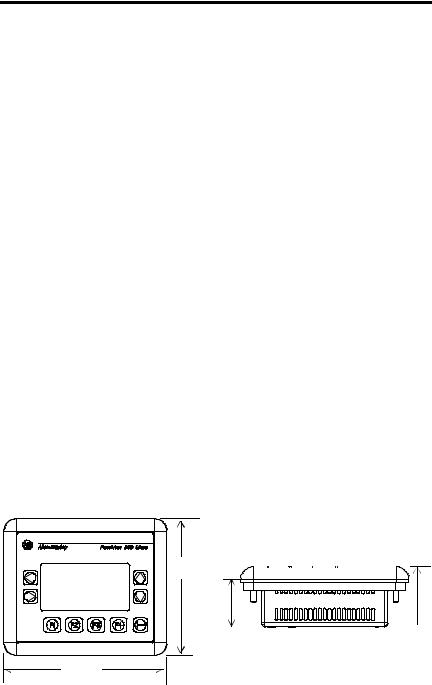

Page 18: Panelview 300 Micro Features

Terminal Overview PanelView 300 Micro This section defines features of the PanelView 300 Micro keypad terminal. Features PanelView 300 Micro Features (Front) Feature Description Function Keys Use the function keys to initiate functions on the terminal (F1 — F4) display. Cursor Keys Use the cursor keys (left, right, up, down) as programmed function keys in addition to the F1 — F4 function keys or to…

-

Page 19

Terminal Overview PanelView 300 Micro Features (Back) Feature Description Power Connection Terminals Connects to a 24V dc (11-30 V dc) external power source. DF1 or DH-485 (RS232) Connects to an SLC, PLC, or MicroLogix controller using an RS-232 Communication Port connection. -

Page 20: Panelview 300 Features

1-10 Terminal Overview PanelView 300 Features This section defines features of the PanelView 300 keypad terminal. PanelView 300 Features (Front) Feature Description Function Keys Use the function keys to initiate functions on the terminal (F1 — F8) display. These keys may have custom legends. Cursor Keys Use the up or down cursor keys to move the cursor up or down in a list or to increment/decrement values.

-

Page 21

Terminal Overview 1-11 PanelView 300 Features (Back) DeviceNet with additional RS-232 Port 10 12 DH-485 without RS-232 Port RS-232 (DH-485 or DF1) without additional RS-232 Port 7, 8, 9, 10, 11, 12 9 or 11 Feature Description Nameplate Label Provides product information. Sealing Gasket Seals the front of the terminal to an enclosure or panel. -

Page 22: Panelview 550 Features

1-12 Terminal Overview PanelView 550 Features This section defines features of the PanelView 550 terminals. PanelView 550 Features (Front) Keypad Terminal Keypad & Touch Screen Terminal Cell 16 Cell 1 Cell 113 Cell 128 Touch Screen Terminal Cell 1 Cell 16 Cell 113 Cell 128 Publication 2711-UM014B-EN-P…

-

Page 23

Terminal Overview 1-13 Feature Description Function Keys On keypad terminals, use the function keys to initiate (F1 — F10) functions on the terminal display. These keys may have custom legends. On keypad & touch screen terminals, you can initiate functions using the function keys and/or touch screen objects. -

Page 24

1-14 Terminal Overview PanelView 550 Keypad or Keypad & Touch Screen Terminals (Back) DH-485 without additional RS-232 Port AC connector shown, DC connector looks different DH-485 with additional RS-232 Port Backlight lamp behind access cover RS-232 (DH-485) Remote I/O, DF1, DH+, DeviceNet, ControlNet, Ethernet, without additional RS-232 Port with additional RS-232 Port 13, 14, 15, 16, 17, or 18… -

Page 25

Terminal Overview 1-15 Feature Description Power Connection Terminals Connects to external power source. Nameplate Label Provides product information. Sealing Gasket Seals the front of the terminal to an enclosure or panel. COMM LED (Green) Indicates when communications is occurring. FAULT LED (Red) Indicates firmware or hardware faults. -

Page 26

1-16 Terminal Overview PanelView 550 Touch Screen Terminal Features (Back) DH-485 without additional RS-232 Port DH-485 with RS-232 Port Backlight lamp behind access cover RS-232 (DH-485) without additional RS-232 Port Remote I/O, DF1, DH+, DeviceNet, ControlNet, Ethernet, with RS-232 Port RS-232 (DH-485) with additional RS-232 Port 13, 14, 15, 16, 17, or 18 Publication 2711-UM014B-EN-P… -

Page 27

Terminal Overview 1-17 Feature Description Power Connection Terminals Connects to external DC power source. Sealing Gasket Seals the front of the terminal to an enclosure or panel. FAULT LED (Red) Indicates firmware or hardware faults. COMM LED (Green) Indicates when communications is occurring. Nameplate Label Provides product information. -

Page 28: Panelview 600 Features

1-18 Terminal Overview PanelView 600 Features This section defines features of the PanelView 600 terminals. PanelView 600 Features (Front) Keypad Terminal Keypad & Touch Screen Terminal Cell 16 Cell 1 Cell 128 Cell 113 Touch Screen Terminal Cell 1 Cell 16 Cell 128 Cell 113 Publication 2711-UM014B-EN-P…

-

Page 29

Terminal Overview 1-19 Feature Description Function Keys (F1 — F10) Use the function keys on keypad terminals to initiate functions on the terminal display. These keys may have custom legends. On the keypad & touch screen terminals, you can initiate functions using the function keys and/or touch screen objects. -

Page 30

1-20 Terminal Overview PanelView 600 Keypad or Keypad & Touch Screen Terminal (Back) Remote I/O, DF1, DH+, DeviceNet, ControlNet, or Ethernet with additional RS-232 Port 10, 11, 12, 13, 14, or 15 DH-485 without additional RS-232 Port 7, 8, 9, 10 11, 12, 13, 14, 15, 16 DH-485 with additional RS-232 Port RS-232 (DH-485) -

Page 31

Terminal Overview 1-21 Feature Description Power Connection Terminals Connects to external power source. Nameplate Label Provides product information. Memory Card Slot Accepts a memory card which stores applications. Sealing Gasket Seals the front of the terminal to an enclosure or panel. FAULT LED (Red) Indicates firmware or hardware faults. -

Page 32

1-22 Terminal Overview PanelView 600 Touch-Screen Terminal Features (Back) Remote I/O, DF1, DH+, DeviceNet, ControlNet, or Ethernet with additional RS-232 Port 11, 12, 13, 14, 15, or 16 DH-485 without additional RS-232 Port 8, 9, 10, 11 12, 13, 14, 15, 16, 17 DH-485 with additonal RS-232 Port RS-232 (DH-485) RS-232 (DH-485) with additional RS-232 Port… -

Page 33

Terminal Overview 1-23 Feature Description Power Connection Terminals Connects to external power source. Nameplate Label Provides product information. Fault LED (Red) Indicates firmware or hardware faults. COMM LED (Green) Indicates when communications is occurring. Sealing Gasket Seals the front of the terminal to an enclosure or panel. Reset Button Resets the terminal. -

Page 34: Panelview 900/1000 Features

1-24 Terminal Overview PanelView 900/1000 This section defines features of the PanelView 900 and 1000 terminals. Features PanelView 900/1000 Terminal Features (Front) Keypad Terminal Touch Screen Terminal Cell 1 Cell 24 Cell 361 Cell 384 Publication 2711-UM014B-EN-P…

-

Page 35

Terminal Overview 1-25 Feature Description Function Keys (F1 — F16) Use the function keys on keypad terminals to initiate functions on the terminal display. These keys may have custom legends. Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry object or to enter configuration mode. -

Page 36

1-26 Terminal Overview PanelView 900/1000 Terminal Features (Back) Remote I/O, DF1, DH+, DeviceNet, Ethernet, or ControlNet with additional RS-232 Port Back View Touch Screen Terminal 11, 12, 13, 14, 15, or 16 DH-485 Version without additional RS-232 Port 8, 9, 10 11, 12, 13, 14, 15, 16, 17 DH-485 with additional RS-232 Port Back View… -

Page 37

Terminal Overview 1-27 Feature Description Power Connection Terminals Connects to external power source. Nameplate Label Provides product information. Reset Button Resets the terminal. Sealing Gasket Seals the front of the terminal to an enclosure or panel. Memory Card Slot Accepts a memory card which stores applications. FAULT LED (Red) Indicates firmware or hardware faults. -

Page 38: Panelview 1400 Features

1-28 Terminal Overview PanelView 1400 Features This section defines features of the PanelView 1400 terminals. PanelView 1400 Terminal Features (Front) Keypad Terminal Touch Screen Terminal Cell 1 Cell 24 Cell 384 Cell 361 Publication 2711-UM014B-EN-P…

-

Page 39

Terminal Overview 1-29 Feature Description Function Keys (F1 — F21) Use the function keys on keypad terminals to initiate functions on the terminal display. These keys may have custom legends. Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry object, or to enter configuration mode. -

Page 40

1-30 Terminal Overview PanelView 1400 Terminal Features (Back and Sides) Remote I/O, DF1, DH+, DeviceNet, ControlNet, or Ethernet with additional RS-232 Port 7, 8, 9 10, 11, 12 13, 14, 15, 16 10, 11, 12, 13, 14, or 15 DH-485 with additional RS-232 Port Left Side RS-232 (DH-485) with additional RS-232 Port Right Side… -

Page 41

Terminal Overview 1-31 Feature Description Brightness Control Adjusts the brightness of the color display. Contrast Control Adjusts the contrast of the color display. Nameplate Label Provides product information. FAULT LED (Red) Indicates firmware or hardware faults. COMM LED (Green) Indicates when communications is occurring. Power Connection Terminals Connects to external power source. -

Page 42: Applications

1-32 Terminal Overview Applications PanelView terminals operate with custom designed applications. The first time you power on the terminal, (no application file loaded), the terminal displays the Configuration Mode menu. Chapter 3 describes the terminal functions you can configure from this menu. Note: Remote I/O terminals provide an out-of-box application for setting Remote I/O communication parameters.

-

Page 43

Terminal Overview 1-33 Touch Screen Operation Applications for touch screen terminals are controlled by touching screen objects. Keypad Operation Applications for keypad terminals are controlled by pressing function keys that correspond to screen objects. Data is entered manually using the numeric entry keys. A function key legend kit is available for each terminal (except the 300 Micro) to create custom labels for the function keys. -

Page 44: Configuration Mode Menu

1-34 Terminal Overview Configuration Mode Menu You can configure terminal functions from the Configuration Mode menu including: • select a language • upload/download applications with a memory card • set or display serial communication parameters • select preset values • obtain terminal and application information •…

-

Page 45: Alarm List

Terminal Overview 1-35 Alarm List PanelView terminals support an Alarm List queue to store information on triggered alarms. The Alarm List stores a maximum of 100 alarms or as many as the terminal can hold in nonvolatile RAM. The number of alarms stored in the list is configured using the PanelBuilder32 software.

-

Page 46: Accessories

2711-NMCD Secures memory card in 550 touch screen terminal and prevents electrostatic discharge. 2711-NMCE Secures memory card in PanelView 300 keypad and 600 touch screen terminals and prevents electrostatic discharge. Contact Allen-Bradley for availability. Not available for purchase. Publication 2711-UM014B-EN-P…

-

Page 47

Terminal Overview 1-37 Antiglare Overlay Self-adhesive filters minimize the reflection of terminal displays. Catalog No. 300M 300 1000 1400 2711-NV4 (Keypad) 2711-NV4T (Touch Screen Terminals) 2711-NV3K (Keypad) 2711-NV3T (Touch Screen Terminals) 2711-NV5 (Keypad) 2711-NV7K (Keypad Terminals) 2711-NV7T (Touch Screen Terminals) 2711-NV6K (Keypad Terminals) 2711-NV6T (Touch Screen Terminals) 2711-NV8 (Keypad Terminals) -

Page 48

1-38 Terminal Overview PanelView File Transfer Utility Catalog No. Description 2711-ND7 Transfers .PVA files between a PanelView terminal and a computer running Windows. Power Supply and Link Couplers The following items are available for all PanelView terminals. Catalog No. Description 1747-NP1 Wallmount Power supply provides power for DH-485 communications when an SLC or network is not connected. -

Page 49

(except PV300 Micro). 2711-NC22 15 meter (49 foot) cable connects an RS-232 terminal to a MicroLogix controller (except PV300 Micro). 2706-NC13 3 meter (10 ft) cable connects an RS-232 terminal to an SLC 5/03 controller or the RS-232 port of a computer or printer. -

Page 50: Replacement Parts

1-40 Terminal Overview Replacement Parts Backlight Lamps Catalog No. 1000 Description 2711-NL1 Halogen backlight lamp for all PV550 terminals. Provides backlighting for LCD display. 2711-NL2 Backlight for PV900 color terminal. 2711-NL3 Backlight for PV600 color terminal. 2711-NL4 Backlight for PV1000 color terminal. Real Time Clock Modules Catalog No.

-

Page 51: Chapter 2 Chapter Objectives

Chapter Applying Power and Resetting Terminal Chapter Objectives This chapter provides information on: • wiring and safety guidelines • connecting AC or DC power • resetting the terminal • power-up sequence Wiring and Safety Use publication NFPA 70E, Electrical Safety Requirements for Employee Workplaces when wiring the PanelView terminals.

-

Page 52: Connecting Ac Power

Applying Power and Resetting Terminal Connecting AC Power Below are AC electrical ratings for the PanelView terminals. The PV550/PV600 touch screen only terminal is available only with DC power, not AC power. Terminal Type Supply Voltage Power Consumption PV550 85 to 264V ac, 47 to 63 Hz 45 VA maximum PV600 85 to 264V ac, 43 to 63 Hz…

-

Page 53

Applying Power and Resetting Terminal PanelView 550 Terminal 120/240V ac, 3 Wire, 120/240V ac, 3 Wire, European Harmonized Color Code U.S. Color Code L1 L2N GND L1 L2N Black (Line) White (Neutral) Blue (Neutral) Green/Yellow Brown (Line) Green (Earth Ground) (Protective Earth) To Power Source To Power Source… -

Page 54: Connecting Dc Power

Electronic circuitry and an internal fuse protect the terminals from reverse polarity and over-voltage conditions. Supply Voltage Terminal Type Power Consumption (24V dc nominal) PV300 Micro 11 to 30V dc 2.5 Watts max. (0.105A @ 24V PV300 18 to 32V dc 10 Watts max. (0.42A @ 24V…

-

Page 55

Applying Power and Resetting Terminal DC Power Connections Connect the power source to the terminal at the 3-screw terminal block (PV300 Micro removable, all others fixed). Explosion Hazard DANGER • Substitution of components may impair suitability for Class I, Division 2. -

Page 56

Applying Power and Resetting Terminal To connect power to the DC versions of the PanelView: 1. Secure the DC power wires to the terminal block screws. PanelView 300 Terminal PanelView 900/1000 Terminal PanelView 550/600 Terminal Power Terminal Power Terminal Block (fixed) Block (fixed) Note: In the PanelView 300, the Earth Ground Earth Ground… -

Page 57: Resetting The Terminal

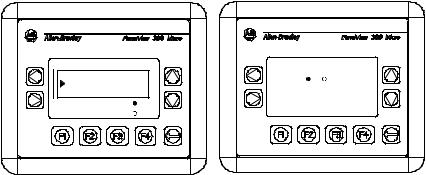

Resetting the Terminal Resetting the terminal re-initializes the PanelView terminal (same as cycling power). To reset the PV300, PV300 Micro, PV550 (keypad, keypad & touch) or the PV600 (keypad, keypad & touch): • Simultaneously press the Left arrow , Right arrow , and Enter ↵…

-

Page 58: Power-Up Sequence

• If an application is not loaded, the Configuration Mode menu appears. Function keys do not appear on touch screen terminals. PV900 Keypad Terminal Note: On PV550/600 terminals, the Reset Video is F9. On PV300 and PV300 Micro terminals, the Reset Video is F2. Publication 2711-UM014B-EN-P…

-

Page 59

Applying Power and Resetting Terminal For Remote I/O Terminals An out-of-box application screen opens allowing you to set Remote I/O parameters for the terminal. This screen is only available for initial setup. Once an application is downloaded, the Remote I/O setup screen is erased. -

Page 60

2-10 Applying Power and Resetting Terminal Press this function key on: To set this RIO Description Options Parameter: 550/600 900/1000/1400 ↵ Rack # Rack address of terminal on RIO network. 0 to 76 On PV550/600: Press ↵ to open the scratchpad. -

Page 61: Chapter 3 Chapter Objectives

Chapter Configuring the Terminal Chapter Objectives This chapter shows how to use the Configuration Mode menu to configure terminal settings and perform operations including how to: • access the Configuration Mode menu • select a language • use a memory card •…

-

Page 62: Accessing The Configuration Mode Menu

Function keys do not List appear on touch screen terminals. PV300/PV300 Micro Keypad Terminal On PV550/600 terminals, the Reset Video button is F9. On PanelView 300, 300 Micro terminals, the Reset Video button is F2. Operations List Select an operation using the Up or Down arrow keys.

-

Page 63: Selecting A Language

Selecting a Language Press the Language button, [F8] key, from the Configuration Mode menu to display the Language Selection screen. Note: On PV300 and PV300 Micro terminals, scroll down on the main configuration menu to select a language. Choisir Français Deutsches Meün auswãhlen…

-

Page 64

Configuring the Terminal Using a Memory Card Select Memory Card from the Configuration Mode menu to transfer applications between a memory card and the terminal. The PanelView 300 Micro does not support a memory card. Chapter 4 describes the transfer procedure. Valid Card Inserted Memory APPLICATIONS ON CARD… -

Page 65

Configuring the Terminal Configuring Select Communication Setup from the Configuration Mode menu to display or change the communication settings for your PanelView Communications terminal. The screen that appears depends on the communication protocol of the terminal. DH-485 Communications The DH-485 screen lets you modify or display DH-485 settings for either a DH-485 or RS-232 PanelView terminal. -

Page 66

Configuring the Terminal Comm LED • solid fill — normal operating state • blinking — no communications established • no fill — hardware failure Fault LED • no fill — normal operating state • blinking — hardware is functioning but an application is not loaded or the current application is corrupted. -

Page 67

Configuring the Terminal DH+ Communications The DH+ screen lets you display or modify communication settings for the DH+ version of the PanelView terminals. Settings downloaded with a DH+ application take IMPORTANT priority over terminal settings and take effect immediately after the download. Node: Baud: 57.6 K… -

Page 68

Displays the starting module group of the terminal: 0,1 2,3 4,5 6,7 Pass-Through Enabled (read only) Enables/disables Pass-Through which allows you to transfer applications between a computer on the Allen-Bradley DH+ network and a terminal on the Remote I/O link. A PLC-5 controller passes data between the two networks. -

Page 69

Configuring the Terminal ControlNet Communications The ControlNet screen lets you display communications settings for a ControlNet terminal. You are only allowed to change the Node Address and Interscan Delay settings. Settings downloaded with a ControlNet application IMPORTANT take priority over terminal settings and take effect immediately after the download. -

Page 70

Value Value Status Indicates Priority Terminal failure. Contact Allen-Bradley for technical support. 1 (Highest) Self test being performed. Wait for end of test. Incorrect node configuration. Check for duplicate nodes. Incorrect network configuration (such as overflow/underflow if signaled by host, out-of-step). Check for a node greater than UMAX. -

Page 71

Configuring the Terminal 3-11 DeviceNet Communications The DeviceNet screen lets you display or modify communication settings for a DeviceNet terminal. Settings downloaded with a DeviceNet application IMPORTANT take priority over terminal settings and take effect immediately after the download. DeviceNet New Node Address F2: Input Size: Output Size:… -

Page 72

3-12 Configuring the Terminal Active Baud (read only) Displays the current baud rate of the PanelView terminal. The new baud is displayed after a reset. If the baud rate was set to AutoBaud, active baud displays the rate set by the terminal. If the baud rate was set to PGM, the active baud displays the most recent baud stored on the communications card. -

Page 73

Configuring the Terminal 3-13 DF1 Communications The DF1 screen lets you display or modify DF1/full duplex communication settings for a DF1 PanelView terminal. Settings downloaded with a DF1 application have IMPORTANT priority over terminal settings and take effect immediately after the download. Typical DF1 Setup Screens DF1 — Full Duplex Communication… -

Page 74

3-14 Configuring the Terminal Node Specifies the node number (0 — 254 decimal) for DF1 network communications. For point-to-point communications with an SLC, PLC, MicroLogix or a 1761-NET DNI module, the default node number of 64 is used. When you press F4, the numeric entry scratchpad opens. Enter a node number and press the Enter ↵… -

Page 75

Configuring the Terminal 3-15 EtherNet/IP Communications The EtherNet/IP screen lets you display or modify some of the EtherNet/IP communication settings for an Ethernet PanelView terminal. Additional parameters (Gateway Address, DNS Server and Domain Name, and Timeout values) are set in the Communications Setup dialog of the PanelBuilder32 software and downloaded with the application. -

Page 76

3-16 Configuring the Terminal IP Address A unique address identifying the PanelView node on the EtherNet/IP network. The IP address is formatted as four sets of decimal numbers with periods between them (10.0.0.1). The range of values for the first set of decimal numbers is 1 — 255, unless all fields are set to 0.0.0.0. -

Page 77

Configuring the Terminal 3-17 Configuring Presets Select Preset Operations from the Configuration Mode menu to set the values of control objects after a reset or power cycle. You can set presets to: • values provided by the PanelView application or •… -

Page 78: Viewing Terminal Information

3-18 Configuring the Terminal Viewing Terminal Select Terminal Info from the Configuration Mode menu to display information about your terminal. This information may be needed Information when calling for technical support. TERMINAL INFO Boot: ############ Firmware: ############ Hardware: ####################################### Filename: ############ Fontfile: ############…

-

Page 79: Adjusting Screen Parameters

Configuring the Terminal 3-19 Adjusting Screen Select Screen Setup from the Configuration Mode menu to adjust settings of the terminal display. Changes take effect immediately. Parameters PanelView 300 Micro Screen Setup The PanelView 300 Micro backlight is always on and intensity is not adjustable.

-

Page 80

3-20 Configuring the Terminal PanelView 300 Screen Setup SCREEN SETUP SCREEN SAVER F1 Contrast F1 Mode F2 Mode Normal F2 Timeout 10 min. F3 Reset Video F7 MORE F8 EXIT F7 MORE F8 EXIT Certain settings may make viewing the screen IMPORTANT difficult. -

Page 81

Configuring the Terminal 3-21 PanelView 550 Screen Setup SCREEN SETUP Backlight Contrast Video Mode Reverse Backlight Timeout 10 min. EXIT Reset Video Certain settings may make viewing the screen IMPORTANT difficult. Do not exit this screen until viewing adjustments are acceptable. Backlight Turns the backlight On, Off or to Timed mode. -

Page 82

3-22 Configuring the Terminal PanelView 600/900/1000 Color — Screen Setup SCREEN SETUP SCREEN SETUP Normal Screen SCREEN SAVER Saver Intensity Contrast Timed Reset Video Timeout Reset 10 min. SCREEN SAVER Video Timeout Intensity Intensity 10 min. EXIT EXIT color palette adjusts with contrast PV600 color touch-screen only PV600/900/1000 color… -

Page 83

Configuring the Terminal 3-23 PanelView 900 Monochrome — Screen Setup SCREEN SETUP SCREEN SAVER SCREEN CONDITIONER Mode Normal Intensity Mode Timed Disabled Video Mode Timeout Hour Minute Normal 10 min. ## : Intensity Reset Video EXIT Certain settings may make viewing the screen IMPORTANT difficult. -

Page 84

3-24 Configuring the Terminal Screen Conditioner Mode Enables or disables the screen conditioner. This parameter sets a daily schedule for conditioning the display of a PV900 monochrome terminal to prevent image burn-in. The conditioning process takes approximately 30 minutes and will not start until the terminal is inactive and in screen saver mode. -

Page 85

Configuring the Terminal 3-25 PanelView 1000 Grayscale -Screen Setup SCREEN SETUP Screen Video Saver Mode Reset Normal Video SCREEN SAVER Timeout Intensity 10 min. EXIT Certain settings may make viewing the screen IMPORTANT difficult. Do not exit this screen until viewing adjustments are acceptable. -

Page 86

3-26 Configuring the Terminal PanelView 1400 Color Setup SCREEN SETUP SCREEN DEGAUSS Normal SAVER Intensity Auto Mode Enabled Timeout Hour Minute Reset 5 min. Touch Screen only Video Intensity Manual ALIGN EXIT Degauss TOUCH GRID Certain settings may make viewing the screen IMPORTANT difficult. -

Page 87

Configuring the Terminal 3-27 Normal Intensity Adjusts the intensity of the display with each key press: 25, 50, 75, 100. The new setting takes effect immediately. Reset Video Resets the display to normal video (default settings). On keypad terminals, the reset video [F15] key is also active on the Configuration Mode menu. -

Page 88: Setting The Time And Date

MMM/DD/YYYY Setting the Time Use screen buttons (touch screens) or function keys to set the time. On PV300, On PV550/PV600 On PV900/1000/1400 PV300 Micro: Press: Press: Use the left and right Hours button [F6] Hour button [F9] key Set current hour…

-

Page 89: Setting Up The Printer

Configuring the Terminal 3-29 Setting up the Printer Select Printer Setup from the Configuration Mode menu to set parameters for those terminals equipped with an RS-232 printer port. Any printer that supports the IBM enhanced character set can be connected to the RS-232 printer port. PRINTER SETUP Handshaking Communication Parameters…

-

Page 90

3-30 Configuring the Terminal Top of Form Notifies the PanelView terminal the printer is at the top of a page. Manually adjust the printer to the top of the page before pressing the Top of Form button. The printer also uses the Perforation Skip Value (if defined in the Printer Setup of the PanelBuilder32 software) when the Top of Form button is pressed. -

Page 91: Using A Memory Card

Chapter Using a Memory Card Chapter Objectives This chapter describes: • supported memory cards • using the memory card retainer • loading application from a memory card • loading application on a memory card • storing font files on a memory card •…

-

Page 92: Using The Memory Card Retainer

Using a Memory Card Using the Memory Card A Memory Card Retainer (Catalog No. 2711-NMCC, -NMCD, -NMCE) is shipped with all PanelView terminals, except the PV300 Retainer Micro and the PV1400. It is required for: • UL508 installations • vibration/mechanical shock environments •…

-

Page 93

Using a Memory Card The Memory Card Retainer protects against: • electrical shock from loose high voltage wires in an electrical enclosure per UL508 When permanently installing a memory card in ATTENTION an electrical enclosure, the memory card retainer must be used to avoid accidental contact of high voltage leads to metal surfaces on the card. -

Page 94: Loading Application From A Memory Card

Using a Memory Card Loading Application The procedure below shows how to load an application on a memory card into the PanelView terminal. from a Memory Card Explosion Hazard — Do not install or remove memory ATTENTION card unless power has been switched off or the area is known to be non-hazardous.

-

Page 95

Using a Memory Card 5. Press Restore From Card, [F2] on keypad terminals, to begin the transfer. Because this operation overwrites the current application in the terminal, you are prompted to abort or continue. Proceed with download? F1 — Abort F2 — Continue The terminal displays the status of the transfer. -

Page 96: Loading Application On A Memory Card

Using a Memory Card Loading Application The steps below show how to load an application in the terminal onto a memory card. on a Memory Card Explosion Hazard — Do not install or remove memory ATTENTION card unless power has been switched off or the area is known to be non-hazardous.

-

Page 97

Using a Memory Card 4. If necessary, press Erase/Format Card, [F4] key on keypad terminals, to format or erase a 2711-NM11, -12, -13, -14, -15 memory card. Do not perform this operation on a IMPORTANT 2711-NM2xx ATA card (where xx is size in megabytes). -

Page 98: Storing Font Files On A Memory Card

Using a Memory Card Storing Font Files Memory cards also store font files for languages used by PanelView applications. The font file contains the character set for the language. on a Memory Card The memory card containing the font file must be inserted in the PanelView terminal while the application is running.

-

Page 99: Chapter 5 Chapter Objectives

Chapter Running Applications Chapter Objectives This chapter describes operating procedures common to most applications: screen security alarms push button operation printing control lists time or date numeric entry controls message displays ASCII entry controls numeric data displays screen selectors bar graphs list indicators analog gauges multistate indicators…

-

Page 100: Screen Security

Running Applications Screen Security Access to some application screens (including the terminal configuration screens) may be restricted. Secured screens require you to enter a password before the screen is displayed. It is the responsibility of the application designer to provide operators with required passwords.

-

Page 101: Control Lists

Running Applications Control Lists Control lists perform functions similar to push buttons. They can modify either individual bits or values at a controller address. Cursor indicates selected item Active selection is highlighted Vertical bar indicates active control list Active List Item Active item is highlighted.

-

Page 102

Running Applications Cursor Indicates the selected item. Move the cursor up or down the control list using the Up and Down arrow keys. Cursor operation is configured by the application designer. If the cursor is at the first or last item in a control list pressing the Up arrow (when at the top) or the Down arrow (when at the bottom) will either: •… -

Page 103

Running Applications Cursor — Piloted Control Lists On a piloted control list, some items are under controller operation only. In addition, some items may be designated as inactive. You cannot select controller items or inactive items. In both cases, the cursor is hollow when you select the item. -

Page 104

Running Applications Two types of controls allow a numeric value at a controller address: Cursor Point and Keypad Enable button. Press F1 to Enter New Speed Current Speed = 100 RPM Cursor Point Motor 1 Active Motor 2 Cursor Point Numeric Entry Cursor Point Cursor points appear as a box. -

Page 105

Running Applications To enter a cursor point: 1. Select the cursor point by: • touching the object (touch screen terminal only) • pressing the associated function key • press the Left or Right arrows until the cursor point shows a vertical bar 2. -

Page 106

Running Applications PanelView 300, 300 Micro Thumbwheel Scratchpad The thumbwheel scratch pad allows an operator to enter values on terminals without a numeric keypad or touch screen by cycling through the available characters one position at a time. Use the Up and Down cursors to cycle through the available characters. -

Page 107: Ascii Entry Controls

Running Applications ASCII Entry Controls ASCII entry controls allow you to send an alphanumeric string (up to 128 characters) to a controller. Like numeric entry controls, the ASCII entry control can appear on a screen as a keypad enable button or a cursor point.

-

Page 108

5-10 Running Applications ASCII Scratchpad — 300 Micro/300 Terminals The thumbwheel scratch pad allows an operator to enter values on terminals without a numeric keypad or touch screen by cycling through the available characters one position at a time. This is the character sequence: <space>… -

Page 109

Running Applications 5-11 ASCII Scratchpad — 550/600 Touch Screen Terminals Cursor Character Keyboard Display Area Cursor Control Keys Controls To select characters from the Character Keyboard, press the cursor control keys to move the cursor over a character and then press the SEL key. -

Page 110

5-12 Running Applications ASCII Scratchpad — 900/1000/1400 Touch Screen Terminals Display Area Character Keyboard Controls Select characters by touching the Character Keyboard on the screen. The character is entered in the Display Area. This area scrolls so you can enter a string that is longer than the Display Area. All characters are sent to the controller even if not visible. -

Page 111

Running Applications 5-13 ASCII Scratchpads in Other Languages The ASCII Scratchpad is available with character keyboards in: • French • German • Italian • Spanish If the PanelView terminal is configured for operation in one these languages, the ASCII scratchpad will display the appropriate Character Keyboard. -

Page 112: Screen Selectors

5-14 Running Applications Screen Selectors The 2 types of screen selector controls are Screen List Selectors and Screen buttons. Screen List Selector Screen Controls Tank Monitor Screen Goto Screen Button Pump Status Valve Status Previous Screen Tank Control Vertical Bar Return Screen Button indicates active list Goto and Return screen buttons can have a variety of appearances…

-

Page 113

Running Applications 5-15 Cursor Operation Cursor operation is configured by the application designer. If the cursor is at the first or last item in a screen list, pressing the Up arrow (when at top) or Down arrow (when at bottom) will either: •… -

Page 114: List Indicators

5-16 Running Applications List Indicators List indicators highlight an item from a list depending upon the status of either a bit or value at a controller address. List Indicator Mixer Speed Mixer Medium Current status Mixer High is highlighted An indicator list may have a maximum of 255 entries. The list automatically scrolls to display the status of an item.

-

Page 115: Numeric Data Displays

Running Applications 5-17 Numeric Data Displays Numeric Data Displays may appear with or without supporting text. Flow= 37 Gallons 0 0 0 2 3 9 . 4 5 Depending on the application design, displayed data may have these properties: • zero fill •…

-

Page 116: Printing

5-18 Running Applications Printing Terminals equipped with an RS-232 printer port can print: • triggered messages in a message display • triggered states of a multistate indicator • alarm messages • alarm list Text is printed without formatting options. Print attributes for objects and alarms are defined in the application.

-

Page 117: Chapter 6 Chapter Objectives

• mounting dimensions • clearances • cutout dimensions • installing the PV300 micro terminal in a panel Hazardous Locations This equipment is suitable for use in Class 1, Division 2, Groups A, B, C, D or non-hazardous locations only. The following DANGER statement applies to use in hazardous locations.

-

Page 118: Enclosures

Installing the PV300 Micro Terminal Enclosures Mount the PanelView 300 Micro terminal in a panel or enclosure to protect the internal circuitry. The terminal meets NEMA 12/13, 4X (indoor use), IP54 or IP65 ratings only when properly mounted in a panel or enclosure with the equivalent rating.

-

Page 119: Cutout Dimensions

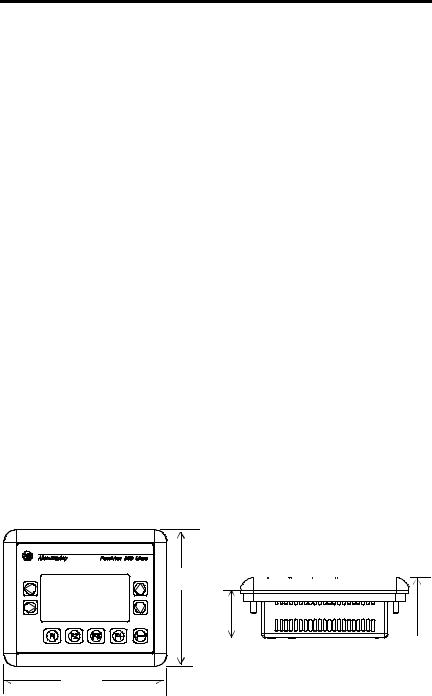

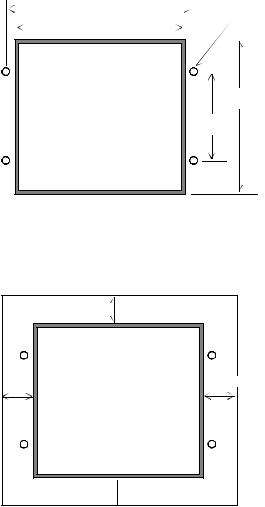

Installing the PV300 Micro Terminal Cutout Dimensions Use the full size template shipped with the PV300 Micro to mark the cutout dimensions. The figure below shows a reduced scale cutout. A full scale template is also available inside the back cover of this document.

-

Page 120: Installing Terminal In Panel

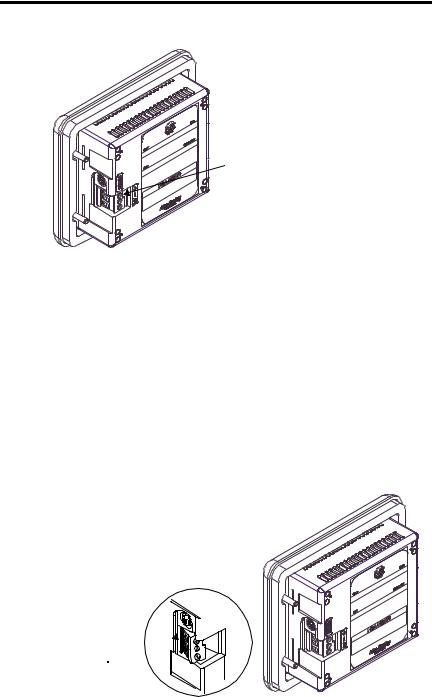

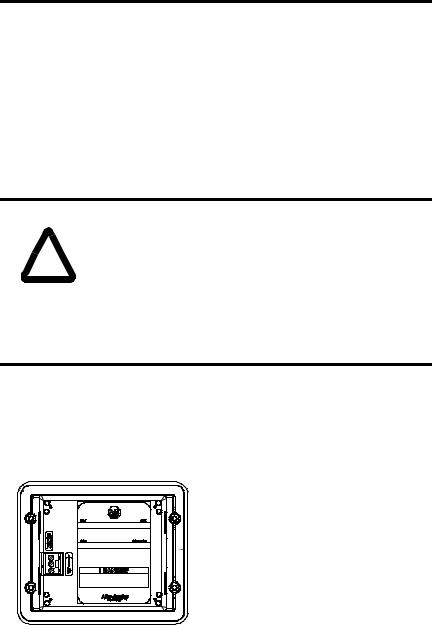

Installing the PV300 Micro Terminal Installing Terminal in Panel To install the PV300 Micro in a panel: • Disconnect all electrical power from the panel ATTENTION before making cutout. • Make sure area around the panel cutout is clear. • Take precautions so that metal cuttings do not enter any components already installed in panel.

-

Page 121

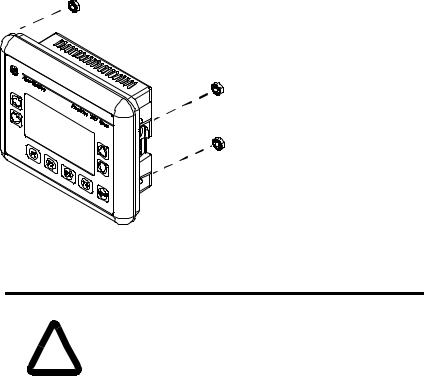

Installing the PV300 Micro Terminal Self-Locking Nuts (4 used, 6 provided) 7. Alternately tighten the self-locking nuts until the terminal is held firmly against the panel. Tighten the nuts to a torque of 10 inch-pounds. Do not overtighten. Mounting nuts must be tightened to a torque of 10… -

Page 122

Installing the PV300 Micro Terminal Publication 2711-UM014B-EN-P… -

Page 123: Chapter 7 Chapter Objectives

Chapter Installing the PV300 Terminal Chapter Objectives This chapter shows how to install the PanelView 300 terminal and covers: • hazardous locations • enclosures • required tools • mounting dimensions • clearances • cutout dimensions • installing the PV300 terminal in a panel Hazardous Locations See the nameplate label on terminal for hazardous location certifications.

-

Page 124: Enclosures

Installing the PV300 Terminal Enclosures Mount the PV300 terminal in a panel or enclosure to protect the internal circuitry. The terminal meets NEMA Type 12/13 and 4X (indoor use) ratings only when mounted in a panel or enclosure with the equivalent rating. Allow enough space within the enclosure for adequate ventilation.

-

Page 125: Mounting Dimensions

Installing the PV300 Terminal Mounting Dimensions The illustration below shows mounting dimensions for the PV300 keypad terminals. Top View 69mm 82 mm 197 mm (2.73 in) (3.21 in) (7.76 in) 140 mm (5.53 in) Cutout Dimensions Use the full size template shipped with the PV300 terminal to mark the cutout dimensions.

-

Page 126: Clearances

Installing the PV300 Terminal Clearances When installing the PV300 terminal, allow space for mounting, air flow, maintenance, memory card and legend strip installation. Side, Top and Bottom Clearances Leave 64 mm (2.5 in) for Mounting and Air Flow Terminal Cutout Recommended Panel Use full size template Cutout Dimensions…

-

Page 127: Installing The Pv300 In A Panel

Installing the PV300 Terminal Installing the PV300 in a To install the PV300 terminal in a panel: Panel • Disconnect all electrical power from the panel ATTENTION before making the cutout. • Make sure the area around the panel cutout is clear.

-

Page 128

Mounting nuts must be tightened to a torque of ATTENTION 10 inch-pounds to provide a proper seal and to prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 129: Chapter 8 Chapter Objectives

Chapter Installing the PV550 Terminal Chapter Objectives This chapter describes how to mount the PV550 terminal in a panel or enclosure including: • hazardous locations • enclosures • required tools • mounting dimensions • clearances • cutout dimensions • installing the PV550 terminal in a panel Hazardous Locations See the nameplate label on terminal for hazardous locations certifications.

-

Page 130: Enclosures

Installing the PV550 Terminal Enclosures Mount the PV550 terminal in a panel or enclosure to protect the internal circuitry. The terminal meets NEMA Type 12/13 and 4X (indoor use) ratings only when mounted in a panel or enclosure with the equivalent rating. Allow enough space within the enclosure for adequate ventilation.

-

Page 131: Clearances

Installing the PV550 Terminal Clearances When installing the PV550 terminal, allow space for mounting, air flow, maintenance, memory card and legend strip installation. PV550 Keypad, Keypad & Touch Screen Terminals PV550 Touch Screen Terminals Leave 25 mm (1.0 in) for Mounting and Air Flow Terminal Cutout Terminal Cutout Use full size template…

-

Page 132: Cutout Dimensions

Installing the PV550 Terminal Cutout Dimensions Use the full size template shipped with the PV550 terminal to mark the cutout dimensions. Below is a reduce size cutout. PV550 Keypad, Keypad & Touch Screen Terminals 243 mm (9.55 in) 191 mm (7.51 in) 25.9 mm 106 mm…

-

Page 133: Installing The Pv550 In A Panel

Installing the PV550 Terminal Installing the PV550 in a To install the PV550 terminal in a panel: Panel • Disconnect all electrical power from the panel ATTENTION before making the cutout. • Make sure the area around the panel cutout is clear.

-

Page 134

Mounting nuts must be tightened to a torque of ATTENTION 10 inch-pounds to provide a proper seal and to prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 135: Chapter 9 Chapter Objectives

Chapter Installing the PV600 Terminal Chapter Objectives This chapter describes how to mount the PV600 terminal in a panel or enclosure including: • hazardous locations • enclosures • required tools • mounting dimensions • cutout dimensions • clearances • installing the PV600 terminal in a panel Hazardous Locations See the nameplate label on terminal for certifications on hazardous locations.

-

Page 136: Required Tools

Installing the PV600 Terminal Required Tools Other than the tools required to make the PV600 panel cutout, the tools required for installation are: • small slotted screwdriver • torque wrench (in. / lbs) • #2 phillips screwdriver • #2 phillips bit for torque wrench Mounting Dimensions The illustration below shows mounting dimensions for the PV600 terminals.

-

Page 137: Cutout Dimensions

Installing the PV600 Terminal Cutout Dimensions Use the full size template shipped with the PV600 terminal to mark the cutout dimensions. Below is a reduce size cutout. PV600 Keypad, Keypad & Touch Screen Terminals 167 mm Recommended Panel Cut-out Dimensions (6.57 in) 264 mm (10.39 in)

-

Page 138: Clearances

Installing the PV600 Terminal Clearances When installing the PV600 terminal, allow adequate space for mounting, air flow, maintenance, memory card and legend strip installation. PV600 Keypad and Keypad & Touch Screen Terminals Side, Top and Bottom Clearances 6.9 mm 51 mm (2.0 in) (0.27 in) Back Clearance for Mounting…

-

Page 139: Installing The Pv600 In A Panel

Installing the PV600 Terminal Installing the PV600 in a To install the PV600 terminal in a panel: Panel • Disconnect all electrical power from the panel ATTENTION before making the cutout. • Make sure the area around the panel cutout is clear.

-

Page 140

Mounting nuts must be tightened to a torque of ATTENTION 10 inch-pounds to provide a proper seal and to prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 141: Chapter 10 Chapter Objectives

Chapter Installing the PV900/1000 Terminals Chapter Objectives This chapter describes how to mount the PV900 and PV1000 terminals in a panel or enclosure including: • hazardous locations and enclosures • required tools • mounting dimensions • clearances • cutout dimensions •…

-

Page 142: Required Tools

10-2 Installing the PV900/1000 Terminals Required Tools Other than the tools required to make the panel cutout, the tools required for installation are: • small slotted screwdriver • torque wrench (in. / lbs) with slotted or phillips head driver Mounting Dimensions PV900 Terminals The illustrations below show mounting dimensions for the PV900 monochrome and color terminals.

-

Page 143

Installing the PV900/1000 Terminals 10-3 PV1000 Terminals The illustrations below show the mounting dimensions for the PV1000 grayscale and color terminals. PV1000 Touch Terminal Mounting Dimensions 6.9 mm Top View (0.27 in) 282 mm (11.11 in) 112 mm 90 mm (4.40 in) (3.54 in) 370 mm… -

Page 144: Clearances

10-4 Installing the PV900/1000 Terminals Clearances Allow adequate space for mounting, air flow, maintenance, memory card and legend strip installation. If using a memory card and/or memory card retainer, IMPORTANT allow a back clearance to load the card. Side, Top and Bottom Clearances Leave 51 mm (2.0 in) for Mounting and Air Flow Terminal Cutout — Front View…

-

Page 145: Cutout Dimensions

Installing the PV900/1000 Terminals 10-5 Cutout Dimensions Use the full size template shipped with the PV900 and PV1000 terminals to mark the cutout dimensions. The following illustrations show reduced cutouts for these terminals with dimensions. PV900 Panel Cutout Dimensions PV900 Keypad Terminals PV900 Touch Screen Terminals 224 mm Recommended Panel Cut-out Dimensions…

-

Page 146: Installing The Pv900/Pv1000 In A Panel

10-6 Installing the PV900/1000 Terminals Installing the To install the PV900/PV1000 terminal in a panel: PV900/PV1000 in a Panel • Disconnect all electrical power from the panel ATTENTION before making the cutout. • Make sure the area around the panel cutout is clear.

-

Page 147

Mounting nuts must be tightened to a torque of ATTENTION 10 inch-pounds to provide a proper seal and to prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 148

10-8 Installing the PV900/1000 Terminals Publication 2711-UM014B-EN-P… -

Page 149: Chapter 11 Chapter Objectives

Chapter Installing the PV1400 Terminal Chapter Objectives This chapter describes how to mount the PV1400 terminal in a panel or enclosure including: • enclosures • recommended tools • mounting dimensions • clearances • cutout dimensions • installing the PV1400 terminal in a panel Enclosures The PV1400 terminal must be mounted in an environment that provides IEC-1131-2 Pollution degree 2 protection.

-

Page 150: Mounting Dimensions

11-2 Installing the PV1400 Terminal Mounting Dimensions The illustrations below show mounting dimensions for the PV1400 terminals. PV1400 Touch Terminal Mounting Dimensions 3.3 mm Top View (0.13 in) 355 mm 394 mm 370 mm (13.97 in) (15.53 in) (14.58 in) 441 mm (17.37 in) PV1400 Keypad Terminal Mounting Dimensions…

-

Page 151: Clearances

Installing the PV1400 Terminal 11-3 Clearances Allow adequate space for mounting, air flow, maintenance, adjusting brightness/contrast, memory card and legend strip installation. If using a memory card, allow a back clearance to IMPORTANT load the card. Side, Top and Bottom Clearances Leave 51 mm (2.0 in) for Mounting and Air Flow Terminal Cutout — Front View…

-

Page 152: Cutout Dimensions

11-4 Installing the PV1400 Terminal Cutout Dimensions Use the full size template provided with the terminal to mark cutout dimensions. The illustration below shows reduced size cutouts with dimensions. PV1400 Keypad Terminals 419 mm (16.50 in) 221 mm 7/32 in (5.56 mm) Typical (8.70 in) 110 mm 18 Holes…

-

Page 153: Installing The Pv1400 In A Panel

Installing the PV1400 Terminal 11-5 Installing the PV1400 in a This section gives procedures for mounting a PV1400 using: • mounting clips (10 shipped with terminal, 10 required) Panel • mounting studs (ordered separately, Catalog No. 2711-NP3) • Disconnect all electrical power from the panel ATTENTION before making the cutout.

-

Page 154

Mounting nuts must be tightened to a torque of ATTENTION 10 inch-pounds to provide a proper seal and to prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 155

Tighten mounting nuts to a torque of 10 ATTENTION inch-pounds (1.1 N•m) to provide a proper seal and prevent potential damage to the terminal. Allen-Bradley assumes no responsibility for water or chemical damage to the terminal or other equipment within the enclosure because of improper installation. -

Page 156

11-8 Installing the PV1400 Terminal 6. Alternately tighten the self-locking nuts (use 3/8 inch socket) until the PV1400 is held firmly against the panel. (The recommended tightening sequence is shown below). The studs have an integral spacer that prevents the gasket from being over-compressed. -

Page 157: Chapter 12 Chapter Objectives

Chapter Terminal Connections Chapter Objectives This chapter describes network and device connections for PanelView terminals. • wiring and safety guidelines • Cable charts • Remote I/O connections • DH+ connections • DH-485 connections • RS-232 (DH-485) connections • RS-232 (DF1) connections •…

-

Page 158: Cable Charts

12-2 Terminal Connections Cable Charts Refer to the following charts for a summary of PanelView terminal connections to controllers and network interface modules. Runtime Communication Cables — To Processors Cables: PanelView to Processor SLC-500, 5/01, 5/02 SLC-5/03, 5/04, 5/05 SLC 5/03 SLC 5/04 SLC 5/05 Protocol…

-

Page 159

Terminal Connections 12-3 Cables: PanelView to Processor MicroLogix 1000, 1200, PLC-5, PLC-5C, PLC-5E ControlLogix 1500LSP Protocol PanelView Standard Comm Port CH0 (25-pin RS-232) CH0 (9-pin RS-232) CH0 (8-pin Mini DIN) (DF1) (DF1) (DF1 or DH-485) RS-232 (DF1) Comm Port (8-pin Mini Din) 1761-CBL-AP00 (1.5ft/0.5m) 1761-CBL-AP00 (1.5ft/0.5m) 1761-CBL-AM00 (1.5ft/0.5m) -

Page 160

12-4 Terminal Connections Cables: PanelView to Processor MicroLogix 1500LRP CompactLogix FlexLogix Protocol PanelView Standard Comm Port CH1 (9-pin RS-232) CH0 (9-pin RS-232) CH0 (9-pin RS-232) (DF1 or DH-485) (DF1 or DH-485) (DF1) RS-232 (DF1) Comm Port (8-pin Mini Din) 1761-CBL-AP00 (1.5ft/0.5m) 1761-CBL-AP00 (1.5ft/0.5m) 1761-CBL-AP00 (1.5ft/0.5m) xxx16… -

Page 161

Terminal Connections 12-5 Application File Upload/Download (Direct) Cables PanelView Standard Type Cable to Personal Computer PanelView 300 Micro 1761-CBL-PM02 (6.5 ft/2 m) 2711-M3A18L1, -M3A19L1 2711-CBL-PM05 (16 ft/5 m) 2711-CBL-PM10 (32 ft/10 m) DH-485 Comm Port only or DH-485 Comm Port & RS-232 Printer Port PanelView 300, 550/550T, 600/600T 1747-PIC 2711-KxA2, -KxC2, -BxA2, -BxA3, -TxA2, -TxC2, 2711-KxA3, -KxC3, -KxG3, -BxA3, -BxC3, -TxA3, -TxC3, -TxG3… -

Page 162: Remote I/O Terminal Connections

12-6 Terminal Connections Remote I/O Terminal This section describes connections for the Remote I/O PanelView terminals including: Connections • Remote I/O port • supported controllers • making Remote I/O connections • Remote I/O Pass-Through Remote I/O Terminal Ports The Remote I/O versions of the PanelView terminal (catalog numbers ending in 1) have a Remote I/O port and an RS-232 port.

-

Page 163

Terminal Connections 12-7 Supported Controllers The Remote I/O terminal connects to any Allen-Bradley 1771 Remote I/O link. Applicable host controllers include almost all Allen-Bradley PLCs, computers, VME controllers, and DEC Q-Bus controllers with a Remote I/O scanner module. New PLC product releases that support 1771 Remote I/O will also work with PanelView. -

Page 164

12-8 Terminal Connections Making Remote I/O Connections To connect a PanelView terminal to a Remote I/O scanner, use cable Catalog No. 1770-CD (equivalent to Belden 9463). The maximum cable length (link distance) is determined by the baud rate. • 2,800 meters (10,000 feet) for 57.6K baud •… -

Page 165

Remote I/O Pass-Through using DH+ Remote I/O terminals allow the transfer of applications from a computer on the Allen-Bradley DH+ link to a PLC-5 or SLC-5/04 controller. The controller passes data to the PanelView terminal over the Remote I/O network. -

Page 166: Dh+ Terminal Connections

have a DH+ port and an RS-232 port. Use the DH+ port to: • communicate with a PLC-5 controller on the Allen-Bradley DH+ link via the processor’s DH+ port. • communicate with an SLC 5/04 controller (Channel 1 port) on the Allen-Bradley DH+ link via the processor’s DH+ port.

-

Page 167

Terminal Connections 12-11 Typical DH+ System Configuration For more information on the Allen-Bradley DH+ link, refer to: • 1785-5.7 Enhanced PLC-5 Programmable Controllers Installation Instructions • 1770-6.2.2 Data Highway/Data Highway Plus/Data Highway II/ Data Highway 485 Cable Installation Manual. PLC-5… -

Page 168

12-12 Terminal Connections Making DH+ Connections Use the Belden 9463 twin axial cable (1770-CD) to connect a DH+ PanelView terminal to the DH+ link. You can connect a DH+ link in 2 ways: • trunk line/drop line — from the drop line to the connector screw terminals on the DH+ connectors of the processor •… -

Page 169: Terminal Connections

Terminal Connections 12-13 DH-485 Terminal This section describes connections for the DH-485 PanelView terminals. Connections • DH-485 terminal ports • Connecting to a single SLC controller (Point-to-Point) • Connecting to a DH-485 network • Connecting a computer • Connecting a Hand-held terminal Note: For PanelView 300 Micro terminals, refer to page 12-39.

-

Page 170

12-14 Terminal Connections Connecting to a Single SLC Controller (Point-to-Point) To connect a DH-485 terminal to a single SLC controller use one of these cables: • 0.3 meter (1 foot) Catalog No. 1747-C11 • 1.83 meter (6 foot) Catalog No. 1747-C10 •… -

Page 171

Terminal Connections 12-15 Connecting to a DH-485 Network This section shows how to connect a DH-485 terminal to multiple SLC controllers on a DH-485 network through the AIC Link Coupler. Note: For PanelView 300 Micro terminals, refer to page 12-39. Link Coupler Catalog No. -

Page 172

12-16 Terminal Connections The illustration below shows how to connect a DH-485 terminal to a MicroLogix or SLC controller using the AIC+ Link Coupler (Catalog No. 1761-NET-AIC). AIC+ PanelView 1000 1761-NET-AIC MicroLogix 1000, 1200, 1500LSP Cable Cat. No. 1761-CBL-AS03 Cat. No. 1761-CBL-AS09 Cat. -

Page 173

Terminal Connections 12-17 Connecting a Computer On DH-485 terminals, PanelView applications are transferred: • through the DH-485 programming connector to the terminal. • through any node on a DH-485 network. To connect a computer to the PanelView terminal, you need: •… -

Page 174

12-18 Terminal Connections Connecting a Computer to DH-485 Connector Using a Power Supply PanelBuilder32 PanelView 1000 Wallmount Power Supply Cat. No. 1747-NP1 To DH-485 To DH-485 Programming Connector Communications Port 25-pin to 9-pin Personal Computer Cable Adapter Interface Converter Cat. No. 1747-C10 (if required) (Cat. -

Page 175

Terminal Connections 12-19 Connecting a Hand-Held Terminal To connect a Hand-Held Terminal (HHT) to the PanelView terminal, use cable Catalog No. 1747-C10. One end of the cable connects to the HHT connector and the other end connects to the DH-485 programming connector on the terminal. -

Page 176: Dh-485) Terminal Connections

12-20 Terminal Connections RS-232 (DH-485) Terminal This section describes connections for the RS-232 (DH-485) PanelView terminals including: Connections • RS-232 ports • connecting to a SLC, CompactLogix, or MicroLogix Controller (point-to-point) • connecting to a MicroLogix Controller through the AIC+ module •…

-

Page 177

Terminal Connections 12-21 Connecting to an SLC, CompactLogix, MicroLogix (Point-to-Point) This section shows how to connect a CompactLogix, MicroLogix 1500LRP, or SLC controller (SLC-5/03, 5/04, or 5/05) to the RS-232 PanelView terminal for point-to-point (DH-485) communications. On terminals with two ports, use the RS-232 Communications Port. For the SLC, CompactLogix or MicroLogix 1500LRP controller, use one of these cables: •… -

Page 178

12-22 Terminal Connections Connecting to a MicroLogix Controller through an AIC+ This section shows how to connect the RS-232 (DH-485) version of the PanelView terminal to a MicroLogix controller through an AIC+ Link Coupler. AIC+ MicroLogix 1000, 1200, 1500LSP Cat. No. 1761-NET-AIC Belden Cable 9842 Catalog No. -

Page 179

Connecting a DH+ to DH-485 Pass-Through Link This section shows connections for transferring applications between a computer on the Allen-Bradley DH+ link and an RS-232 (DH-485) PanelView terminal, through an SLC 5/04 controller. The RS-232 (DH-485) Communications port on the terminal connects to the CH0 port of the controller using one of the cables listed below. -

Page 180: Df1) Terminal Connections

12-24 Terminal Connections RS-232 (DF1) Terminal This section describes connections for the RS-232 (DF1) versions of the PanelView terminal including: Connections • compatible controllers • RS-232 terminal ports • connecting to a controller (point-to-point) • using a modem • connecting to a DeviceNet or EtherNet/IP network Note: For PanelView 300 Micro terminals, refer to page 12-39.

-

Page 181

Terminal Connections 12-25 RS-232/DF1 Port Connector The DF1 port on the PanelView terminal is a 9-pin, male, RS-232 connector. The table below shows the pinout descriptions for this port and how these pins map to the DF1 ports on the controllers. DF1 Port MicroLogix/ DNI 9-pin DCE… -

Page 182

12-26 Terminal Connections Connecting to an SLC, PLC or MicroLogix 1500LRP The following shows a point-to-point connection between the DF1 port of the PanelView and an SLC or PLC controller. PanelView MicroLogix 1500LRP SLC 5/03, 5/04, 5/05 DF1 Port 2711-NC13, -NC14 Cable DF1 Port PLC 5 9 to 25-Pin… -

Page 183

Terminal Connections 12-27 Connecting to a DeviceNet or EtherNet/IP Network The following illustration shows a DF1 PanelView terminal connected to a single controller (MicroLogix, SLC or PLC) on: • a DeviceNet network via 1761-NET-DNI modules or • an EtherNet/IP network via 1761-NET-ENI modules MicroLogix 1000 1761-NET-DNI Module for DeviceNet DF1 PanelView… -

Page 184: Controlnet Connections

• ControlNet System Overview (Publication 1786-2.9) • ControlNet System Planning and Installation Manual (1786-6.2.1) • ControlNet Cable System Component List (AG-2.2) The Allen-Bradley website (www.ab.com) provides information and product descriptions of ControlNet products. Under the Products and Services heading, select Communications.

-

Page 185

Terminal Connections 12-29 Compatible ControlNet Controllers The ControlNet PanelView terminal communicates with a PLC-5C (using PCCC commands) or a ControlLogix processor (using CIP protocol) using unscheduled and scheduled messaging. The following controllers are supported: • ControlLogix using 1756-CNB module • PLC-5/20C, -5/40C, -5/60C, -5/80C ControlNet Terminal Ports ControlNet versions of the PanelView terminal (catalog numbers ending in 15) have a ControlNet communication port and an RS-232… -

Page 186

12-30 Terminal Connections Typical ControlNet Network Below is a typical ControlNet network with a PanelView terminal installed on a network drop. PanelView 1000 RS-232 Port ControlNet Port BNC Coaxial Cable Printer Computer for developing PanelView applications 1784-KTC(X) Card to Serial Link ControlNet (RSLinx) &… -

Page 187

Terminal Connections 12-31 Making ControlNet Connections Use the pinout information below to connect the PanelView to a ControlNet network. Follow the ControlNet network layout and design as IMPORTANT specified in the ControlNet Cable System Planning and Installation Manual (Publication 1786-6.2). Redundant BNC Cable Connectors NAP Connector Channel B… -

Page 188

ControlNet cables, taps, connectors. Refer to the ControlNet Cable System Planning and Installation manual (Publication 1786-6.2.1) for descriptions of these components. For information on purchasing these items, refer to the Allen-Bradley ControlNet Cable System Component List (Publication AG-2.2). Item Catalog Number… -

Page 189: Devicenet Terminal Connections

Terminal Connections 12-33 DeviceNet Terminal This section describes connections for the DeviceNet PanelView terminals including: Connections • DeviceNet connectors • connections • typical DeviceNet network DeviceNet Terminal Ports The DeviceNet versions of the PanelView terminals (catalog numbers ending in 10) have a DeviceNet port and an RS-232 serial port. •…

-

Page 190

12-34 Terminal Connections Making DeviceNet Connections Use one of the cables below to connect the DeviceNet version of the PanelView terminal to a DeviceNet network. Cable Publication No. DeviceNet Cable, 50 meters (164 feet) 1485C-P1A50 DeviceNet Cable, 100 meters (328 feet) 1485C-P1A150 DeviceNet Cable, 150 meters (492 feet) 1485C-P1A300… -

Page 191

Terminal Connections 12-35 Typical DeviceNet Network Below is a typical DeviceNet network with PanelView terminals installed on 2 of the network drops. A DeviceNet network requires a 24V dc power supply. DeviceNet power consumption is 24mA — 90mA @24V dc. The PanelView terminal does not receive its power from the network. -

Page 192: Ethernet/Ip Connections

12-36 Terminal Connections EtherNet/IP Connections The EtherNet/IP PanelView terminal can communicate on an EtherNet TCP/IP network with the following devices: • PLC-5E or PLC-5 with 1761-NET-ENI or 1785-ENET module • SLC-5/05 or SLC with 1761-NET-ENI module • ControlLogix controller with 1756-ENET/B or 1761-NET-ENI module •…

-

Page 193

Terminal Connections 12-37 Ethernet Connector The Ethernet connector is an RJ45, 10/100Base-T connector. The pinout for the connector is shown below: Pin Name RJ45 Connector When to use a straight-through and cross-over pin-out: • Direct point-to-point 10/100Base-T cables, with cross over pin-out (1-3, 2-6, 3-1, 6-2), connect the PanelView Ethernet port directly to another SLC 5/05 Ethernet port (or a computer 10/ 100Base-T port). -

Page 194

12-38 Terminal Connections Typical EtherNet/IP Configuration The following illustration shows a ControlLogix Controller (with 1756-ENET/B modules), a PLC-5E controller, SLC 5/05, a MicroLogix/ CompactLogix/FlexLogix (with 1761-NET-ENI module), and an Ethernet PanelView terminal connected to an EtherNet/IP network. Note that each node has a unique IP address. PLC-5E Controller SLC 5/05 ControlLogix 5550 Controller… -

Page 195: Panelview 300 Micro Terminal Connections

Terminal Connections 12-39 PanelView 300 Micro This section describes how to connect the PanelView 300 Micro terminal. Refer to the following topics in this section: Terminal Connections • RS-232 communications port • Connecting to a MicroLogix Controller • Connecting to a SLC, PLC-5, ControlLogix, MicroLogix, CompactLogix, or FlexLogix Controller •…

-

Page 196

12-40 Terminal Connections Connecting to an SLC, PLC-5, ControlLogix, MicroLogix 1500LRP, CompactLogix, or FlexLogix Directly connect the PanelView 300 Micro terminal to an SLC, PLC-5 ControlLogix, MicroLogix 1500LRP, CompactLogix, or FlexLogix processor using the following cables. Use DH-485 (SLC only) or DF1 protocols for communications. -

Page 197

Terminal Connections 12-41 Connecting to an Advanced Interface Converter DH-485 versions of the PanelView 300 Micro can operate on a DH-485 network through an Advanced Interface Converter (AIC+) module. Use the following cables. AIC+ PanelView 300 Micro 1761-CBL-PM02, 2711-CBL-PMxx (to Port 1 of AIC+) 1761-CBL-HM02, 2711-CBL-HMxx (to Port 2 of AIC+) 1761-CBL-AP00… -

Page 198

Terminal Connections Connecting to a Personal Computer (Application File Transfers) Transfer applications between a computer and PV300 Micro terminal using one of the following cables. Note: Applications for the PanelView 300 Micro terminal are developed using PanelBuilder32 Software (Catalog No. 2711-ND3, V3.60 or later). -

Page 199

Terminal Connections 12-43 Windows CE Pocket PanelView File Transfer (PocketPFT) Utility Supports the direct transfer of PanelBuilder32 application files from the PocketPFT software over an RS-232 link. The PocketPFT software and an RS232 cable is available from Rockwell Software as part of the MaintenCE suite of tools. -

Page 200: Connecting A Computer Or Printer To The Terminal

12-44 Terminal Connections Connecting a Computer or Most of the PanelView terminals have an RS-232 serial port to: • download/upload applications over a serial link Printer to the Terminal • and/or connect a printer that supports the IBM enhanced character set PanelView terminals that don’t have an additional RS-232 Printer Port include the 300 Micro, the 300 (except for DeviceNet), and the -xxA2/ -xxA5 versions of the 550/600 and 900 monochrome terminals.

-

Page 201: Chapter Objectives

Chapter Troubleshooting and Maintenance Chapter Objectives This chapter tells how to isolate and correct common operating problems and perform routine maintenance tasks. • equipment required • using troubleshooting chart • LED indicators • cleaning display window • replacing clock module •…

-

Page 202

4. Power terminal block not fully seated (PV300 connected to the proper terminals. terminals only). 4. Verify power terminal block is snapped onto base of PV300 Micro. Application file will not 1. Communication cable disconnected. 1. Check communication cable type and download (first download). -

Page 203

2. Change the field width for the object. Can’t enter Configuration Mode 1. Left and right arrow keys are assigned to screen 1. Contact Allen-Bradley technical support for when pressing Left and Right objects in the terminal application. assistance. -

Page 204: Indicators

13-4 Troubleshooting and Maintenance Indicators On PanelView terminals (except PanelView 300 Micro), use the COMM and Fault LED indicators to isolate operating problems. The illustration below shows the location of these indicators on some terminals. See chapter 1 for LED locations on other terminals. COMM LED Fault LED COMM LED…

-

Page 205

Troubleshooting and Maintenance 13-5 Remote I/O LED Indications This pattern: Indicates: Solid Fill Normal operating state (no communication faults) Comm No Fill Communications not functioning • Verify that baud rate and rack settings match the PLC settings • Verify proper terminal to controller connections •… -

Page 206: Cleaning The Display Window

13-6 Troubleshooting and Maintenance Cleaning the Display To clean the display window: Window Use of abrasive cleansers or solvents may damage ATTENTION the window. Do not scrub or use brushes. 1. Disconnect power from the terminal at the power source. 2.

-

Page 207: Replacing The Backlight

Troubleshooting and Maintenance 13-7 The clock module replacement kits for the PanelView terminals are listed in Chapter 1 under Replacement Parts. Replacement instructions are provided with the kits. The clock module contains lithium. Do not attempt ATTENTION to dispose of the module in a fire or incinerator. Doing so may cause the clock module to explode.

-

Page 208

13-8 Troubleshooting and Maintenance Publication 2711-UM014B-EN-P… -

Page 209: Appendix A — Specifications

Appendix Specifications PanelView 300 Micro Electrical DC Power Supply Voltage Limits 11 to 30V dc (24V nominal) Power Consumption 2.5W maximum (0.105A @24Vdc) Mechanical Enclosure NEMA Type 12/13, 4X (Indoor use only), IP54, IP65 Weight 284 grams (10 oz.) Dimensions 133 (H) x 112 (W) x 48 (D) Inches 5.23 (H) x 4.38 (W) x 1.87 (D)

-

Page 210

Specifications Character Sizes (Pixel size = 0.48 x 0.48 mm) Size in Pixels Dimensions in mm Characters/Row Maximum Rows width x height) Width x Height 4 x 6 1.9 x 2.9 6 x 8 2.9 x 3.8 6 x 16 2.9 x 7.7 6 x 24 2.9 x 11.5… -

Page 211

Specifications Terminal Memory Total Application Flash Memory 240K bytes (application screens) Environment Operating Temperature 0 to 55° C (32 to 131° F) Storage Temperature -25 to 85° C (-4 to 188° F) Relative Humidity (non-condensing) 5 to 95% at 0 to 55° C (32 to 131° F) Heat Dissipation 18 Watts (69 BTU/HR) Impulse Shock (operating/non-operating) -

Page 212

Specifications PanelView 550 Electrical DC Power Supply Voltage Limits 18 to 30V dc (24V dc nominal) Power Consumption 18 Watts, max. (0.75A @ 24V dc) Supply Voltage Limits (touch screen only) 18 to 32V dc (24V dc nominal) Power Consumption (touch screen only) 18 Watts, max. -

Page 213

Specifications Environment Operating Temperature 0 to 55° C (32 to 131° F) Storage Temperature -20 to 70° C (-4 to 158° F) Relative Humidity (non-condensing) 5 to 95% at 0 to 30° C (32 to 86° F) 5 to 75% at 31 to 40° C (88 to 104° F) 5 to 50% at 41 to 55°… -

Page 214

Specifications PanelView 600 Color Electrical Keypad & Touch DC Power Supply Voltage Limits 85 to 264V ac, 43 to 63 Hz Power Consumption 60 VA maximum AC Power Supply Voltage Limits 18 to 32V dc (24V dc nominal) Power Consumption 34 Watts max. -

Page 215

Specifications Character Sizes (Pixel size = 0.36 x 0.37 mm) Size in Pixels Characters/Row Maximum Rows Dimensions in mm width x height) Width x Height 6 x 9 2.9 x 5.9 8 x 16 2.9 x 5.9 8 x 24 2.9 x 8.9 16 x 24 5.8 x 8.9… -

Page 216

Specifications Environment Operating Temperature 0 to 50° C (32 to 122° F) Storage Temperature -25 to 70° C (-13 to 158° F) Relative Humidity (non-condensing) 5 to 95% at 0 to 40° C (32 to 104° F) Heat Dissipation 17 Watts (577 BTU/HR) Impulse Shock (operating/non-operating) 15G/30G Vibration (operating) -

Page 217

Specifications PanelView 900 Electrical Monochrome and Color AC Power — PV900M and PV900C Supply Voltage Limits 85 to 264V ac, 47 to 63 Hz Power Consumption 110 VA maximum DC Power — PV900M Supply Voltage Limits 18 to 30 V dc (24V dc nominal) Power Consumption 58 Watts max. -

Page 218

A-10 Specifications Display PV900M Type AC Gas Plasma Size 210 x 131 mm (8.27 x 5.17 in.) Pixels 640 x 400 Touch Cells 384 (24 columns x 16 rows) Touch Cell Size 26 x 25 pixels PV900C Type Active Matrix Thin-Film Resistor (TFT) with Cold Cathode Fluorescent (CCF) Backlight Size 171 x 130 mm (6.73 x 5.12 in.) -

Page 219

Specifications A-11 Character Sizes PV900M (Pixel size = 0.33 x 0.33 mm) Size in Pixels Characters/Row Maximum Rows Dimensions in mm width x height) Width x Height 8 x 16 2.6 x 5.3 8 x 24 2.6 x 7.9 16 x 24 5.3 x 7.9 24 x 32 7.9 x 10.6… -

Page 220

A-12 Specifications PanelView 1000 Color & Electrical Grayscale AC Power — PV1000G and PV1000C Supply Voltage Limits 85 to 264V ac, 47 to 63 Hz Power Consumption 100 VA maximum DC Power — PV1000G Supply Voltage Limits 18 to 32 V dc (24V dc nominal) 40 Watts max. -

Page 221

Specifications A-13 Display PV1000G Type Electroluminescent Size 211 x 158 mm (8.3 x 6.2 in.) Pixels 640 x 480 Touch Cells 384 (24 columns x 16 rows) Touch Cell Size 26 x 30 pixels PV1000C Type Active Matrix Thin-Film Resistor (TFT) with Cold Cathode Fluorescent (CCF) Backlight Size 211 x 158 mm (8.3 x 6.2 in.) -

Page 222

A-14 Specifications PanelView 1400 Color Electrical AC Power Supply Voltage Limits 85 to 264V ac, 43 to 63 Hz Power Consumption 200 VA maximum Mechanical Enclosure NEMA Type 12/13, 4X (Indoor use only) IP54, IP65 LED Indicators COMM Green Fault Weight Keypad 20.3 kg (44.75 lbs) -

Page 223

Specifications A-15 Character Sizes PV1400 (Pixel size = 0.32 x 0.32 mm) Size in Pixels Characters/Row Maximum Rows Dimensions in mm width x height) Width x Height 8 x 20 2.5 x 6.4 16 x 24 5.1 x 7.6 24 x 32 7.6 x 10.2 32 x 40 10.2 x 12.7… -

Page 224

A-16 Specifications Agency Certifications 900M 900C 1000G 1000C 1400 Micro Emissions (Class B: Light Industrial) EN50081- 1:1992 Emissions (Class A: Industrial) EN50081-2:1993 Immunity (Industrial) EN61000-6-2:1999 Immunity (Industrial) EN50082-2:1995 Programmable Controllers Equipment Requirements and Tests) EN61131 2:1995 Low Voltage Directive (Safety Sections of EN61131-2) UL508 UL1604 Class 1, Div 2, Groups A, B, C, D, T4… -

Page 225

Appendix Messages, Codes and Self-Test Numbers This appendix lists: • terminal messages and codes that may appear during terminal operation • description of self-test numbers Types of Terminal Status Messages Indicate the terminal is performing an operation that may limit access Messages to the terminal, such as an application download or a communication problem. -

Page 226

Messages, Codes and Self-Test Numbers General Terminal Messages Error Number Terminal Type Meaning Recommended Action Messages 200-206, 300, A fault has Minor Fault A minor fault was detected that could Press any key to recover from a minor 318-321, 328, 329, occurred. -

Page 227

Messages, Codes and Self-Test Numbers Error Number Terminal Type Meaning Recommended Action Messages Unformatted card Reminder Memory card is unformatted, contains an Reformat the card or replace it with a unrecognizable format or is corrupt. new card. Try again. No Card Inserted Reminder You tried to transfer data to/from a Install a memory card and try again. -

Page 228

Messages, Codes and Self-Test Numbers Error Number Terminal Type Meaning Recommended Action Messages File not supported Reminder/File File is incompatible with the terminal’s In PanelBuilder32, click the Catalog & Transfer Status firmware. Revisions button on the Setup tab on the Application Settings dialog. -

Page 229